Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "Film Processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

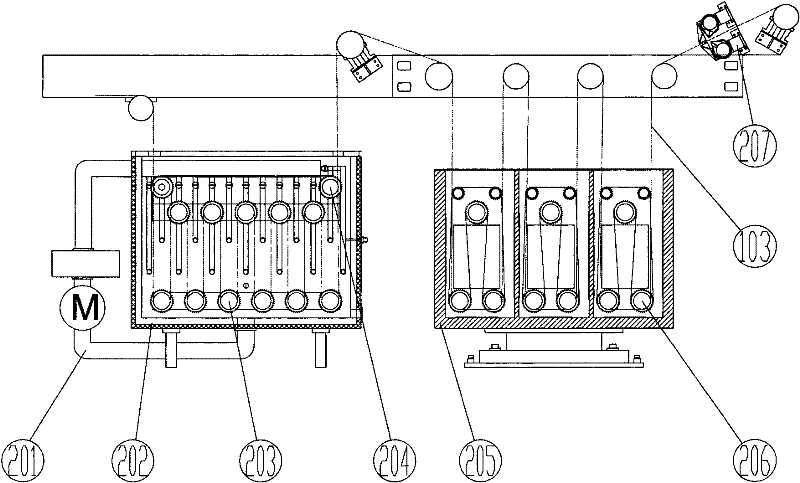

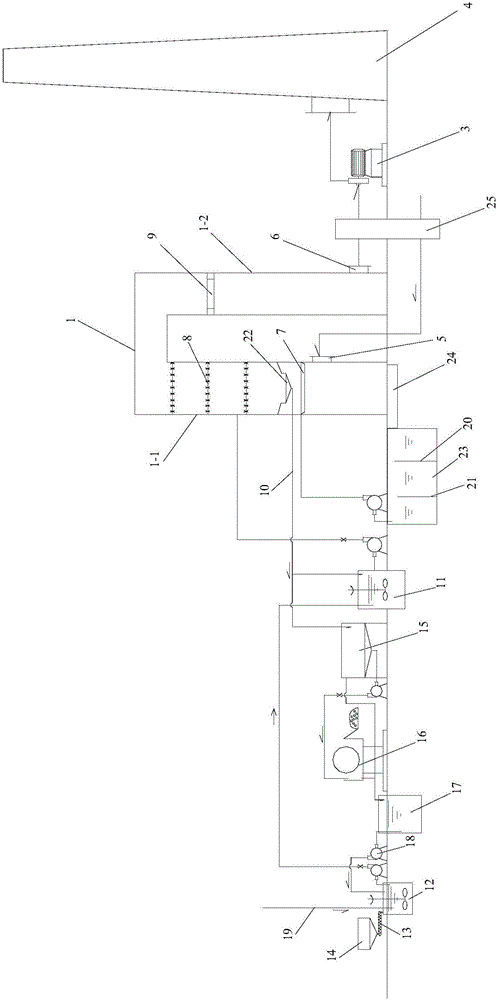

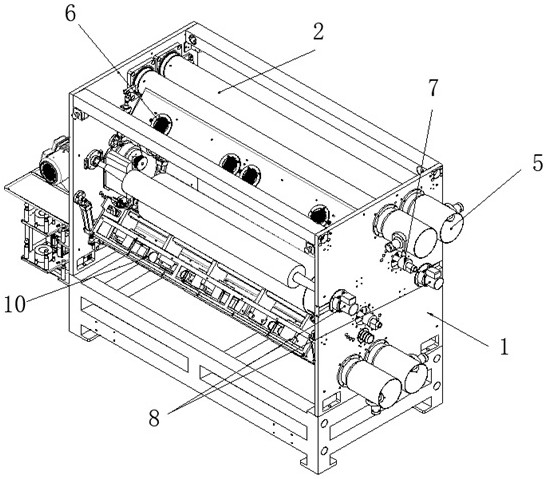

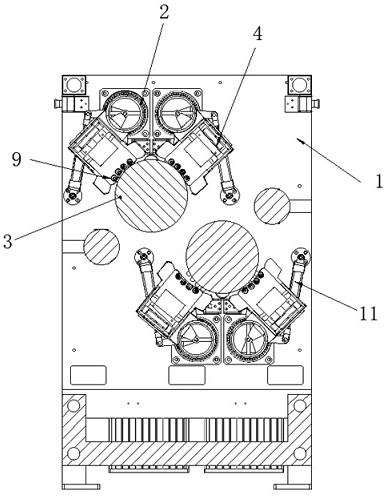

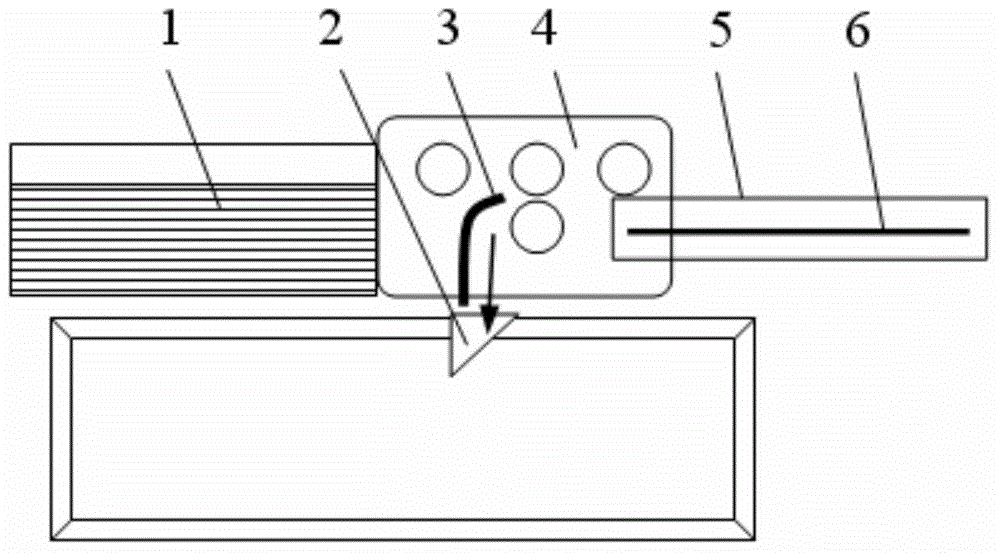

Film processor

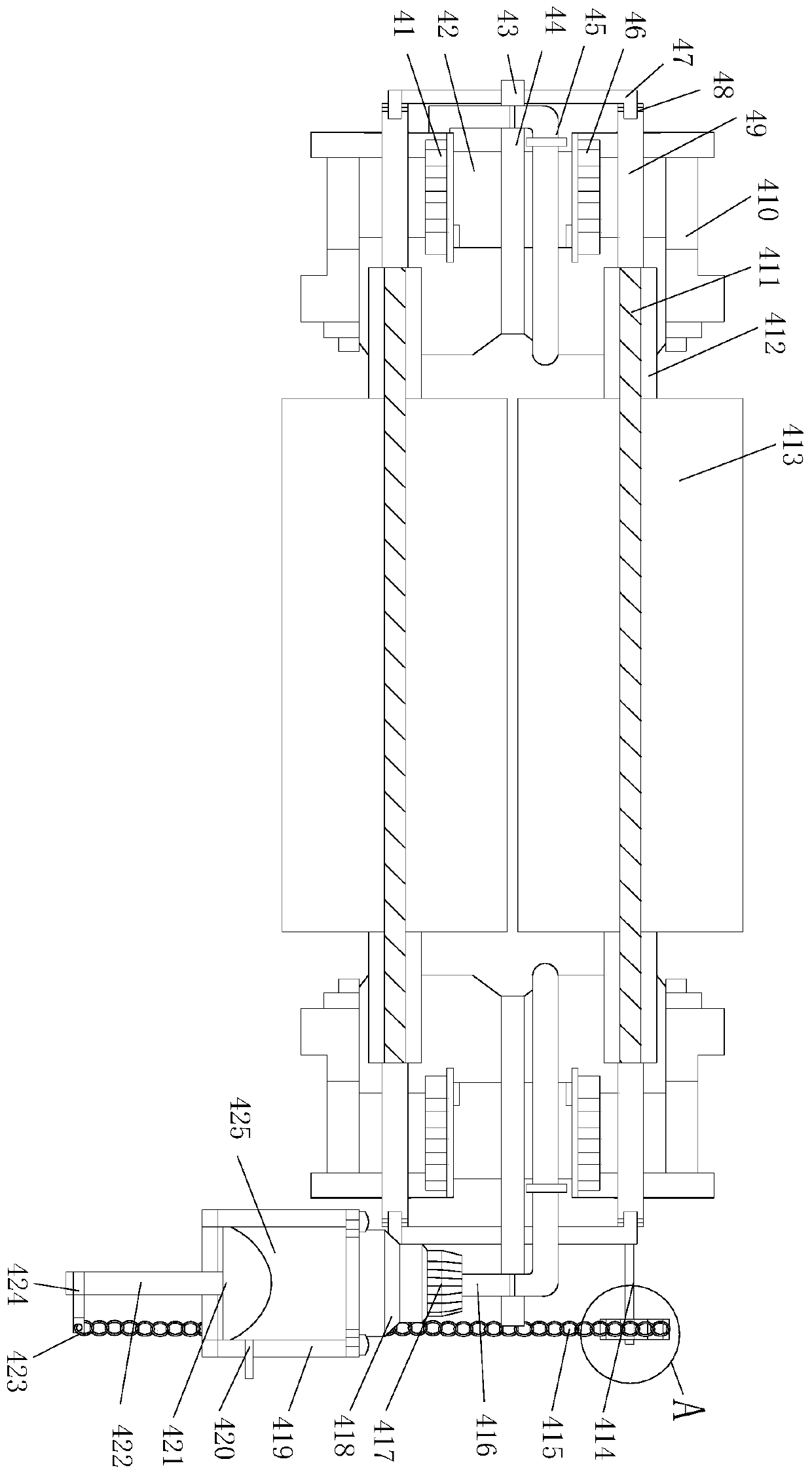

The invention aims to provide a film processor with high safety performance, stable speed and good finished product quality, and the film processor comprises an unwinding mechanism, a film processing mechanism, a traction mechanism, an oven mechanism, a cooling traction mechanism, a winding mechanism, a transmission guide roller group, a frame and an electrical control system; the unwinding mechanism and the winding mechanism are used for adjusting material coils through automatic correction devices in the transversal direction; two processing grooves of the film processing mechanism are respectively used for carrying out different treatments to a film; the oven mechanism comprises two groups of air nozzles which are lined symmetrically and uniformly heat the film, and a multi-guide roller mechanism can adapt to the needs of different mechanical speeds; two groups of cooling rollers are adopted for the cooling traction mechanism, so that the temperature of the film which is from an oven is quickly and uniformly reduced; explosion-proof electrical elements are adopted for the electrical control system, so that the safety in a production process is ensured; and the whole processor is electrically controlled automatically, and can run at high constant speed continuously and safely.

Owner:SINOMECH CORP

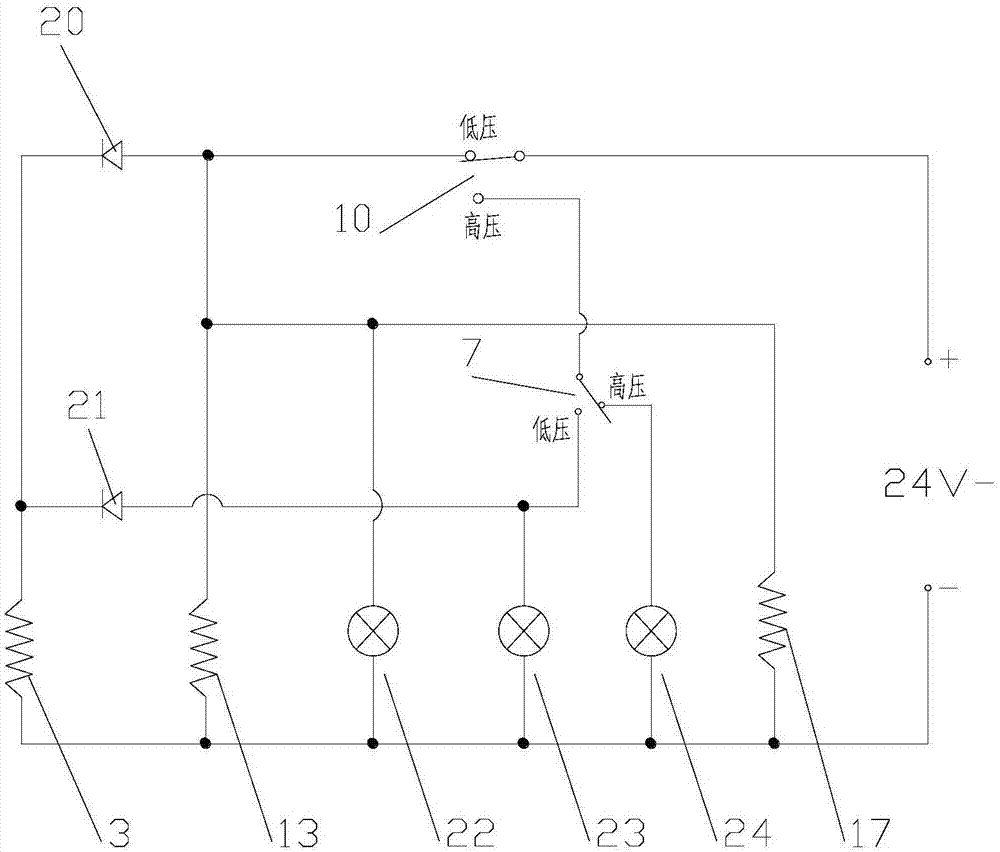

Film effluent non-backpressure water purifier

PendingCN107381719AImprove capacity utilizationReduce volumeWater treatment parameter controlTreatment involving filtrationWater storageWater storage tank

The invention provides a film effluent non-backpressure water purifier which comprises a film processor, a water pressure type water storage tank, a low-flow rate throttle valve, a flush valve, a water inlet valve, a drainage valve, a one-way valve and an electrical control device; a purified water outlet of the film processor is respectively communicated with a purified water chamber of the water pressure type water storage tank and an inlet of the one-way valve through a purified water pipeline, a concentrated water outlet of the film processor is respectively communicated with outlets of the flush valve and the low-flow rate throttle valve, and outlets of the flush valve and the low-flow rate throttle valve are firstly and mutually communicated with each other and then are respectively communicated with a concentrated water chamber of the water pressure type water storage tank and an inlet of the drainage valve; the water inlet valve is arranged on a water inlet pipeline of the film processor; the electrical control device comprises a first pressure switch and a second pressure switch and is used for controlling the opening and the closing of the water inlet valve, the drainage valve and the flush valve; the first pressure switch is arranged on the purified water pipeline; the second pressure switch is arranged on a pipeline of the outlet of the one-way valve. Compared with the prior art, the film effluent non-backpressure water purifier provided by the invention is low in development cost and manufacturing cost, high in reliability and convenient to popularize and apply.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

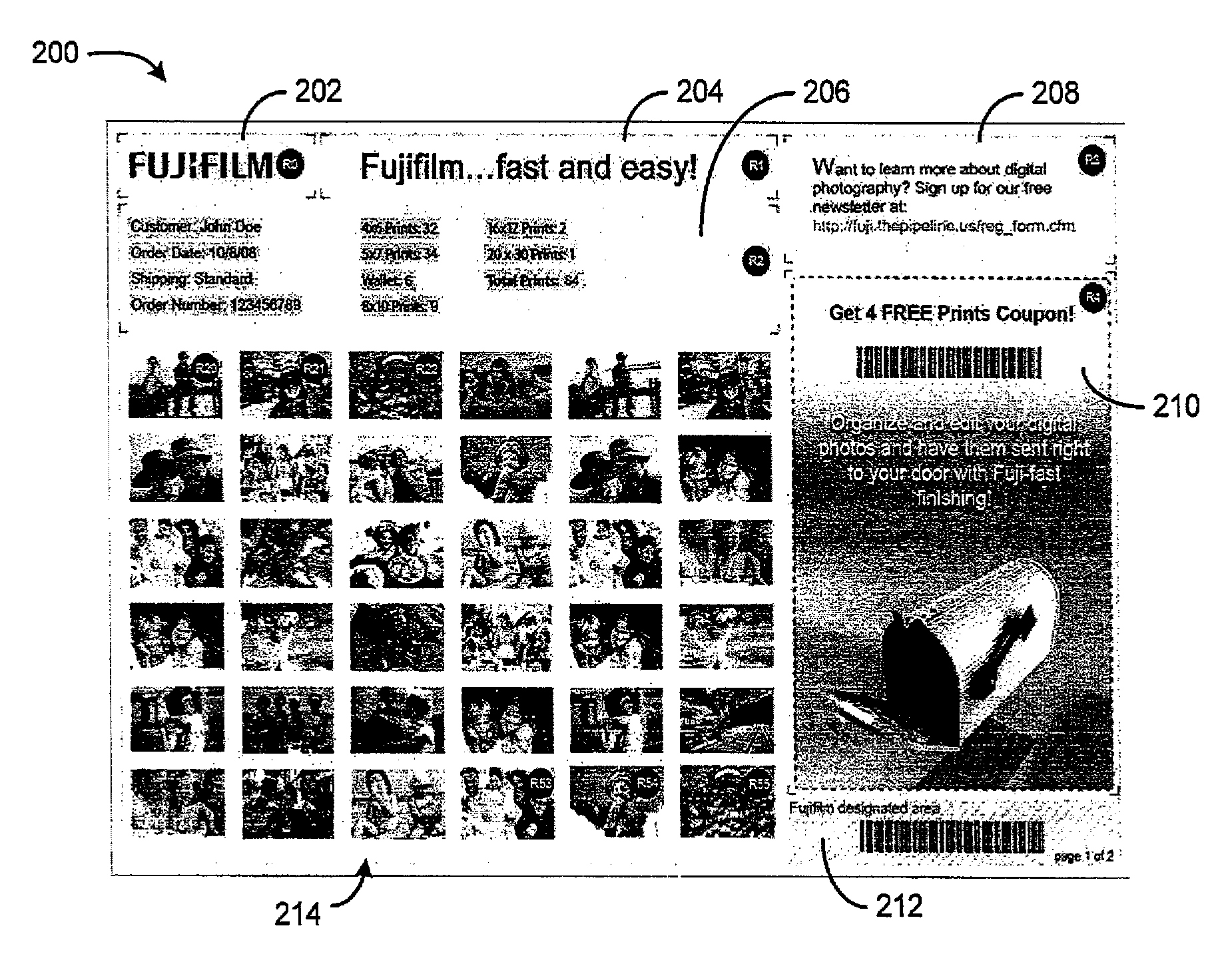

System and method for generating an enhanced index print product

ActiveUS8666833B2Processed material treatmentDigital data processing detailsData-drivenFilm Processor

Owner:FUJIFILM NORTH AMERICA CORP

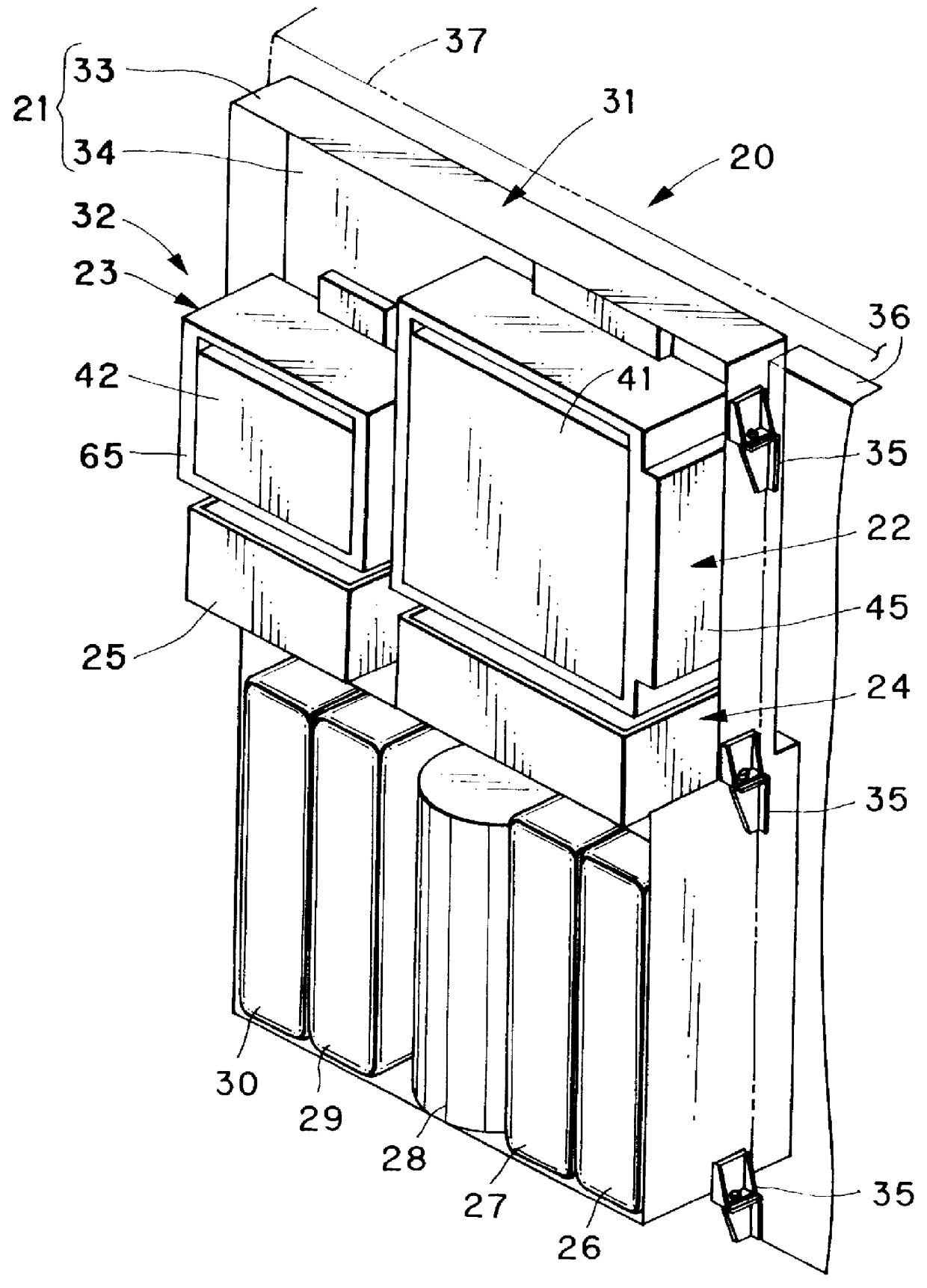

Replenisher supply device for photosensitive material processor

InactiveUS6132114AConvenient inspectionEasy maintenanceLiquid processing circulationEngineeringFilm Processor

A photo film processor has a bath component, which contains processing liquid and processes photo film by use of the processing liquid. A processor body contains the bath component. A replenisher supply device has two cartridge holders loadable with two replenisher cartridges, which contain replenisher liquid for adjustment of the processing liquid. Two tanks store the replenisher liquid having flowed out of the replenisher cartridges. A maintenance opening is formed in the processor body. A panel is secured to the maintenance opening movably between closed and open positions. On the panel, the cartridge holders and the tanks are mounted. The panel, when in the closed position, closes the maintenance opening, and when in the open position, is positioned outside the maintenance opening, for allowing inspection and / or maintenance of the bath component.

Owner:FUJIFILM CORP +1

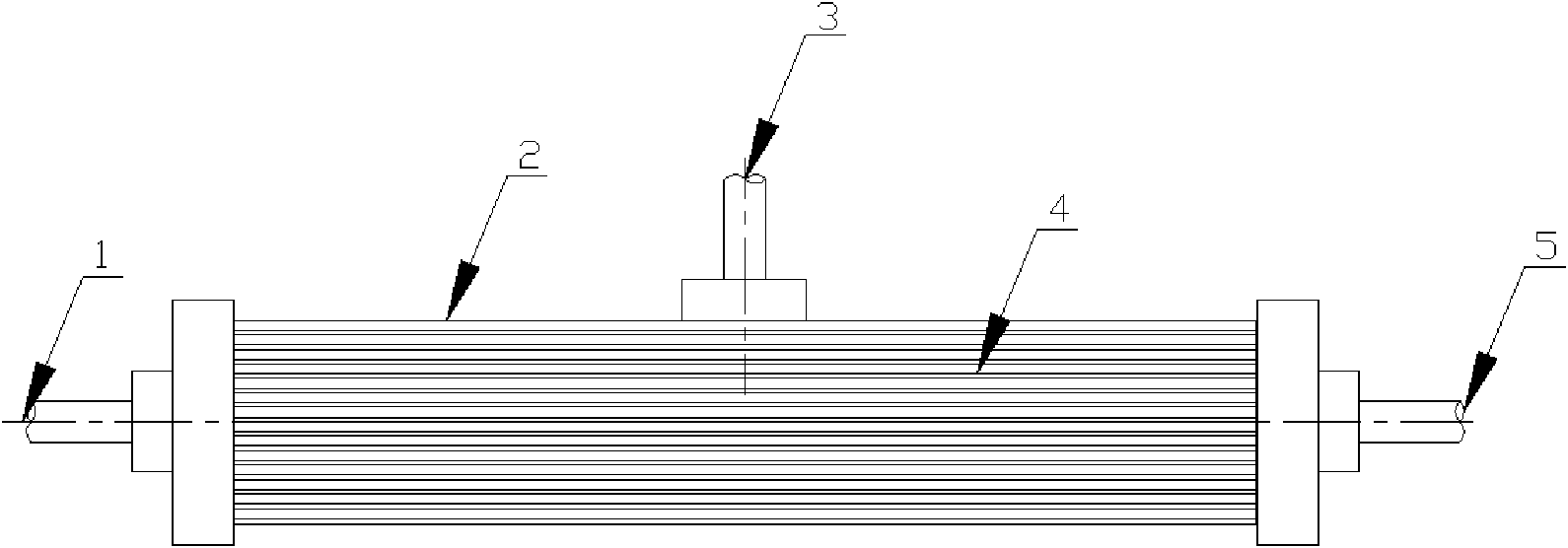

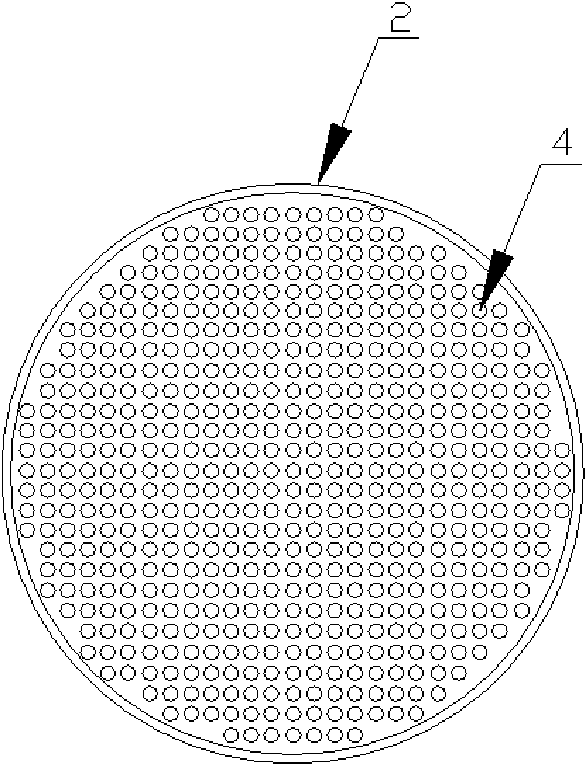

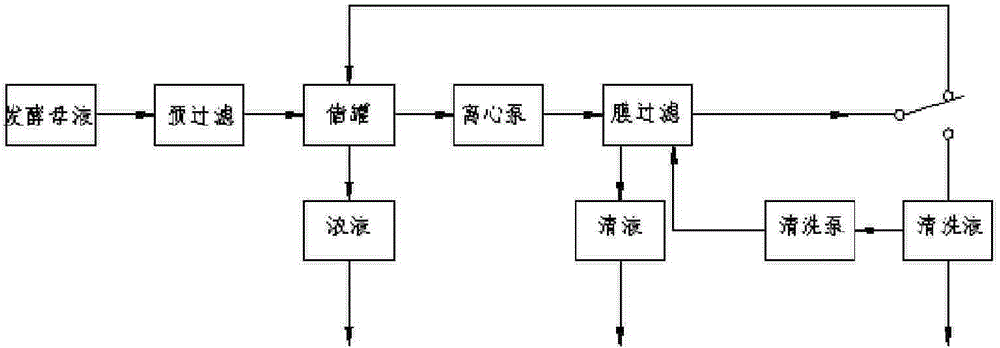

Concentration technology for zymogen liquid

ActiveCN101642680AImprove concentration efficiencyEasy to operateSemi-permeable membranesTissue/virus culture apparatusZymogenPolymer science

The invention discloses a concentration technology for zymogen liquid. The concentration technology adopts macromolecule polyacrylonitrile fiber hollow film filter tube combined equipment as concentration equipment and depends on the pressure difference of an inlet and an outlet, zymogen liquid with lower concentration continuously and circularly flows in a film processor comprising unnumbered fiber film tubes, water continuously leaks out from millipores of the walls of the fiber film tubes, and finally the purpose of concentration can be achieved; and during backwashing, the fiber film tubesare processed by reverse washing by cleaner, substances piled around the millipores of the film tubes in the original concentration and filtration are cleanly washed, and film processing equipment can be guaranteed to be regenerated. The invention is the concentration technology for the zymogen liquid, having the advantages of simplicity, high reliability, easy running operation, low overhaul andmaintenance, reasonable structure of products, and high safety, economy, durability, concentration efficiency of the zymogen liquid and production efficiency.

Owner:湖南豫园生物科技股份有限公司

Cyclic treatment recycling technology for liquid waste generated in surface treatment of steel wires and equipment

InactiveCN106591865AEasy to handleReduce manufacturing costMetallic material coating processesLiquid wasteFilm Processor

The invention discloses a cyclic treatment recycling technology for liquid waste generated in surface treatment of steel wires and equipment, and belongs to the field of metal surface treatment. The cyclic treatment recycling technology for the liquid waste generated in surface treatment of steel wires and the equipment are characterized in that the equipment comprises a settling pond, an acid adding pond, a finished product working solution pond, a liquid waste collecting tank and a film processor; deslagging separation filtering equipment is arranged on the lower portion of the settling pond; the deslagging separation filtering equipment can separate liquid from solid residues in the settling pond; clear liquid separated by the deslagging separation filtering equipment can be injected to the acid adding pond through a clear liquid pump; the clear liquid added with concentrated acid in the acid adding pond is concentrated by the film processor, and then a concentrated solution generated is injected to the finished product working solution pond, and the clear liquid separated out of the film processor is led into the liquid waste collecting tank; and the finished product working solution pond is connected with the settling pond through a backflow liquid guide pipe and a backflow liquid guide pump. By means of the cyclic treatment recycling technology for the liquid waste generated in surface treatment of steel wires and the equipment, an old working solution can be effectively treated and be recycled; and in addition, the old working solution can be treated through the reasonable and efficient technology, production cost is reduced, and the purposes of environmental protection and saving are achieved.

Owner:刘长江

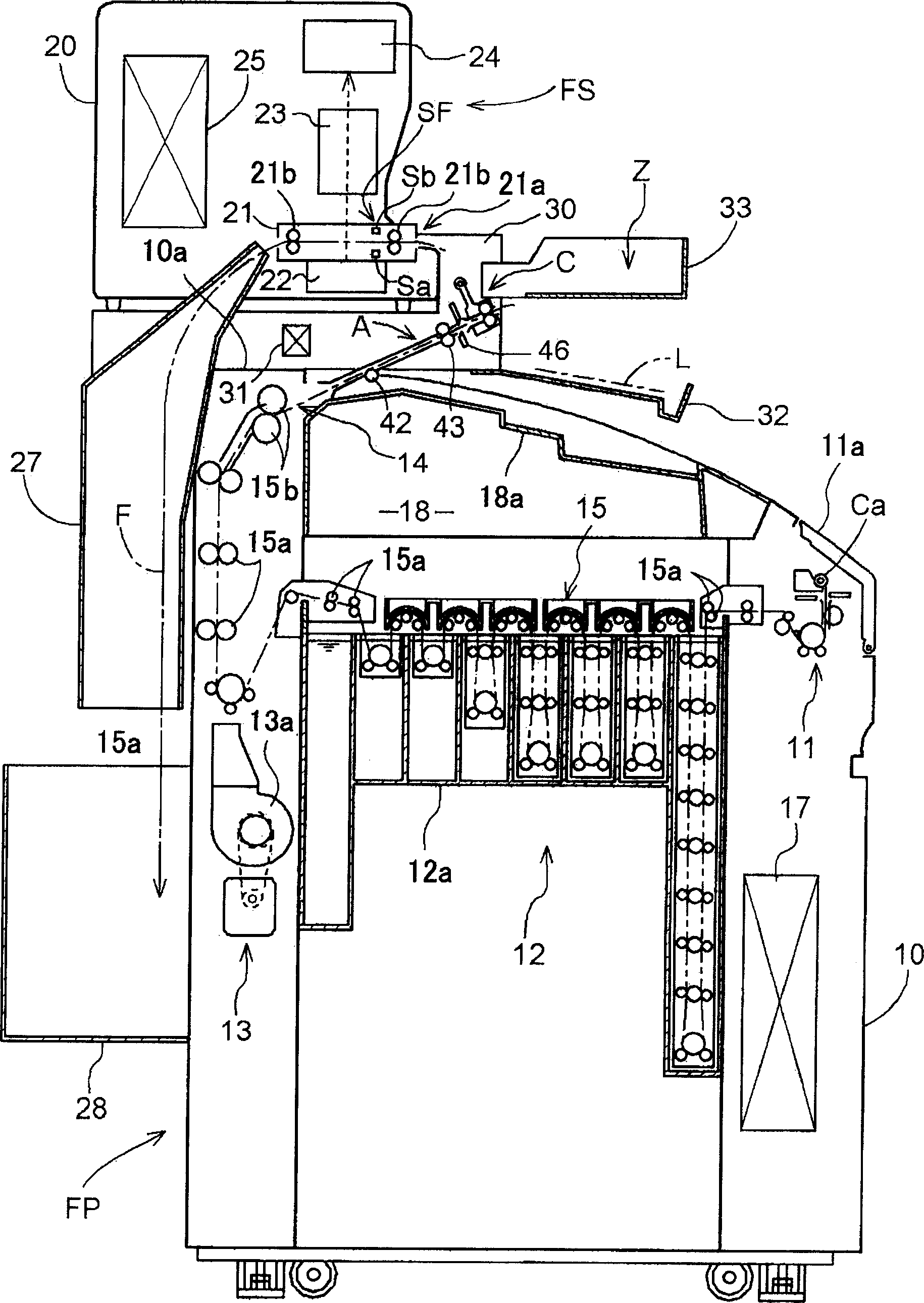

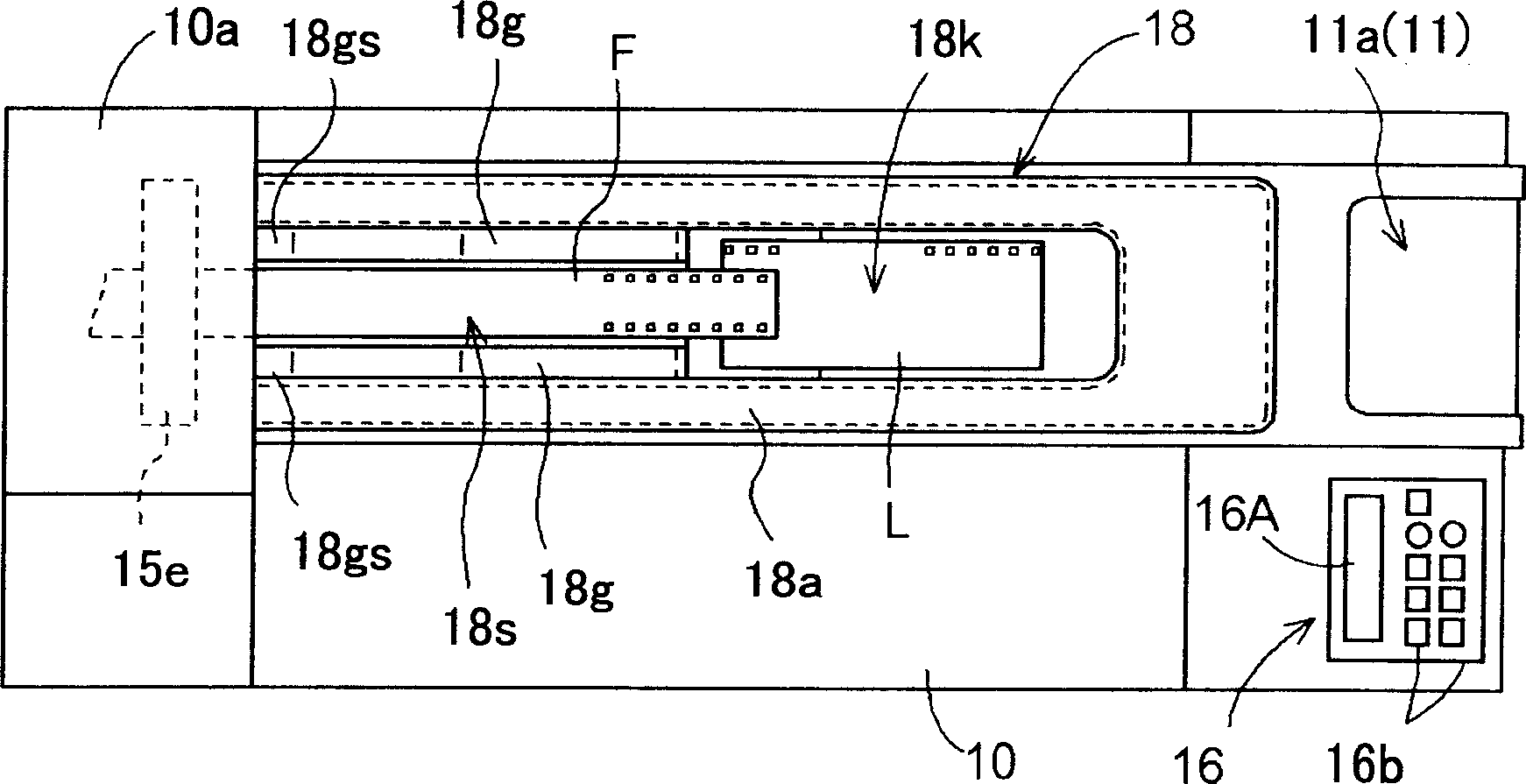

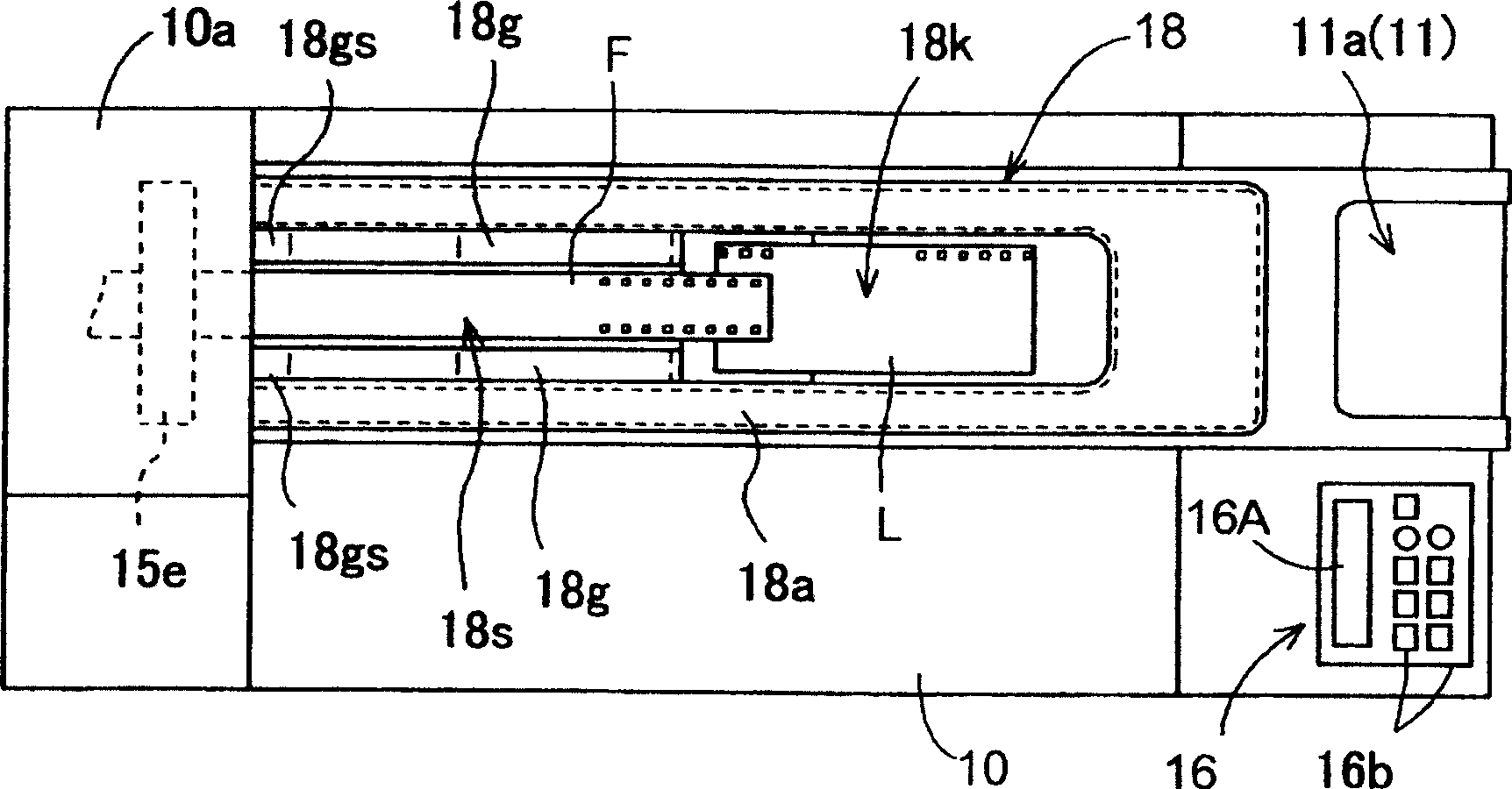

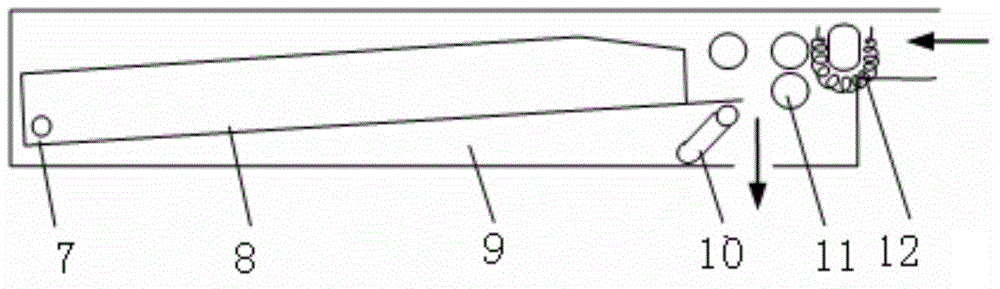

Film treatment device

InactiveCN1908810AReasonable structureEasy to take outLiquid processingPictoral communicationSheet filmFilm Processor

The invention is to rationally constitute a film processing device capable of easily performing a series of processing from developing undeveloped photographic film to acquiring image data and processing for acquiring image data from developed photographic film. A film scanner FS is arranged above a film processor FP, and the film insertion part 11 of the film processor FP and the supply part 21A of the film scanner FS are formed in a direction where an operator operates. The film processing device is equipped with a supply and conveyance mechanism A for supplying film F from the ejection part 14 of the film processor FP to the supply part 21A of the film scanner FS.

Owner:NORITZ CORP

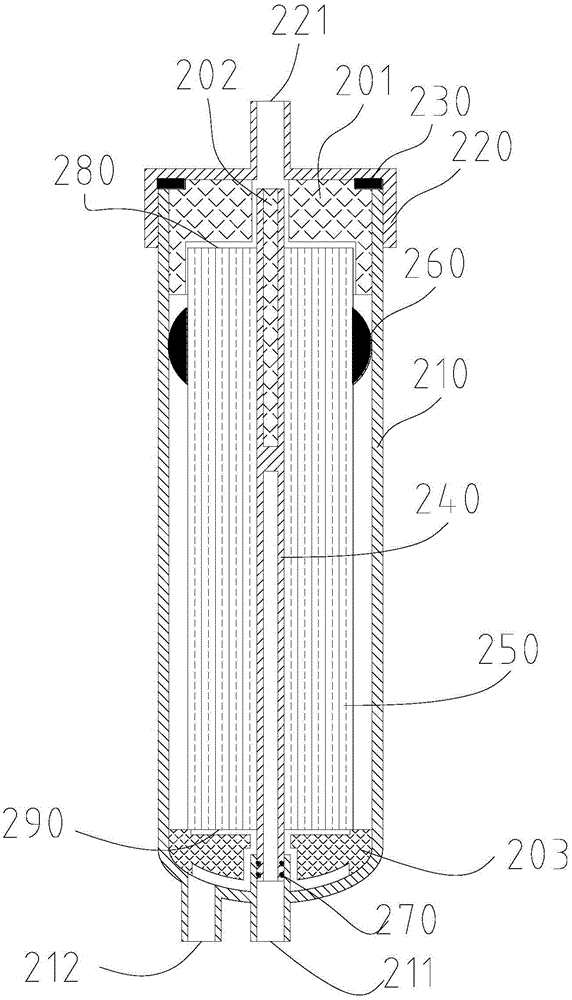

Film processor

InactiveCN105461020ALess quantitySave spaceTreatment involving filtrationReverse osmosisEnvironmental engineeringFilm Processor

The invention provides a film processor which comprises a shell and a rolled film assembly. Filler is arranged in the shell and used for reducing the space capable of containing raw water or concentrated water inside the film processor. Compared with the prior art, the space capable of containing raw water or concentrated water inside the film processor can be reduced to the maximum degree, so that the amount of the raw water or concentrated water needing to be replaced is reduced, and the purpose of reducing the consumed water yield to the maximum limit is achieved.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

Water purifier

PendingCN106116006AReduce connectorsEasy maintenanceTreatment involving filtrationMultistage water/sewage treatmentProcess engineeringFilm Processor

The invention discloses a water purifier. The water purifier comprises a film processor, and also comprises a water way centralizing and separating body, wherein a concentrated water inlet, a concentrated water drainage opening and a concentrated water outlet are formed in the water way centralizing and separating body, the concentrated water inlet communicates with a concentrated water opening of the film processor, and the concentrated water outlet communicates with a water inlet of the film processor. Compared with the prior art, the water purifier disclosed by the invention has the beneficial effects that a water-air separator, a small-flow throttling device, a large-flow throttling device, a magnetized drinking water processor and a one-way valve in the prior art are integrated into the same component namely the water way centralizing and separating body, so that the number of pipeline connecting connectors are reduced, the inner pipeline of a machine can be simple and clear, the system is simplified, besides, the simplification of assembling working procedures is facilitated, the production efficiency is improved, the servicing and the maintenance of the machine are also facilitated, and the maintenance process is simple and rapid; after the system is simplified, the improvement of the consistency of product properties is facilitated, batch production is facilitated, and the quality of batch products is guaranteed.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

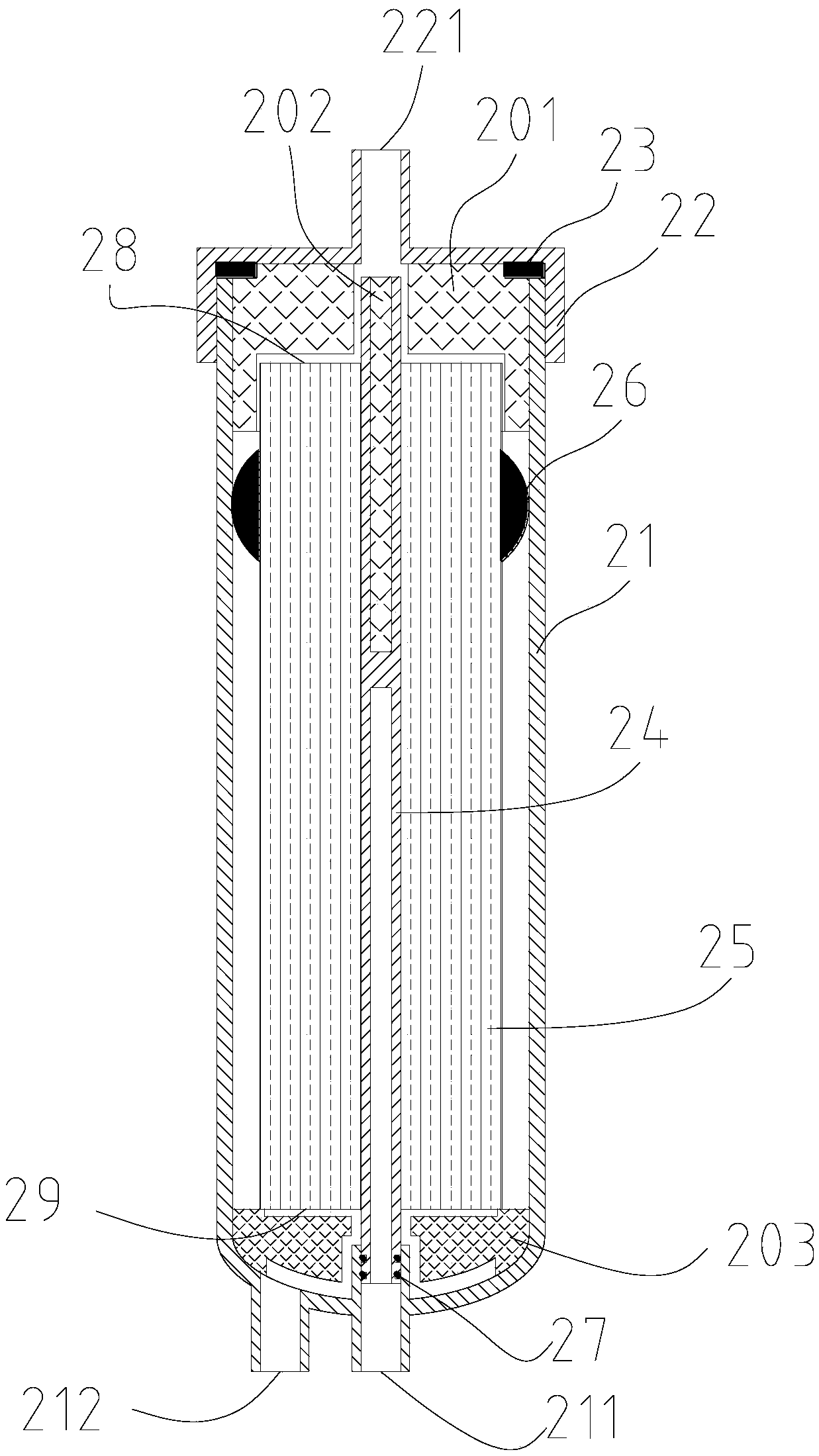

Water purifier

InactiveCN105502580ALess quantitySave spaceWater/sewage treatment bu osmosis/dialysisWater/sewage treatment apparatusDihydrogen oxideWater production

The invention provides a water purifier which comprises a filter processor and a water production backflow pipe. A water stopper is arranged on the water production backflow pipe. The film processor is filled with filler. The filler is used for reducing the space capable of containing raw water or concentrate water in the film processor and then reducing the water yield of raw water or concentrate water through the water production backflow pipe. Compared with the prior art, the water purifier has the advantages that the film processor is filled with the filler, the space capable of containing raw water or concentrate water in the film processor can be reduced to the maximum extent, the volume of raw water or concentrate water needing to be replaced is reduced, and the consumed water yield is reduced to the maximum extent.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

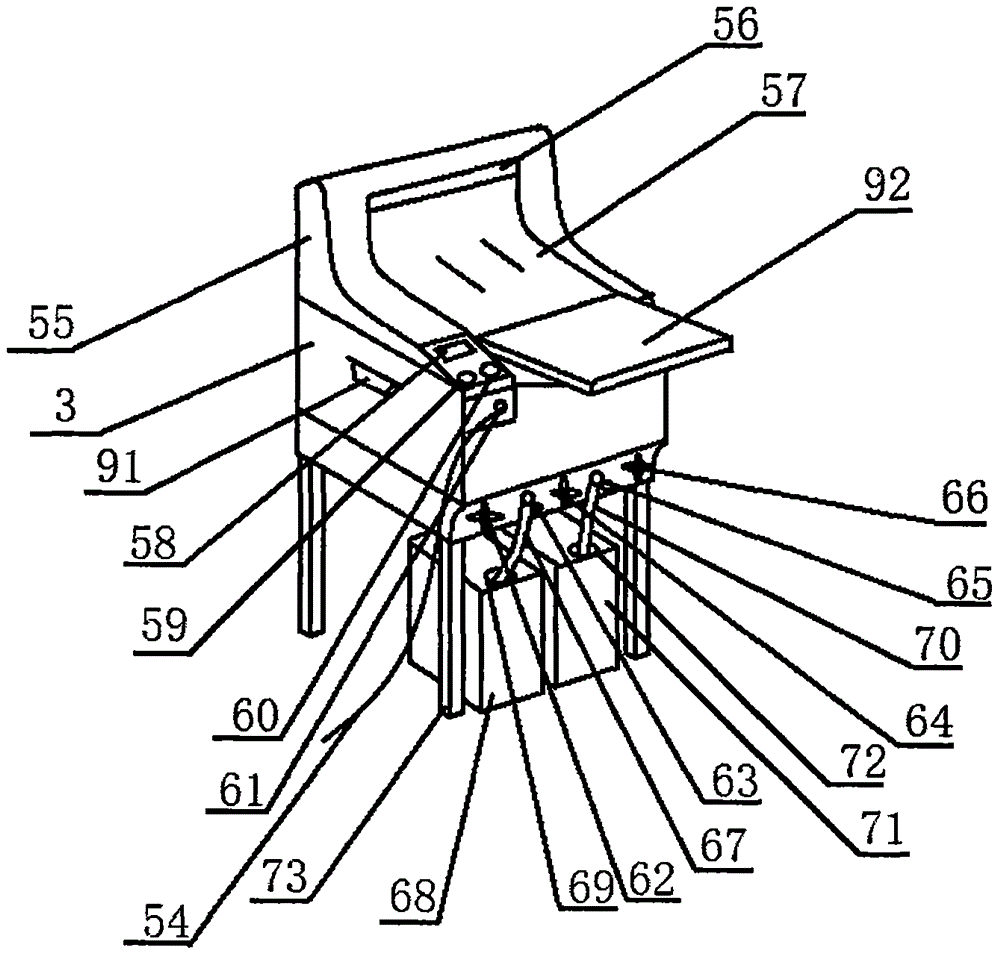

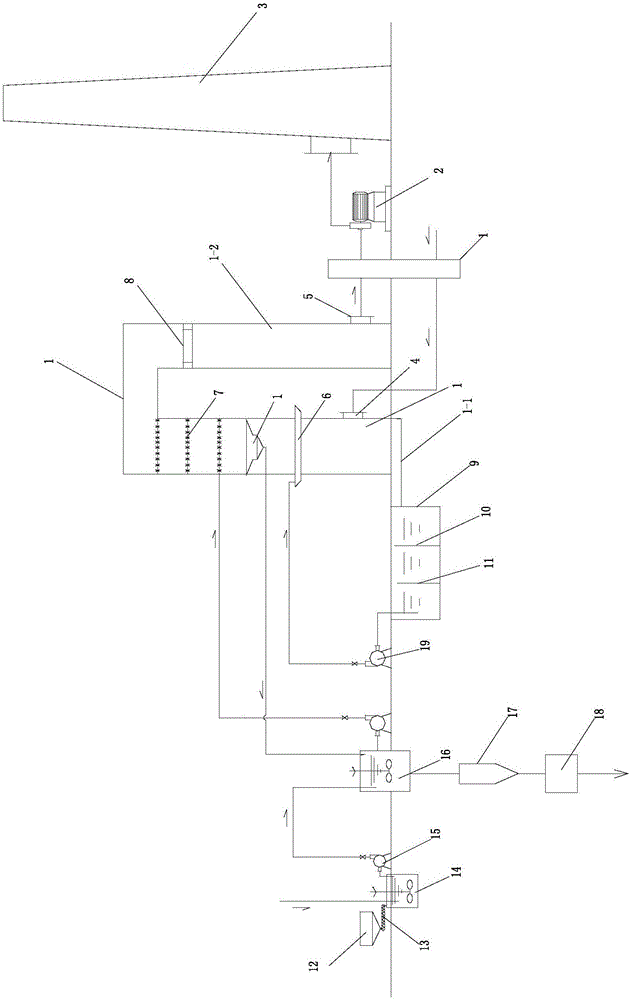

Boiler flue gas dust removal and desulfurization system

InactiveCN106823711AIncrease flow lengthLower the altitudeGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a boiler flue gas dust removal and desulfurization system, belonging to the technical field of flue gas desulfurization for environmental protection. The boiler flue gas dust removal and desulfurization system comprises a desulfurizing tower, an induced draft fan and a chimney which are connected in sequence, wherein the desulfurizing tower consists of a desulfurizing main tower and a desulfurizing subsidiary tower; the top of the desulfurizing main tower is communicated with the top of the desulfurizing subsidiary tower; the bottom of the desulfurizing main tower is provided with a flue gas inlet pipe; the bottom of the desulfurizing subsidiary tower is provided with a flue gas outlet pipe; the flue gas outlet pipe is communicated with the induced draft fan; the lower part of the desulfurizing main tower is provided with a water film processor; the water film processor is arranged above the flue gas inlet pipe; the lower part of the desulfurizing main tower is provided with a lime slurry discharging pipe; the lime slurry discharging pipe is respectively connected with a desulfurizing circulation pool and a lime slurry concentrating circulation device; and the desulfurating circulation pool is connected with a multistage lime slurry sprinkling pipe. In the boiler flue gas dust removal and desulfurization system disclosed by the invention, harmful gases such as SO3, chloride and fluoride can be effectively removed, and the rate of removal can reach 95% or above.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

High-salinity water processing device

InactiveCN105540938AReduce processing efficiencyLow costWater contaminantsWater/sewage treatment by electrochemical methodsSaline waterBrackish water

A high-salinity water processing device is characterized in that the high-salinity water processing device sequentially comprises a scale inhibition device, a brackish water film processor, a bacterium killing bacteria-proof processor and a reverse-osmosis membrane processor. Compared with the prior art, the high-salinity water processing device has the advantages of being low in processing efficiency, low in energy consumption and low in cost.

Owner:佛山市雅洁源科技股份有限公司

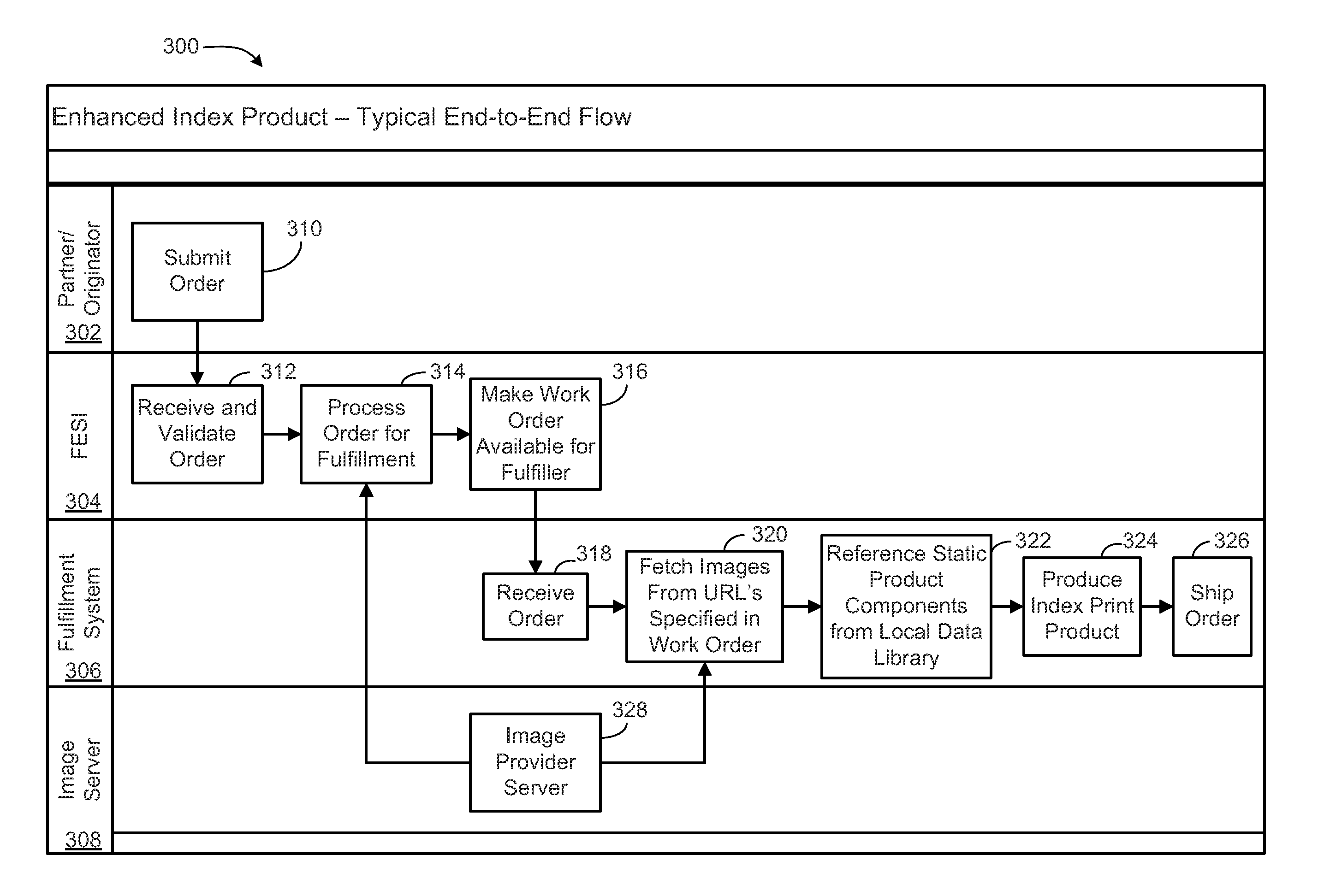

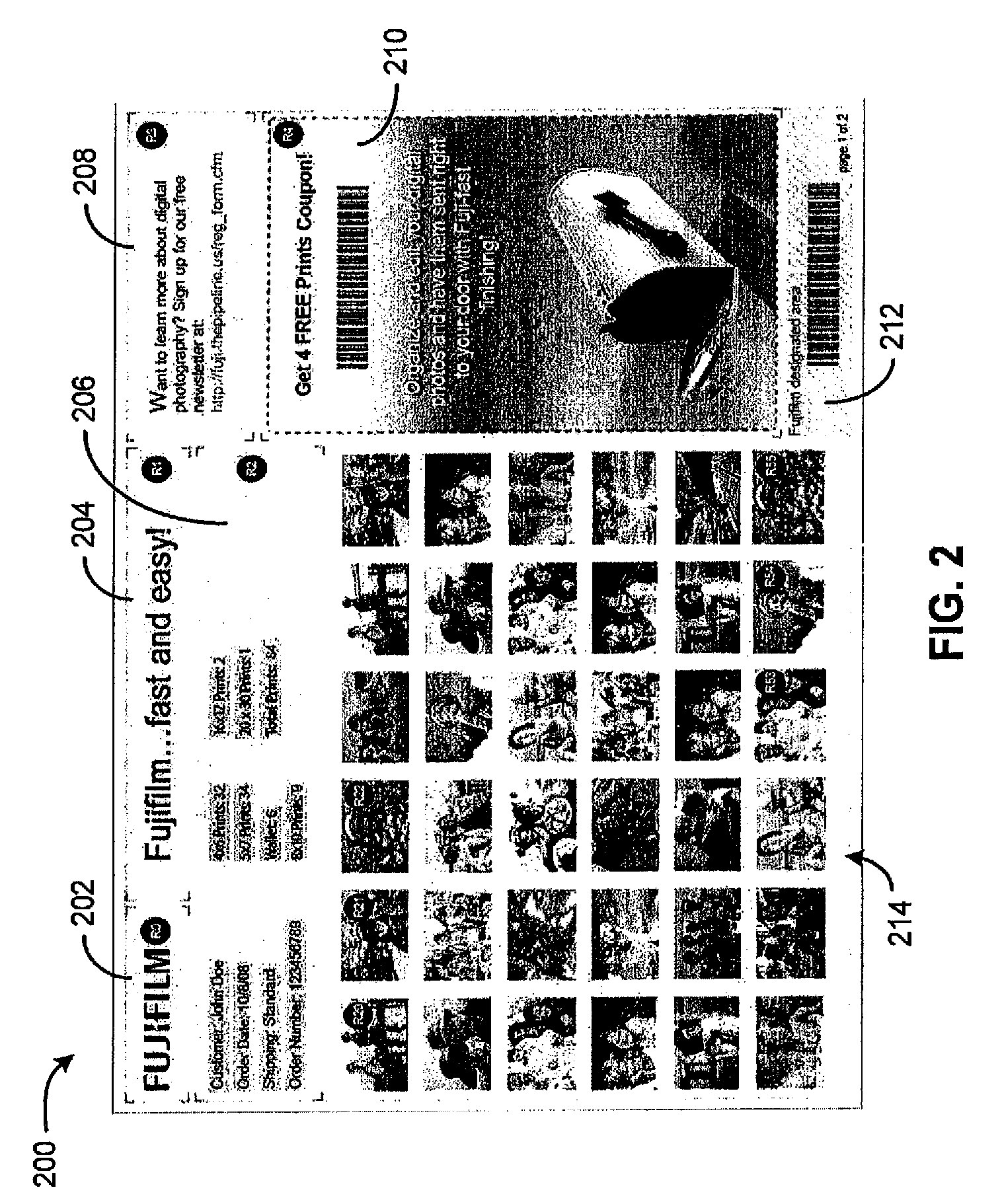

System and Method for Generating an Enhanced Index Print Product

ActiveUS20110288948A1Processed material treatmentDigital data processing detailsFilm ProcessorData-driven

The present invention is directed to a data driven methodology to construct index print products for photographic images. A system and method are provided for defining an index print product as a collection of regions which may be pieced together to present a final index product. The index product is customizable for and by any one or more retailers or integration partner providers for a unique appearance and offering to end customers. More specifically, the present invention relates to providing dynamic index print products of photographic images wherein the index print product may also include other content that is individually specified, provided and maintained by partner providers of a film processor or fulfillment center. Providers are able to leverage customized marketing and brand messaging or other advertisement to add value to their index print product.

Owner:FUJIFILM NORTH AMERICA CORP

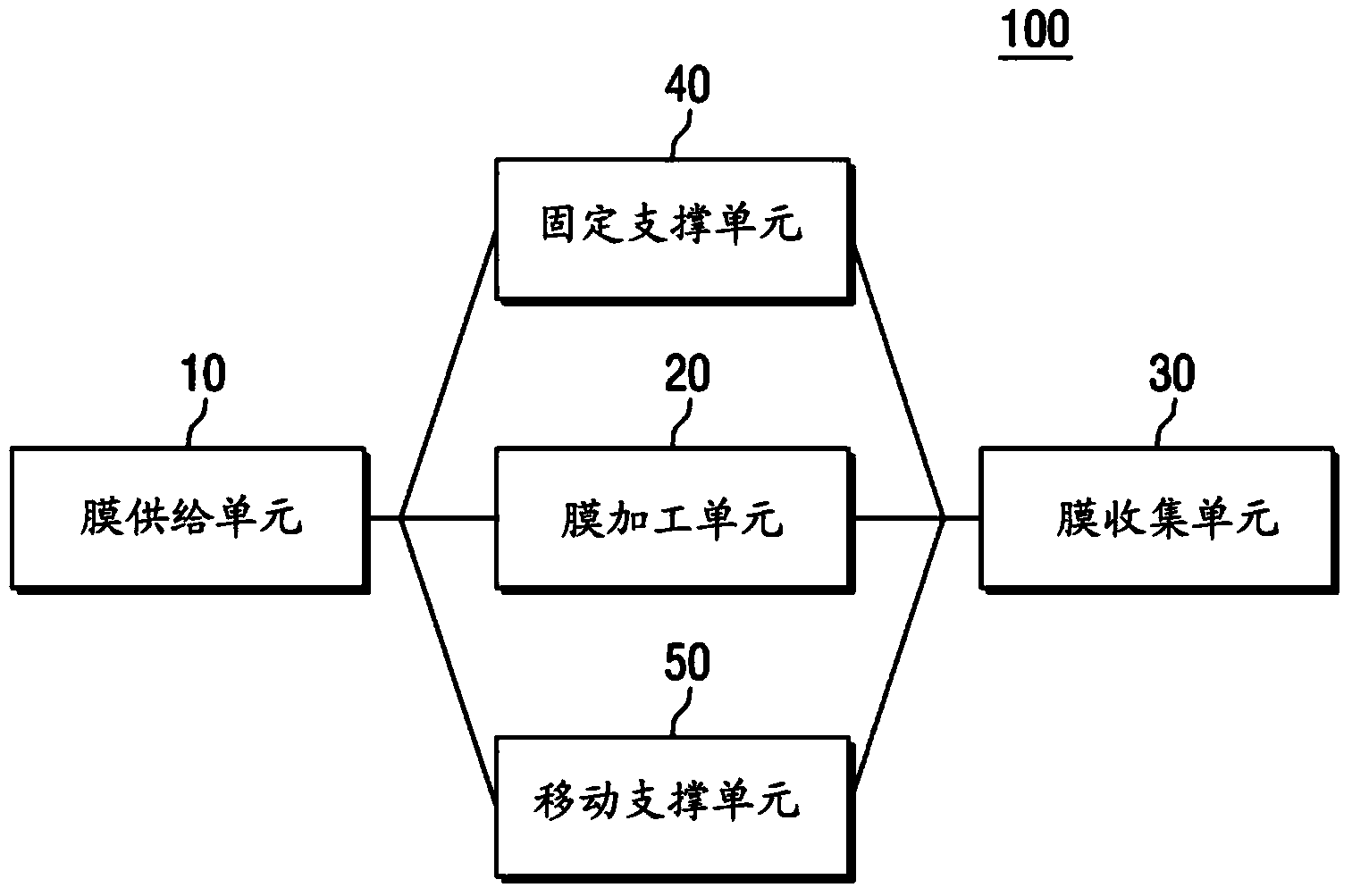

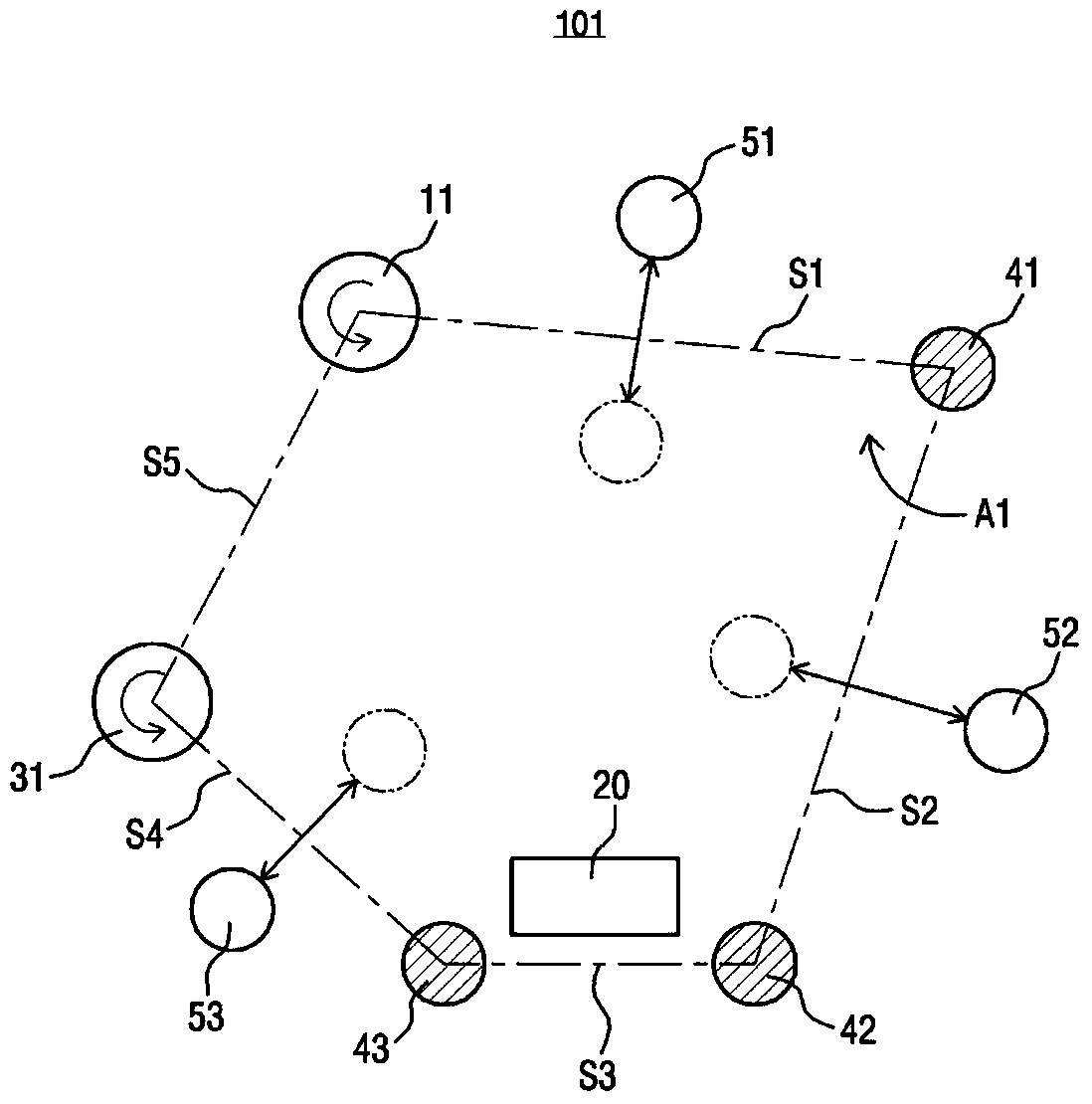

Film treating apparatus

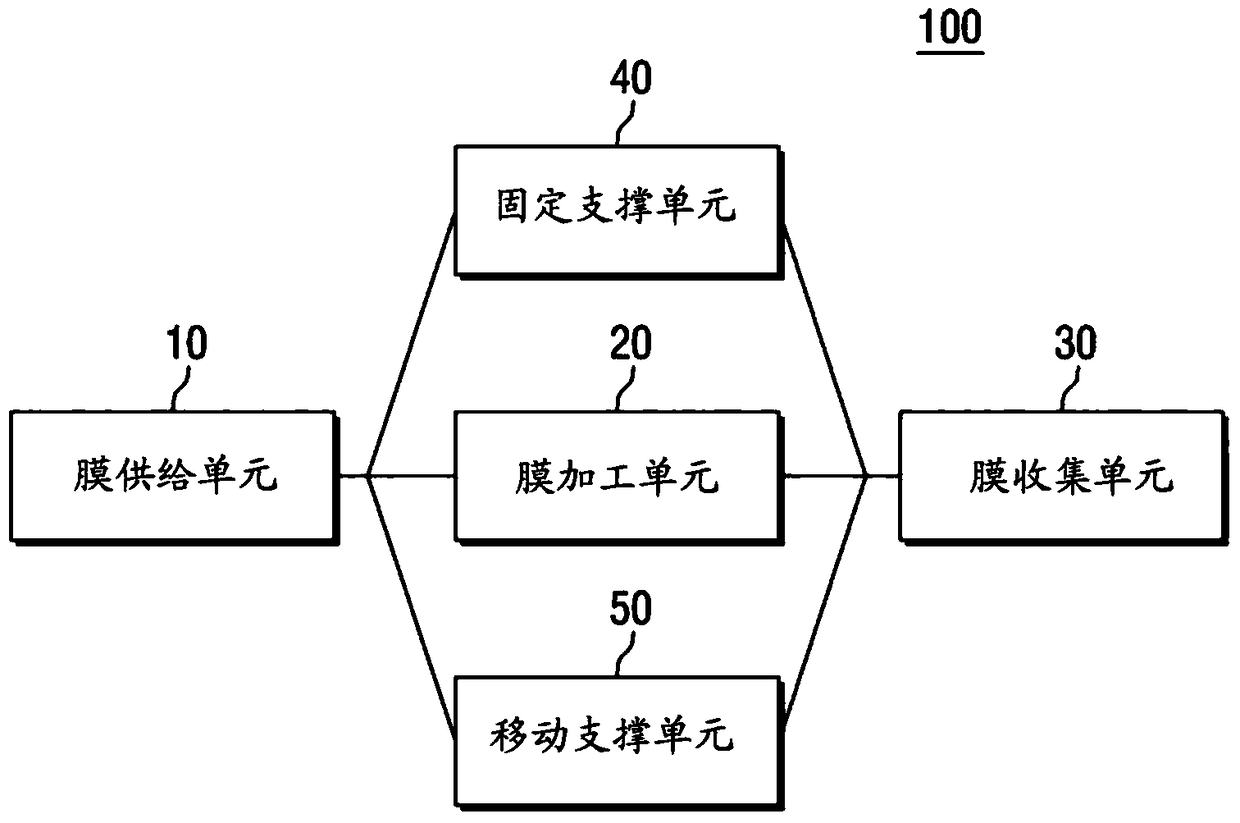

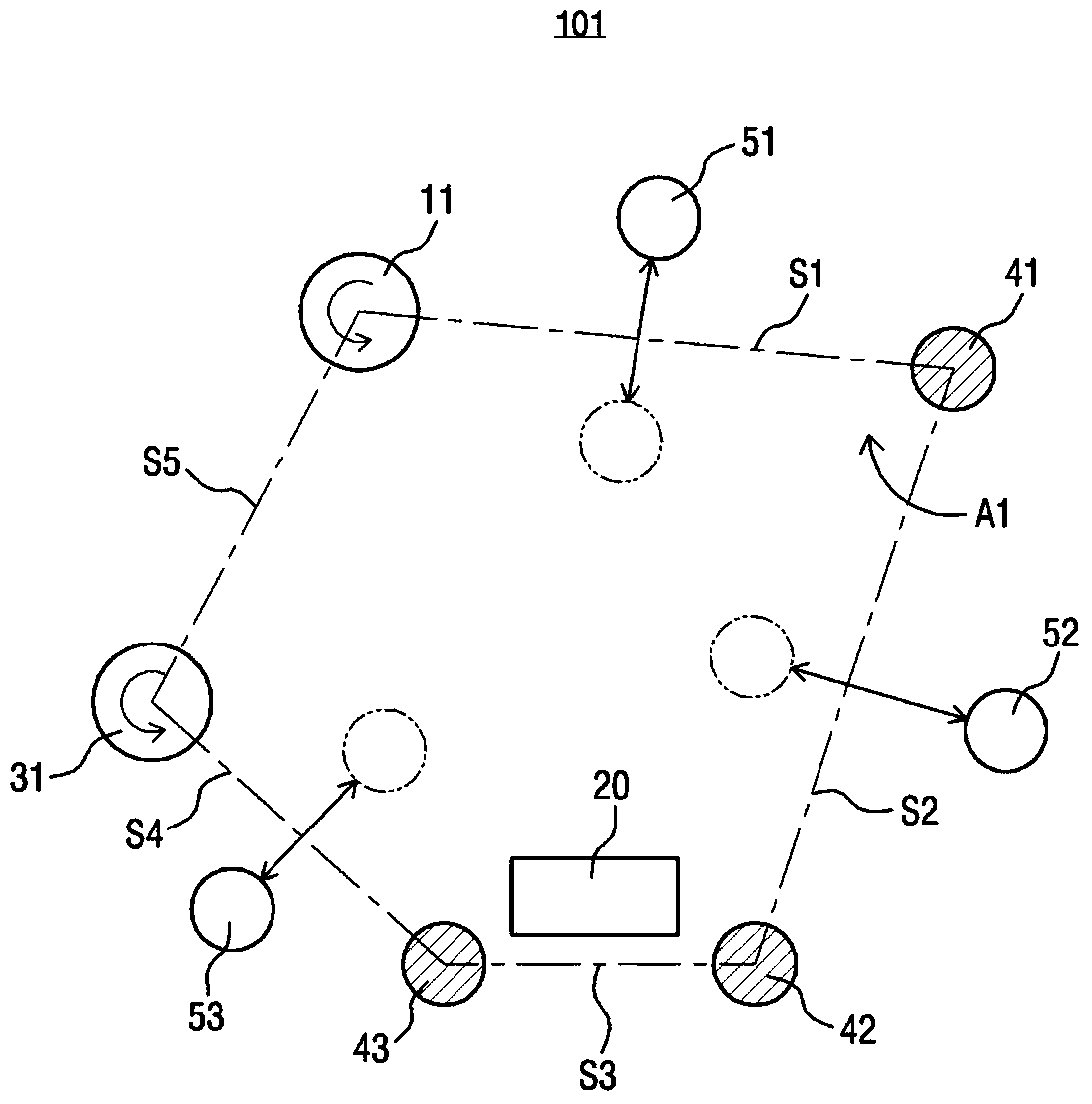

ActiveCN104167367ALamination ancillary operationsSemiconductor/solid-state device manufacturingFilm ProcessorElectrical and Electronics engineering

A film treating apparatus includes a film feeder configured to feed a film having first and second surfaces, a film processor configured to process the film fed from the film feeder, a film collector configured to collect the film processed by the film processor, a fixed support unit configured to support at least one of the first or second surface of the film and to guide the movement of the film, and a variable support unit configured to apply tension to the film while moving from the first surface of the film toward the second surface of the film.

Owner:SAMSUNG DISPLAY CO LTD

An image processor

ActiveCN107861332BWon't hurtGood flexibilityLiquid processing with progressive mechanical movementElectric machineryFilm Processor

The invention discloses a developing machine for an imaging department. The developing machine for the imaging department structurally comprises a film outlet, a stage, a film inlet, a transmission drying mechanism, a bench, support feet and a housing. The support feet are welded to four corners of the bottom end of the bench, the housing is arranged on the bench, the stage is arranged on the housing, the top of the stage is provided with the film outlet, the bottom of the stage is provided with the film inlet, the transmission drying mechanism and a motor are arranged inside the housing, andthe transmission drying mechanism is mechanically connected with the motor. By providing the structures such as a sponge clamp, a first vacuum tube, a second vacuum tube and a reflow tube, the problemof friction between a transmission roller and the film during drying is solved; the sponge clamp can absorb liquid drops on the film and may also reduce friction; by using the vacuum suction principle herein, the wetting problem of the sponge clamp is solved, and the liquid drops can be recycled.

Owner:安络杰医疗器械上海有限公司

Film treatment device

Owner:NORITZ CORP

High speed motion picture film processor

InactiveUS20110097074A1Reduce leakageAvoid leavingLiquid processing circulationPositive pressureOxygen sensor

A high speed motion picture film processor has a developer tank having a positive pressure relative to an ambient air pressure outside of the tank. A gas make-up system adds nitrogen inside of the developer tank while a system of seals minimizes leakage. Two seals are used along a periphery of the developer tank; one is below a sprocket level while the other is above the sprocket level. These two barriers can utilize a liquid reservoir that is filled by operation of the processor with excess liquid returning to the developer tank and they are constructed so as to allow movement. A film entrance sealing device and a film exit sealing device, each with its own housing, are also used with the developer tank; these units use a pair of rollers and a pair of flexible barriers to separate a tank gas chamber from an air chamber which is at a lower pressure and which contains a partial pressure of nitrogen fed into the entrance sealing device. The level of developer fluid is maintained at approximately the centerline of a first roller shaft but below that of a second roller shaft. The sprocket shaft has two smaller shafts mounted in metal bearings and a center tube on which the sprockets are mounted. Oxygen sensors with throttling exhaust devices outside the developer tank sound an alarm when oxygen level is too high in the developer tank. Reservoir fluid seals may also be used on secondary tanks.

Owner:MICHELSON MANFRED G

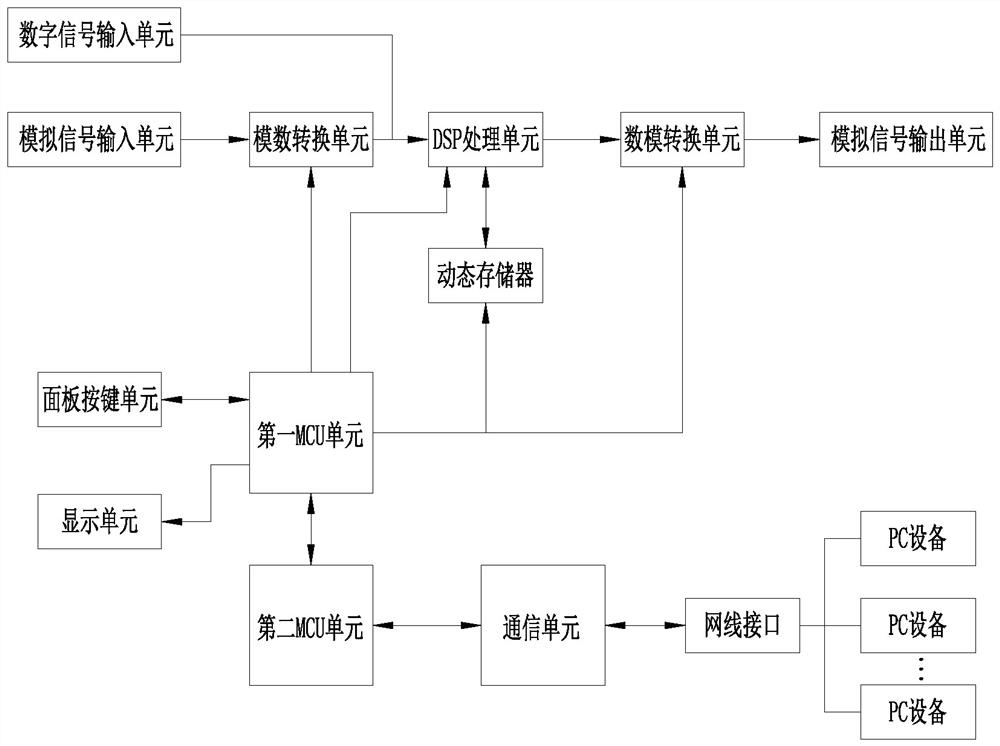

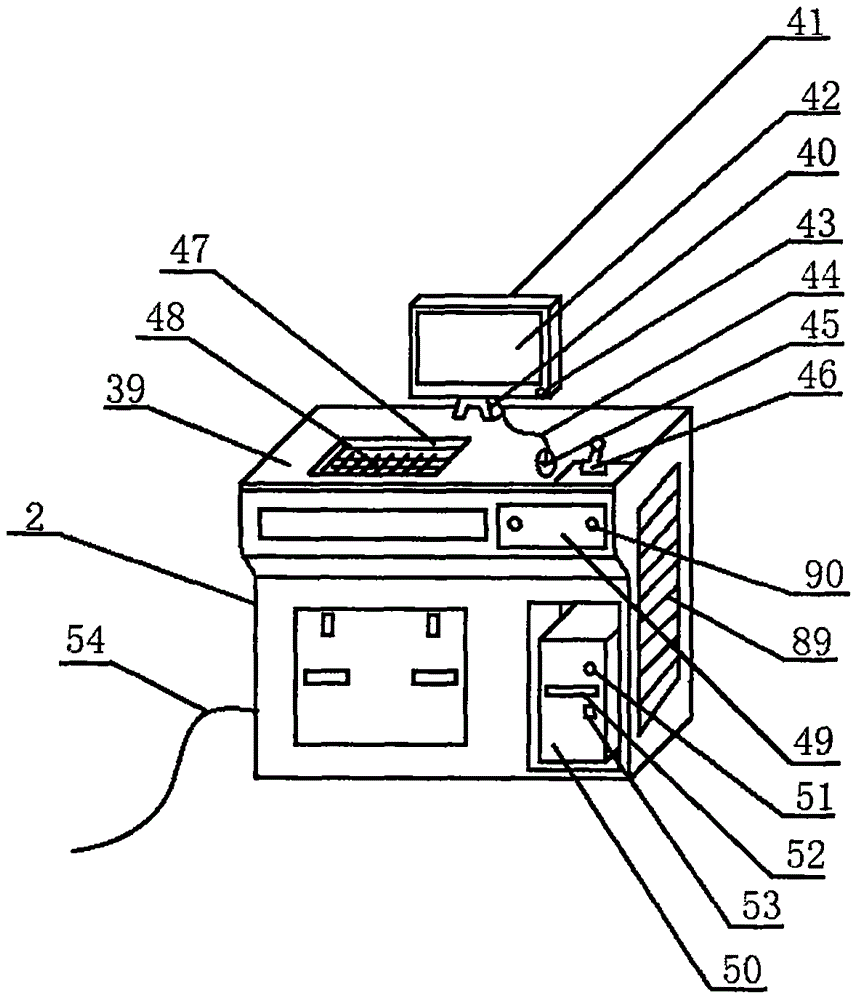

Film processor

PendingCN113301443AReduce configuration requirementsEasy to upgradeTransmissionSelective content distributionNetworked systemNetwork communication

A film processor comprises a processing module, a network communication module and a power supply module. The processing module comprises a digital signal input unit, an analog signal input unit, an analog-to-digital conversion unit, a DSP unit, a digital-to-analog conversion unit, a first MCU unit, an analog signal output unit, a display unit and a panel key unit. The network communication module comprises a second MCU unit, a communication unit and a network cable interface which are connected in sequence. The second MCU unit is used for controlling online communication and is connected with the first MCU unit. The communication unit is a TCP / IP and UDP Ethernet communication unit and is used for HTTP, TCP and UDP data communication, scripts for browsing the HTTP by a B / S WEB webpage are stored in the communication unit, and the communication unit is used for controlling a plurality of pieces of PC equipment. The network cable interface is connected with the communication unit and is used for inputting and outputting network communication data. By the technical scheme, a plurality of pieces of PC equipment or network system equipment can achieve simultaneous access and control in real time in a webpage mode.

Owner:FIRST AUDIO MFG CO LTD

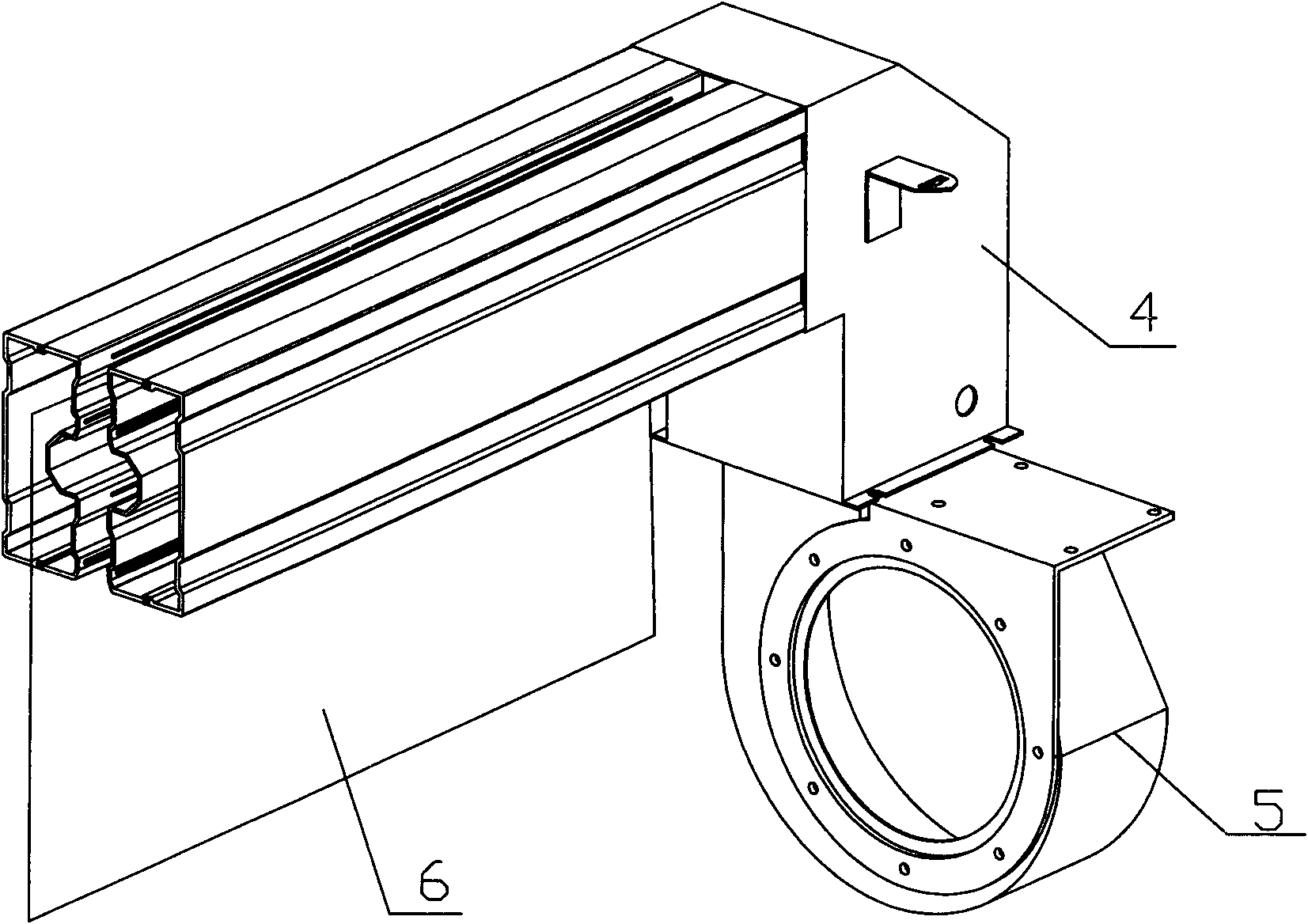

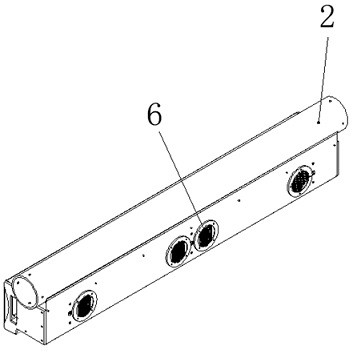

Small film processor drying air duct

InactiveCN101673044AImprove thermal efficiencyExtended service lifeLiquid processingElectricityEngineering

The invention relates to a small processor drying air duct for medical treatment and industry, in particular to a small film processor drying air duct. The small film processor drying air duct consists of an upper rectangular air guide cylinder and a lower rectangular air guide cylinder, wherein jet orifices are arranged on the upper rectangular air guide cylinder and the lower rectangular air guide cylinder. The invention has the advantages that hot air injected by the drying air duct is more uniform, and the thermal efficiency is greatly improved; compared with an air supply mode of an original single-cylinder arrangement method, the drying air duct can save electricity by about 20 percent and has convenient mounting and maintenance as well as prolonged service life.

Owner:HUQIU IMAGING TECH SUZHOU

film processor

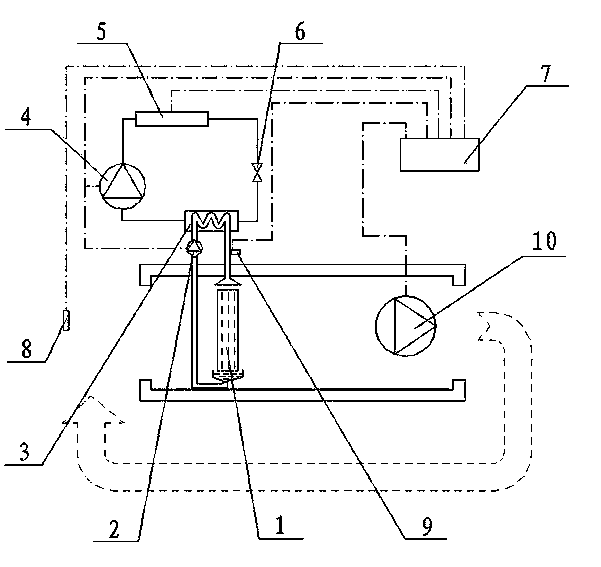

The invention discloses a film developing machine. The film developing machine comprises a shell (1), the top part of the shell (1) is sunken inward to form a water tank (2), and the water tank (2) is equipped with There are a flushing liquid combination (19), a horizontal flushing barrel and a heater (3); wherein, one end of the flushing liquid combination (19) is connected to the air pump (5) through the air pipe (4), and the other end is connected to the air pump (5) through the The water pipe (6) is connected with the flushing barrel; the gas generated by the air pump (5) can enter the flushing liquid combination (19) through the air pipe (4) and the flushing liquid combination ( 19) The flushing liquid is pressed into the flushing barrel along the water pipe (6) to perform the film flushing operation. The film developing machine has a simple structure, takes up little space, is easy to carry, is easy to operate, and can quickly and efficiently develop the film.

Owner:WUHU HUANGYAN IND

Membrane treatment device

ActiveCN104167367BLamination ancillary operationsSemiconductor/solid-state device manufacturingFilm ProcessorElectrical and Electronics engineering

Owner:SAMSUNG DISPLAY CO LTD

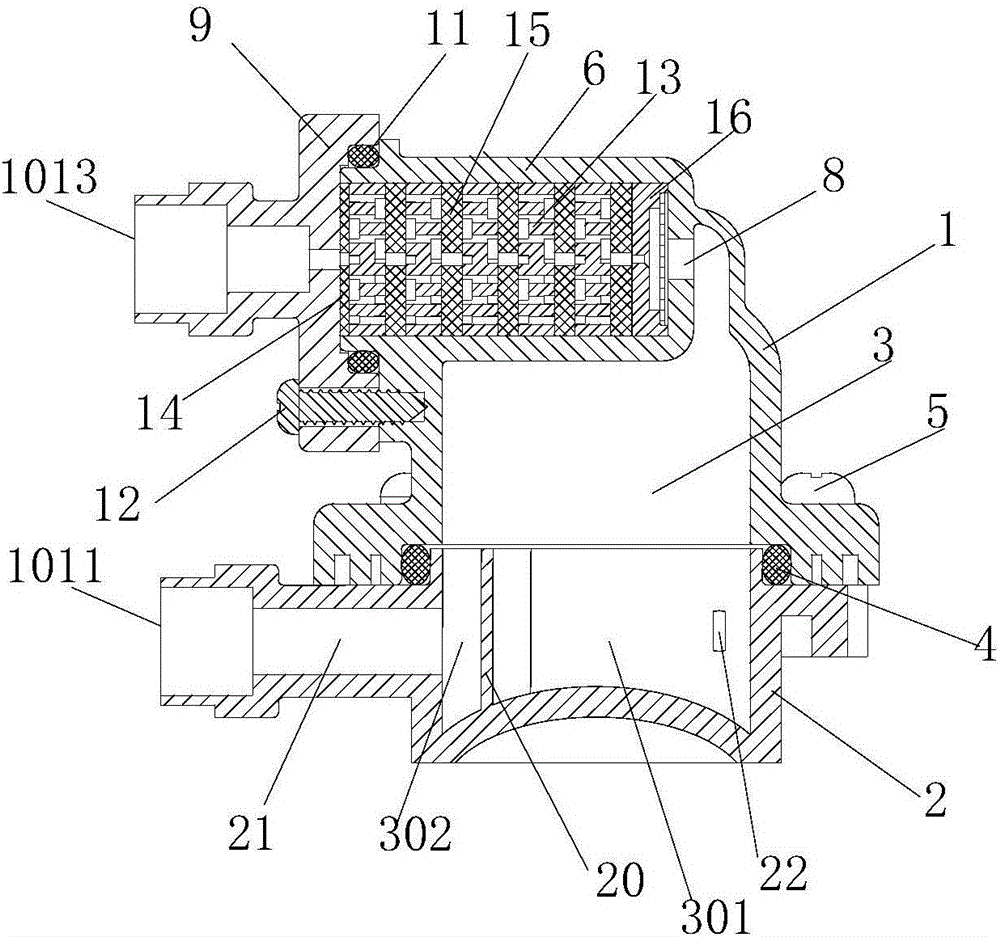

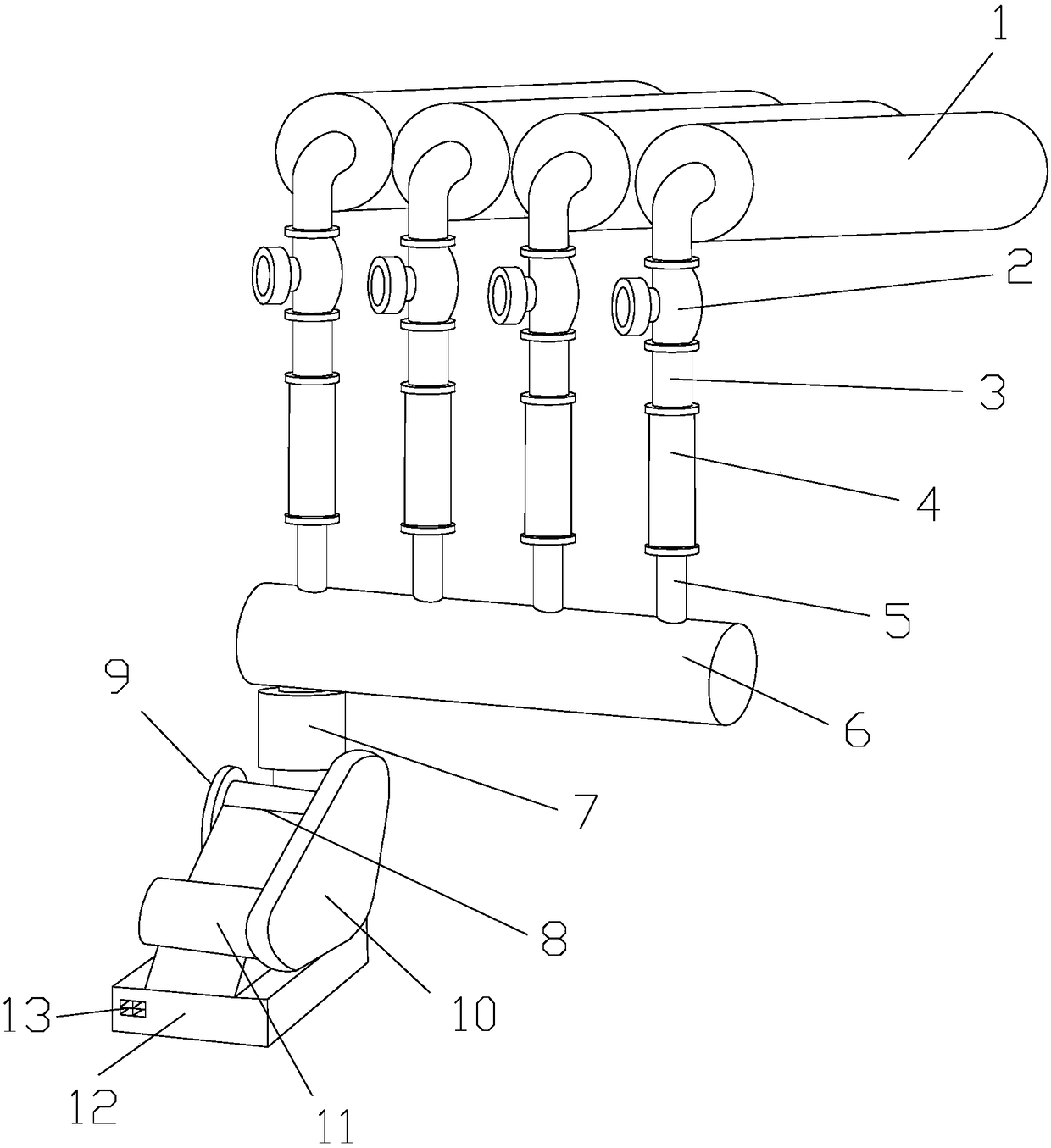

Roller heat dissipation device of low-temperature plasma metal film processor

ActiveCN113179621AImprove cooling effectElectric discharge tubesModifications for power electronicsCooling effectEngineering

The invention discloses a roller heat dissipation device of the low-temperature plasma metal film processor. The device comprises a fixed frame, a rotary opening and closing exhaust pipeline and a discharge roller are symmetrically arranged on the fixed frame, an air suction opening is fixedly formed in one side of the rotary opening and closing exhaust pipeline, and an exhaust fan is arranged at the air suction opening. A plurality of air inlet pipelines are arranged on the rotary opening exhaust pipeline, the air inlet pipelines are inserted into the electrode opening and closing mechanism, the outer pipe wall of the rotary opening exhaust pipeline is fixedly connected with the electrode opening and closing mechanism through a connecting plate, and a plurality of air inlets are formed in the electrode opening and closing mechanism; a plurality of electrode tubes are fixedly mounted on one side, close to the discharge roller, of the electrode opening and closing mechanism. The device has the beneficial effects that high temperature on the discharge roller can be cooled through cooling circulating water through the cooling water rotary joint, and meanwhile, the high temperature on the discharge roller and the electrode pipes is pumped away through the rotary opening and closing exhaust pipeline in cooperation with an exhaust fan at an exhaust opening; and the overall good cooling effect is achieved.

Owner:南京珀斯佩特电子科技有限公司

Method for solving expansion problem of hot water tank of straight drink machine and straight drink machine

PendingCN107319940AAvoid dripping problemsPrevent leakageWater treatment parameter controlTreatment involving filtrationLeaking waterWater storage

The invention provides a method for solving an expansion problem of a hot water tank of a straight drink machine, and the straight drink machine. The straight drink machine comprises a film processor, a pressurized water storage tank, a hot tank, a drain vale and a hot tank water inlet valve, wherein a water inlet of the film processor communicates with a water source, a purified water outlet of the same communicates with a water purification cavity of the pressurized water storage tank and an inlet of the hot tank water inlet valve, and a concentrated water outlet of the same communicates with a concentrated cavity of the pressurized water storage tank and an inlet of the drain valve, an outlet of the hot tank water inlet valve communicates with a water inlet of the hot tank, and the hot tank is provided with a water outlet; after the hot tank stops draining each time, a water level in the hot tank is reduced to be not higher than an upper control water level of the hot tank by reducing the amount of water in the concentrated water cavity in the pressurized water storage tank; and a set distance is formed between the upper control water level and the inner surface of the top of the hot tank. Compared with the prior art, the method utilizes the hot tank water inlet valve to replace a hot tank water outlet valve function of controlling water in and out of the hot tank, and thus the problem that the water outlet of the hot tank drips and leaks water due to unreliable sealing of the hot tank water outlet valve is thoroughly avoided.

Owner:JIANGSU CIKON ENVIRONMENTAL APPLIANCE CO LTD

Device for barium enema examination of upper digestive tract

The invention relates to an upper gastrointestinal barium penetration detection device, which belongs to the technical field of medical devices. The upper gastrointestinal barium penetration detection device of the present invention comprises a fluoroscopy inspection equipment main body, a monitoring control system and an automatic film processor, a perspective plate is arranged on the fluoroscopy inspection equipment main body, a central symmetry line is arranged on the perspective plate, and the lower side of the perspective plate is There is a protective plate, a perspective standing platform is provided on the lower front side of the perspective plate, a circular standing frame is arranged on the perspective standing platform, a manual console carrier is provided on the lower right side of the main body of the perspective inspection equipment, and a There is a manual control cable, and the manual control cable is connected with the imaging measuring instrument, and the imaging measuring instrument is provided with an electronic imaging screen. The invention has complete functions, is convenient to use, saves time and effort when performing X-ray detection of the digestive tract of patients, is scientific and convenient, safe and efficient, and reduces the work difficulty of medical personnel.

Owner:姜言

Concentration technology for zymogen liquid

ActiveCN101642680BIncrease collection rateHigh recovery rateSemi-permeable membranesTissue/virus culture apparatusZymogenPolymer science

The invention discloses a concentration technology for zymogen liquid. The concentration technology adopts macromolecule polyacrylonitrile fiber hollow film filter tube combined equipment as concentration equipment and depends on the pressure difference of an inlet and an outlet, zymogen liquid with lower concentration continuously and circularly flows in a film processor comprising unnumbered fiber film tubes, water continuously leaks out from millipores of the walls of the fiber film tubes, and finally the purpose of concentration can be achieved; and during backwashing, the fiber film tubesare processed by reverse washing by cleaner, substances piled around the millipores of the film tubes in the original concentration and filtration are cleanly washed, and film processing equipment can be guaranteed to be regenerated. The invention is the concentration technology for the zymogen liquid, having the advantages of simplicity, high reliability, easy running operation, low overhaul andmaintenance, reasonable structure of products, and high safety, economy, durability, concentration efficiency of the zymogen liquid and production efficiency.

Owner:湖南豫园生物科技股份有限公司

Flexible film transmission and guide device of film processor

The invention relates to a steering (turning) transmission and guide device used by a film processor in the process of processing a film, in particular to a flexible film transmission and guide deviceof a film processor. The flexible film transmission and guide device comprises a flexible guide belt roll shaft driven by a film transmission sheet, wherein a turning position below the flexible guide belt roll shaft driven by a film transmission sheet is connected by a circular flexible guide belt which is of an L shape. The invention has the advantages of guaranteeing the processing quality, ensuring the operation of a processing shaft bracket to be easy and free, effectively reducing the operation load of a motor, prolonging the service life of the whole machine and having safety and reliability.

Owner:HUQIU IMAGING TECH SUZHOU

Intelligent fast loading machine

Owner:成都军区昆明总医院

Flue gas desulphurization system for boiler

InactiveCN106731636AIncrease flow lengthLower the altitudeGas treatmentDispersed particle separationFlue gasSlurry

The invention discloses a flue gas desulphurization system for a boiler, and belongs to the technical field of environmental protection of flue gas desulphurization. The flue gas desulphurization system comprises a desulphurization tower, a draught fan and a chimney, wherein the desulphurization tower, the draught fan and the chimney are connected in sequence; the desulphurization tower consists of a desulphurization primary tower and a desulphurization secondary tower; the top of the desulphurization primary tower is communicated with the top of the desulphurization secondary tower; the bottom of the desulphurization primary tower is provided with a flue gas inlet pipe; the bottom of the desulphurization secondary tower is provided with a flue gas outlet pipe; the flue gas outlet pipe is communicated with the draught fan; the lower part of the desulphurization primary tower is provided with a water-film processor; the water-film processor is arranged above the flue gas inlet pipe; the bottom of the desulphurization primary tower is provided with a grey water ditch; the grey water ditch is communicated with a sedimentation tank; supernatant fluid in the sedimentation tank is pumped into the water-film processor through a clear water pump; the upper part of the desulphurization primary tower is provided with multiple stages of lime slurry spraying pipes; a dehydrator is arranged in the desulphurization secondary tower. By using the flue gas desulphurization system for the boiler, which is provided by the invention, harmful gases of SO3, chloride, fluoride and the like can be effectively removed; the removal rate reaches 95 percent or above.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

Sea water desalination device utilizing solar energy

InactiveCN108439542AImprove stabilityImprove work efficiencyGeneral water supply conservationSeawater treatmentWater desalinationPower belt

The invention discloses a sea water desalination device utilizing solar energy. The device comprises a film processor, an automatic control valve, a valve connecting pipe, a flow monitor tube, an output branch pipe, a main output pipe, a water pump output connector, a water pump main body, a water pump water inlet, a water pump power belt box, a low-voltage direct-current motor, a motor base and asolar power interface; the film processor is connected with the automatic control valve through a connecting pipeline, the valve connecting pipe is arranged on the lower portion of the automatic control valve, the valve connecting pipe is fixedly connected with the automatic control valve through a flange, the flow monitor pipe is arranged on the lower portion of the valve connecting pipe, the stability of work of the equipment can be effectively improved, when the pressure in the equipment is too high, a drain valve can be automatically switched on, the phenomenon that the permeation pressure is too high, so that the work efficiency is lowered is prevented, the work efficiency and work stability of the equipment are effectively improved, and the degree of automation of use of the equipment is improved.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

Falling film constant temperature and humidity system

InactiveCN103557558AReduce energy consumptionEasy to replaceSpace heating and ventilation safety systemsLighting and heating apparatusFrequency conversionControl system

The invention discloses a falling film constant temperature and humidity system which comprises a refrigeration system, an air supply system, a control system and a falling film processing system. The control system is used for maintaining constant temperature and constant humidity of indoor environment. The falling film processing system comprises at least one falling film processor, a water pump and an evaporator, and the falling film processor, the water pump and the evaporator are mutually communicated. The refrigeration system comprises a compressor, a condenser and a throttling device. The evaporator and the condenser are communicated with the compressor and the throttling device, the water pump, the compressor, the condenser and the air feeding system are connected with the control system, the water pump, the evaporator and the refrigeration system are arranged outdoors, the falling film processor and the air supply system are arranged indoors, the control system is connected with a temperature and humidity sensor and a temperature sensor, and a frequency conversion fan is adopted in the air supply system. The falling film constant temperature and humidity system is simple in work process, low in energy consumption, easy to replace and capable of improving air quality.

Owner:杭州上岛电器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com