Water purifier

A water purifier and concentrated water technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor product performance consistency, inconvenient maintenance and inconvenience Mass production and other problems, to achieve the effect of facilitating mass production, reducing pipeline connection joints, and simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

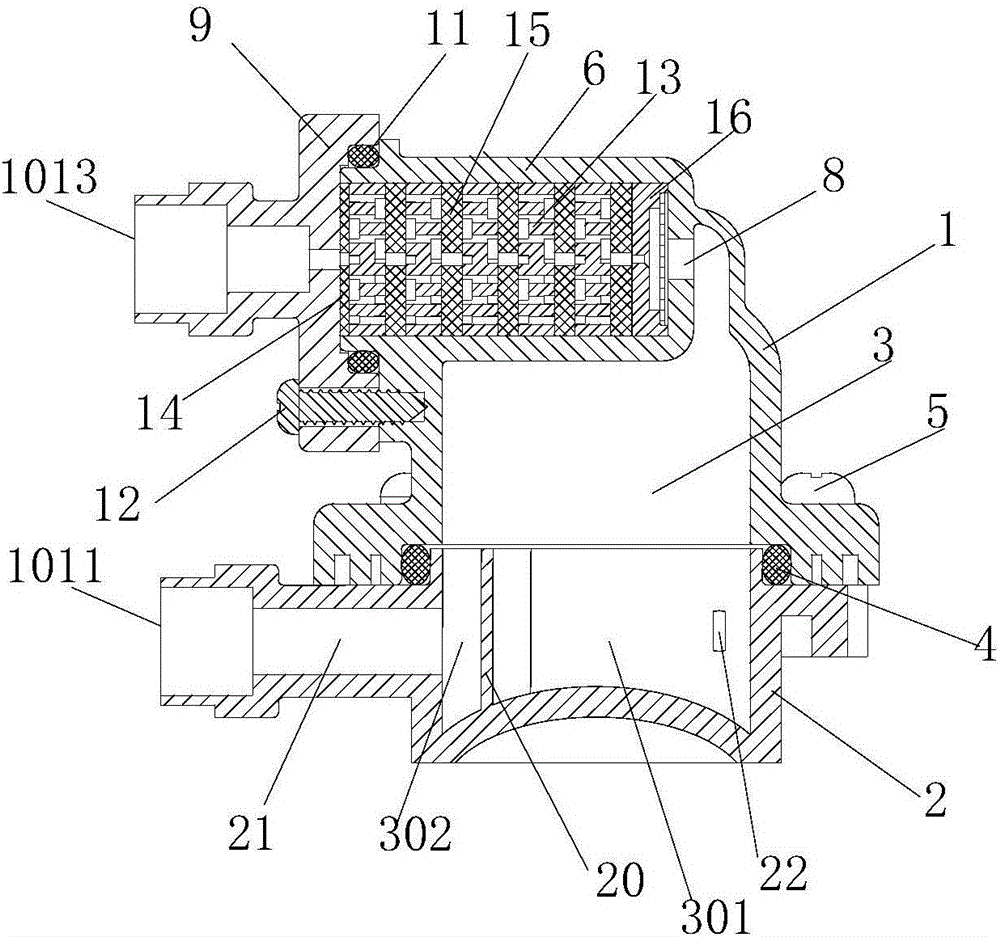

[0046] Such as figure 1 as shown, figure 1A schematic structural diagram of a water purifier provided by the present invention, the water purifier includes: a waterway collection body 101, a water pump 102, a pretreatment filter element 103, a membrane processor 104, a one-way valve 105, and a large flow throttling device 106 And magnetized water processor 107. A concentrated water outlet 1011 , a concentrated water inlet 1012 and a concentrated water discharge port 1013 are provided on the waterway collector 101 . The concentrated water outlet 1011 of the waterway collector 101 is connected to the inlet of the one-way valve 105 , and the outlet of the one-way valve 105 is connected to the inlet of the pretreatment filter element 103 . The inlet of the pretreatment filter element 103 is also connected to the raw water inlet 108 . The outlet of the pretreatment filter element 103 is connected to the water inlet of the membrane processor 104, the concentrated water port of th...

Embodiment 2

[0054] Such as Figure 9 As shown, it is a structural schematic diagram of another water purifier provided by the present invention. The water purifier includes: a waterway collection body 101, a water pump 102, a pretreatment filter element 103, a membrane processor 104, a one-way valve 105 and magnetized water Processor 107. A concentrated water outlet 1011 , a concentrated water inlet 1012 and a concentrated water discharge port 1013 are provided on the waterway collector 101 . The concentrated water outlet 1011 of the waterway collector 101 is connected to the inlet of the one-way valve 105 , and the outlet of the one-way valve 105 is connected to the inlet of the pretreatment filter element 103 . The inlet of the pretreatment filter element 103 is also connected to the raw water inlet 108 . The outlet of the pretreatment filter element 103 is connected to the water inlet of the membrane processor 104, the concentrated water port of the membrane processor 104 is connecte...

Embodiment 3

[0059] Such as Figure 12 As shown, it is a structural schematic diagram of another water purifier provided by the present invention. The water purifier includes: a waterway collector 101 , a water pump 102 , a pretreatment filter element 103 , a membrane processor 104 and a one-way valve 105 . A concentrated water outlet 1011 , a concentrated water inlet 1012 and a concentrated water discharge port 1013 are provided on the waterway collector 101 . The concentrated water outlet 1011 of the waterway collector 101 is connected to the inlet of the one-way valve 105 , and the outlet of the one-way valve 105 is connected to the inlet of the pretreatment filter element 103 . The inlet of the pretreatment filter element 103 is also connected to the raw water inlet 108 . The outlet of the pretreatment filter element 103 is connected to the water inlet of the membrane processor 104, the concentrated water port of the membrane processor 104 is connected to the concentrated water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com