Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63results about How to "Compact unit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

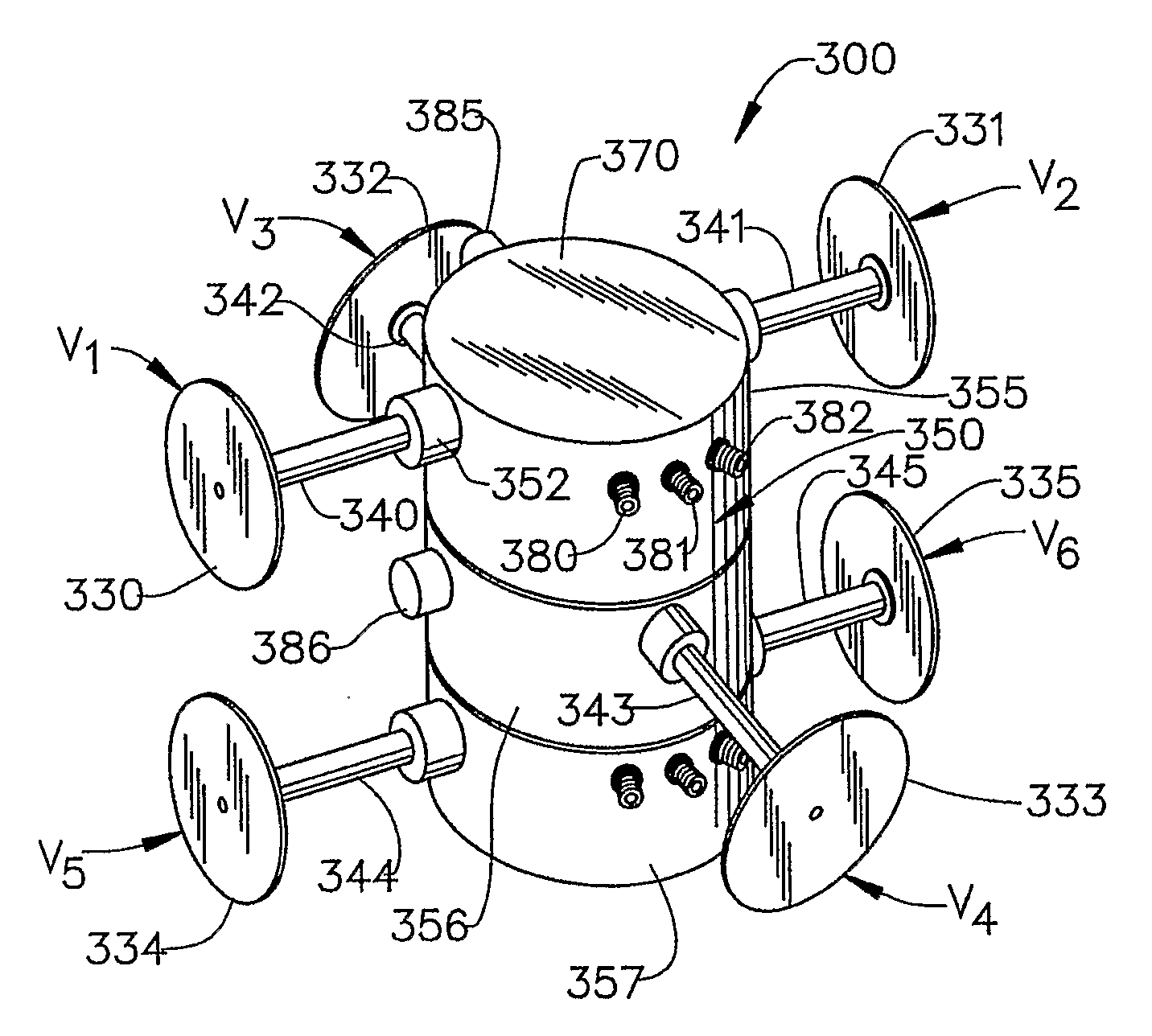

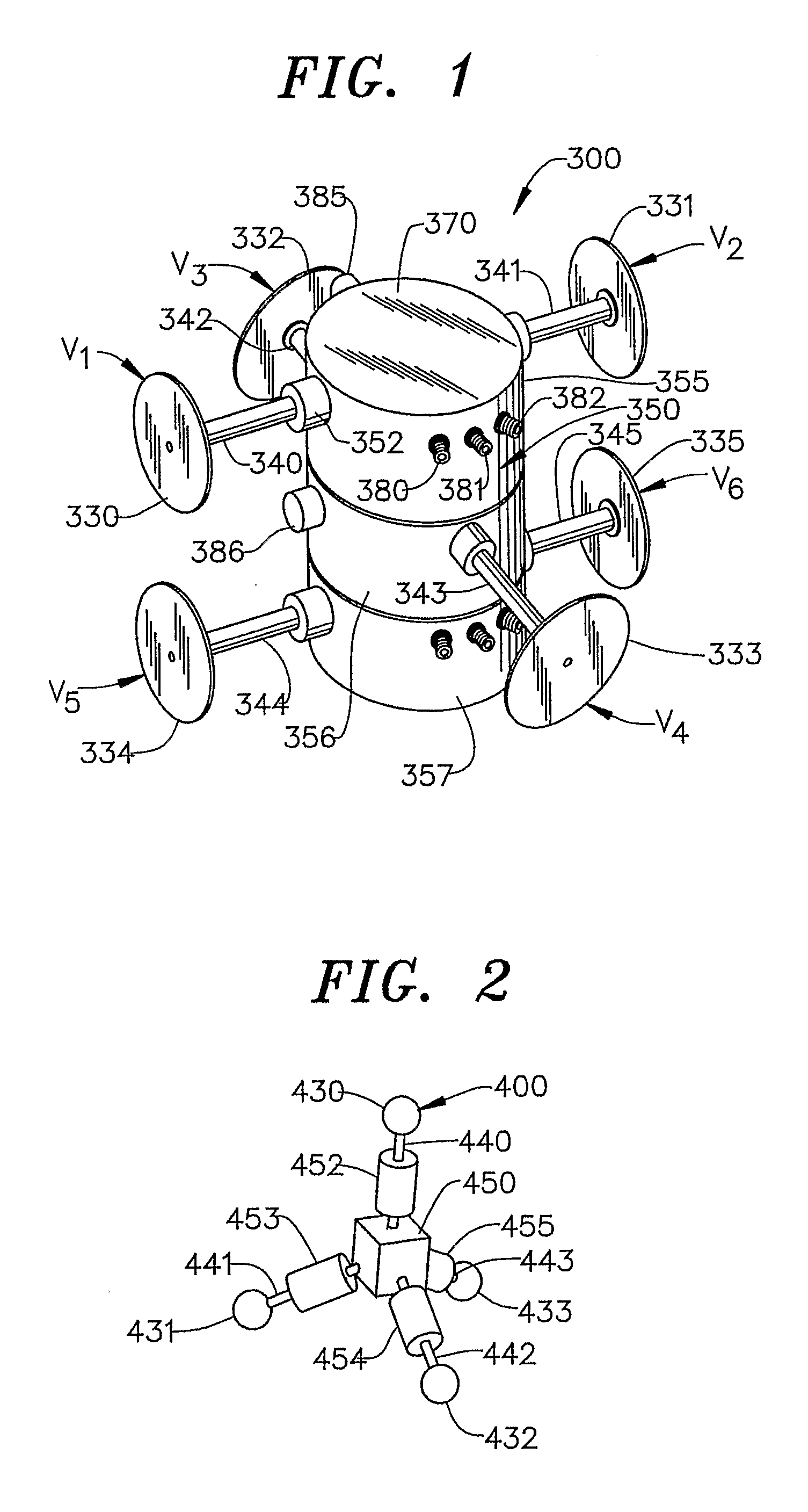

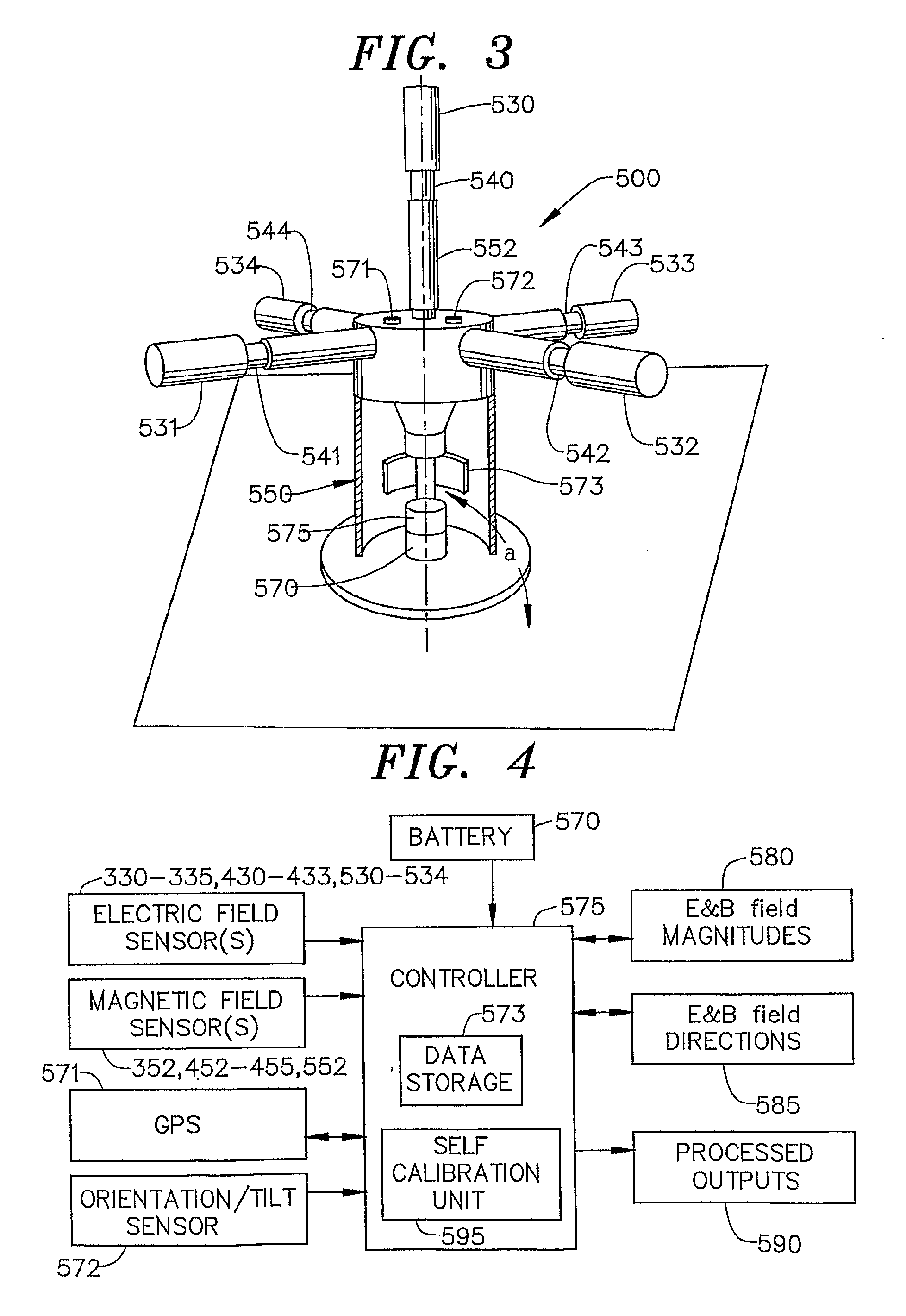

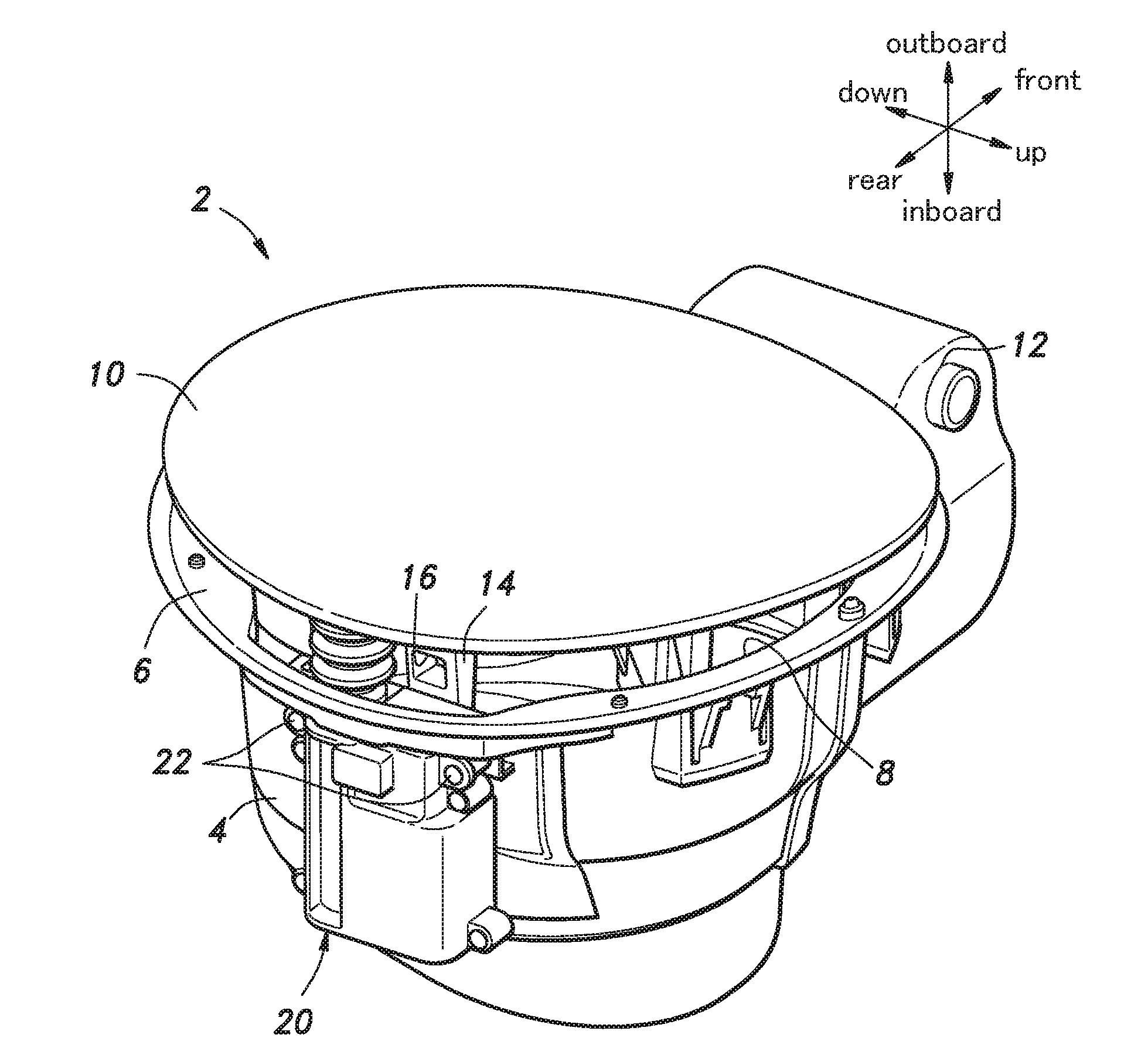

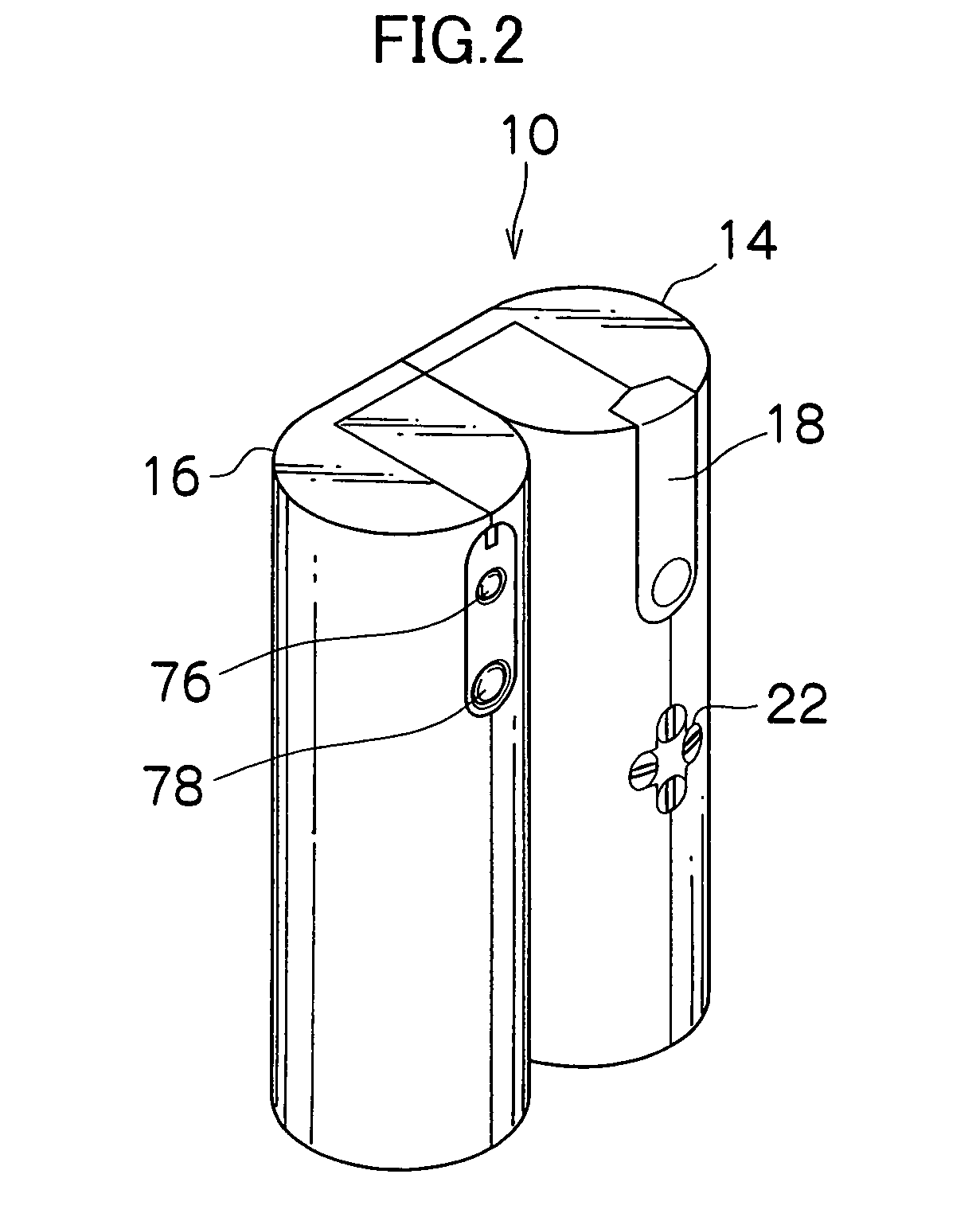

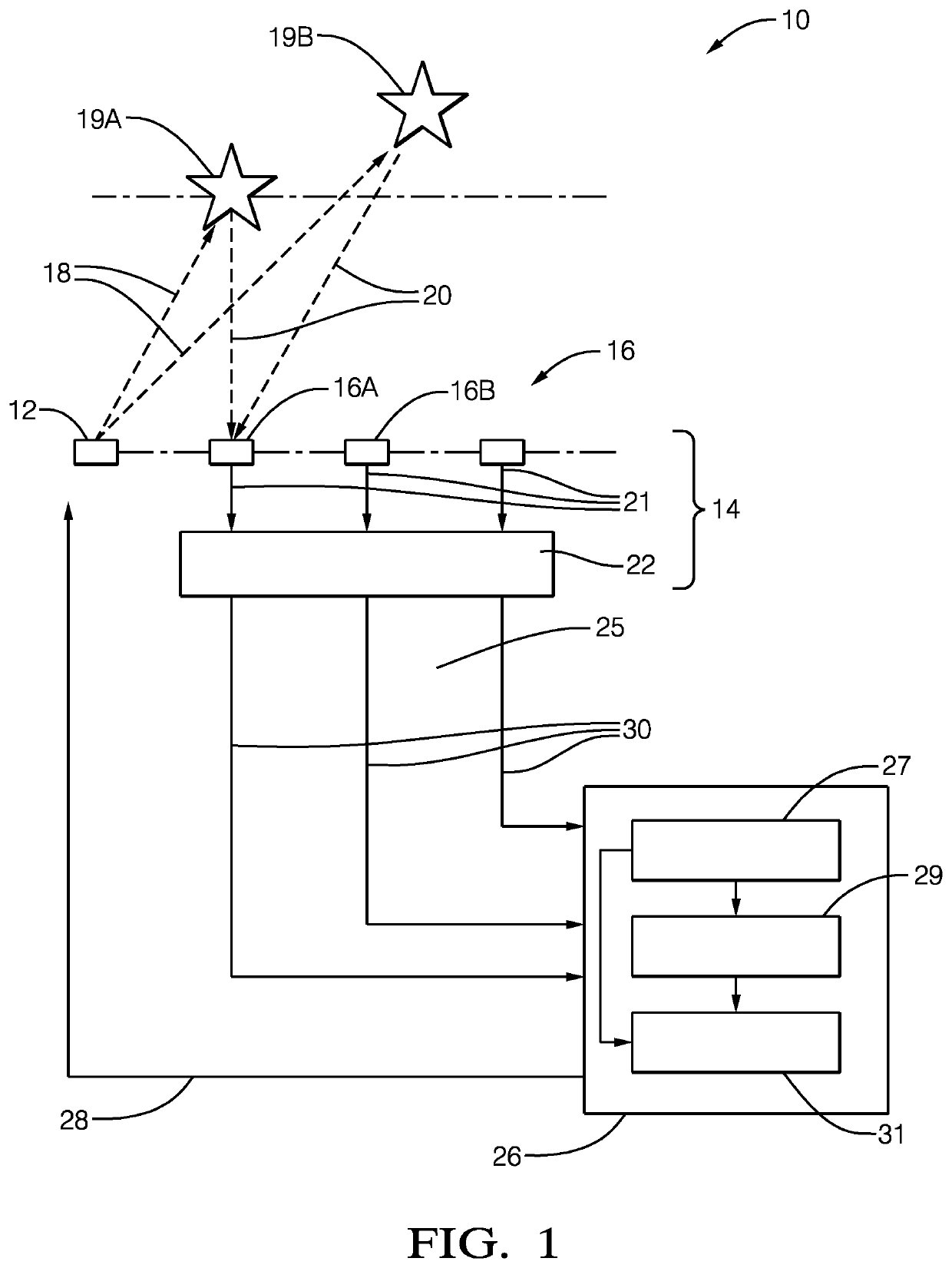

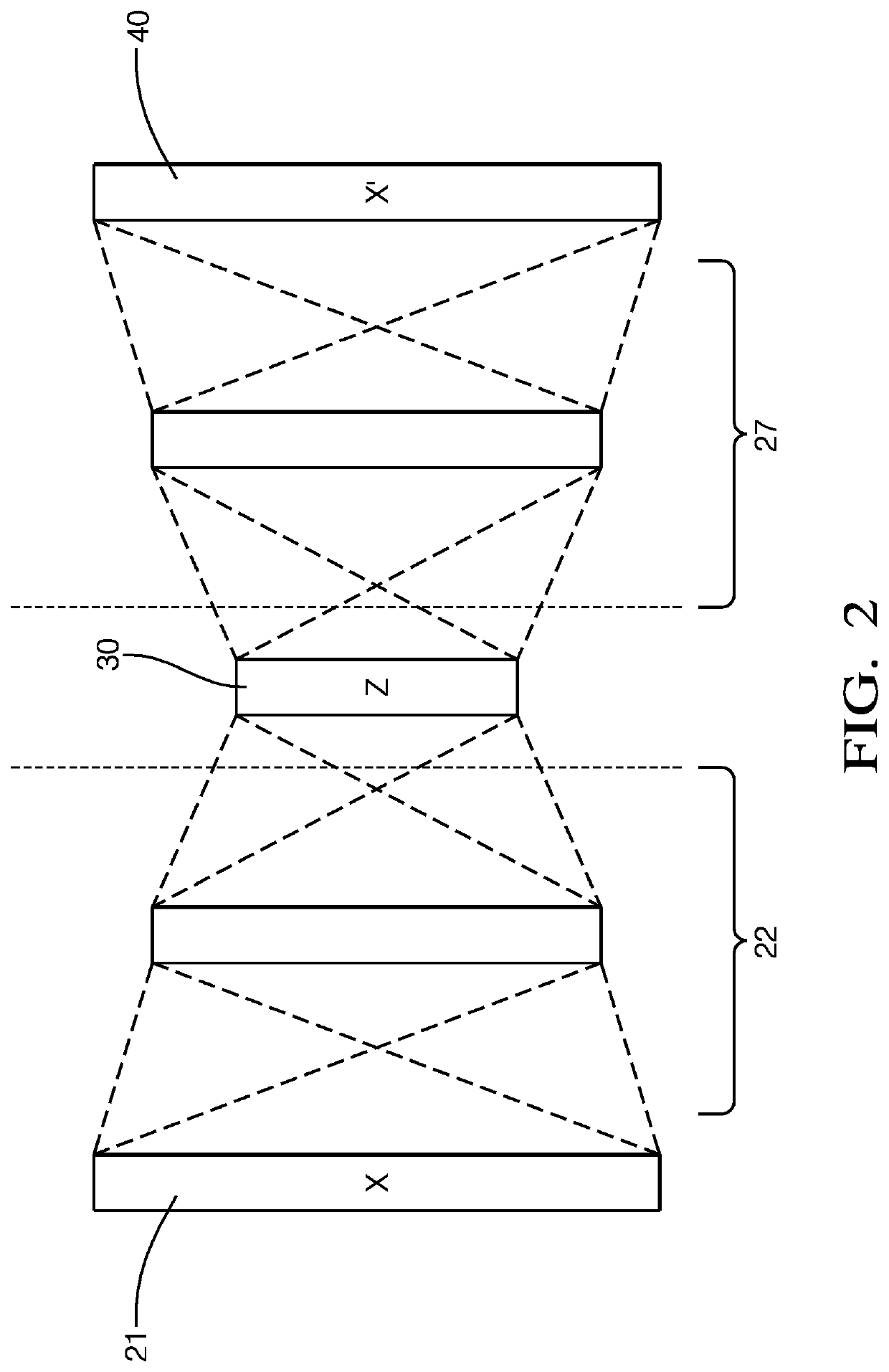

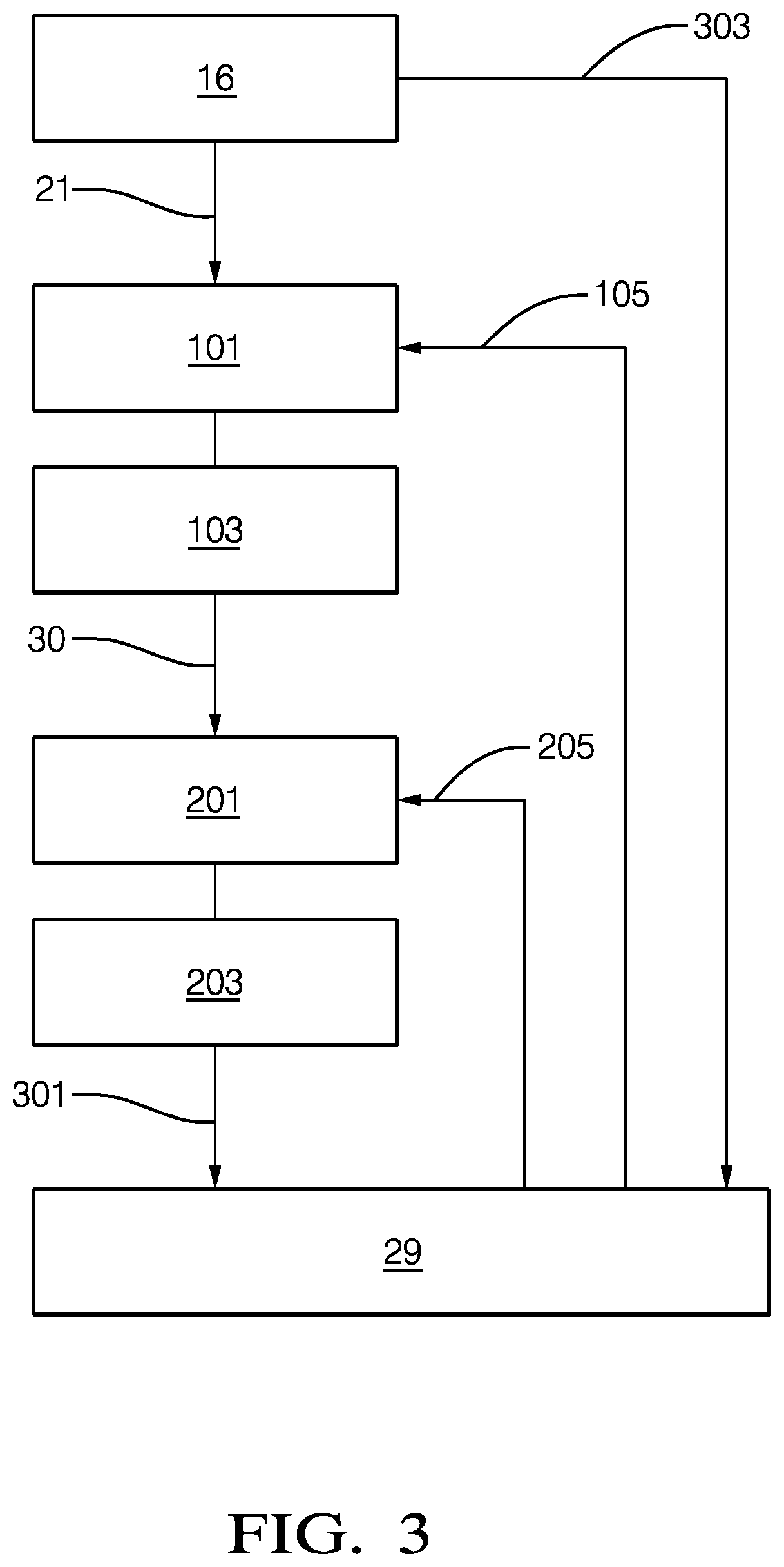

Integrated Sensor System Monitoring and Characterizing Lightning Events

A compact sensor system integrates electric and magnetic field sensors to accurately measure, with a high level of sensitivity, electric and magnetic fields. The sensor system is self-contained so as to include a built-in power source, as well as data storage and / or transmission capability. The integrated sensor system also preferably includes a global positioning system (GPS) to provide timing and position information, a sensor unit that can determine the orientation and tilt of the sensor system, and self-calibrating structure which produces local electric and / or magnetic fields used to calibrate the sensor system following deployment. The system measures the electromagnetic signals produced by lightning and more has the capability to determine the direction and distance to a lightning event without input from sensors at other locations. Furthermore, the system can detect both conventional short-duration lightning events and also the less common, but more destructive, continuing current lightning.

Owner:QUASAR FEDERAL SYST

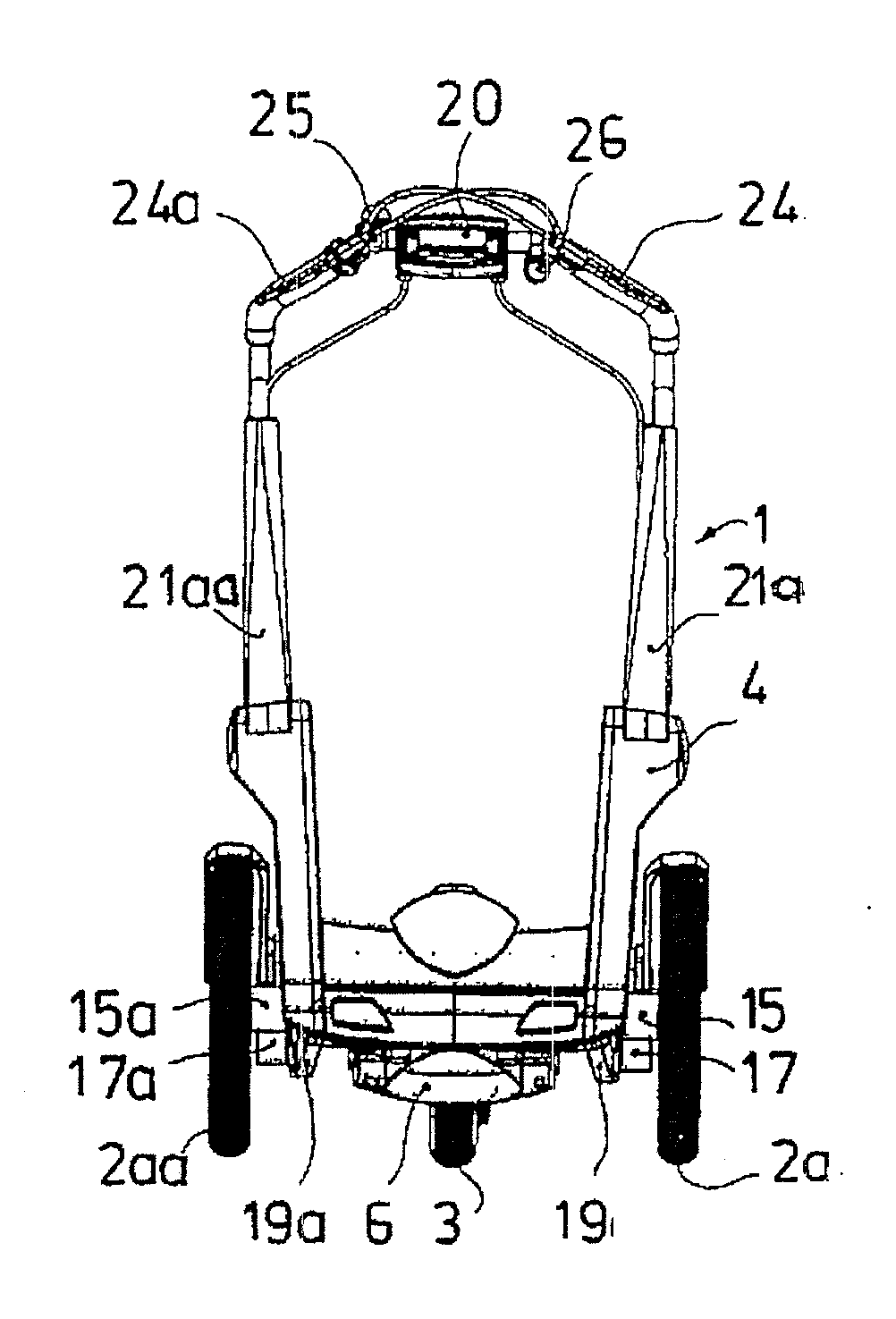

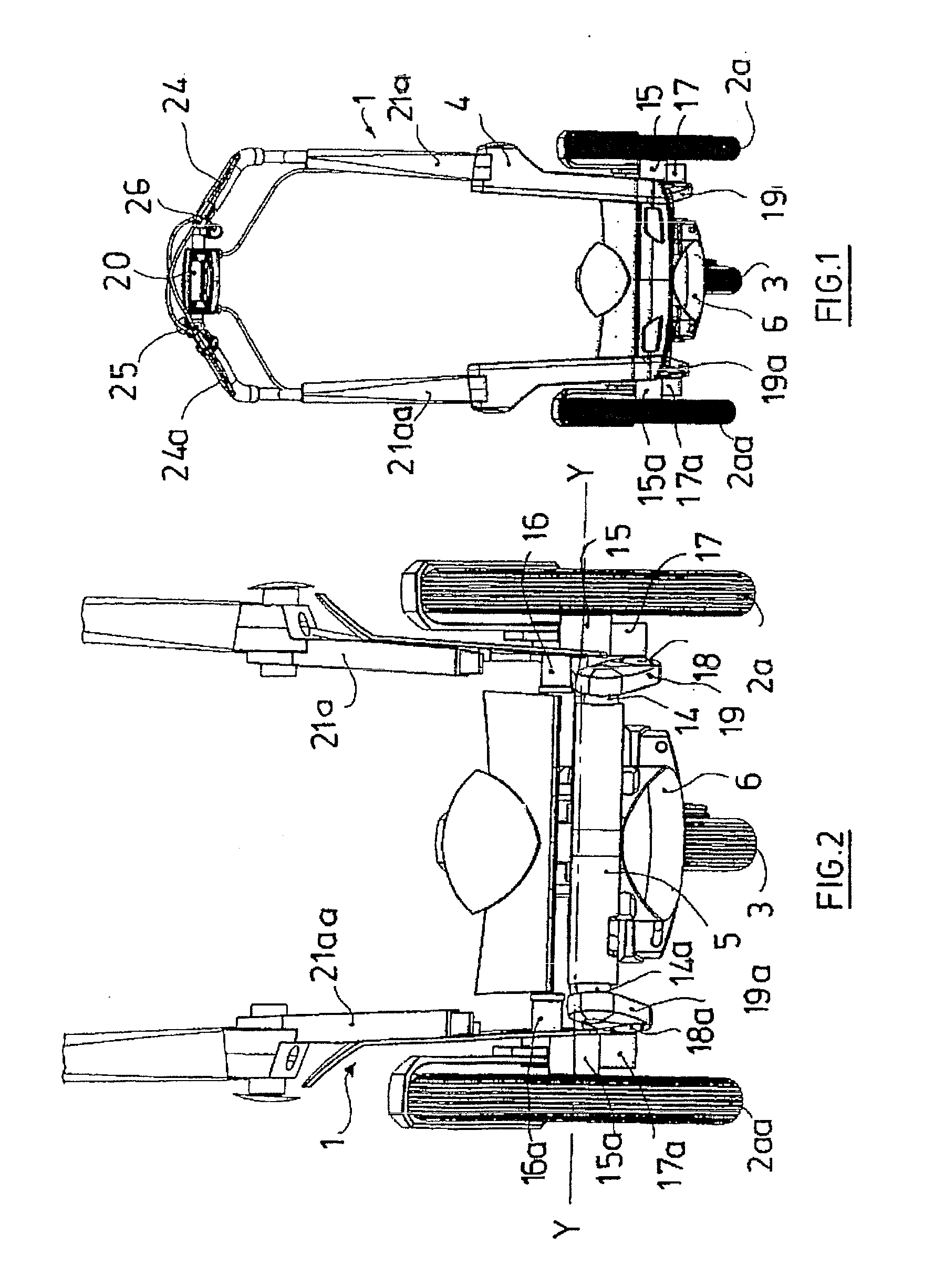

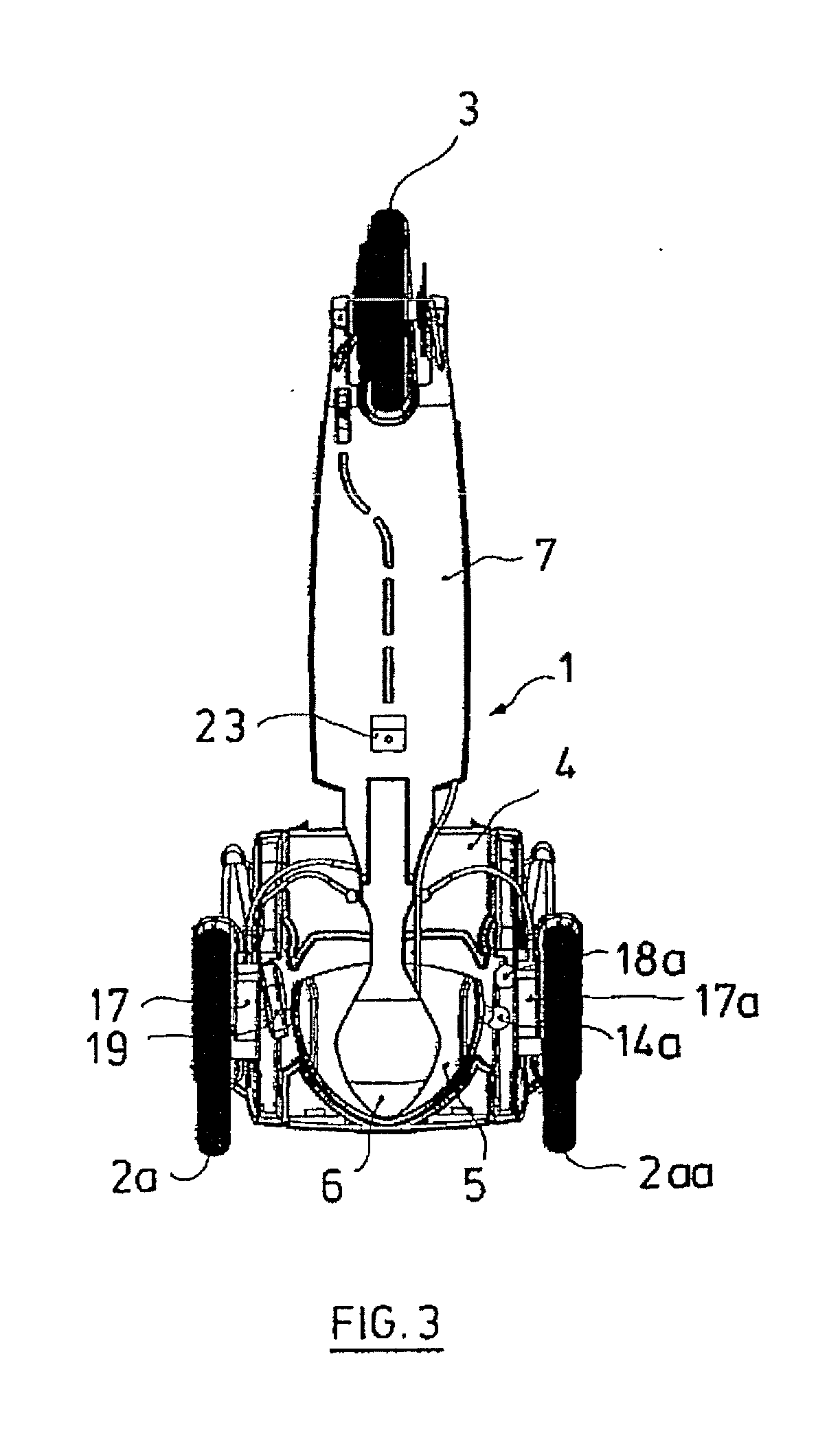

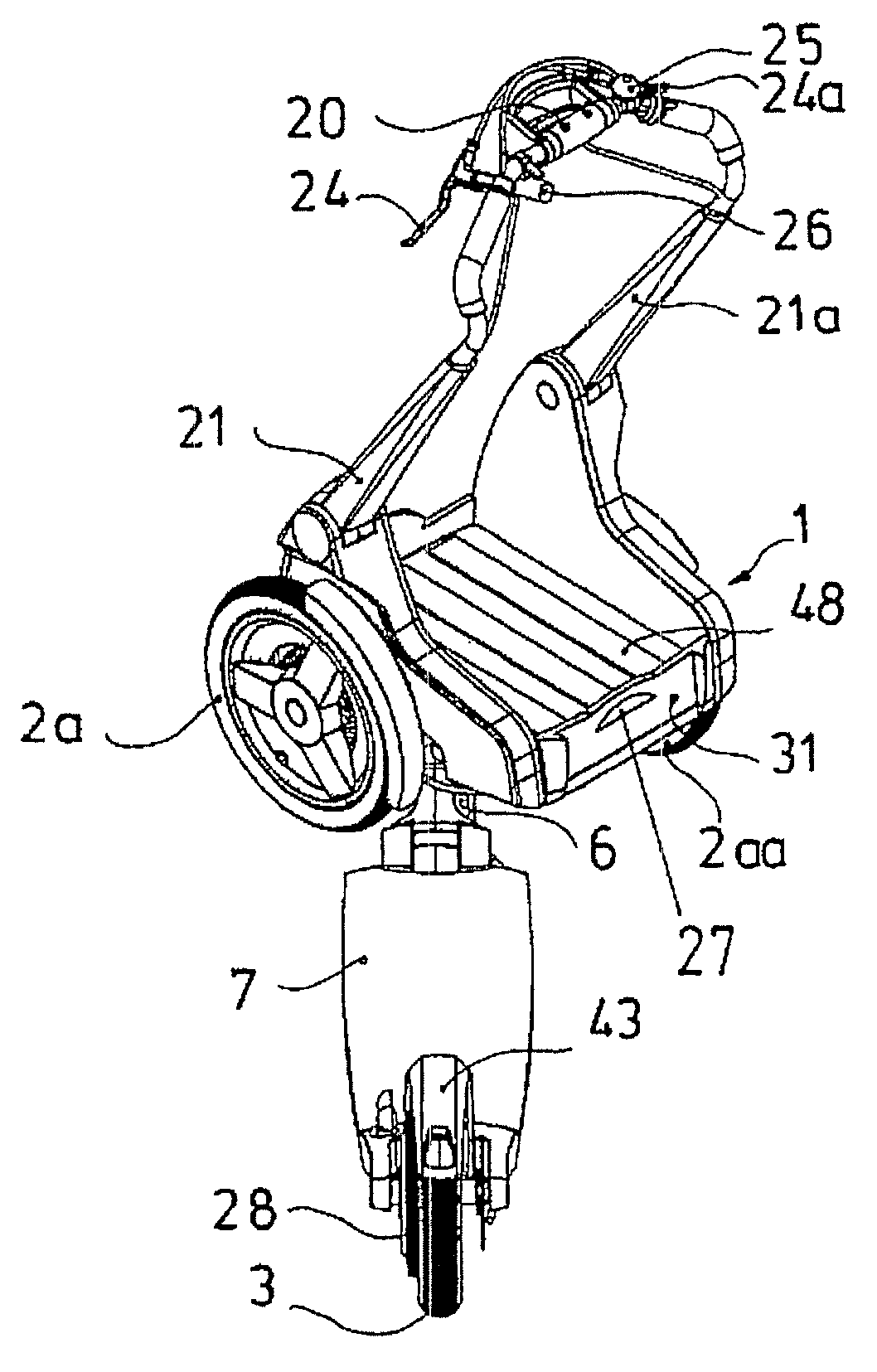

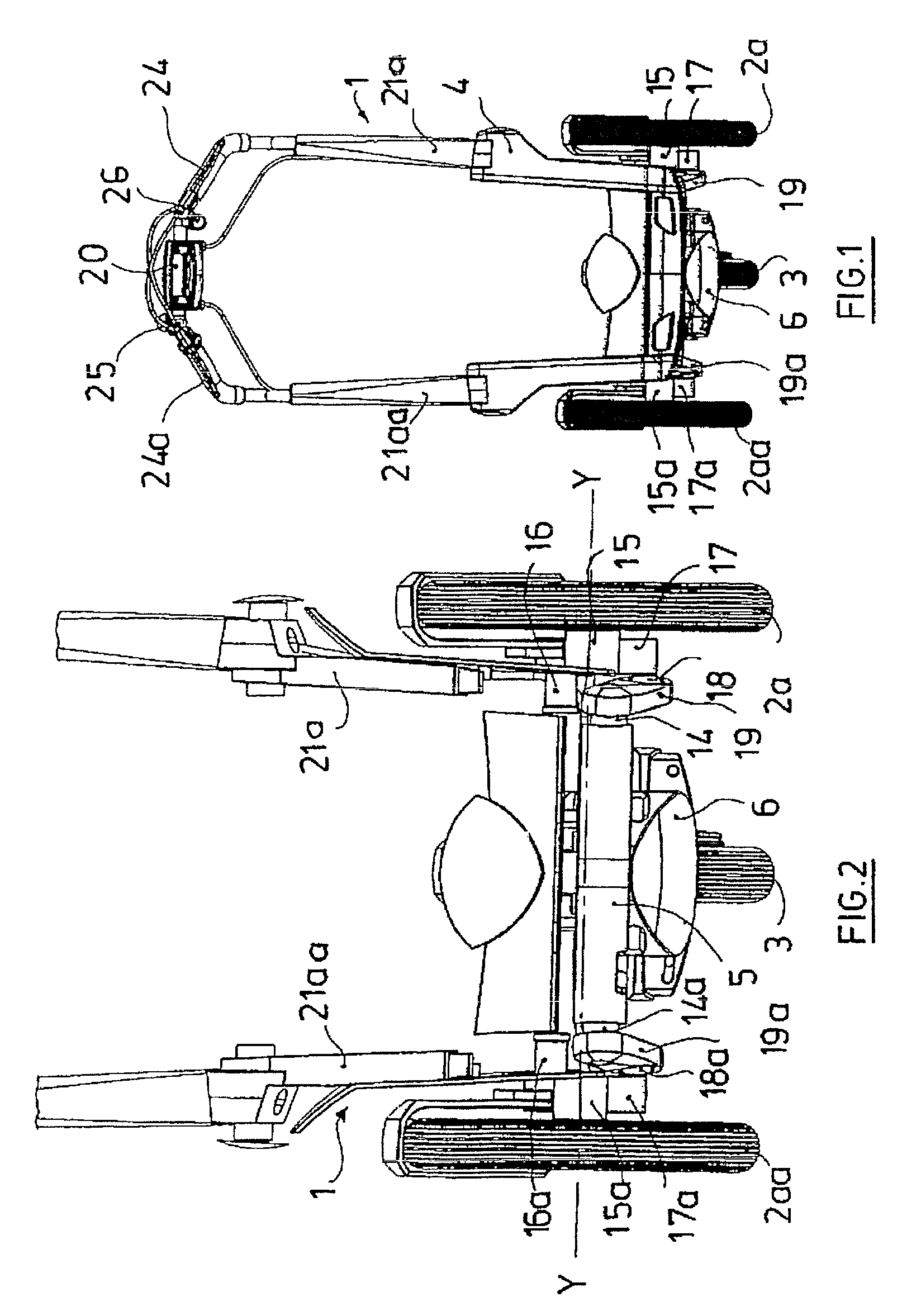

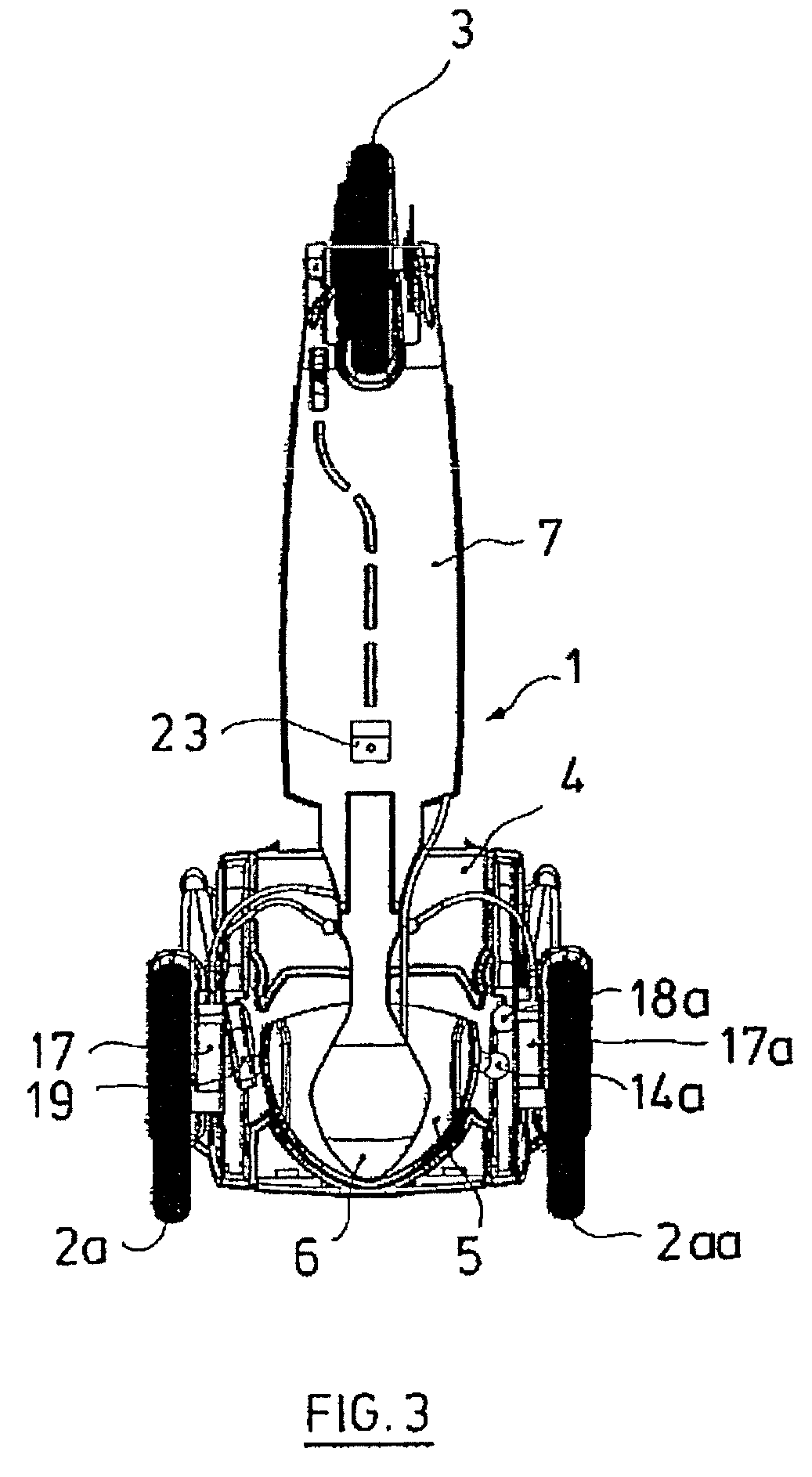

Load and/or transport cart

InactiveUS20130153322A1Optimization rangeSmall sizePassenger cyclesCarriage/perambulator accessoriesSteering angleStub axle

A load and transport cart includes, under a loading platform, a triangular steering plate and, therebelow, a front part of a footboard, wherein the steering plate has a bore, an annular-segment shaped groove, an elongated hole and two opposing first ball heads. The first ball heads each lie in an articulated manner in a respective bearing at one end of a respective steering lever and, at the other end of each lever is a bearing for a respective further ball head of a respective triangular swinging fork on a stub axle of which a respective front wheel is rotatably mounted, wherein each of the swinging forks is rotatably mounted on the loading platform via pivot pins, and wherein the steering axis is located in front of an imaginary axis and can be deflected to the left or right by the steering angle of 45°.

Owner:CONSTIN HANS PETER

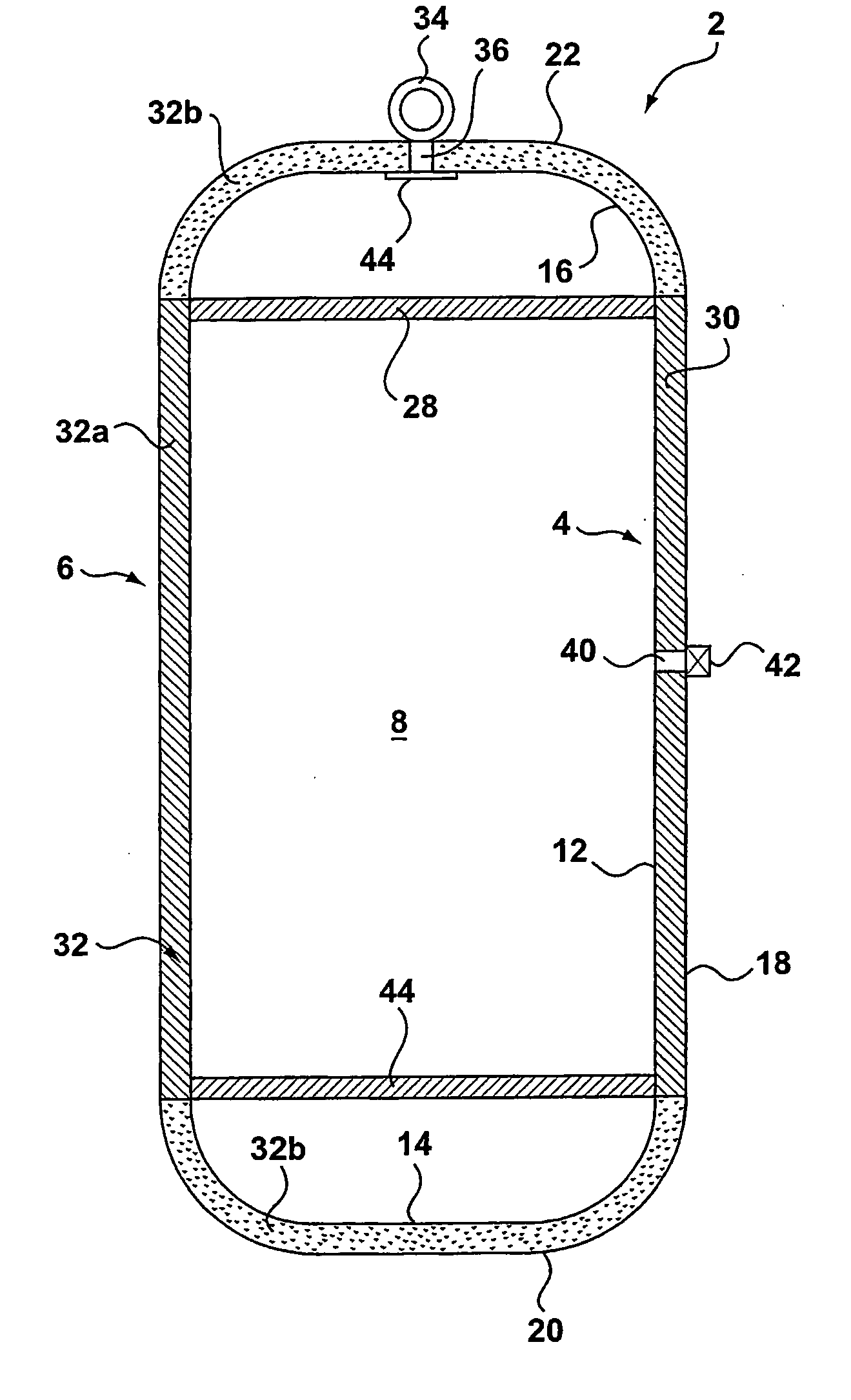

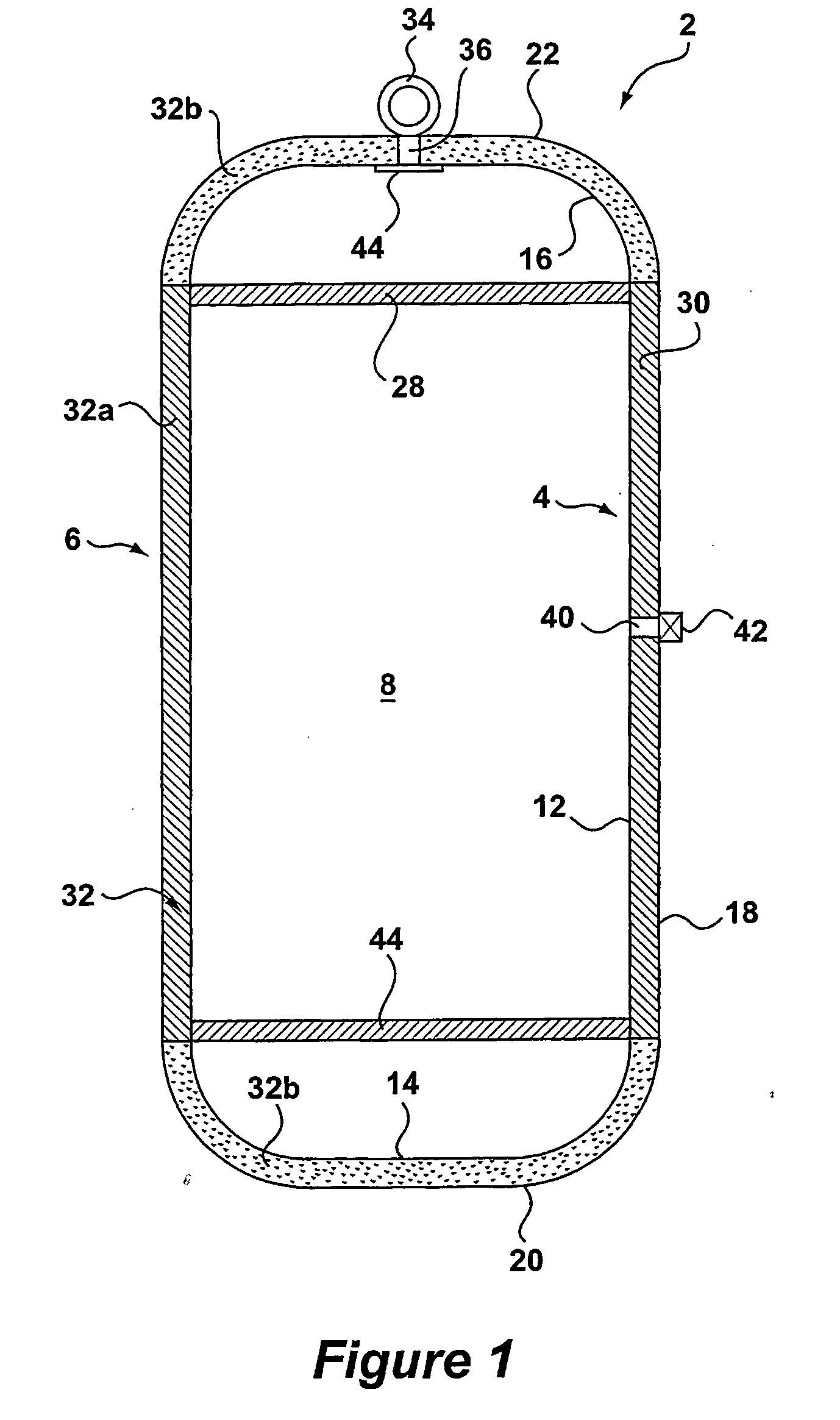

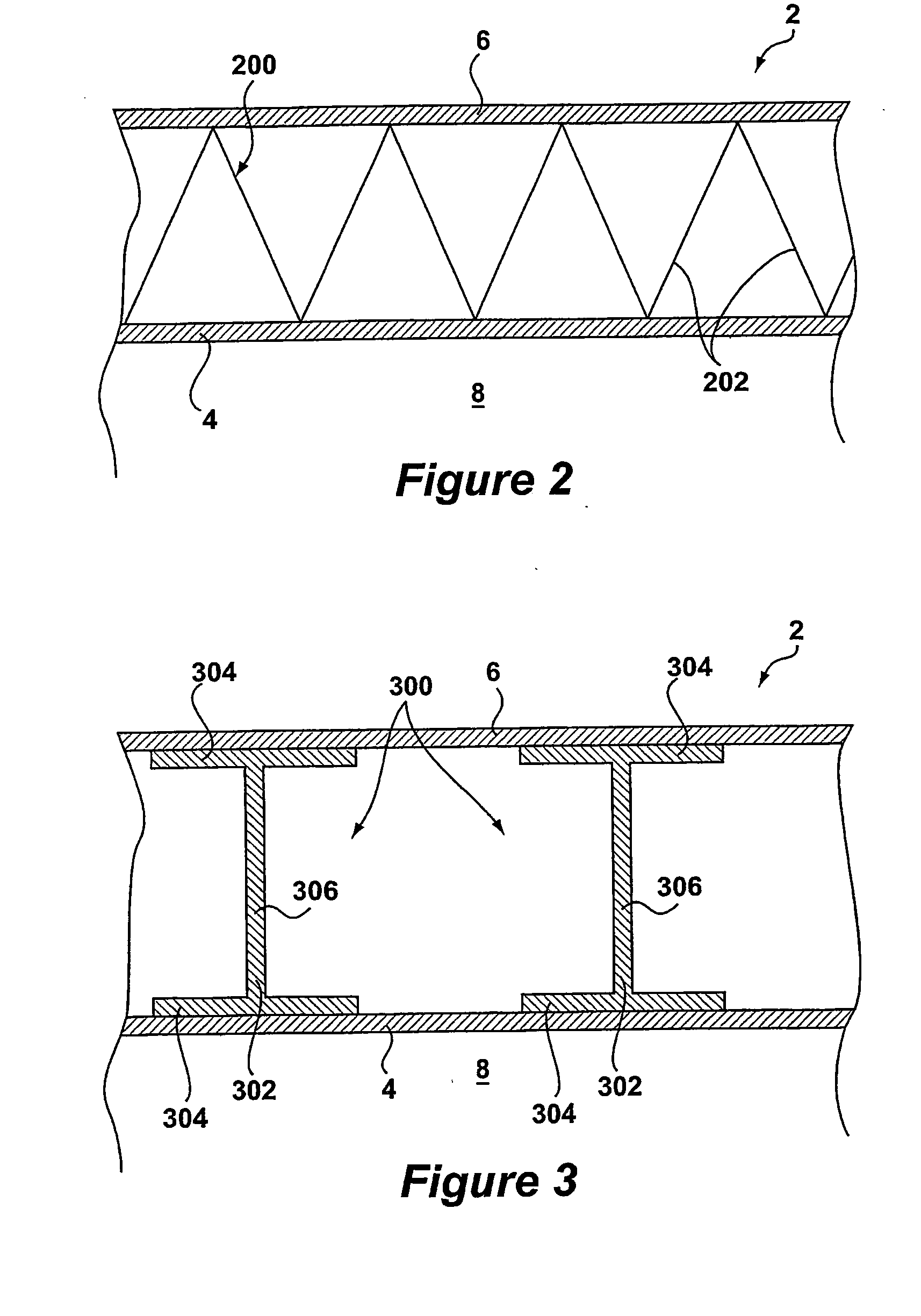

Underwater enclosure apparatus and method for constructing the same

InactiveUS20060159523A1Low curing temperatureMore temperaturePipe laying and repairNon-magnetic metal hullsRadial stressHydrostatic pressure

Apparatus for providing an enclosure, for example as a housing or to provide buoyancy, at underwater locations is disclosed comprising an inner shell and an outer shell, with a structural filler disposed between the two. The shells are prepared from fibre-reinforced plastic, with the fibres being oriented to provide resistance to both longitudinal and radial stresses induced in the apparatus by the hydrostatic pressure. The filler may be a structural filler comprising structural members extending between the inner and outer shells and occupying less than 60% of the volume of the cavity between the two shells. Alternatively, the filler may be a substantially void-free structural filler, such as a polyester resin. Methods of fabricating the apparatus are disclosed. In addition, a method of deballasting a buoyancy module is disclosed, in which the ballast, for example water, is withdrawn from the module by means of reduced pressure. Apparatus for deballasting is also disclosed.

Owner:COOPER CAMERON CORP

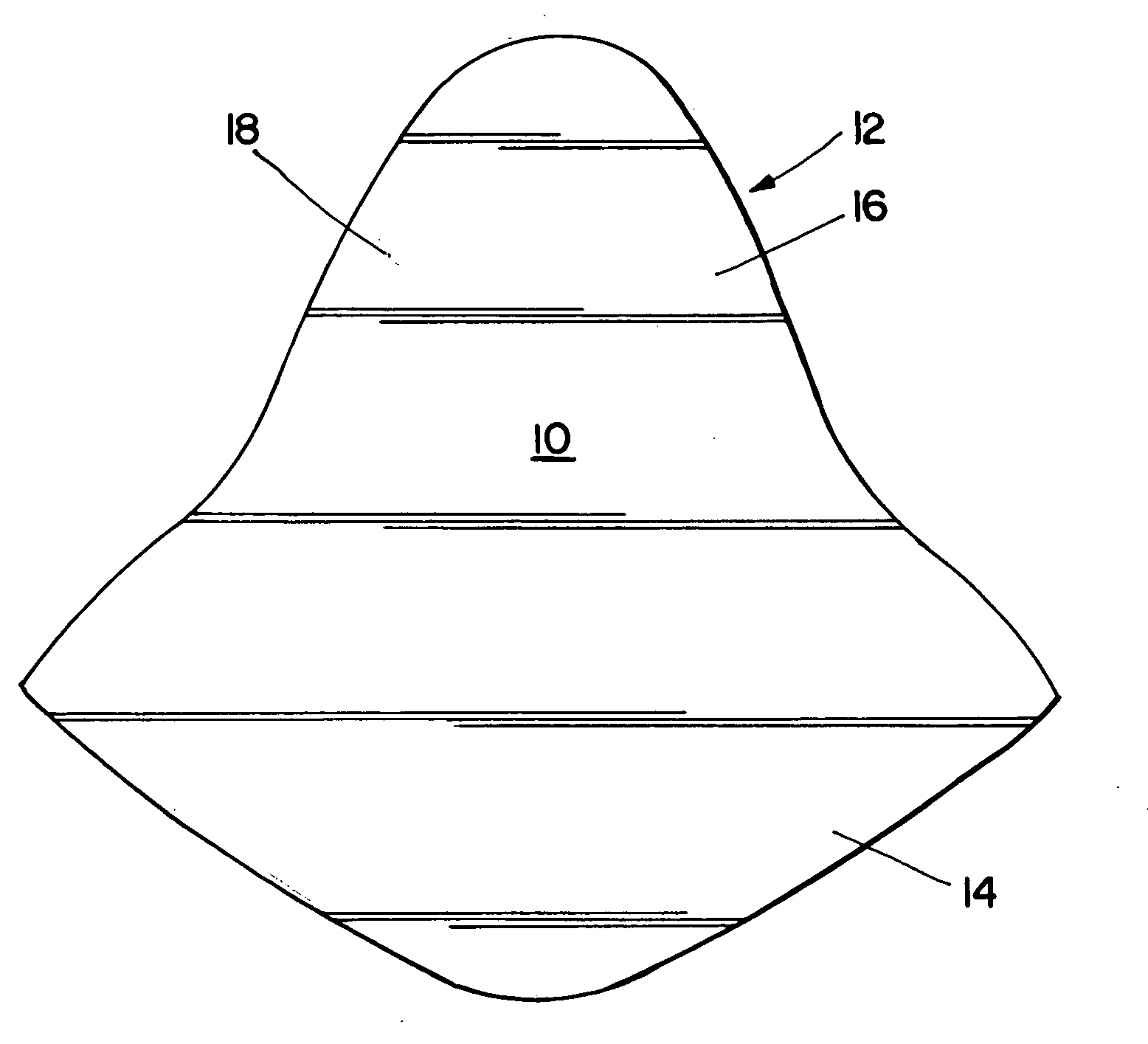

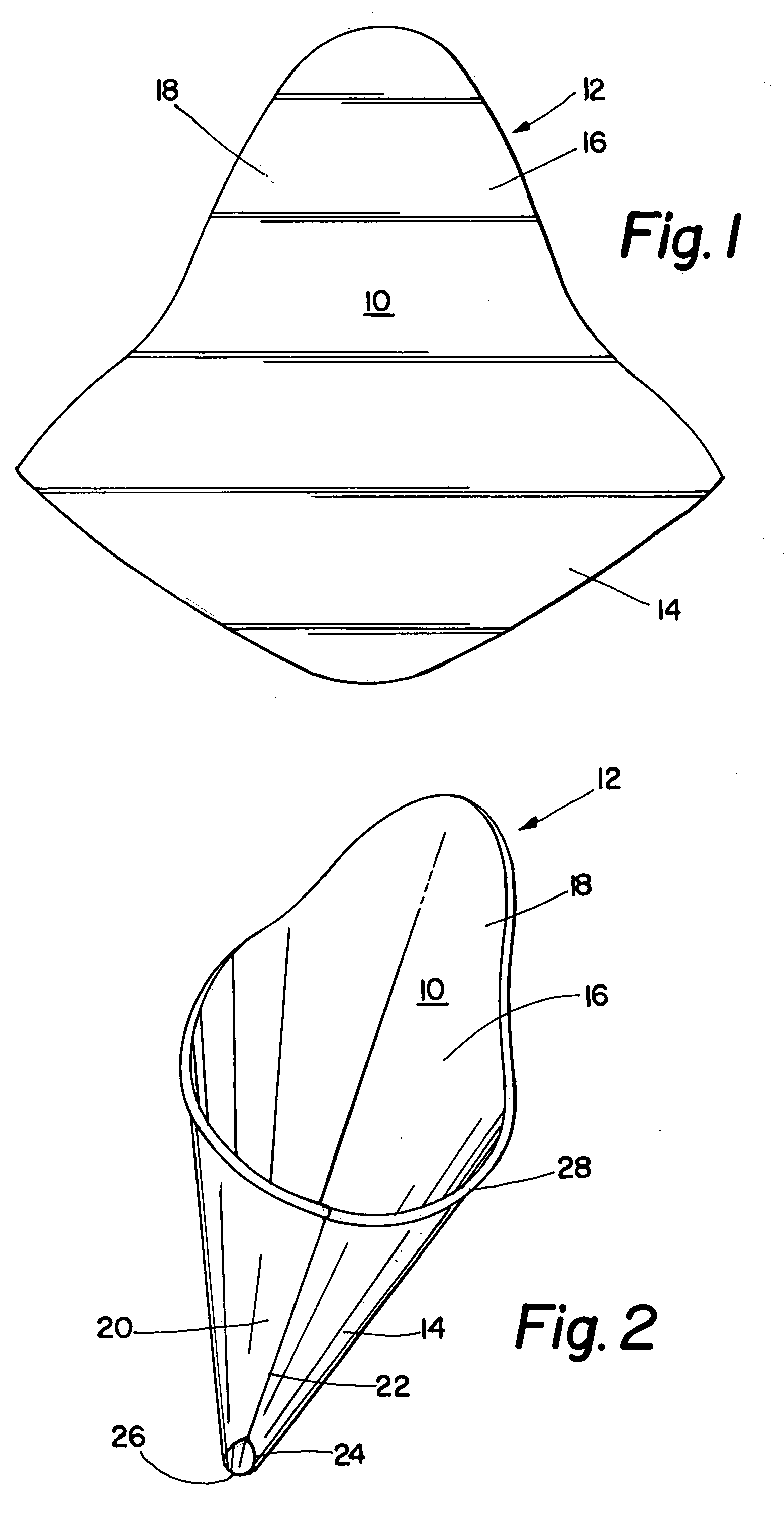

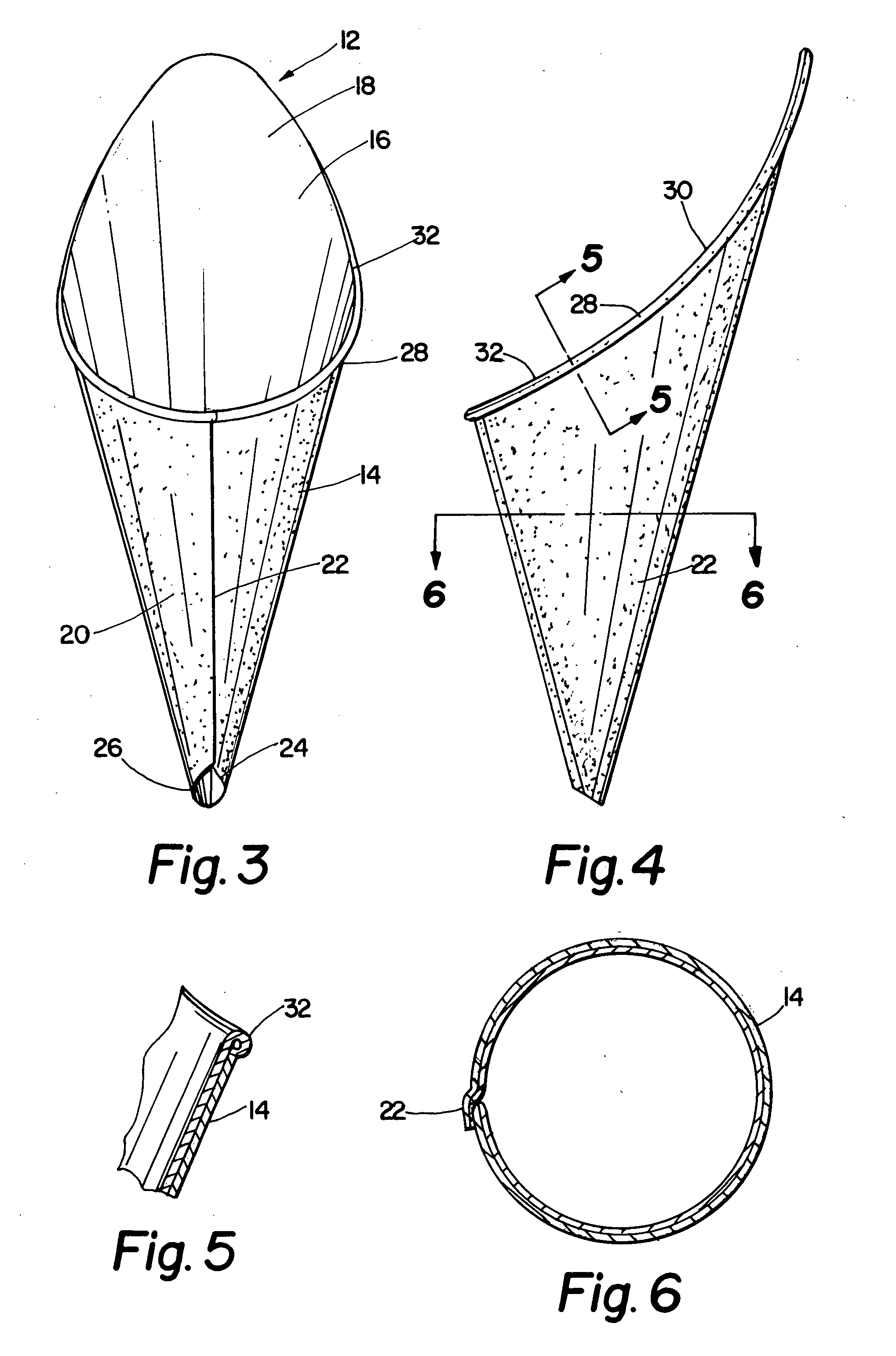

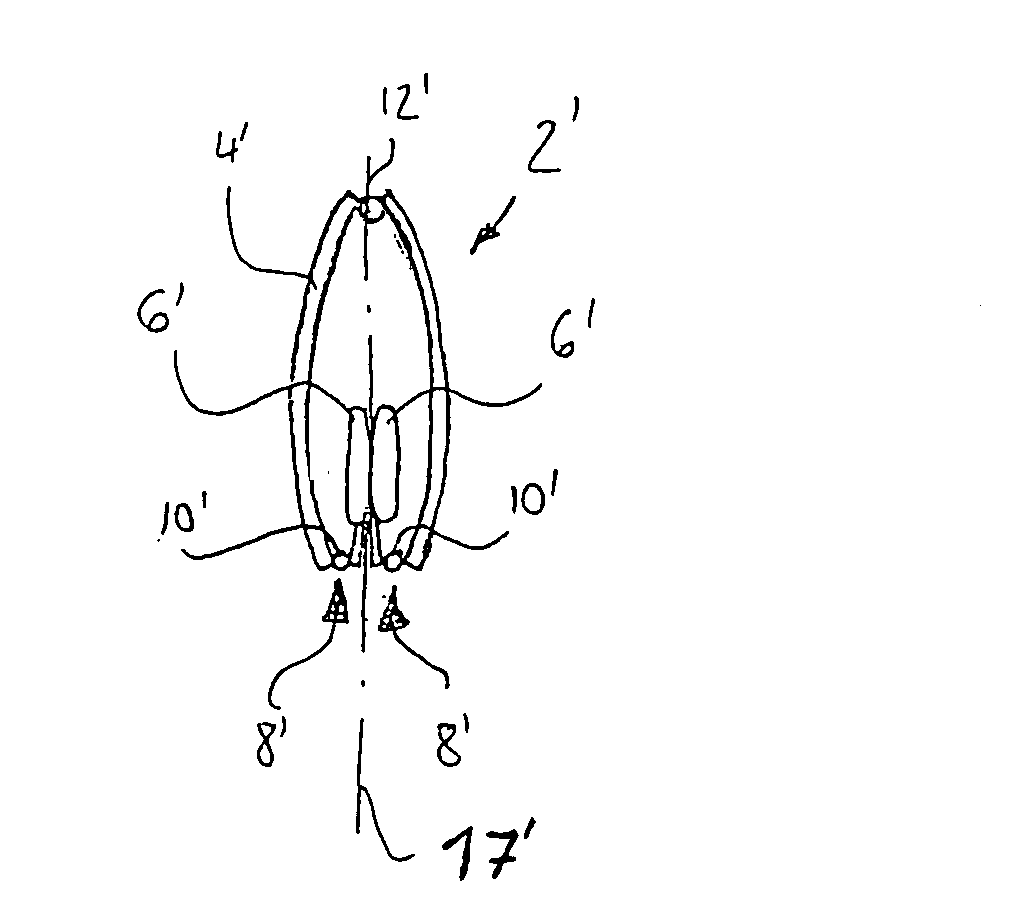

Female urination device

InactiveUS20090089919A1Easily disposableCompact unitBathroom accessoriesSuction devicesFemale urination deviceAbsorbent material

A urination device that permits a woman to direct her urine into a toilet while in the standing position is disclosed. The device is generally funnel-shaped in configuration with an elongated lip portion at its entrance and is formed from biodegradable material so as to be readily disposable. The exposed edges of the device are rolled to prevent the creation of any discomfort or irritation when the device is used. An absorbent material is attached to the outer surface of the device for personal wiping purposes. The elongated lip portion can be folded onto the funnel-shaped portion creating a compact unit for carrying purposes.

Owner:RUDOLPH CYNTHIA K

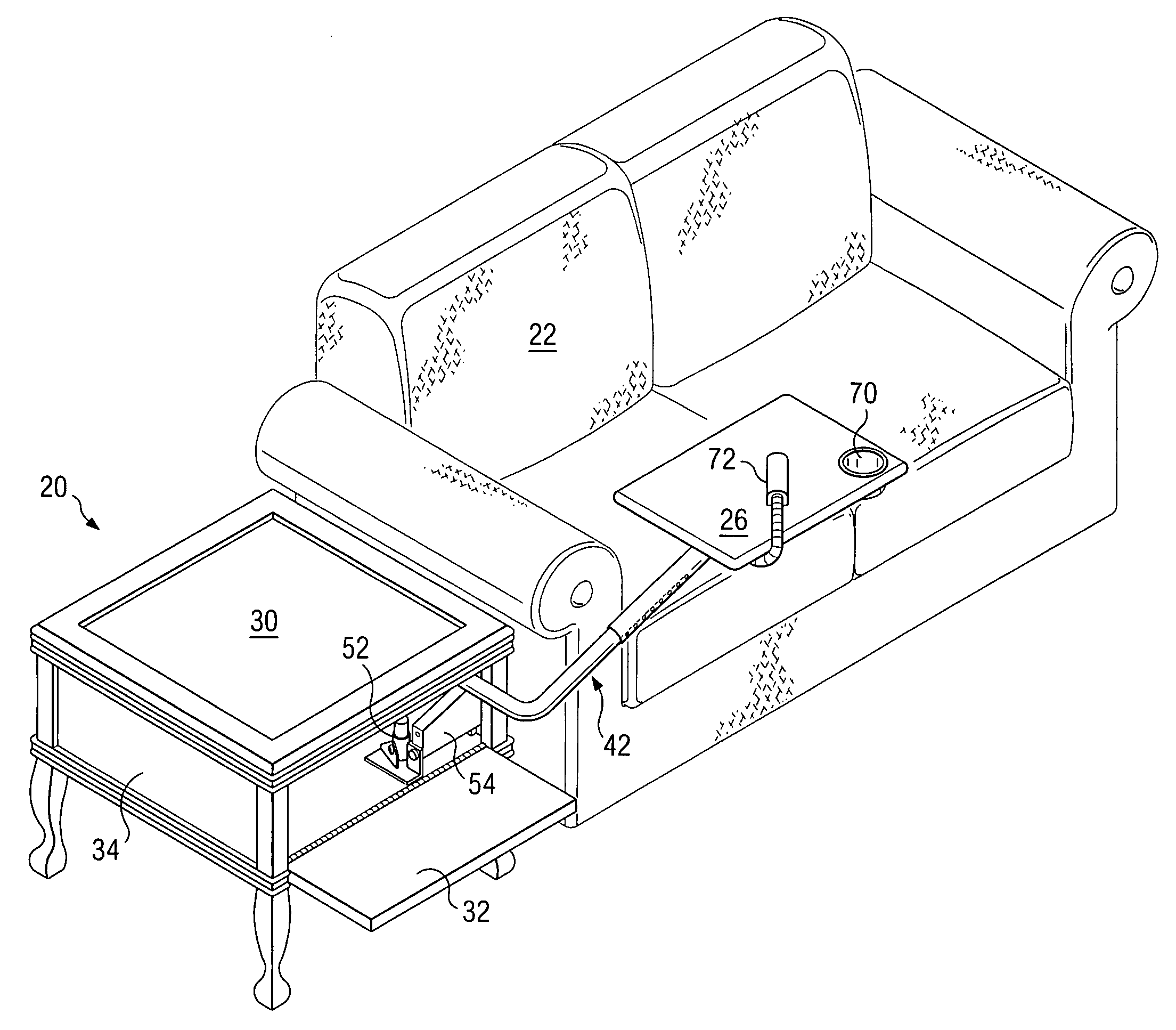

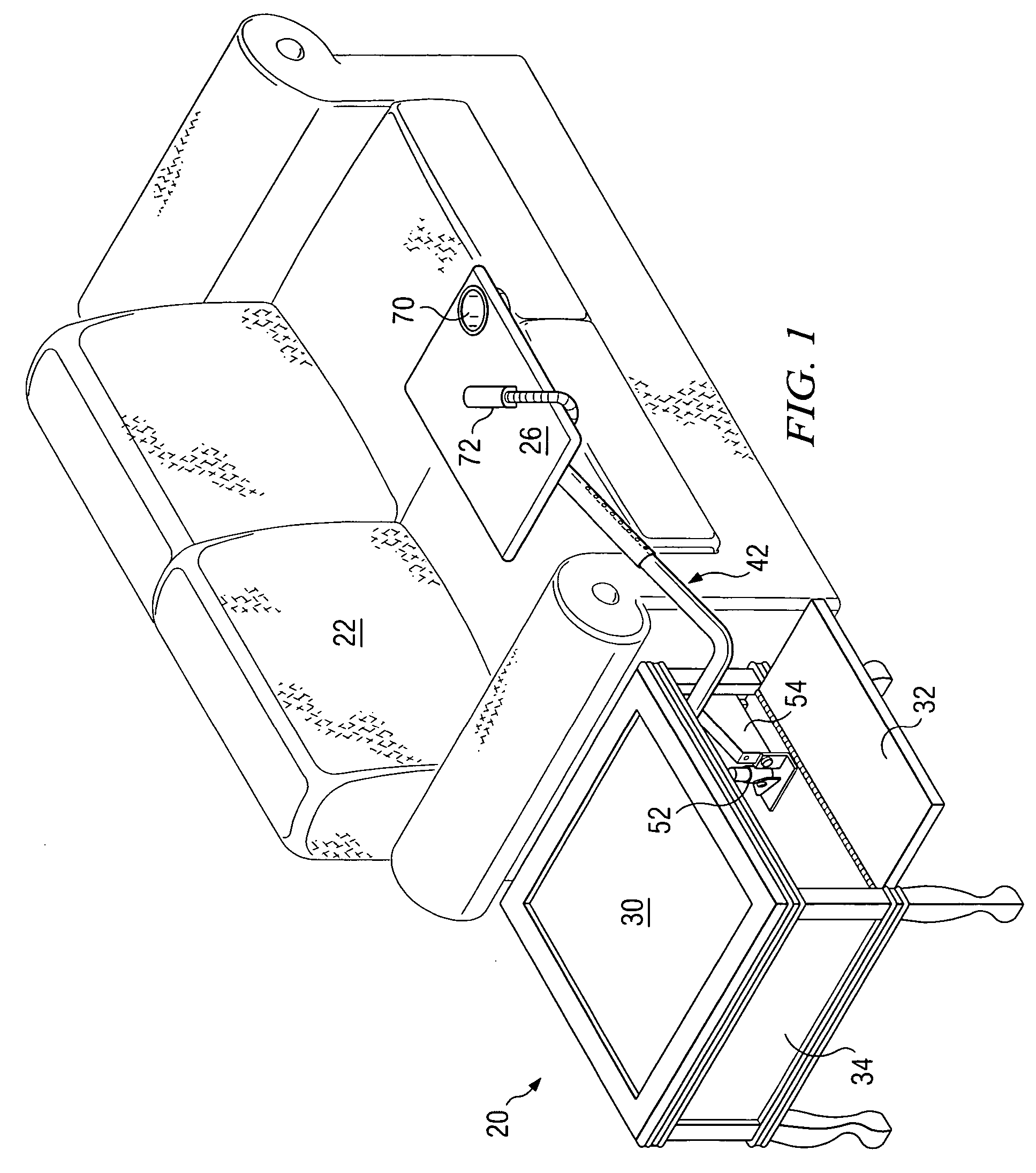

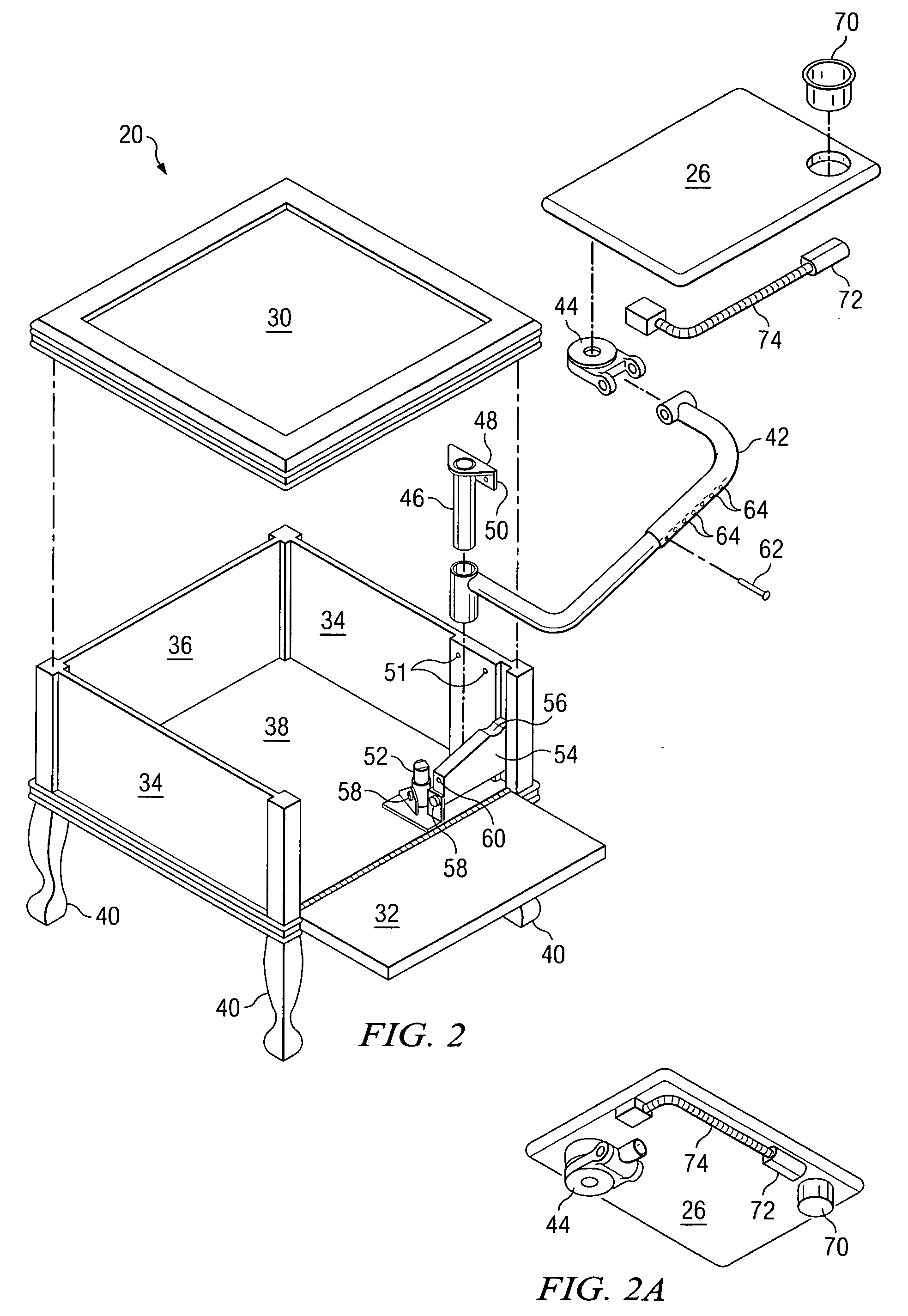

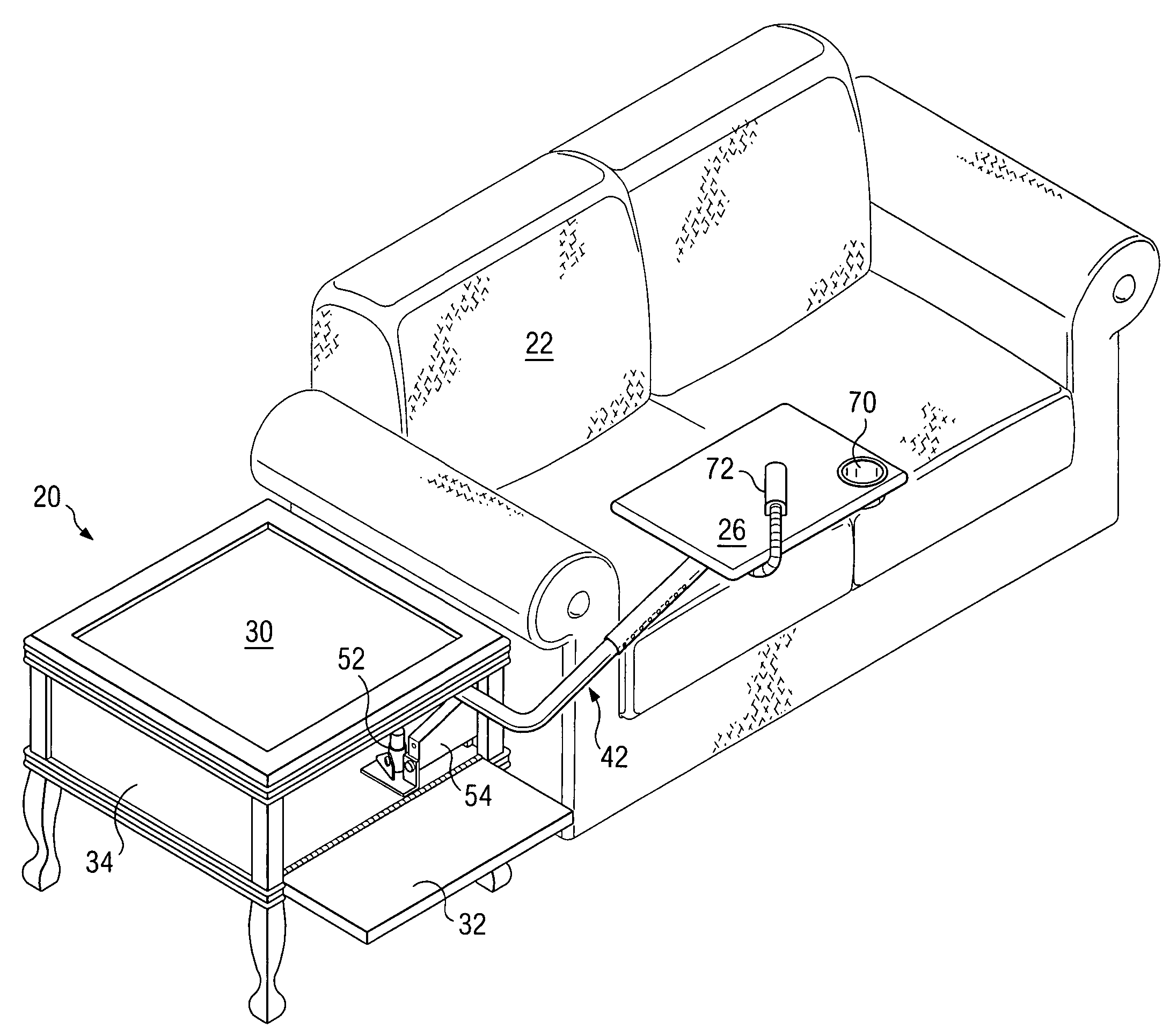

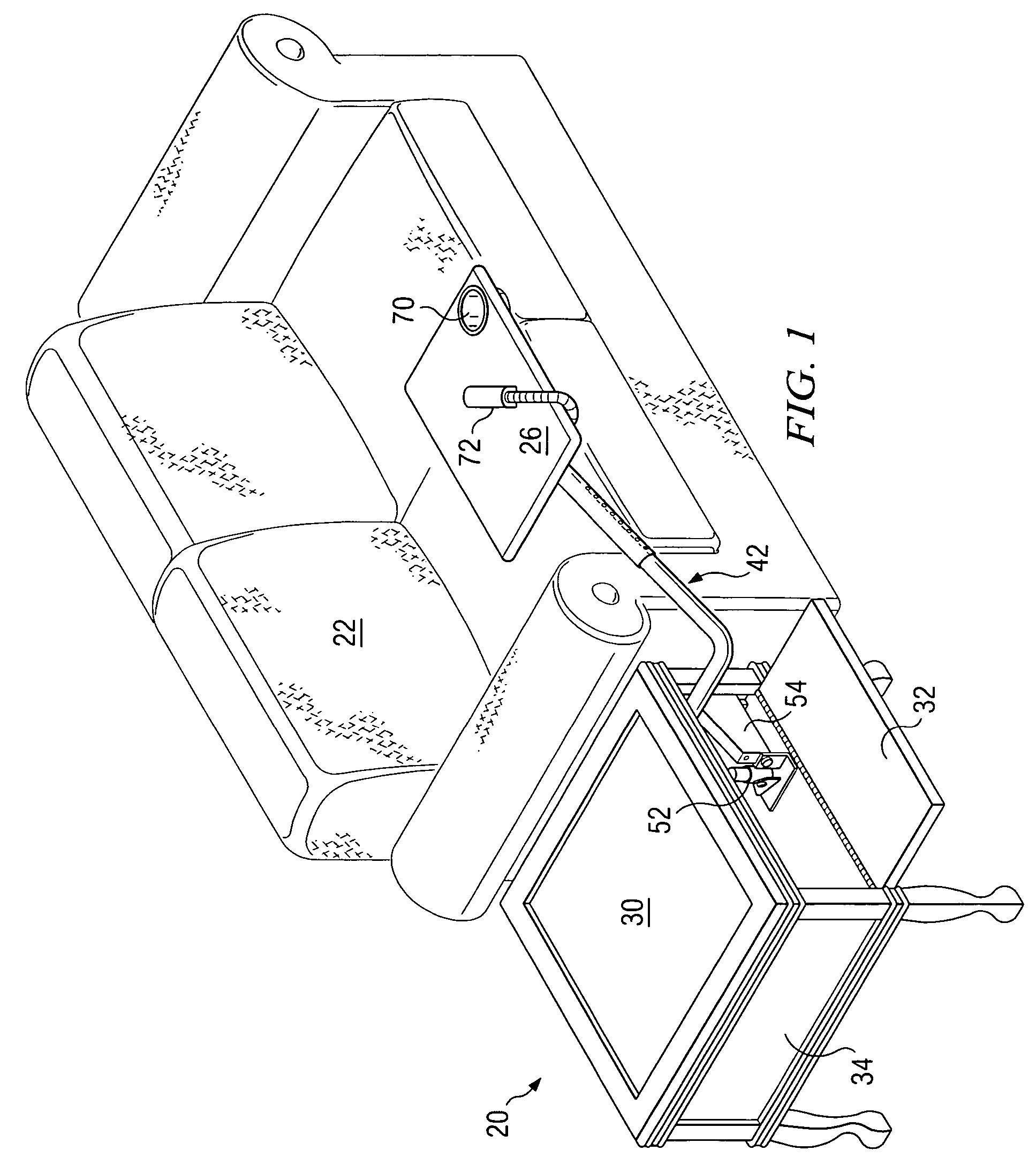

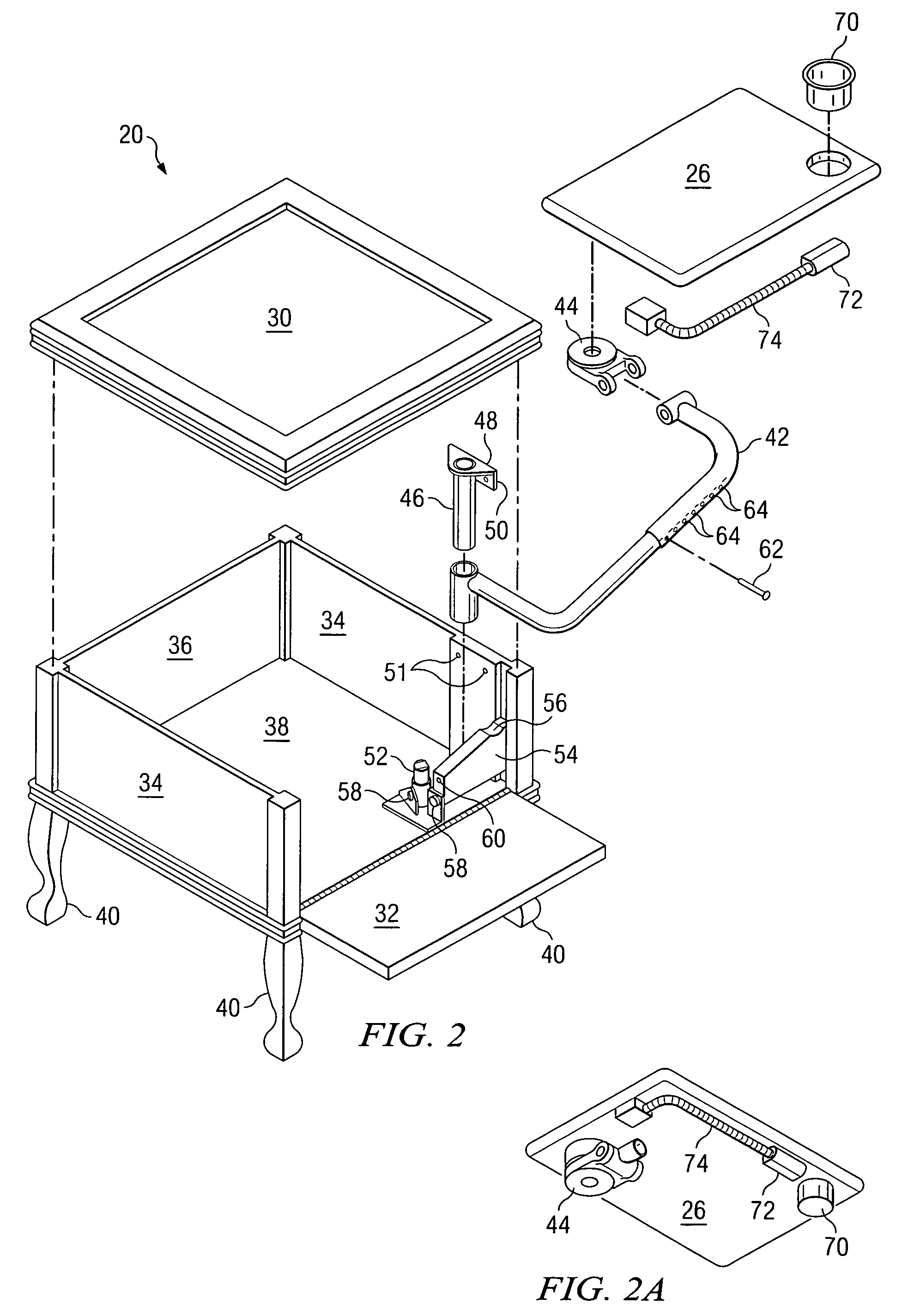

Multi-functional table

ActiveUS20060156962A1Less spaceSmall size tableCabinetsRevolvable tablesEngineeringSpace requirements

A multi-functional table comprises an adjustable second support surface recessed below the upper support surface which extends outward therefrom for use as by a person seated adjacent to the table. When not in use, the second support surface is stored beneath the upper support surface of the table, requiring no additional storage or space requirements for the second support surface.

Owner:HOLT GARY W

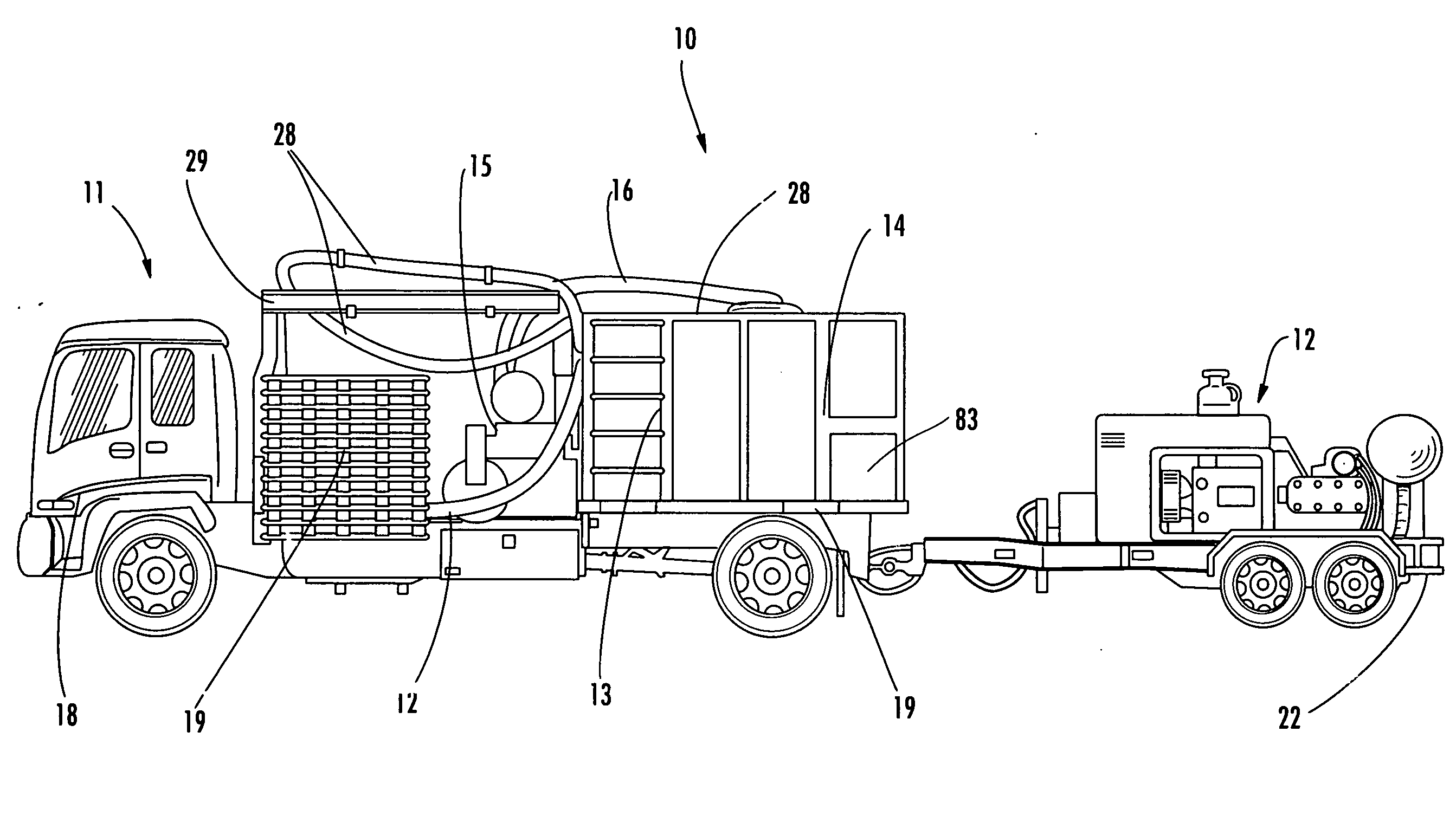

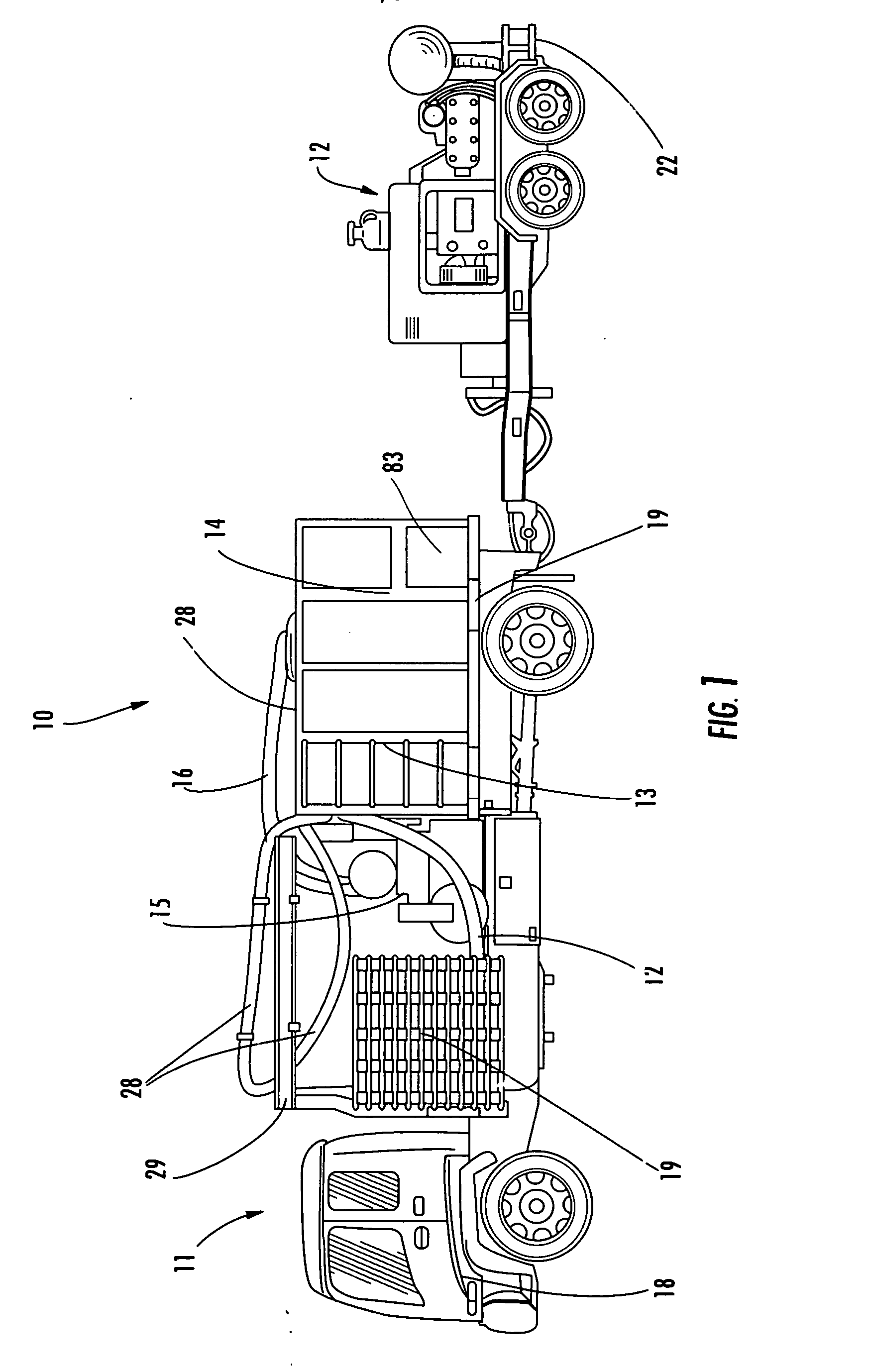

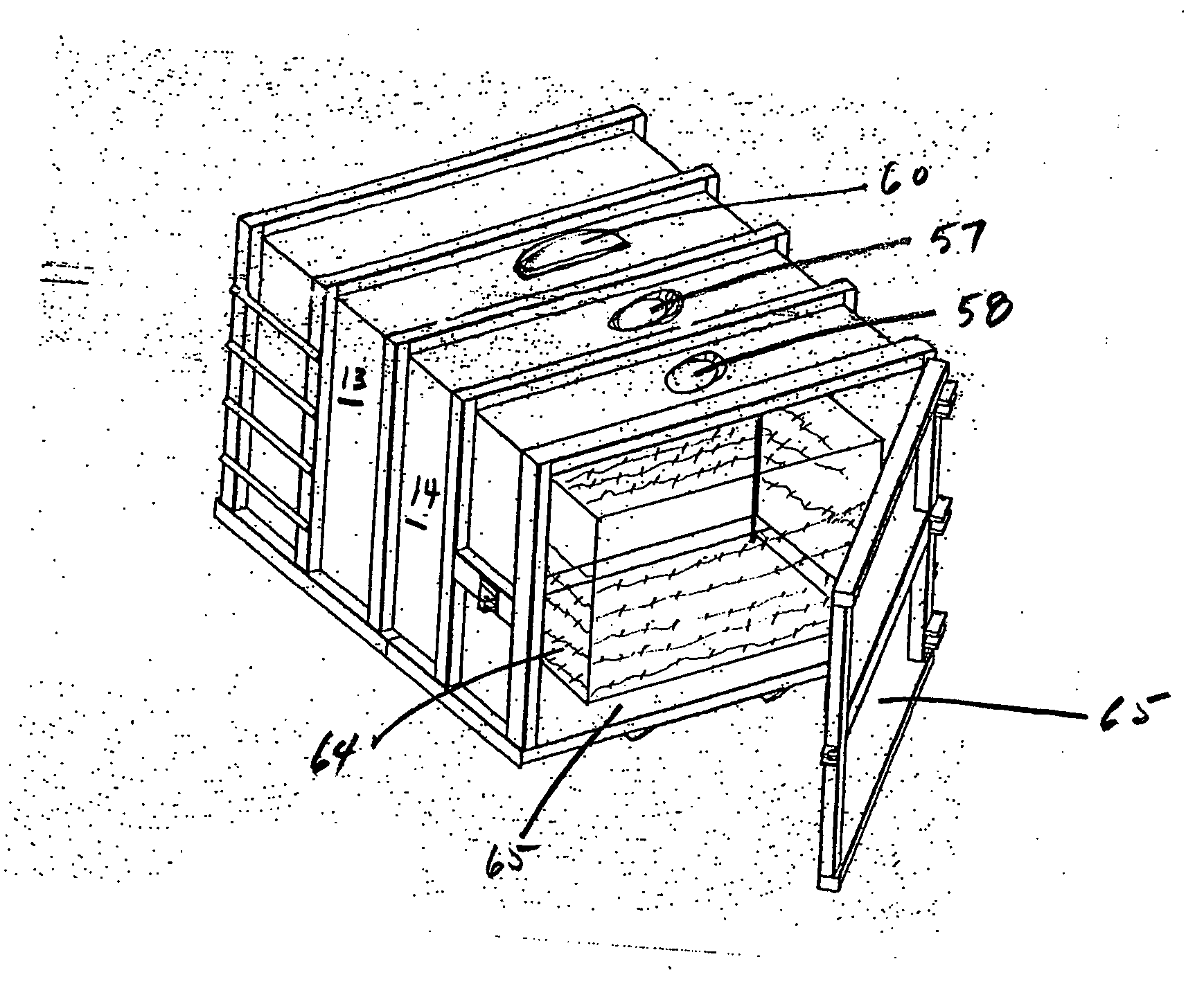

Transportable holding tank for stripe removal system

InactiveUS20060185689A1Safe and fast over-the-road travelCompact unitSuction cleanersRoad cleaningLiquid wasteCarrying capacity

A transportable holding tank for containing clean water and for accepting waste from a stripe removal system. The holding tank is carried on a flatbed vehicle and requires less deck space, thus effectively increasing the cargo-carrying capacity of the vehicle compared with that available if the vehicle were carrying a conventional round or elliptical holding tank. Construction of the tank enables the holding tank to withstand a partial vacuum imposed for pumping waste into the tank. Hooks secured inside of the tank permit a bag for separating solid waste from liquid waste for easy disposal of semi dried materials.

Owner:CROCKER JAMES P

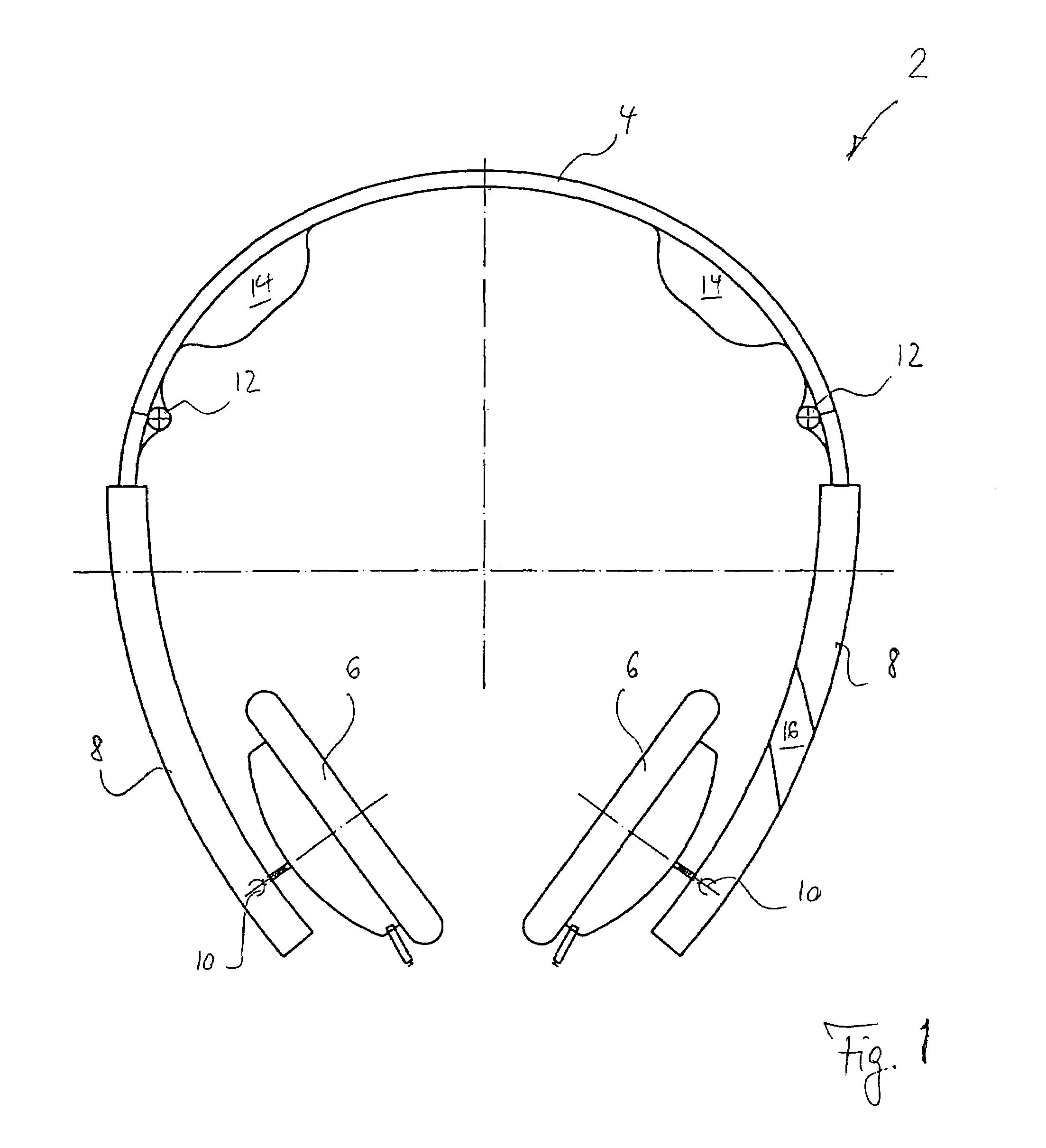

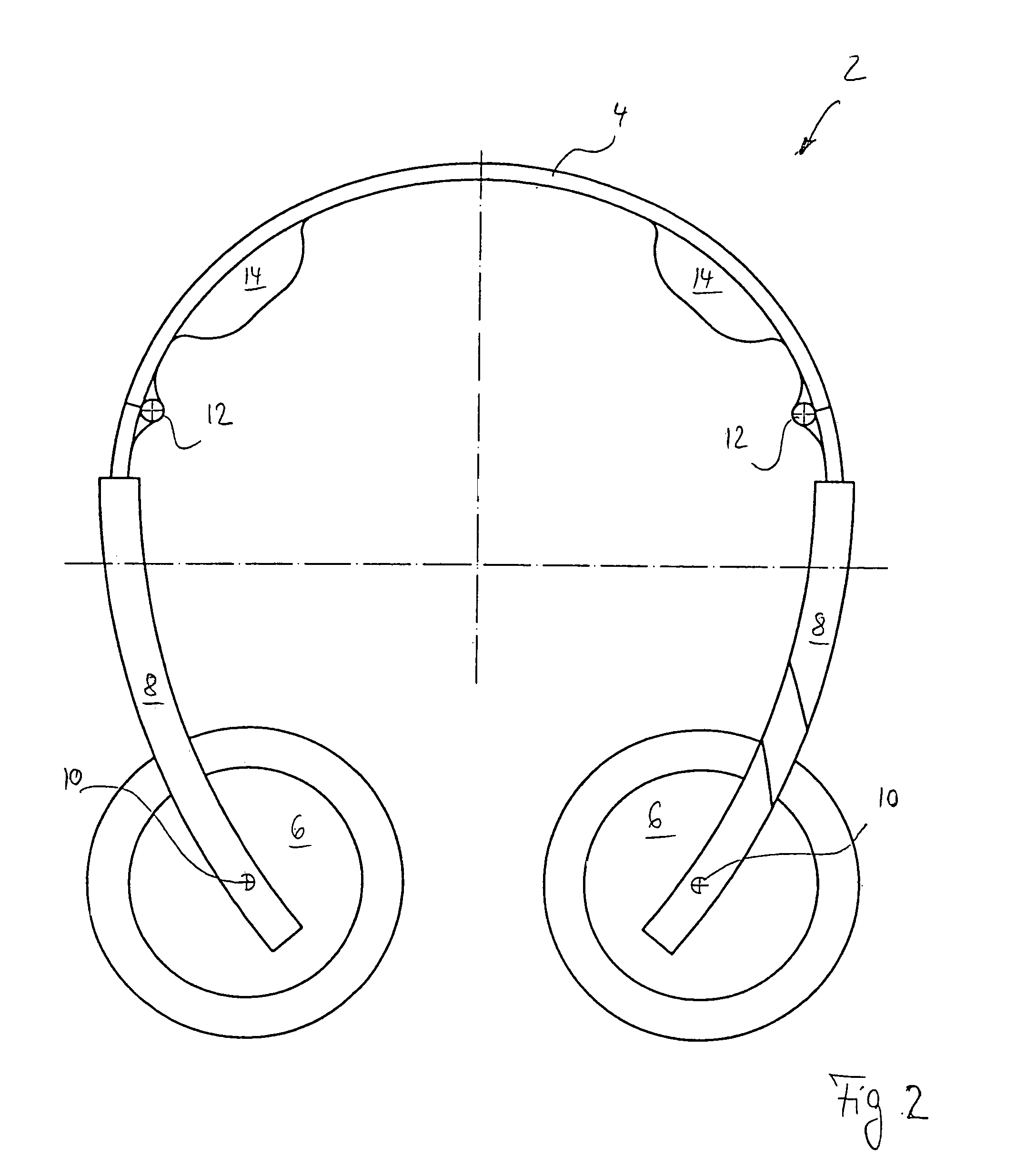

Headphones

InactiveUS7292703B2Less susceptible to troubleReduce amountDeaf-aid setsEarpiece/earphone manufacture/assemblyTransducerEngineering

According to the invention a headphone set comprises a hoop band, to each of the two ends of which is fixed a respective acoustic transducer and which extends accurately in a plane, with at least one joint for folding the ends of the hoop band inwardly in the plane and an elastic region for resiliently expanding and narrowing the hoop band is either characterized in that the fixing of each of the transducers to the ends of the hoop band has a joint for pivoting the transducers into the plane and that arranged in the region of the two ends of the hoop band is a respective connecting structure which can be connected to each other and which then in co-operating relationship hold the folded-in ends of the hoop band in a crossed position or that the one joint for folding the ends of the hoop band inwardly is arranged at the apex of the hoop band, that the headphone set is of mirror image symmetry about a plane and that the fixing of each of the transducers to the ends of the hoop band has a joint for pivoting the transducers into the plane of symmetry which is at a right angle to the plane of the hoop band.

Owner:SENNHEISER ELECTRONICS GMBH & CO KG

Multi-functional table

Owner:HOLT GARY W

Load and/or transport cart

InactiveUS8631892B2Small sizeOptimization rangePassenger cyclesSteering linkagesSteering angleStub axle

A load and transport cart includes, under a loading platform, a triangular steering plate and, therebelow, a front part of a footboard, wherein the steering plate has a bore, an annular-segment shaped groove, an elongated hole and two opposing first ball heads. The first ball heads each lie in an articulated manner in a respective bearing at one end of a respective steering lever and, at the other end of each lever is a bearing for a respective further ball head of a respective triangular swinging fork on a stub axle of which a respective front wheel is rotatably mounted, wherein each of the swinging forks is rotatably mounted on the loading platform via pivot pins, and wherein the steering axis is located in front of an imaginary axis and can be deflected to the left or right by the steering angle of 45°.

Owner:CONSTIN HANS PETER

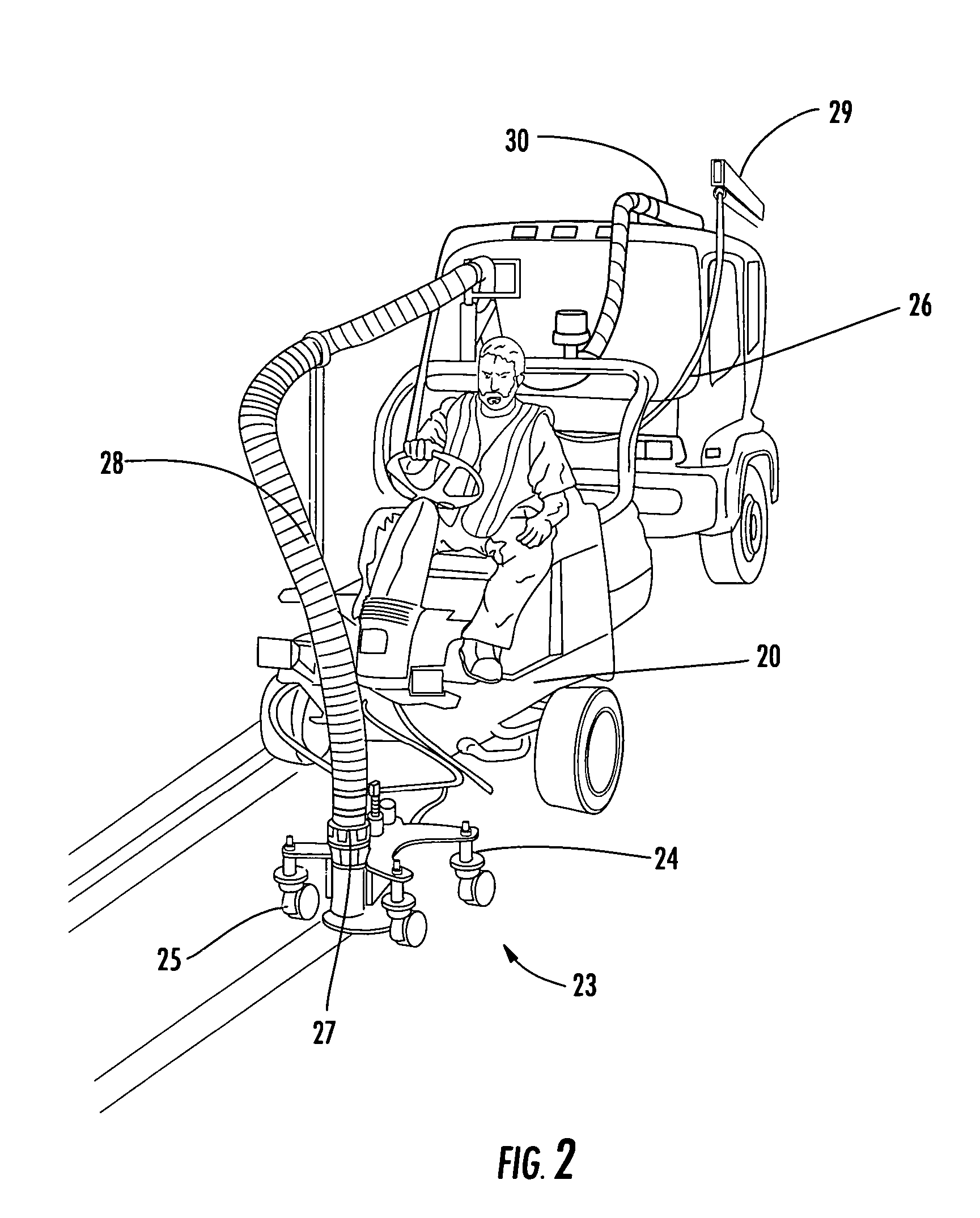

Stripe removal system

ActiveUS20060000491A1Quickly deployReduce dimensionElectrostatic cleaningMultistage water/sewage treatmentTruckEngineering

A system for removing paint and other coatings from hard surfaces is mounted on a truck for over-the-road travel. The truck bed carries a high power vacuum pump, a self propelled tractor with an attached blast head, a liquid reservoir, a sump or vacuum tank, and a ramp for loading the tractor. The reservoir is connected to a low pressure pump that transfers water to the high pressure pump. The high pressure pump is connected to the blast head by a high pressure hose. A vacuum hose is connected to the sump which has an internal enclosure for separating the waste materials from the liquid for easy dumping of semi dried materials.

Owner:WATERBLASTING

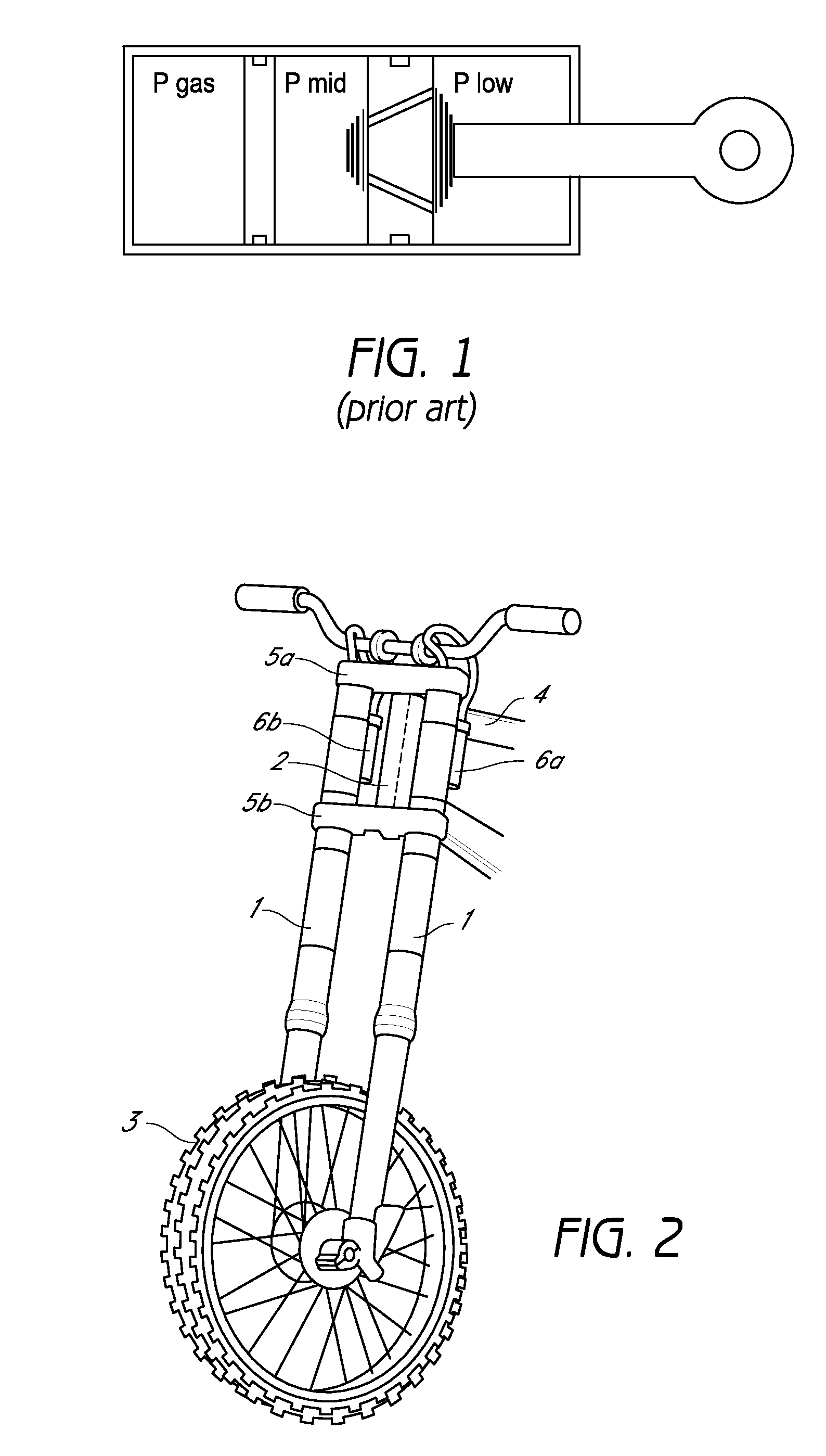

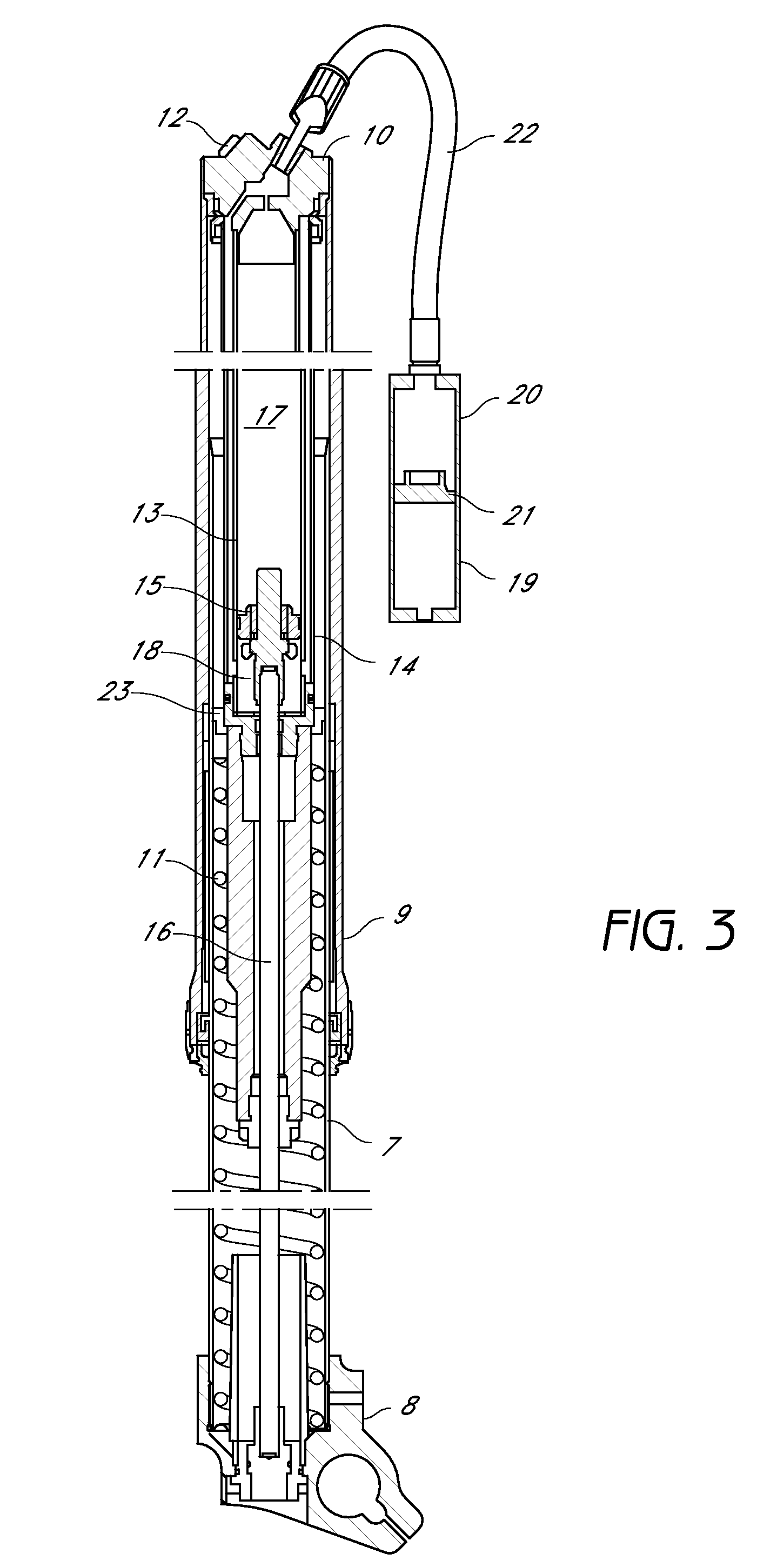

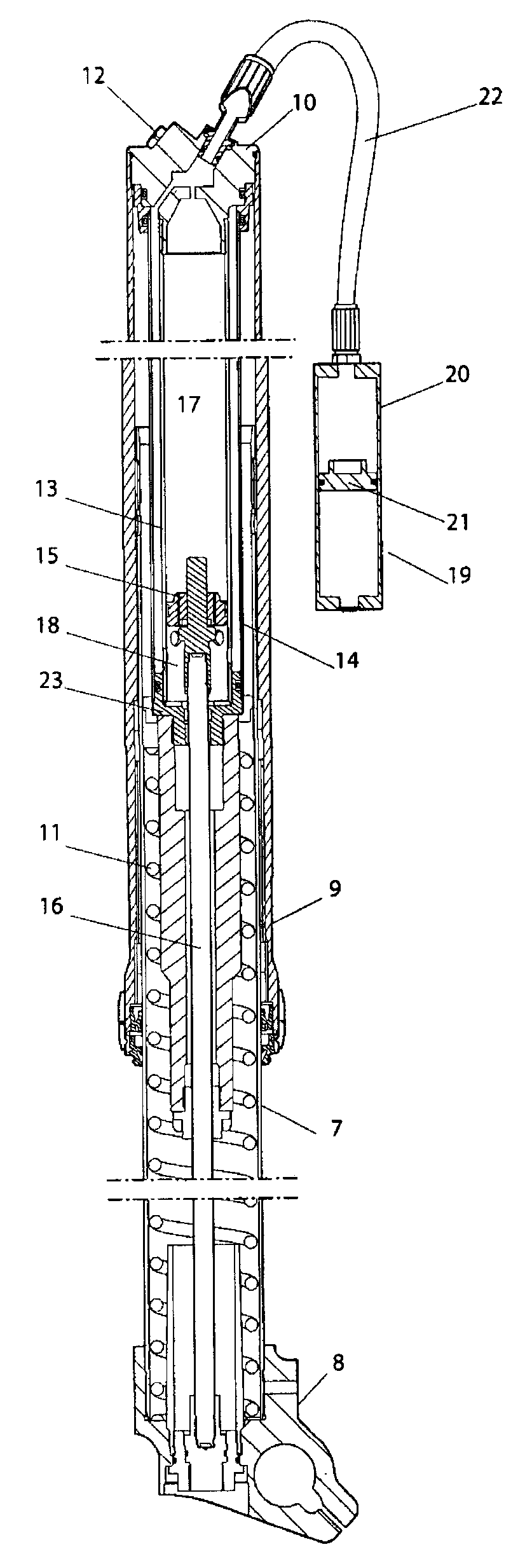

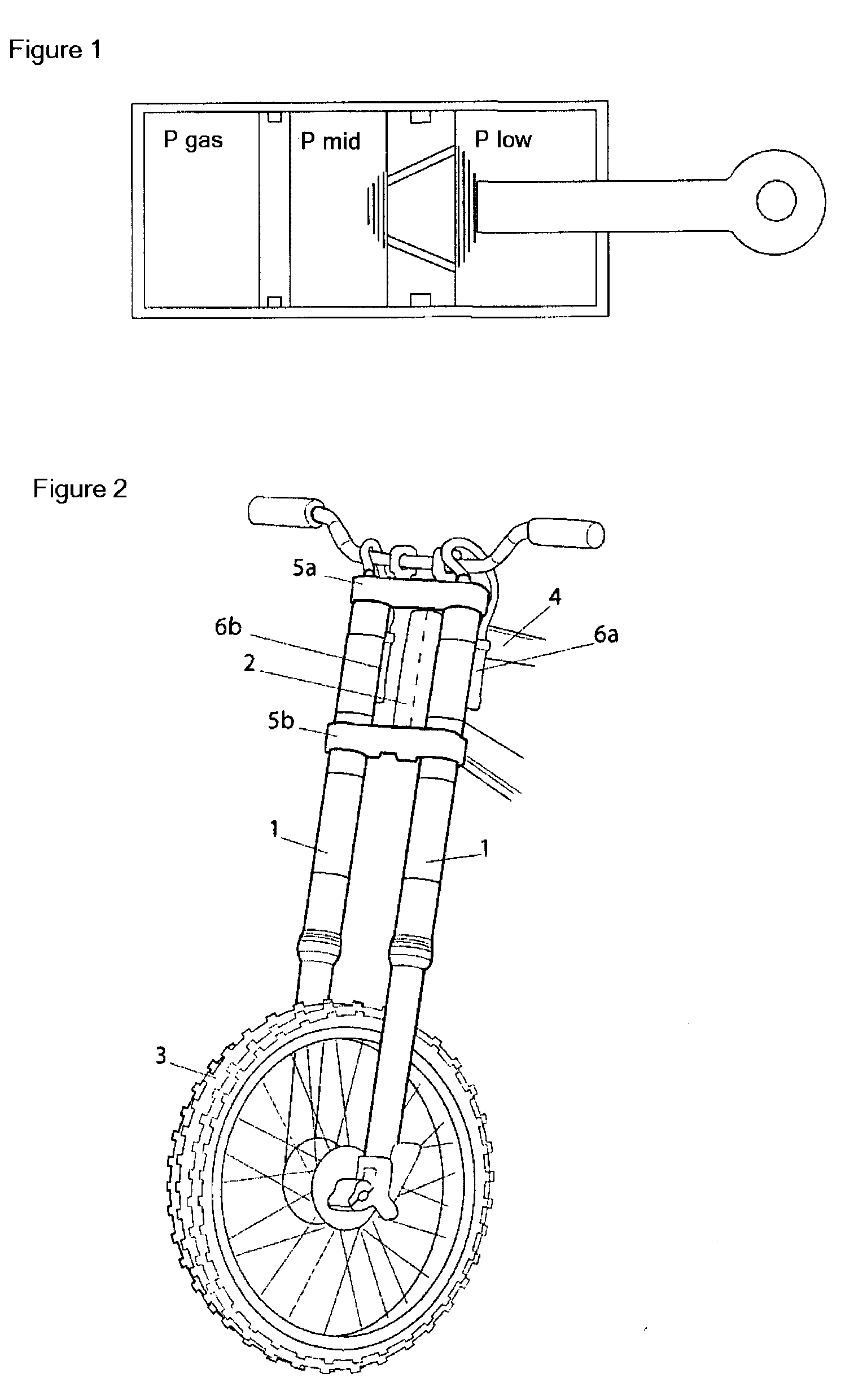

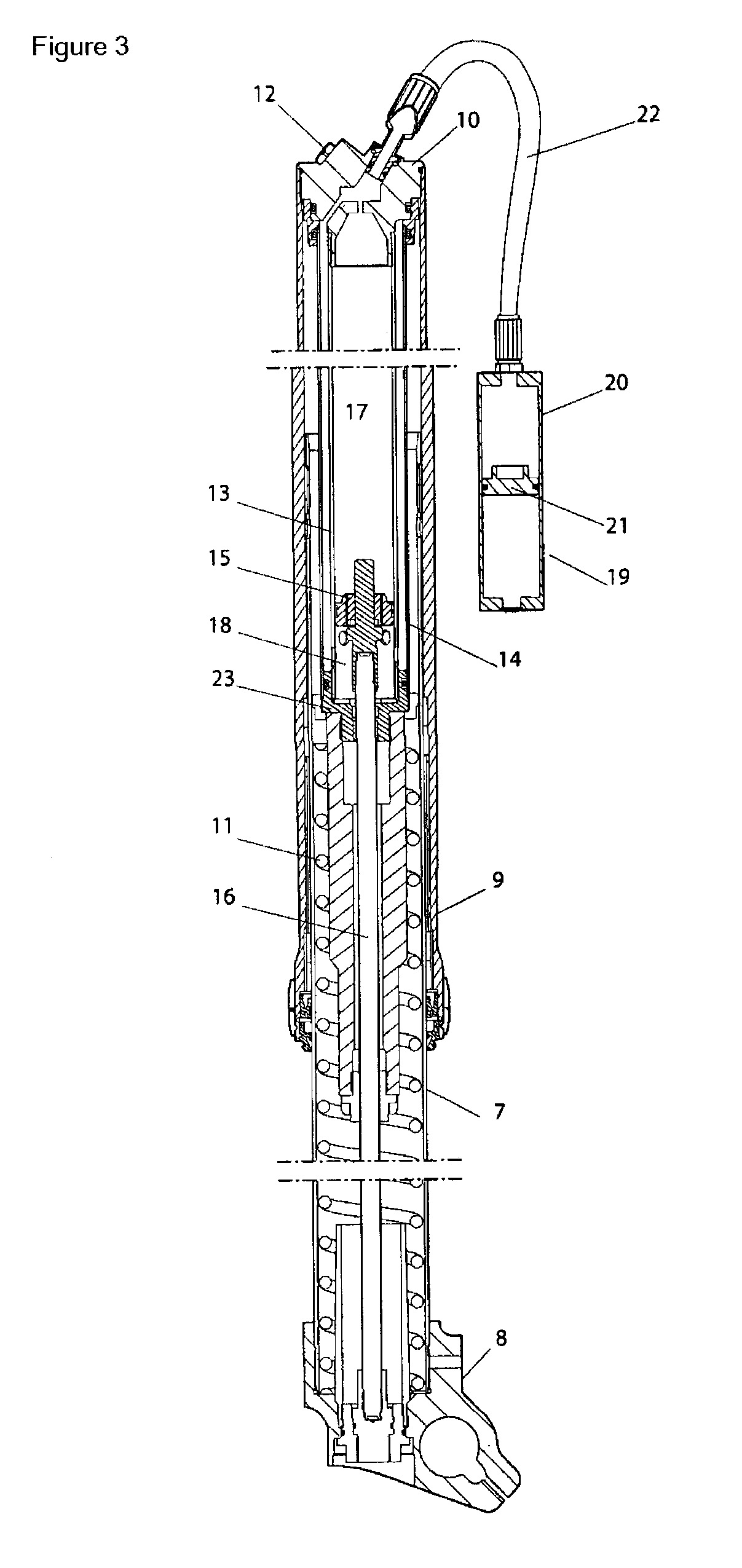

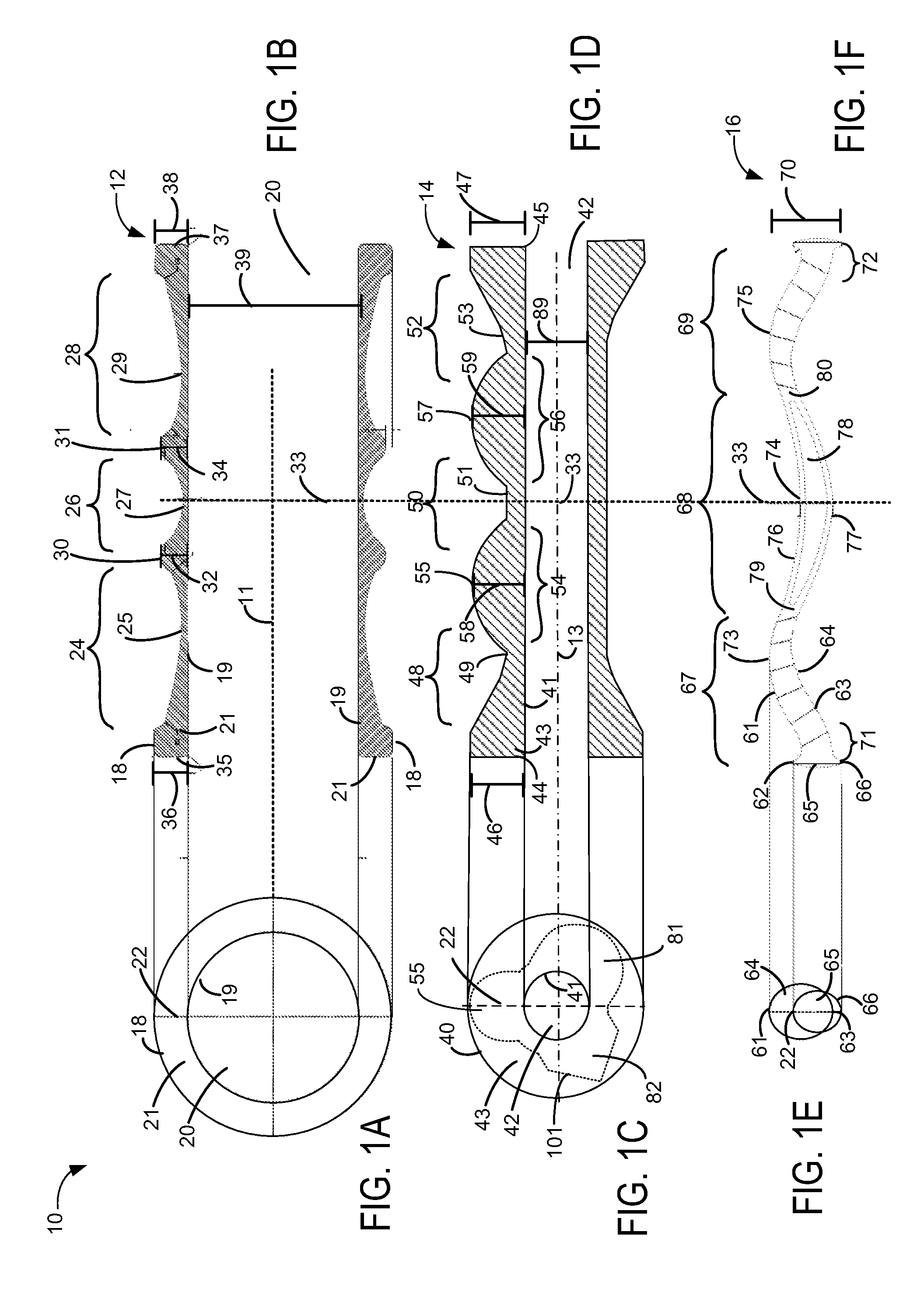

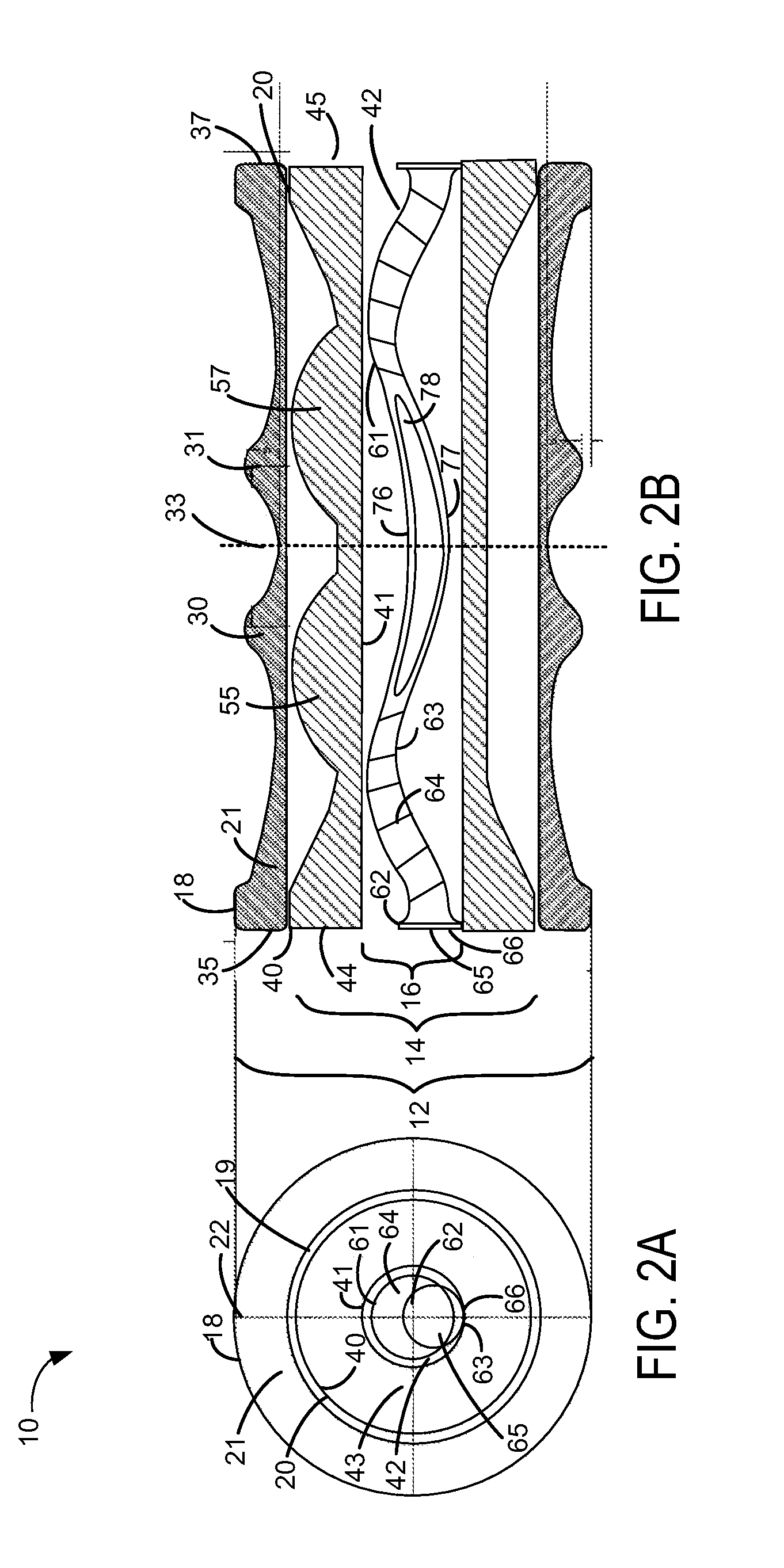

Arrangement for telescopic fork leg with parallel damping

ActiveUS7766138B2Compact unitSimple adaptationWheel based transmissionFrictional rollers based transmissionTerrainEngineering

A device for telescopic fork legs, preferably for a motorcycle or bicycle. The device is a compact removable unit that comprises parallel medium flow passages that run between upper and lower sides of the piston. This unit that is simple to adapt to different front fork dimensions and to use as a kit for providing an existing front fork with parallel damping. Parallel damping achieves simple adaptation of the damping characteristics to different types of terrain.

Owner:OHLINS

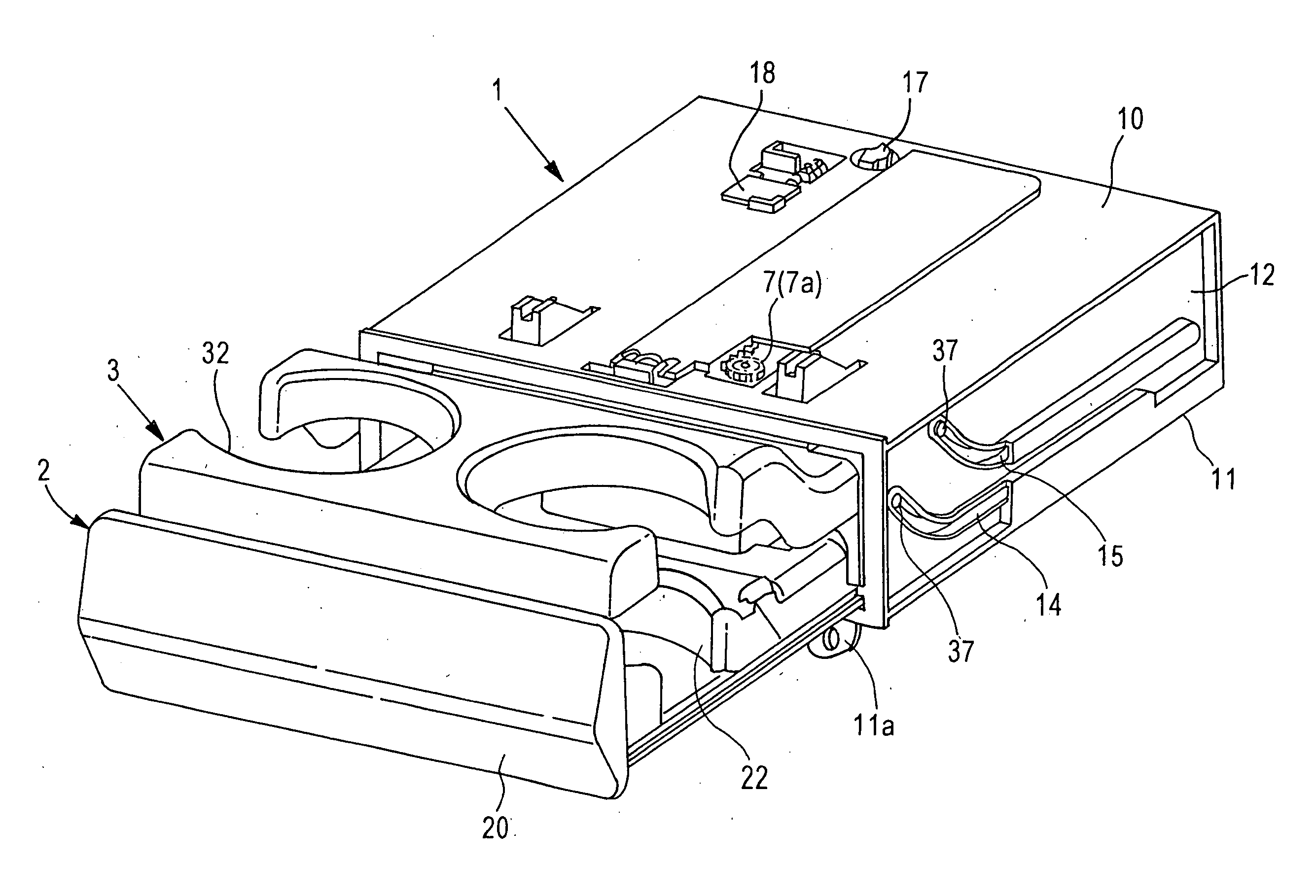

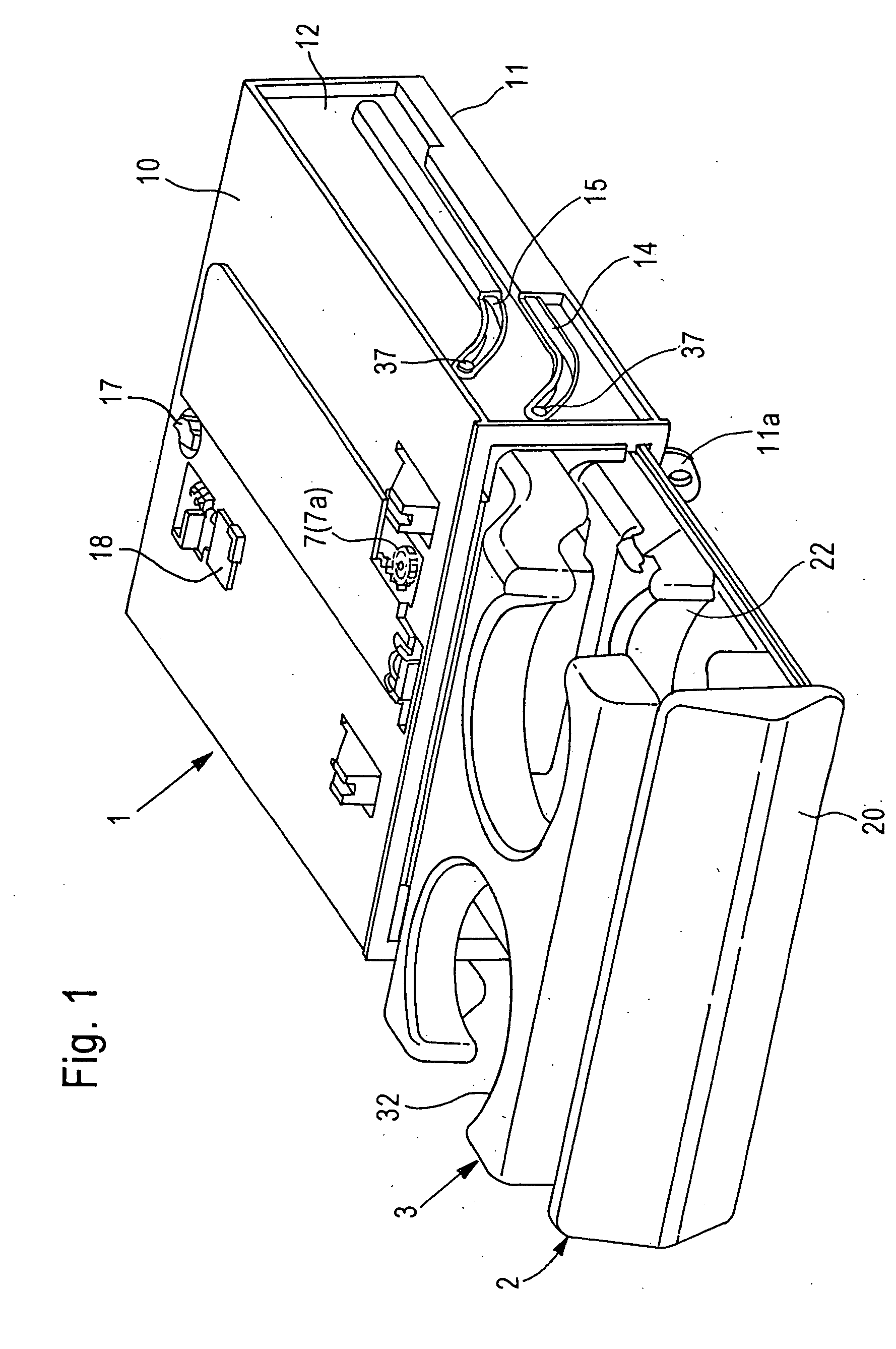

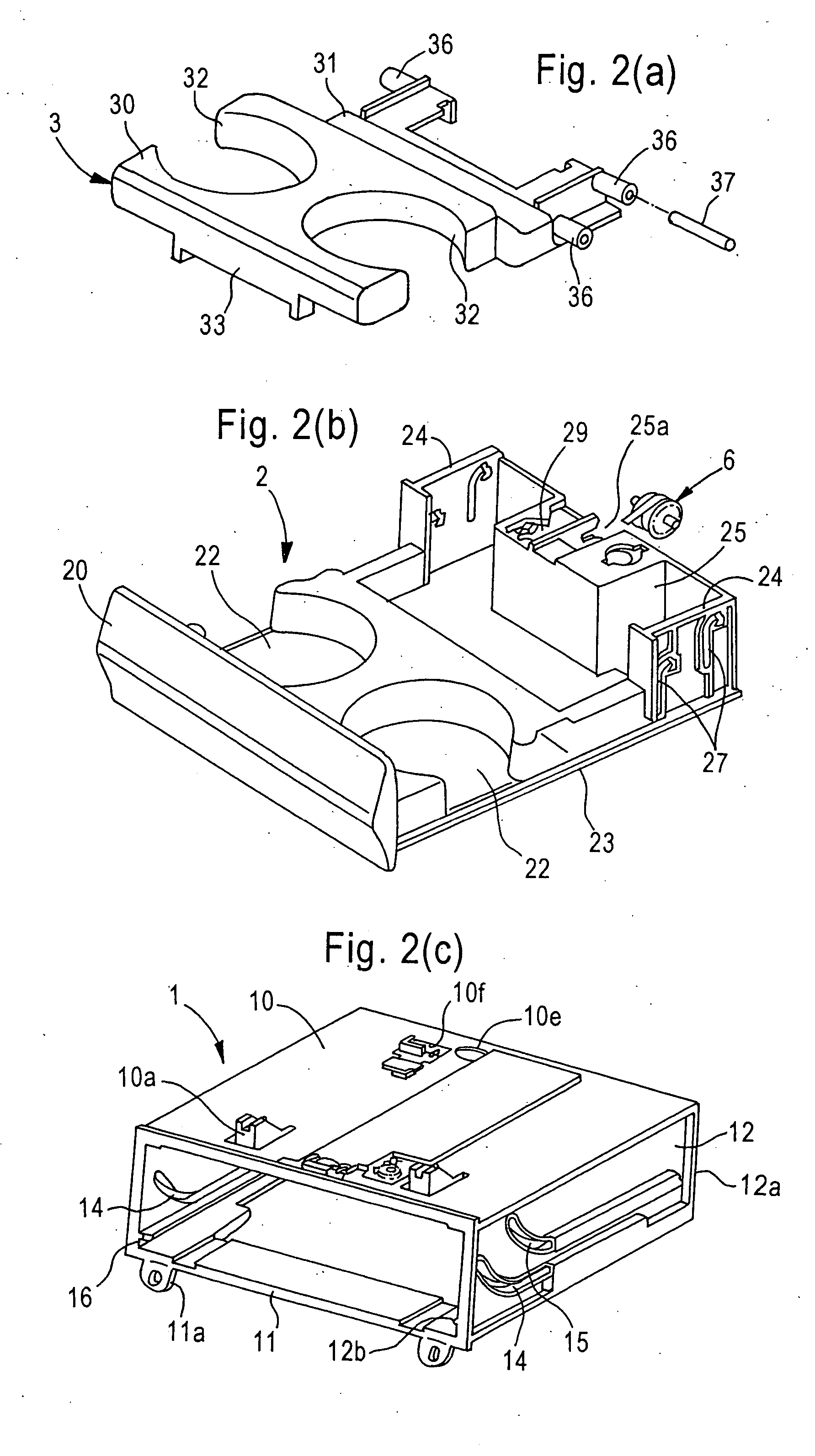

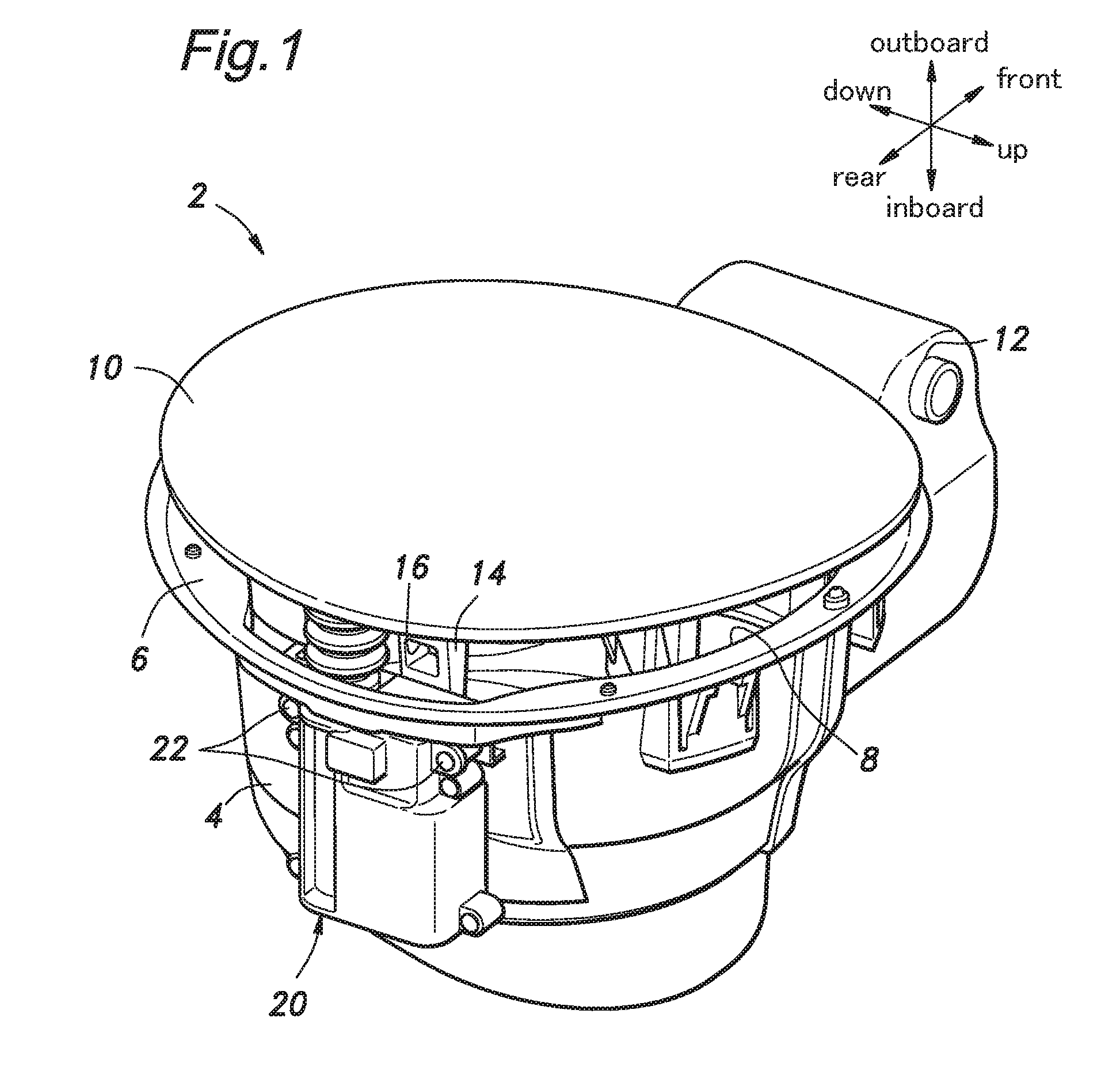

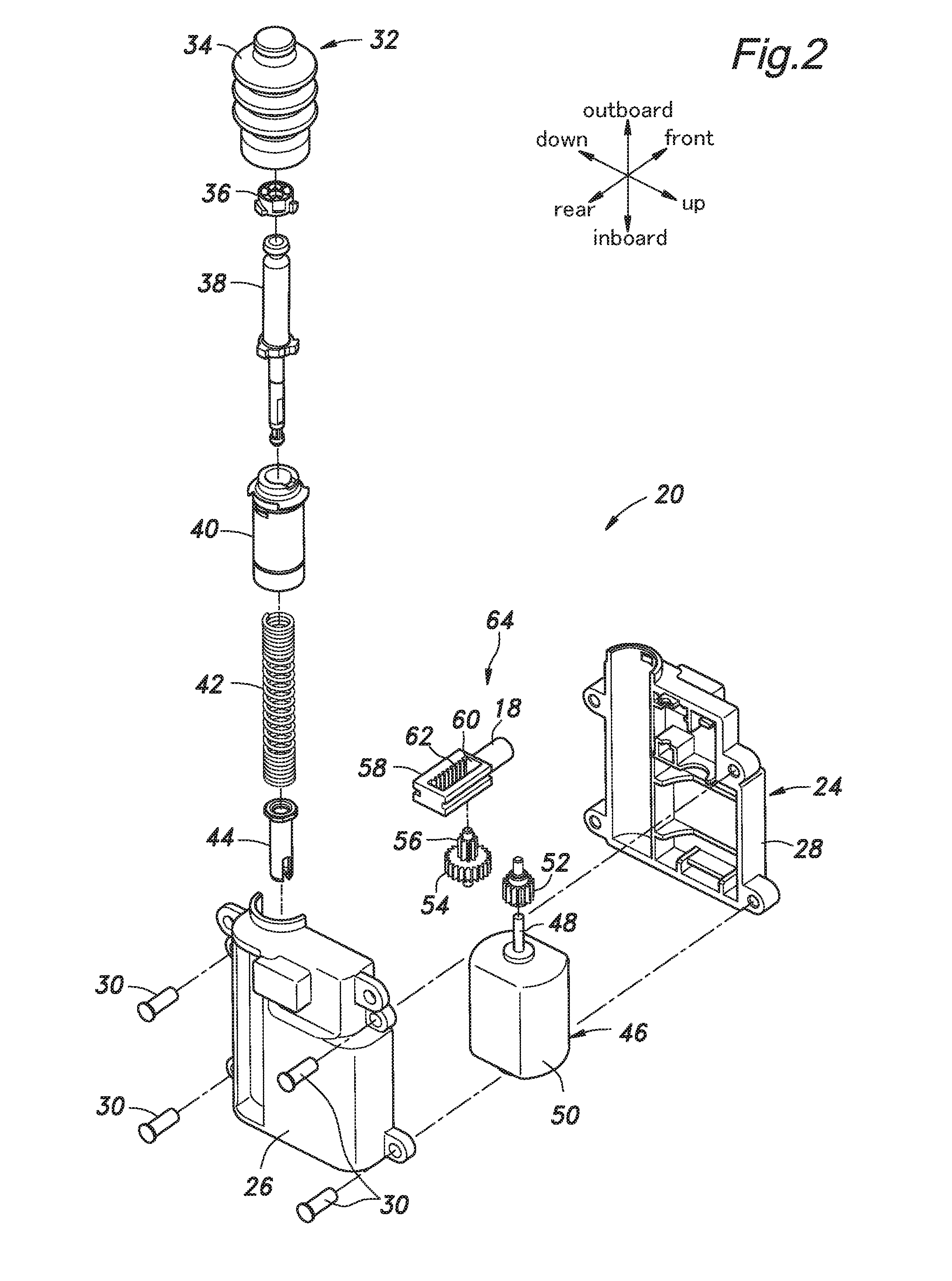

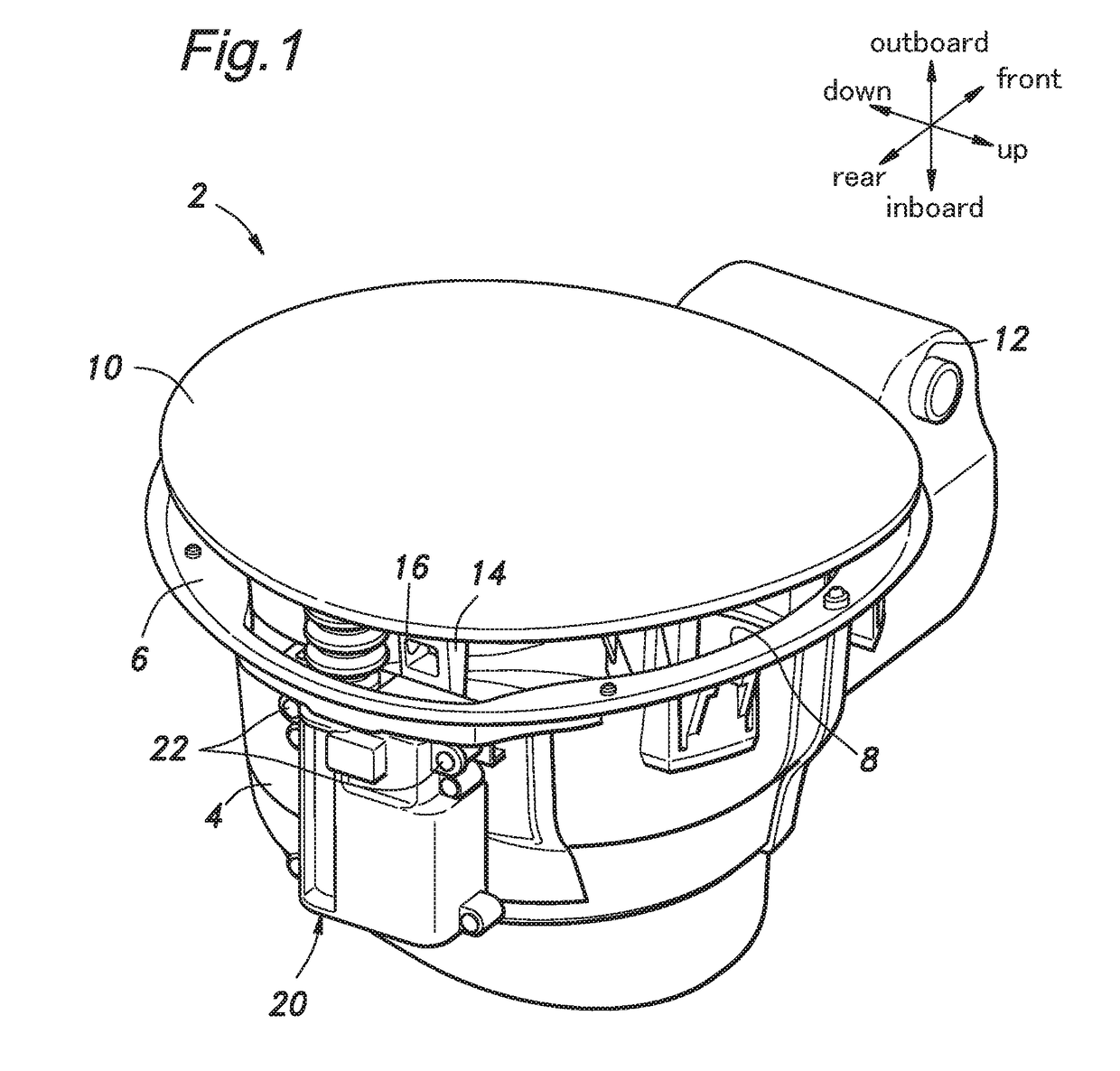

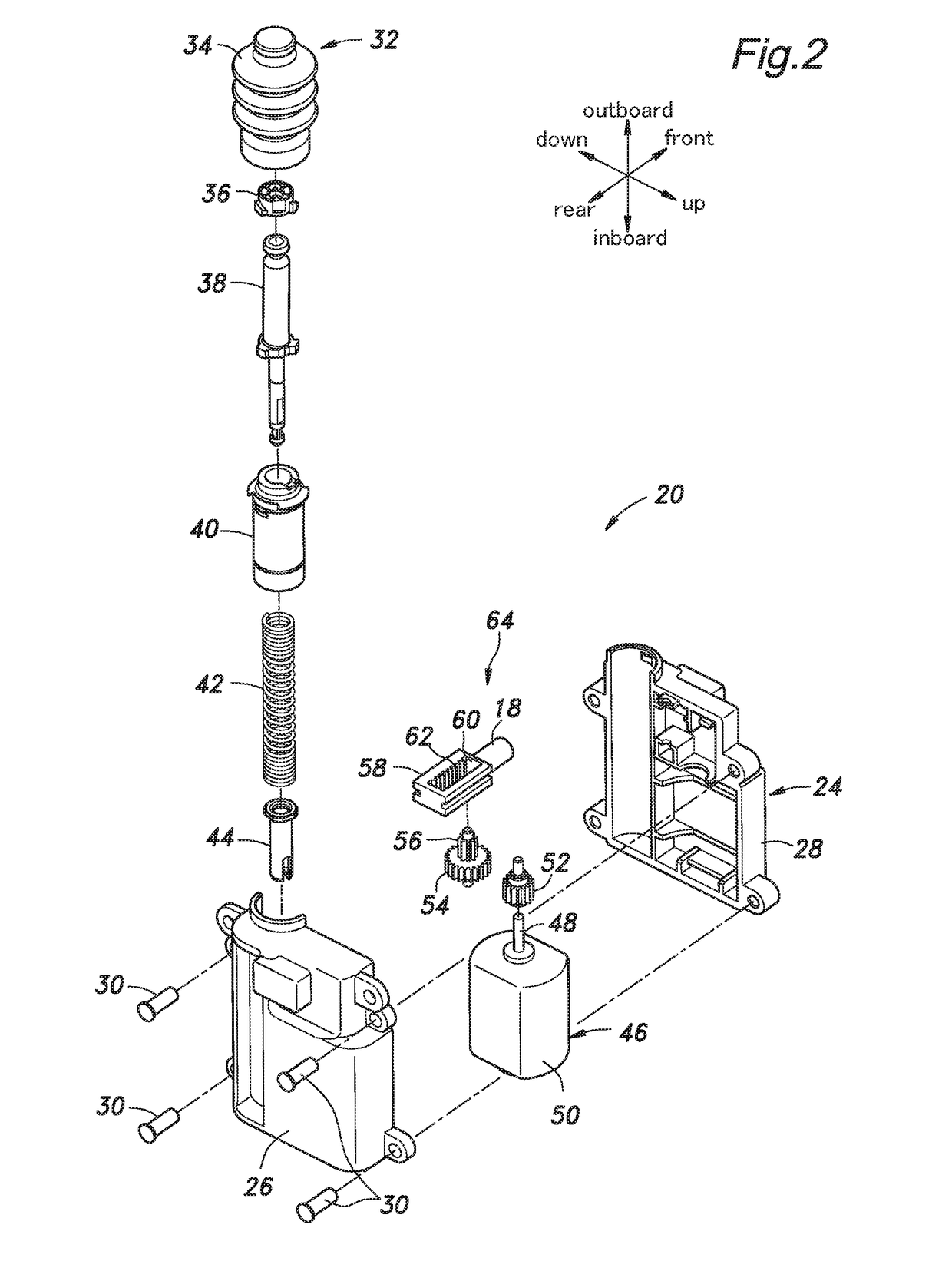

Cup holder unit

InactiveUS20060027617A1Improve design flexibilityReduce appearanceVehicle arrangementsTravelling carriersEngineeringMechanical engineering

A cup holder unit includes a housing case; a rest tray that switches between a pulled out position where it is moved forward from the case and a stored position where it is pushed in the case; and a holder member switchable from a non-usable position where it is superposed above the tray and stored in the case to a usable position where it is raised by a forward movement of the tray. The cup holder unit has shafts projecting from the holder member to be spaced apart from each other; clearance slots disposed in upright walls of the tray; and guide grooves disposed in the case and slanted upwardly toward front to slidably receive the shafts therein via the clearance slots. Each clearance slot includes a vertical slot and an arc-shaped slot turning toward a rear side from an upper section of the vertical slot.

Owner:NIFCO INC +2

Arrangement for telescopic fork leg with parallel damping

ActiveUS20090145706A1Compact unitSimple adaptationWheel based transmissionFrictional rollers based transmissionTerrainEngineering

A device for telescopic fork legs, preferably for a motorcycle or bicycle. The device is a compact removable unit that comprises parallel medium flow passages that run between upper and lower sides of the piston. This unit that is simple to adapt to different front fork dimensions and to use as a kit for providing an existing front fork with parallel damping. Parallel damping achieves simple adaptation of the damping characteristics to different types of terrain.

Owner:OHLINS

Lid device

ActiveUS20160375762A1Effective installationReduced dimensionMechanical controlsSuperstructure subunitsElectrical and Electronics engineering

Owner:NIFCO INC

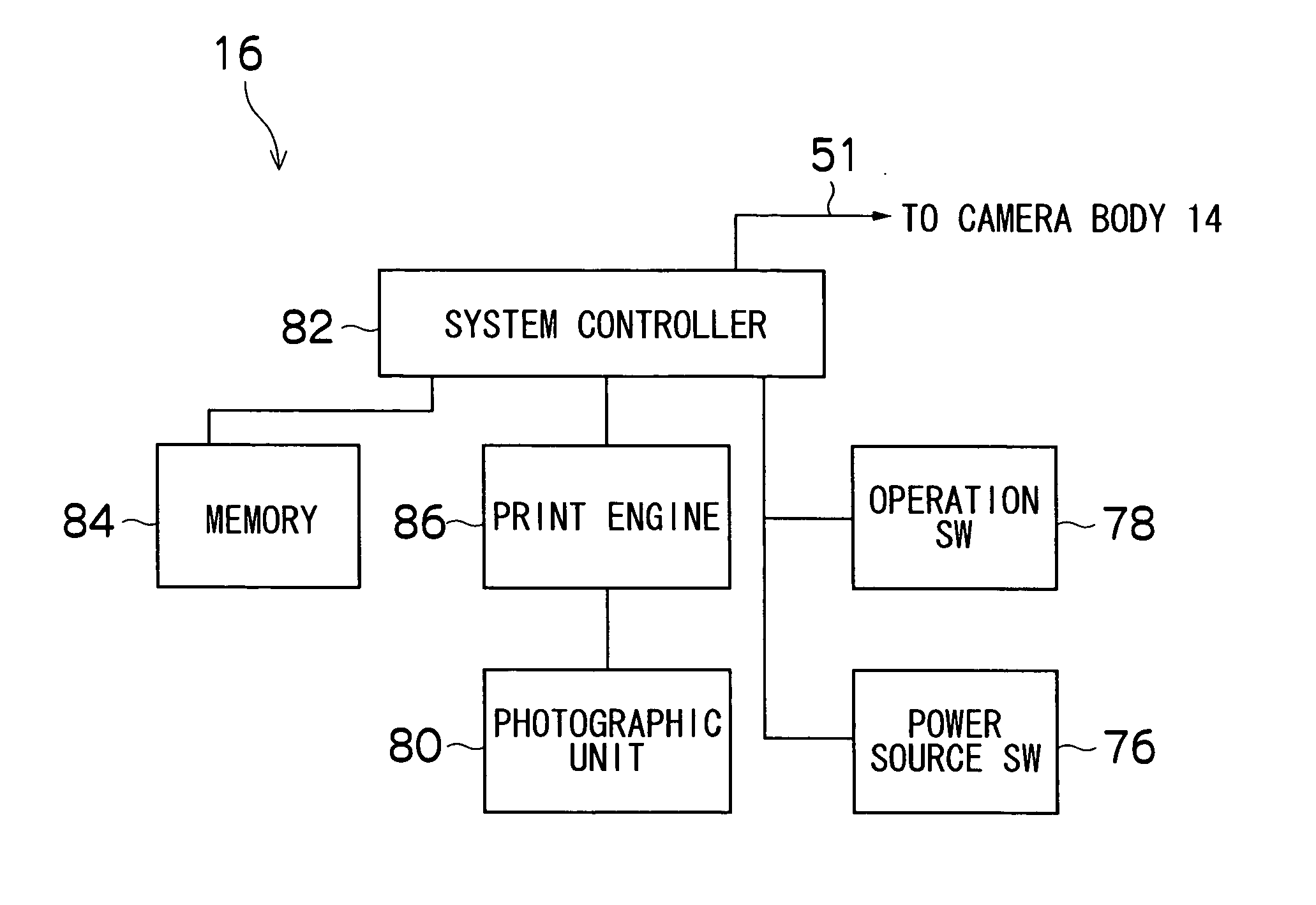

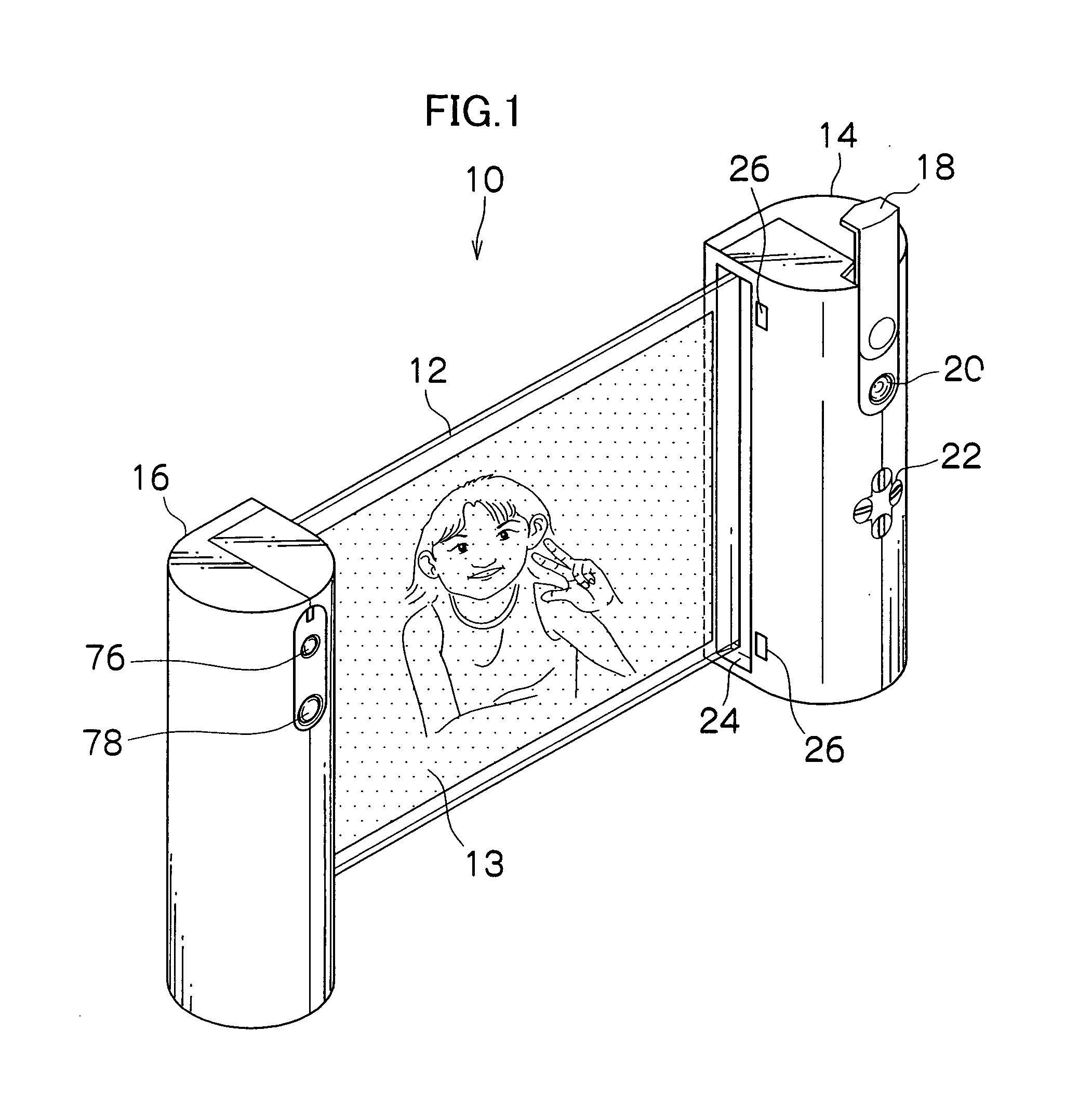

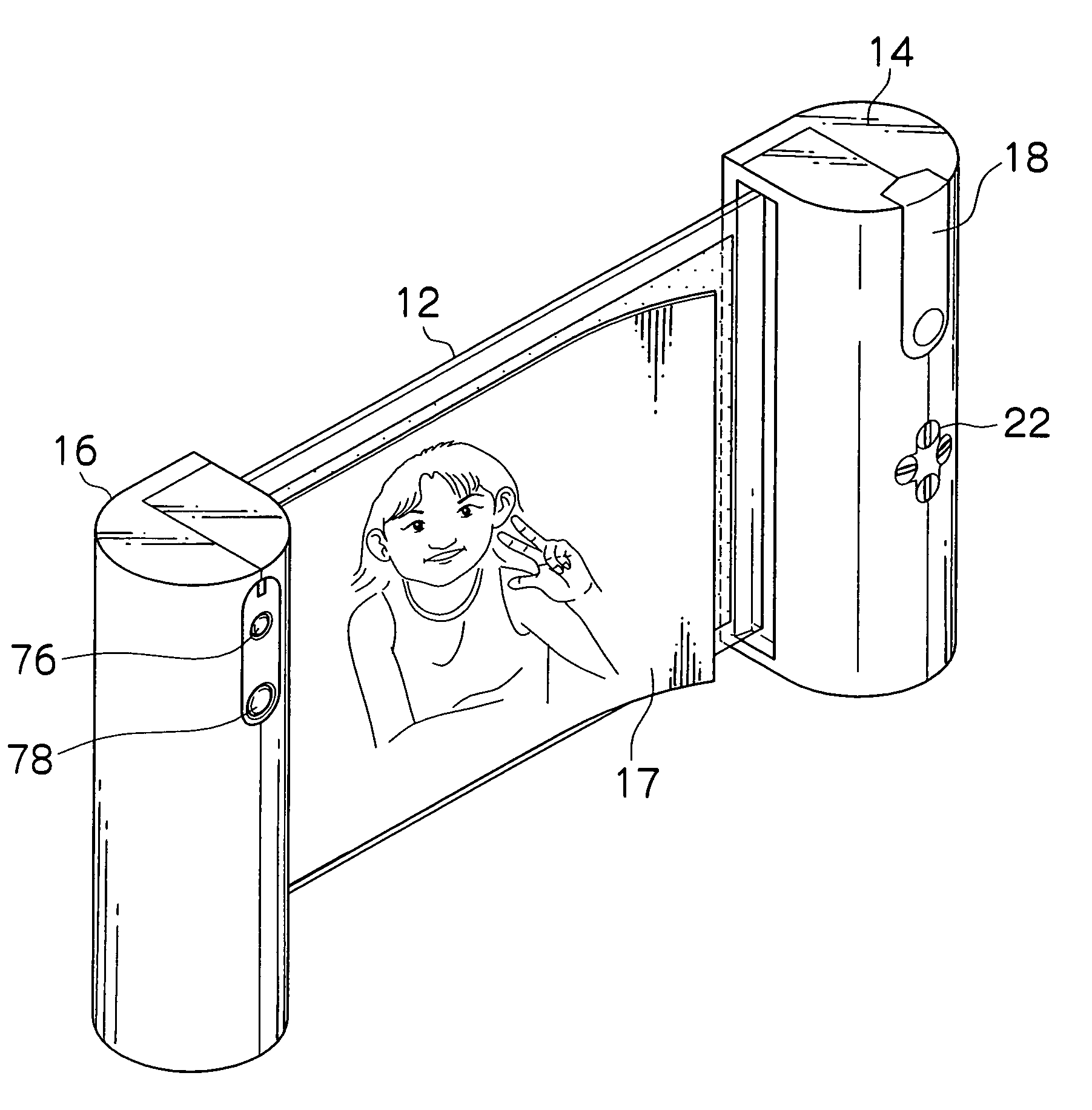

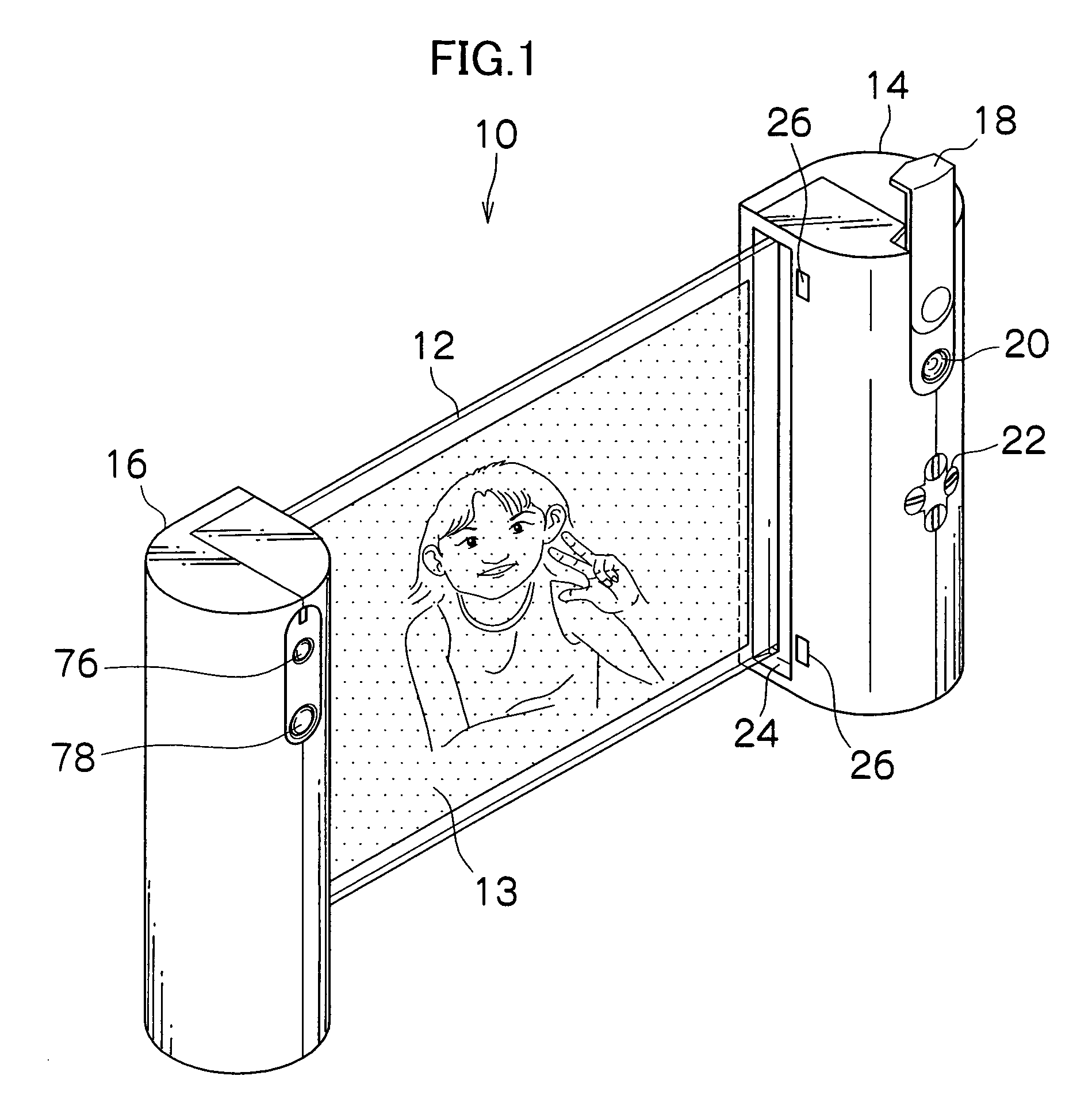

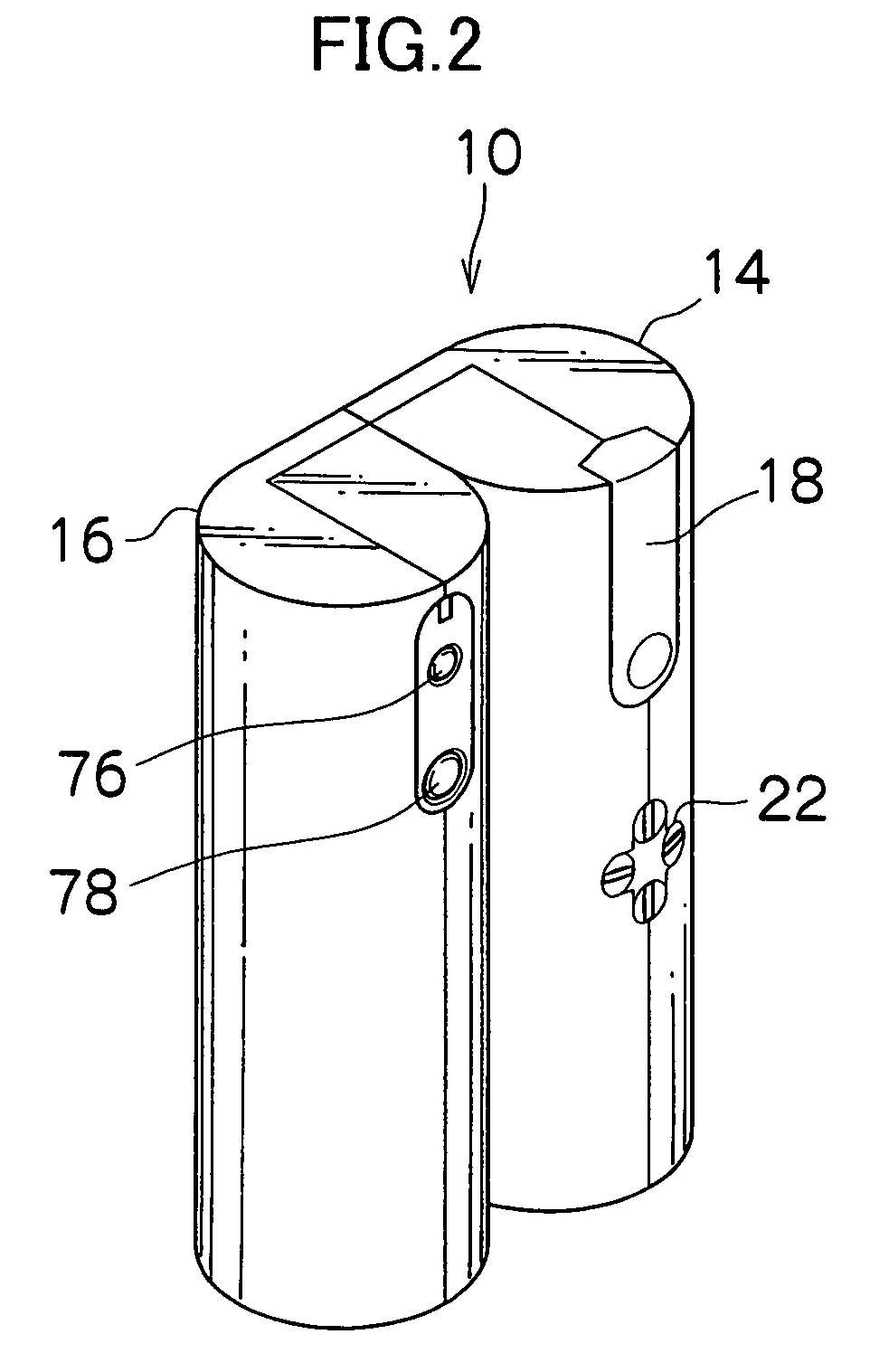

Digital camera

InactiveUS20060039031A1Compact unitEasy to storeTelevision system detailsDigital computer detailsComputer graphics (images)Display device

The present invention provides a digital camera comprising a planar image display device, a camera body coupled to an end of the image display device, and a printer device coupled to another end of the image display device. In the digital camera, the camera body and / or the printer device can store the image display device, and the camera body and the printer device can be coupled to each other through a coupling device when the image display device is stored.

Owner:FUJIFILM CORP

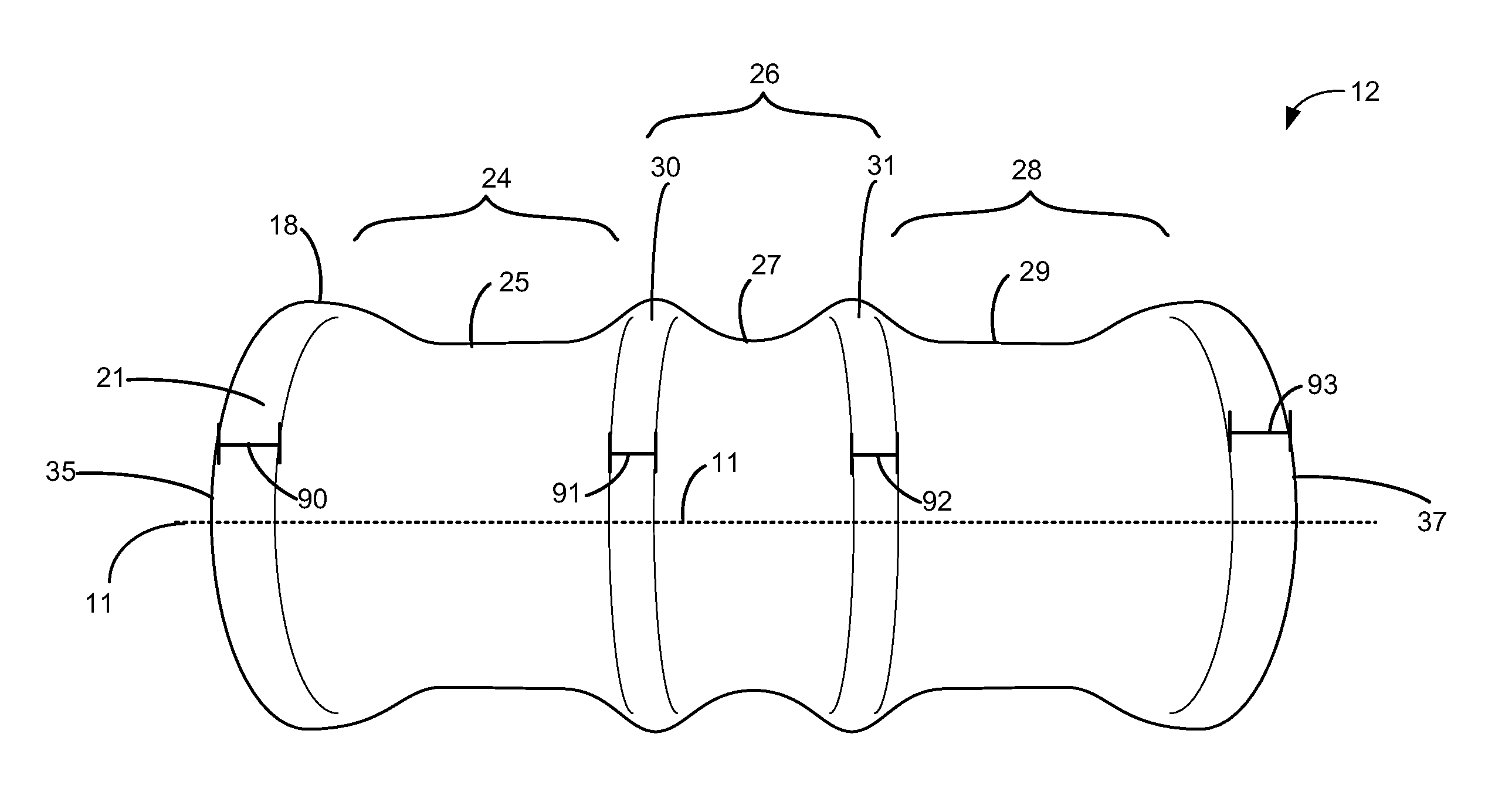

Massage system

InactiveUS20150133835A1Free from painExtended range of motionRoller massageSuction-kneading massageMedicineMassage

A system is provided for a three-part self-massage system including three massage devices configured to be removably coupled and assembled inside one another. Additionally, the three massage devices may include zones of varying densities of foam and shaped to include contours and projections including nodules, knobs, bumps, grooves, and / or ridges, such that the massage devices may be used for varying massage techniques. In this way, the three massage devices may be combined into one compact unit for easier storage and transport.

Owner:PHLEX THERAPEUTICS

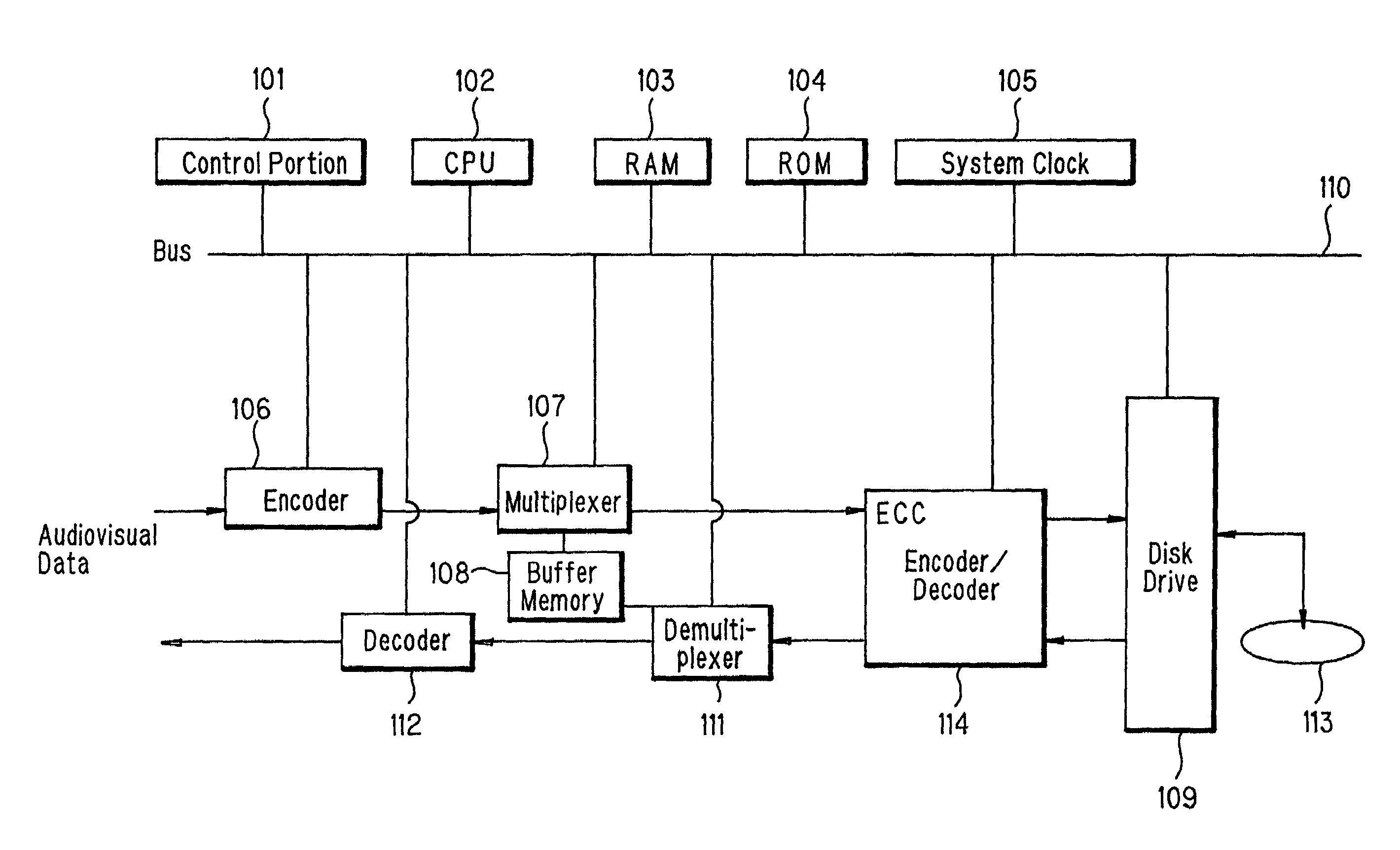

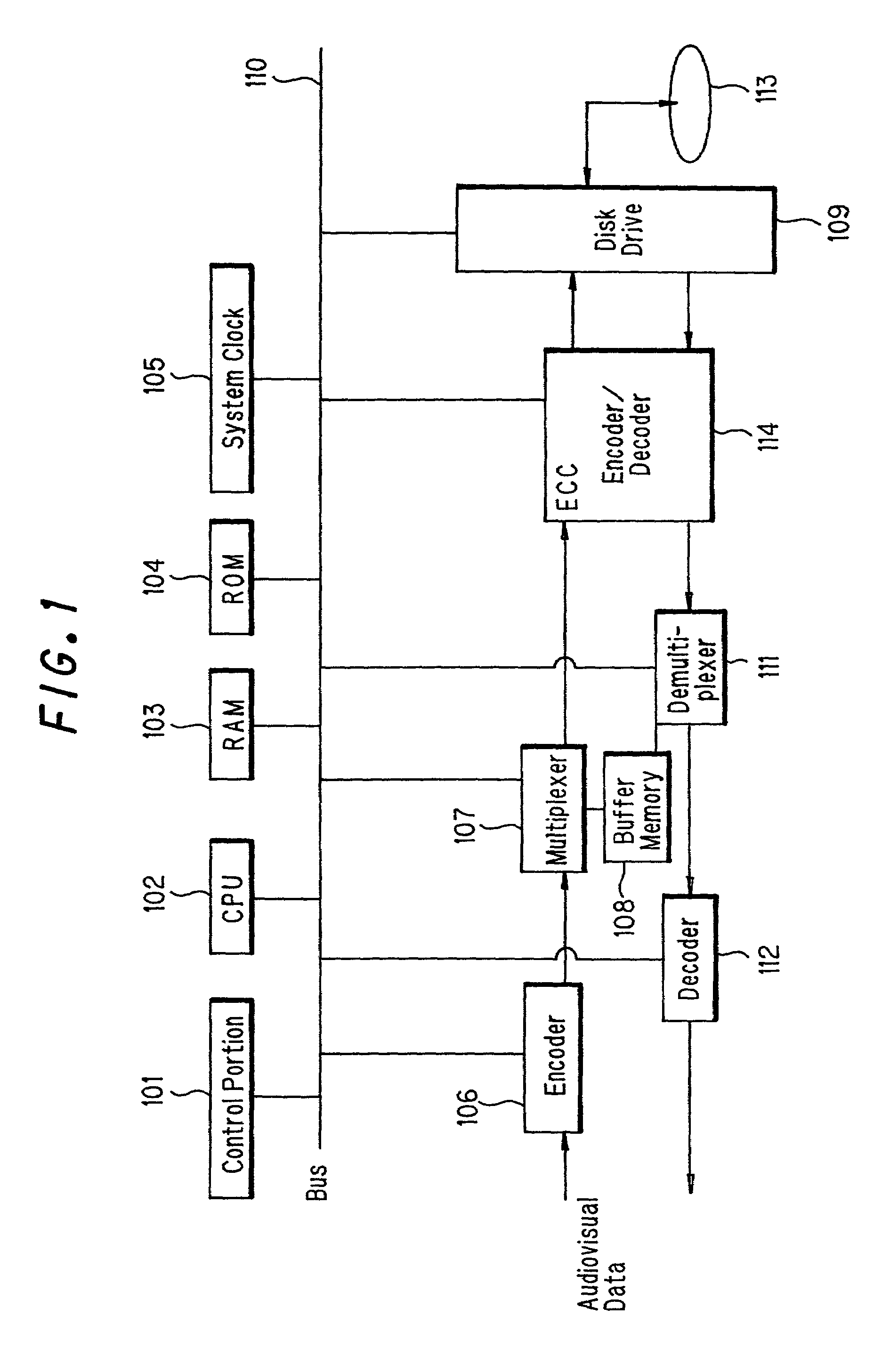

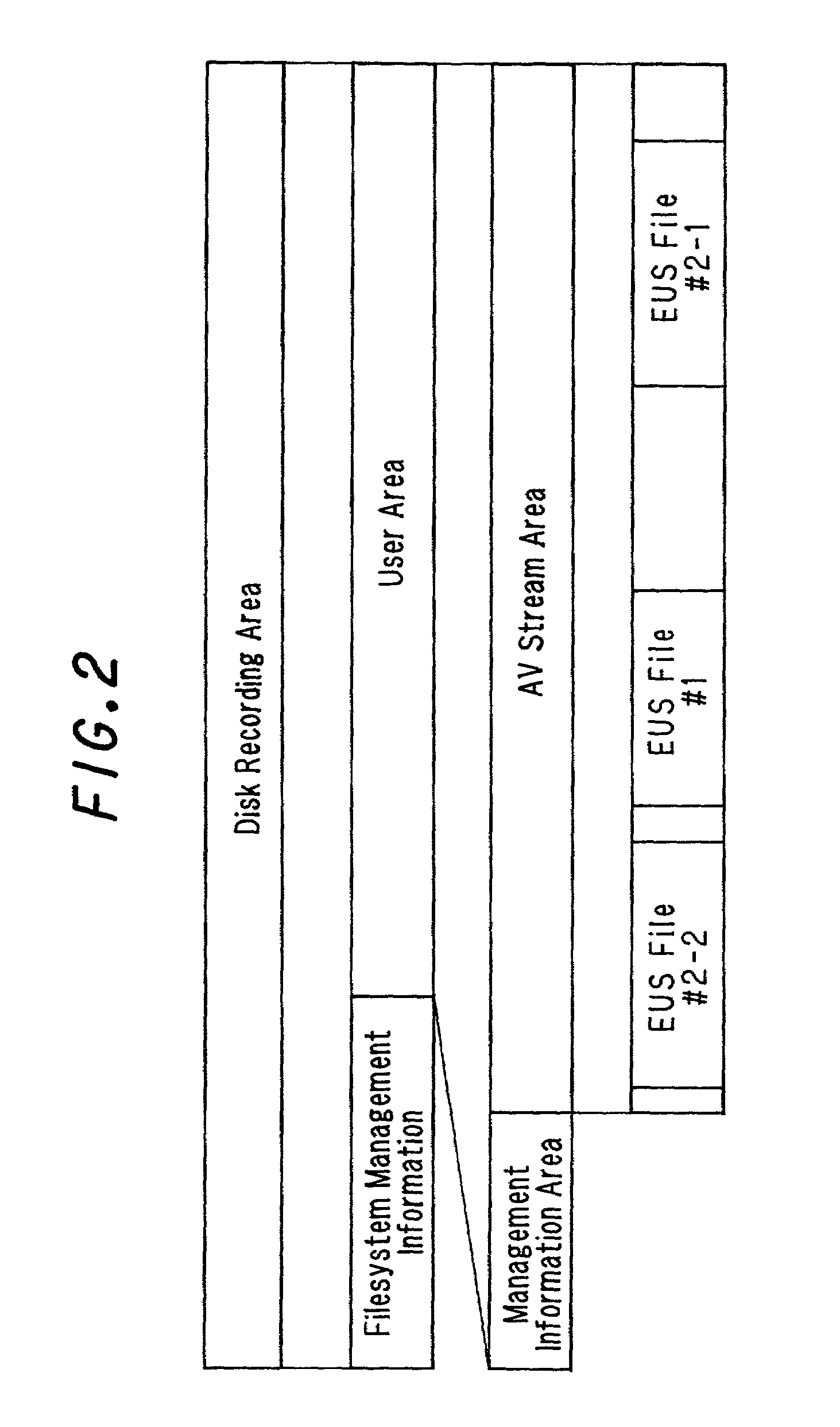

Recording method, recording medium and recorder

InactiveUS7457530B1Reduce capacityEasy to controlTelevision system detailsData buffering arrangementsOriginal dataData needs

When audio dubbing is implemented, error correction is performed for each ECC block. Therefore, even when one byte of data in an ECC block is rewritten, the whole ECC block to which the byte belongs needs to be read and rewritten. When audio dubbing data is scattered in ECC blocks, almost all ECC blocks, or all the data needs be rewritten in order to record audio dubbing data. By constructing ECC blocks including audio dubbing data so as not to contain original data, it is no longer necessary to read and rewrite unnecessary original data when audio dubbing data is overwritten.

Owner:SHARP KK

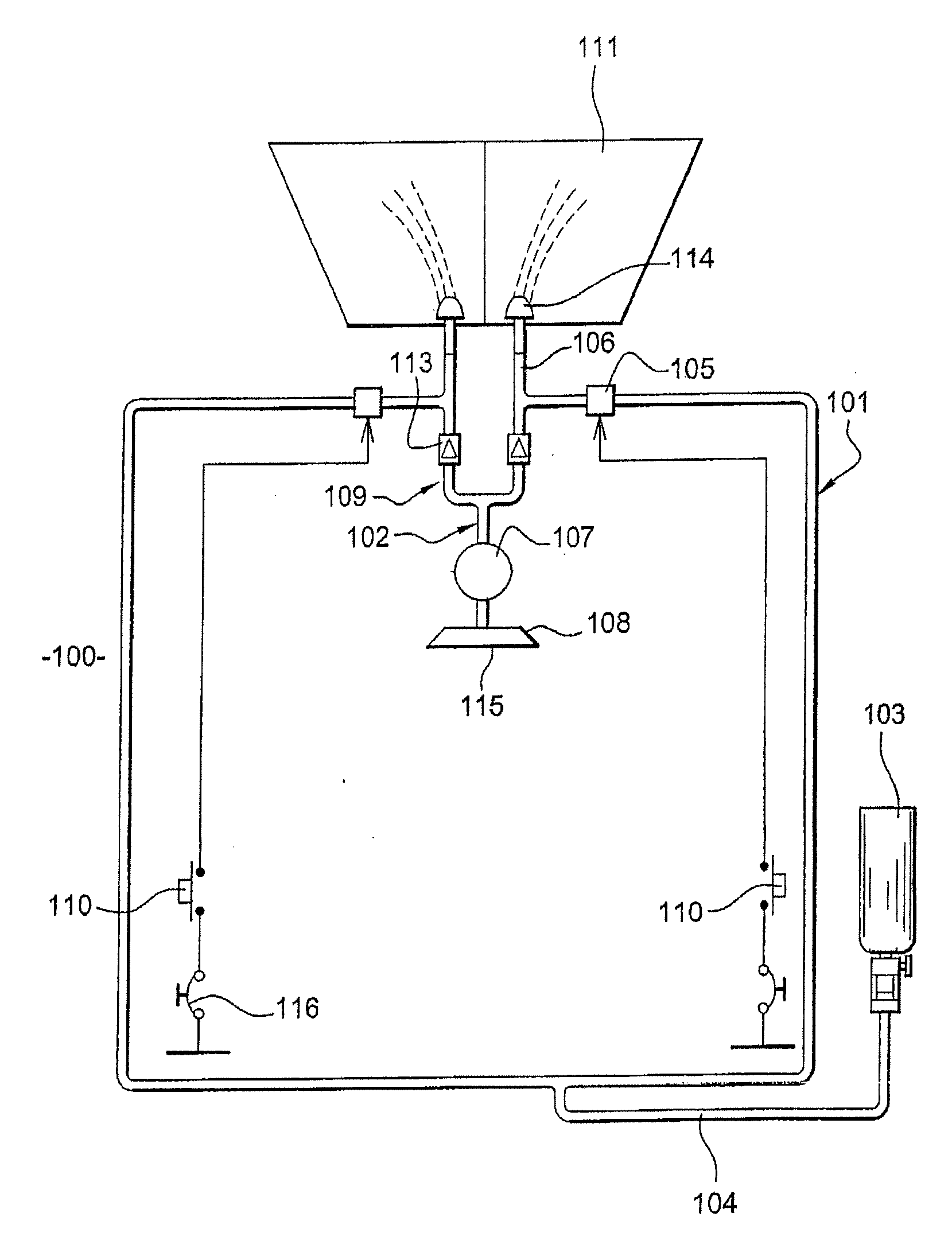

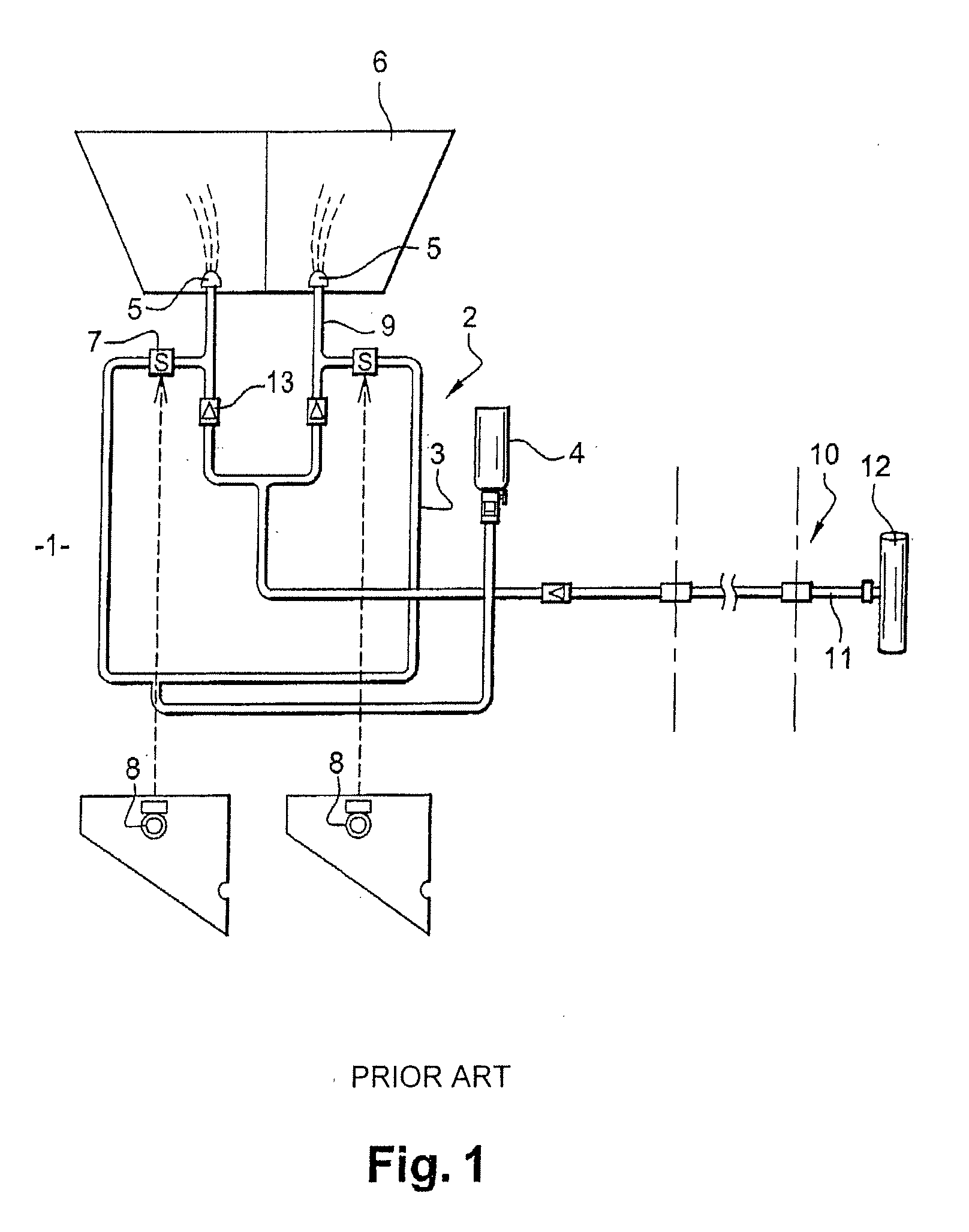

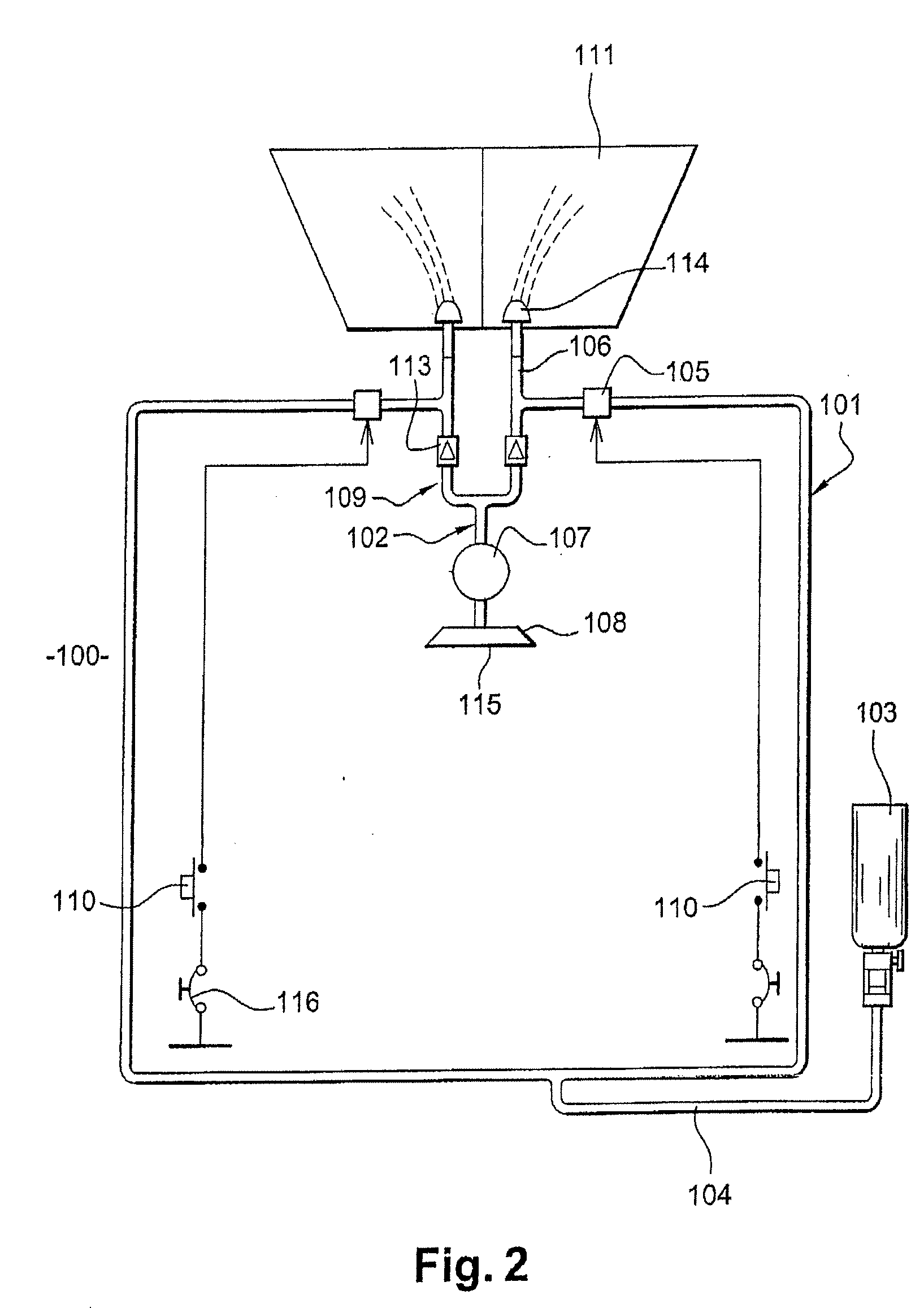

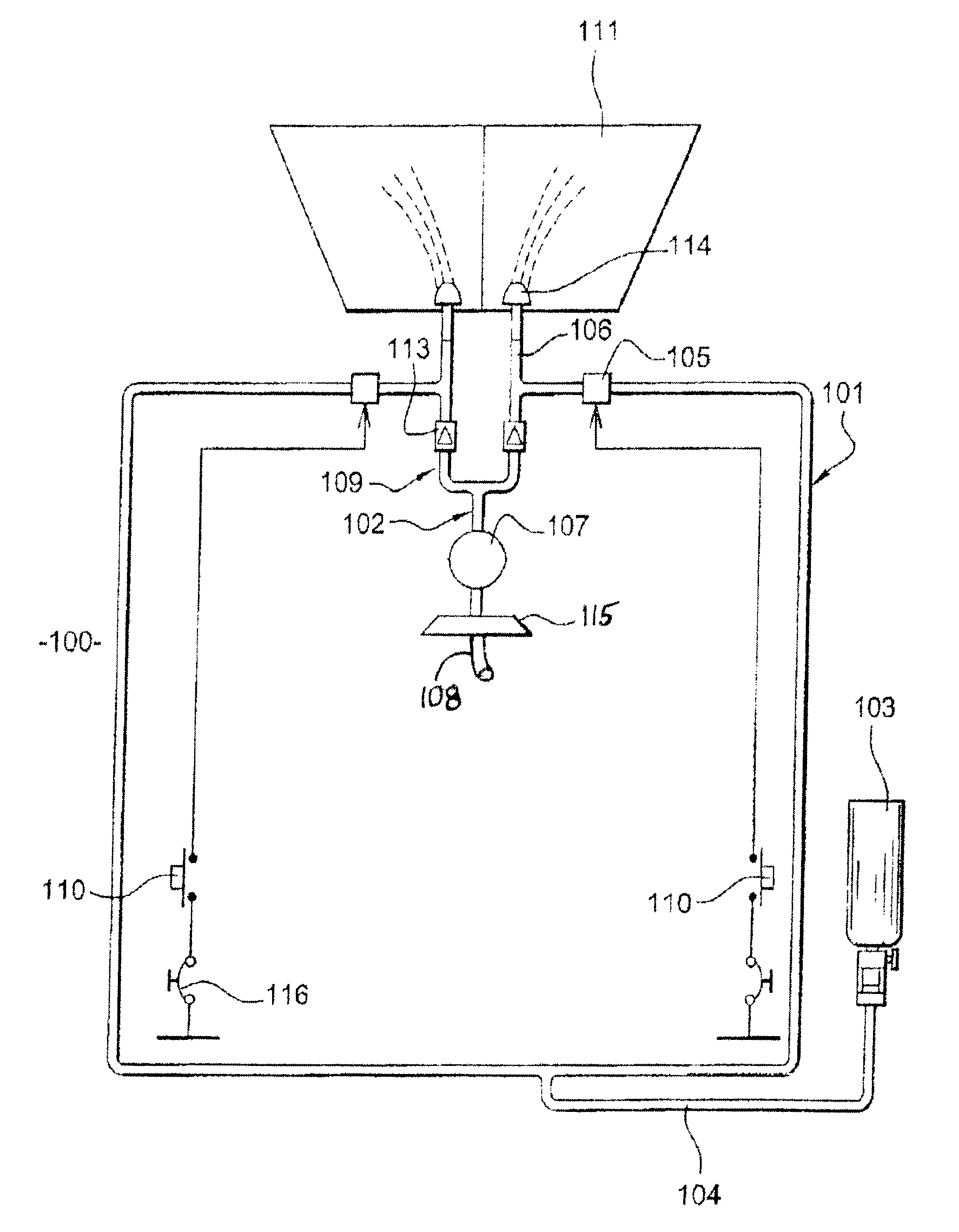

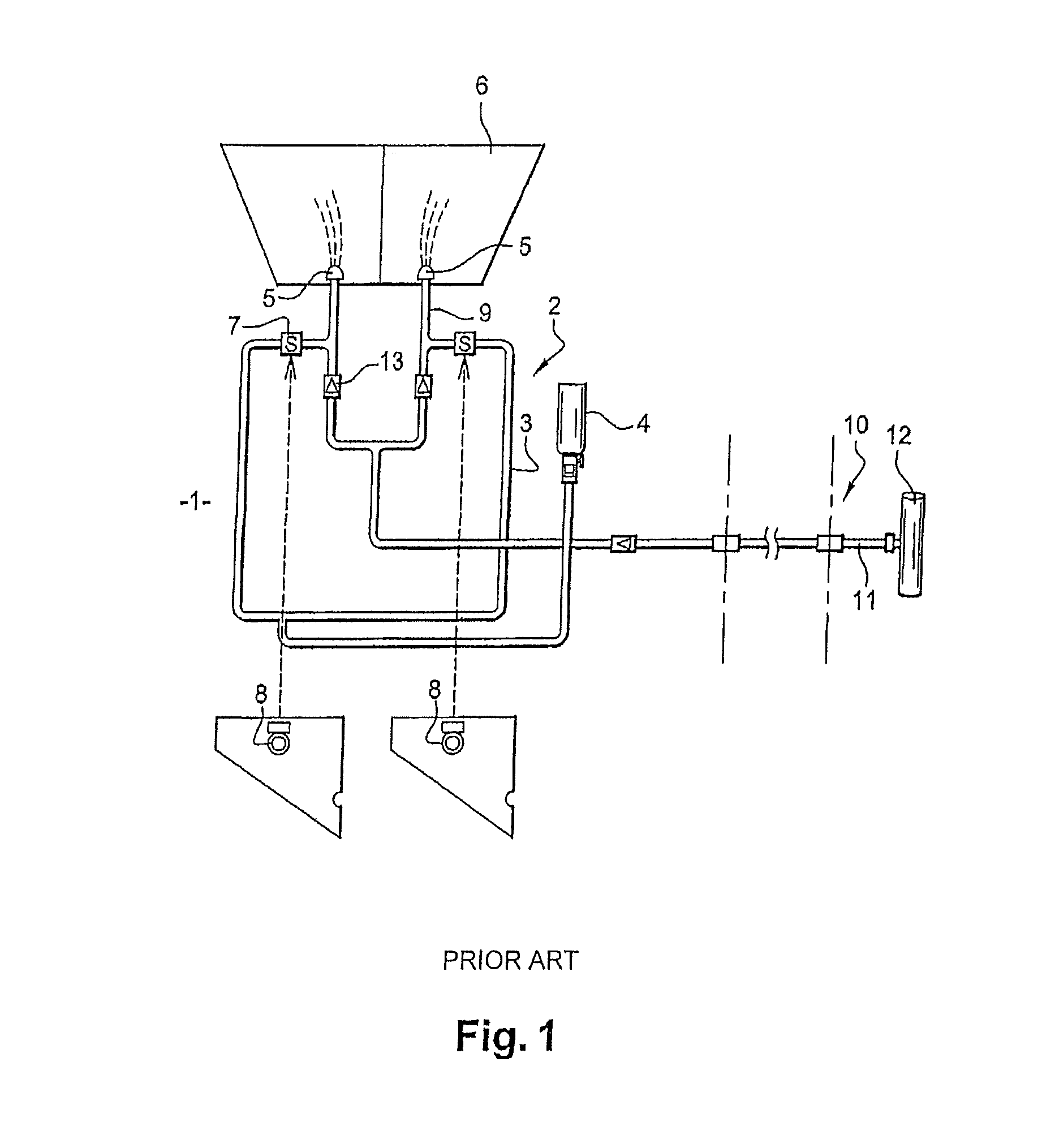

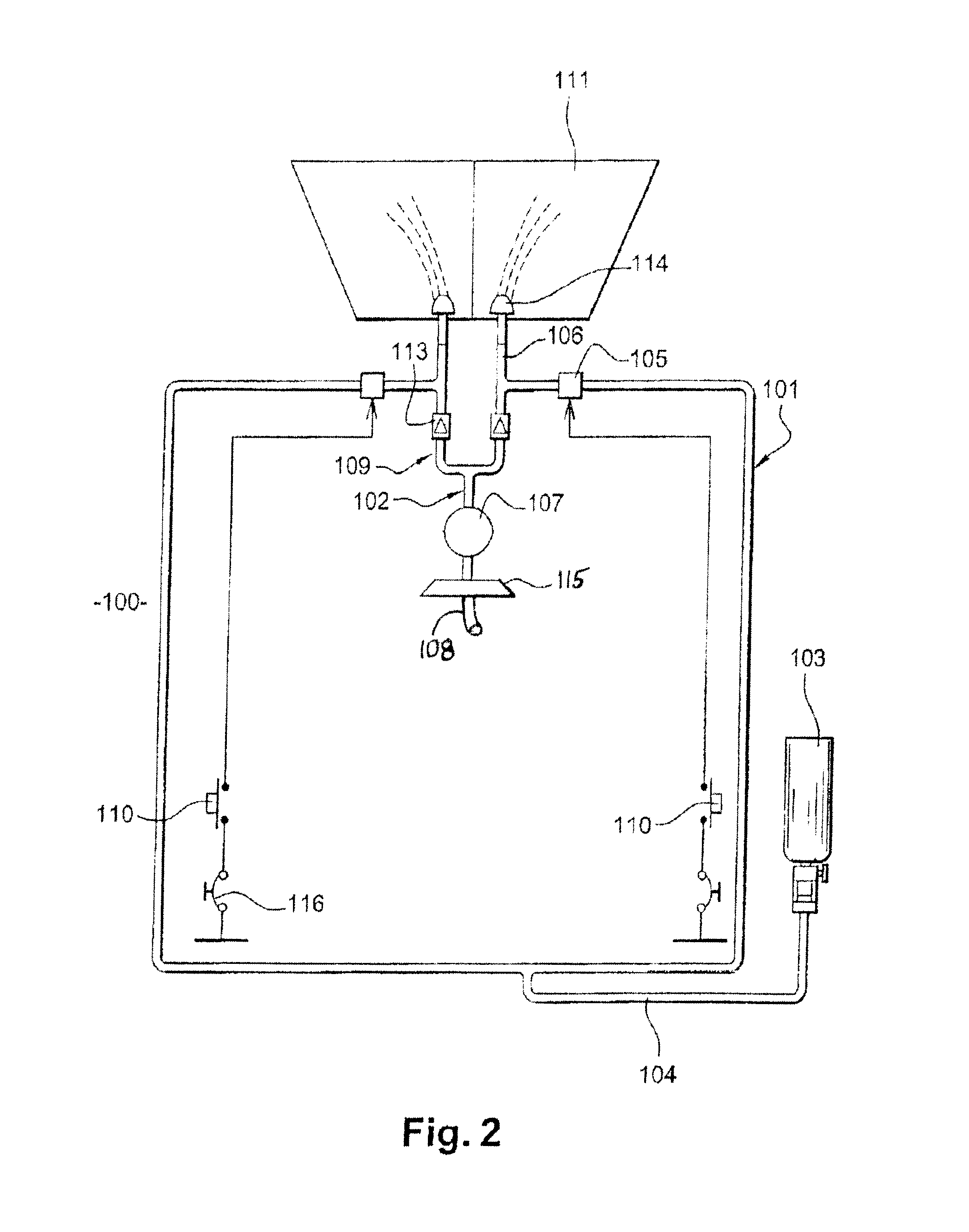

System for the spraying of spray liquid for aircraft windshield, and cockpit provided with such a spraying system

ActiveUS20080087741A1Reduce general space requirementShorten the lengthDe-icing equipmentsSpray nozzlesFlight vehicleEngineering

A system for spraying liquid (100) for a windshield (111) of an aircraft including a spray-liquid supply circuit (101), a pressurized-gas supply circuit (102) designed to purge the spray-liquid supply circuit, and at least one nozzle (114) disposed downstream from the circuits and designed to spray the spray liquid and pressurized gas on a windshield, characterized in that the system includes an auxiliary means of compression (107) ready to compress gas designed to circulate in the pressurized-gas supply circuit, the auxiliary means of compression being positioned near the nozzle. Also, an aircraft cockpit provided with at least such a spray system.

Owner:AIRBUS OPERATIONS (SAS)

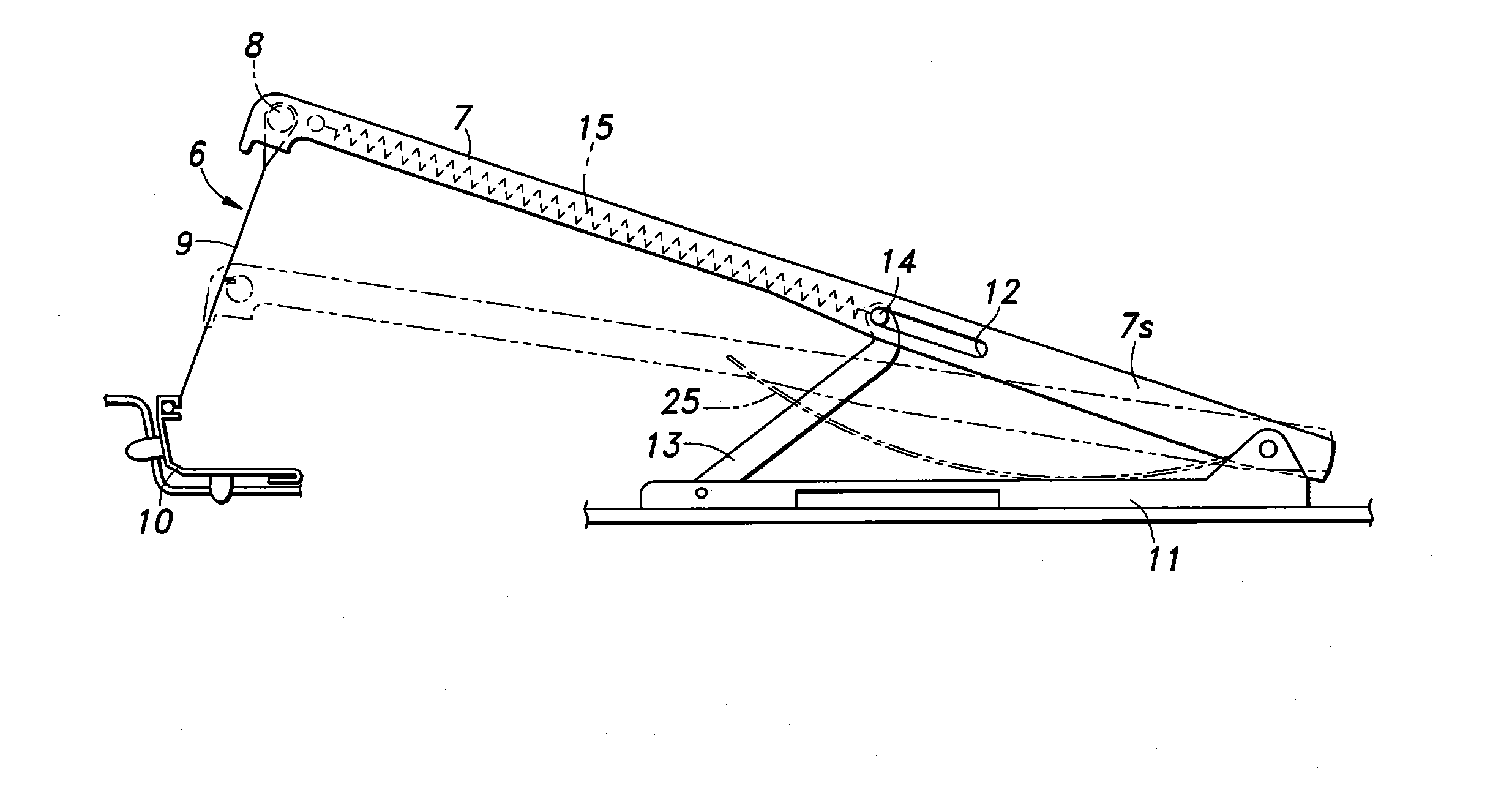

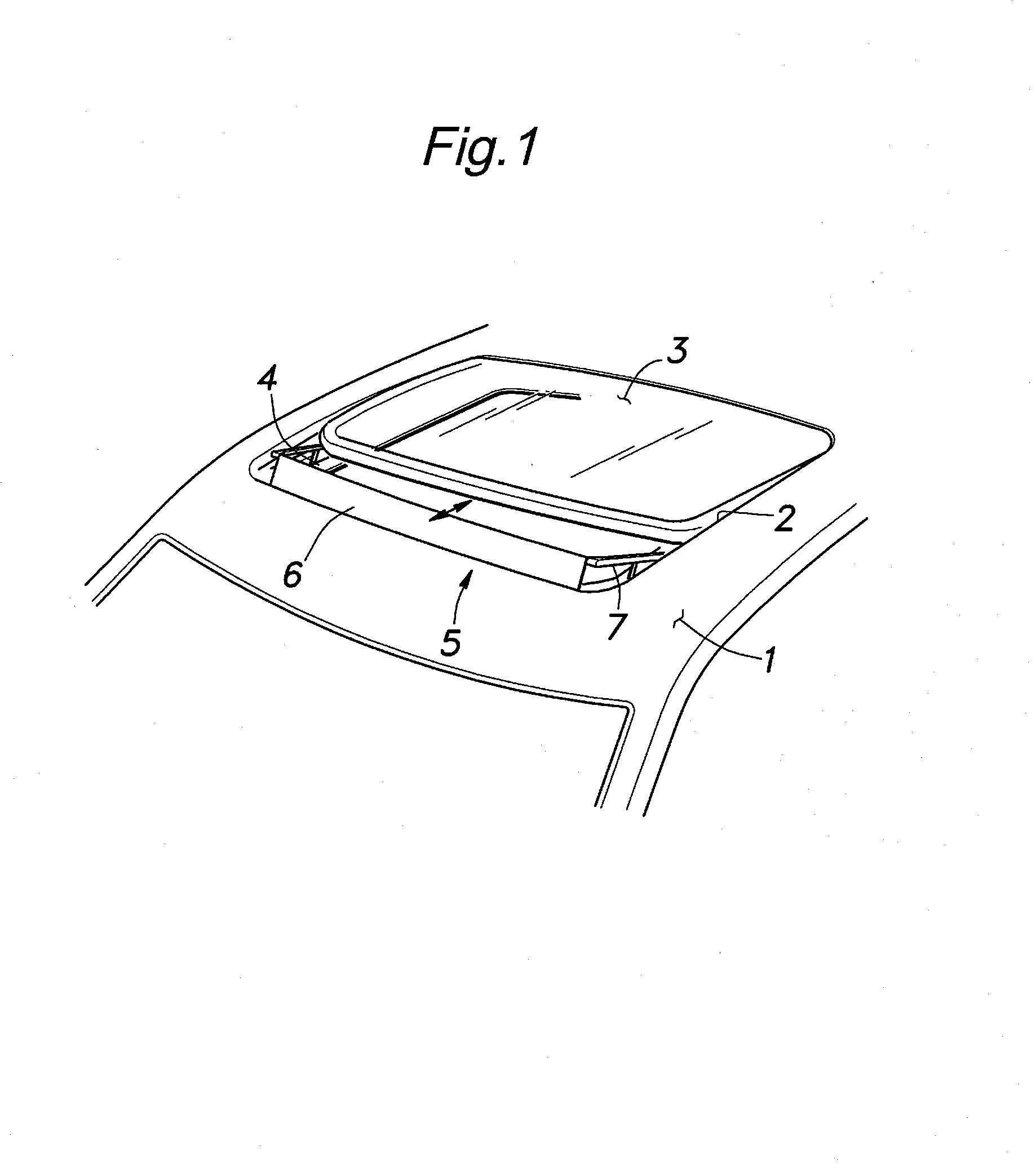

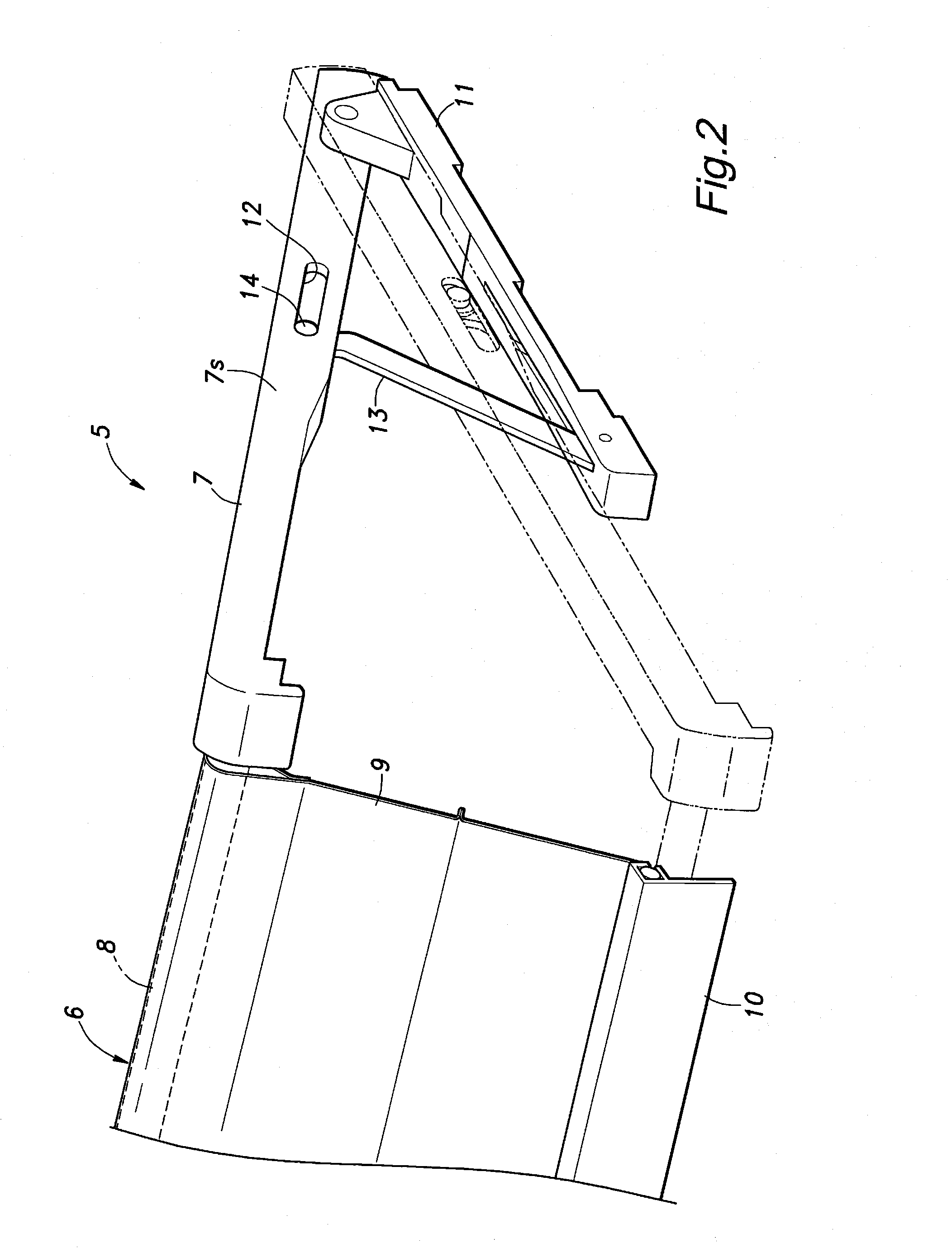

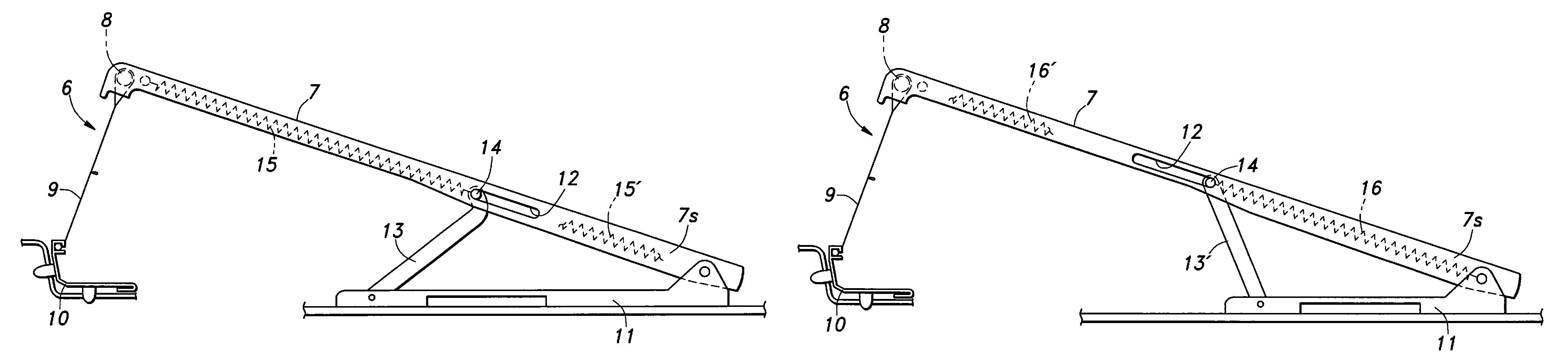

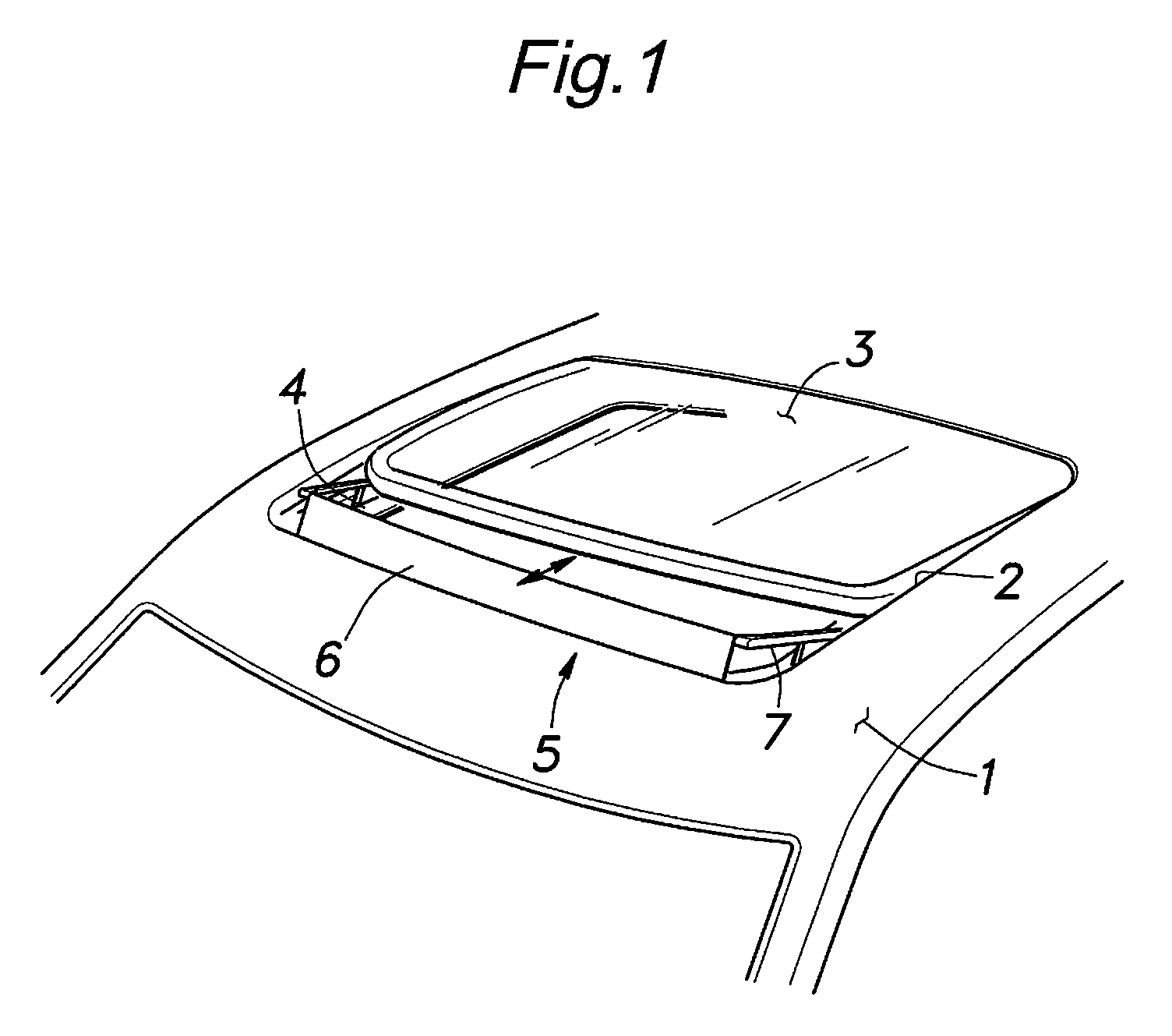

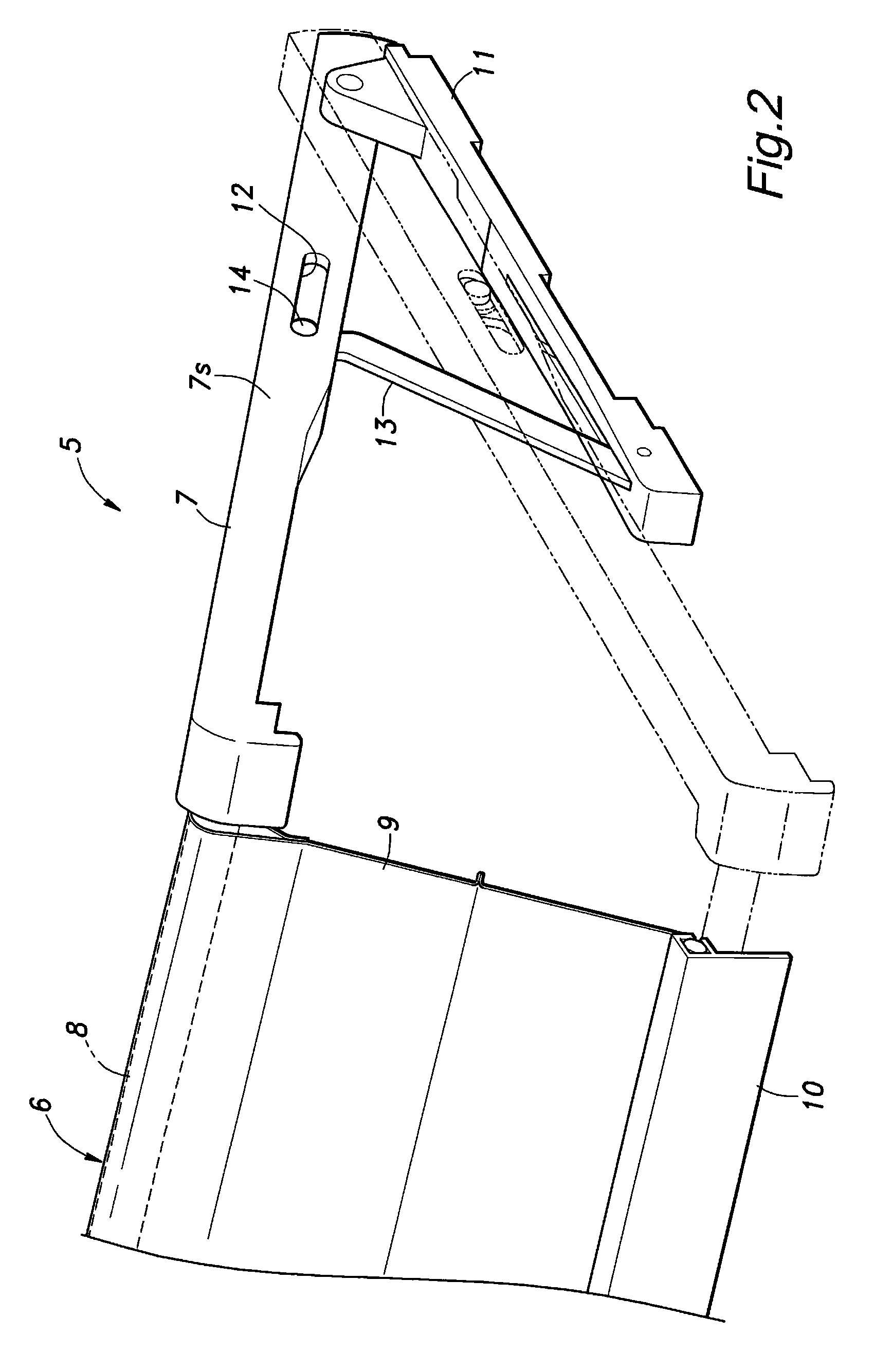

Deflector device for a sunroof device

ActiveUS20120086239A1Sufficient forceGood lookingEngine sealsSuperstructure subunitsEngineeringCoil spring

In a deflector device for a sunroof device, a pair of arm members (7) extend in a fore and aft direction, and are each pivotally supported by a fixed roof panel part at a rear end thereof, and a blade (6) extends laterally between front ends of the arm members. A link member (13, 13′) is pivotally connected to a fixed roof part at a base end thereof, and engaged by an intermediate part of each arm member at a free end thereof so that the free end may be moveable along a lengthwise direction, and a coil spring (15, 15′, 16, 16′) is connected between the free end of the link member and a part of the arm member so as to urge the arm member in an upward direction. Thereby, the blade can be supported in the deployed or raised position with an adequate spring force.

Owner:YACHIYO IND CO LTD

Digital camera

InactiveUS7679644B2Compact unitEasy to storeTelevision system detailsColor television detailsComputer graphics (images)Display device

The present invention provides a digital camera comprising a planar image display device, a camera body coupled to an end of the image display device, and a printer device coupled to another end of the image display device. In the digital camera, the camera body and / or the printer device can store the image display device, and the camera body and the printer device can be coupled to each other through a coupling device when the image display device is stored.

Owner:FUJIFILM CORP

Radar system and method for receiving and analyzing radar signals

ActiveUS20190353753A1Reduce data volumeIncrease transfer rateCode conversionNeural learning methodsRadar systemsField of view

A radar system suitable for an automated vehicle comprises at least one receiving element configured to detect reflected radar signals reflected by an object in a field-of-view of the system. The receiving element is further configured to generate detected signals indicative of the reflected radar signals detected by the receiving element. Furthermore, an auto-encoding device performing an auto-encoding operation on the detected signals is embedded in the receiving element such that the receiving element outputs the detected signals in an encoded form.

Owner:APTIV TECH LTD

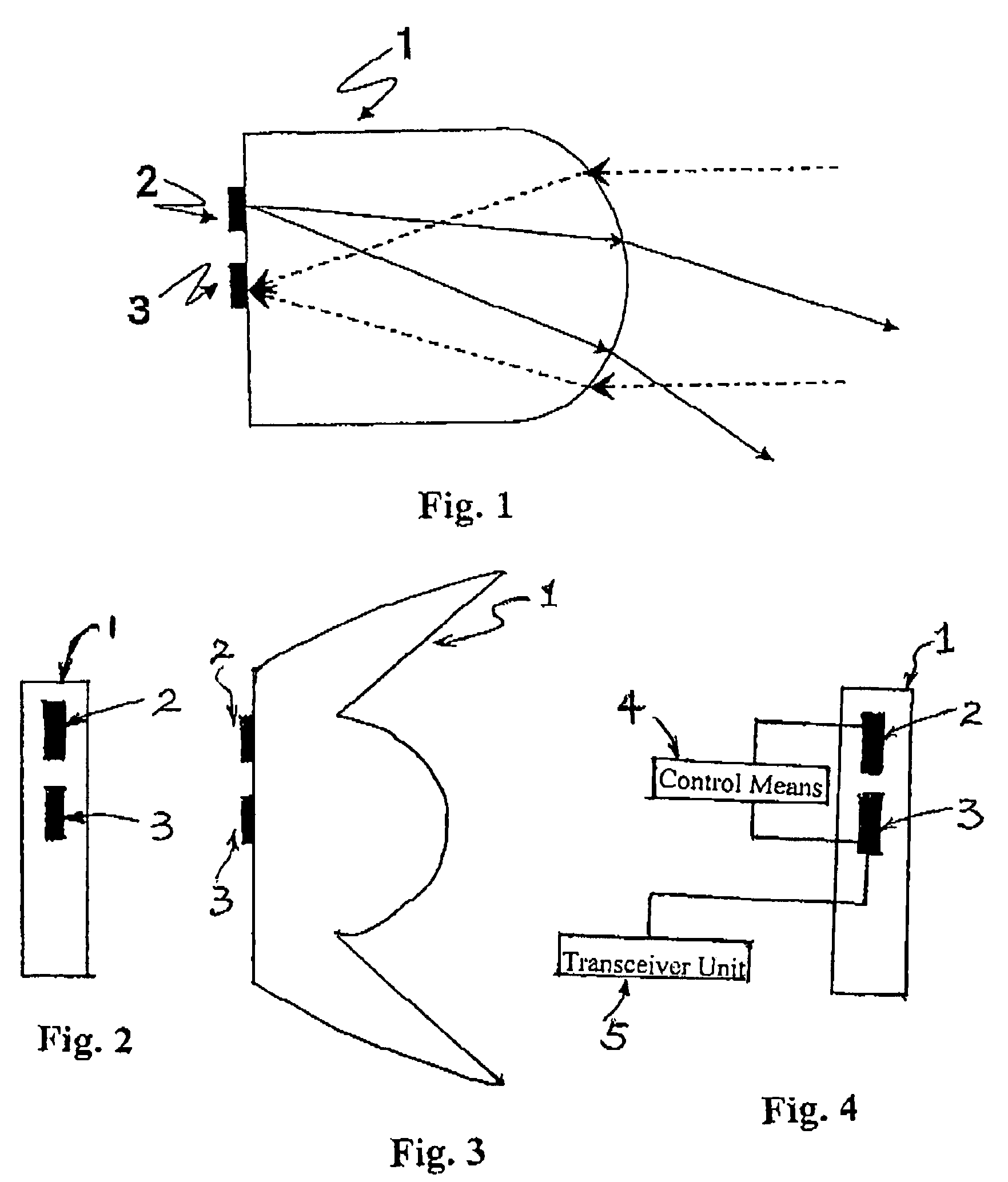

Multifunctional illumination device

ActiveUS7322723B2Compact designRobust designWave based measurement systemsLighting support devicesLight beamField of view

An illumination device has an illumination means formed by an arrangement of a plurality of semiconductor light sources (2) grouped together to form a field. Sensor elements (3) are arranged at individual positions of the field instead of the semiconductor sources (2). A multifunctional headlight can thus be advantageously created. The headlight can be embodied as a robust, compact, low-space unit. By virtue of the fact that the light sources (2) and the sensor elements (3) do not necessarily use the same lens system (1) i.e. each individual element of the multifunctional headlight can be provided with an individually designed lens system (1), the beam path of the illumination device can be separated from the field of vision of the sensor system and can thus be determined independently over large areas.

Owner:CHEMTRON RES

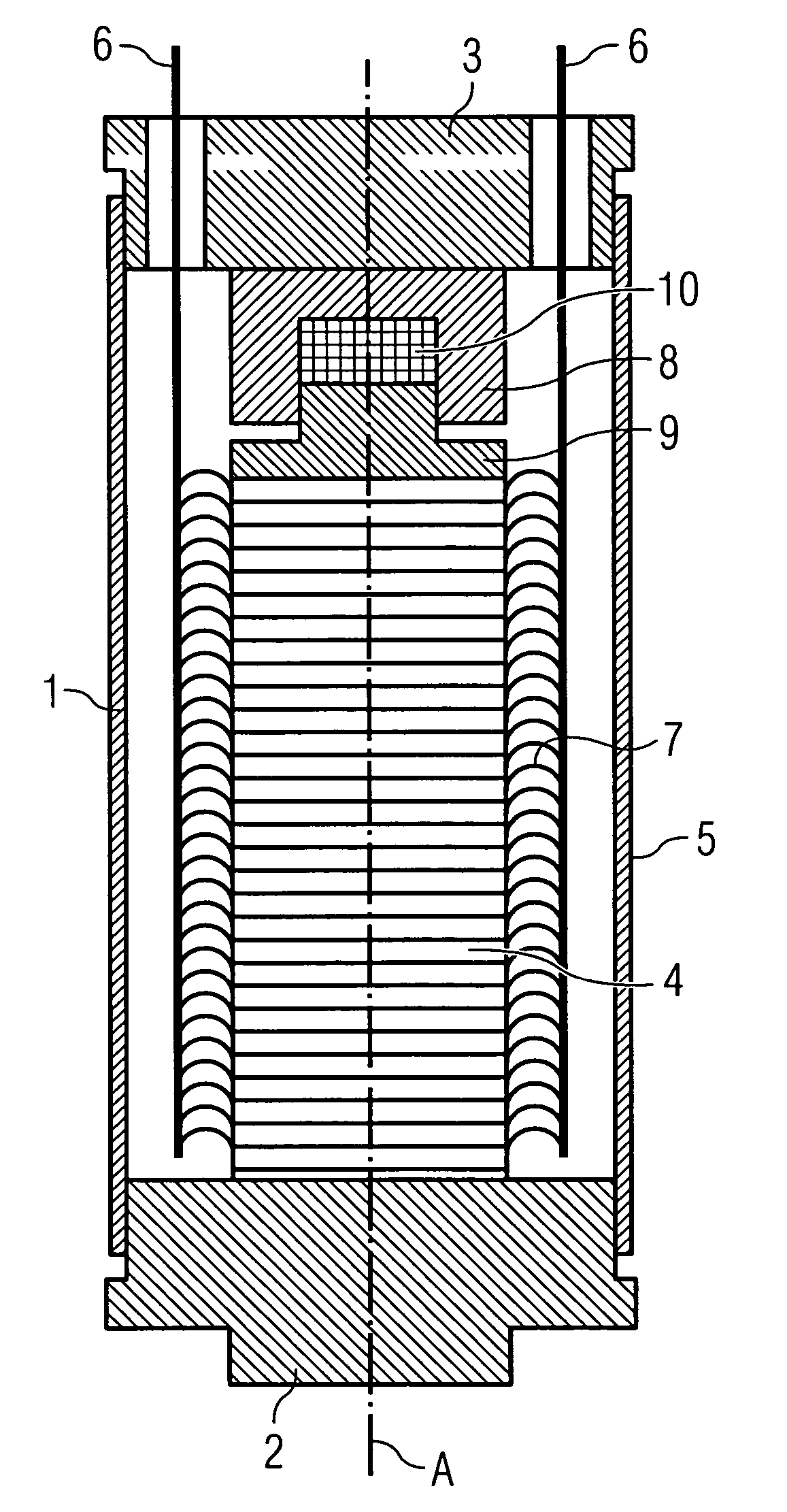

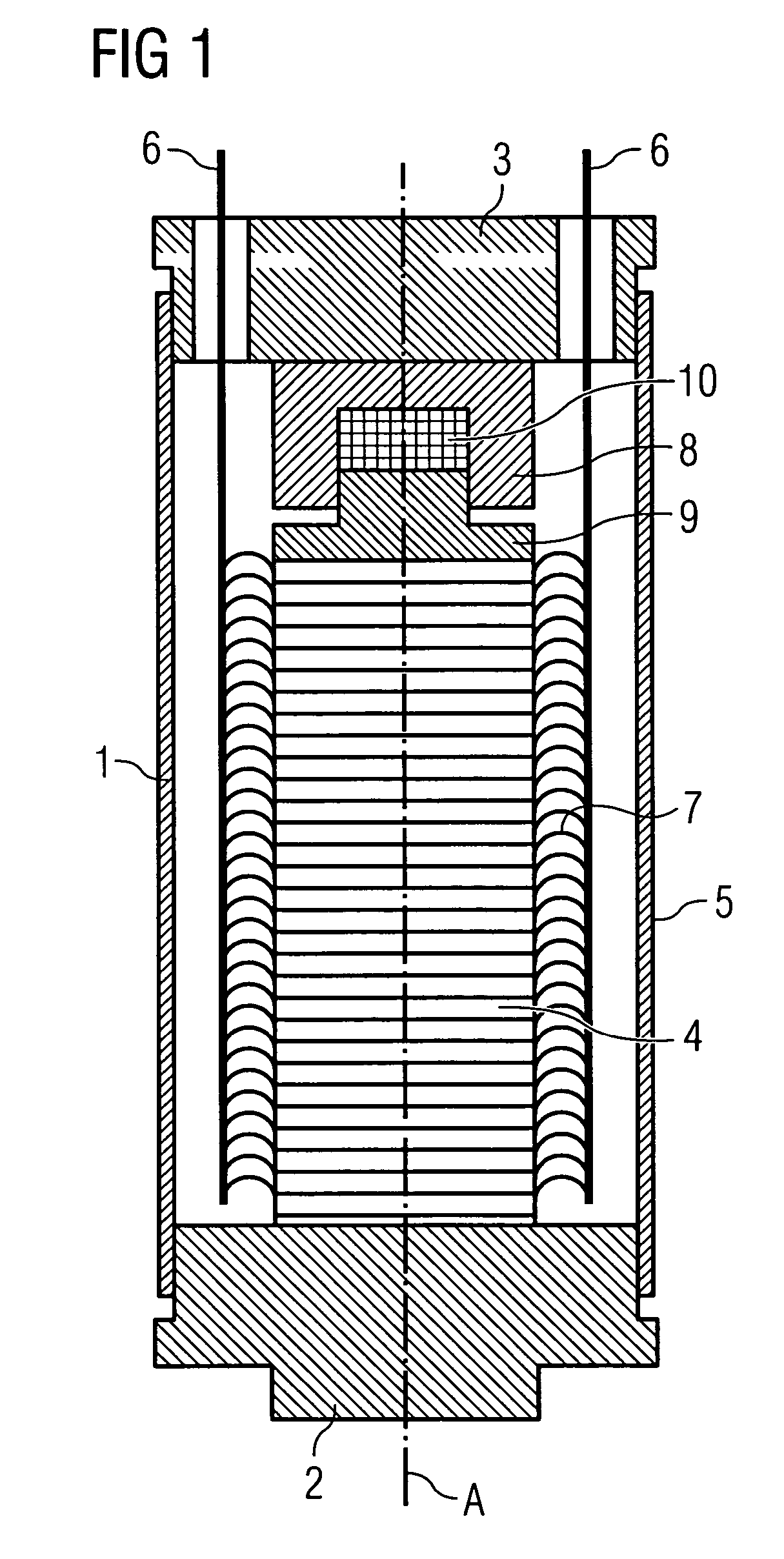

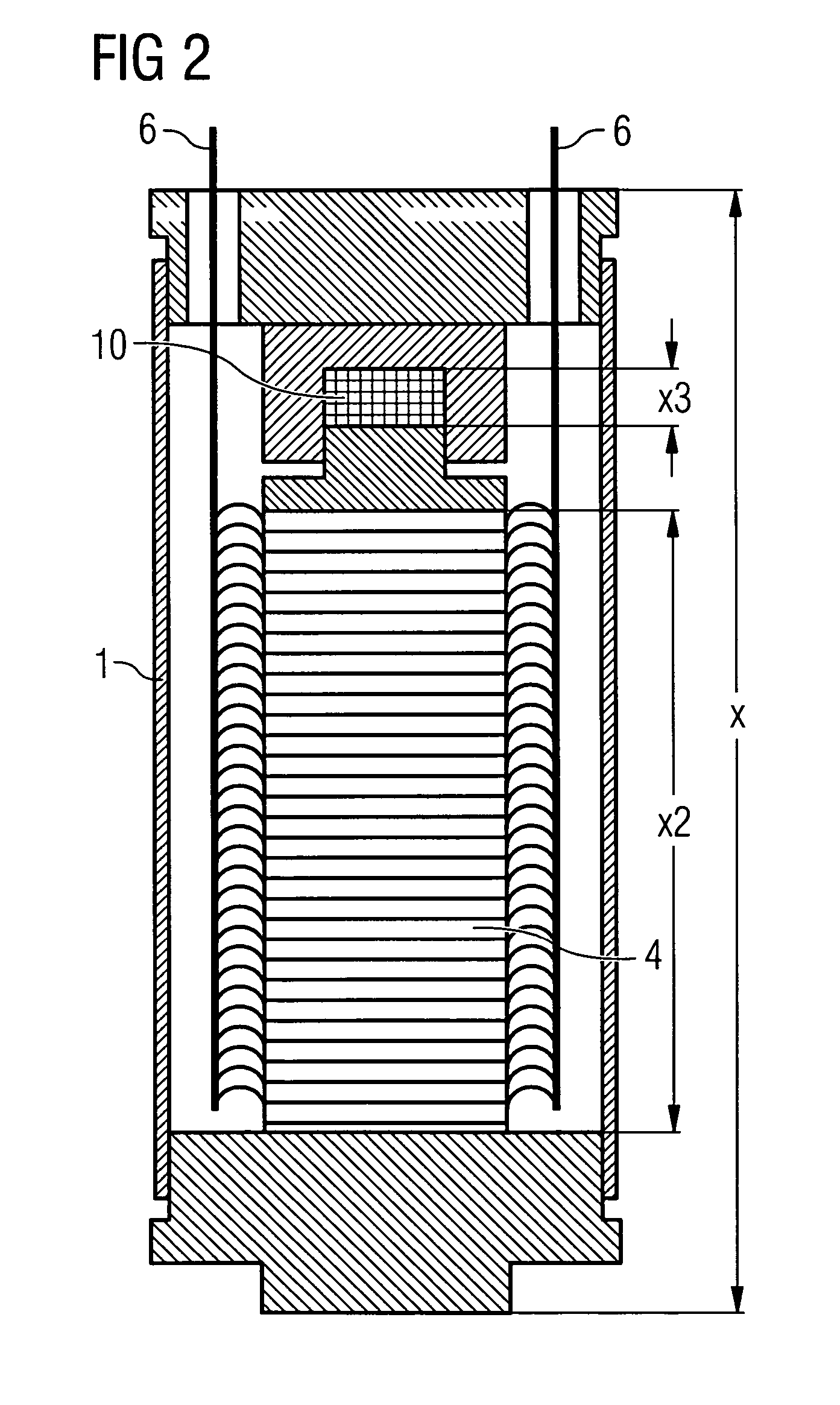

Piezoelectric actuator with compensator

InactiveUS6983895B2Reduce thermal effectsLow production costMovable spraying apparatusSpray nozzlesPiezoelectric actuatorsEngineering

A temperature compensated actuator device comprises a piezoelectric stack having first and second ends along a central axis and having a first thermal expansion coefficient; and a compensator arranged on one end of the piezoelectric stack. The compensator comprises a first member in form of a cylinder; a second member in form of a piston plate wherein the first member and the second member are arranged movably along the axis with respect to each other and define a hollow space between them; and a compensation member having a thermal expansion coefficient higher than the first thermal expansion coefficient for filling the hollow space.

Owner:SDST SIEMENS DIESEL SYST TECH +1

Environment friendly process for biodiesel

InactiveCN101486923AReduce consumptionReduce investmentBiofuelsLiquid hydrocarbon mixture productionLiquid wasteWax

The invention discloses environmental protection technology for bio-diesel production, which comprises the following units: 1) raw material preparation; 2) pre-esterification; 3) fine esterification; 4) washing desulphurization esterification; 5) refined methyl ester separation; 6) low-temperature dewaxing; 7) emission recovery; and 8) wastewater treatment. The environmental protection technology has the advantages that: 1. energy saving and emission reduction: the low temperature is served as technology heat and reduces the consumption of the energy; after the unit separation and purification, the produced exhaust gas and waste liquid can be reused in the technology, thus reducing the pollution emissions; 2. rapid esterification speed: high esterification rate; the hydrous grease is separated promptly by a liquid separating tank, thus avoiding a reverse reaction and reducing the esterification time to 1 hour; the acid value recovery problem is solved, so that the esterification is more thorough; the esterification rate can reach more than 98%; 3.output improving: the environmental protection technology has compact technology and reasonable procedure and can realize continuous and large-scale flowing production; and 4. low bio-diesel solidifying point: the wax in the bio-diesel is removed effectively by using a jacketed crystallizer and a full-automatic pressing filter, and the solidifying point is reduced.

Owner:迟洪军

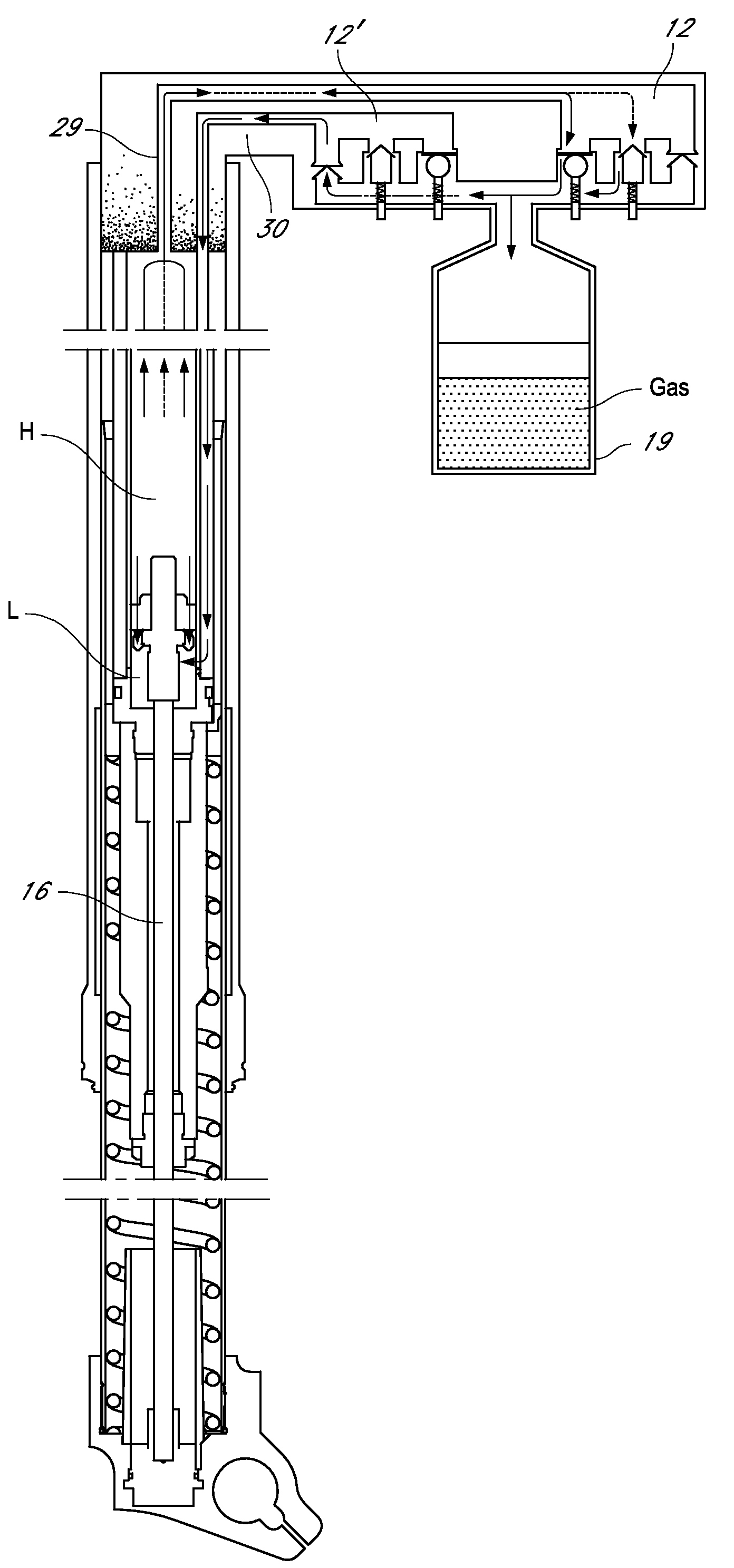

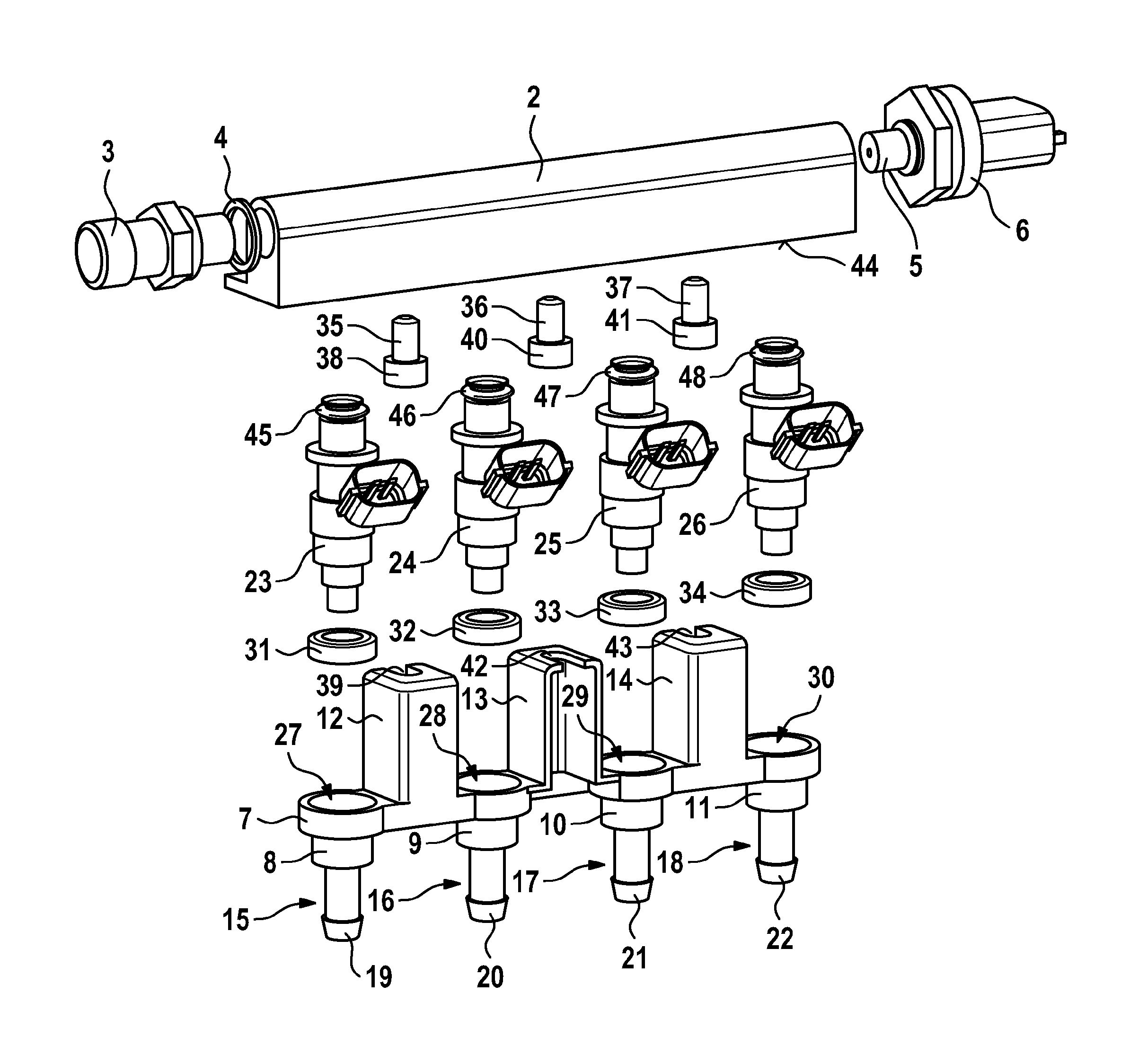

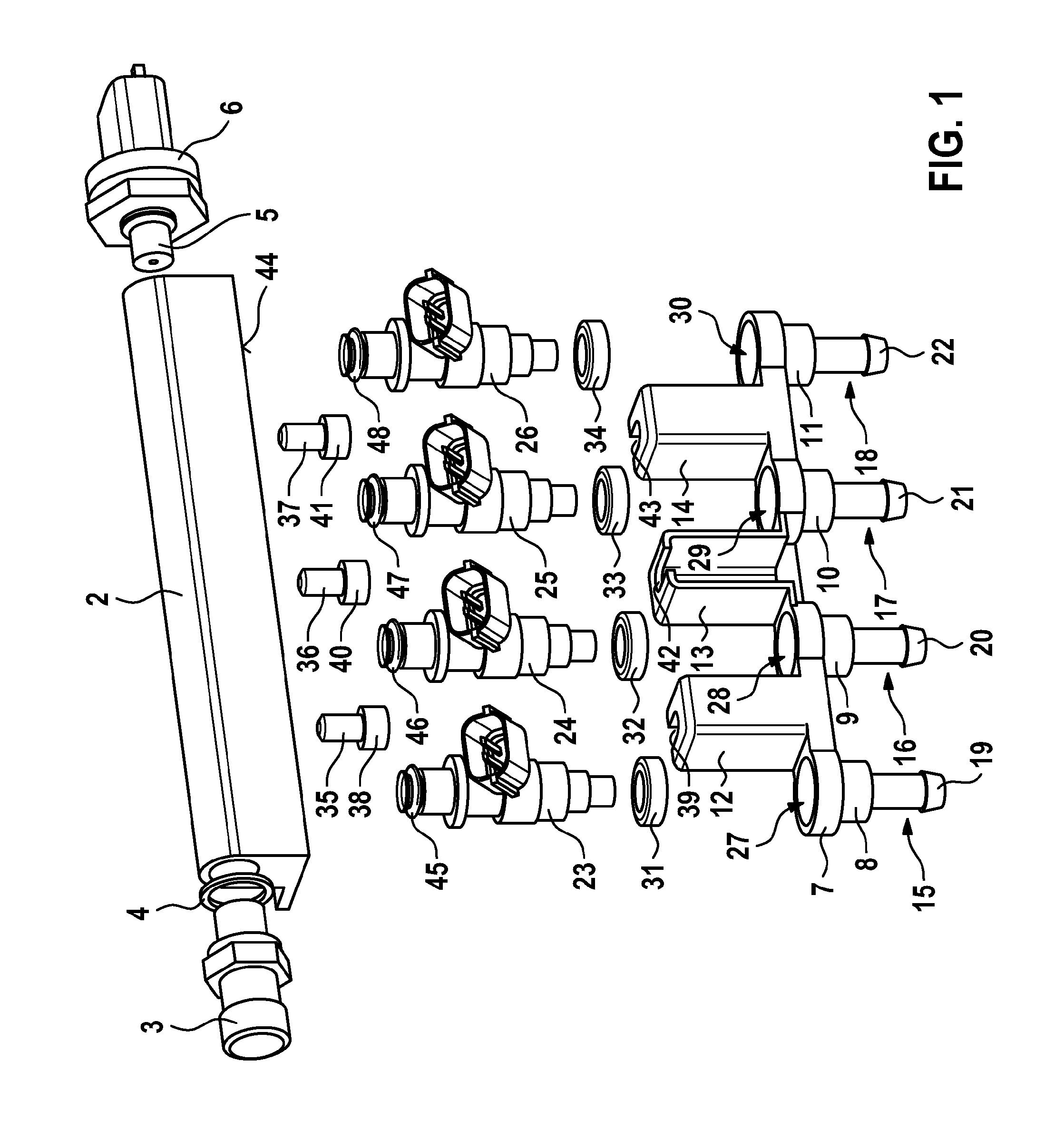

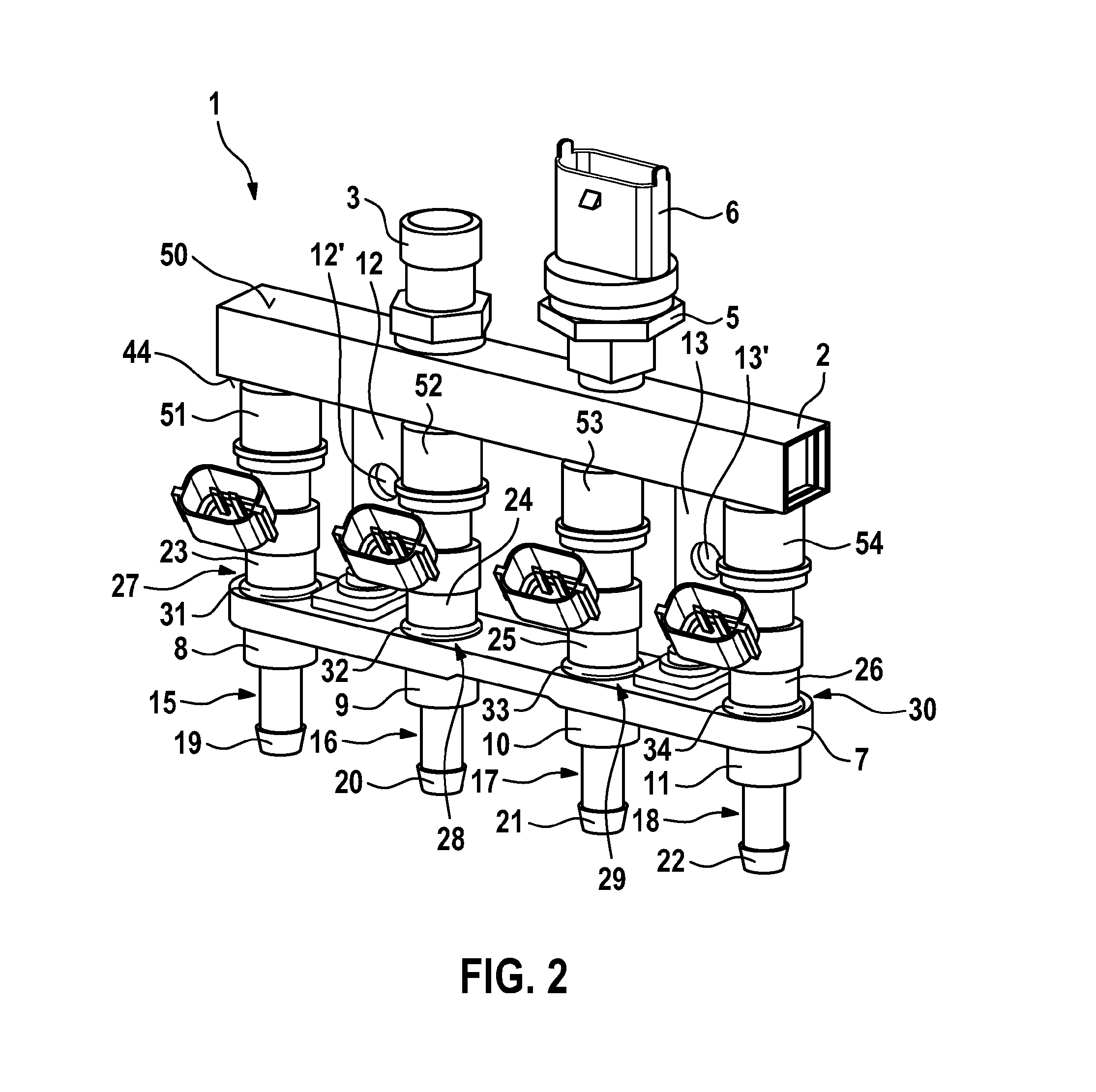

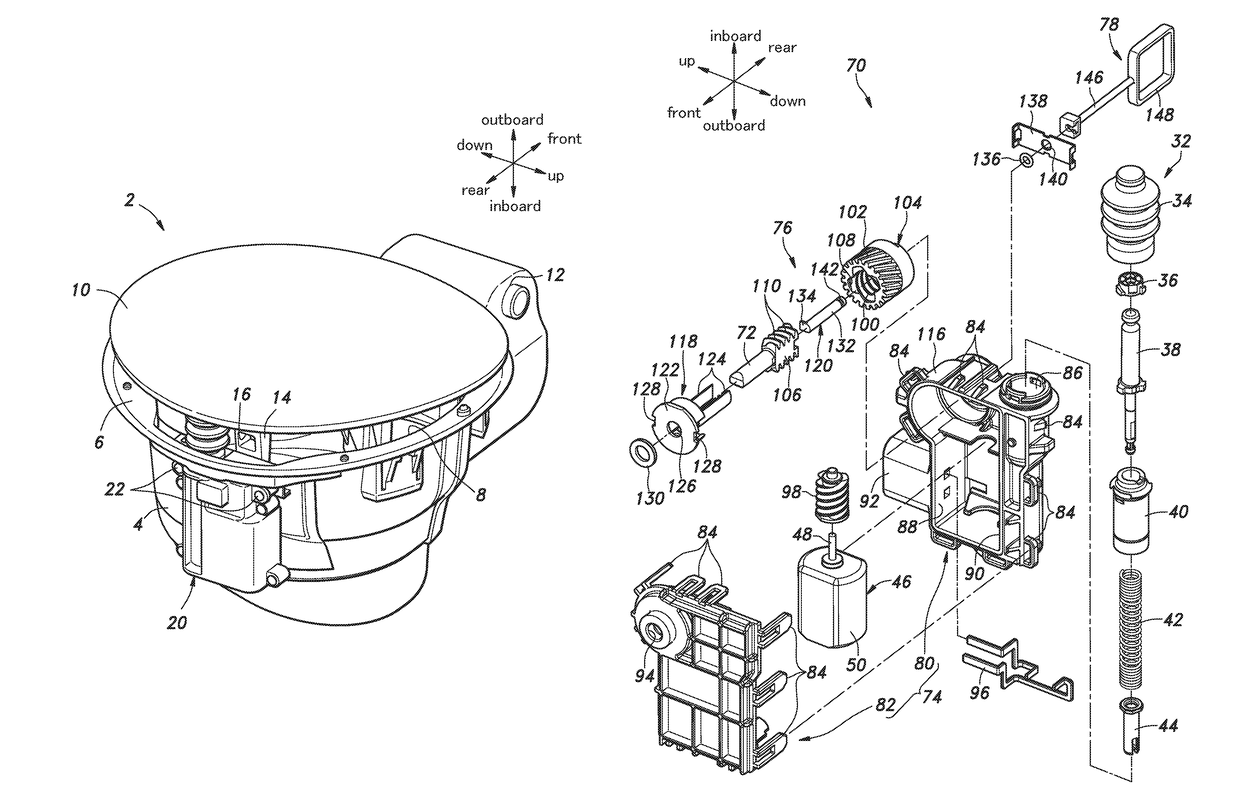

Injector system

InactiveUS20130340713A1Quality improvementEasy to installInternal combustion piston enginesFuel supply apparatusCompressed natural gasFuel distribution

An injector system which is in particular used as an injector block for fuel injection systems of mixture-compressing, spark-ignited internal combustion engines includes a fuel distribution rail, a counter bracket, a first injector, and at least one second injector. Here, the counter bracket has a first connecting piece and a second connecting piece. The first injector is joined to the counter bracket on an input side of the first connecting piece with the aid of an elastic sealing ring. The second injector is joined to the counter bracket on an input side of the second connecting piece with the aid of an elastic sealing ring. In this case, the counter bracket is connected to the fuel distribution rail. The fuel distribution rail is used for distributing compressed natural gas to the injectors. The injector system has a compact design.

Owner:ROBERT BOSCH GMBH

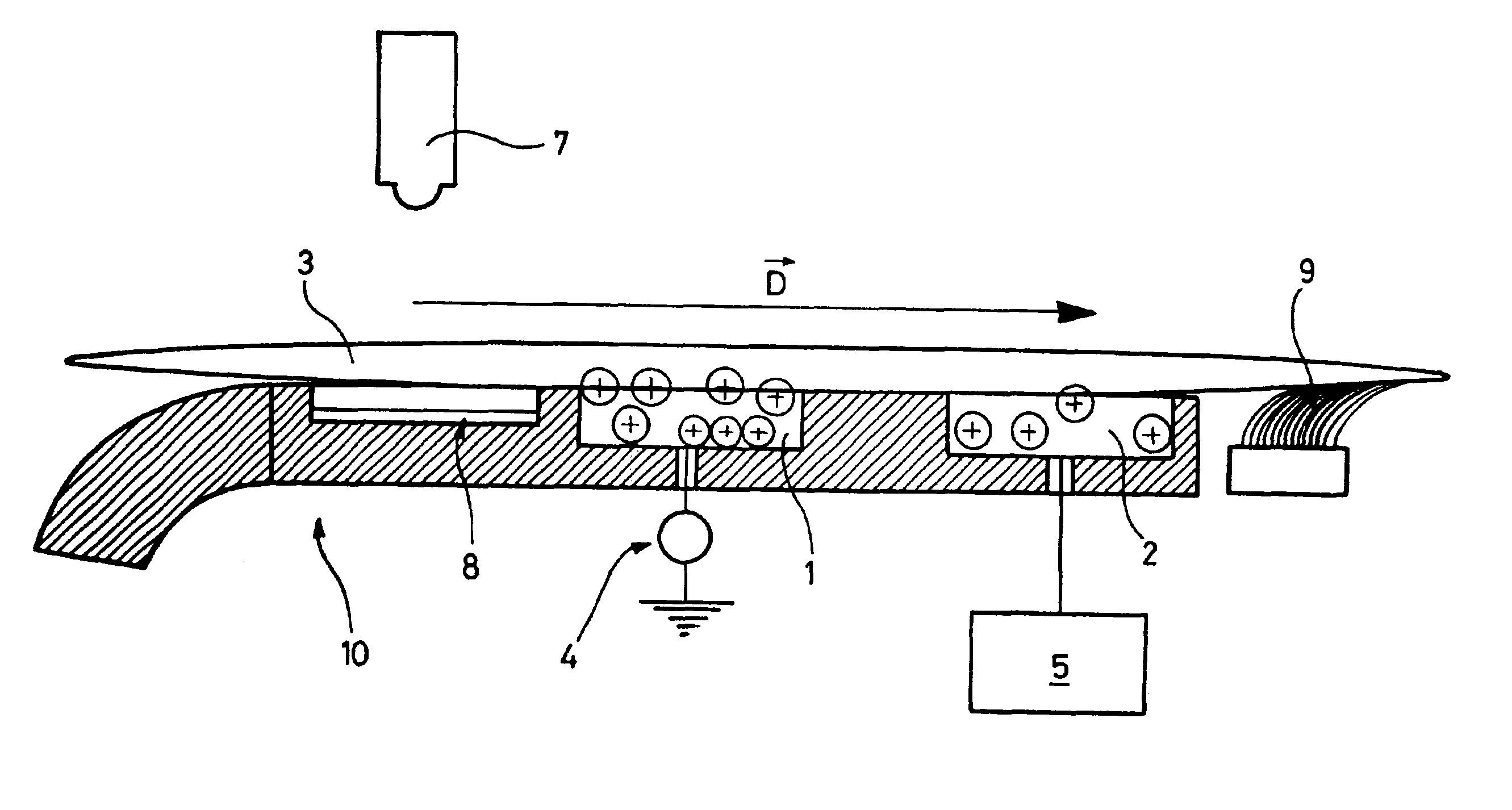

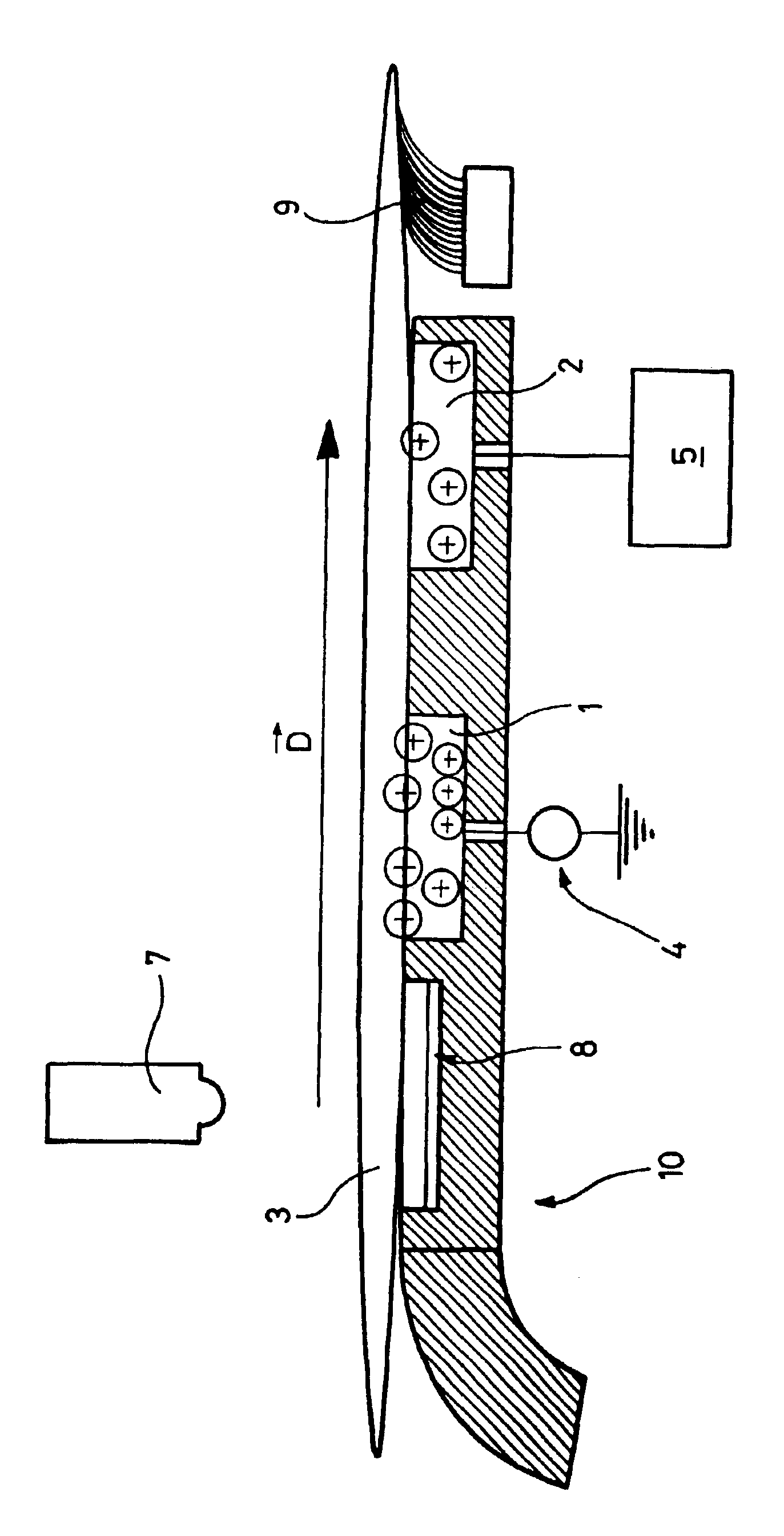

Method of detecting plastics articles, and a detector device

InactiveUS6888356B2Improve reliabilityReduce consumptionTravelling carriersHoldersPlastic materialsEngineering

The method of detecting plastics material, in particular for a postal sorting installation through which articles pass, is intended to distinguish automatically between articles having an outside surface made of plastics material and articles having an outside surface made of paper. The method consists in moving each article past an electrostatic generator, and then past a member for evaluating electrostatic charge so as to compare the charge on the article with a reference value in order to detect whether the article is a plastics article or a paper article. The method increases the reliability of detection.

Owner:SOLYSTIC

Deflector device for a sunroof device

ActiveUS8292360B2Sufficient forceGood lookingEngine sealsSuperstructure subunitsSpring forceCoil spring

In a deflector device for a sunroof device, a pair of arm members (7) extend in a fore and aft direction, and are each pivotally supported by a fixed roof panel part at a rear end thereof, and a blade (6) extends laterally between front ends of the arm members. A link member (13, 13′) is pivotally connected to a fixed roof part at a base end thereof, and engaged by an intermediate part of each arm member at a free end thereof so that the free end may be moveable along a lengthwise direction, and a coil spring (15, 15′, 16, 16′) is connected between the free end of the link member and a part of the arm member so as to urge the arm member in an upward direction. Thereby, the blade can be supported in the deployed or raised position with an adequate spring force.

Owner:YACHIYO IND CO LTD

System for the spraying of spray liquid for aircraft windshield, and cockpit provided with such a spraying system

A system for spraying liquid (100) for a windshield (111) of an aircraft including a spray-liquid supply circuit (101), a pressurized-gas supply circuit (102) designed to purge the spray-liquid supply circuit, and at least one nozzle (114) disposed downstream from the circuits and designed to spray the spray liquid and pressurized gas on a windshield, characterized in that the system includes an auxiliary means of compression (107) ready to compress gas designed to circulate in the pressurized-gas supply circuit, the auxiliary means of compression being positioned near the nozzle. Also, an aircraft cockpit provided with at least such a spray system.

Owner:AIRBUS OPERATIONS (SAS)

Lid device

ActiveUS9862265B2Effective installationReduced dimensionMechanical controlsFuel supplyEngineeringElectrical and Electronics engineering

Owner:NIFCO INC

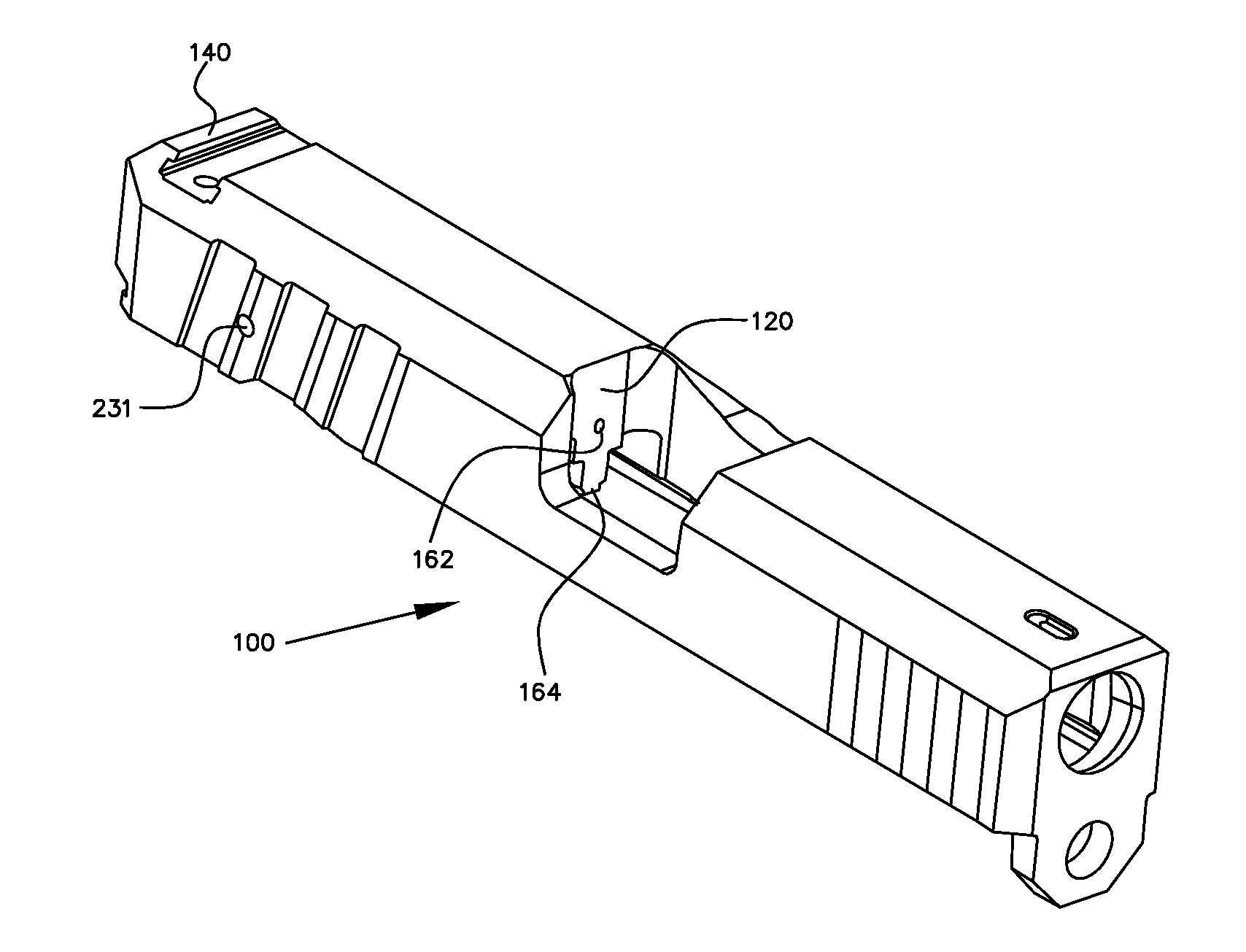

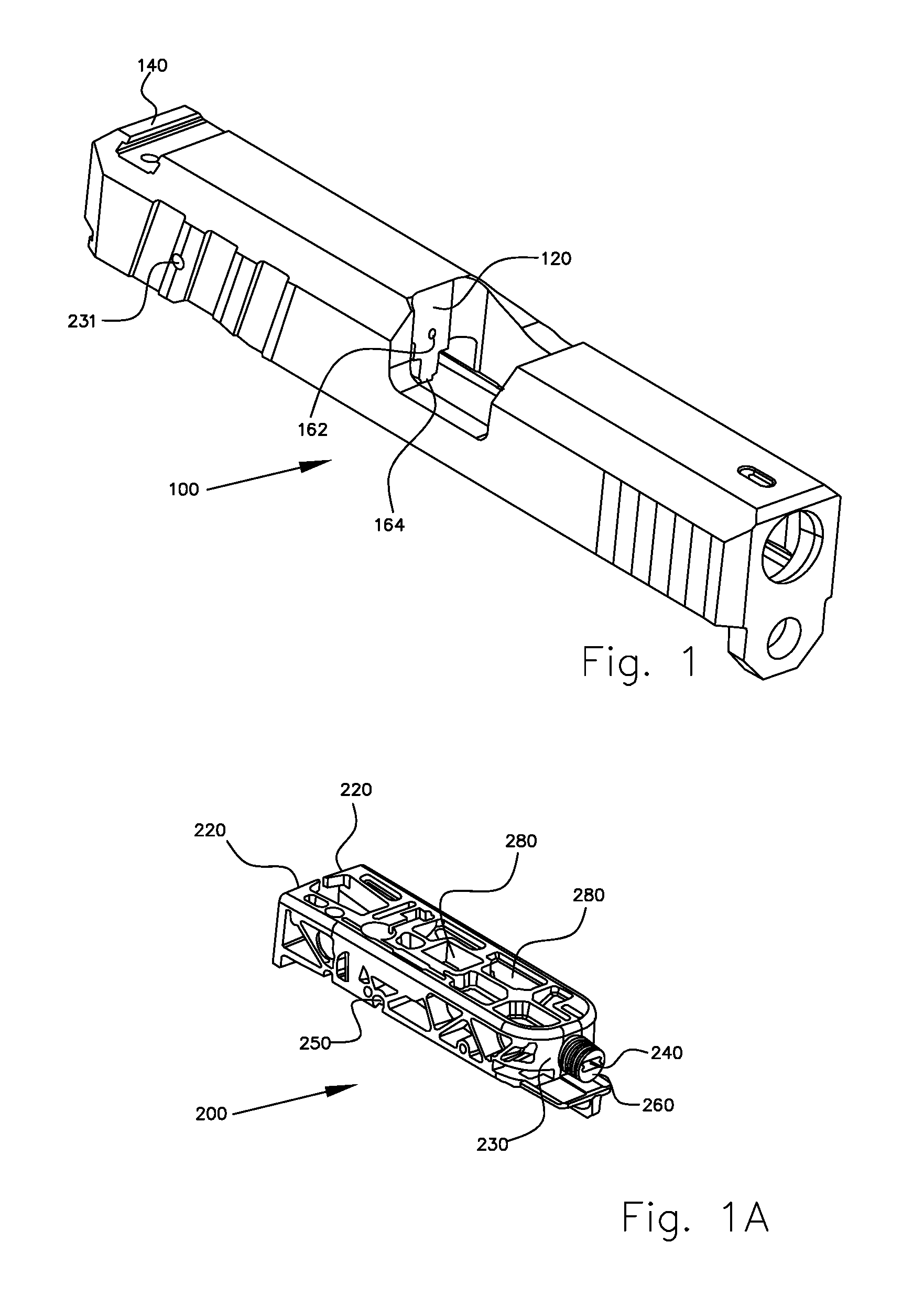

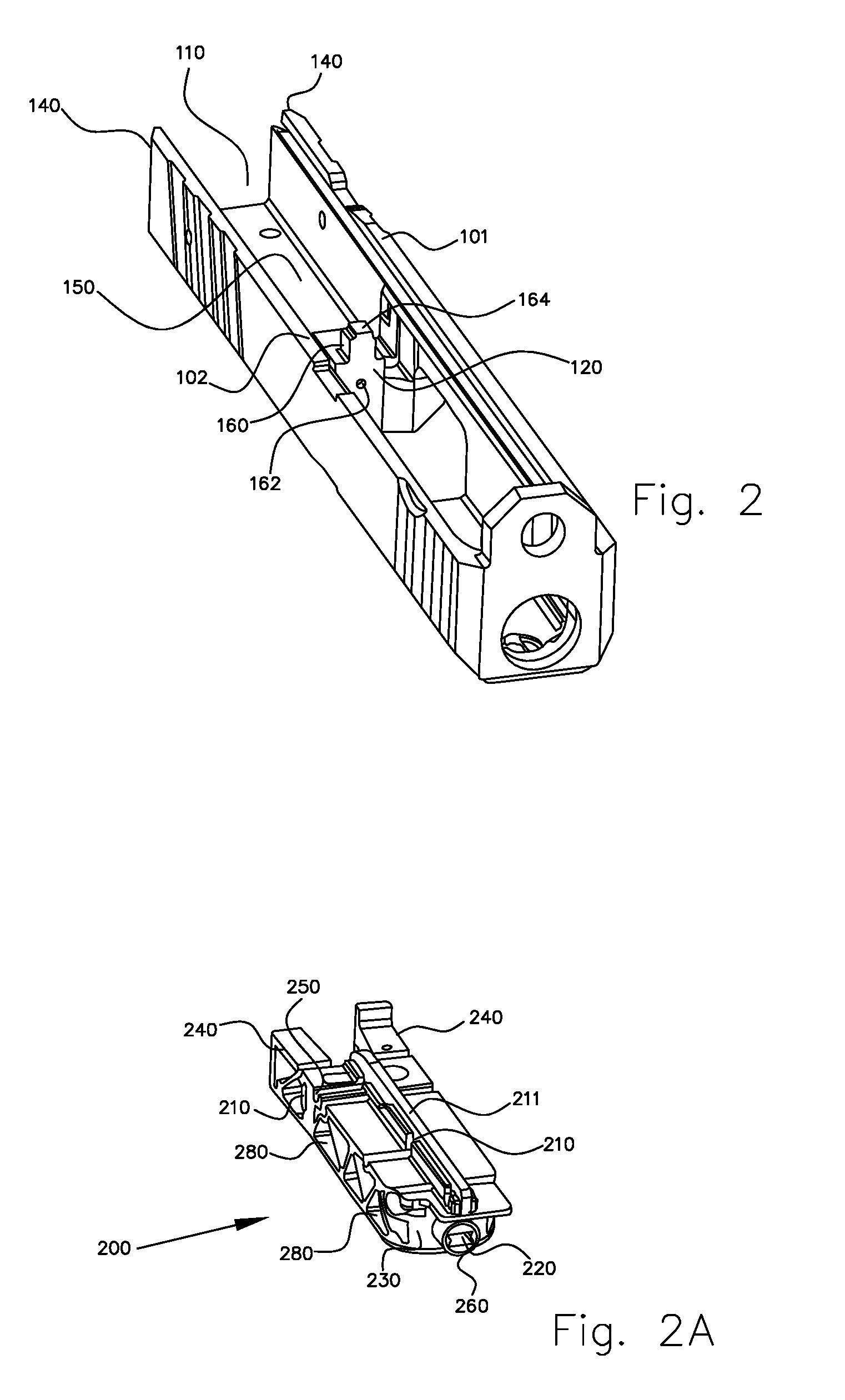

Breech Device

ActiveUS20120192472A1Low production costLess expenseBreech mechanismsShoulder-fired smallarmsEngineeringMechanical engineering

A breech device (100) for a handgun has an impact base (120) in a central recess (110) in said breech device (100). The impact base (120) is in the form of a front end face of an impact-base member (160) in the central recess. A main functional region (150) is between said impact base (120) and a rear end face (140) of said breech device. At least one percussion member (300) for firing a cartridge and also a surface of a cartridge slide (211) are in the main functional region (150). The surface of the cartridge slide (211) is adapted to abut cartridges mounted in a magazine (100) in a neutral position of the breech device.

Owner:WALTHER & CO AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com