Overhead cam engine

A top-mounted engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problem of single cam with large workload, small lateral size, difficulty in meeting the requirements of reasonable gas distribution phase of intake valve and exhaust valve, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

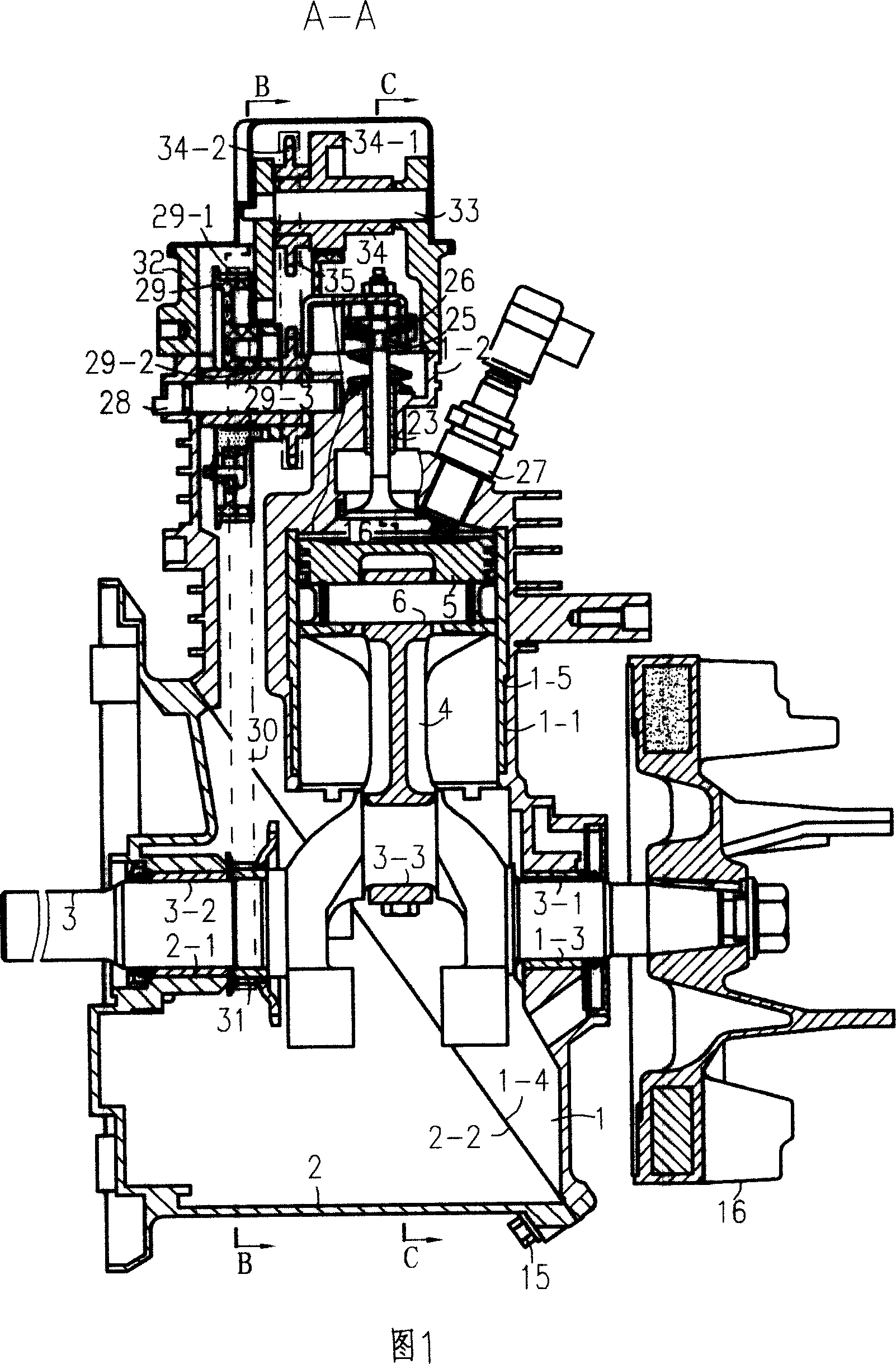

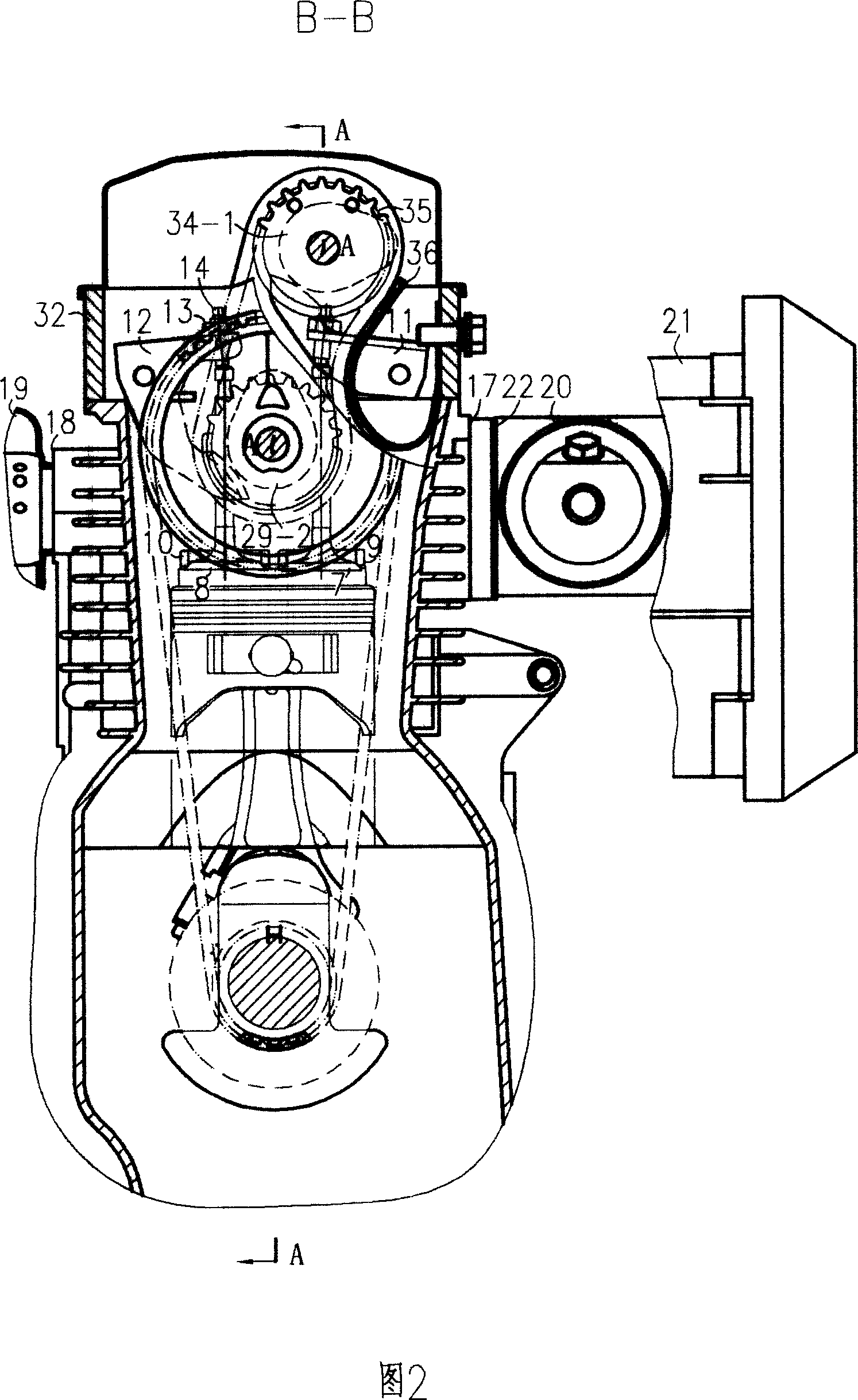

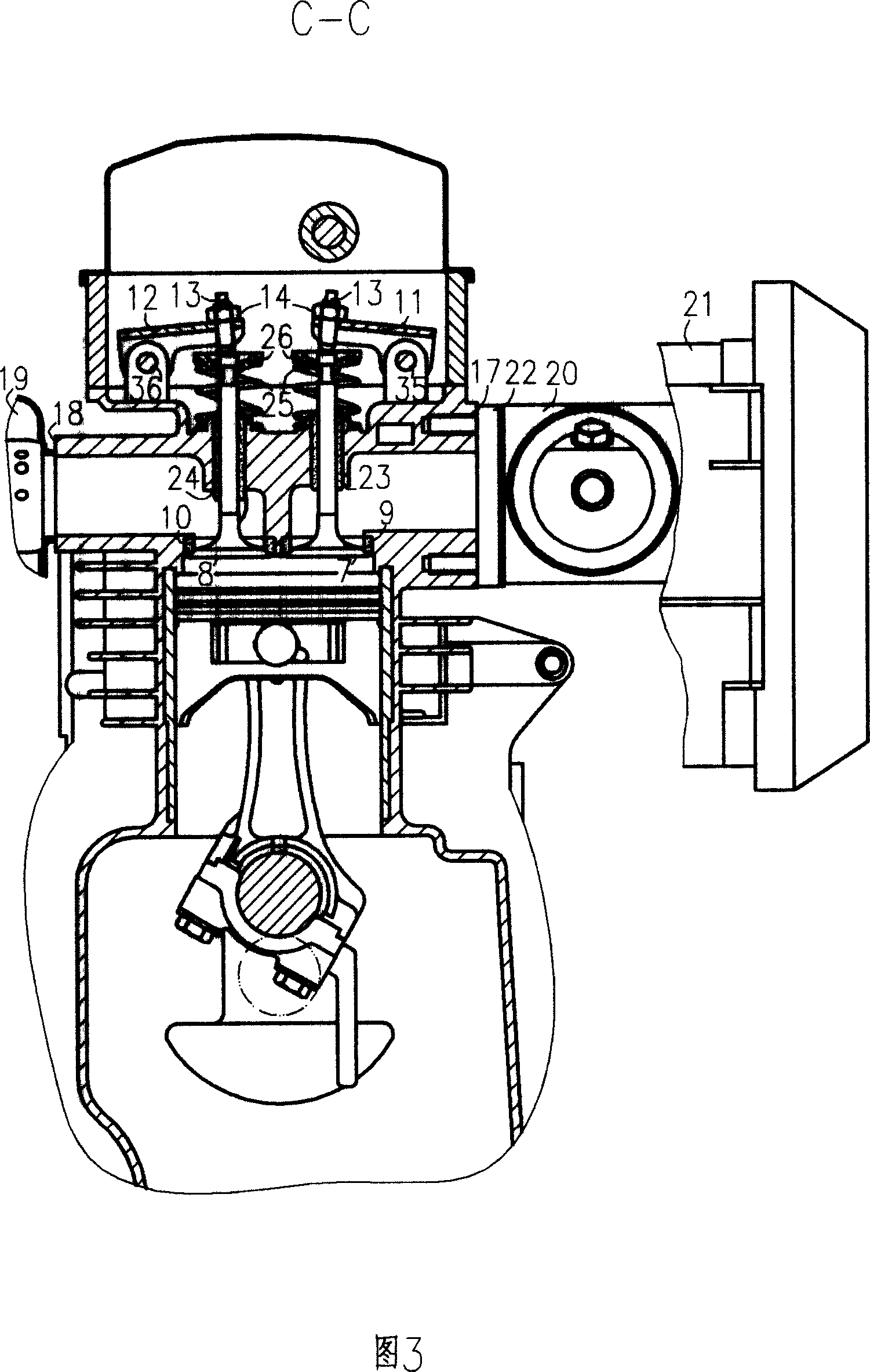

[0011] See Fig. 1, the present invention comprises a cylinder block 1, and the bottom of cylinder block 1 is connected crankcase, and in crankcase and cylinder block 1, crankshaft 3 is connected piston 5 by connecting rod device; Cylinder block 1 comprises cylinder outer wall 1-1 And the cylinder liner 1-5 integrally cast with it, the bearing bush 1-3 is pressed on the outer wall 1-1 of the cylinder, the inclined surface 1-4 of the cylinder block 1 is combined with the inclined surface 2-2 of the oil base 2 to form a crankcase, And connect with screw 15; The top of cylinder block 1 is connected with the cylinder head 1-2 that is integrated with it;

[0012] The two shaft diameters 3-1 and 3-2 of the crankshaft 3 are respectively supported on the bearing bush 1-3 of the cylinder block 1 and the bearing bush 2-1 of the oil base 2; the flywheel 16 is fixed on one end of the crankshaft 3 in a conventional manner;

[0013] One end of the piston 5 and the connecting rod 4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com