Cloth cutting device for clothing manufacture

A fabric and main body technology, which is applied in the field of clothing fabric cutting devices, can solve the problems of not being able to adjust the cutting method and cutting position, and achieve the effects of increasing stability and increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

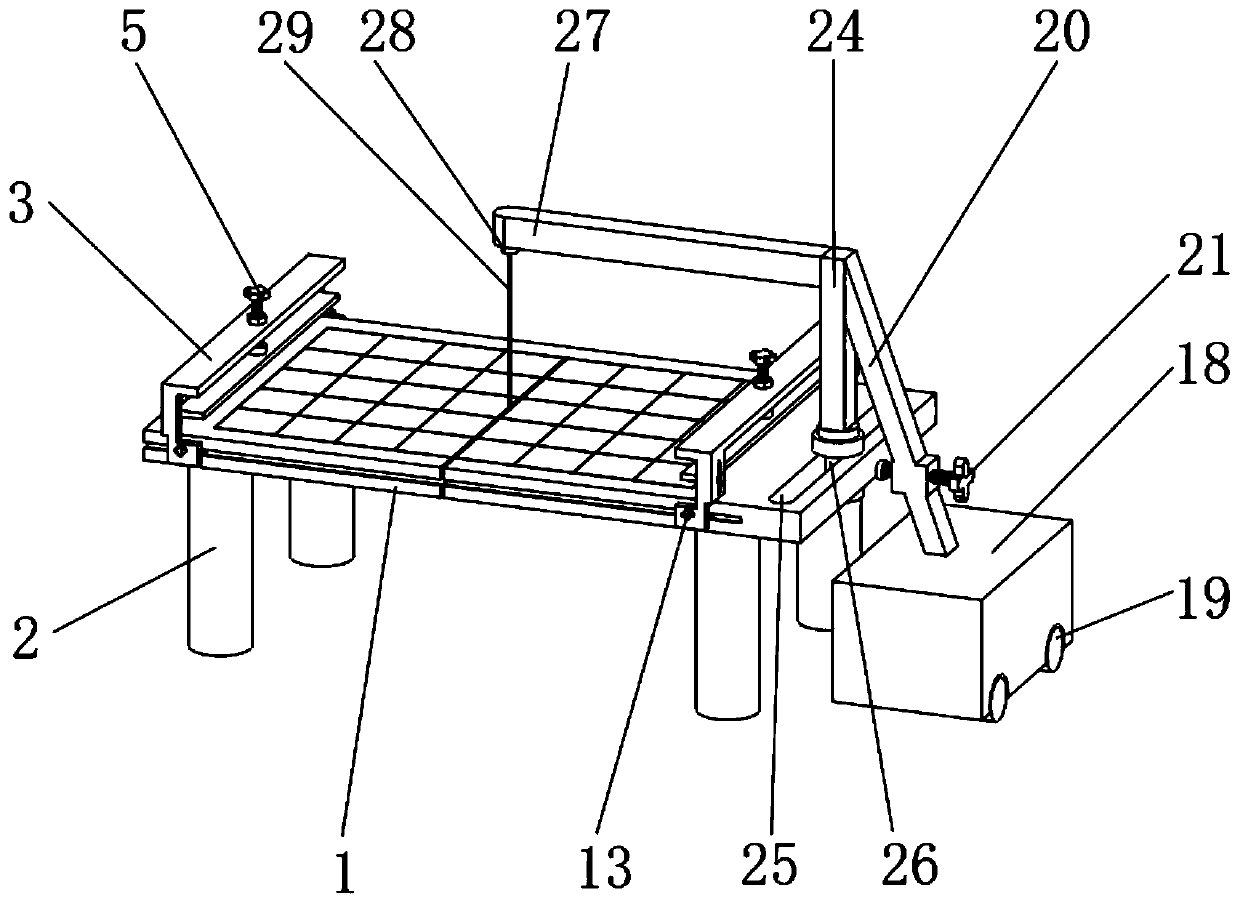

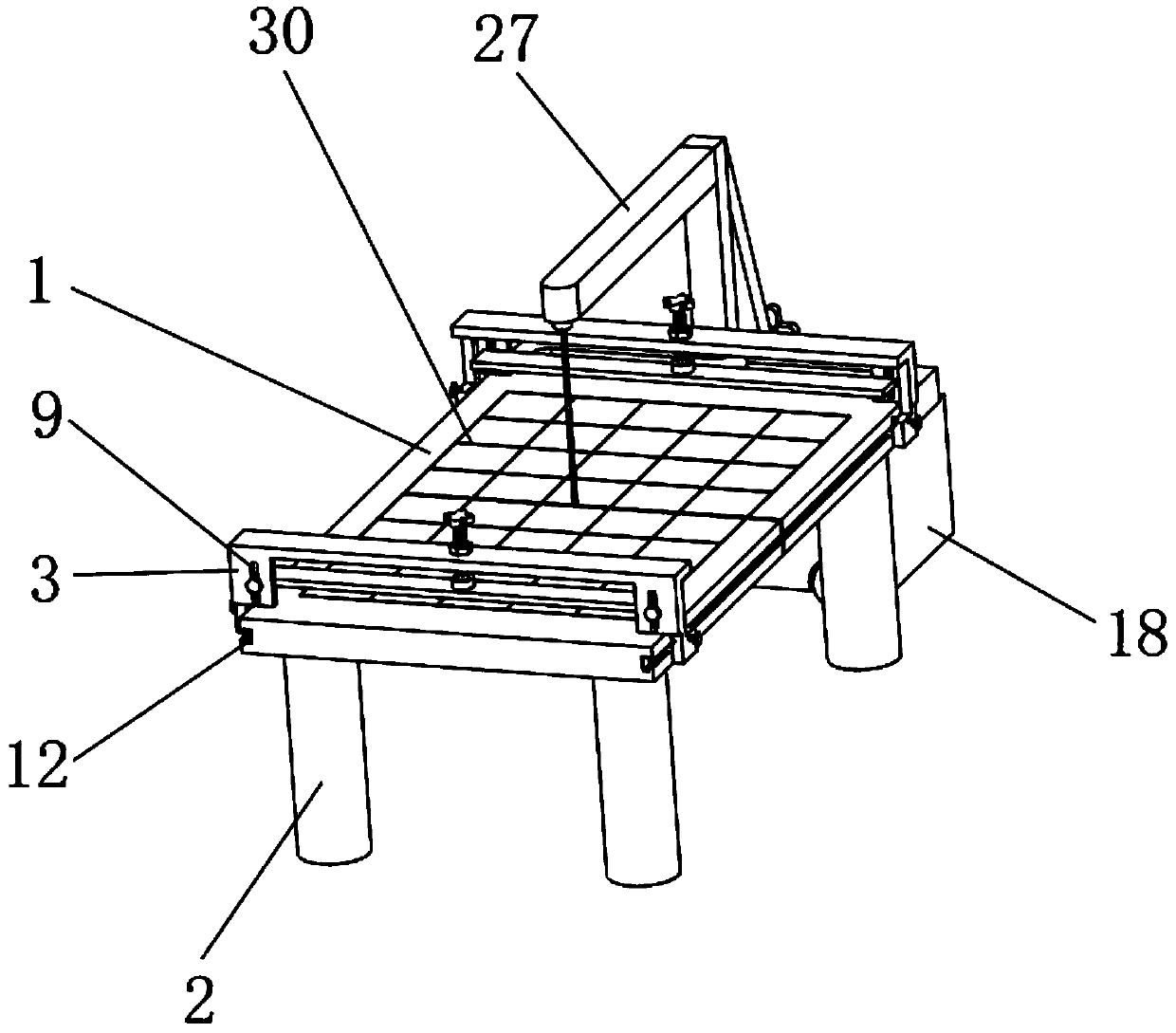

[0033] A clothing cloth cutting device, such as figure 1 , Figure 6 As shown, it includes a main body 1 and a base 18. The top outer wall of the main body 1 is provided with a third sliding groove 25. The bottom outer wall of the main body 1 is welded with four identical support legs 2. The bottom of the base 18 is connected by a shaft. There are four identical base rollers 19, a first connecting frame 20 is welded on the top outer wall of the base 18, a cutting translation column 24 is welded at one end of the first connecting frame 20, and one end of the cutting translation column 24 is connected by a shaft There is a cutting translation pulley 26, the cutting translation pulley 26 is slidably connected to the inner wall of the third chute 25, the outer wall of one side of the cutting translation column 24 is welded with a second connecting frame 27, and the outer wall of the bottom surface of the second connecting frame 27 is connected by a bolt A knife seat 28 is fixed, ...

Embodiment 2

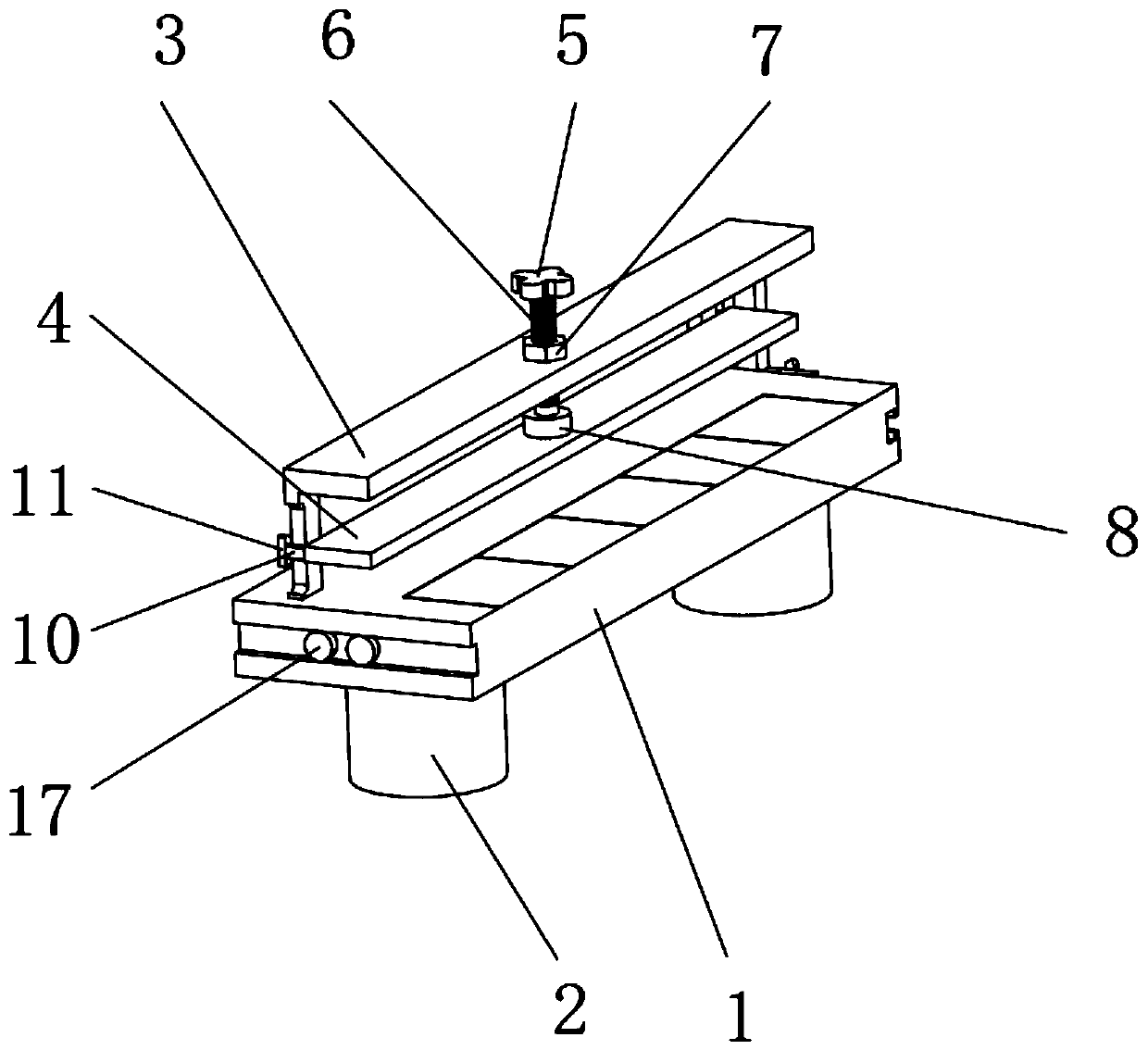

[0044] A clothing cloth cutting device, such as figure 1 As shown, in order to solve the problem of firmness and stability during the use of the pressing plate 4; this embodiment makes the following improvements on the basis of embodiment 1: the outer wall of the pressing plate frame 3 is provided with two identical first chute 9, and the outer wall of one side of the pressing plate 4 is welded with two identical first sliding rods 10, the outer walls of the two first sliding rods 10 are slidably connected to the inner walls of the two first slide grooves 9, and one end of the first sliding rod 10 is welded with a pressing plate The limit block 11, by setting the first chute 9 and the first slide rod 10, can play the role of guiding and positioning during the lifting and pressing process of the pressing plate 4, and further limits the level of the pressing plate 4 by setting the pressing plate limiting block 11. The displacement in the direction increases the stability of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com