Small film processor drying air duct

A technology of small film and processing machines, applied in optics, instruments, liquid processing equipment, etc., can solve the problems of misjudgment, uniformity and heat error, difficulty in reading and viewing films, etc., and achieves improved service life, convenient installation and maintenance, The effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] figure 1 , figure 2 As shown in the figure, a drying air duct of a small film developing machine adopts a special structure of upper rectangular air guide tube 1 and lower rectangular air guide tube 1 to supply hot air, plus an injection port 3 designed for air guide and interception , so that the sprayed hot air has a uniform temperature and a uniform wind speed, which greatly improves the effect and efficiency of hot air injection.

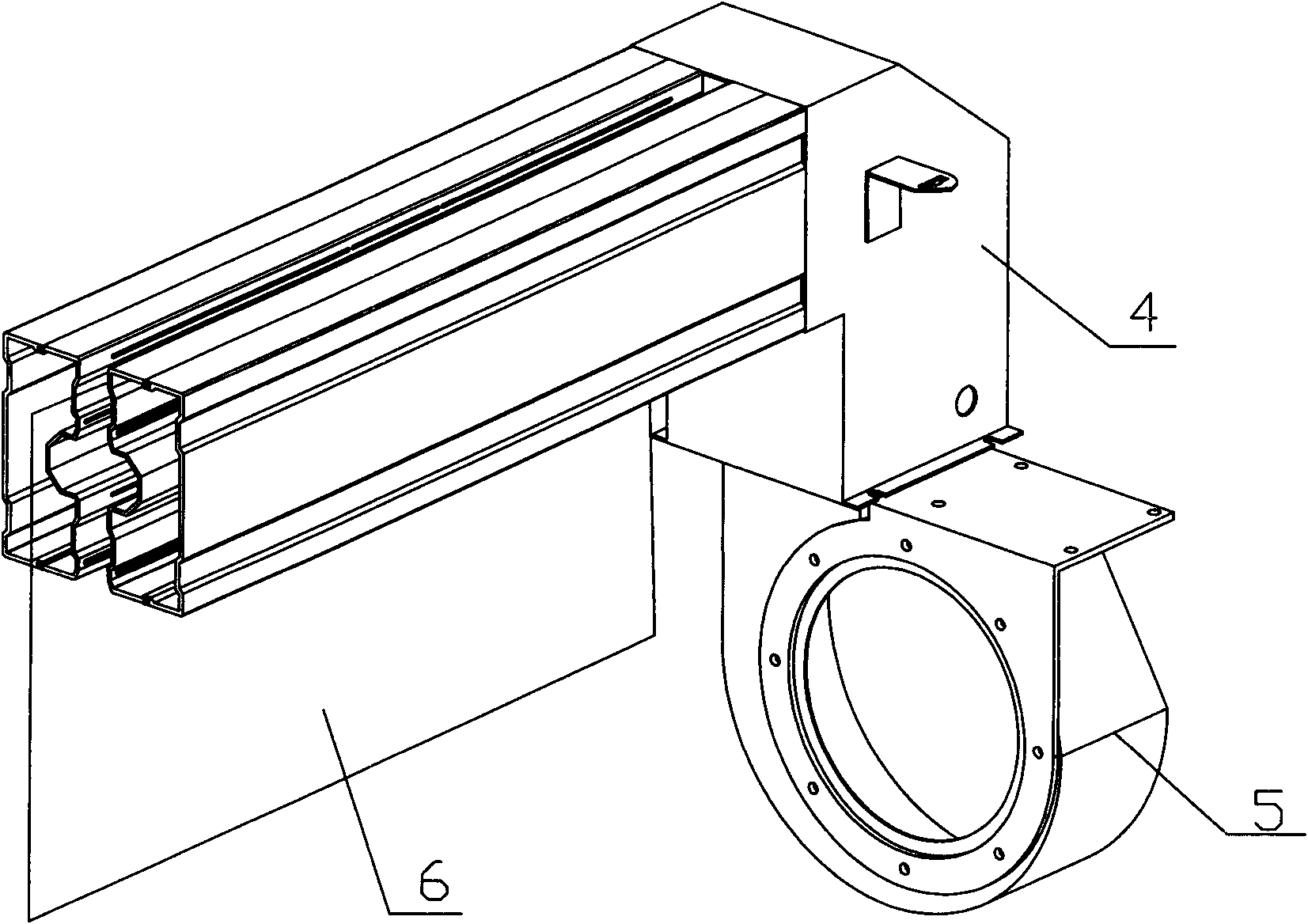

[0012] Such as image 3 As shown, the drying air duct of the small film developing machine is connected with the fan 5 through the heating cylinder 4 to form a drying air duct blowing system of the small film developing machine. The wind provided by the fan 5 passes through the heating cylinder 4 to heat the air, and sends the hot air to the drying air duct of the small film developing machine. At this time, the film 6 passes through the middle of the drying air duct of the small film developing machine from bottom to top, and is passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com