Methods and apparatus to use engine valves as both intake and exhaust valves

a technology of engine valves and intake and exhaust, which is applied in the direction of valve arrangements, machines/engines, non-mechanical valves, etc., can solve the problem of limiting the amount of this

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

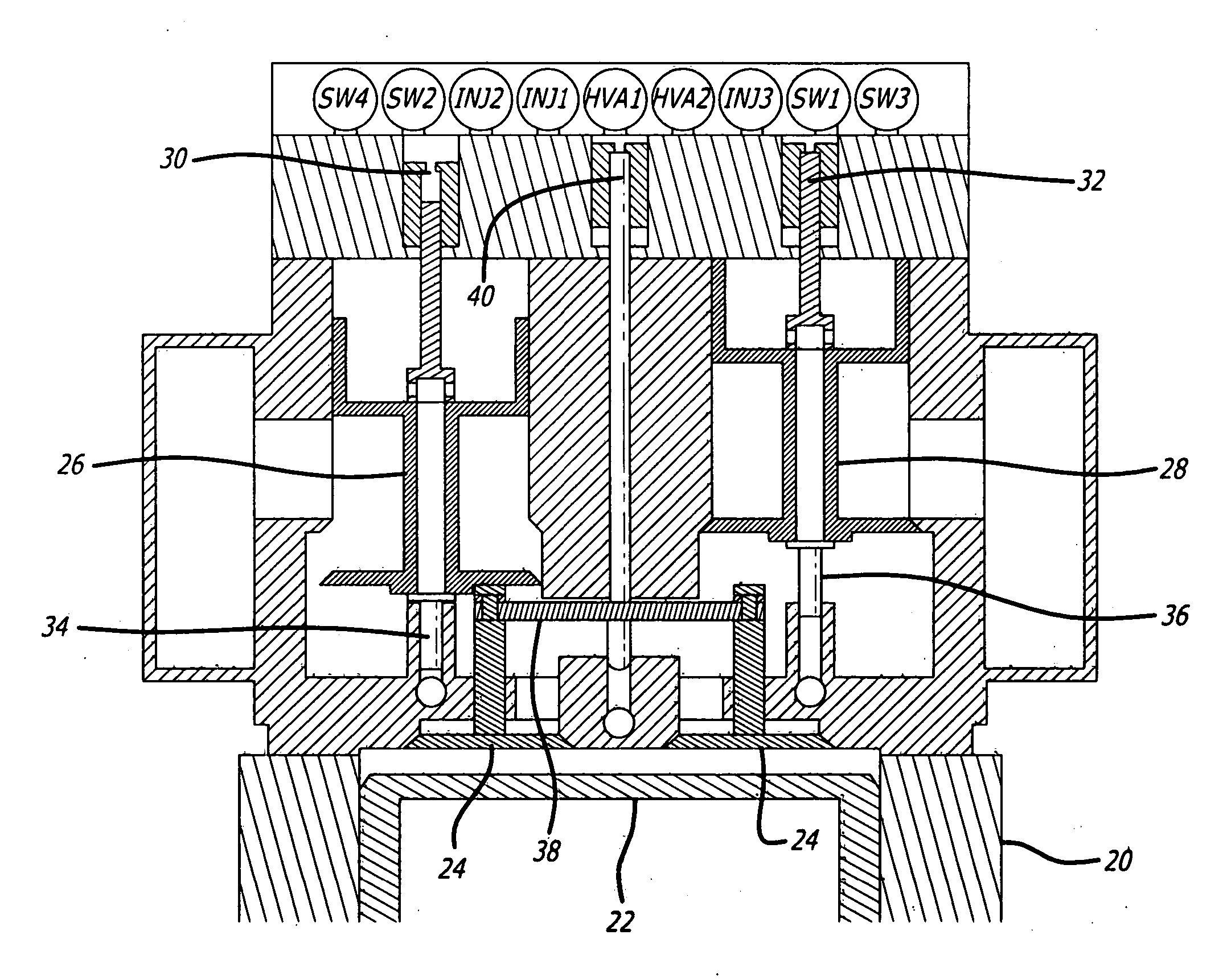

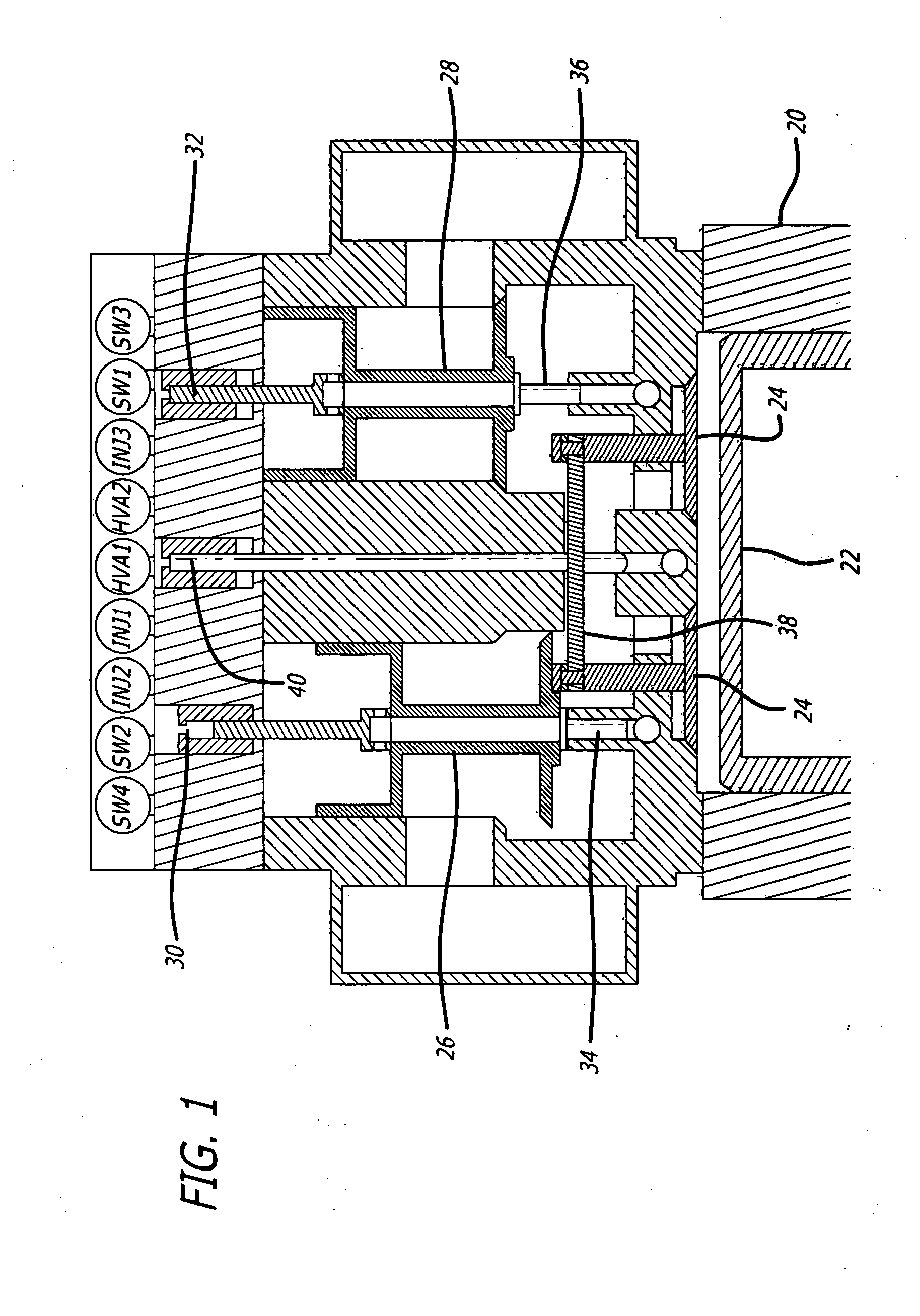

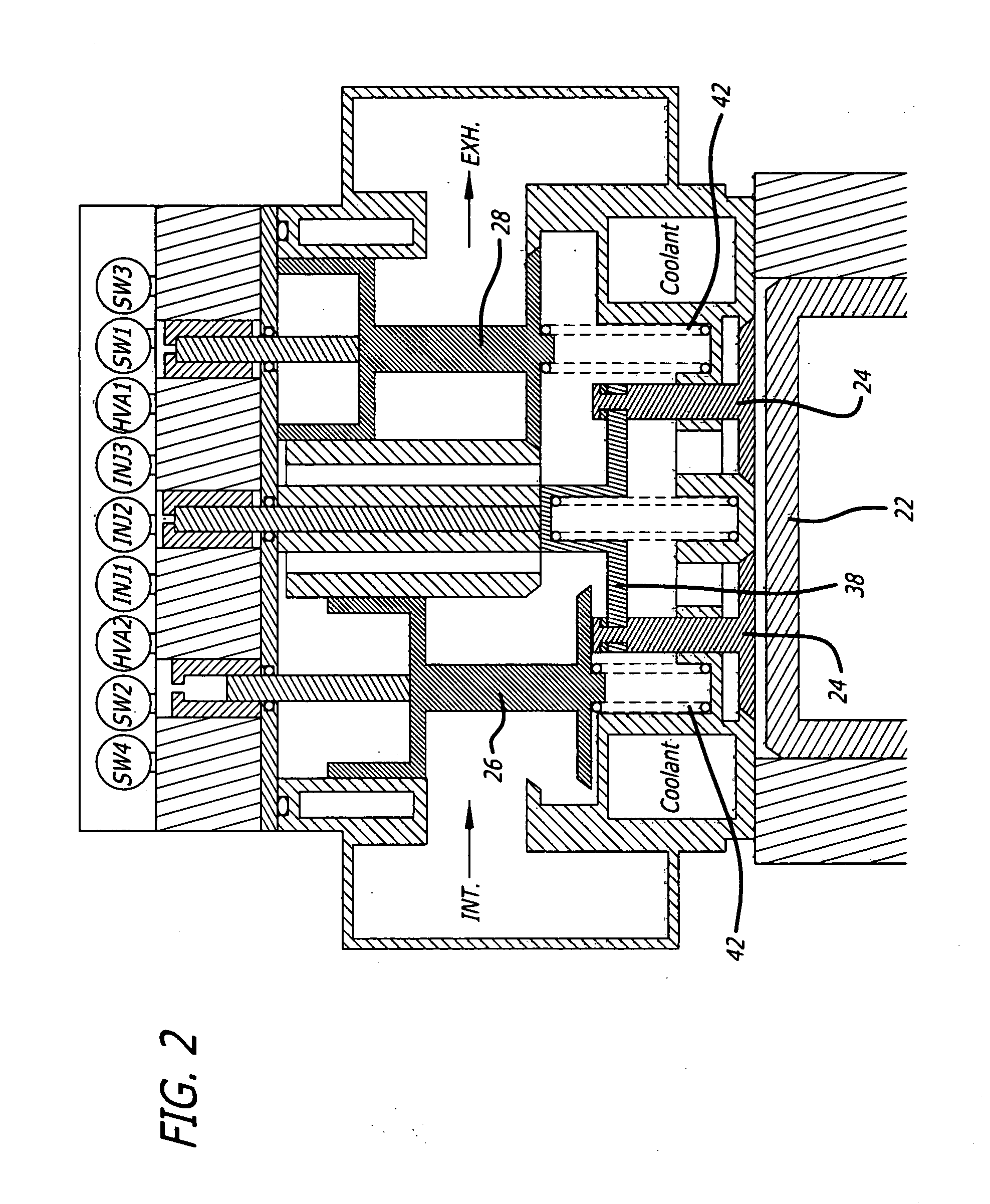

[0014] The preferred embodiments of the present invention are intended to be used on diesel engines, though this is not a limitation of the invention, as the invention is also applicable to gasoline engines, or engines intended to operate on other fuels. Also, while the present invention is preferably to be used on turbocharged engines, this too is not a limitation of the invention, as the present invention is also applicable to non-turbocharged engines. Further, the preferred embodiments are intended to be used on engines having multiple intake and multiple exhaust valves, as is characteristic of most modern engines, though this too is a preference, not a limitation of the invention.

[0015] The present invention is intended to increase the volumetric efficiency of engines, in the exemplary embodiments disclosed herein, engines having two intake valves and two exhaust valves per cylinder, by selectively using all four valves, the two intake and the two exhaust valves, as both the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com