Film effluent non-backpressure water purifier

A water purifier, no back pressure technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. The utilization rate is large, the manufacturing cost is reduced, and the effect of easy promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] like figure 1 As shown, it is a structural schematic diagram of a water purifier without back pressure with membrane outlet provided by the present invention. The membrane outlet water purifier without back pressure includes a membrane processor 4, a pressurized water storage tank 14, a small flow throttle valve 15, a flushing valve 13, a water inlet valve 3, a drain valve 17, a one-way valve 8, and a water outlet valve. 11 and an electrical control device, the electrical control device is electrically connected to the flushing valve 13, the water inlet valve 3 and the drain valve 17, and the electrical control device includes a first pressure switch 7 and a second pressure switch 10. The water purification outlet of the membrane processor 4 is respectively connected to the water purification cavity of the pressurized water storage tank 14 and the inlet of the one-way valve 8 through the water purification pipeline 6, and the first pressure switch 7 is arranged on the w...

Embodiment 2

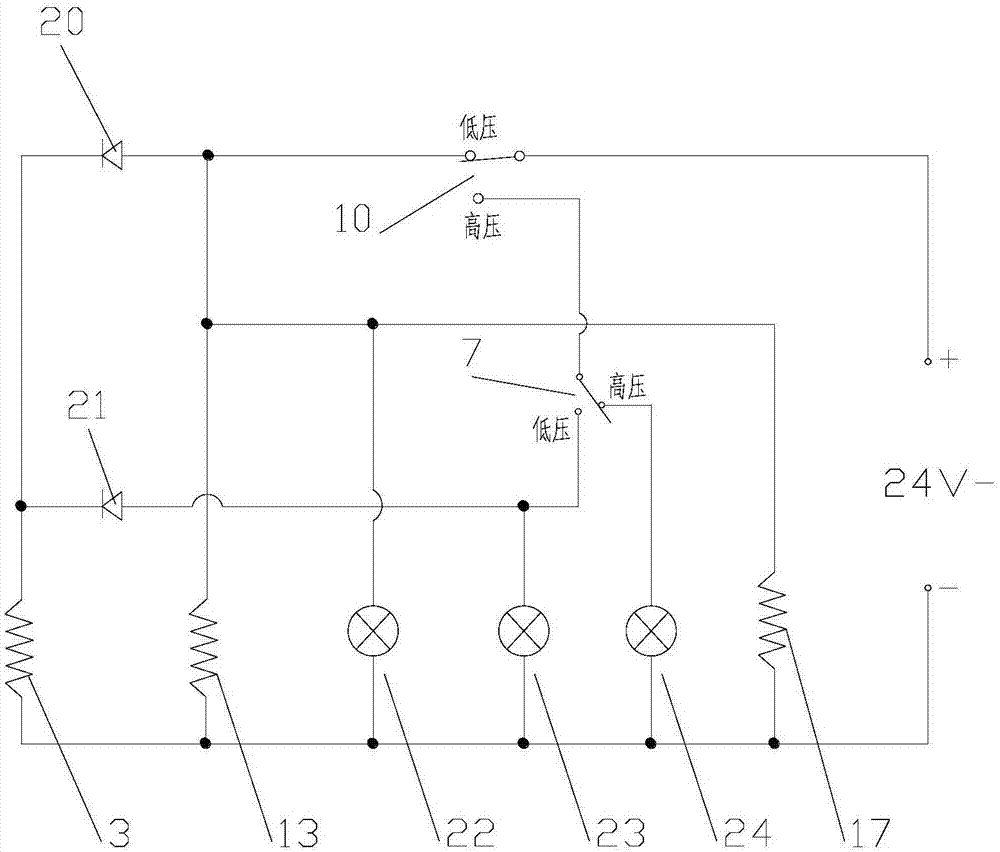

[0045] like image 3 It is a schematic diagram of the electric connection between the electric control device and each valve body in this embodiment. The electrical control device in the water purifier of this embodiment is different from Embodiment 1 in that: the first pressure switch 7 in the electrical control device in this embodiment has three electrical terminals and is controlled by water pressure. Pressure switch, its three electrical terminals are respectively the common terminal (also known as the power supply terminal), the high water pressure conduction terminal and the low water pressure conduction terminal. The electrical control device also includes a second diode 21, a water-making indicator light 23, a water outlet indicator light 22 and a standby indicator light 24. terminal and the negative pole of the first diode 20, allowing the current to flow from the low water pressure conduction end of the first pressure switch 7 to the negative pole of the first diod...

Embodiment 3

[0047] like Figure 4 As shown in FIG. 1 , it is a structural schematic diagram of another water purifier without back pressure with membrane outlet provided by the present invention. The difference between the water purifier of this embodiment and that of Embodiment 1 is that the water purifier with membrane water outlet without back pressure in this example also includes a pretreatment filter element 2, which is arranged on the water inlet pipeline of the membrane processor 4, and the pretreatment filter element The water inlet of the filter element communicates with the water source 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com