Casting sand box

A technology of the sand box and the bottom of the sand box, which is applied in the directions of casting molding equipment, mold boxes, manufacturing tools, etc., can solve the problems of increasing the casting cost, the casting effect is not particularly good, and the casting efficiency is not very high, so as to reduce the collapse rate and improve the efficiency of the casting. Upper plane effect, uniform adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

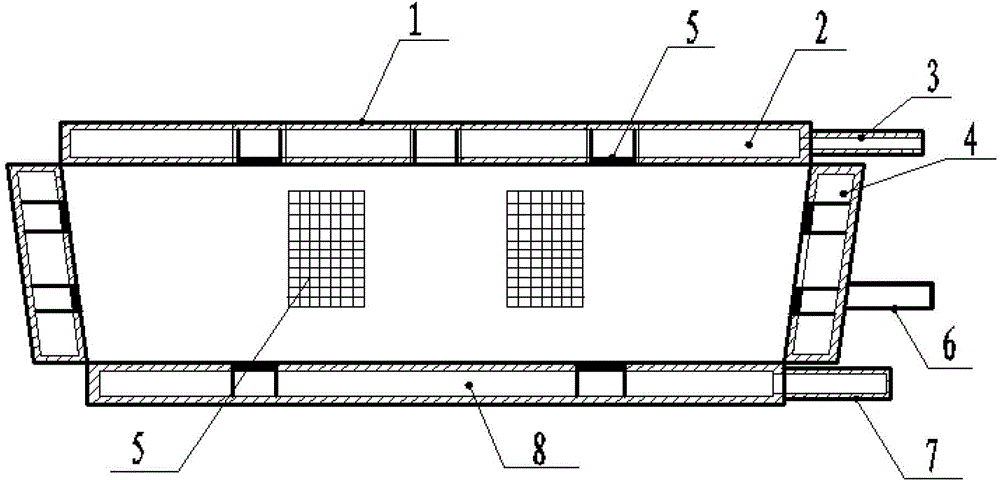

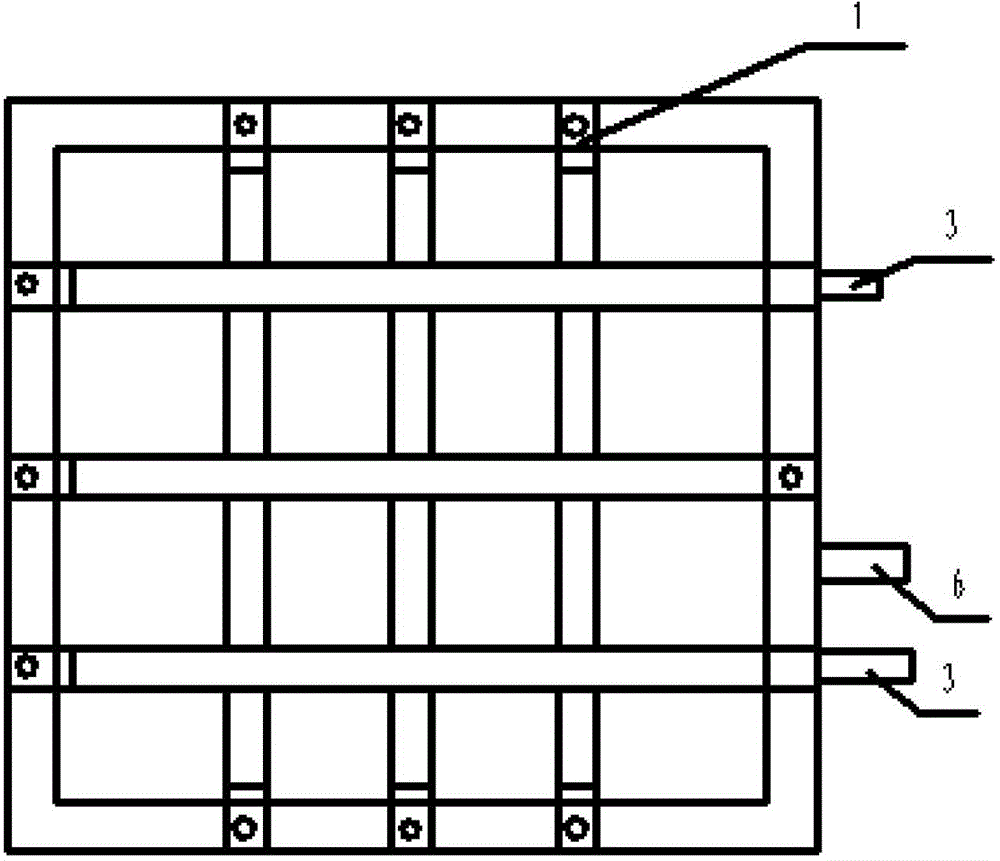

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] When using vacuum lost foam casting technology to cast special-shaped castings with side holes, due to the fluidity of dry sand, sometimes the side holes cannot be well filled, and the horizontal holes cannot be cast or collapsed during casting, resulting in defective products In order to solve the above problems, the inventor designed a sand box, which is in the shape of a terrace, and the wall of the sand box is an inverted trapezoid with a large upper part and a smaller lower part. The sand box not only has a large upper surface area, but also can be filled with more The dry sand (compared to the rectangular sand box of the same volume); and the upper suction lifting pressure bar can also be made larger, close to the upper surface area of the sand box. The bottom of the sand box and the wall of the sand box form an obtuse angle, and the wall of the sand bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com