Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Uniform adsorption capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound type pneumatic non-contact gas claw

InactiveCN102530548AReduce hoop shear stressReplaceableCharge manipulationConveyor partsRefluxPositive pressure

The invention discloses a compound type pneumatic non-contact gas claw which comprises a gas claw casing and a shunting ring, wherein the gas claw casing is provided with a downwardly opening cylinder cavity; a workpiece grabbing through hole is formed at the center of the shunting ring; the gas claw casing includes a gas claw top cover, a gas claw middle part and a bottom sucking disc, which are detachably and hermetically connected; the gas claw top cover is provided with a gas inlet communicated with the cylinder cavity; the gas claw middle part is provided with a rotary reflux cavity forming the main body section of the cylinder cavity; the bottom sucking disc is provided with a circular sucking disc concave cavity communicated with the cylinder cavity; the shunting ring is in clearance sleeve in the circular sucking disc concave cavity; an annular clearance gas injection channel is defined by the back side of the shunting ring and the cambered curve of the bottom wall of the circular sucking disc concave cavity; three groups of small pressurizing holes surrounding the grabbing through hole are uniformly distributed on the shunting ring in an equal-radian manner; a workpiece to be grabbed is suspended in front of the grabbing through hole to achieve the dynamic balance and the non-contact grabbing and handing functions under the combined action of negative pressure generated at the high pressure gas rotary reflux center, positive pressure generated in high pressure gas overflowing out of the annular clearance gas injection channel and the self-weight of the workpiece.

Owner:NINGBO UNIV

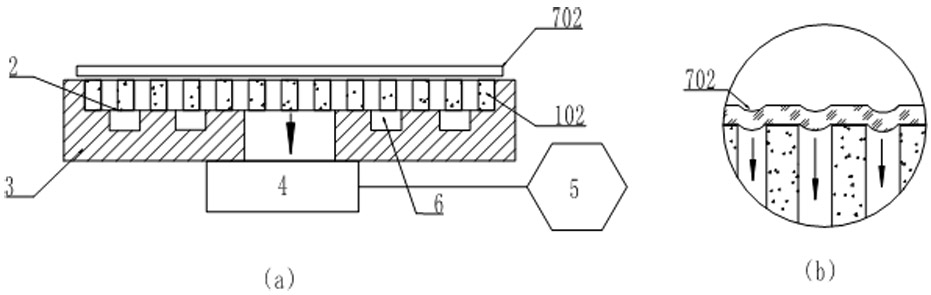

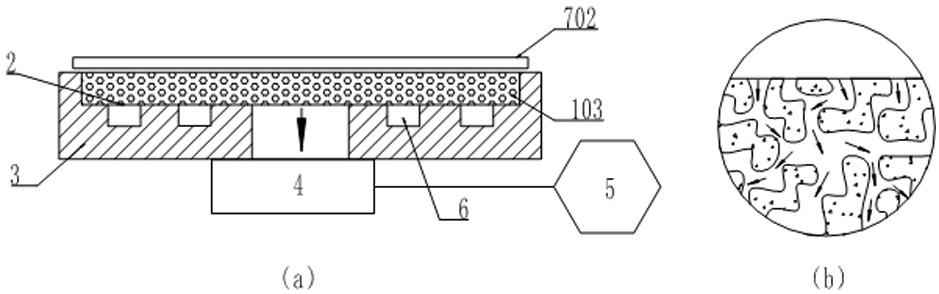

Porous vacuum chuck and preparation method thereof

ActiveCN112407936AImprove adsorption capacityReduce lossesConveyorsFinal product manufactureEngineeringTitanium alloy

The invention belongs to the technical field of vacuum adsorption, and particularly relates to a porous vacuum chuck and a preparation method thereof. The porous vacuum chuck comprises a porous adsorption part, a sealing layer and a base, wherein the porous adsorption part is fixed on the base through the sealing layer, and a penetrating through hole is formed in the middle of the base; the porousadsorption part is made of one or more of aluminum oxides, zirconium oxides, zirconia toughened alumina (ZTA), silicon carbides, silicon nitrides, zinc oxides, titanium oxides, stannic oxides, hydroxyapatite or quartz; the sealing layer is made of ceramic, glass or resin, and the thickness of the sealing layer is 10-500 microns; and the base is made of aluminum oxides, zirconium oxides, ZTA, silicon carbides, silicon nitrides, quartz, stainless steel, titanium alloys or aluminum alloys. The porous vacuum chuck is small in flow loss, stable adsorption of an adsorbate can be achieved under thecondition that the adsorbate cannot completely cover an adsorption area, and product defects such as sunken deformation cannot be caused.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

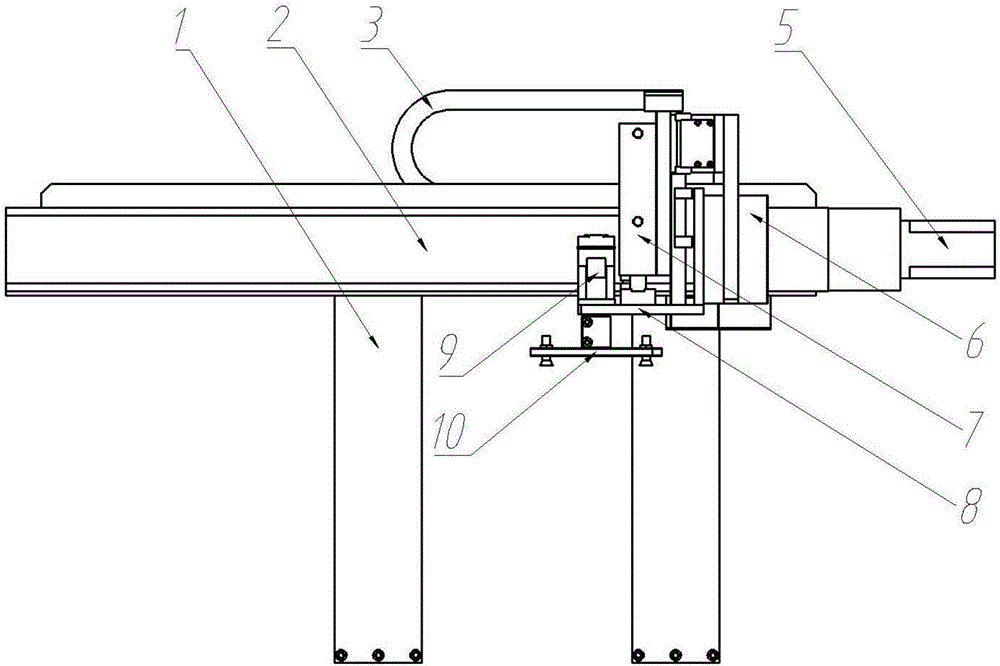

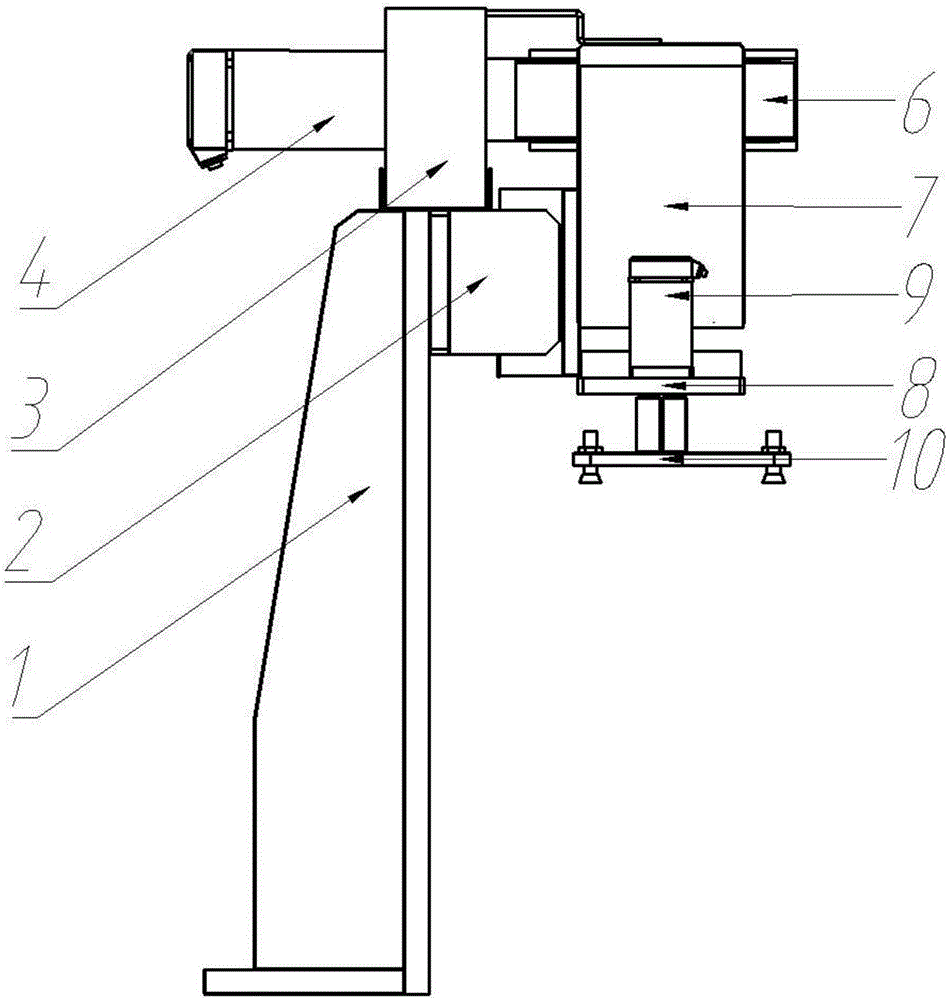

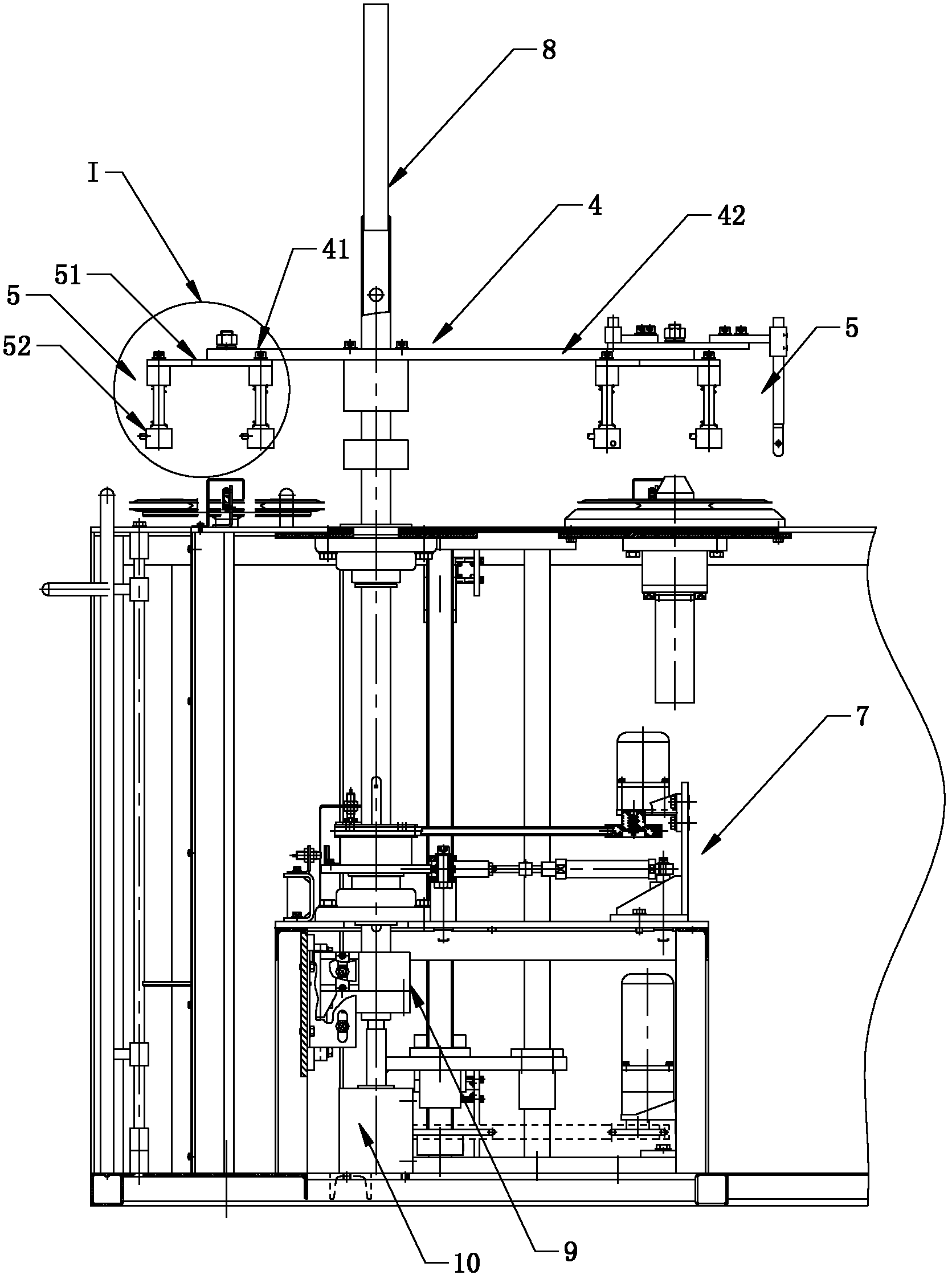

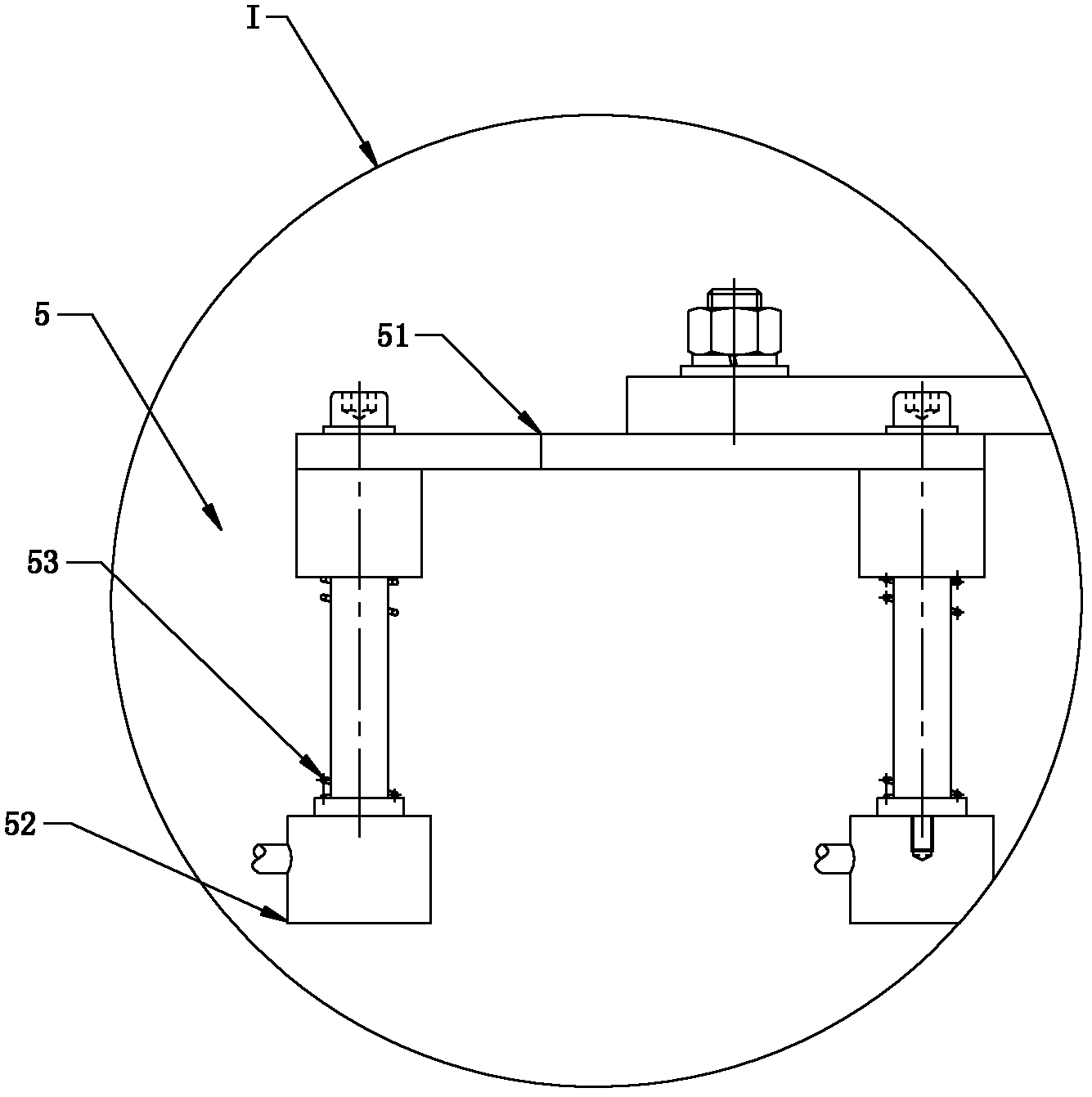

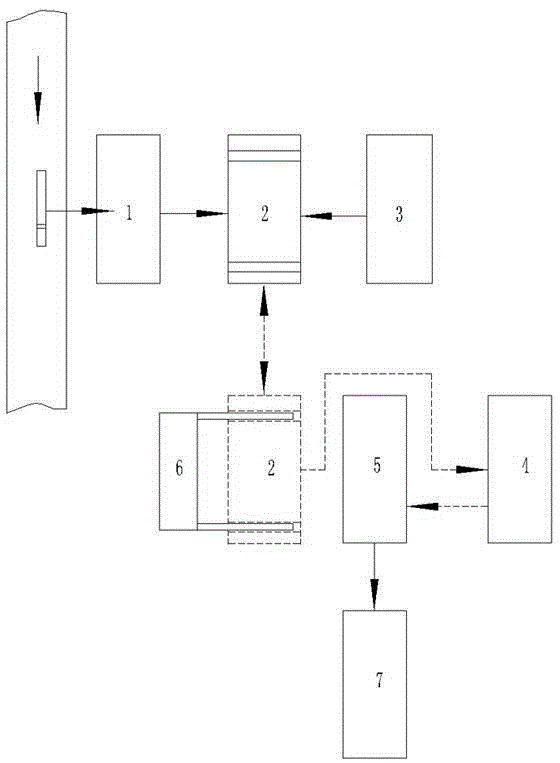

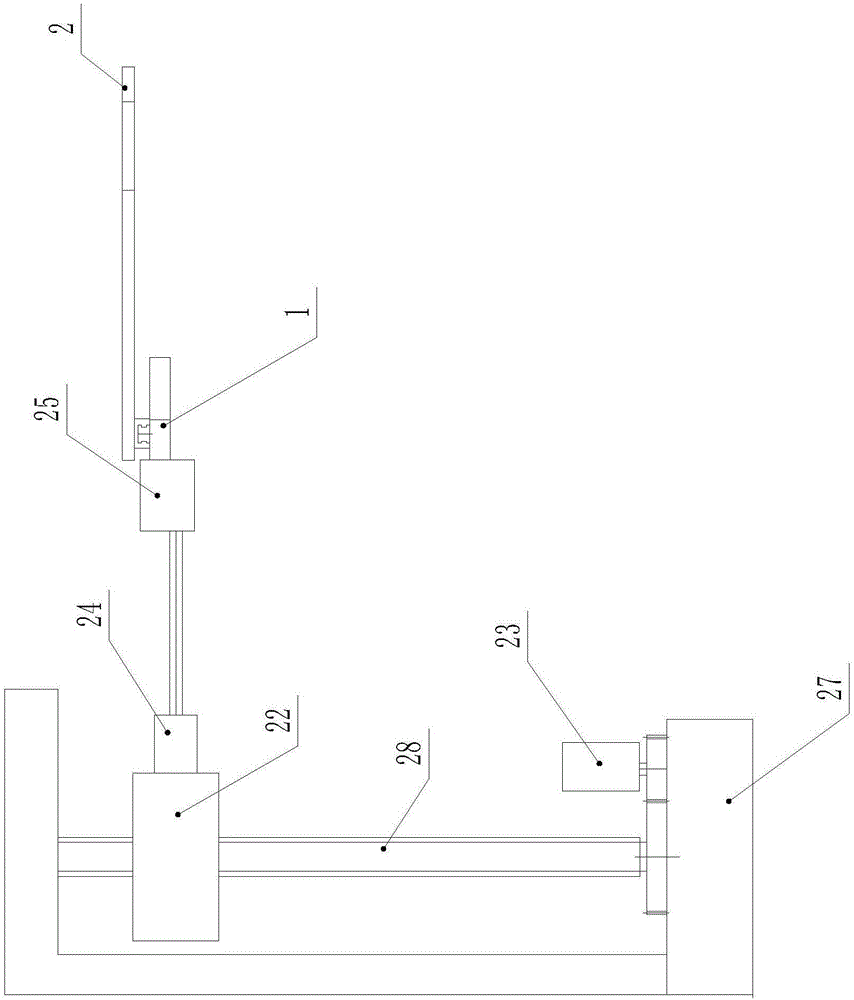

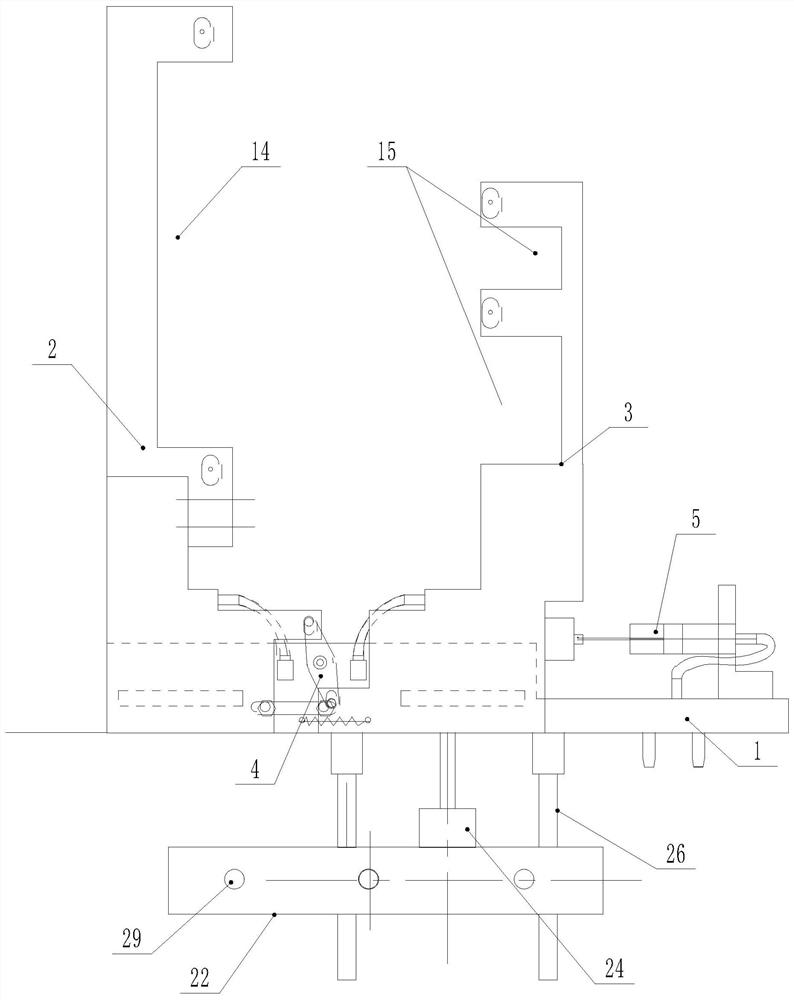

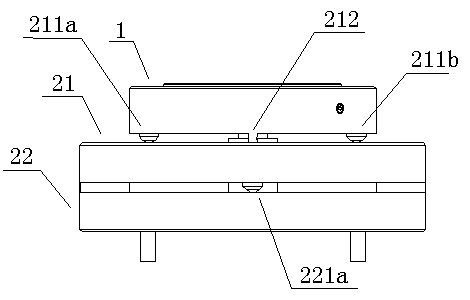

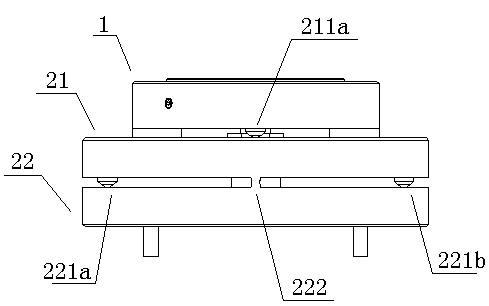

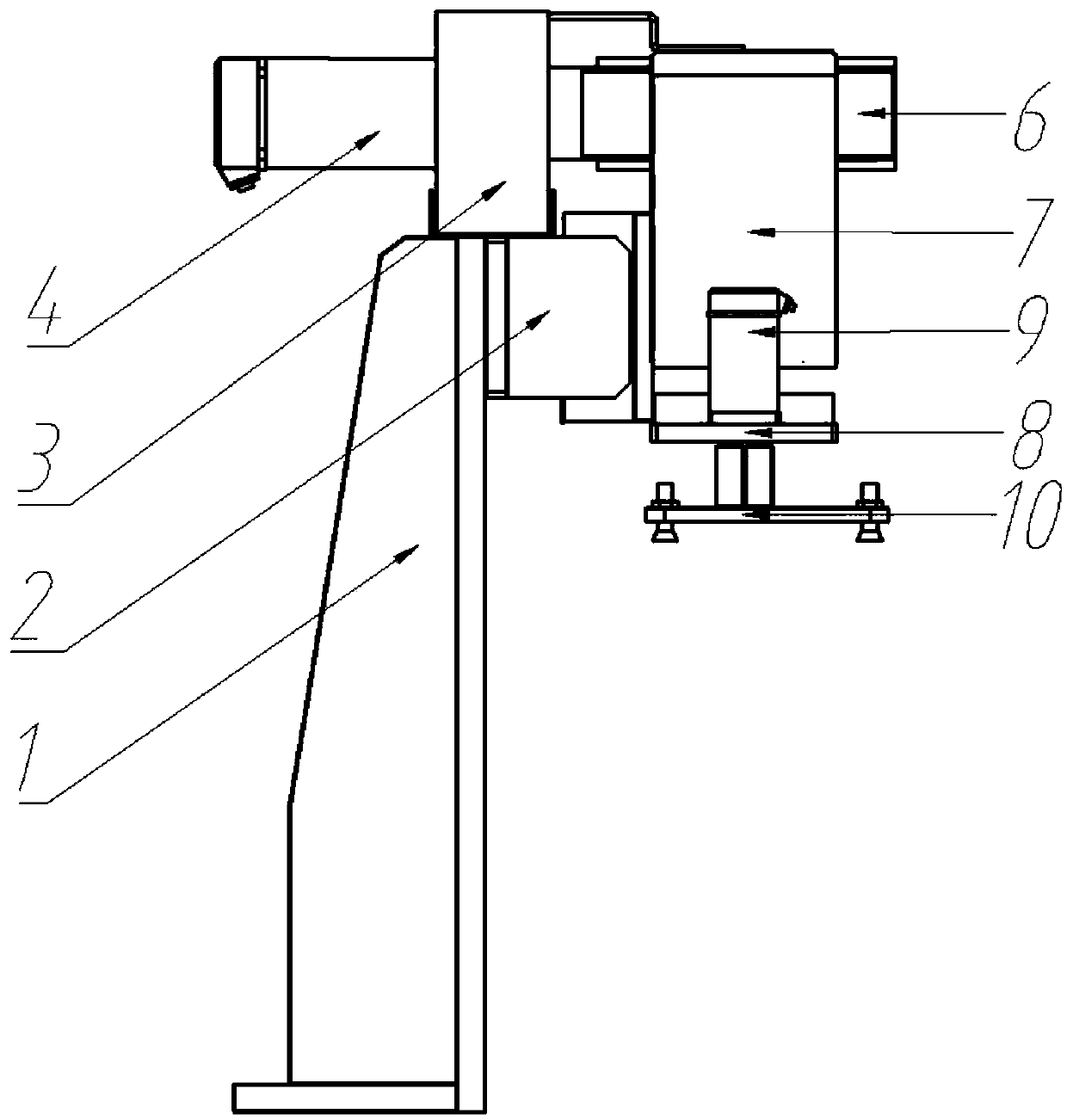

Automatic skew detection silicon chip series welding feeding device

ActiveCN106298610ARealize adjustment and correctionRealize automatic deviation correctionWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingControl theorySilicon chip

The invention provides an automatic skew detection silicon chip series welding feeding device which comprises a support frame, a horizontal moving guiderail fixed at the top end of the support frame, a horizontal position adjustment motor installed at the end part of the horizontal moving guiderail, a slide platform installed on the horizontal moving guiderail and moving in the horizontal direction, a vertical moving guiderail fixed on the slide platform, a vertical position adjustment motor installed at the rear end of the vertical moving guiderail, a cylinder installed on the vertical moving guiderail and moving along the vertical moving guiderail vertically, a grip support plate installed at an expansion end of the cylinder, an angle position adjustment motor installed on the support plate, and a negative pressure retraction grip connected on an output shaft of the angle position adjustment motor in a sleeving manner, and the output shaft of the angle position adjustment motor faces downwards. The automatic skew detection silicon chip series welding feeding device automatically feeds a silicon chip and automatically rectifies the position, the adjustment and correction of the silicon chip in the horizontal, vertical and angular positions of a horizontal plane is implemented through three axes association in the moving process of the silicon chip, and the accuracy is greatly improved.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

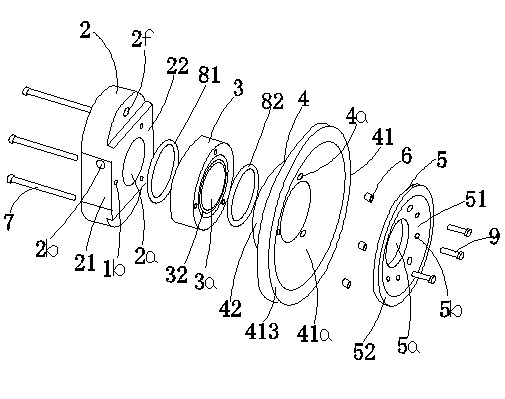

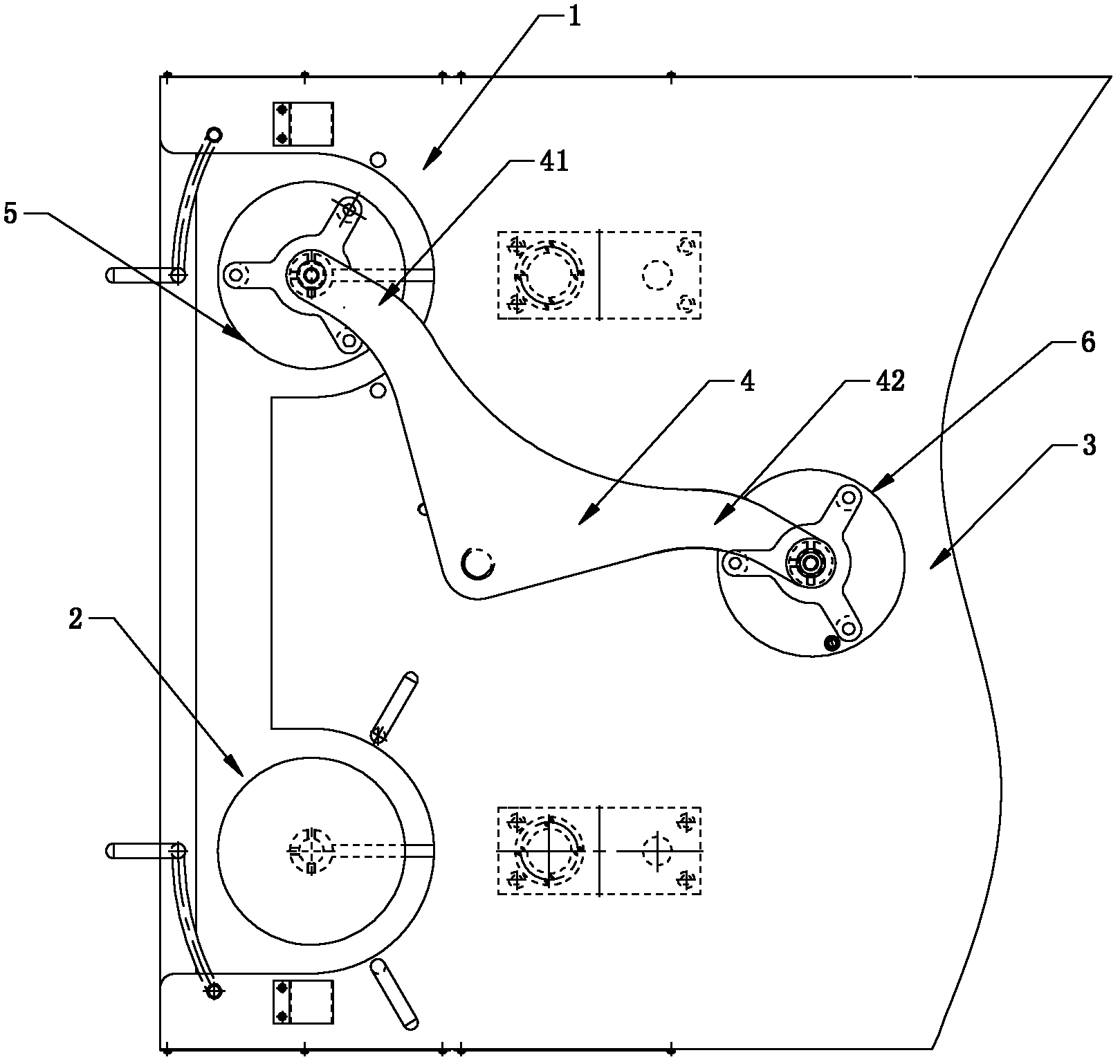

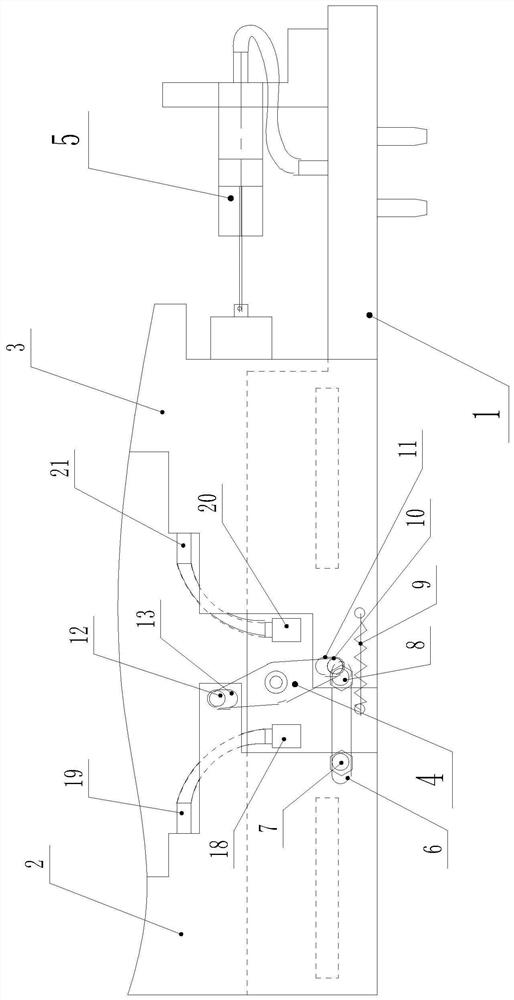

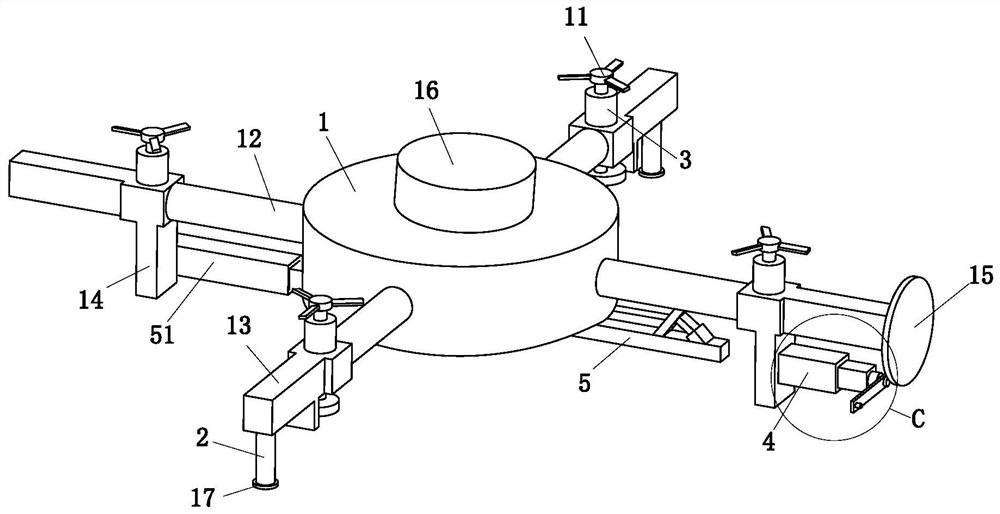

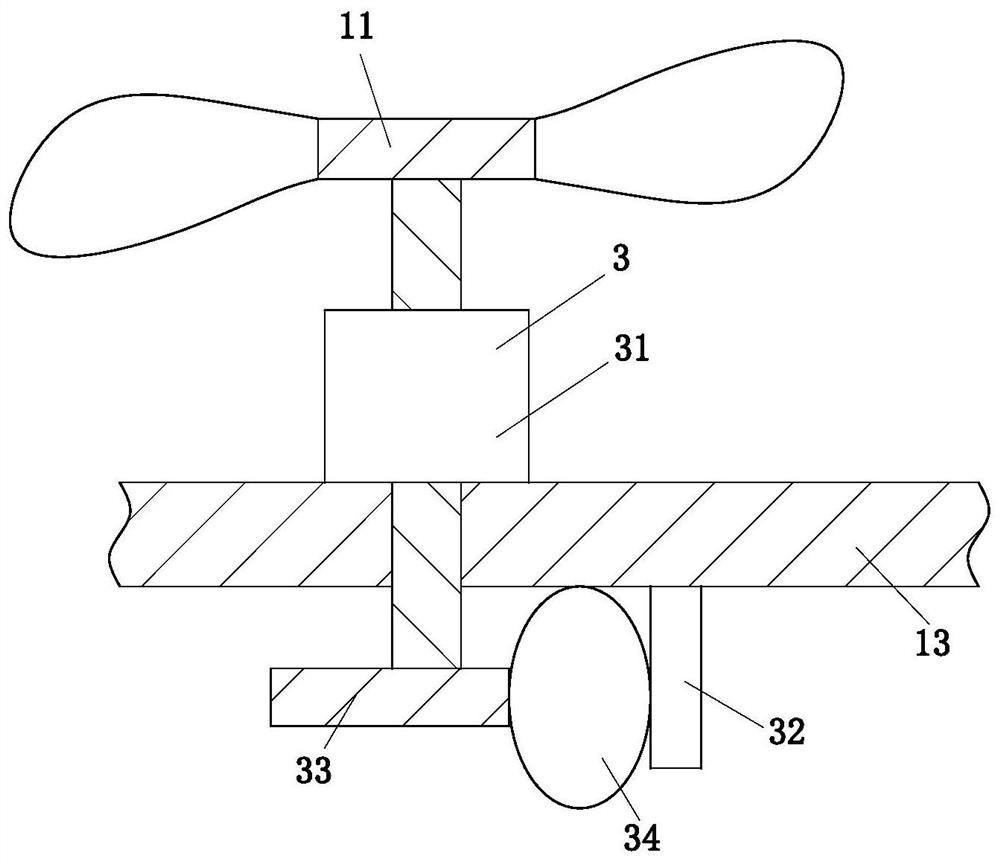

Shuttle plate replacing device for shuttle plate coiling machine of fishing net loom

InactiveCN102633162AUniform adsorption capacityNot easy to fall offFilament handlingIsoetes triquetraEngineering

The invention discloses a shuttle plate replacing device for a shuttle plate coiling machine of a fishing net loom. The device is characterized in that a blank plate placing station used for placing a blank plate, a full plate placing station used for placing a full plate and a coiling station used for coiling are arranged on the coiling machine; the blank plate placing station, the full plate placing station and the coiling station are distributed at three peaks of an equilateral triangle; the shuttle plate replacing device comprises a rotating claw which is rotatably mounted on a frame; therotating center of the rotating claw is the center of the equilateral triangle; the rotating claw is provided with a first claw part and a second claw part; a first adsorbing device which is used foradsorbing and conveying the blank plate on the blank plate placing station to the coiling station is mounted on the first claw part; a second adsorbing device which is used for adsorbing and conveying the full plate on the coiling station to the full plate placing station is mounted on the second claw part; and the rotating claw is driven by a shuttle plate replacing driving device to deflect back and forth. According to the invention, the blank plate and the full plate on the shuttle plate replacing device can be automatically replaced, so that the coiling efficiency of the shuttle plate coiling machine is increased and the manpower resource is saved.

Owner:JIANGSU JIANGHAI MASCH CO LTD

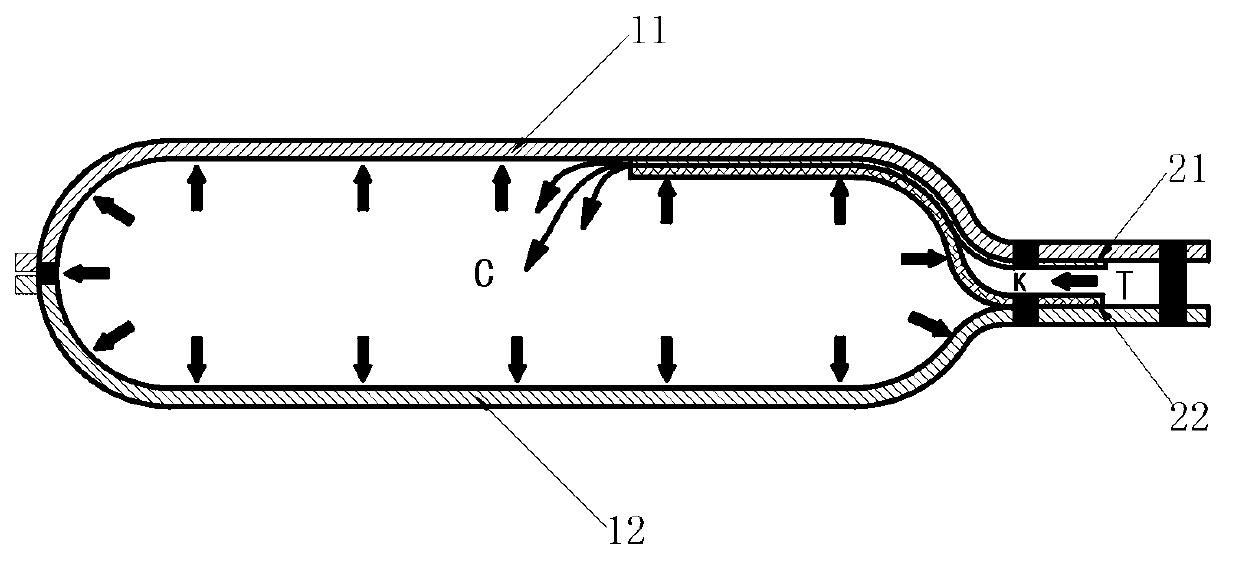

Polar membrane material with adsorptivity, unidirectional check valve and air bag

ActiveCN103275630ALess prone to bonding defectsEvenly distributedNon-macromolecular adhesive additivesFilm/foil adhesivesEngineeringCheck valve

The invention discloses a polar membrane material with adsorptivity, a unidirectional check valve and an air bag. The polar membrane with adsorptivity forming the air bag and the unidirectional check valve is prepared by compositing a self-adhesive layer on one side of a PE substrate, and the self-adhesive layer is made of EVA added with a maleic-anhydride-grafted PE. The material is good in adsorption uniformity, and can improve airtight effect of the conventional unidirectional check valves.

Owner:GREEN PACKAGING TECH (JIANG SU) CO LTD

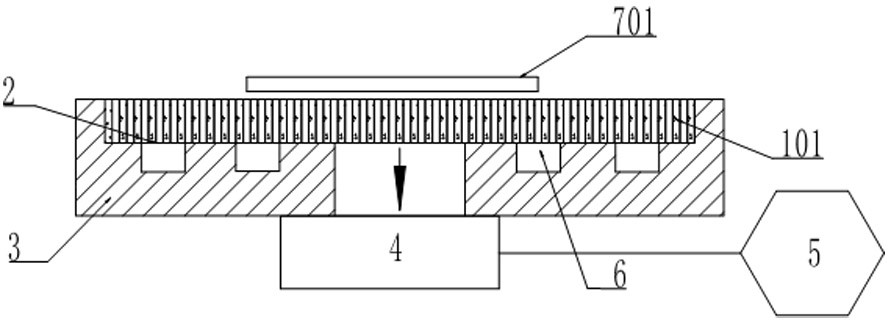

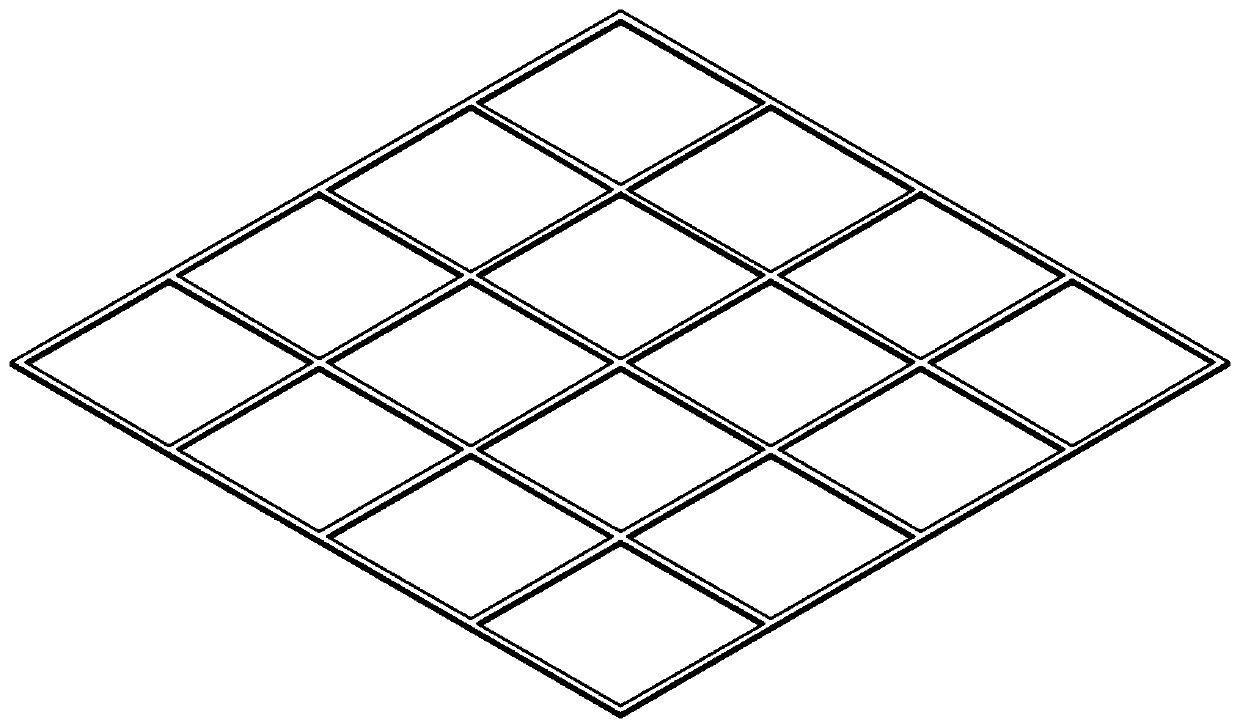

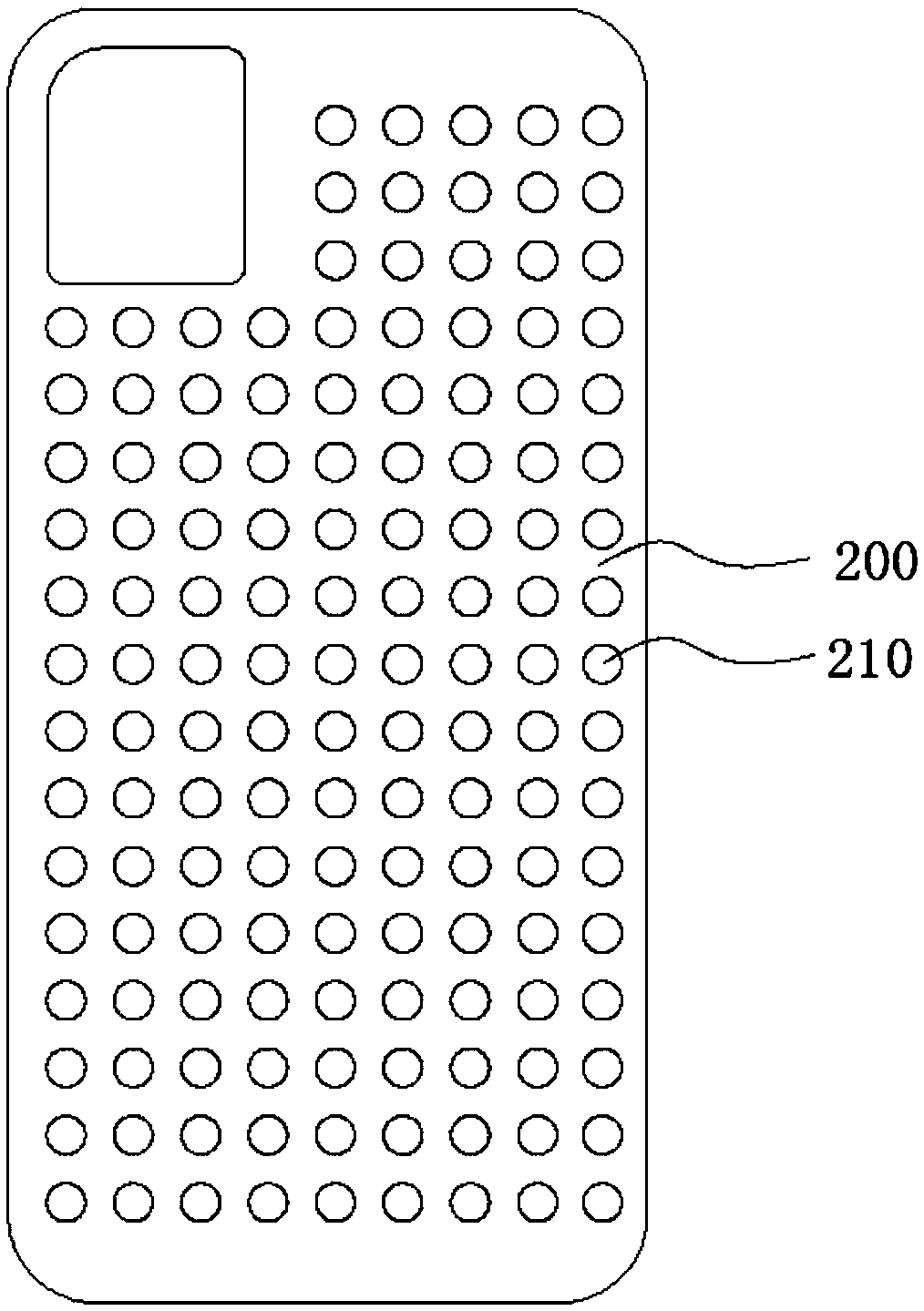

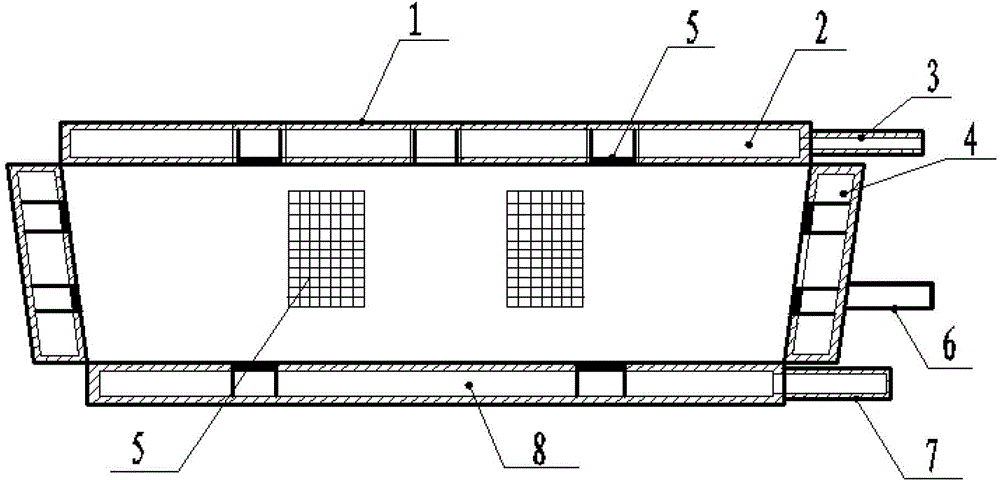

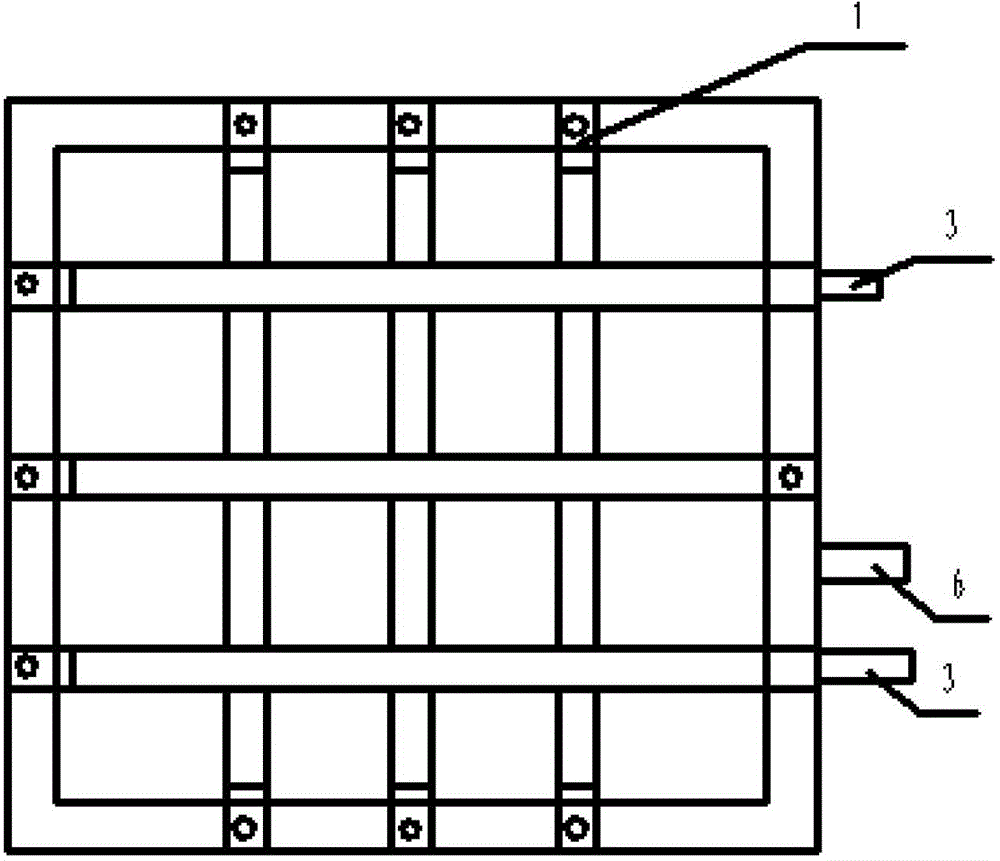

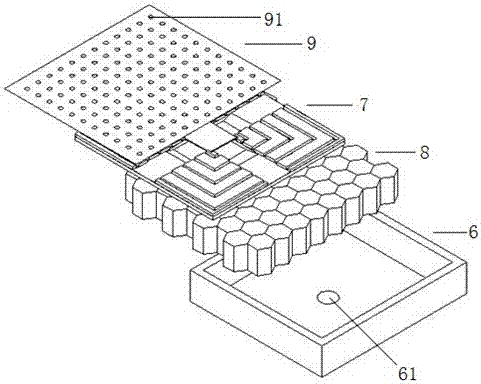

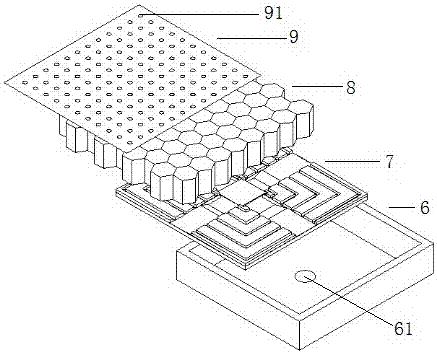

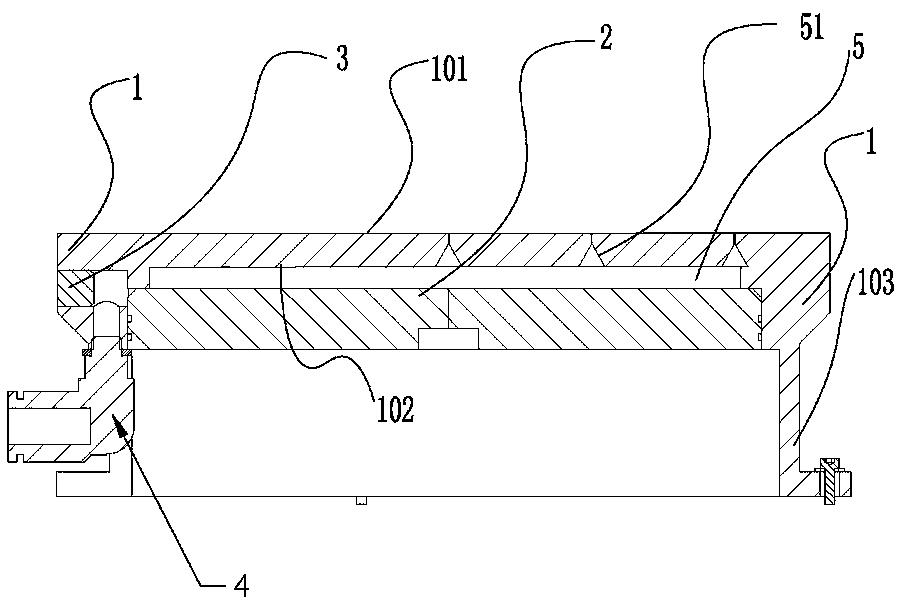

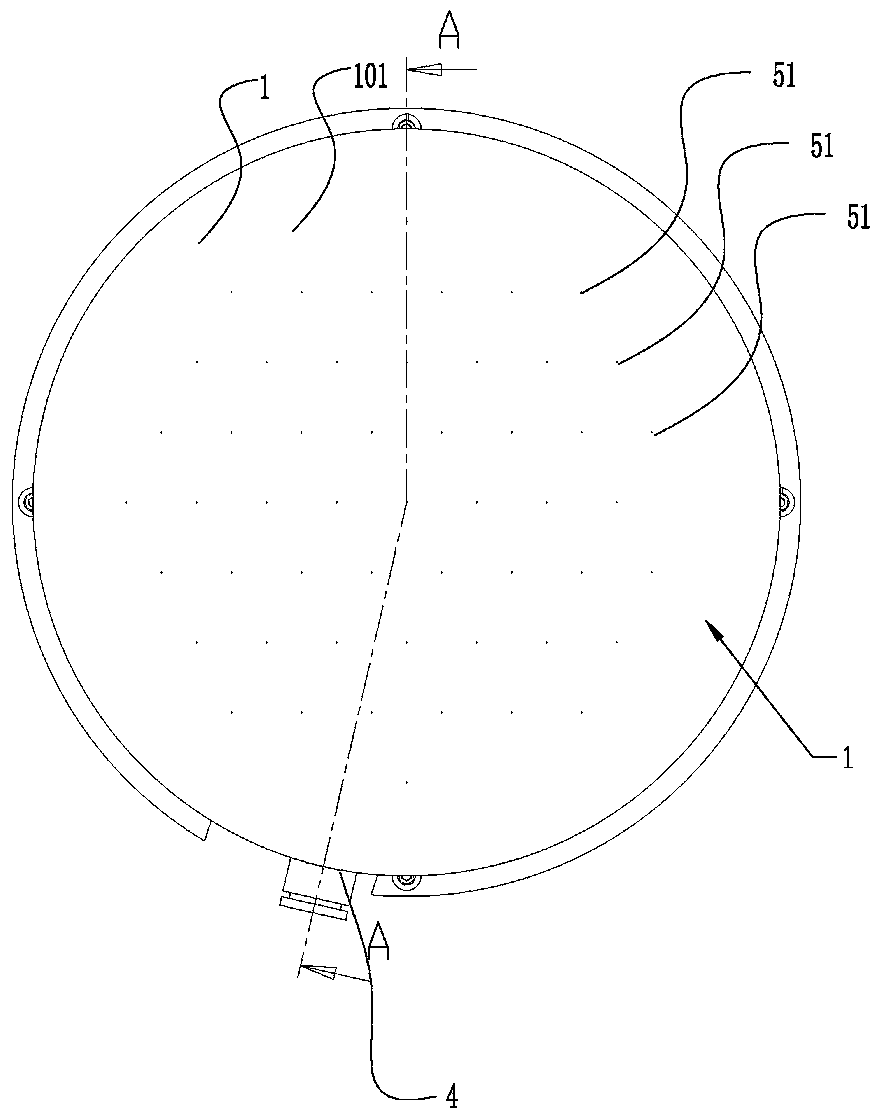

Independent block adsorption platform, control circuit and control method

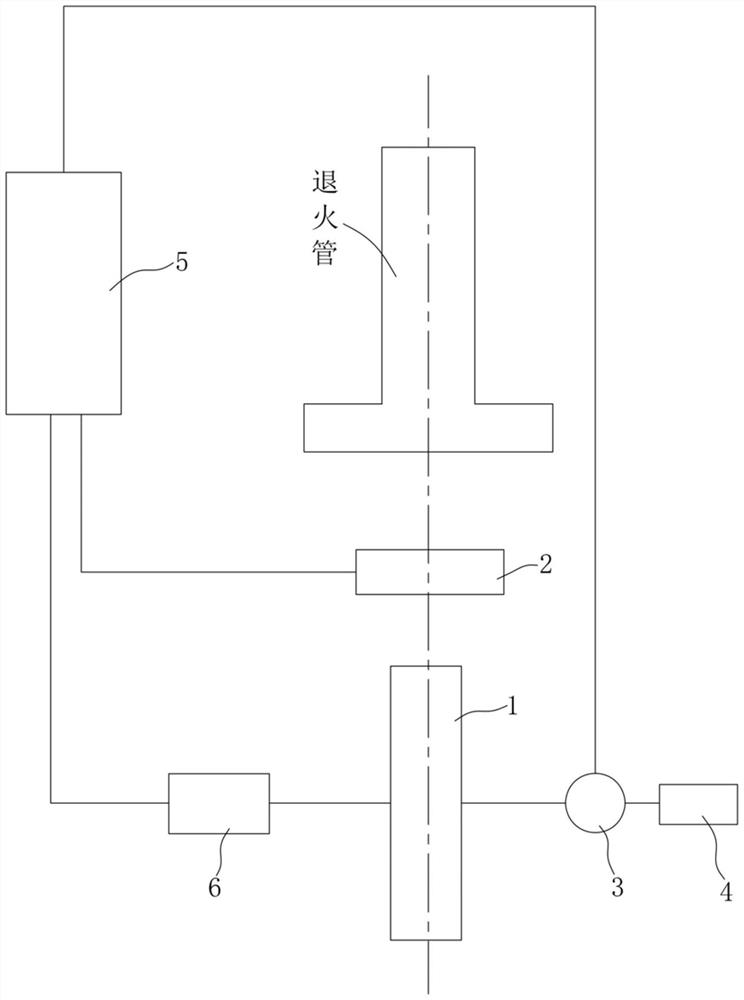

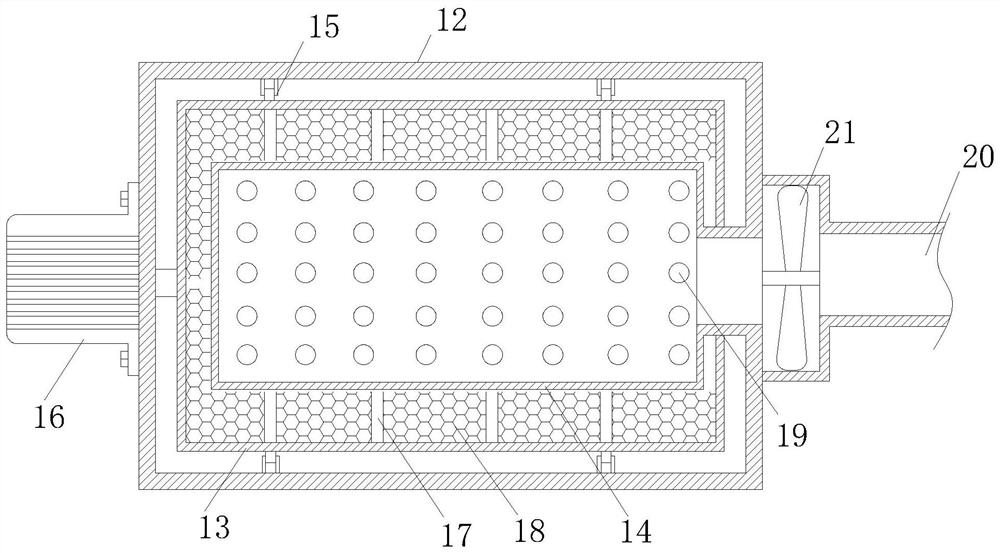

InactiveCN109702802AUniform adsorption capacityStrong adsorptionMetal working apparatusControl circuitMotherboard

The invention provides an independent block adsorption platform, a control circuit and a control method. The independent block adsorption platform comprises an adsorption main platform, air hole plateand a sealing frame, the adsorption main platform is divided into M*N groove areas, each groove area is communicated with a vacuumizing device through a vent pipeline, a corresponding valve is connected between each groove area and the corresponding vent pipeline in series, and each valve can work independently; air holes are uniformly distributed in the air hole plate, the air hole plate is arranged above the adsorption main plate; the sealing frame is composed of M*N frames and is correspondingly arranged between the adsorption main plate and the air hole plate; and M and N are positive integers, and at least one of the M and the N is a positive integer greater than 1.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Money bundle transfer assembly matched with money binder

ActiveCN104150015AImprove fitCompact structureWrapping material feeding apparatusAssembly lineManipulator

The invention discloses a money bundle transfer assembly matched with a money binder. The money bundle transfer assembly comprises a money bundle stacking mechanism, a paper feeding mechanism and the two-barred-cross money binder, and the money bundle stacking mechanism, the paper feeding mechanism and the two-barred-cross money binder are sequentially arranged on one side of a money bundle conveyor belt. A moving platform is arranged between the money bundle stacking mechanism and the paper feeding mechanism, a steering walking mechanism is arranged below the moving platform and moves perpendicular to the axis of the money bundle stacking mechanism and the axis the paper feeding mechanism, and a mechanical hand matched with the moving platform is used for lifting and transferring money bundle stacks into the two-barred-cross money binder. Assembly lines which are distributed in parallel are adopted, the structure is compact, and occupied space is small.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

Vacuum adsorption clamp

Owner:CONPROFE TECH GRP CO LTD +1

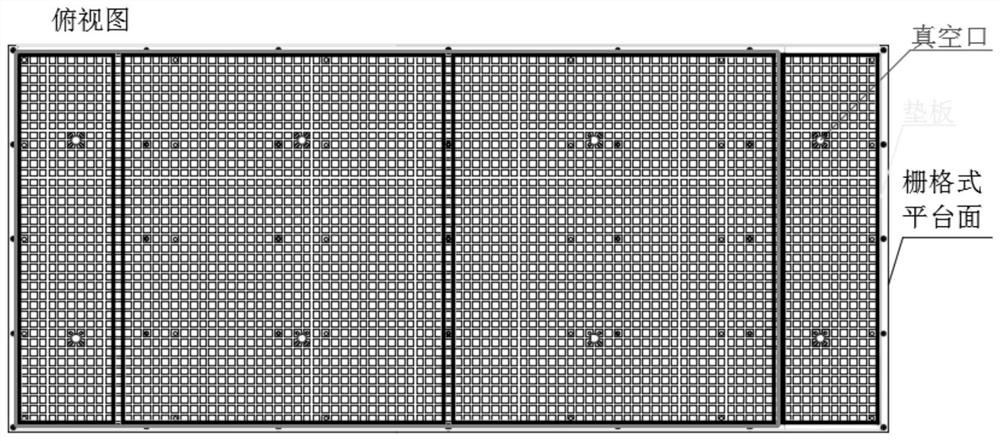

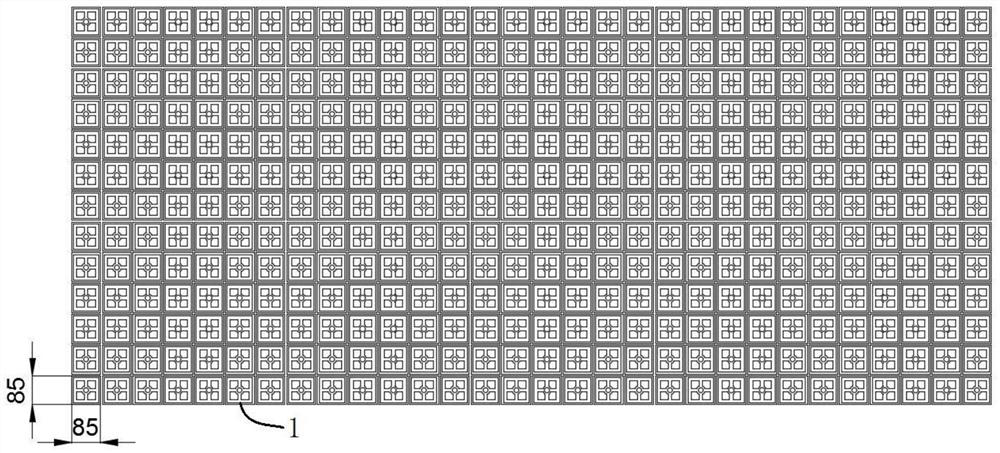

Lifting movable table for large plate nesting, generating method of machining table, machining method for large plate nesting and storage medium

PendingCN111605020AUniform adsorptionAvoid damageWood working apparatusWork benchesEngineeringControl valves

The invention discloses a lifting movable table for large plate nesting, a generating method of a machining table, a machining method for large plate nesting and a storage medium. The table comprisesa controller, a plurality of vacuum cups and driving devices, wherein each vacuum cup is controlled to lift up and down by the independent driving device, and each vacuum cup is provided with a vacuumport control valve; the controller is electrically connected with each driving device and each vacuum port control valve; and the vacuum cups are arranged along a horizontal plane in preset gaps. When the vacuum cups lift up to the preset height, the machining table for bearing and adsorbing plates is formed, and the size of the machining table is determined by the position and number of the lifting vacuum cups. The table can determine the position and number of the lifting vacuum cups according to the size of the plate to be machined so as to generate the corresponding size of machining table, and can be compatible with different sizes of raw material plates. Moreover, a plurality of independently controlled vacuum cups are used to assemble the machining table, so that the adsorption force of each position of the machining table is uniform.

Owner:广州纬纶信息科技有限公司

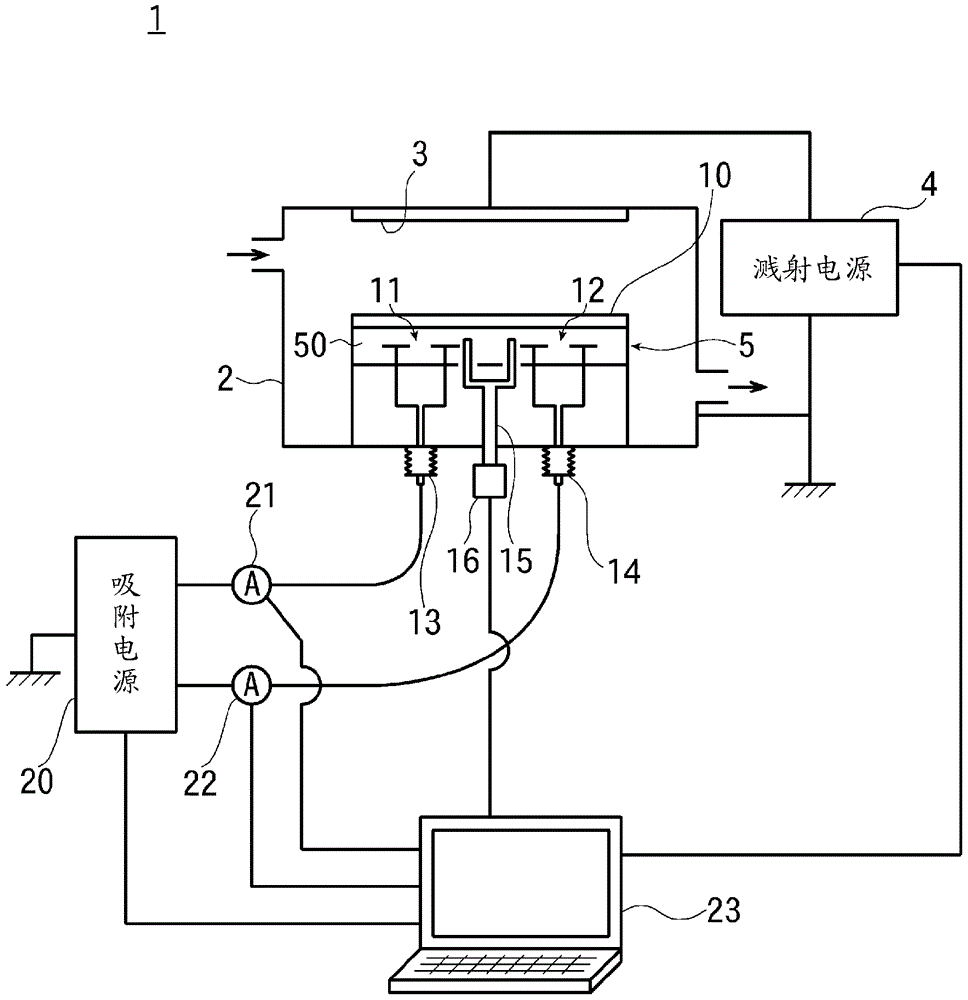

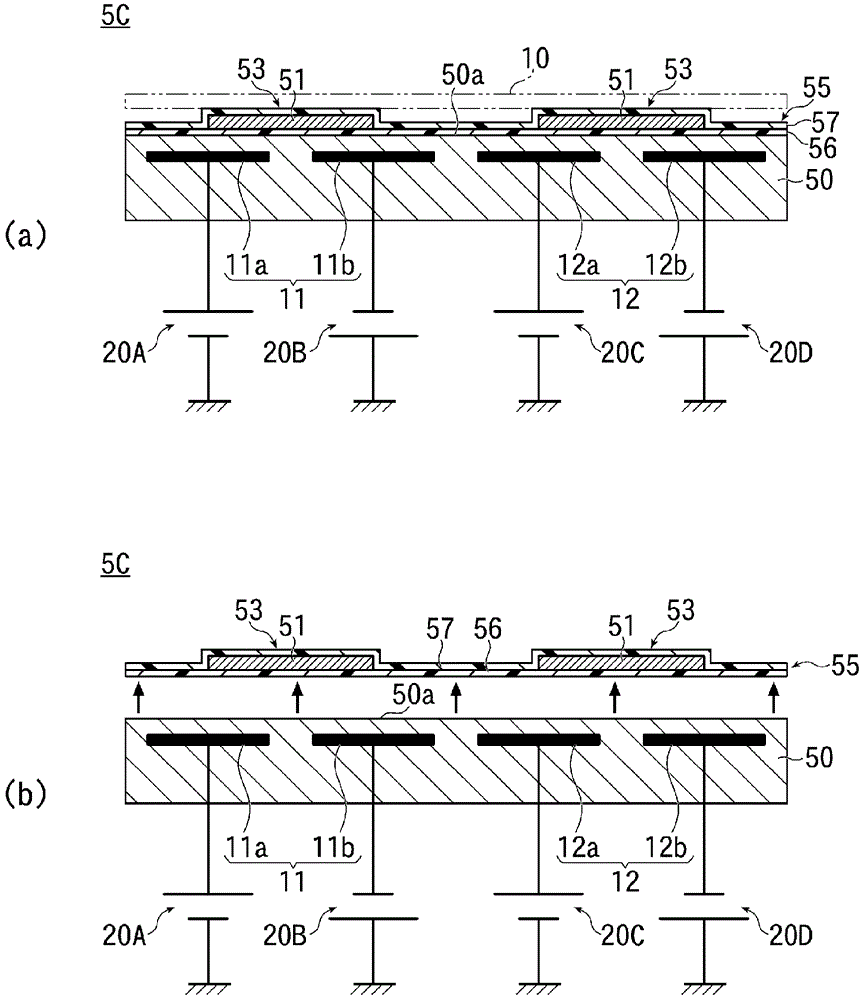

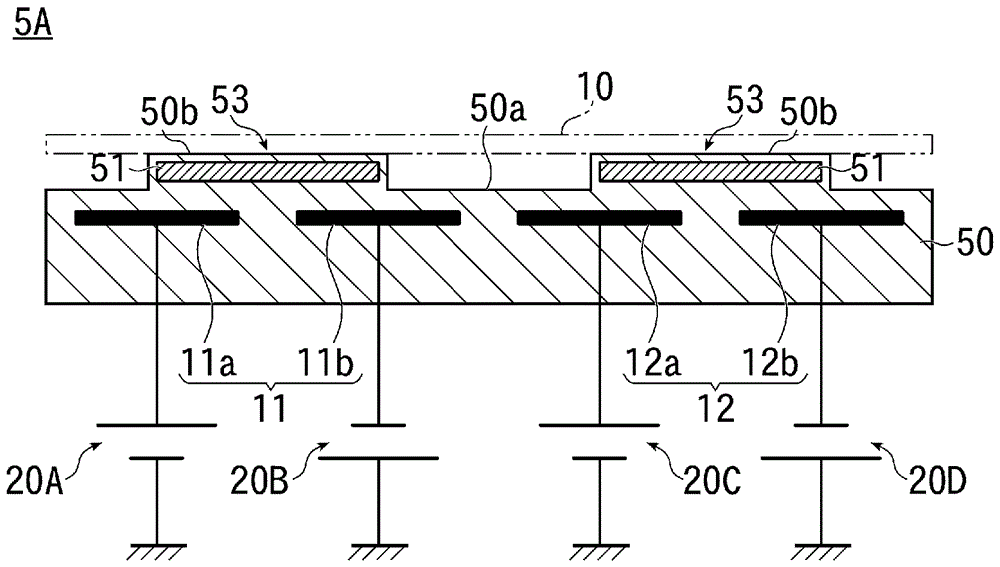

Attraction device and vacuum processing device

ActiveCN106796915APrevent peelingExtend your lifeElectric discharge tubesVacuum evaporation coatingDielectricElectricity

Owner:ULVAC INC

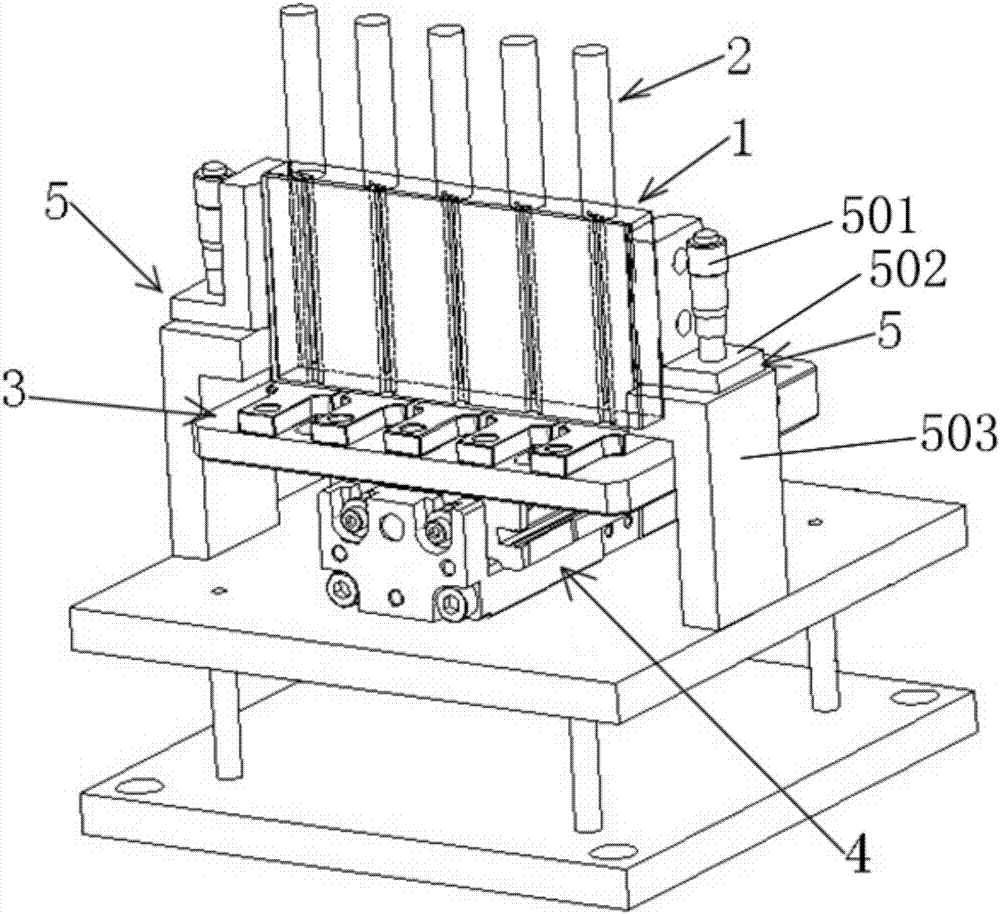

Material supply device

PendingCN107186456AFalling steadilyTimely adjustmentAssembly machinesMountingsReciprocating motionProcess engineering

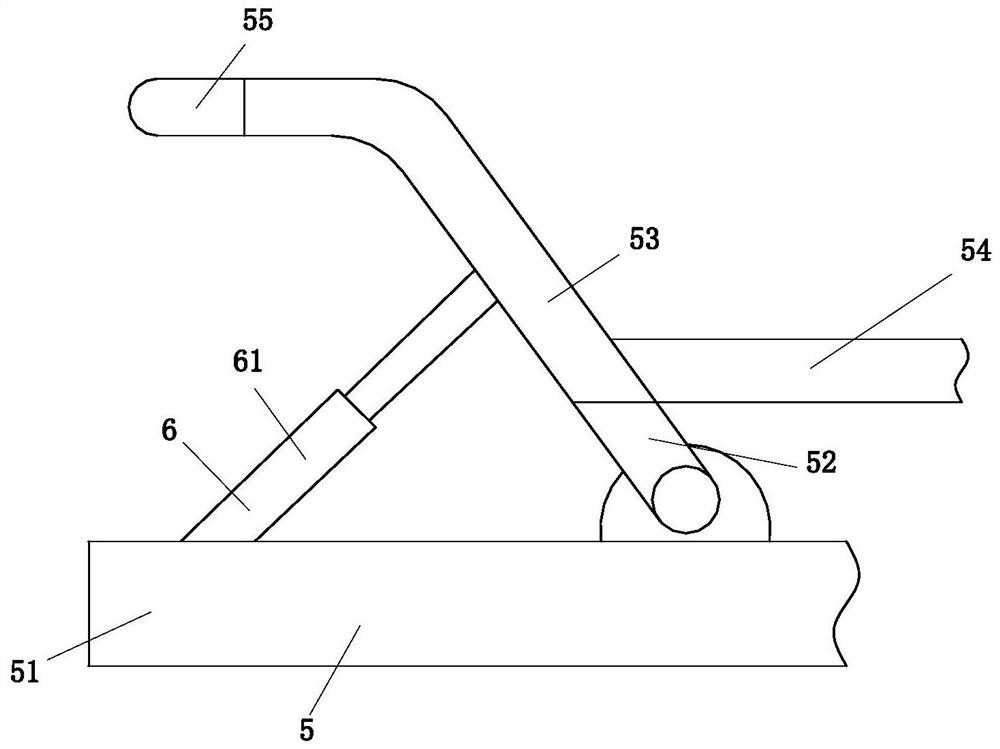

The invention relates to a material supply device. The material supply device comprises a storage unit, an extruding part, a supply unit, a drive part and regulating units, wherein the extruding part can be supported on the storage unit in a movable mode; the supply unit is positioned below the storage unit and is opposite to the extruding part; and certain gap is formed between the supply unit and the storage unit. The two ends, in the length direction, of the storage unit are fixedly connected with the regulating units for regulating height of the storage unit. The supply unit is fixedly arranged on the drive part which can drive the supply unit to perform linear reciprocating motion. According to the material supply device provided by the invention, a magnet sheet is put into the storage unit, the size of the gap between the storage unit and the supply unit is regulated through the regulating units, and the drive part drives the supply unit to move, so that only one magnet sheet drops into the supply unit every time, and therefore, automatic supply of single magnet sheet is realized, manual operation is replaced, efficiency is improved, a rejection rate of the magnet sheet is reduced, and cost is reduced.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

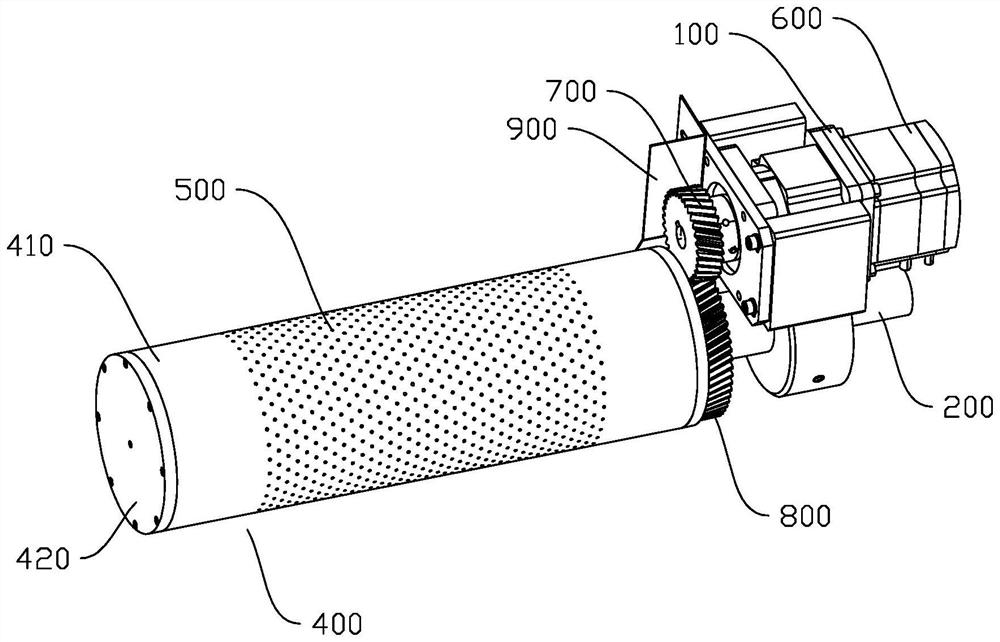

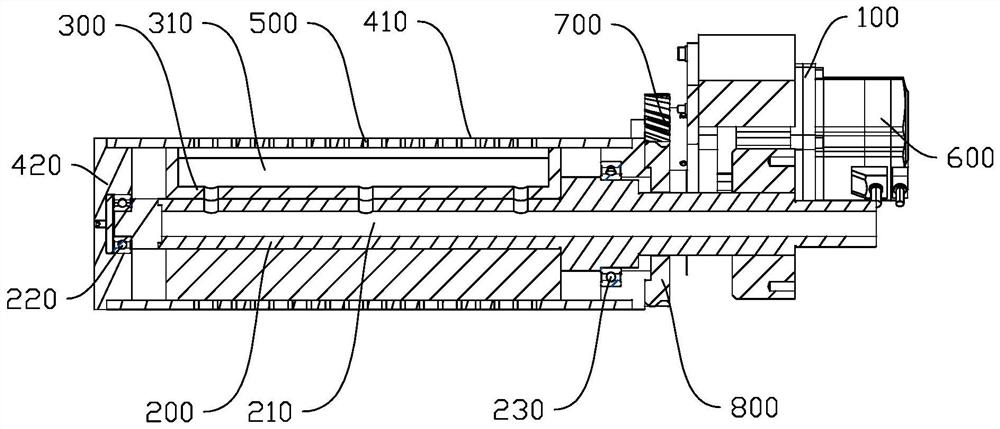

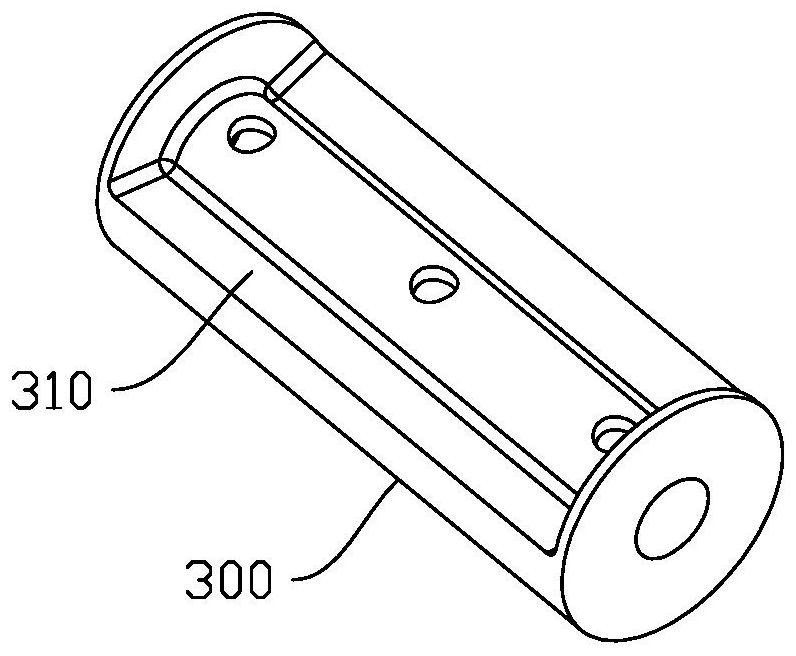

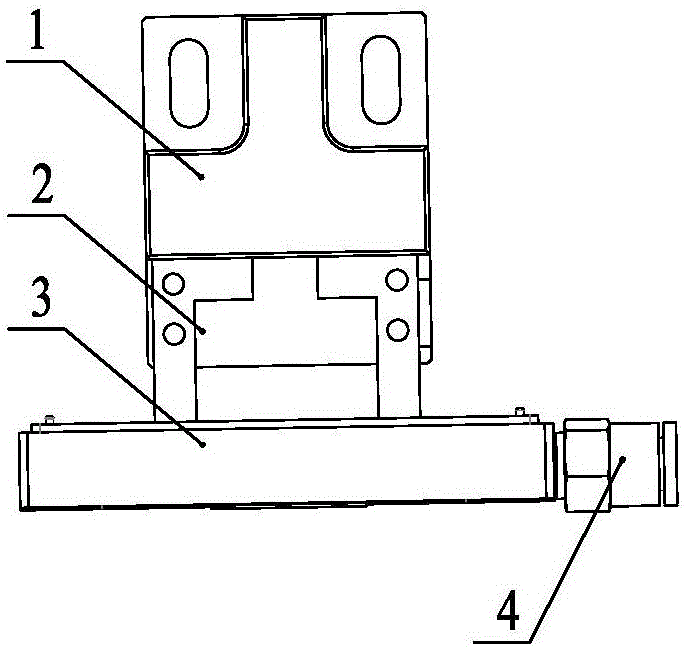

Roller conveying device

The invention discloses a roller conveying device. The roller conveying device comprises a supporting base, a ventilation shaft, an air distribution cylinder, a roller and a rotary driving mechanism. The ventilation shaft is connected with the supporting seat, and a main air channel is arranged in the ventilation shaft; an air distribution groove is formed in the surface of the outer circle of the air distribution cylinder, and the air distribution groove is communicated with the main air channel; the roller is rotatably arranged on the ventilation shaft in a sleeving mode and covers the air distribution cylinder, a plurality of evenly-distributed air holes are formed in the roller, and the air distribution groove is communicated with the air holes right opposite to the air distribution groove; the rotation driving mechanism is arranged on the supporting base, and the output end of the rotation driving mechanism is in transmission connection with the roller. And the orientation of the notch of the air distribution groove is the adsorption position and the conveying area of the material, and is the working area or the adsorption area of the roller. The air distribution channel of the roller conveying device is simple in structure, switching between the working state and the non-working state of the air holes is determined by the air distribution cylinder, and due to the fact that the air holes in the working area are communicated with the same air distribution groove, adsorption force of the air holes in the working area is even.

Owner:ZHUHAI AUTO VISION TECH CO LTD

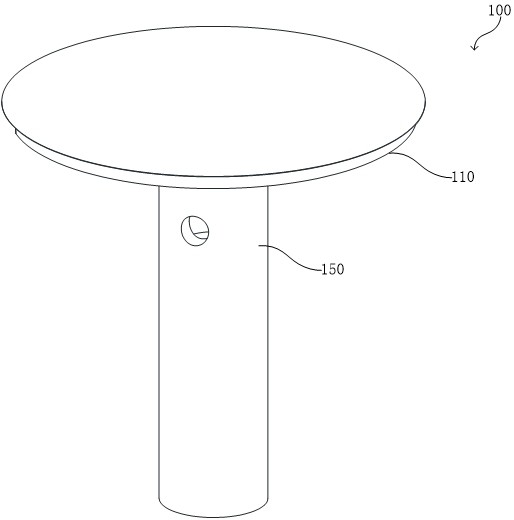

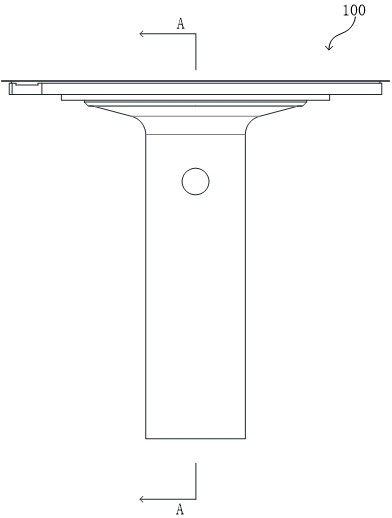

Rotary type workpiece adsorption platform

The invention relates to a rotary type workpiece adsorption platform which is characterized by comprising a mounting bracket, a fixed plate, a platform body, an air pipe joint and a rotating shaft, wherein the rear side edge of the adsorption platform is pivoted with the lower side edge of the fixed plate through the rotating shaft; the fixed plate is fixedly mounted on the mounting bracket; a cavity is formed in the platform body; air holes communicating with the cavity are formed in the upper surface of the platform body; an air suction opening communicating with the cavity is formed in the platform body; the air pipe joint is mounted at the air suction opening; and the air pipe joint is used for connecting an external vacuum generator. The rotary type workpiece adsorption platform is simple, compact and reasonable in structure, uniform in adsorption force and stable in adsorption, cannot damage a workpeice, can realize rotatable adjustment, and is suitable for switching of space stations.

Owner:WUXI CHUANGHENG MACHINERY

Automatic photoetching plate feeding and taking device of chip photoetching machine

The invention discloses an automatic photoetching plate feeding and taking device of a chip photoetching machine. The automatic photoetching plate feeding and taking device comprises a machine base. A lifting base is arranged on the machine base in a vertical lifting manner and provided with a horizontal base. The horizontal base is provided with a material taking mechanism. The material taking mechanism comprises a support. A first absorbing plate and a second absorbing plate are arranged on the support in a sliding manner and are the same in sliding direction, the sliding direction of the first absorbing plate and the sliding direction of the second absorbing plate are perpendicular to the sliding direction of the horizontal base, and the support is provided with a synchronous opening and closing mechanism. Each of the first absorbing plate and the second absorbing plate is provided with a negative pressure suction port. The negative pressure suction ports correspond to the edge of the lower plate face of a photoetching plate. The first absorbing plate or the second absorbing plate is driven by an opening and closing power device. The opposite sides of the first absorbing plate and the second absorbing plate are provided with avoiding concave openings. The automatic feeding and taking device enters from the two sides of the photoetching plate through opening and closing of the first absorbing plate and the second absorbing plate and directly adsorbs the photoetching plate; and the first absorbing plate and the second absorbing plate do not make contact with a plate film, so that plate film abrasion or tearing is avoided.

Owner:江苏晋誉达半导体股份有限公司

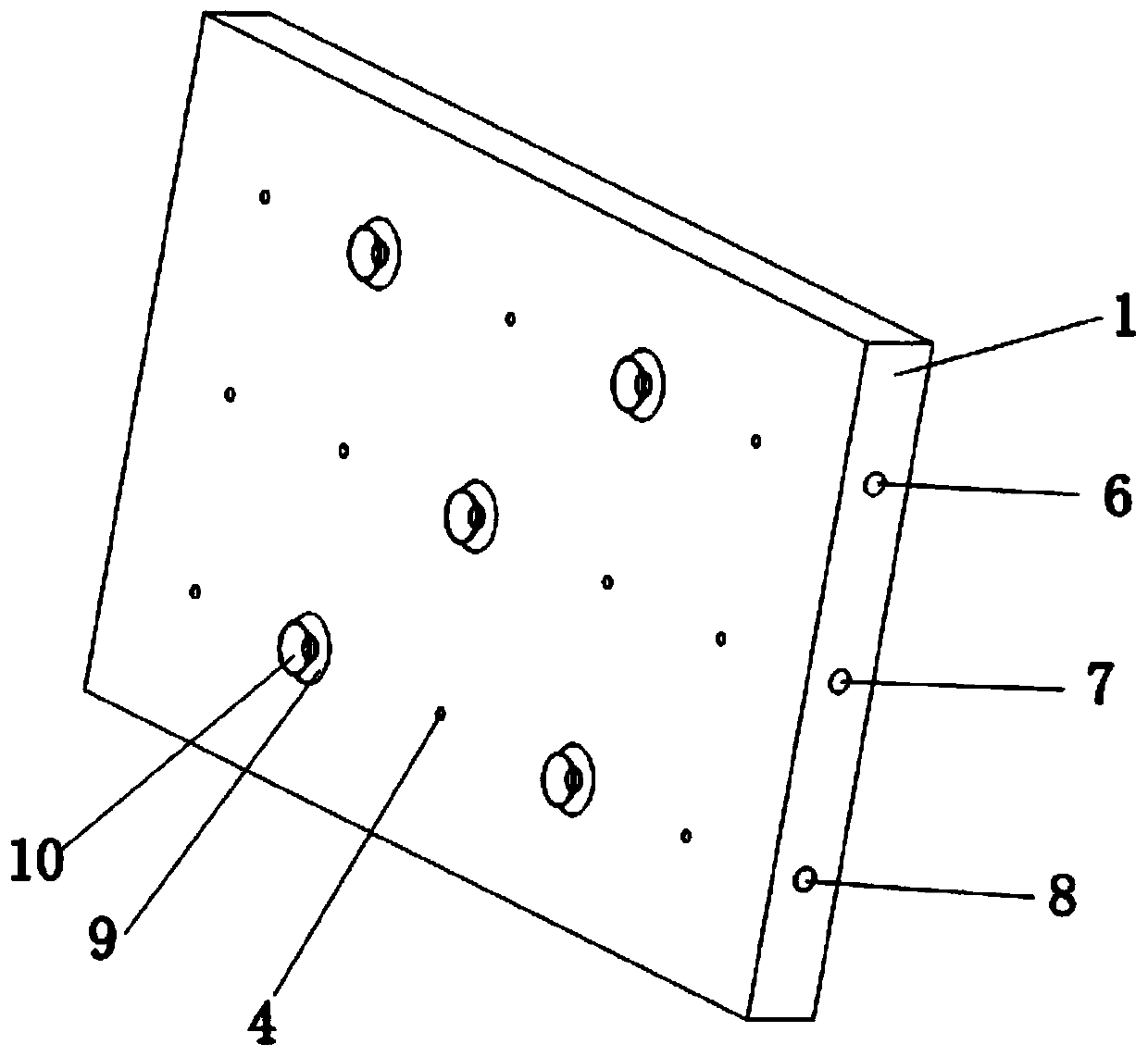

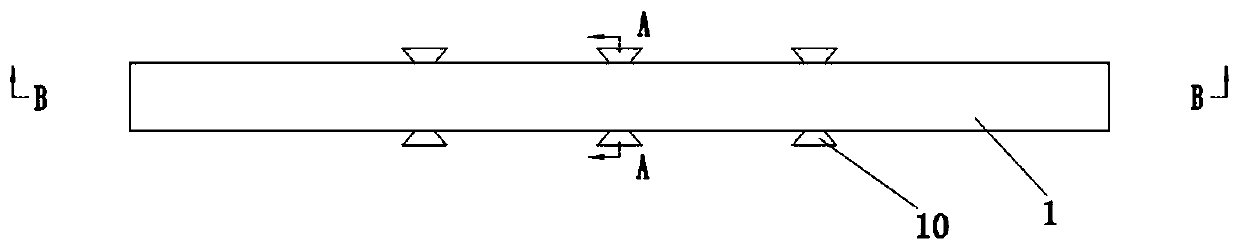

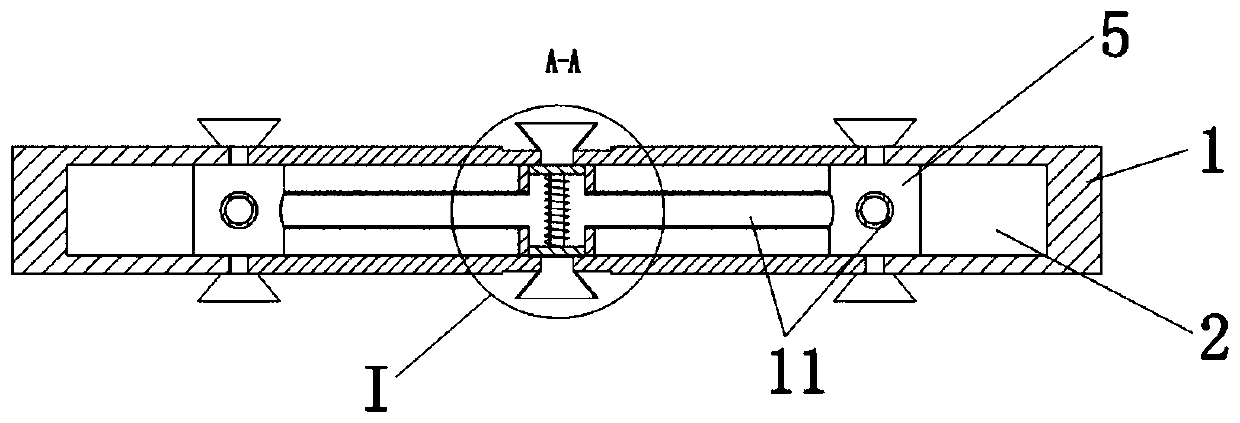

A double-sided switching vacuum adsorption plate

ActiveCN110695720BReliable clampingUniform adsorption capacityLarge fixed membersPositioning apparatusEngineeringAdsorption effect

The invention provides a double-sided switching vacuum adsorption plate comprising a plate body. The plate body comprises a first contact plate and a second contact plate which are oppositely arrangedon the front face and the back face. The plate body is provided with a cavity between the first contact plate and the second contact plate. The first contact plate and the second contact plate are evenly provided with five groups of large adsorption holes at the center of the plate body and a plurality of evenly distributed small adsorption holes. An adsorption switching device is fixed into thecavity. The first contact plate and the second contact plate are provided with annular grooves at the positions corresponding to the large adsorption holes. Conical suction cups are fixed to the innerwalls of the large adsorption holes in a sealed manner. When the outer walls of the conical suction cups are completely attached to the inner walls of the grooves, the inner walls of the conical suction cups completely coincide with the outer surface of the first contact plate and the second contact plate. According to the double-sided switching vacuum adsorption plate, in the whole grabbing process of the workpiece, the manner of acting on the workpiece is to make soft contact with the workpiece first of fall and then increase adsorption force, so that the workpiece can be effectively protected and prevented from being damaged; and meanwhile, the adsorption effect is improved, production quality control is guaranteed, and the production efficiency is improved.

Owner:深圳市粤海翔精密科技有限公司

Workpiece adsorption platform

The invention relates to a workpiece adsorption platform which is characterized by comprising a platform body and an air pipe joint, wherein a cavity is formed in the platform body; air holes communicating with the cavity are formed in the upper surface of the platform body; an air suction opening communicating with the cavity is formed in the platform body; the air pipe joint is mounted at the air suction opening; and the air pipe joint is used for connecting an external vacuum generator. The workpiece adsorption platform is simple, compact and reasonable in structure, uniform in adsorption force and stable in adsorption and cannot damage a workpeice.

Owner:WUXI CHUANGHENG MACHINERY

Casting sand box

Owner:河北青峰车体模具有限公司

A photolithographic plate automatic feeding and unloading device for a chip photolithography machine

The invention discloses a photolithography plate automatic feeding and retrieving device of a chip photolithography machine, which comprises a machine base, a lifting seat is installed on the machine base for vertical lifting, a horizontal base is installed on the lifting seat, and a horizontal base is installed on the horizontal base. The material retrieving mechanism, the material retrieving mechanism includes a support, and the first suction plate and the second suction plate are slidably installed on the support. The sliding direction of the first suction plate and the second suction plate is the same and perpendicular to the sliding direction of the horizontal base. The support is provided with a synchronous opening and closing mechanism, and both the first suction plate and the second suction plate are provided with a negative pressure suction port, which corresponds to the edge of the lower plate surface of the photolithography plate, and the first suction plate Or the second suction plate is driven by the opening and closing power device, and the opposite sides of the first suction plate and the second suction plate are provided with avoidance notches. The automatic feeding and retrieving device enters and directly absorbs the photoresist plate from both sides of the photoresist plate through the opening and closing of the first suction plate and the second suction plate, and the first suction plate and the second suction plate do not contact the plate film, thereby Abrasion or tearing of the plate film is avoided.

Owner:江苏晋誉达半导体股份有限公司

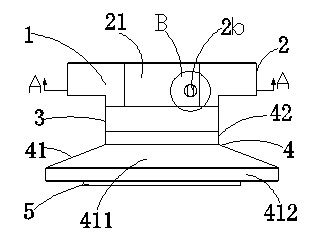

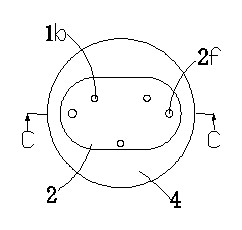

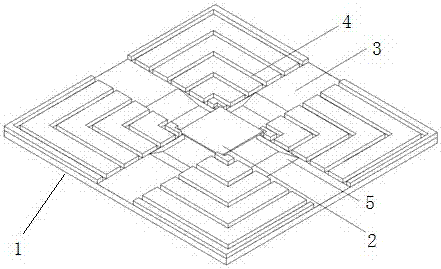

A vacuum adsorption platform based on deflector

The invention relates to improvement on working platforms in material processing, in particular to a vacuum adsorption platform based on a guide plate. The vacuum adsorption platform based on the guide plate is characterized by comprising a base plate (1) and a baffle plate (2) fixed on the base plate (1), wherein the base plate (1) is provided with cross main airflow passages (3), a plurality of branch airflow passages (4) and a suction opening corresponding to the baffle plate (2) in position, the baffle plate (2) is positioned at a cross point of the main airflow passages (3), and the main airflow passages (3) are communicated with the branch airflow passages (4). The vacuum adsorption platform based on the guide plate has the advantages of original high strength, original high flatness, low flowing resistance, uniform adsorption force, large effective adsorption area and lower cost.

Owner:FOSHAN SHUNDE DISTRICT YINMEI FINE HARDWARE TECH +1

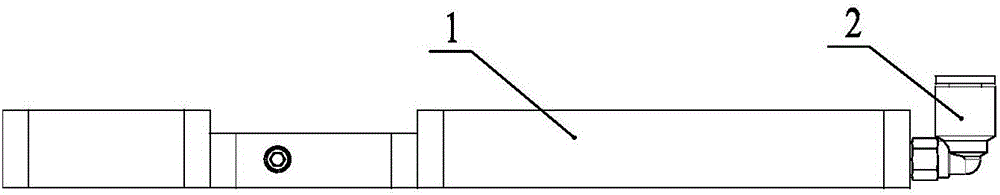

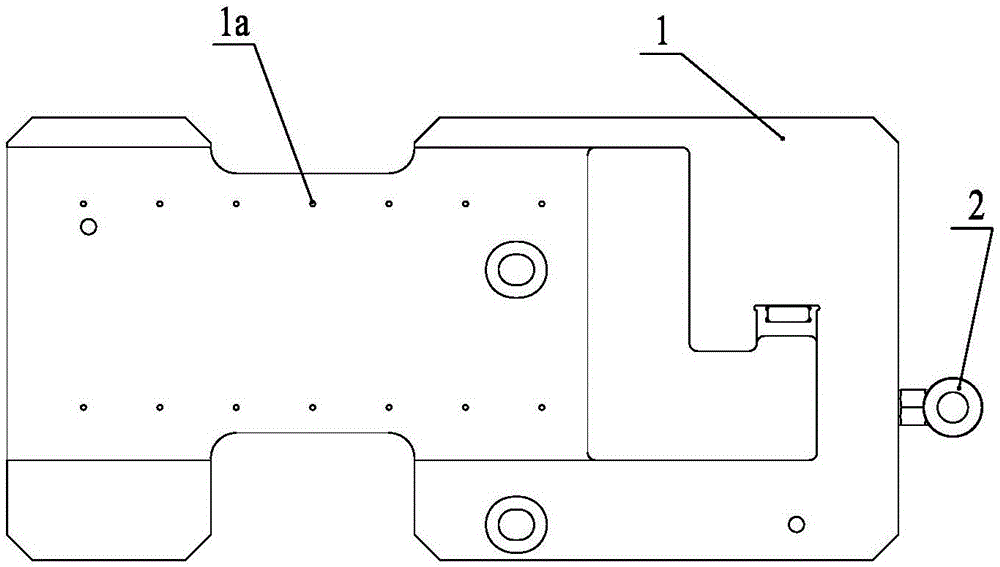

Clamping mechanism for SMT screen plate measurement

InactiveCN103217134AEnsuring Thickness Measurement AccuracyGuaranteed measurement accuracyMeasurement devicesEngineeringApplication areas

Owner:KUNSHAN THETA MICRO

The banknote transfer assembly matched with the banknote binding machine

ActiveCN104150015BImprove fitCompact structureWrapping material feeding apparatusSmall footprintManipulator

The invention discloses a banknote handle transfer assembly matched with a banknote binding machine. A mobile platform is set between the mechanism and the paper feeding mechanism, and a steering mechanism perpendicular to the axis of the banknote stacking mechanism and the paper feeding mechanism is set under the mobile platform, and the banknote stack is lifted and conveyed by the manipulator matched with the mobile platform. into the double cross binder. The present invention adopts the assembly lines arranged in parallel, has a compact structure and occupies less space.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

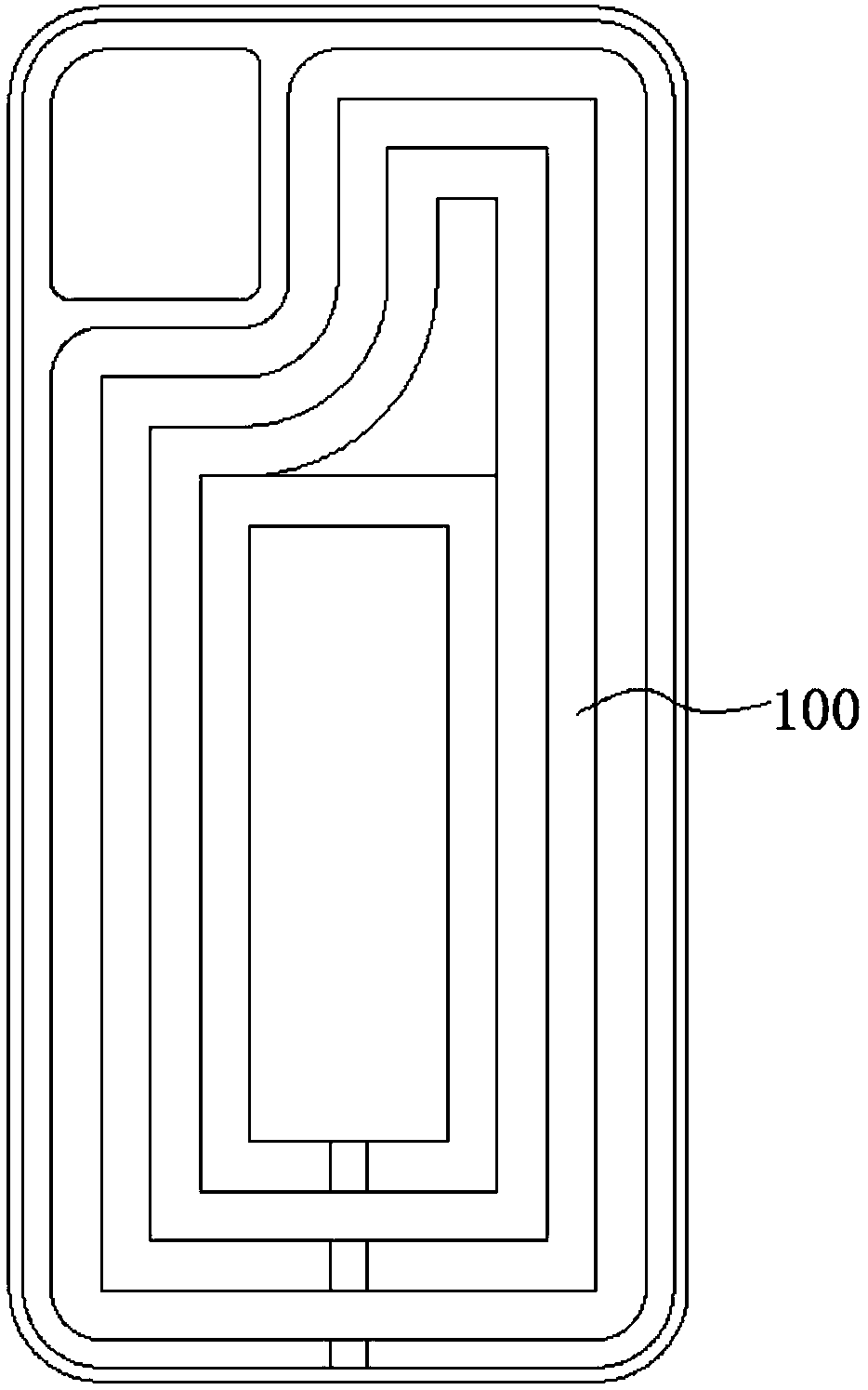

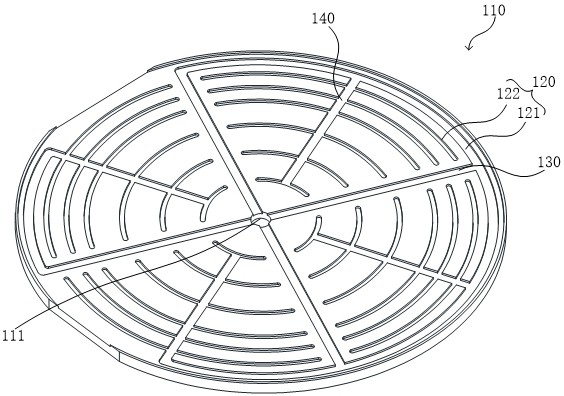

Electrostatic chuck device and degumming machine

ActiveCN112802794AImprove adsorption capacityUniform adsorption capacitySemiconductor/solid-state device manufacturingEngineeringMechanical engineering

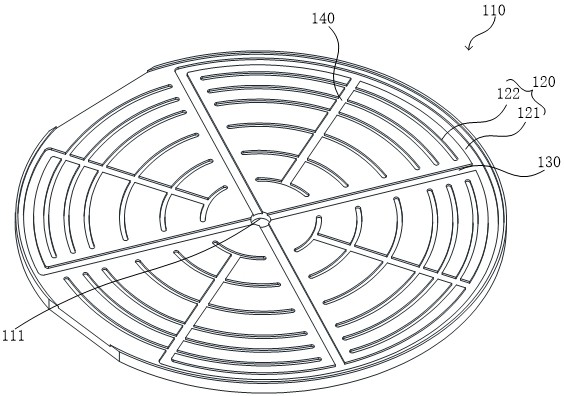

The invention discloses an electrostatic chuck device and a degumming machine, and the electrostatic chuck device comprises: an electrostatic chuck, which is provided with a placement surface, wherein the placement surface comprises: a plurality of circumferential air paths which form a concentric multi-layer structure along the radial direction; a plurality of radial air paths, which are communicated with an air hole in the center of the placement surface and the circumferential air path on the outermost layer, and are blocked from the other circumferential air paths; and a plurality of backflow air paths, each of which is communicated with all the circumferential air paths between any two adjacent radial air paths. The problems that the electrostatic chuck is large in middle adsorption force and small in edge adsorption force are solved.

Owner:宁波润华全芯微电子设备有限公司

Polar membrane material with adsorptivity, unidirectional check valve and air bag

ActiveCN103275630BUniform adsorption capacityTight adsorptionNon-macromolecular adhesive additivesFilm/foil adhesivesElectrical polarityEngineering

The invention discloses a polar membrane material with adsorptivity, a unidirectional check valve and an air bag. The polar membrane with adsorptivity forming the air bag and the unidirectional check valve is prepared by compositing a self-adhesive layer on one side of a PE substrate, and the self-adhesive layer is made of EVA added with a maleic-anhydride-grafted PE. The material is good in adsorption uniformity, and can improve airtight effect of the conventional unidirectional check valves.

Owner:GREEN PACKAGING TECH (JIANG SU) CO LTD

A silicon chip serial welding and feeding device capable of automatic deviation correction

ActiveCN106298610BRealize adjustment and correctionRealize automatic deviation correctionWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingSilicon chipControl theory

The invention provides an automatic skew detection silicon chip series welding feeding device which comprises a support frame, a horizontal moving guiderail fixed at the top end of the support frame, a horizontal position adjustment motor installed at the end part of the horizontal moving guiderail, a slide platform installed on the horizontal moving guiderail and moving in the horizontal direction, a vertical moving guiderail fixed on the slide platform, a vertical position adjustment motor installed at the rear end of the vertical moving guiderail, a cylinder installed on the vertical moving guiderail and moving along the vertical moving guiderail vertically, a grip support plate installed at an expansion end of the cylinder, an angle position adjustment motor installed on the support plate, and a negative pressure retraction grip connected on an output shaft of the angle position adjustment motor in a sleeving manner, and the output shaft of the angle position adjustment motor faces downwards. The automatic skew detection silicon chip series welding feeding device automatically feeds a silicon chip and automatically rectifies the position, the adjustment and correction of the silicon chip in the horizontal, vertical and angular positions of a horizontal plane is implemented through three axes association in the moving process of the silicon chip, and the accuracy is greatly improved.

Owner:FOSHAN NANHAI GUANGDONG TECH UNIV CNC EQUIP COOP INNOVATION INST +1

Vacuum hole bracket for LED wafer automatic sorting machine

The invention discloses a vacuum hole bracket for an LED wafer automatic sorting machine. The vacuum hole bracket comprises a vacuum bracket body, wherein a vacuum hole bracket sealing cover is connected below the vacuum bracket body, and a gap is formed between the vacuum bracket body and the vacuum hole bracket sealing cover to form a negative pressure cavity; and the vacuum hole bracket is provided with an upper surface and a lower surface, the upper surface is a plane, the lower surface is a plane, a plurality of micropores are distributed in the lower surface of the vacuum hole bracket, the multiple micropores are arranged in a hexagonal shape, the arrangement shape of the micropores is matched with the shape of a wafer, the negative pressure cavity generates larger adsorption force by the negative pressure through the micropores, a blue film is adsorbed on the upper surface of the vacuum hole bracket, and the adsorption force generated by the plurality of micropores is uniform, so that the blue film is not deformed, and the flatness of the blue film of the welding wafer is guaranteed.

Owner:山东泓瑞光电科技有限公司

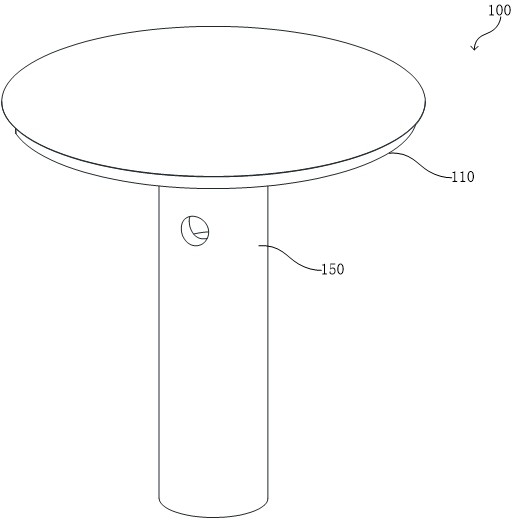

A suspended intelligent fire extinguishing device based on UAV

ActiveCN109364407BReduce stressReduce in quantityAircraft componentsFire rescueCutting glassUncrewed vehicle

The invention belongs to the technical field of fire-fighting equipment, specifically a suspended intelligent fire-extinguishing device based on an unmanned aerial vehicle, including a control box, a propeller, a frame, a mounting plate and a support frame; also includes a column, a drive unit, a cutting unit, Water spray unit, suction cup #1 and air tank. Through the mutual cooperation between the drive unit, cutting unit and water spray unit, on the one hand, after the cutting unit cuts the glass, the drone drives the fire extinguishing device into the room, and the fire extinguishing device extinguishes the fire at the fire point to avoid glass factors affecting the fire extinguishing efficiency. This improves the fire extinguishing efficiency based on the unmanned aerial vehicle fire extinguishing device; on the other hand, the drive unit generates gas during the drive propeller movement, and the gas acts on the fire extinguishing device as a power source, reducing the number of external power equipment and reducing unmanned The pressure of the drone, thereby improving the fire extinguishing efficiency based on the drone fire extinguishing device.

Owner:温州恒基包装有限公司

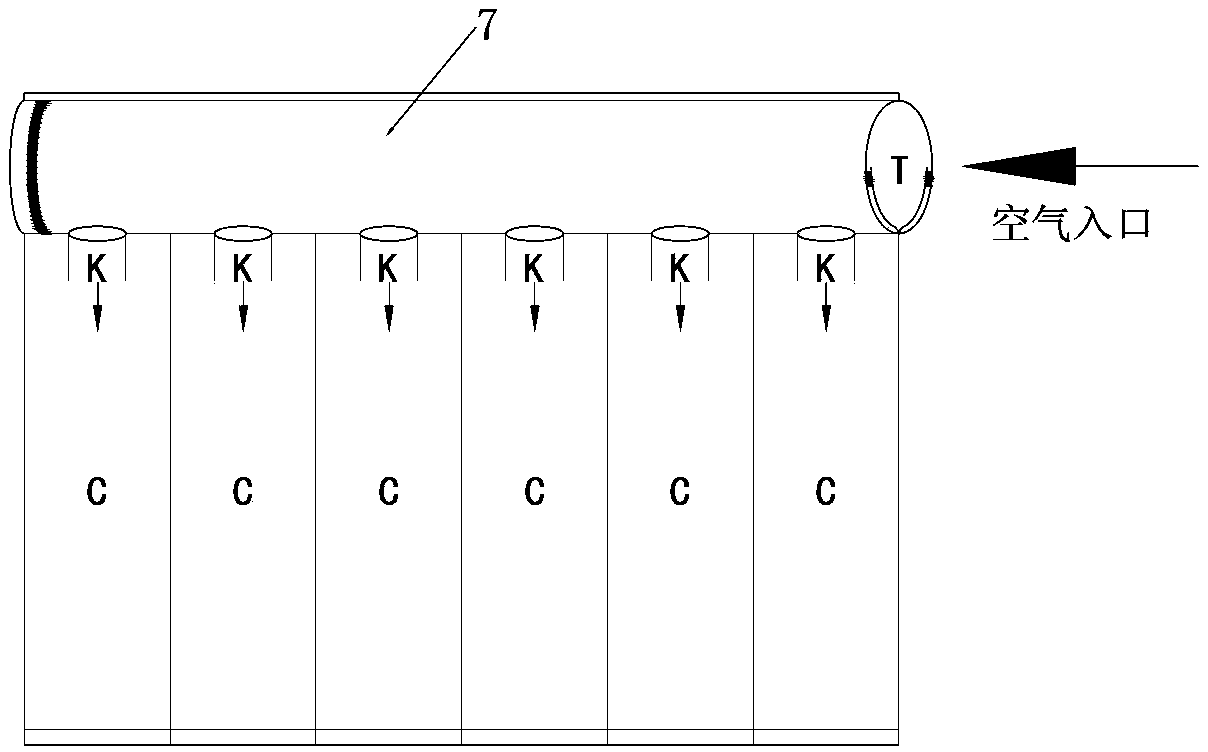

Tool and system for cleaning optical fiber drawing channel

PendingCN114082713AUniform adsorption capacityAvoid shakingGlass making apparatusDirt cleaningEngineeringMechanical engineering

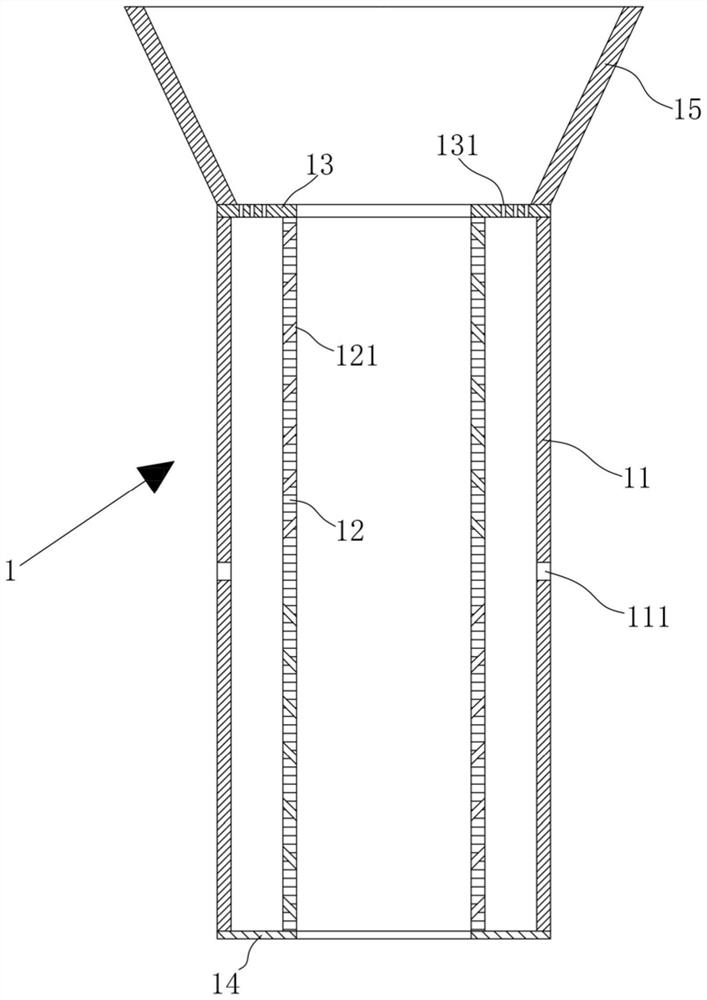

The invention relates to the technical field of optical fiber drawing equipment, in particular to a tool and system for cleaning an optical fiber drawing channel. The tool and system for cleaning the optical fiber drawing channel comprise an outer cylinder, an inner cylinder, an upper annular plate and a lower annular plate, wherein the outer cylinder is provided with at least two connectors, the connectors are suitable for being externally connected with a negative pressure mechanism, and all the connectors are evenly distributed in the circumferential direction of the outer cylinder; a through cavity suitable for optical fibers to pass through is formed in the inner cylinder, the inner cylinder is coaxially arranged in the outer cylinder, the inner cylinder and the outer cylinder are arranged at intervals to form a dust discharging channel with an annular section, and air holes are evenly distributed in the inner cylinder; the upper annular plate covers the upper end surface of the dust discharging channel in a sealing manner; and the lower annular plate covers the lower end surface of the dust discharging channel in a sealing manner. According to the tool and system for cleaning the optical fiber drawing channel, optical fibers can be effectively prevented from shaking; and meanwhile, dust cannot be diffused into the workshop, so that the cleanliness of the workshop is guaranteed.

Owner:JIANGDONG TECH CO LTD +2

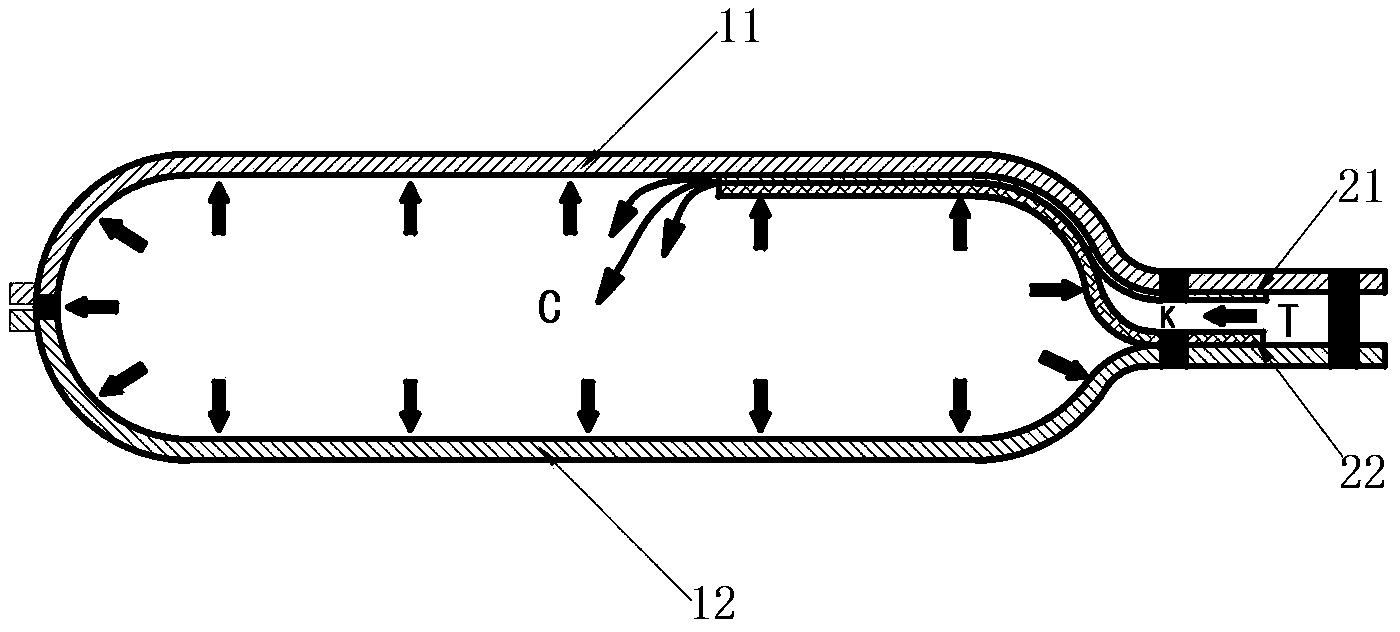

A Cotton Condensation Device with Uniform Feeding

ActiveCN109457328BUniform adsorption capacityIncrease frictionFibre cleaning/opening by air draught arrangementsFibre cleaning/opening machinesPulp and paper industryMechanical engineering

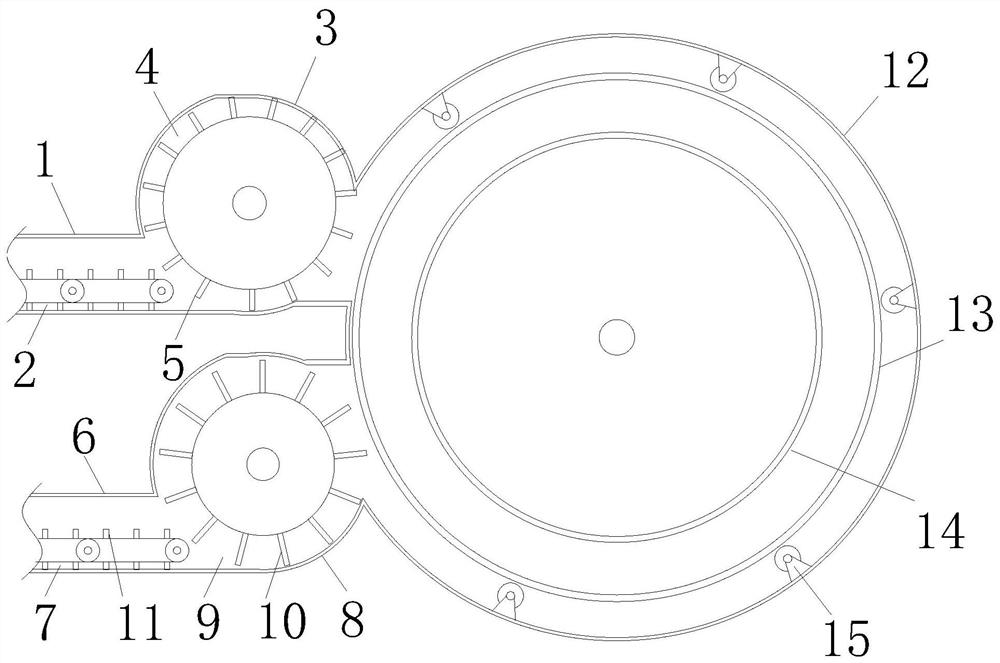

The invention discloses a cotton coagulation device with an even conveying function. The device comprises a cotton inlet pipe, a cotton outlet pipe is arranged at the lower side of the cotton inlet pipe, and a cotton coagulation box is arranged at the right side of the cotton inlet pipe and the cotton outlet pipe; a cotton inlet conveying belt is installed in the cotton inlet pipe, a cotton conveying wheel box is installed between the cotton inlet pipe and the cotton coagulation box, and a cotton conveying wheel is installed in the cotton conveying wheel box; a cotton outlet conveying belt isinstalled in the cotton outlet pipe, a cotton scraping wheel box is arranged between the cotton outlet pipe and the cotton coagulation box, and a cotton scraping wheel is installed in the cotton scraping wheel box; a cotton coagulation dust cage is arranged in the cotton coagulation box, and an air pipe is arranged in the cotton coagulation dust cage. The cotton coagulation device is simple in structure, stable in operation and capable of achieving a good cotton coagulation effect and even conveying, and blocking does not easily occur.

Owner:GUANGDE TIANYUN NEW TECH

An electrostatic chuck device and glue remover

ActiveCN112802794BImprove adsorption capacityUniform adsorption capacitySemiconductor/solid-state device manufacturingMechanical engineeringPhysics

The invention discloses an electrostatic chuck device and a degumming machine. An electrostatic chuck device is characterized in that: an electrostatic chuck is provided with a placement surface, and the placement surface includes: a plurality of circumferential air passages , forming a concentric multi-layer structure along the radial direction; a plurality of radial air passages, which communicate with the air hole in the center of the placement surface and the peripheral air passage in the outermost layer, and are blocked from the rest of the peripheral air passages; a plurality of return air passages, each of the return air passages communicates with all the circumferential air passages between any two adjacent radial air passages, and each of the return air passages faces one end of the air hole It communicates with the innermost circumferential air passage, and is blocked from the air hole; wherein, the air flow is blown out from the air hole and flows to the outermost circumferential air passage along the plurality of radial air passages, and then flows to the outermost circumferential air passage. It flows to the return air passage, and then flows to the circumferential air passages on both sides of the return air passage. The invention solves the problems of large adsorption force in the middle and small adsorption force of the edge of the electrostatic chuck.

Owner:宁波润华全芯微电子设备有限公司

Acoustic wave dialysis slimming device

The invention discloses an acoustic wave dialysis slimming device. The acoustic wave dialysis slimming device comprises an operating probe and a negative pressure system; the operating probe comprisesa shell and an ultrasonic generator, a plane with the middle part provided with a round groove arranged at one end of the shell is an operating end surface, the ultrasonic generator is disposed in the shell, the ultrasonic generator is in a hemispherical shape with an opening facing the operating end face, and the ultrasonic generator is connected to an alternating current power source and supplyelectric power to generate ultrasonic waves; and the negative pressure system includes a vacuum pump and an air guiding tube, the first end of the air guiding tube is disposed inside the shell and opened in the round groove of the operation end surface, and the second end of the air guiding tube is connected with the vacuum pump and the space surrounded by the round groove of the operating end face is in a vacuum state by vacuuming.

Owner:青岛绮薇安生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com