A large-diameter circular pipe toothless saw cutting machine

A sawing machine and large-diameter technology, which is applied in the field of large-diameter round pipe toothless sawing machines, can solve the problems of low degree of automation, limited application range, and non-adjustable spacing, and achieve convenient connection and operation. Wide range, the effect of improving cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

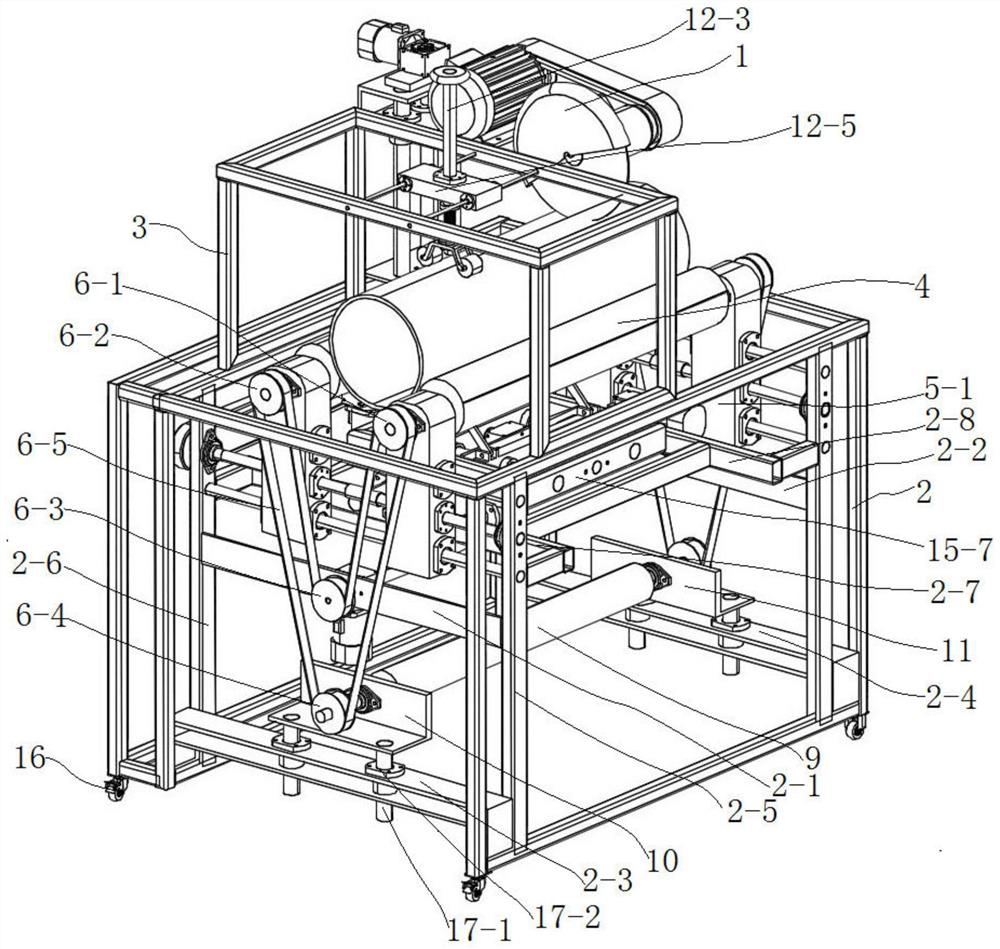

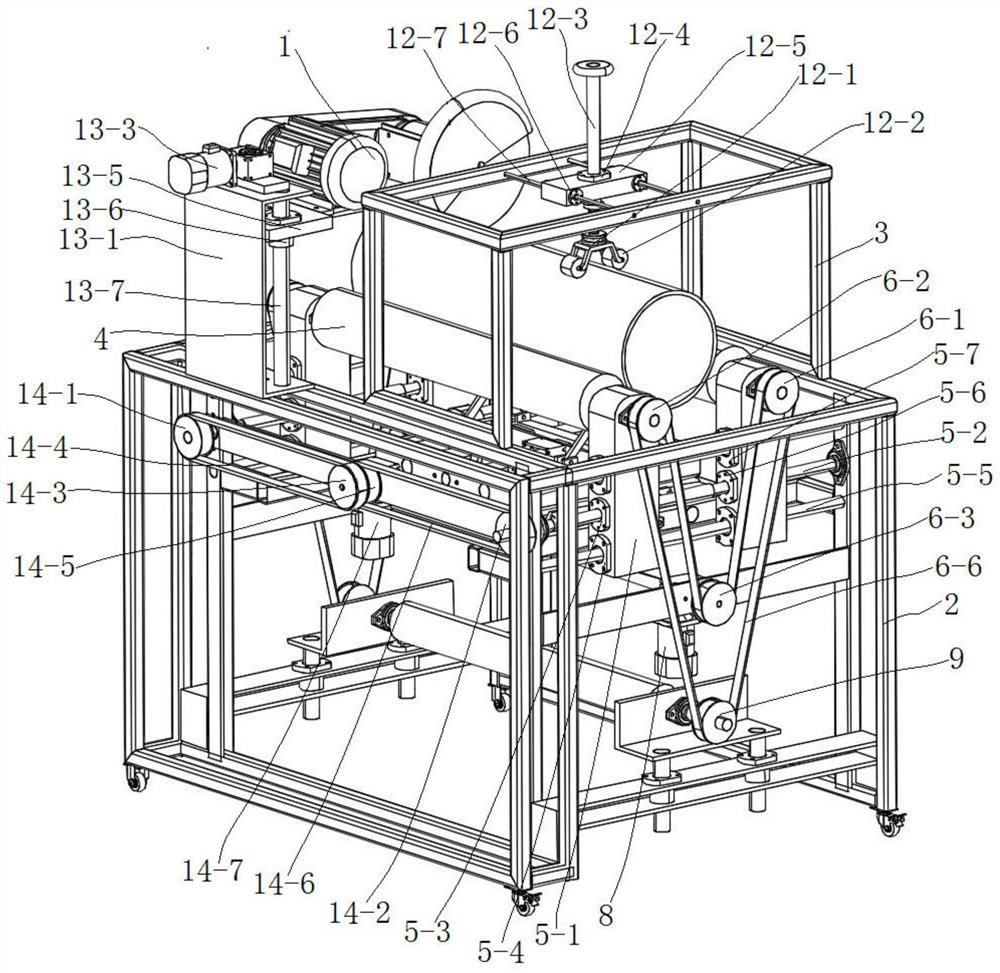

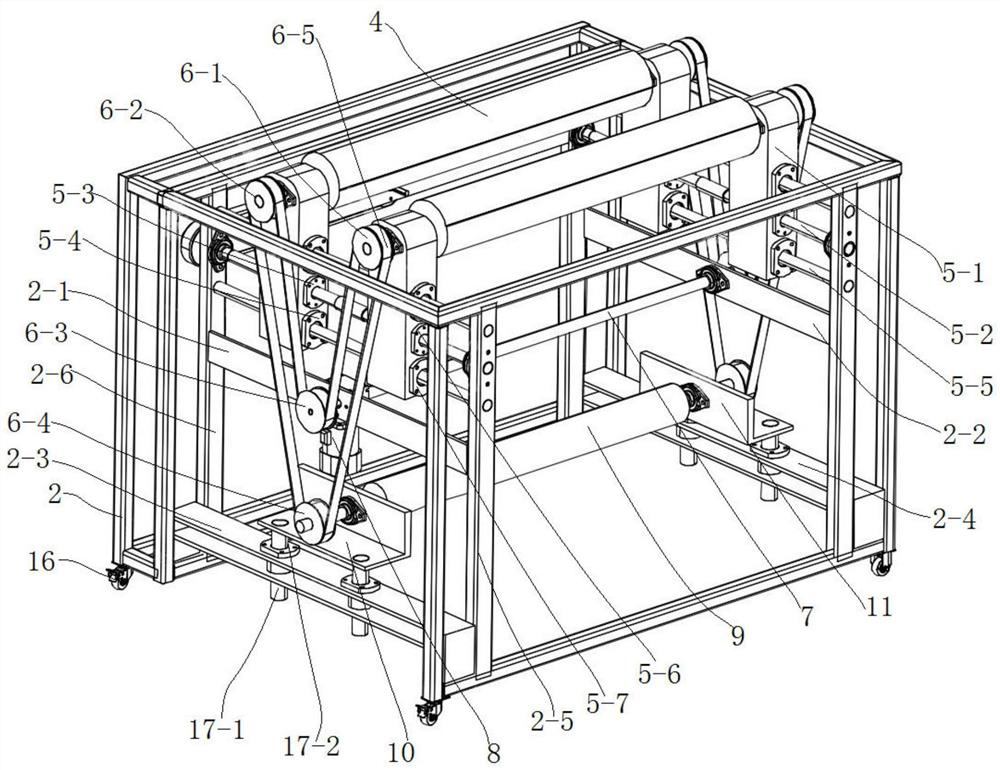

[0032] combine figure 1 with figure 2 , a large-diameter round pipe toothless saw cutting machine in this embodiment includes a toothless saw 1, a lower support frame 2, an upper support frame 3 and a round pipe rotation support mechanism, and the bottom four corners of the lower support frame 2 are installed There are universal casters 16 with brake function, which are easy to move; the toothless saw 1 is installed on the toothless saw feeding device that can drive the toothless saw to move up and down, and the toothless saw feeding device is fixed on the bottom of the lower support frame 2 On the right end of the first top frame; through the toothless saw feeding device, the toothless saw 1 is controlled to descend while cutting, so as to complete the purpose of cutting large-diameter round pipes;

[0033] In this embodiment, the toothless saw feeding device (see Figure 4 Shown) comprises feed frame 13-1 and the second screw mandrel 13-2 of vertical arrangement, and feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com