Roller heat dissipation device of low-temperature plasma metal film processor

A low-temperature plasma and metal thin film technology, which is applied in the modification of power electronics, cooling/ventilation/heating transformation, discharge tubes, etc., can solve problems such as the inability to meet the heat dissipation requirements of electrode tubes and discharge rollers, and achieve a good cooling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

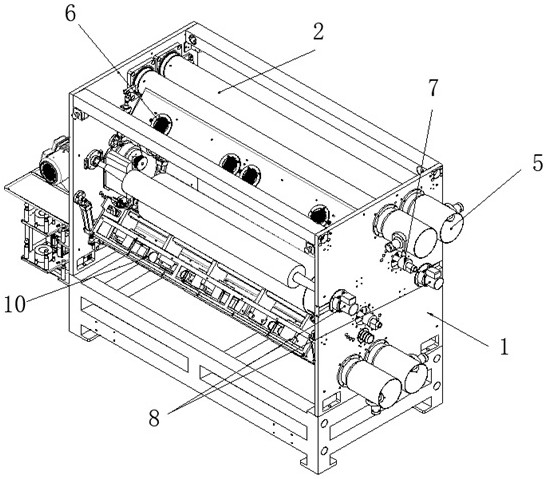

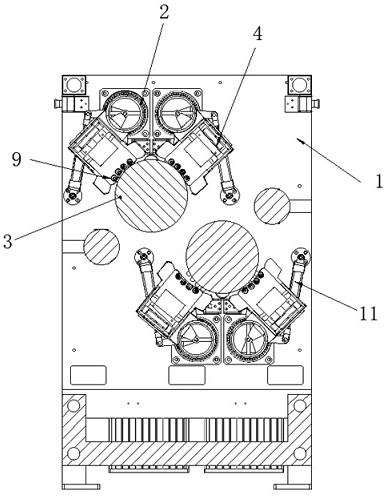

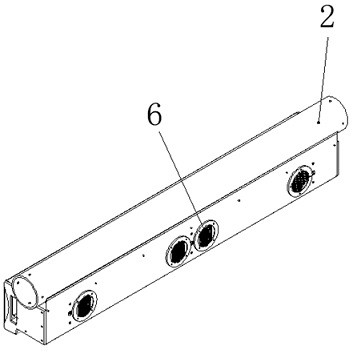

[0025] In the actual working process, the metal film enters the discharge roller 3 through the guide roller. When the whole metal film machine is working, the discharge roller 3 and the electrode tube 9 will generate heat at the same time. First, the cooling water is poured into the discharge roller through the water-cooled rotary joint 7 In the roller 3, the cooling water is circulating water, which is poured into one side and flows out from the other side to realize the cooling of the discharge roller 3; at the same time, the exhaust fan provided at the exhaust port 5 can extract the heat, and the external air passes through the inlet The tuyere 6 enters the half frame of the electrode opening and closing mechanism 4, and then enters the rotary opening and closing exhaust duct 2 through the air inlet duct 10. Since the electrode opening and closing mechanism 4 is close to the discharge roller 3, when the external air passes through the discharge roller 3, it can also lower th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com