Independent cam engine brake device

An engine braking, cam-type technology, applied in the direction of engine control, engine components, machines/engines, etc., can solve the problems of high cost, high braking power, complex compression braking structure, etc., and achieve low cost, good rigidity, Avoid the effect of braking force drop and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

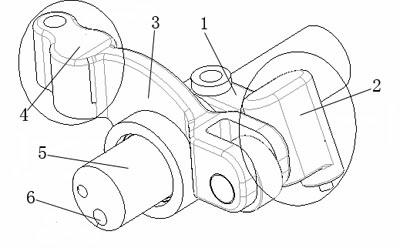

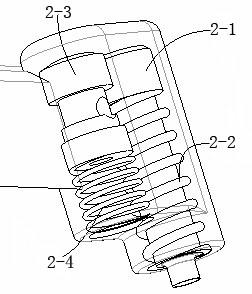

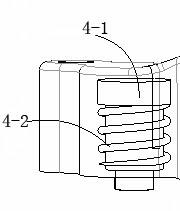

[0013] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 , 2 , shown in 3, a kind of independent cam type engine brake device, by rocker shaft support 1, braking active part 2, exhaust rocker 3, brake driven part 4, rocker shaft 5, brake oil Road 6 and exhaust valve 7, characterized in that: there is a brake oil circuit 6 inside the rocker shaft 5, the rocker shaft support 1, and the exhaust rocker arm 3 are installed on the rocker shaft 5, and the rocker shaft support 1. There is an oil circuit inside the exhaust rocker arm 3 that communicates with the brake oil circuit 6. The end of the rocker arm shaft support 1 is the brake active part 2, and the front end of the exhaust rocker arm 3 is the brake slave part 4; the brake active The part 2 is a cavity structure, the cavity of the brake active part 2 communicates with the oil circuit of the rocker shaft support 1, the control valve 2-3 is installed in the cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com