Intake valve timing in multi-valve, camless engines

a technology of camless and intake valve, which is applied in the direction of machines/engines, non-mechanical valves, output power, etc., can solve the problems of reducing the maximum power output of the engine, and achieve the effect of improving the combustion system of the engine, reducing the maximum output power of the engine, and high turbulence flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

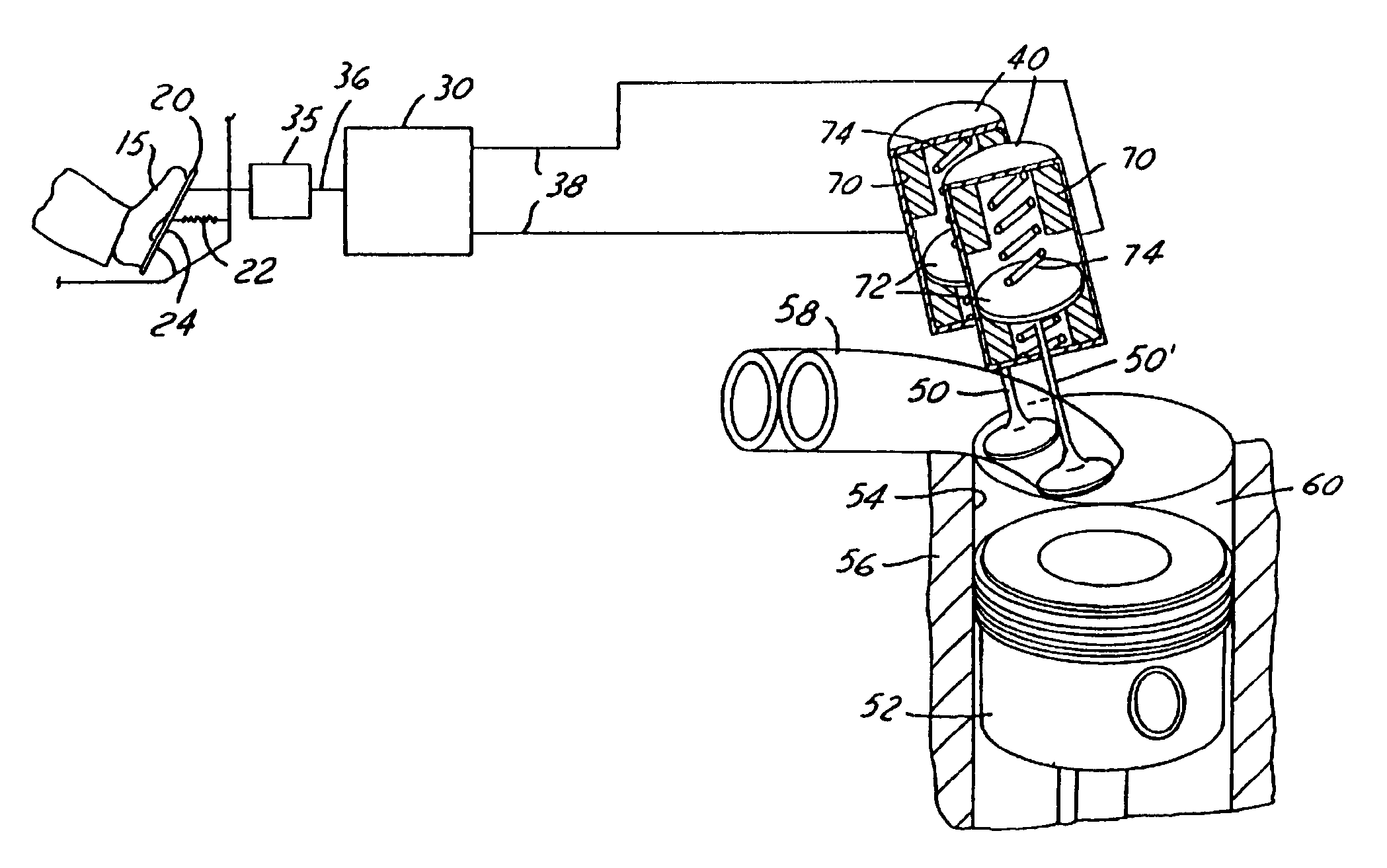

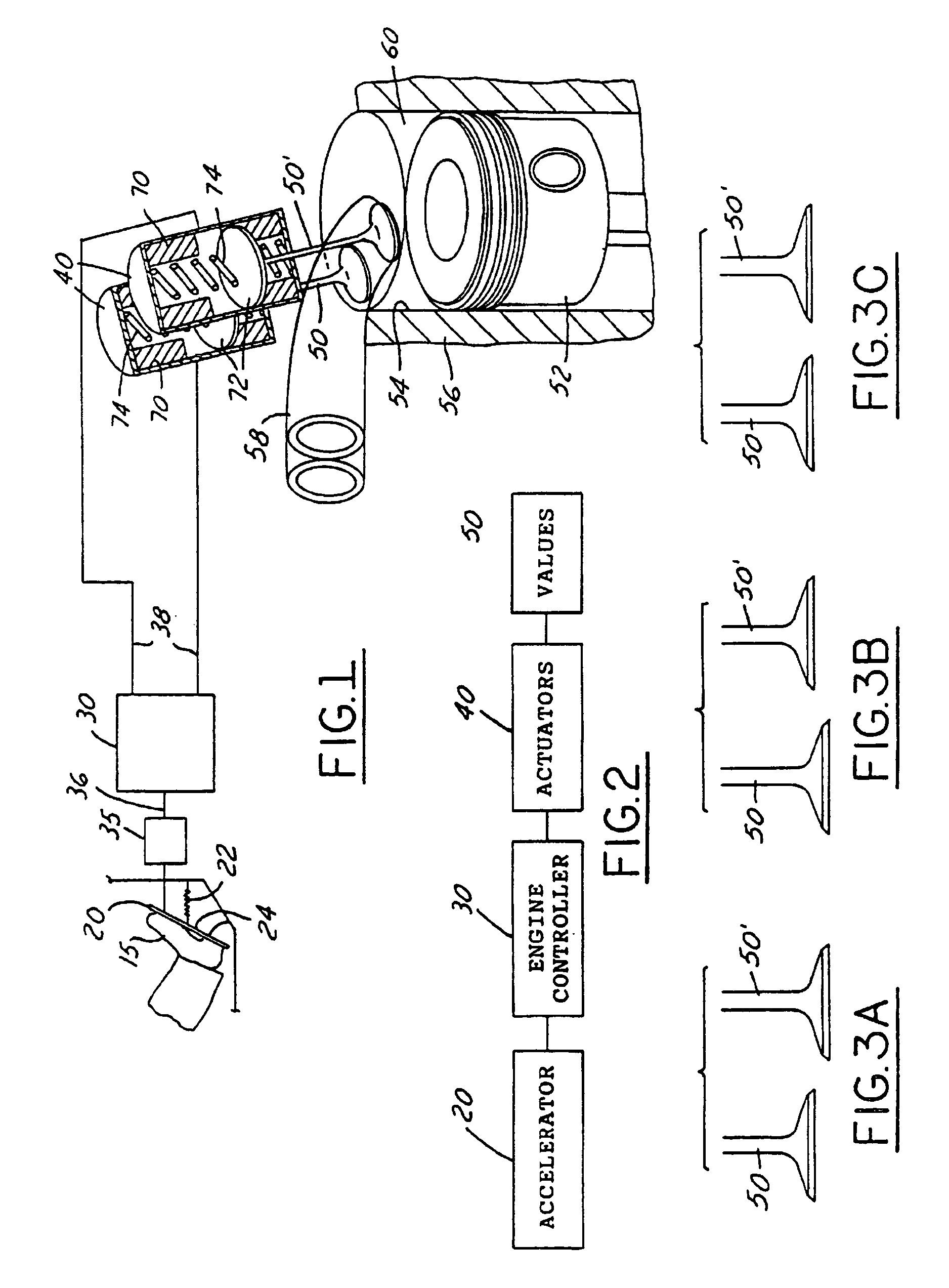

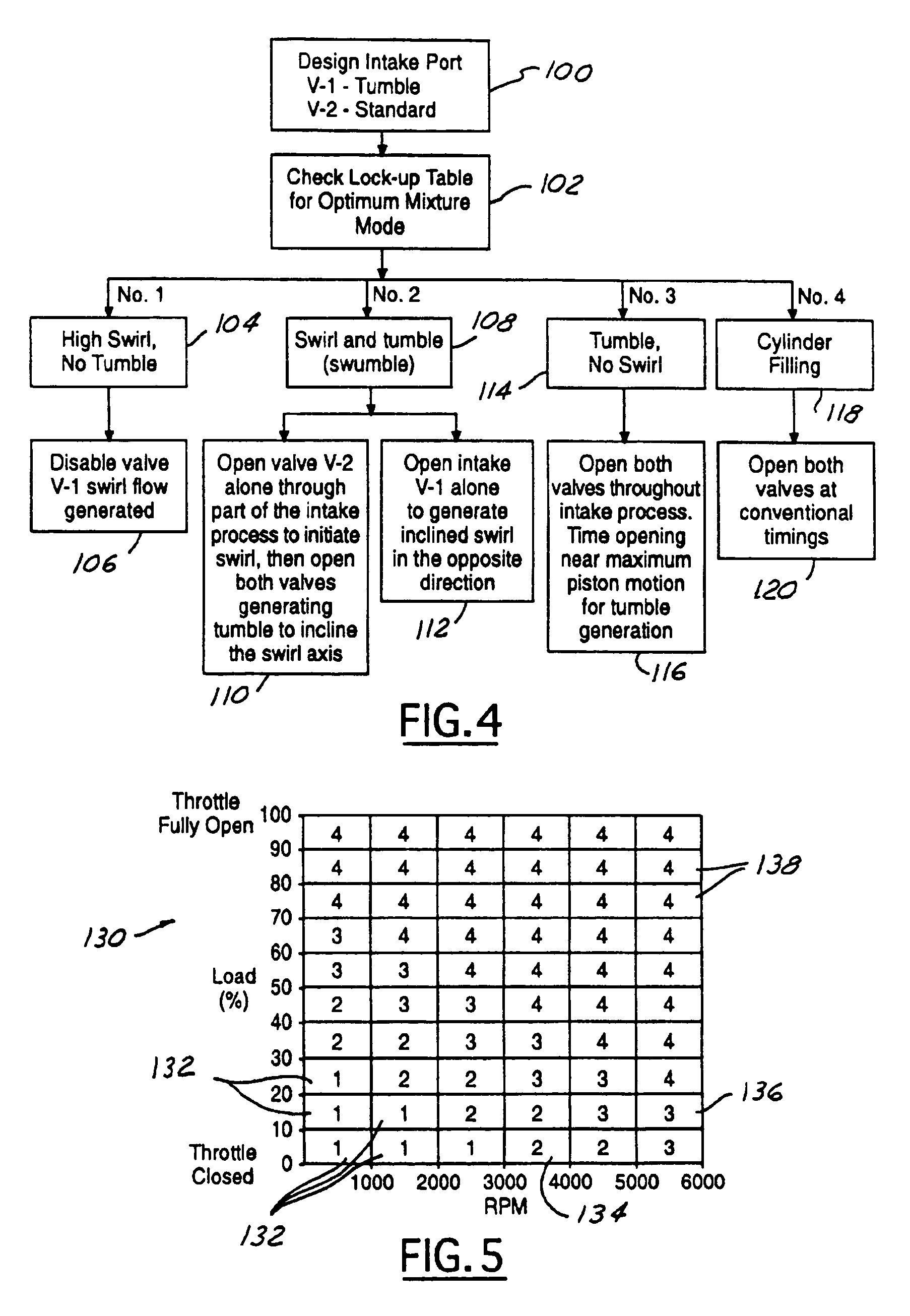

[0017]The formation of swirl or tumble motion of air / fuel mixtures in combustion chambers is important for increasing the burn rate of the fuel in spark ignited engines. In tumble, the inducted air rotates about an axis perpendicular to the axis of the cylinder. Swirling air flow motion has its axis of rotation parallel to the cylinder axis. Finally, the word “swumble” denotes in-cylinder flow motion with an axis of rotation inclined relative to the cylinder axis.

[0018]In many cases, the generation of the tumble and / or swirl flows of air comes at the expense of reducing the discharge coefficient of the flow through the valve by masks or other obstructions to flow being placed in the vicinity of the valve opening. Thus, the power output of the engine is reduced or degraded. The present invention generates high swirl and tumble air flows by delaying or advancing the opening of one intake valve relative to the other in the multi-valve engine and does not degrade the discharge coeffici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com