Cylinder cam engine without bent axle

A cylindrical cam and engine technology, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problems of high processing difficulty, complicated crankshaft manufacturing process, affecting engine manufacturing cost, etc., and achieve the effect of simple overall structure and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

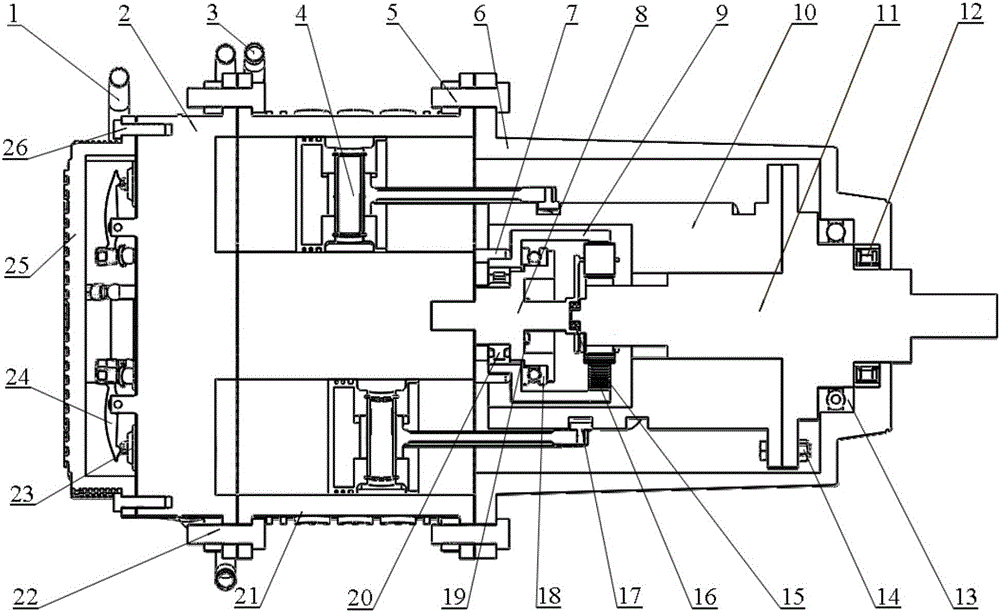

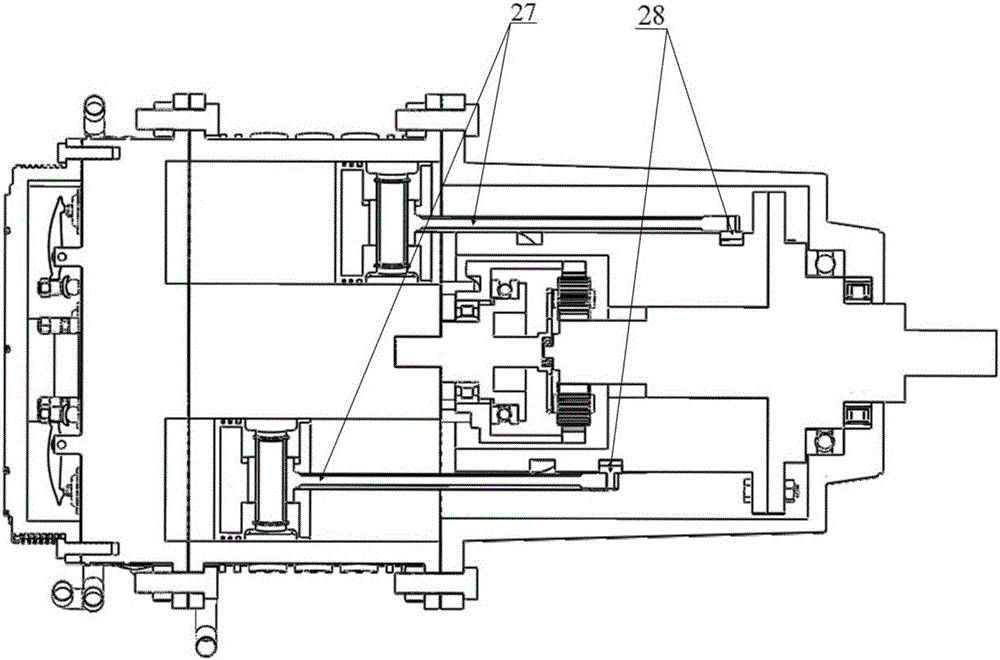

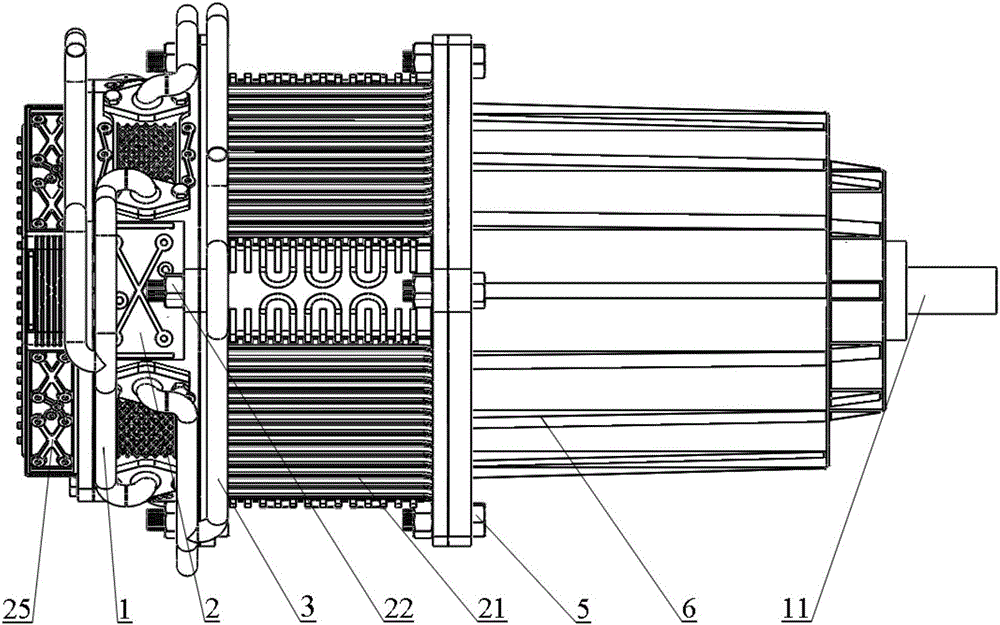

[0019] combined with Figure 1-10 , to further describe the present invention.

[0020] The present invention consists of an intake manifold 1, a cylinder head 2, an exhaust manifold 3, an upper piston connecting rod group 4, a lower box connecting bolt group 5, a lower box 6, a valve ejector rod 7, a planetary gear bracket 8, and a Gas cam 9, rotary cam 10, output shaft 11, one-way bearing 12, output shaft thrust bearing 13, output shaft connecting bolt group 14, planetary gear 15, output shaft rotary bearing 16, roller 17, gas distribution cam thrust bearing 18, Planetary gear bracket fixing screw 19, planetary gear bracket bearing 20, cylinder box 21, cylinder head connecting bolt group 22, valve spring group 23, valve rocker arm group 24, gas distribution system end cover 25, gas distribution system end cover connection bolts Group 26, lower piston connecting rod group 27, roller 28 form; Output shaft gear 11.1 is a structural feature of the aforementioned output shaft 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com