Method for preparing metal binding agent diamond scroll saw

A technology of diamond wire saw and metal bond, which is applied in the direction of metal sawing equipment, metal processing equipment, tool manufacturing of sawing machine devices, etc. Application prospects, the effect of enhancing the binding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment relates to a manufacturing method of a wire saw for cutting semiconductor materials (such as silicon and silicon carbide, gallium arsenide, bismuth telluride), optoelectronic materials, piezoelectric crystals, magnetic materials, and the like.

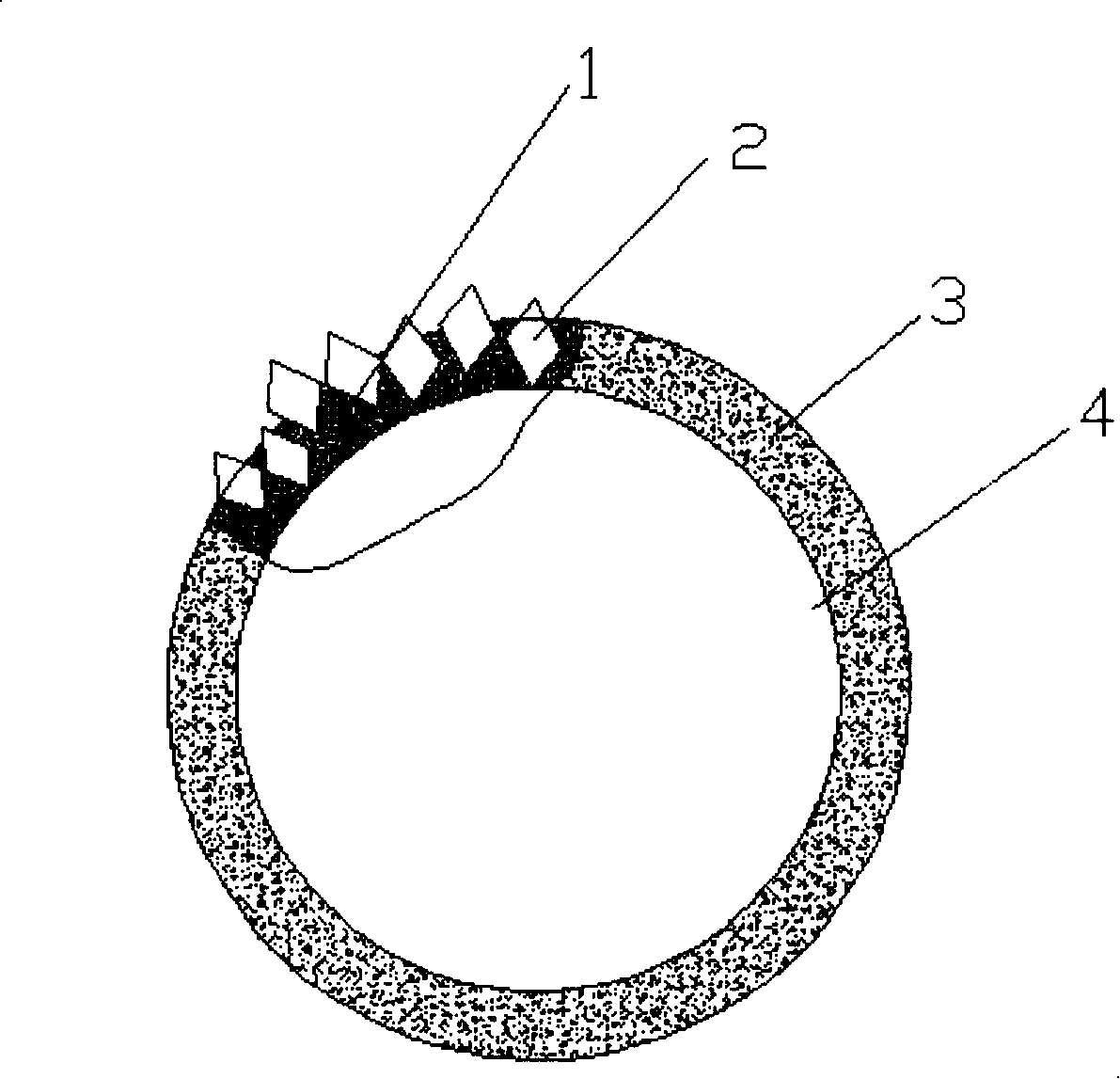

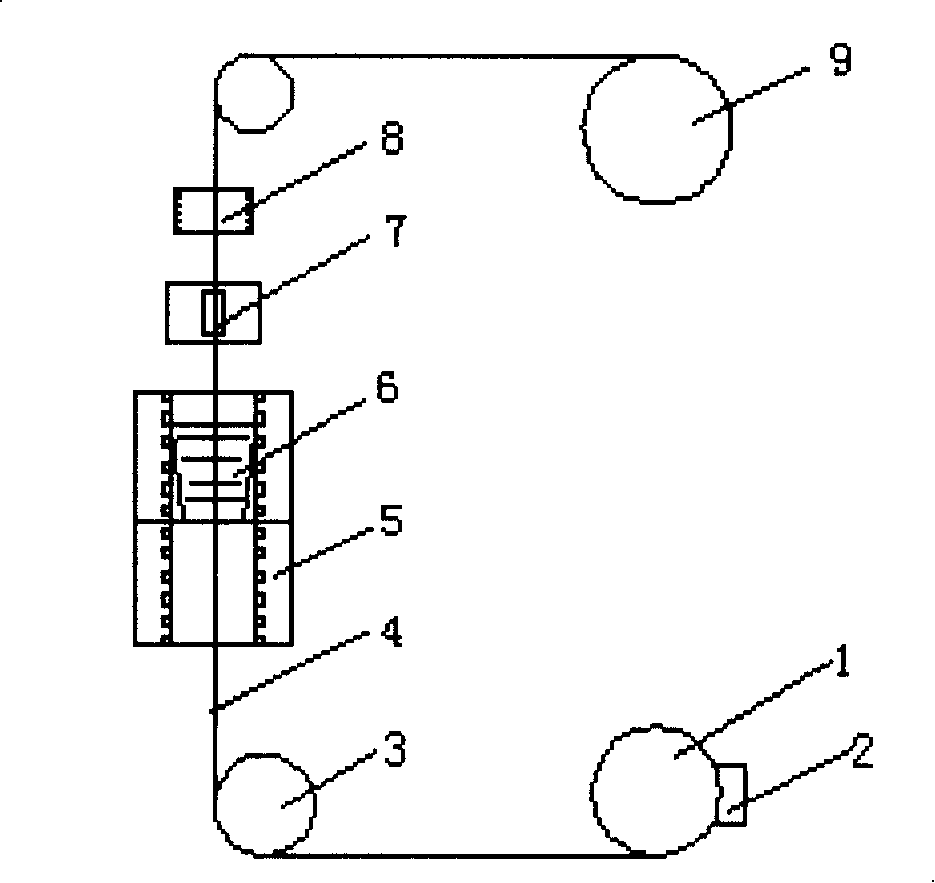

[0025] Refer to attached figure 1 : a preparation method of a metal bond wire saw, the method comprising the following steps:

[0026] (1) Surface treatment of metal saw wire: Size of metal saw wire: diameter 0.2mm, length: 100m; first wash in the self-prepared alkaline solution for about 5 minutes, and rinse with water after completion. Then wash it in the self-prepared acid solution for about 5 minutes, then rinse with water after pickling to remove the residual acid solution.

[0027] (2), help plating treatment: put the steel wire in the self-provided NH 4 Cl, ZnCl 2 , KCl mixed solution dip-plating, and scrubbing with mechanical force, so that the surface is evenly coated with plating flux and dried.

[...

Embodiment 2

[0051] This embodiment introduces a metal bond wire saw for cutting semiconductor materials (such as silicon and silicon carbide, gallium arsenide, bismuth telluride), optoelectronic materials, piezoelectric crystals, and magnetic materials.

[0052] refer to figure 1 , its preparation method comprises the following steps:

[0053] (1) Surface treatment of metal saw wire: Size of metal saw wire: diameter 0.2mm, length: 100m; first wash in the self-prepared alkaline solution for about 5 minutes, and rinse with water after completion. Then wash it in the self-prepared acid solution for about 5 minutes, then rinse with water after pickling to remove the residual acid solution.

[0054] (2), help plating treatment: put the steel wire in the self-provided NH 4 Cl, ZnCl 2 , KCl mixed solution dip-plating, and scrubbing with mechanical force, so that the surface is evenly coated with plating flux and dried.

[0055] (3), batching, with 98.14g commercially available zinc alloy, th...

Embodiment 3

[0061] The feature of this implementation is that in the preparation step (3) seasoning, the concentration of abrasive grains is 25%, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com