Efficient lubrication system of engine cylinder heads of contravariant small-sized dual-cylinder generator set

A technology of generator set and engine cylinder, which is applied in the direction of engine lubrication, machine/engine, engine components, etc., can solve the problems of affecting the roundness and sealing of the cylinder head, air bubbles mixed into the oil, and the crankshaft oil throwing resistance is large, etc. To achieve the effect of improving the lubrication effect, preventing premature aging, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

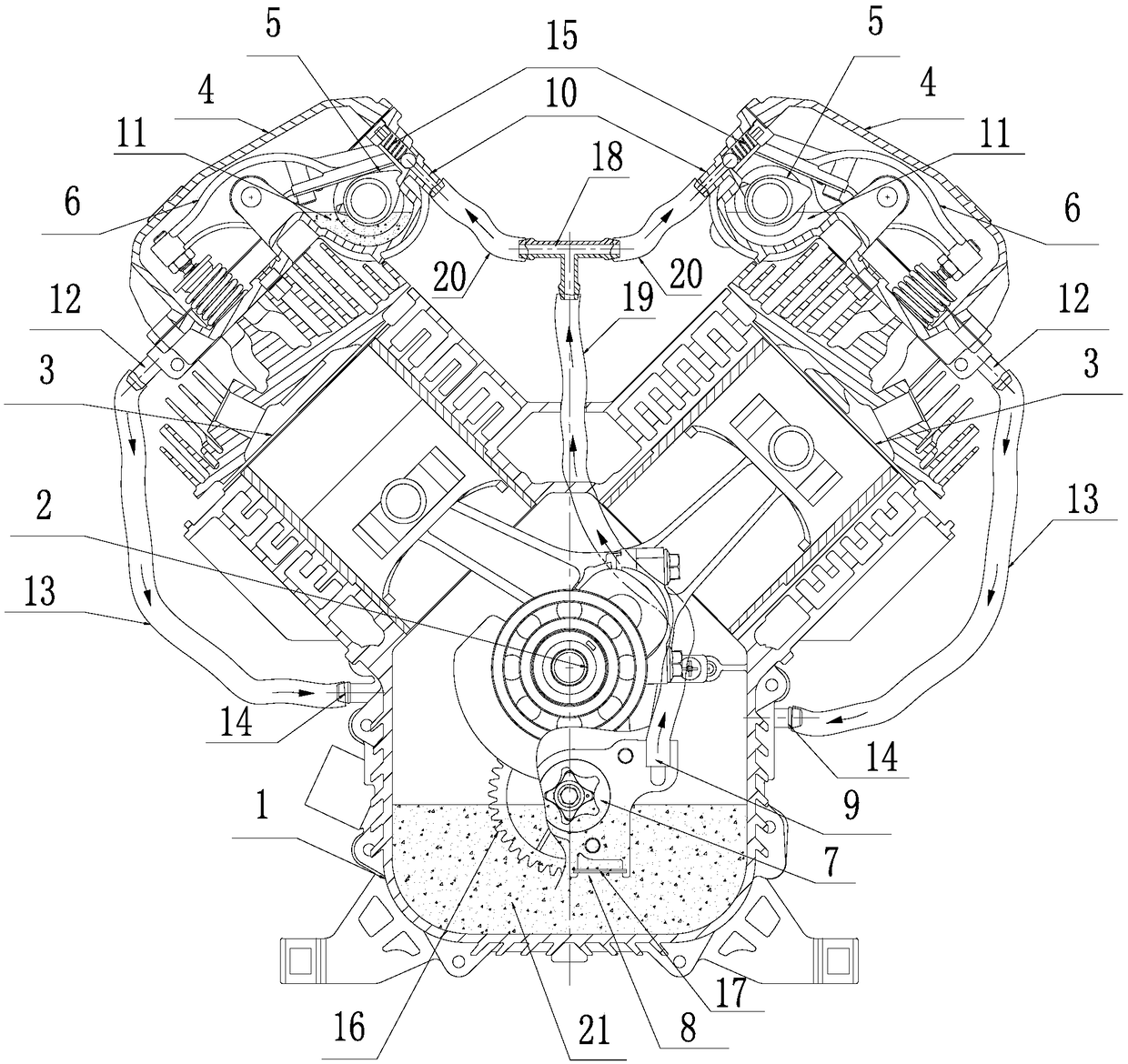

[0022] Example: Combine figure 1 Shown is a specific embodiment of the engine cylinder head high-efficiency lubrication system of an inverter small twin-cylinder generator set according to the present invention. Its main structure includes an overhead cam twin-cylinder engine coaxially connected with the generator. The engine has a crankcase body 1, the crankshaft 2 arranged in the crankcase body 1, two cylinders 3 connected to the crankcase body 1, and a cylinder head mechanism correspondingly arranged on the top of each cylinder 3, the cylinder head mechanism includes a cylinder head cavity 4 and the cam 5 located therein and the valve rocker mechanism 6 cooperating with the cam 5 . and if figure 1 As shown in , the twin-cylinder engine in this embodiment is a V-shaped twin-cylinder engine, and its two cylinders 3 are distributed in a V shape.

[0023] The main improvement of the present invention is: an oil injection pump 7 is arranged in the crankcase body 1, such as fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com