Topping cam engine

An overhead cam and engine technology, applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of increasing the size of the overall size of the cylinder head, achieve the effect of reducing friction loss, avoiding the increase of wheelbase, and reducing the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] specific implementation

[0031] An embodiment of the present invention will be described below based on an embodiment of the present invention shown in the accompanying drawings.

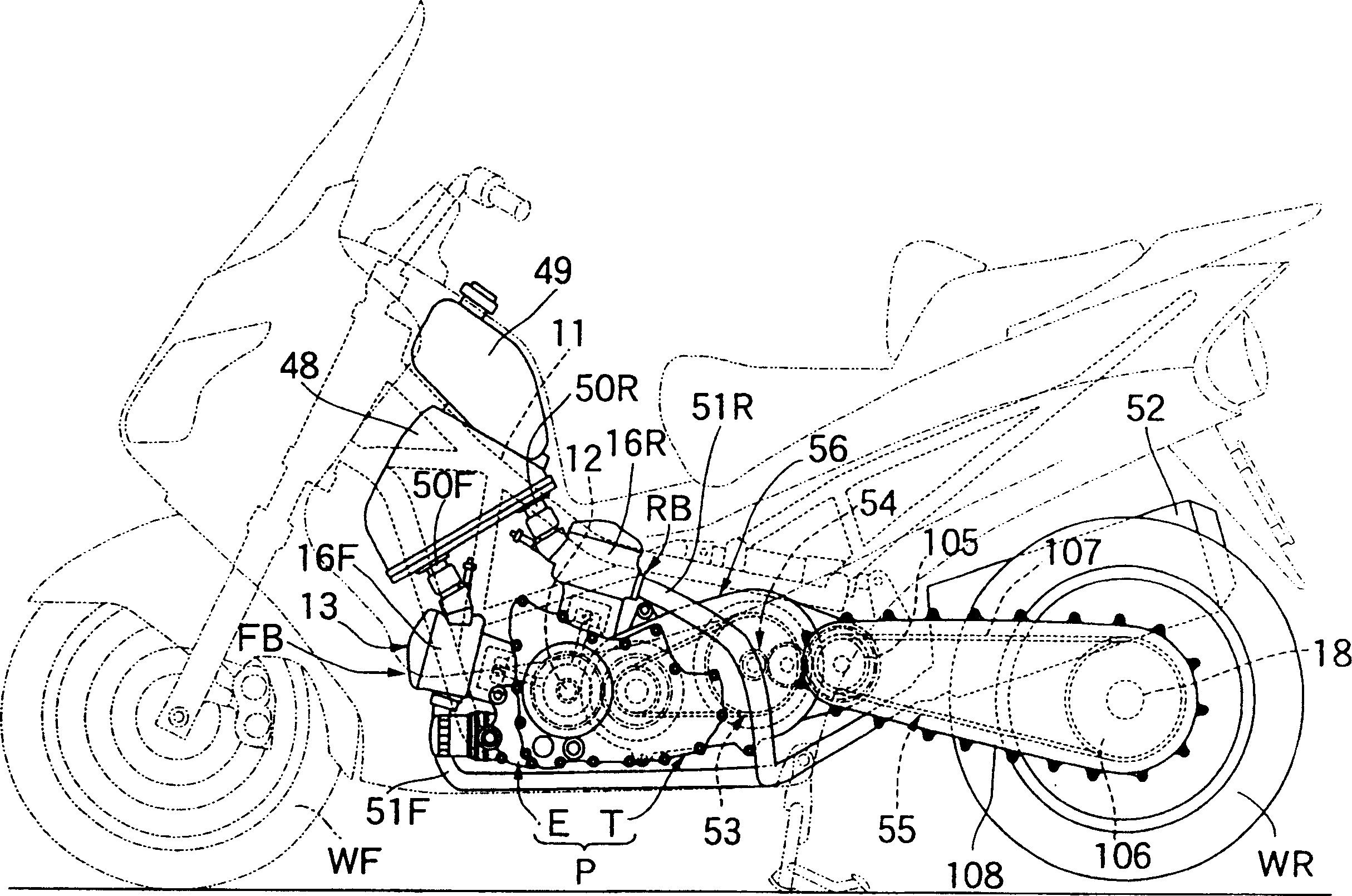

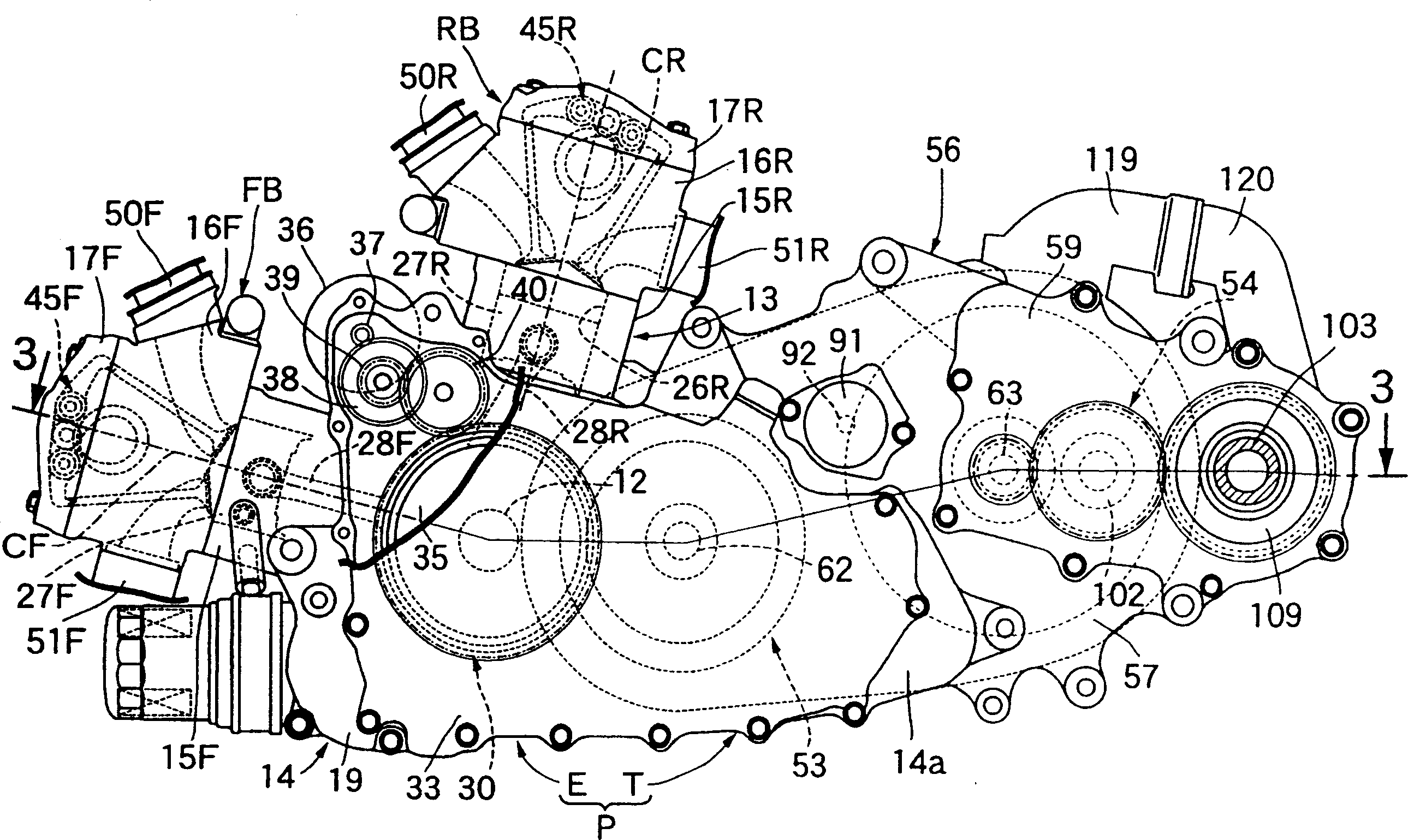

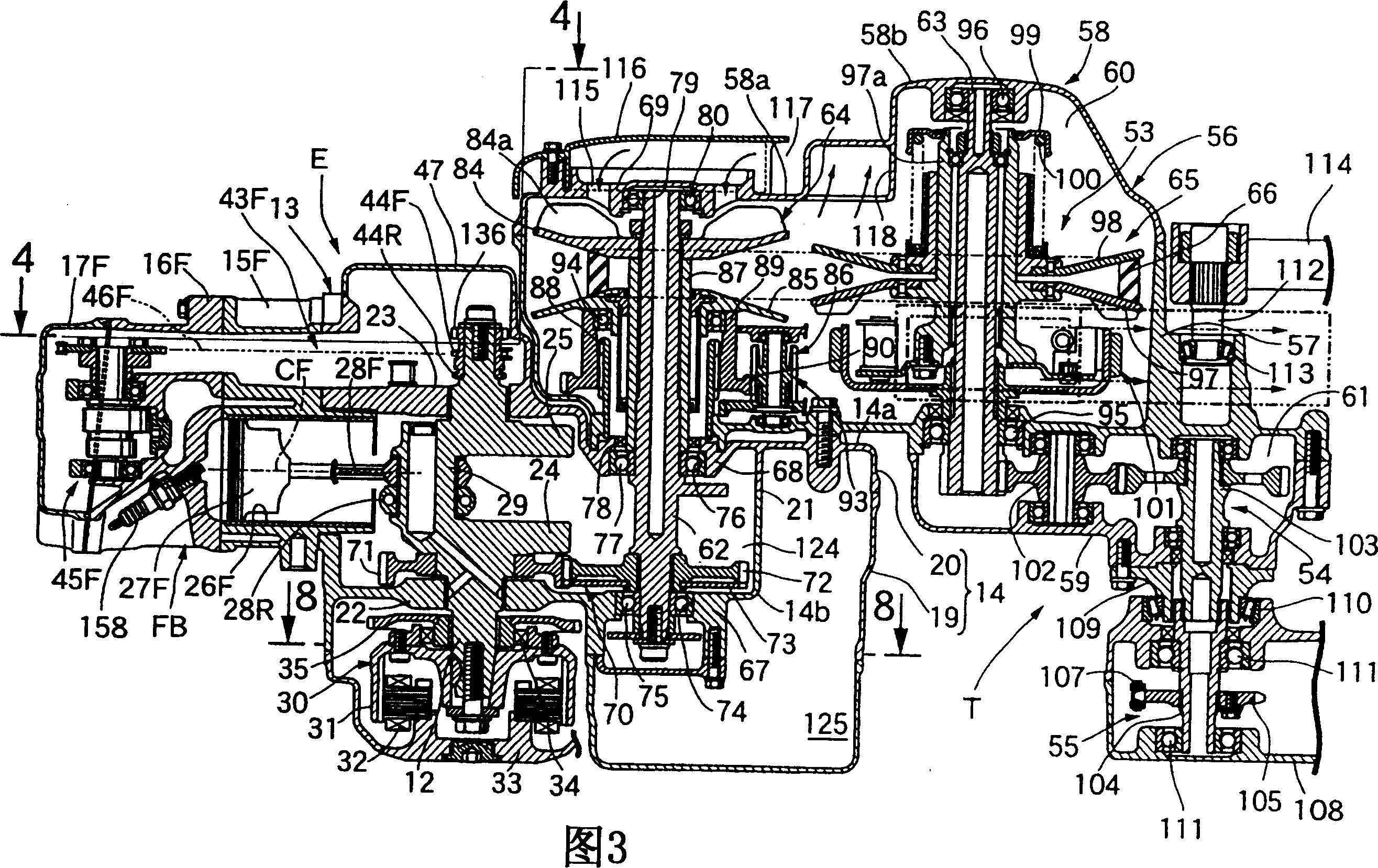

[0032] Figure 1-11 represent an embodiment of the present invention, figure 1 For a side view of a motorcycle, figure 2 for following with figure 1 The side view of the removed part of the power assembly seen in the same direction, Figure 3 is along figure 2 A cross-sectional view of line 3-3 in, Figure 4 It is a cross-sectional view along line 4-4 in Fig. 3, and Fig. 5 is along Figure 4 In view of the 5-5 line, Image 6 It is a figure corresponding to FIG. 5 in which the state of the swing arm is omitted, Figure 7 It is a sectional view along line 7-7 in Fig. 5, Figure 8 It is a sectional view along line 8-8 in Fig. 5, Figure 9 for along Figure 4 The sectional view of line 9-9 in, Figure 10 for along Figure 4 sectional view of line 10-10 in, Figure 11 for along Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com