Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

51results about How to "Uneven temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

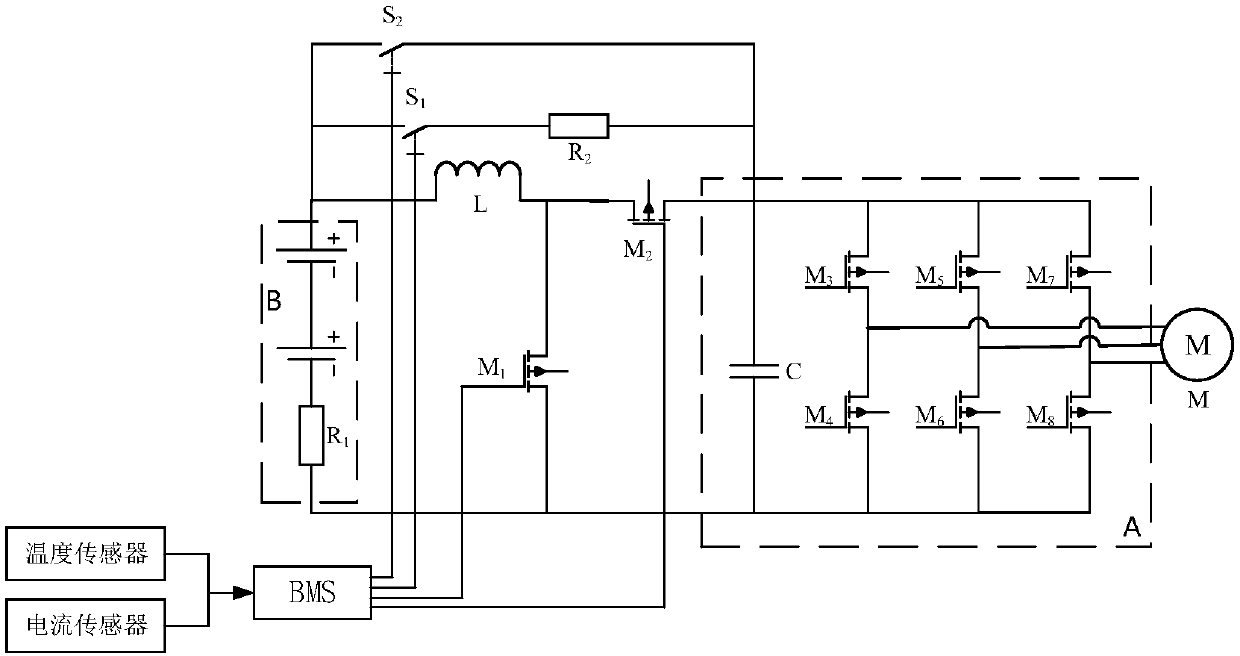

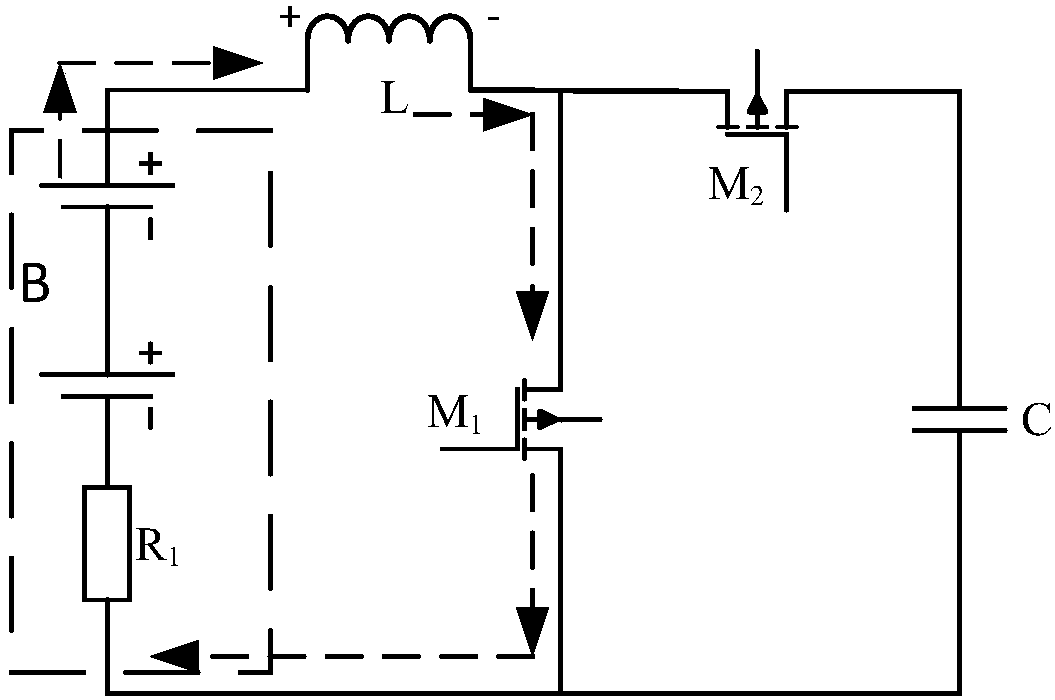

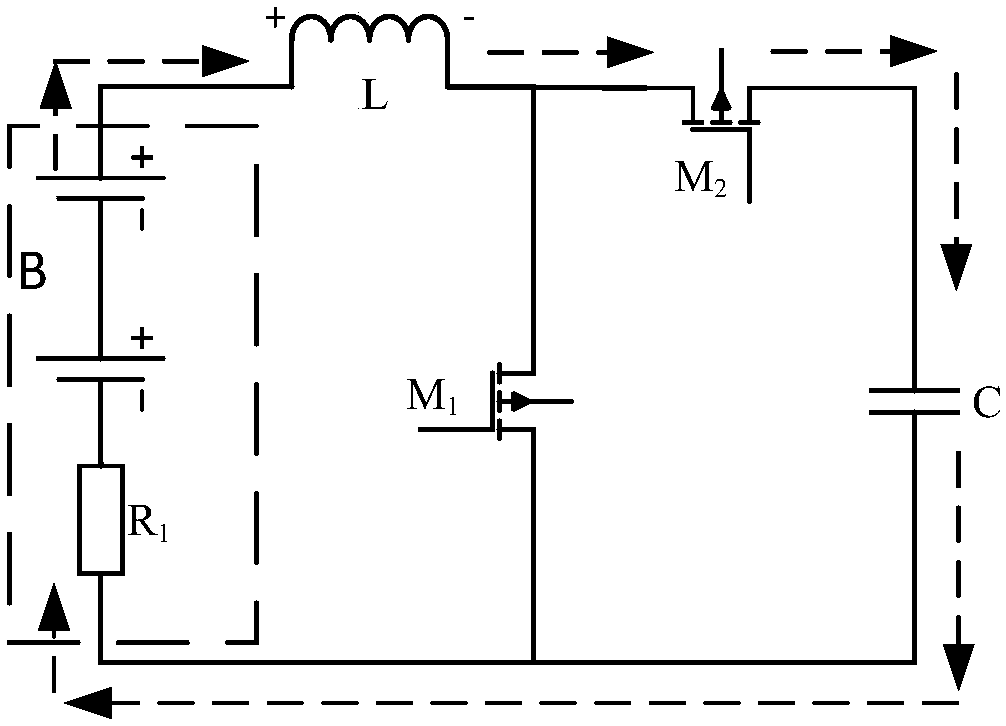

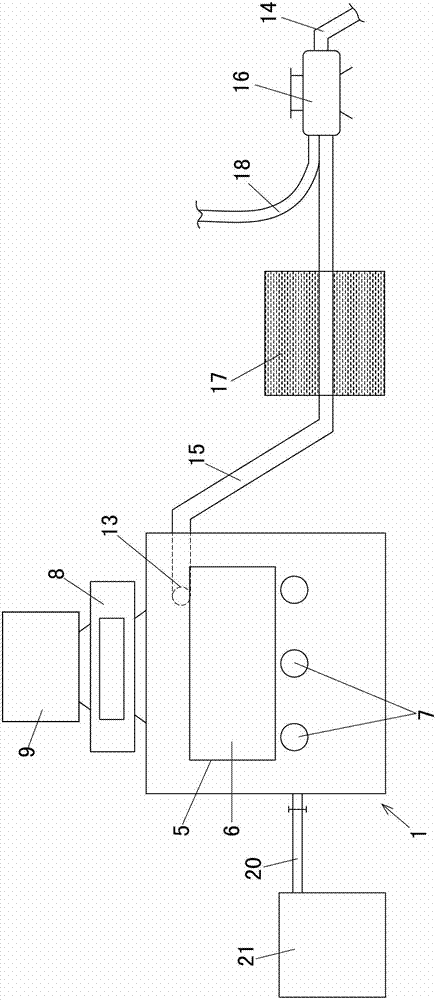

Lithium ion battery low-temperature alternating current heating device for electric bicycle

InactiveCN107666028AEvenly heatedHeating evenlySecondary cells charging/dischargingCapacitanceElectrical battery

The invention relates to a lithium ion battery low-temperature alternating current heating device for an electric bicycle. The lithium ion battery low-temperature alternating current heating device isused for performing alternating current heating on a power battery. The lithium ion battery low-temperature alternating current heating device comprises a control unit, an energy conversion circuit,an energy storage inductor, a capacitor, a pre-charging circuit and a starting switch, wherein the power battery, the energy storage inductor, the energy conversion circuit and the capacitor are sequentially connected to form a loop; the pre-charging circuit and the starting switch are parallelly connected between the power battery and the capacitor; the control unit is respectively connected withthe energy conversion circuit, the pre-charging circuit and the starting switch, and controls the on-off state of the starting switch according to the temperature information of the power battery, sothat the conversion between the alternating current heating state and the normal power supply state of the power battery can be realized; during the entering of the alternating current heating state,the control unit controls the work state of the energy conversion circuit according to the current information of the power battery in real time; the inside heating is realized in the alternating current charging and discharging process of the power battery. Compared with the prior art, the lithium ion battery low-temperature alternating current heating device has the advantages that the heatingis uniform; the efficiency is high; the newly added devices are few; the cost is low, and the like.

Owner:TONGJI UNIV

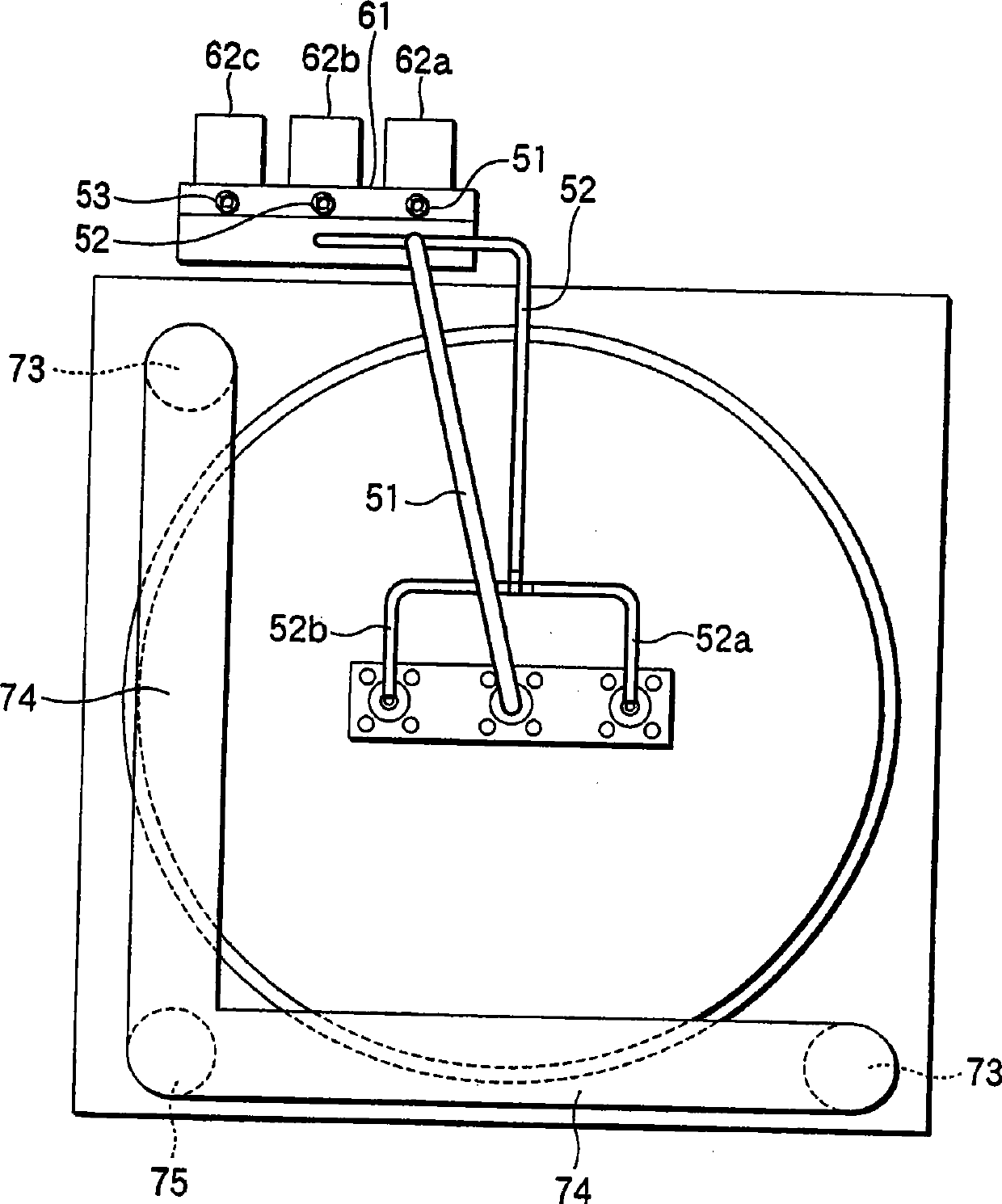

Control device for induction heating device and method for controlling induction heating system and induction heating device

ActiveCN102652459AUniform temperature distributionSimple and reliable induction heating controlFurnace typesIncreasing energy efficiencyAlternating currentMagnetic energy

A transverse type induction heating device crosses an alternating magnetic field with a plate surface of a conductive plate being threaded, thereby inductively heating the conductive plate. A control device for this induction heating device controls AC power output to a heating coil of the induction heating device and comprises: a magnetic energy regeneration bidirectional current switch for outputting AC power to the heating coil; a frequency setting device for setting an output frequency based on at least one of the relative permeability, resistivity, and plate thickness of the conductive plate; and a gate control device for controlling the switching operation of the magnetic energy regeneration bidirectional current switch on the basis of the output frequency set in the frequency setting device.

Owner:NIPPON STEEL CORP

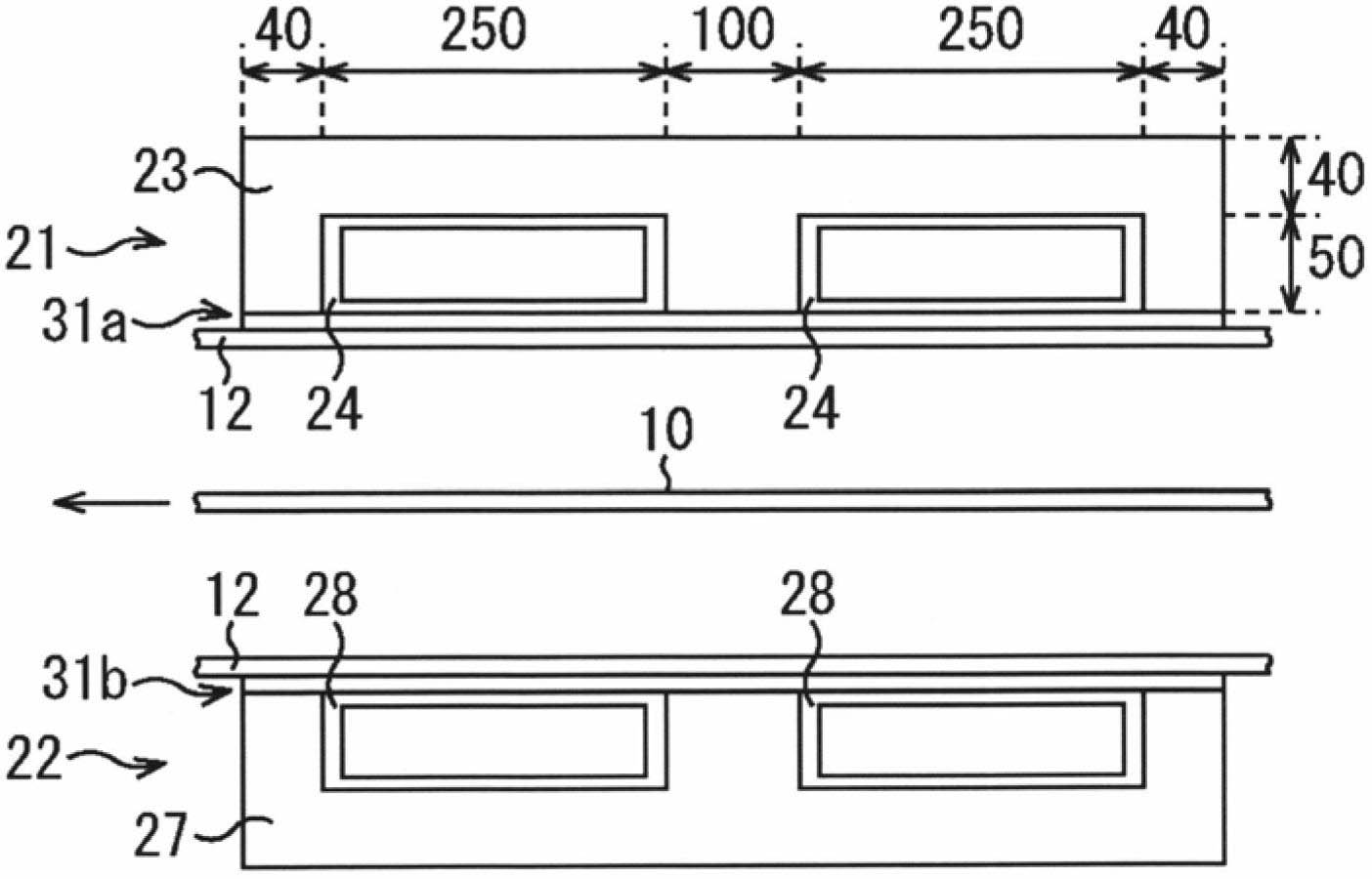

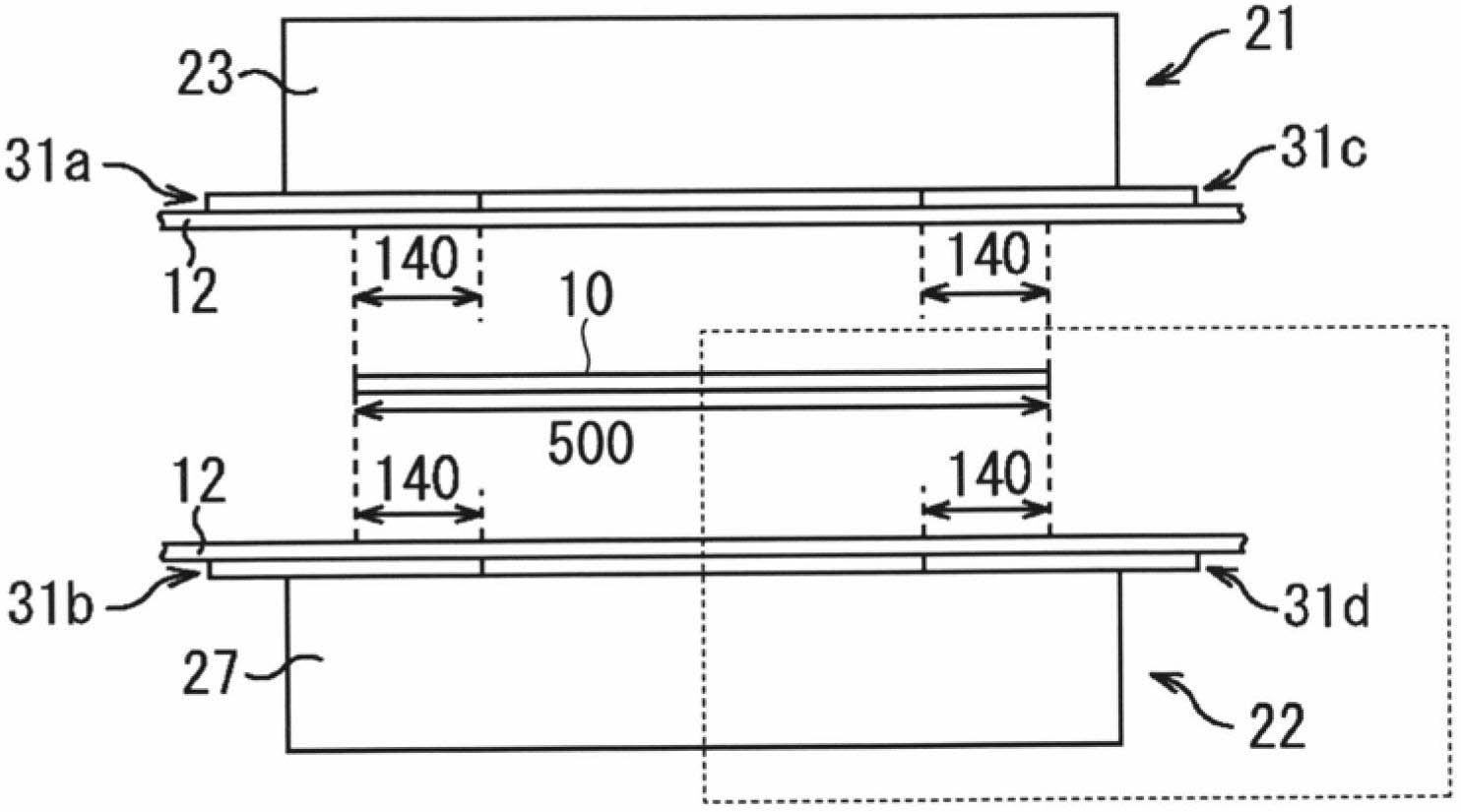

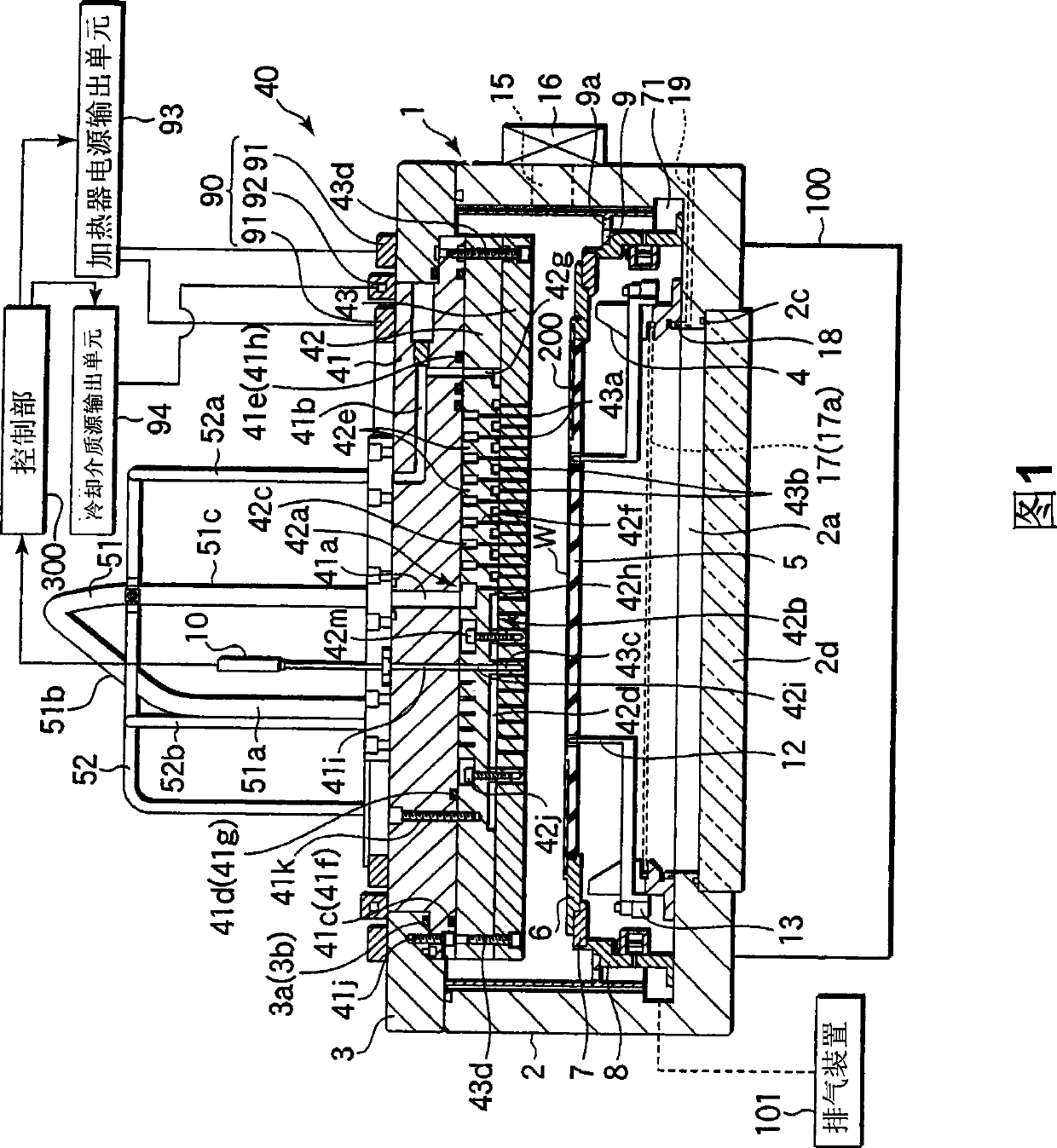

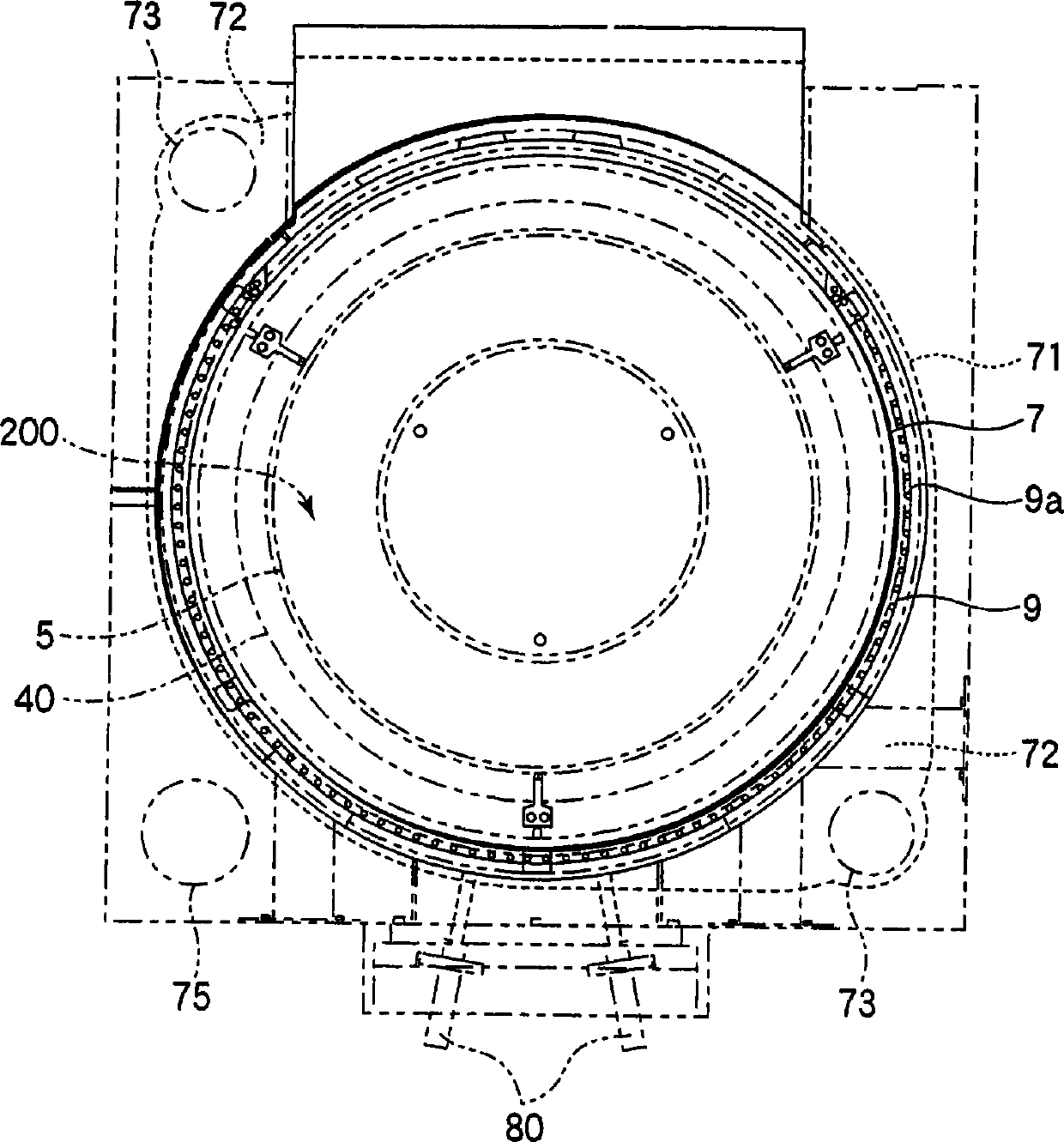

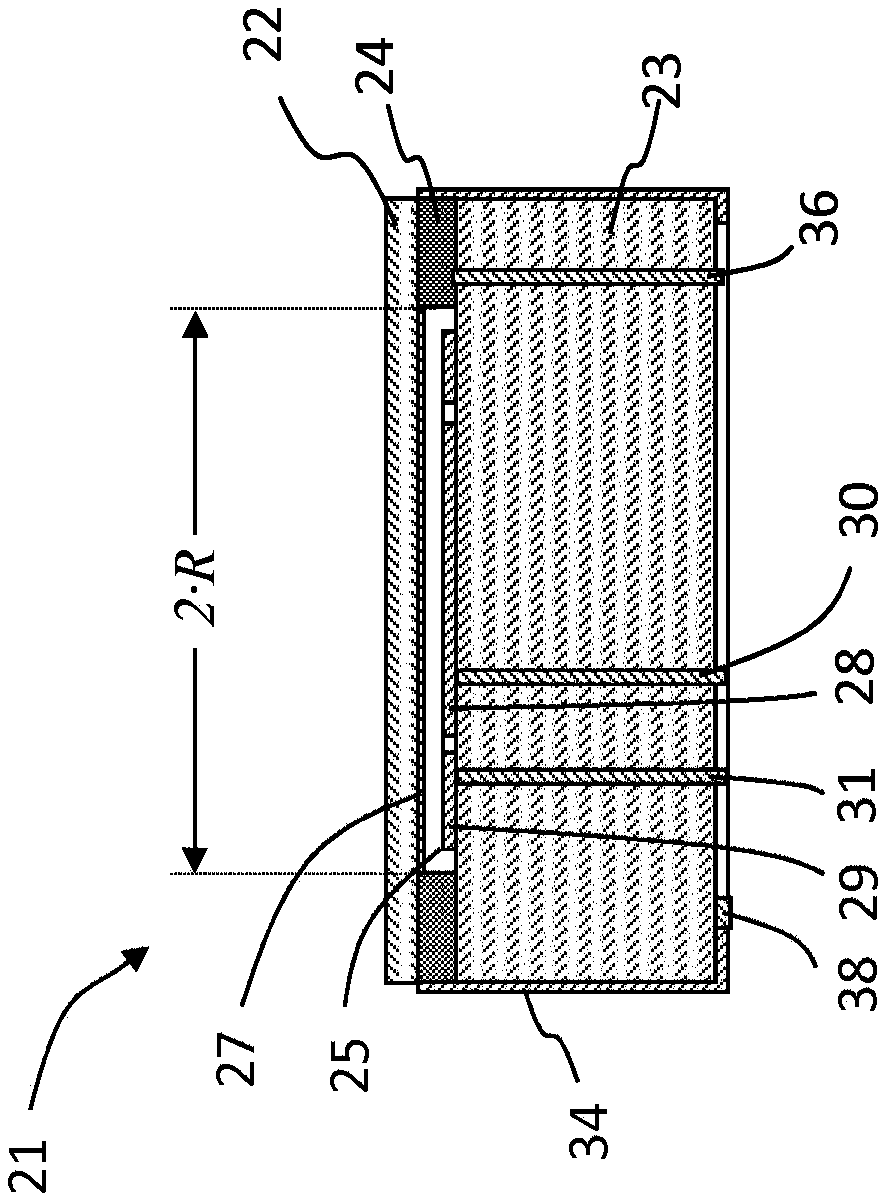

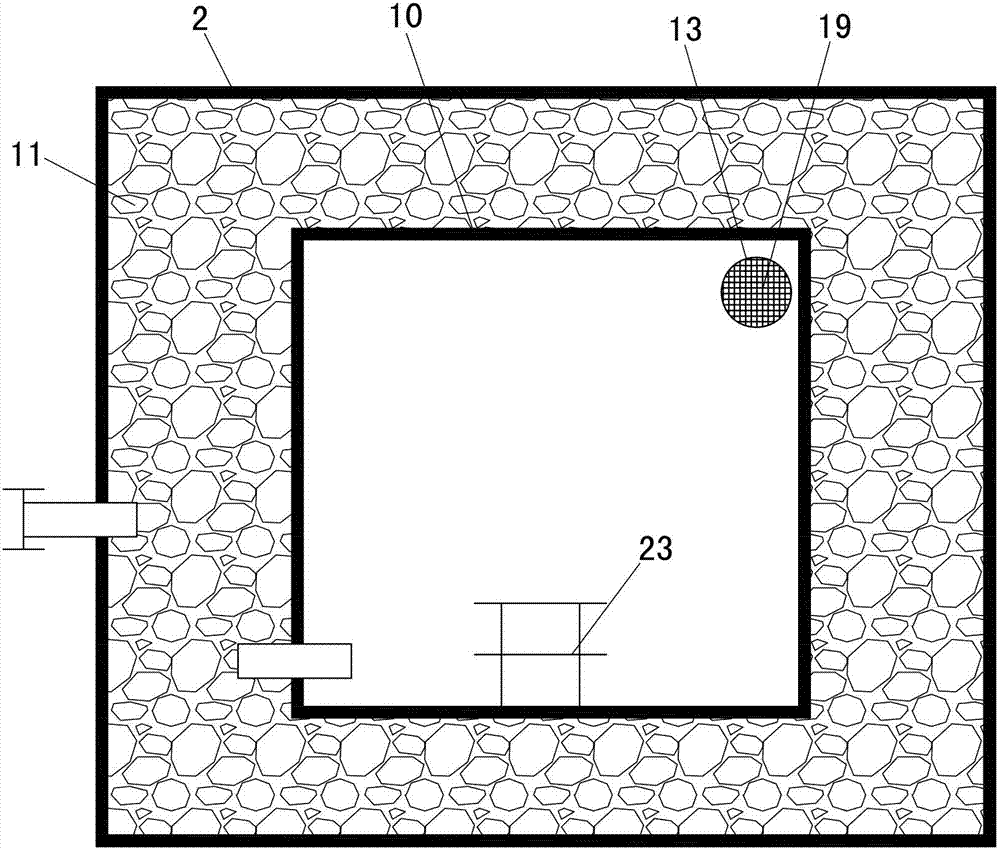

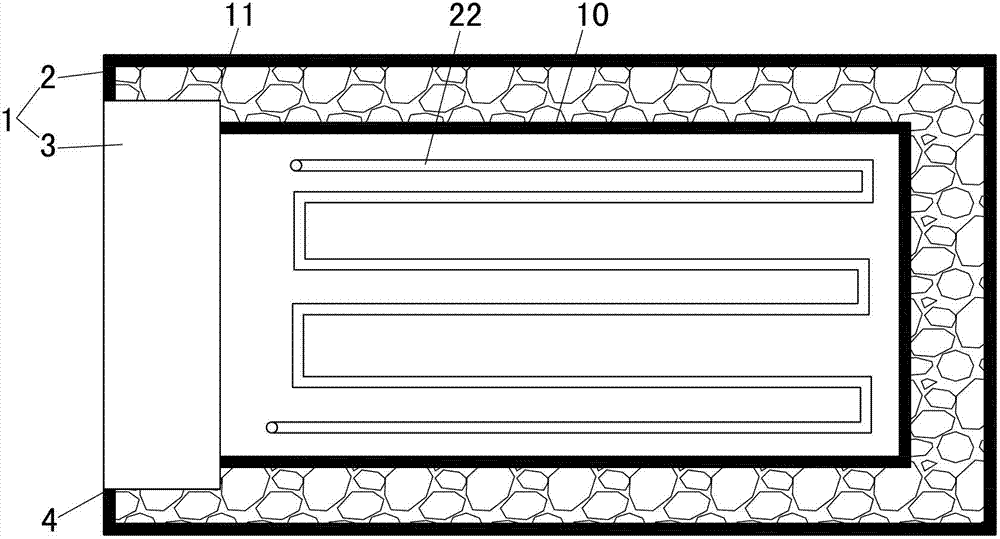

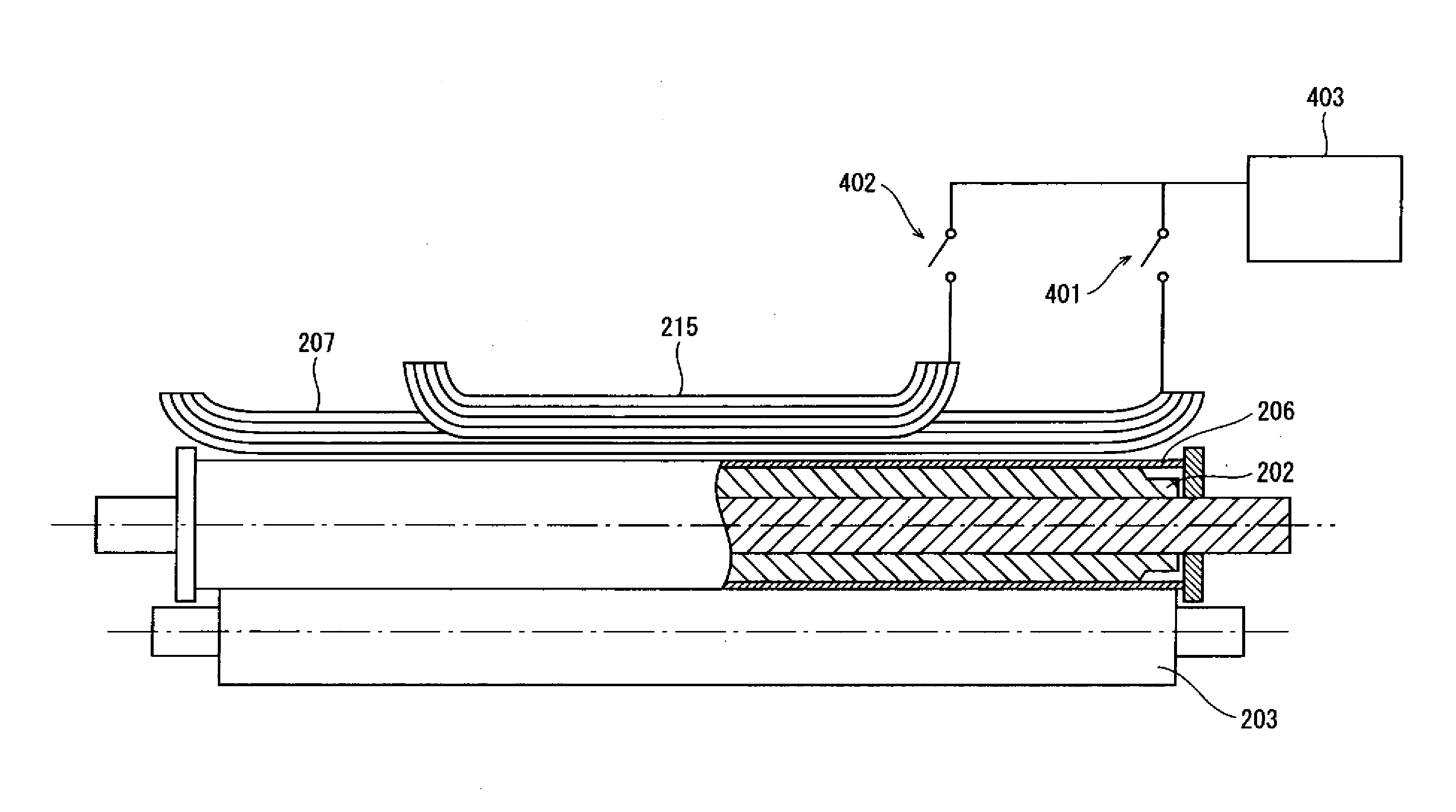

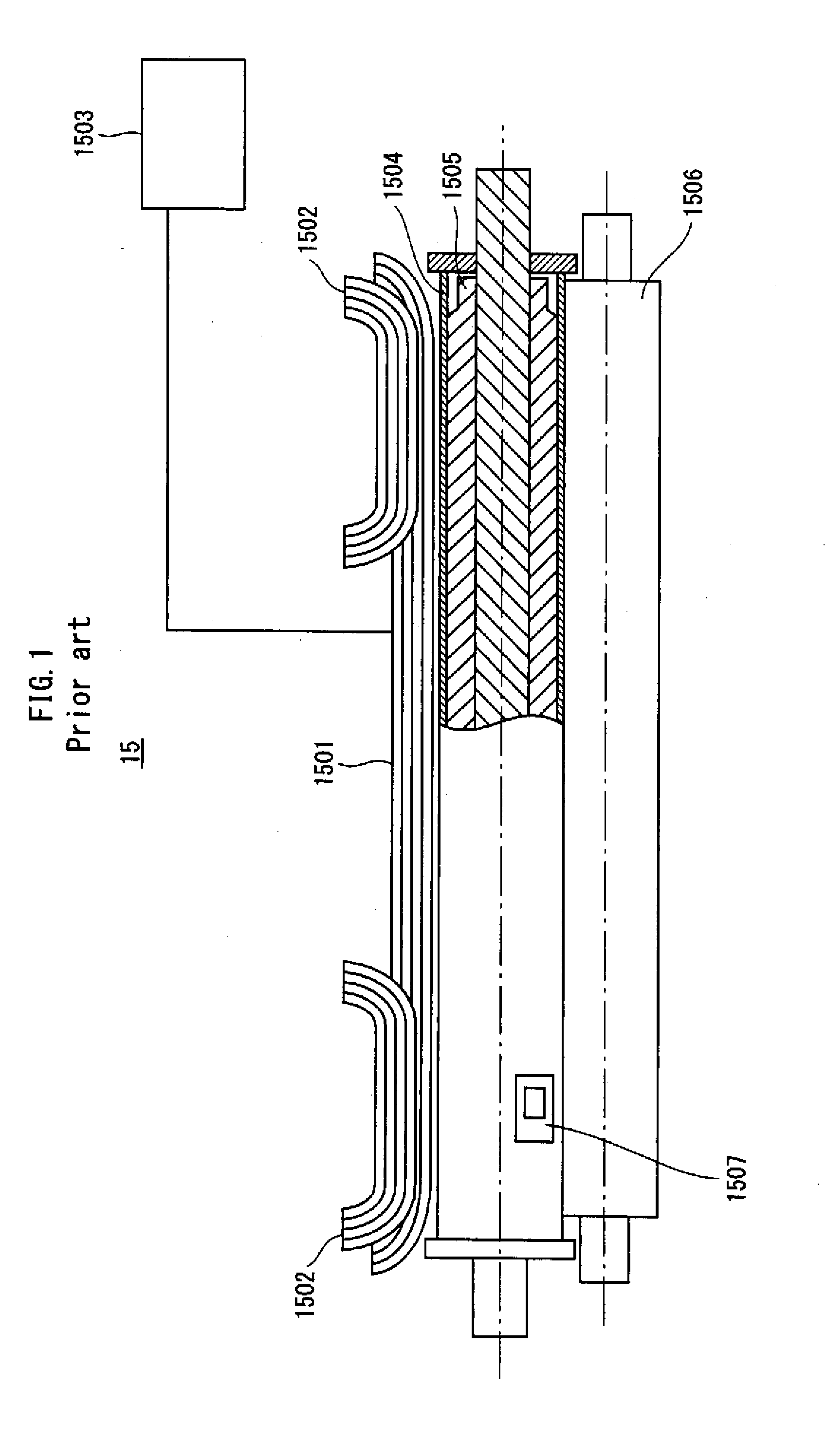

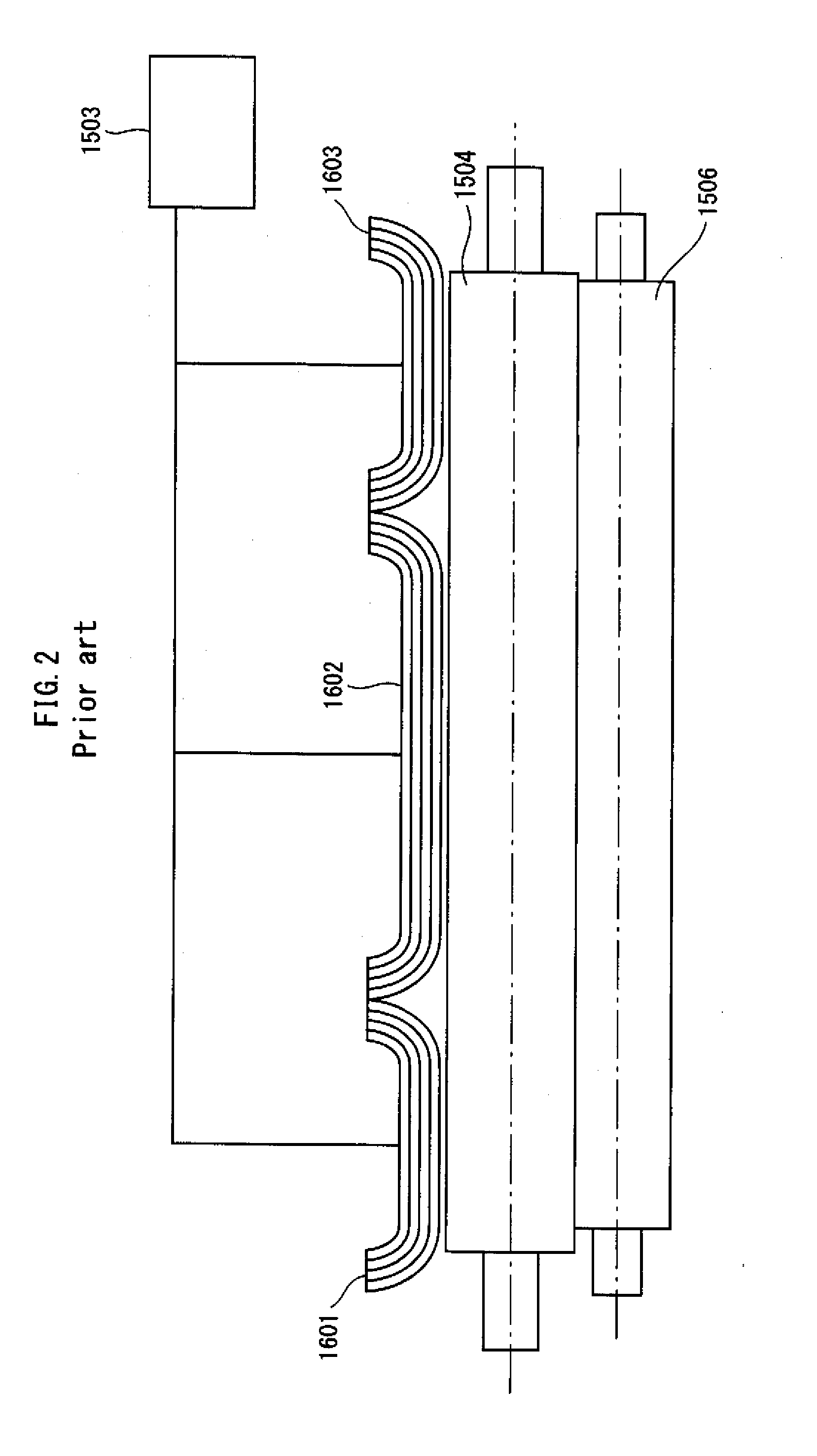

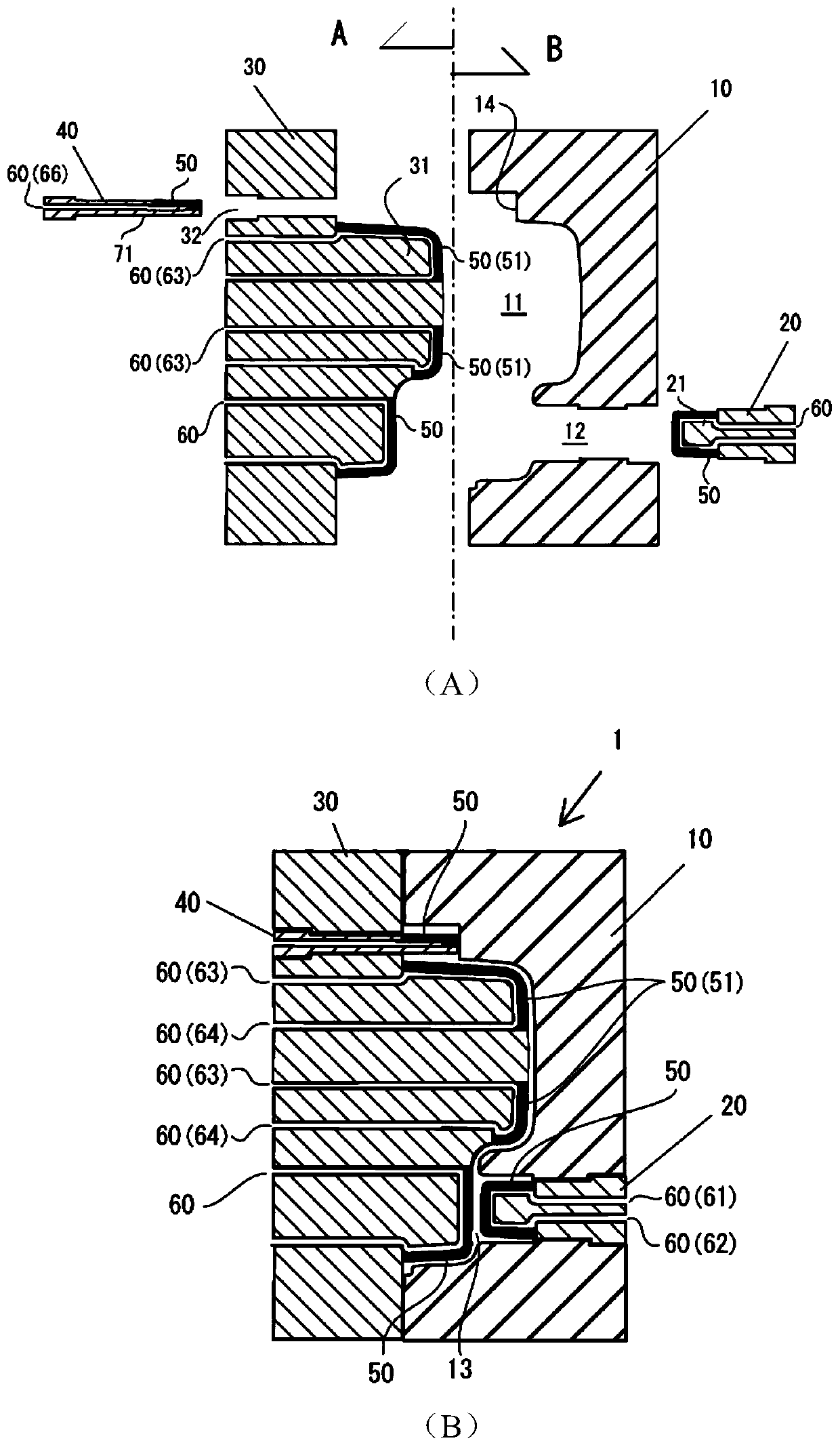

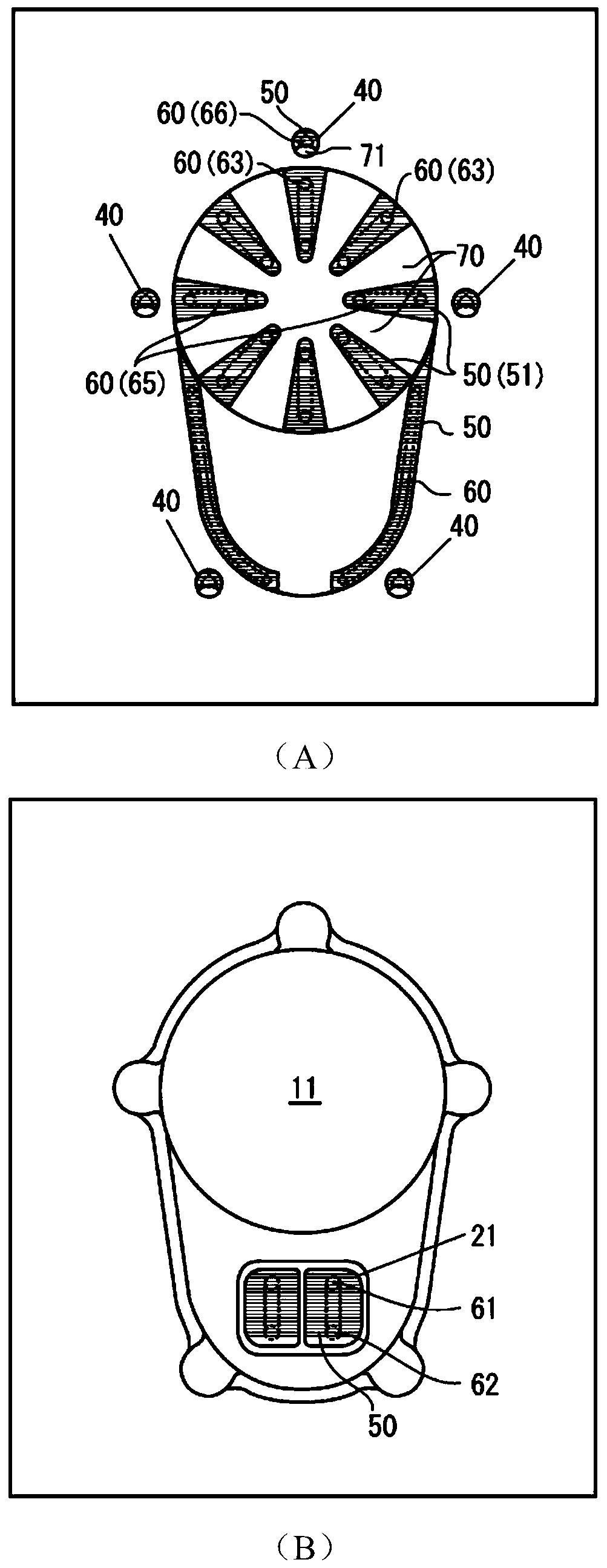

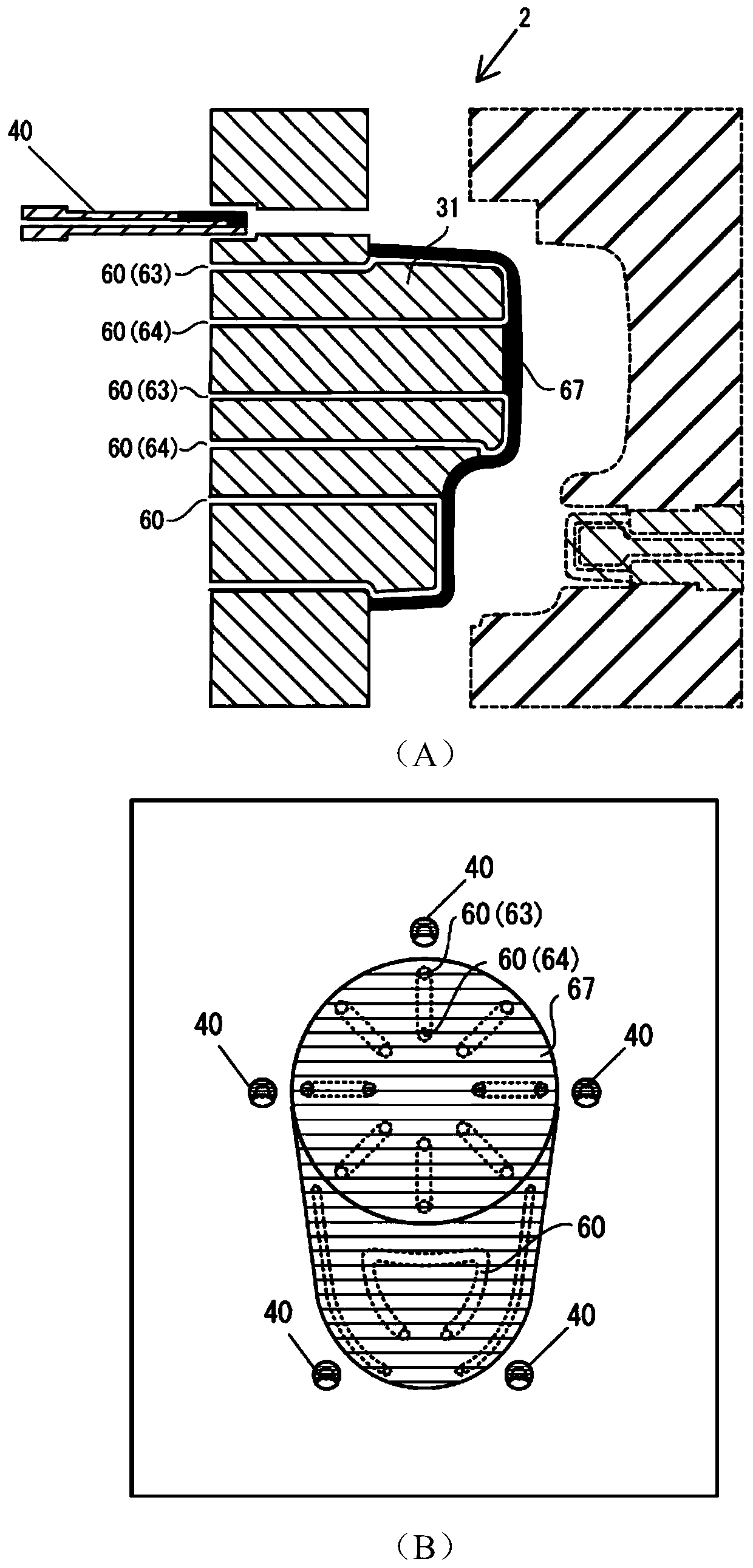

Substrate processing apparatus and substrate placing table

InactiveCN101374973AUneven temperature distributionGood film-forming propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringSemiconductor

A film forming apparatus is provided with a processing container (2) for storing a semiconductor wafer (W); a substrate placing table (5) arranged inside the processing container (2) for placing the semiconductor wafer (W); a shower head (40) arranged at a position facing the placing table (5) as a processing gas blowing mechanism for blowing out a processing gas into the processing container (2); and an exhauster (101) for exhausting inside the processing container (2). The substrate placing table (5) is provided with a placing table main body (5a), and a heat blocking body (200), which is arranged on the placing table main body (5a) in a region outside a region where the semiconductor wafer (W) is placed, and reduces heat diffusion from the placing table main body to the shower head (40).

Owner:TOKYO ELECTRON LTD

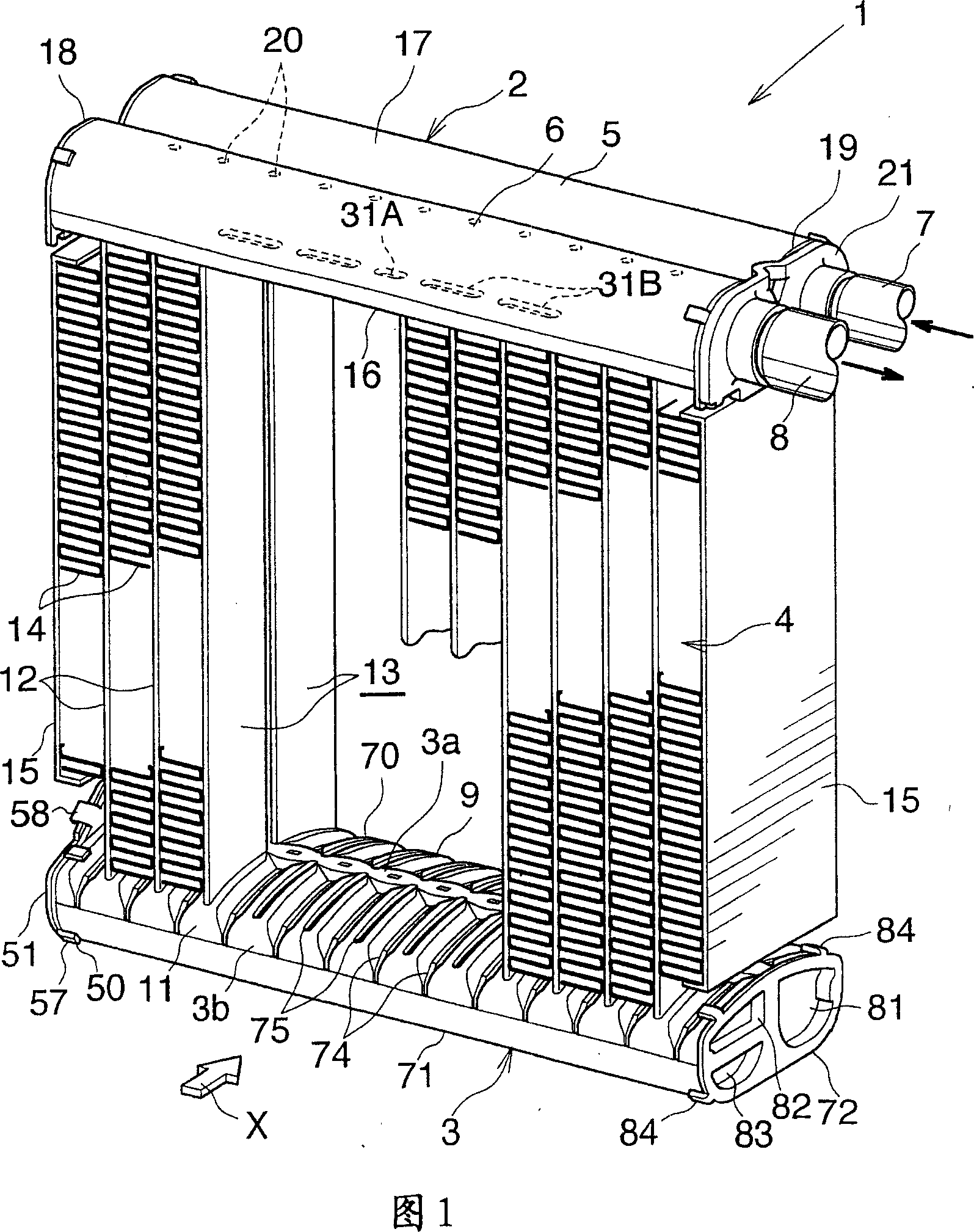

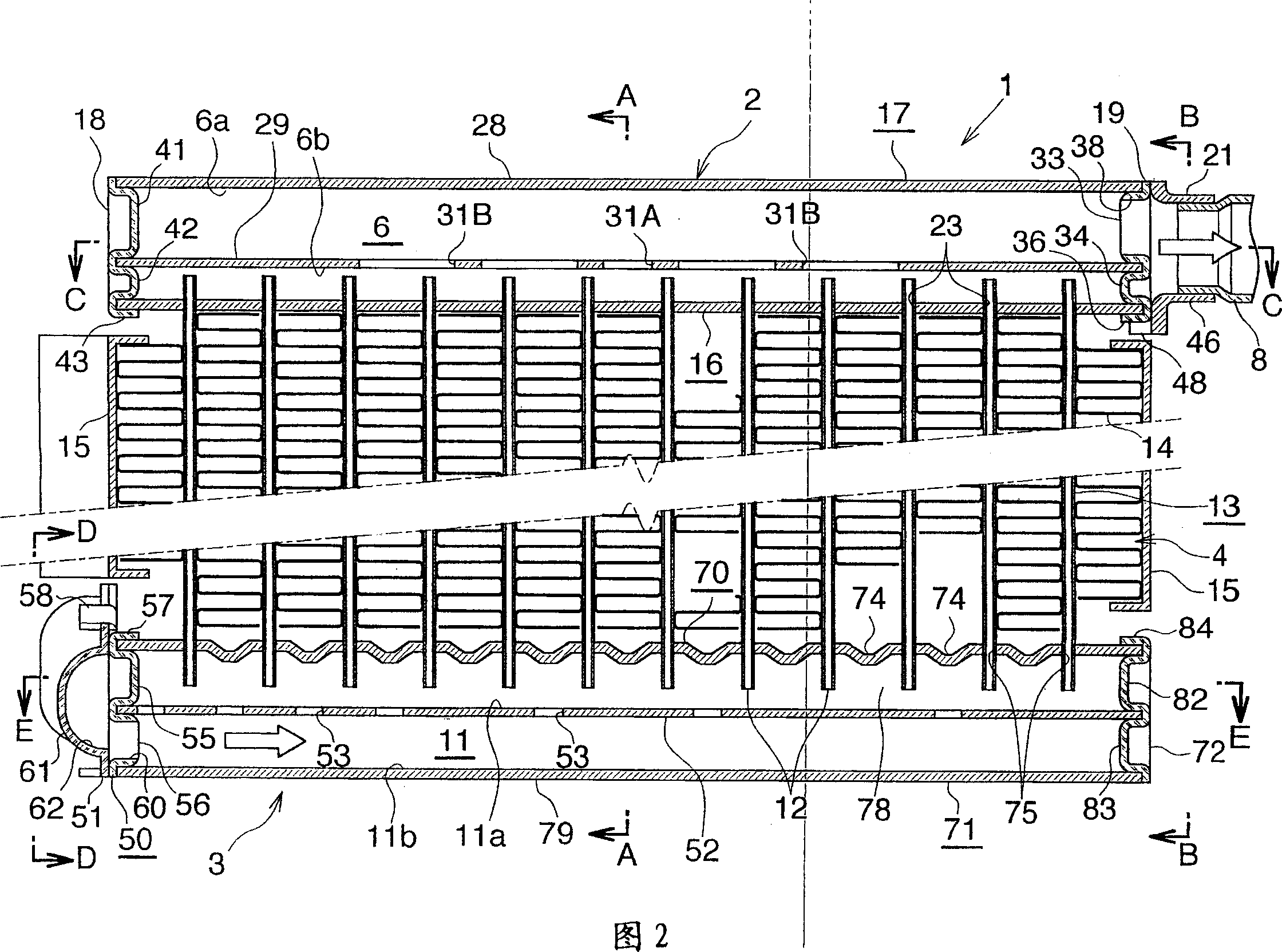

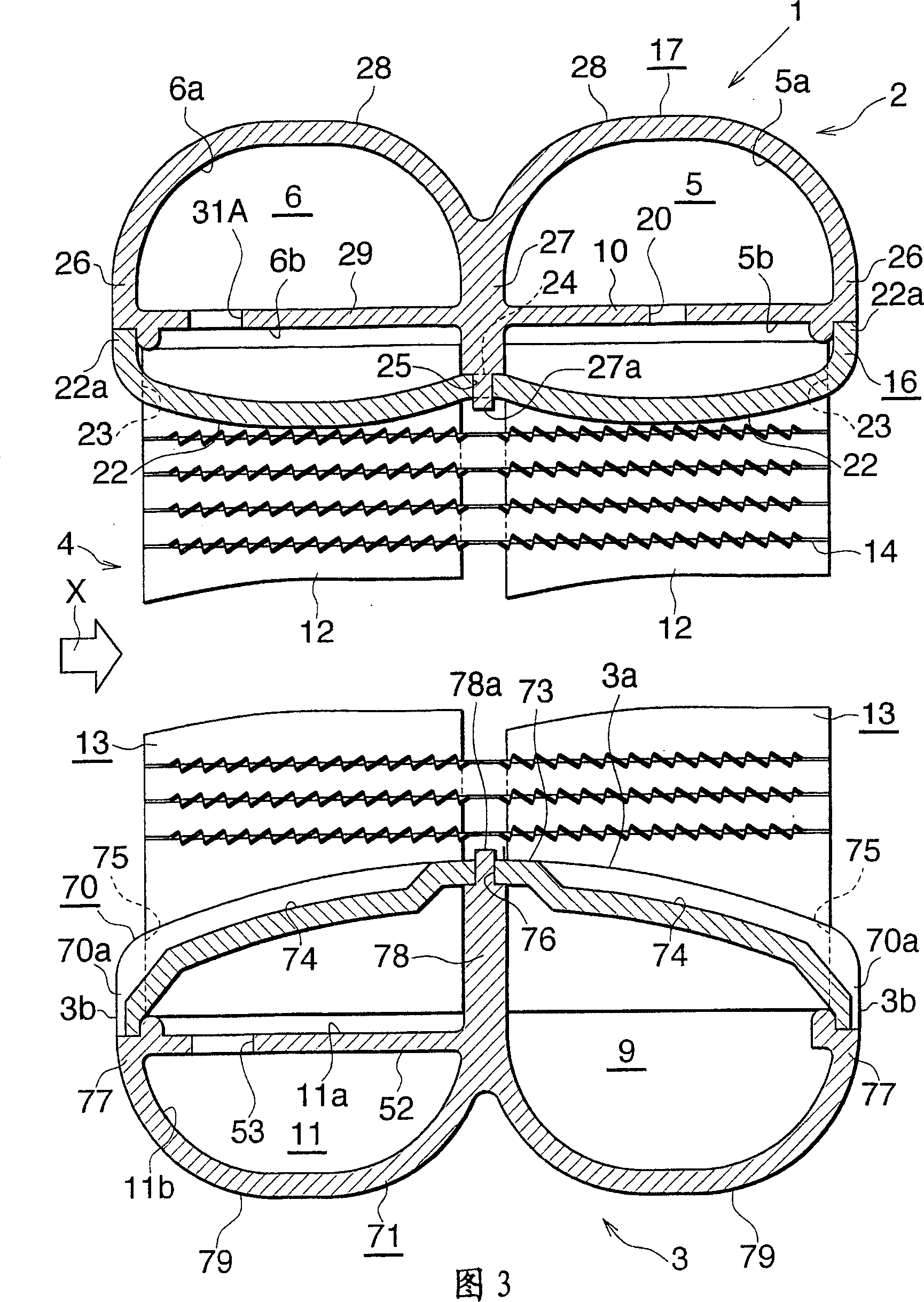

Heat exchangers

InactiveCN1950664AEasy to set upReduce in quantityAir-treating devicesEvaporators/condensersPlate heat exchangerEngineering

An evaporator 1 comprises a heat exchange core 4 having heat exchange tubes 12 in groups 13, a refrigerant inlet header 5 and a refrigerant outlet header 6 which are arranged toward one end of each of the heat exchange tubes 12, and a refrigerant inflow header 9 and a refrigerant outflow header 11 which are arranged toward the other end of each heat exchange tube 12. The outflow header 11 has its interior divided by a flow dividing control wall 52 into two spaces 11a, 11b arranged one above the other. The inflow header 9 and the lower space 11b of the outflow header 11 are held in communication each at one end thereof. The control wall 52 has a plurality of refrigerant passing holes 53 arranged at a spacing longitudinally thereof.

Owner:KEIHIN THERMAL TECH CORP

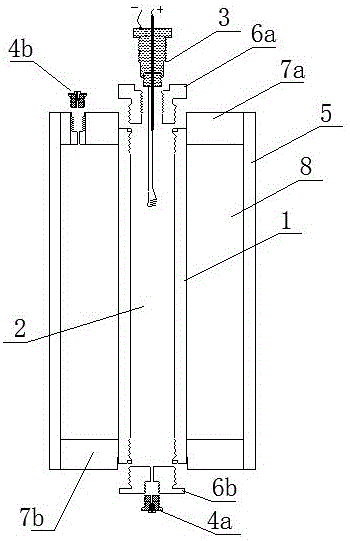

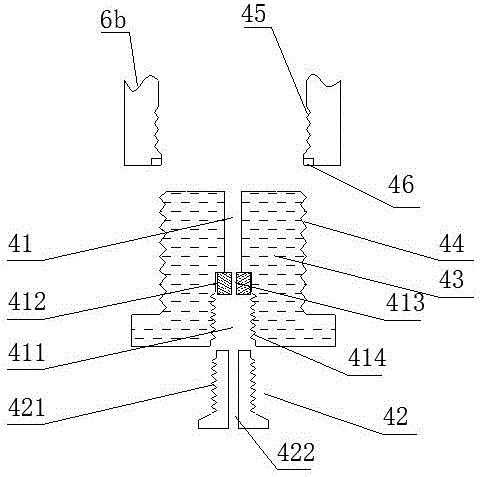

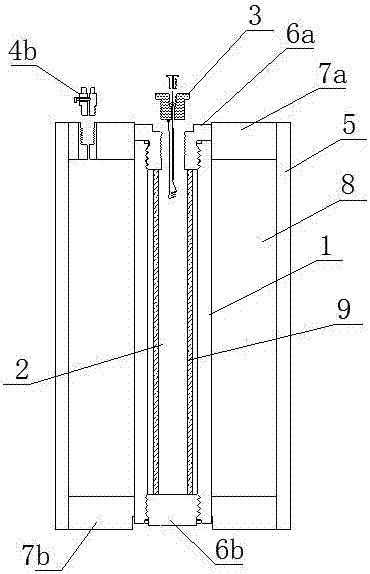

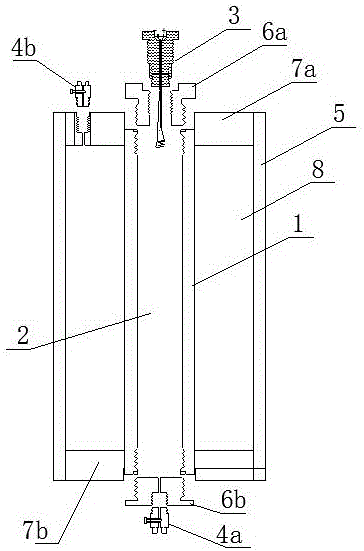

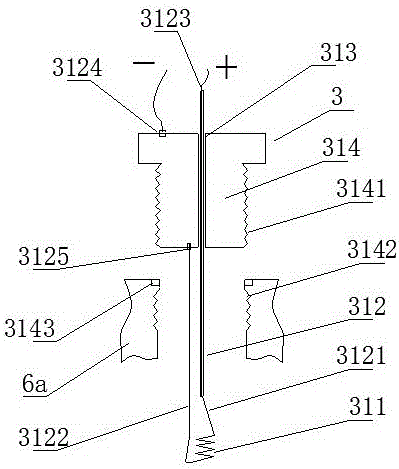

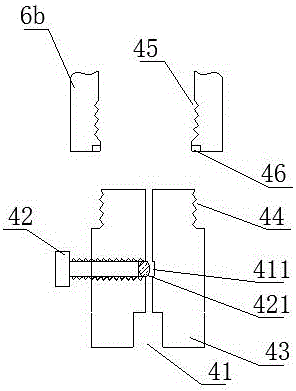

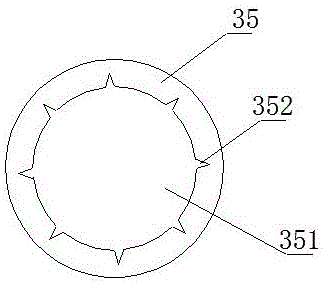

Gas-inflating-and-locking-integrated gas blaster

InactiveCN106643314AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesCheck valvesEngineeringLiquid carbon

The invention discloses a gas-inflating-and-locking-integrated gas blaster. The gas-inflating-and-locking-integrated gas blaster comprises an inner tube, an inner-tube filling cavity, an ignition mechanism, an inner-tube gas inflating mechanism and an outer tube. The inner-tube filling cavity is formed in the inner tube, a first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner tube in a sealed mode respectively, the outer tube is arranged on the outer layer of the inner tube, a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealed mode, the ignition mechanism and the inner-tube gas inflating mechanism are installed on the first sealing inner cover or the second sealing inner cover, and an outer-tube gas inflating mechanism is installed on the first sealing outer cover or the second sealing outer cover; a sealed cavity between the inner tube and the outer tube is an outer-tube filling cavity, the inner-tube filling cavity is filled with supercritical oxygen and carbonaceous organic materials, and the outer-tube filling cavity is filled with liquid easy-to-gasify materials such as liquid carbon dioxide or liquid nitrogen. The gas-inflating-and-locking-integrated gas blaster has the advantages that the manufacturing cost is low, the mixing uniformity of reaction materials is high, the heat releasing efficiency is high, the transportation safety is good, and the blasting power is large.

Owner:郭远军

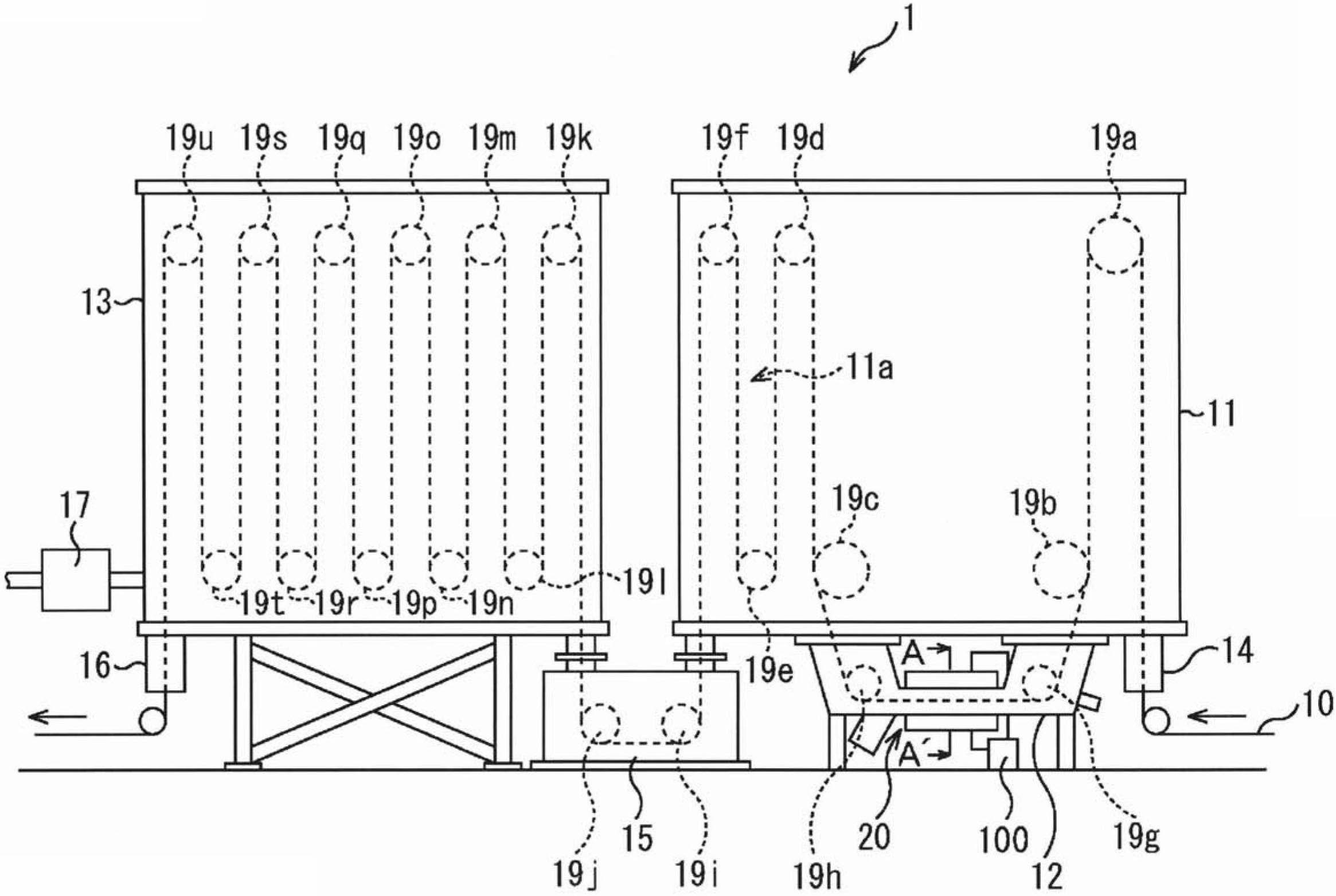

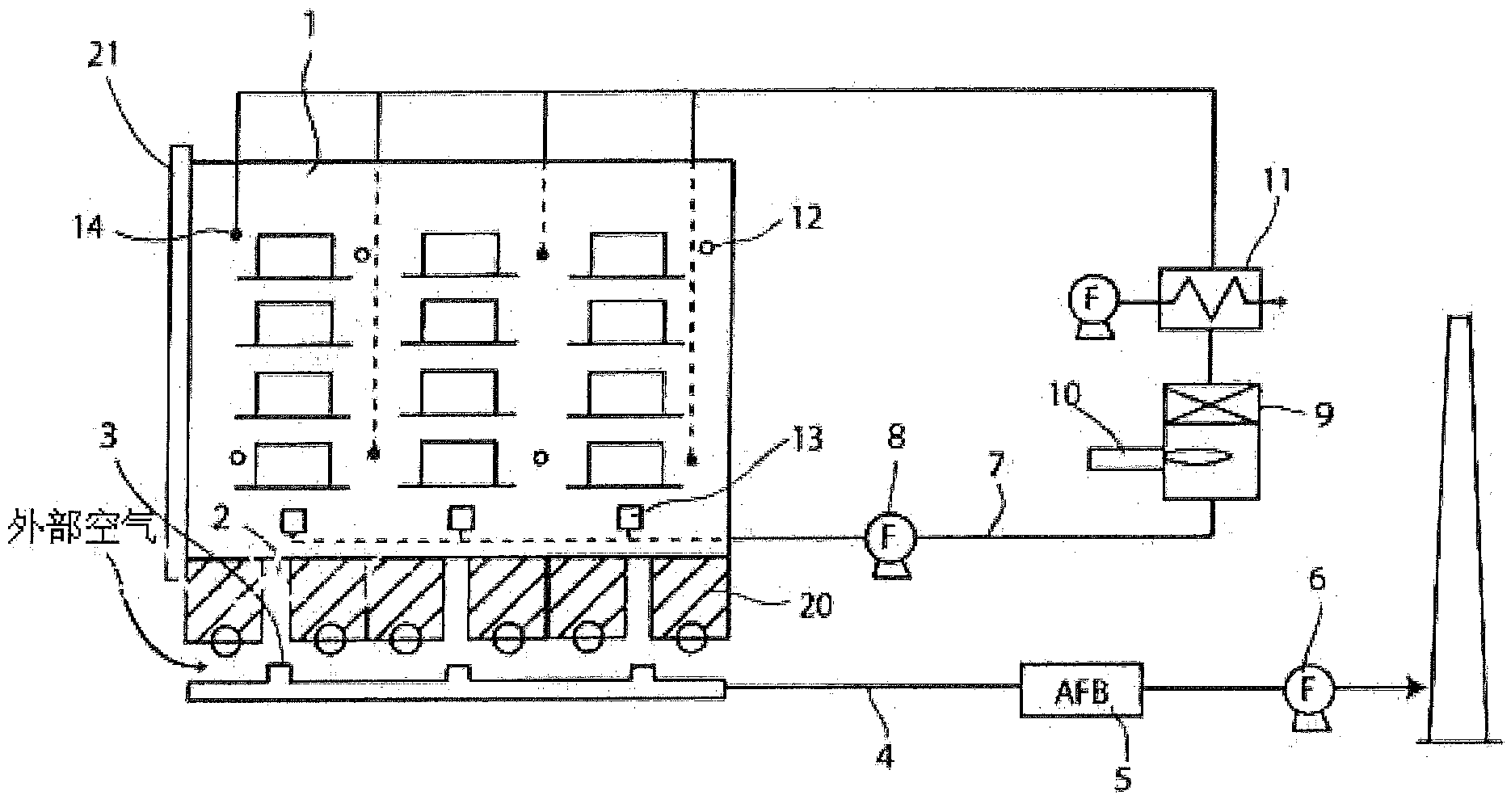

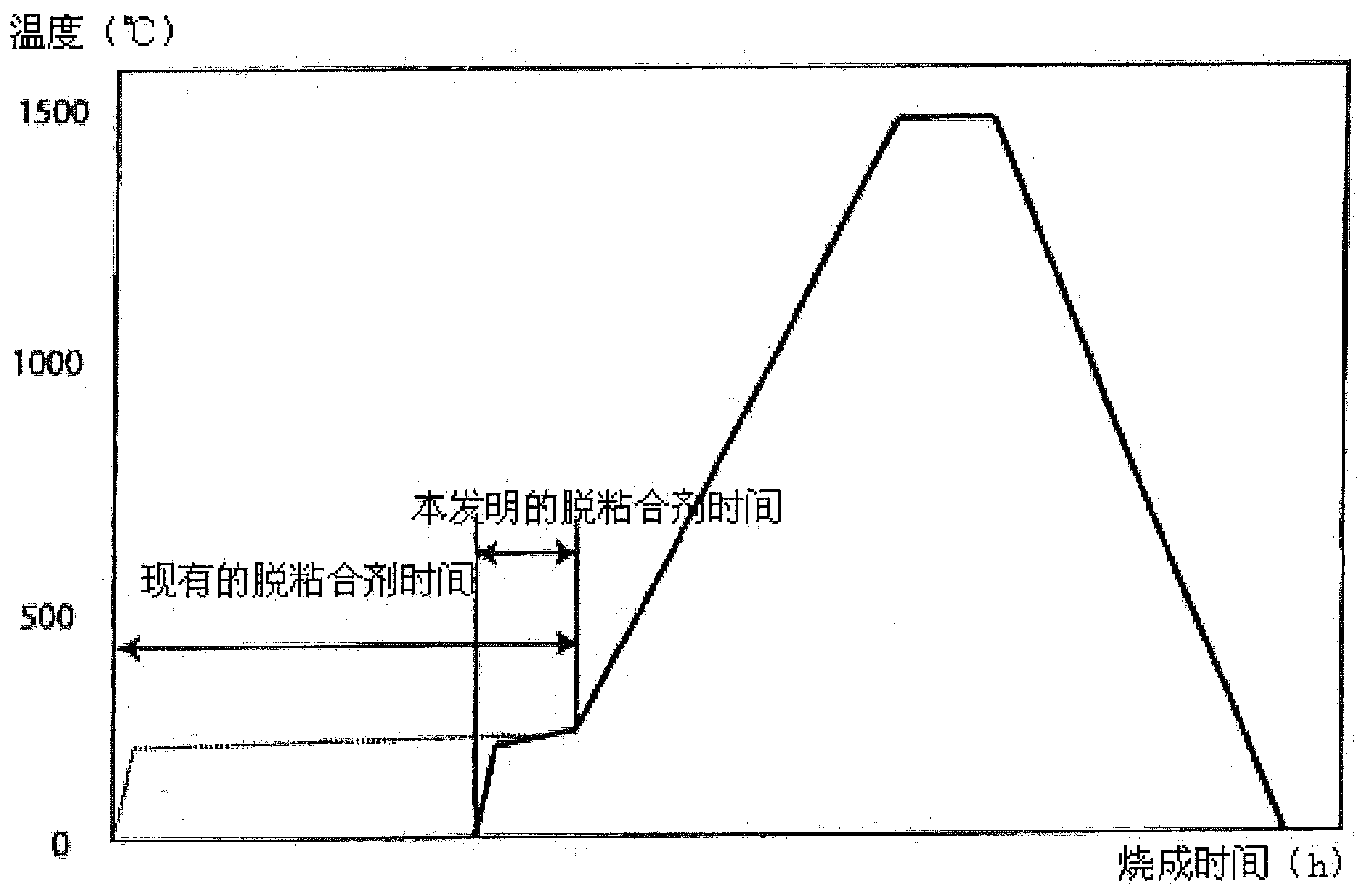

Shuttle kiln for sintering ceramic porous body

ActiveCN103384807AStir wellUniform temperature distributionMaintainance of heating chambersFurnace typesTemperature differenceKiln

Provided is a shuttle kiln capable of sintering a ceramic porous body containing an organic binder at a shorter time than before and without creating cuts caused by the temperature difference between the inside and the outside. This shuttle kiln is suitable for sintering a ceramic porous body containing an organic binder. The shuttle kiln is provided with a gas suction path (4) for sucking the gas in a furnace and discharging said gas via an afterburner (5), and a circulation path (7) for burning an organic binder gas by sucking the gas in the furnace and discharging said gas to the outside of the furnace and for returning the gas back into the furnace.

Owner:NGK INSULATORS LTD

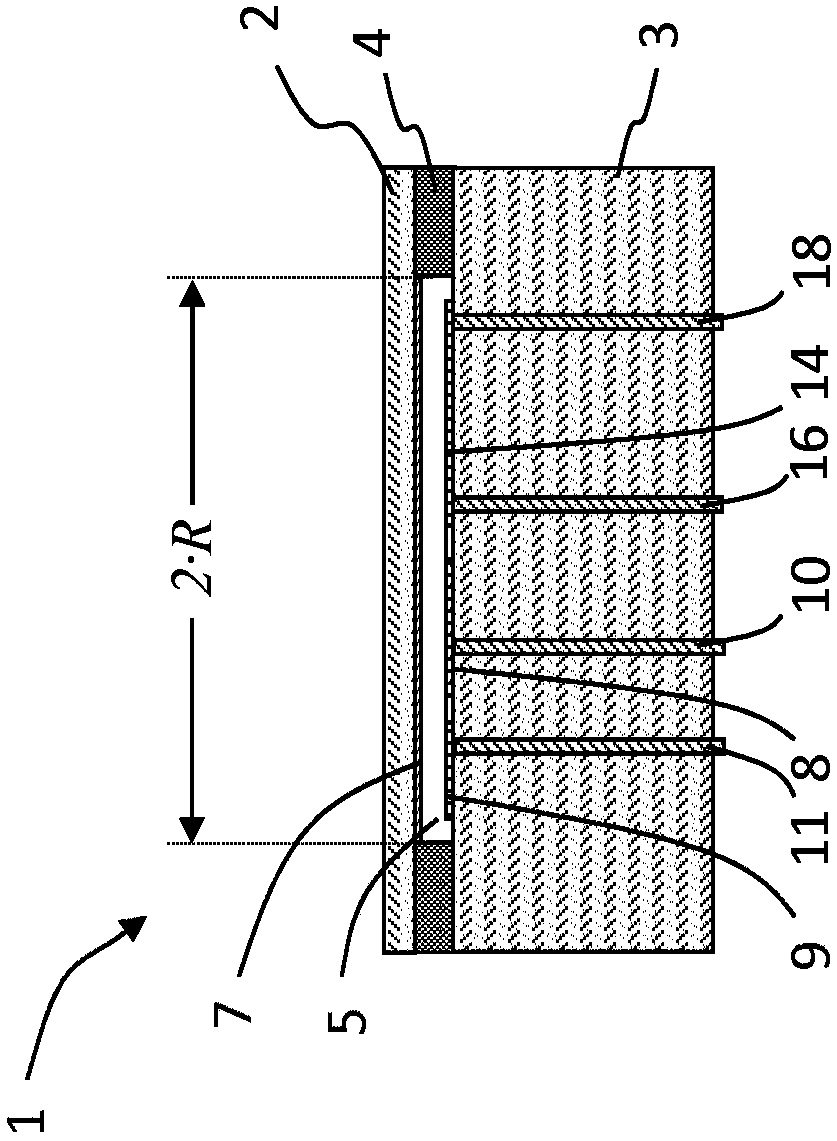

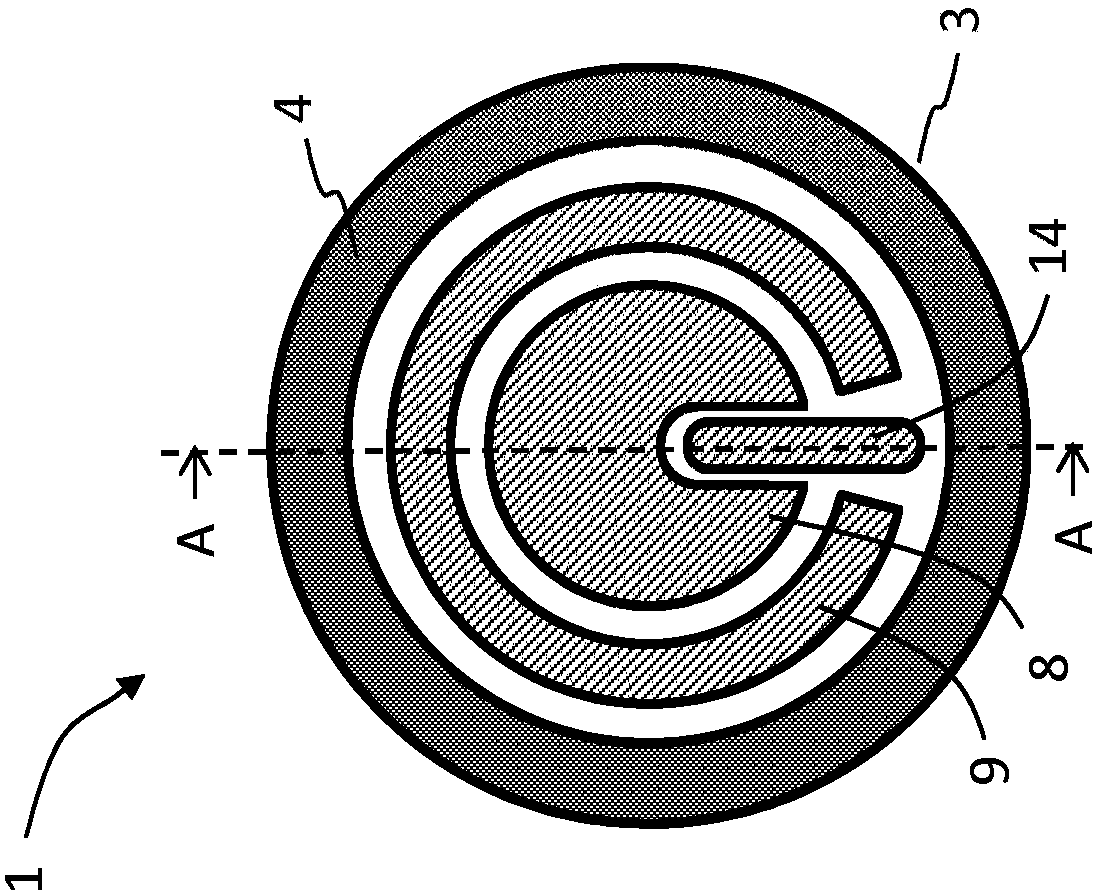

Ceramic pressure measurement cell having at least one temperature transducer and pressure sensor having a pressure measurement cell of this type

ActiveCN108369148AUneven temperature distributionThermometers using electric/magnetic elementsFluid pressure measurement by electric/magnetic elementsTransducerConductive materials

A pressure measurement cell comprises: a ceramic counter body (3); a ceramic measuring diaphragm (2) which is joined in a pressure-tight manner with the counter body (3), creating a measurement chamber between the counter body (3) and the measuring diaphragm (2), by means of a circumferential joint (4), wherein the measuring diaphragm can be deformed by a pressure to be measured; an electrical converter for converting a pressure-dependent deformation of the measuring diaphragm into an electrical signal; and a temperature transducer for providing at least one electrical signal dependent on a temperature or on a temperature gradient of the pressure measurement cell, characterized in that the temperature transducer comprises at least one first thermocouple having a galvanic contact between afirst conductor with an electrically conductive material (14) and a second conductor with at least one second electrically conductive material.

Owner:EHNDRESS KHAUZER GMBKH KO KG

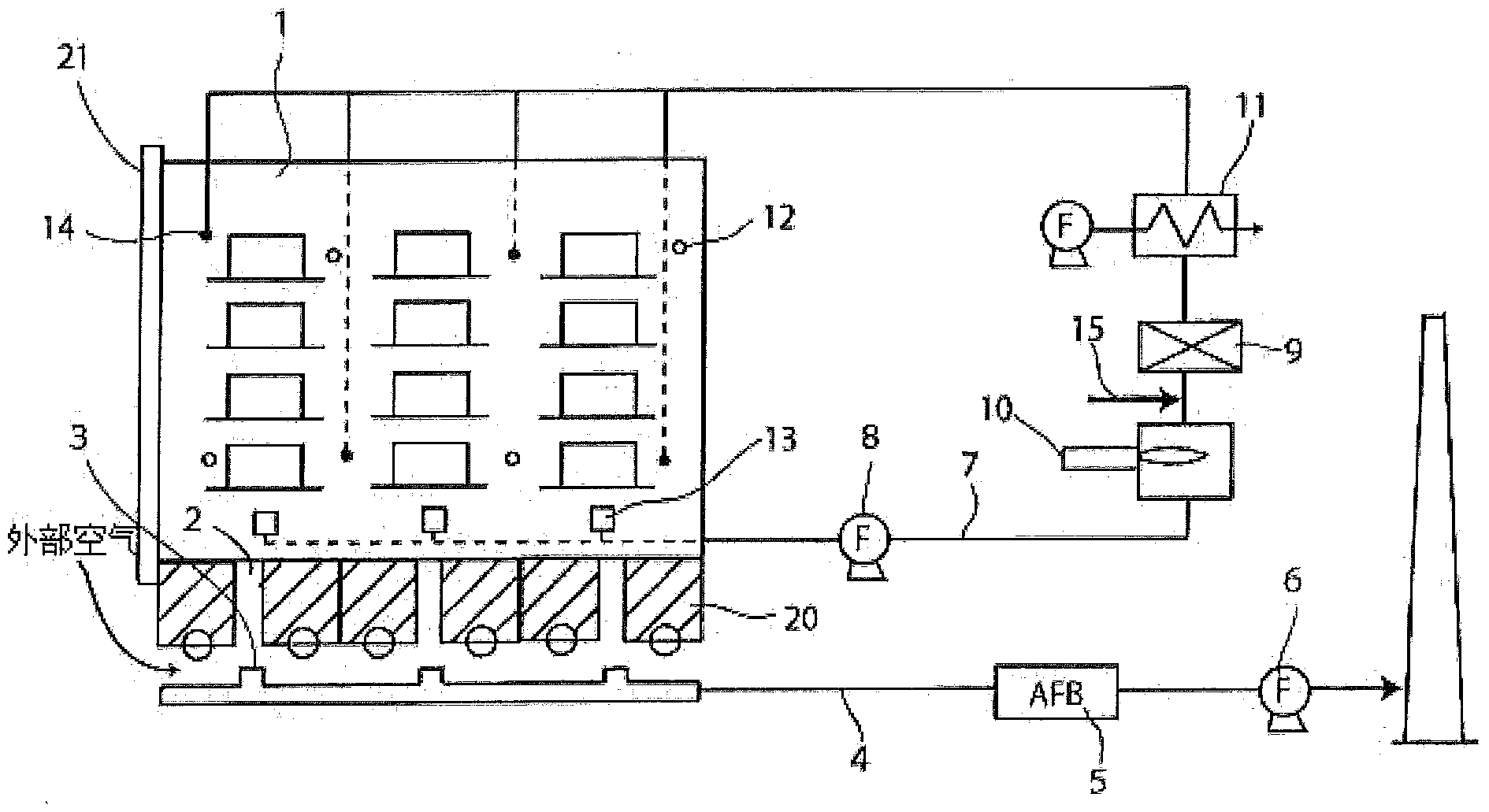

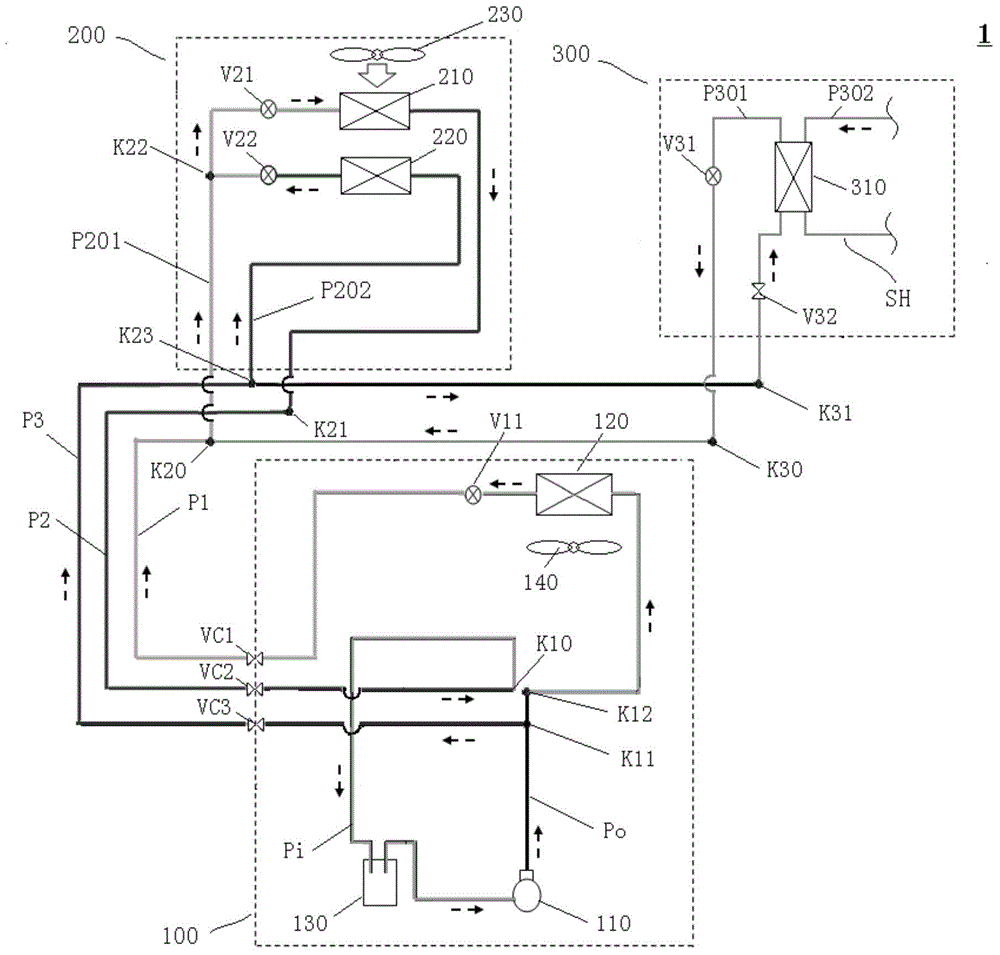

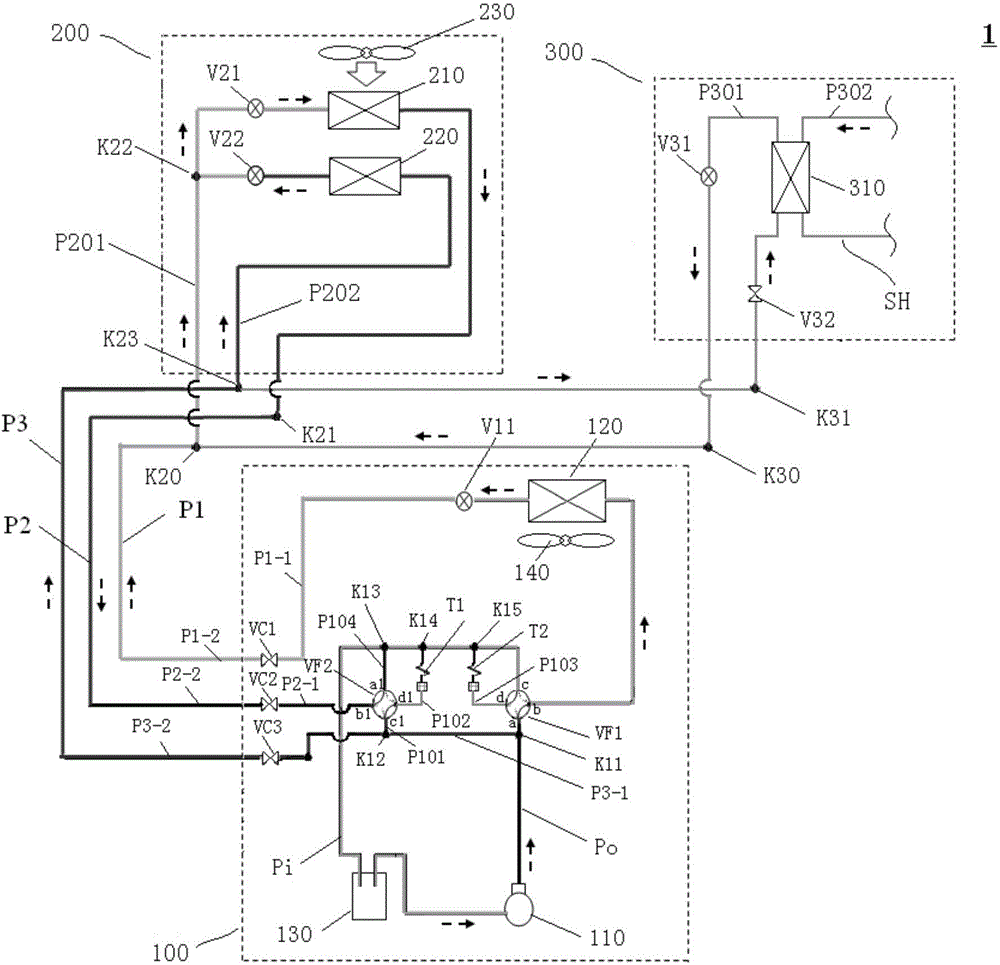

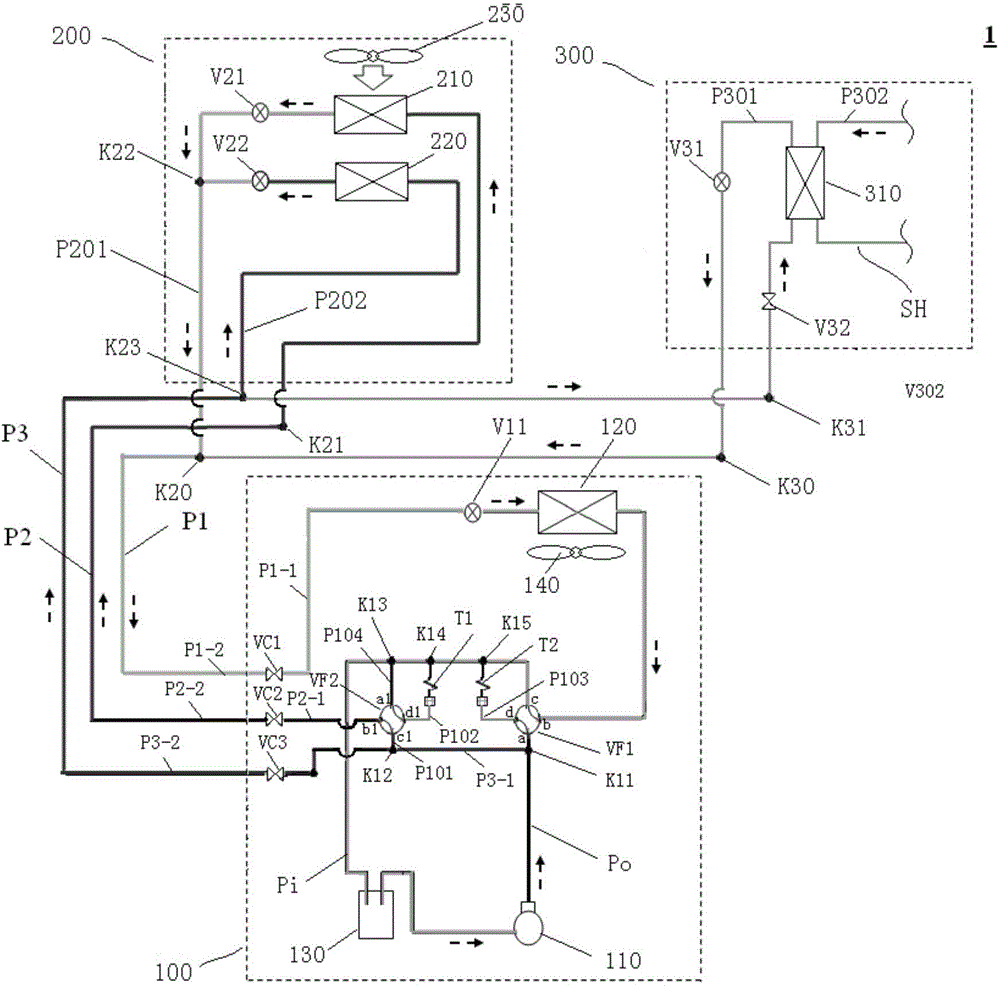

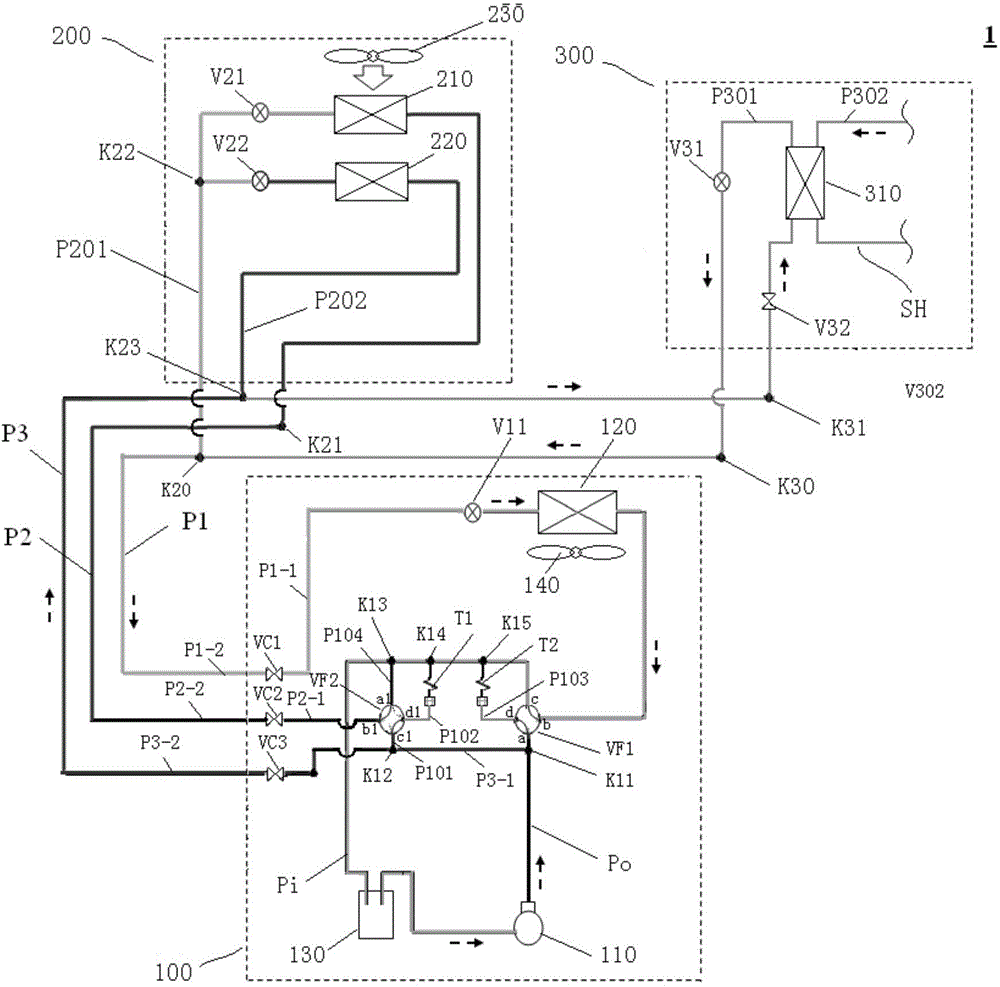

Air conditioning system and control method thereof

ActiveCN106152263AAvoid uneven temperature distributionImprove comfortMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention discloses an air conditioning system and a control method thereof. The air conditioning system can provide fluid which is fully dehumidified and heated for the indoor space in an energy-saving mode and has the function of providing hot water. The air conditioning system comprises an outdoor unit, a dehumidifying and heating indoor unit and a refrigerating fluid water heat exchange unit, wherein the outdoor unit, the dehumidifying and heating indoor unit and the refrigerating fluid water heat exchange unit are connected through a first connecting pipe, a second connecting pipe and a third connecting pipe; one end of the third connecting pipe is connected to a discharge pipe connected to the discharge side of a compressor, the dehumidifying and heating indoor unit is provided with a second indoor side pipe, a second indoor side refrigerating fluid adjusting device and a second heat exchanger are arranged in the middle of the second indoor side pipe, and the other end of the third connecting pipe is connected to the other end of the second indoor side pipe; and the refrigerating fluid water heat exchange unit is provided with a refrigerating fluid pipe, a water loop and a refrigerating fluid water heat exchanger, one end of the refrigerating fluid pipe is connected to the first connecting pipe, and the other end of the refrigerating fluid pipe is connected to the third connecting pipe.

Owner:DAIKIN IND LTD

Device for testing material burst at high temperature

ActiveCN103091348AReduced service lifeExtended service lifeMaterial thermal analysisThermometer applicationsElectrical resistance and conductanceTemperature resistance

The invention discloses a device for testing material burst at high temperature, and belongs to a piece of experimental equipment. The device comprises a high-temperature resistance furnace. The high-temperature resistance furnace comprises a furnace body and a furnace door. The front plate of the furnace body is provided with a first window, and the furnace door is hinged on the front plate of the furnace body, wherein the furnace door is provided with a second window, a quartz glass plate is installed on the second window, and the first window is communicated with the second window. The furnace door has a plurality of through-holes which are arranged in the internal cavity of the furnace body. A temperature inspecting instrument is arranged outside the furnace body, the temperature inspecting instrument is connected with a plurality of temperature sensors, and each temperature sensor passes through each through-hole and then enters the internal cavity of the furnace. The device for testing the material burst at high temperature disclosed by the invention can observe the test material burst process at high temperature, and can measure and test the temperatures of different parts of the internal part of the test material in real time.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

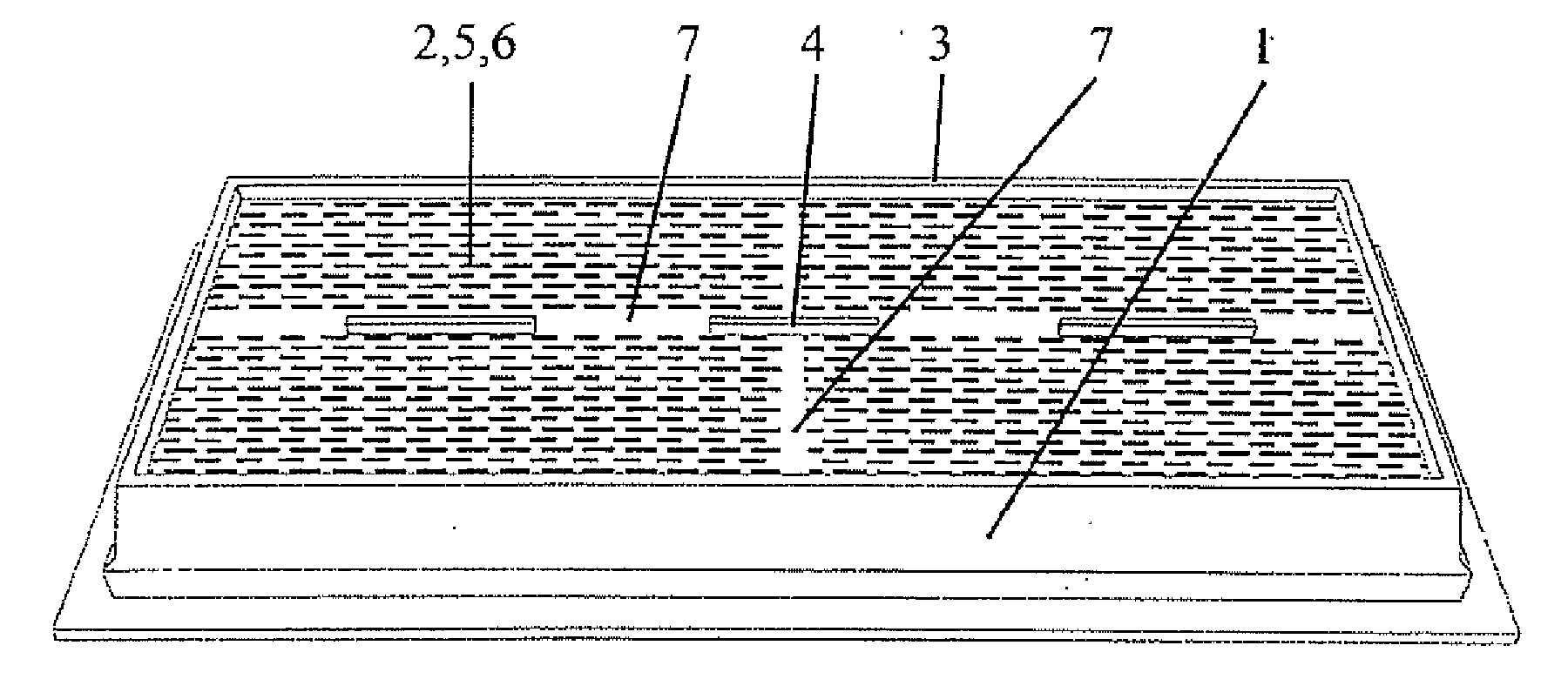

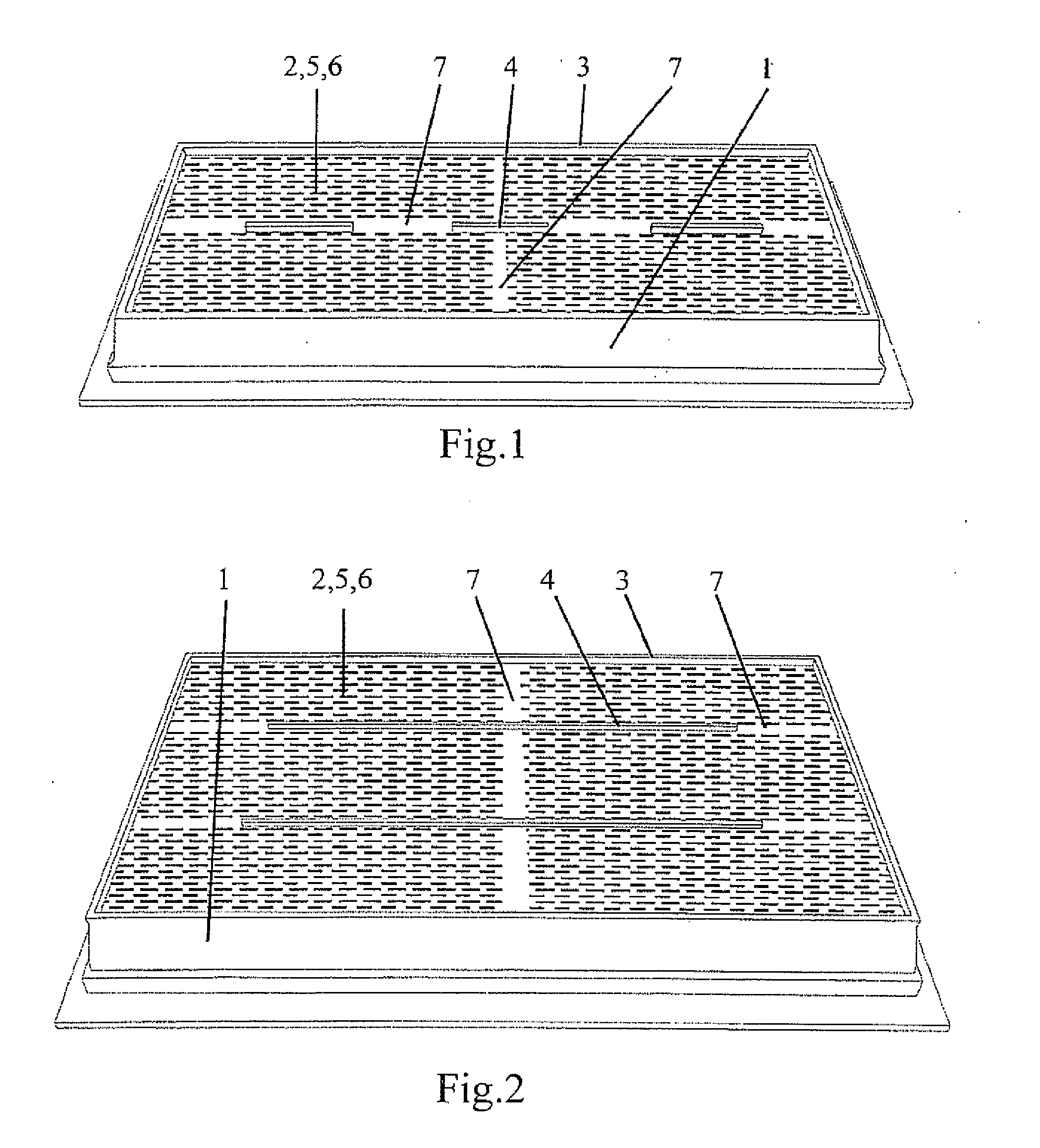

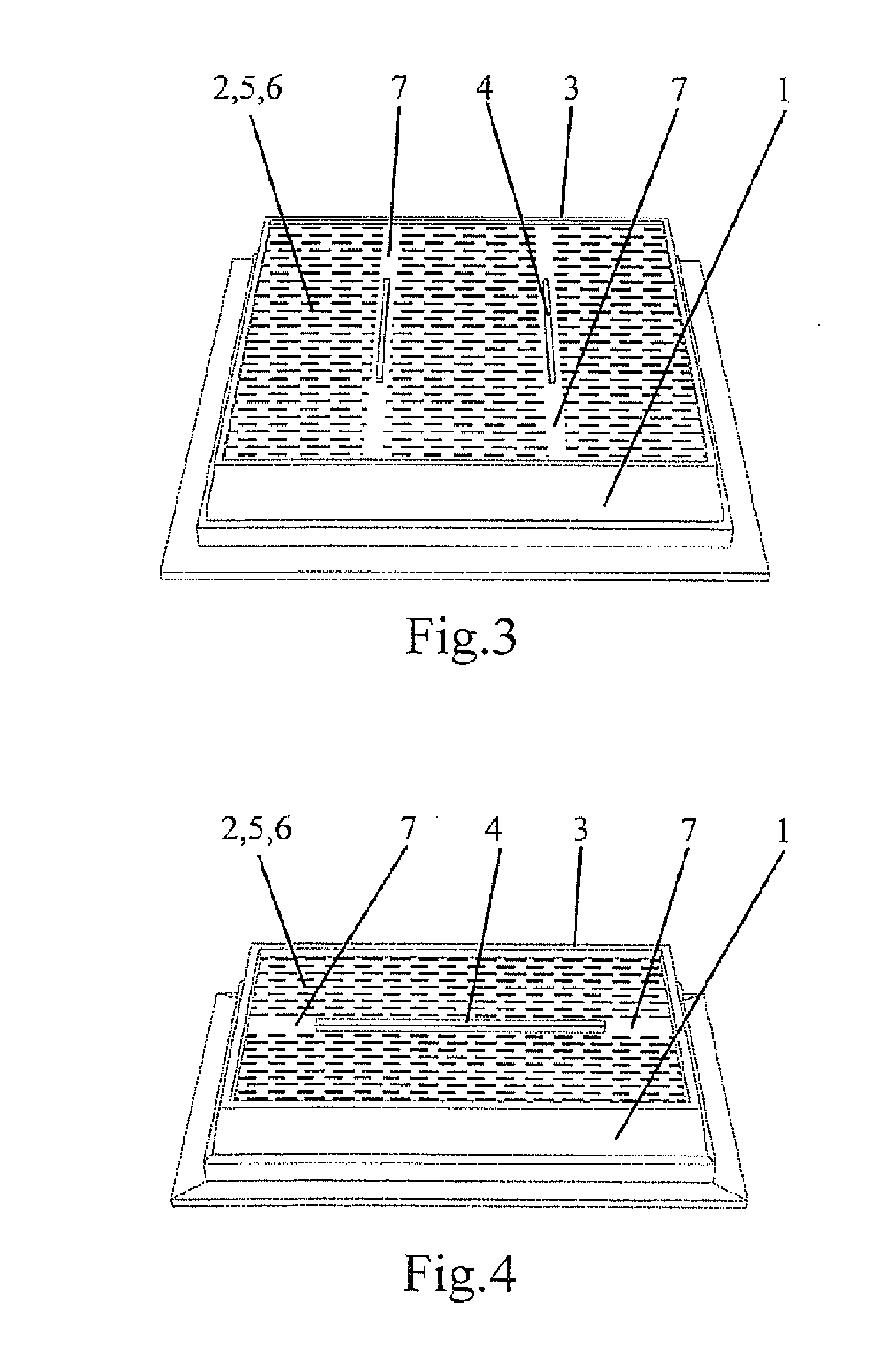

Induction Cookware for Keeping Food Warm

InactiveUS20120037615A1Avoid breakingPrevent ruptureFurnaces without endless coreCooking-vessel materialsMaterials scienceCooker

An item of induction cookware for keeping food warm comprises a base with ribs, between which the base is coated with a ferromagnetic material. According to the invention, the ferromagnetic material is divided into fields. This prevents constriction points in the ferromagnetic material, at which intense local heating can occur, which can cause the induction cookware to break.

Owner:GASTROS

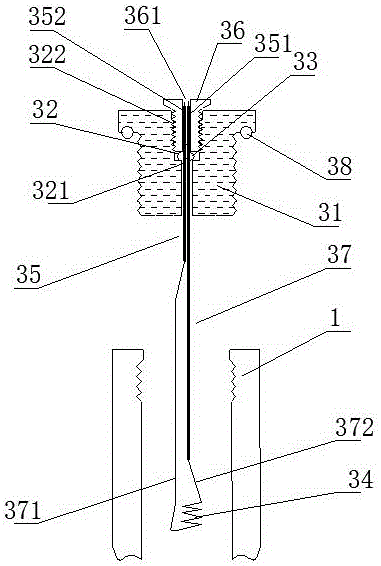

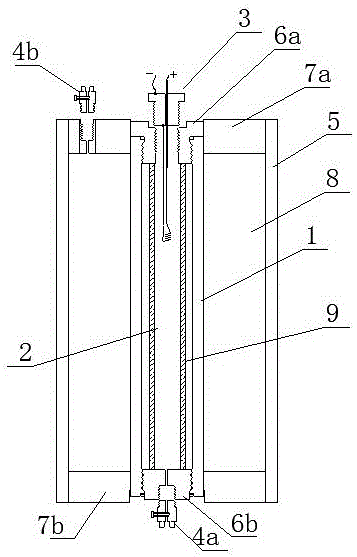

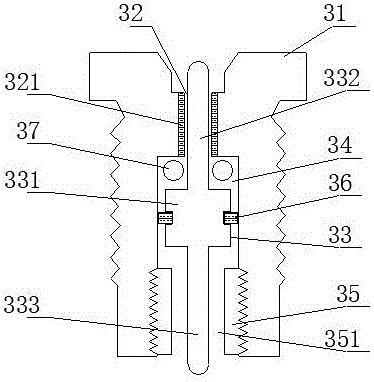

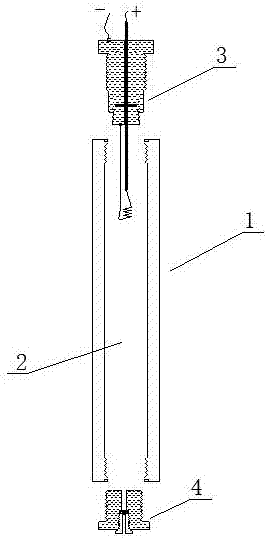

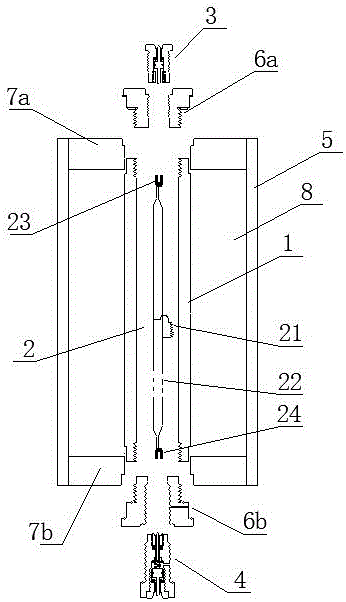

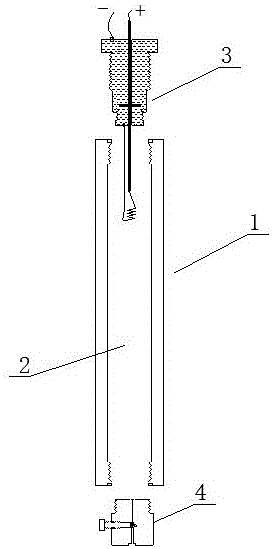

Inflation and ignition integrated gas blaster

PendingCN106931838AReduce mixReduce production processBlasting cartridgesCheck valvesHeating efficiencyNitrogen gas

The invention discloses an inflation and ignition integrated gas blaster. The inflation and ignition integrated gas blaster comprises an inner pipe, an inner pipe filling cavity, an inflation and ignition mechanism, an inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; the two ends of the inner pipe are in sealed connection with a first inner sealing cap and a second inner sealing cap correspondingly; the first inner sealing cap and the second inner sealing cap are connected through a connecting piece; the outer pipe is arranged outside the inner pipe; a first outer sealing cap and a second outer sealing cap are connected between the inner pipe and the outer pipe in a sealed mode; the inflation and ignition mechanism is installed on the first inner sealing cap; the first outer sealing cap is provided with the inflation mechanism; a sealed cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer pipe filling cavity is filled with liquid carbon dioxide, liquid nitrogen or other liquid substances liable to gasify. The inflation and ignition integrated gas blaster has the advantages of being low in manufacturing cost, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

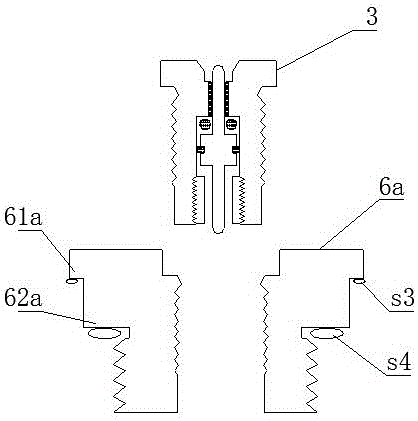

Plug-in type gas blaster

PendingCN106595397AUniform responseAdequate responseBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a plug-in type gas blaster. The plug-in type gas blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube gas inflation mechanism and an outer tube. The inner tube is internally provided with the inner tube filling cavity. A first sealed inner cover and a second sealed inner cover are connected to the two ends of the inner tube in a sealed manner correspondingly. The outer tube is arranged on the outer layer of the inner tube. A first sealed outer cover and a second sealed outer cover are connected between the inner tube and the outer tube in a sealed manner. The ignition mechanism and the inner tube gas inflation mechanism are mounted on the first sealed inner cover or the second sealed inner cover. The first sealed outer cover or the second sealed outer cover is provided with an outer tube gas inflation mechanism. A seal cavity formed between the inner tube and the outer tube is an outer tube filling cavity. The inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter. The outer tube filling cavity is filled with liquid matter easy to gasify such as liquid carbon dioxide or liquid nitrogen. The plug-in type gas blaster has the beneficial effects of being low in manufacturing cost, high in reaction material mixing uniformity, high in heating efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Fixing device and image forming apparatus

InactiveUS20120045240A1Low costSmall sizeElectrographic process apparatusElectromagnetic inductionSolid of revolution

A fixing device including a fixing rotational body and fixing images on sheets of various sizes, comprising: a main excitation coil heating the rotational body by electromagnetic induction and having an effective heating length L1 corresponding to a maximum-size sheet; an auxiliary excitation coil having an effective heating length L2 shorter than L1; a high-frequency power source supplying power to the main and auxiliary coils; and a switch selectively connecting the main or auxiliary coils to the power source, wherein the main coil is positioned along an outer circumferential surface of the rotational body, the auxiliary coil is positioned farther from the rotational body than the main coil is and layered on a central portion of the main coil in a longitudinal direction thereof, and L2 satisfies the following relationship: L2≦L1·η2 / η1, where η1 and η2 are thermal conversion efficiencies of the main and auxiliary coils, respectively.

Owner:KONICA MINOLTA BUSINESS TECH INC

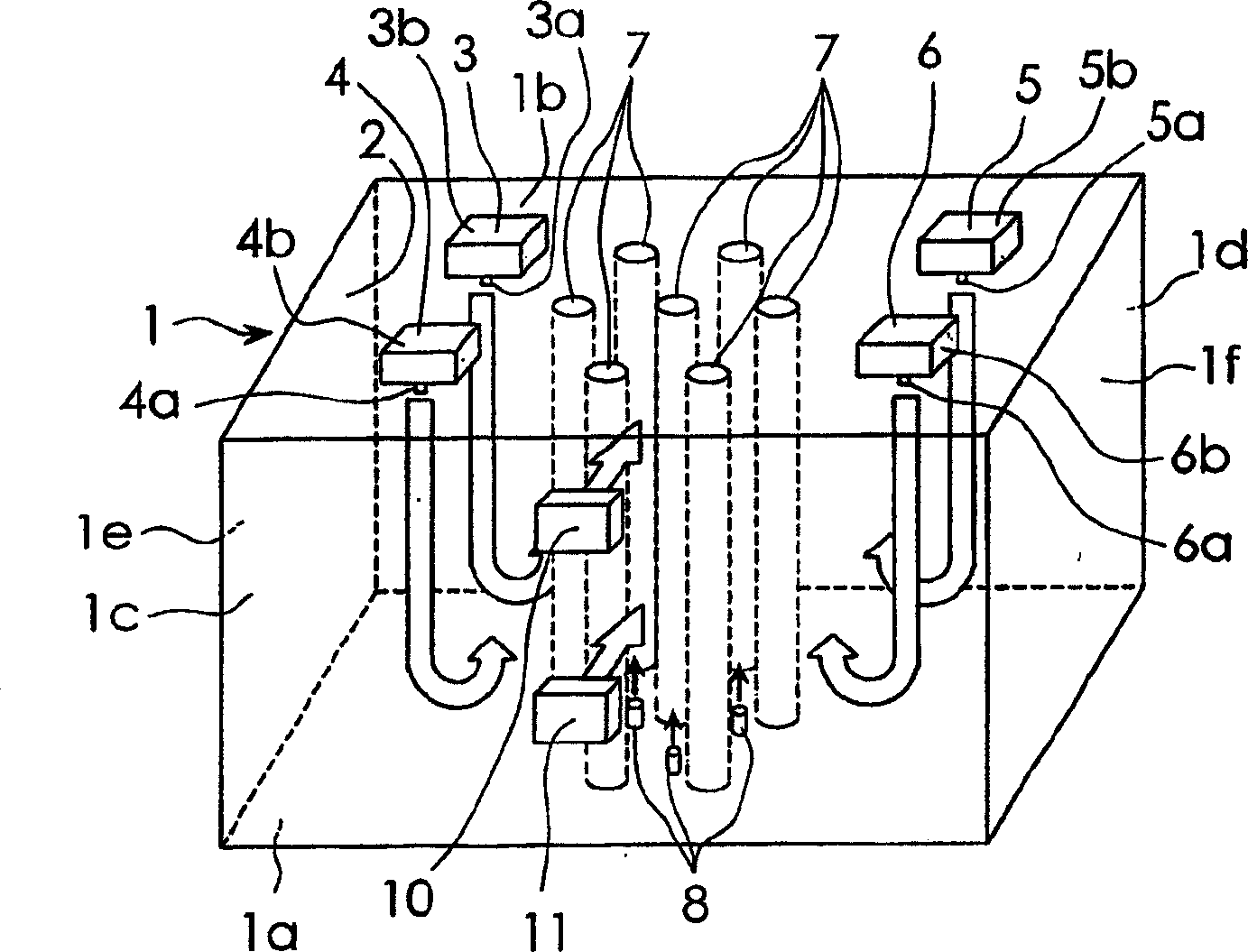

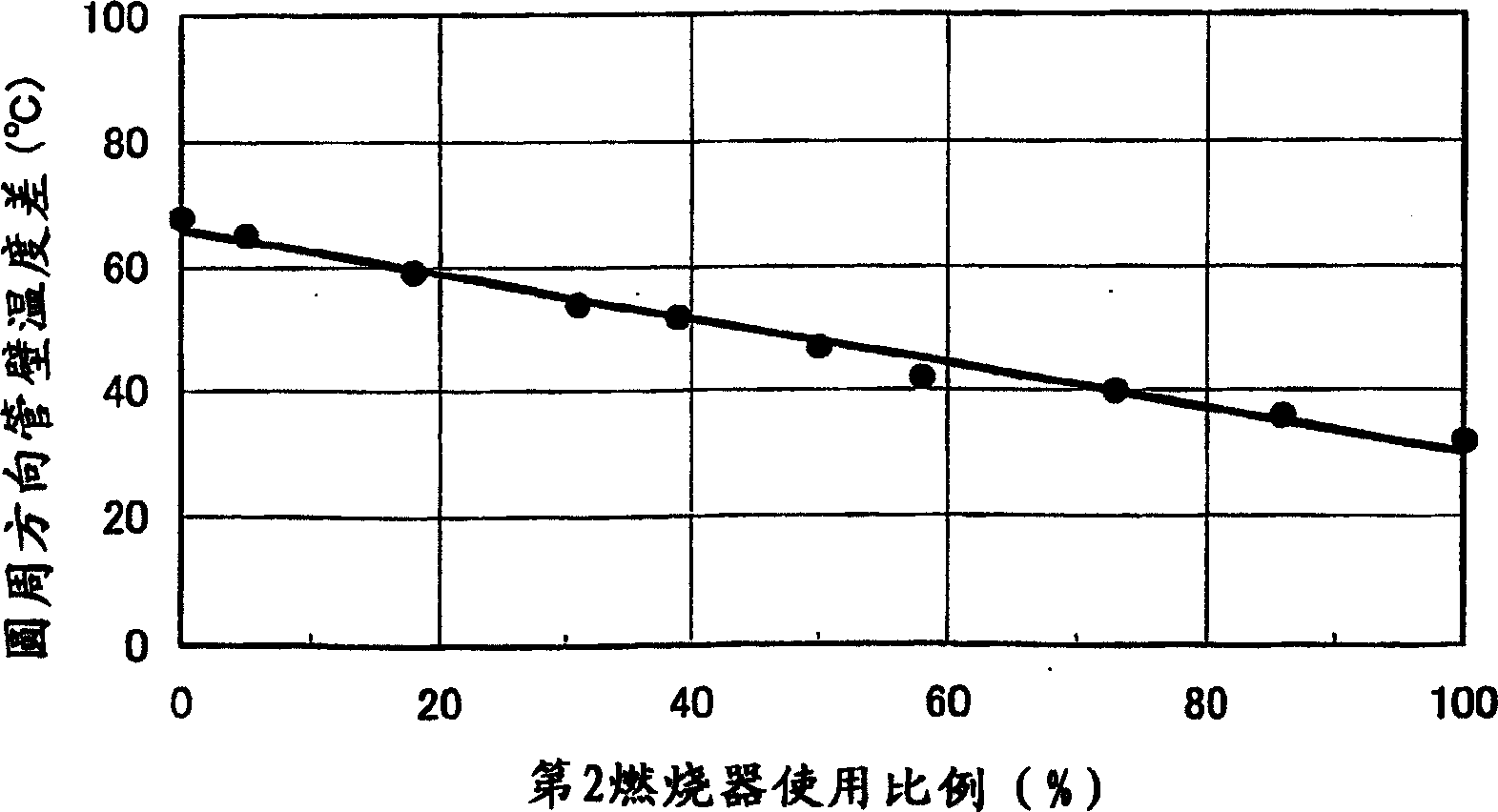

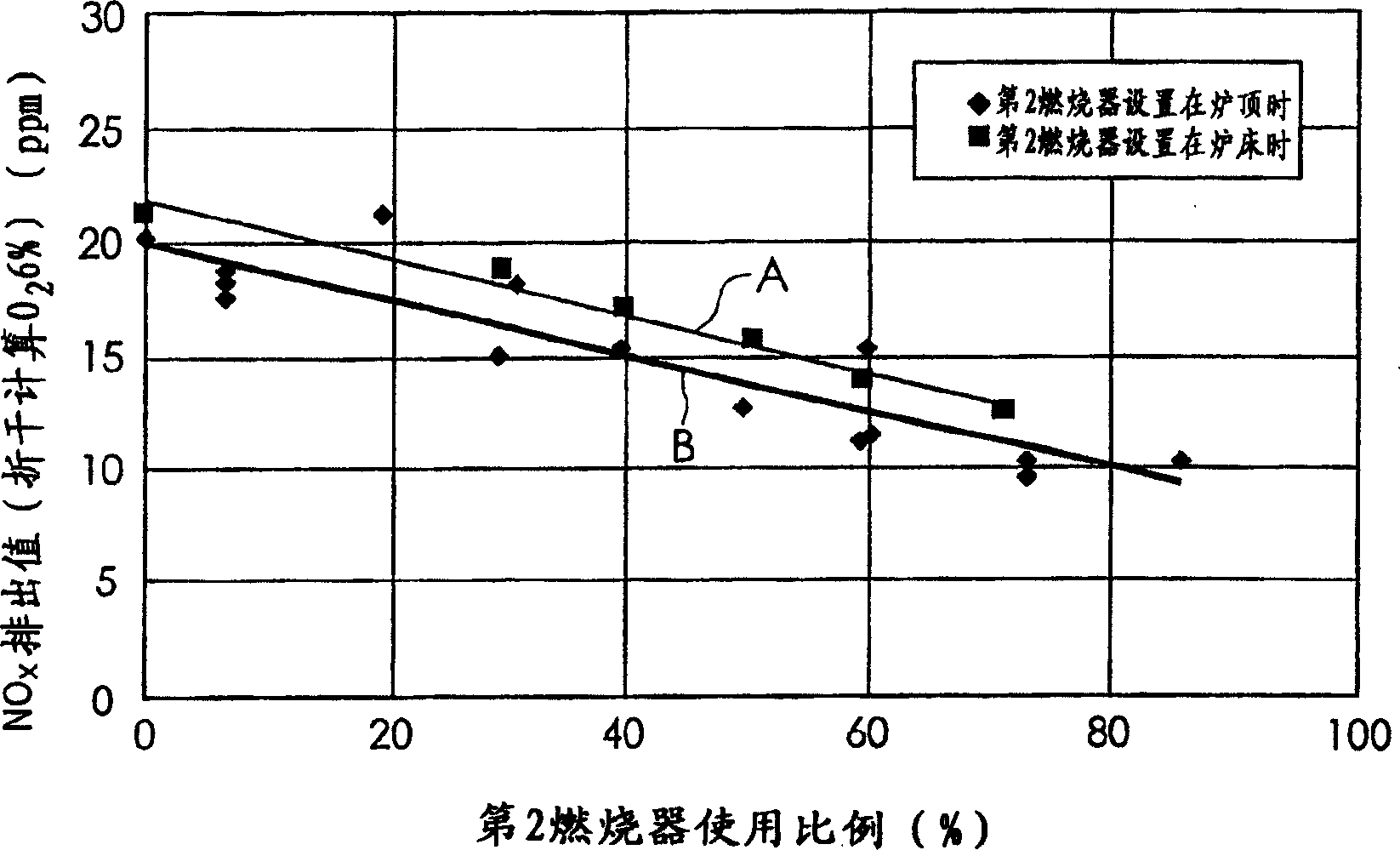

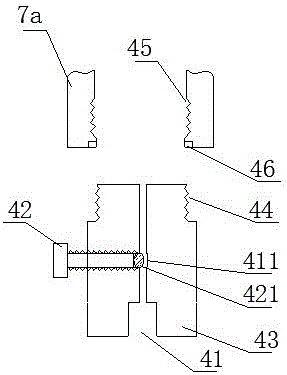

Reactor combustion control method and reactor

InactiveCN1643303AUneven temperature distributionReduce yieldCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCombustor

A reactor combustion control method using a high temperature air combustion technology capable of reducing a temperature difference in a reactor without producing cracking and caulking in reaction tubes and the reactor controlled by using the method, the reactor wherein second burners ( 8 ) are disposed in a space formed between two or more reaction tubes ( 7 ) adjacent to each other so as to inject fuel in the extending direction of the reaction tubes ( 7 ), and partial combustion air feeding devices ( 10 ) and ( 11 ) for the second burners discharging exhaust gas in a combustion chamber ( 2 ) to the outside of the reactor through a permeable heat reservoir and feeding combustion air heated to a high temperature by the latent heat of the heat reservoir to the second burners ( 8 ) are installed; the method comprising the steps of raising the temperature in the reactor by the combustion of only the first burners ( 3 a) to ( 6 a) until the inside of a reactor body ( 1 ) is brought into a high temperature air combustion state, starting the combustion of the second burners ( 8 ) after the inside of the reactor body ( 1 ) is brought into the high temperature air combustion state, and decreasing the amount of combustion of the plurality of first burners ( 3 a) to ( 6 a) according an increase in combustion amount of the second burners ( 8 ) whereby a necessary combustion state can be provided.

Owner:CHIYODA CORP

Inflation and ignition integrated air blaster

InactiveCN106643324AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses an inflation and ignition integrated air blaster. The inflation and ignition integrated air blaster comprises an inner tube, an inner tube filling cavity, an inner tube inflation and ignition head, an outer tube inflation head and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner correspondingly; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the inner tube inflation and ignition head is mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matter; and the outer tube filling cavity is filled with liquid easy-to-gasify matter such as liquid carbon dioxide and liquid nitrogen. The inflation and ignition integrated air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

Air inflation and ignition integrated blaster and fracturing device

The invention discloses an air inflation and ignition integrated blaster and a fracturing device. The air inflation and ignition integrated blaster comprises a tube body, a filling cavity located in the tube body, as well as an air inflation and ignition head and a cover body respectively located at the two ends of the tube body, wherein the filling cavity is filled with supercritical oxygen and a reductive simple substance; the air inflation and ignition head comprises a plugging substrate, an air inflation hole, a sealing ball valve, a conductive contact and an electric heating wire; the air inflation hole penetrates through the plugging substrate; a sealing shrink mouth is formed in the lower part of the air inflation hole; the sealing ball valve is mounted above the sealing shrink mouth; the conductive contact penetrates through the sealing ball valve and is fixedly connected with the sealing ball valve in a clamping manner; the spherical surface of the lower part of the sealing ball valve is a rough surface; the degree of tightness of the sealing ball valve is adjusted by a sealing locking screw; a contact window, through which the conductive contact penetrates, is formed in the middle of the sealing locking screw; the conductive contact is connected with the electric heating wire by a wire; and a connecting piece is connected between the plugging substrate and the cover body. The air inflation and ignition integrated blaster has the advantages that a powder filling process is simple, the safety is high, the mixing uniformity of materials is high, and the end of the blaster is prevented from flying out.

Owner:郭远军

Air blaster

PendingCN106643327AReduce mixReduce production processBlasting cartridgesCheck valvesTransport securityNitrogen gas

The invention discloses an air blaster. The air blaster comprises an inner tube, an inner tube filling cavity, an ignition mechanism, an inner tube inflation mechanism and an outer tube, wherein the inner tube filling cavity is formed in the inner tube; the two ends of the inner tube are connected with a first sealing inner cover and a second sealing inner cover in a sealing manner respectively; the outer tube serves as the outer layer of the inner tube; a first sealing outer cover and a second sealing outer cover are connected between the inner tube and the outer tube in a sealing manner; the ignition mechanism and the inner tube inflation mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer tube inflation mechanism is mounted on the first sealing outer cover or the second sealing outer cover; the sealing cavity between the inner tube and the outer tube is an outer tube filling cavity; the inner tube filling cavity is filled with supercritical oxygen and carbon-containing organic matters; and the outer tube filling cavity is filled with such liquid easy-to-gasify matters as liquid carbon dioxide and liquid nitrogen. The air blaster has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, good transport security and high blasting power.

Owner:郭远军

Gas blasting device

InactiveCN106767183AReduce mixReduce production processBlasting cartridgesCheck valvesLiquid carbonEngineering

The invention discloses a gas blasting device which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, a first inflation mechanism and an outer pipe, wherein the inner pipe filling cavity is arranged in the inner pipe; the two ends of the inner pipe are in sealing connection with a first inner sealing cover and a second inner sealing cover; the first inner sealing cover and the second inner sealing cover are connected through a connecting piece; the outer pipe is arranged on the outer layer of the inner pipe; a first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe in a sealing manner; the ignition mechanism and the first inflation mechanism are mounted on the first inner sealing cover; a second inflation mechanism is mounted on the first outer sealing cover; the sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbon-containing organic matters; the outer pipe filling cavity is filled with liquid easy gasifying materials such as liquid carbon dioxide or liquid nitrogen. The gas blasting device has the advantages that the manufacture cost is low, the heat release efficiency is high, the transport security is good and the blast power is high.

Owner:郭远军

Mold and molding system

Owner:SHIPPO KANAGATA INDS

Gas blasting machine convenient to inflate

InactiveCN106643318AReduce wall thicknessReduce weightBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses a gas blasting machine convenient to inflate. The gas blasting machine comprises an inner pipe, an inner pipe filling cavity, a first inflating conductive head, a second inflating conductive head and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are connected to between the inner pipe and the outer pipe; the inner pipe is in clearance fit with the first sealing outer cap and the second sealing outer cap; the outer pipe is in sealing connection with the first sealing outer cap and the second sealing outer cap; the first sealing inner cap is in sealing connection with the first sealing outer cap, and the second sealing inner cap is in sealing connection with the second sealing outer cap; the first inflating conductive head is mounted in the first sealing inner cap, and the second inflating conductive head mounted in the second sealing inner cap; and an outer pipe filling cavity is formed between the inner pipe and the outer pipe. The gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in homogeneity degree of reacting materials, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

Ejector pin sealing type gas blasting machine

PendingCN106643321AReduce mixReduce production processBlasting cartridgesExplosivesNitrogen gasEngineering

The invention discloses an ejector pin sealing type gas blasting machine which comprises an inner pipe, an inner pipe filling cavity, an ignition mechanism, an inner pipe inflating mechanism and an outer pipe, wherein the inner pipe filling cavity is formed in the inner pipe; two ends of the inner pipe are hermitically connected with a first sealing inner cover and a second sealing inner cover respectively; the outer pipe is arranged on the outer layer of the inner pipe; a first sealing outer cover and a second sealing outer cover are hermitically connected between the inner pipe and the outer pipe; the ignition mechanism and the inner pipe inflating mechanism are mounted on the first sealing inner cover or the second sealing inner cover; an outer pipe inflating mechanism is mounted on the first sealing outer cover or the second sealing outer cover; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe filling cavity is filled with supercritical oxygen and carbonaceous organic materials; and the outer pipe filling cavity is filled with liquid gasification-liable substances such as liquid carbon dioxide or liquid nitrogen. The ejector pin sealing type gas blasting machine has the advantages of low manufacturing cost, high reaction material mixing uniformity, high heat release efficiency, high transportation safety and high blasting power.

Owner:郭远军

Inflating type gas blasting machine

PendingCN106643319AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesEngineeringMechanical engineering

The invention discloses an inflating type gas blasting machine. The inflating type gas blasting machine comprises an inner pipe, an inner pipe inflating conductive head, an outer pipe inflating head and an outer pipe, wherein a first sealing inner cap and a second sealing inner cap are respectively in sealing connection to two ends of the inner pipe; the outer layer of the inner pipe is the outer pipe; a first sealing outer cap and a second sealing outer cap are respectively connected between the inner pipe and the outer pipe; a sealing cavity between the inner pipe and the outer pipe is an outer pipe filling cavity; the inner pipe inflating conductive head is arranged at the shaft center part of the first sealing inner cap; a first radial air hole in the radial direction is formed in the second sealing inner cap; a second mounting cavity and an axial through hole which communicate with each other are formed in the shaft center part of the second sealing inner cap; the axial through hole penetrates through the first radial air hole; a conductive connection head is mounted in the second mounting cavity; a first radial air hole in the radial direction is formed in the second sealing outer cap; and the outer pipe inflating head is arranged on the inner side surface of the second sealing outer cap. The inflating type gas blasting machine disclosed by the invention has the advantages of being low in manufacturing cost, high in heat releasing efficiency, good in transportation safety and high in blasting power.

Owner:郭远军

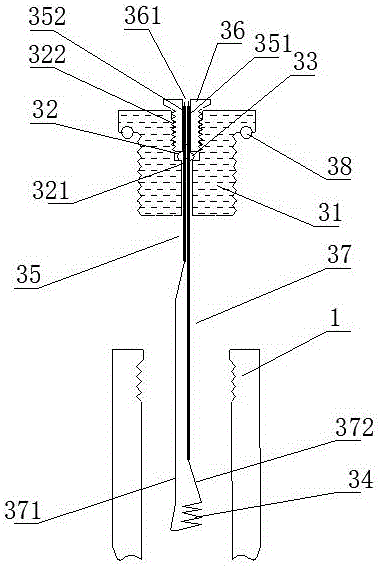

Inflating and igniting integrated initiator and cracking device

The invention discloses an inflating and igniting integrated initiator and a cracking device. The initiator comprises a housing, a filling cavity located in the housing and an inflating and igniting head connected at one end of the housing. Supercritical oxygen and a carbon-containing organic matter or a reductive elementary substance fill the filling cavity. The inflating and igniting head comprises a plugging base body, an inflating hole, a sealed ball valve, a conductive joint and a sealed locking screw. The inflating hole penetrates through the plugging base body from top to bottom, a sealed shrunk port is formed in the lower portion of the inflating hole, the sealed ball valve is mounted above the sealed shrunk port, the conductive joint penetrates through the sealed ball valve and is fixedly locked on the sealed ball valve, the lower spherical surface of the sealed ball valve is a non-smooth surface, an internal thread is arranged in the upper port of the inflating hole, the internal thread is in threaded connection to the sealed locking screw, a joint window for penetrating through the conductive joint is formed in the middle portion of the sealed locking screw, and the conductive joint is connected to an electric heating wire through a wire. The initiator disclosed by the invention has the advantages of being simple in filing process, good in safety, high in material mixing uniformity, low in manufacturing cost of inflating and igniting structure and good in sealing property.

Owner:郭远军

Dual supercritical state gas detonator

InactiveCN106871731AImprove reaction efficiencyHigh reaction heat generation temperatureBlasting cartridgesExplosivesDetonatorDetonation

The invention discloses a dual supercritical state gas detonator. The dual supercritical state gas detonator comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation ignition head, an outer pipe inflation head and an outer pipe. The inner pipe is internally provided with the inner pipe filling cavity. A first sealing inner cover and a second sealing inner cover are connected to the two ends of the inner pipe in a sealing manner correspondingly. The outer layer of the inner pipe is provided with the outer pipe. A first sealing outer cover and a second sealing outer cover are connected between the inner pipe and the outer pipe in a sealing manner. A sealing cavity formed by the inner pipe, the outer pipe, the first sealing outer cover and the second sealing outer cover is an outer pipe filling cavity. The outer pipe filling cavity is filled with liquid carbon dioxide or liquid nitrogen. The inner pipe filling cavity comprises a first inner cavity and a second inner cavity which are sealed and isolated through a thermoplastic sheet. The first inner cavity and the second inner cavity are filled with supercritical oxygen and supercritical state alkane correspondingly. The dual supercritical state gas detonator has the beneficial effects that the manufacturing cost is low, the reaction material mixing uniformity is high, the heat releasing efficiency is high, the transporting safety is good, and the detonation power is high.

Owner:郭远军

Inflation lead integral gas blasting device

InactiveCN106643320AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesLiquid stateNitrogen

The invention discloses an inflation lead integral gas blasting device. The device comprises an inner pipe, an inner pipe filling cavity, an inner pipe inflation electric conducting head, an outer pipe inflation head and an outer pipe; the inner pipe filling cavity is in the inner pipe; two ends of the inner pipe are tightly connected with a first sealing inner cover and a second sealing inner cover; the outer layer of the inner pipe is the outer pipe; a first sealing outer cover and a second sealing outer cover are tightly connected between the inner pipe and the outer pipe; the inner pipe inflation electric conducting head is mounted on the first sealing inner cover or the second sealing inner cover; the outer pipe inflation head is mounted on the first sealing outer cover or the second sealing outer cover; an outer pipe filling cavity is a sealing cavity between the inner pipe and the outer pipe; an electric heating wire is mounted in the inner pipe filling cavity; supercritical oxygen and carbon-contained organic matters are filled in the inner pipe filling cavity; and such liquid-state gasified matters as liquid-state carbon dioxide or liquid-state nitrogen are filled in the outer pipe filling cavity. The inflation lead integral gas blasting device has the advantages of low production cost, high mixing uniformity of reaction materials, high heat releasing efficiency, good transportation safety and high blasting power.

Owner:郭远军

Gas filling and locking integrated detonator and fracturing device

The invention discloses a gas filling and locking integrated detonator and a fracturing device. The gas filling and locking integrated detonator comprises a shell, a filling cavity, an ignition mechanism and a gas filling mechanism. The filling cavity is formed in the shell. The shell is connected with the sealing ignition mechanism and the gas filling mechanism. The filling cavity is filled with supercritical oxygen and carbonaceous organic materials or reducibility elementary substances. The gas filling mechanism comprises a gas filling hole, a gas filling locking valve rod and a gas filling valve seat. The gas filling valve seat penetrates through the gas filling hole in the axial direction. A gas locking cavity is formed in the upper portion of the gas filling hole. A rubber sealing pipe valve is installed at the bottom of the gas locking cavity. A pipe valve through hole is formed in the center of the rubber sealing pipe valve. An internal thread is arranged on the inner wall of an edge opening of the gas locking cavity. The side edge of the gas filling locking valve rod is provided with an external thread matched with the internal thread. A gas filling through hole is formed in the axis position of the gas filling locking valve rod. The gas filling and locking integrated detonator and the fracturing device have the advantages that manufacturing cost is low, reaction material mixing uniformity is high, heat release efficiency is high and transporting safety is good.

Owner:郭远军

Gas detonation device convenient to inflate

PendingCN106595400AUneven temperature distributionReduce heat absorption efficiencyBlasting cartridgesExplosivesDetonationEngineering

The invention discloses a gas detonation device convenient to inflate. The gas detonation device comprises an inner pipe, an inner pipe filling cavity, a first inflation conductive head, a second inflation conductive head and an outer pipe. The inner pipe filling cavity is formed in the inner pipe, a first inner sealing cover and a second inner sealing cover are connected to the two ends of the inner pipe in a sealed mode correspondingly, and the outer pipe is arranged outside the inner pipe. A first outer sealing cover and a second outer sealing cover are connected between the inner pipe and the outer pipe. The inner pipe is in clearance fit with the first outer sealing cover and the second outer sealing cover, and the outer pipe is connected with the first outer sealing cover and the second outer sealing cover in a sealed mode. The first inner sealing cover and the second inner sealing cover are connected with the first outer sealing cover and the second outer sealing cover in a sealed mode correspondingly. The first inflation conductive head and the second inflation conductive head are mounted on the first inner sealing cover and the second inner sealing cover correspondingly, and an outer pipe filling cavity is located between the inner pipe and the outer pipe. The gas detonation device has the advantages of being low in manufacturing cost, high in reaction material mixing uniformity, high in heat releasing efficiency, good in transporting safety and high in detonation power.

Owner:郭远军

Thimble sealed type trigger and cracking device

InactiveCN106595398AAvoid safety hazardsReduce mixingBlasting cartridgesExplosivesEngineeringThermal efficiency

The invention discloses a thimble sealed type trigger and a cracking device. The thimble sealed type trigger comprises a shell, a filling cavity, an ignition mechanism and an air inflation mechanism. The inside of the shell is the filling cavity, and the shell is connected with the sealed ignition mechanism and the air inflation mechanism. The filling cavity is filled with supercritical oxygen and carbonaceous organic material or elementary substance with reductibility. The air inflation mechanism comprises an air inflation hole, a valve rod and an air inflation valve seat. The middle of the air inflation hole is an air locking cavity, and the valve rod is movably installed in the air locking cavity through a thread structure. An ejector header and an ejector header sealed ring are installed at the top of the valve rod, and the ejector header is sleeved with the ejector header sealed ring. The thimble sealed type trigger and the cracking device have the advantages that manufacturing cost is low, mixing uniformity of reaction materials is high, heat releasing efficiency is high, and conveying safety is good.

Owner:郭远军

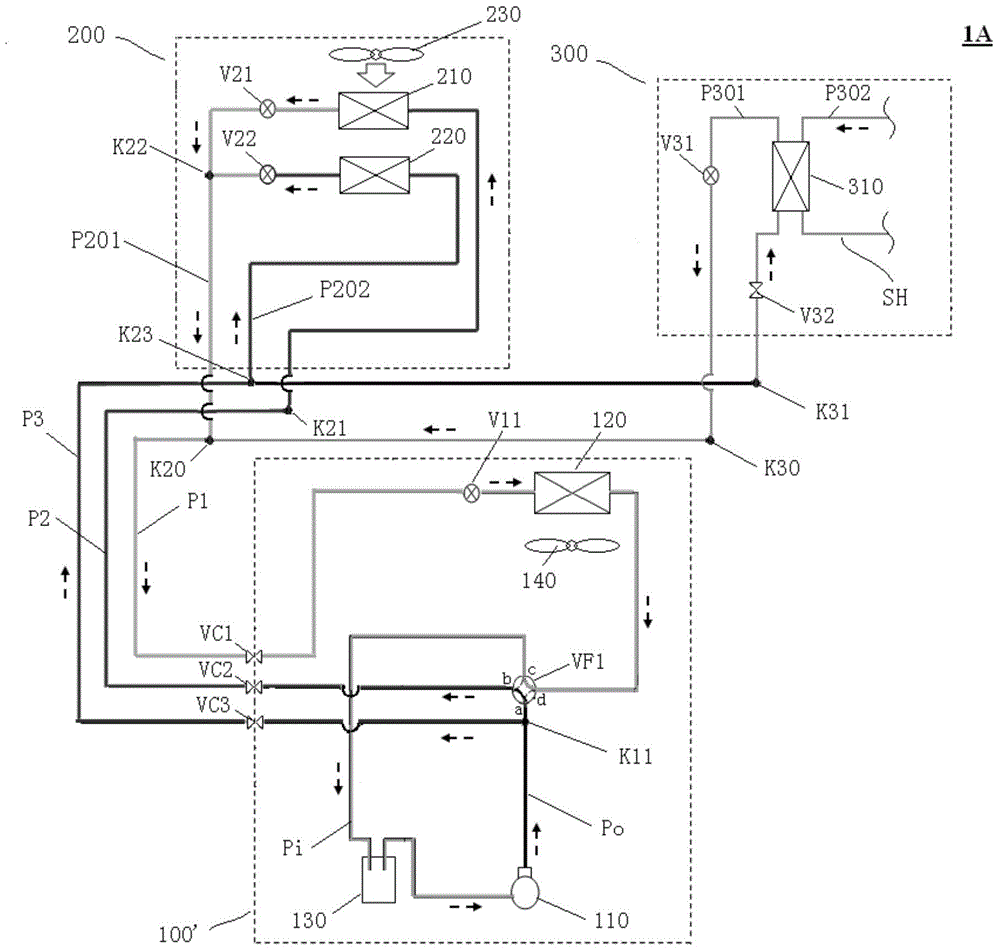

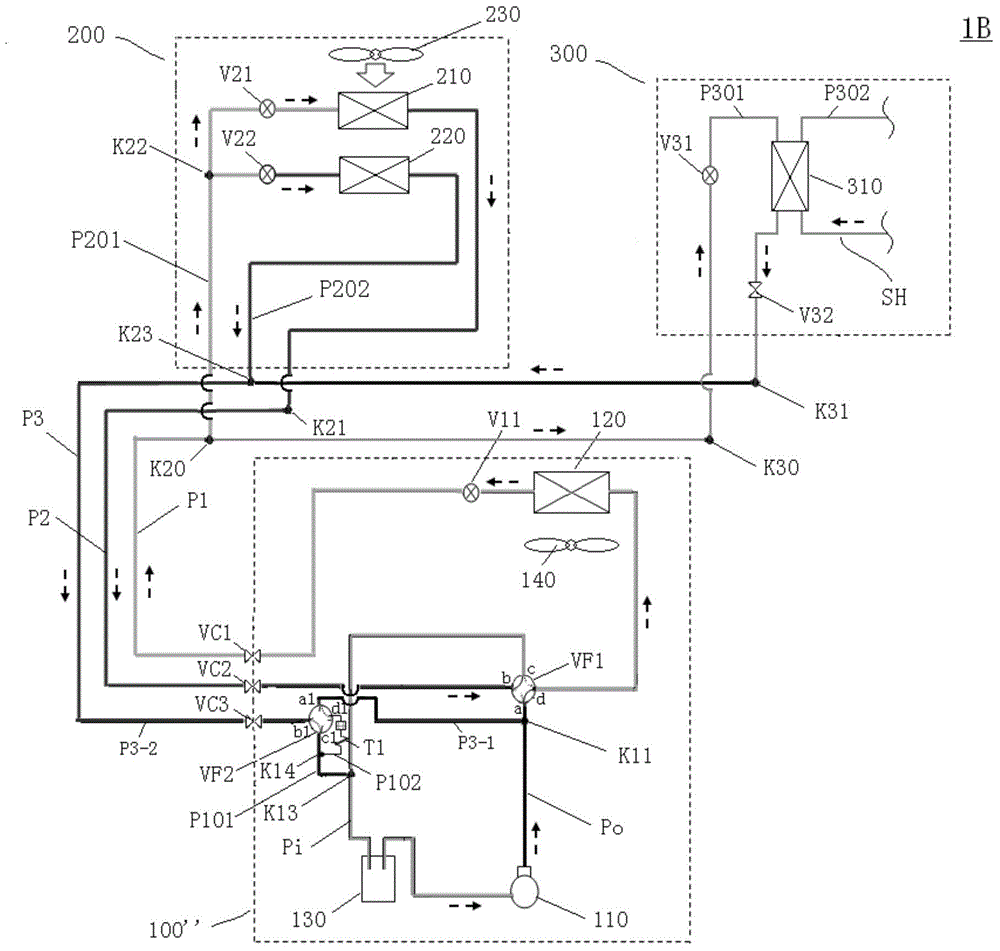

Air conditioner system and control method thereof

ActiveCN106152332AUniform temperature distributionImprove comfortSpace heating and ventilation safety systemsLighting and heating apparatusRefrigerantElectrical and Electronics engineering

The invention provides an air conditioner system and a control method thereof. According to the air conditioner system and the control method thereof, fluid subjected to sufficient dehumidification and heating can be supplied into a room in an energy saving mode, and a hot water supply function is achieved. The air conditioner system comprises an outdoor unit and a dehumidification and heating indoor unit which are connected through a first connecting piping, a second connecting piping and a third connecting piping. The air conditioner system further comprises a refrigerant water-heat exchange unit, a first switching device and a second switching device, wherein the refrigerant water-heat exchange unit comprises a refrigerant piping, a water loop and a refrigerant water-heat exchanger; one end of the refrigerant piping is connected with the first connecting piping, and the other end of the refrigerant piping is connected with the third connecting piping; the first switching device can be switched between the state that a discharge pipe communicates with the first connecting piping and the state that the first connecting piping communicates with a suction pipe; and the second switching device can be switched between the state that the second connecting piping communicates with the suction pipe and the state that the second connecting piping communicates with the third connecting piping.

Owner:DAIKIN IND LTD

Opposite-inflatable air blasting device

InactiveCN106643317AReduce mixReduce production processBlasting cartridgesChemical industryEngineeringMechanical engineering

The invention discloses an opposite-inflatable air blasting device. The device comprises an inner pipe, an inner pipe inflatable conductive head, an outer pipe inflatable head and an outer pipe, the two ends of the inner pipe are connected with a first seal inner cover and a second seal inner cover in a sealed mode respectively, the outer pipe is arranged on the outer layer of the inner pipe, the first seal outer cover and the second seal outer cover are connected between the inner pipe and the outer pipe, a seal cavity formed between the inner pipe and the outer pipe is an outer pipe filling cavity, the inner pipe inflatable conductive head is arranged at the axial core of the first seal inner cover, a first radial air hole is formed in the second seal inner cover in the radial direction, the axial core of the second seal inner cover is provided with a second installation cavity and an axial through hole which are communicated with each other, the axial through hole penetrates through the first radial air hole, a conductive connector is installed in the second installation cavity, the first radial air hole is formed in the second seal outer cover in the radial direction, and an outer pipe inflatable head is arranged on the inner side face of the second seal outer cover. The device has the advantages of being low in manufacturing cost, high in heat release efficiency, good in transport safety and large in blast power.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com