Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Cam engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cam engine is a reciprocating engine where, instead of the conventional crankshaft, the pistons deliver their force to a cam that is then caused to rotate. The output work of the engine is driven by this cam.

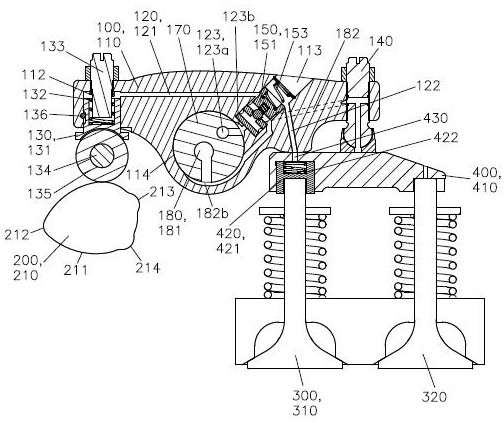

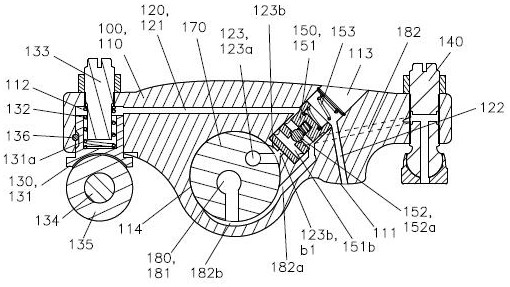

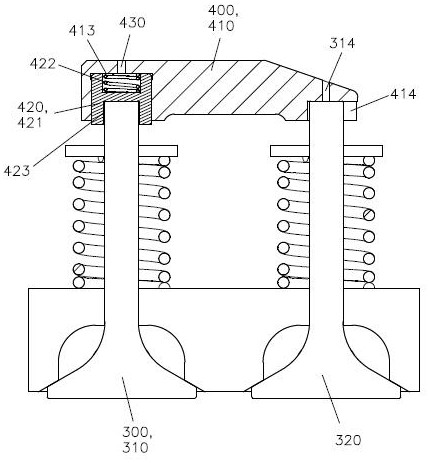

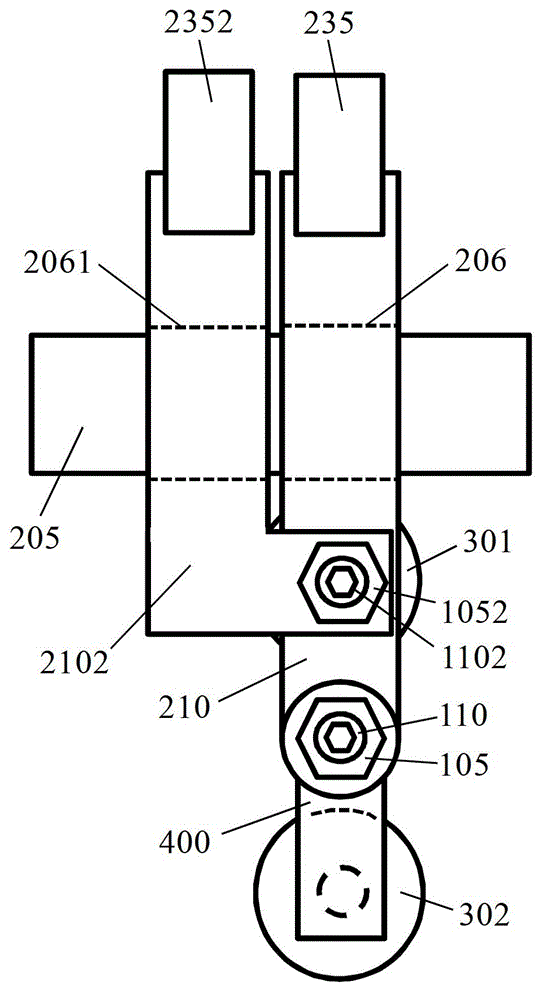

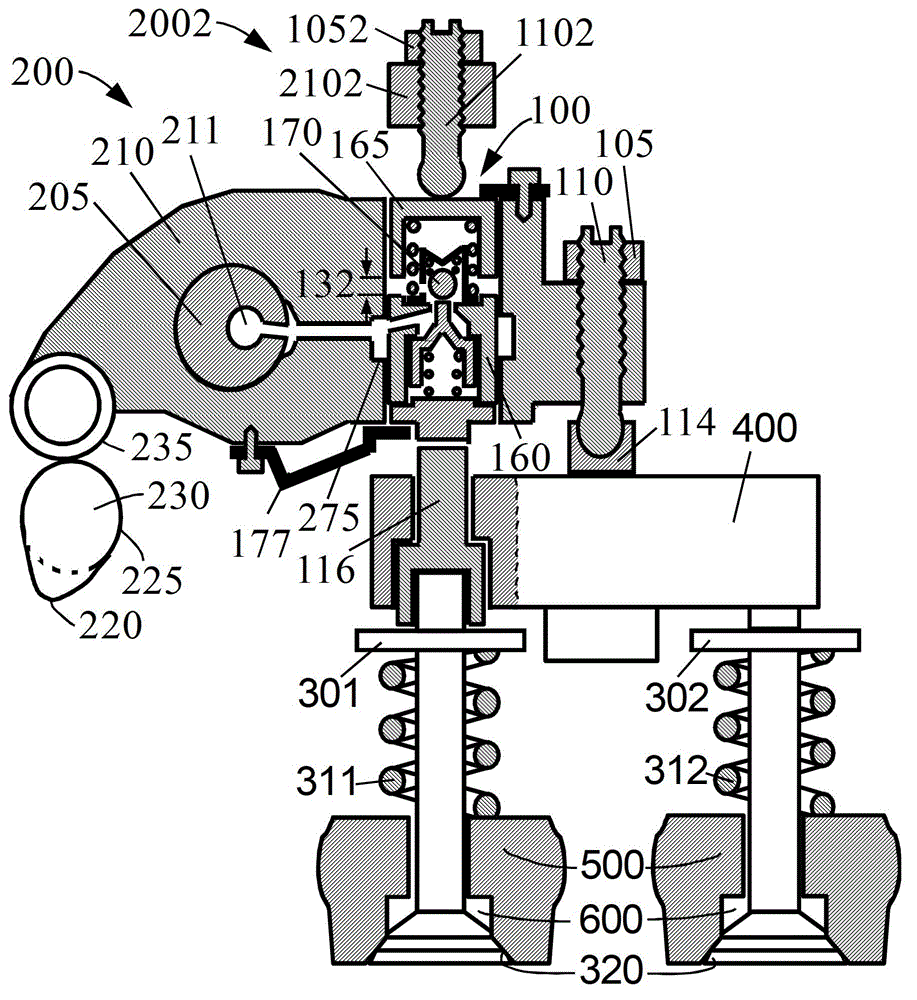

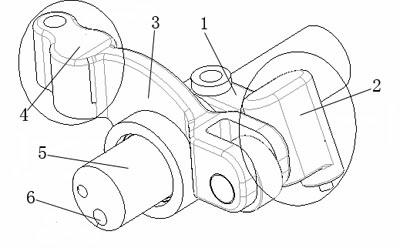

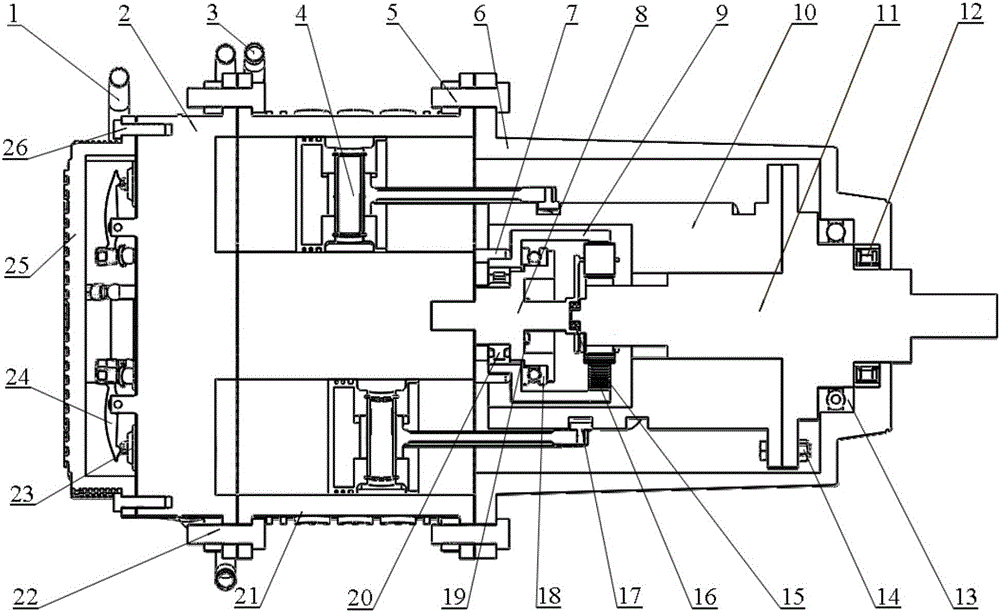

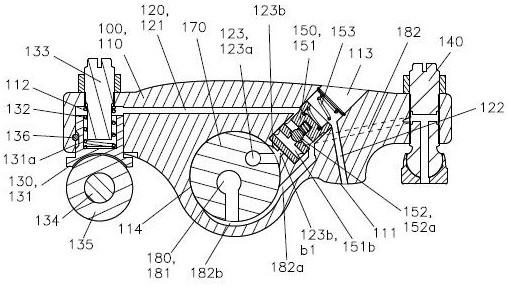

Self-resetting single-valve double-piston hydraulic driving device and method for overhead cam engine

The invention relates to a self-resetting single-valve double-piston hydraulic driving device and method for an overhead cam engine. The self-resetting single-valve double-piston hydraulic driving method comprises the steps that a driving main piston and a driving auxiliary piston are correspondingly arranged on a rocker arm body and a valve bridge body, the driving auxiliary piston is connected with an exhaust valve, and a driving oil way communicates with the driving main piston, the driving auxiliary piston and a driving control valve; when the driving control valve opens the driving oil way, the driving main piston and the driving auxiliary piston achieve hydraulic linkage, the rocker arm body and the valve bridge do not move during lift driving, and the driving auxiliary piston opensthe exhaust valve; when the main lift starts, a main piston body oil way and an auxiliary piston oil way are disconnected, and the driving auxiliary piston automatically resets; and when the driving oil way is disconnected, in the integrated cam driving lift process, the driving main piston absorbs the driving lift of an integrated cam assembly to the rocker arm body, the rocker arm body does notmove, and the integrated cam driving lift is not transmitted to one side of the exhaust valve. The self-resetting single-valve double-piston hydraulic driving method is simple in principle and compactin structure, and the reliability and durability of engine driving operation are improved.

Owner:JIANSU JOINTEK PRECISION MASCH CO LTD

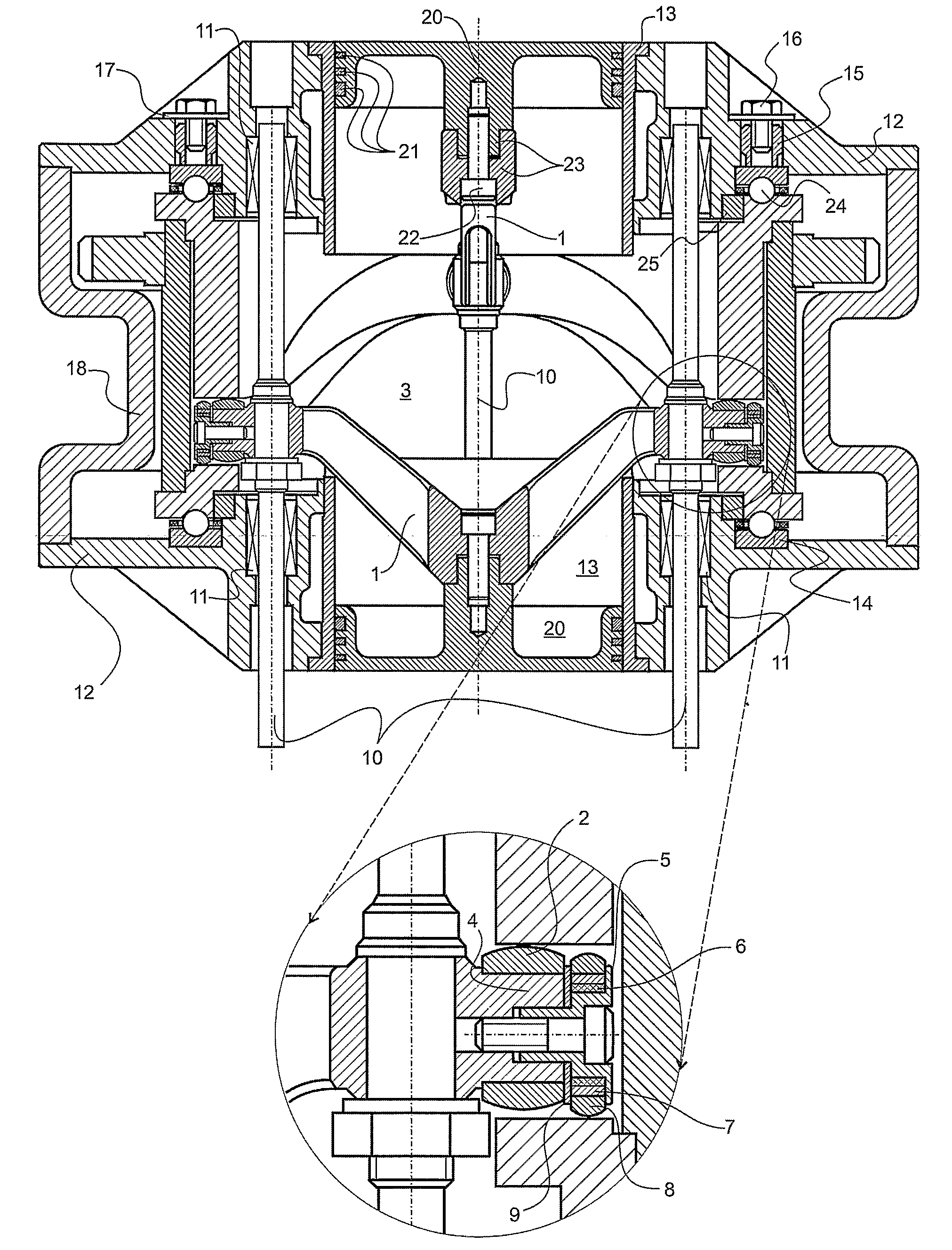

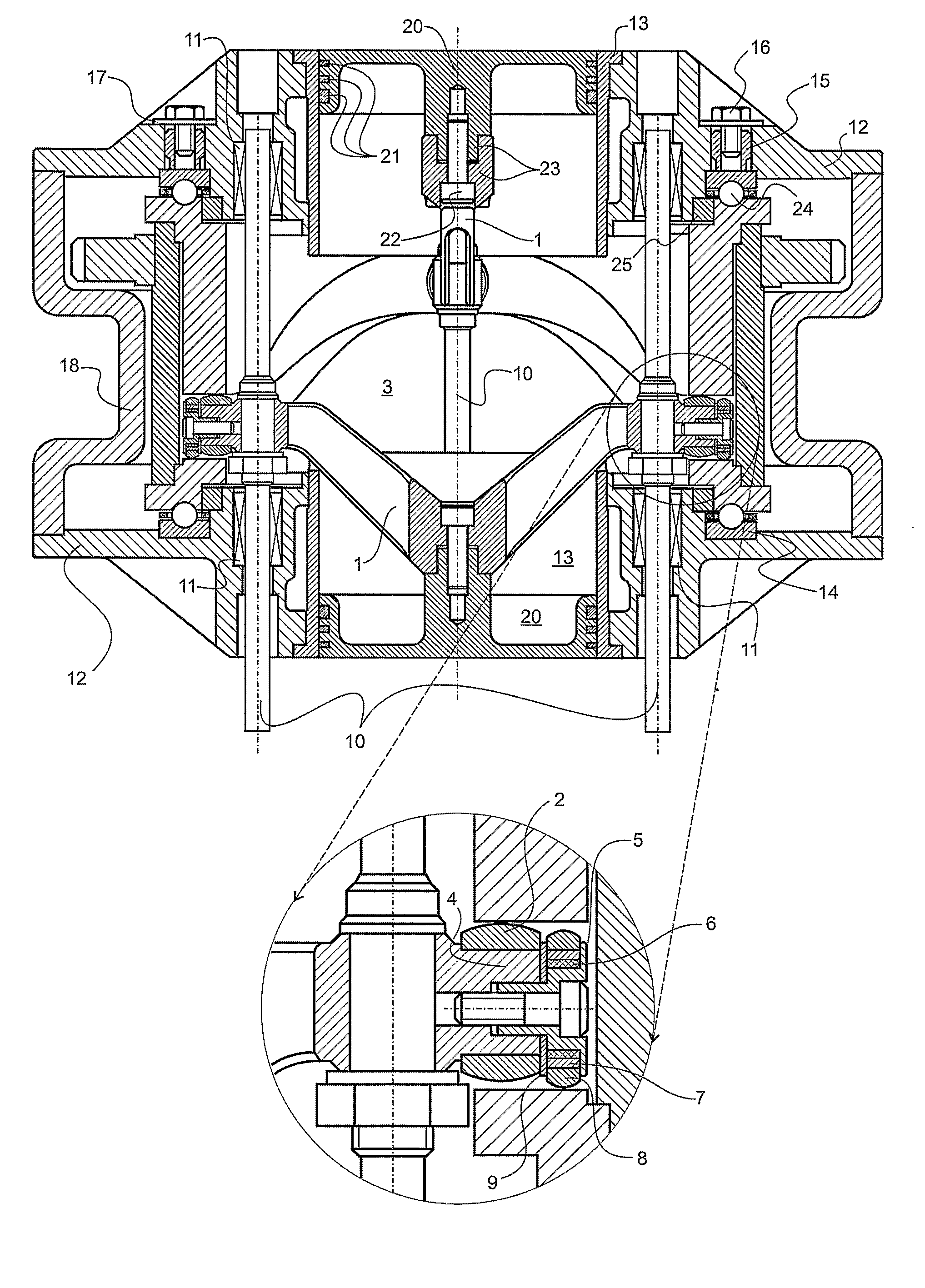

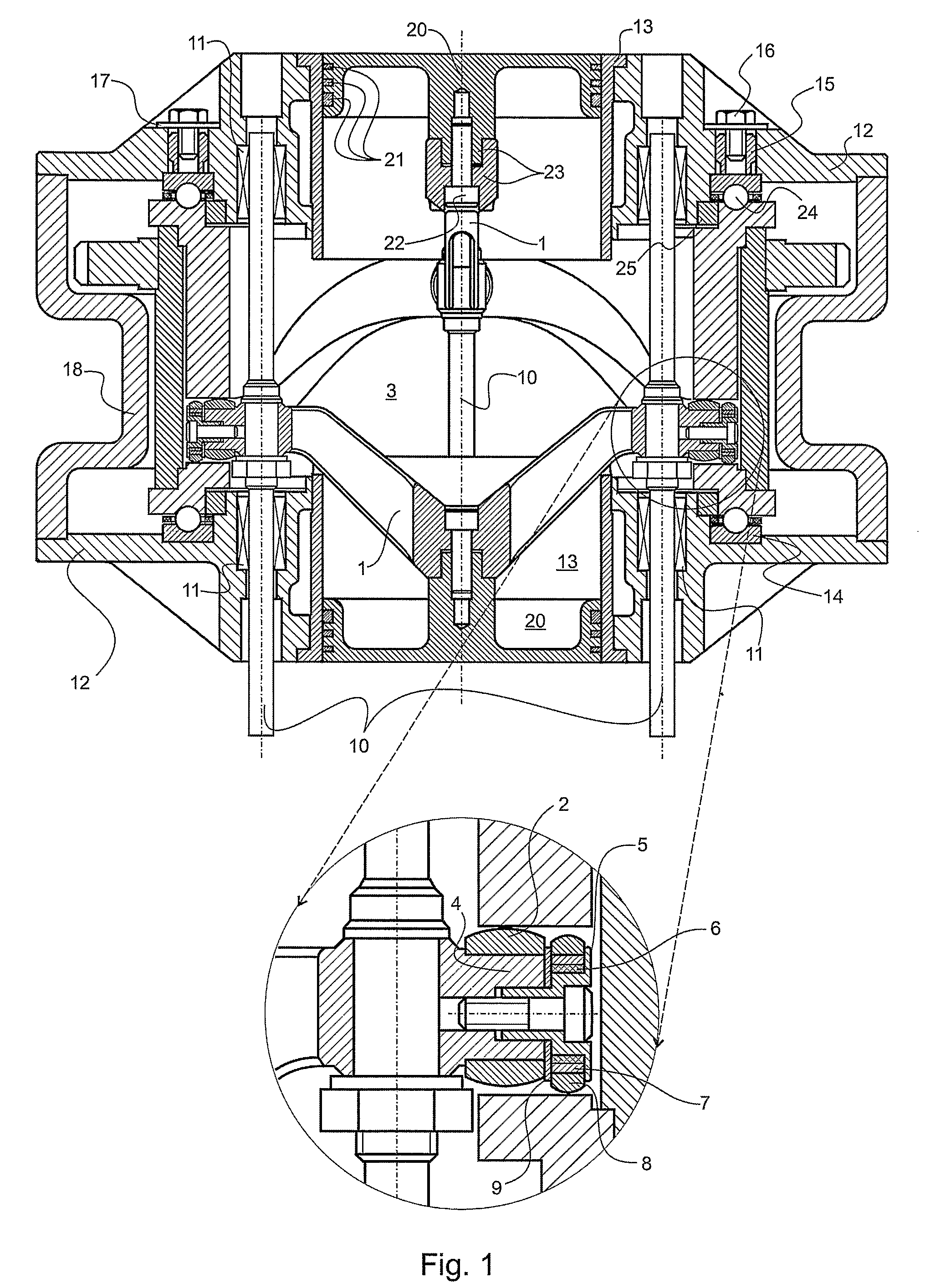

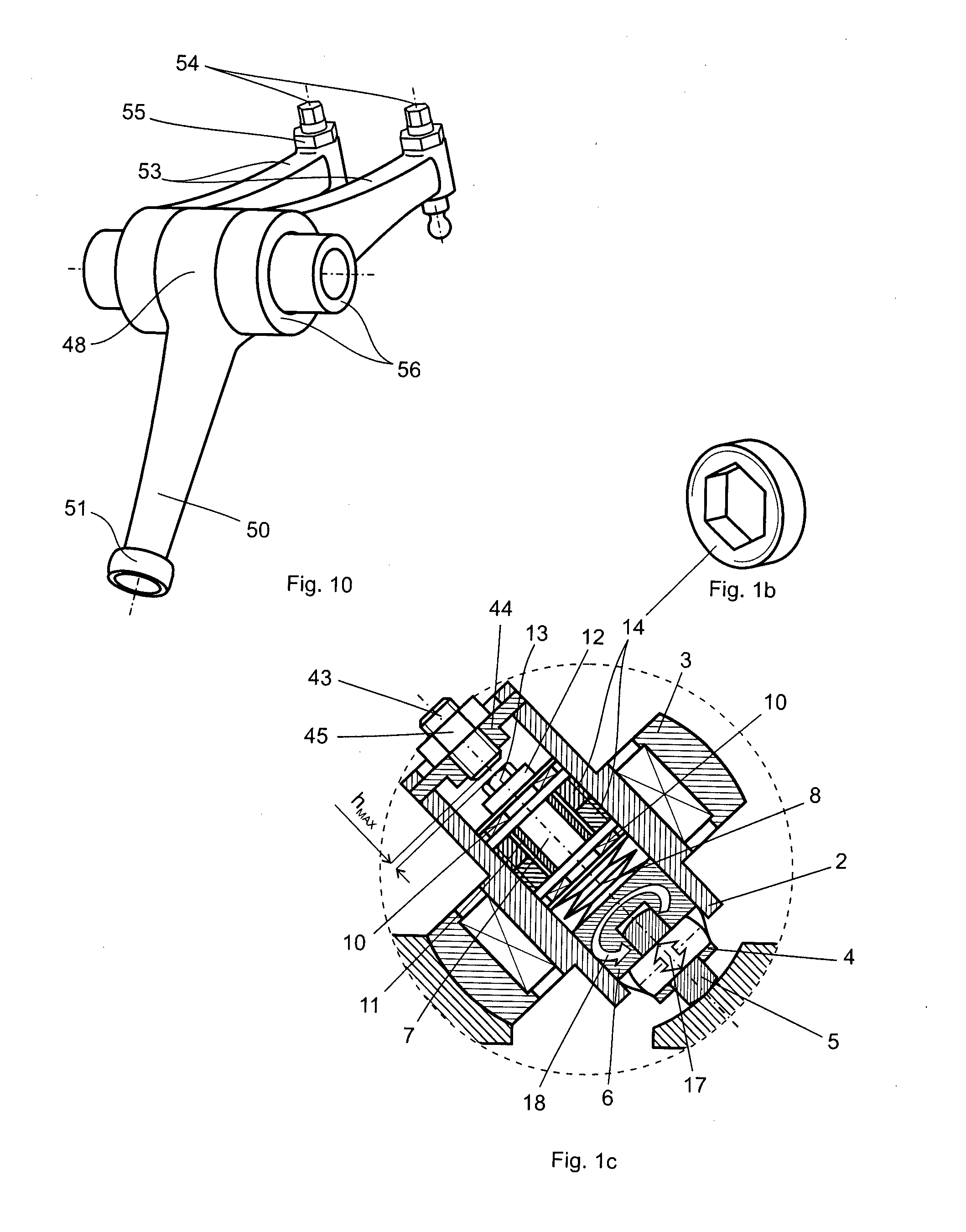

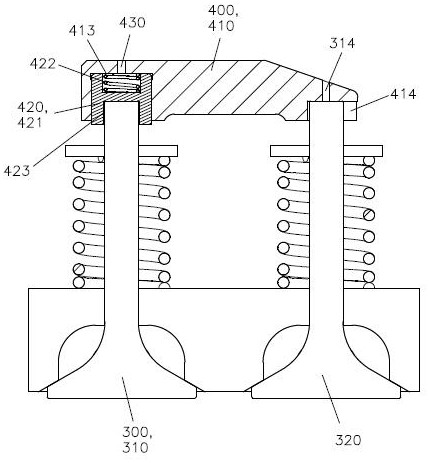

Piston Cam Engine

InactiveUS20080289606A1Balanced reliabilityReduce noiseInternal combustion piston enginesReciprocating piston enginesEngineeringInternal combustion engine

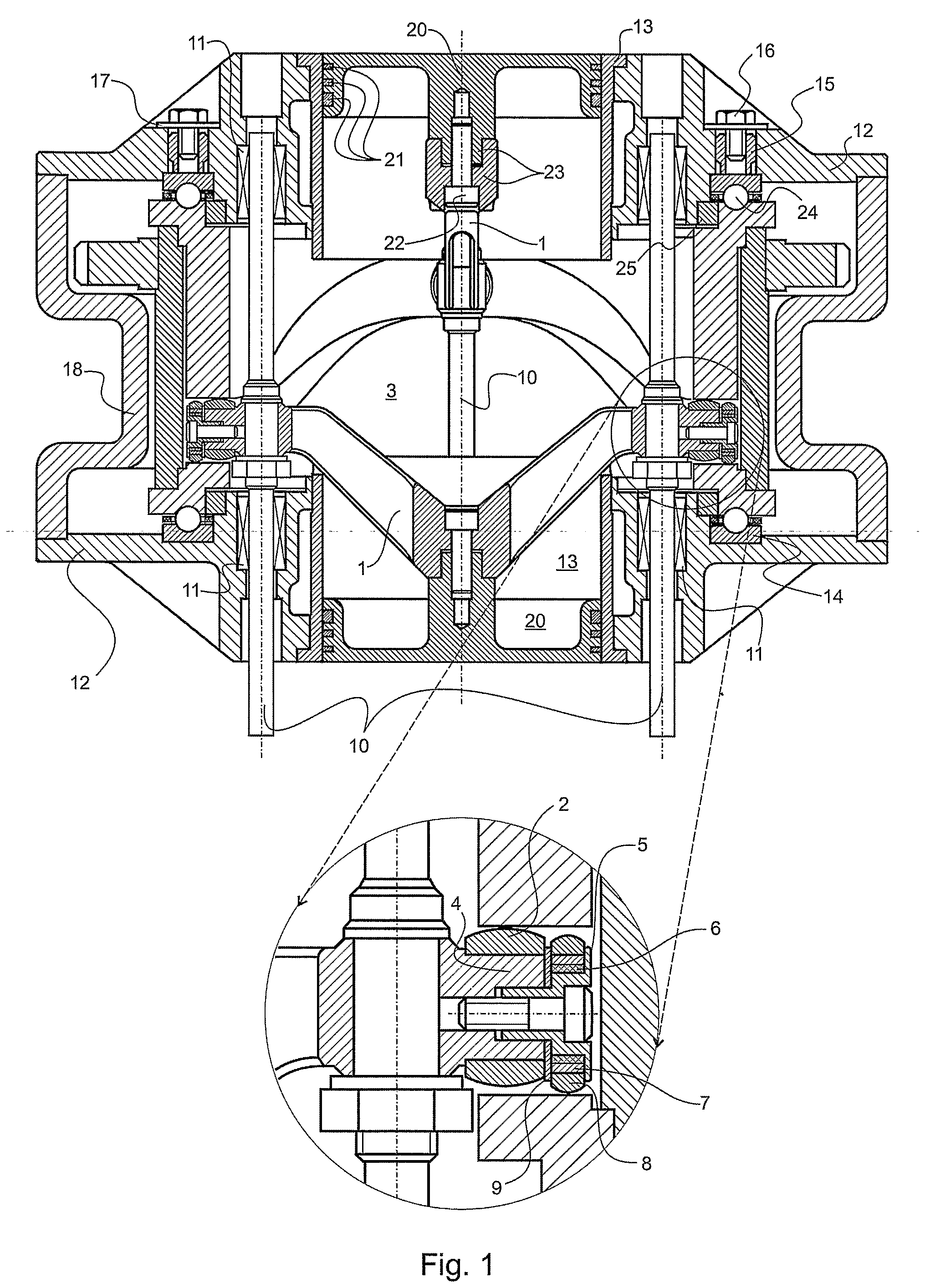

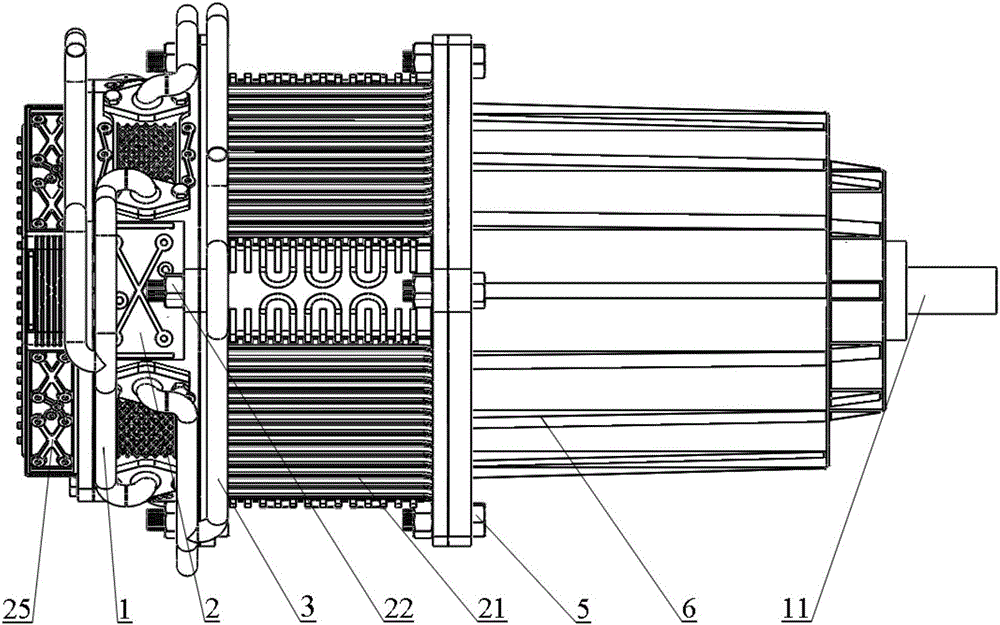

The invention relates to a piston cam engine used in different field of the mechanical engineering, as internal-combustion engines compressors, pumps etc. The cam engine comprises cylinders (13) with pistons (20), a cylindrical tubular 3D cam (3) having a cam groove on the inner cylindrical surface and at least two guides (10) which are guide columns. The cam (3) is composed and includes two coaxial bushes (3a, 3b), each one having corrugated cam section (95a or 95b) from its one side and flange (35) from its other side besides the bushes (3a, 3b) are positioned against each other with its corrugated ends at a distance from each other, and further comprises spacer (37) between the flanges (35) of the bushes (3a, 3b), so as to form the cam groove having a constant section.

Owner:BAHNEV BOYAN K

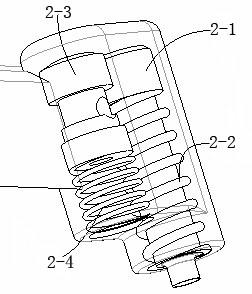

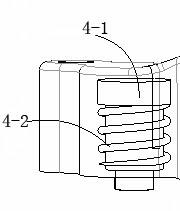

Single valve opened engine auxiliary valve actuator

ActiveCN103912336AReduce loadEliminate the effect of ignition operationValve arrangementsMachines/enginesValve actuatorLocking mechanism

Discloses is a single valve opened engine auxiliary valve actuator. The single valve opened engine auxiliary valve actuator comprises an auxiliary cam and an auxiliary valve gap compensating mechanism. The auxiliary valve gap compensating mechanism is integrated within a common rocker arm of an engine and between the auxiliary cam and a valve of the engine; in a non-operating position of the auxiliary valve gap compensating mechanism, a gaps can be generated between the auxiliary cam and the valve to cancel the movement transmission between the auxiliary cam and the valve; in an operating position of the auxiliary valve gap compensating position, connection can be formed between the auxiliary cam and the valve to generate engine-assisted valve motion. The auxiliary valve gap compensating mechanism can be a hydraulic locking mechanism or a mechanical clutch mechanism. The single valve opened engine auxiliary valve actuator can be used for generating special cam engine braking or waste gas circulating auxiliary valve movement, thereby improving the performance of the engine.

Owner:SHANGHAI UNIVERSOON AUTOPARTS CO LTD

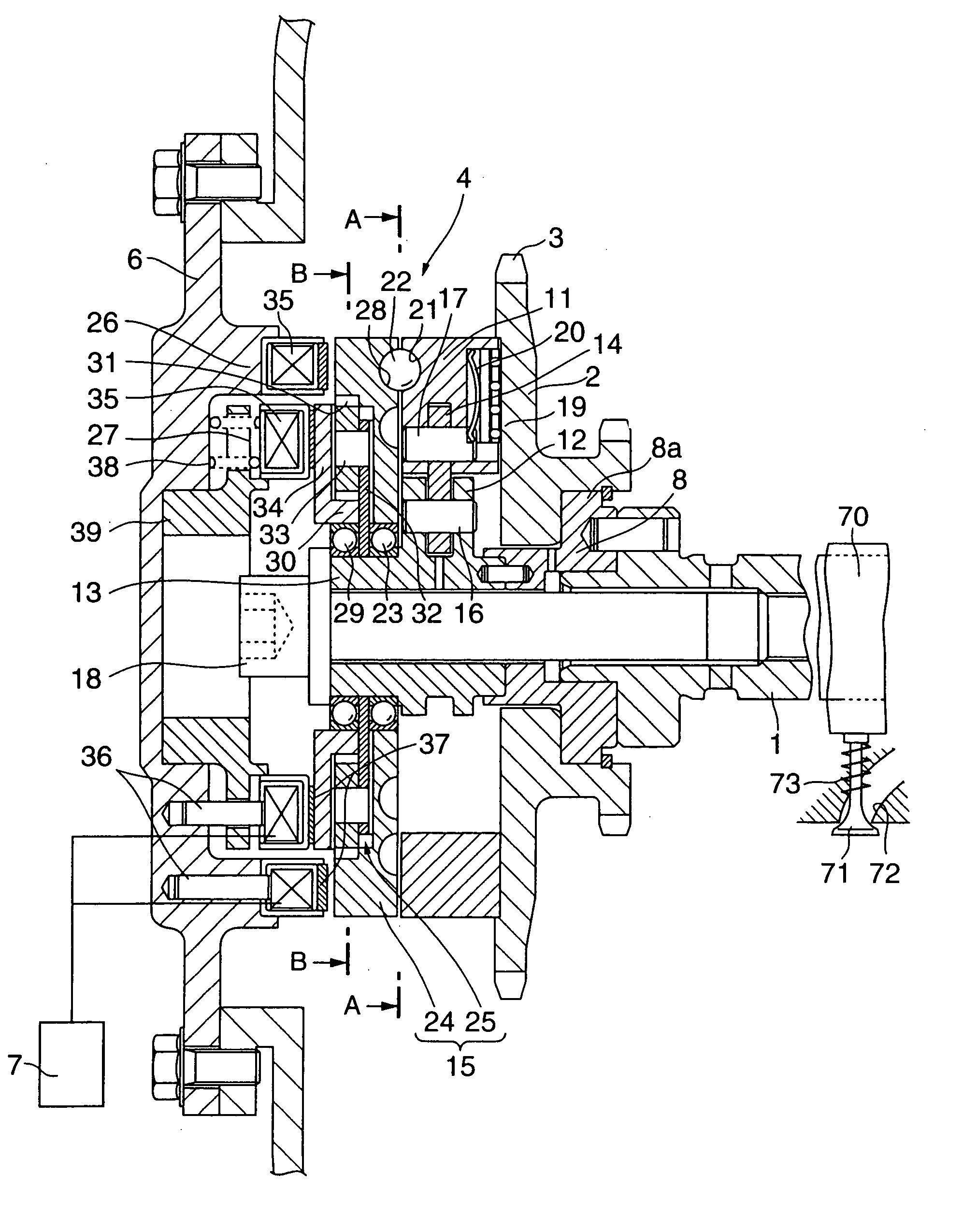

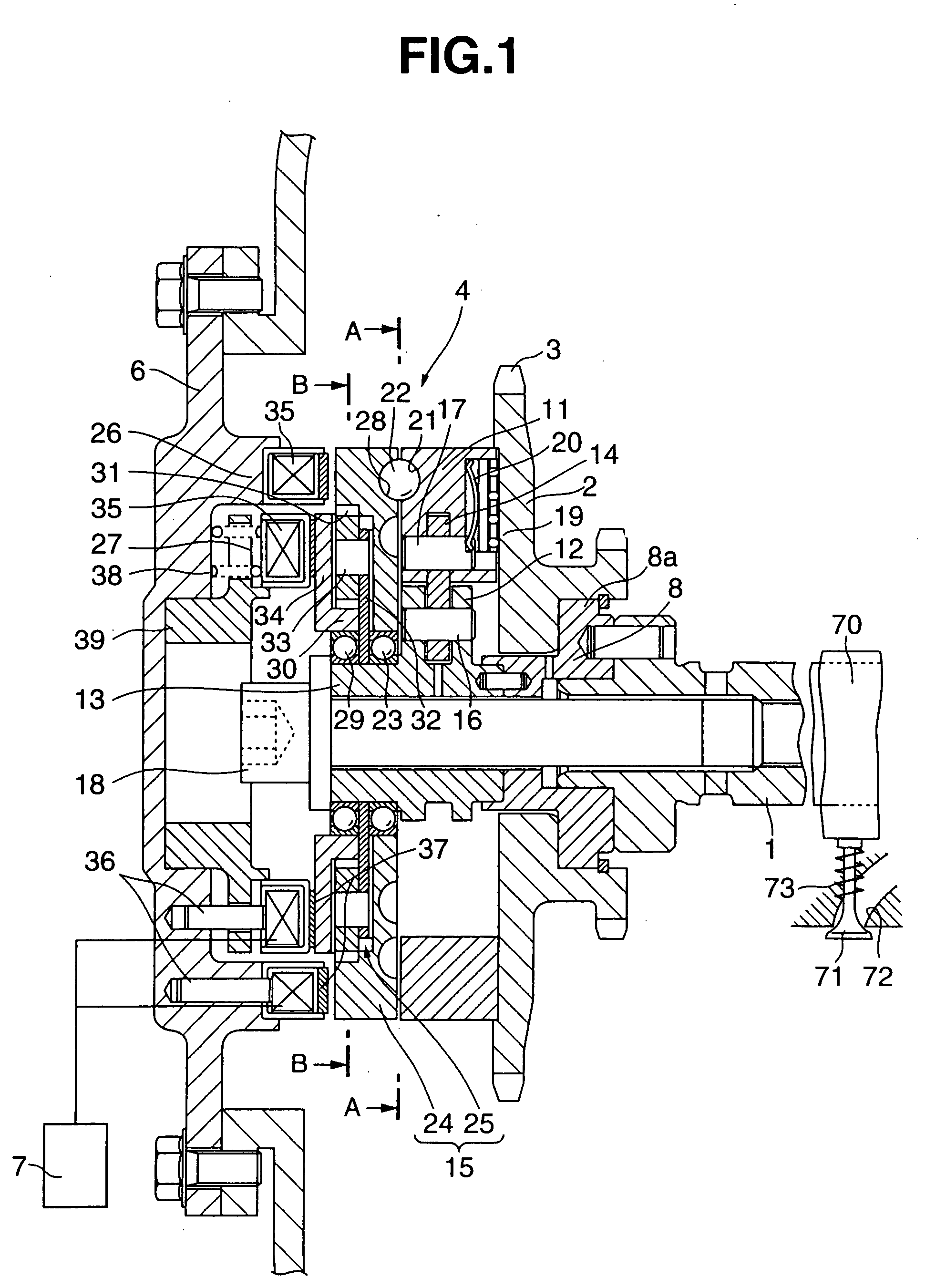

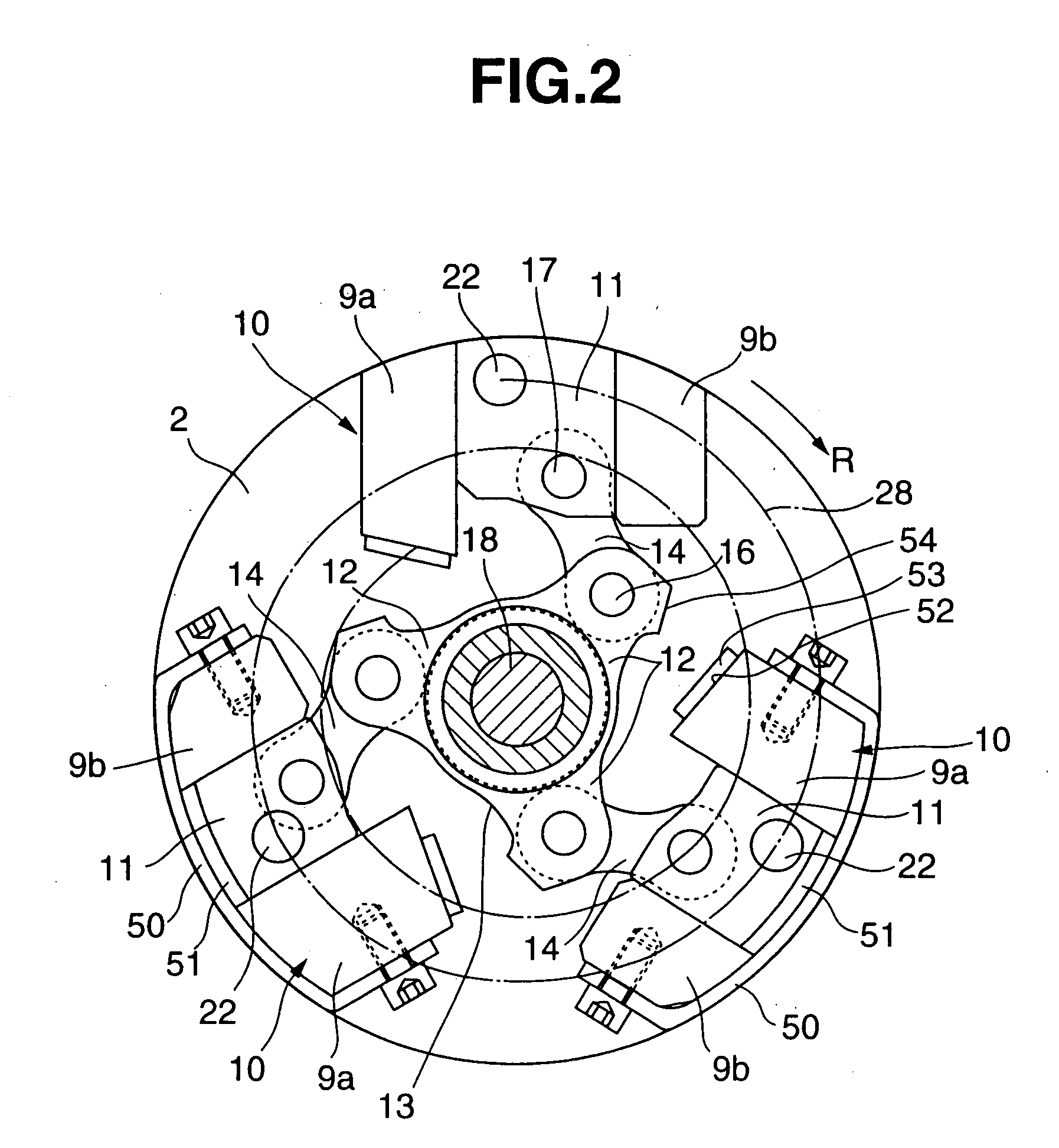

Valve timing control device for internal combustion engine

A valve timing control device includes a drive pulley driven by a crankshaft of an engine, and a driven camshaft. The camshaft has a cam that serves to open and close an intake port. An engine valve is spring-loaded by a valve spring, whereas the cam opens or closes the engine valve against the bias of the spring. Torque is transmittable between the drive pulley and the camshaft, and a rotation angle adjusting mechanism is provided therebetween. The rotation angle adjusting mechanism has a movable operating member being movable in a substantially radial direction.

Owner:HITACHI LTD

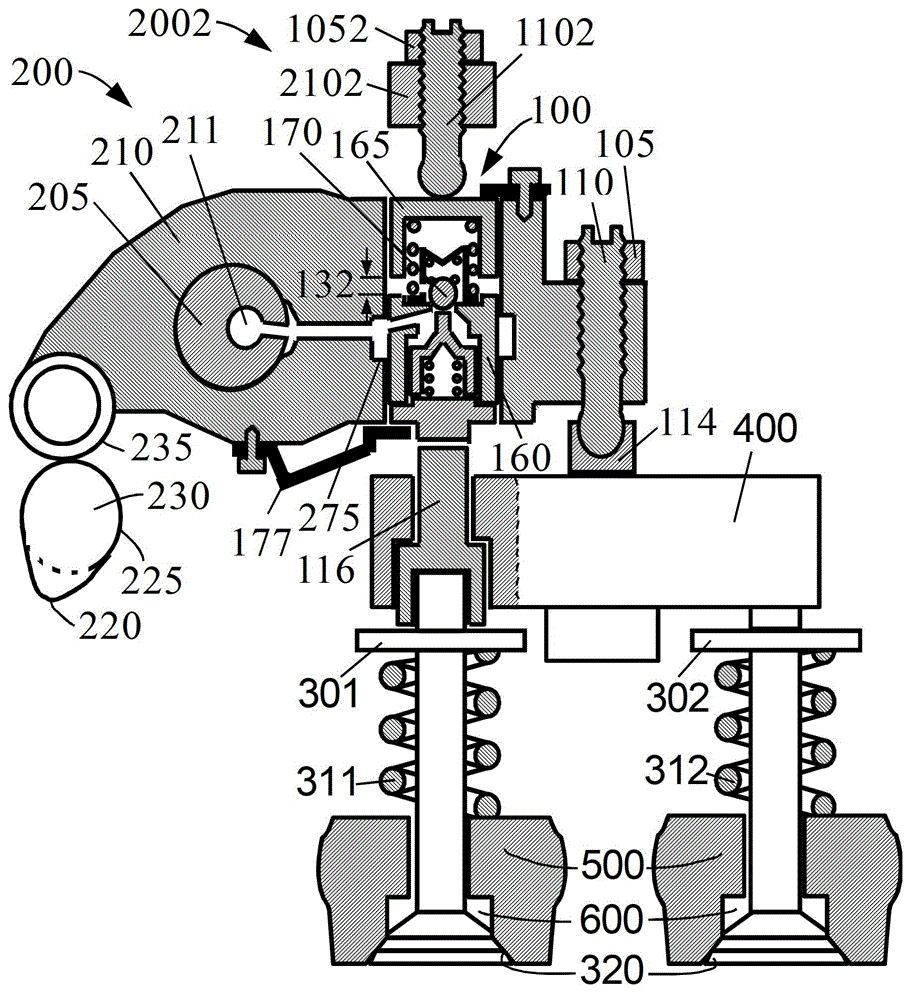

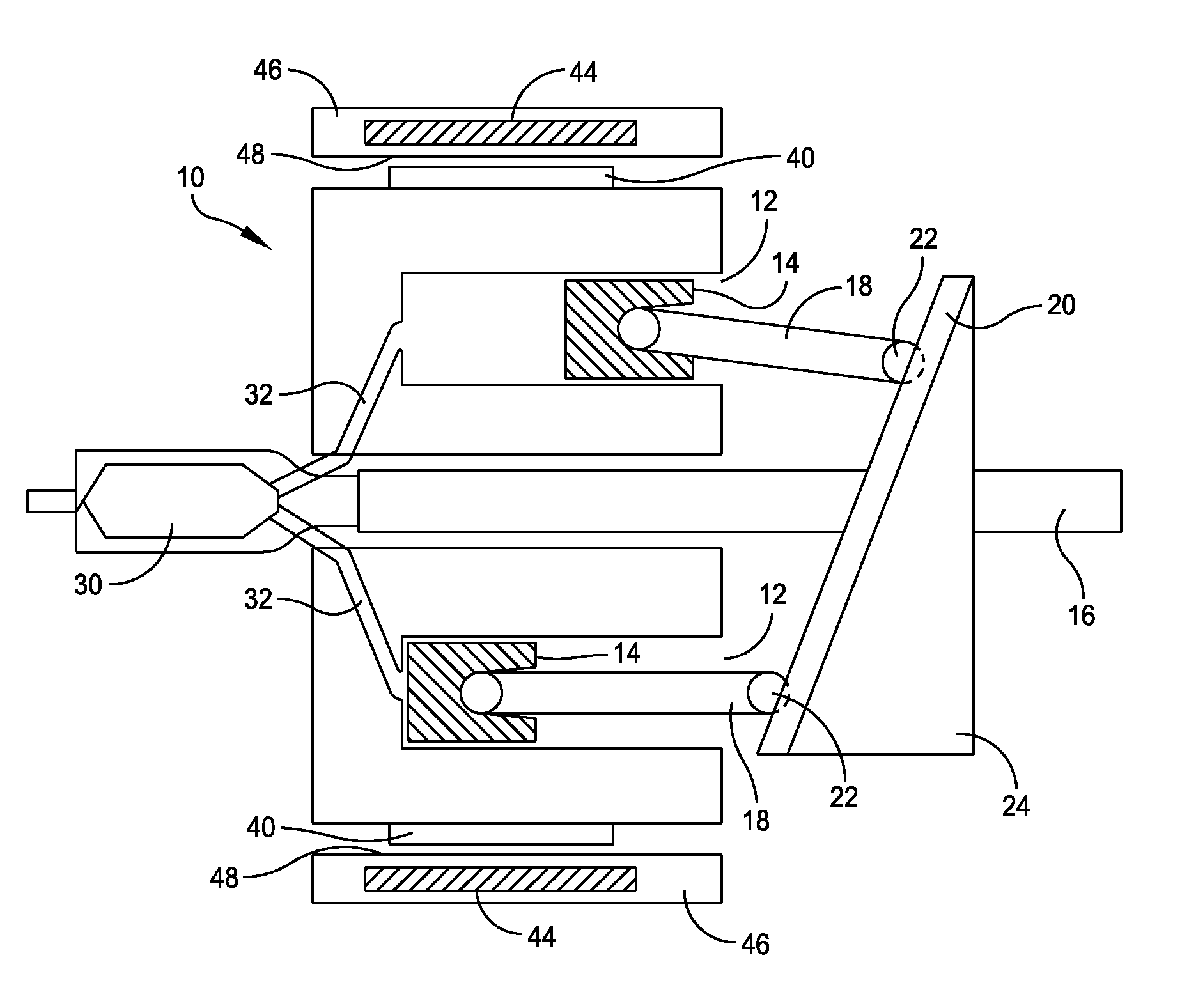

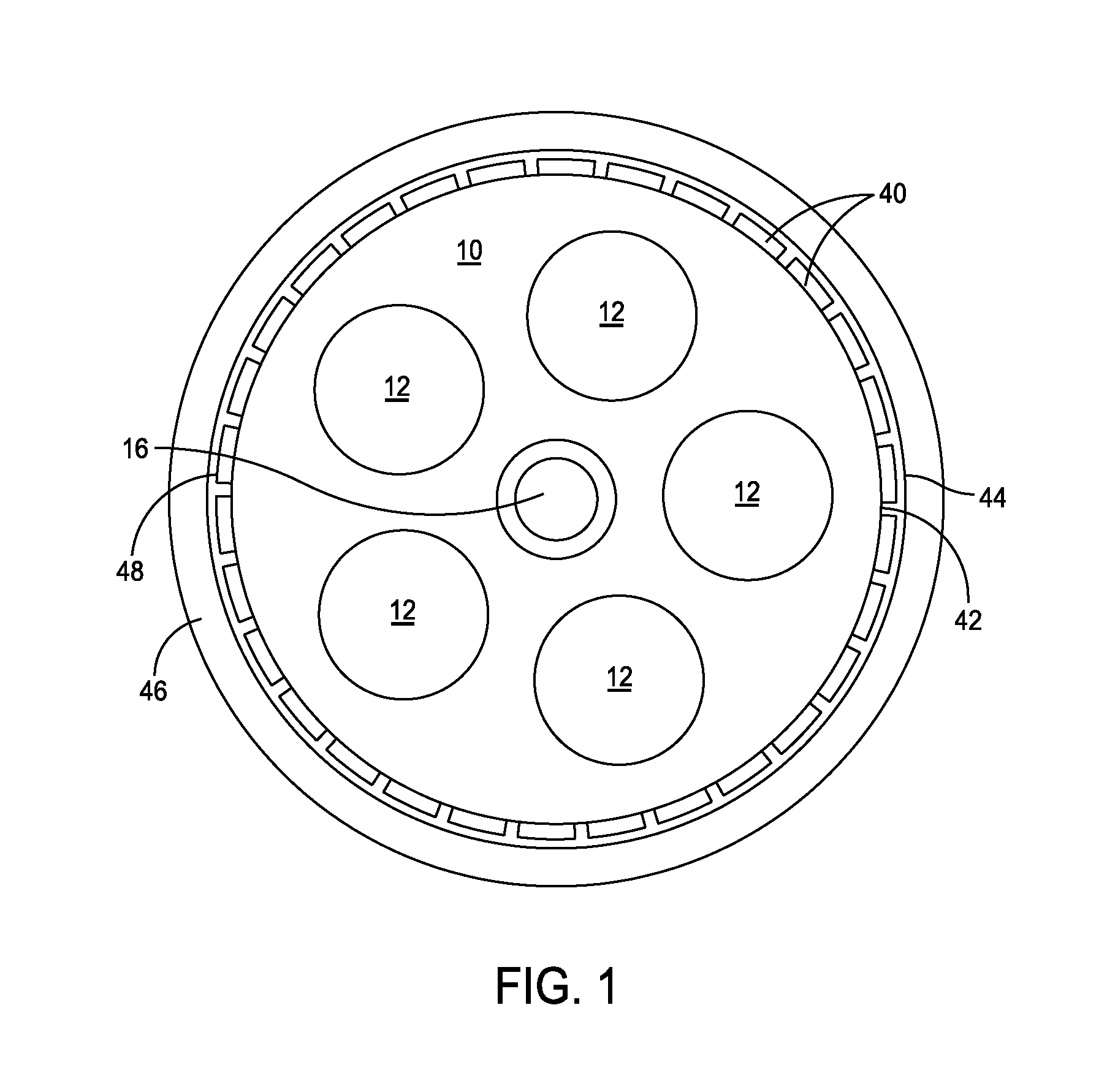

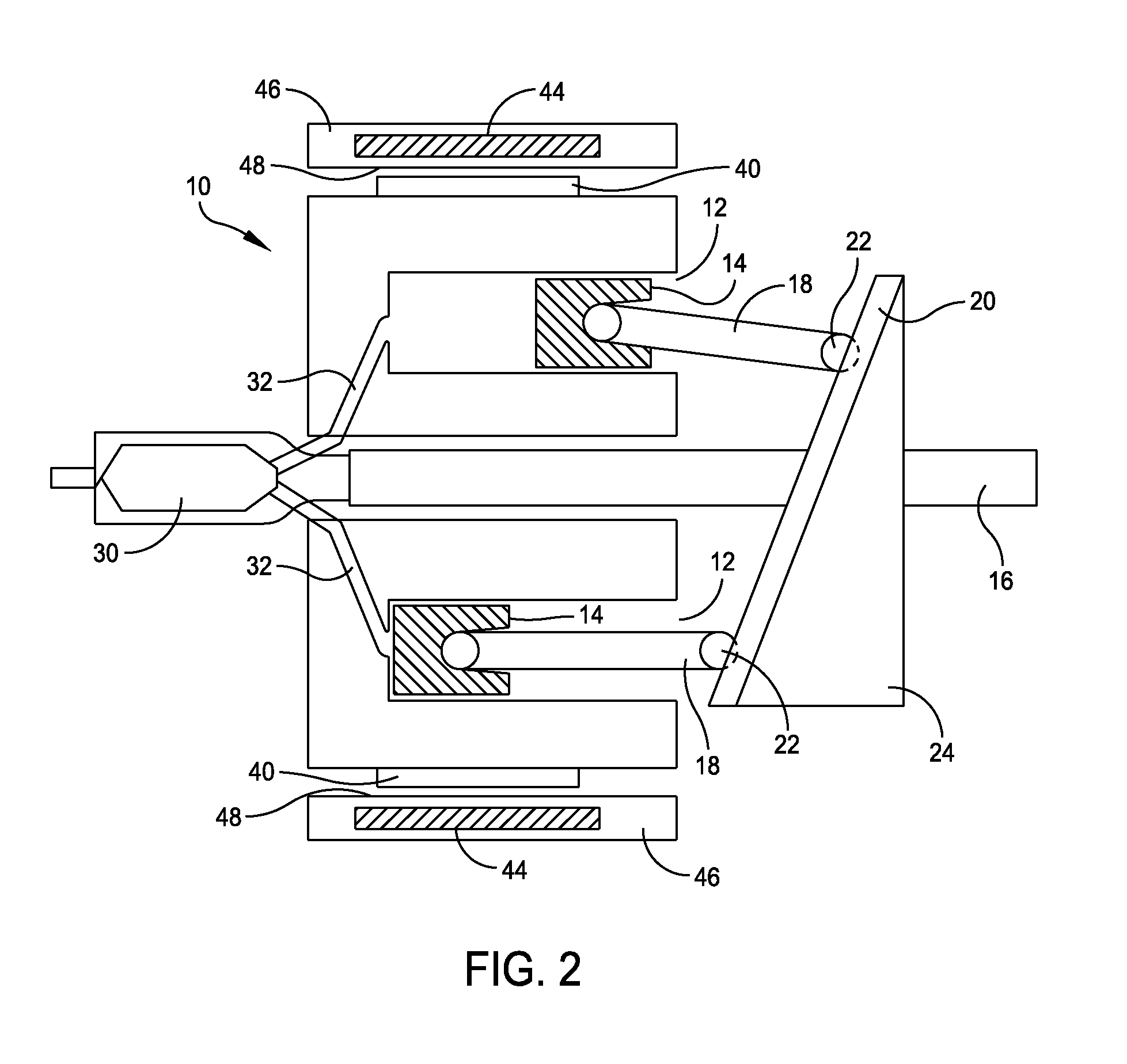

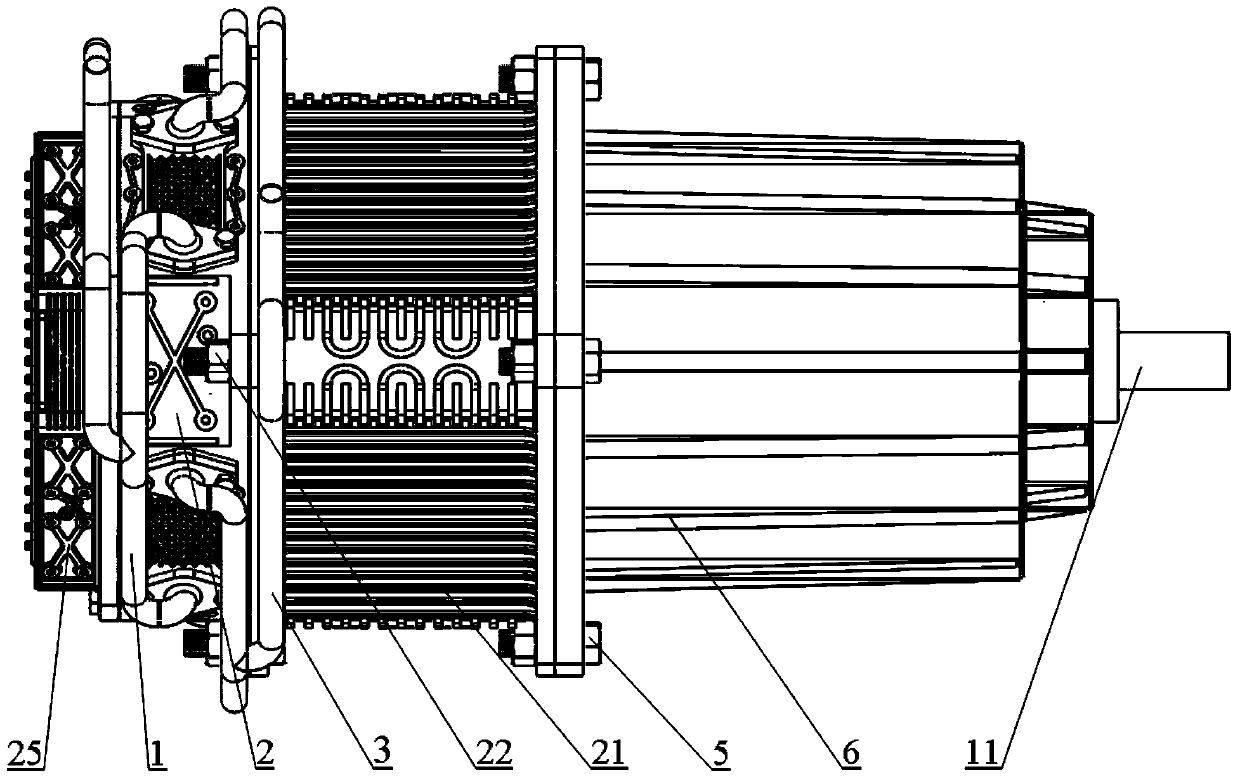

Integrated external combustion cam engine-generator

InactiveUS8334604B1Reduce weight and sizeSynchronous machine detailsInternal combustion piston enginesCombustionEngineering

An integrated engine and generator is provided and includes a stationary non-rotating shaft. An engine block is provided that is capable of rotation about the shaft. The engine block comprises a plurality of cylinders with each cylinder including a piston translating in rectilinear motion while rotating about the shaft. A stationary generator housing and stator surrounds the block and has stator windings wound into the housing. Magnets are affixed to an outer surface of the block to rotate with the block, with the magnets separated from the housing by an air gap. The stator windings are electrically configured to match pole pairs of the magnets in order to generate electrical current upon block rotation.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

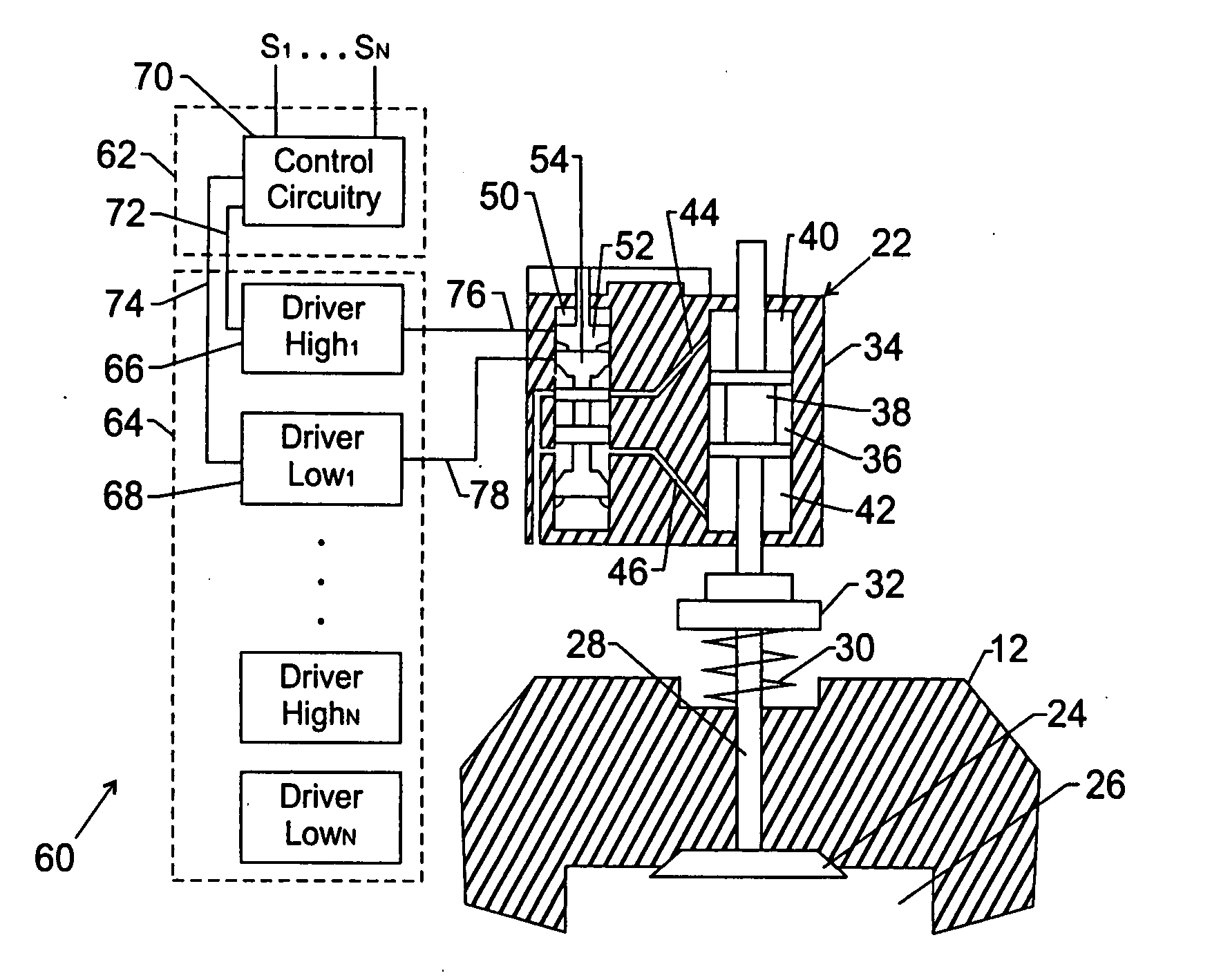

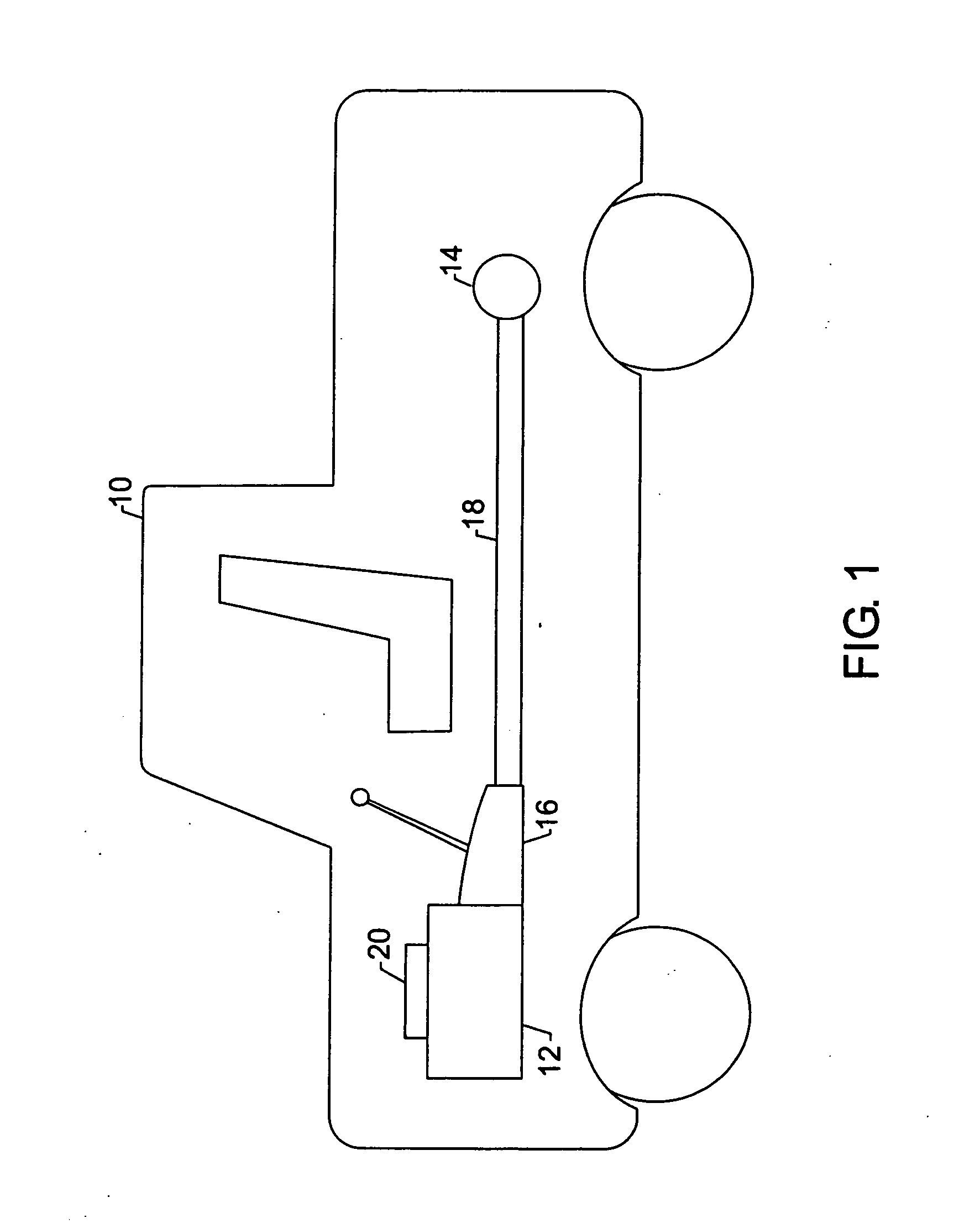

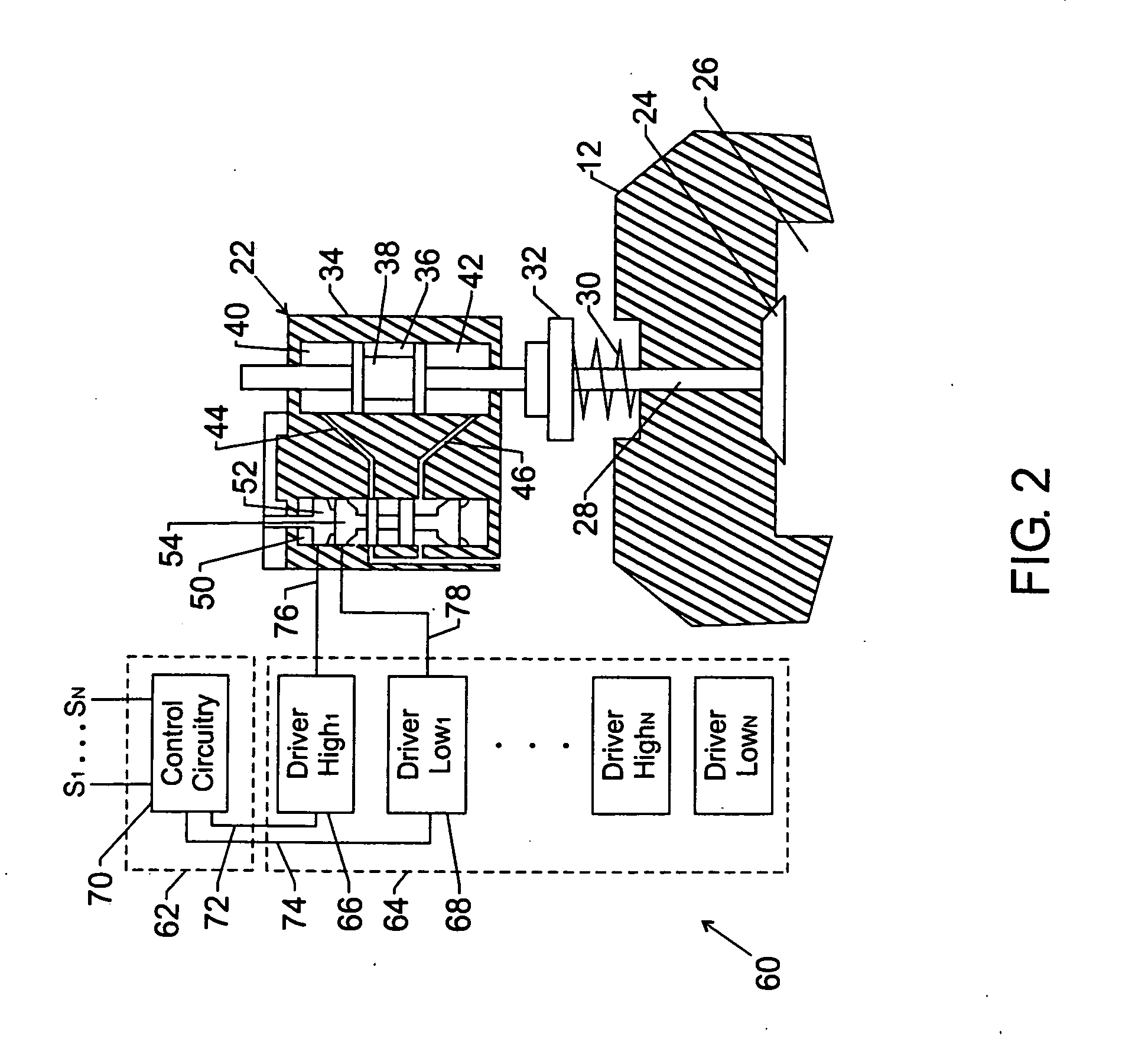

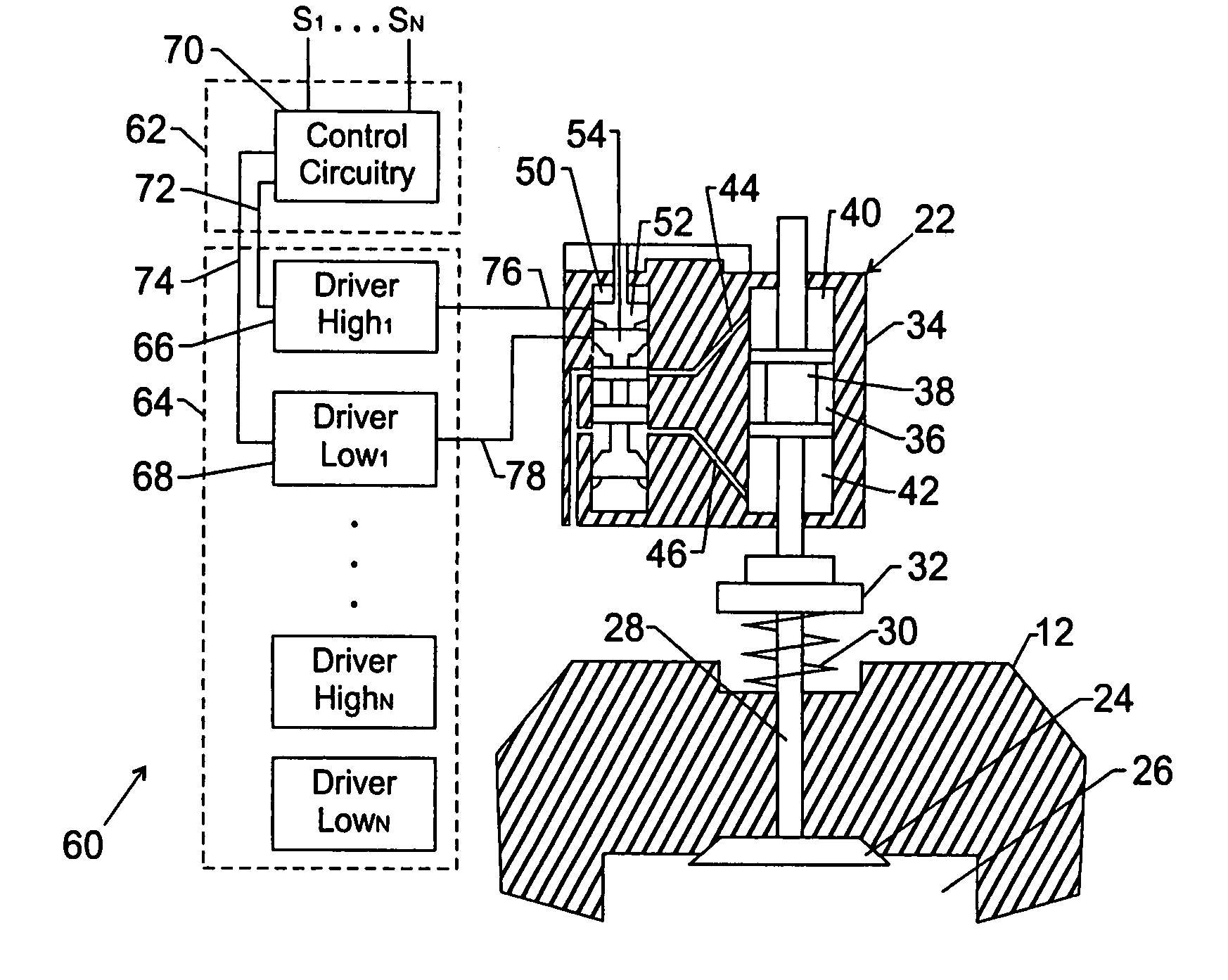

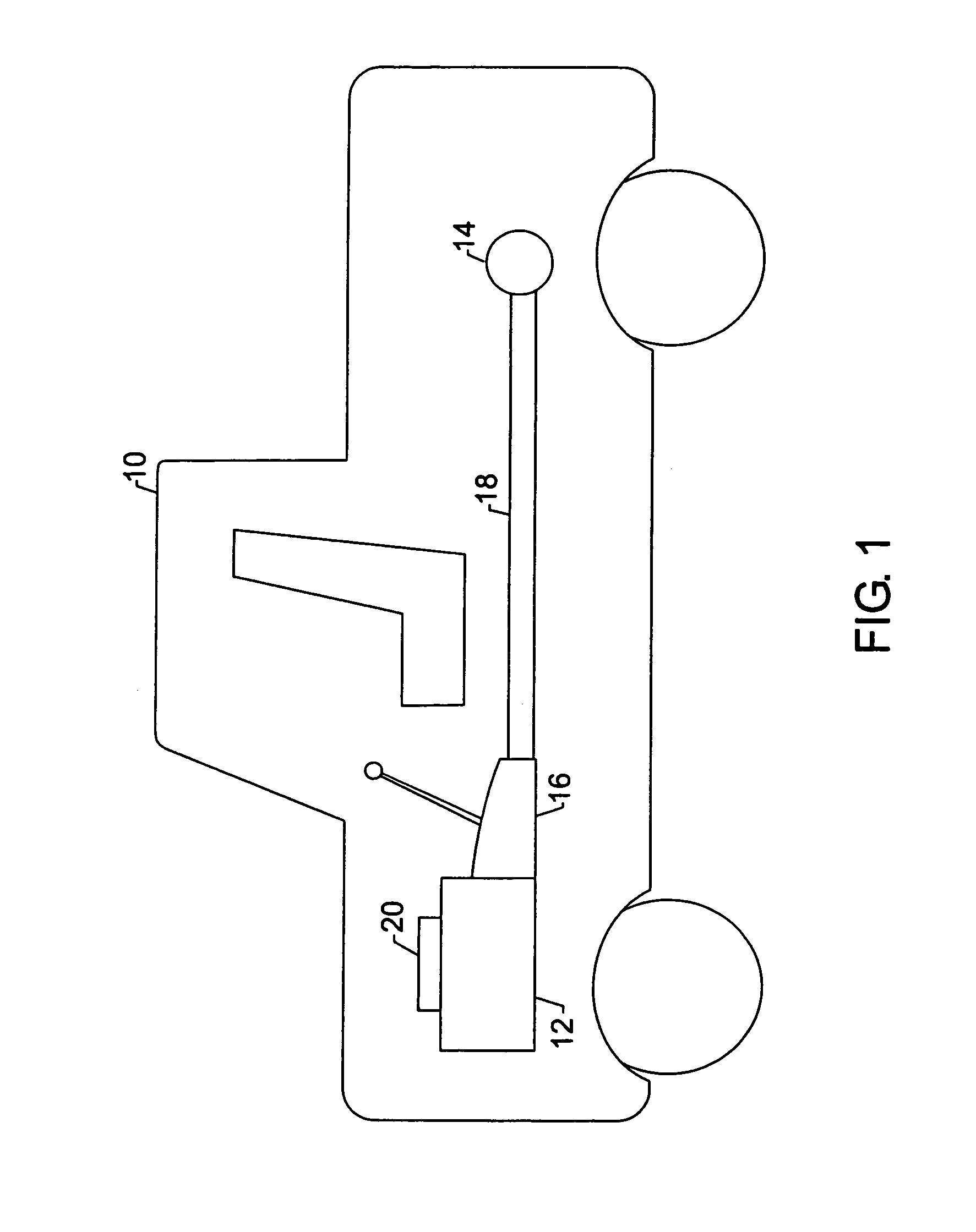

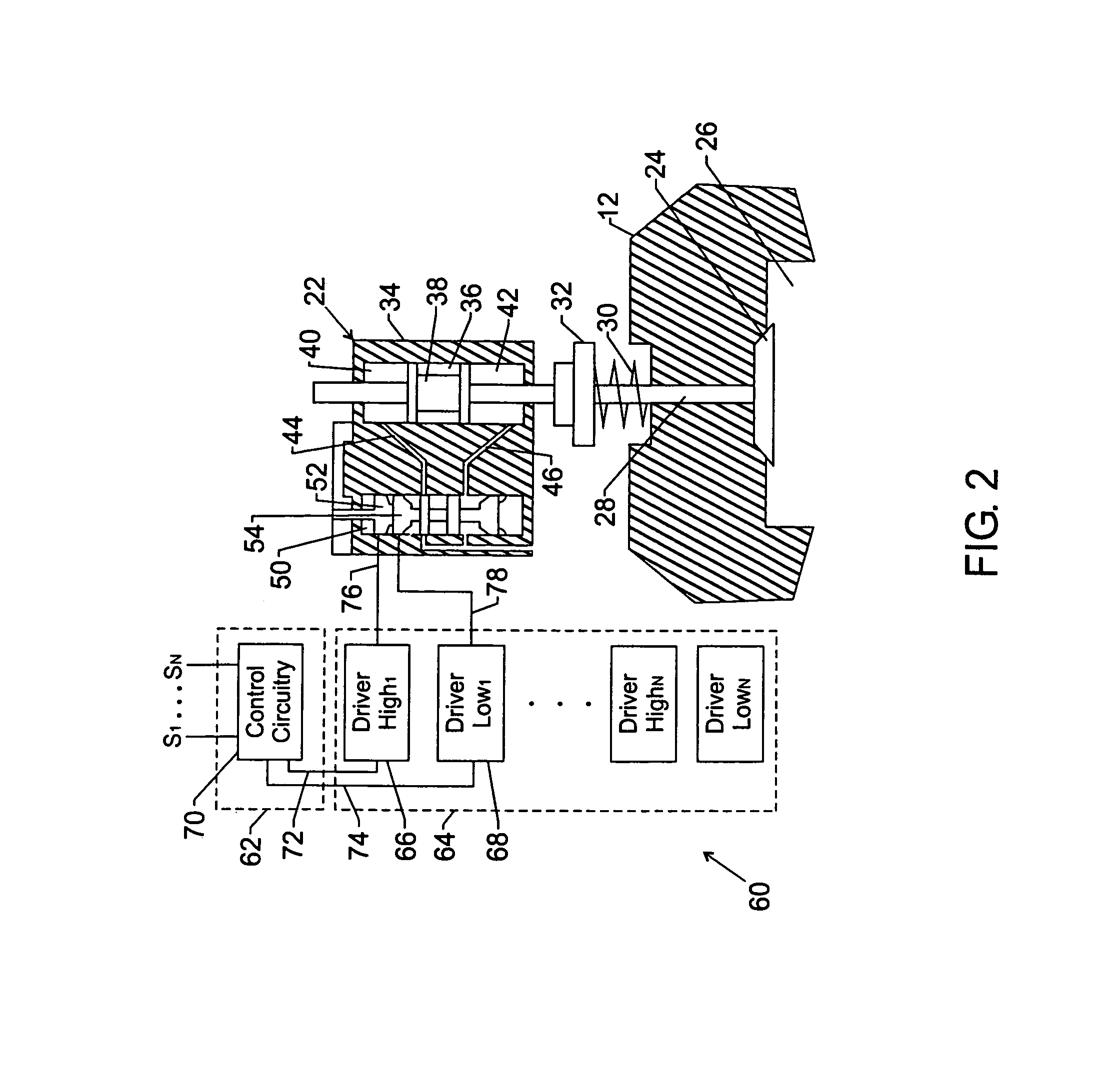

Quasi resonant gate controller for a power driver

InactiveUS20060070591A1Electrical controlInternal combustion piston enginesCapacitanceDriver circuit

A drive circuit for a power device includes a power transistor utilized to drive the power device. The drive circuit utilizes a resonant circuit that drives the power transistor at a high current level when the gate of the power transistor is in its Miller region. In one embodiment, the drive circuit includes dual transistors and an inductor tuned to the gate capacitance to drive the gate of the power transistor. The drive circuit may be useful in a variety of areas, such as with a valve controller for a camless engine.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

Quasi resonant gate controller for a power driver

A drive circuit for a power device includes a power transistor utilized to drive the power device. The drive circuit utilizes a resonant circuit that drives the power transistor at a high current level when the gate of the power transistor is in its Miller region. In one embodiment, the drive circuit includes dual transistors and an inductor tuned to the gate capacitance to drive the gate of the power transistor. The drive circuit may be useful in a variety of areas, such as with a valve controller for a camless engine.

Owner:CONTINENTAL AUTOMOTIVE SYST INC

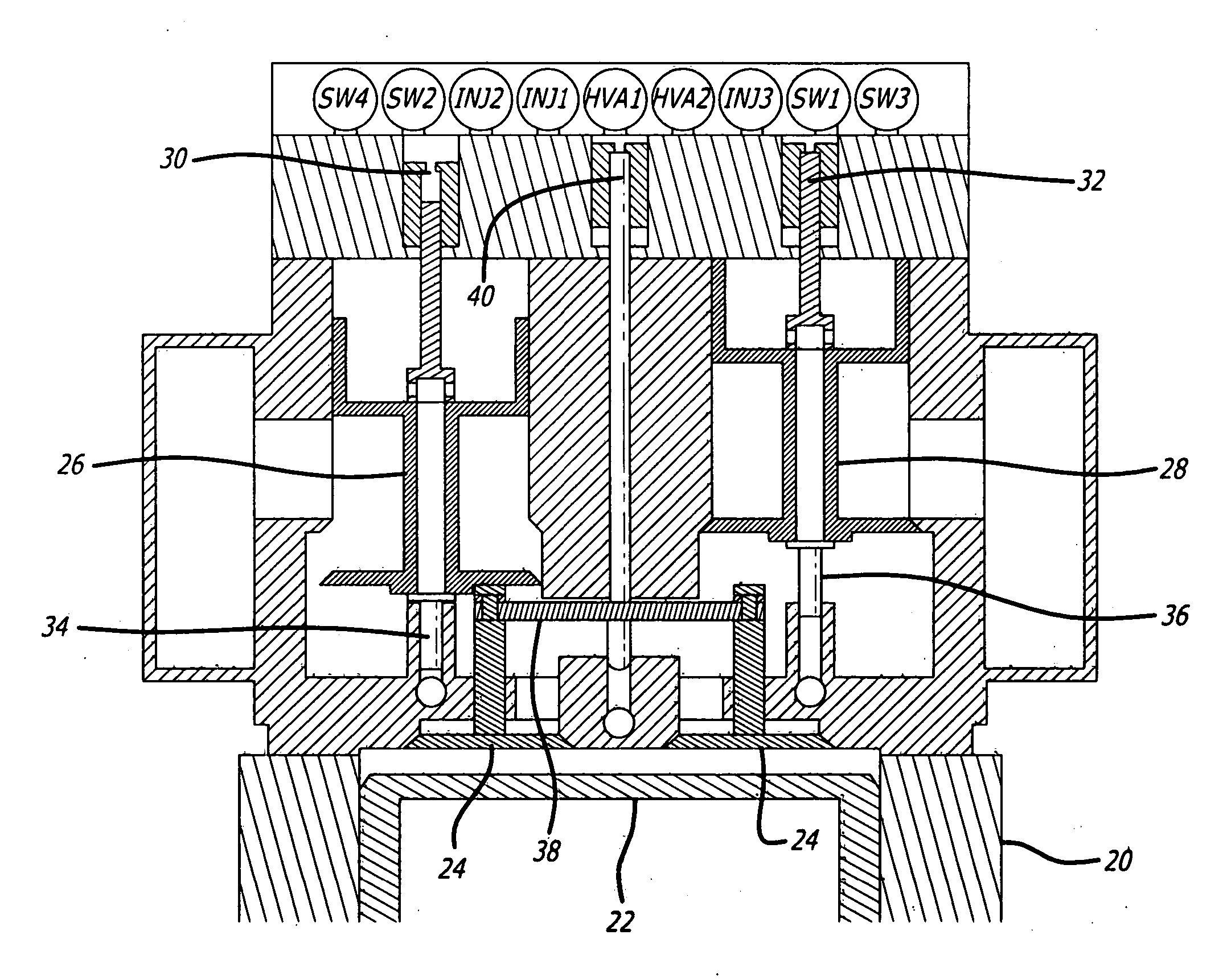

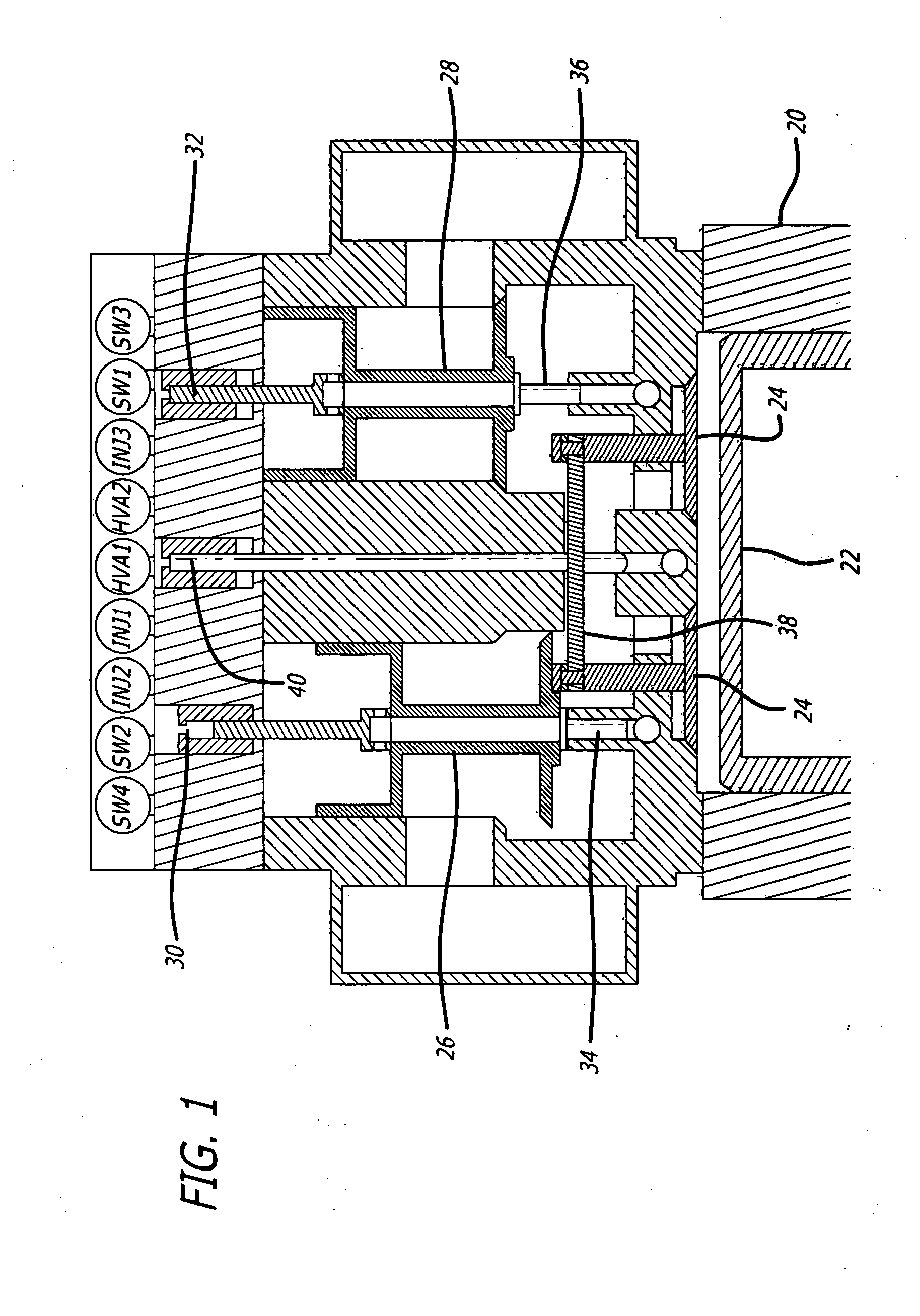

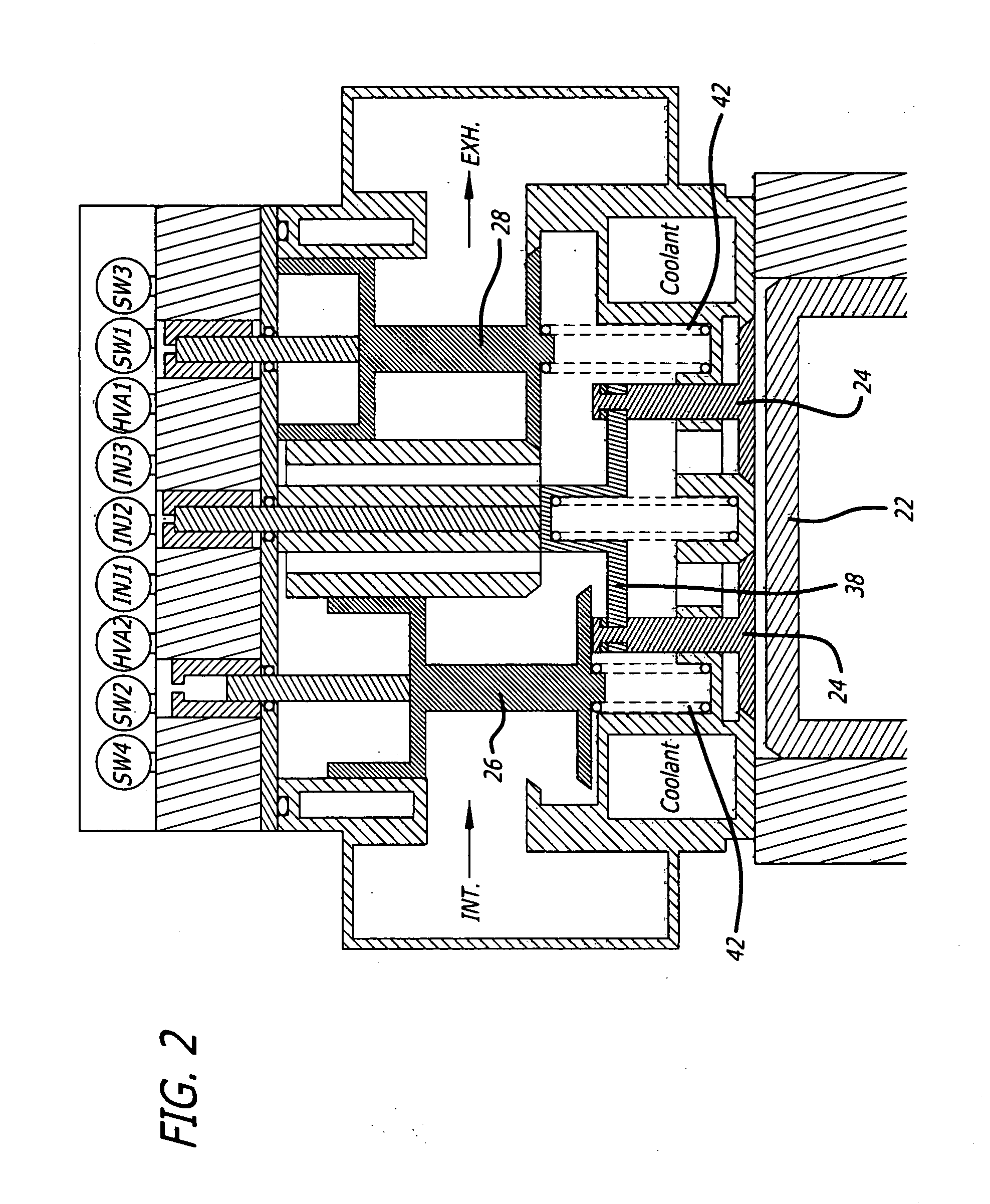

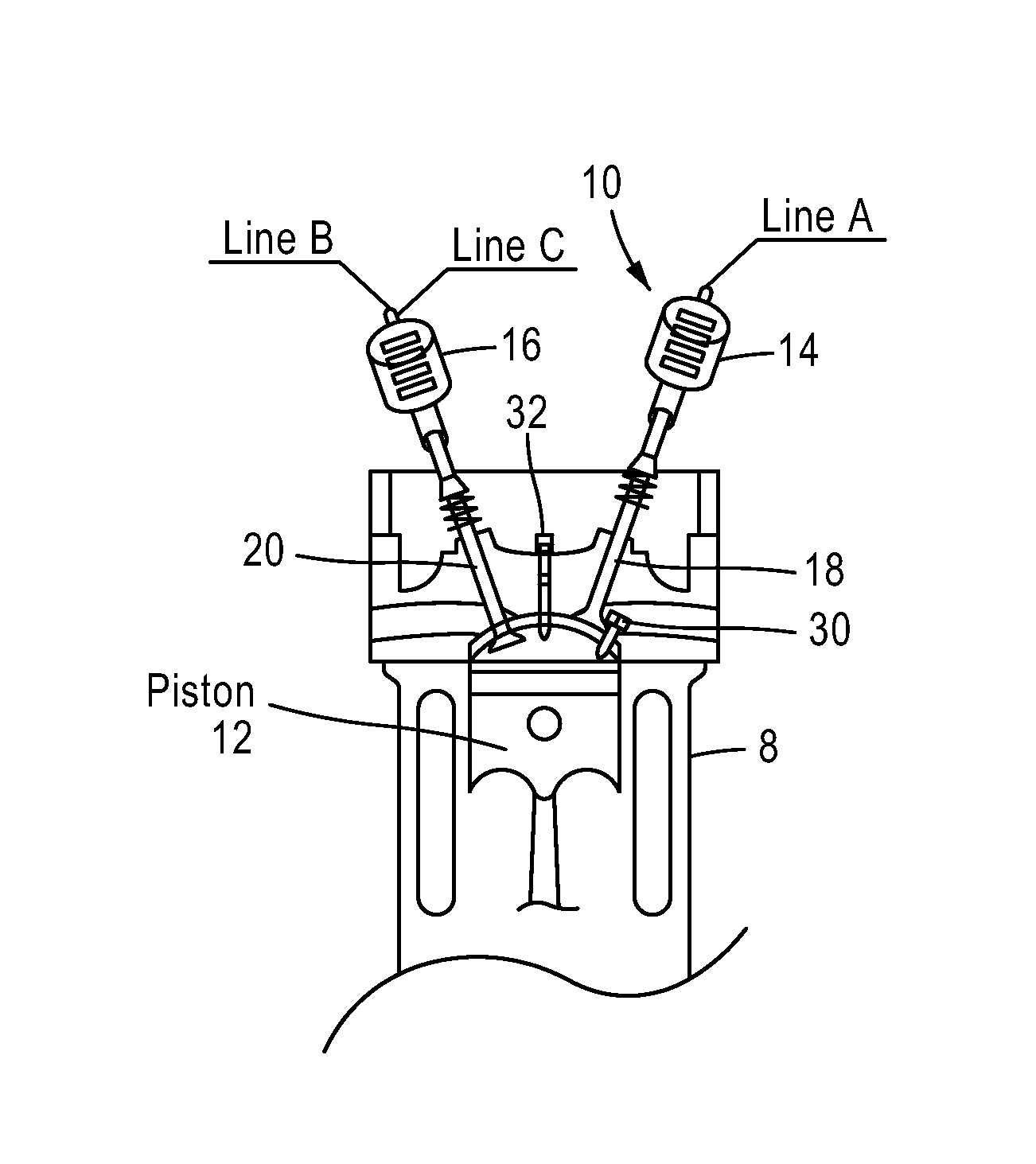

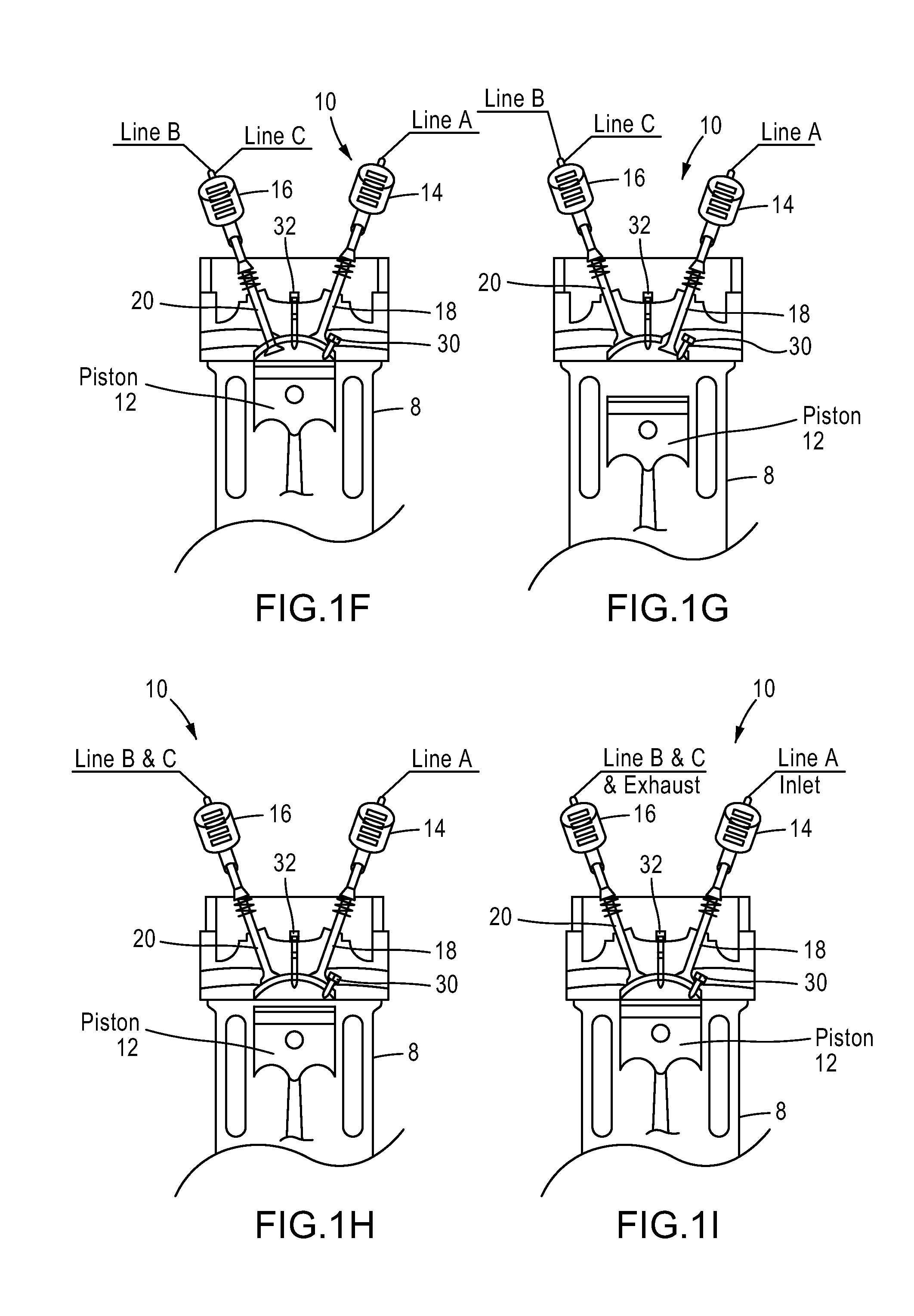

Methods and apparatus to use engine valves as both intake and exhaust valves

Methods and apparatus to selectively use engine valves as both intake and exhaust valves and to selectively operate the engine as a 2 cycle or as a 4 cycle engine. In a disclosed embodiment, the intake valves and the exhaust valves, are manifolded together through a small manifold, with the manifold being connectable to the intake manifold or the exhaust manifold through two-way valves. In preferably a camless engine, the engine valves may be controlled to operate the intake valves as intake valves only or to operate as both intake valves and exhaust valves, and to operate the exhaust valves as exhaust valves only or to operate the exhaust valves as both intake valves and exhaust valves. Exemplary embodiments are disclosed.

Owner:STURMAN DIGITAL SYST

Independent cam engine brake device

The invention relates to an independent cam engine brake device, which is characterized in that: oil passages in a rockshaft stool and an exhaust rocker are communicated with a brake oil passage; the tail end of the rockshaft stool is a brake driving part; the front end of the exhaust rocker is a brake driven part; a cavity of the brake driving part is communicated with the oil passage of the rockshaft stool; a brake driving piston is arranged on the right of a control valve in the cavity of the brake driving part, and is sleeved with a driving piston return spring; a cavity of the brake driven part is communicated with the oil passage of the exhaust rocker; a brake driven piston is arranged in the cavity of the brake driven part, and is sleeved with a driven piston return spring; and an exhaust valve is arranged above the tail end of the brake driven part. The independent cam engine brake device is simple in structure, high in rigidity and low in cost, can effectively make up the defect of foot brake power, avoids brake force reduction and failure caused by using a brake for a long time, and ensures vehicle safety.

Owner:CHINA FIRST AUTOMOBILE

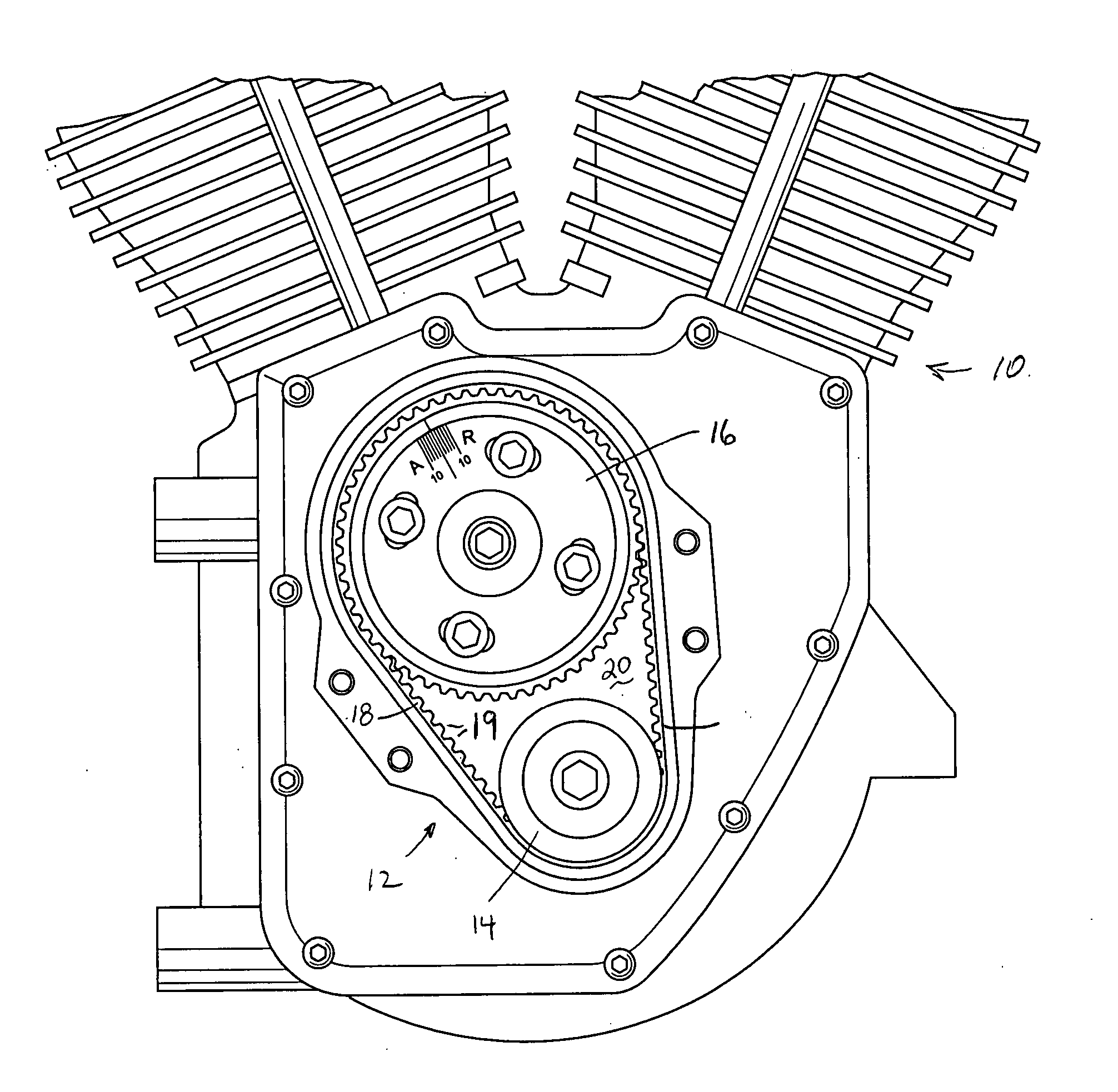

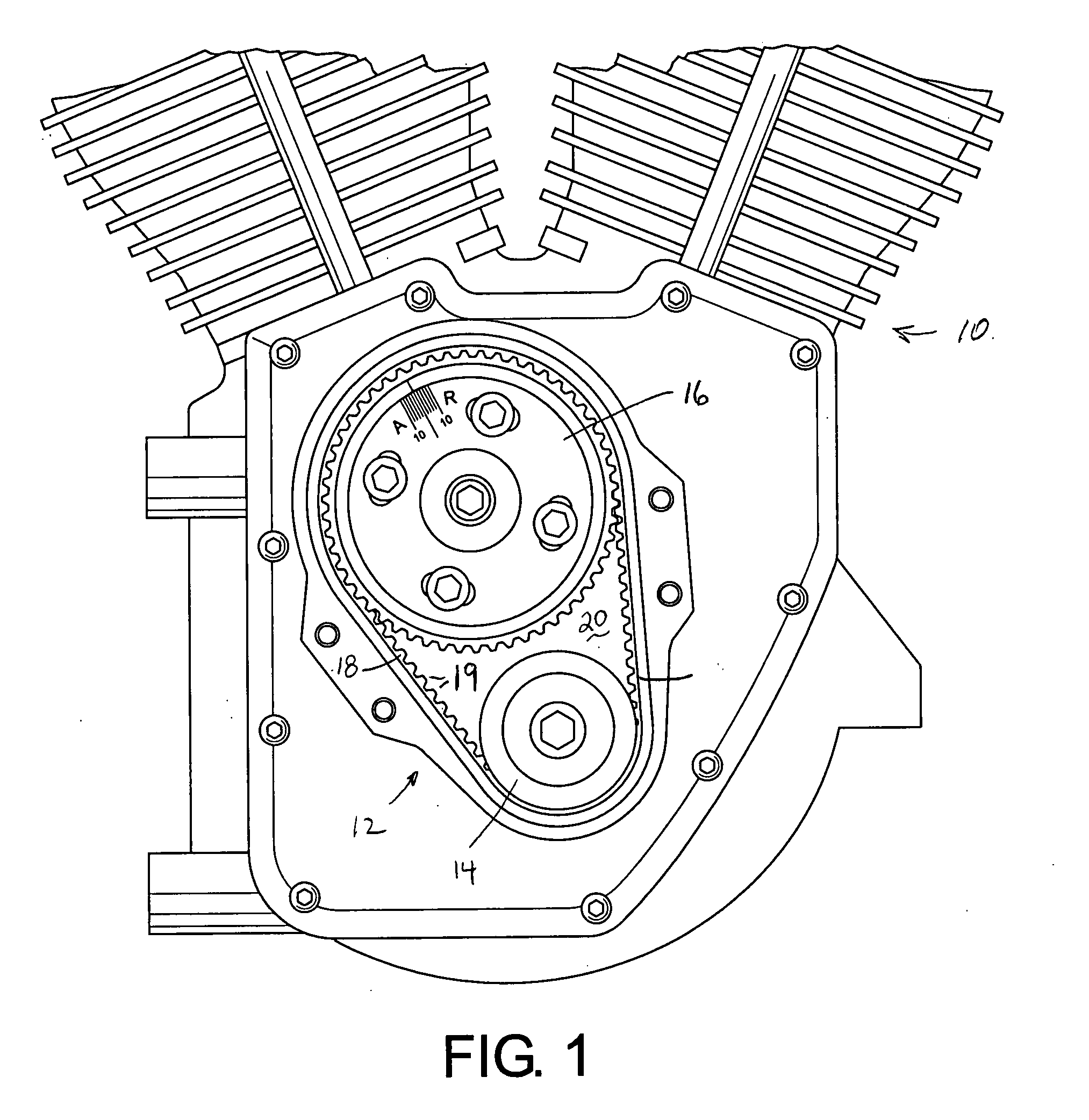

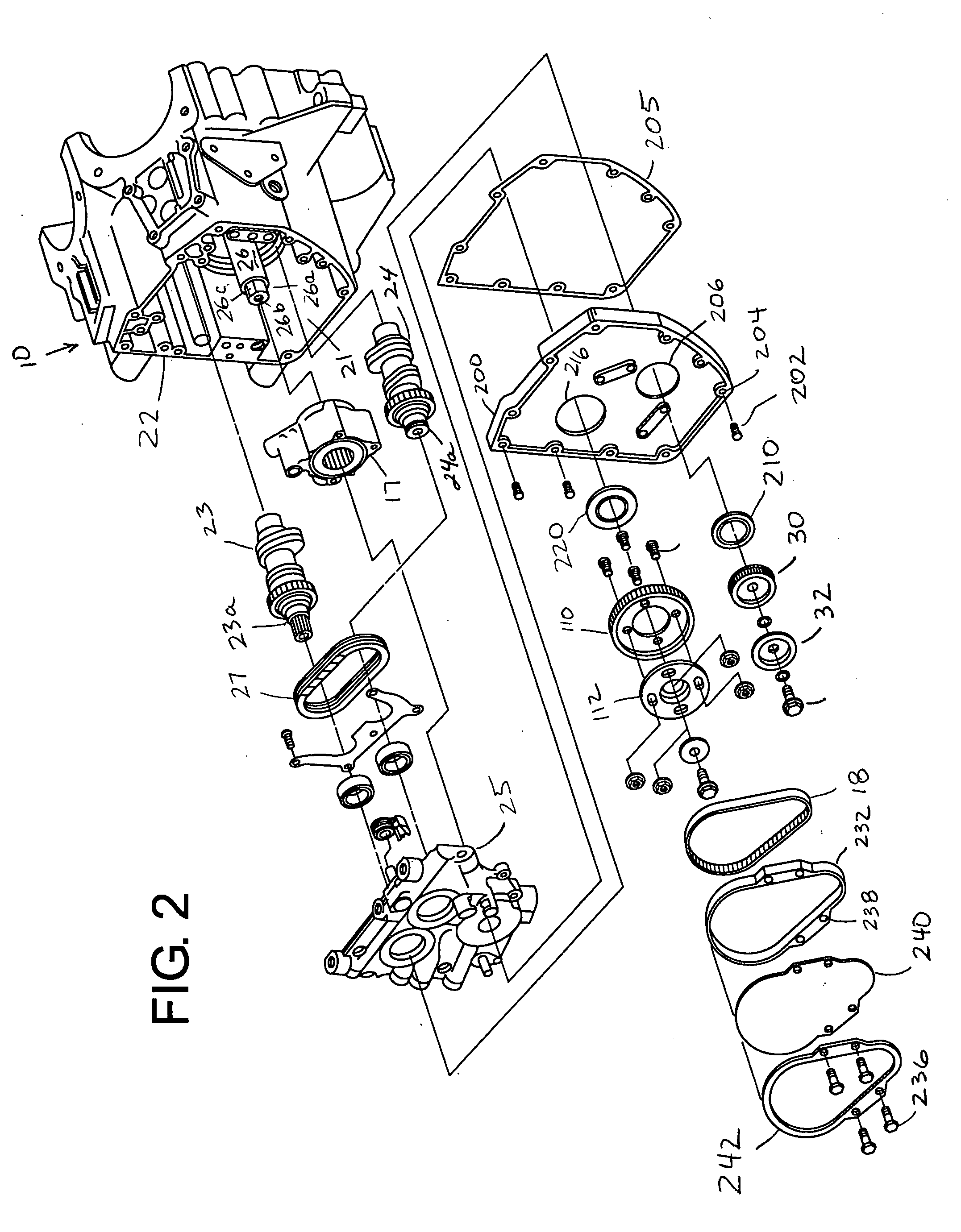

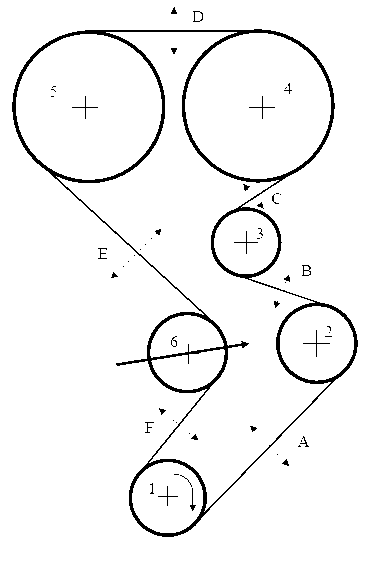

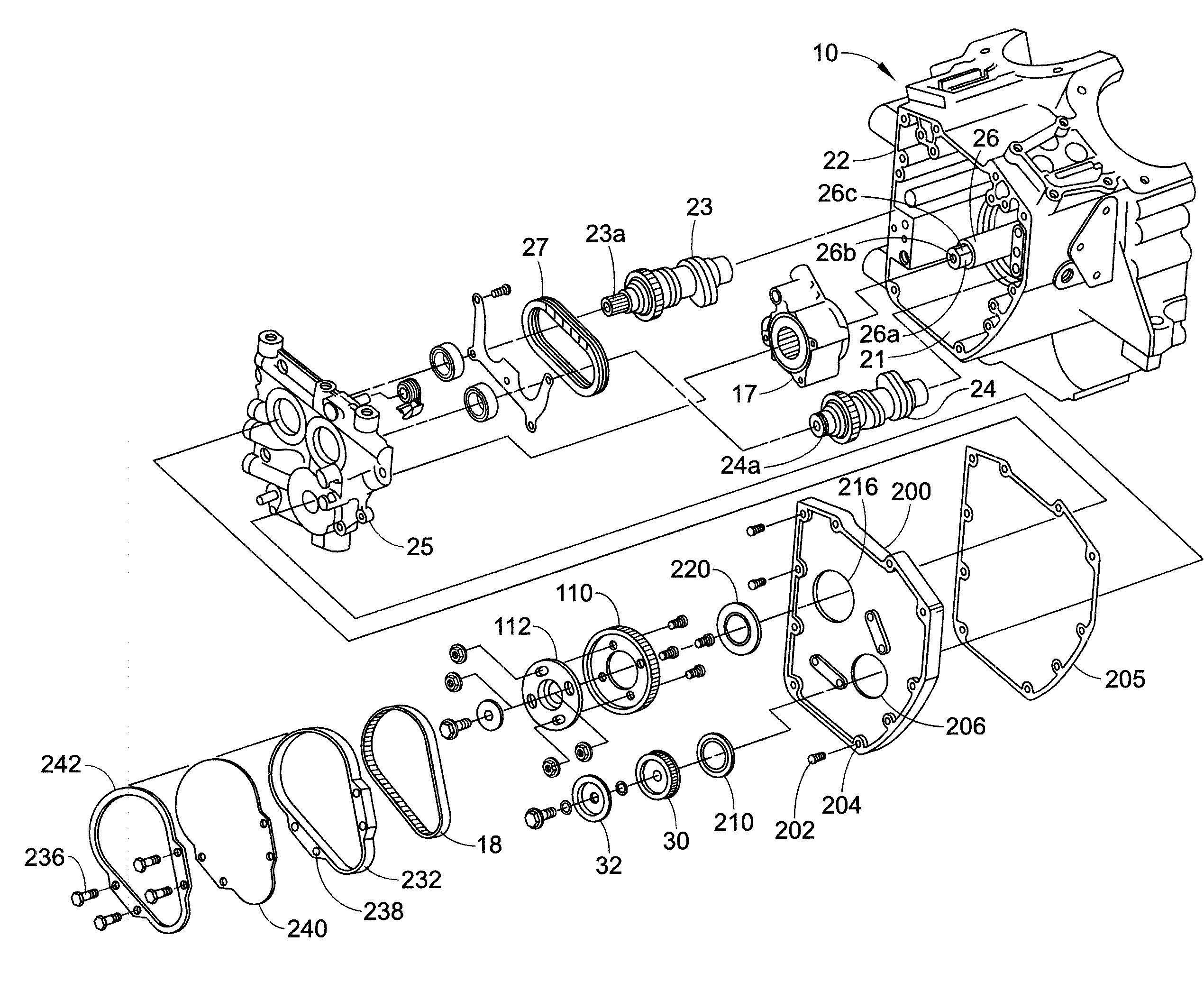

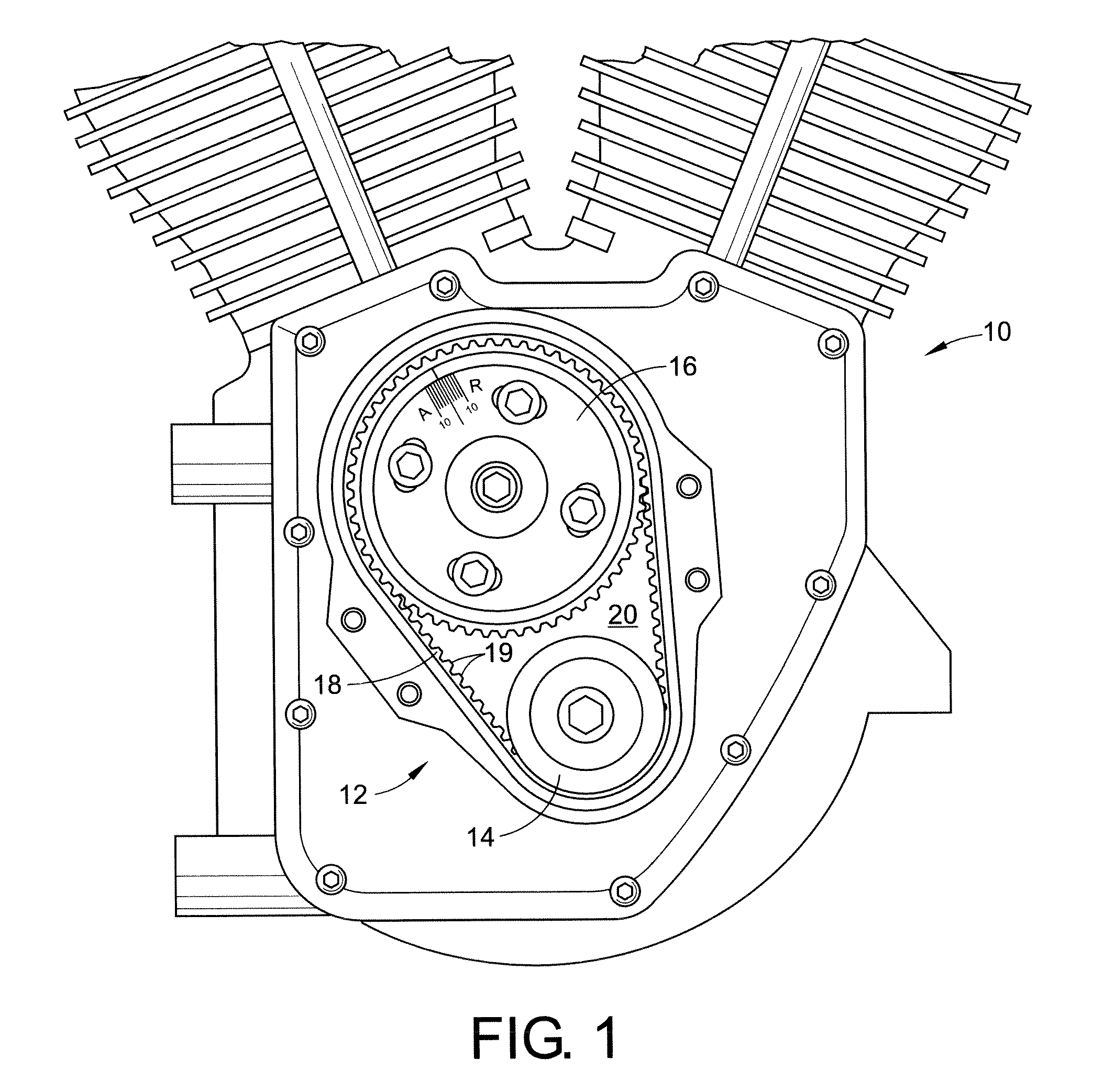

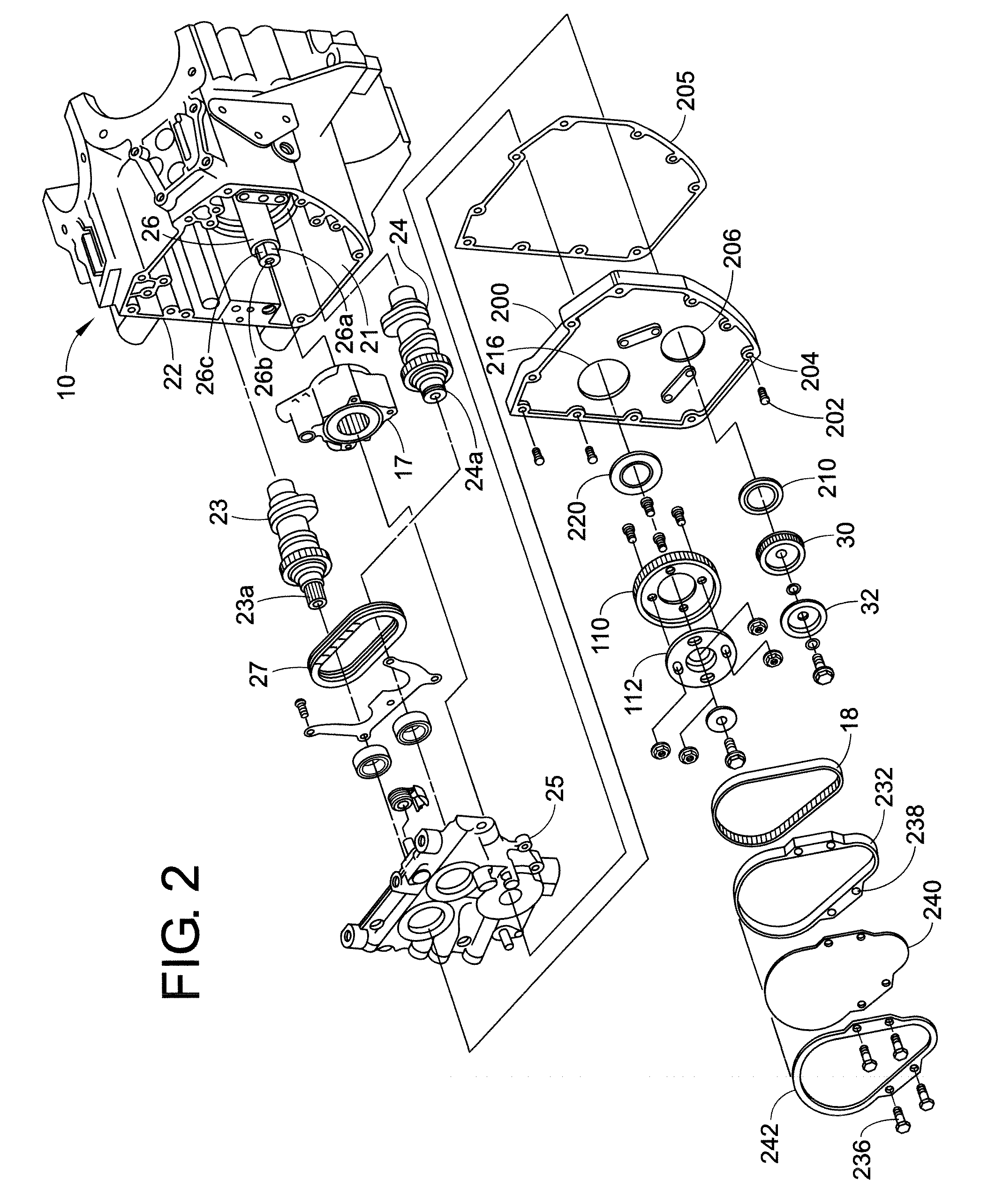

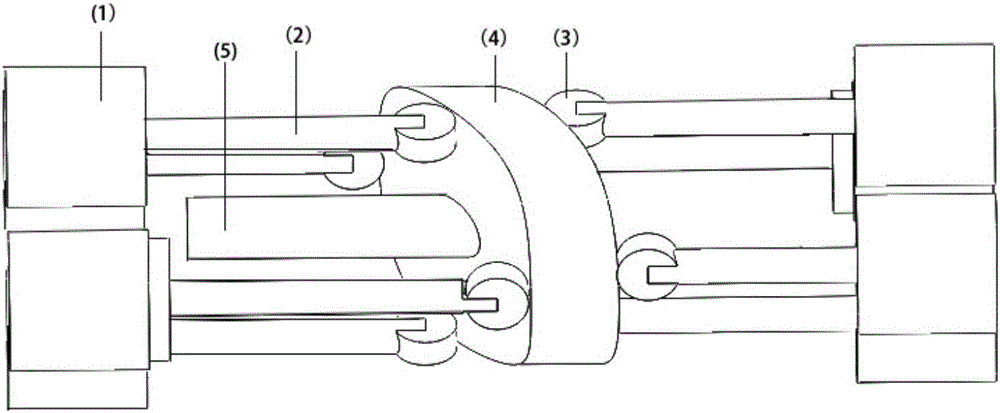

Air cooled twin Cam V-Twin motorcycle engine timing belt system

A timing belt system for an air cooled Twin Cam V-Twin motorcycle engine is provided. The timing belt system includes a crankshaft pulley assembly including a crankshaft pulley affixed to the crankshaft and a pulley flange affixed to the crankshaft pulley. The timing belt system also includes a camshaft pulley assembly including a spider gear having spindle affixed to the rear cam end of the Twin Cam engine and a hub having slotted apertures fastened to a camshaft pulley fastened. A timing belt having teeth is connects the crankshaft pulley to the camshaft pulley to turn the camshafts in synchronized rotation with the crankshaft. The spider can be rotated relative to the camshaft pulley and fastened thereto using bolts extending through the slotted apertures to Advance or Retard the timing of the camshafts relative to the crankshaft.

Owner:WOOD BOB

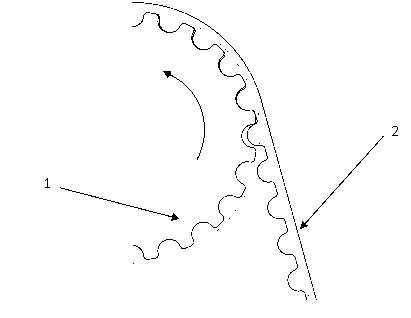

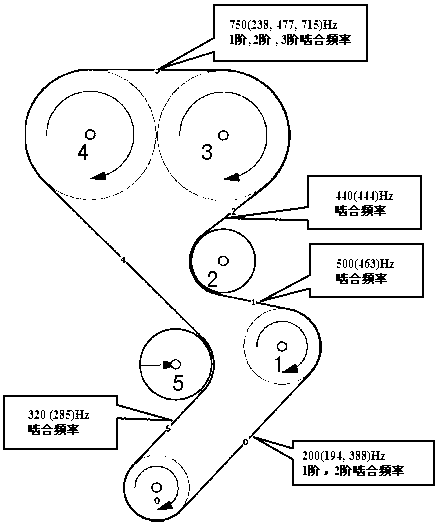

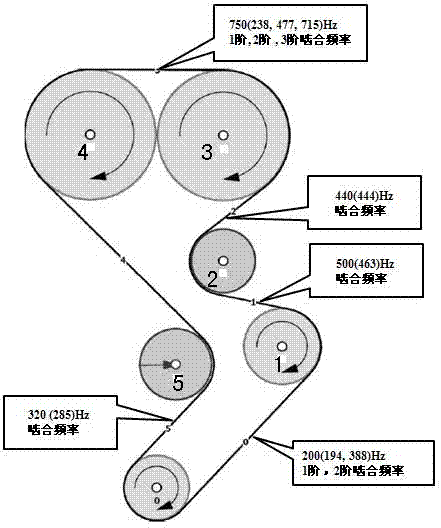

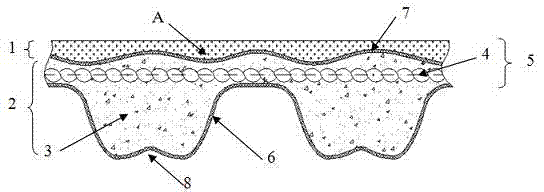

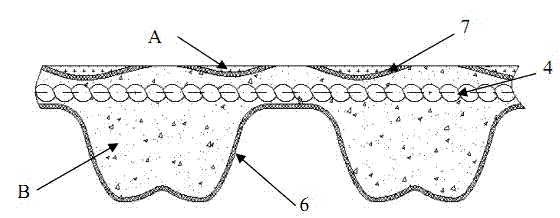

Low-noise automobile timing driving belt

The invention relates to a timing belt, in particular to a low-noise automobile timing driving belt. The low-noise automobile timing driving belt comprises an annular belt body, wherein the belt body is formed by binding a belt back and a meshed part, the meshed part is provided with a plurality of tooth parts which are spaced along the inner circumferential surface of the belt body, a core rope skeleton is embedded inside the meshed part along the circumferential direction of the belt body, an interlayer fabric is arranged between the belt back and the meshed part, and the inner circumferential surface of the meshed part is provided with a tooth-shaped fabric layer covering the tooth parts. Through the measurement, when the low-noise automobile timing driving belt is applied to a 1.8L top-mounted double-cam engine, the resonance phenomenon is eliminated, the noise is remarkably lowered, and the noise is hardly heard when a timing system protection shield is covered.

Owner:NINGBO FENGMAO FAR EAST RUBBER

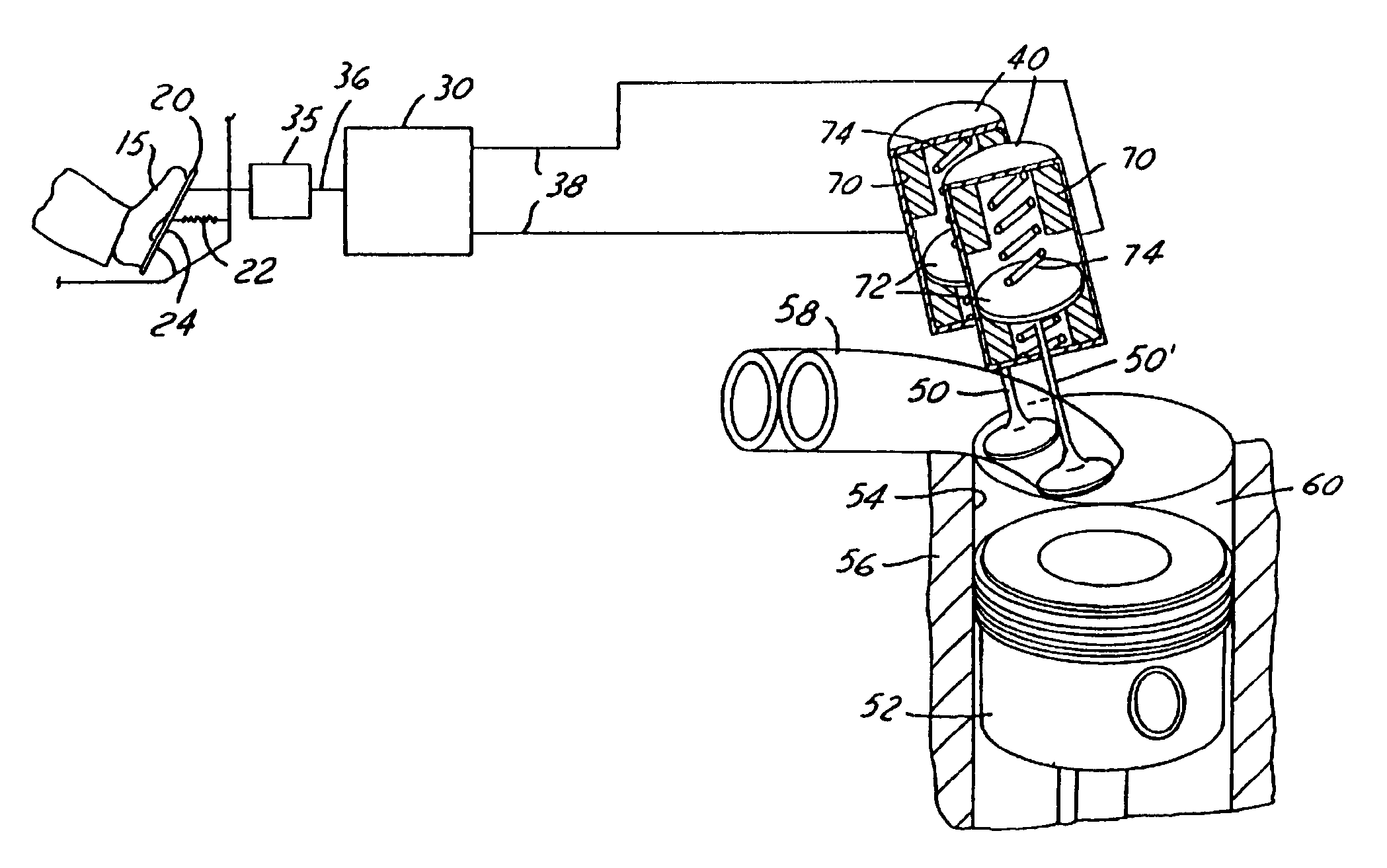

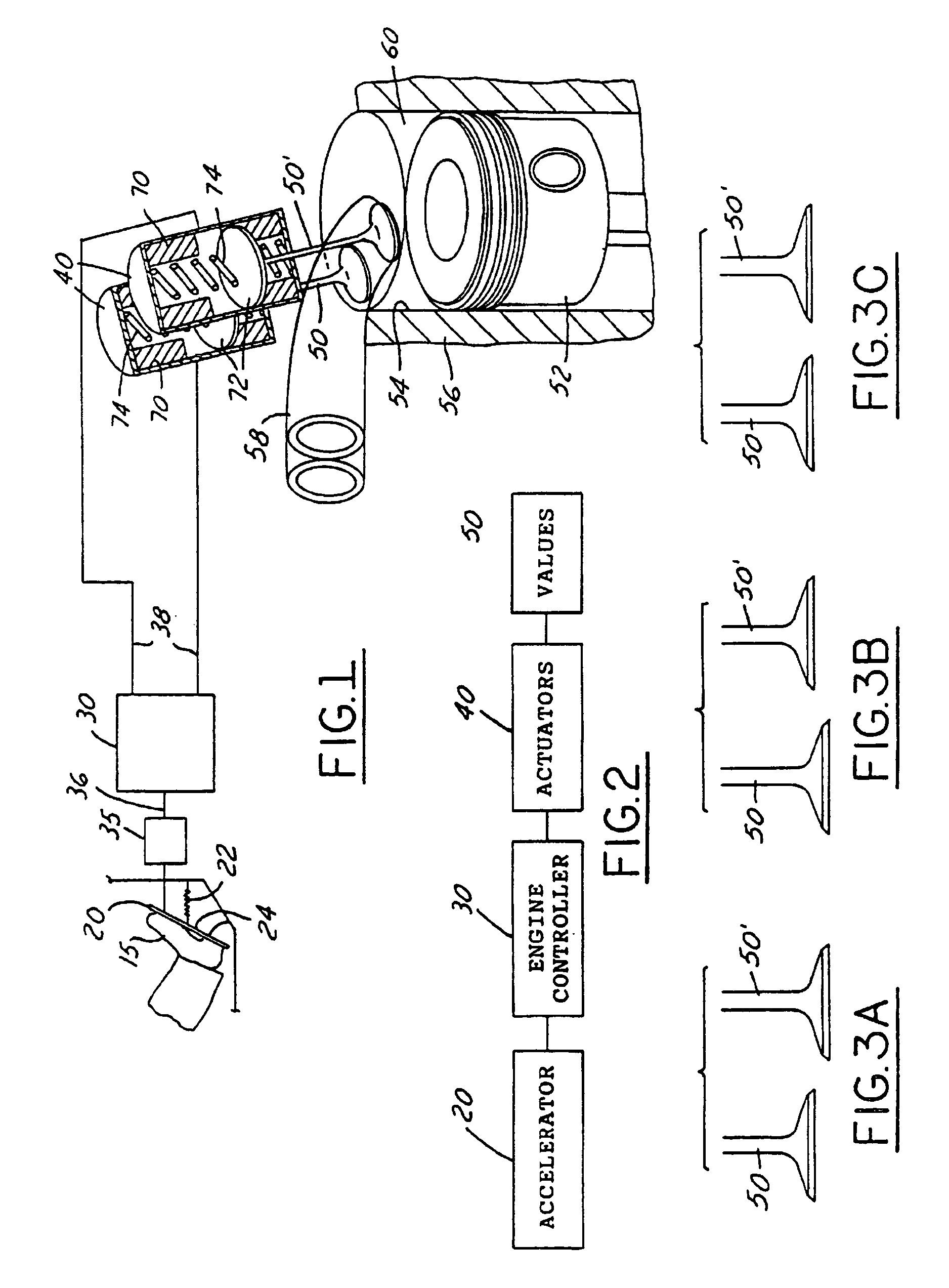

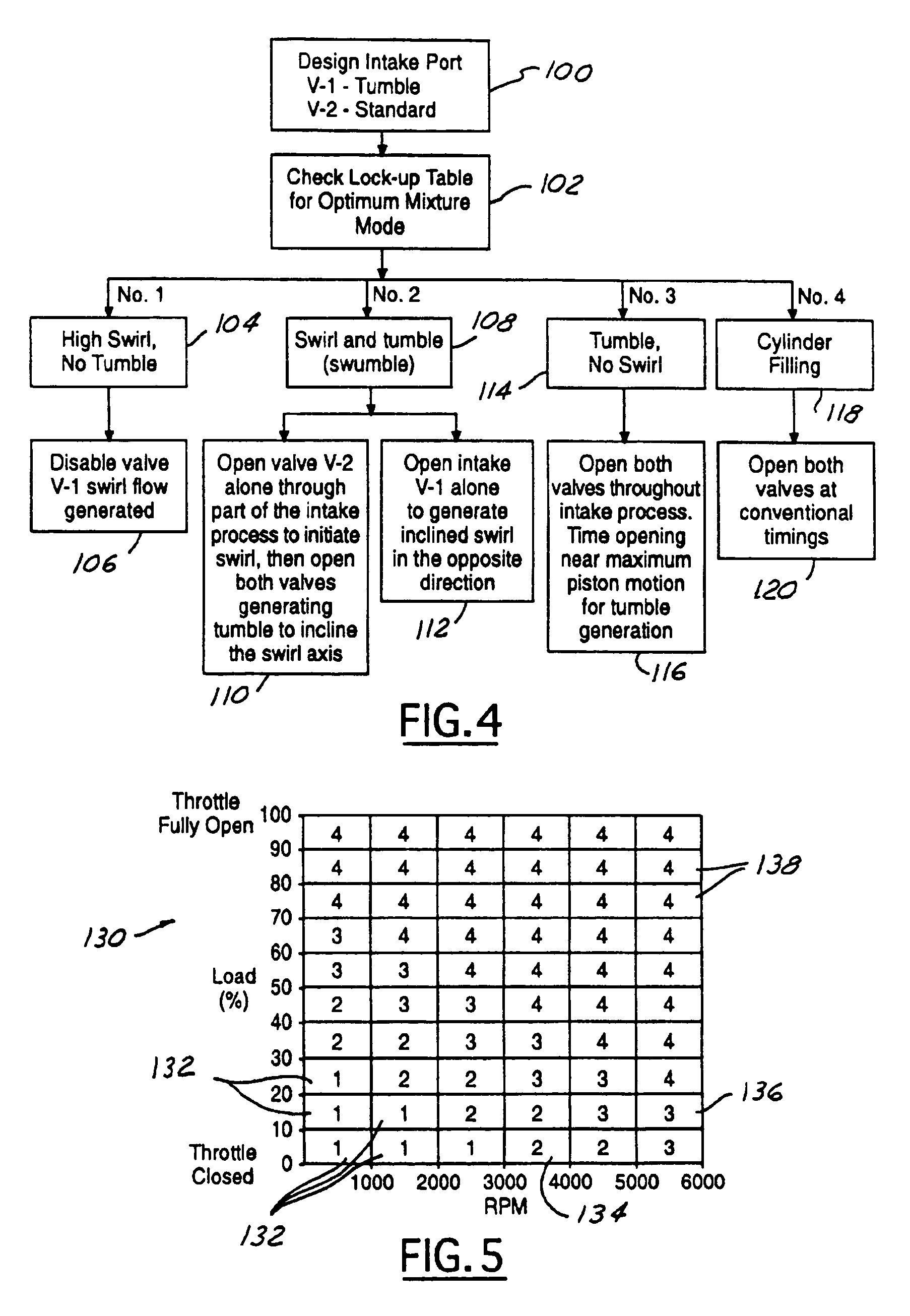

Intake valve timing in multi-valve, camless engines

InactiveUSRE42667E1Promote combustionHigh turbulence flow fieldInternal combustion piston enginesOutput powerMulti-valveCombustion chamber

Two intake valves are independently operated by electromechanical actuators and activated by the engine electronic controller. One tumble-type intake valve and one conventional intake valve are provided in each cylinder. The valve members are individually opened and closed to achieve a desired air flow pattern in the combustion chamber to optimize combustion which increases fuel economy and reduces undesirable emissions. The opening and closing of the valve members depends on the engine speed, engine load, and other factors.

Owner:FORD GLOBAL TECH LLC

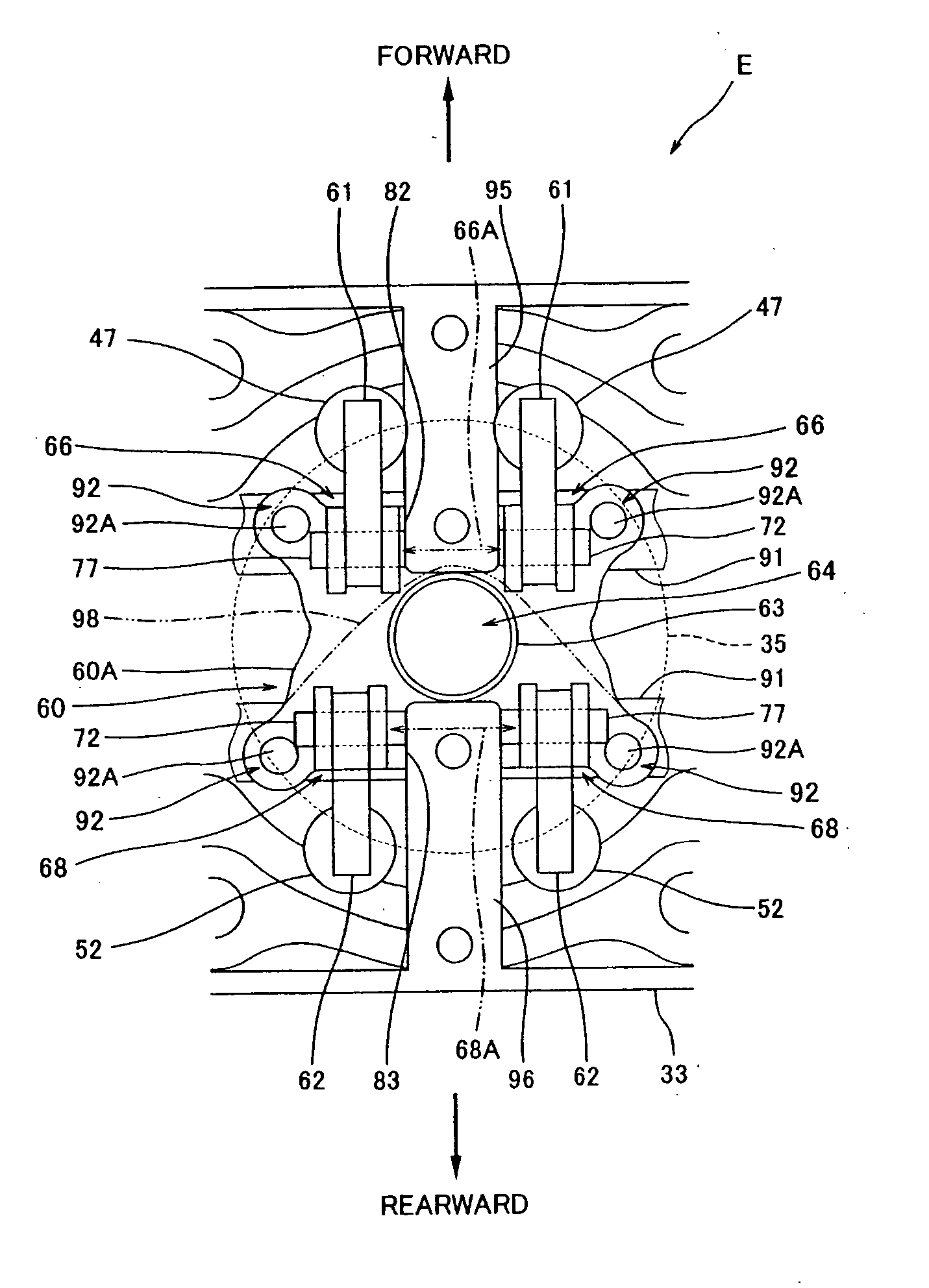

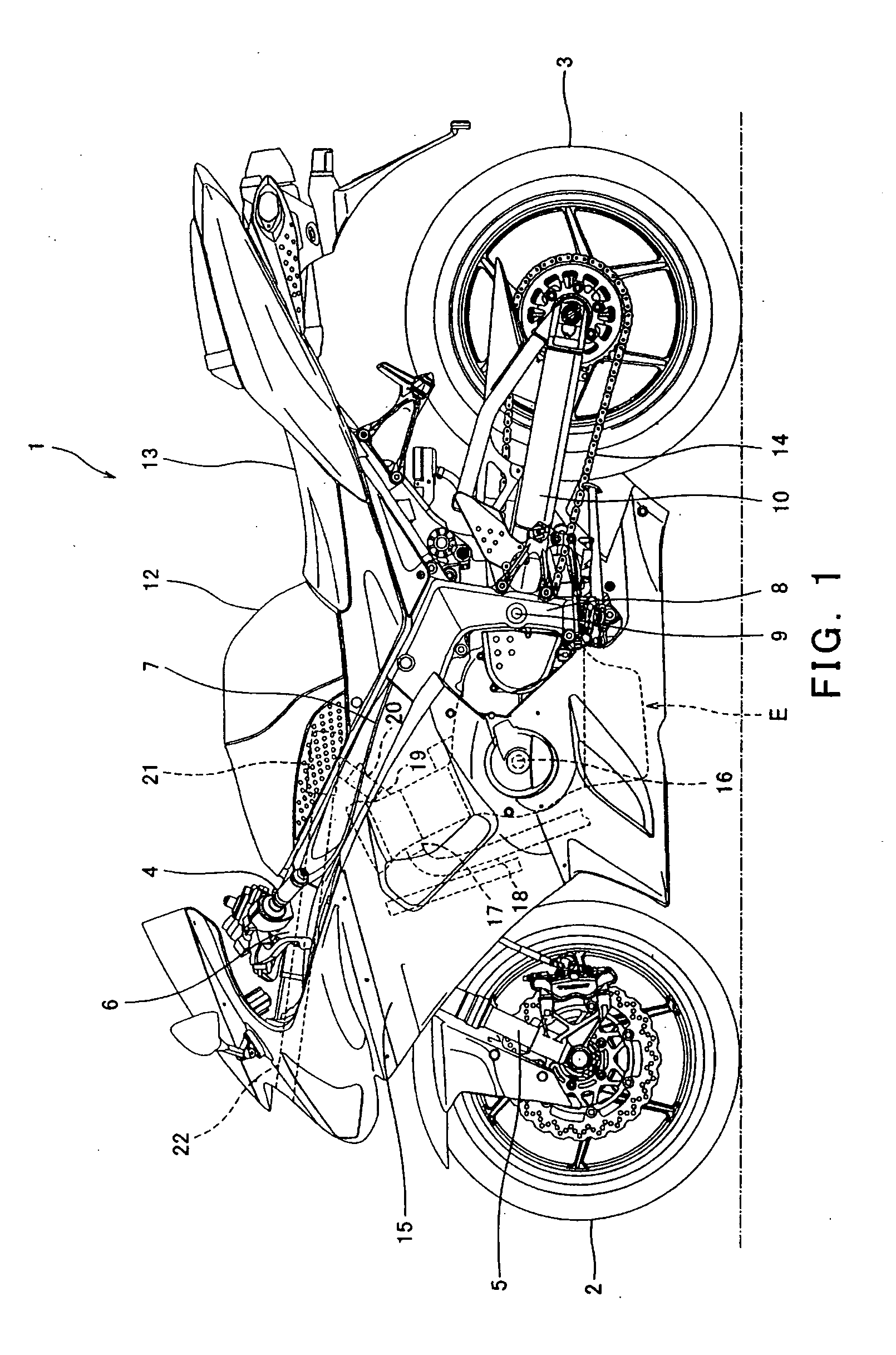

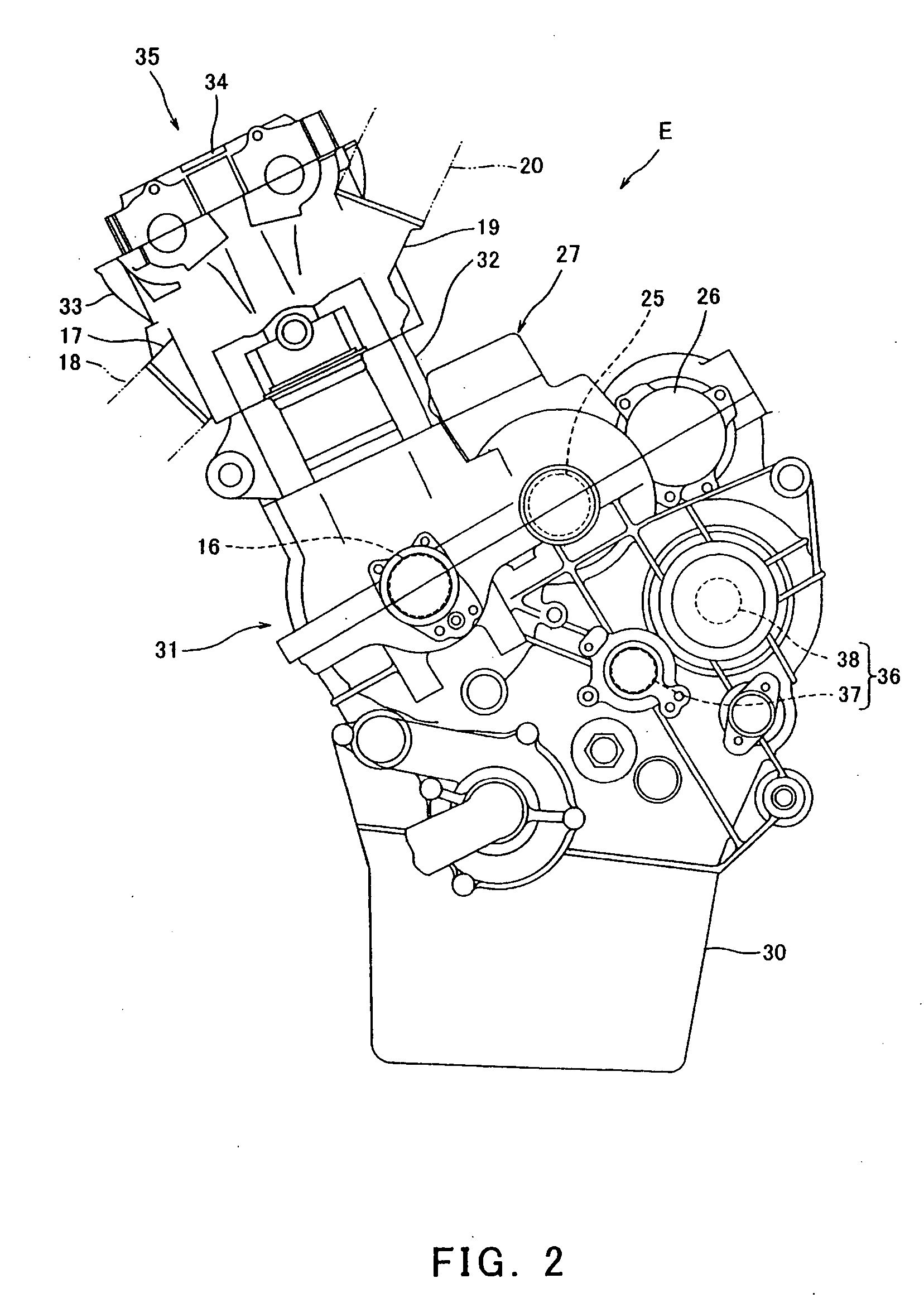

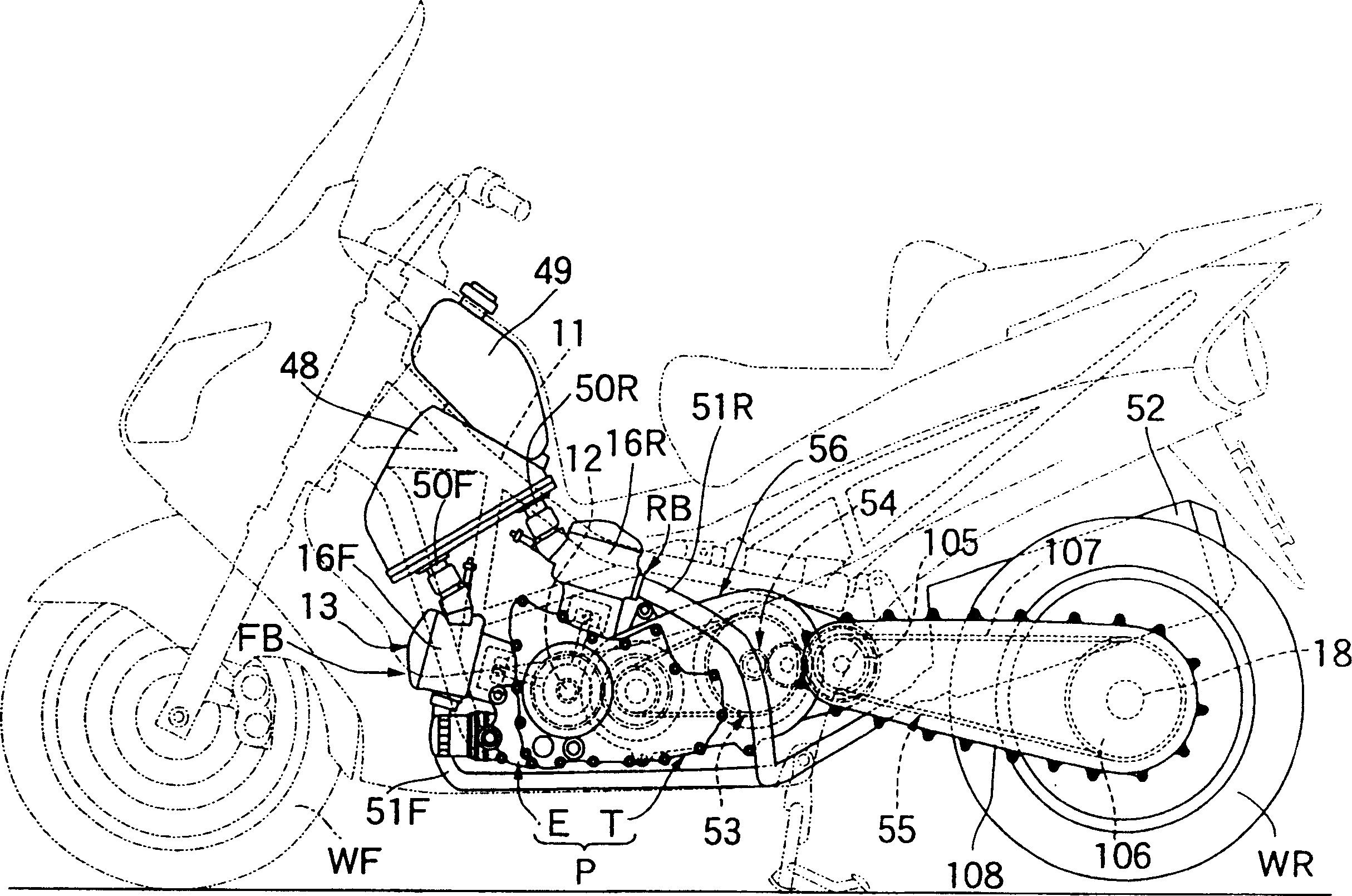

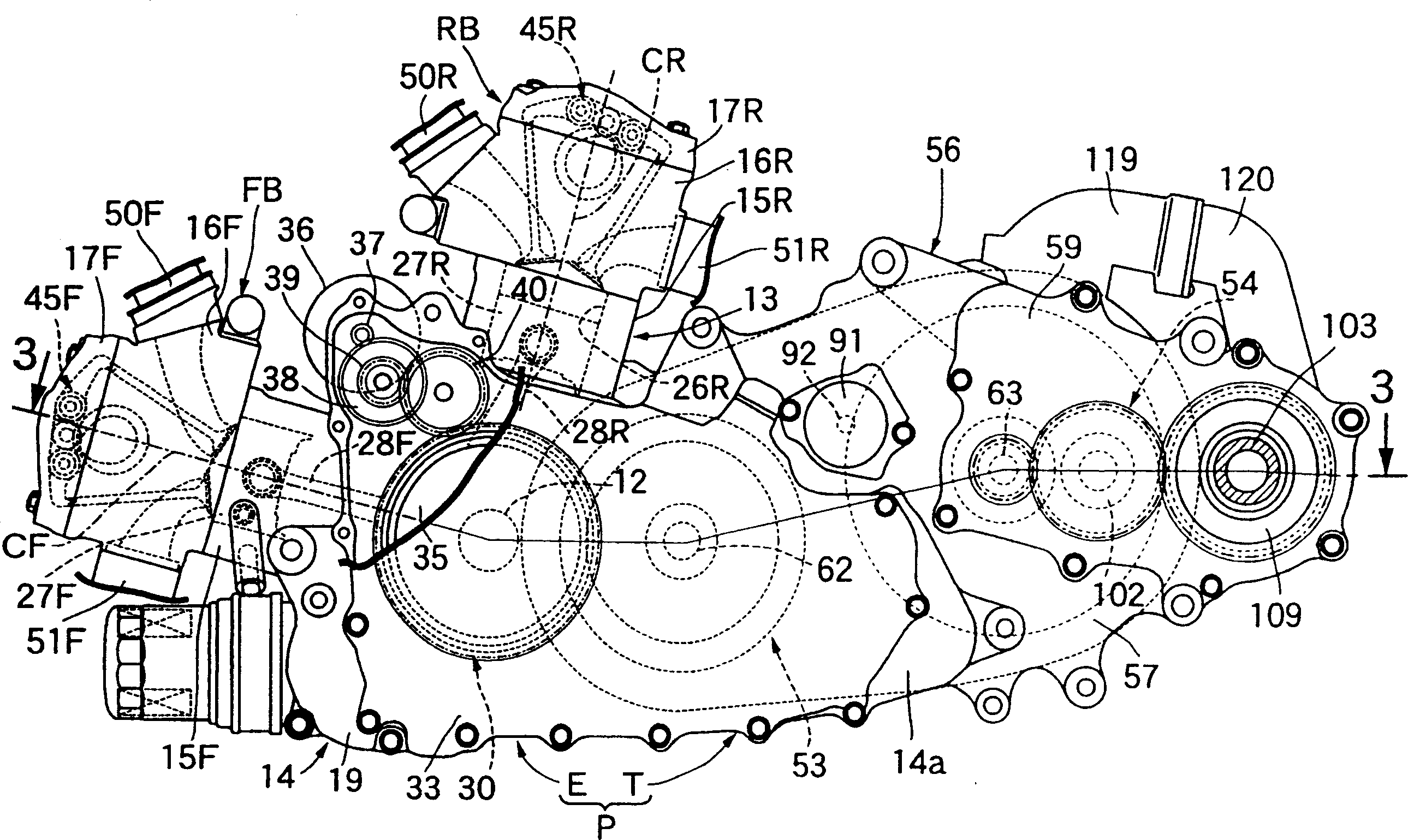

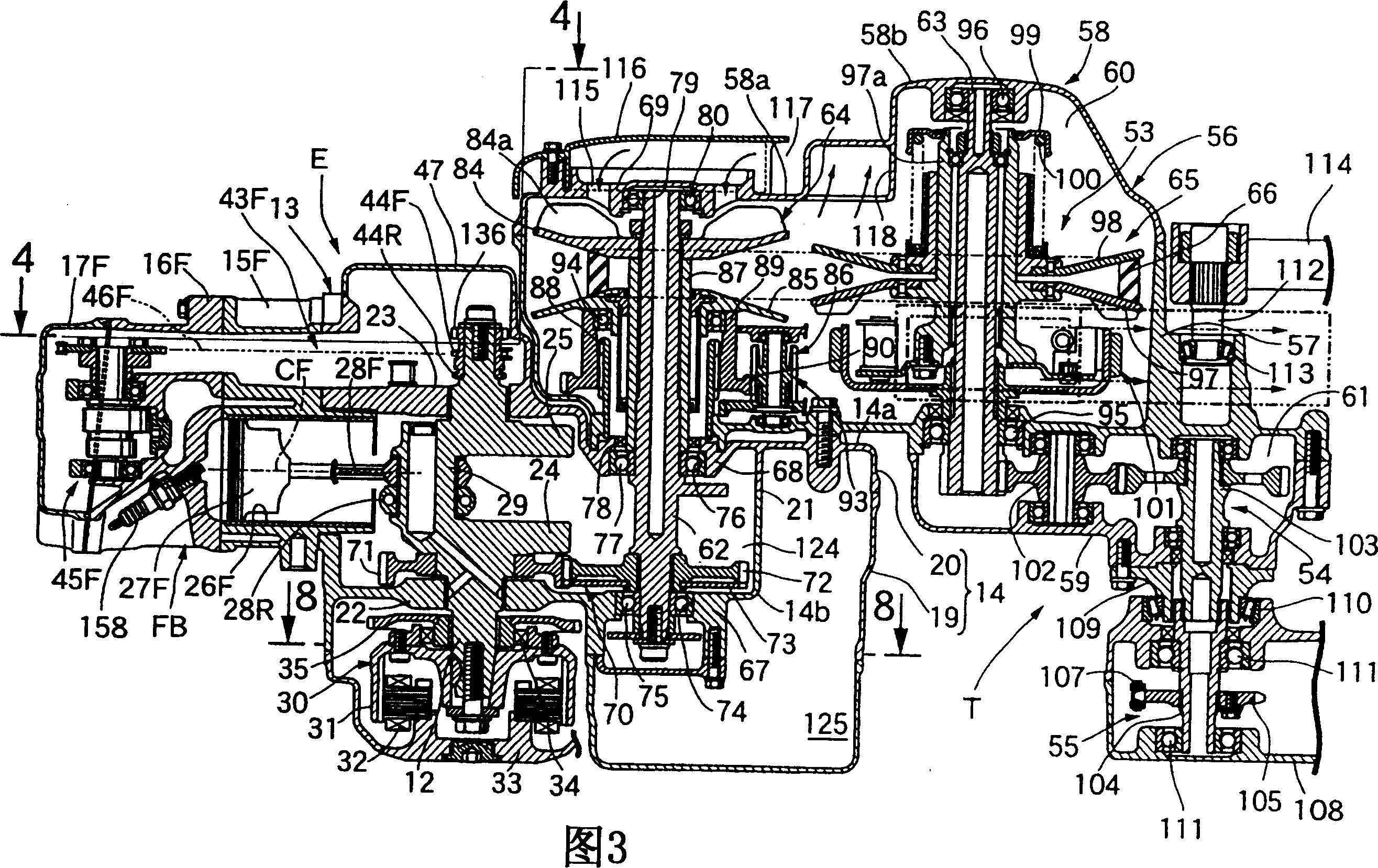

Twincam engine and motorcycle comprising the same

InactiveUS20070144477A1Improve wear resistanceIncrease stiffnessCam-followersValve drivesExhaust valveReciprocating motion

A twincam engine including a rocker arm configured to transmit rotation of a cam to reciprocate at least one of intake and exhaust valves, the rocker arm being pivotally attached to a cylinder head between a center axis of a valve stem of the intake valve and a center axis of a valve stem of the exhaust valve.

Owner:KAWASAKI HEAVY IND LTD

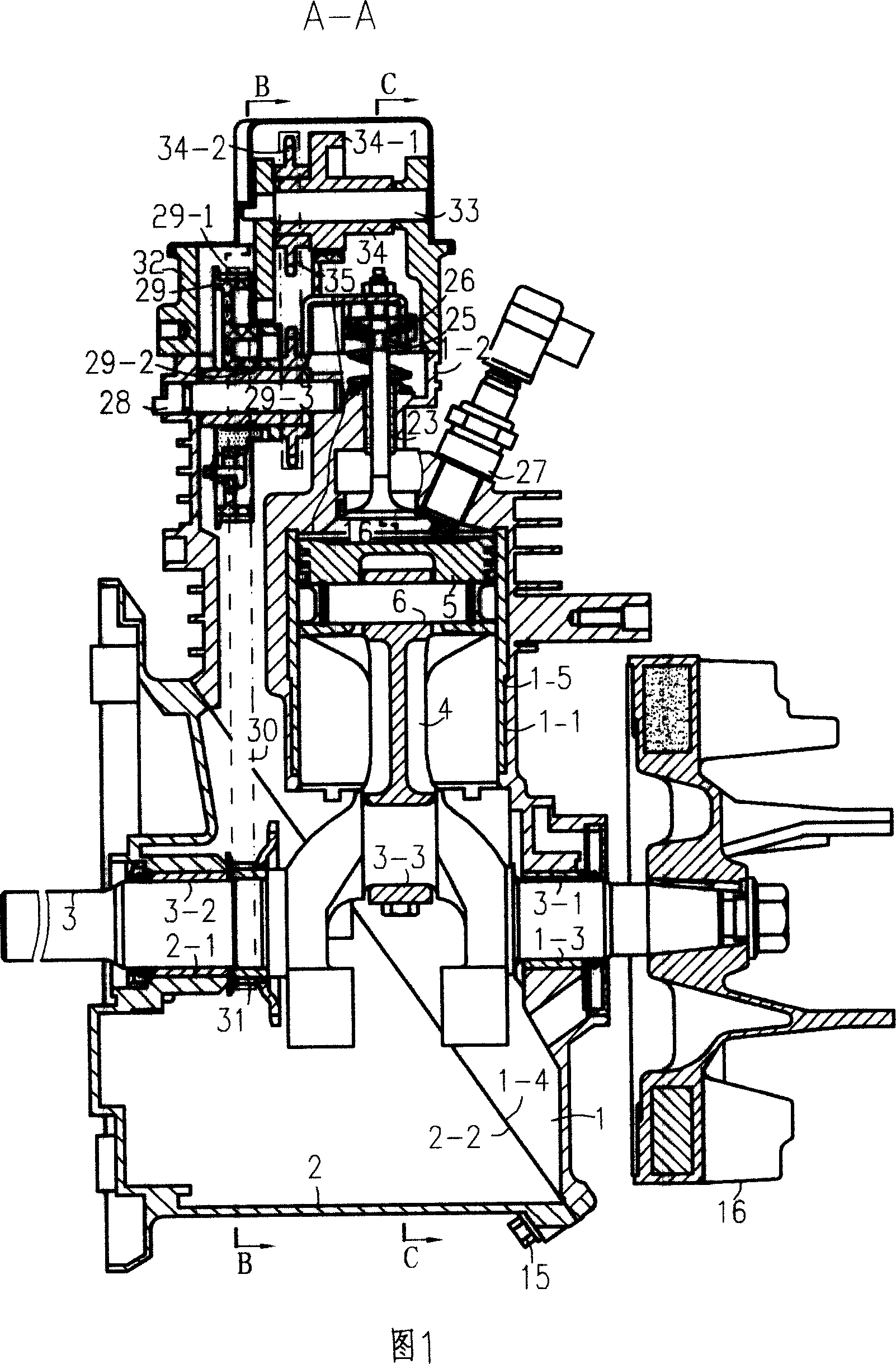

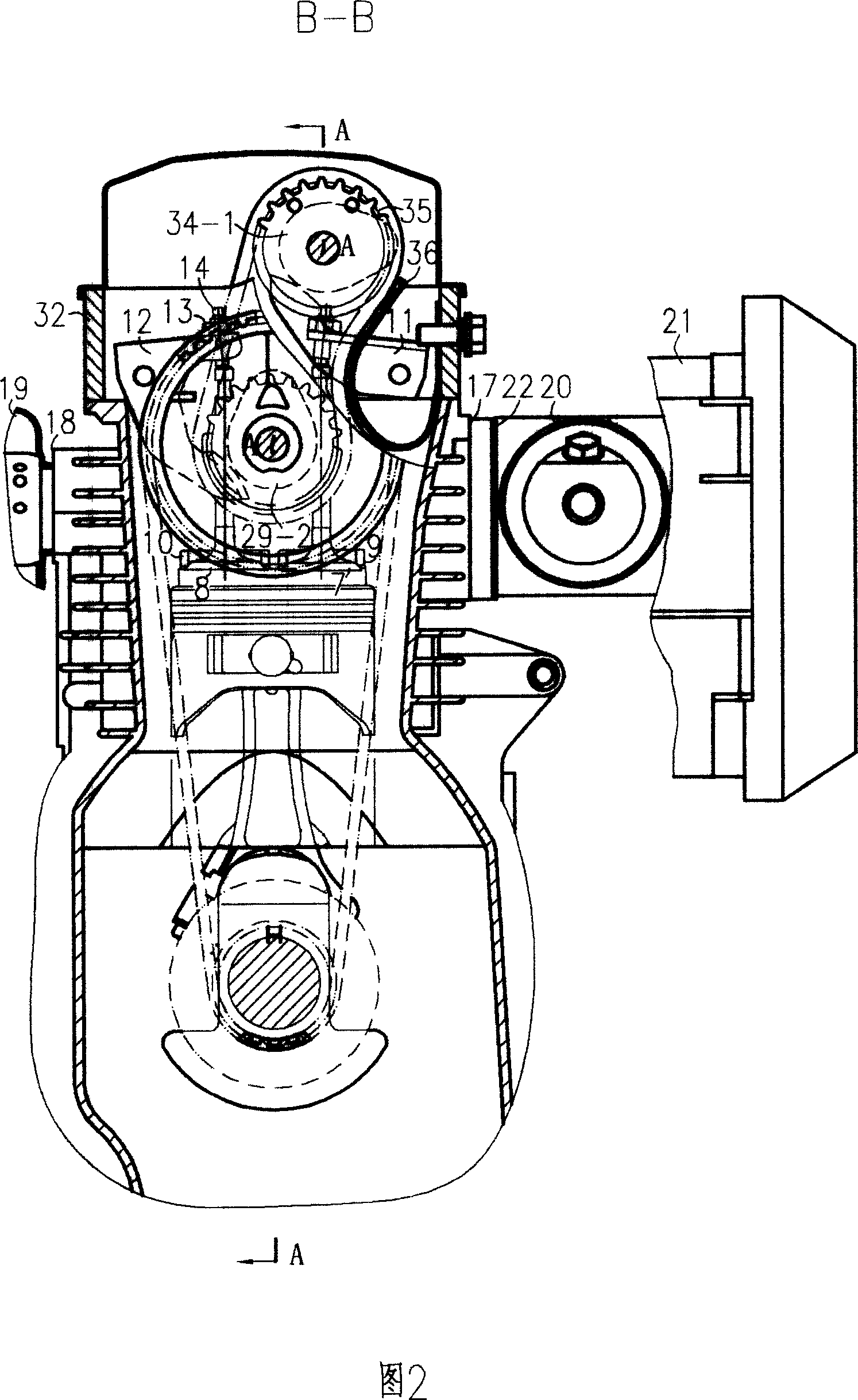

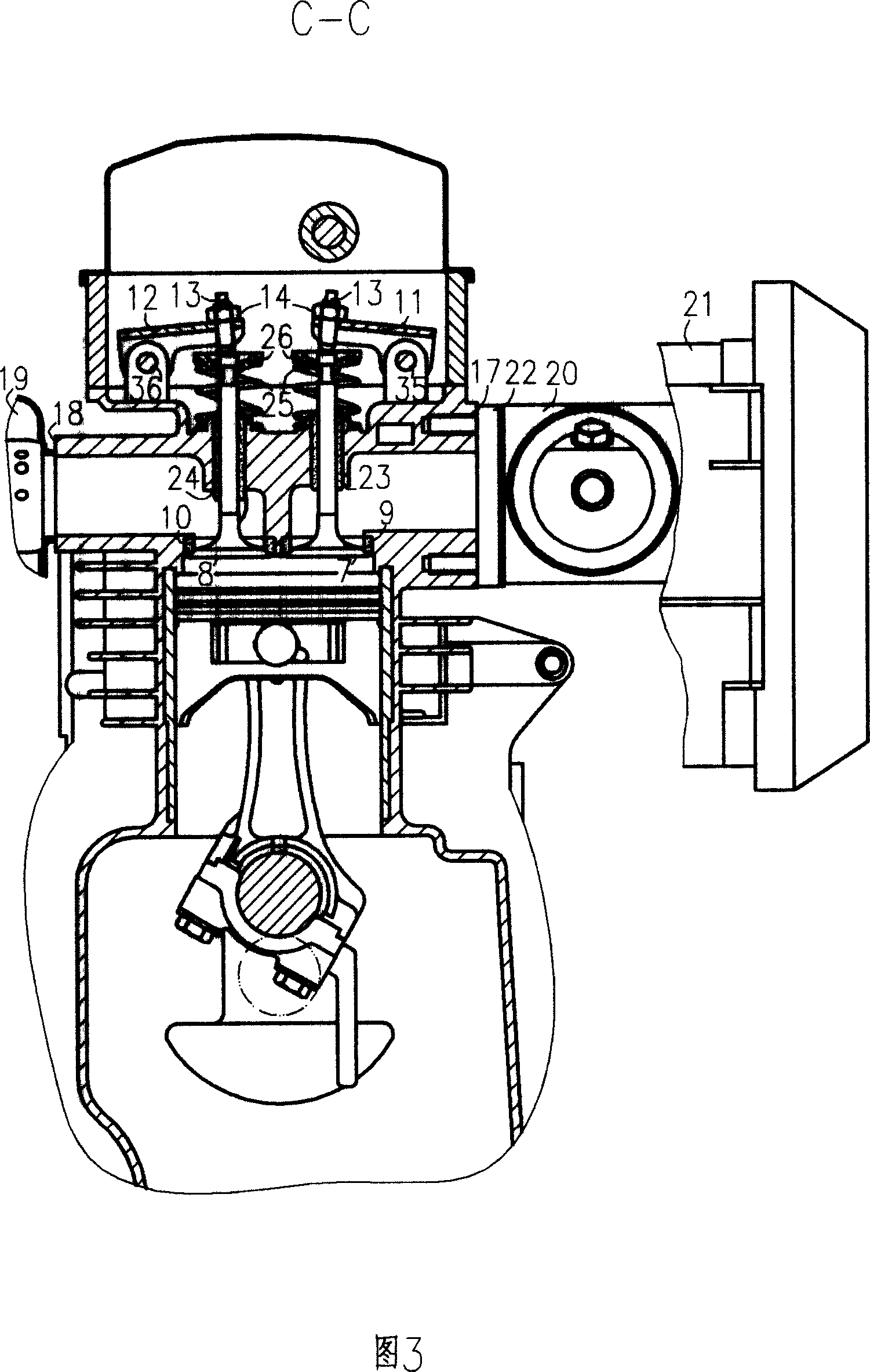

Overhead cam engine

InactiveCN101012760AReduce workloadExtend working lifeValve drivesMachines/enginesExhaust valveEngineering

The invention relates to an overhead cam engine. For there is a heavy working load of prior cam engine and intake and outtake valves can not achieve the valve phase demand when they are opened and closed, the design is improved. The invention comprises cylinder body, cylinder head and crankshaft box. The crankshaft is connected with the piston through a linkage device. It is characterized in that at the position of cylinder head, intake and outtake valves are installed in parallel; an outtake crankshaft and an outtake cam are set between intake and outtake valves; the upper end of cylinder head is connected with a support and on the support intake camshaft and intake cam are set; cam faces of intake and outtake cams control intake and outtake valves opening or closing by a rocker; the outtake camshaft is connected with the crankshaft by the transmission device and the intake camshaft is connected with the outtake camshaft by the transmission device. The working load of invention is small. When intake and outtake valves are opened and closed the reasonable valve phase can be achieved.

Owner:WUXI SOUTHEAST VEHICLE TECH

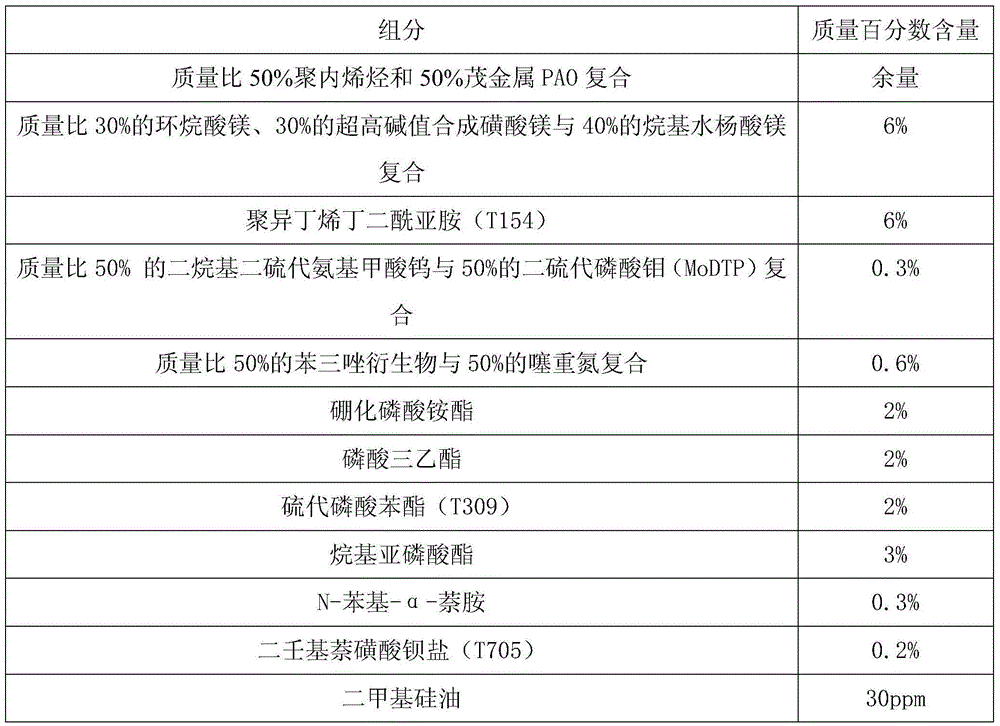

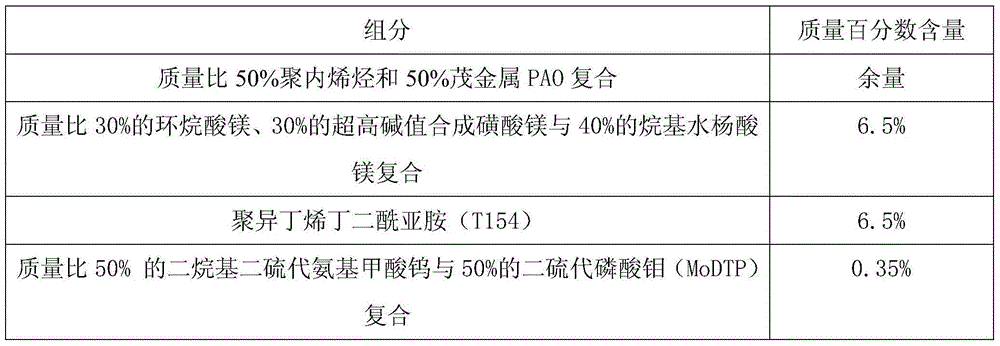

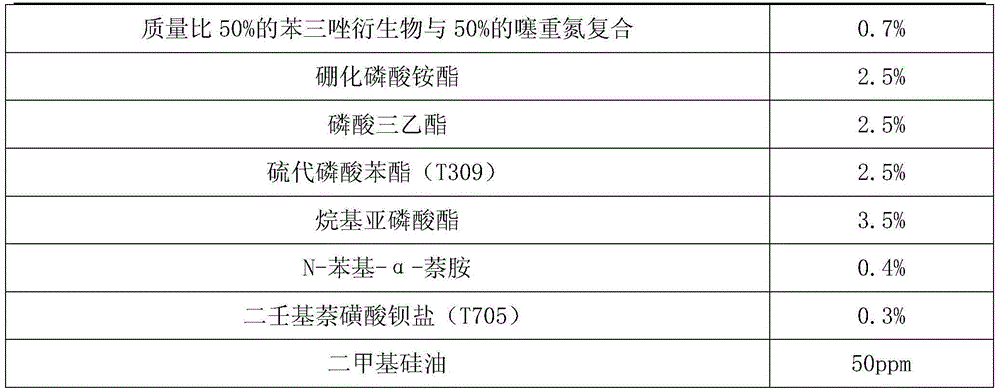

Lubricating agent for piston type cam engine

InactiveCN104962362AImprove the finishBase value maintenance period is longBase-materialsEngineeringCleansing Agents

The invention discloses a lubricating agent for a piston type cam engine. According to the lubricating agent, poly-internal-olefin and metallocene PAO (synthetic base oil) are compounded into base oil and are matched with a plurality of additives. The lubricating agent comprises a cleaning agent, a dispersing agent, an anti-oxidization preservative, an anti-oxidant, an aid, an extreme pressure agent, an anti-wear agent, a friction improver, a metal deactivator, an anti-rusting agent and an anti-foaming agent. The lubricating agent can be directly applied to a lubricating system of the piston type cam engine and has the beneficial effects that the lubricating property, cooling property, sealing property, cleaning property, rust resistance, liquidity and startability are good, the neutralization capacity for dispersing oil sludge and acid is strong, the surface smoothness of a kinematic pair is high, the base value holding period is long, the operation is convenient, and the cost is low.

Owner:GUANGXI UNIV

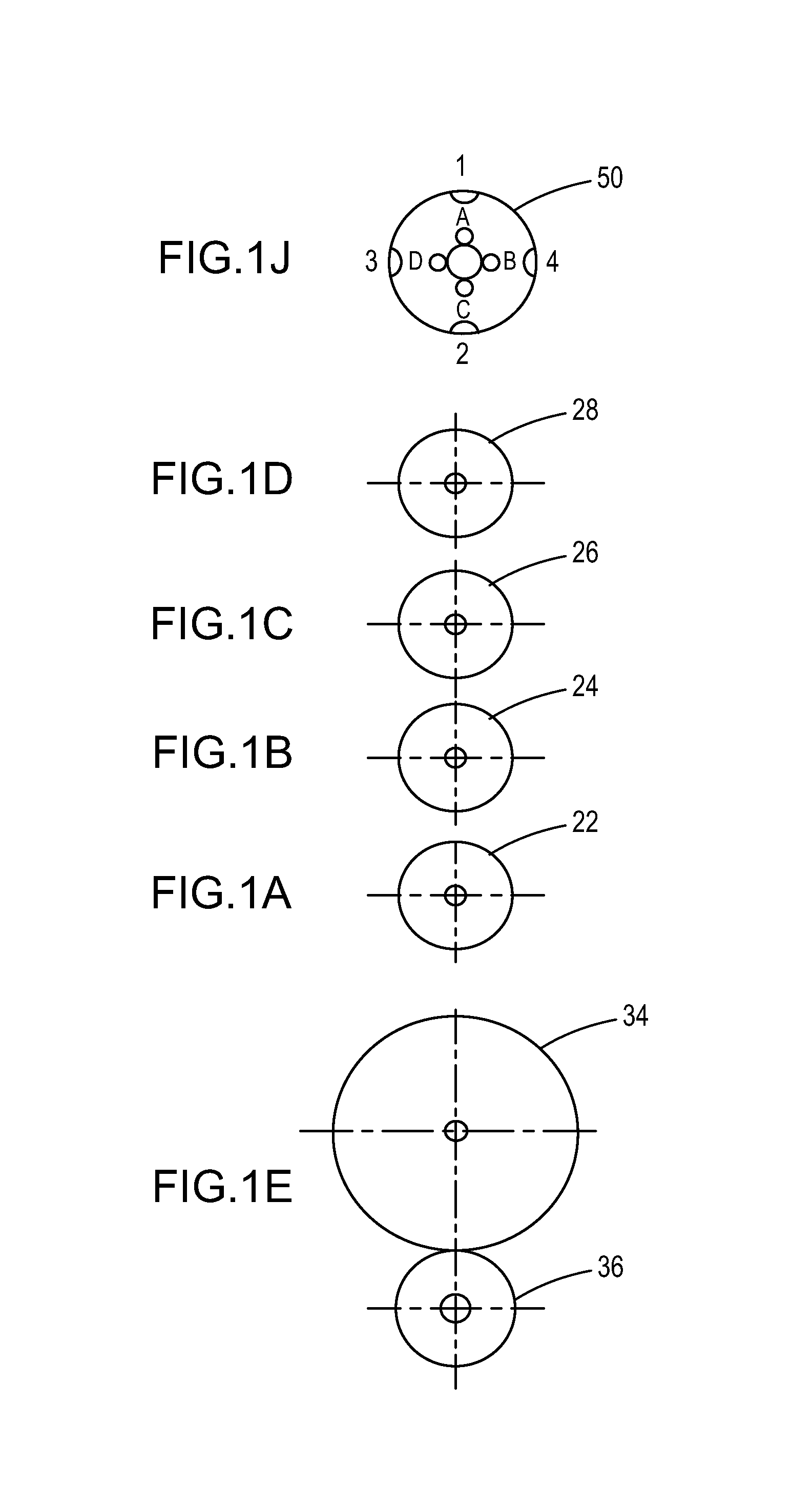

Piston cam engine

InactiveUS7793623B2Balanced reliabilityReduce noiseReciprocating piston enginesEngineeringInternal combustion engine

The invention relates to a piston cam engine used in different field of the mechanical engineering, as internal-combustion engines compressors, pumps etc. The cam engine comprises cylinders (13) with pistons (20), a cylindrical tubular 3D cam (3) having a cam groove on the inner cylindrical surface and at least two guides (10) which are guide columns. The cam (3) is composed and includes two coaxial bushes (3a, 3b), each one having corrugated cam section (95a or 95b) from its one side and flange (35) from its other side besides the bushes (3a, 3b) are positioned against each other with its corrugated ends at a distance from each other, and further comprises spacer (37) between the flanges (35) of the bushes (3a, 3b), so as to form the cam groove having a constant section.

Owner:BAHNEV BOYAN K

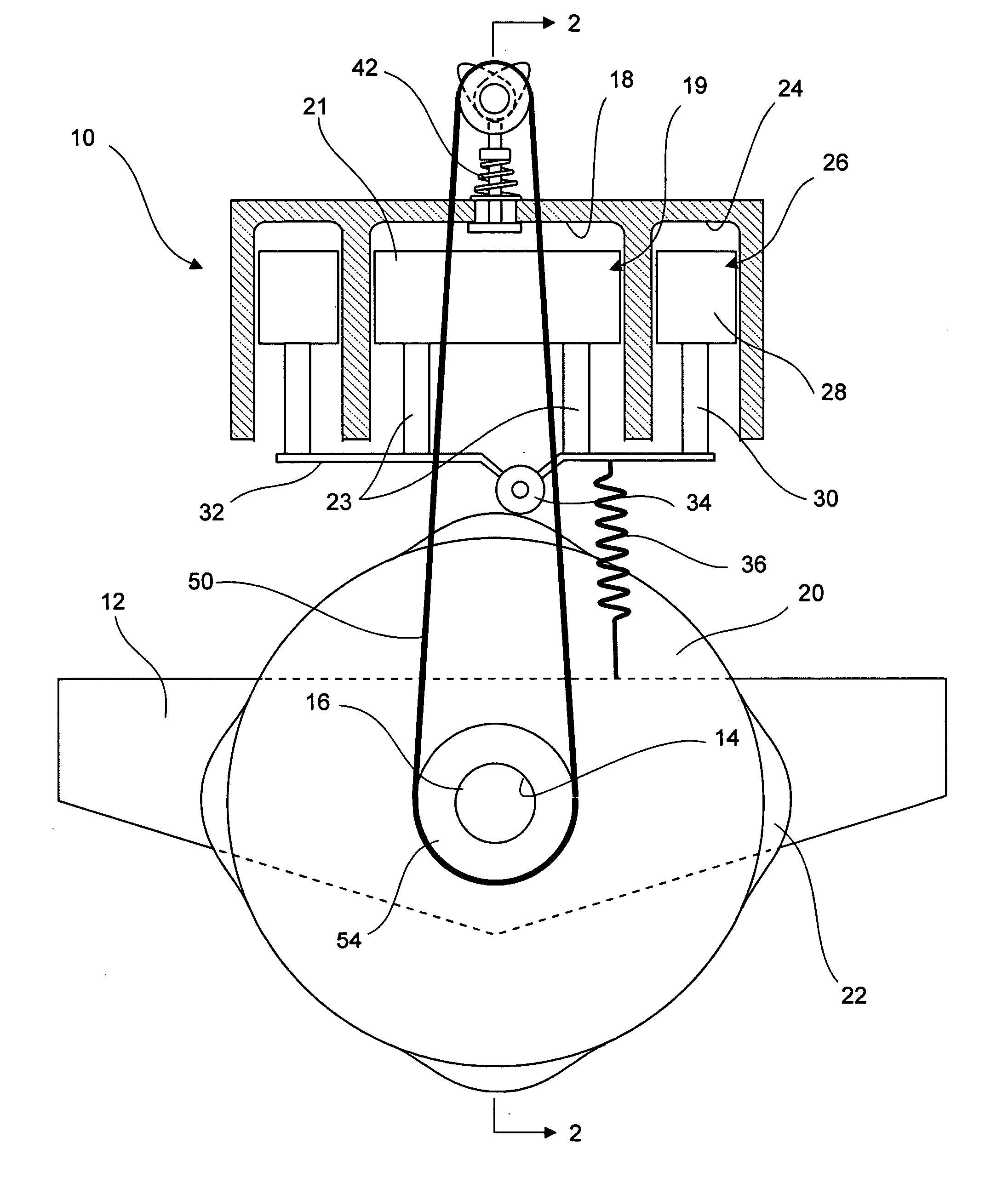

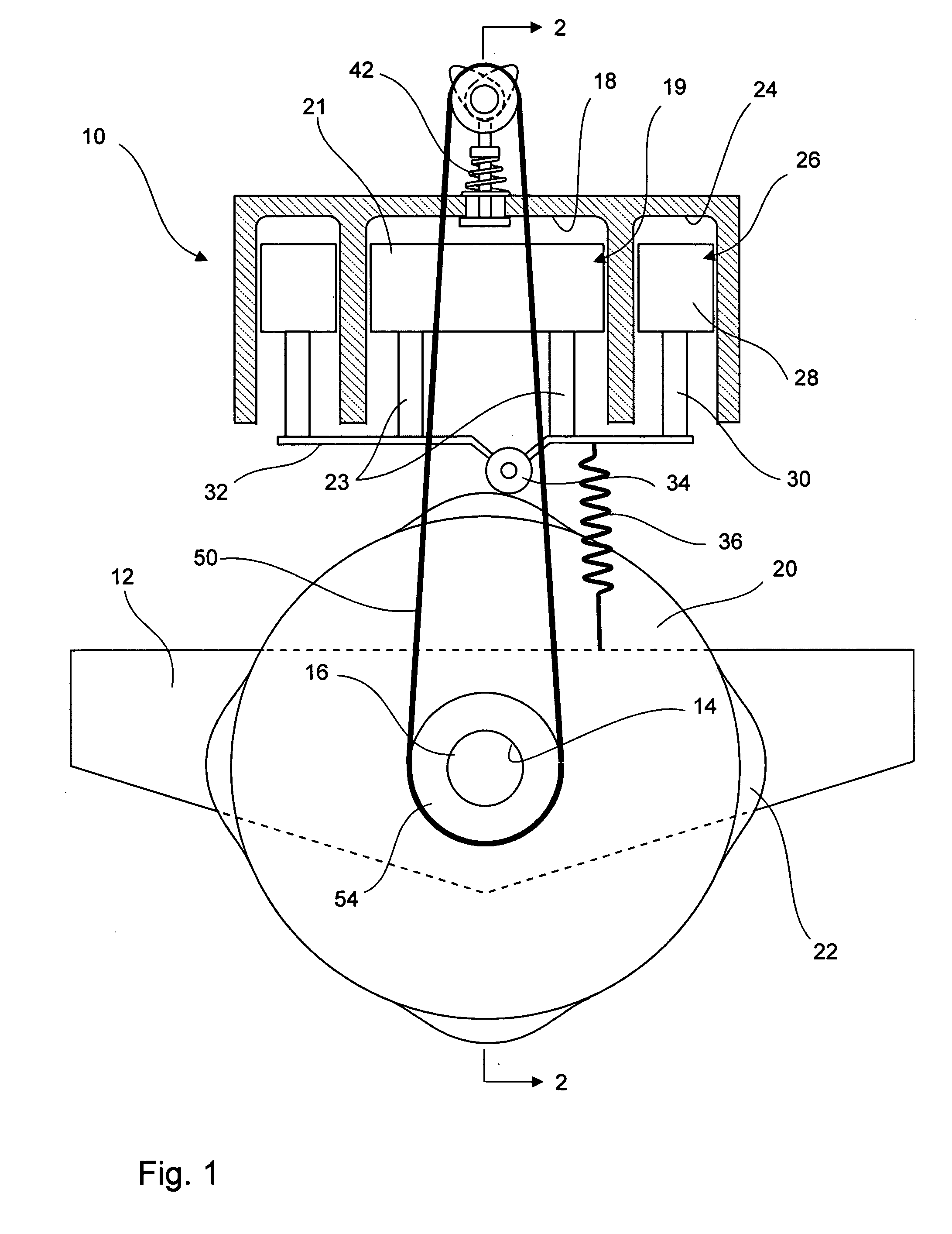

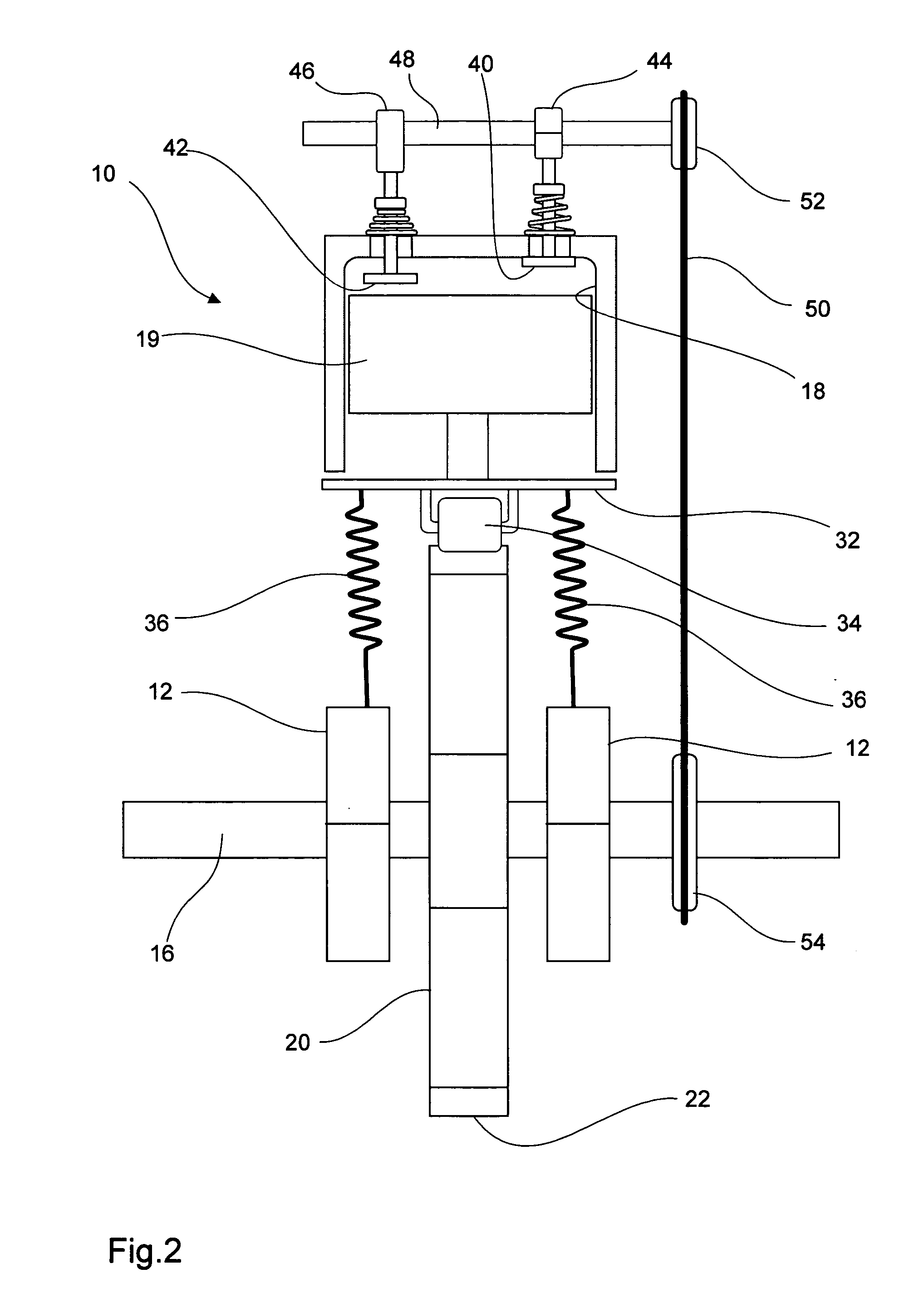

Piston-cam engine

A piston-cam engine includes a drive cylinder, a drive piston operably disposed therein having a piston head and a shaft, a support frame having a drive shaft rotatably movably connected thereto, a cam having a peripheral surface and having a plurality of lobes thereon, a roller member connected to the piston shaft and adapted for engagement with the peripheral surface of the cam, and a biasing element for biasing the roller member continuously against the peripheral surface of the cam. A support drive plate interconnects the piston shaft and the roller member and one or more slave cylinder(s) is provided adjacent the drive cylinder and has a slave piston operably disposed therein and has a piston head and a shaft, wherein the slave piston shaft is connected to the support drive plate to absorb part of a force exerted on the support plate during operation of the engine.

Owner:CHANEY RAY O

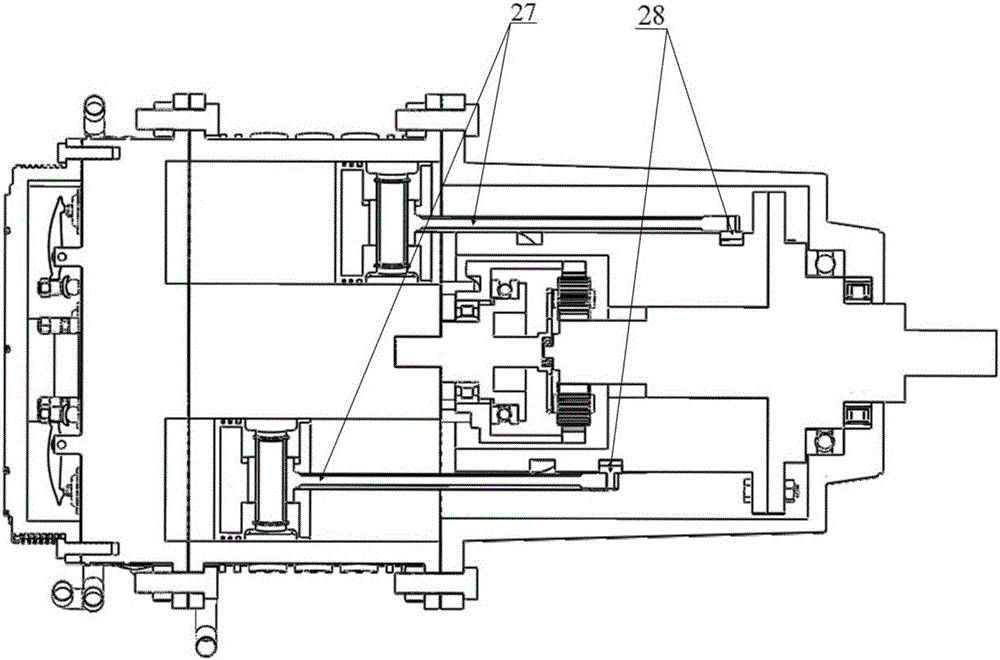

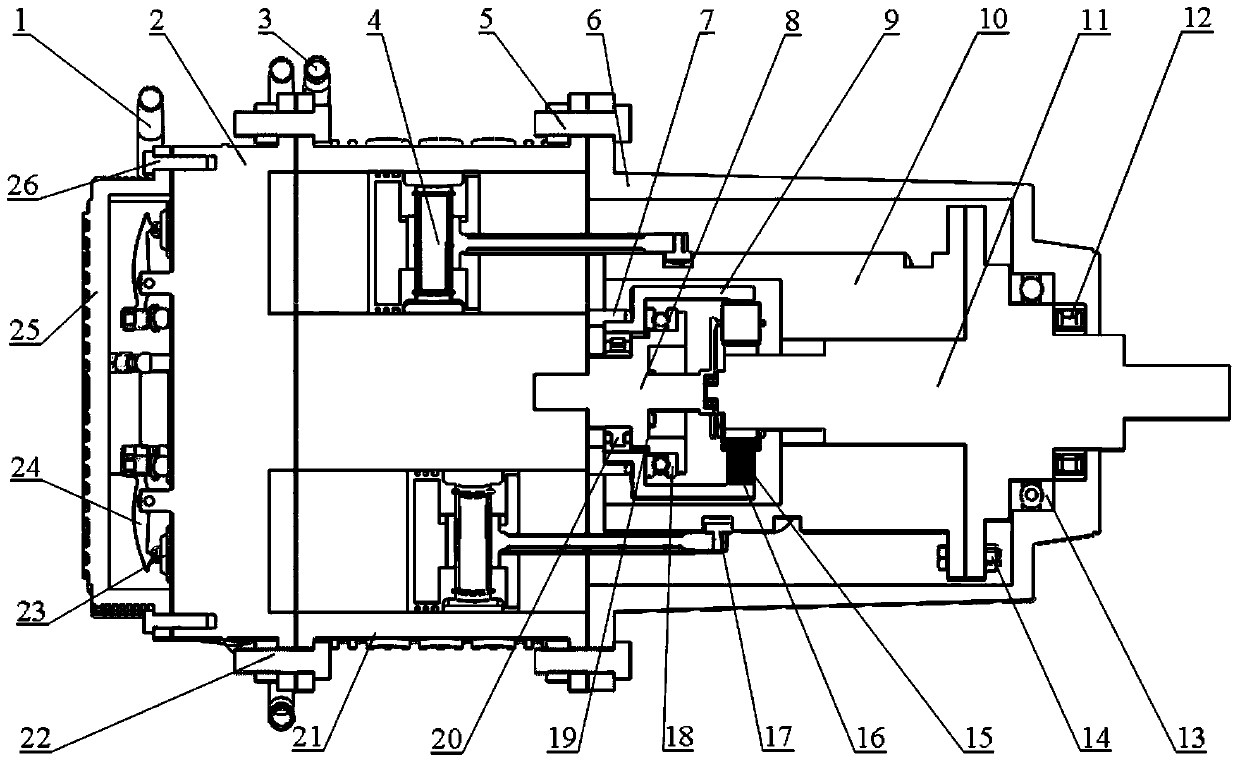

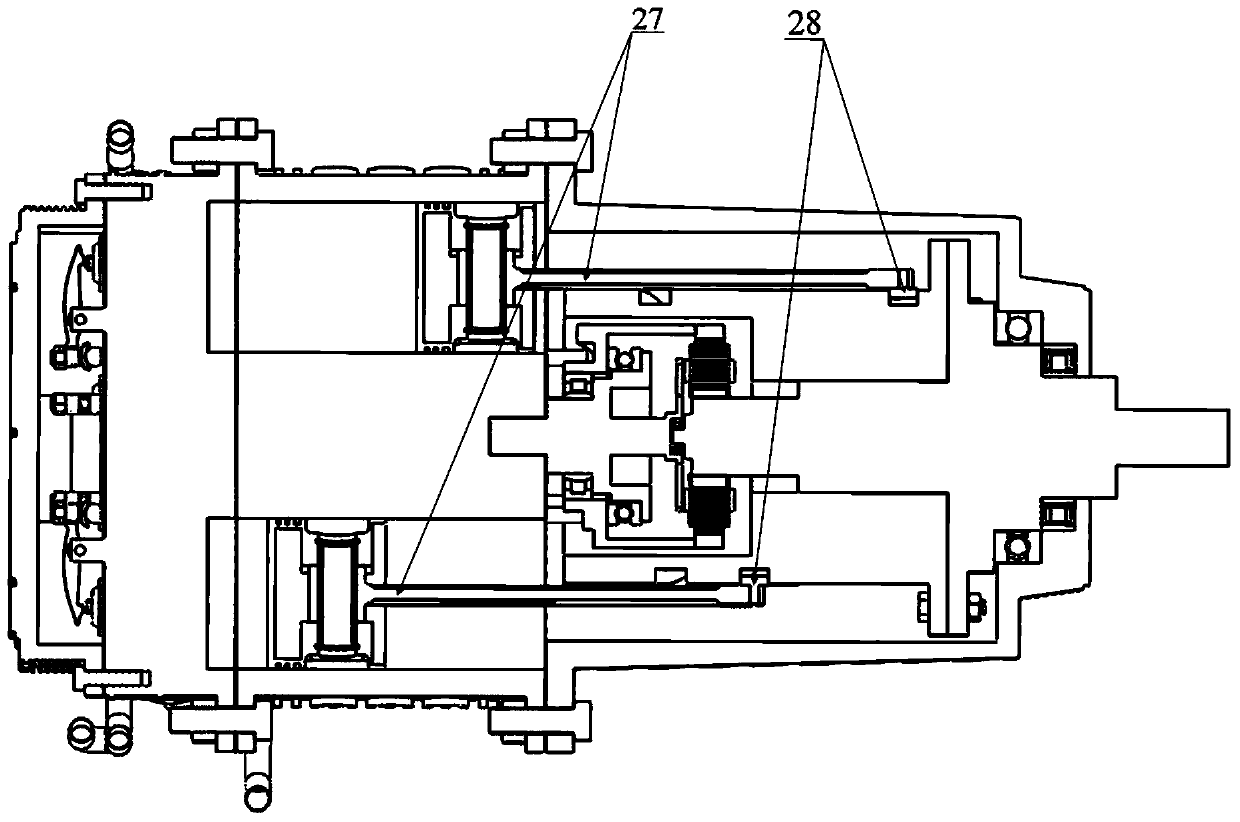

Cylinder cam engine without bent axle

InactiveCN105863837ASimple structureReduce volumeValve drivesMachines/enginesGear wheelTransmitted power

The invention relates to a cylinder cam engine without a bent axle. The cylinder cam engine without the bent axle mainly comprises an engine body set, piston connecting rod sets, a rotating cam, a gas distribution cam, a gas distribution planetary gear train, a gas distribution system, a bearing packing, a bolt set and the like. The cylinder cam engine without the bent axle is characterized in that when the engine works, the upper piston connecting rod set and the lower piston connecting rod set make reciprocating motion in a cylinder tank body; a roller 17 and a roller 28 roll in an upper rotating cam groove 10.1 and a lower rotating cam groove 10.2 respectively to enable the rotating cam to rotate; an output shaft is driven to rotate, and as power output, the output shaft transmits power to the gas distribution cam through a planet gear; the gas distribution cam rotates to trigger a valve ejection rod to act; and a valve rocker arm set acts to enable a gas spring set to act to achieve regular gas distribution of all cylinders. The cylinder cam engine without the bent axle is excellent in reliability, the single-cylinder acting output shaft is rotated by 180 degrees, the overall structure is simple, the size is small, and the efficiency is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Air cooled Twin Cam V-Twin motorcycle engine timing belt system

A timing belt system for an air cooled Twin Cam V-Twin motorcycle engine is provided. The timing belt system includes a crankshaft pulley assembly including a crankshaft pulley affixed to the crankshaft and a pulley flange affixed to the crankshaft pulley. The timing belt system also includes a camshaft pulley assembly including a spider gear having spindle affixed to the rear cam end of the Twin Cam engine and a hub having slotted apertures fastened to a camshaft pulley fastened. A timing belt having teeth is connects the crankshaft pulley to the camshaft pulley to turn the camshafts in synchronized rotation with the crankshaft. The spider can be rotated relative to the camshaft pulley and fastened thereto using bolts extending through the slotted apertures to Advance or Retard the timing of the camshafts relative to the crankshaft.

Owner:WOOD BOB

Camless engine operating system

A camless engine operating system that includes an inlet valve switch configured to detect rotational movement of an inlet valve power disc and to output an inlet actuator voltage. A voltage level of the inlet actuator voltage is synchronous with the rotational movement of the inlet valve power disc. An inlet valve is movable to open and close an intake port of a combustion chamber. An inlet valve mechanical force moves the inlet valve to open the intake port. An inlet actuator is configured to exert the inlet valve mechanical force onto the inlet valve. The inlet actuator voltage received by the inlet actuator controls the inlet actuator to exert the inlet valve mechanical force onto the inlet valve.

Owner:KELI JACOB B +1

Horizontally-opposed cylindrical cam engine

The invention relates to internal combustion engine devices, in particular to power transmission systems of internal combustion engines, and specifically relates to a horizontally-opposed cylindrical cam engine. The horizontally-opposed cylindrical cam engine comprises a cylindrical cam, wherein contour lines of the left and right end faces of the cylindrical cam are transverse curves; a power shaft is fixed in the center of the cylindrical cam; four pistons with push rods are arranged on each of the left and right end faces of the cylindrical cam; rollers are arranged at the bottom ends of the push rods of the pistons; the rollers move along the contour lines of the end faces of the cylindrical cam; and the linear back-and-forth movement of the push rods of the pistons is converted into the rotational motion of the cylindrical cam. According to the horizontally-opposed cylindrical cam engine, the contour lines are designed as cosine curves, so that the continuous change of a roller acceleration curve is achieved, namely, the rollers do not have sudden impact at upper and lower dead points; and the linear motion of the rollers is converted into the rotational motion of the cam according to the self characteristic of the cam, so that the power conversion from the reciprocating rectilinear movement of the pistons to the rotational motion is achieved, and the horizontally-opposed cylindrical cam engine has good power output stability.

Owner:ZHEJIANG UNIV

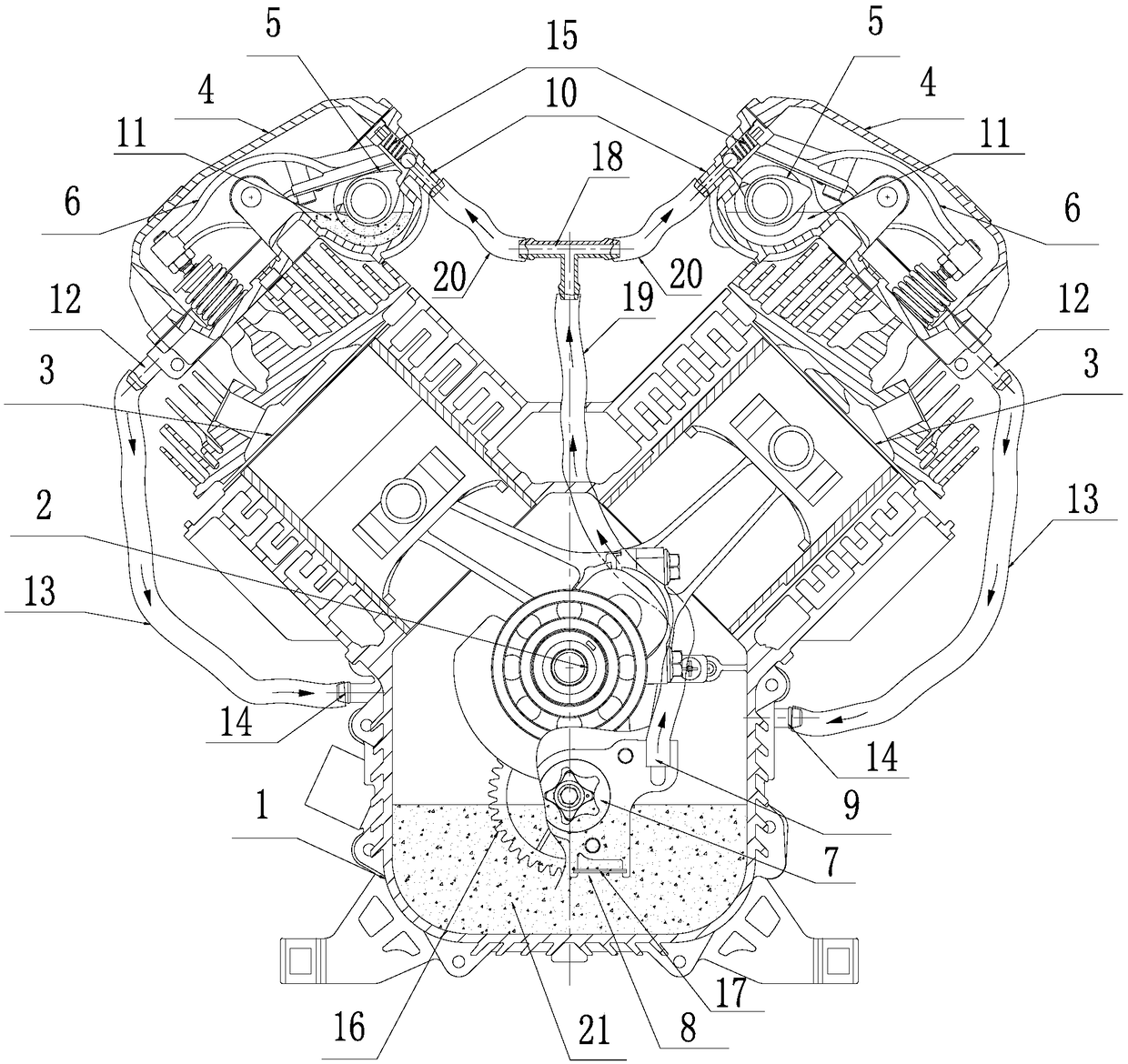

Efficient lubrication system of engine cylinder heads of contravariant small-sized dual-cylinder generator set

PendingCN109386340AGuaranteed feasibilityGuaranteed reliabilityLubrication of auxillariesDrip or splash lubricationPulp and paper industryCam

The invention discloses an efficient lubrication system of engine cylinder heads of a contravariant small-sized dual-cylinder generator set. Cylinder head mechanisms of a top cam-type dual-cylinder engine in the set are mainly improved. According to the improvement core, the efficient lubrication system is characterized in that an oil injection pump is arranged in a crankshaft box, an oil inlet ofthe air injection pump is soaked in an engine oil pool of the bottom of the box, oil outlets are connected with cylinder head oil inlets formed in cylinder head cavities of the two sides through pipes and distribution valves separately, a concave cavity is formed in the portion, below a cam, in each cylinder head cavity and used as a cam engine oil pool which is used for storing engine oil flowing into the cavities, and the engine oil is thrown to an air door rocker mechanism through cam rotation; cylinder head oil outlets are further formed in the cylinder head cavities and connected with oil return holes formed in the crankshaft box through oil return pipes. According to the efficient lubrication system, internal mechanisms of cylinder heads are more efficiently lubricated, the structural design of the cylinder heads is conveniently simplified, and heat dissipation is even.

Owner:苏州帕瓦麦斯动力有限公司

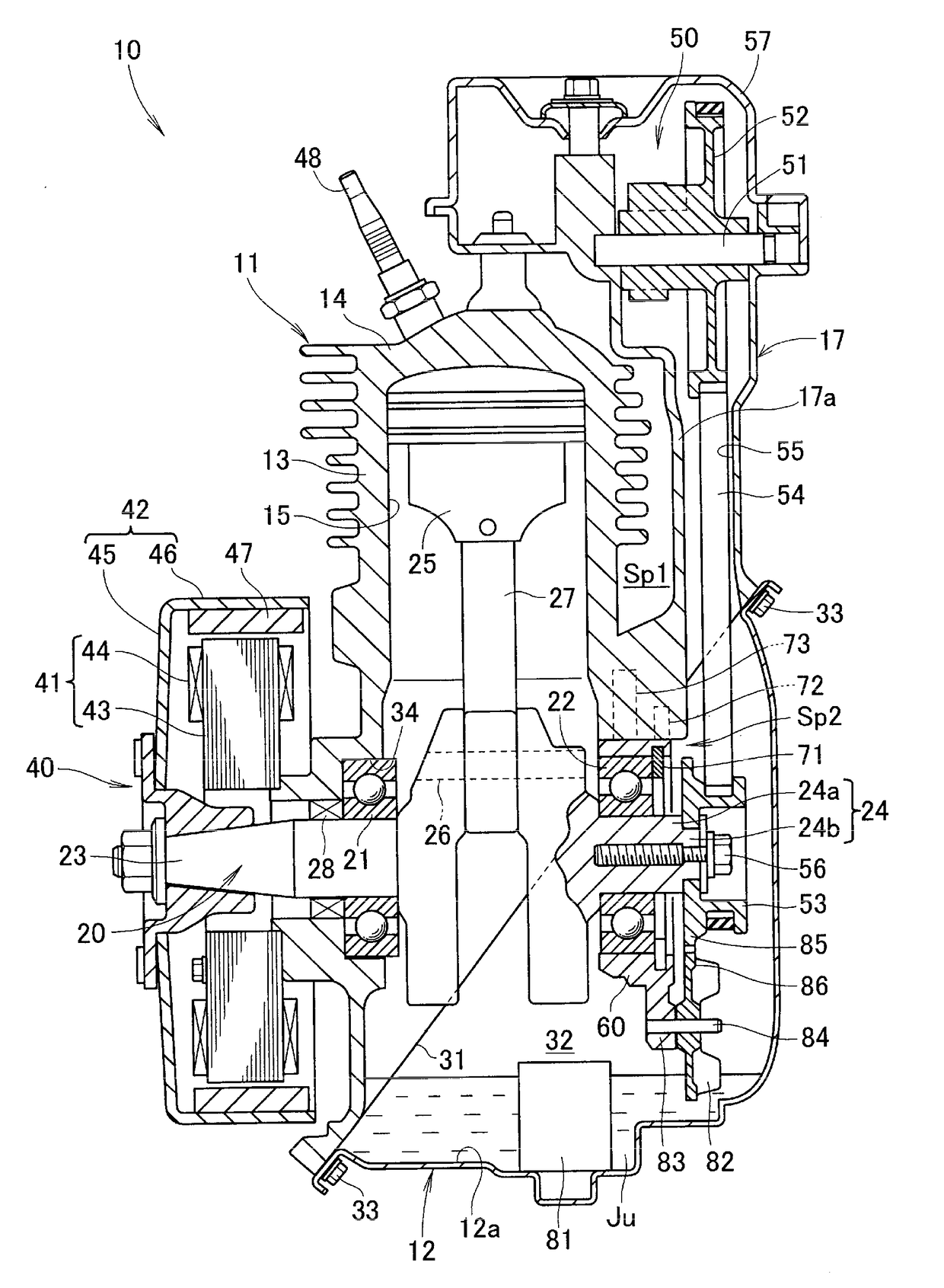

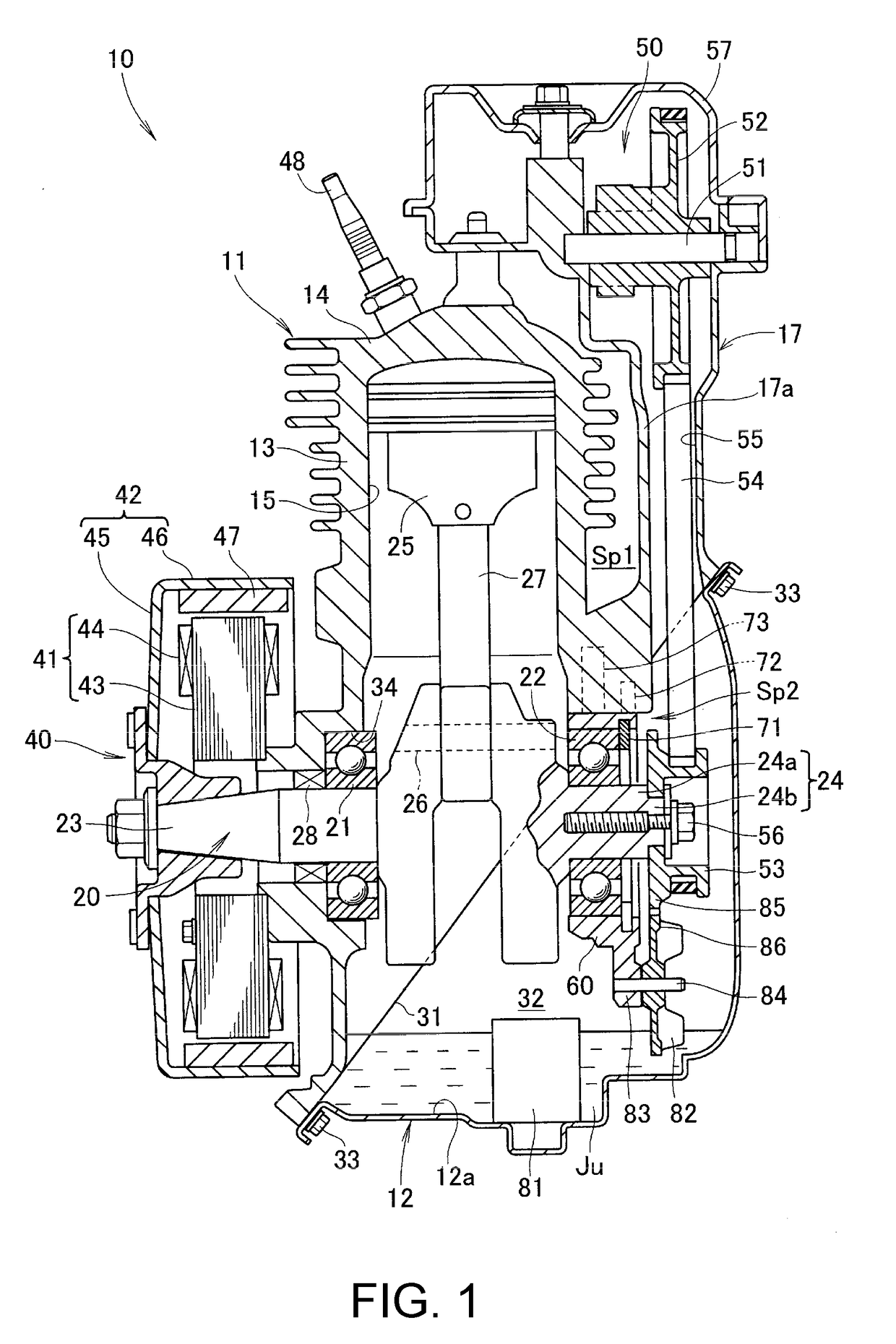

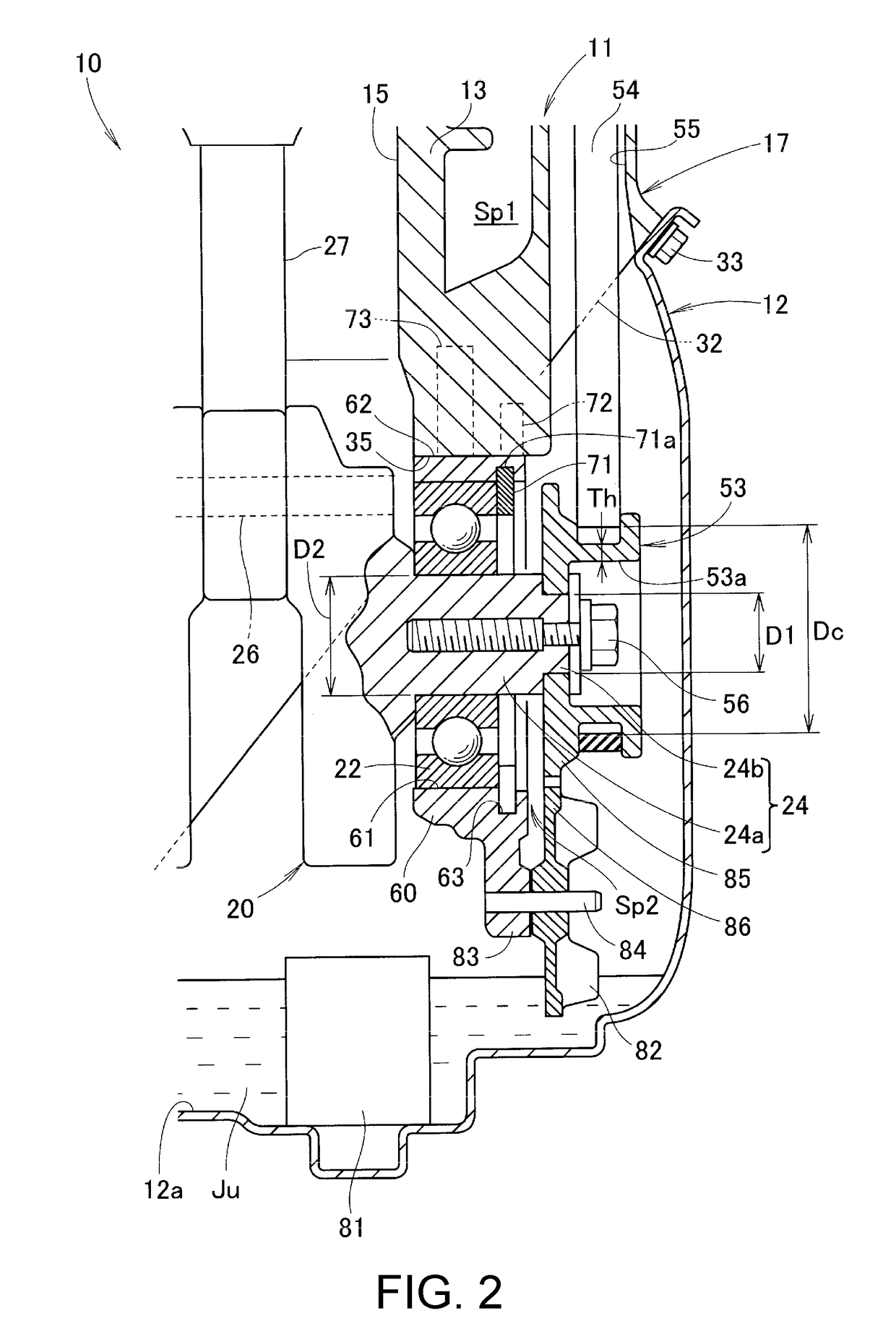

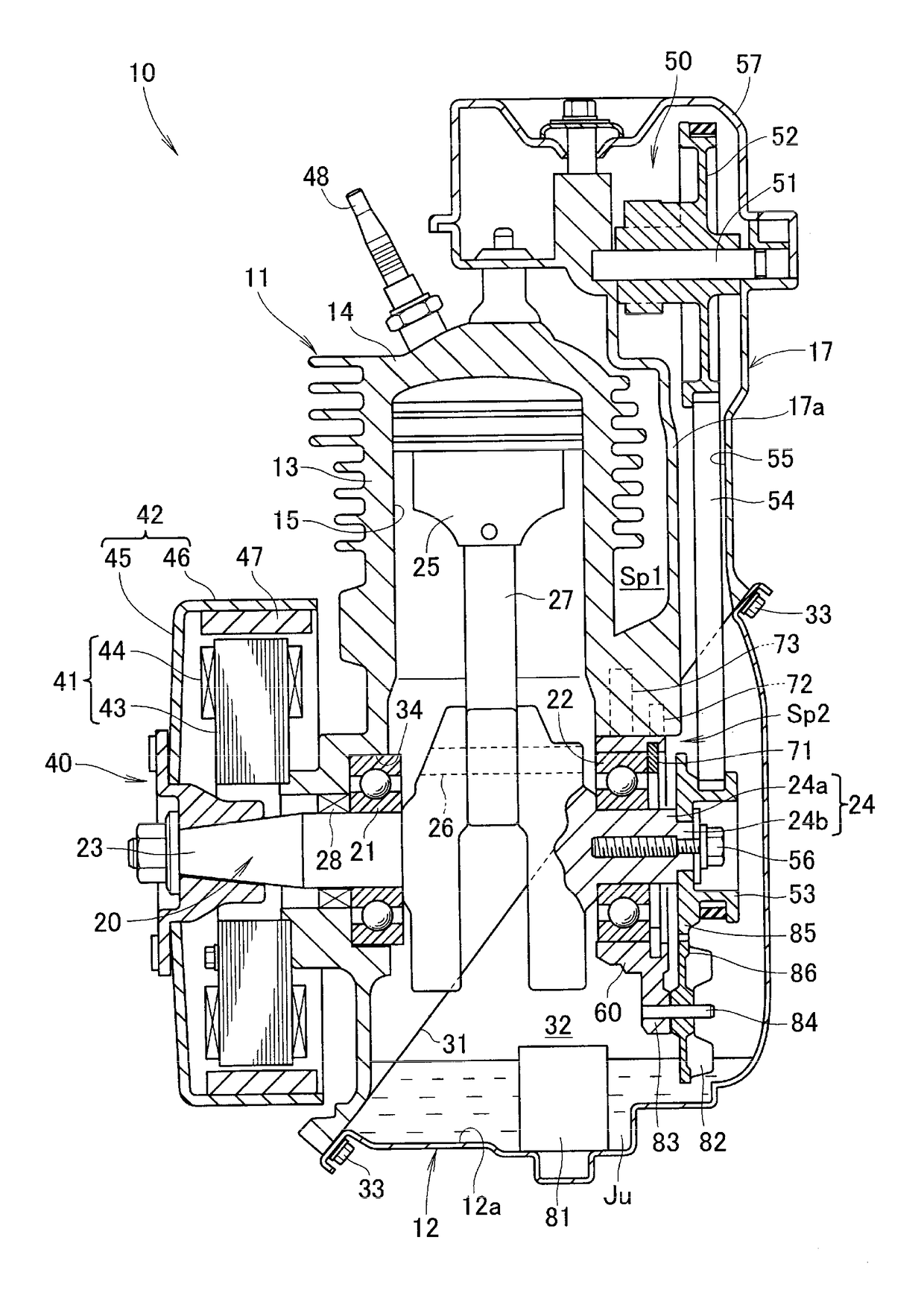

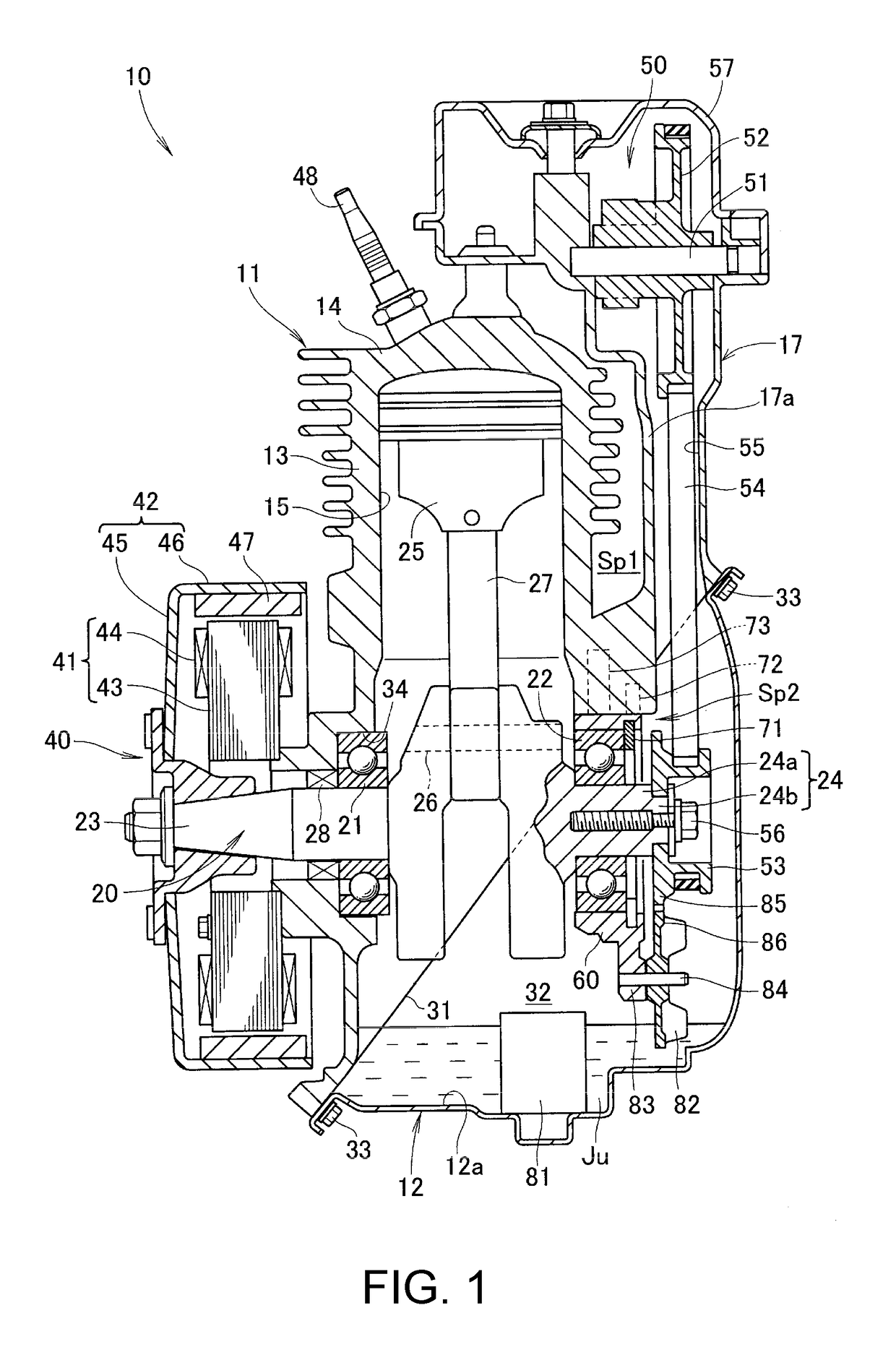

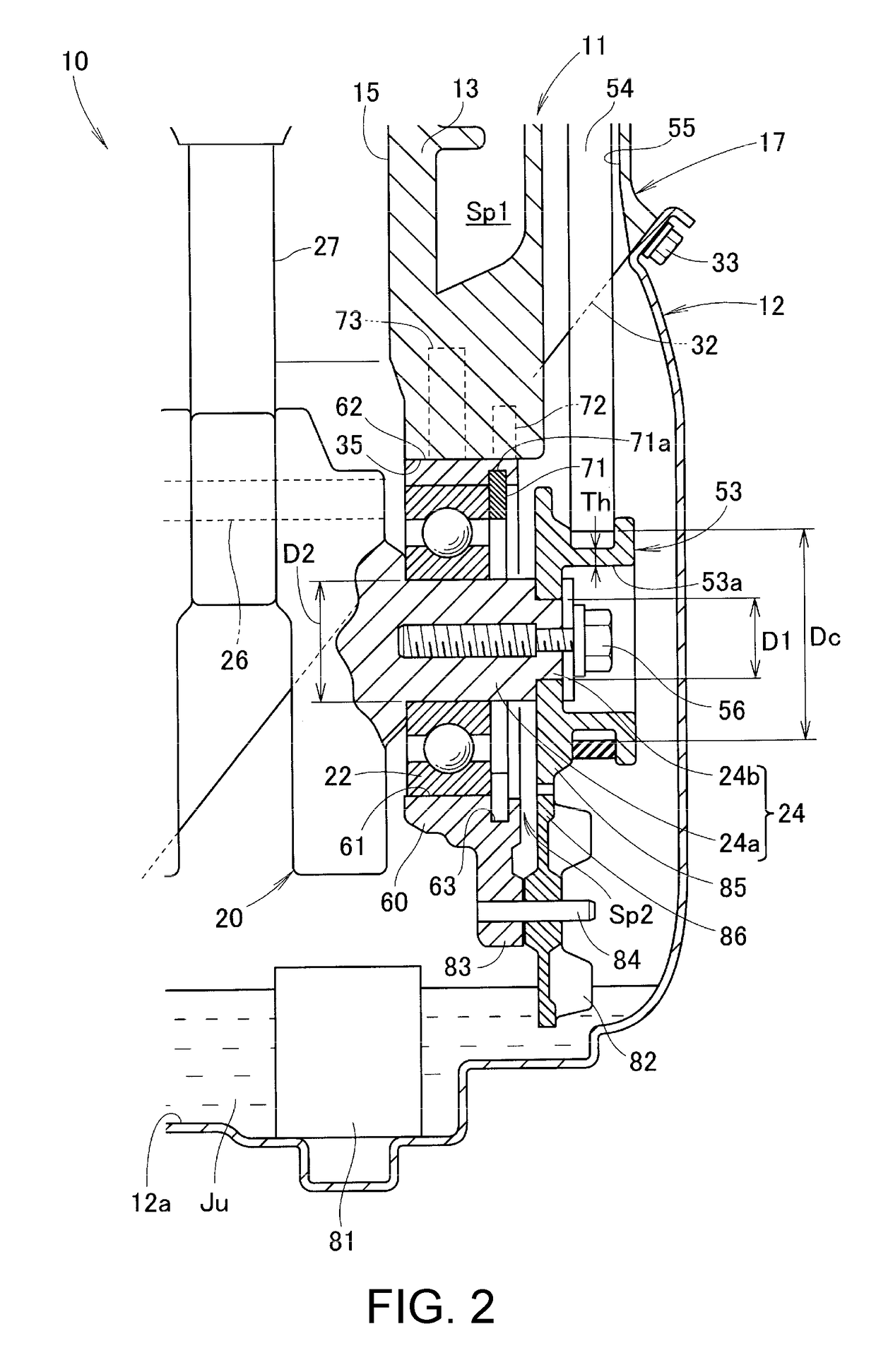

Overhead camshaft engine

In an overhead cam engine (10) having a first bearing (21) supported by the cylinder block (11), and a second bearing (22) supported by a bearing retaining member (60) attached to the cylinder block inside a crankcase chamber (12) for rotatably supporting a crankshaft (20), the crankshaft is provided with a reduced diameter portion (24b) having a smaller outer diameter than an adjoining part of the crankshaft on a side of the second bearing facing away from a cylinder (15) defined in the cylinder block, and a crankshaft pulley (53) is mounted on the reduced diameter portion.

Owner:HONDA MOTOR CO LTD

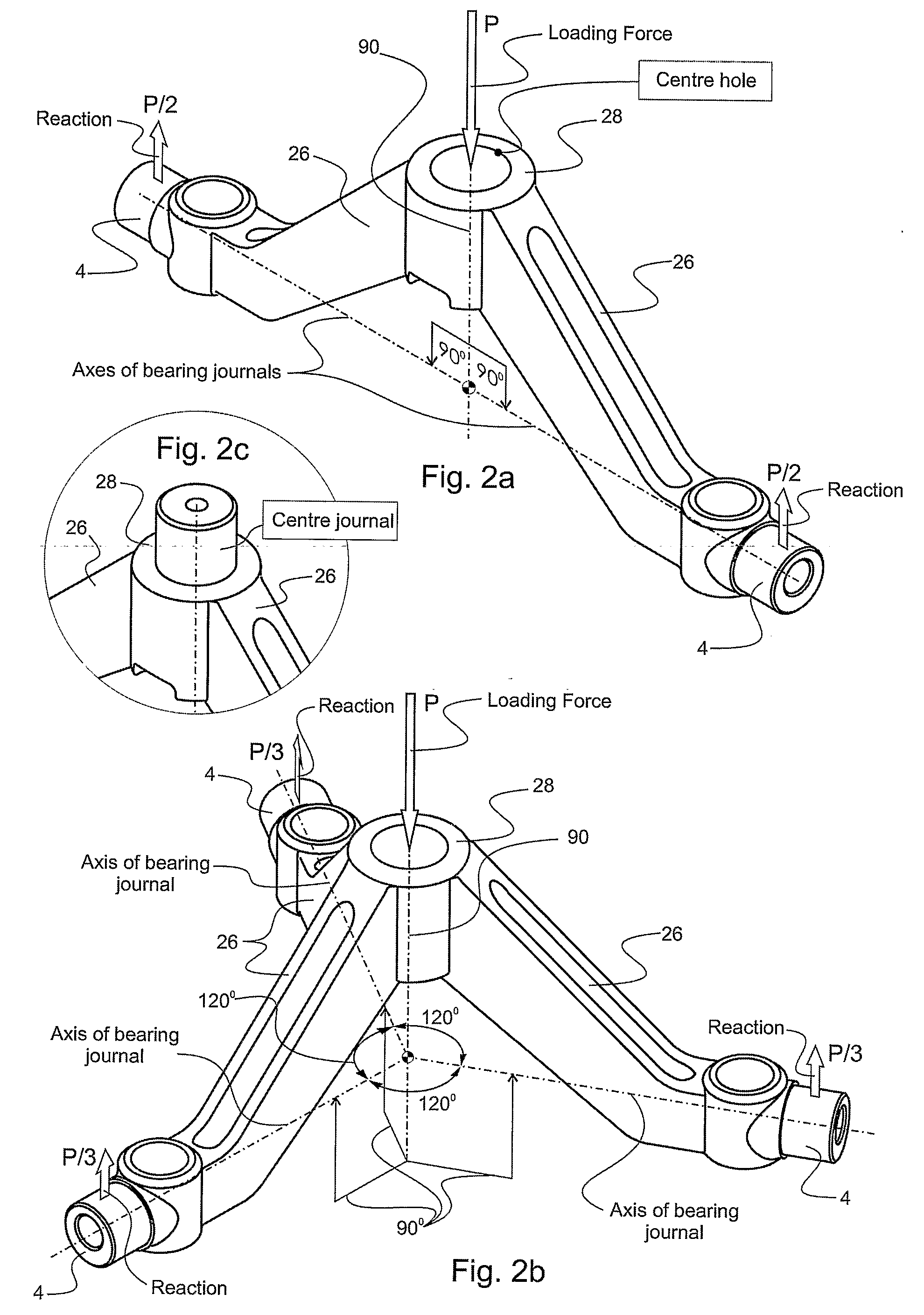

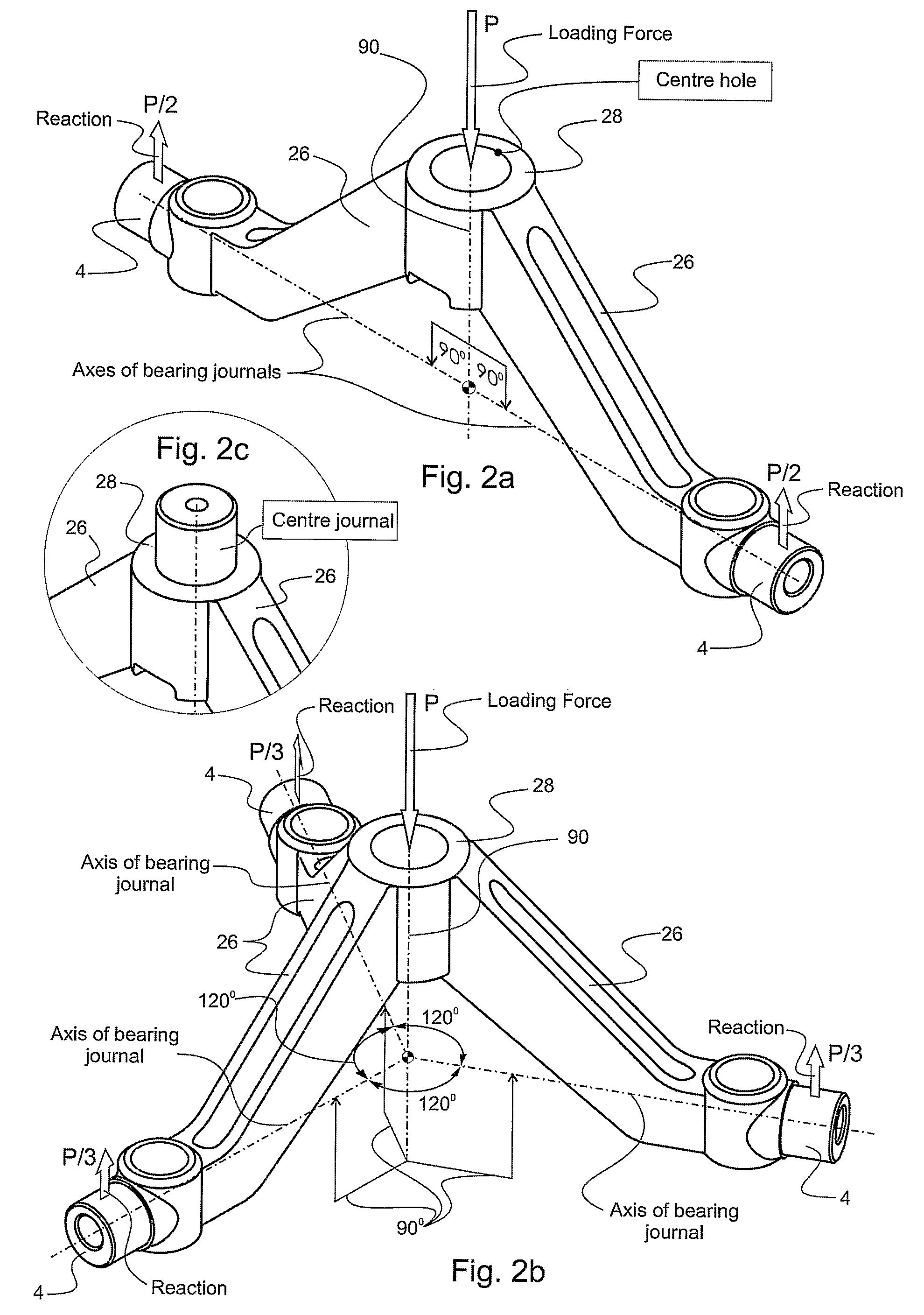

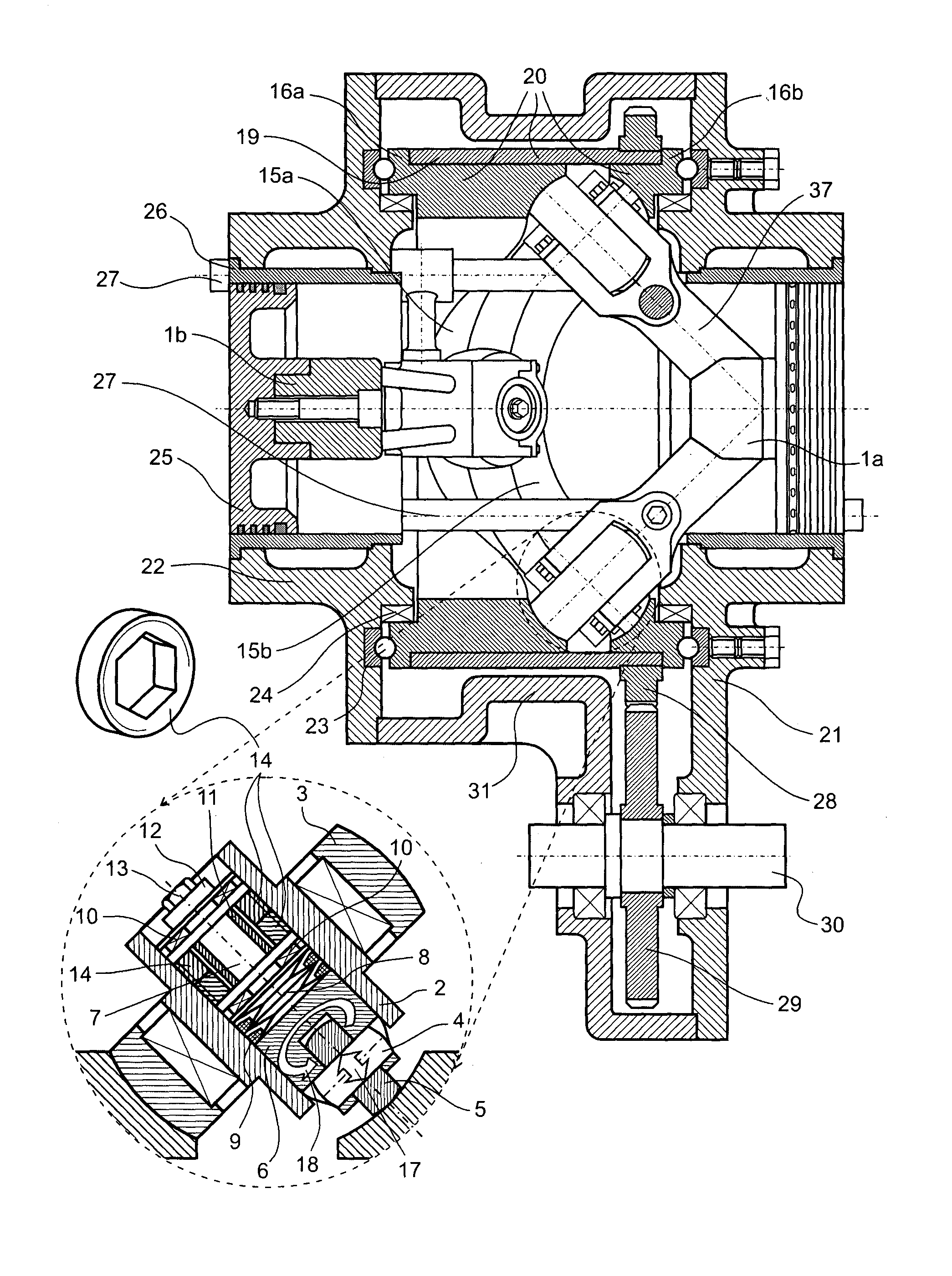

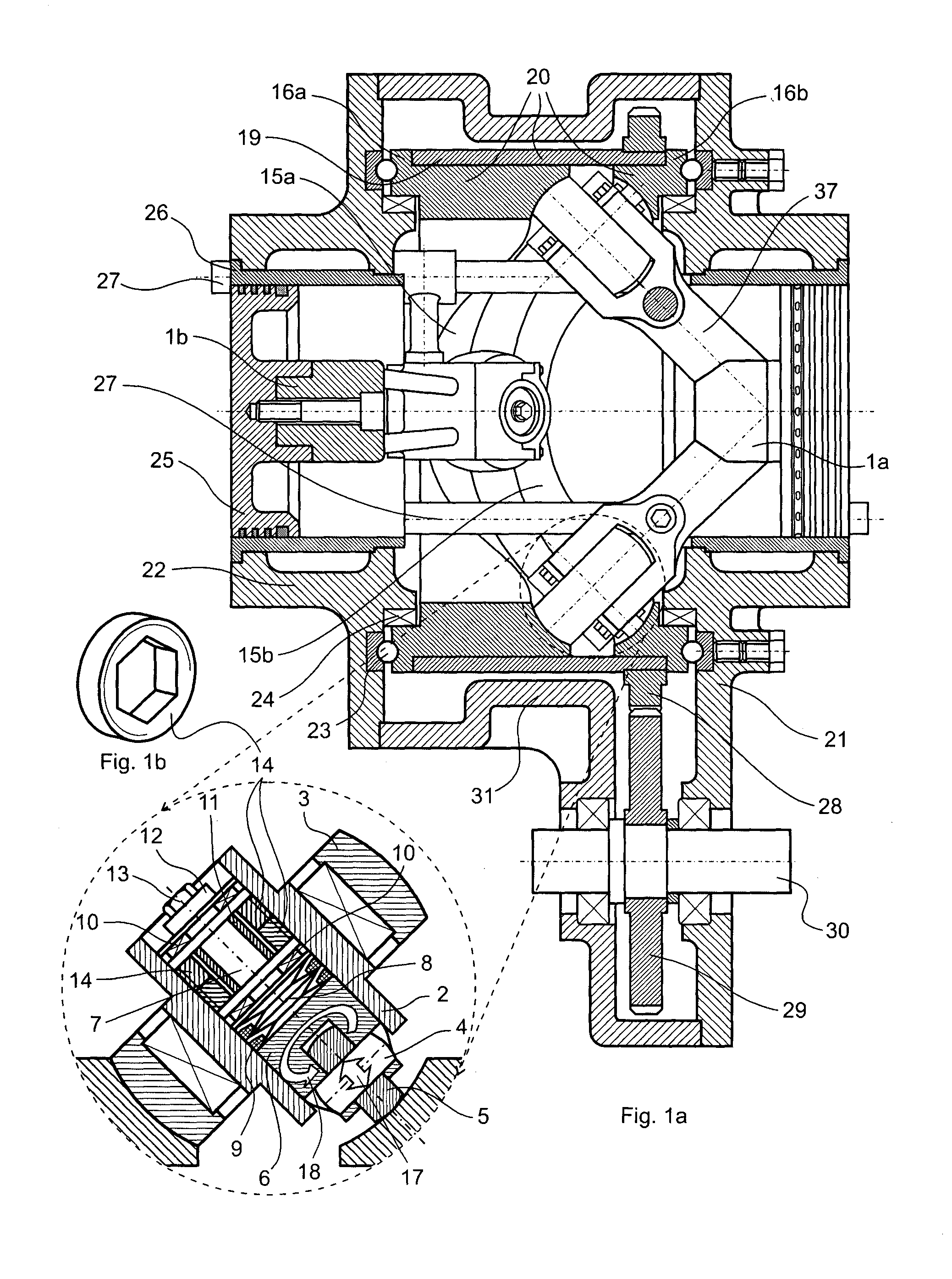

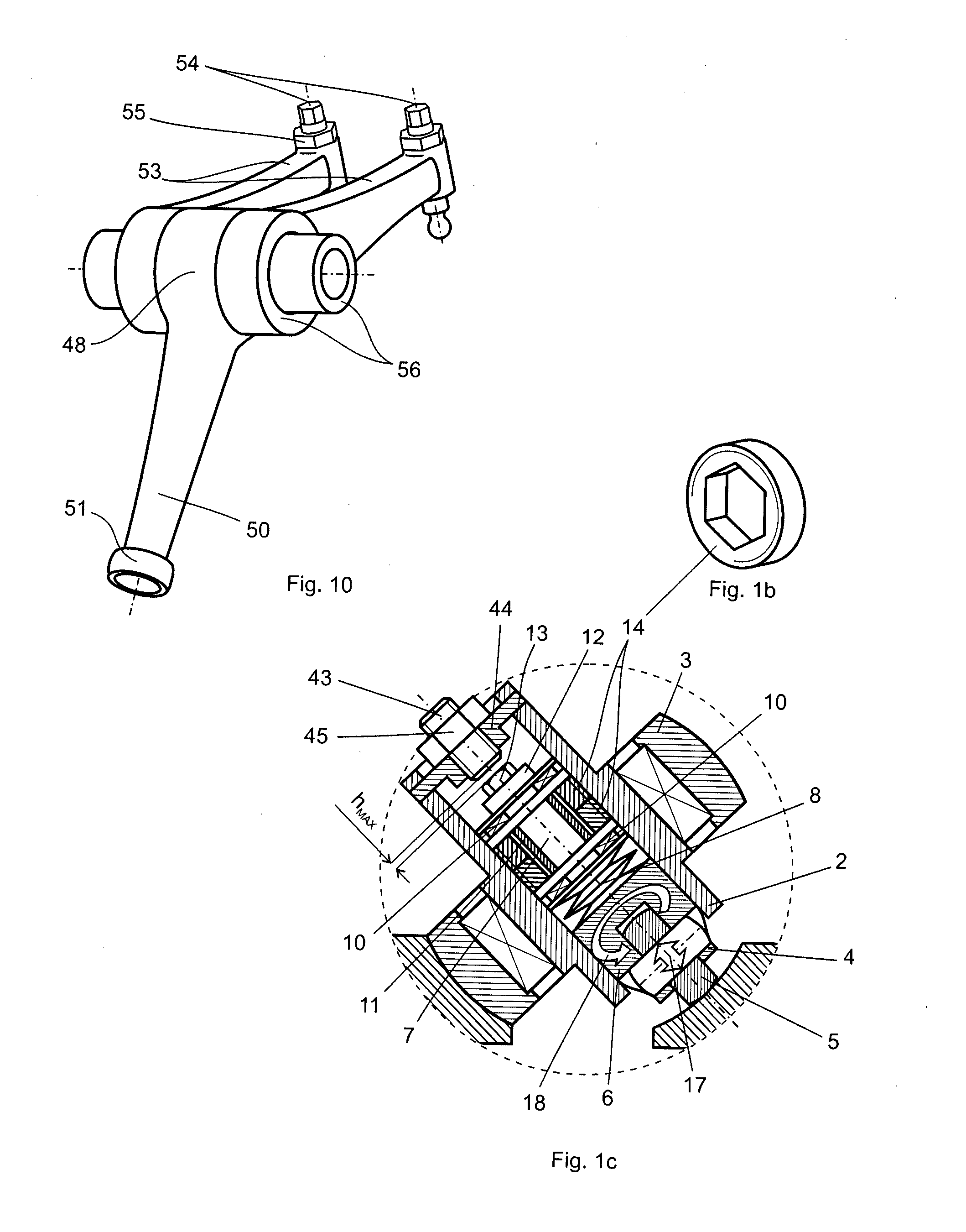

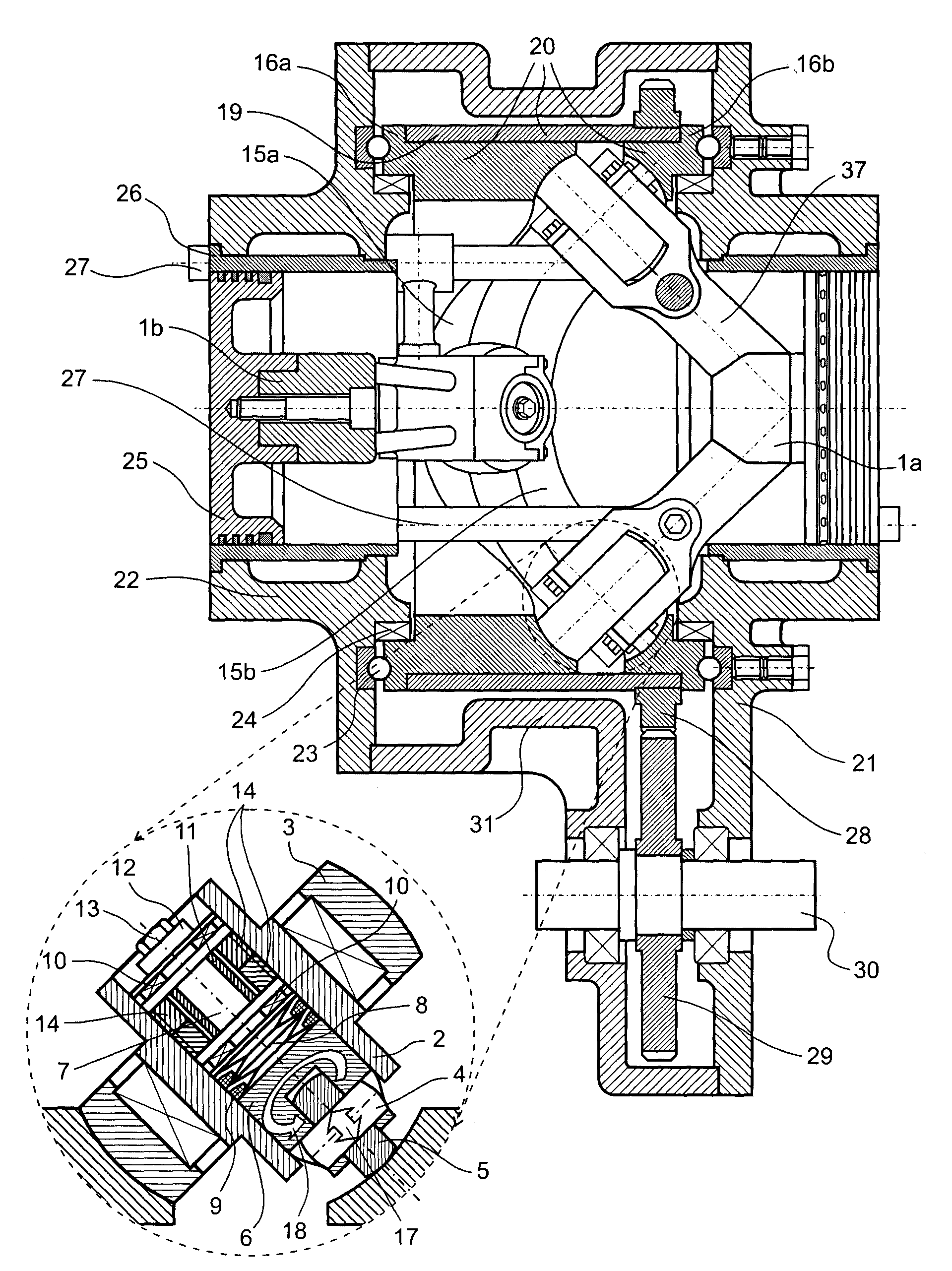

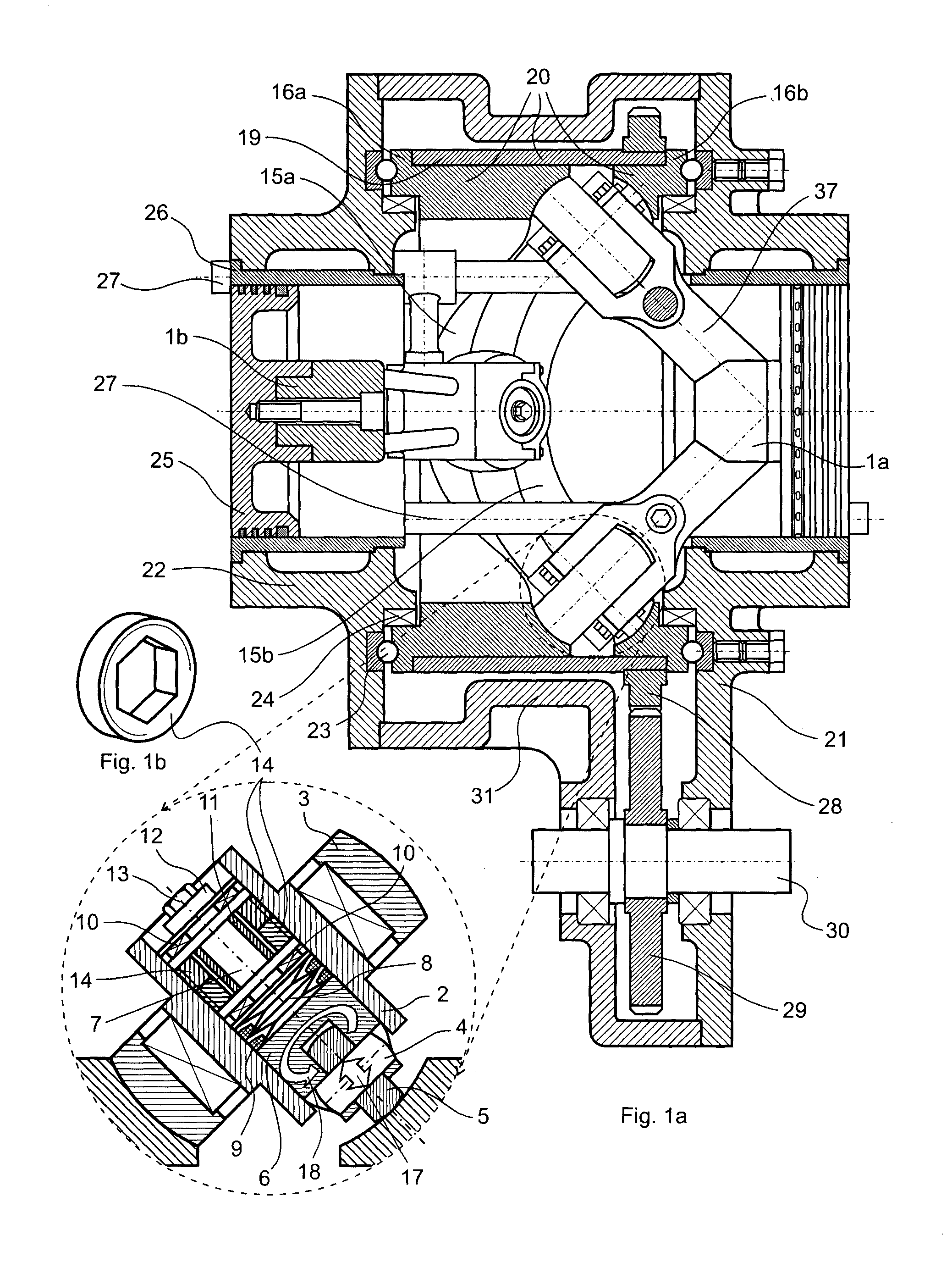

Cam Engine

ActiveUS20140150643A1Increased functional reliabilityReduce movementInternal combustion piston enginesPiston pumpsCombustionEngineering

The invention relates to a cam engine used in different field of the mechanical engineering, as internal-combustion engines, compressors, pumps etc. The cam engine comprises cylinders (26) with pistons (25), cylindrical tubular 3D cam (20) having a cam groove on the inner cylindrical surface and at least two asynchronously moving followers (1a and 1b) with arms (37) having main and additional rollers (3, 5).

Owner:BAHNEV BOYAN

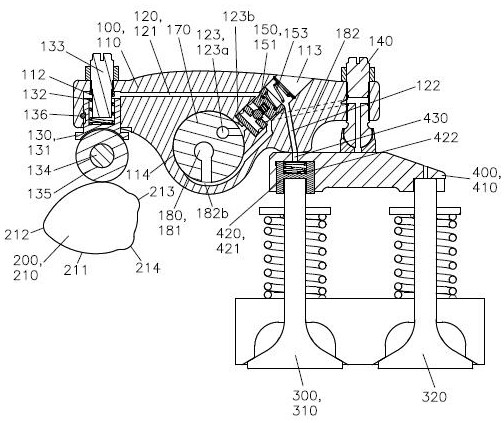

Topping cam engine

InactiveCN1530521AAvoid situations where the included angle increasesSmall sizeValve drivesCylinder headsExhaust valveCombustion chamber

To compact a combustion chamber and downsize a cylinder head in an overhead cam engine, wherein a cam shaft is provided between intake and exhaust valve springs and is rotatably supported by the cylinder head; and wherein the cam shaft is provided with a first cam to drive one of an intake valve and an exhaust valve and is provided with a second cam to drive the other of the intake valve and the exhaust valve. A cylinder head 16F supports a cam shaft 131 with its axis line approximately disposed above a cylinder axis line. A second cam 143 is disposed between intake and exhaust valve springs 129 and 130 and is formed to be smaller than a first cam 142. The first cam 142 is disposed farther from the position between the intake and exhaust valve springs 129 and 130 along the direction of the axis line of the cam shaft 131.

Owner:HONDA MOTOR CO LTD

Low-noise automobile timing driving belt

The invention relates to a timing belt, in particular to a low-noise automobile timing driving belt. The low-noise automobile timing driving belt comprises an annular belt body, wherein the belt body is formed by binding a belt back and a meshed part, the meshed part is provided with a plurality of tooth parts which are spaced along the inner circumferential surface of the belt body, a core rope skeleton is embedded inside the meshed part along the circumferential direction of the belt body, an interlayer fabric is arranged between the belt back and the meshed part, and the inner circumferential surface of the meshed part is provided with a tooth-shaped fabric layer covering the tooth parts. Through the measurement, when the low-noise automobile timing driving belt is applied to a 1.8L top-mounted double-cam engine, the resonance phenomenon is eliminated, the noise is remarkably lowered, and the noise is hardly heard when a timing system protection shield is covered.

Owner:NINGBO FENGMAO FAR EAST RUBBER

Cam engine

ActiveUS9243617B2Increased functional reliabilityReduce movementInternal combustion piston enginesPiston pumpsCombustionEngineering

The invention relates to a cam engine used in different field of the mechanical engineering, as internal-combustion engines, compressors, pumps etc. The cam engine comprises cylinders (26) with pistons (25), cylindrical tubular 3D cam (20) having a cam groove on the inner cylindrical surface and at least two asynchronously moving followers (1a and 1b) with arms (37) having main and additional rollers (3, 5).

Owner:BAHNEV BOYAN

Cylindrical cam crankless engine

InactiveCN105863837BSimple structureReduce volumeValve drivesMachines/enginesTransmitted powerReciprocating motion

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Overhead camshaft engine

Owner:HONDA MOTOR CO LTD

Overhead cam engine self-resetting single-valve double-piston hydraulic drive device and method

The invention relates to a self-resetting single-valve double-piston hydraulic drive device and method for an overhead cam engine. A main driving piston and a driving auxiliary piston are respectively arranged on a rocker arm body and a valve bridge body, and the driving auxiliary piston is connected with an exhaust valve. The driving oil circuit is connected to the driving main piston, driving auxiliary piston and driving control valve; when the driving control valve opens the driving oil circuit: the driving main piston and the driving auxiliary piston realize hydraulic linkage. The auxiliary piston opens the exhaust valve; at the beginning of the main lift, the oil circuit of the main piston body and the auxiliary piston are disconnected, and the driving auxiliary piston automatically resets; when the driving oil circuit is disconnected: the main piston is driven during the integrated cam driving The driving lift of the rocker arm body by the integrated cam assembly is absorbed, the rocker arm body does not move, and the driving lift of the integrated cam is not transmitted to the side of the exhaust valve; the invention has a simple principle and a compact structure, and improves the reliability and reliability of the engine driving operation. durability.

Owner:JIANSU JOINTEK PRECISION MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com