Attraction device and vacuum processing device

A technology for adsorption devices and main parts, applied in positioning devices, holding devices using electrostatic attraction, vacuum evaporation plating, etc., can solve the problems of reduced heat transfer capacity between the substrate and the adsorption device, and avoid the reduction of yield, Prevents transportation errors and prolongs life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

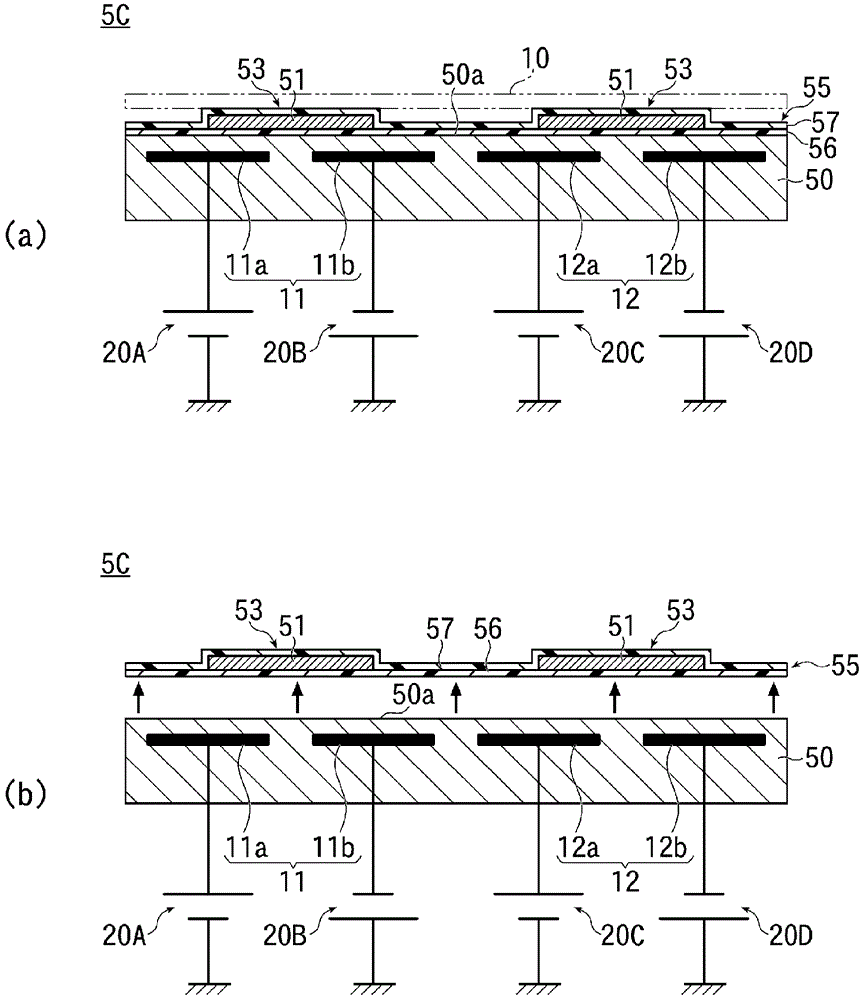

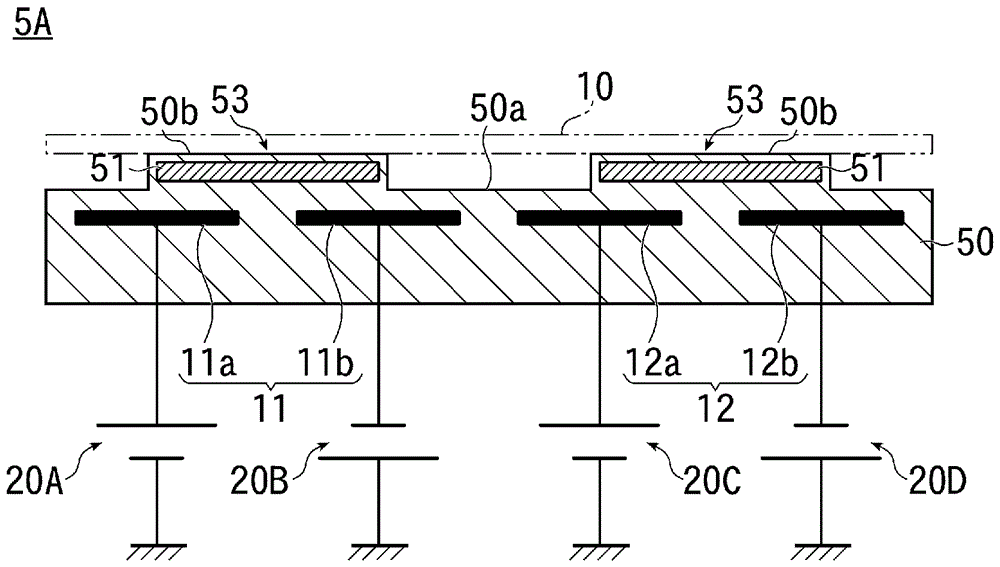

[0041] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

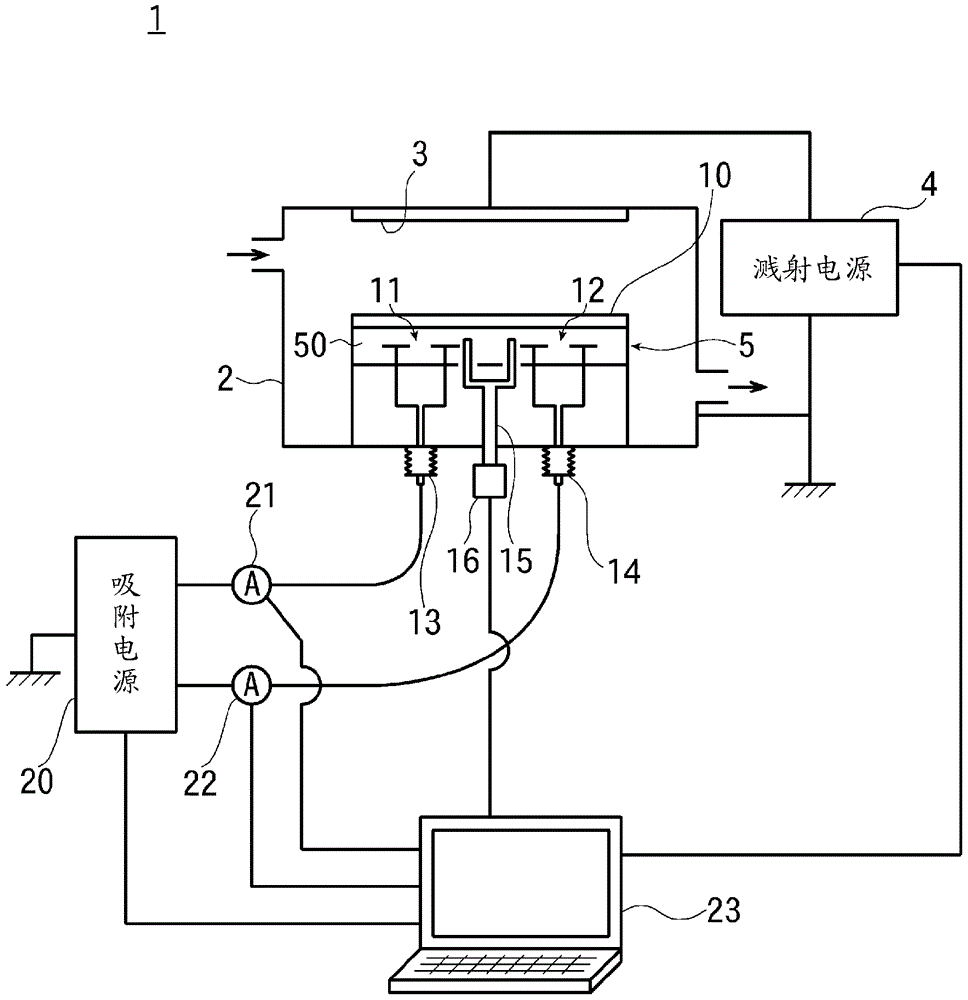

[0042] figure 1 It is a schematic configuration diagram of a sputtering apparatus which is an embodiment of the vacuum processing apparatus of the present invention.

[0043] exist figure 1 In the figure, reference numeral 2 denotes a vacuum chamber of the sputtering apparatus 1 of the present embodiment, and the vacuum chamber 2 is configured to be connected to an unshown vacuum exhaust system to introduce sputtering gas.

[0044]The target 3 as a film formation source is arrange|positioned in the upper part in the vacuum chamber 2. As shown in FIG.

[0045] The target 3 is connected to a sputtering power supply 4, and a negative bias voltage is applied thereto. In addition, the positive side of the sputtering power supply 4 is grounded together with the vacuum chamber 2 .

[0046] A suction device 5 for suction-holding a substrate (object to be suctioned) 10 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com