Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "To achieve the purpose of cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

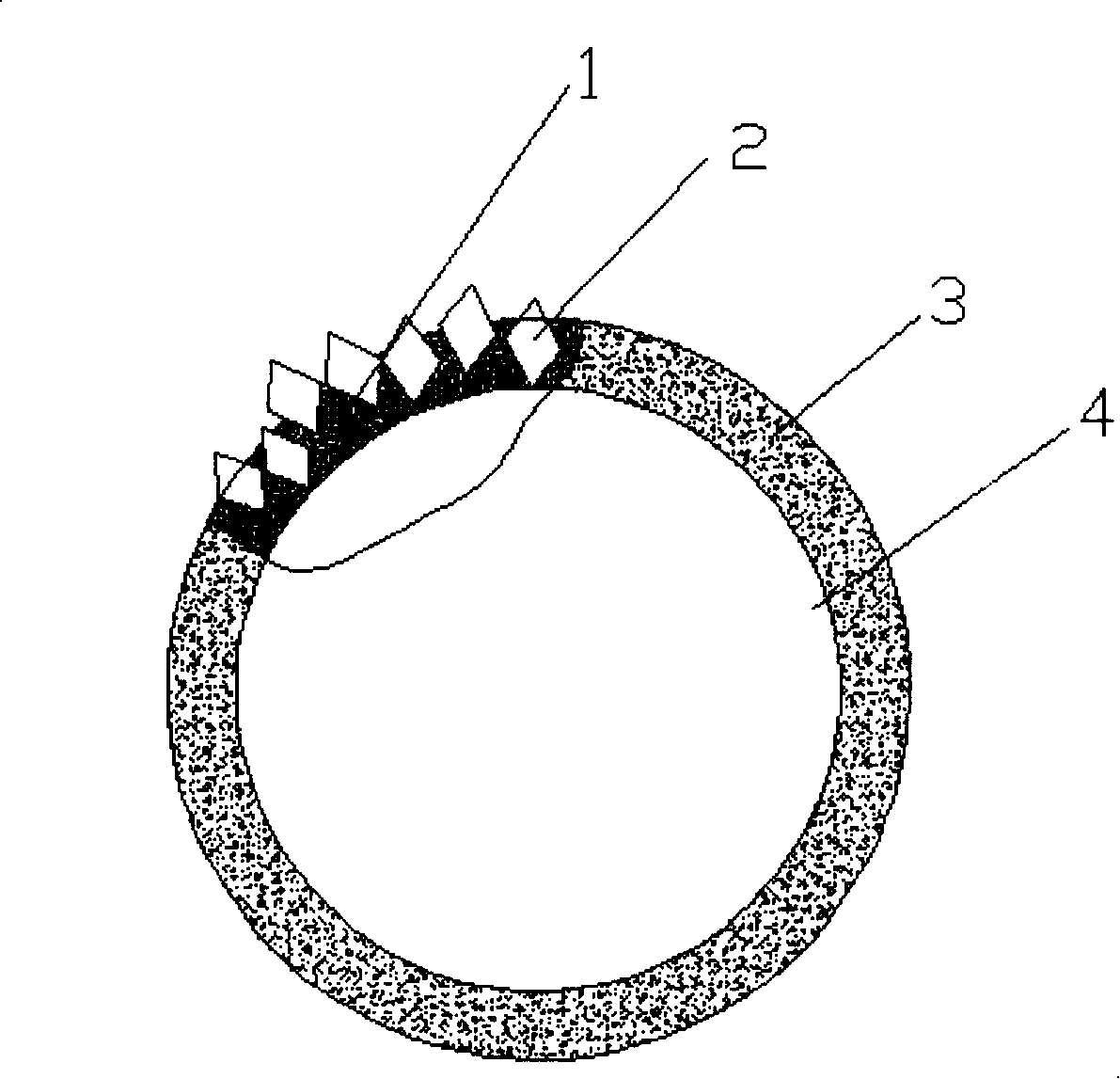

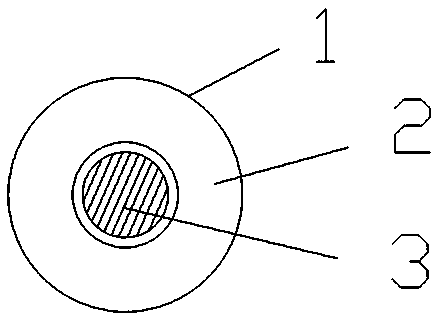

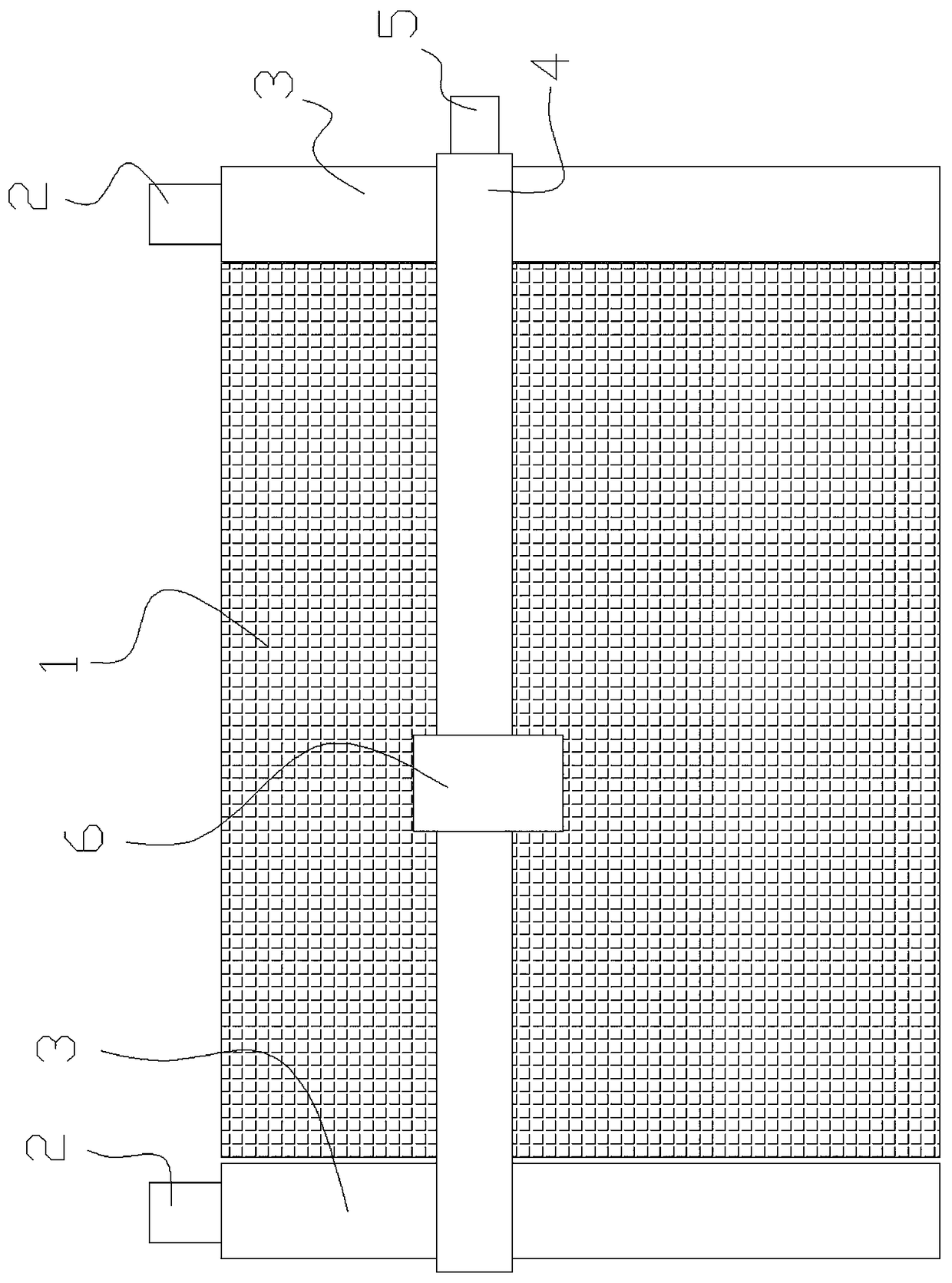

Method for preparing metal binding agent diamond scroll saw

InactiveCN101209505ATo achieve the purpose of cuttingImprove bindingMetal sawing tool makingMetal sawing toolsDiamond wire sawDiffusion reaction

The invention provides a preparation method and the product of a metal binder diamond wire saw, comprising the preparation steps of (1) steel wire surface, (2) plating auxiliary disposal of the steel wire, (3) burdening, (4) plating of steel wire and (5) post-processing. The thickness of the binder coating ranges from 1 / 2 to 2 / 3 of the grain diameter of the diamond. By a series of chemical and diffusion reaction, the surface of the steel wire is covered by a layer of uniform and firm coating 3; a diamond mill grain 2 is also uniformly held in a metal binding layer 1, thus achieving the cutting object.

Owner:ZHEJIANG UNIV OF TECH

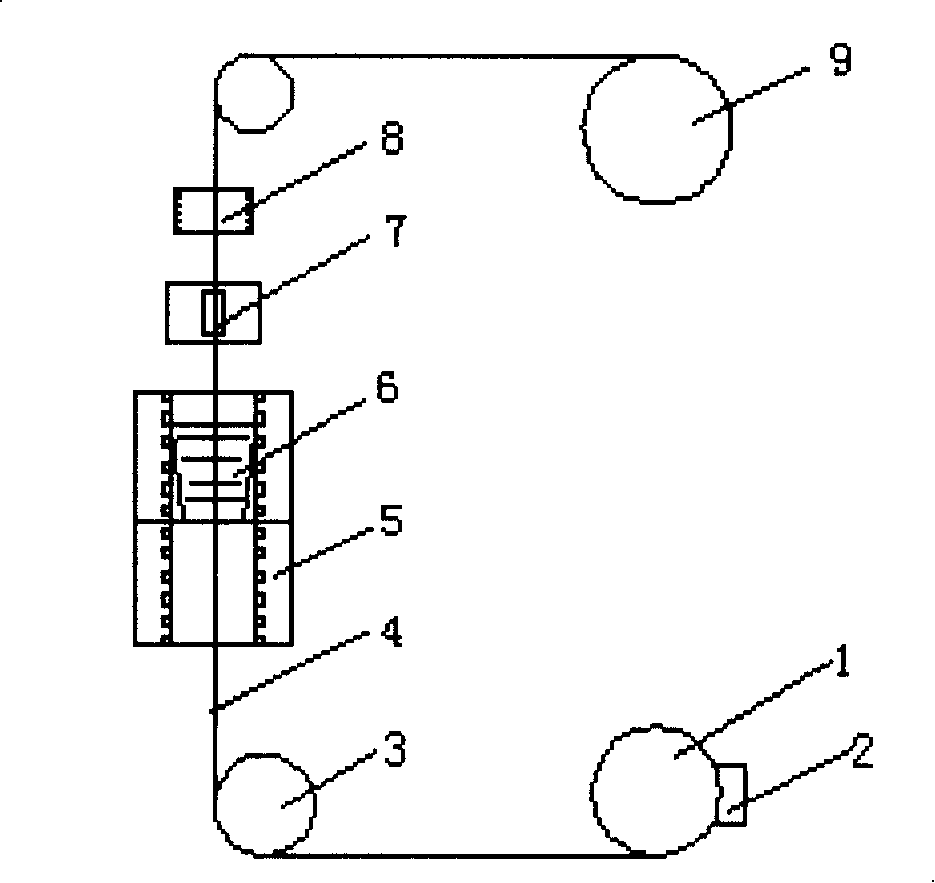

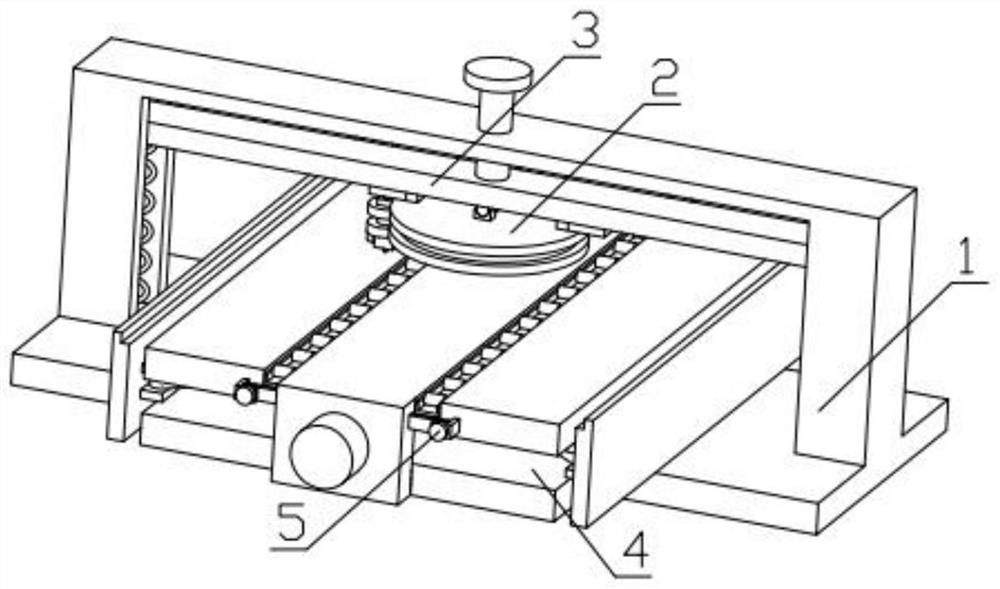

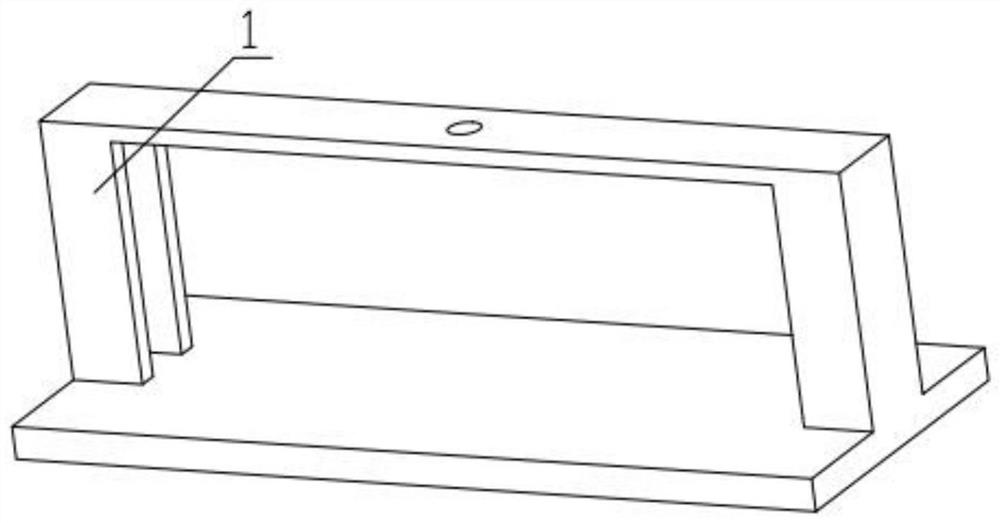

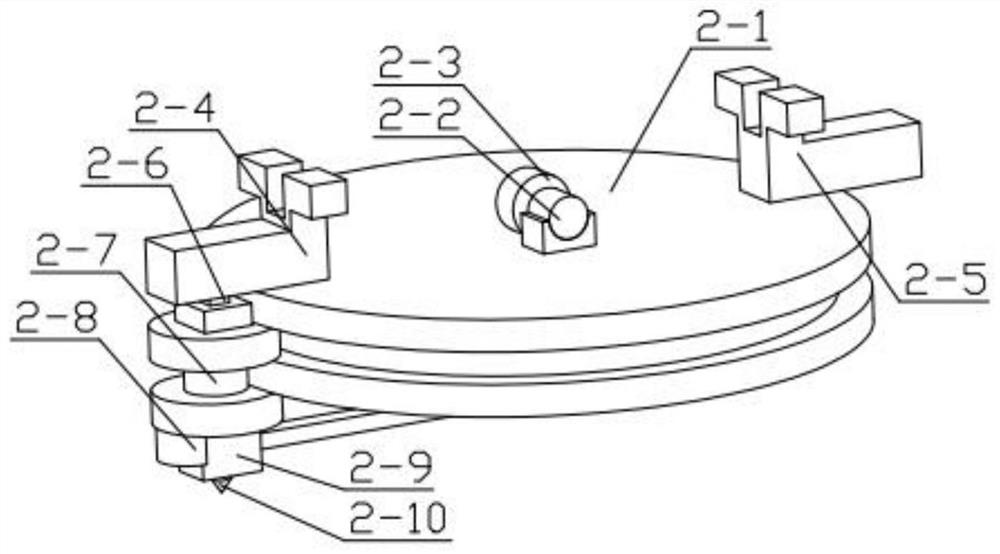

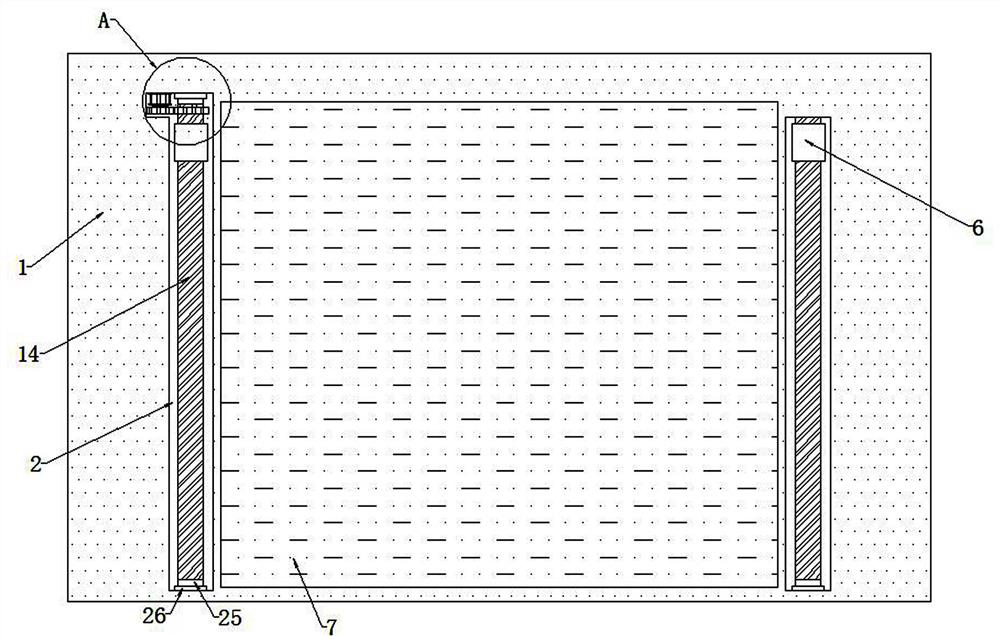

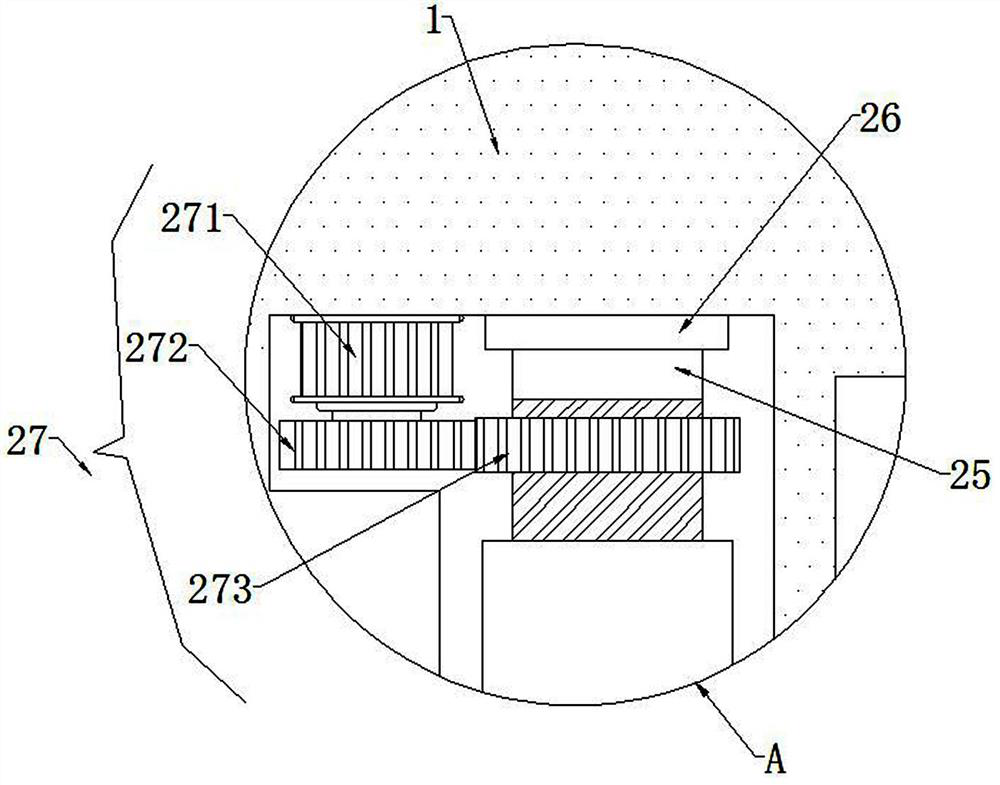

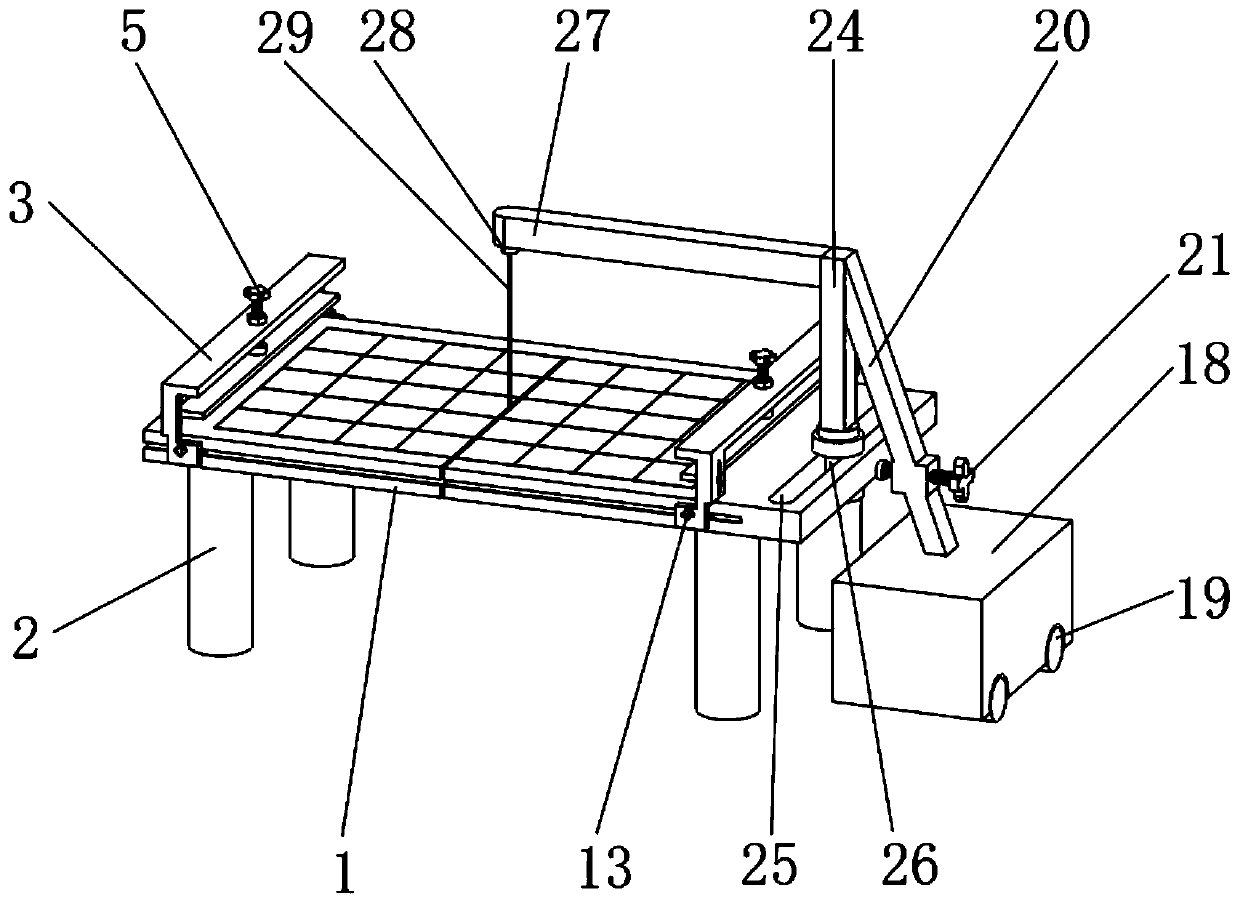

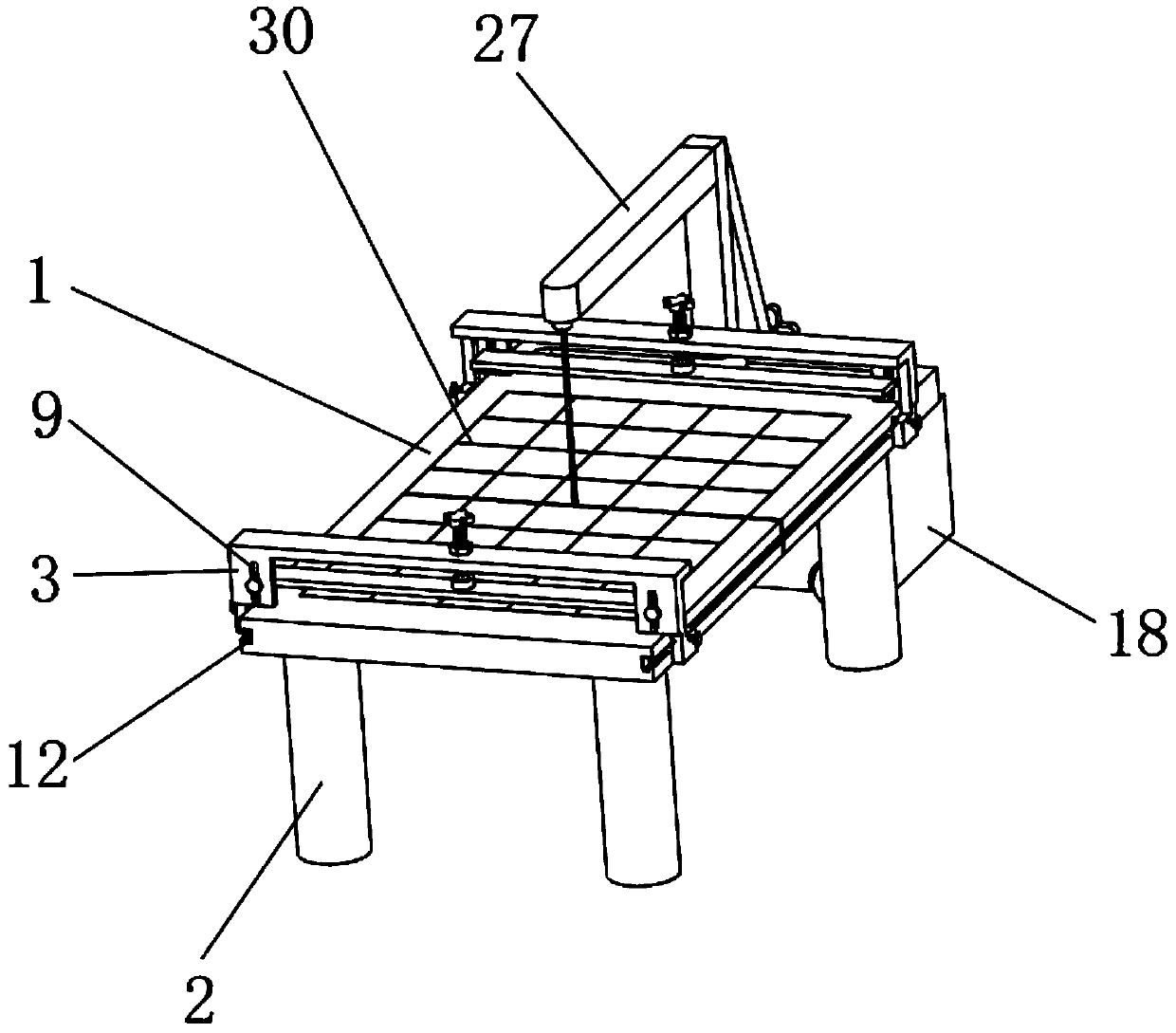

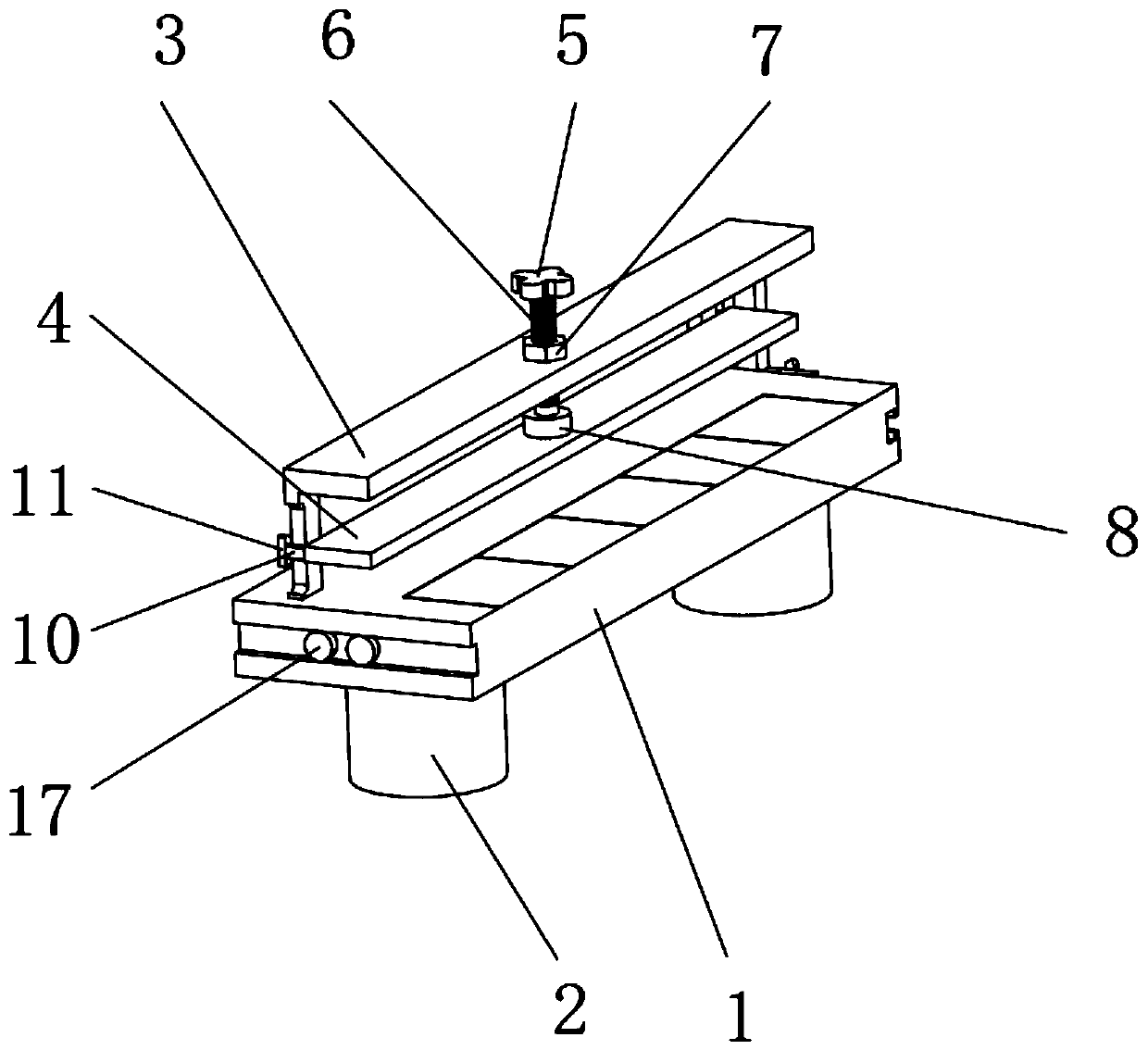

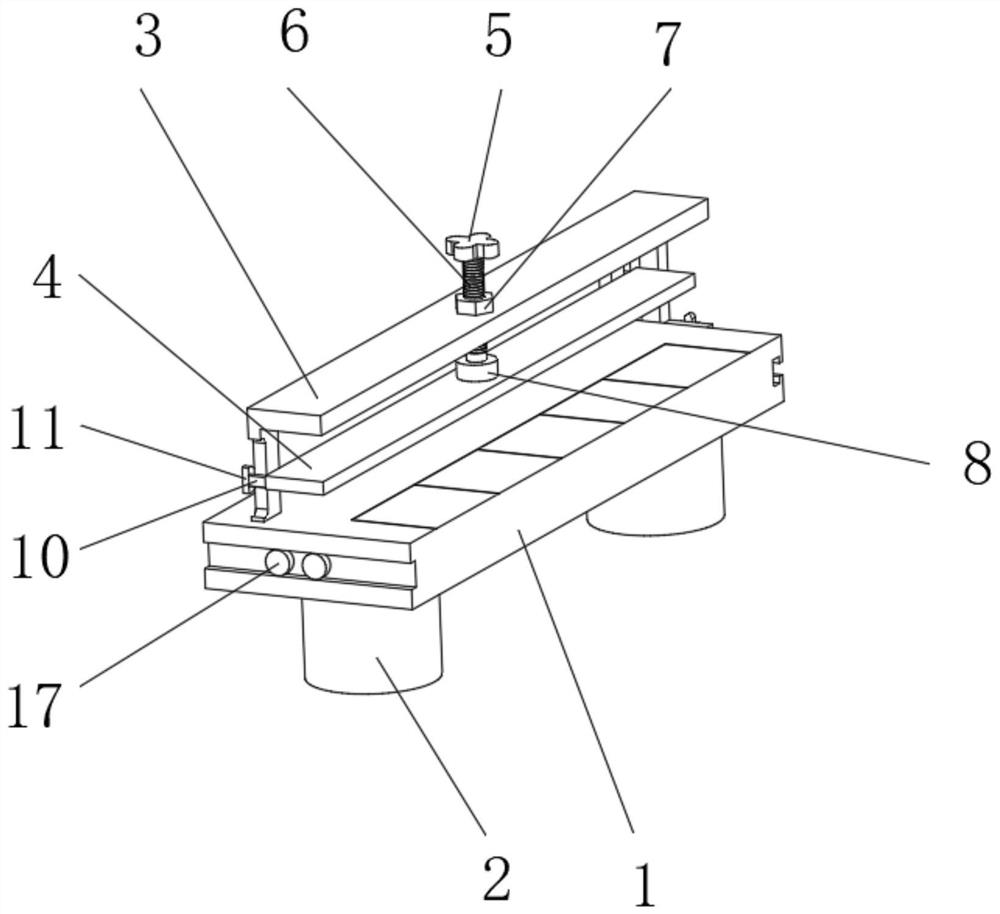

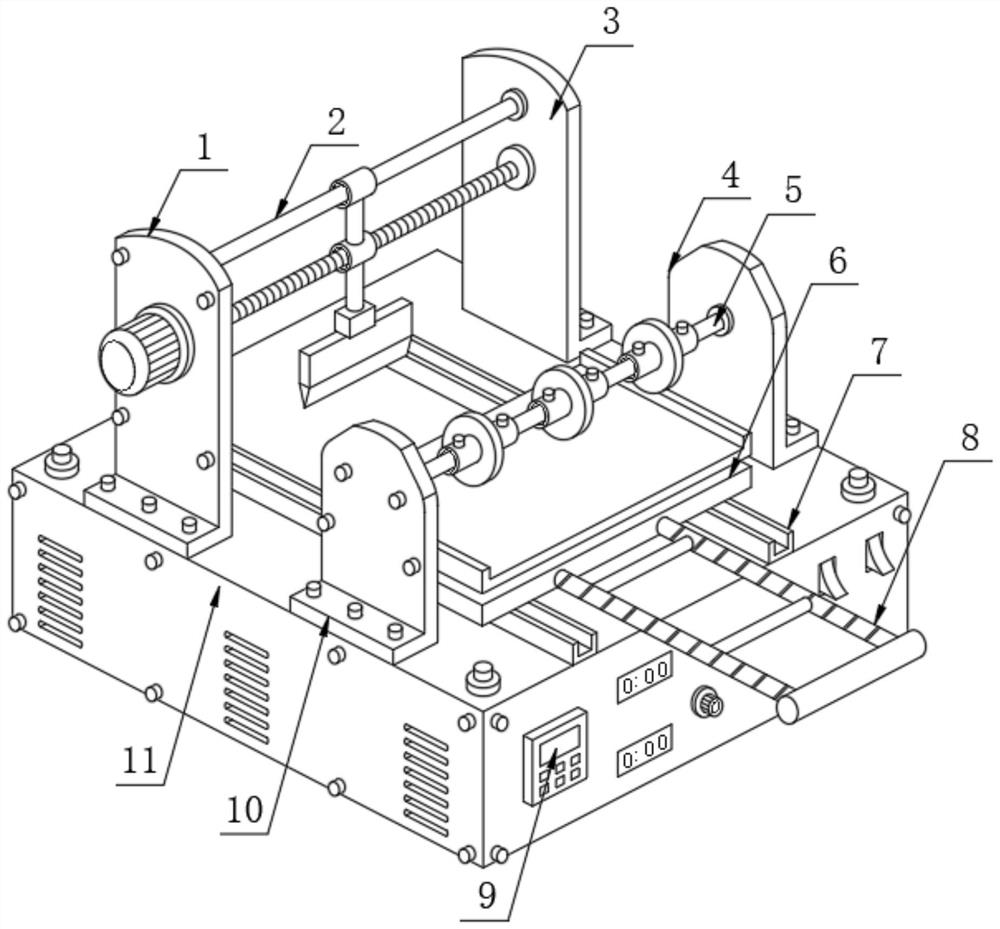

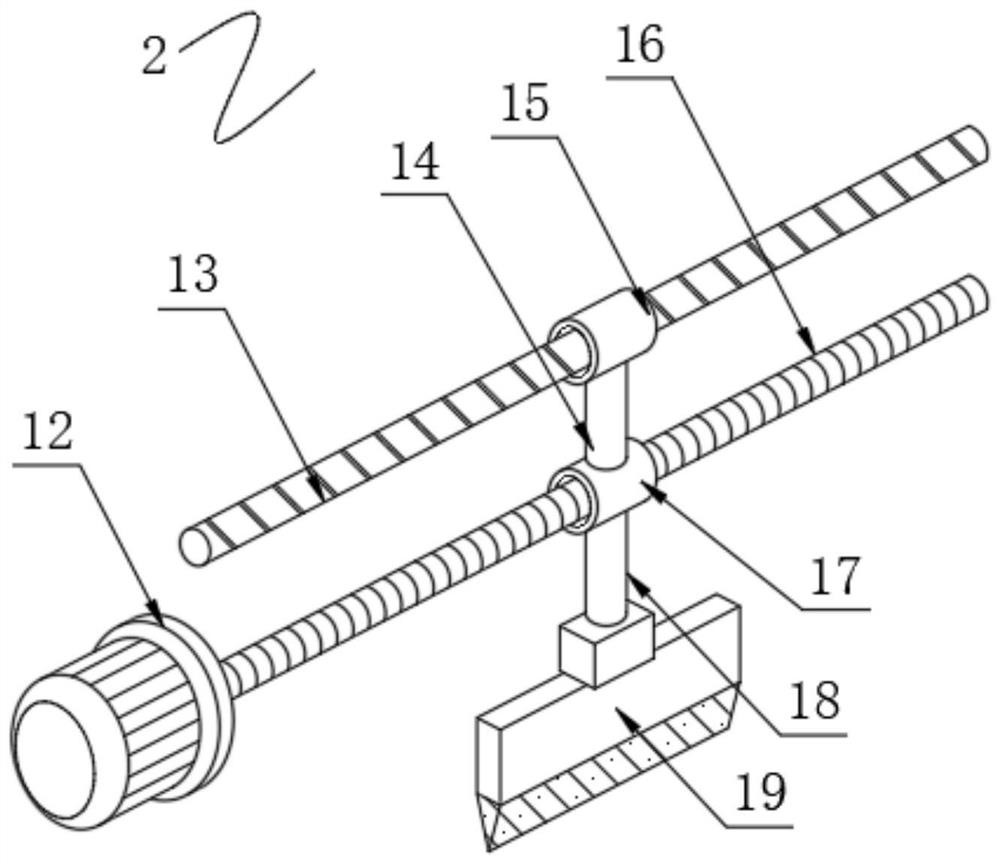

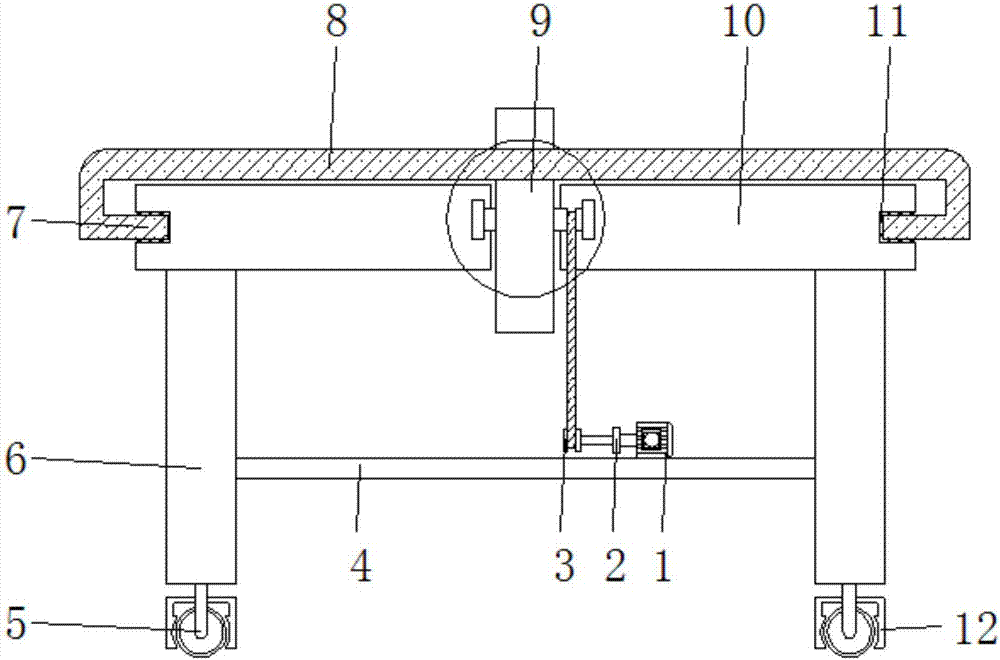

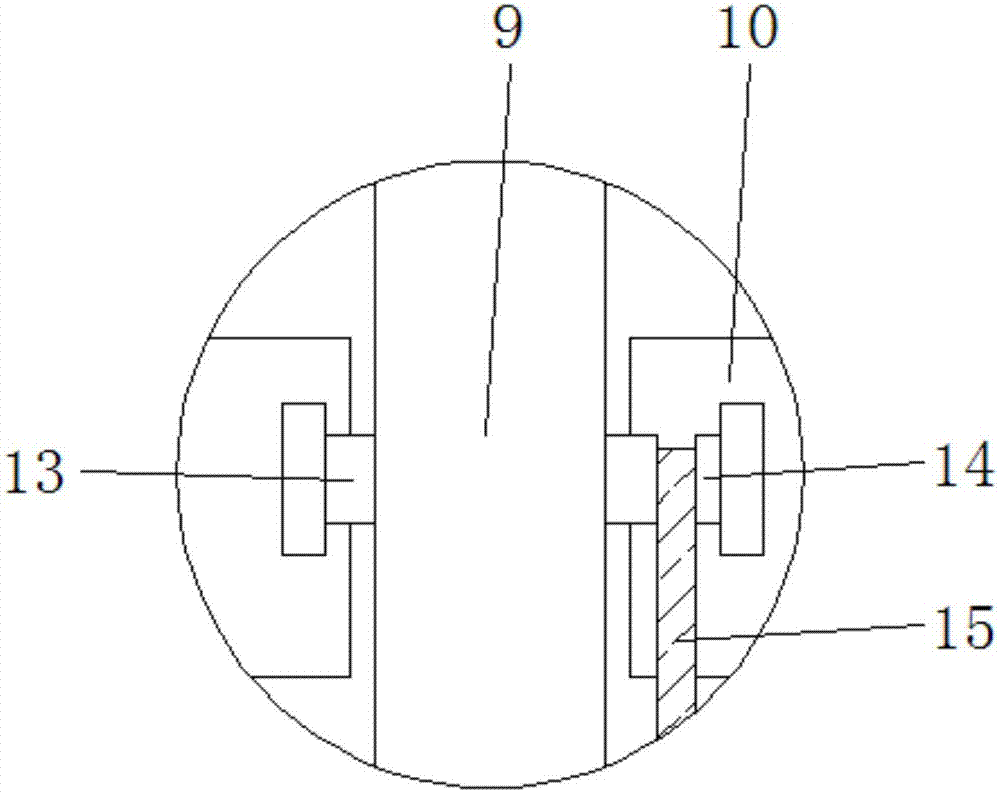

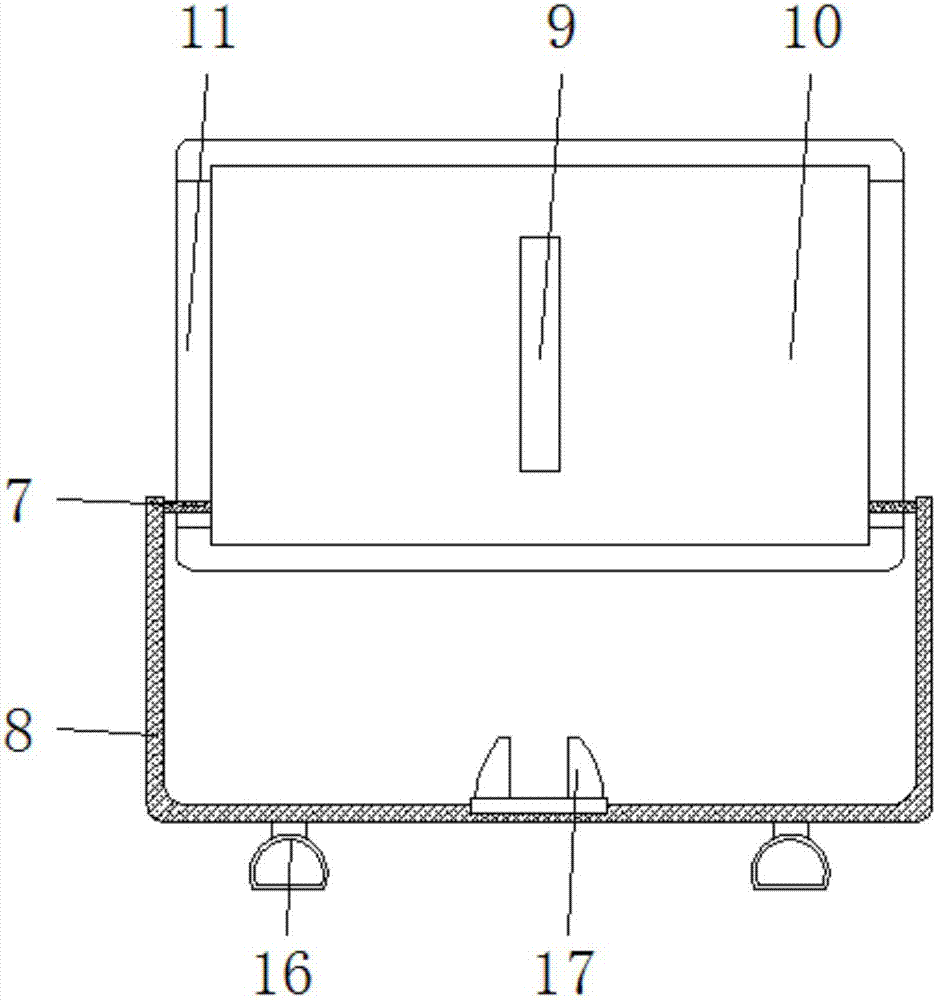

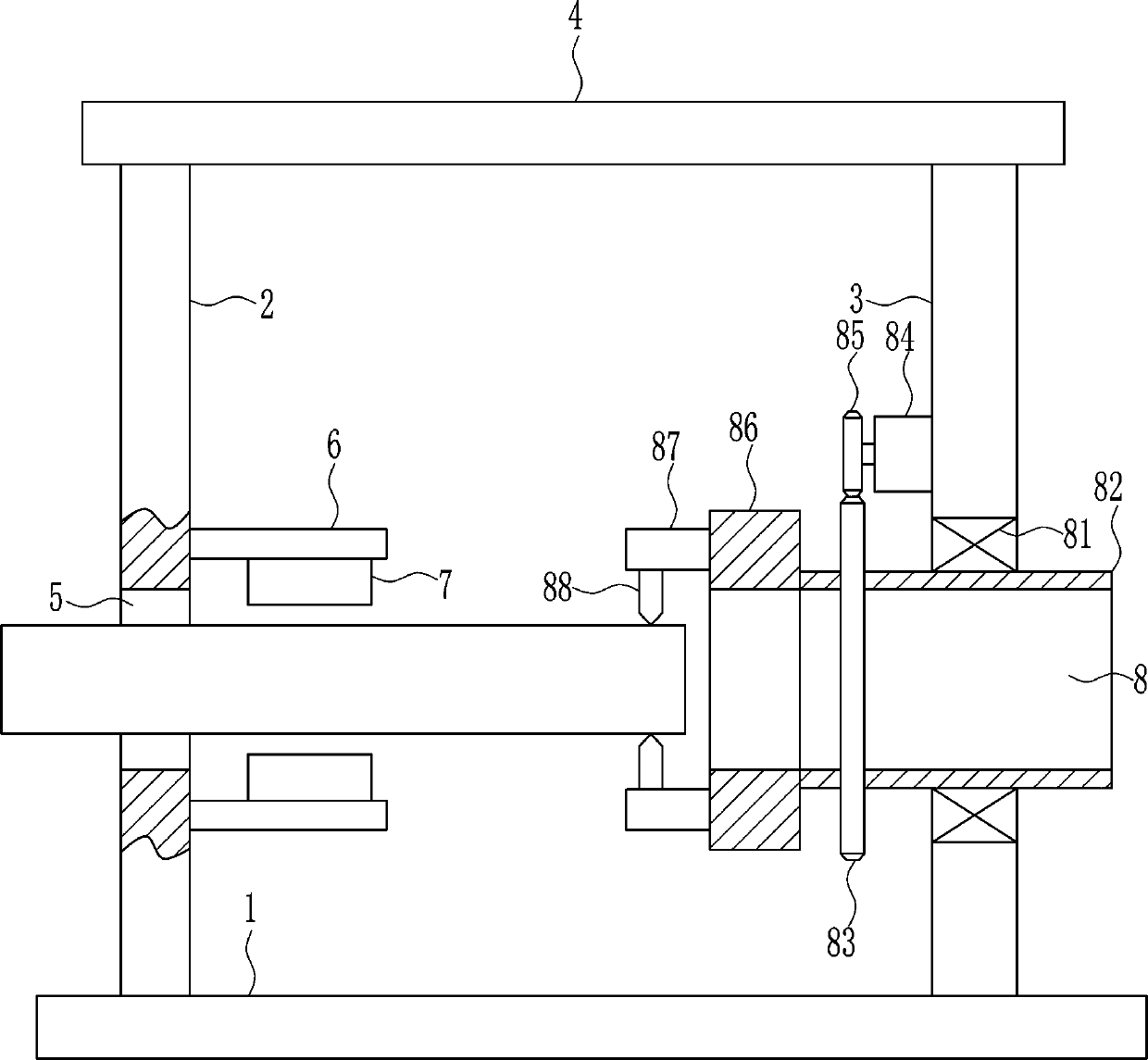

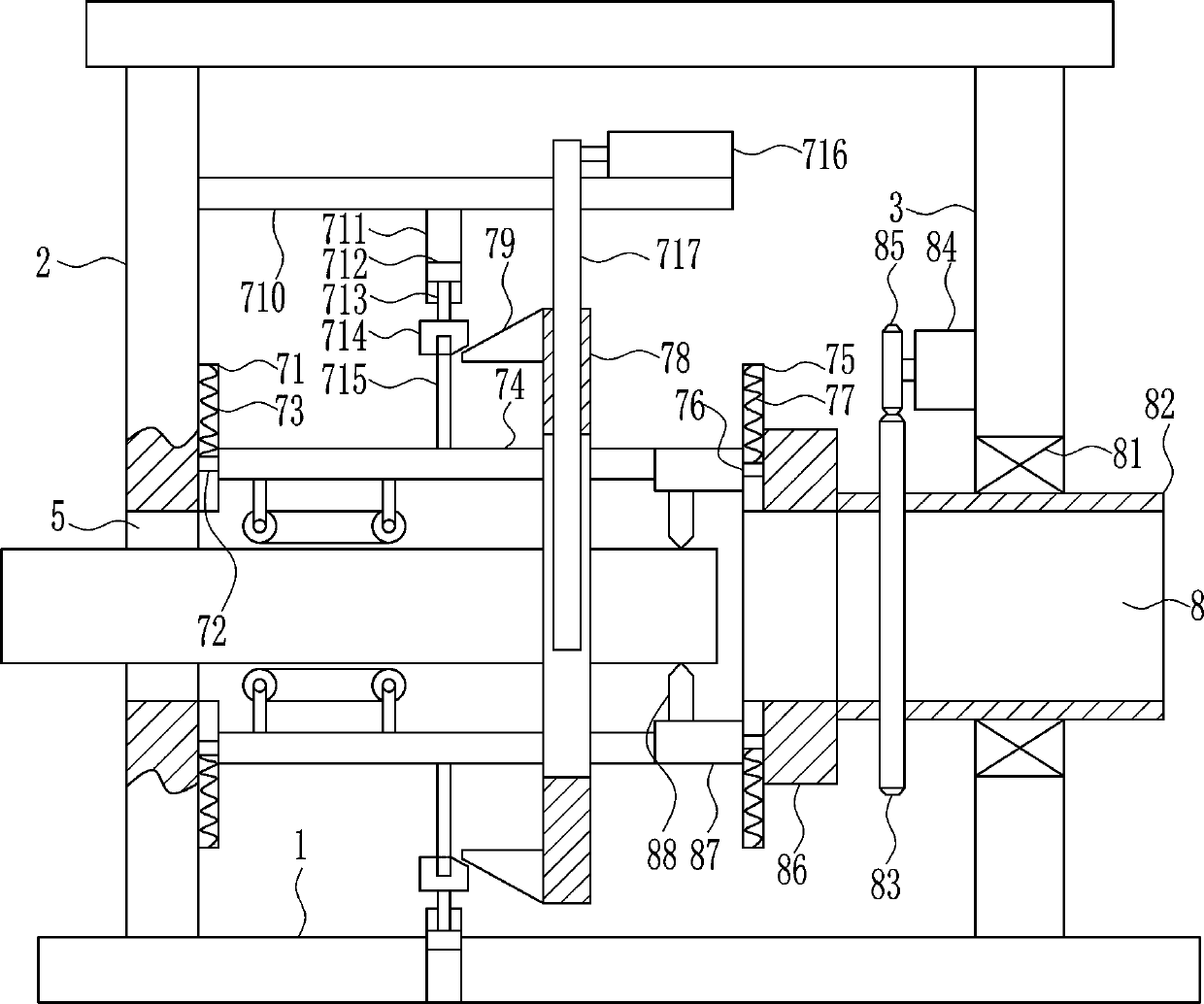

Heat-preservation material cutting machine capable of adjusting distance

InactiveCN107571307AOperation saves time and effortTo achieve the purpose of cuttingMetal working apparatusEngineeringMechanical engineering

The invention discloses a heat-preservation material cutting machine capable of adjusting the distance. The heat-preservation material cutting machine comprises a work table, to-be-cut heat-preservation materials are placed on two L-shaped plates of a groove, and a threaded rod squeezes a baffle by rotating a rotary button, so that the distance between the two L-shaped plates is adjusted. The heat-preservation materials of different sizes all can be placed, and the application range is increased. The cutting position of the heat-preservation materials can further be adjusted through a bolt, amotor and an air cylinder are started after adjusting is finished, and thus the cutting purpose can be achieved. After cutting is finished, the cut materials are removed. According to the heat-preservation material cutting machine capable of adjusting the distance, a second spring between two elastic rods can be squeezed, so that a transverse rod and the air cylinder are removed, and thus regulardetaching for detecting and maintaining can be achieved; in the mounting process, in a similar way, the squeezed elastic rods are moved into through holes and fixed to the lower side wall of a connecting rod under rebounding force of the second spring; and through the effect of a supporting beam, operation is stable, the distance between the L-shaped plates can be adjusted, and the application range is increased.

Owner:南京华域云脑信息科技有限公司

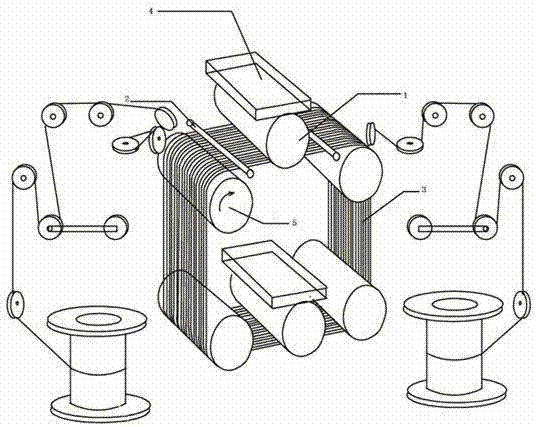

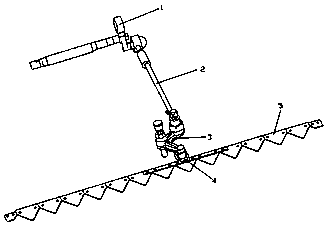

Process adopting extra-fine steel wire to cut silicon rod

The invention discloses a process adopting an extra-fine steel wire to cut a silicon rod. The process comprises the working procedures of preparing mortar, bonding the rod, loading the rod, carrying out preheating for cutting, carrying out cutting, discharging and the like. Parameters in the cutting process are set. The silicon rod can be cut into silicon wafers with the required size. According to the cutting process, the rate of forming the silicon wafers of each kilogram in a cutting mode can be effectively increased, the cutting ability is improved, cutting consumption and abrasion loss are reduced, and the cutting cost is lowered.

Owner:阳光硅谷电子科技有限公司

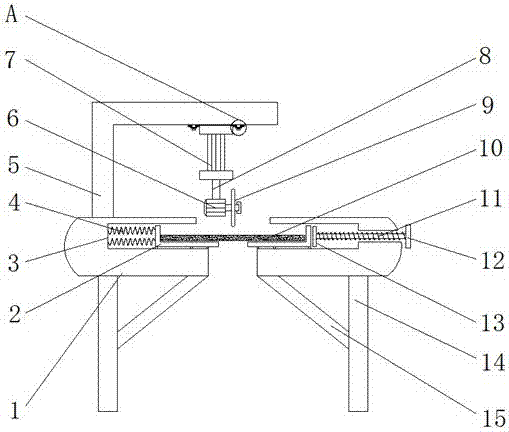

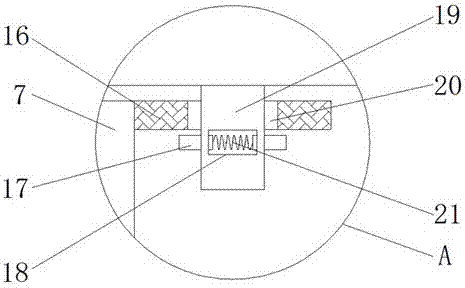

Novel industrial glass pipe cutting device

ActiveCN106746566AAchieve reductionHighly corrosiveGlass severing apparatusEngineeringBolt connection

The invention relates to a glass cutting device, in particular to a novel industrial glass pipe cutting device. The invention aims to solve the technical problem so as to provide the novel industrial glass pipe cutting device, which has less possibilities on damaging glass pipes and hurting workers or equipment when being used for cutting the glass pipes, and is time and labor saving during a cutting process. In order to solve the technical problem, the invention provides the novel industrial glass pipe cutting device, which comprises a bottom plate and the like, wherein a left support plate is arranged at the left side above the bottom plate in a welding way; a right support plate is arranged at the right side above the bottom plate in a welding way; a top plate is arranged on the upper ends of the left support plate and the right support plate through a welding way; a through hole is formed in the lower side of the left support plate; fixing plates are symmetrically arranged at the right side of the left support plate through a bolt connection way. The novel industrial glass pipe cutting device provided by the invention achieves the effects that the possibilities on damaging the glass pipes and hurting the workers or the equipment when being used for cutting the glass pipes are less, and the time and the labor are saved during the cutting process.

Owner:临泉县蓝天钢化玻璃有限公司

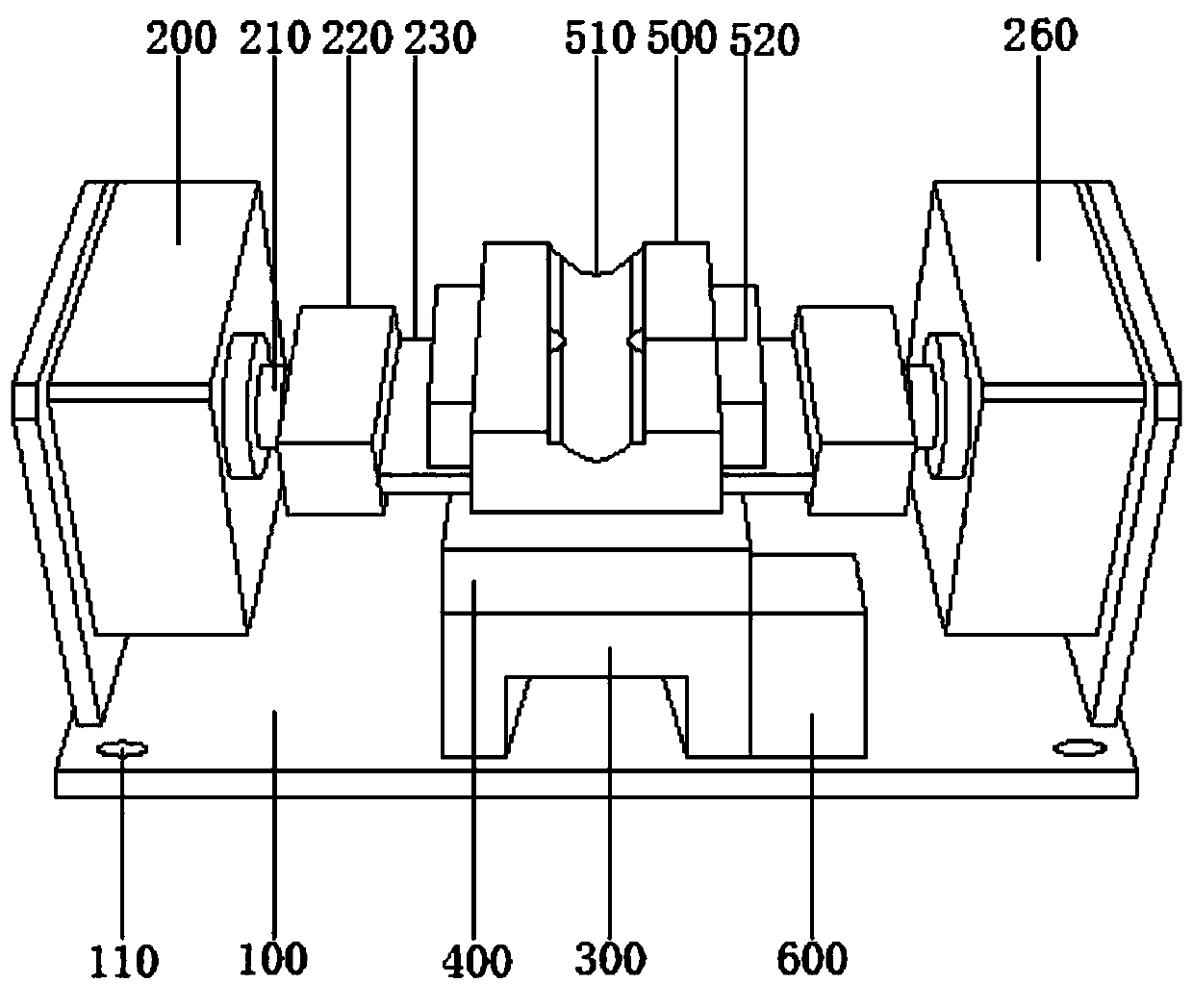

High-precision bearing production technology for rail transit

InactiveCN109465679AAvoid overlappingImprove machining accuracyGrinding work supportsVibration measurementMegasonic cleaning

The invention discloses a high-precision bearing production technology for rail transit. The high-precision bearing production technology comprises the following steps of: carrying out receiving inspection; selecting an outer / inner ring blank; carrying out heat treatment; grinding an outer / inner ring end face; carrying out centerless grinding on an excircle; carrying out fine grinding on the excircle; grinding the flange of an outer ring (grinding an inner ring raceway); grinding an outer ring raceway (grinding the flange of an inner ring and grinding the inner diameter); superfinishing the inner / outer ring raceway; cleaning; inspecting the inner / outer diameter; carrying out ultrasonic cleaning; sorting and assembling; assembling a roller; riveting and pressing; carrying out radial internal clearance inspection; carrying out vibration measurement; carrying out laser marking; cleaning a finished product; carrying out oil immersion and dust prevention; carrying out appearance inspection;packaging; carrying out causal inspection; and putting in a storehouse for storage. The high-precision bearing production technology has high processing efficiency, stable processing process, high processing quality and high precision.

Owner:柳州中通科技有限公司

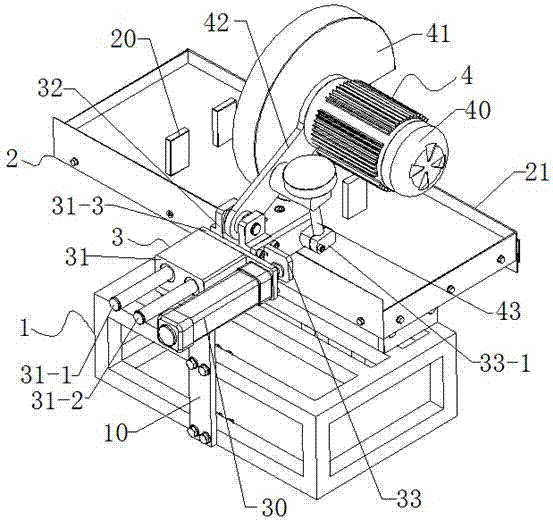

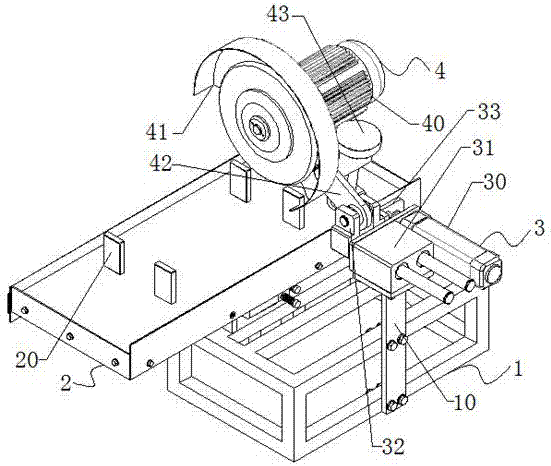

Cutting mechanism with clamping device

InactiveCN105478887AAchieve directional movementAchieve rotationShearing machine accessoriesDrive motorEngineering

The present invention discloses a cutting mechanism with a clamping device. The cutting mechanism comprises a base and a cutting mechanism. The cutting mechanism is disposed on the edge of the rear side of the base. A first drive motor is arranged at the left end of the upper surface of the base, and a second drive motor is arranged at the right end of the upper surface of the base. The output end of the first drive motor is connected with a first electric push rod, and the output end of the second drive motor is connected with a second electric push rod. A slide groove is further disposed on the upper surface of the base. Two slide blocks are disposed within the slide groove. Each slide block is provided with a vertical rotating shaft. Each rotating shaft is fixedly connected with a clamping plate. Each clamping plate comprises a flat surface and a curved surface. The present invention aims to provide the cutting mechanism with the clamping device, which solves the problem of the existing technology that the flat surface and the curved surface are difficultly simultaneously clamped by the cutter fixture for cutting, and realizes the aim of cutting the flat or curved workpieces with one set of device.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

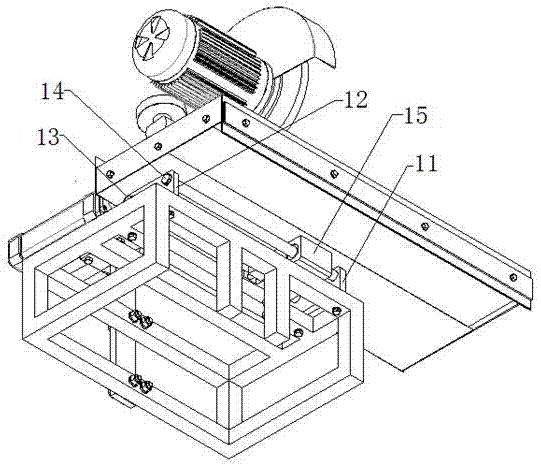

Wood cutting device

The invention discloses a wood cutting device, which relates to the field of wood processing equipment. The frame is fixedly connected, and the support frame is provided with a support plate one and a support plate two, and a slide bar one and a slide bar two are connected between the support plate one and the support plate two, and the slide bar one and the slide bar two A sliding seat is connected to the top, and the sliding seat can slide back and forth on the first slide bar and the second slide bar. The lower surface of the workbench is welded to the upper surface of the sliding seat. seat and push seat, the lower surface of the guide rail seat is welded to the upper surface of the support column, the guide rail seat is provided with guide rail one and guide rail two, and the cutting device includes a motor, a cutting knife and an adjusting knife holder. The structure of the present invention is simple, The overall use is safe and the cutting efficiency is high.

Owner:涟水县佳兴木材加工厂

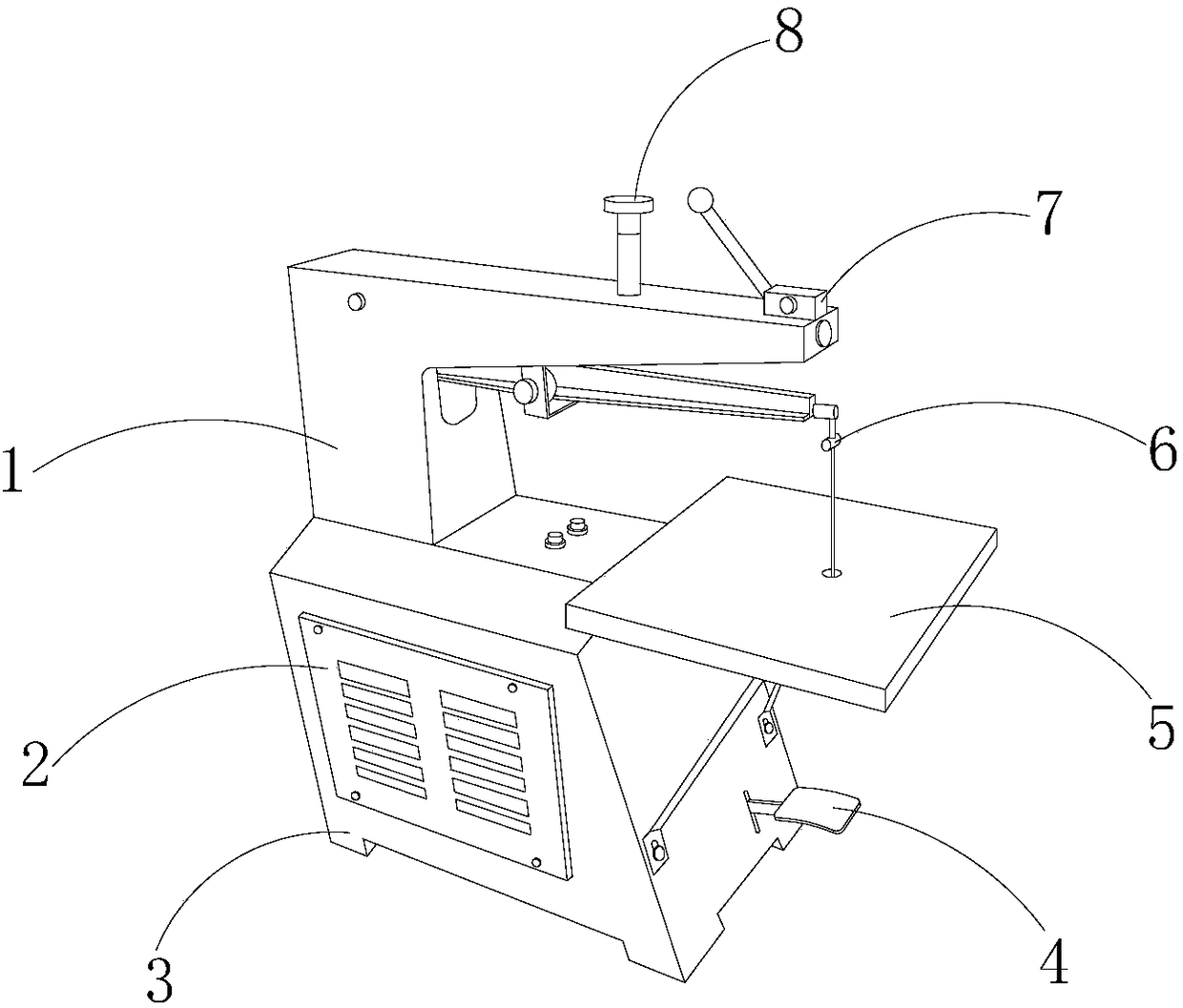

Diamond fret saw cutting equipment

InactiveCN108466377AHigh degree of automationIncrease line speedWorking accessoriesFine working devicesDiamond wire sawReciprocating motion

The invention discloses diamond fret saw cutting equipment which structurally comprises a cutting device, cooling devices, supporting bottom feet, a pedal, a workbench, a diamond fret saw, a loading and unloading fret saw spanner and a fret saw tightness adjusting rotary knob. The cutting device is high in automation degree and high in linear speed. When a workpiece is constantly rotated, the diamond fret saw makes point contact with the workpiece for cutting, the working way is simple and rapid, the labor intensity of workers is greatly reduced, and therefore the cutting purpose is achieved.After a worker starts a power switch, a driving motor drives a second gear to rotate in a reciprocating mode, a first gear is pulled by a pull rope to do reciprocating motion, at the moment, the firstgear drives a first pulley and a second pulley to rotate, and the rotating direction is made to face one direction always.

Owner:FOSHAN KERUIFEI NEW ENERGY TECH CO LTD

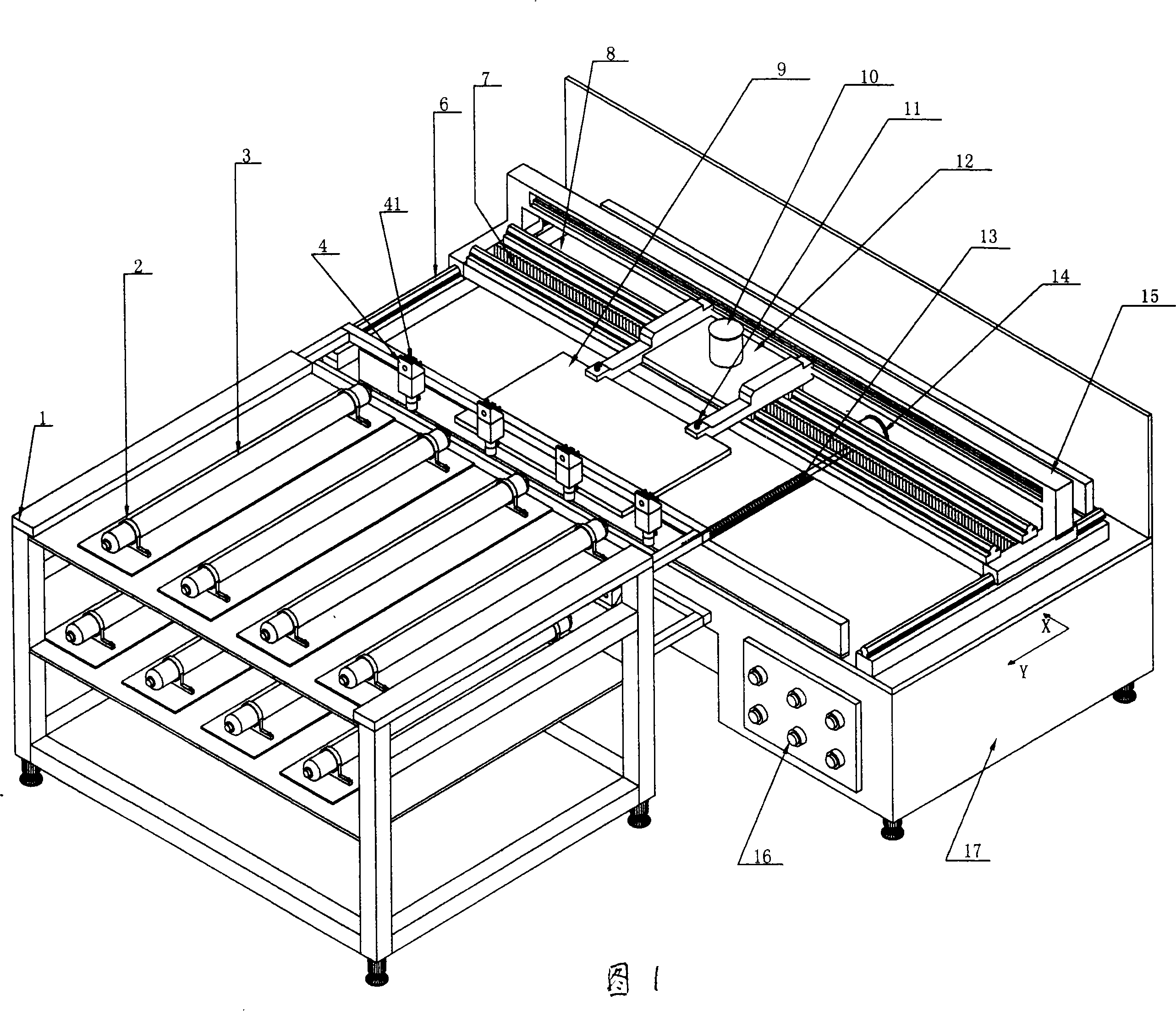

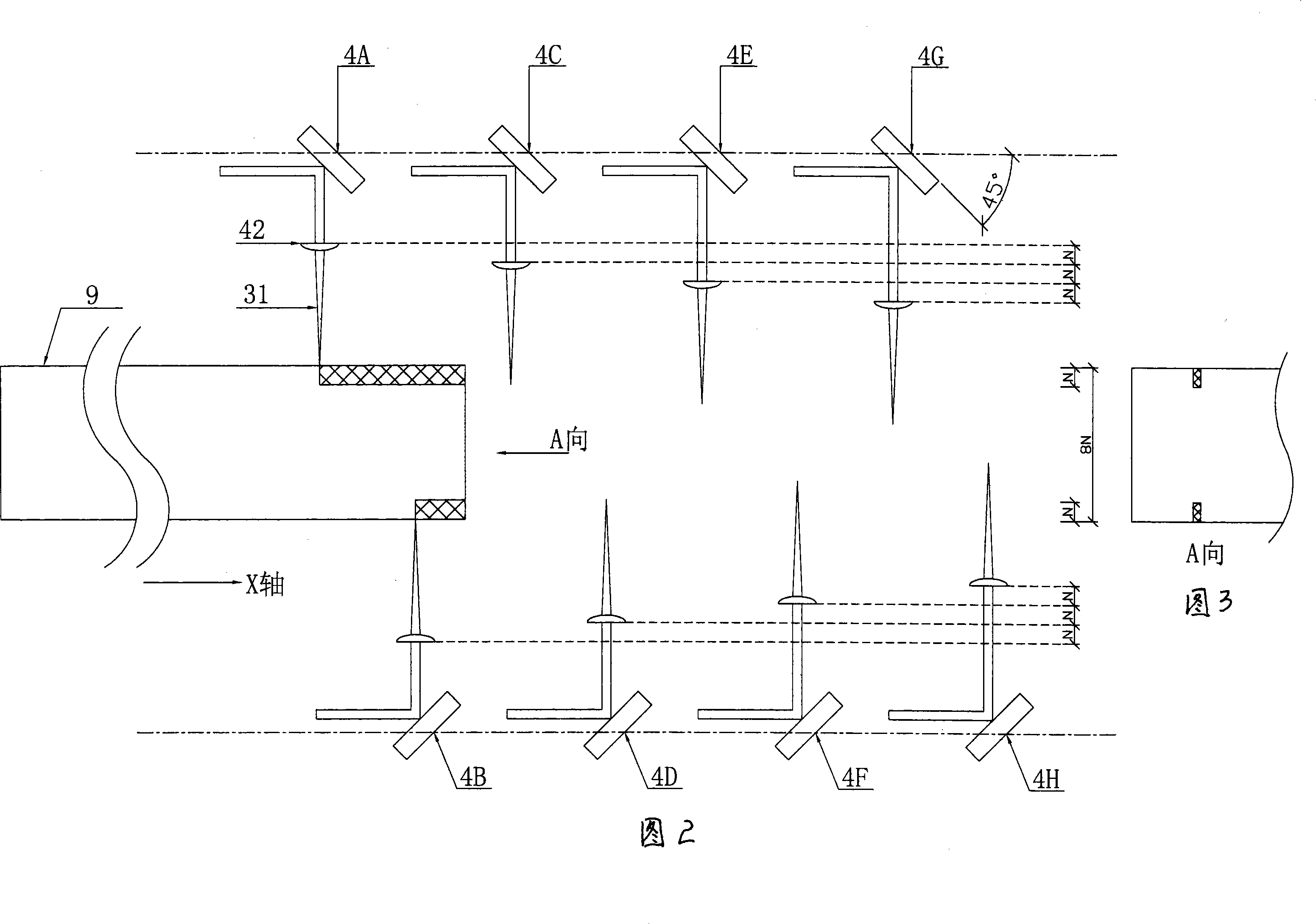

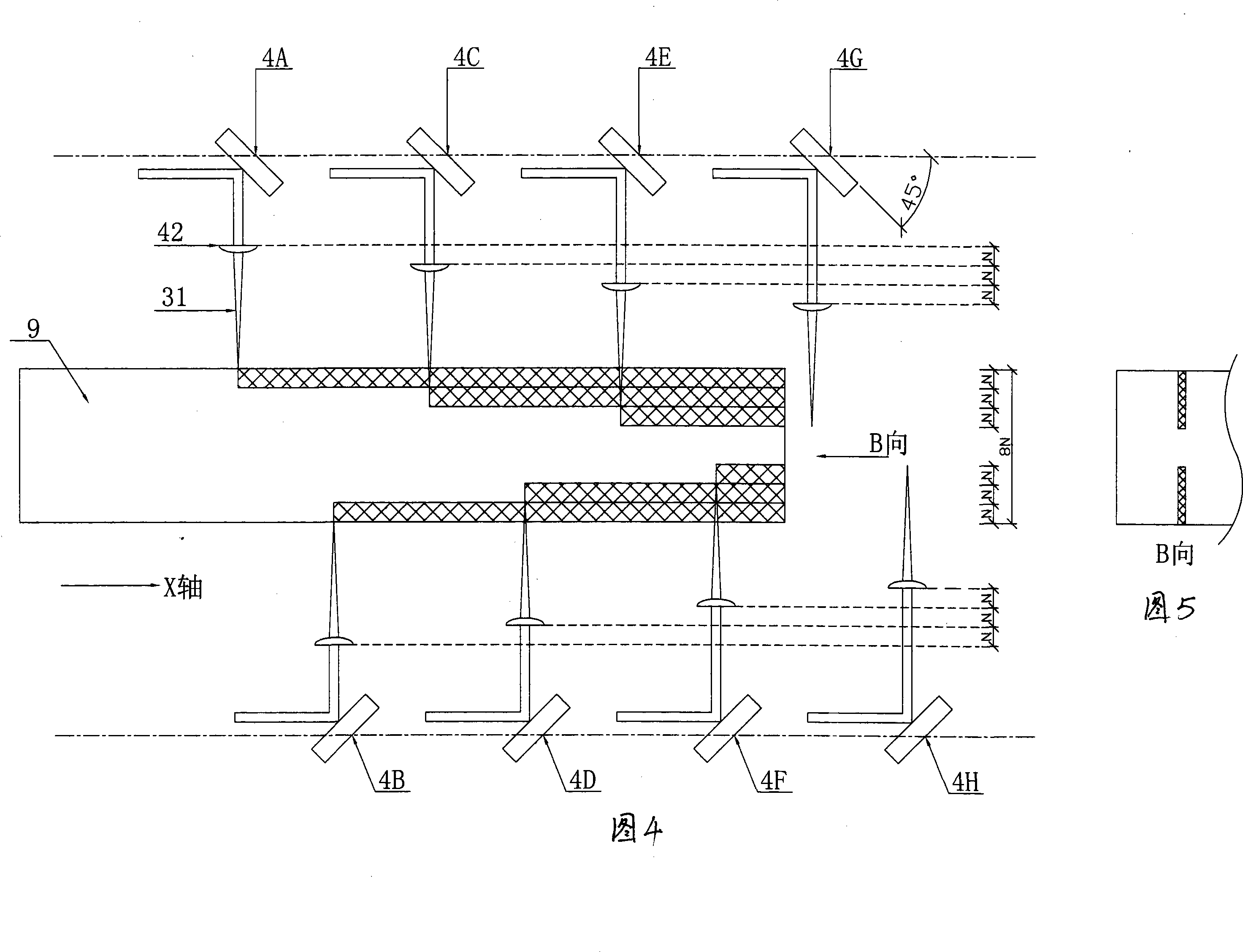

A method for processing straight-grained wood using laser cutting

InactiveCN101157234AIncrease profitImprove machining accuracyWood charring/burningLight beamLaser cutting

The invention discloses a method for processing straight line lumber by using a laser. The invention comprises a material feeding mechanism and a laser cutting mechanism, a plurality of groups of laser cutting mechanisms with the power of 10Watt or 100Watt grades which are arranged on the work piece travel, each laser head emits a laser beam simultaneously, and the center points are positioned on the same cutting plane, the work piece is pushed in a straight line to pass through each laser head, a first group laser beam cuts on the work piece to generate a first layer of cutting slot, a second group laser beam cuts to generate a second layer of cutting slot on the base of a first cutting slot of the work piece, a third group laser beam cuts to generate a third layer of cutting slot on the base of a second cutting slot of the work piece, after passing through the plurality of groups of laser heads, the total depth of the cutting slot of the accumulated cutting on the work piece of the laser beam is larger than or equal to the depth of the work piece, the work piece is completely cut, and the next cutting is performed in circulation. The design of the invention has the advantages that the manufacture cost and the price cost are low, the processing precision is high, and the cutting efficiency is high, and the invention is very suitable for the straight line cutting processing of slice material in the decoration and furniture processing industry.

Owner:陈伟良

Aluminum wire layer stripper

PendingCN111064133AFast peeling and cuttingTo achieve the purpose of cuttingApparatus for removing/armouring cablesWire rodStructural engineering

The embodiment of the invention discloses an aluminum wire layer stripper. The stripper comprises a clamping device, a rotating device and a cutting device, a cable is clamped and fixed through the clamping device, the size of a clamping opening can be adjusted through a clamping opening adjusting mechanism to adapt to wires with different specifications, and external rotating torque is transmitted to the cutting device through the rotating device to drive the cutting device to rotate so as to cut an aluminum wire layer on the outer edge of the cable. The stripper does not need manual operation, is high in stripping and cutting speed, is not prone to causing the problem of strand loosening, is suitable for wires of various specifications, does not need to be provided with a plurality of dies, is compact in overall structural design, can achieve the purpose of cutting in an extremely small space, and is simple and effective.

Owner:BEIJING TIANZE ELECTRIC POWER GRP CO LTD

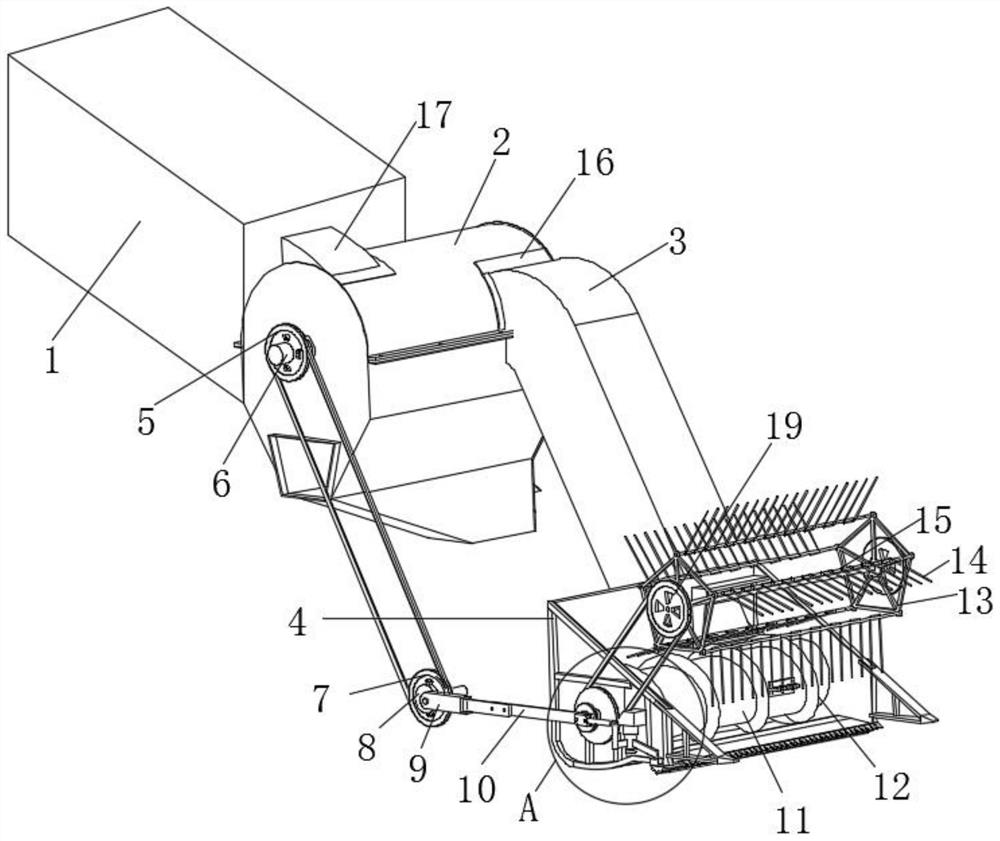

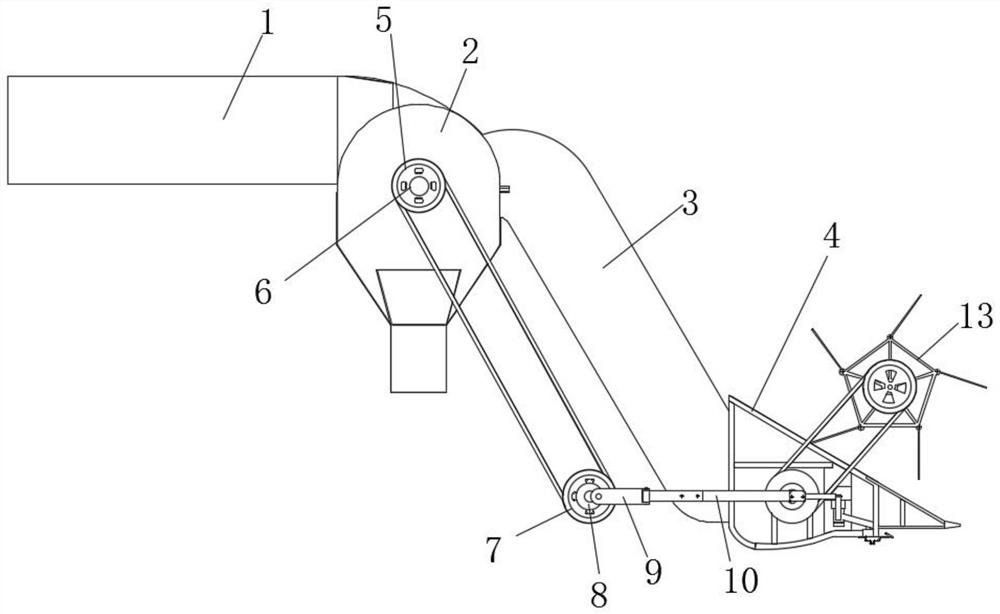

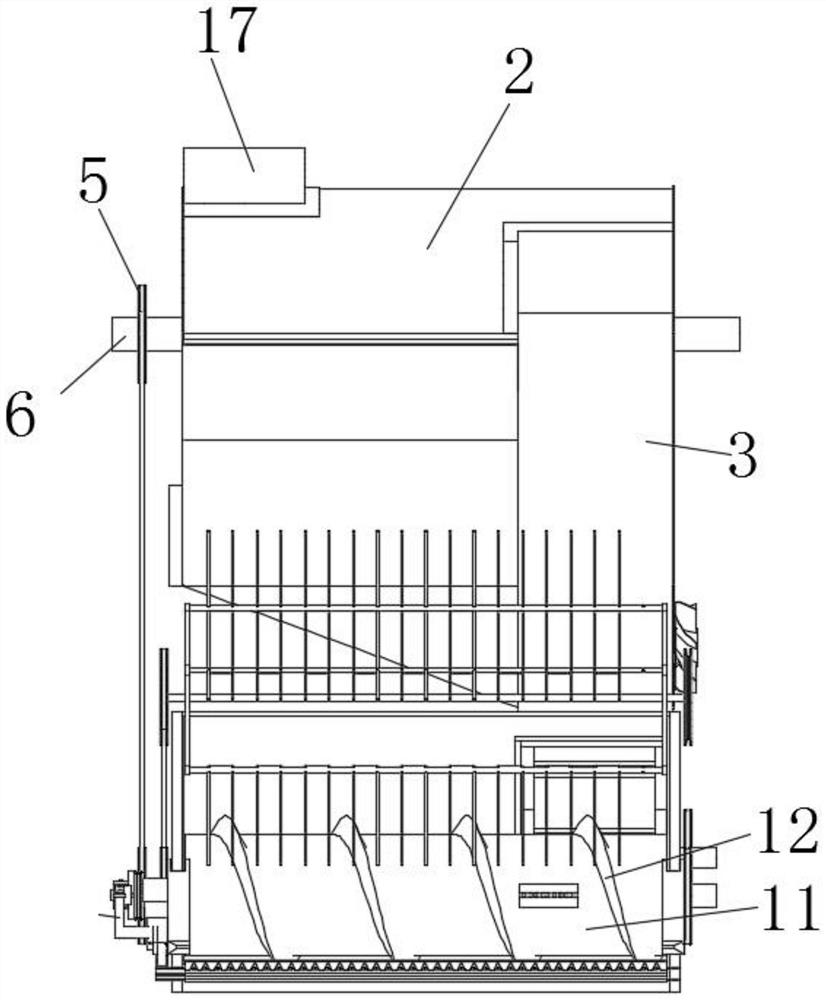

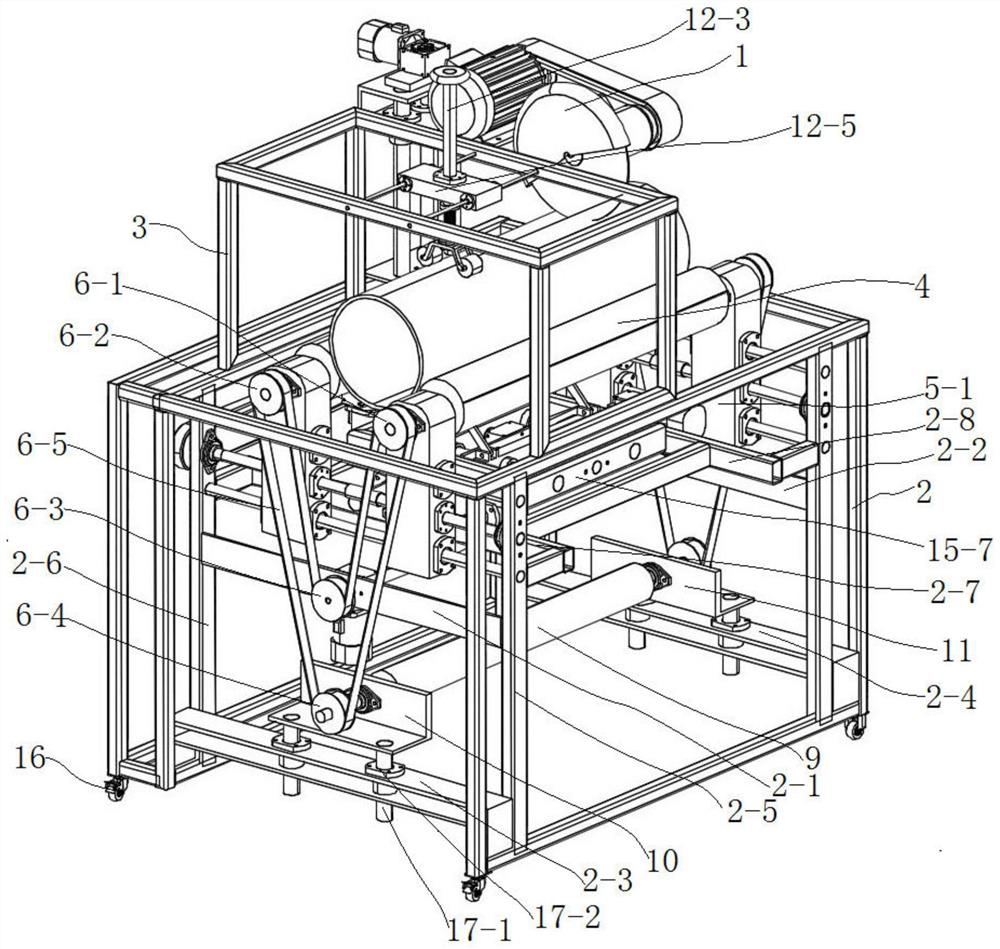

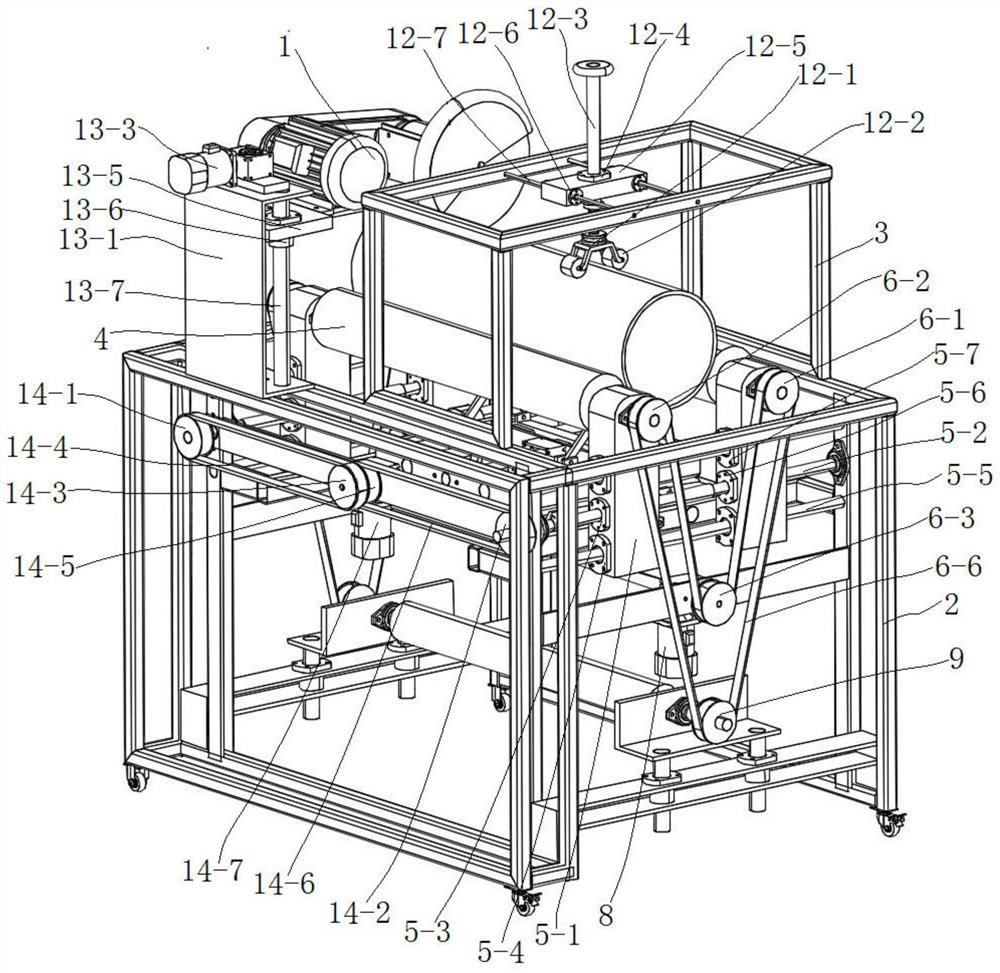

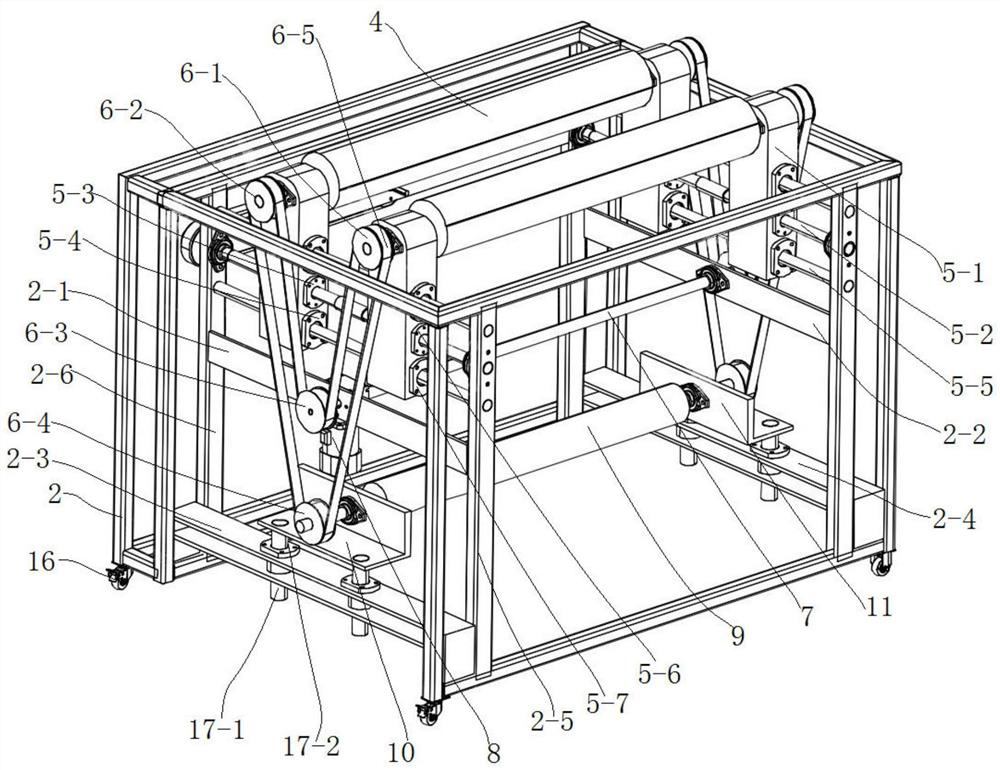

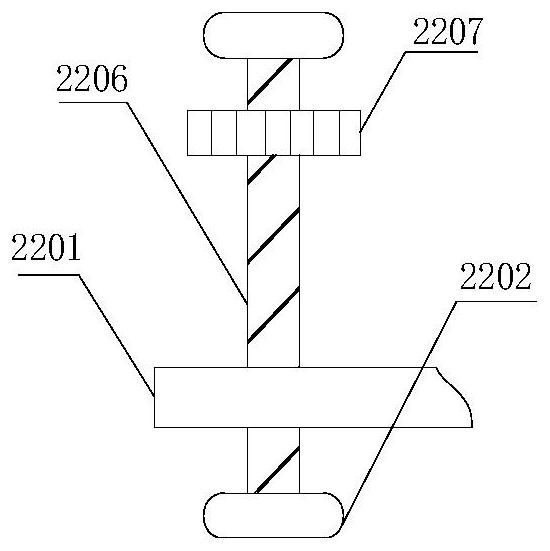

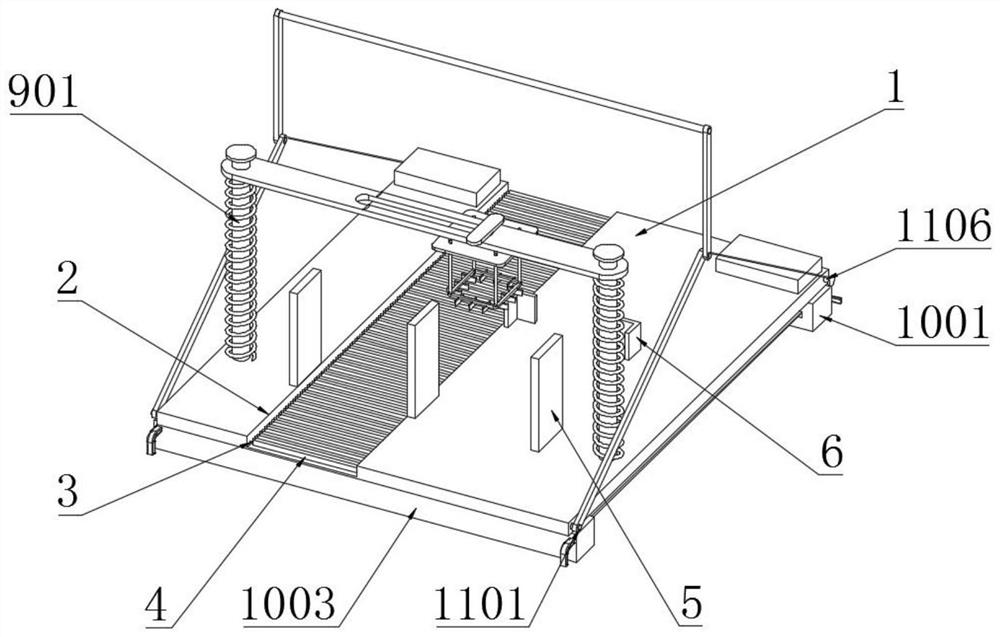

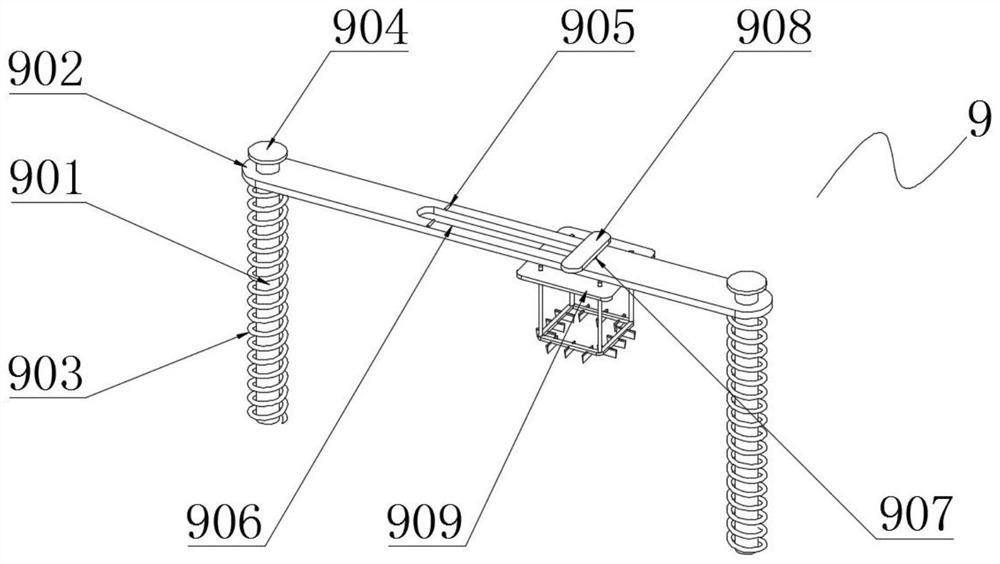

Crop straw harvesting and bundling machine and working method thereof

ActiveCN112425350ATo achieve the purpose of cuttingRealize the delivery workReaper-bindersAgricultural scienceAgricultural engineering

The invention discloses a crop straw harvesting and bundling machine. The machine comprises a crushed material bundling box and a material collecting box, a crushed material pipe is arranged at one end of the top of the material collecting box, the crushed material bundling box is arranged at one side of the material collecting box, the material collecting box communicates with the crushed material bundling box through the crushed material pipe, and a feeding port is formed at the side wall of one end of the material collecting box; and a conveying frame is arranged at one side of the bottom of the feeding port, after crop straw enters the material collecting box, a driving wheel drives a crushing wheel to rotate through a belt, a crushing shaft is driven to rotate through rotation of thecrushing wheel, the crop straw entering the material collecting box is crushed, and fruits and straw are separated. The fruits leak out through a leaking plate and are collected, the straw enters thecrushed material bundling box through the crushed material pipe to achieve bundling work, straw collecting and bundling work is conducted while the crop straw and the fruits are separated, straw scattering is avoided, straw centralized treatment is facilitated, and the phenomenon that traditional straw is not easy to treat and incinerate on site is avoided.

Owner:ANHUI DENGSHI MACHINERY MFG

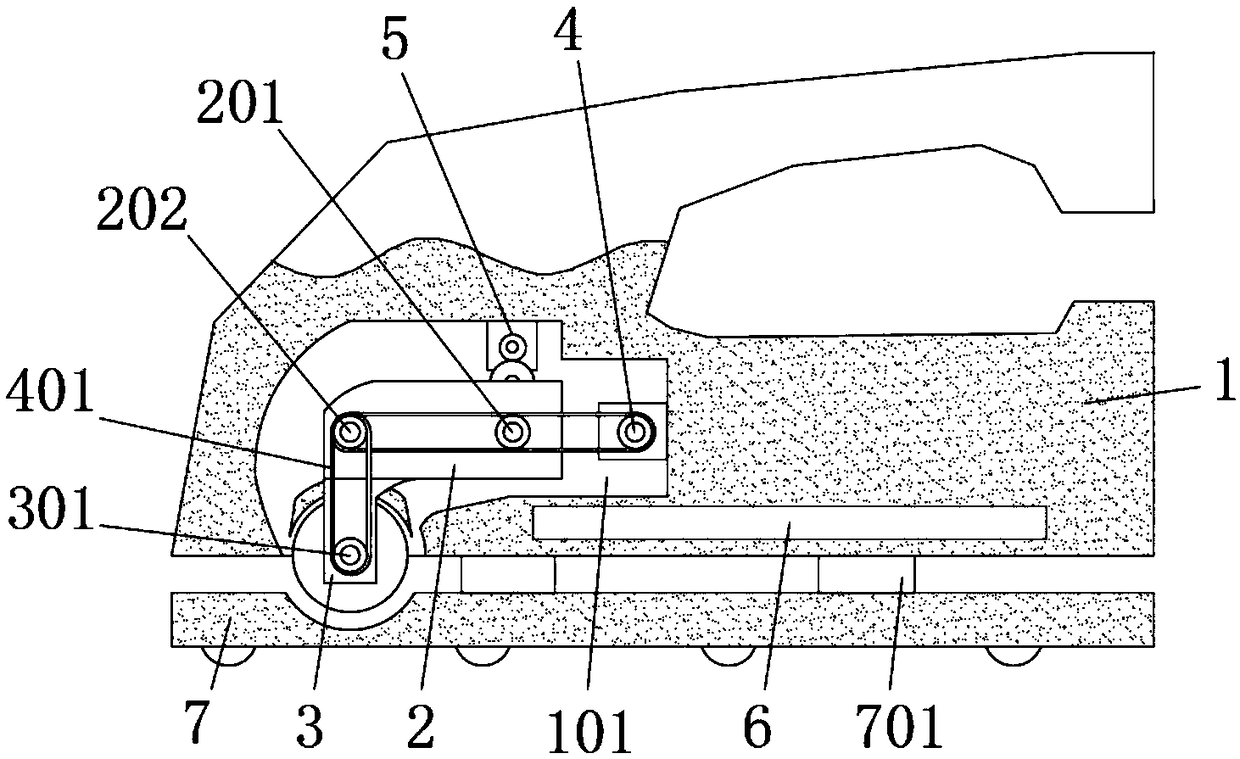

Hand-held clothes cutting device with positioning ranging rod

ActiveCN109023898AEasy to measure outRealize the purpose of shrinking the cutting knifeSevering textilesClothes making applicancesEngineering

The invention discloses a hand-held clothes cutting device with a positioning ranging rod, and relates to the technical field of clothes cutting. The hand-held clothes cutting device with a positioning ranging rod includes a casing, wherein a first groove is formed in one end of the casing; a mounting box is arranged in the first groove; two sides of one end of the mounting box are movably connected to the casing through a transmission shaft; one end of the transmission shaft is fixedly connected with the mounting box, and the other end of the transmission shaft is movably connected to the casing; the transmission shaft is axially connected with a variable gear fixedly; a second motor is arranged at one side of the variable gear; and the second motor is fixedly connected with the casing. The hand-held clothes cutting device with a positioning ranging rod can drive the mounting box to rotate by setting the second motor and the transmission shaft to achieve the aim of shrinking a cutter,can drive the cutter to rotate through cooperative setting of a first rotating shaft, a second rotating shaft, a third rotating shaft and a belt to achieve the aim of cutting, can measure clothes bysetting the ranging rod, thus being convenient for measuring the size while cutting.

Owner:南通新华宁工艺服装有限公司

Flexible glass cutting device

InactiveCN111875244AAvoid scratchesReduce work intensityGlass severing apparatusCutting glassEngineering

The invention relates to the related field of glass processing, in particular to a flexible glass cutting device which comprises an installation frame, a cutting mechanism, an extrusion mechanism, a glass fixing mechanism and a convenient pushing mechanism. The cutting mechanism is installed on the extrusion mechanism in a sliding mode, and the extrusion mechanism is fixedly installed on the installation frame. The glass fixing mechanism is fixedly mounted on the installation frame, and the convenient pushing mechanism is fixedly mounted on the glass fixing mechanism. The device has the function of cutting glass with different sizes and thicknesses, has the function of cutting circles with different diameters, has the function of correcting and fixing the position of the glass, and has thefunction of conveniently pushing the glass on an operation table.

Owner:哈尔滨市阿城区胜达建筑材料厂

Slicing device for bread processing

PendingCN112692892ATo achieve the purpose of slicingEasy to assemble and disassembleMetal working apparatusElectric machineryEngineering

The invention belongs to the technical field of bread processing and slicing, and relates to a slicing device for bread processing, wherein the slicing device comprises a box, a first groove is formed in the bottom of the inner wall of the box, bearings are fixedly connected to the front side and the rear side of the inner wall of the first groove, rotating shafts are arranged in the bearings in a penetrating manner, and threaded columns are fixedly connected to the rotating shafts. The slicing device for bread processing has the beneficial effects that a driving motor in a driving assembly works, a driving gear and a driven gear can be driven to rotate in a meshed manner, then the threaded columns can be driven to rotate, threaded sleeves drive a slicing table to move front and back through connecting plates, and therefore the purpose of driving bread to move front and back is achieved; through the work of a heating lamp, the surface of a slicing knife can be heated, and excessive bread chippings caused by too low temperature of the slicing knife during bread cutting are avoided; and through the arrangement of a mounting cap, threaded connection and separation of the mounting cap and the slicing knife can be achieved, and convenient disassembly and assembly of the slicing knife can be achieved.

Owner:安徽麦吉食品有限公司

Cloth cutting device for clothing manufacture

ActiveCN110699941AImprove stabilityTo achieve the purpose of cuttingSevering textilesEngineeringHorizontal orientation

The invention discloses a cloth cutting device for clothing manufacture and relates to the technical field of cutting devices. In order to solve the problem of inflexible cutting position, the cloth cutting device for clothing manufacture specifically comprises a main body and a base, wherein a third sliding groove is formed in the outer wall of the top of the main body, four supporting legs whichare the same are welded to the outer wall of the bottom of the main body, four base rollers which are the same are connected to the bottom of the base through shafts, a first connecting frame is welded to the outer wall of the top of the base, and a cutting translation column is welded to one end of the first connecting frame. By arrangement of the third sliding groove, a cutting translation pulley and the base rollers, a cutting translation pulley can slide along the direction of the third sliding groove as required, so that the position of a cutting knife in the horizontal direction is adjusted, and a purpose of cutting materials through a pushing knife in a fixed state is achieved; the cross section of the cutting translation pulley is I-shaped, so that the stability of the cutting translation column in the vertical direction can be improved, and the stability of the cutting knife is improved.

Owner:湖南浚林服饰有限公司

A garment fabric cutting device

ActiveCN110699941BImprove stabilityTo achieve the purpose of cuttingSevering textilesIndustrial engineeringPulley

Owner:湖南浚林服饰有限公司

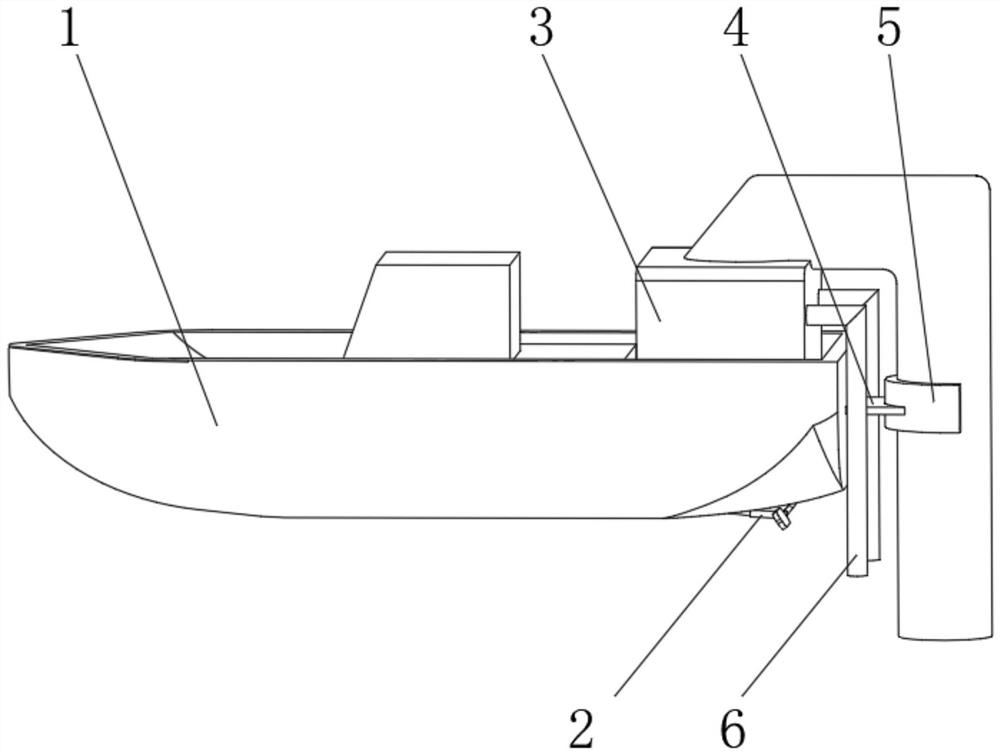

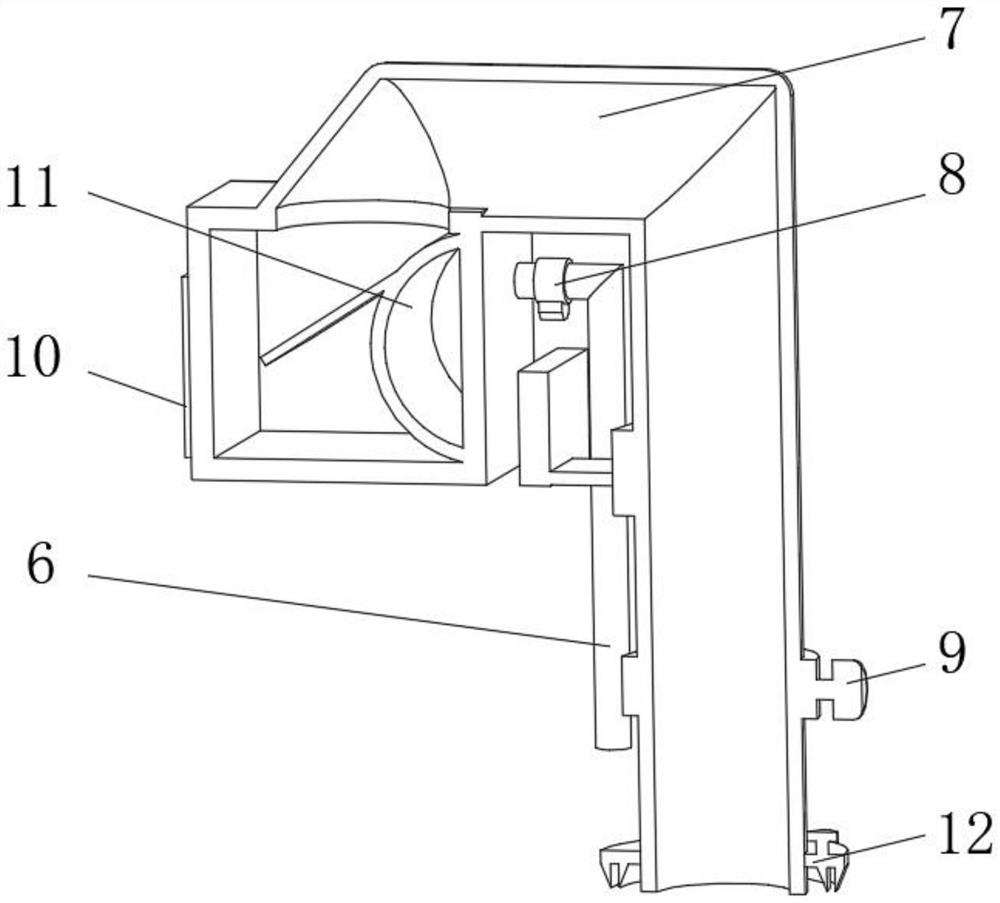

River channel dredging ship

InactiveCN113638460ATo achieve the purpose of cuttingGuaranteed to proceed normallyMechanical machines/dredgersMowersRiver routingFishery

The invention discloses a river channel dredging ship, and relates to the technical field of desilting. The river channel dredging ship comprises a ship body, wherein a driving propeller is installed at the bottom of the ship body, a collecting frame is fixedly connected to the inner side of the ship body, a fixing plate is fixedly connected to the outer side of the ship body, an arc-shaped limiting clamping plate is fixedly connected to the side, away from the ship body, of the fixing plate, the side, close to the fixing plate, of the collecting frame communicates with a water outlet pipe, the top of the collecting frame communicates with a feeding pipe, a water suction pump is installed at the position, close to the collecting frame, of the outer side of the water outlet pipe, a mud suction pump is installed at the position, away from the collecting frame, of the outer side of the feeding pipe, a material taking door is installed on the side, away from the water outlet pipe, of the collecting frame, and a filtering device is mounted on the inner wall of the collecting frame. According to the river channel dredging ship, the purpose of cutting entanglements such as underwater aquatic plants is achieved, normal dredging work is effectively guaranteed, and the dredging efficiency of the device is improved.

Owner:唐志奇

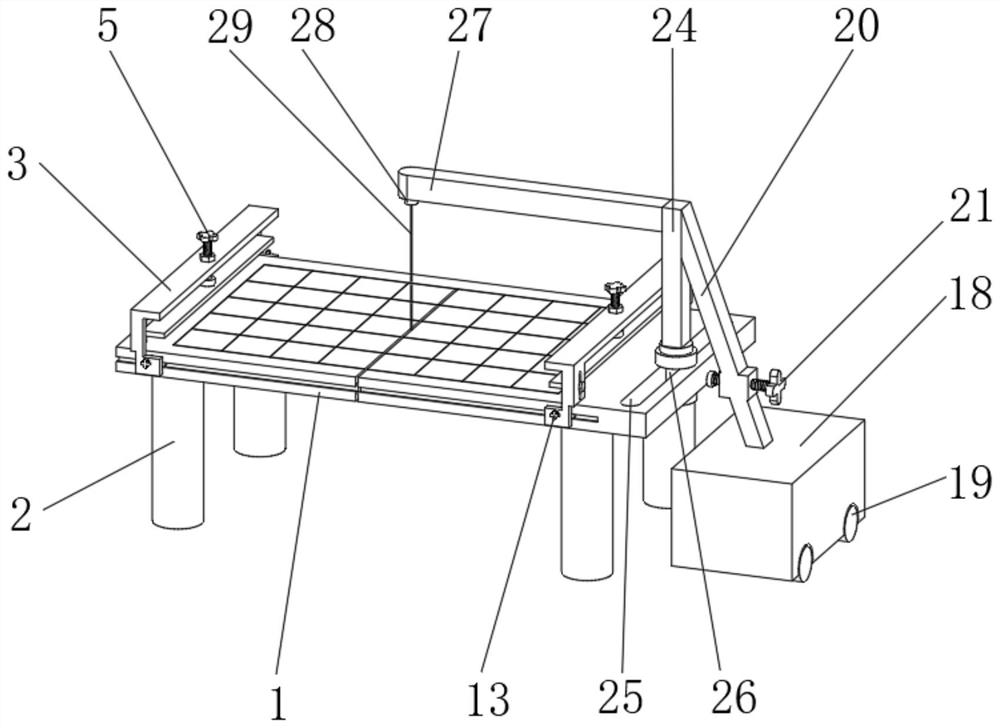

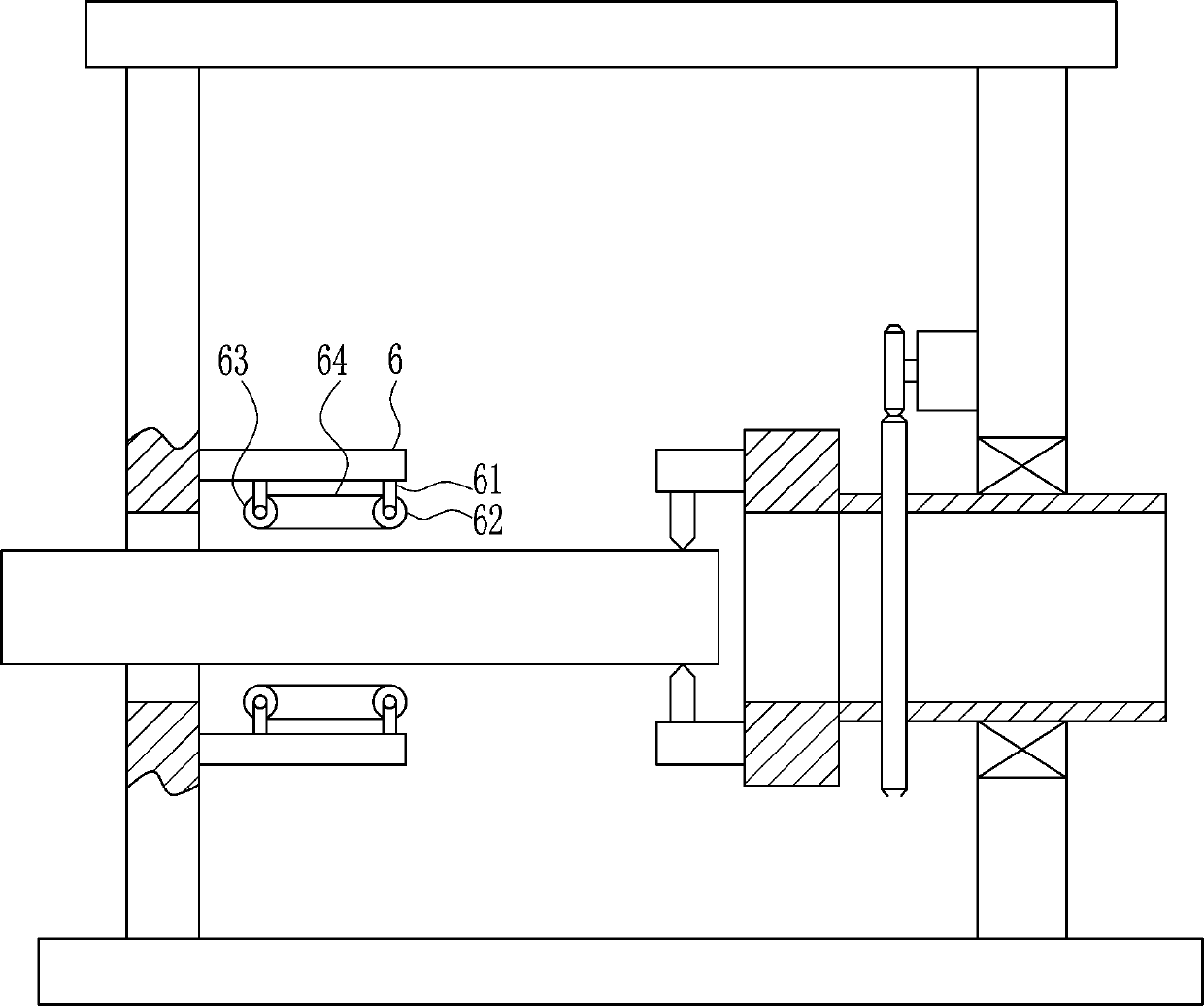

Cutting equipment for aluminum veneer and cutting process thereof

InactiveCN112008128AImprove efficiencyEnd face appearance is beautifulMilling equipment detailsPositioning apparatusStructural engineeringSingle plate

The invention discloses cutting equipment for an aluminum veneer and a cutting process thereof. The cutting equipment comprises a machine tool, a first moving mechanism, a cutting device, a first bottom plate, a first limiting plate, a second limiting plate, a positioning plate and a jig frame; the second limiting plate and the first limiting plate are horizontally and longitudinally arranged on the left half portion of the machine tool, a positioning plate is arranged between the second limiting plate and the first limiting plate, the positioning plate is matched with a square area defined bythe second limiting plate and the first limiting plate, and the jig frame is arranged on the positioning plate; the first moving mechanism is horizontally and longitudinally arranged at the right half part of the machine tool, and the first bottom plate is horizontally arranged on the first moving mechanism and is in sliding connection with the first moving mechanism; and the cutting device is arranged on the first bottom plate, and the cutting end of the cutting device is arranged vertically downwards and moves horizontal-transversely, horizontal-longitudinally and vertically up and down inthe square area. According to the cutting equipment, by arranging the first moving mechanism, the second moving mechanism and a third moving mechanism, three-dimensional cutting in the horizontal transverse direction, the horizontal longitudinal direction and the vertical direction is achieved, and the cutting efficiency is improved.

Owner:江苏佰大幕墙科技有限公司

A continuous cutting device for the production of paper-plastic bags

ActiveCN111362041BTo achieve the purpose of cuttingImprove cutting efficiencyArticle deliveryControl switchWorkbench

The invention relates to the technical field of paper-plastic bag production and cutting, and discloses a continuous cutting device for paper-plastic bag production. The first L-shaped bracket and the second L-shaped bracket are respectively fixed on the sides, the control switch is fixed on the front surface of the workbench, and the battery is fixed on the rear surface of the workbench. The first L-shaped bracket and the second L-shaped bracket The front side of the front side is provided with the 3rd L-shaped support and the 4th L-shaped support, is provided with the first cutting assembly between the first L-shaped support and the second L-shaped support, between the 3rd L-shaped support and the 4th L-shaped support A second cutting assembly is arranged between them, and a pushing assembly is connected above the square slide rail. The invention cuts the paper-plastic bag in the horizontal and vertical positions, can complete the cutting in a short time, and can achieve continuous cutting with high cutting efficiency.

Owner:安徽宜人医用包装有限公司

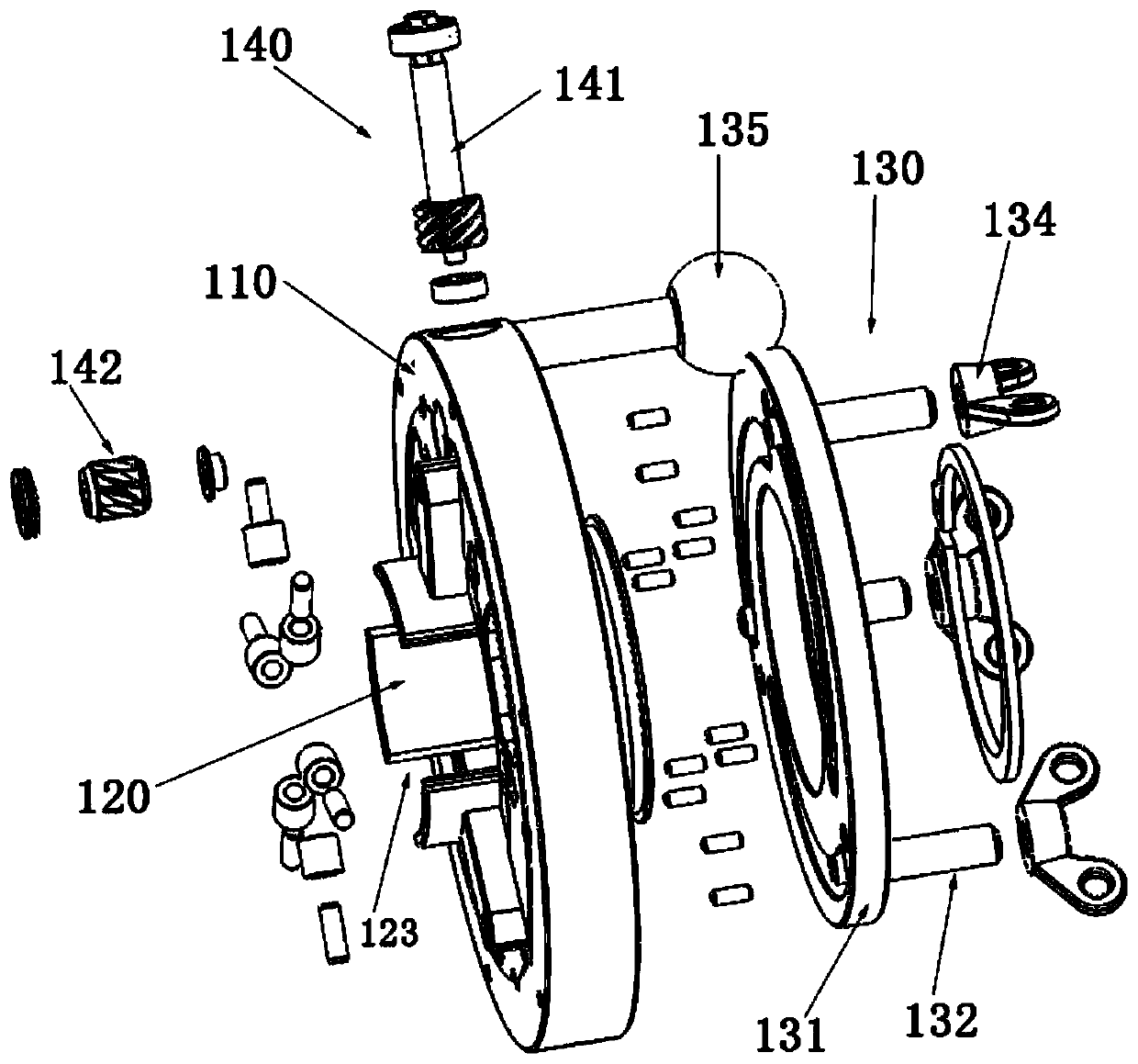

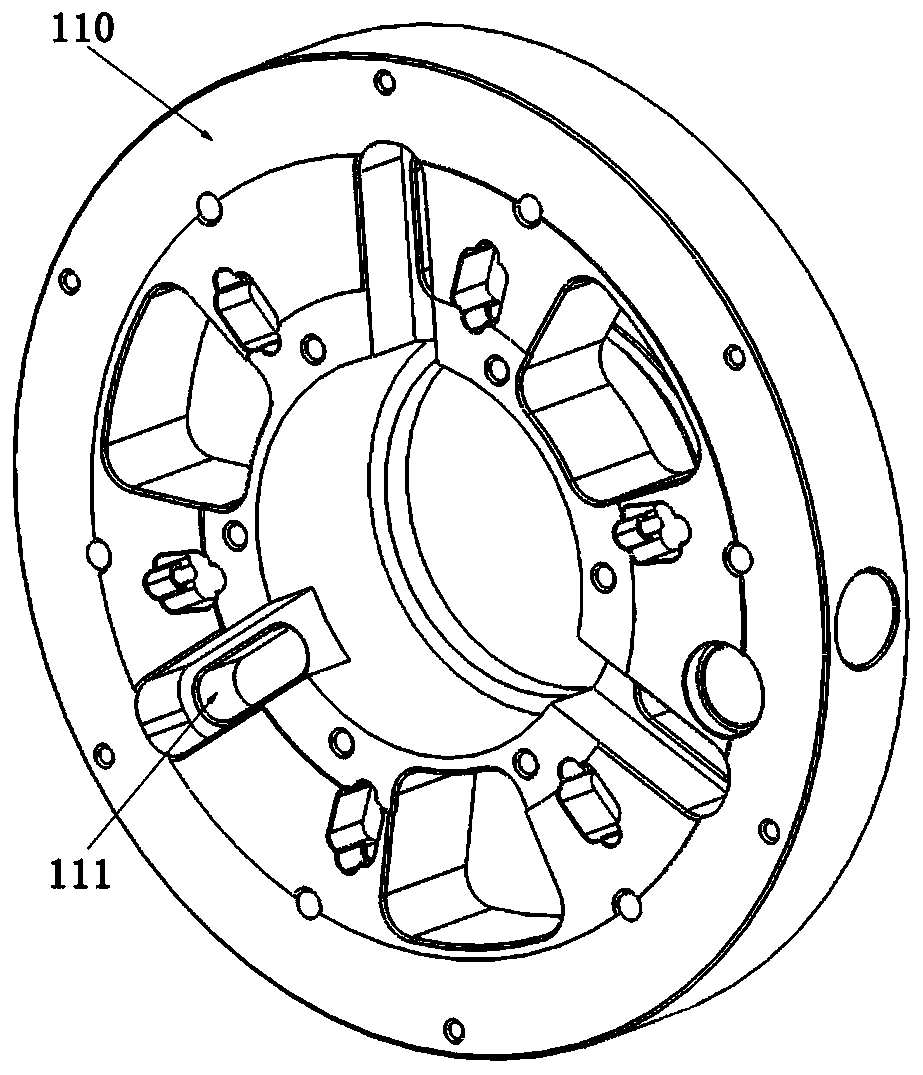

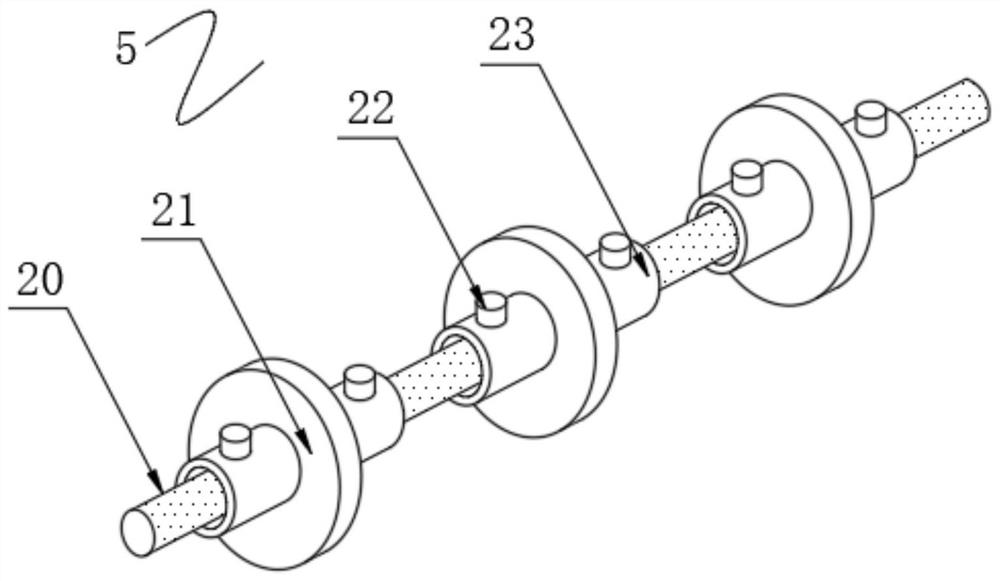

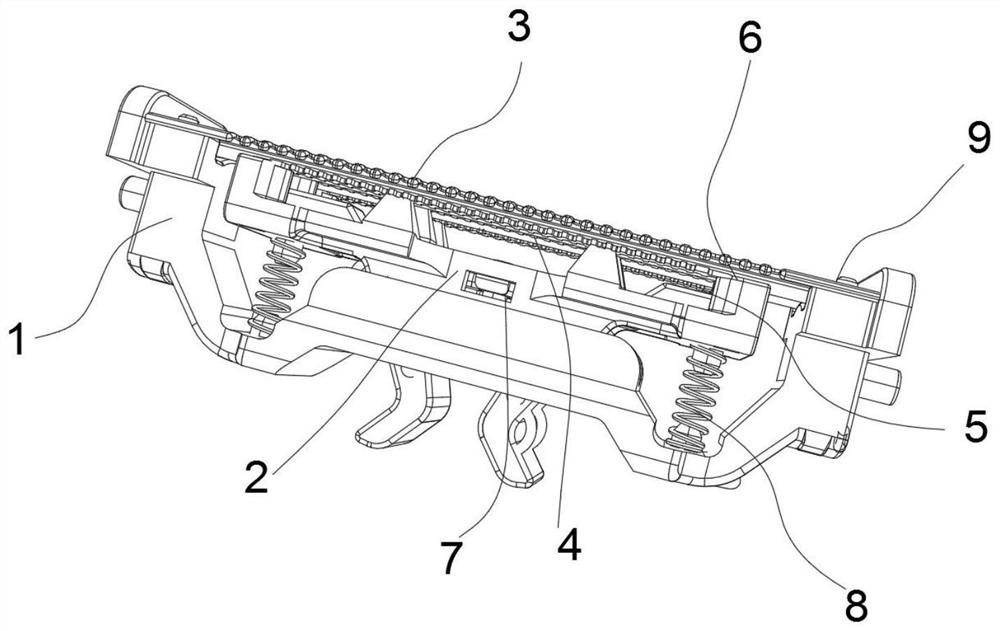

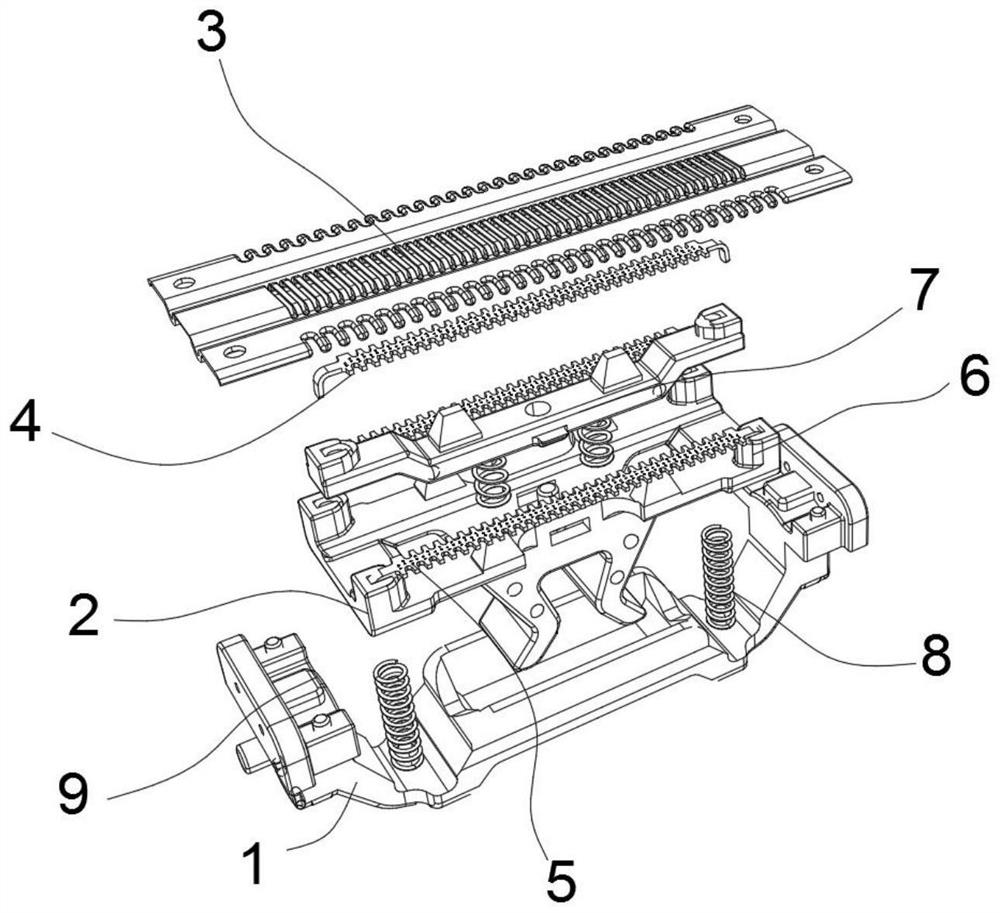

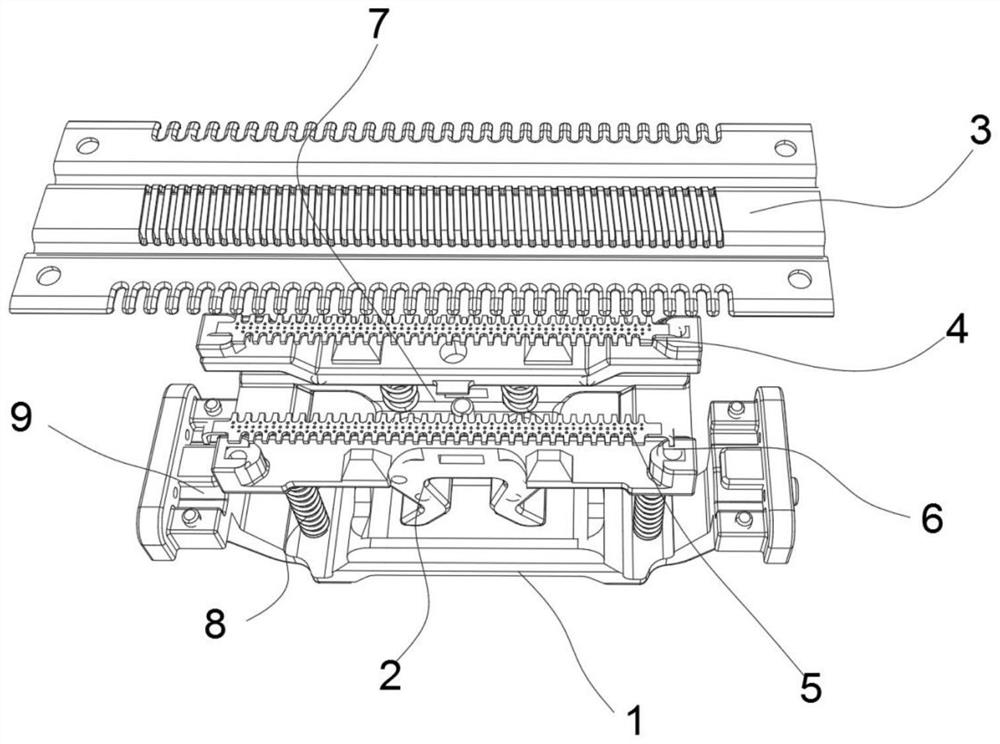

Reciprocating type shaver head

PendingCN114290382AEfficient shavingRazor heads, efficient in useMetal working apparatusStructural engineeringKnife blades

The invention discloses a reciprocating type shaver head which comprises a static knife rest, a middle movable knife rest, a static knife blade, a first movable knife blade and a second movable knife blade, the middle movable knife rest is installed in the static knife rest in a sliding mode, and the static knife blade is arranged on the surface of the static knife rest. When the device is used, long or short beards of a user can be efficiently and simply shaved, the phenomenon that a shaver cannot well shave the beards due to the fact that the beards are long is avoided, the practical effect of the device is greatly improved, the working range of the device is also enlarged, and the device is suitable for popularization and application. According to the invention, the working quality of the equipment is guaranteed, the whole equipment can be quickly mounted and spliced, the mounting steps are greatly simplified, and a large amount of materials are saved, so that the overall cost of the equipment is greatly reduced, the equipment assembly time is shortened, and the equipment is more convenient to use.

Owner:利民(番禺南沙)电器发展有限公司

Simple shear for garden beautification

PendingCN108651046ADesign scienceSimple structureHedge trimming apparatusArchitectural engineeringSimple shear

The invention discloses a simple shear for garden beautification. The simple shear comprises a sleeve with one annularly closed end, a stretching rod with at least one end extending out of a sleeve and wrapped by the sleeve and two blades with handles. One end of the stretching rod extends out of the closed annulus of the sleeve, a circle of protrusion is arranged at the position, close to the closed annulus, of the stretching rod, and a spring part is arranged between the protrusion and the closed annulus. Through holes are formed in the handle ends of the blades, a pair of triangular fixingracks is arranged at the non-annularly-closed end of the sleeve and is provided with through holes I, and the through holes and the through holes I are connected to two ends of a middle part. The middles of the two blades are correspondingly provided with fixing holes, connecting rods provided with fixing holes I at ends are fixed in the fixing holes of the two blades, and the other end of each connecting rod is fixed to the corresponding end of the stretching rod. The simple shear is convenient to operate, and opening and closing of the blades can be controlled only by pulling the stretchingrod.

Owner:江苏省宜兴中等专业学校

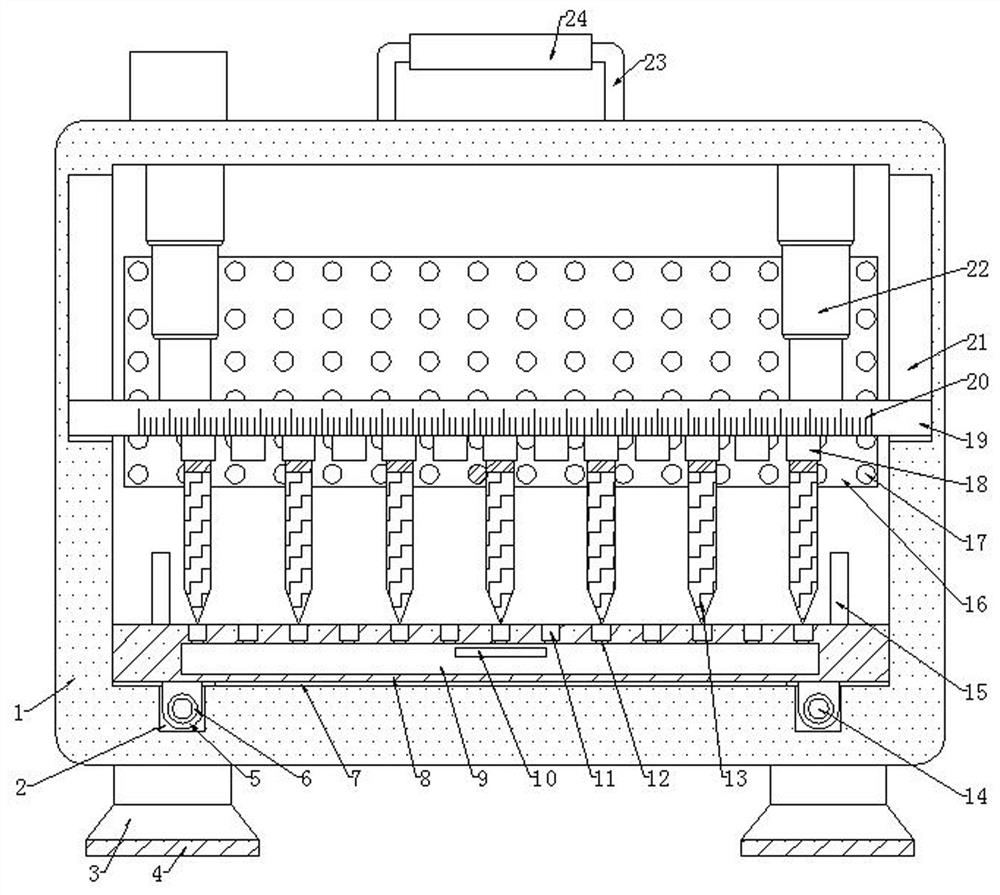

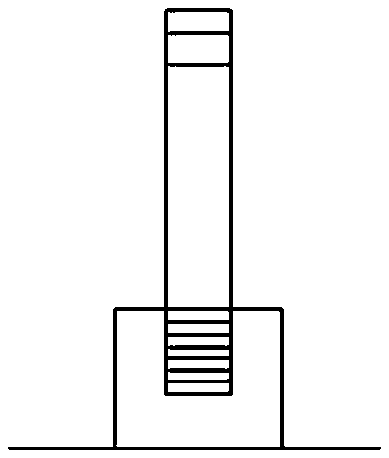

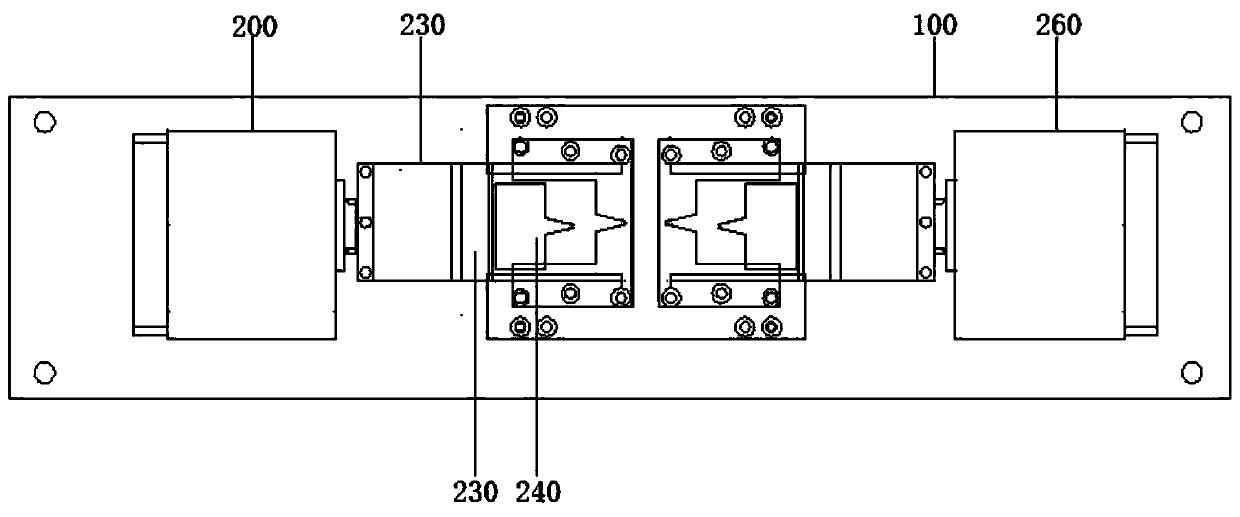

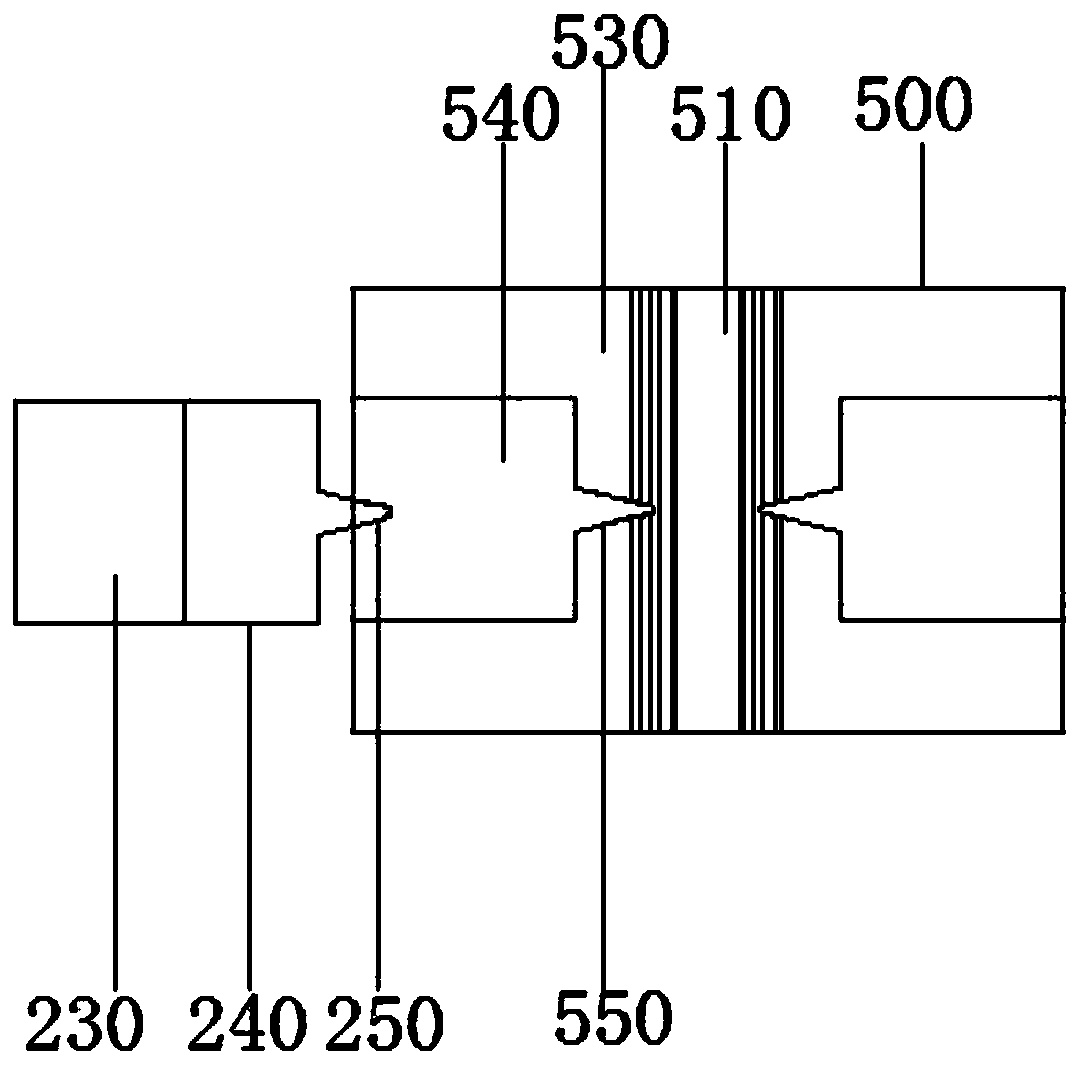

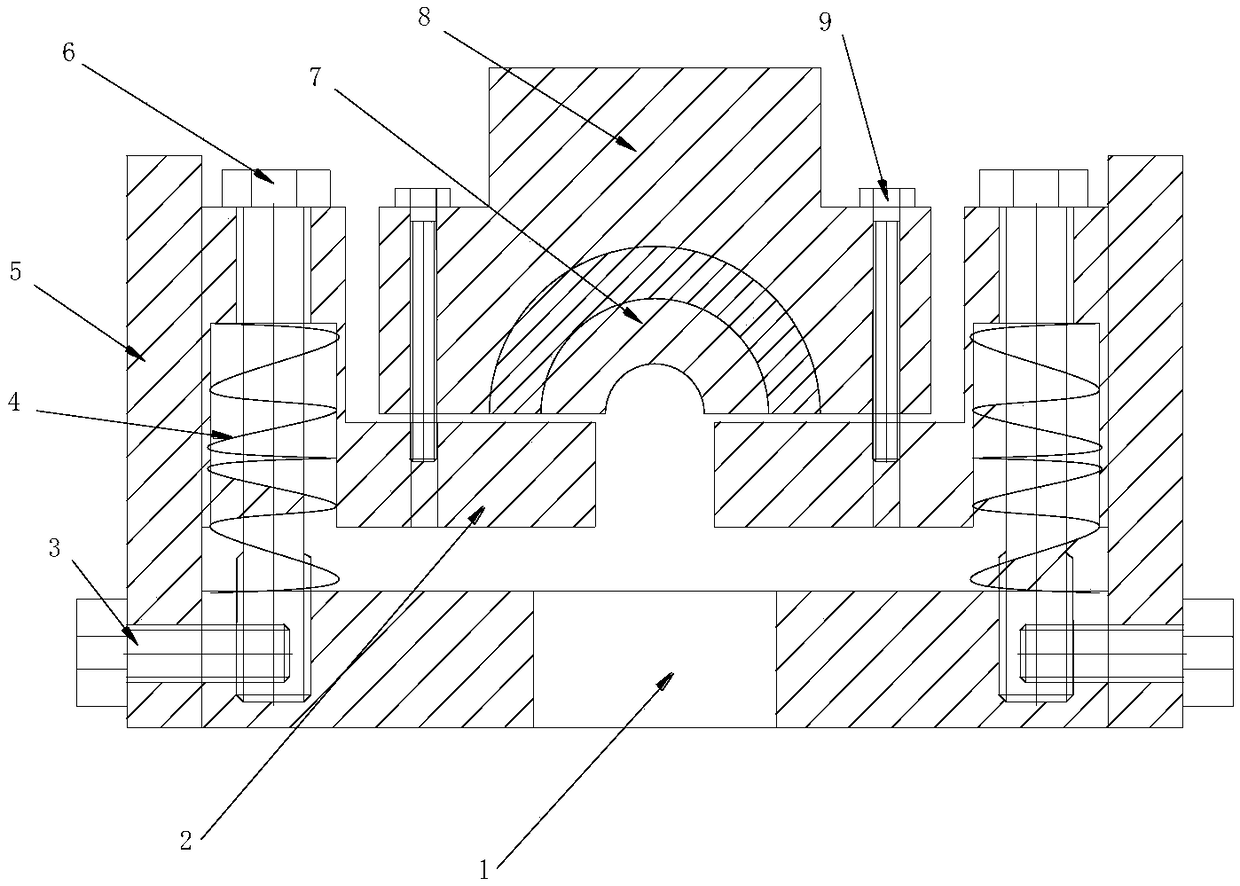

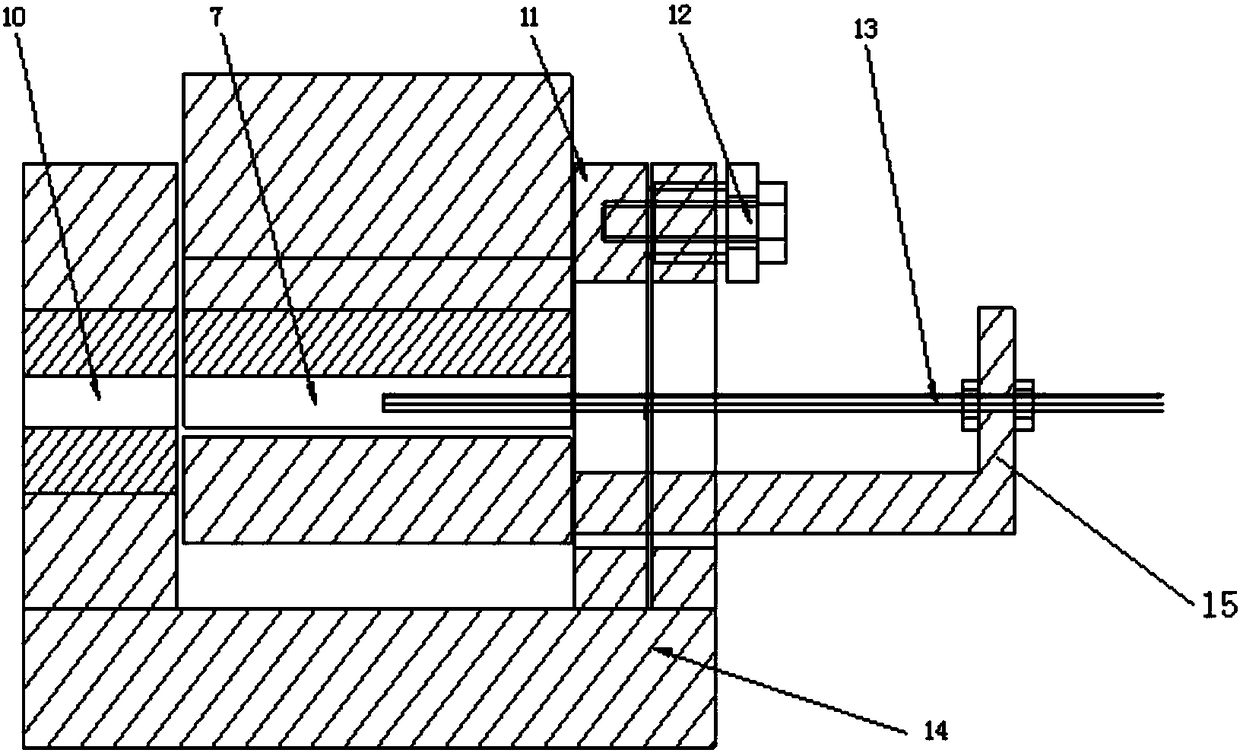

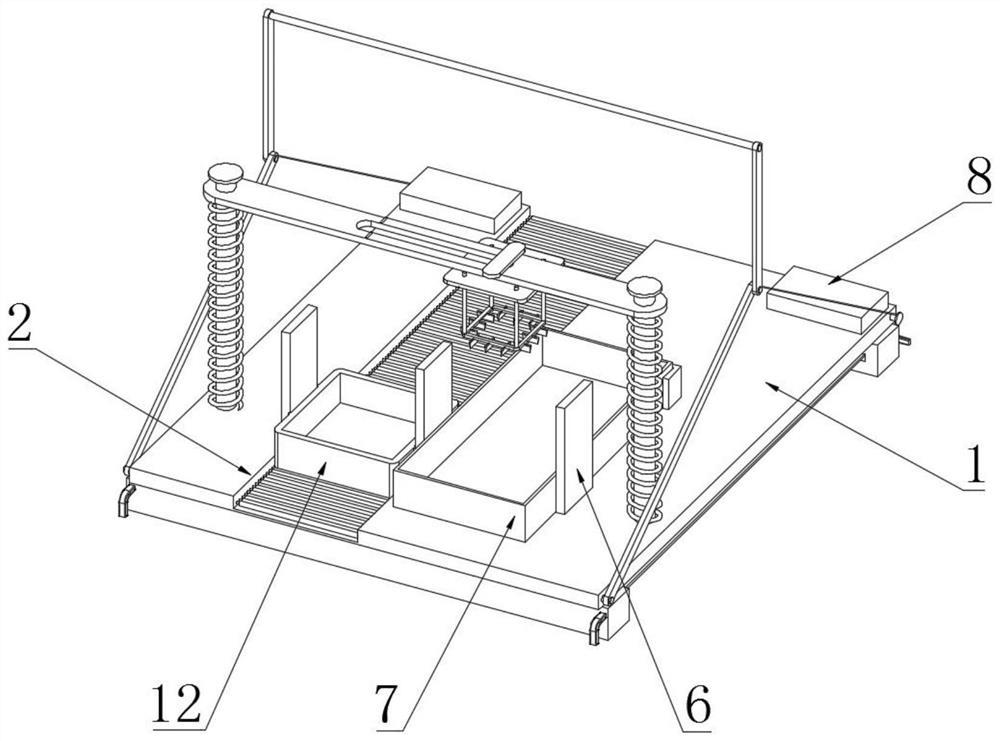

Pneumatic forming pin shearing and coating removing integrated equipment

The invention particularly relates to pneumatic forming pin shearing and coating removing integrated equipment which belongs to the technical field of pin correction processing devices. The equipmentcomprises a bottom frame, a main cylinder, an auxiliary cylinder, a gantry, a top frame, a contact plate and a side frame, the top of the bottom frame is fixedly connected with the main air cylinder,the auxiliary air cylinder and the gantry through screws. According to the pneumatic forming, pin shearing and coating removing integrated equipment, the purposes of straightening and forming can be achieved; the limiting is facilitated, a cutting plate controlled by an air cylinder is matched to move; force is applied to the cutting tool carrying a cutting head and a die groove in a die plate; the shearing purpose is achieved; copper wire heads subjected to pin shearing fall into a waste box along a transfer groove; the recycling performance is good, potential safety hazards of waste materials to operators is reduced, at the same time, the side frame is matched, a grinder driven by a built-in motor can be matched to conduct coating removing work on outer portions of pins, and the equipment has the effects of pin limiting, cutting, recycling and coating removing, is high in integration degree, and effectively improves the overall processing efficiency.

Owner:WUHAN CHENYANG ELECTRONICS TECH

Wooden product cutting device high in safety coefficient

InactiveCN107263611ASmooth rotationStable power deliveryFeeding devicesCircular sawsDrive wheelTransmission belt

The invention discloses a wooden product cutting device high in safety coefficient. The wooden product cutting device high in safety coefficient comprises a cutting piece and a rack, supporting plates are symmetrically welded to the bottom end of the rack, a placing plate is welded between the two supporting plates, a motor is fixed to the end face of the placing plate, an output shaft of the motor is in transmission connection with a driving wheel through a gear speed reducer, the driving wheel is in rotation connection with a driven wheel rotatably mounted on the rack through a transmission belt penetrating the rack, the cutting piece is rotatably mounted on the rack through the driven wheel and a limiting bearing at the two ends, the cutting piece is located in the middle of the rack and penetrates the rack, rotating grooves are formed in the two ends of the rack, T-shaped rotating shafts matched with the rotating grooves are mounted in the rotating grooves in a sliding manner, and a push plate is welded to the outer ends of the two T-shaped rotating shafts. The device can carry out stable and rapid cutting, and meanwhile, a worker can be protected.

Owner:德清县兴拓木板厂(普通合伙)

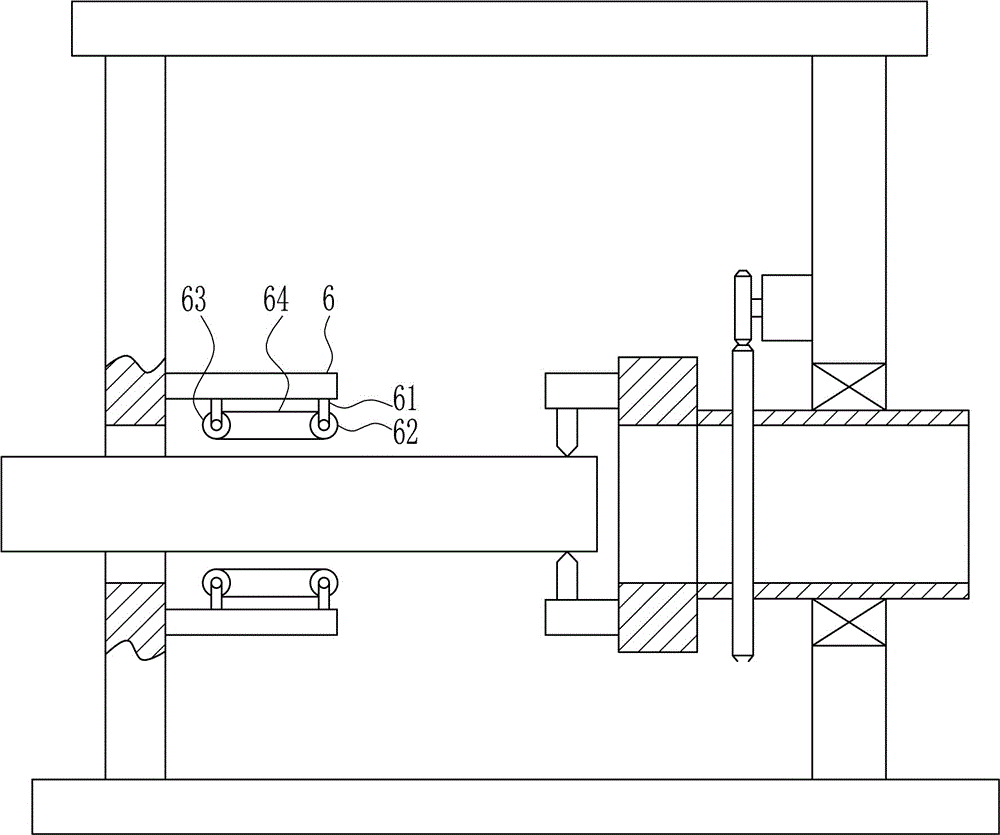

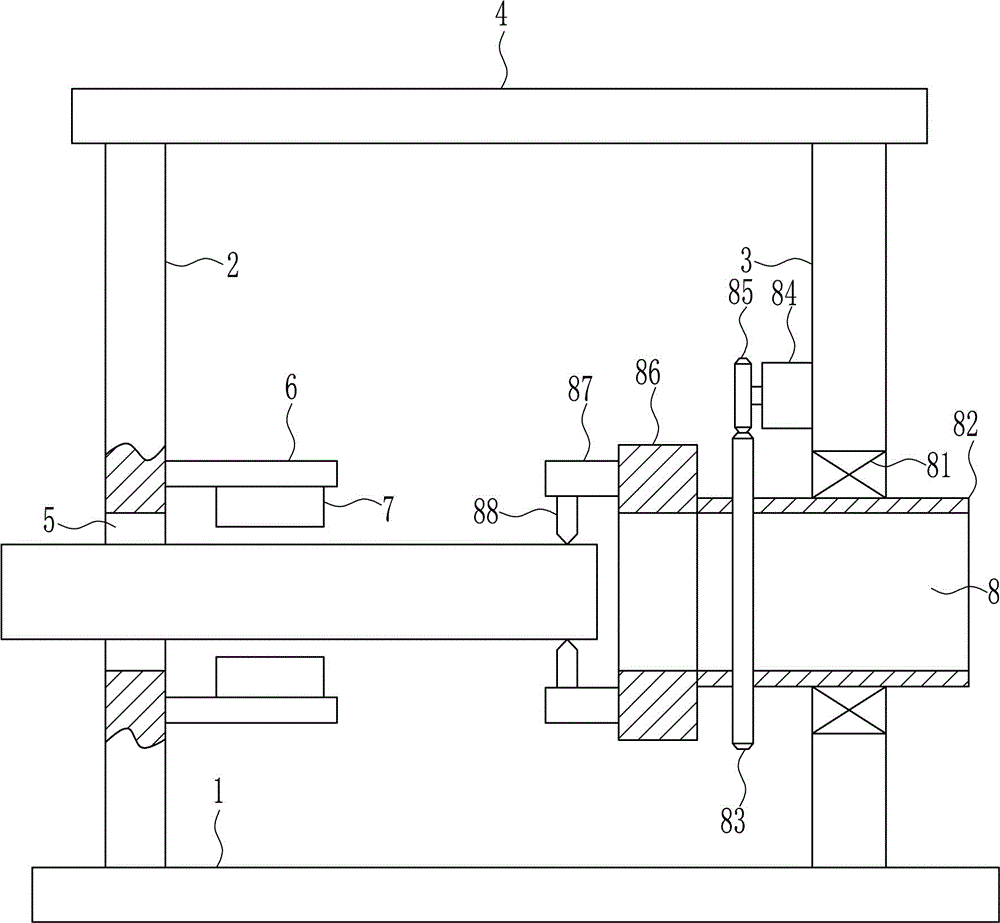

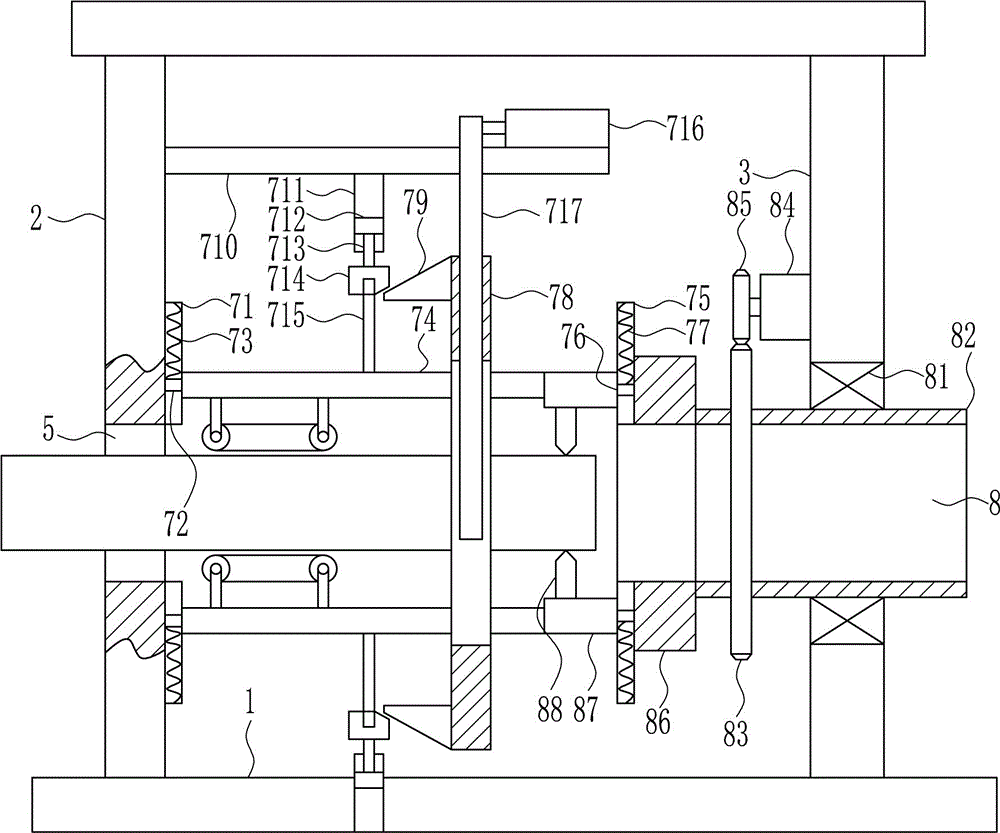

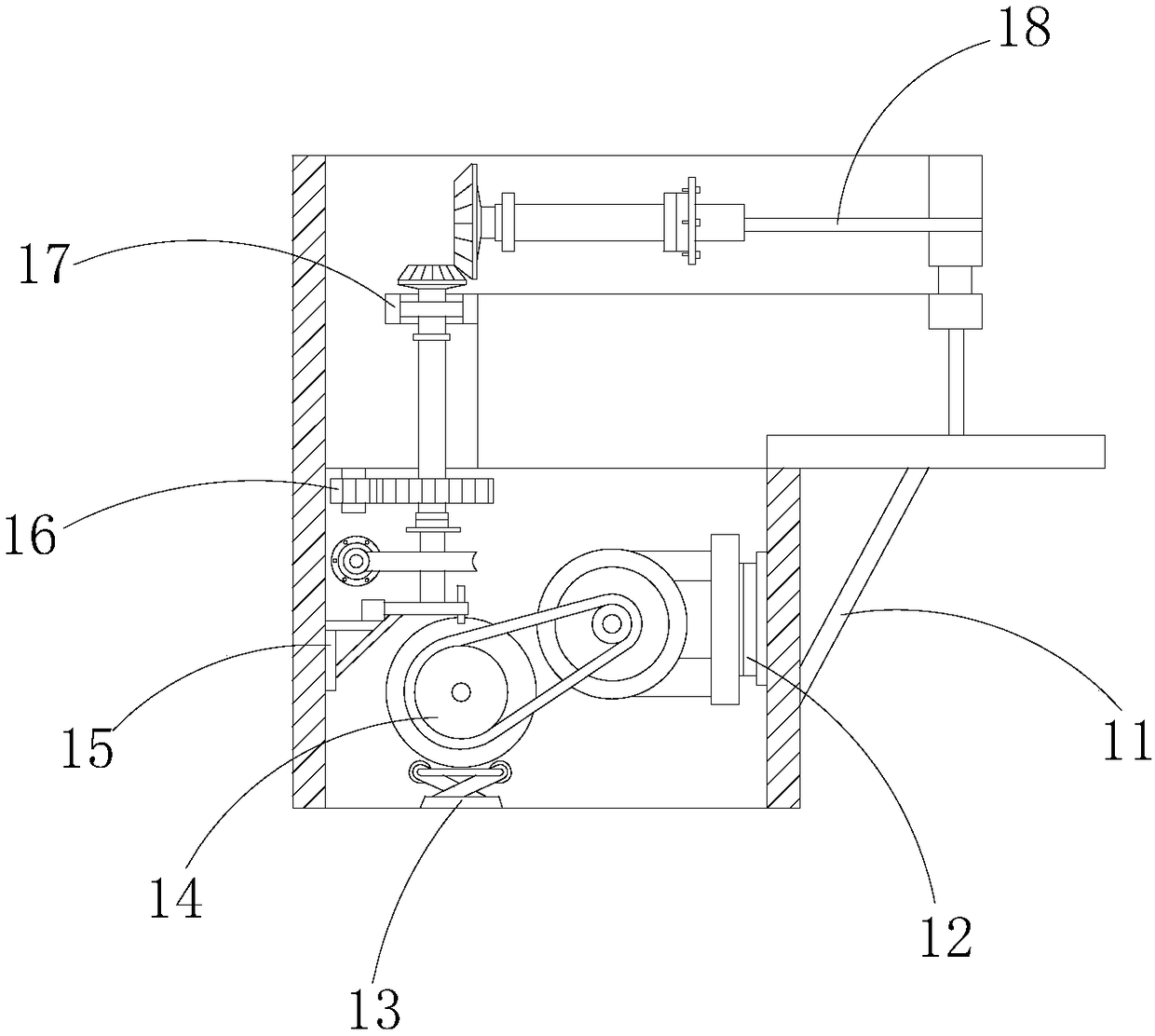

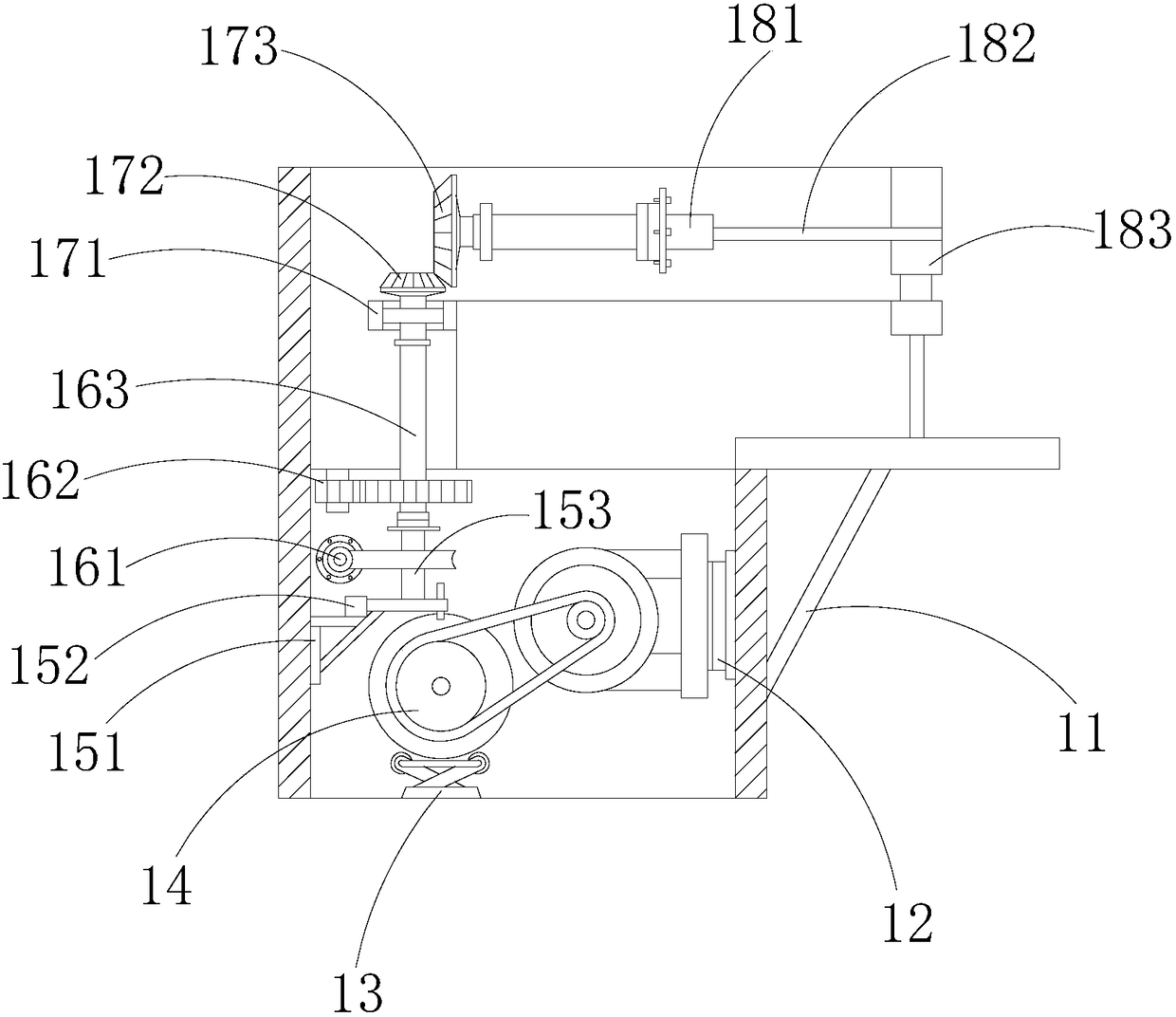

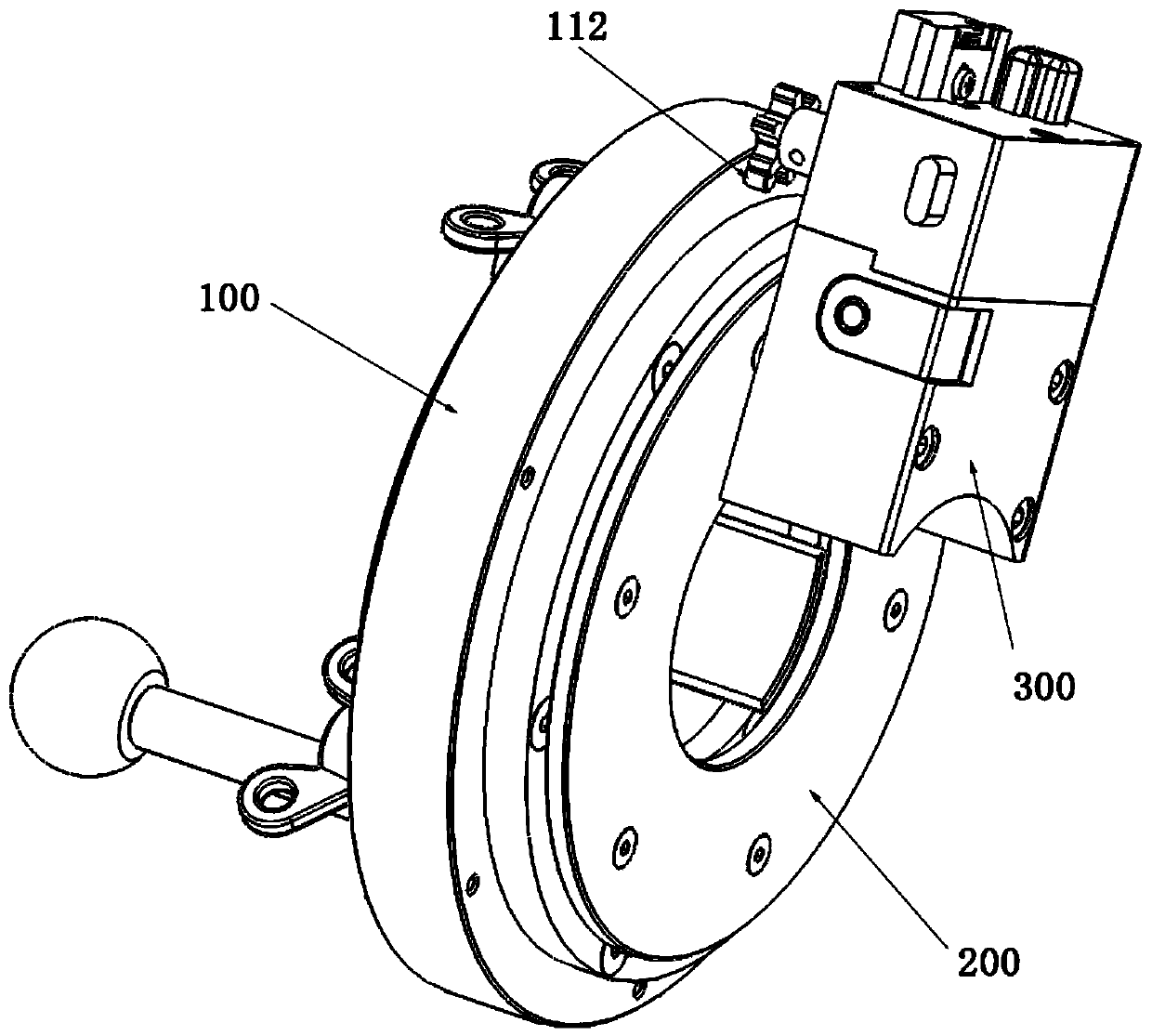

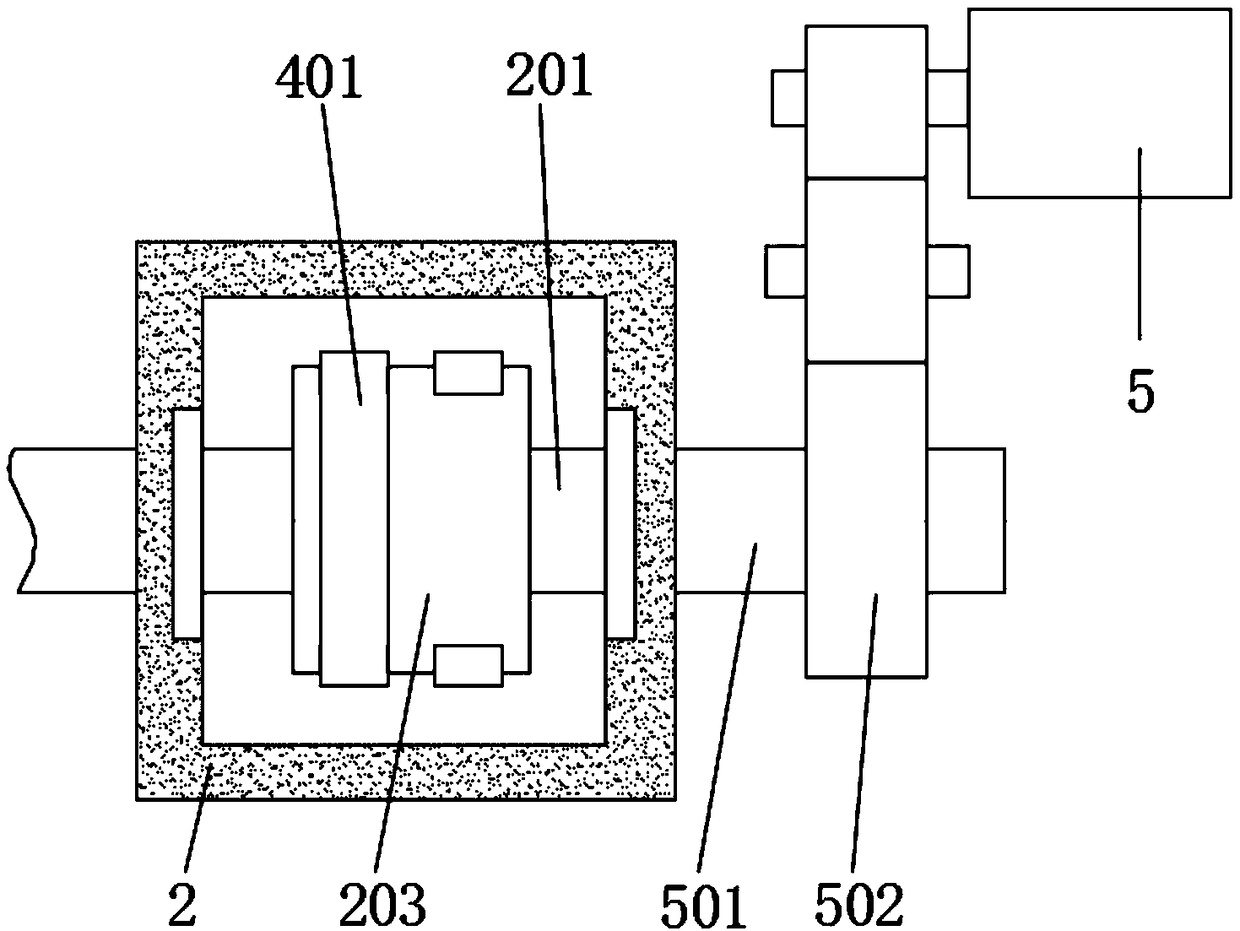

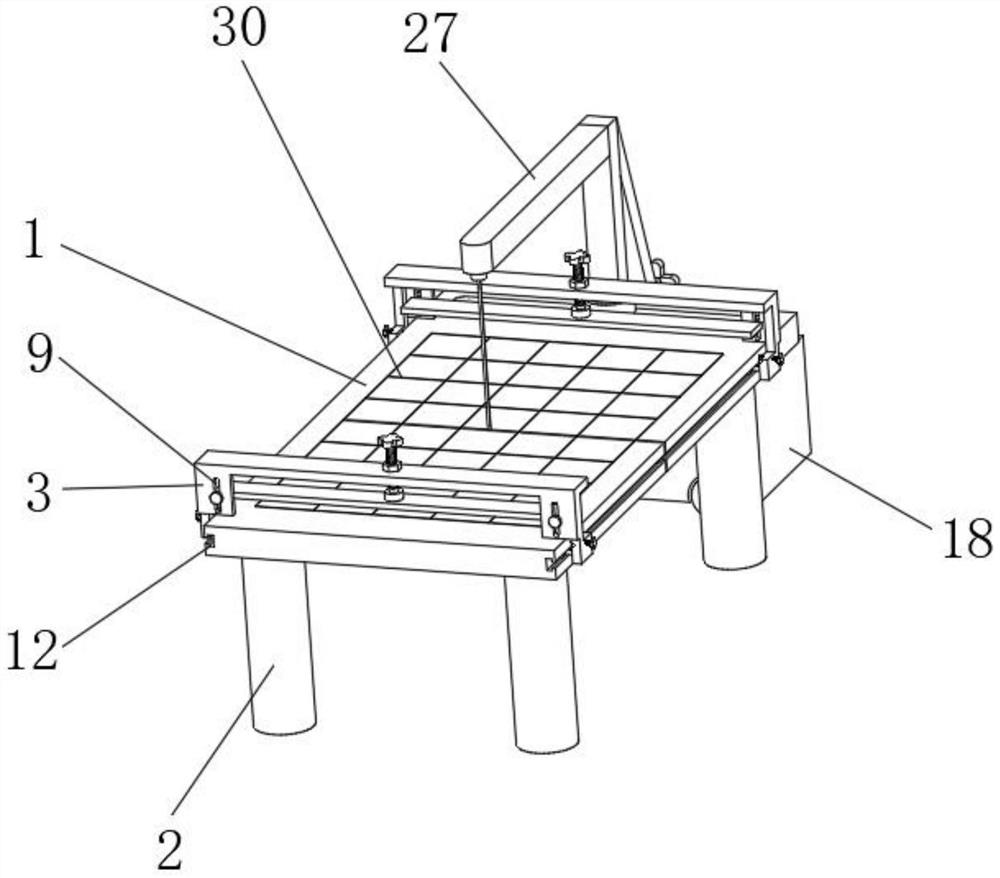

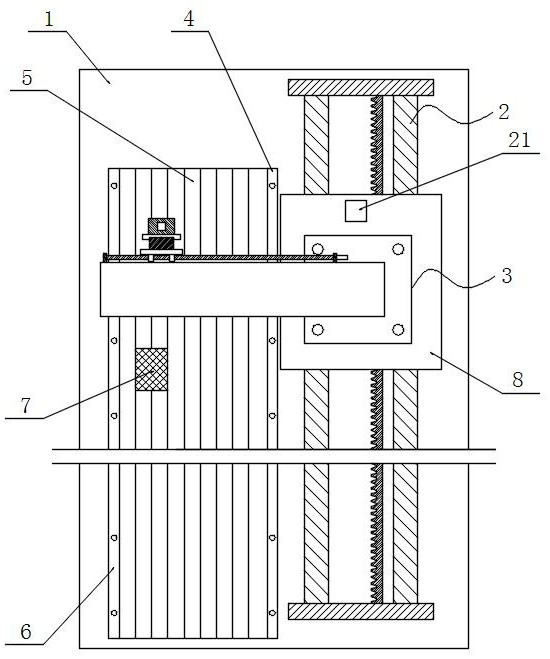

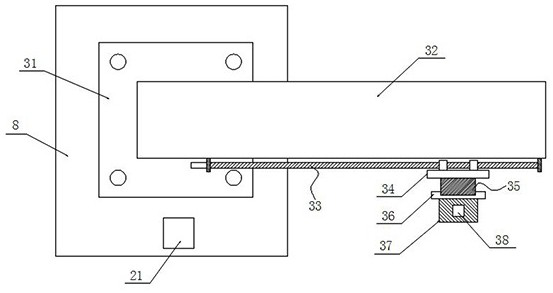

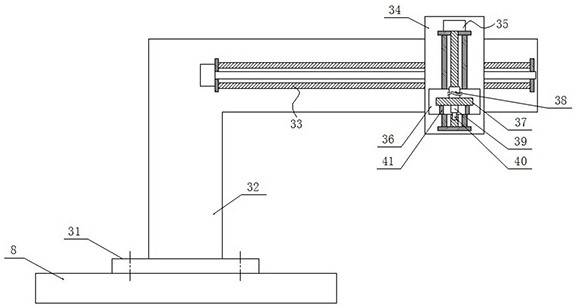

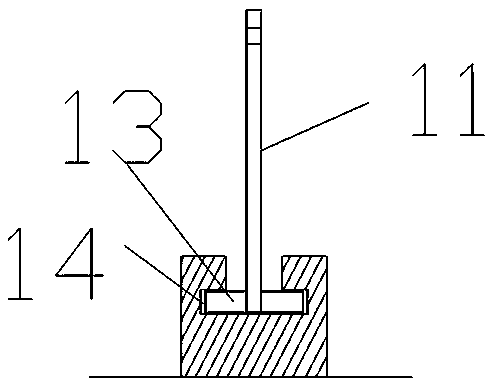

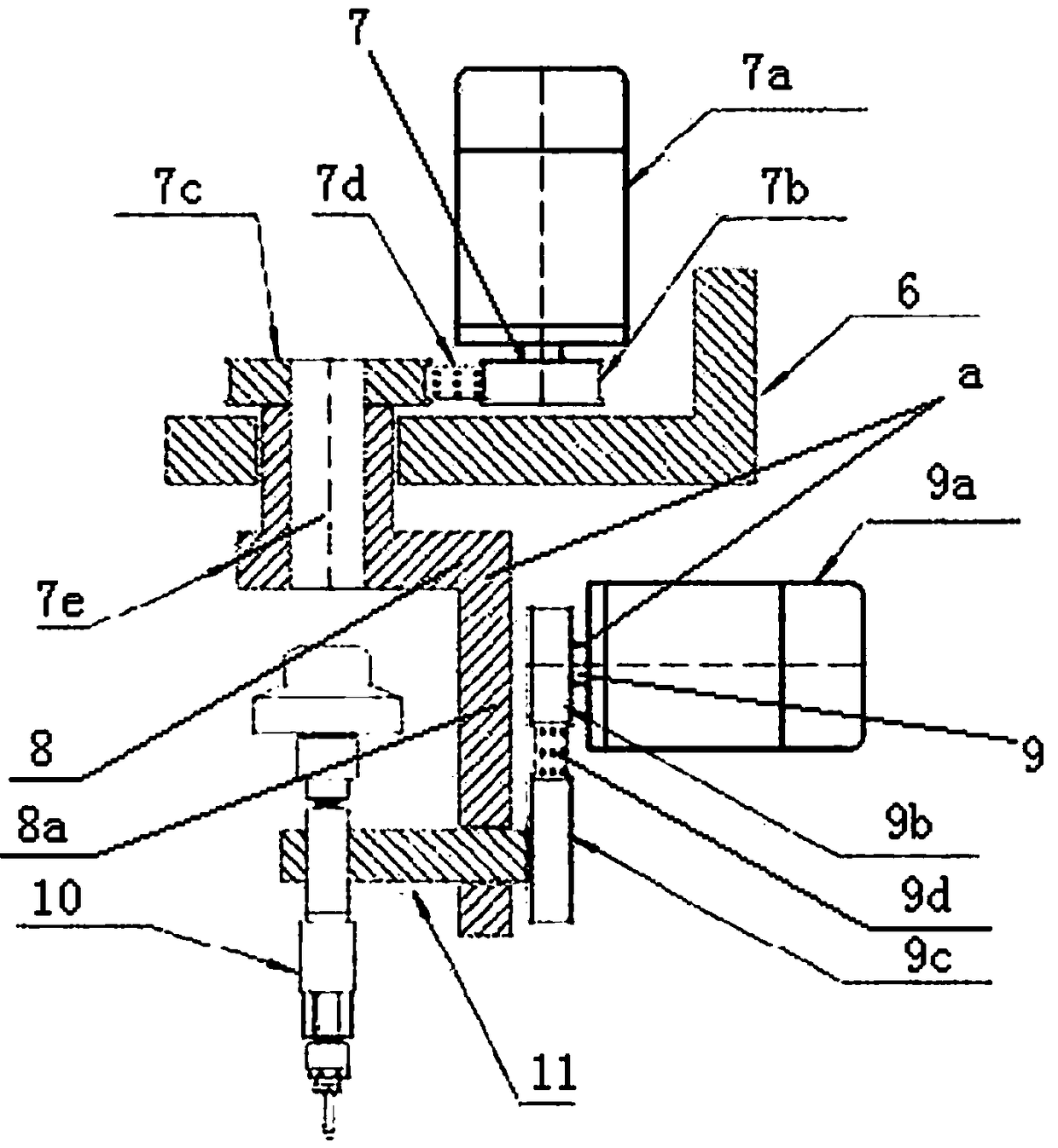

Water jet scalpel deflection mechanism

PendingCN109365916ASimple deflection adjustmentTo achieve the purpose of cuttingMetal working apparatusWater jetMechanical engineering

The invention relates to a water jet scalpel deflection mechanism which comprises a cross beam drive by power so as to move front and back along a guide rail, a moving seat arranged on the cross beamand driven by power so as to move left and right, a power perpendicular rotating mechanism arranged on the moving seat, and a deflection mechanism driven by the power perpendicular rotating mechanismso as to rotate. The water jet scalpel deflection mechanism is characterized in that the deflection mechanism comprises an inverted L-shaped rotating seat, a power rotation component arranged on a perpendicular seat of the inverted L-shaped rotating seat, and a water jet scalpel cutting head driven by the power rotation component; the water jet scalpel cutting head is fixed onto a fixed seat of the power rotation component; and the rotation axis of the power rotation component is perpendicular to the perpendicular seat of the inverted L-shaped rotating seat. Compared with the prior art, the water jet scalpel deflection mechanism provided by the invention has the advantages of simplicity in adjusting water jet scalpel deflection, and capability of cutting in a way of large-angle deviating from the Z axis.

Owner:FOSHAN YONGSHENGDA MACHINERY

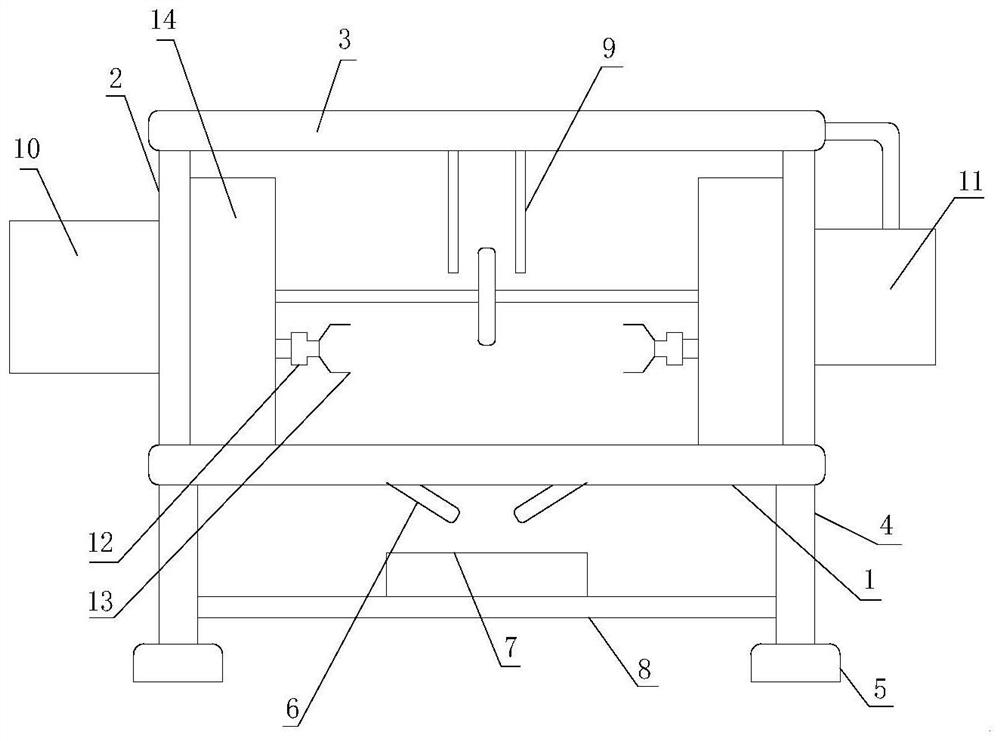

A large-diameter circular pipe toothless saw cutting machine

ActiveCN112045545BSimple structureFirmly connectedGrinding carriagesGrinding drivesBraced frameIndustrial engineering

The invention discloses a large-diameter circular pipe toothless saw cutting machine, which comprises a toothless saw, a lower support frame and an upper support frame, and the toothless saw is installed on the right end of the first top frame of the lower support frame through a toothless saw feeding device Above; the upper support frame is fixed on the left end of the first top frame of the lower support frame; the second top frame of the upper support frame is equipped with a round tube auxiliary positioning and pressing mechanism; the lower support frame is equipped with a round tube rotation support mechanism, The circular tube rotation support mechanism includes two support rollers, and there is a space for placing the circular tube between the two support rollers and the circular tube auxiliary positioning and pressing mechanism; the left and right ends of the two support rollers are equipped with adjustable spacing mechanisms; Both the left and right ends of the two support rollers are provided with a belt pulley transmission mechanism for driving the support rollers to rotate; a circular pipe transmission mechanism is provided under the two support rollers. The invention can realize automatic and continuous cutting of large-diameter circular pipes once.

Owner:CHANGZHOU INST OF TECH

Full-automatic cutting device for thermal insulation sandwich panel

InactiveCN113695660ATo achieve the purpose of cuttingAvoid manual cuttingShearing machinesDriving apparatusThermal insulationElectric machinery

The invention relates to the technical field of production and processing of thermal insulation sandwich panels, and discloses a full-automatic cutting device for a thermal insulation sandwich panel. The full-automatic cutting device comprises a bottom plate, two side plates, a top plate and supporting legs, wherein a cutting mechanism and a moving mechanism are arranged above the bottom plate; the cutting mechanism comprises a motor, a first worm and a cutting knife; the moving mechanism comprises a moving rod, a limiting block, a concave plate, a second worm, a first worm gear, a threaded rod and a second worm gear; the top of the bottom plate is fixedly connected with the bottoms of the side plates; the tops of the side plates are fixedly connected with the bottom of the top plate; and the bottom of the bottom plate is fixedly connected with the tops of the supporting legs. According to the full-automatic cutting device for the thermal insulation sandwich panel, the second worm can drive the second worm gear to rotate through rotation of the first worm gear, so that the threaded rod can rotate, and finally, the moving rod drives the clamped thermal insulation sandwich panel to move, so that the purpose of automatic cutting is achieved.

Owner:安徽瑞业钢构股份有限公司

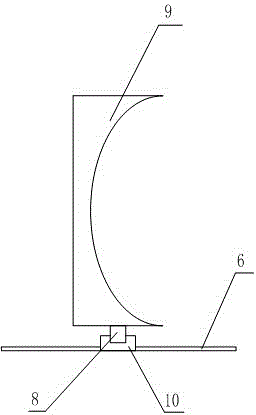

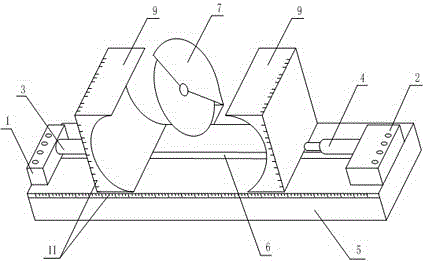

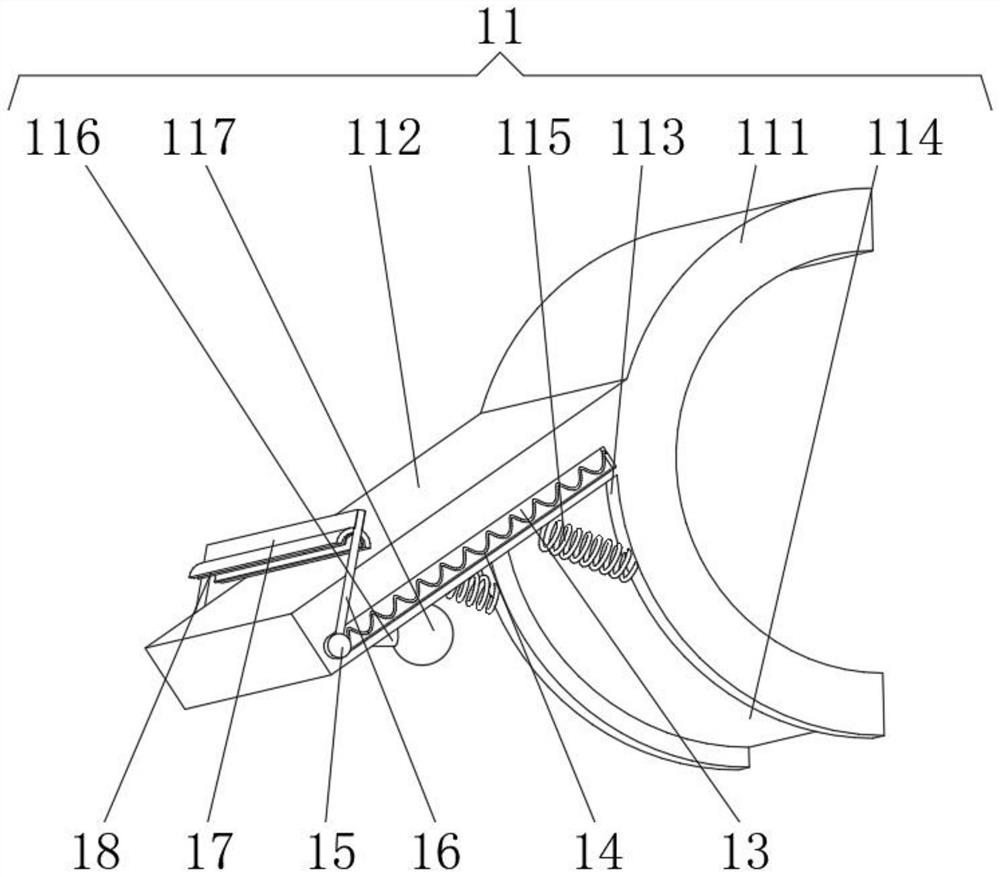

A blanking device for a punching machine in an upsetting workshop

The invention discloses a punch press blanking device for a heading workshop. The punch press blanking device for the heading workshop comprises a vertically placed semicircular cutter in a half circular ring shape, wherein a blade of the semicircular cutter is arranged on an inner arc; two annular cross sections of the semicircular cutter are arranged on a pair of limiting sliding blocks respectively; a semicircular cutter fastening module is arranged on an outer arc of the semicircular cutter in a matching manner; the bottom surface of the semicircular cutter fastening module and the two annular cross sections of the semicircular cutter share one surface; the semicircular cutter fastening module is also connected with a pair of limiting sliding blocks through module fastening bolts; and buffer springs are also arranged in the interiors of the vertical side surfaces, far away from the blade of the semicircular cutter, of a pair of limiting sliding blocks respectively. The punch press blanking device for the heading workshop solves the problems in the prior art of the punch press blanking device for the heading workshop of large raw material waste, frequent damages of turning tools and high production cost.

Owner:XIAN AEROSPACE HUAYANG PRINTING & PACKAGING MACHINERY

A high-efficiency oocyte separation and collection device for animal ovaries

ActiveCN109852533BScientific and reasonable structureEasy to useBioreactor/fermenter combinationsBiological substance pretreatmentsAnimal sciencePetri dish

The invention discloses a high-efficiency oocyte separation and collection device for animal ovaries, which comprises a bottom plate, a feeding chute is provided in the middle of the top of the bottom plate, and a guide shaft is connected to the bottom of the feeding chute for equidistant rotation, and the guide shaft The middle part is sleeved with a rubber sleeve, and the top of the bottom plate is equidistantly welded with a limit plate, and a separation mechanism is installed at the position corresponding to the limit plate at the top of the bottom plate. The structure of the invention is scientific and reasonable, and it is safe and convenient to use. In the chute, through the pressing of the lower pressure plate, the purpose of cutting is realized by using the connecting ring and the cutting blade, and the original position is restored by the return spring. Through the action of the rubber sleeve and the guide shaft, the culture dish can be easily pushed to replace the next culture dish. The plate continues to cut, which realizes the purpose of fast operation and convenient cutting, and achieves high-efficiency separation of oocytes. At the same time, the limit plate prevents the cutting blade from contacting the bottom of the culture dish and avoids damage to the cutting blade.

Owner:TAISHAN MEDICAL UNIV

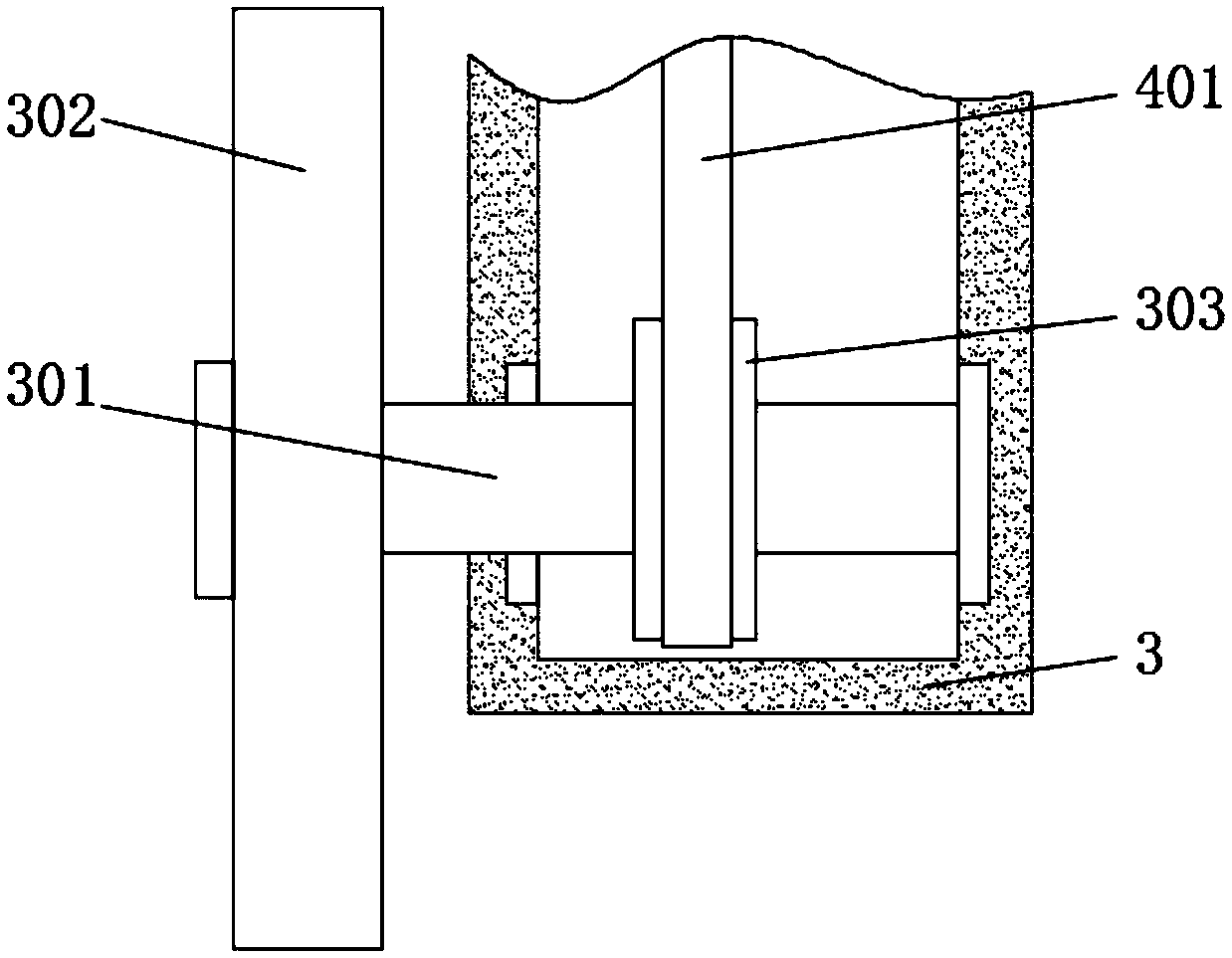

Lower cutting knife driving device

The invention relates to a lower cutting knife driving device. The lower cutting knife driving device comprises a crank; one end of the crank is connected with a power device, and the other end of thecrank is connected with a steering pull rod; the steering pull rod is connected with a rocker arm assembly; the other end of the rocker arm assembly is arranged in a horizontal sliding groove of a lower cutting knife device in a sleeved manner. Longitudinal reciprocating driving of the crank and the steering pull rod is converted into horizontal reciprocating driving of the lower cutting knife device to achieve the goal of cutting, and a lower cutting knife of a harvester works. The lower cutting knife driving device has the advantages that a driving chain is simple, parts are few, processingis simple, manufacturing cost is low, universality is high, the requirement on an installation technique is not high, driving is reliable and maintenance is convenient, and can be applied to all types of small and medium-sized combine harvesters.

Owner:湘潭县燕军农机服务专业合作社

A kind of industrial glass pipe cutting equipment

ActiveCN106746566BCutting saves time and effortQuick cutGlass severing apparatusEngineeringBolt connection

The invention relates to a glass cutting device, in particular to a novel industrial glass pipe cutting device. The invention aims to solve the technical problem so as to provide the novel industrial glass pipe cutting device, which has less possibilities on damaging glass pipes and hurting workers or equipment when being used for cutting the glass pipes, and is time and labor saving during a cutting process. In order to solve the technical problem, the invention provides the novel industrial glass pipe cutting device, which comprises a bottom plate and the like, wherein a left support plate is arranged at the left side above the bottom plate in a welding way; a right support plate is arranged at the right side above the bottom plate in a welding way; a top plate is arranged on the upper ends of the left support plate and the right support plate through a welding way; a through hole is formed in the lower side of the left support plate; fixing plates are symmetrically arranged at the right side of the left support plate through a bolt connection way. The novel industrial glass pipe cutting device provided by the invention achieves the effects that the possibilities on damaging the glass pipes and hurting the workers or the equipment when being used for cutting the glass pipes are less, and the time and the labor are saved during the cutting process.

Owner:临泉县蓝天钢化玻璃有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com