Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "Calcium arsenite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium arsenate is the inorganic compound with the formula Ca3(AsO4)2. A colourless solid, it was originally used as a pesticide and as a germicide. It is highly soluble in water, as compared with lead arsenate, which makes it more toxic.

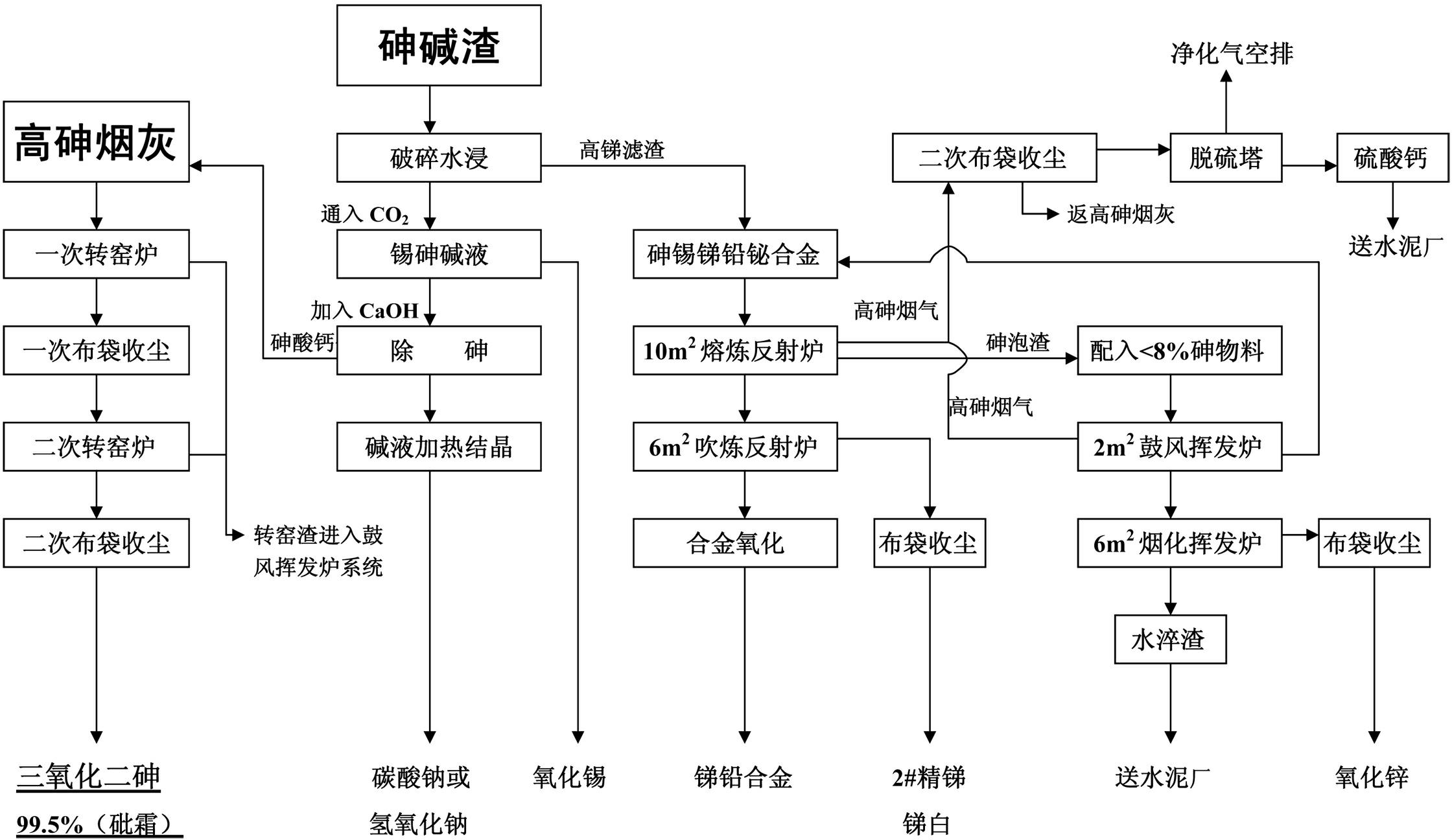

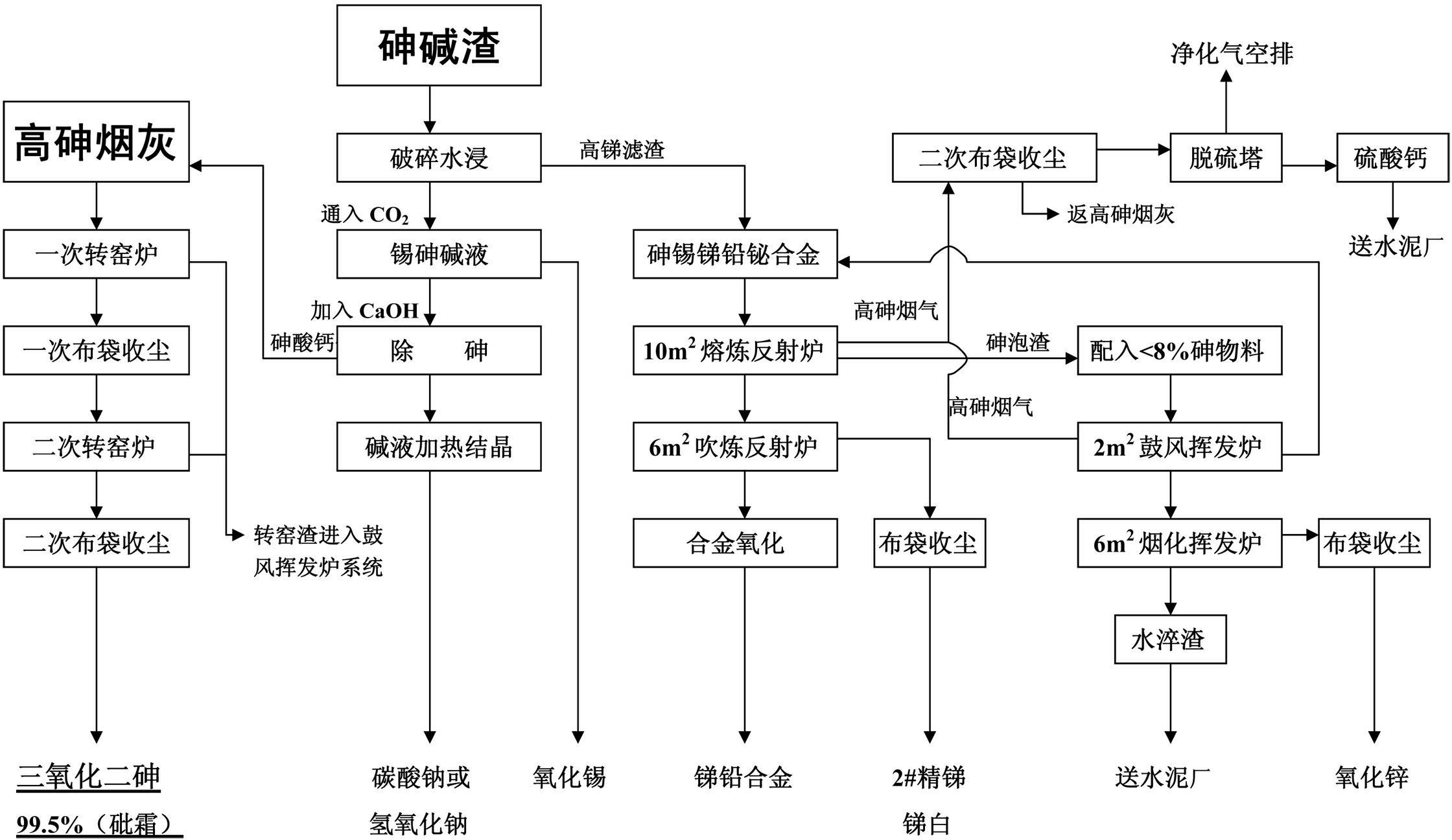

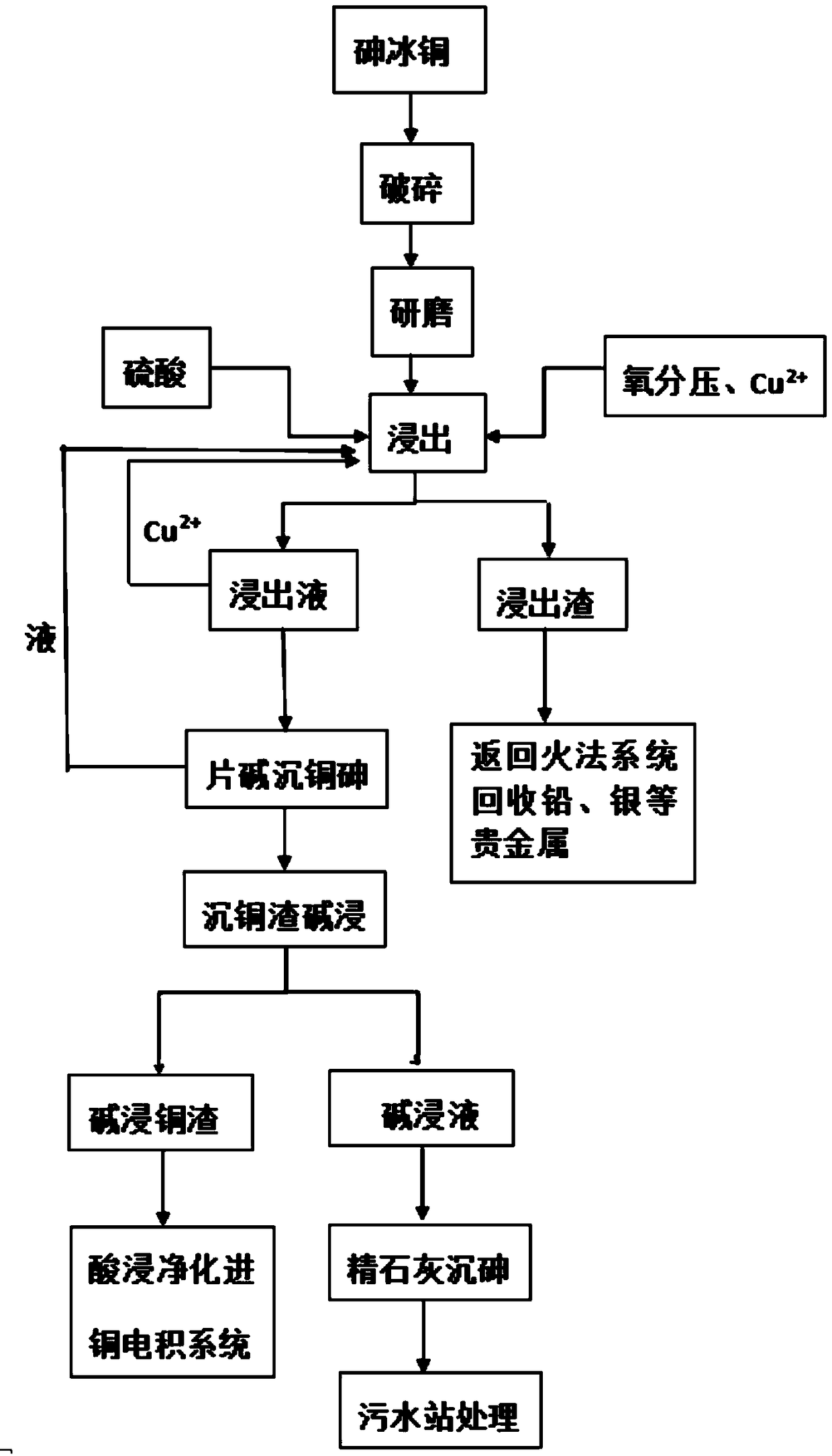

A comprehensive recovery method for complex arsenic-containing and valuable metal slag dust materials

ActiveCN102286665ANo pollutionCement productionProcess efficiency improvementRecovery methodTin dioxide

Disclosed is a comprehensive recovery method for a complex material containing arsenic and valuable metal slags, comprising passing the materials containing arsenic through a primary rotating kiln to volatilize the arsenic, and through a secondary rotating kiln to purify the arsenic, so that an arsenic product containing 99.5% As 2 O 3 is produced; reduction smelting slags from the primary and secondary rotating kilns in a blowing volatilization furnace, with the resultant highly arsenious dust being returned to the primary rotating kiln for treatment, and the slags being used as a raw material in a cement manufactory and a raw material for zinc after undergoing strongly reductive dearsenization and volatilization of zinc in a fuming furnace; the resultant alloy containing arsenic being subjected to basic oxidizing refinement, and the oxidized / refined alloy after dearsenizations containing Pb > 72%, Sb > 12%, As 2 O 3 <0.02%, being sold as a lead-antimony alloy; the basic slags from the refinement, containing As 2 O 3 10%-20%, being subjected to crushing, dissolution in base, and filtration, with the slags thereof being returned to a blowing volatilization furnace for treatment; precipitating tin from the basic solution containing tin and arsenic by blowing in CO 2 , with the filtered tin oxide being sold as a raw material for tin; adding Ca(OH) 2 into the basic filtrate containing arsenic to precipitate arsenic, returning the filtered slags of calcium arsenate to the primary rotating kiln for treatment, and evaporating the remaining basic solution to concentrate and recover the base.

Owner:LEIYANG YANXIN NON FERROUS METALS

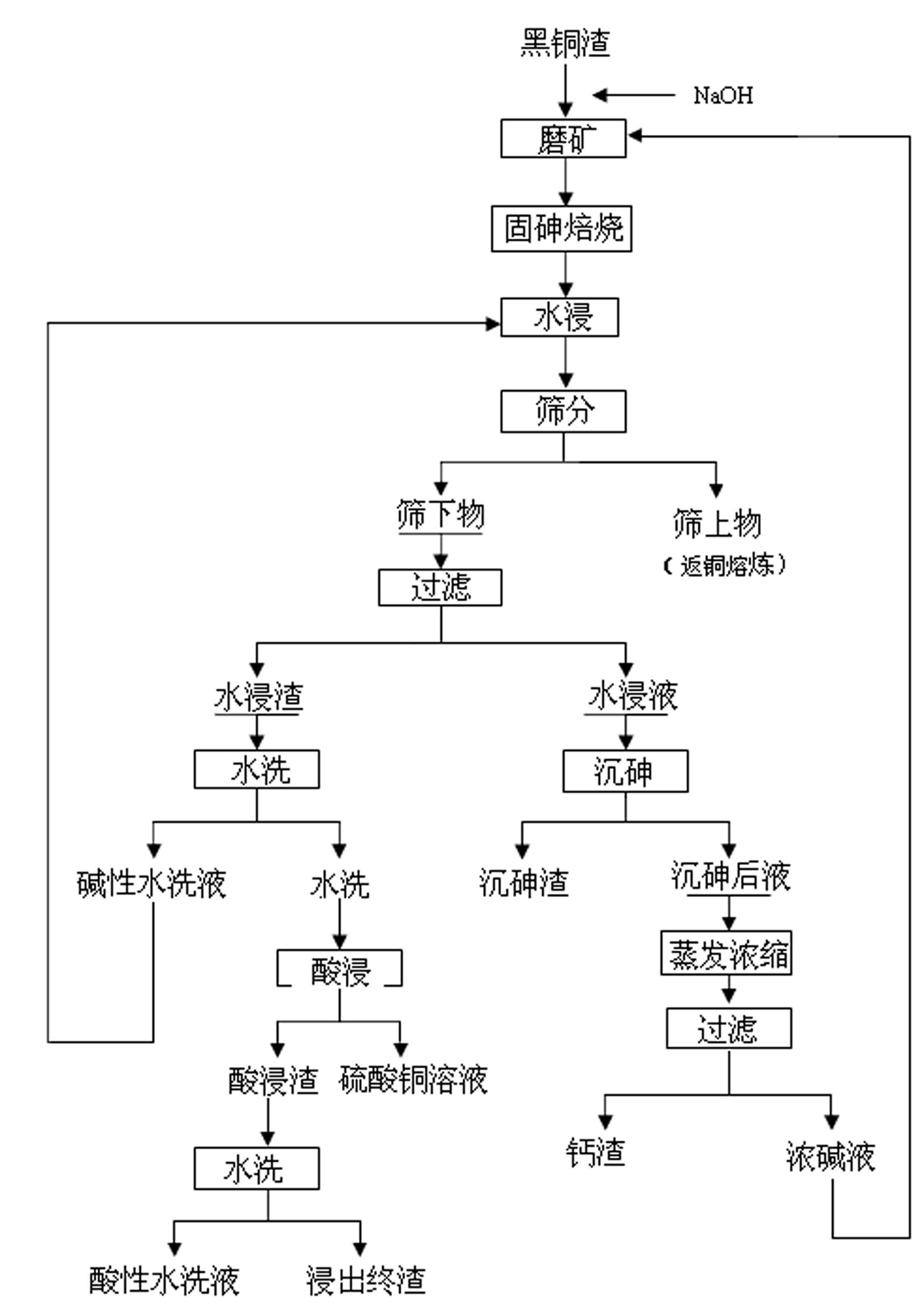

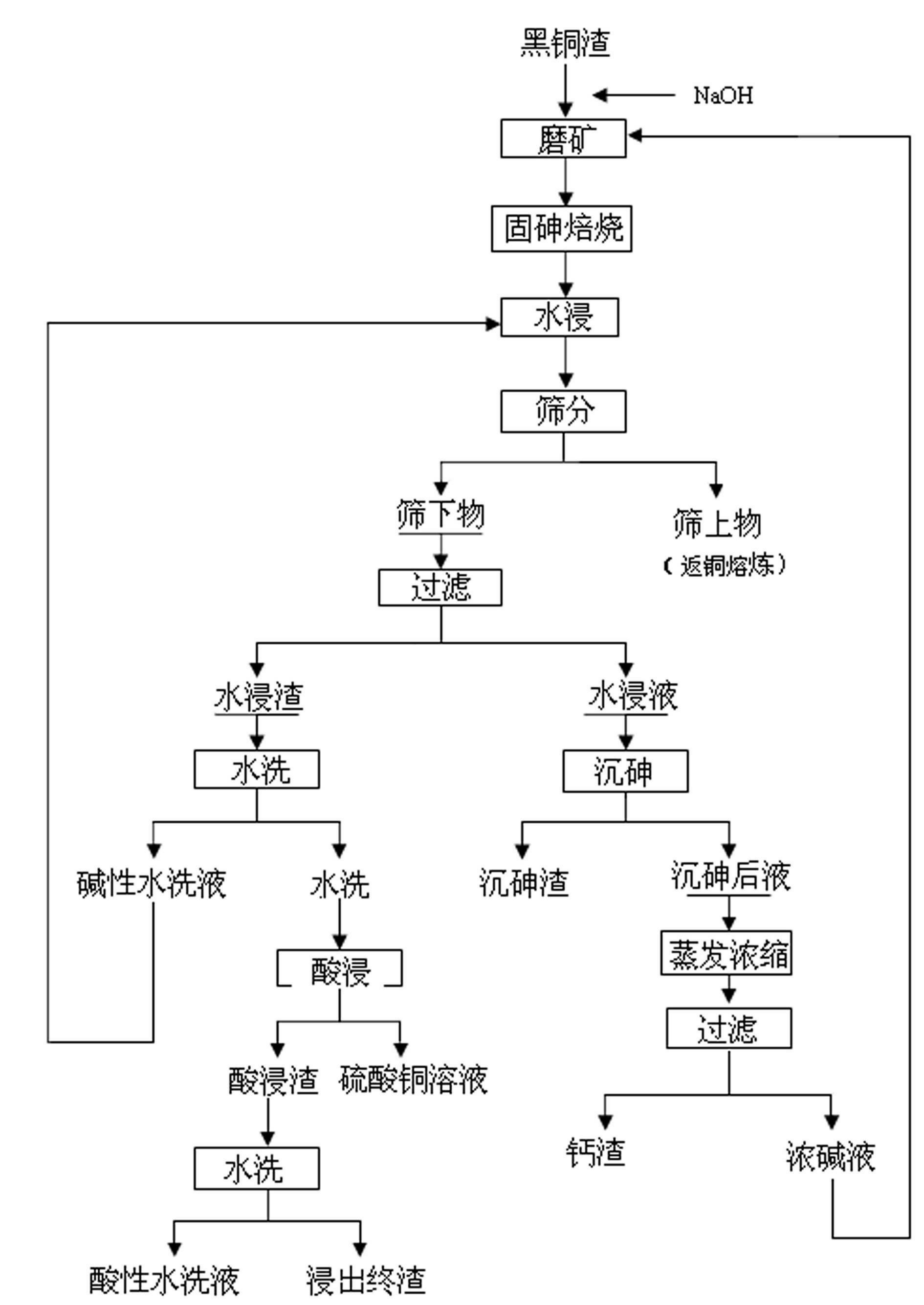

Method for treating arsenic-containing waste copper slag

InactiveCN102634672ASolve the open circuit problemHigh enrichment ratioProcess efficiency improvementArsenateEnvironmental engineering

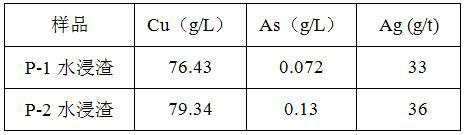

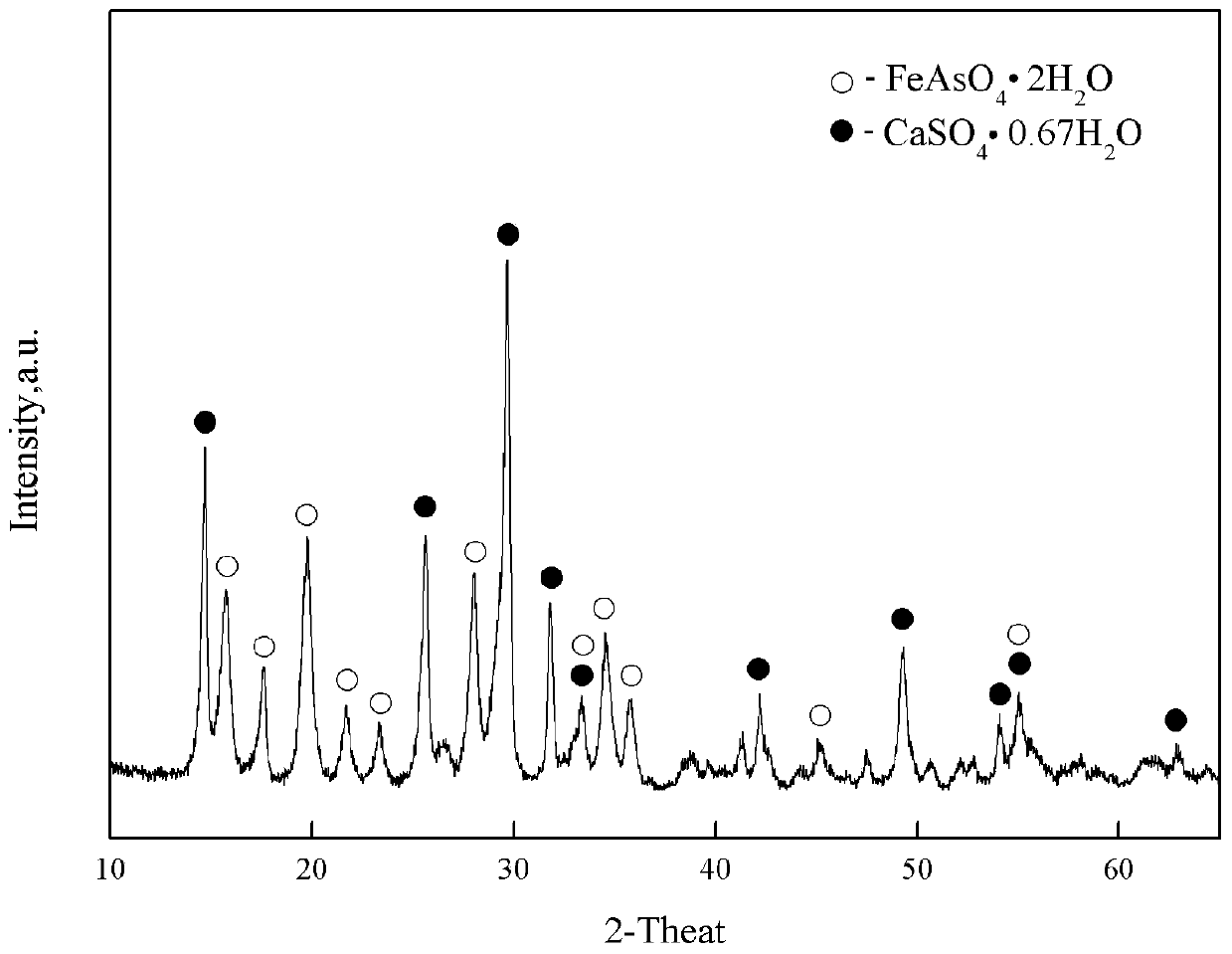

The invention provides a method for treating arsenic-containing waste copper slag. The method comprises the following steps of: adding alkali and arsenic fixation roasting on the arsenic-containing waste copper slag from a copper electrolysis purification procedure to convert the arsenic into low-toxicity, water-soluble and nonvolatile arsenate, leaching the roasting slag into water to remove the arsenic, recovering copper and enriching antimony bismuth silver by virtue of acid leaching, and embedding calcium arsenate sediment converted from the arsenic in the water leaching solution; and comprehensively recovering valued metals such as copper, silver, antimony and bismuth in the black copper slag. The method is a safe and effective wet smelting method for recovering the valued metals in the black copper slag, and the arsenic and the copper are leached separately; the recovery rate of the copper in the black copper slag reaches 99.6 percent, and the removal rate of the arsenic reaches over 98 percent; over 95 percent of antimony and over 98 percent of bismuth enter the slag, and over 98 percent of silver also enters the acid leaching slag by adding trace chlorine radicals during acid leaching, so that the antimony, the bismuth and the silver are comprehensively recovered; and the method has the advantages of low equipment investment, short flow, low running cost and safe and reliable operating environment.

Owner:JINCHUAN GROUP LIMITED

Method for separating arsenic and selenium from copper anode slime alkaline leach liquor

ActiveCN104911358ANo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumPregnant leach solutionBarium salt

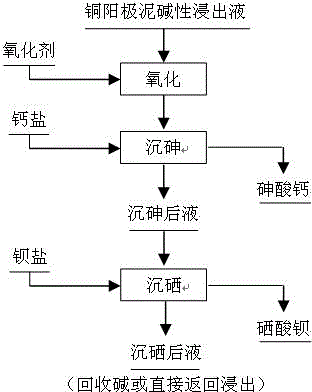

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

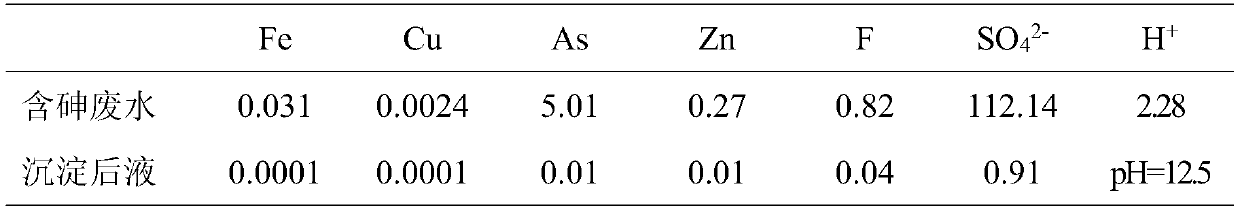

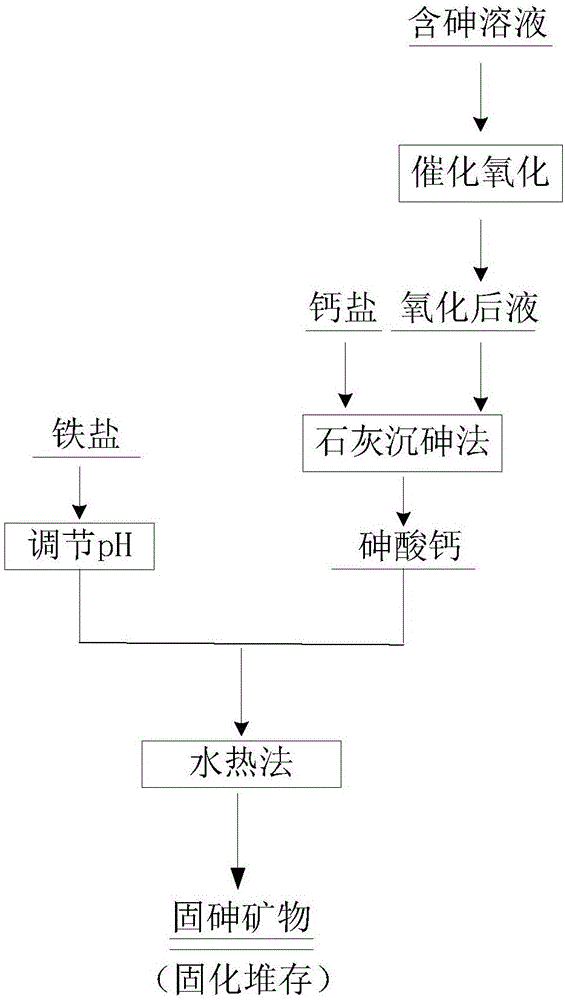

Method for treating arsenic-containing wastewater and solidifying arsenic

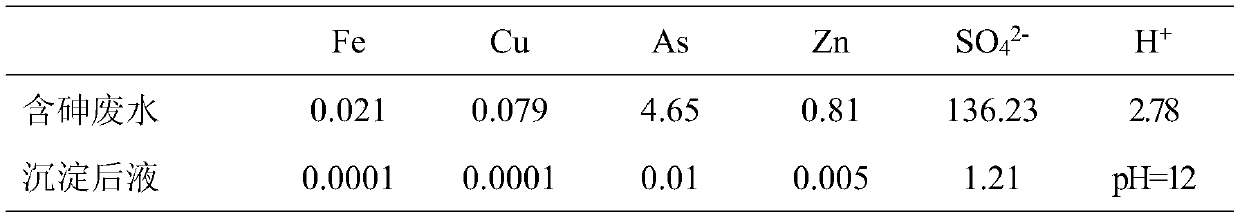

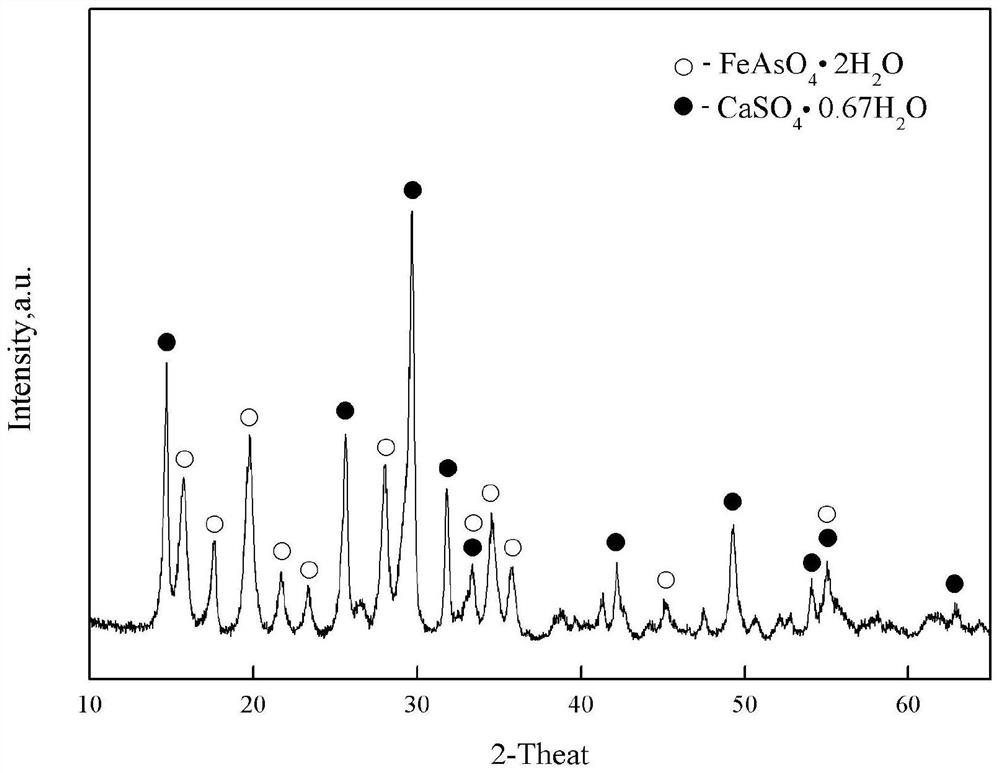

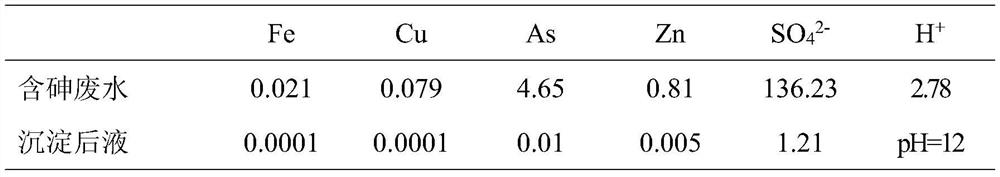

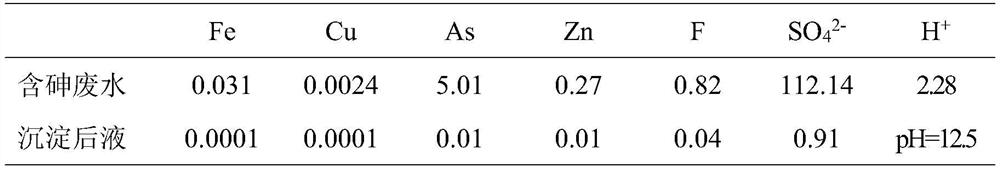

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

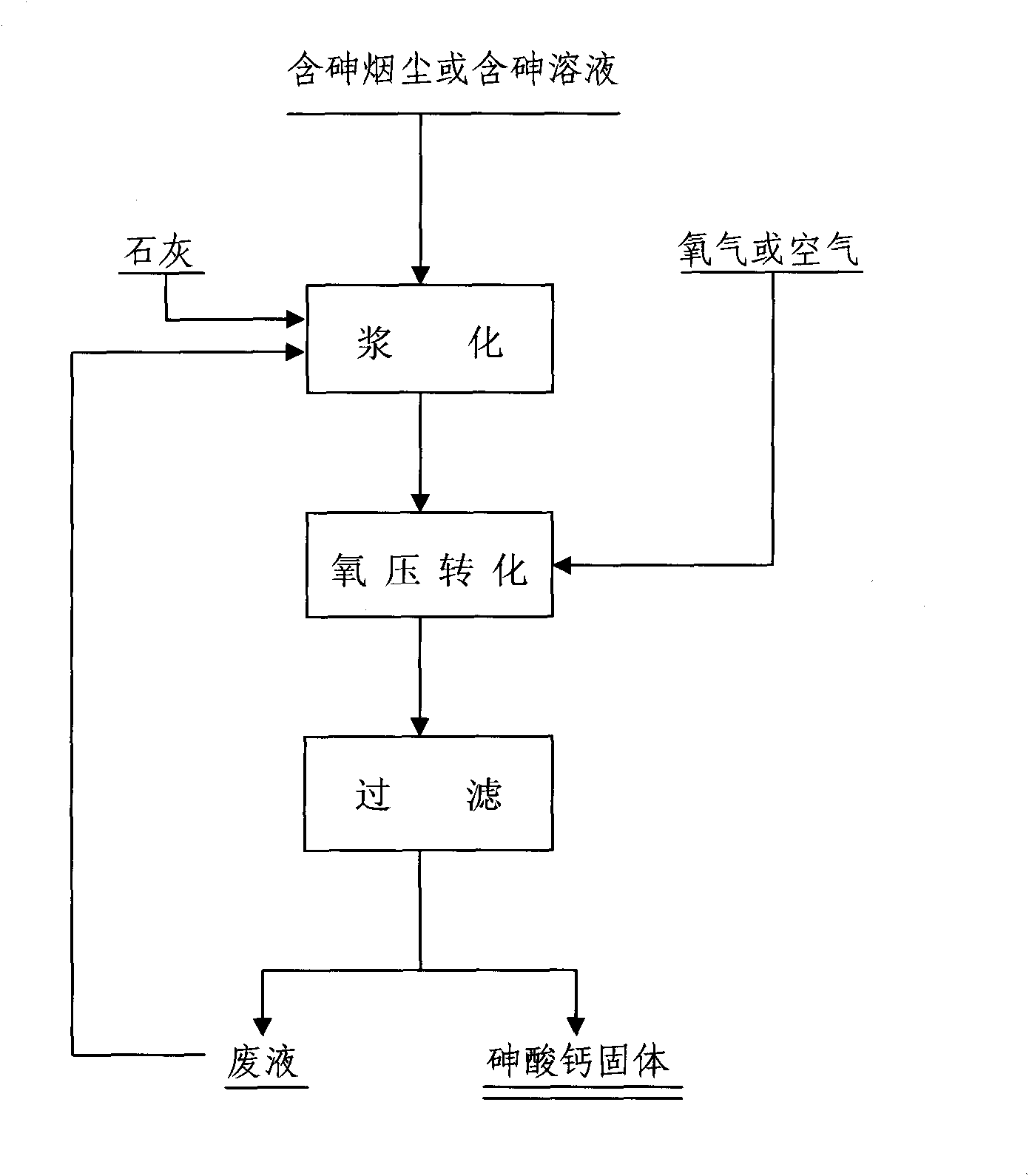

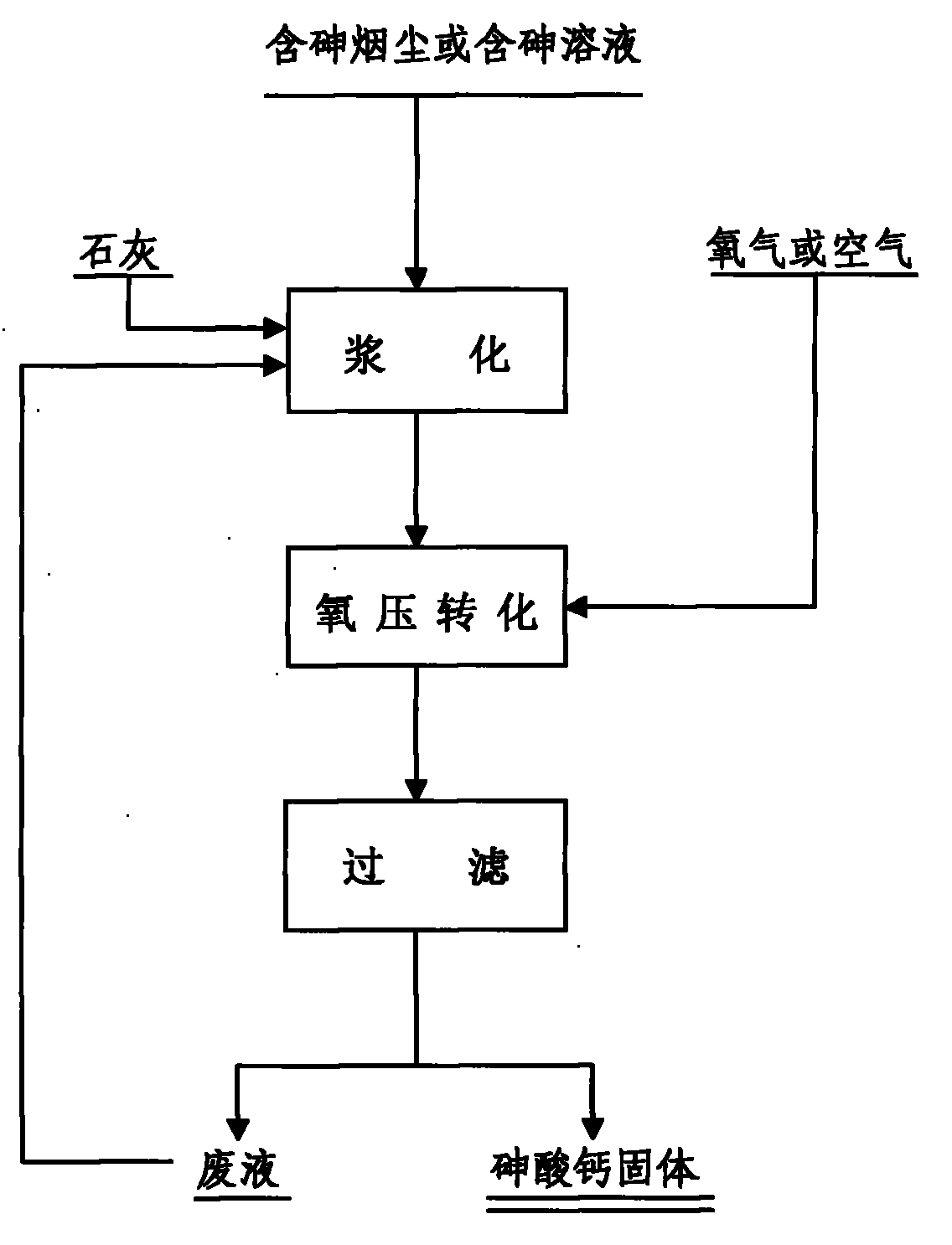

Method for synthesizing calcium arsenate by oxygen pressure conversion

InactiveCN101817554ANo pollution in the processEliminate pollutionArsenites/arsenatesDispersed particle separationWater insolubleWastewater

The invention relates to a method for synthesizing water insoluble calcium arsenate by oxidizing arsenic in arsenic-containing smoke dust or solution and belongs to the technical field of metallurgy. The method comprises the following steps of: (1) mixing and stirring the arsenic-containing smoke dust or solution with weighed lime to make slurry; and (2) adding the slurry material into a closed stirring reactor, introducing the air or oxygen into the closed container till the oxygen partial pressure in the closed container reach 0.6 to 1.5MPa, stirring the slurry material under a closed condition to perform an reaction to oxide trivalent arsenic in the slurry material into pentavalent arsenic and convert the pentavalent arsenic into water insoluble calcium arsenate, cooling the reaction solution, and filtering the reaction solution to obtain solid calcium arsenate. In the method, the arsenic in the arsenic-containing smoke dust or solution is oxidized into the pentavalent arsenic and the pentavalent arsenic is converted into the water insoluble calcium arsenate, neither waste gases nor waste water is produced in the process, the problem of opening a way for the arsenic in various kinds of arsenic-containing smoke dust is solved, and the environmental pollution caused by arsenic is eliminated.

Owner:YUNNAN TIN GROUP HLDG

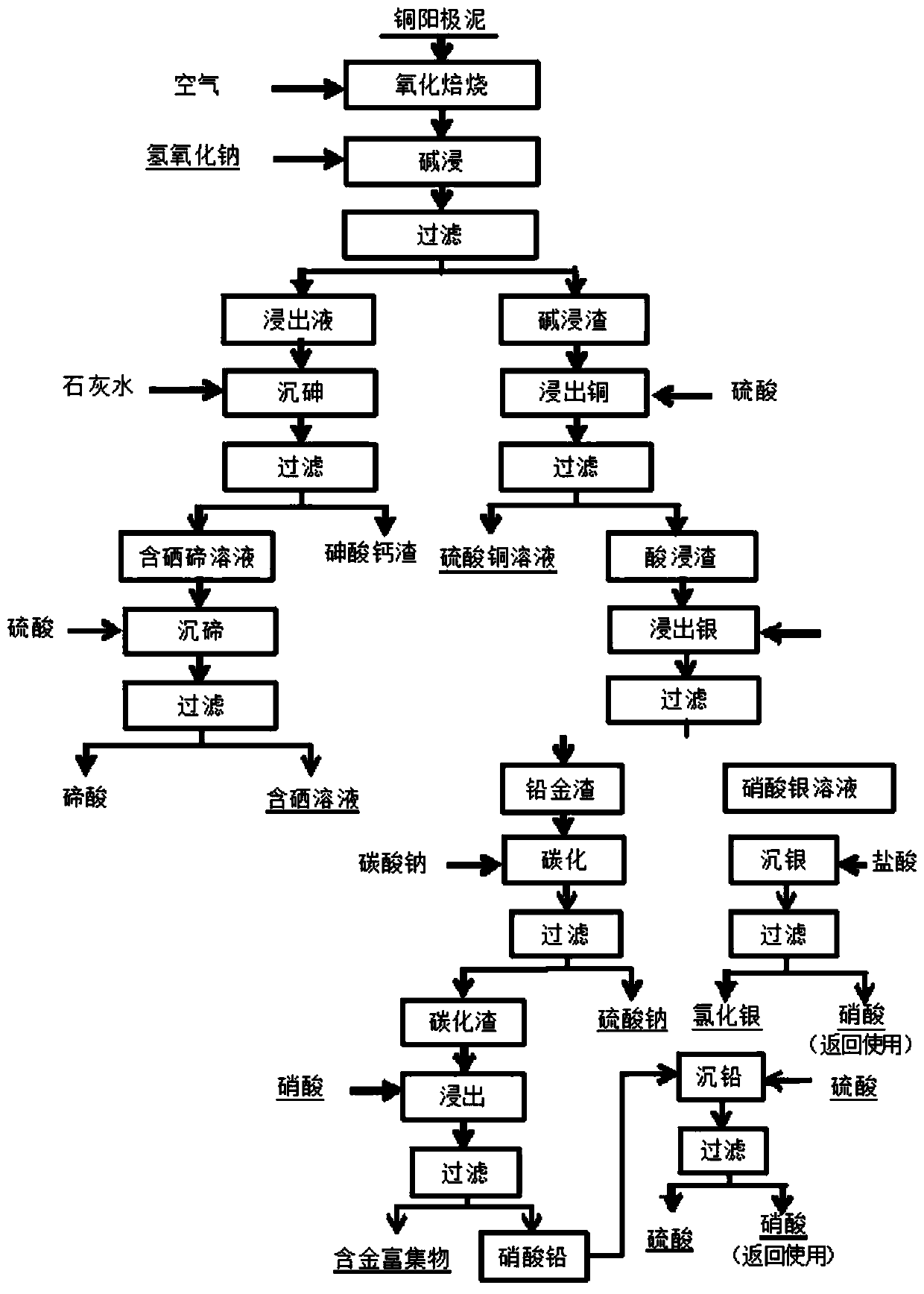

Method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud

ActiveCN111575483AAvoiding the problem of hard-to-leach telluriumAchieve recyclingProcess efficiency improvementSelenium/tellurium oxyacid saltsSlagLead nitrate

The invention discloses a method for separating selenium, tellurium, arsenic, copper, lead and silver and enriching gold from copper anode mud, and relates to the technical field of rare and preciousmetal metallurgy. The method comprises the following steps that roasted products obtained through low-temperature oxidization roasting of the copper anode mud and sodium hydroxide react to obtain selenium, tellurium and arsenic containing leaching liquor and alkaline leaching slag; the leaching liquor and whitewash react to obtain a selenium and tellurium containing solution and calcium arsenate slag; the alkaline leaching slag and sulfuric acid react to obtain copper sulfate and acid leaching slag; sulfuric acid and the selenium and tellurium containing solution react to obtain telluric acidand a selenium containing solution; the acid leaching slag and nitric acid react to obtain a silver nitrate solution and lead and gold slag; silver nitrate and hydrochloric acid react to obtain silverchloride and nitric acid; the lead and gold slag and a sodium carbonate solution react to obtain carbonization slag and a sodium sulfate solution; the carbonization slag and nitric acid react to obtain a lead nitrate solution and gold containing enrichment; and the lead nitrate solution and sulfuric acid react to obtain a lead sulfate and sulfuric acid solution. The method aims to solve the problems that existing methods for recycling metal from copper anode mud, the cost is high, recycled metal is single, and the comprehensive recovery effect is poor.

Owner:KUNMING BOREN PRECIOUS METALS +1

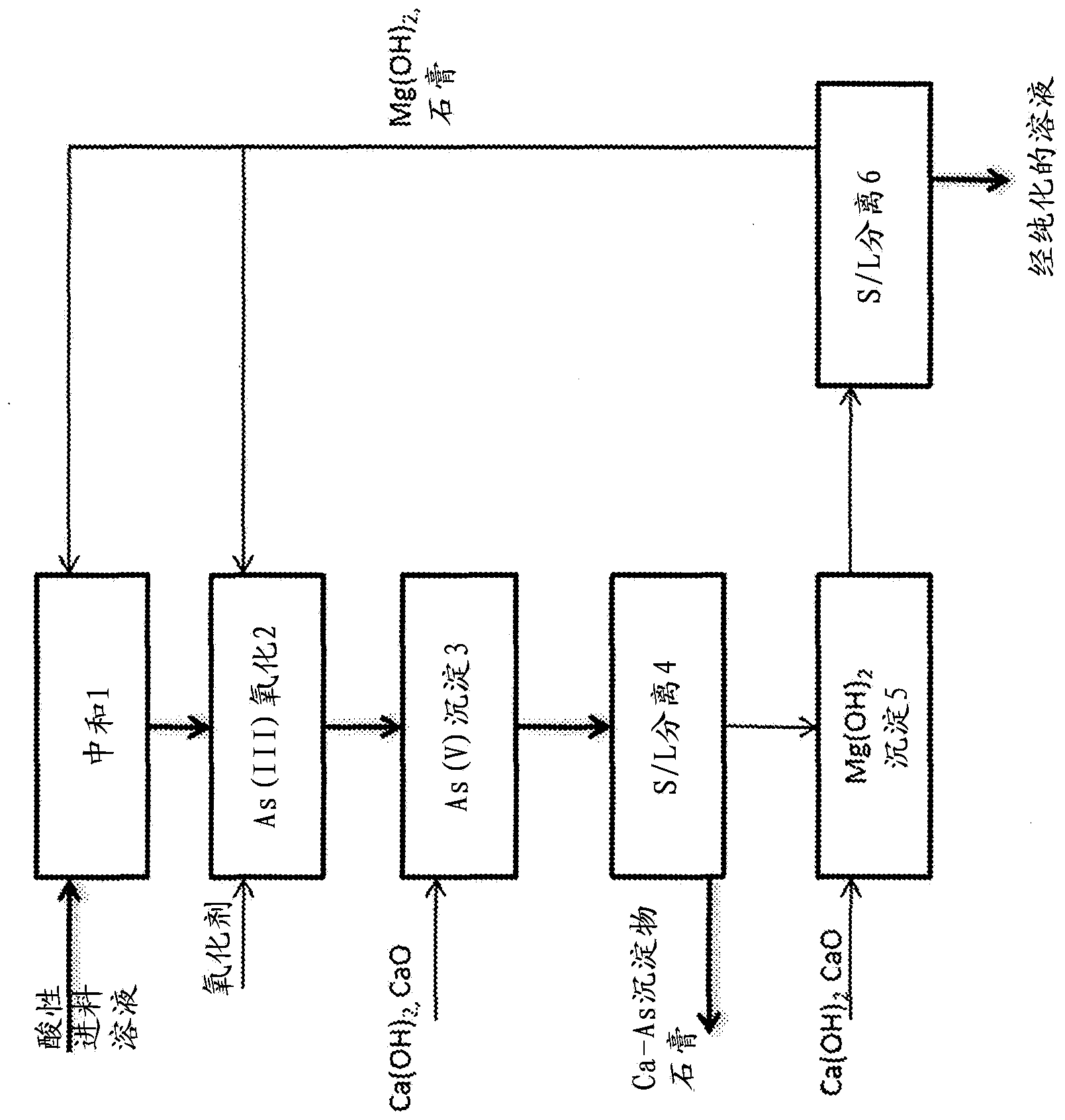

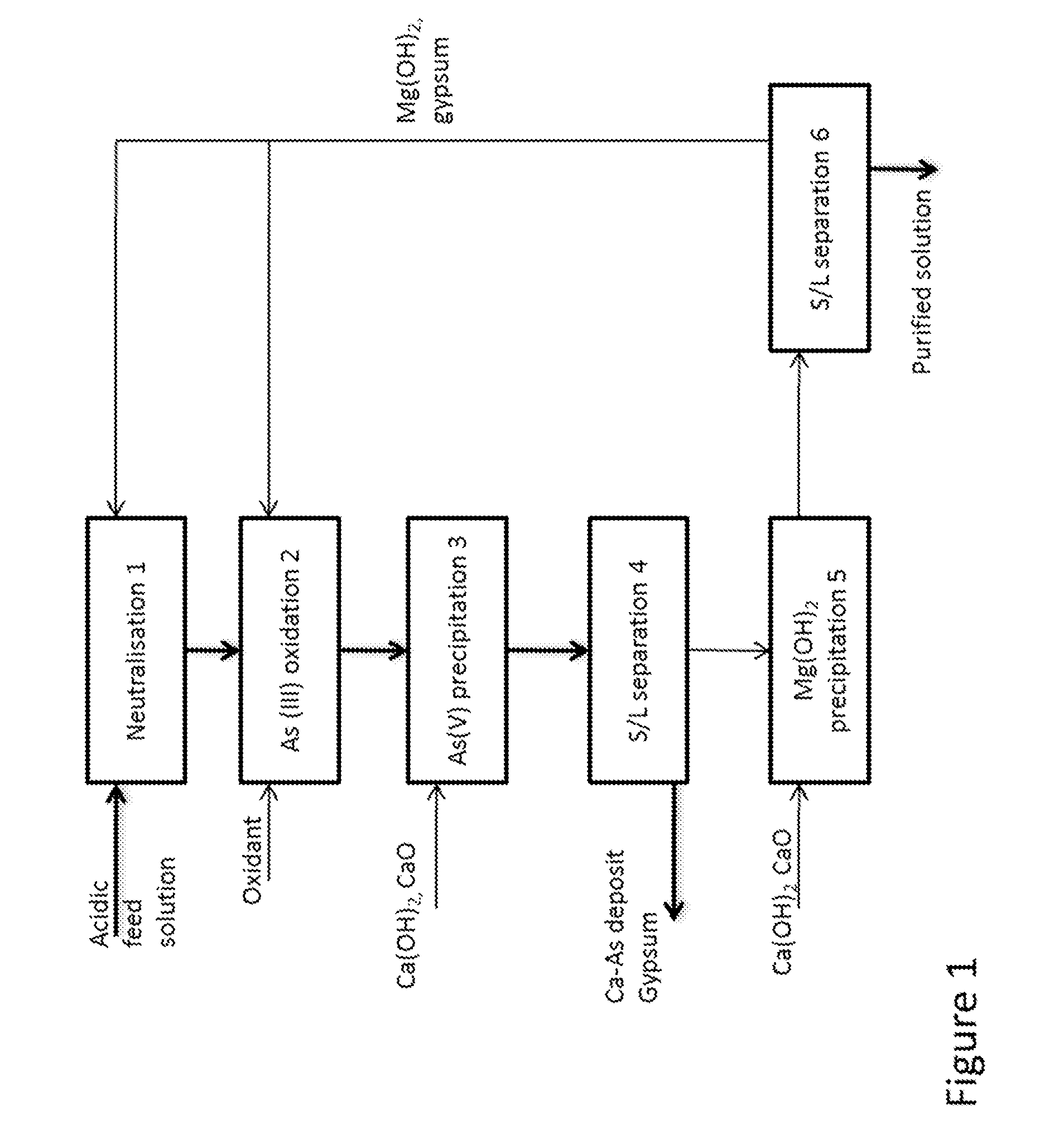

Method for producing a poorly soluble calcium-arsenic compound

InactiveCN103415472AArsenites/arsenatesCalcium/strontium/barium sulfatesCalcium arseniteArsenic Compound

The invention relates to a method for precipitating pentavalent calcium arsenate from an acidic solution, in which arsenic is at least partially in trivalent form. The acidic solution is neutralised before being routed to an arsenic oxidation stage,and a poorly soluble calcium-arsenic compound is precipitated from the solution, in which all the arsenic is pentavalent.

Owner:OUTOTEC OYJ

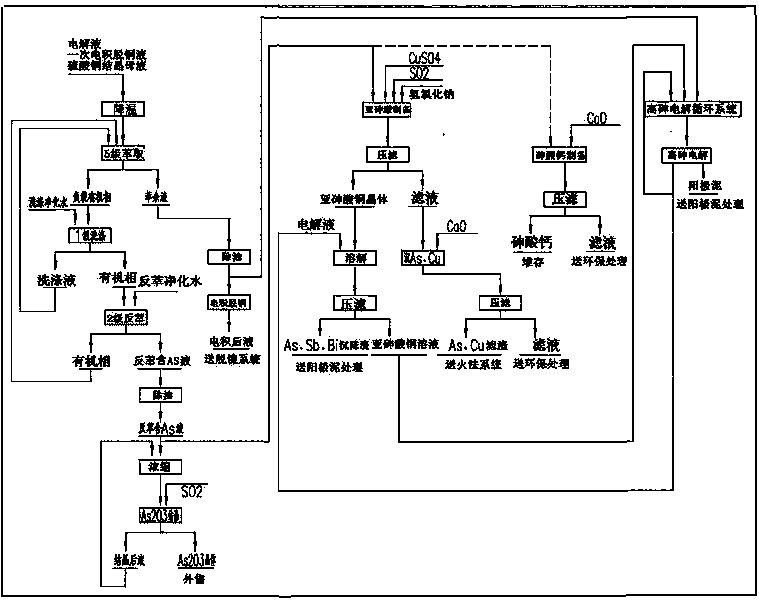

Compound technology for removing As, Sb, Bi by utilizing copper electrolyte

ActiveCN104018185AReduce power consumptionReduce energy consumptionElectrolysis componentsPhotography auxillary processesElectrolytic agentArsenic product

The invention discloses a compound technology for removing, Sb, Bi by utilizing copper electrolyte. A process for removing As by means of solvent extraction and a process of removing Sb and Bi by means of solution self-purification are combined; copper arsenite crystals are prepared by As in a back-extraction solution and is used as a high arsenic electrolytic additive; during high arsenic electrolysis, Sb and Bi in the solution can be effectively removed through As (III), and a majority of Sb and Bi in an anode plate enter anode mud. According to the compound technology, the aims of removing As, Sb and Bi can be fulfilled; meanwhile, an electro-deposition induced decoppering and dearsenification method is eliminated in the main process, and a small quantity of nickel removal liquid in the auxiliary process needs to be subjected to electro-deposition treatment. The compound technology is low in power consumption; the amount of H3As gas, black copper plates and black copper powder is obviously reduced; a dearsenification product is sold in a form of As2O3 or stacked in a form of calcium arsenate. According to the method, the operating environment is optimized, the defects that the As removal product contains a large amount of copper in the electro-deposition induced decoppering and dearsenification method and needs to be returned to a pyrogenic process system for separating copper and arsenic are overcome; the electro-deposition during the main impurity removal process is avoided, and the energy consumption is obviously reduced.

Owner:CHINA NERIN ENG

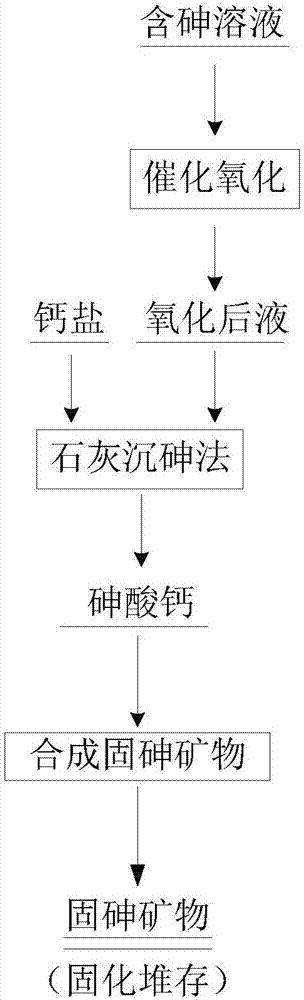

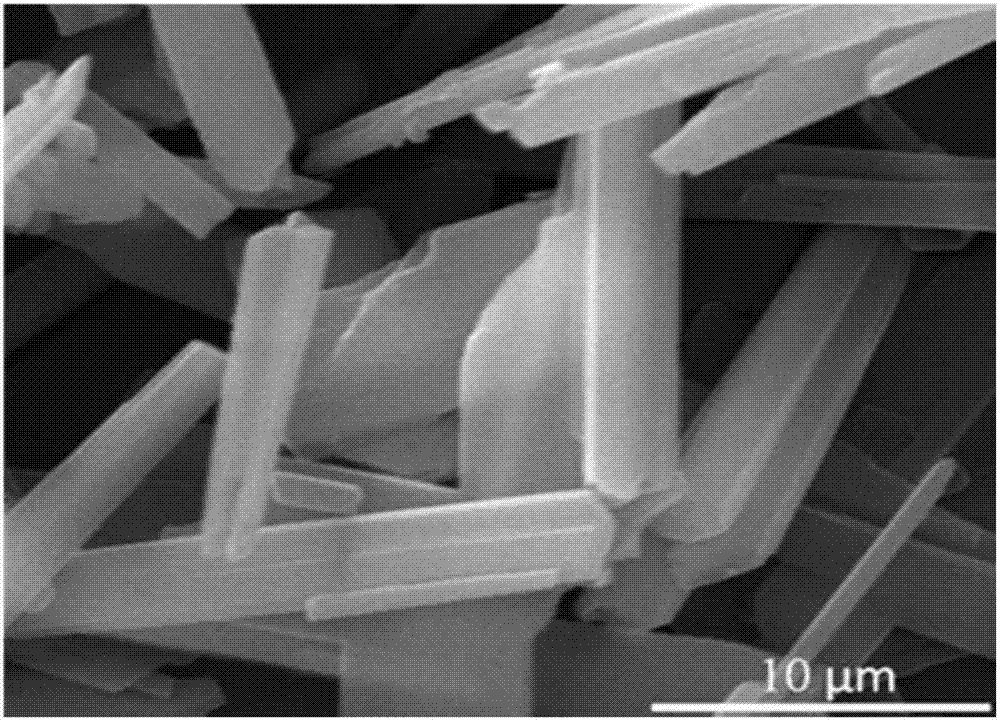

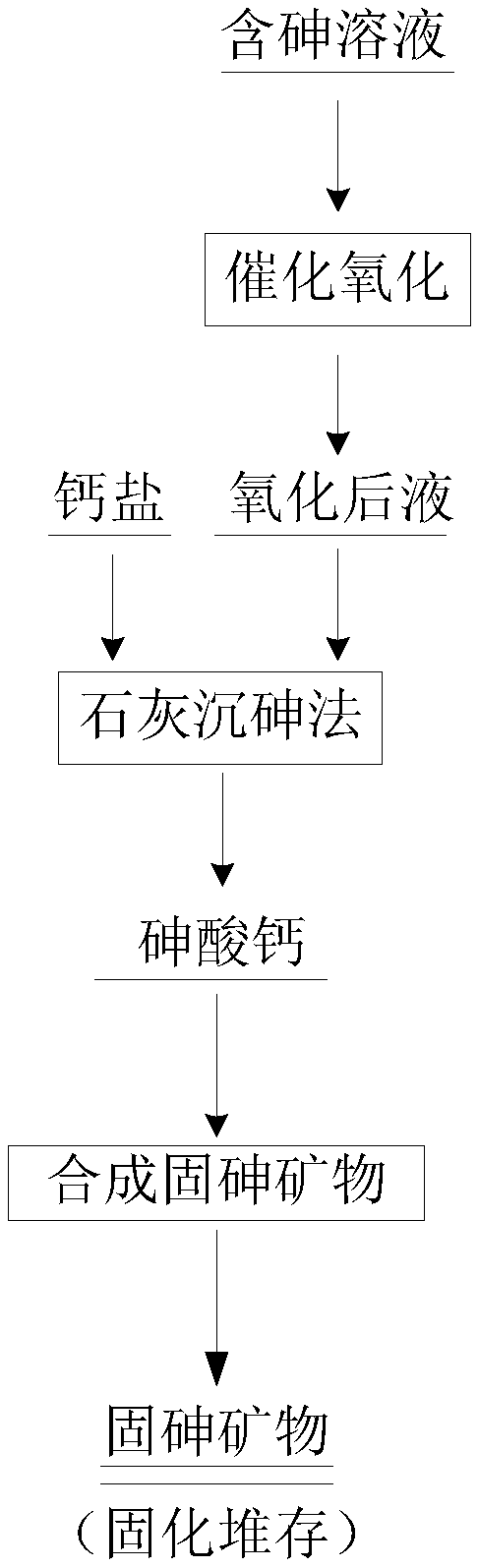

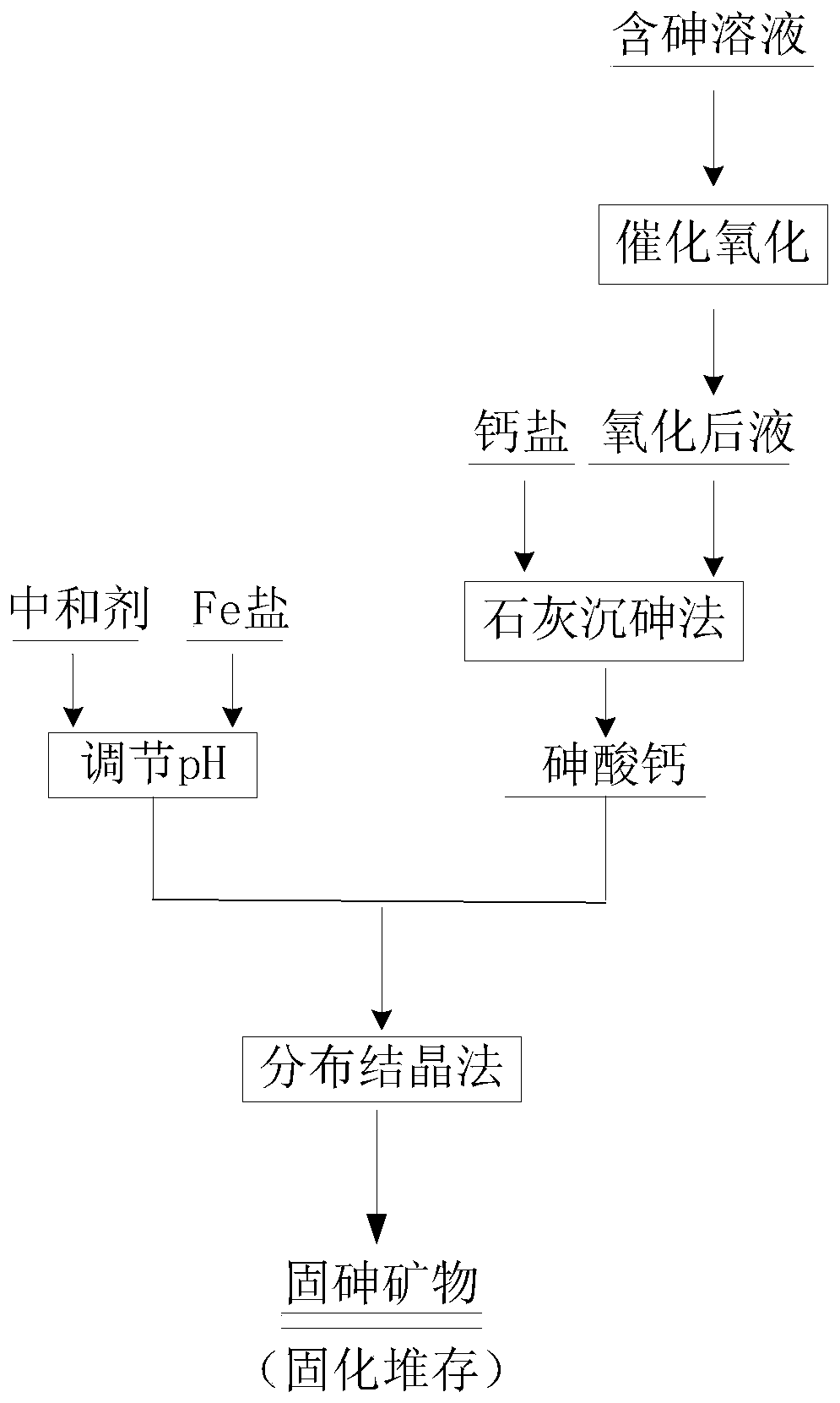

Preparing method for high-stability solid arsenic mineral

The invention relates to a preparing method for high-stability solid arsenic mineral. A high-arsenic containing solution is subjected to arsenic removal and is cured, and the arsenic containing solution is subjected to harmless treatment. After trivalent arsenic in the arsenic containing solution is converted into pentavalent arsenic through catalytic oxidation, after oxidization, liquid is synthesized into the high-stability solid arsenic mineral through combination of the lime arsenic deposition method and one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and the solid arsenic mineral can be directly stacked. Calcium arsenate is obtained through the lime arsenic deposition method firstly and then is converted into the high-stability solid arsenic mineral through one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and toxicity leaching conforms to the GB5085.3-2007(solid waste distinguishing standard-leaching toxicity identification) rule. According to the preparing method, the technology process is short, the arsenic deposition effect is good, the liquid can be directly discharged after arsenic deposition, and the synthesized solid arsenic mineral is high in stability and can be stably stacked within the wide pH value range of 2-11 and under the strong reducing condition.

Owner:CENT SOUTH UNIV

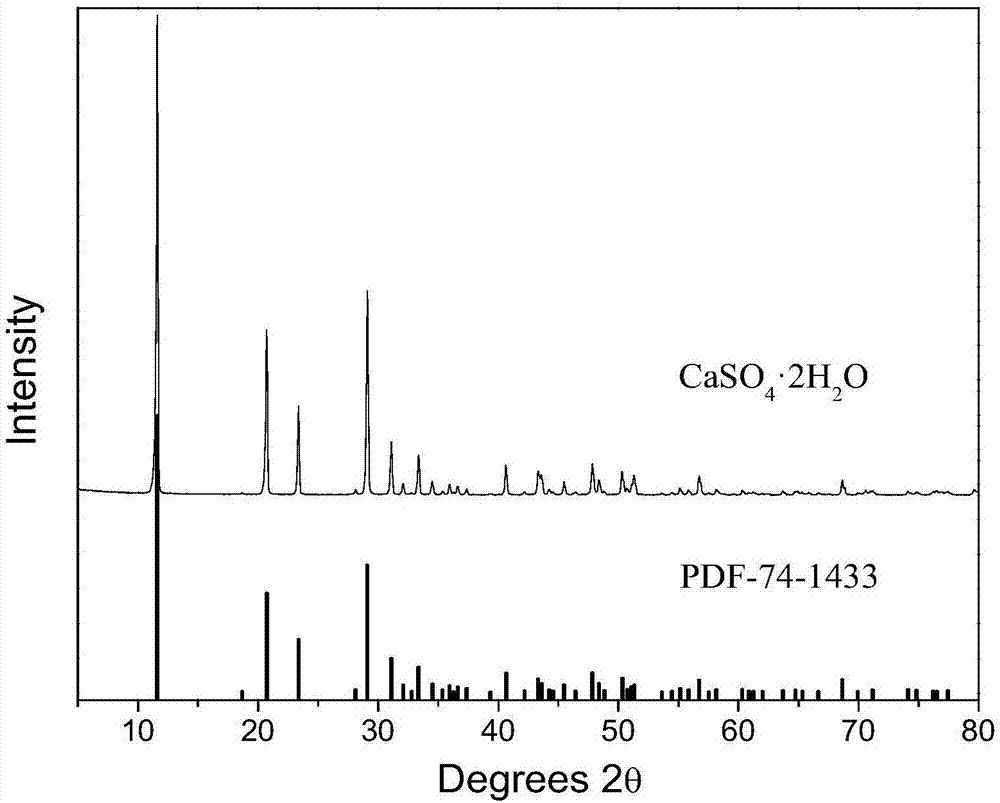

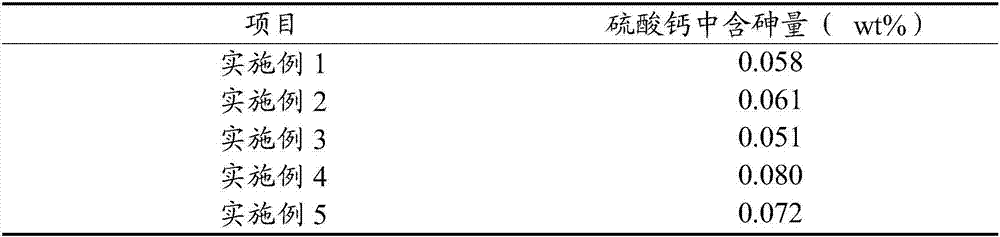

Acid hydrolysis method of calcium arsenate and/or calcium arsenite

ActiveCN107151027AReduce arsenic levelsEmbedding lessCalcium/strontium/barium sulfatesSulfate radicalsDecomposition

The invention provides an acid hydrolysis method of calcium arsenate and / or calcium arsenite. The method comprises the following steps: (1) carrying out double decomposition reaction between calcium arsenate and / or calcium arsenite and a compound containing sulfate radicals in a solution to obtain a mixed system, wherein the pH value of the calcium arsenate and / or the calcium arsenite during the double decomposition reaction is less than or equal to 5.0; (2) carrying out solid-liquid separation of the mixed system to obtain calcium sulfate and an arsenic-containing solution. According to the acid hydrolysis method provided by the invention, the calcium sulfate is produced under a condition that the pH value of the calcium arsenate and / or the calcium arsenite is less than or equal to 5.0, so that a very small amount of arsenic can be embedded in to a calcium sulfate crystal lattice, and the calcium sulfate with low arsenic content can be obtained. An embodiment proves that the arsenic content in the calcium sulfate obtained by adopting the acid hydrolysis method is low to about 0.05 percent by weight, and the calcium sulfate can be used as a cement additive.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Method for preparing high-stability solid arsenic minerals by hydrothermal process

The invention relates to a method for preparing high-stability solid arsenic minerals by a hydrothermal process. Arsenic is removed from a high-arsenic solution and solidified, and harmless treatment is carried out on the arsenic-containing solution. According to the method, trivalent arsenic in the arsenic-containing solution is changed into pentavalent arsenic through catalytic oxidation; and after oxidation, the high-stability solid arsenic minerals are obtained by synthesizing the solution by a lime arsenic precipitation process and the hydrothermal process, and the high-stability solid arsenic minerals can be directly stacked. First, calcium arsenate is obtained by the lime arsenic precipitation process, and then, the calcium arsenate is converted to the high-stability solid arsenic minerals by adopting the hydrothermal process. Toxicity extraction meets the Identification Standards for Solid Wastes and Identification Standards for Extraction Toxicity GB5085.3-2007. The technical process is short, and the arsenic precipitation effect is great. After the arsenic is precipitated, the solution can be directly discharged, and the stability of the synthesized solid arsenic minerals is high. The solid arsenic minerals can be stably stacked in a wide pH value range which is between 2 and 11 under a strong reduction condition.

Owner:CENT SOUTH UNIV

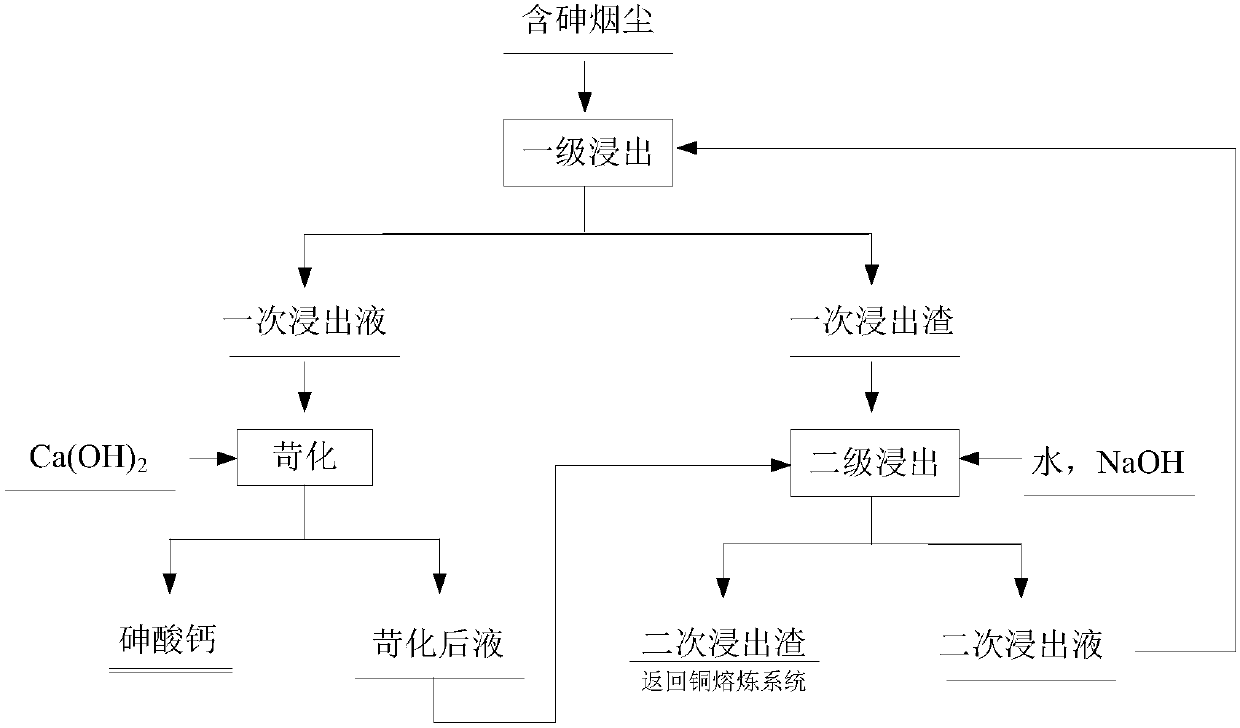

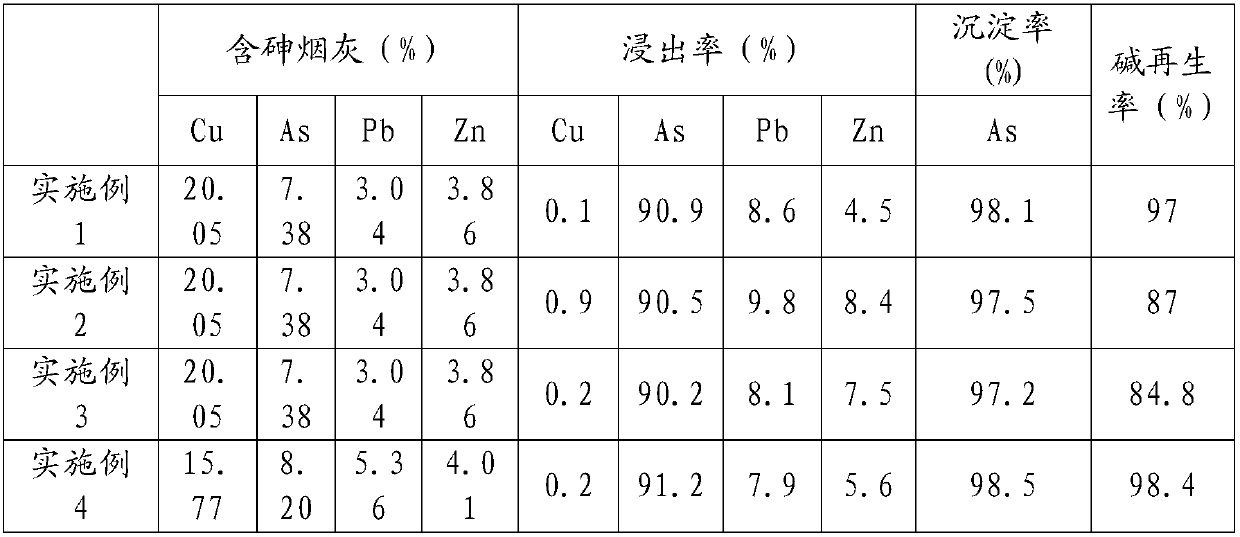

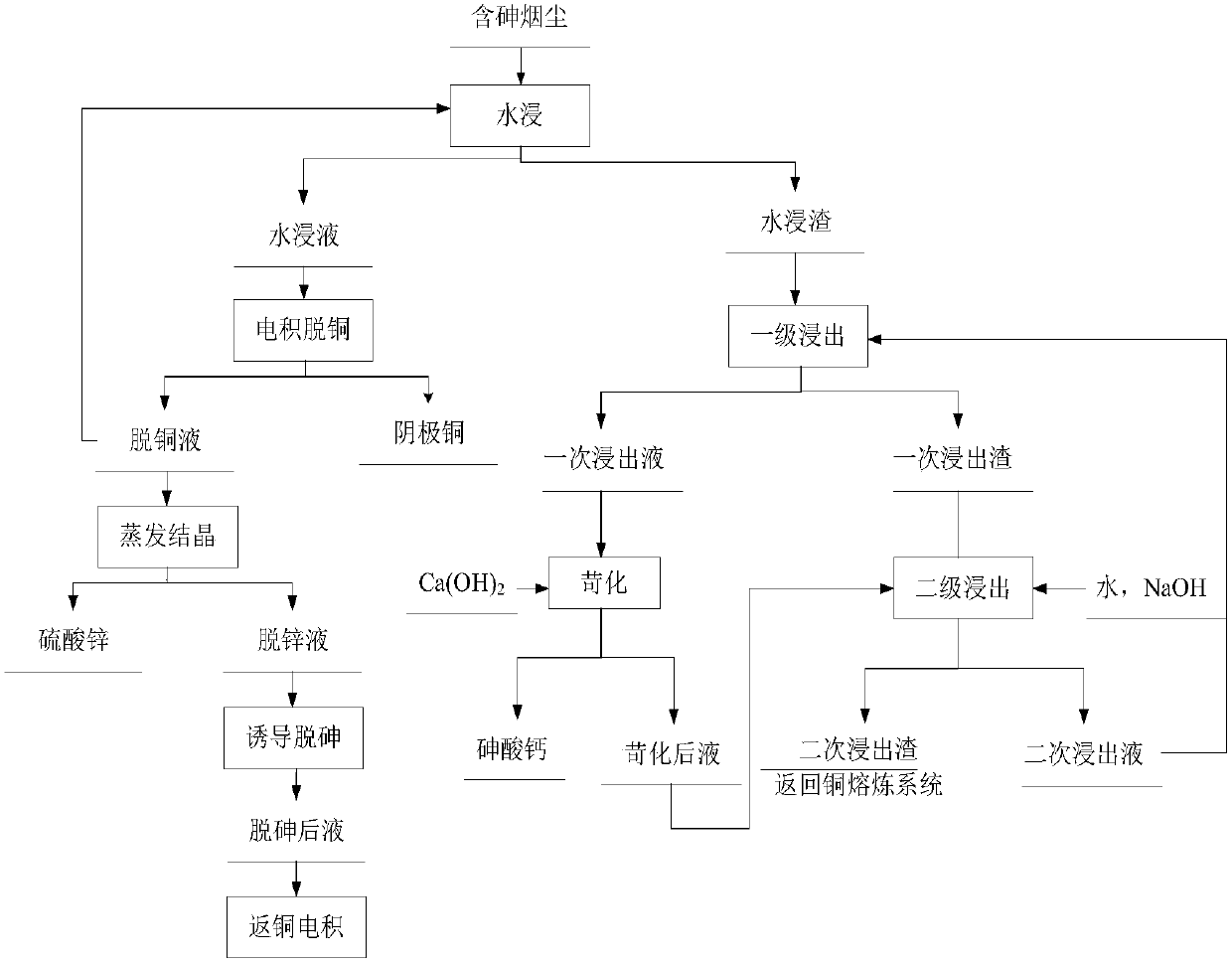

Efficient arsenic removal method for copper smelting high-arsenic smoke ash

ActiveCN107739837AEfficient leachingAvoid leachingProcess efficiency improvementCalcium arseniteSmelting process

The invention discloses an efficient arsenic removal method for copper smelting high-arsenic smoke ash. The method comprises the following steps that 1, first-stage normal-pressure alkaline leaching is conducted on arsenic-containing smoke dust under the leaching conditions that leaching is conducted by adopting secondary leachate and the NaOH concentration is controlled at 40 g / L-60 g / L, solid-liquid separation is conducted, and primary leachate and primary leaching residues are obtained; 2, second-stage normal-pressure alkaline leaching is conducted on the primary leaching residues obtainedin the step 1 under the leaching condition that the NaOH concentration ranges from 60 g / L to 80 g / L, solid-liquid separation is conducted, and secondary leachate and secondary leaching residues are obtained; and 3, lime causticization is conducted on the primary leachate obtained in the step 1, solid-liquid separation is conducted, and calcium arsenate and causticization liquid are obtained. The method is suitable for treating high-arsenic-containing smoke dust generated in the copper smelting process, can achieve arsenic removal of the arsenic-containing smoke dust and comprehensive recoveryand utilization of valuable elements, and has the advantages of being environmentally friendly, economical, capable of saving energy and high in resource utilization rate.

Owner:紫金铜业有限公司 +1

Method for producing a poorly soluble calcium-arsenic compound

The invention relates to a method for precipitating pentavalent calcium arsenate from an acidic solution, in which arsenic is at least partially in trivalent form. The acidic solution is neutralised before being routed to an arsenic oxidation stage,and a poorly soluble calcium-arsenic compound is precipitated from the solution, in which all the arsenic is pentavalent.

Owner:OUTOTEC OYJ

A kind of preparation method of highly stable arsenic-fixing mineral

The invention relates to a preparing method for high-stability solid arsenic mineral. A high-arsenic containing solution is subjected to arsenic removal and is cured, and the arsenic containing solution is subjected to harmless treatment. After trivalent arsenic in the arsenic containing solution is converted into pentavalent arsenic through catalytic oxidation, after oxidization, liquid is synthesized into the high-stability solid arsenic mineral through combination of the lime arsenic deposition method and one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and the solid arsenic mineral can be directly stacked. Calcium arsenate is obtained through the lime arsenic deposition method firstly and then is converted into the high-stability solid arsenic mineral through one of the distribution crystallization method, the regulation and control growth method and the hydrothermal method, and toxicity leaching conforms to the GB5085.3-2007(solid waste distinguishing standard-leaching toxicity identification) rule. According to the preparing method, the technology process is short, the arsenic deposition effect is good, the liquid can be directly discharged after arsenic deposition, and the synthesized solid arsenic mineral is high in stability and can be stably stacked within the wide pH value range of 2-11 and under the strong reducing condition.

Owner:CENT SOUTH UNIV

Method for low-cost dearsenification of copper smelting high-arsenic fume

ActiveCN107779607AReduce alkali consumptionEffective enrichment of arsenicPhotography auxillary processesProcess efficiency improvementPregnant leach solutionArsenic fumes

The invention discloses a method for low-cost dearsenification of copper smelting high-arsenic fume. The method comprises the following steps: A, performing neutral leaching on arsenic-containing fume, and after leaching is completed performing solid-liquid separation so as to obtain neutral leachate and natural leachate slag; B, performing primary normal-pressure alkali leaching on the natural leachate slag obtained in the step A, and after leaching is completed, performing solid-liquid separation so as to obtain primary leachate and primary leachate slag, wherein the final alkali concentration of the leachate is controlled to be less than 50g / L; C, performing secondary normal pressure alkali leaching on the primary leachate slag obtained in the step B, and after leaching is completed, performing solid-liquid separation so as to obtain secondary leachate and secondary leachate slag, wherein the NaOH concentration is 40-150g / L; D, performing rotational flow electrodeposition process copper removal by using the leachate obtained in the step A, wherein products are standard cathode copper and a copper removal after liquid; and E, performing lime causticization on the primary leachateobtained in the step B, and performing solid-liquid separation, thereby obtaining calcium arsenate and a causticization after liquid. The method is capable of low-cost high-efficiency dearsenification of c arsenic-containing fume and solving the influence of continuous increase of arsenic in copper concentrate to the copper smelting process, and has the advantages of environment protection, economy, energy conservation and resource utilization rates.

Owner:紫金铜业有限公司 +1

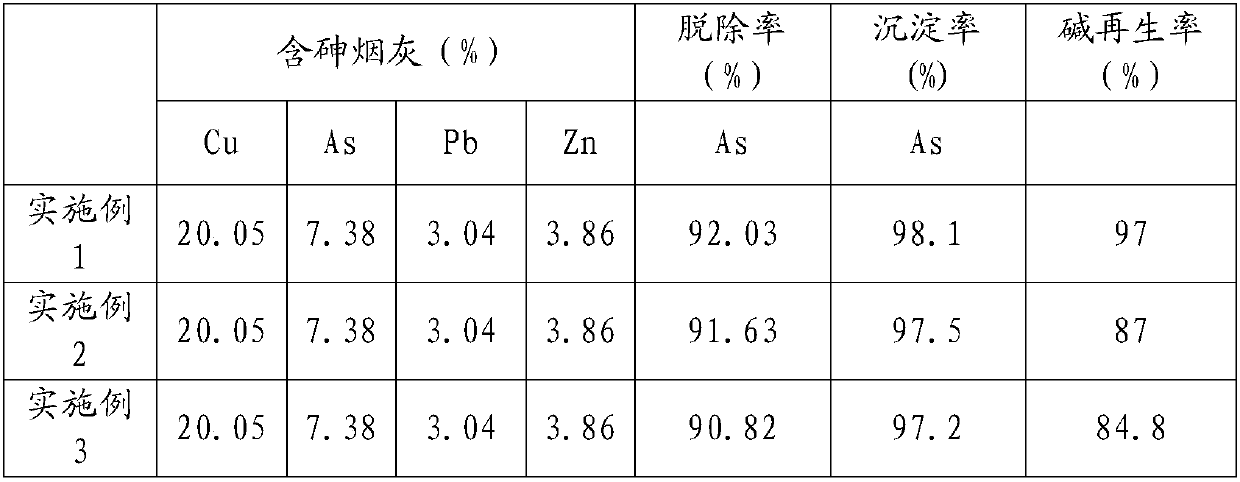

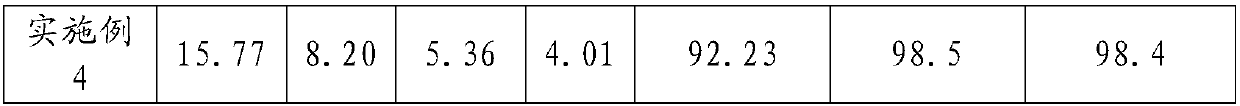

Method for efficiently separating copper arsenic in arsenic matte

InactiveCN109136550APollution is notElectrowinning requires noProcess efficiency improvementPregnant leach solutionArsine

The invention belongs to the field of chemical engineering, and discloses a method for efficiently separating copper arsenic in arsenic matte. The method includes the steps: (1) crushing the arsenic matte, grinding the crushed arsenic matte, and screening the grinded arsenic matte to obtain arsenic matte powder; (2) oxygen pressure leaching: performing oxygen pressure leaching on the arsenic mattepowder by the aid of sulfuric acid solution and Cu2<+> ions, and performing liquid solid separation after leaching is completed to obtain copper-containing leaching solution and lead-silver-containing leaching slag; (3) depositing the copper arsenic in the leaching solution, and performing alkaline leaching on copper arsenic slag to obtain alkaline leaching copper slag and high-arsenic-containing alkaline leaching solution; (4) fine lime arsenic depositing: adding fine lime into the alkaline leaching solution acquired in the step (3) to deposit the arsenic to obtain calcium arsenate. The method is simple in process and free from pollution, a works can not directly contact with harm of generated arsenide hydrogen in the production process, environments cannot be polluted, and precious metals such as copper, lead and silver in lead matte can be effectively recycled.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

Method for preparing high-stability arsenic fixing minerals through adjusted and controlled growth process

The invention relates to a method for preparing high-stability arsenic fixing minerals through an adjusted and controlled growth process. The method comprises the step of removing arsenic from a high-arsenic solution and curing the high-arsenic solution, thereby realizing innocent treatment on an arsenic containing solution. According to the method, after trivalent arsenic in the arsenic-containing solution is converted into pentavalent arsenic through catalytic oxidation, the oxidized solution is synthesized into high-stability arsenic fixing minerals through a lime arsenic precipitation process-adjusted and controlled growth process, and the high-stability arsenic fixing minerals can be directly piled up. Calcium arsenate is firstly obtained through the lime arsenic precipitation process, and then calcium arsenate is converted into high-stability arsenic fixing minerals through the adjusted and controlled growth process, so that toxicity leaching meets regulations of GB5085.3-2007(solid waste identification standards-leaching toxicity identification). The method is short in technological process and is good in arsenic precipitation effect; the arsenic-precipitated solution can be directly exhausted, and the synthesized arsenic fixing minerals are high in stability, and can be stably piled up within a wide pH value range of 2-11 under strong reducing conditions.

Owner:CENT SOUTH UNIV

Comprehensive treatment method for high-arsenic lead zinc flue dust ash

ActiveCN106521167AEfficient extractionReduce processingProcess efficiency improvementChemical industryResource utilization

The invention discloses a comprehensive treatment method for high-arsenic lead zinc flue dust ash. According to the method, high-arsenic lead zinc flue dust ash is leached with a dilute sulfuric acid solution, the zinc and the arsenic in the residue are separated to obtain lead-rich residue, the leaching liquid is subjected to copper precipitation with sodium sulfide, the valuable element zinc is extracted and separated with an organic phase, CaO is added to make the arsenic in the solution generate calcium arsenate so as to be precipitated and removed, the extraction organic phase is subjected to back extraction with an acetate solution, the back extraction liquid is precipitated with ammonium carbonate, and separation, washing, drying and calcination are performed to obtain the active zinc oxide product. According to the present invention, the comprehensive treatment method has characteristics of simple process, simple equipment, easy and safe operation, secondary resource comprehensive utilization, circular economy achieving, energy saving, emission reducing, and good promotion and application value, and is the effective resource utilization process technology route for producing the high added value chemical industry product by using the industrial waste.

Owner:KUNMING UNIV OF SCI & TECH

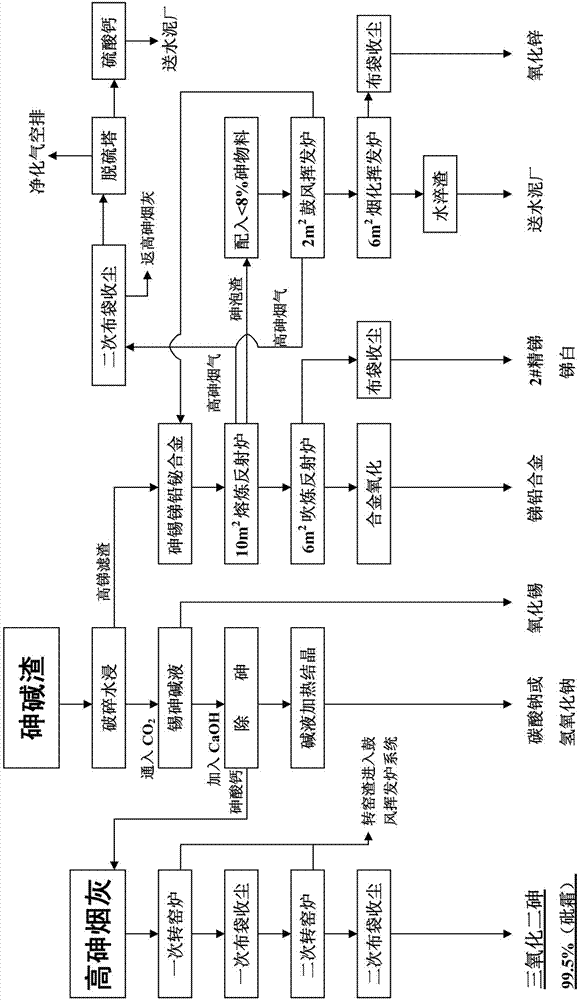

Comprehensive recovery process for antimony smelting arsenic alkali residues

ActiveCN112941312AMeet the requirements for arsenic content in general demandHarmlessAlkali metal oxidesProcess efficiency improvementCalcium hydroxideSlag

The invention discloses a comprehensive recovery process for antimony smelting arsenic alkali residues. The comprehensive recovery process comprises the following steps of (1) crushing and briquetting, specifically, firstly breaking the antimony smelting arsenic alkali residues, then mixing the broken antimony smelting arsenic alkali residues with a reducing agent, a slag former and fuel, finely grinding the mixture, adding water for mixing and preparing the mixture into a block mass; (2) arsenic and antimony pyrogenic volatilization, specifically, calcining and volatilizing to obtain alkaline residues and an antimony-containing arsenic trioxide crude product; (3) alkaline residue leaching, specifically, firstly breaking the alkaline residues, finely grinding the broken alkaline residues, after adding water, carrying out heating leaching, solid-liquid separation, and washing to obtain silicon dioxide residues and an arsenic-containing alkaline solution; and (4) arsenic removal and purification of the alkaline solution, specifically, adding an arsenic removal agent and a purifying agent into the arsenic-containing alkali solution, heating for deep arsenic removal reaction, carrying out solid-liquid separation to obtain calcium arsenate / calcium hydroxide mixed salt and arsenic-removed alkali solution, and concentrating and crystallizing the arsenic-removed alkali solution to obtain solid sodium hydroxide / sodium carbonate mixed alkali. The method is high in arsenic and antimony volatilization rate, high in alkali recovery rate and extremely low in arsenic content, byproducts can be efficiently recycled, no three wastes are discharged, the cost is low, harmlessness and recycling of the arsenic alkali residues are achieved, and the method is suitable for large-scale industrial treatment.

Owner:刘义冬

Comprehensive recovery method for complicated materials containing arsenic and valuable metal slag dust

ActiveCN102286665BNo pollutionCement productionProcess efficiency improvementTin dioxideRecovery method

Owner:LEIYANG YANXIN NON FERROUS METALS

Separation method for antimony and arsenic in antimony and arsenic material

ActiveCN108796234AHigh recovery ratePrevent volatilizationProcess efficiency improvementPregnant leach solutionNitrogen oxides

The invention discloses a separation method for antimony and arsenic in an antimony and arsenic material. The separation method comprises the following steps of uniformly mixing the antimony and arsenic material with sodium peroxide, calcining the mixture at 300-390 DEG C, adding water into the calcined product, stirring the calcined product, leaching the calcined product at 50-65 DEG C, filteringthe calcined product after leaching to obtain a lixivium; and adding calcium oxide into the lixivium, stirring the lixivium at a constant temperature, filtering the lixivium after full reaction to obtain filter residues and filtrate, and drying the filter residues to obtain a calcium arsenate product. By taking sodium peroxide as a primary raw material, the calcining temperature is relatively low, antimony and arsenic are prevented from being volatilized in the calcining process, and the antimony and arsenic recovery rates in later period are relatively high. Sodium peroxide which replaces sodium nitrate is taken as an oxidant, so that the material is oxidized more fully without generating oxynitride, and the environment is not polluted. As alkali is not added, the raw materials are low in cost and equipment is not corroded.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Stabilization of hazardous materials

ActiveCN110944724ATransportation and packagingContaminated soil reclamationPhosphateFerrous Arsenate

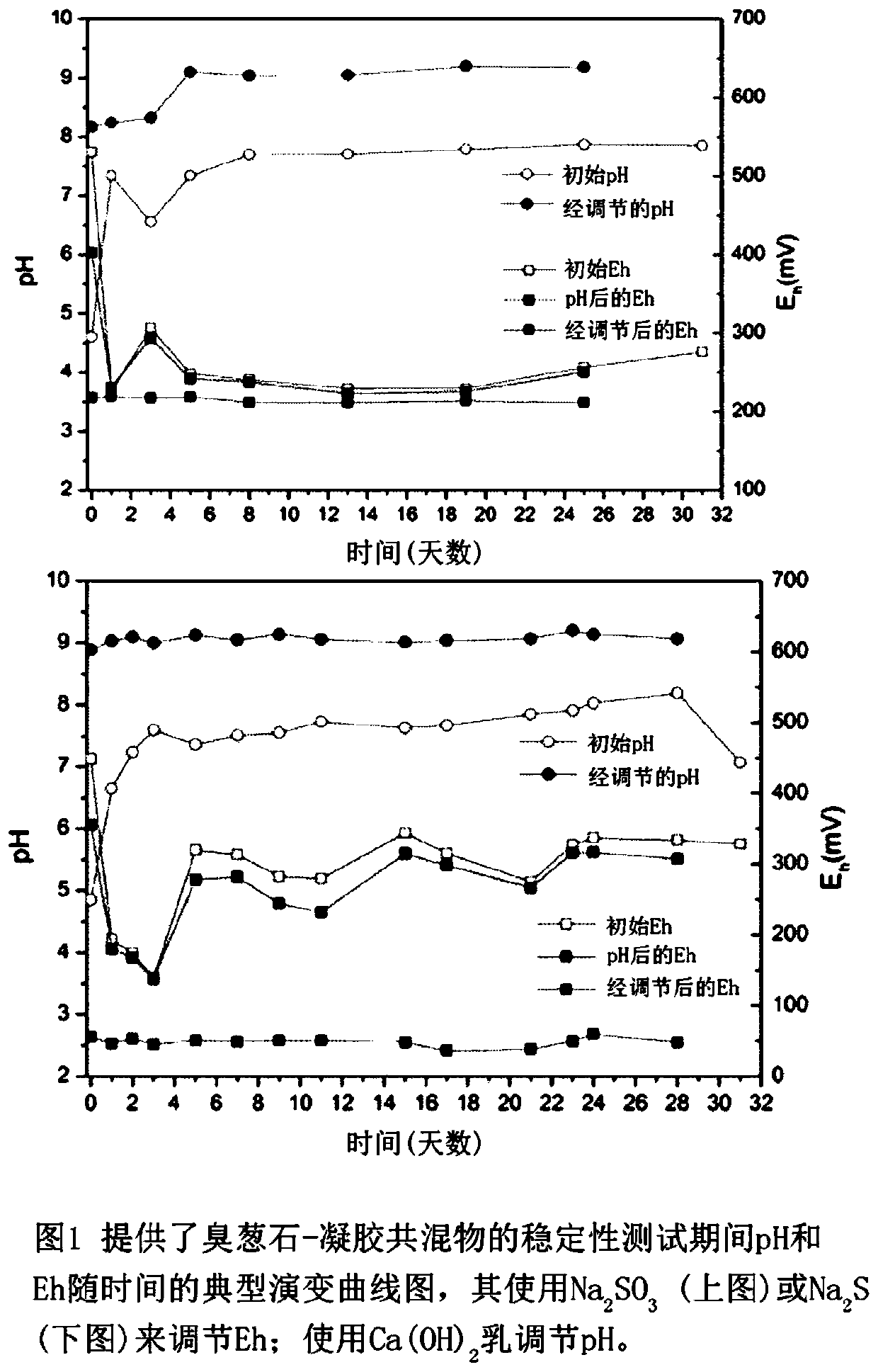

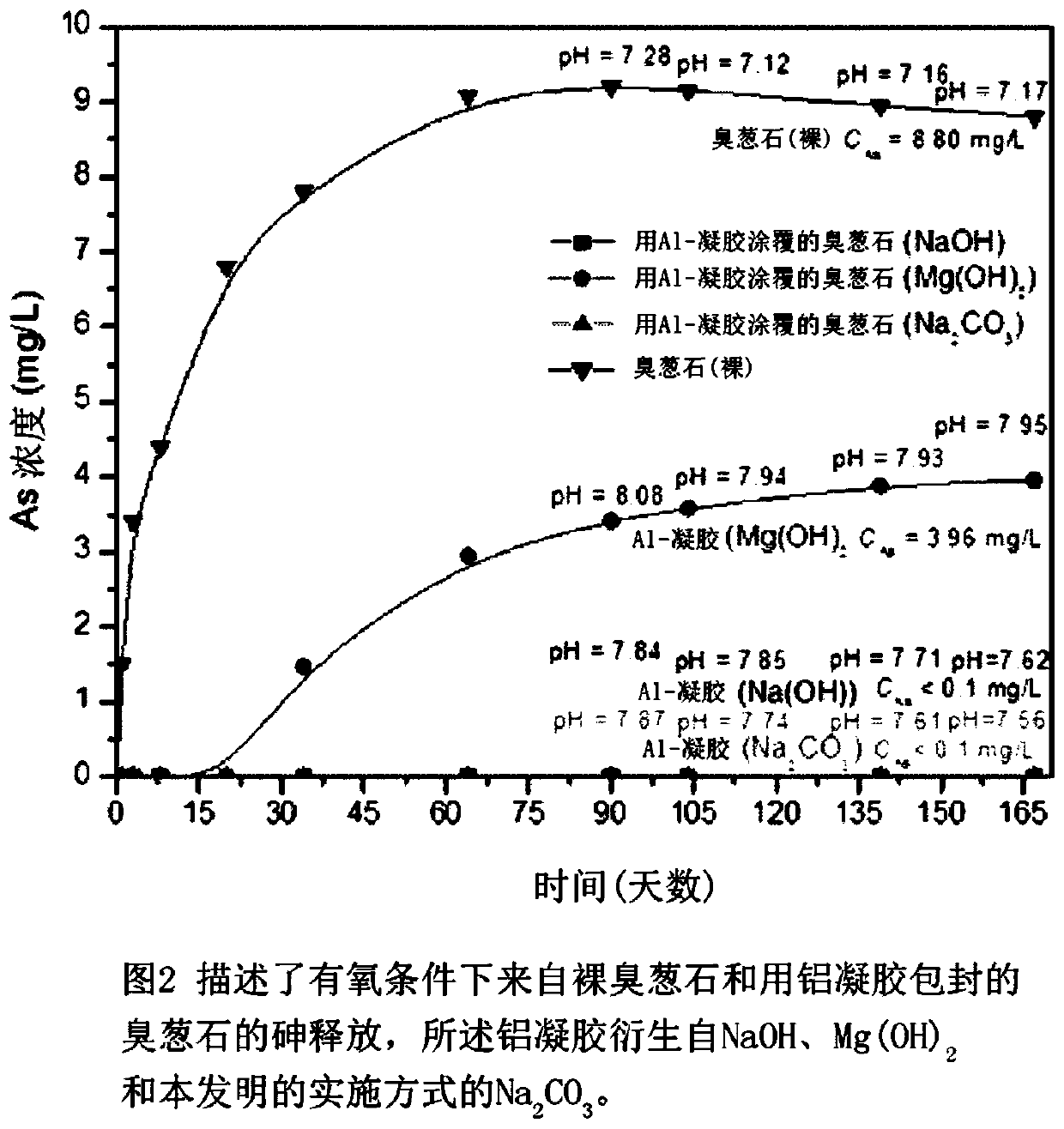

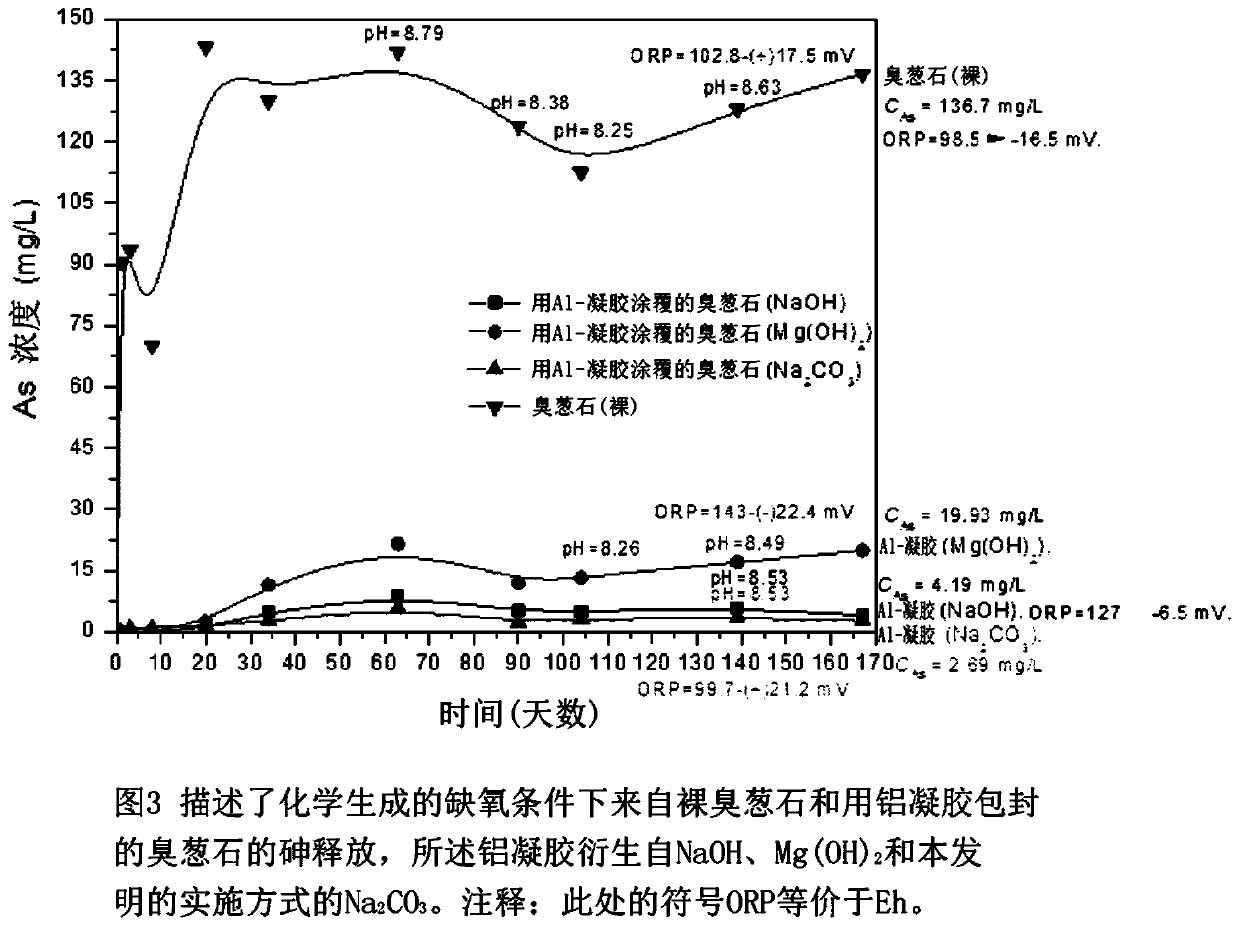

The invention relates to stabilization and / or solidification of hazardous materials which might be generated by activities like mining, milling or smelting industrial operations, such as arsenical wastes (such as scorodite, arsenic sulfides, calcium arsenates or arsenites, mixed calcium arsenates-phosphates, ferrous arsenate, ferric arsenite, or arsenic trioxide), antimony, mercury or selenium-containing wastes through the encapsulation of the arsenical wastes in the mineralized products of hydrolyzed aluminum gels created through the partial neutralization of A1(SO4)1.5 by a carbonate.

Owner:MCGILL UNIV

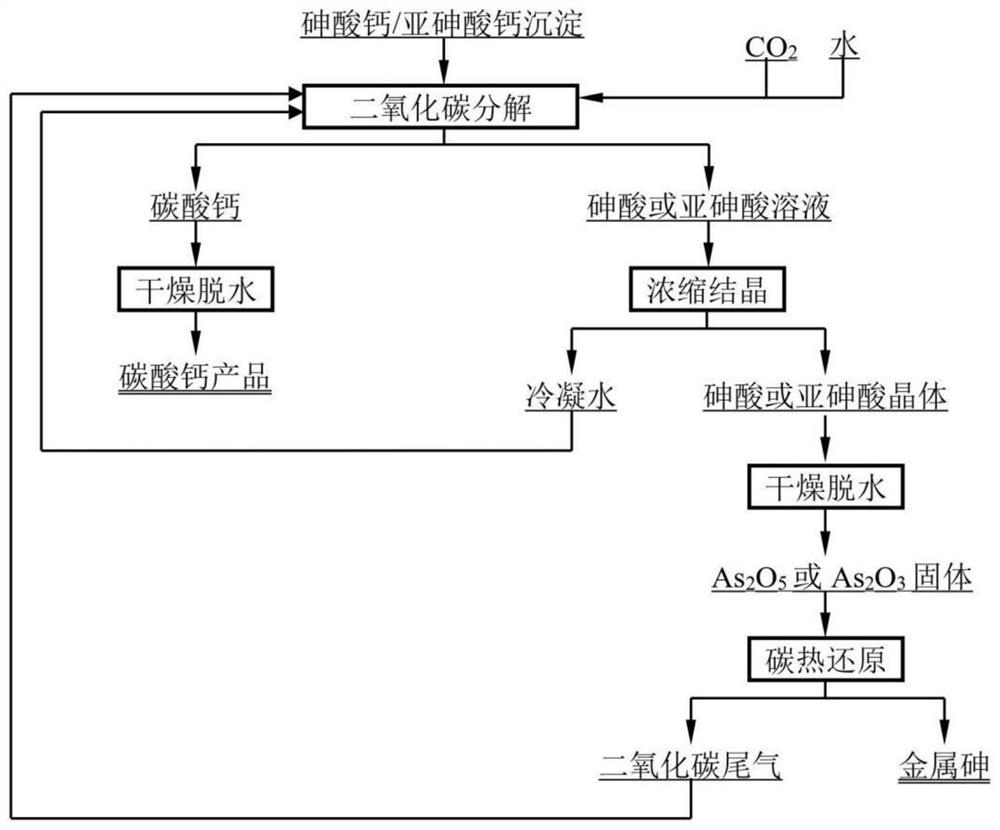

Method for comprehensively recovering calcium and arsenic from calcium arsenate/calcium arsenite precipitate

ActiveCN112609092ASmall footprintReduce hazardous waste disposal feesCalcium/strontium/barium carbonatesProcess efficiency improvementArsenous acidAqueous solution

The invention relates to a method for comprehensively recovering calcium and arsenic from calcium arsenate / calcium arsenite precipitate. The method comprises the following steps that (1) the calcium arsenate / calcium arsenite precipitate is mixed with water according to a liquid-solid ratio of (2-10):1 for size mixing, carbon dioxide gas is introduced at a leaching temperature of 25-100 DEG C, and the calcium and arsenic precipitate reacts with an aqueous solution of carbon dioxide to obtain mixed slurry; liquid-solid separation is performed on the mixed slurry to obtain a calcium carbonate solid and an arsenic-containing solution; the calcium carbonate solid is dried and dehydrated to obtain a calcium carbonate product; (2) the arsenic-containing solution is concentrated, crystallized and dried to obtain As2O5 or As2O3 solid; and (3) carbon is added into the obtained As2O5 or As2O3 solid for high-temperature carbon thermal reduction to obtain metal arsenic and carbon dioxide gas. Harmless, recycling and environment-friendly treatment of the calcium-arsenic precipitate is realized in the whole process.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

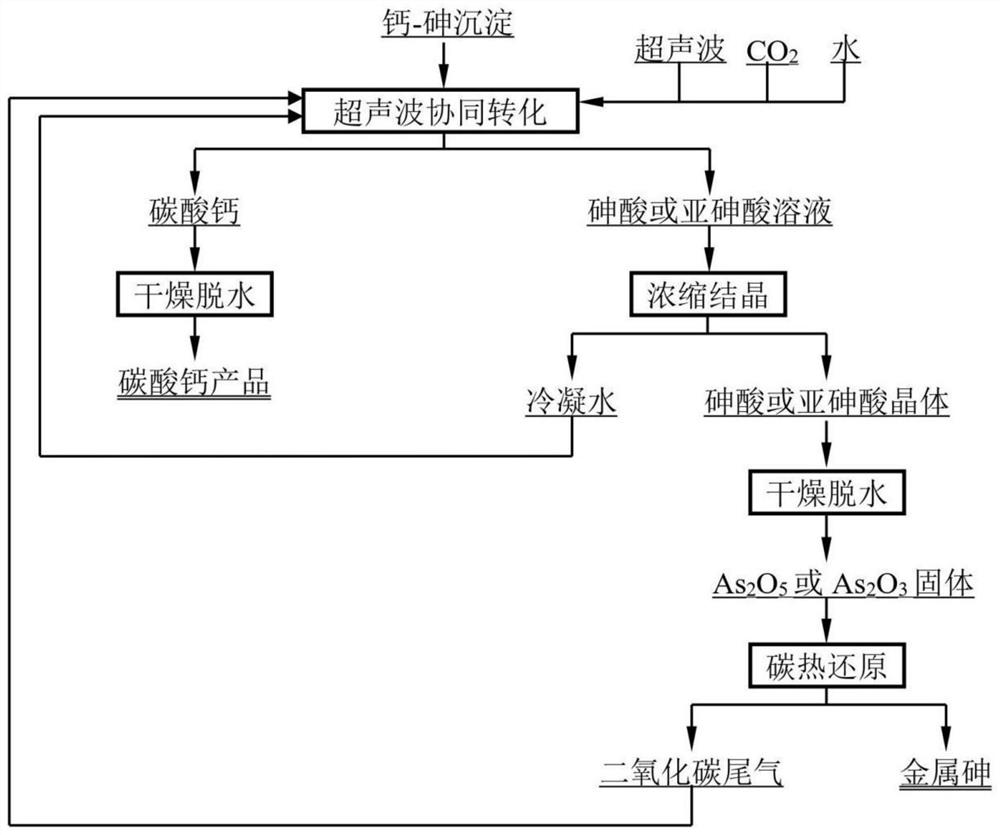

Method for synergistically converting and decomposing calcium-arsenic precipitate through ultrasonic waves

ActiveCN112813265AHarmlessRealize resourcesCalcium/strontium/barium carbonatesProcess efficiency improvementUltrasonic cavitationCalcium arsenite

The invention relates to a method for synergistically converting and decomposing a calcium-arsenic precipitate through ultrasonic waves. The method for synergistically converting and decomposing the calcium-arsenic precipitate through the ultrasonic waves comprises the following steps that (1), the calcium-arsenic precipitate and water are mixed according to a liquid-solid ratio of (2 to 10) to 1 for size mixing, carbon dioxide gas is introduced at a leaching temperature of 25-90 DEG C, a cavitation generation device is introduced, the calcium-arsenic precipitate is reacted with an aqueous solution of carbon dioxide, and mixed slurry is obtained; (2), liquid-solid separation is carried out on the mixed slurry to obtain calcium carbonate and an arsenic-containing solution; and (3), evaporative crystallization-carbon thermal reduction is carried out on the arsenic-containing solution to obtain metal arsenic. According to the method for synergistically converting and decomposing the calcium-arsenic precipitate through the ultrasonic waves, the calcium-arsenic precipitate (calcium arsenate, calcium arsenite or a mixture of the calcium arsenate and the calcium arsenite) can be quickly converted and decomposed, so that calcium carbonate with low arsenic content is obtained from the calcium-arsenic precipitate under the action of an ultrasonic cavitation effect, the conversion rate of the calcium-arsenic precipitate is effectively improved, the content of arsenic in the calcium carbonate is further reduced, and finally, the purposes of reducing the hazardous waste disposal cost of the arsenic of enterprises and performing harmless disposal are achieved.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM +1

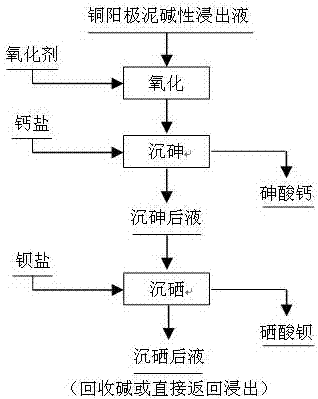

A method for separating arsenic and selenium from copper anode slime alkaline leaching solution

ActiveCN104911358BNo need to adjust pHRealize separation and enrichmentProcess efficiency improvementElemental selenium/telluriumFiltrationPost precipitation

The invention discloses a method for separating arsenic and selenium from copper anode slime alkaline leach liquor. The method comprises the following steps: 1) oxidation, namely adding an oxidizing agent or introducing oxidizing gas into the copper anode slime alkaline leach liquor, so that oxidized copper anode slime alkaline leach liquor is obtained; 2) arsenic precipitation, namely adding a calcium salt into the oxidized copper anode slime alkaline leach liquor, stirring the obtained mixture so as to produce a precipitate, and carrying out filtration and separation on the precipitate so as to obtain a calcium arsenate precipitate and arsenic post-precipitation liquid; and 3) selenium precipitation, namely adding a barium salt into the arsenic post-precipitation liquid obtained in the step 2), stirring the obtained mixture so as to produce a precipitate, carrying out filtration and separation on the precipitate so as to obtain a barium selenate precipitate and selenium post-precipitation liquid, and carrying out evaporative crystallization on the selenium post-precipitation liquid so as to recycle alkali, or directly returning to a leaching process. The method disclosed by the invention is short in technological process, less in equipment and simple in operation, and can be used for realizing the separation and enrichment of arsenic and selenium, the precipitation rate of arsenic is higher than 96%, and the precipitation rate of selenium is higher than 99%; by virtue of carrying out evaporative crystallization on a solution for recycling or directly returning the solution to a leaching process, the recovery of alkali is realized.

Owner:CENT SOUTH UNIV

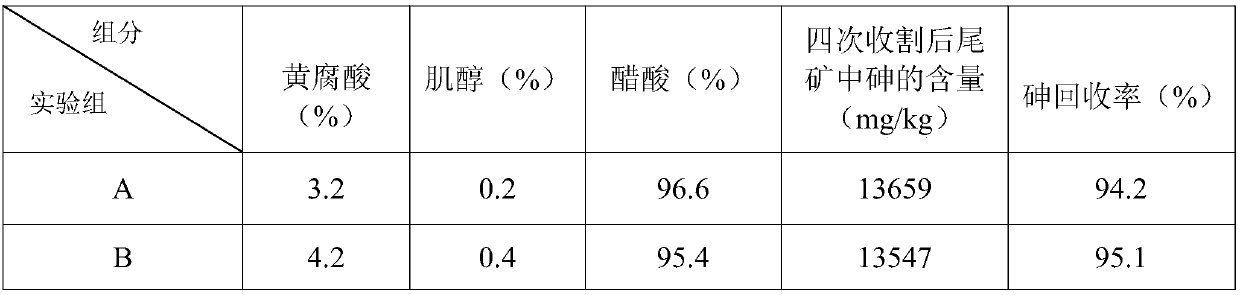

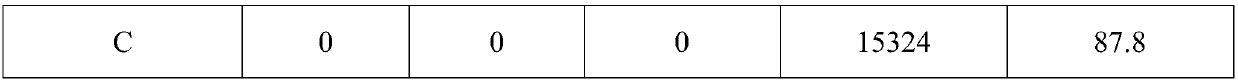

Chemical agent for preventing arsenic spreading pollution in arsenic-resistant plants and using method of chemical agent

ActiveCN109570226ALow priceEnlargement of leaf stomataContaminated soil reclamationOrganic fertilisersPollutionChemical agent

The invention relates to a chemical agent for preventing arsenic spreading pollution in arsenic-resistant plants. The chemical agent comprises the following components in percentages by mass: fulvic acid 3.2%-4.8%, inositol 0.2%-0.8% and calcium acetate 94.4%-96.6%, wherein the fulvic acid is a leaf diffuser; the inositol is a catalyst; and the calcium acetate is a main reaction substance. The invention further relates to a using method of the chemical agent. The using method comprises the following steps: laying arsenic-containing tailings or waste residues and spreading borrowed soil and a base fertilizer, after planting ciliate desert-grass, spraying the chemical agent to stems and leaves every 15-30 days, harvesting for the first time after the ciliate desert-grass grows for a period of time, harvesting again at set intervals, and remaining stubbles and turning and digging soil between the plants after harvesting every time. The calcium-containing chemical agent is sprayed on the arsenic-resistant plants, and reacts with an arsenic substance to generate calcium arsenate, thus, insects die due to acute poisoning after eating the stems and leaves of the plants, arsenic-containingdead bodies drop to tailings ground surrounding the plants, are turned into soil, and are absorbed by the plants again, and an effect of greatly reducing outward diffusion of arsenic is achieved.

Owner:林西金易来砷业有限公司

A method for preparing highly stable arsenic-fixed minerals by distribution crystallization

ActiveCN106823233BSimple processEasy to operateChemical protectionCatalytic oxidationReduced properties

Owner:CENT SOUTH UNIV

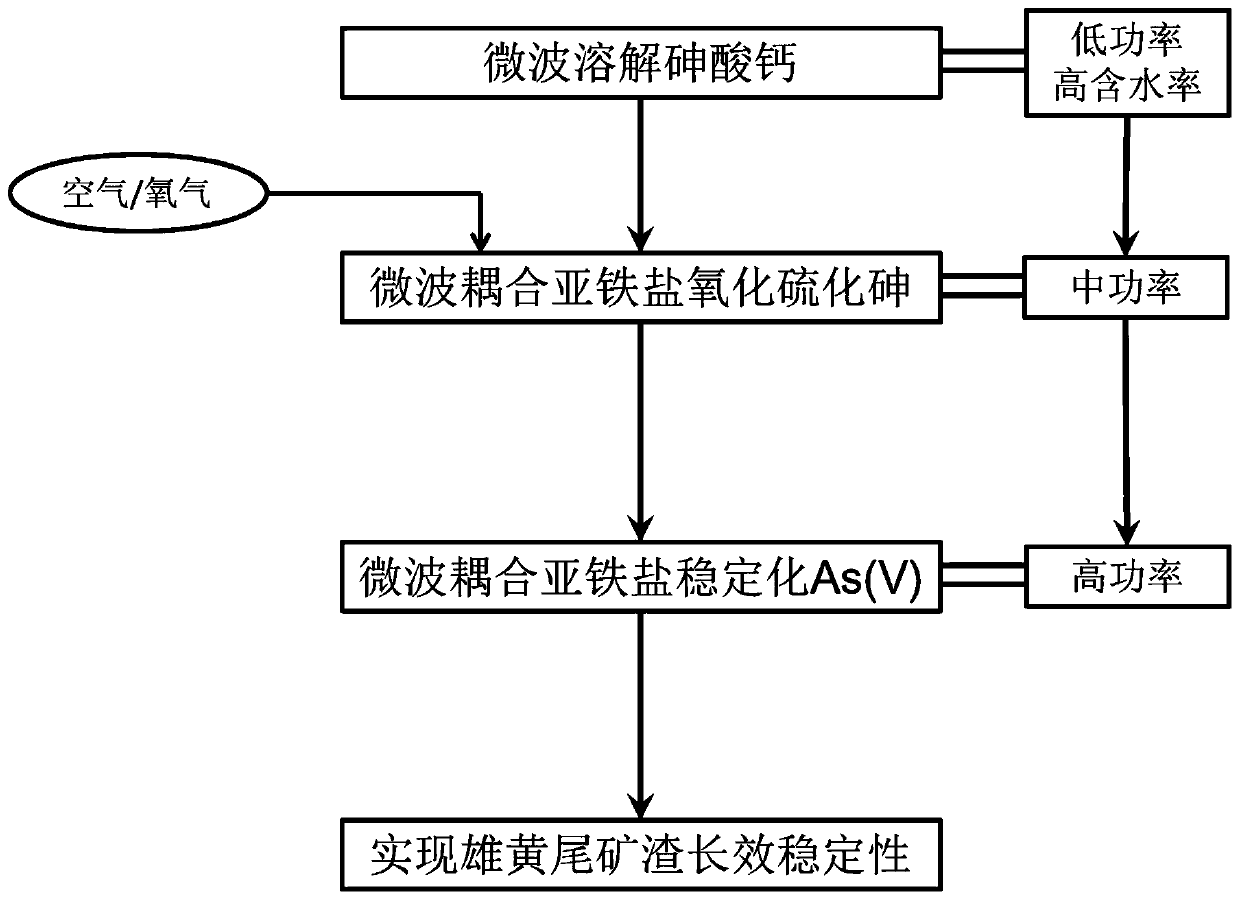

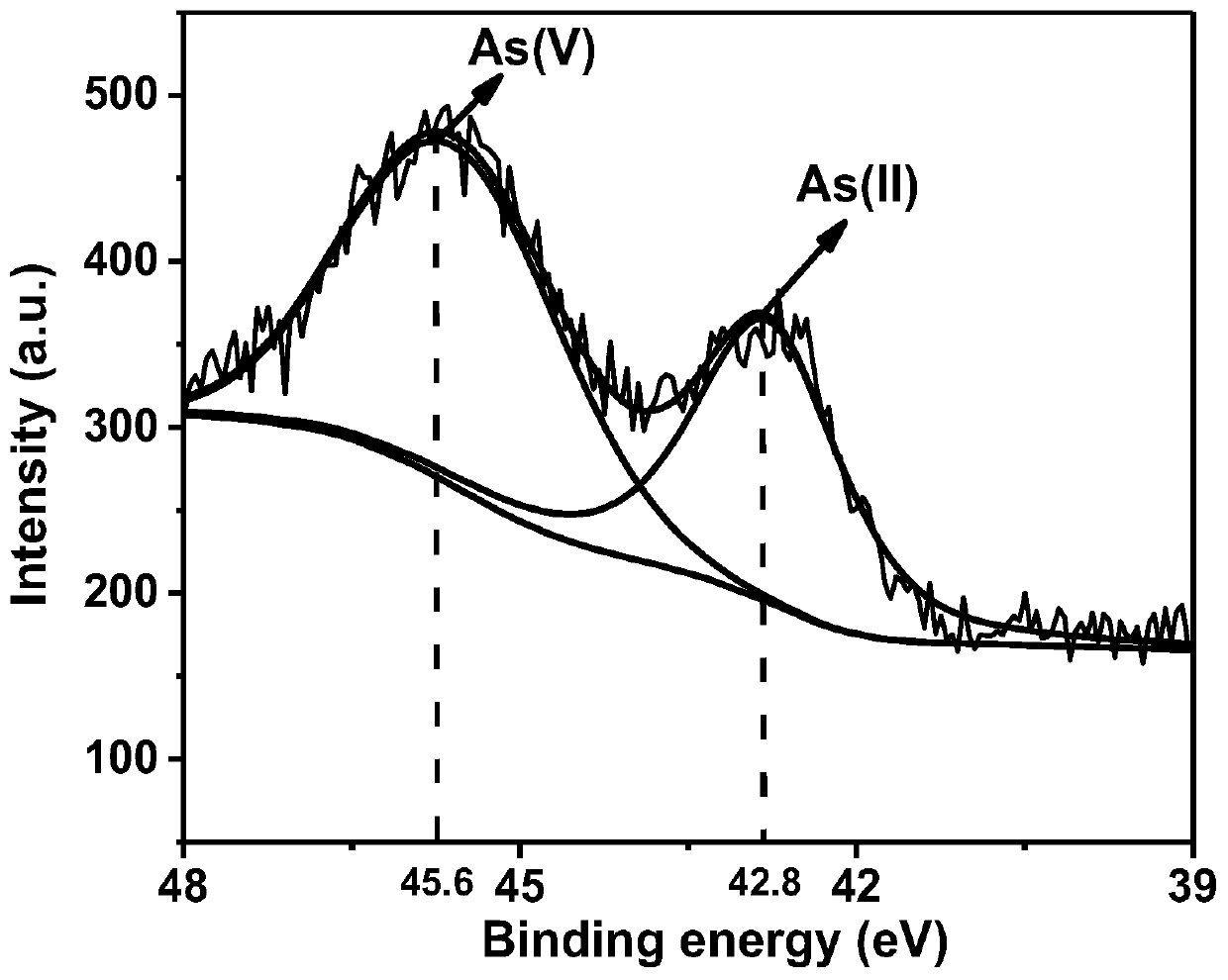

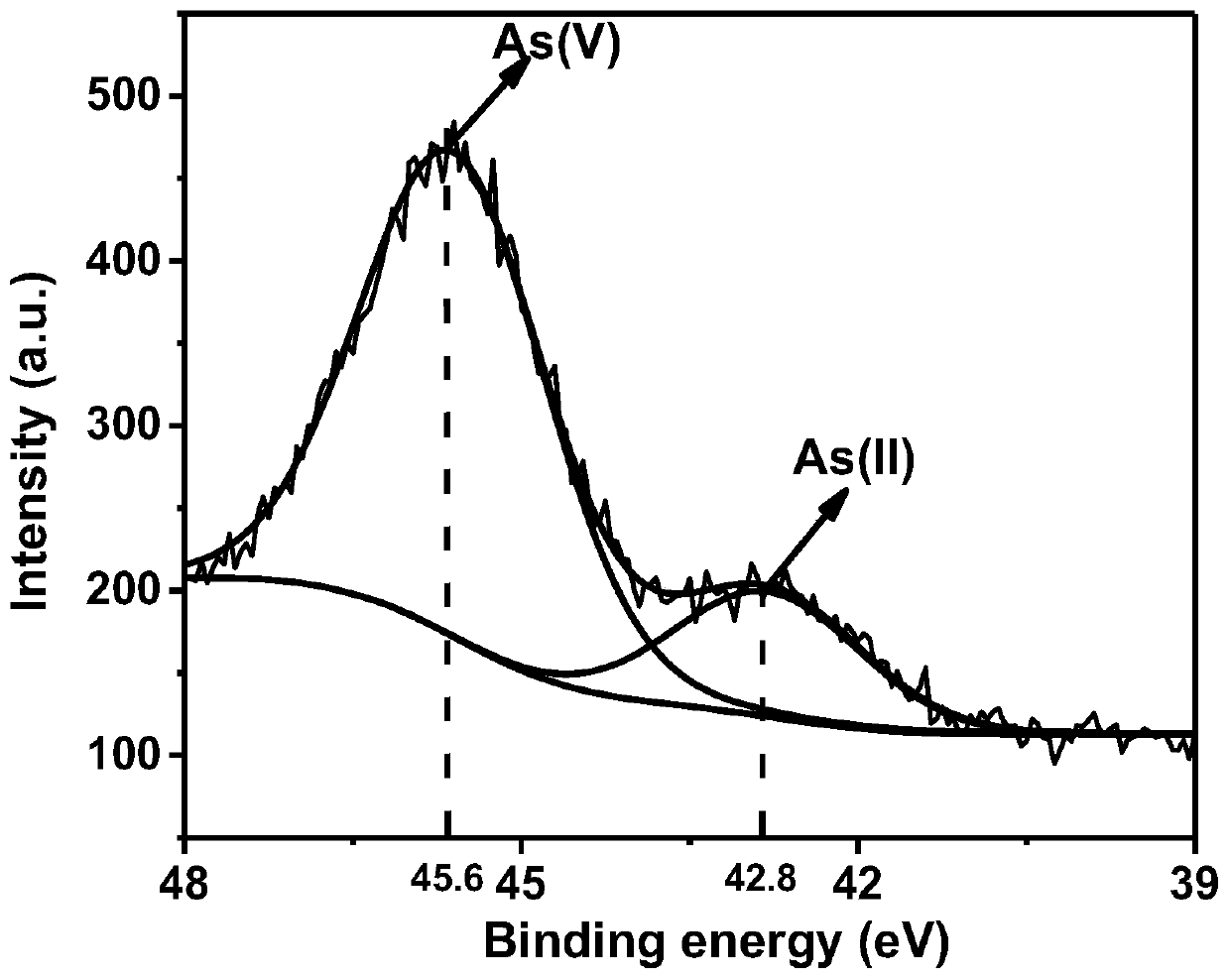

A kind of realgar tailing slag stabilization disposal method

ActiveCN108704239BAchieve dissolutionAchieve stabilizationChemical protectionFerrous saltsPhysical chemistry

The invention discloses a stabilized treatment method for realgar tailing residues. The stabilized treatment method for the realgar tailing residues comprises the following steps of (1) crushing the realgar tailing residues, adding water inside, uniformly stirring, and carrying out first-stage microwave treatment under the action of a microwave field at the power ranging from 100W to 300W; (2) adding water and ferrous salt inside, uniformly stirring, feeding air or oxygen, and meanwhile, carrying out second-stage microwave treatment under the action of a microwave field at the power ranging from 300W to 500W; and (3) carrying out third-stage microwave treatment under the action of a microwave field at the power ranging from 500W to 700W, so that the stabilization of the realgar tailing residues is realized. According to the stabilized treatment method for the realgar tailing residues provided by the invention, through designing a whole process technology of the method, especially improving parameters and conditions of a key microwave treatment process, and dissolving, oxidizing and stabilizing the realgar tailing residues for three stages, the problems of slow calcium arsenate dissolution rate, slow arsenic sulfide oxidation rate and insufficient product long-time stability can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510BHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateCalcium arsenite

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. First, the arsenic in the arsenic-containing wastewater is separated and enriched in the form of calcium arsenate or / and calcium arsenite precipitation, and then the obtained arsenic enrichment Oxidation in ferric sulfate or ferrous sulfate solution, through normal pressure reaction or pressurized hydrothermal reaction or normal pressure hydrothermal reaction, the arsenic in it is solidified in the form of scorodite crystals, and the obtained scorodite crystal grains Complete development, uniform distribution, stable structure under acidic conditions. The invention has the advantages of high operation efficiency, good arsenic fixation effect, convenient operation, low arsenic solidification treatment cost, etc., and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

A kind of separation method of antimony and arsenic in antimony arsenic material

ActiveCN108796234BHigh recovery ratePrevent volatilizationProcess efficiency improvementNitrogen oxideSodium nitrate

The invention discloses a separation method for antimony and arsenic in an antimony and arsenic material. The separation method comprises the following steps of uniformly mixing the antimony and arsenic material with sodium peroxide, calcining the mixture at 300-390 DEG C, adding water into the calcined product, stirring the calcined product, leaching the calcined product at 50-65 DEG C, filteringthe calcined product after leaching to obtain a lixivium; and adding calcium oxide into the lixivium, stirring the lixivium at a constant temperature, filtering the lixivium after full reaction to obtain filter residues and filtrate, and drying the filter residues to obtain a calcium arsenate product. By taking sodium peroxide as a primary raw material, the calcining temperature is relatively low, antimony and arsenic are prevented from being volatilized in the calcining process, and the antimony and arsenic recovery rates in later period are relatively high. Sodium peroxide which replaces sodium nitrate is taken as an oxidant, so that the material is oxidized more fully without generating oxynitride, and the environment is not polluted. As alkali is not added, the raw materials are low in cost and equipment is not corroded.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com