Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "The feeding process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

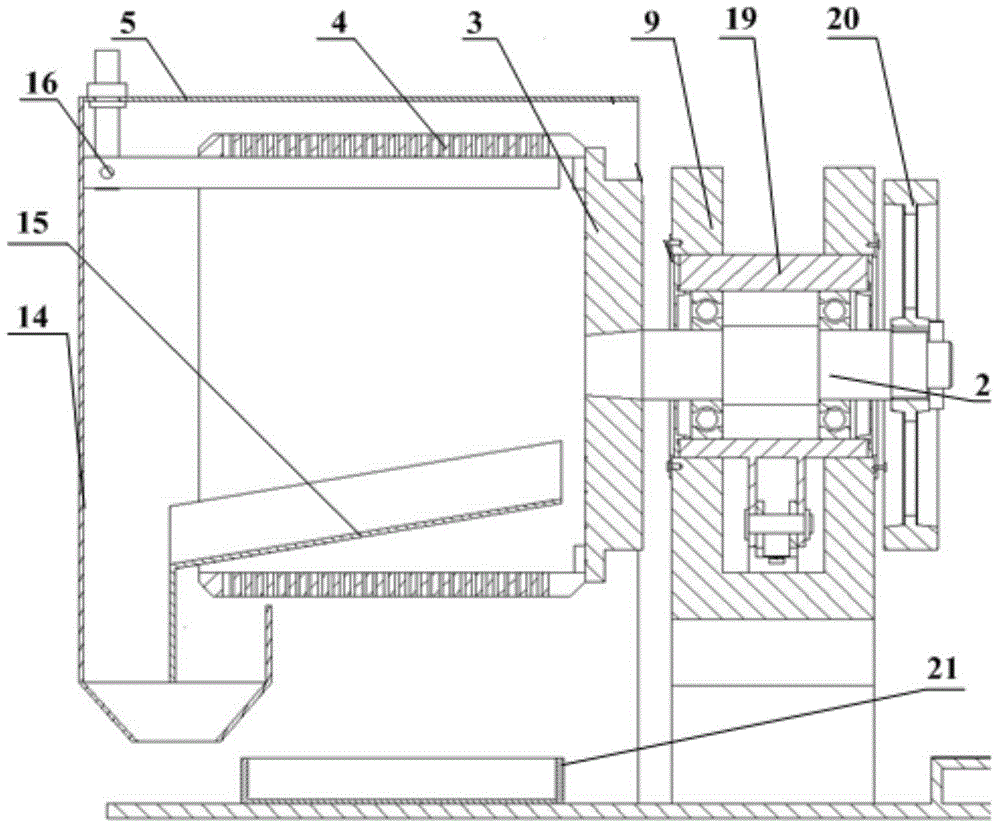

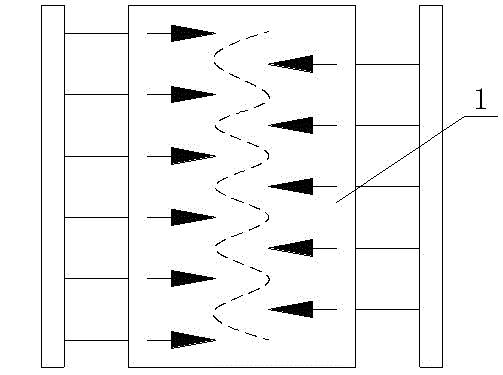

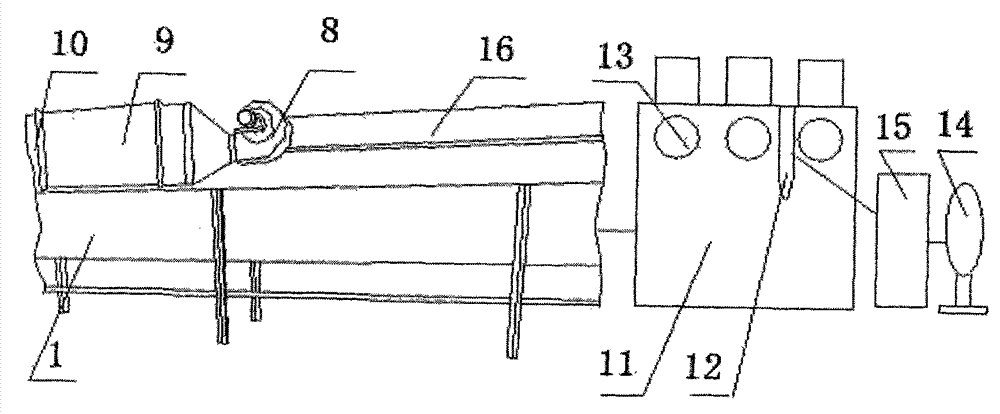

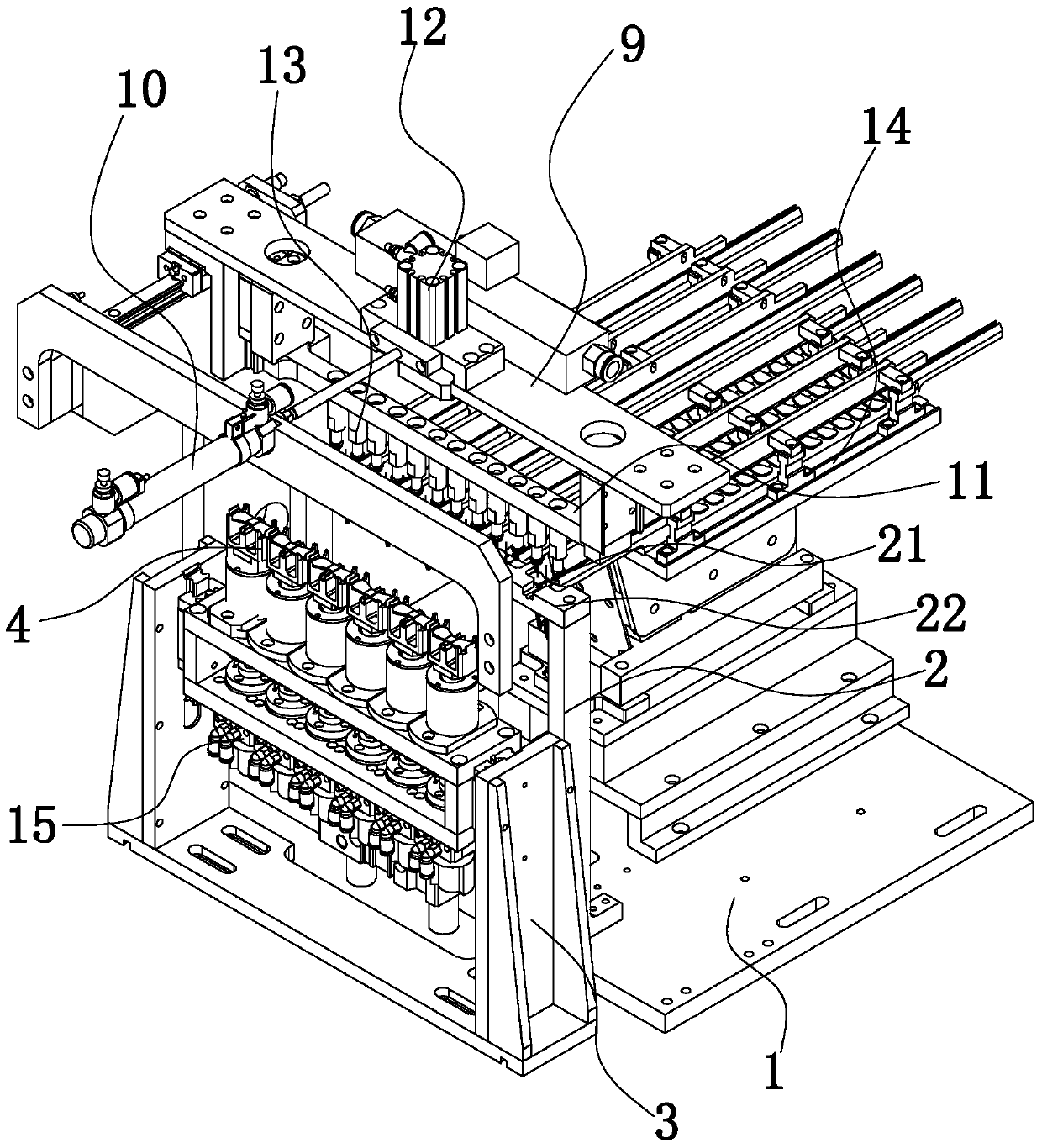

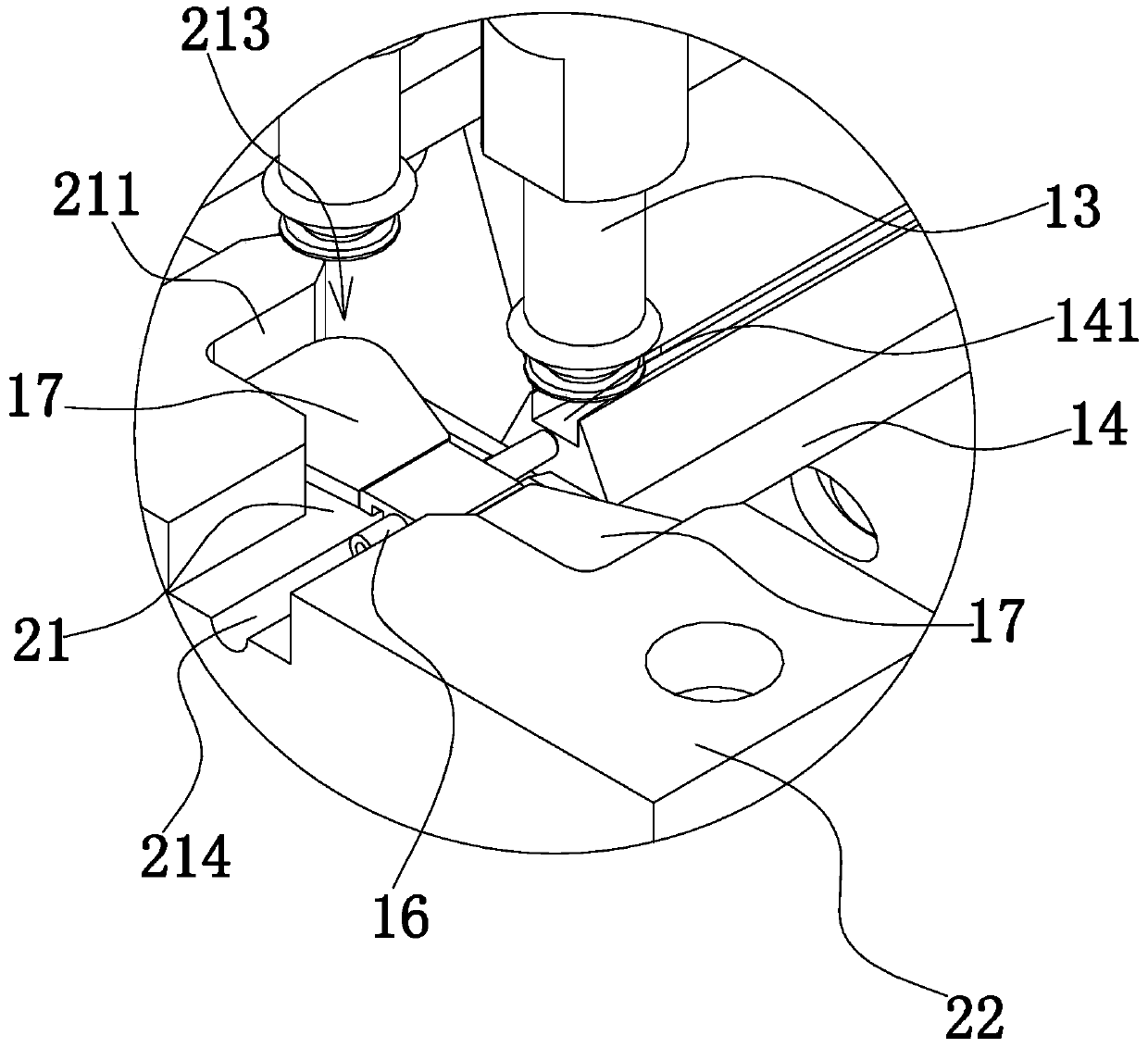

Slurry feeding type metal part material increase manufacturing method and device

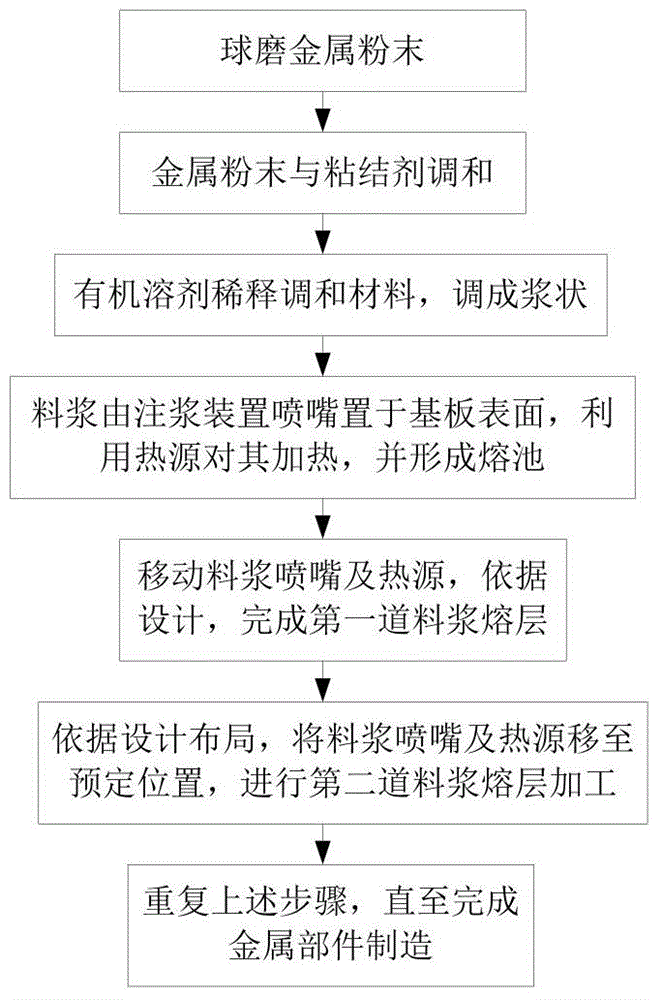

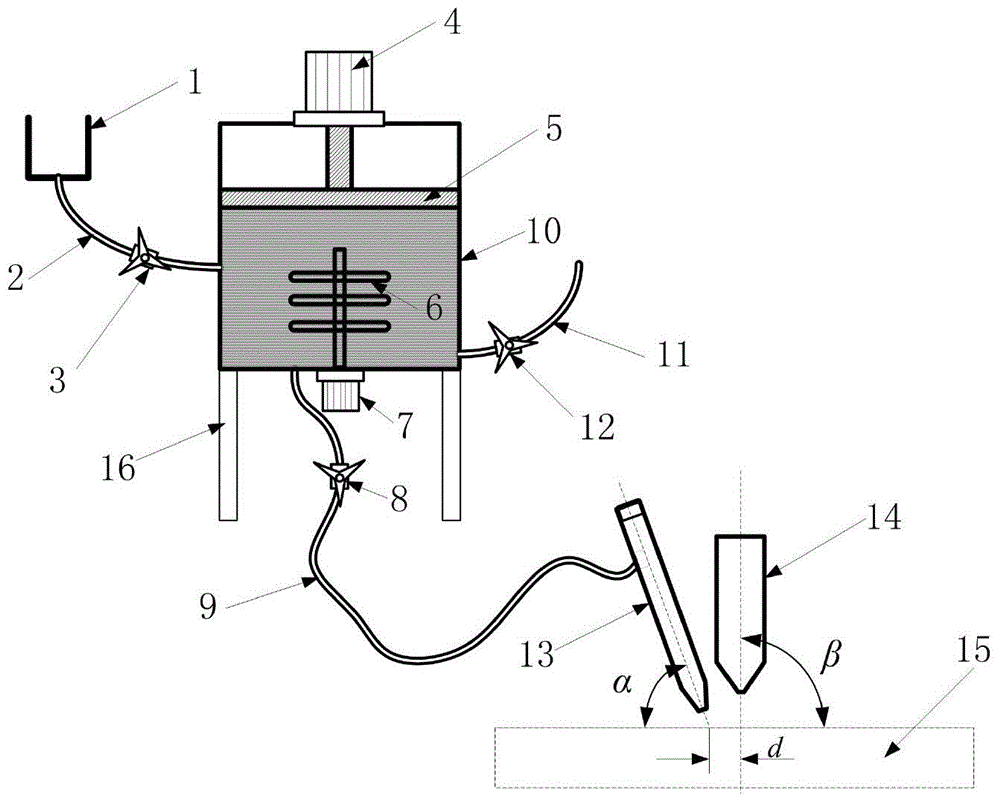

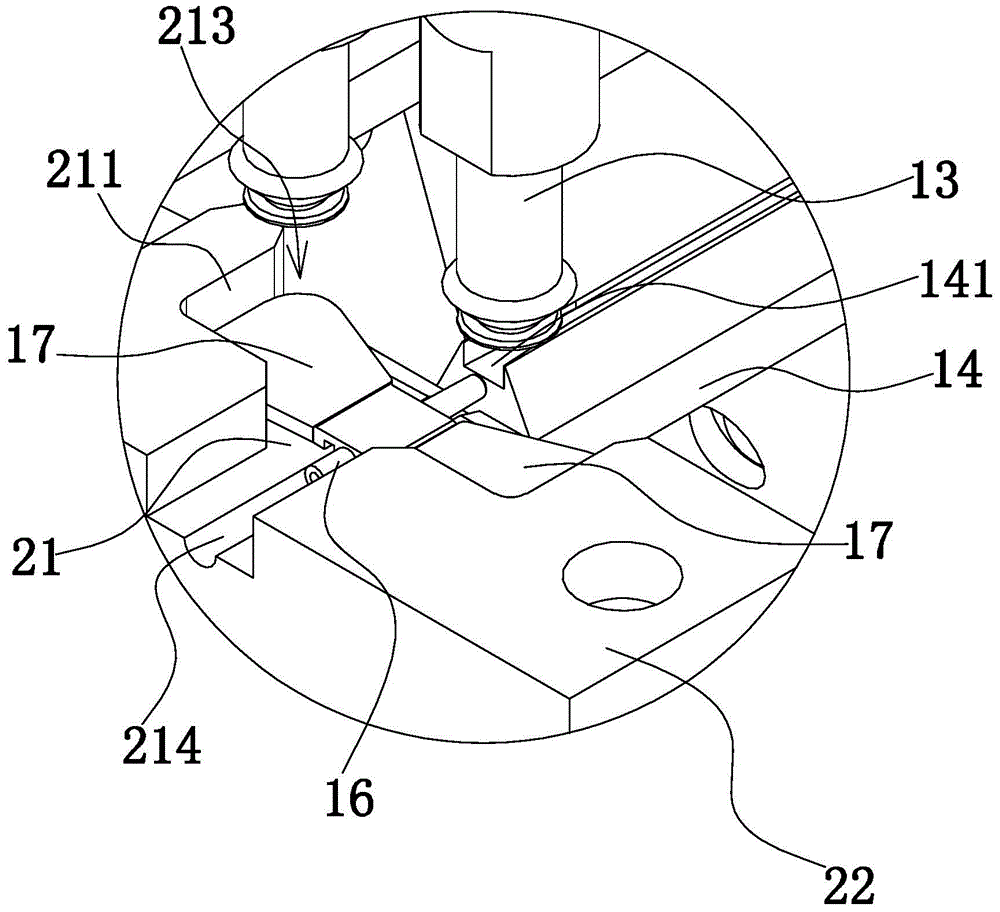

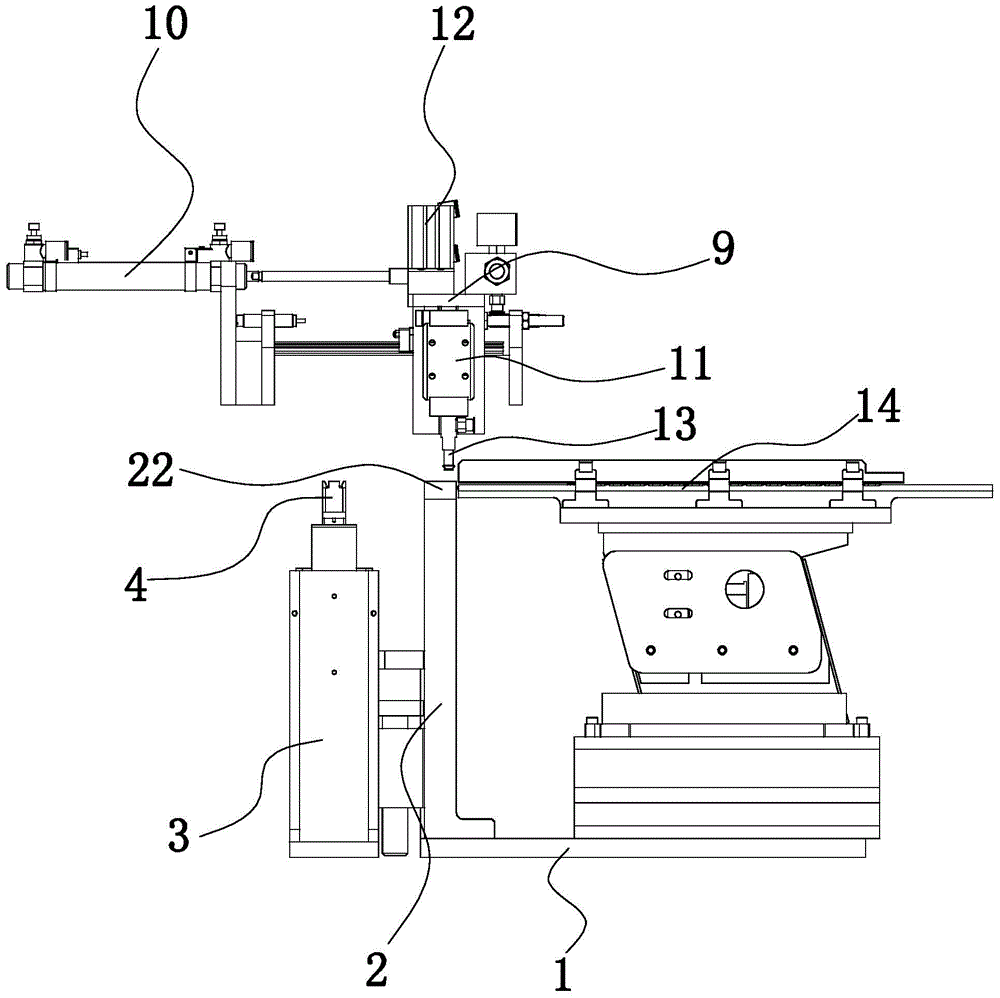

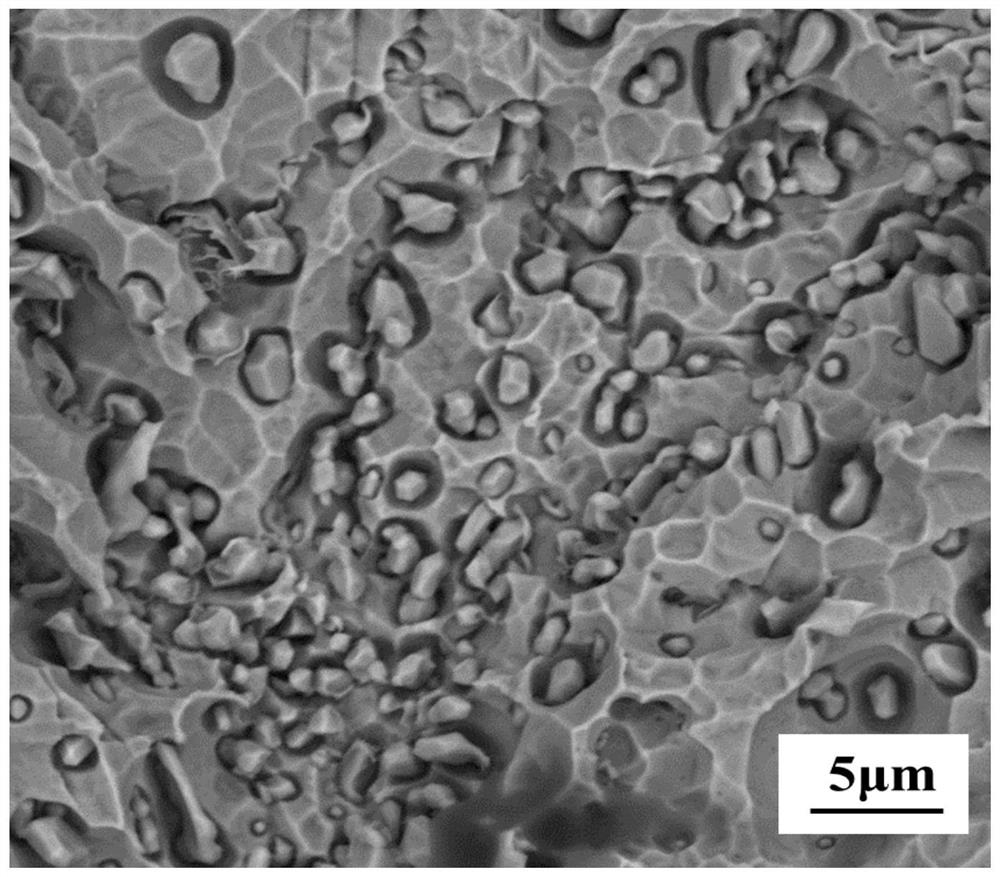

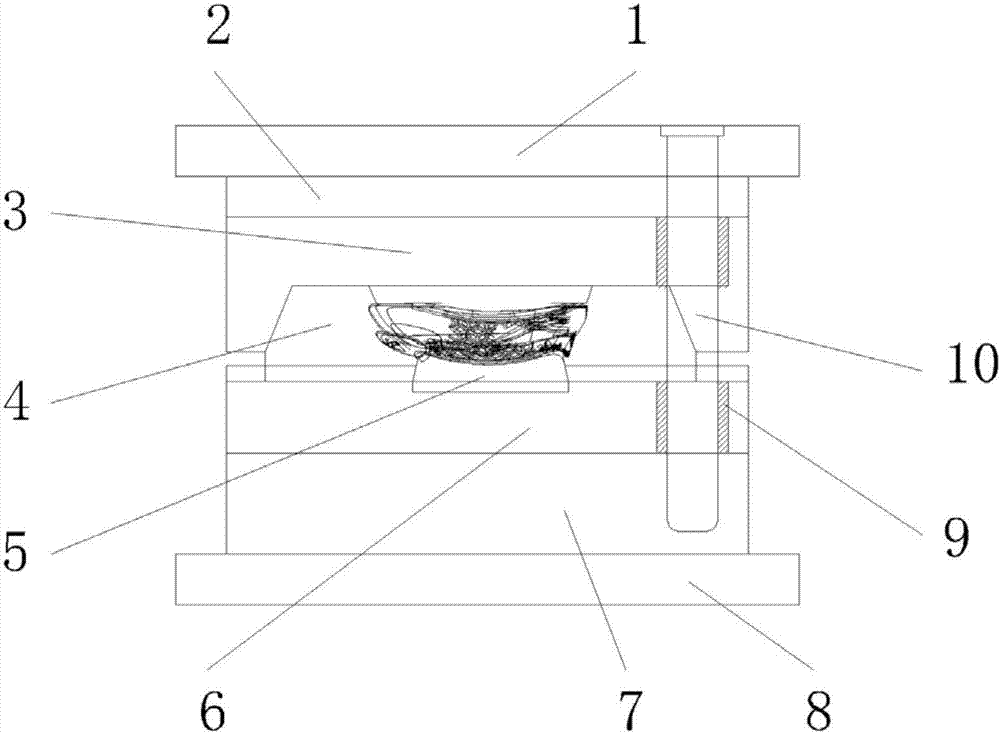

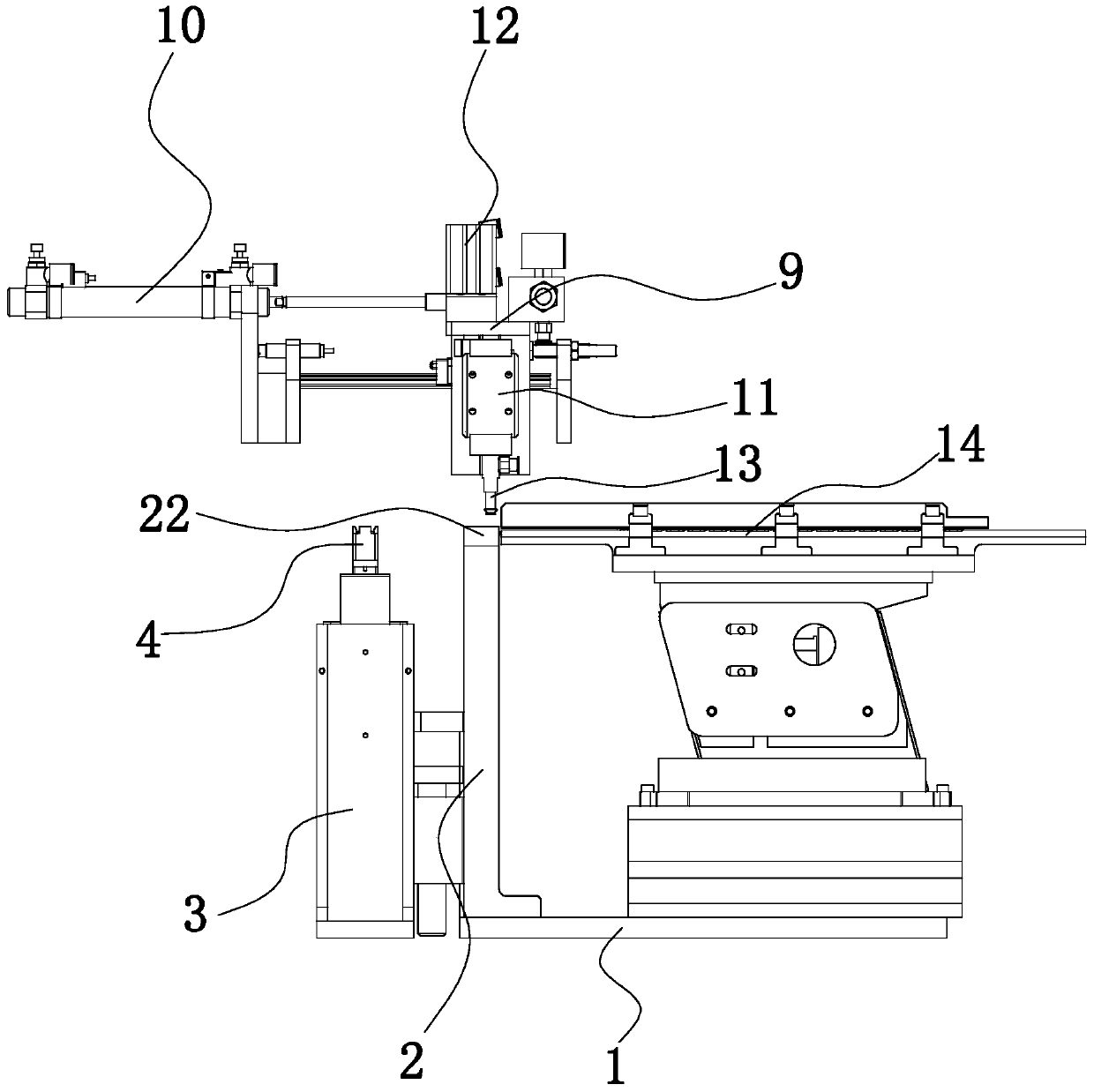

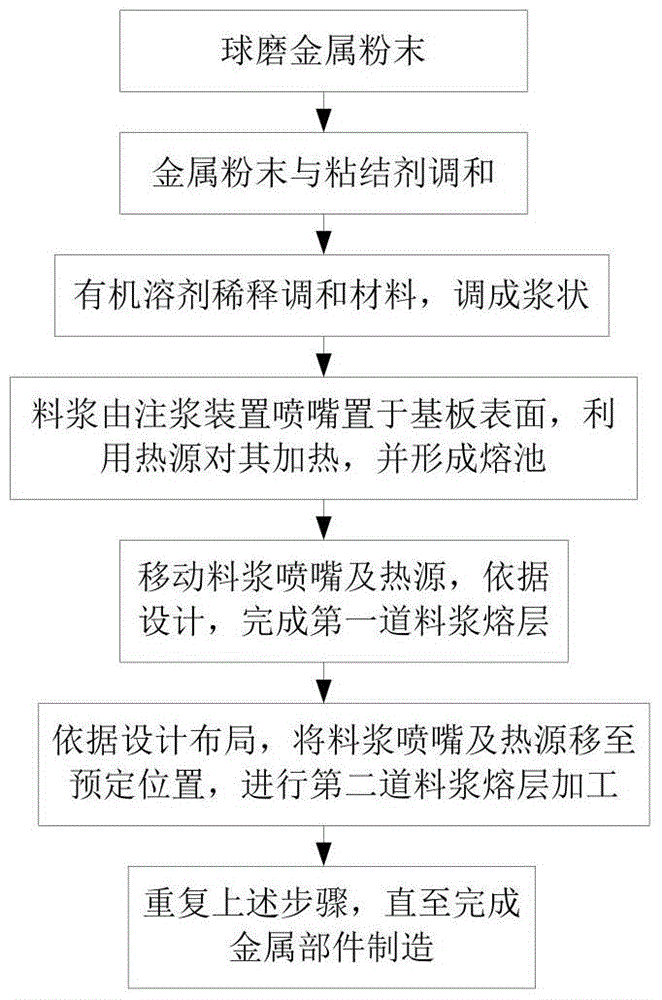

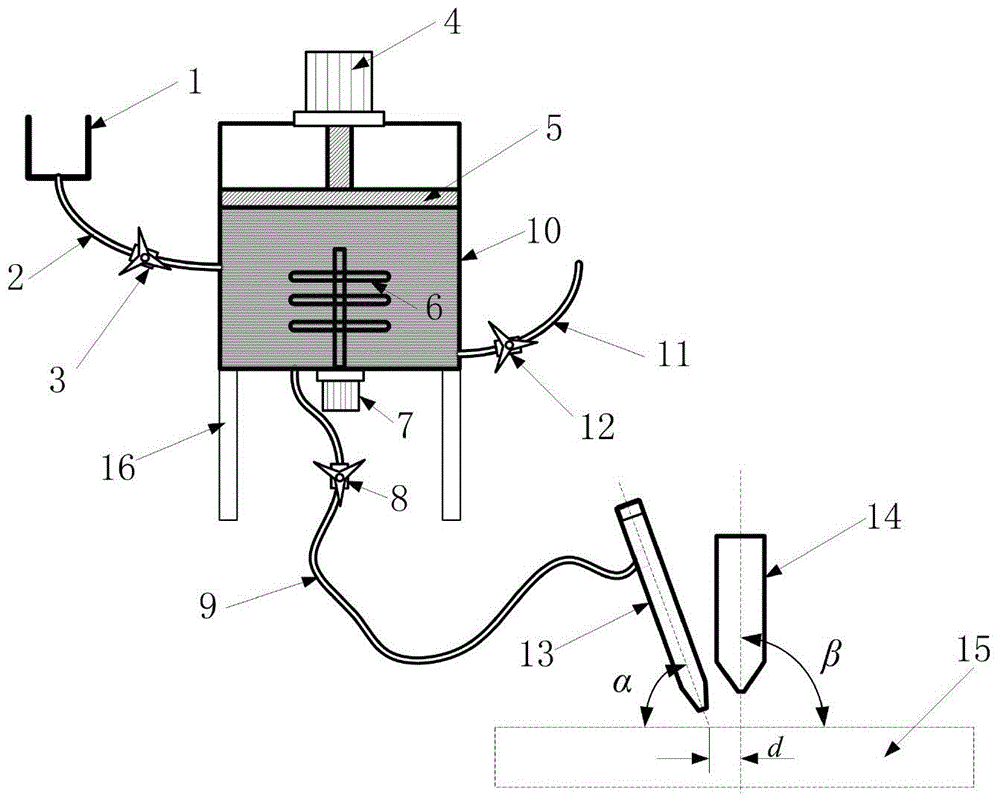

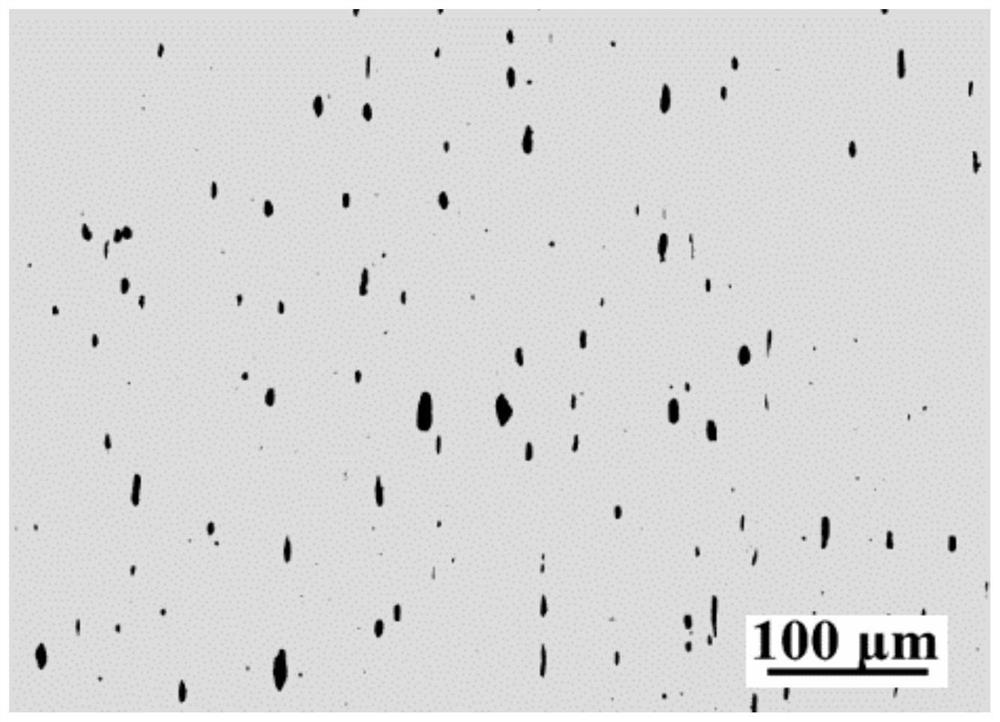

The invention discloses a slurry feeding type metal part material increase manufacturing method. The method comprises the steps that metal powder, binders and organic solvents are mixed together to form a solid-liquid two-phase slurry material, and slurry is taken as adding materials for material increase manufacturing; the slurry is sent out through a slurry feeding device, a heat source is adopted to conduct heating on the slurry material, fusion between layers of the slurry is achieved, and metal parts are formed by overlaying melt layers of the slurry layer by layer. By means of the slurry feeding type metal part material increase manufacturing method, the problems existing in powder feeding type and wire feeding type metal material increase manufacturing are solved, and advantages of the powder feeding type and the wire feeding type metal material increase manufacturing are synthesized, so that the slurry feeding type metal part material increase manufacturing method has the advantages that the material manufacturing cost is low, the material utilization is over 90%, requirements for the shape and the size of powder are low, powder pollution does not exist, the adding materials are stable and controllable, and the applicability is strong. The invention further discloses the slurry feeding device of the metal part material increase manufacturing method.

Owner:JIANGSU UNIV OF SCI & TECH

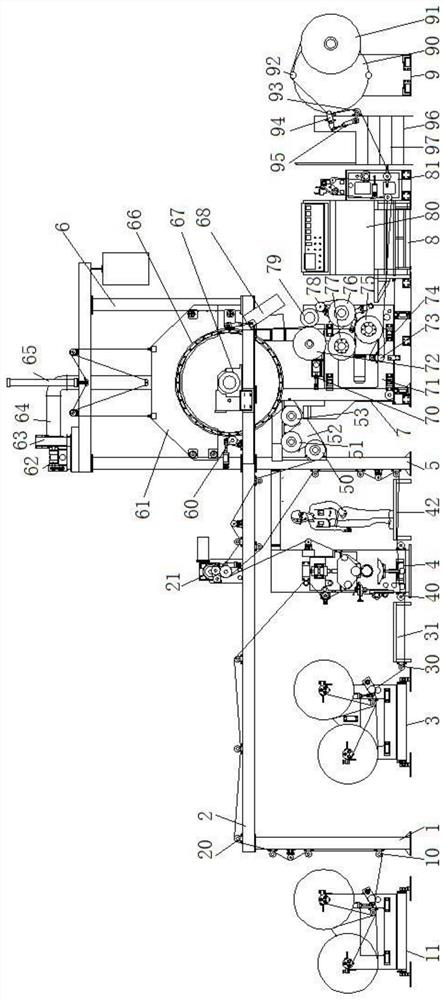

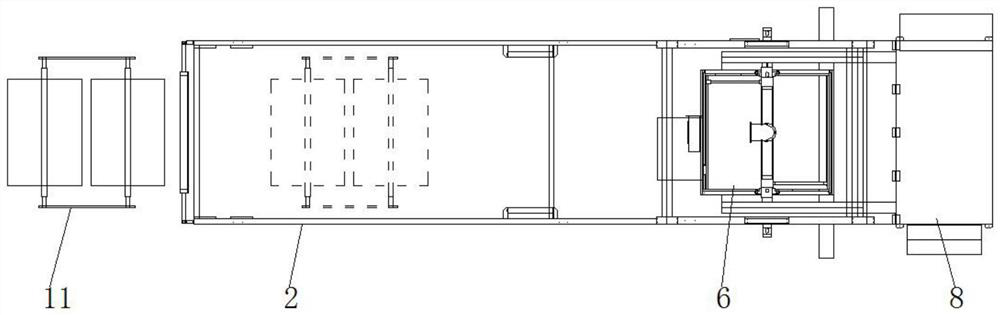

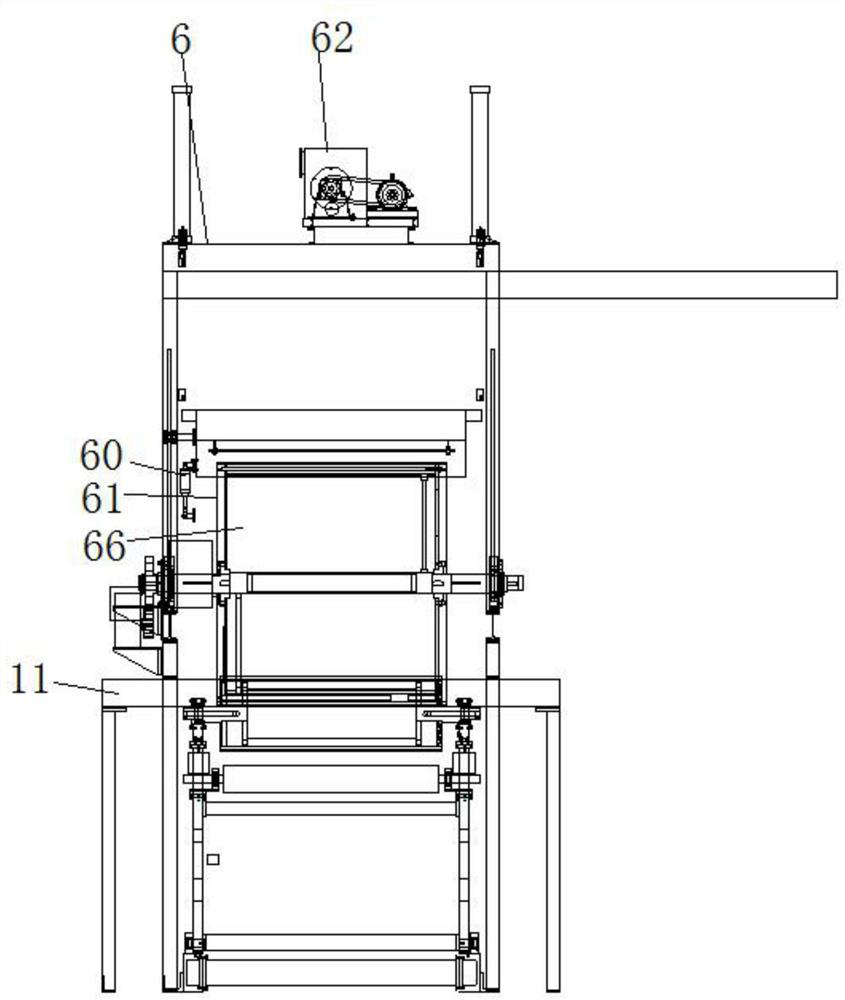

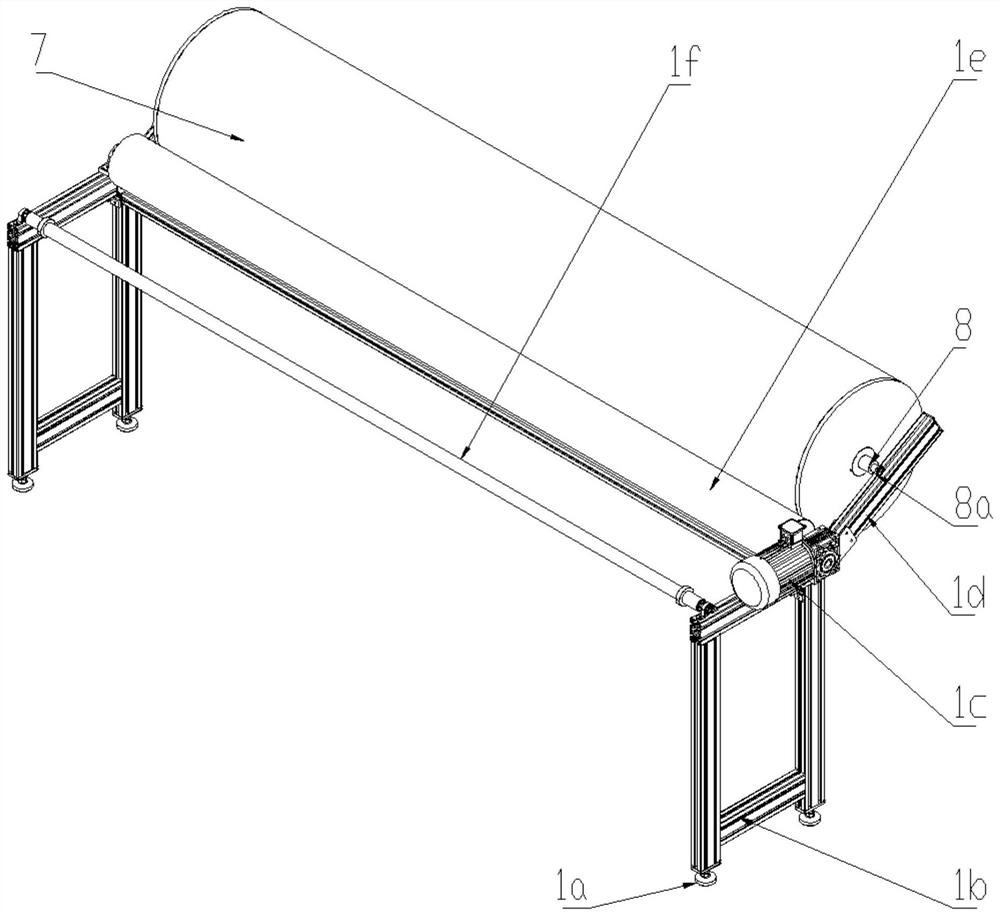

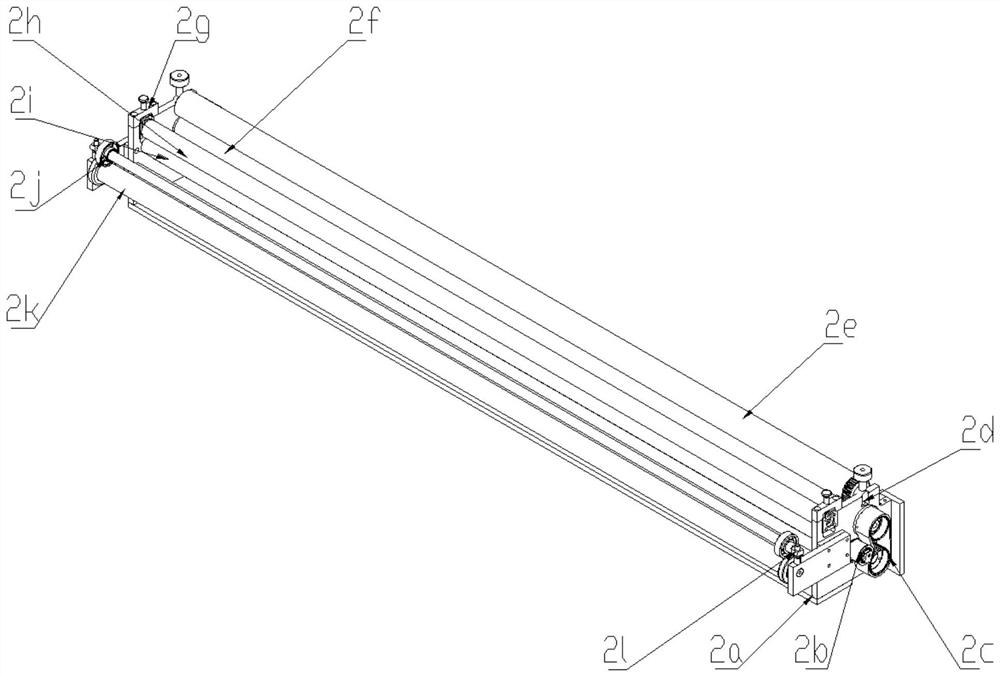

Production line for cloth cutting

ActiveCN109626048APrevent slippingUniform feedingSevering textilesTextile disintegration and recoveryProduction lineMechanical equipment

The invention discloses a production line for cloth cutting, aims at solving disadvantage that when cutting processing is performed on cloth, mechanical equipment have various problems in actual production to influence the processing quality, and the production efficiency is influenced by material receiving in a manual manner in the prior art and provides the production line for cloth cutting. Theproduction line for cloth cutting sequentially comprises a cloth releasing machine, a cloth strip cutting machine, a cloth block cutting machine and a cloth transferring machine in a cloth moving direction. The production line avoids the cloth from skidding, is beneficial to stably releasing the cloth at a constant speed, prolongs the service life of a hot knife, is beneficial to cutting the cloth, saves the manpower and improves the production efficiency by adopting automatic material receiving and is suitable for being used when the cloth is cut.

Owner:福建山普新材料有限公司

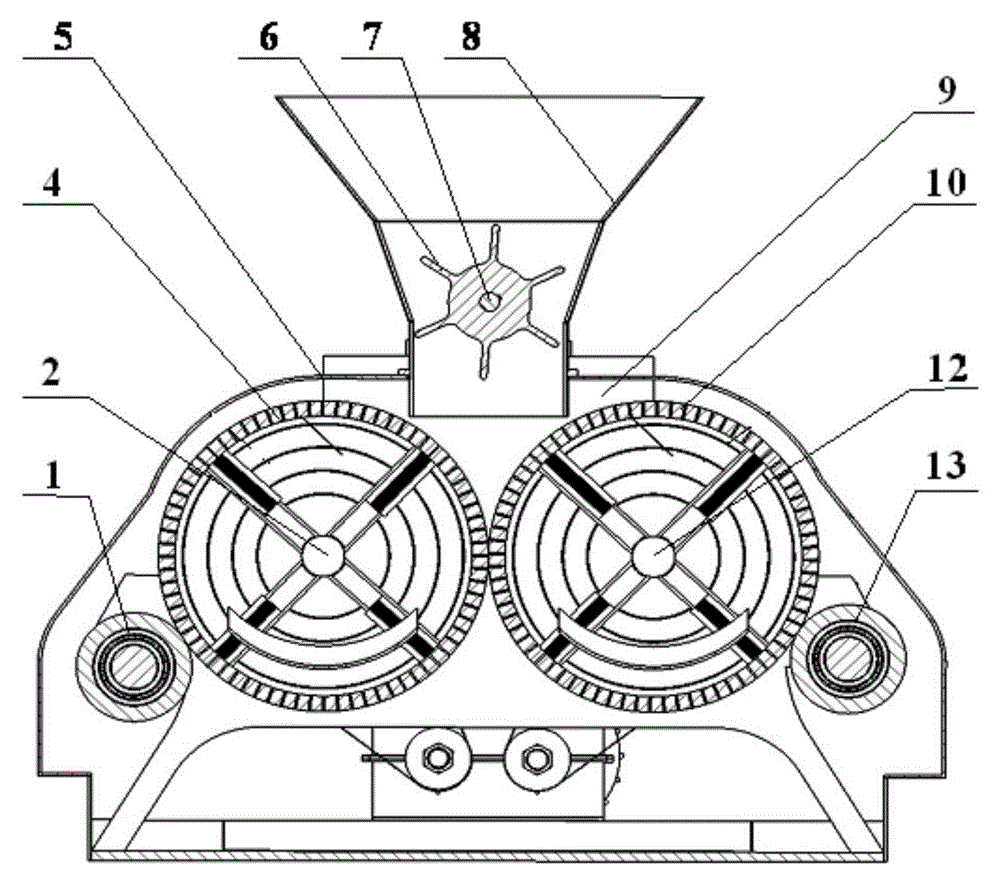

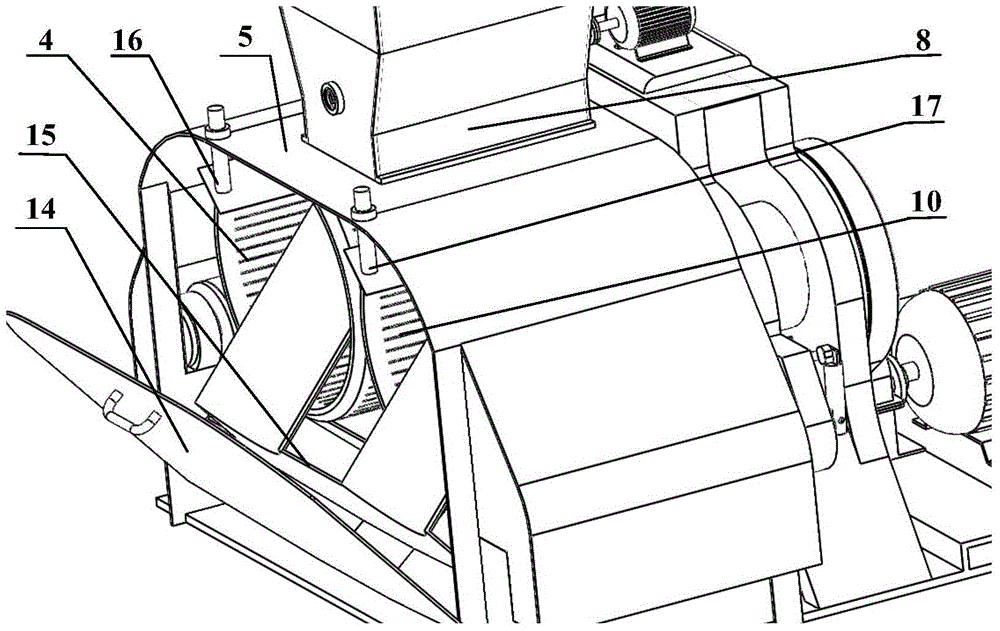

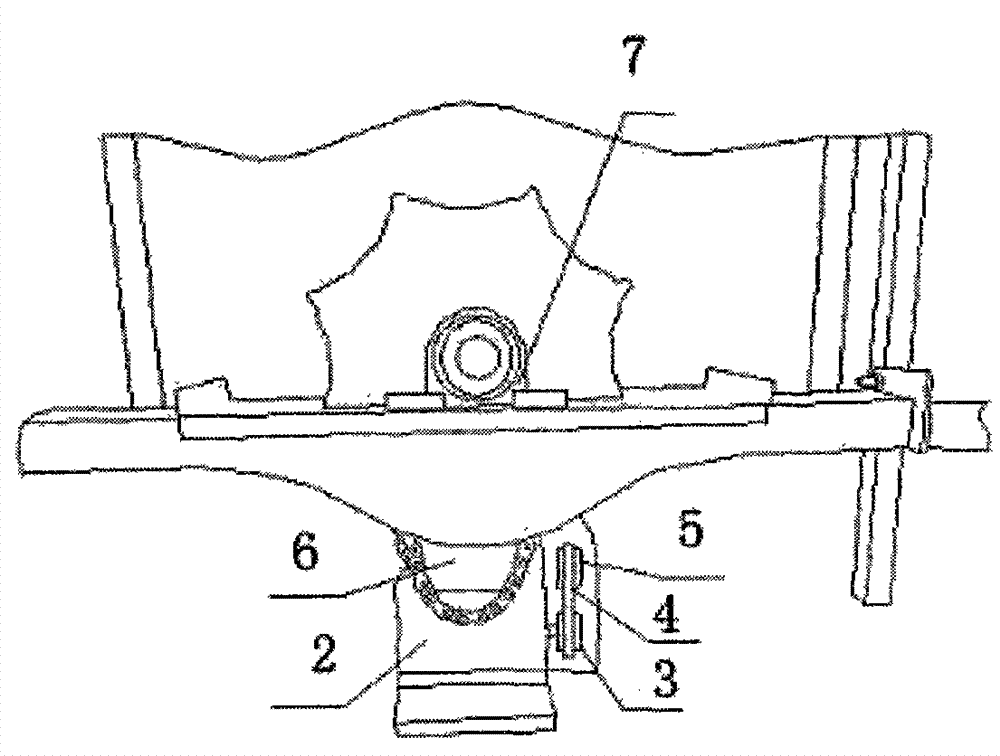

Double supporting rollers-type double circular molds granulator

InactiveCN105013397AEasy to disassemble and replaceImprove support stiffnessGranulation by pressingImpellerReducer

The invention discloses a double supporting rollers-type double circular molds granulator, which comprises a first supporting roller, a first rotating shaft, a first circular mold, a casing, an impeller, an impeller shaft, a hopper, a support, a second circular mold, a second rotating shaft, a second supporting roller, a door cover, a material collecting trough, a first scraper, a second scraper, a first bearing sleeve, a first belt wheel, a residual material groove, a gear reducer, a main motor, a second belt wheel, a second bearing sleeve, a first synchronous belt, a third belt wheel, a first compaction wheel, a second compaction wheel, a fourth belt wheel, a second synchronous belt, and an impeller motor. The double circular molds granulator has the advantages that dismounting and replacing of the circular molds are convenient and fast, the supporting rollers support the circular molds, support rigidity of the circular molds can be greatly increased, the granulator can be used for extruding the difficultly-extruded materials, width of the circular molds can be increased greatly, granulation efficiency is greatly increased; the scraper is employed for cooperating the material collecting trough for collecting the material, the material collecting trough is arranged on the door cover, when the door cover is opened, a cutter on the scraper is dismounted so that the circular molds can be rapidly replaced.

Owner:NANJING UNIV OF SCI & TECH

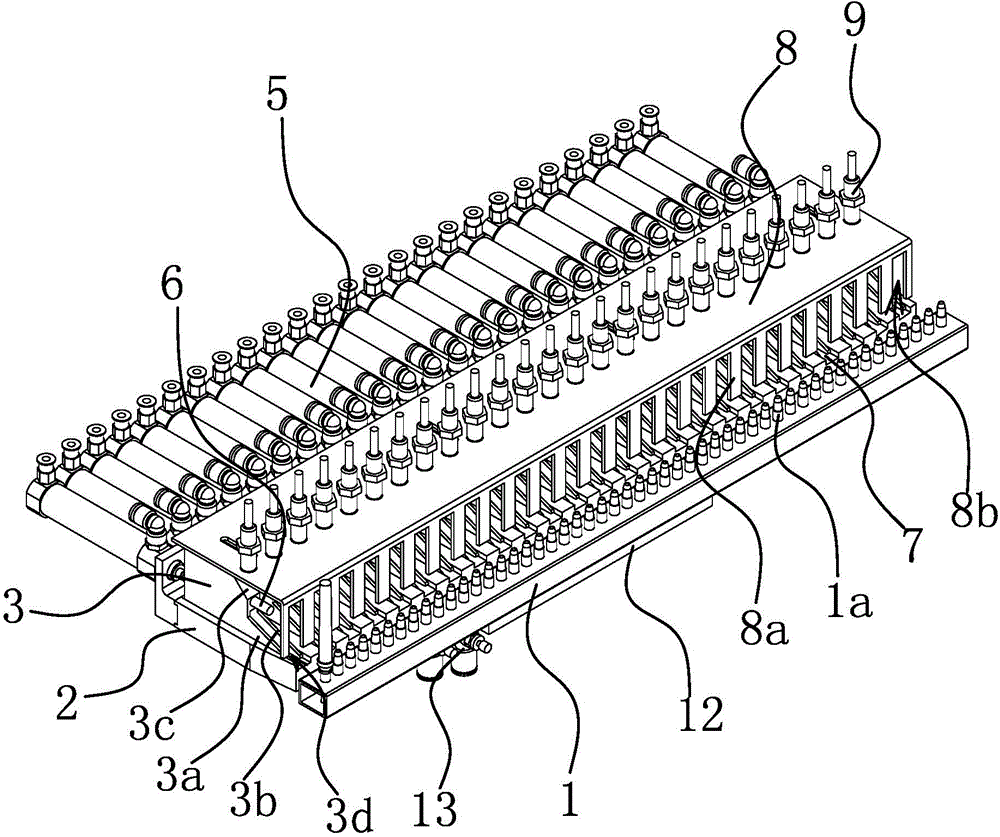

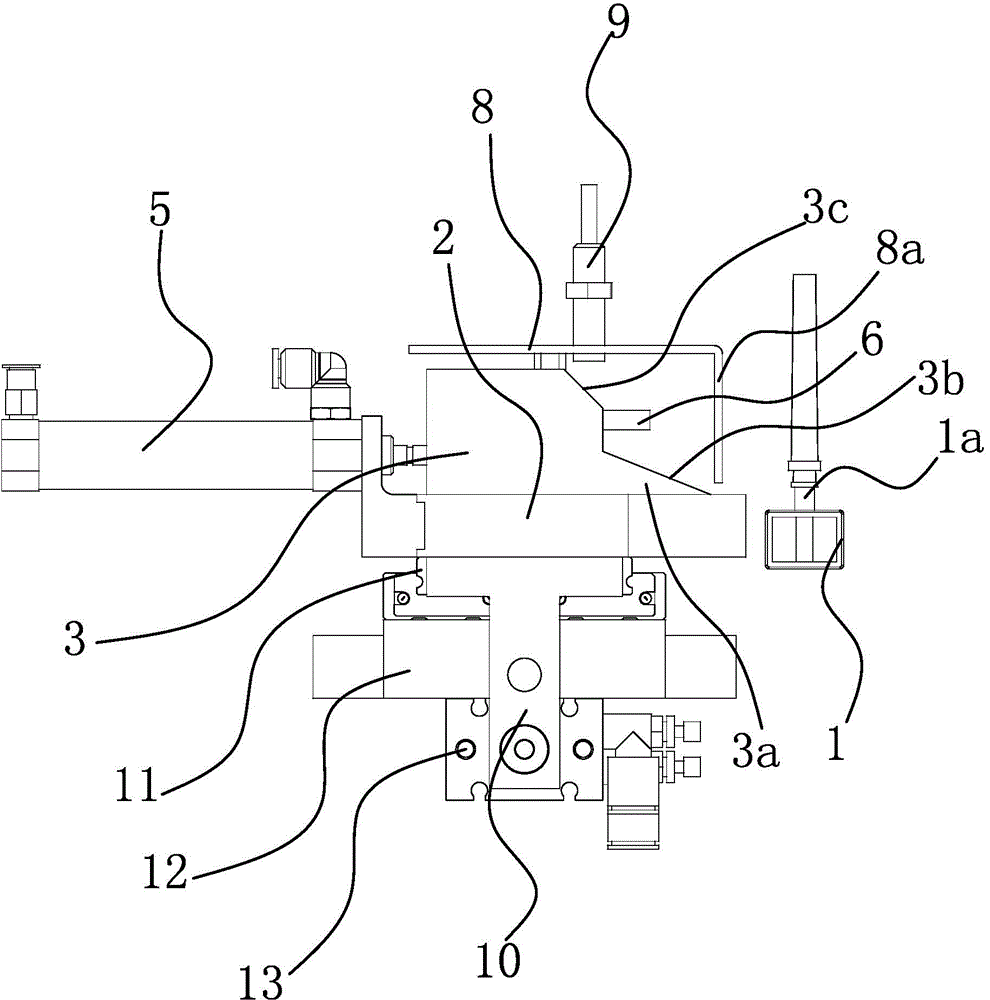

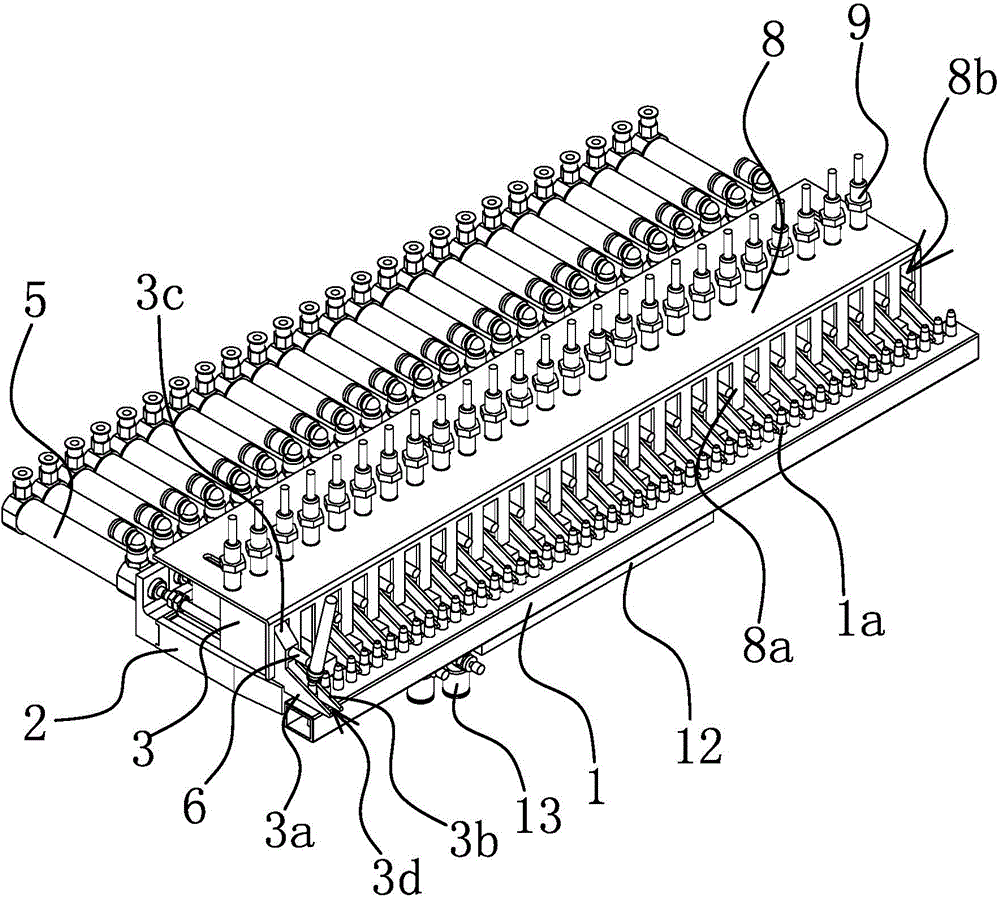

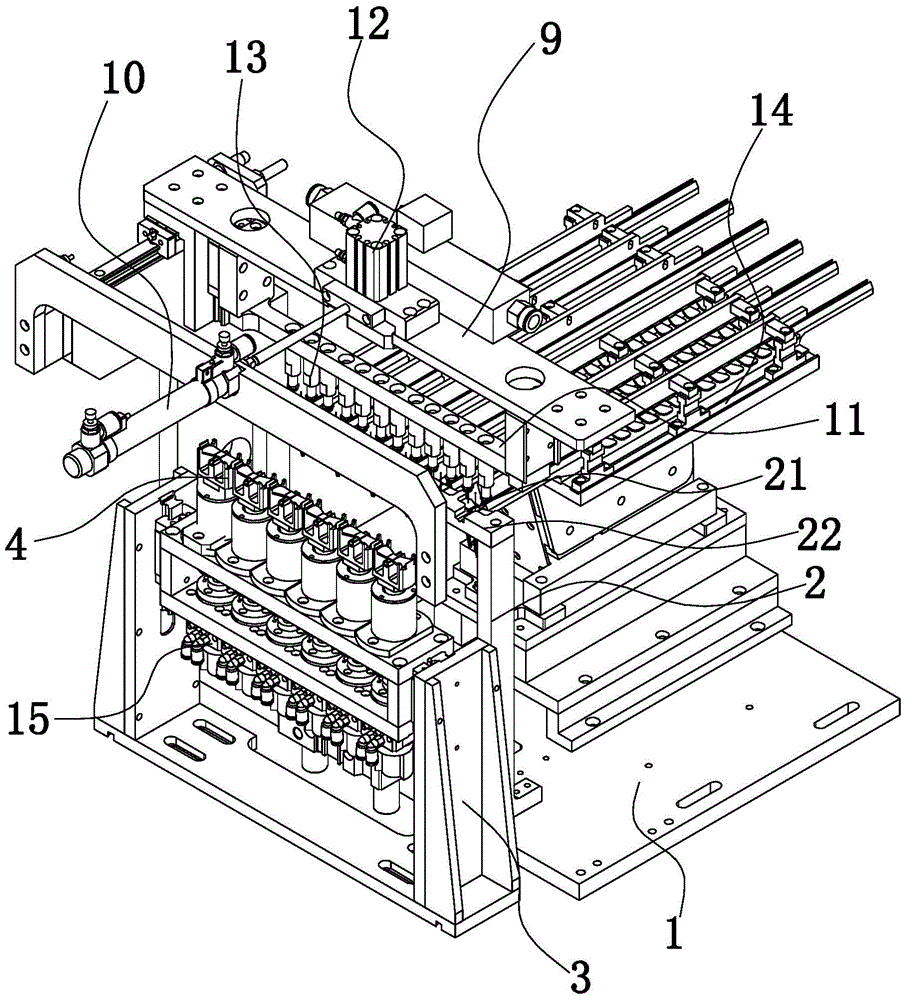

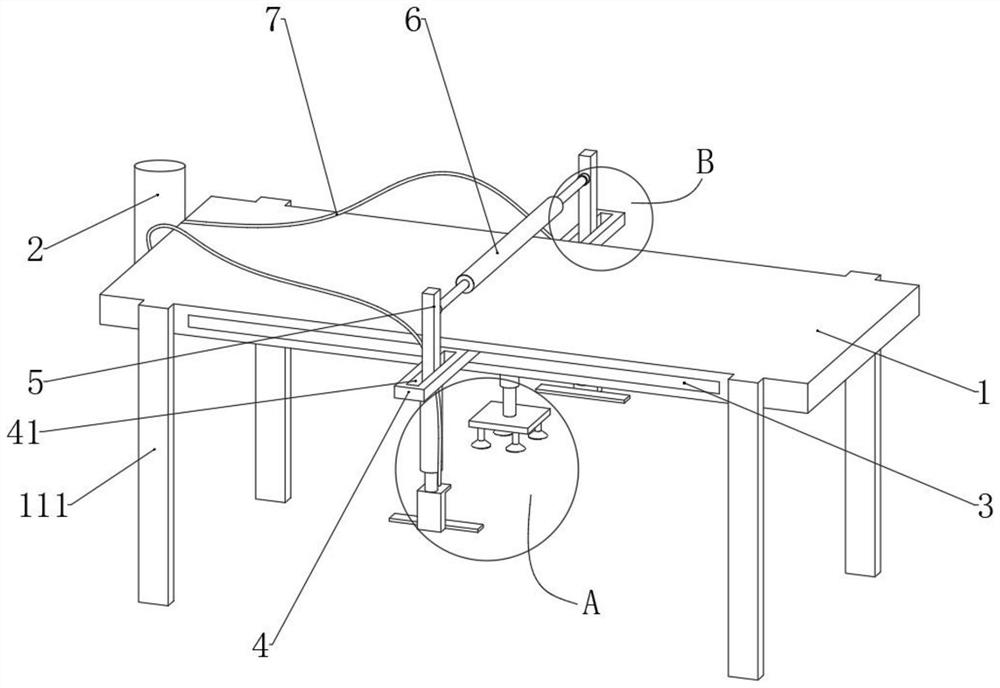

Discharging device for medical accessory assembling machine

ActiveCN104609172AReliable feeding processThe feeding process is stableConveyor partsElectrical and Electronics engineeringAssembly machine

The invention provides a discharging device for a medical accessory assembling machine and belongs to the technical field of medical accessory assembling machines. The discharging device solves the problems that a discharging device for medical accessories in the prior art carries out discharging unstably and is low in reliability. The discharging device for the medical accessory assembling machine comprises a carrier arranged on a rack of an assembling machine rack and an installing base located on one side of the carrier. The carrier is provided with a plurality of locating columns, wherein the locating columns are sleeved with the medical accessories and locate the medical accessories. A plurality of discharging blocks are arrayed and arranged on the installing base at intervals. Two discharging plates are arranged at the bottoms of the front ends of the discharging blocks. The upper surfaces of the discharging plates are discharging slopes with low front portions and high rear portions. A discharging port is formed between the two discharging plates. A first drive source capable of driving the discharging blocks to move is arranged on the installing base. The installing base is provided with a guiding structure. The discharging blocks can move along the guiding structure to enable the locating columns to be located in the discharging port. Discharging ejector rods are arranged on the end faces of the front ends of the discharging blocks. The discharging device has the advantage that the discharging process is stable and reliable.

Owner:MAIDER MEDICAL IND EQUIP

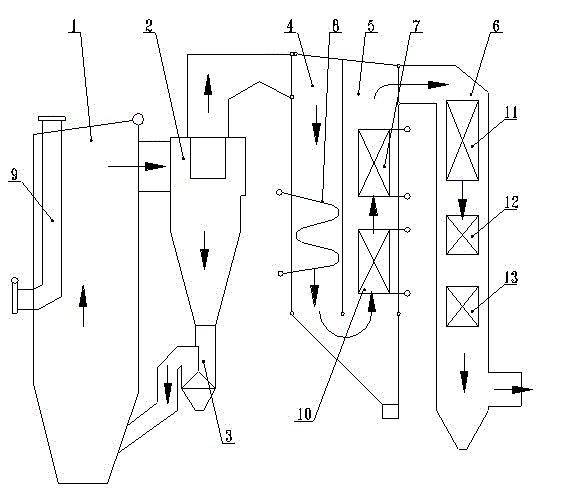

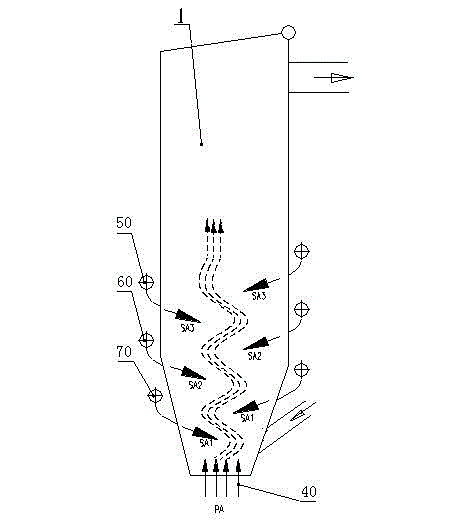

Circulating fluidized bed boiler unit for high efficiency combustion of biomass and recovery of waste heat

InactiveCN103148479AUniform and reasonable temperature fieldNo fusion bonding occursFluidized bed combustionApparatus for fluidised bed combustionEngineeringSuperheater

The invention relates to a circulating fluidized bed boiler unit for high efficiency combustion of biomass and recovery of waste heat. The circulating fluidized bed boiler unit comprises a hearth, a tail flue and a secondary air distribution system and is characterized in that the tail flue is provided with three tandem parallel channels, i.e., a first tail flue, a second tail flue and a third tail flue , an inlet of the first tail flue is connected with a horizontal flue outlet of a cyclone separator, the outlet steers 180 DEG and is then connected with an inlet of the second tail flue, an outlet of the second tail flue steers 180 DEG and is then connected with an inlet of the third tail flue, a heating surface is arranged in the tail flue, a coarse-pitch tipping-tube medium-temperature superheater is arranged in the first tail flue, the secondary air distribution system is an air distribution structure with upper-lower and horizontally left-right staggered junction formed by air distribution units staggerly arranged at the lower part, the waist part and the central part of the front and rear walls of the hearth, and the air distribution structure enables multiple layers of secondary air jet to be mutually crosswise sprayed into the hearth in a height direction and a horizontal direction. The boiler unit provided by the invention has high combustion efficiency, discharges a small amount of CO, reduces fly ash content in flue gas and guarantees that main steam parameters accord with design requirements.

Owner:HANGZHOU BOILER GRP CO LTD

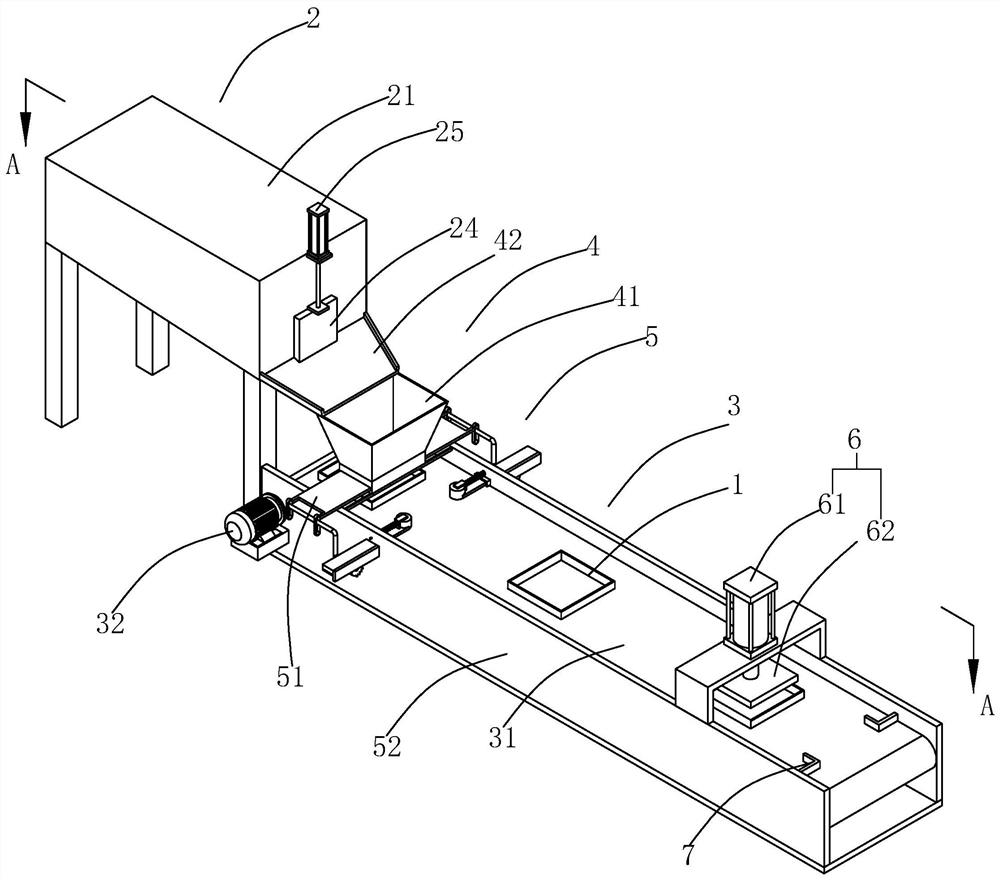

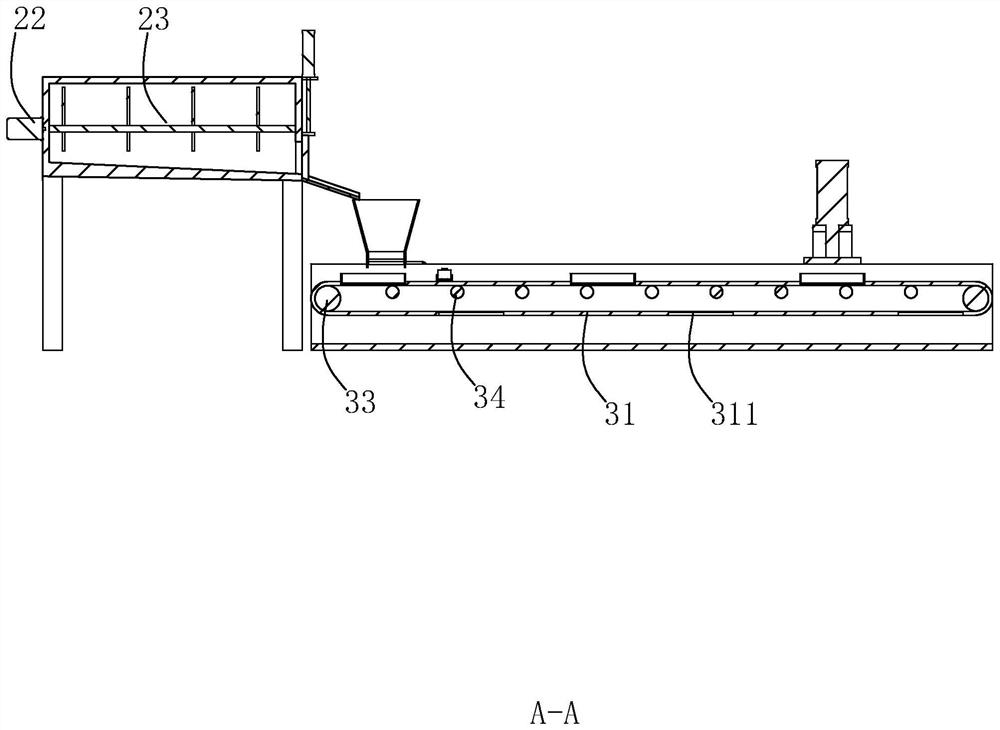

Automatic forming production line of insulation quilt

ActiveCN111376422ARealize the effect of automatic moldingSmooth transmissionProcess engineeringManufacturing line

The invention relates to an automatic forming production line of an insulation quilt, in particular to the technical field of insulation quit forming devices and methods. The automatic forming production line comprises a stirring mechanism used for stirring an insulation quilt raw material, a conveying mechanism used for conveying an insulation quilt mold, a pre-storing mechanism used for pre-storing the stirred raw material, a discharging mechanism used for automatically discharging the raw material in the pre-storing mechanism according to the insulation quilt mold conveyed by the conveyingmechanism, and a compacting mechanism used for compacting the discharged raw material in the insulation quilt mold to be formed. The automatic forming production line has the effect of insulation quilt automatic forming.

Owner:山东宇能环境工程有限公司

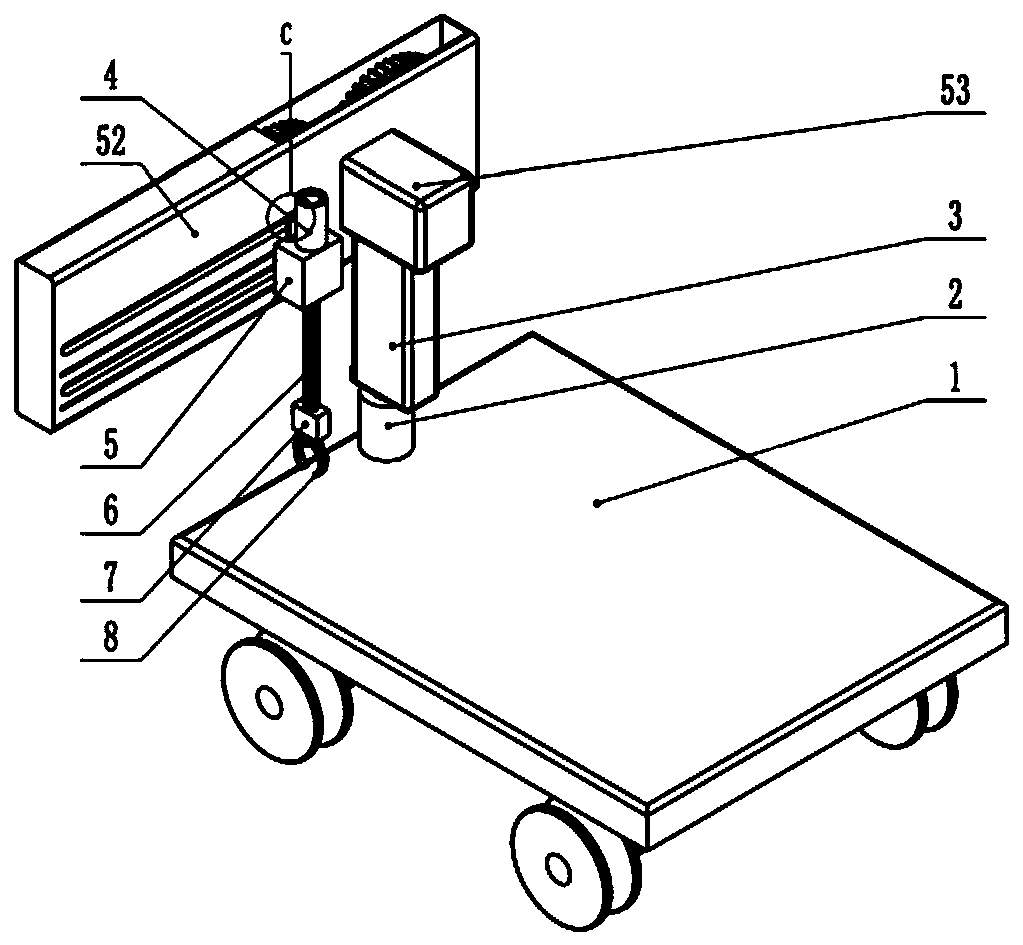

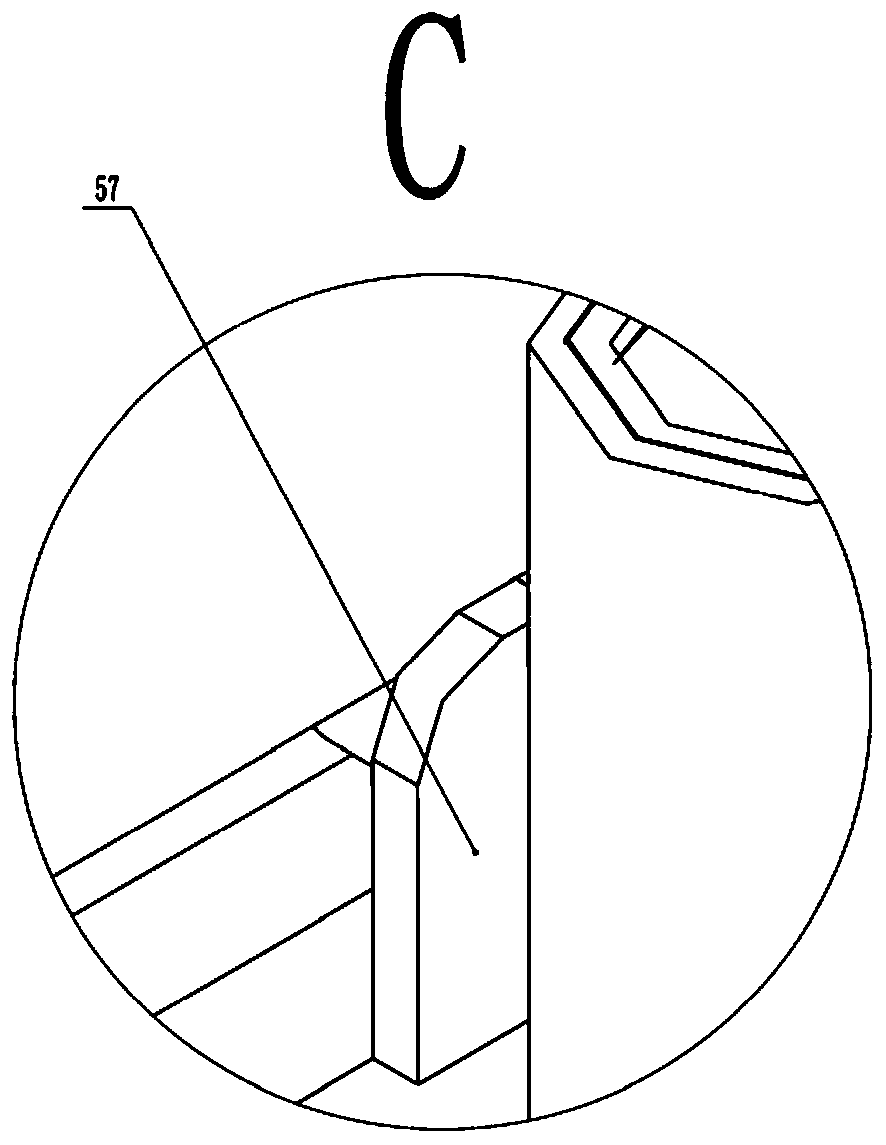

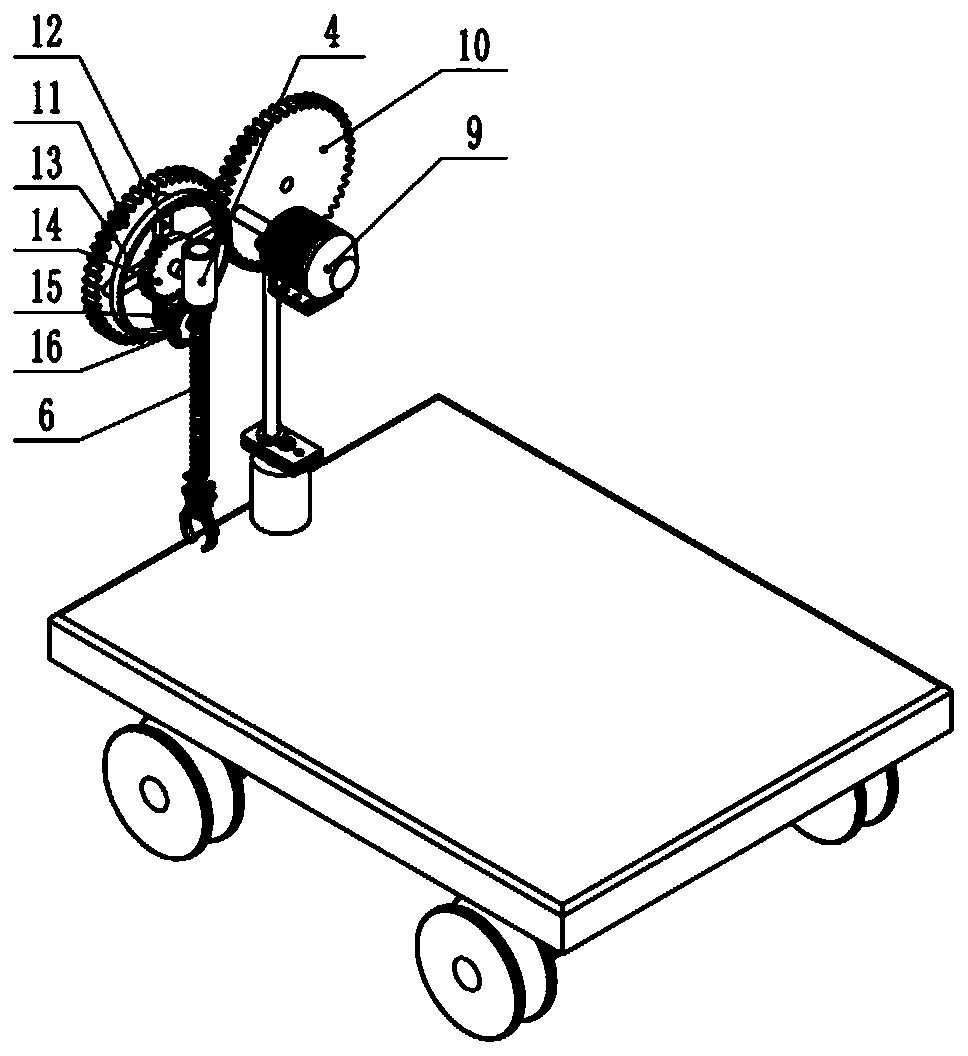

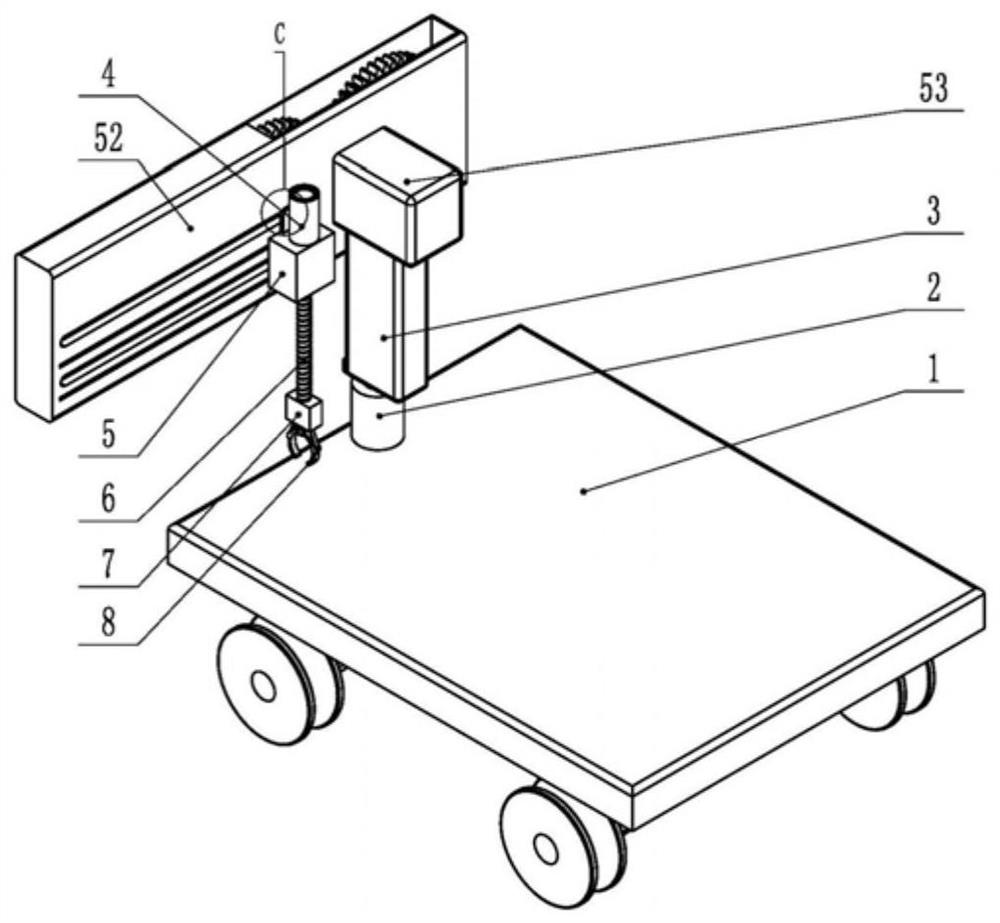

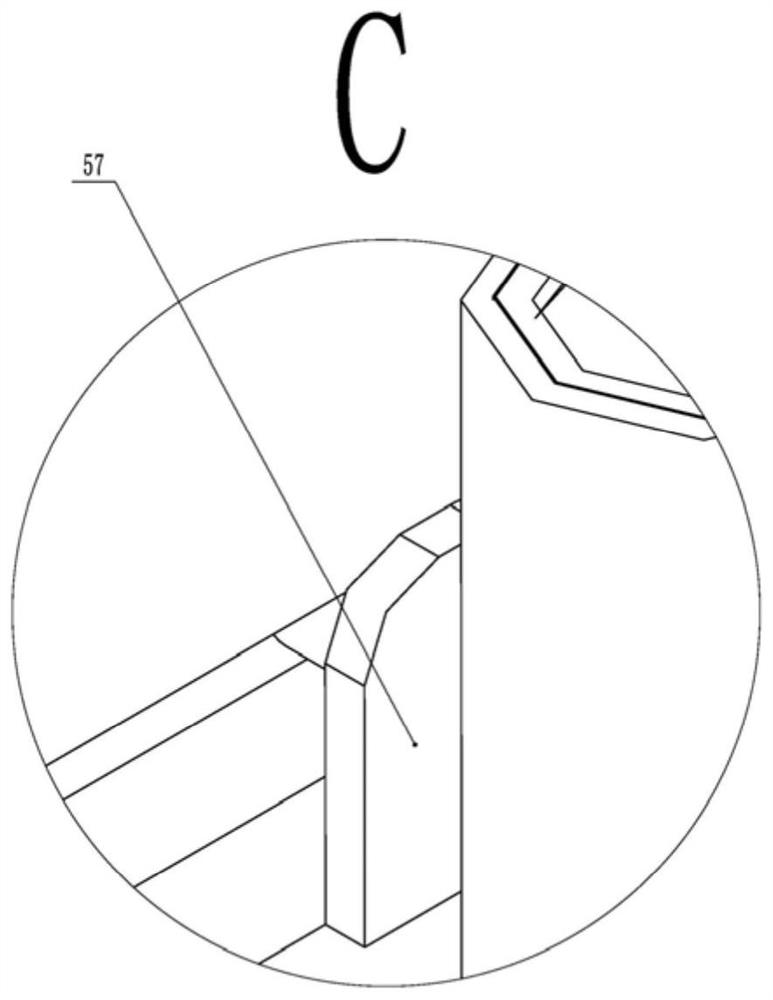

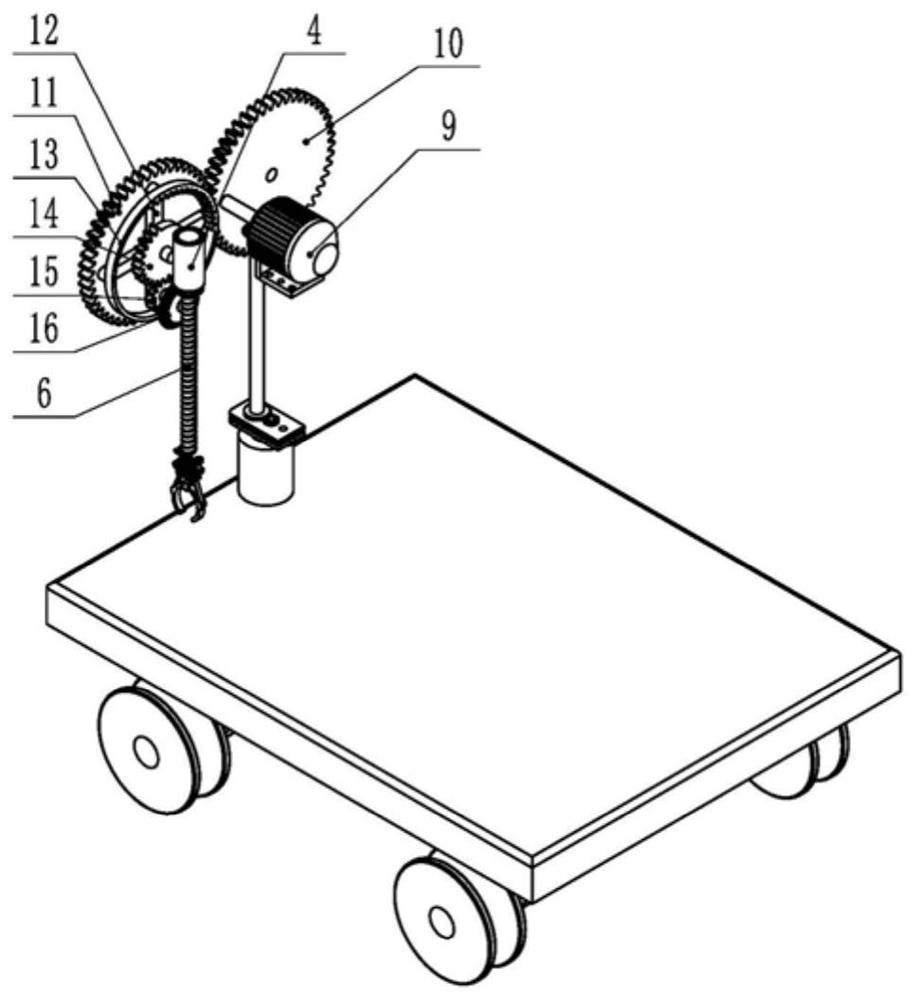

Multifunctional railway transport vehicle

ActiveCN110697588ALow costThe feeding process is stableCranesLoad-engaging elementsControl theoryMechanical engineering

The invention discloses a multifunctional railway transport vehicle. A fixed column is fixedly connected to the middle of the rear side of the upper end surface of a vehicle plate, wherein a rotatingbox is rotationally connected to the upper end surface of the fixed column, and a rotating structure capable of controlling the rotating box to rotate intermittently is mounted at the lower end of theinterior of the rotating box; a motor box is fixedly connected to the upper end surface of the rotating box; a main box is fixedly connected to the rear end surface of the motor box; a sliding blockbox is slidably connected to the middle of the front end surface of the main box; a threaded rod is mounted in the sliding block box; a gripper box is fixedly connected to the lower end surface of thethreaded rod; arc-shaped rods are mounted on the front side and the rear side of the lower end of the gripper box; a stroke shortening structure capable of enabling the arc-shaped rods to move towards the left lower direction or the right upper direction is mounted in the main box; and a control structure capable of controlling the two arc-shaped rods to be opened and closed and enabling the twoarc-shaped rods to ascend or descend by a certain distance in the opening and closing process is mounted in the gripper box. The multifunctional railway transport vehicle solves the problem that goodsneed to be loaded and unloaded before and after railway transportation, and the existing manual carrying efficiency is poor; manual carrying can be replaced, and time and labor are saved.

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

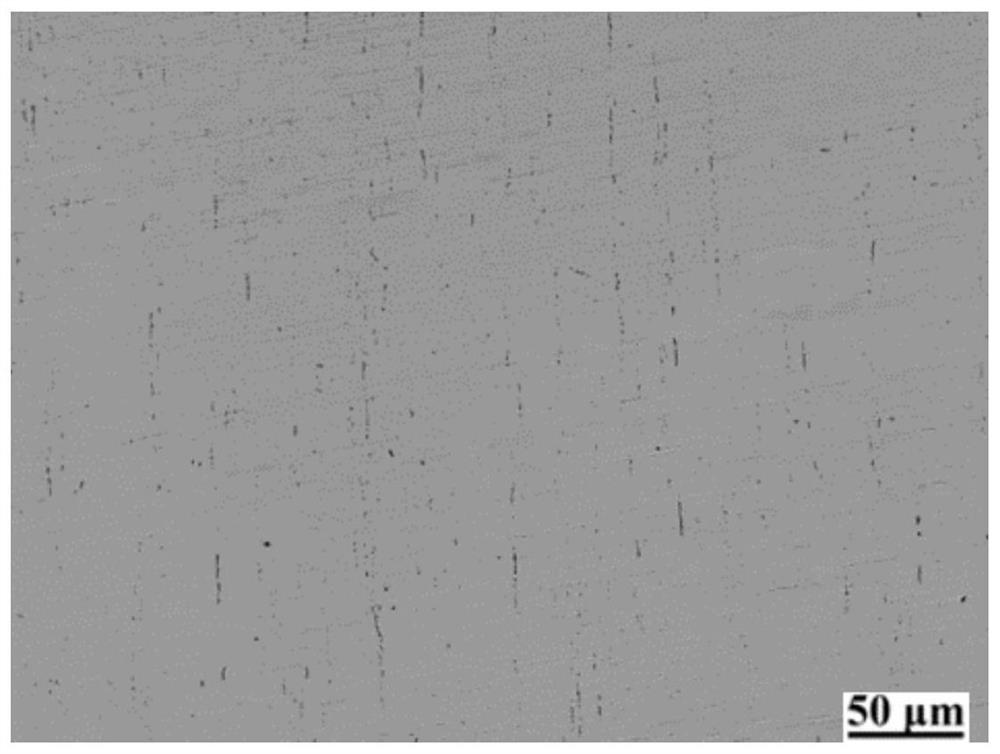

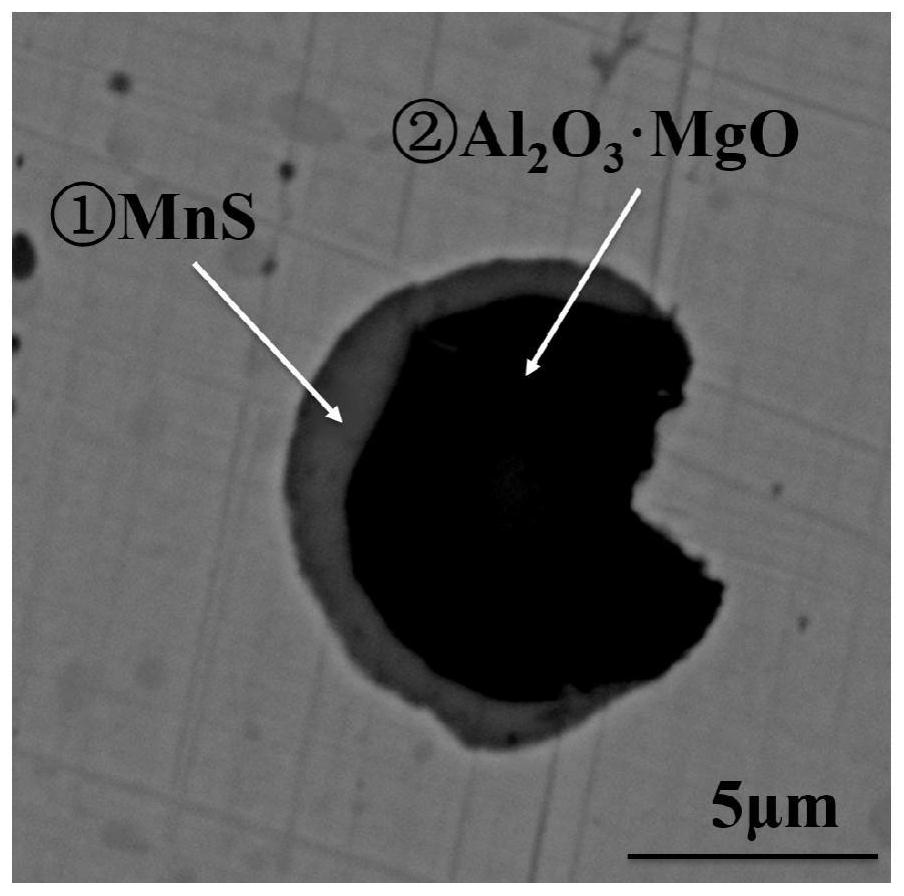

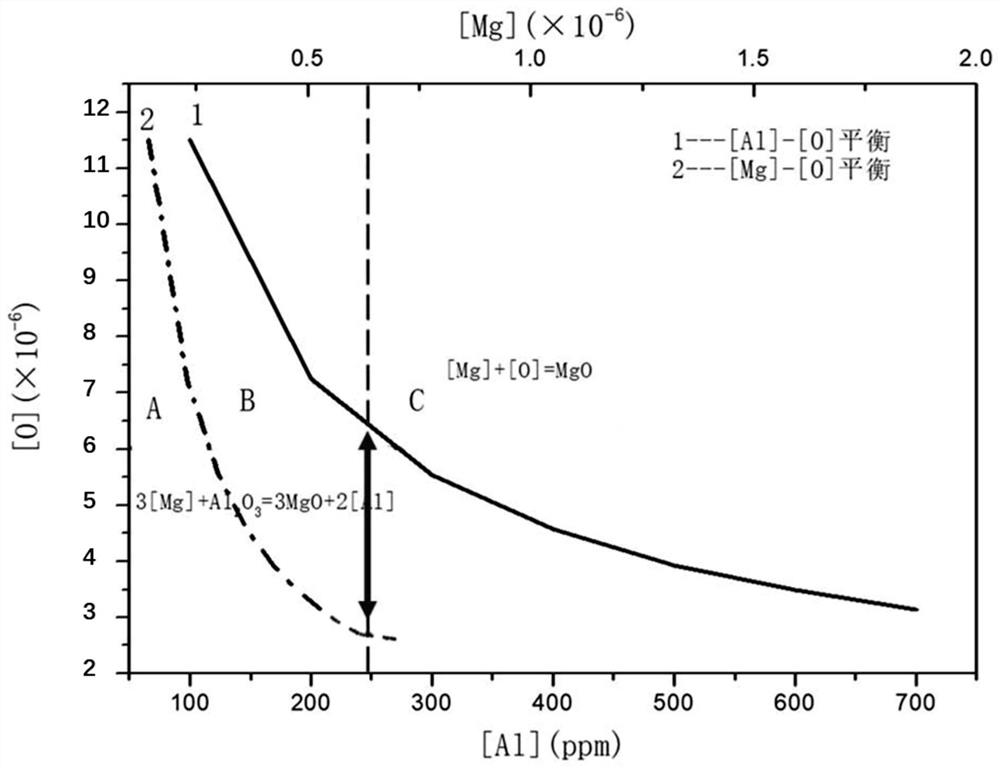

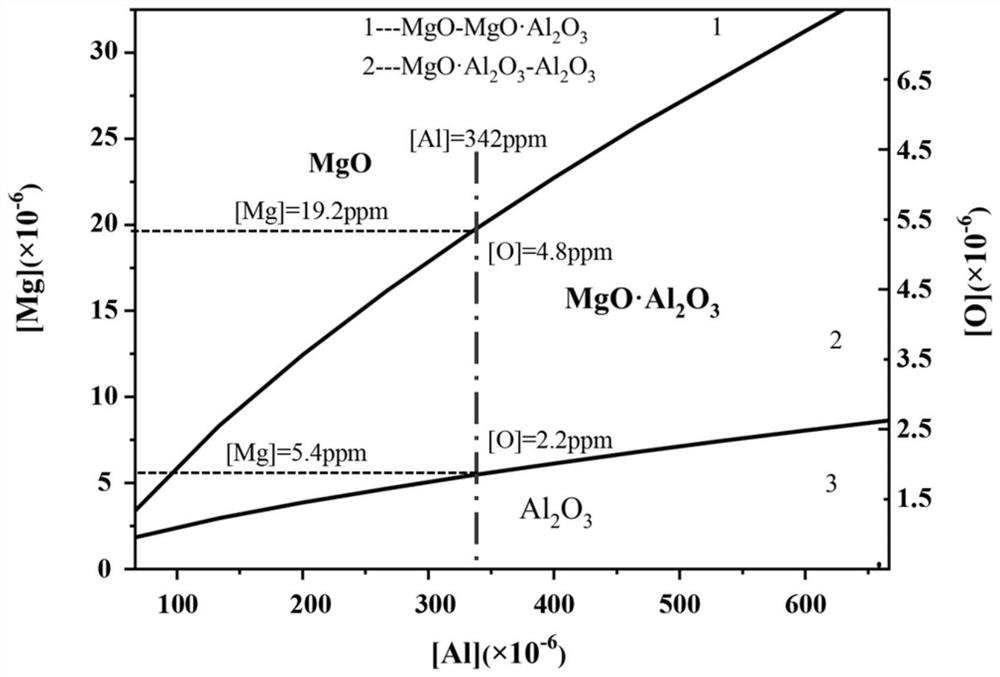

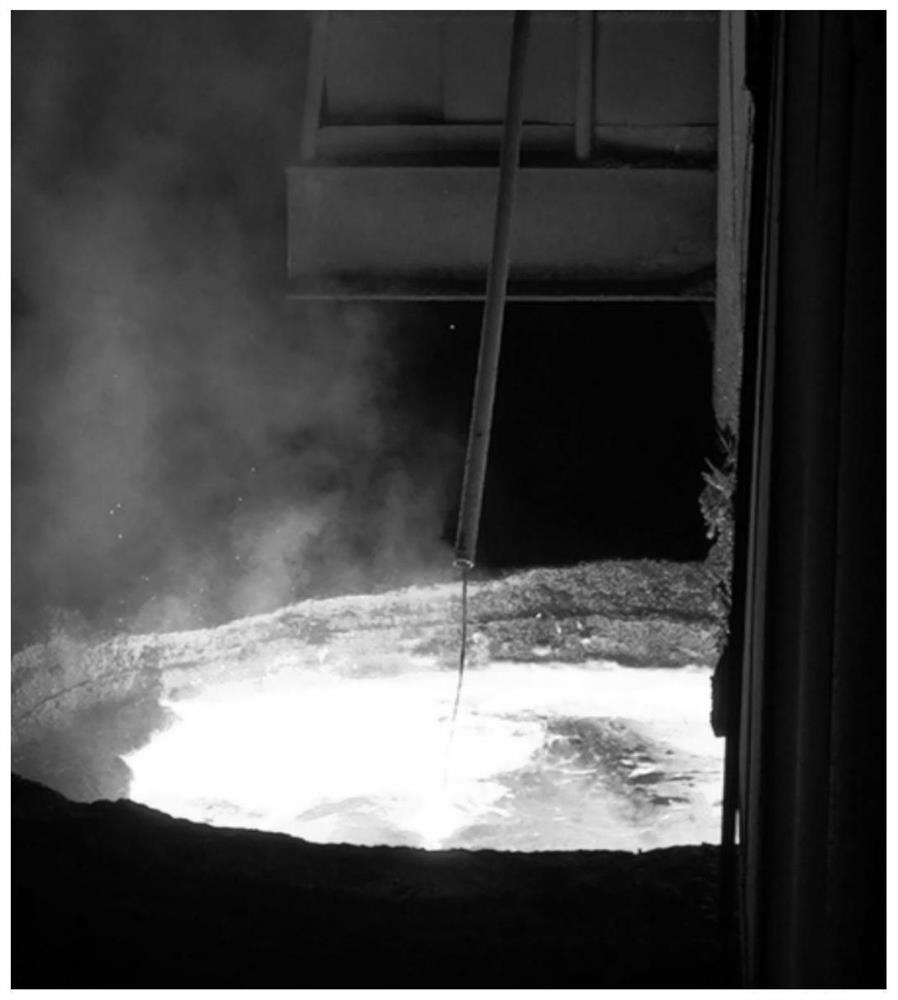

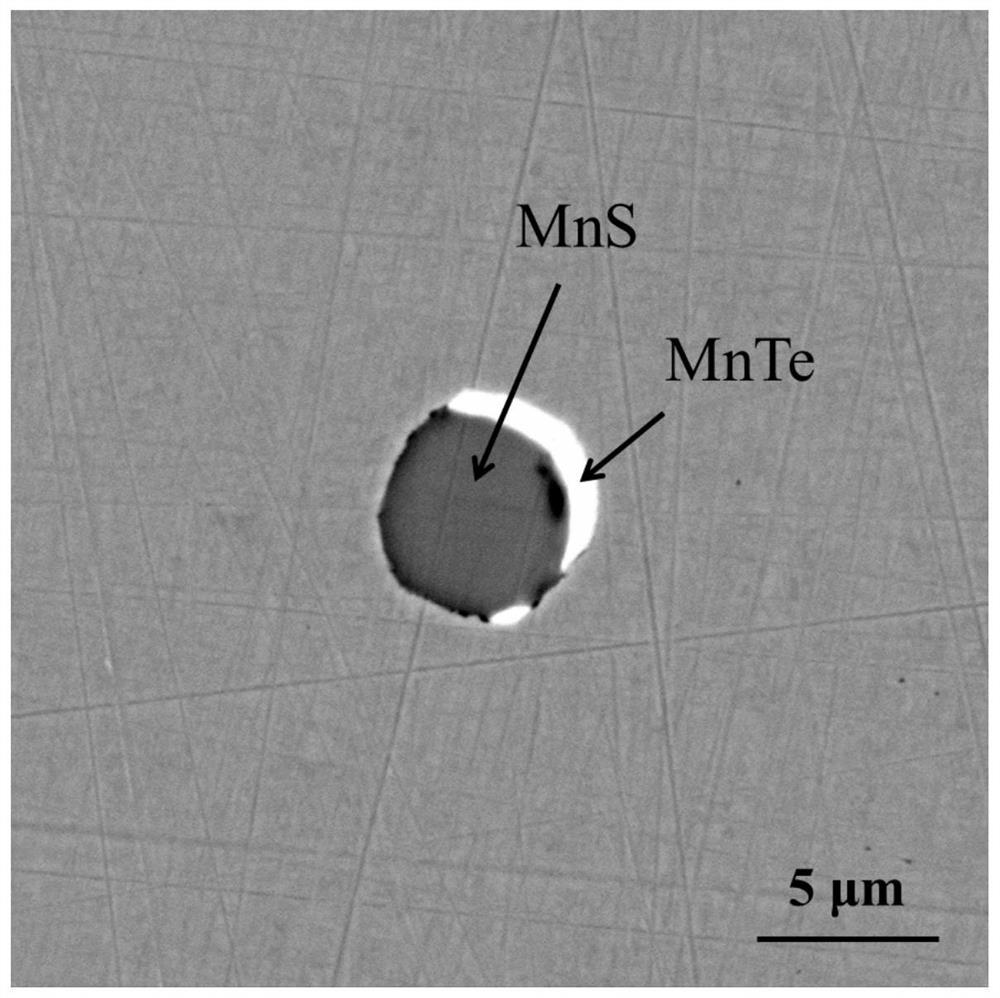

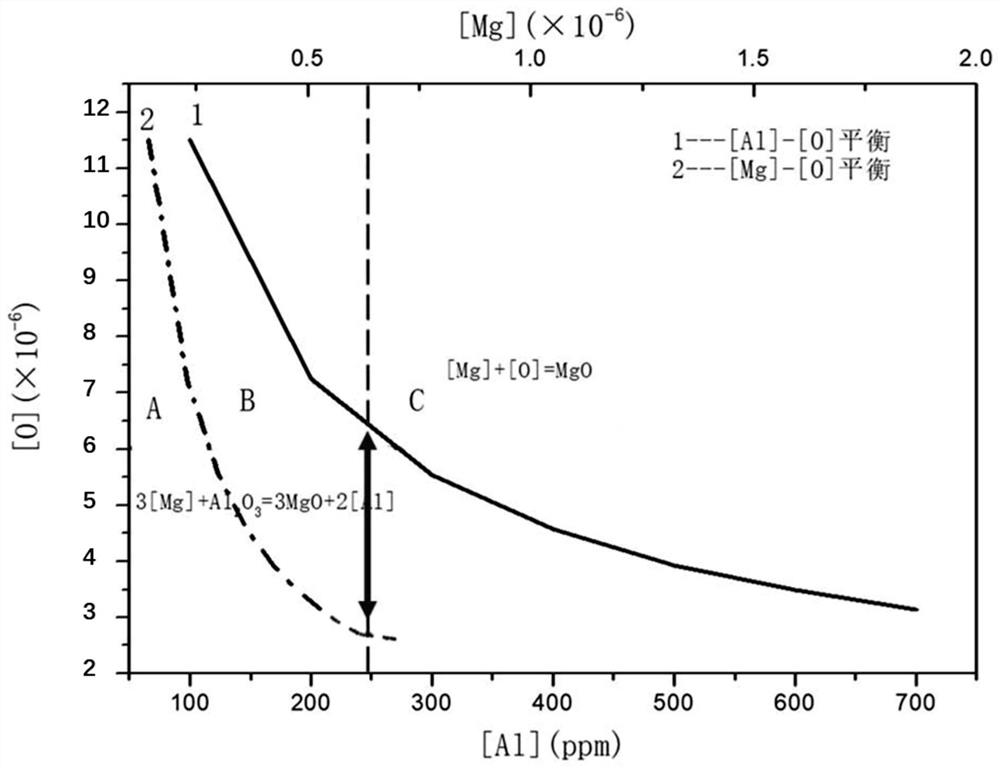

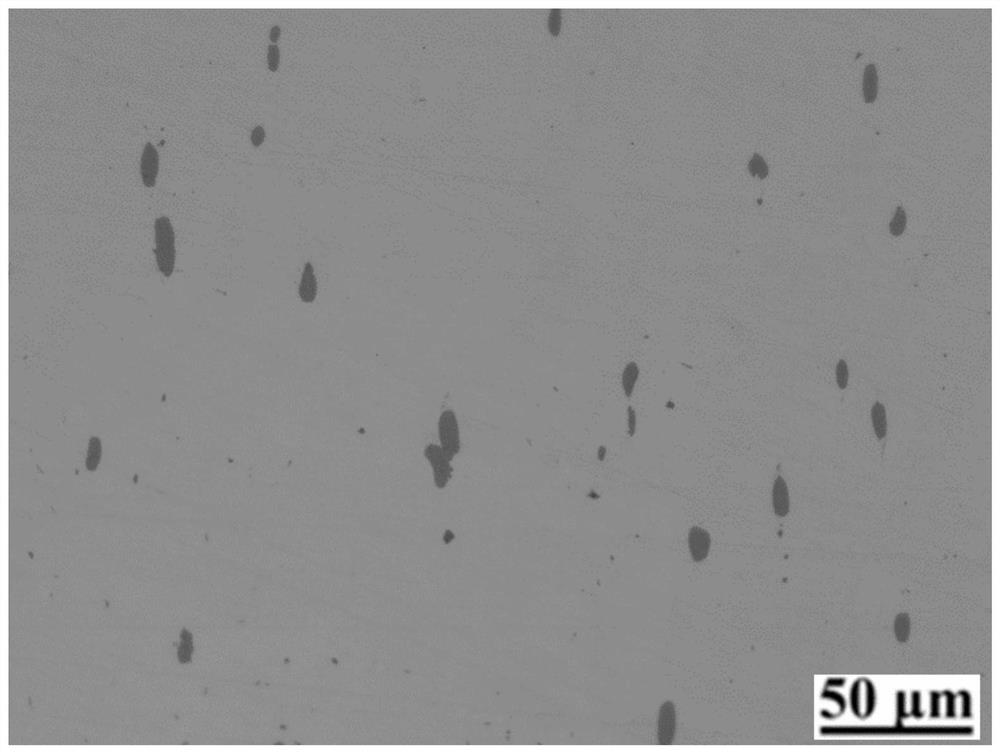

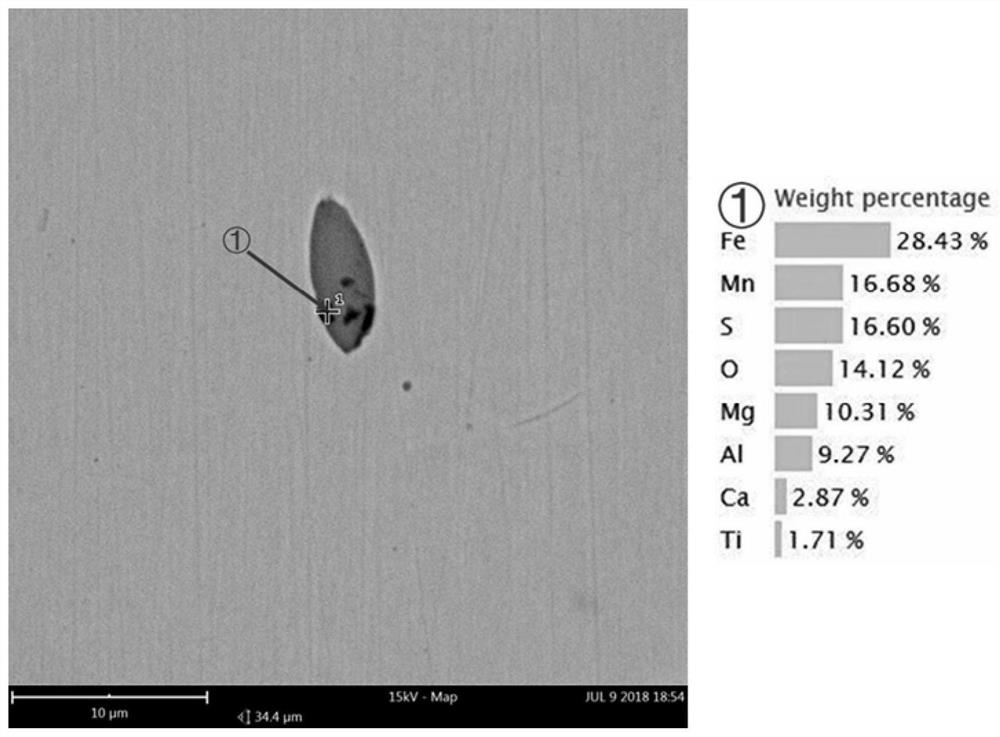

Magnesium Addition Technology for Free Cutting Steel Containing Magnesium

Owner:SHANGHAI UNIV

Directional feeding device of needle seats

ActiveCN105109975AGuaranteed stabilityImprove stabilityConveyor partsTransfer mechanismBiomedical engineering

Owner:MAIDER MEDICAL IND EQUIP

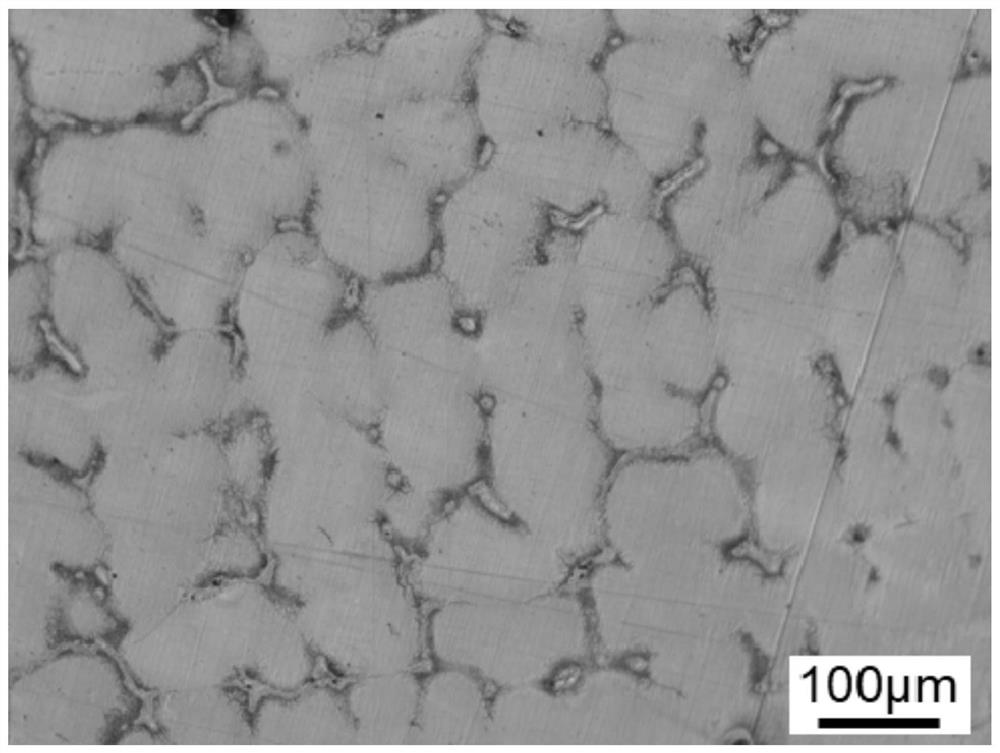

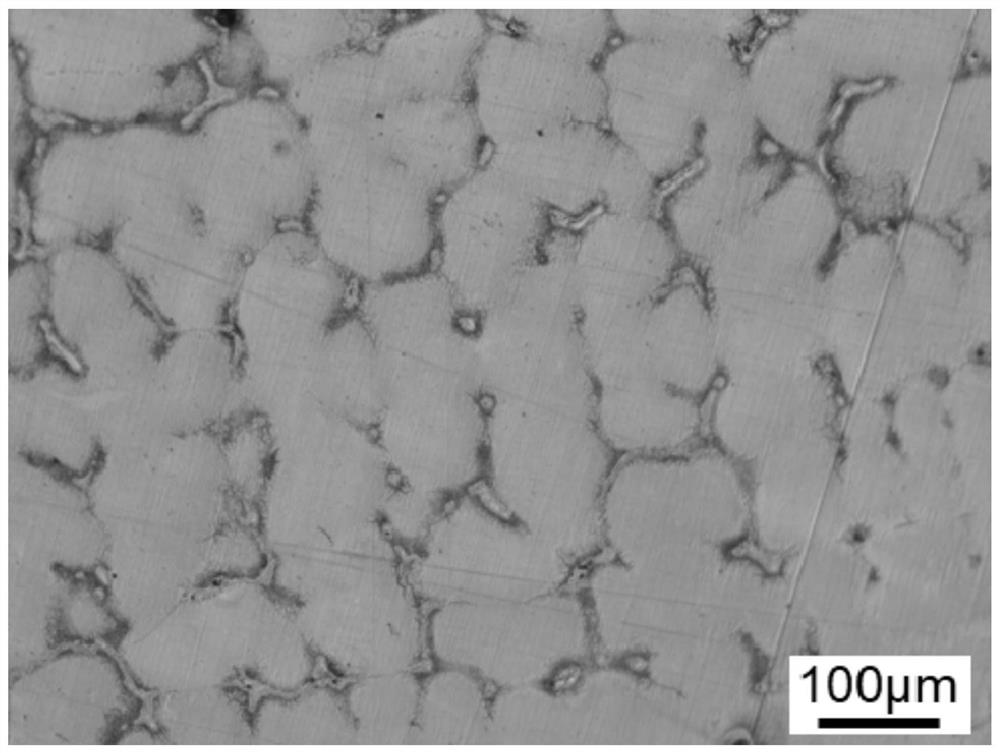

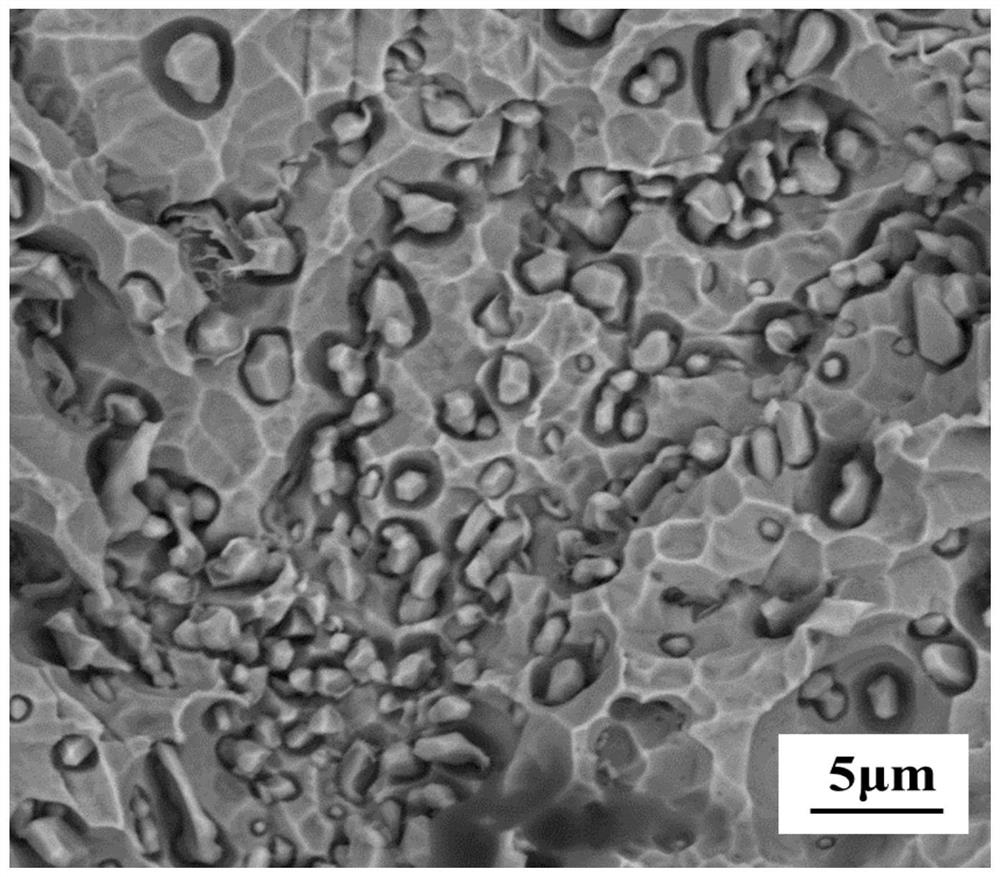

Method for modifying carbide of austenitic heat-resistant steel

The invention discloses a method for modifying carbide of austenitic heat-resistant steel. The method for modifying the carbide of the austenitic heat-resistant steel comprises the following steps that electric furnace smelting, AOD furnace smelting, LF furnace refining, nickel-magnesium cored wire feeding, continuous casting or die casting, blooming cogging or die casting, rolling, full solid solution and aging solid solution are sequentially carried out on magnesium-containing austenitic heat-resistant steel raw materials to obtain the modified austenitic heat-resistant steel, wherein in the final stage of LF furnace refining, a nickel-magnesium cored wire is fed, and the nickel-magnesium cored wire comprises, by mass, 7%-25% of Mg, 5%-45% of Ni, 20%-40% of Cr, 0.1%-5.5% of N and the balance Fe and inevitable impurity elements. According to the method for modifying the austenitic heat-resistant steel, the wire feeding process is stable, the reaction is smooth, violent splashing is avoided, the yield of the magnesium element is high and reaches 20%-35%, and the production cost is low.

Owner:上大新材料(泰州)研究院有限公司 +1

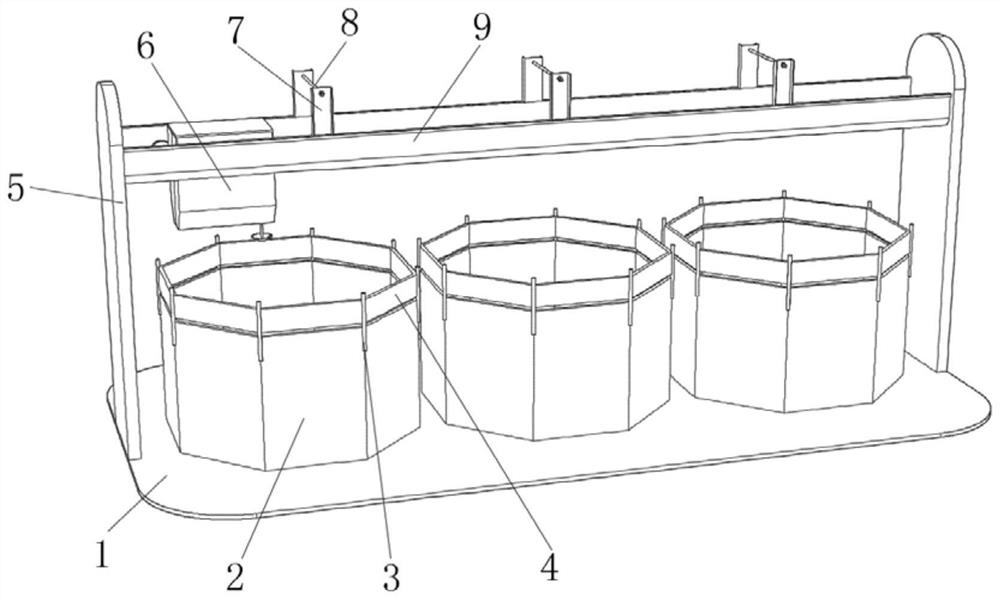

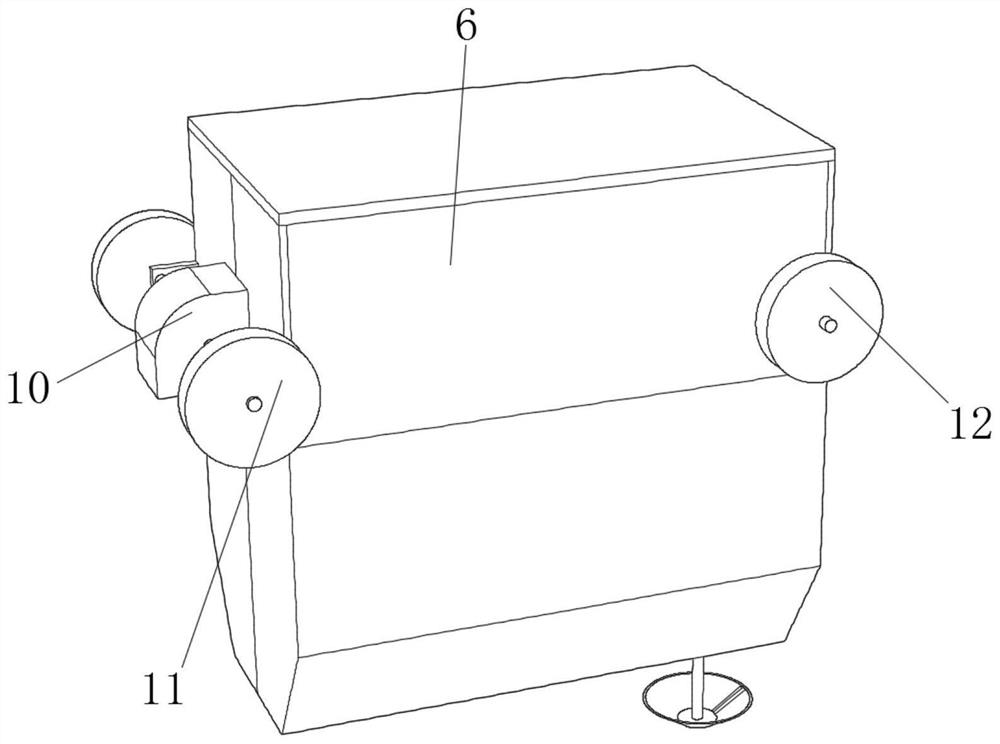

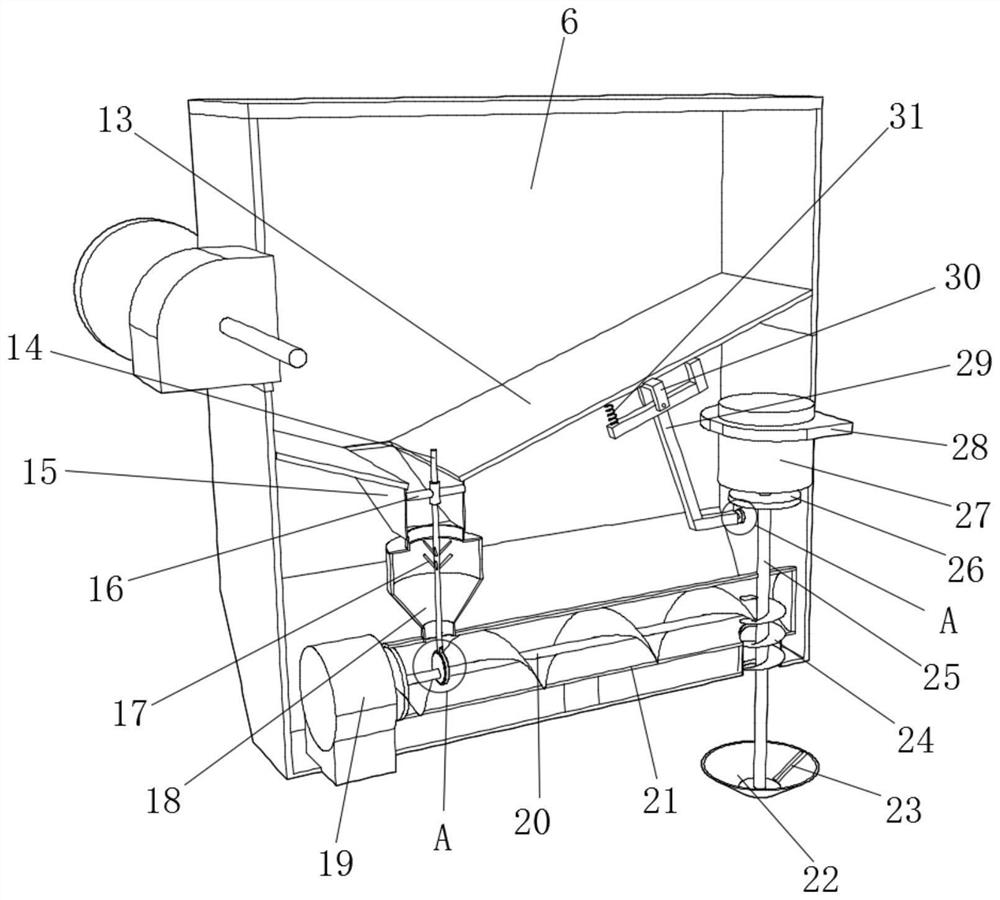

Aquaculture automation system capable of improving aquaculture efficiency

InactiveCN113475445AAvoid cloggingImprove the performance of aquacultureClimate change adaptationPisciculture and aquariaAnimal scienceDrive wheel

The invention belongs to the field of aquaculture, particularly relates to an aquaculture automation system capable of improving aquaculture efficiency, and aims to solve the problem that a feed hopper is easy to block when an existing traditional feeder is used. According to the following scheme, the aquaculture automation system comprises a bottom plate and a feeding box, and a plurality of aquaculture barrels are arranged on the upper surface of the bottom plate; two mounting plates are fixedly connected to the upper surface of the bottom plate, two guide rails are fixedly connected between the mounting plates, walking wheels and driving wheels are movably connected to the two sides of the feeding box, and the walking wheels and the driving wheels make contact with the guide rails. According to the aquaculture automation system, an insertion rod can move up and down while swinging in the feed hopper, so that feed is discharged, and feed is prevented from being blocked in the feed hopper. Meanwhile, the bottom of a sliding plate can be knocked through swinging of a swinging rod, the feed is prevented from staying on the sliding plate and being affected with damp and deteriorated, the discharging amount of the feed can be stabilized, and the feed is prevented from being thrown unevenly.

Owner:ZHEJIANG EAST VOCATIONAL TECH COLLEGE

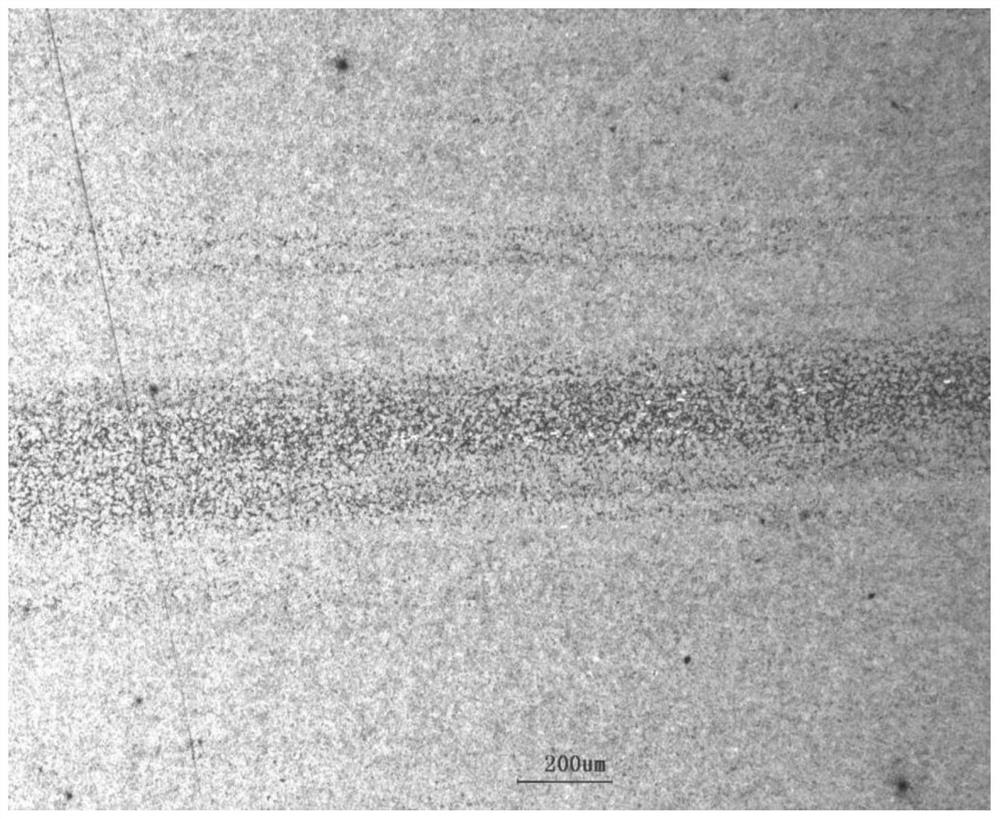

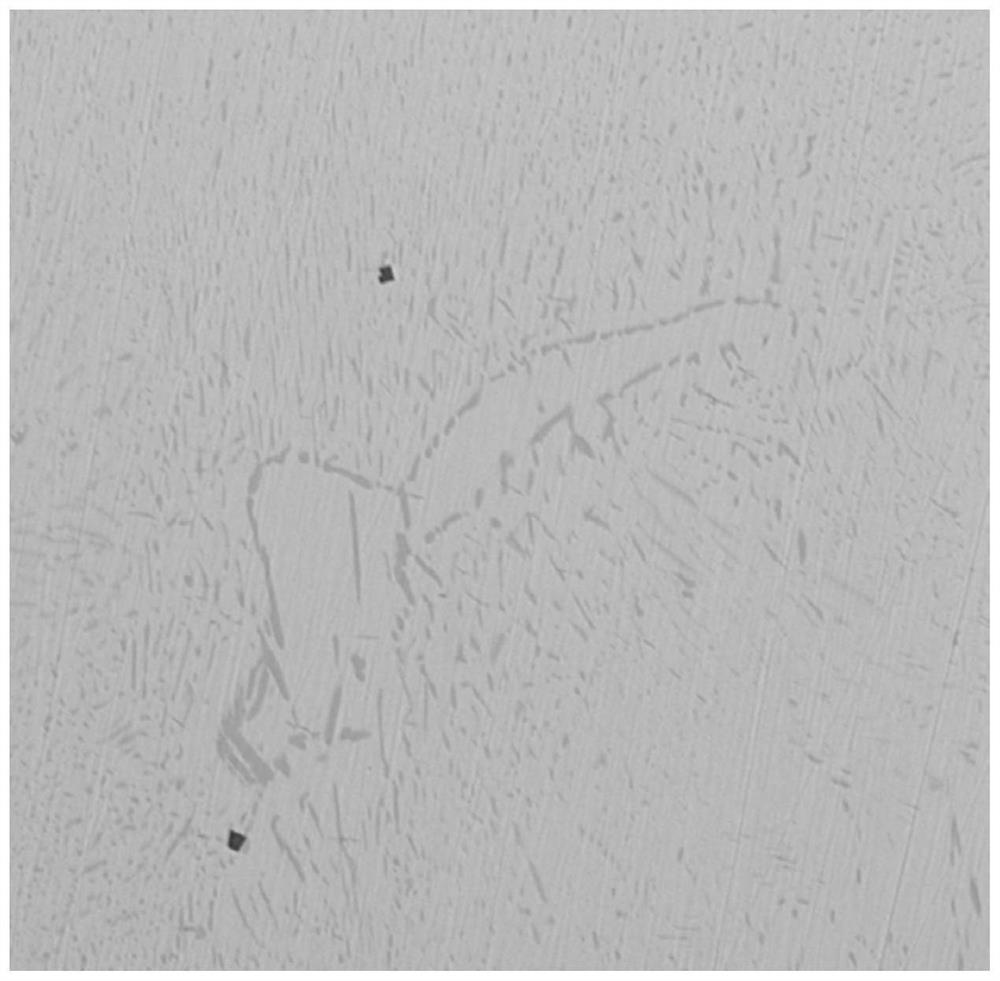

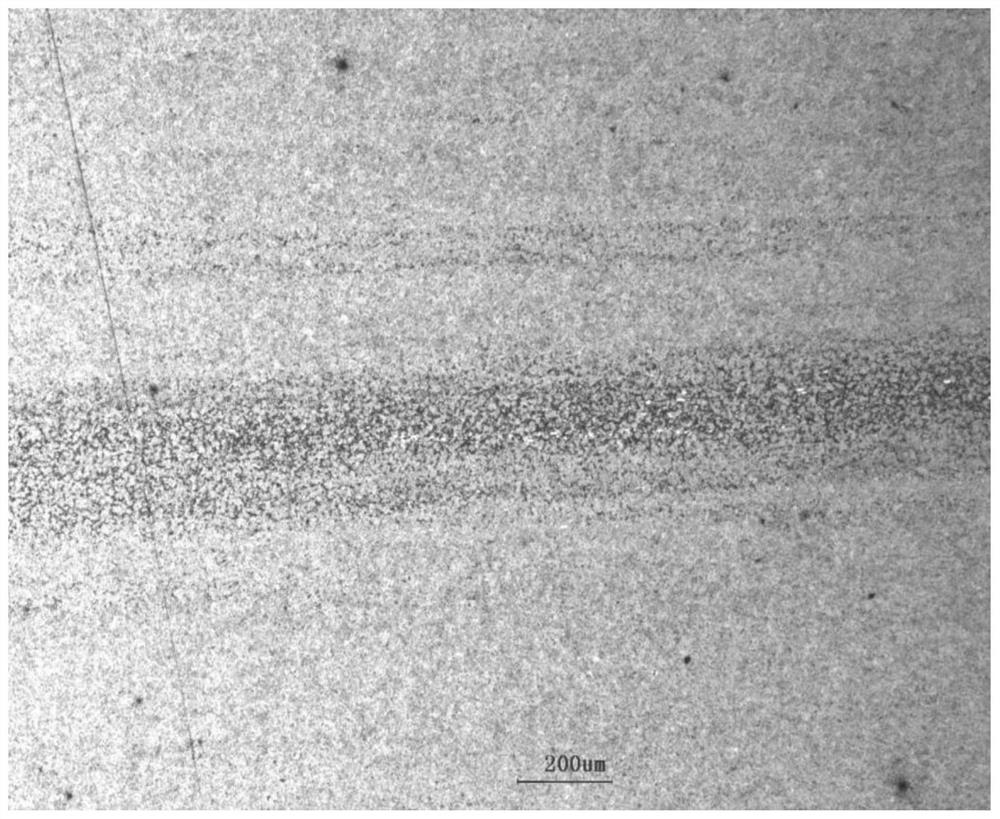

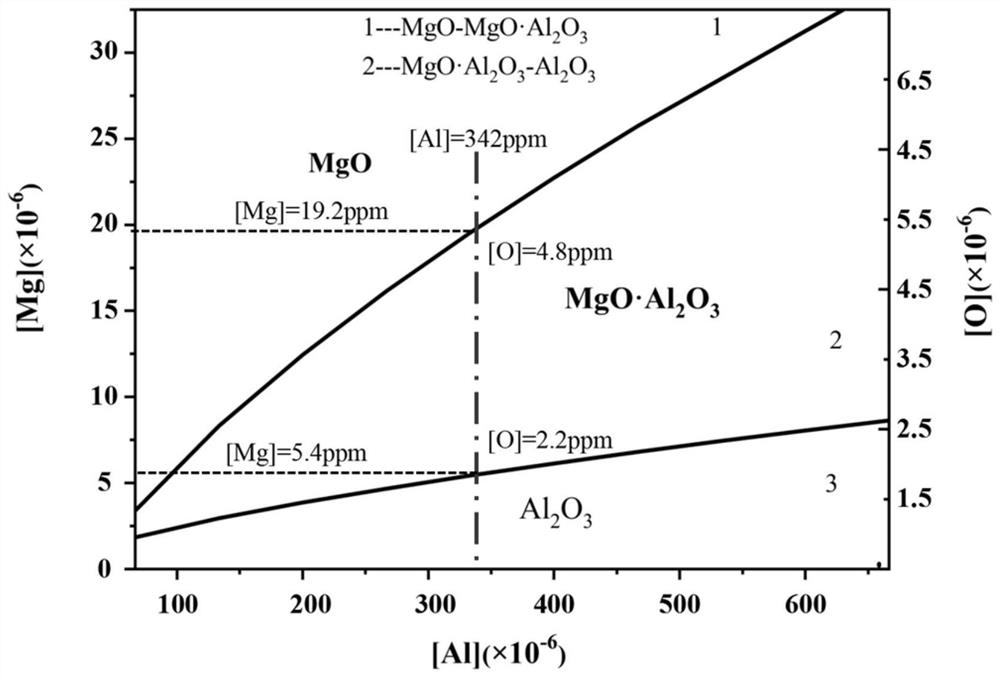

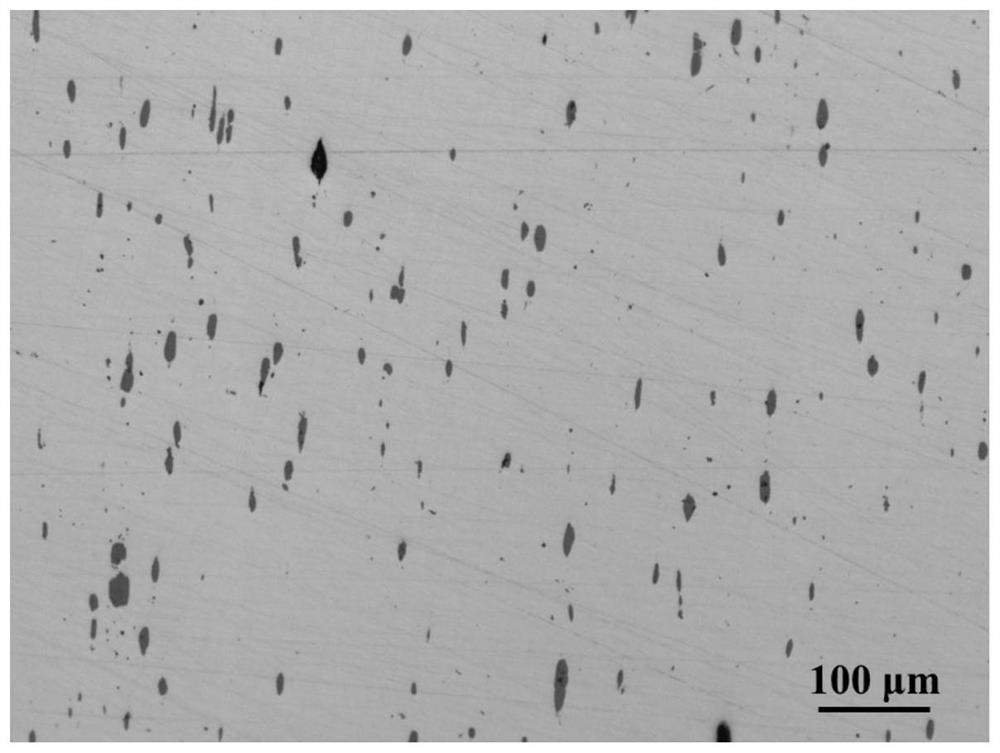

Method for modifying martensite gas valve steel carbide

ActiveCN113088630ASmall sizeImprove segregationProcess efficiency improvementElectric furnaceYarnSlag

The invention discloses a method for modifying martensite gas valve steel carbide. The method comprises the following step of sequentially performing electric furnace smelting, AOD furnace smelting, LF refining, continuously casting, rolling and pickling on martensite gas valve steel raw materials to obtain modified martensite gas valve steel, wherein in the final stage of LF refining, a magnesium-containing core-spun yarn is fed, before the magnesium-containing core-spun yarn is fed, the alkalinity of a molten steel slag layer is kept to be 3.0-5.0, the white slag making time is longer than 25 min, the weight of a slag layer of molten steel is not lower than 3.5% of the weight of the molten steel, the steel temperature is controlled to be 1467-1497 DEG C, and the oxygen activity of the molten steel is 2.2-4.8 ppm. According to the martensitic gas valve steel prepared through the method for modifying the martensite gas valve steel carbide, the average size of the carbide is reduced to 20 micrometers or below from over 50 micrometers, the segregation condition is effectively relieved, the size of the carbide is greatly refined, and segregation is greatly relieved.

Owner:上大新材料(泰州)研究院有限公司 +1

Round-concave integrated wallpaper wall cloth printing and embossing production line

InactiveCN113415073AStrong and firmImprove feeding efficiencyLamination ancillary operationsLaminationThermal deformationMechanical engineering

The invention discloses a round and concave integrated wallpaper wall cloth printing and embossing production line which comprises a first supporting frame, a left top mounting frame, a gluing mechanism, a second supporting frame, a right top mounting frame, an embossing mechanism and a material receiving mechanism. The upper end of the first supporting frame and the upper end of the second supporting frame are both supported on the lower end face of the left top mounting frame; and a plurality of sets of second tension rollers and a set of sizing material pressing mechanism are installed on the upper end face of the left top installation frame, and a PVC discharging mechanism is arranged at the left side of the first supporting frame. According to the circular-concave integrated wallpaper wall cloth printing and embossing production line, physical plastic deformation pretreatment is conducted on a printing material through traction preheating, so that the quality problem caused by thermal deformation of the printing material in the printing process is reduced, the preheating area of large hot rollers is large, the attaching effect is stable and firm, and meanwhile, the influence of chromatic aberration on the printing material is reduced; and an embossing unit adopts a high-pressure hydraulic structure, profound and powerful effects are achieved, and cooling and shaping are then carried out, so that a product has vivid, fine and three-dimensional effects.

Owner:安徽辉盛机电科技有限公司

A method for modifying carbides of martensitic valve steel

ActiveCN113088630BSmall sizeImprove segregationProcess efficiency improvementElectric furnaceSlagCarbide

Owner:上大新材料(泰州)研究院有限公司 +1

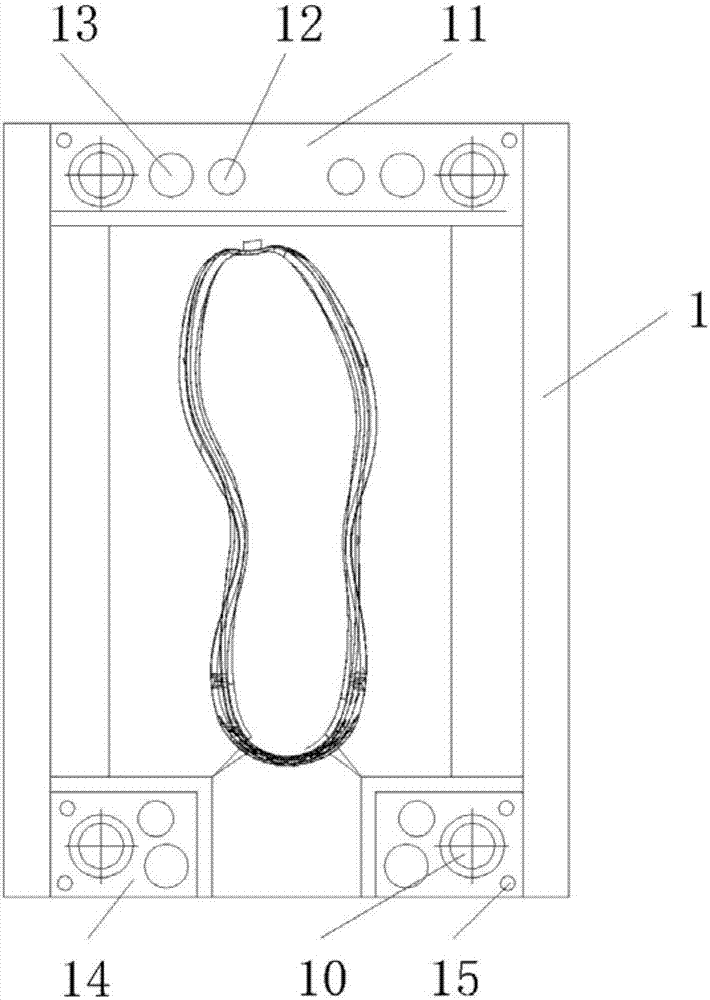

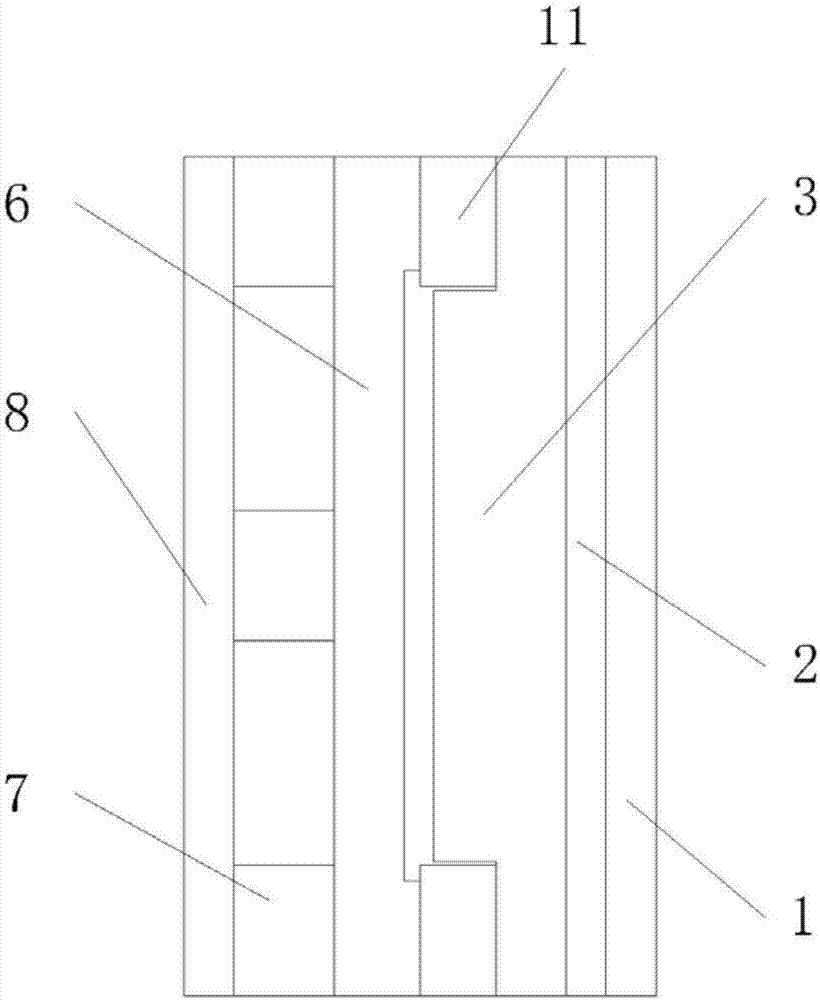

Template of honeycomb type structure insole and preparing method of template

The invention discloses a template of a honeycomb type structure insole and a preparing method of the template. The template comprises a first clamping plate and a second clamping plate, a material stripping plate is fixed to the upper portion of the first clamping plate, and an upper template is mounted above the material stripping plate; a sliding block is embedded in the upper template, a first press plate is fixed to the upper end of an inner core, and positioning holes are formed in the outer sides of the upper end of the first press plate; guide pillars are mounted on the side surface of the first press plate, pull rods are mounted on the first press plate on the inner sides of the guide pillars, and steel sleeves are mounted on the connection portions of the upper template and the guide pillars; the lower ends of the guide pillars are mounted on a lower template, a pad foot is fixed to the upper portion of the second clamping plate, and the lower template is fixed to the pad foot. The template of the honeycomb type structure insole adopts a honeycomb type structure design, reduces the overall weight of the insole and greatly improves the elasticity of the insole, tolerance between the lower template and the upper template is automatically compensated, so that the template meets the requirements of acceptable products, the product defect rate is reduced, the template is good in prepared molding effect, can better conduct sole processing operation and promotes the development of the mould industry.

Owner:泉州市丰阳精密模具有限公司

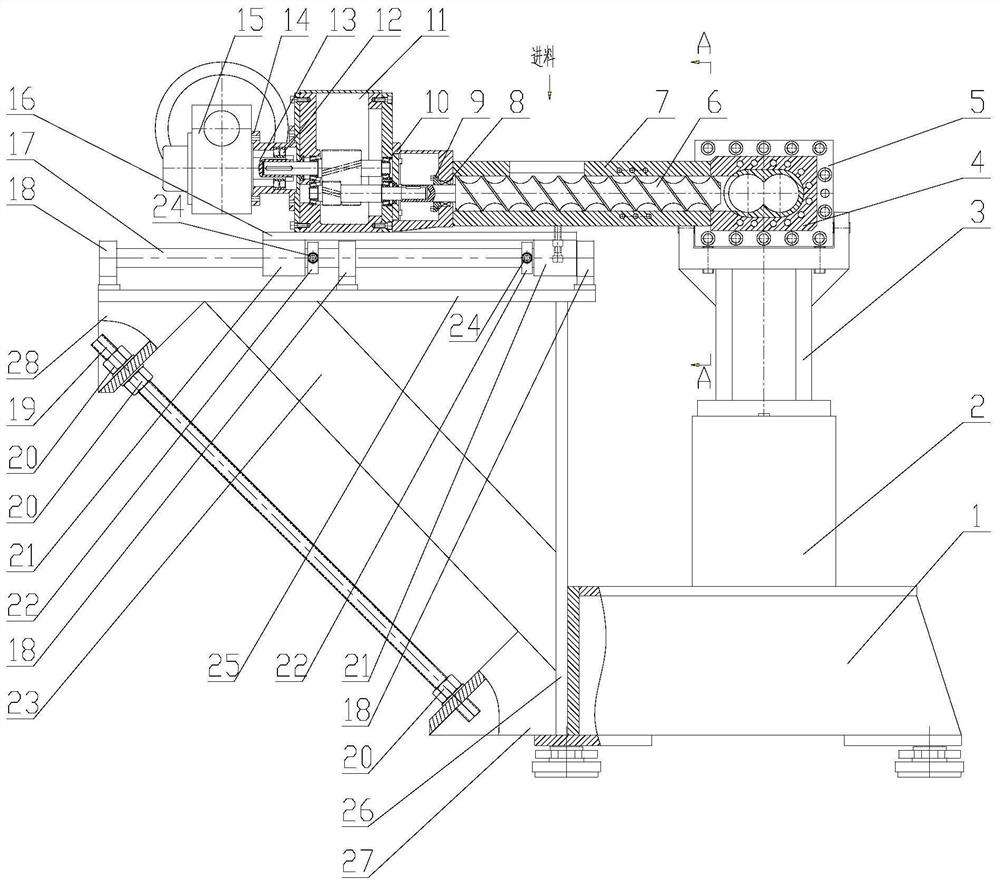

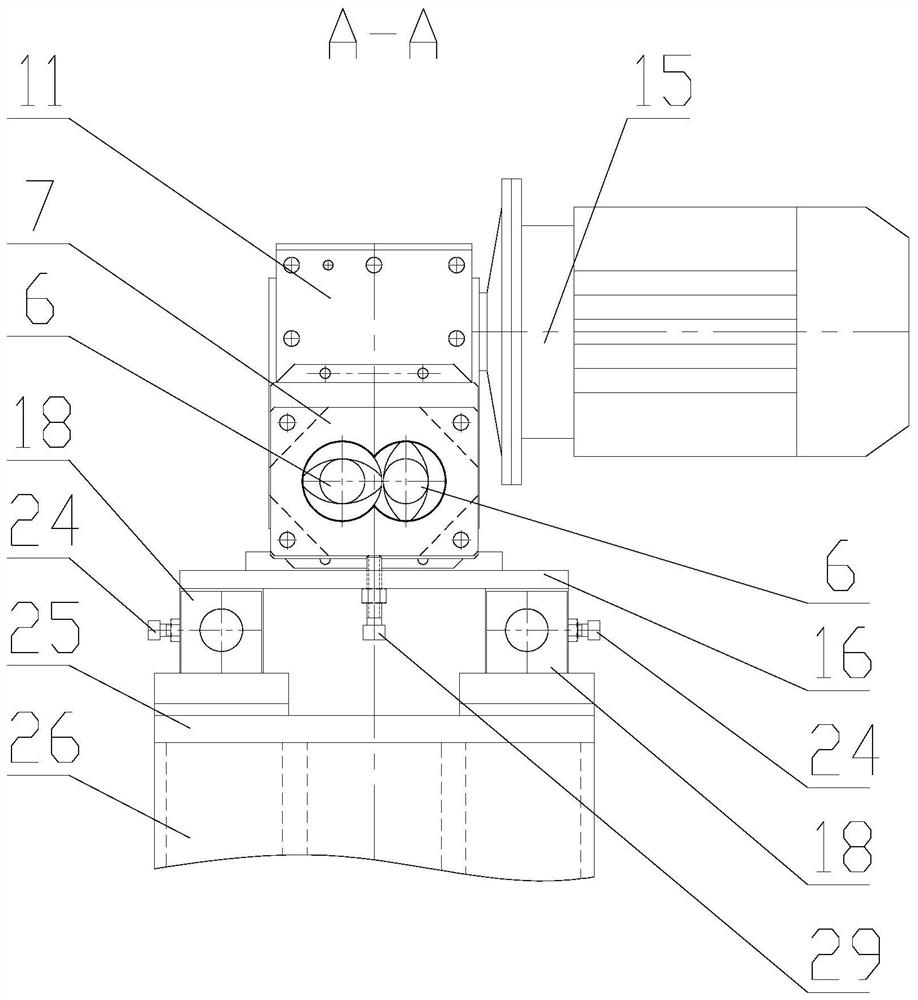

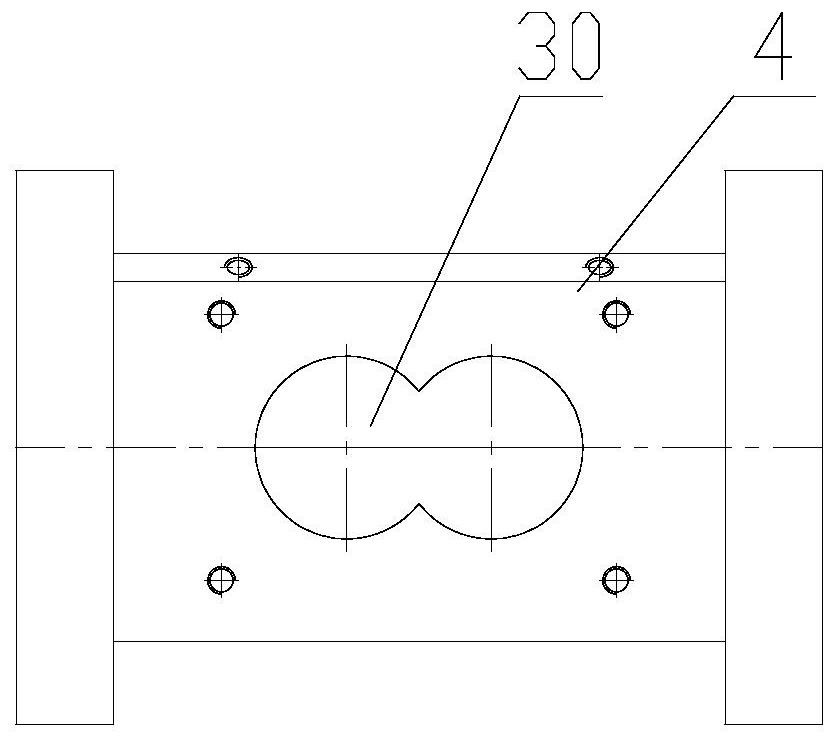

Installing structure of forced side feeding machine of double-screw extruder

The invention discloses an installing structure of a forced side feeding machine of a double-screw extruder. The installing structure comprises the forced side feeding machine, a forced side feeding machine side feeding cylinder is connected to a double-screw extruder side feeding cylinder body, the front portion of the side feeding cylinder is provided with a water inlet connector, a cooling water channel and a water drainage connector, a connecting flange at the rear end of the side feeding cylinder is connected to the front end face of a gearbox through a connecting body, the rear end face of the gearbox is connected to the front end face of a gear motor through the connecting flange, the bottom of the gearbox is installed on the upper portion of a feeding machine bottom plate, a sliding bearing is installed on the lower portion of the feeding machine bottom plate and installed on a sliding bearing sliding rod, and a limiting ring is installed on the sliding bearing sliding rod and fixed to the sliding bearing sliding rod through a fixing screw to limit a sliding bearing. According to the installing structure of the forced side feeding machine of the double-screw extruder, the problems that the forced side feeding machine side feeding cylinder is difficult to install, position and adjust, and the side feeding cylinder cannot be cooled through water, so that a feeding port sprays materials, and the gearbox is difficult to assemble and maintain are solved.

Owner:NANJING GIANT MACHINERY

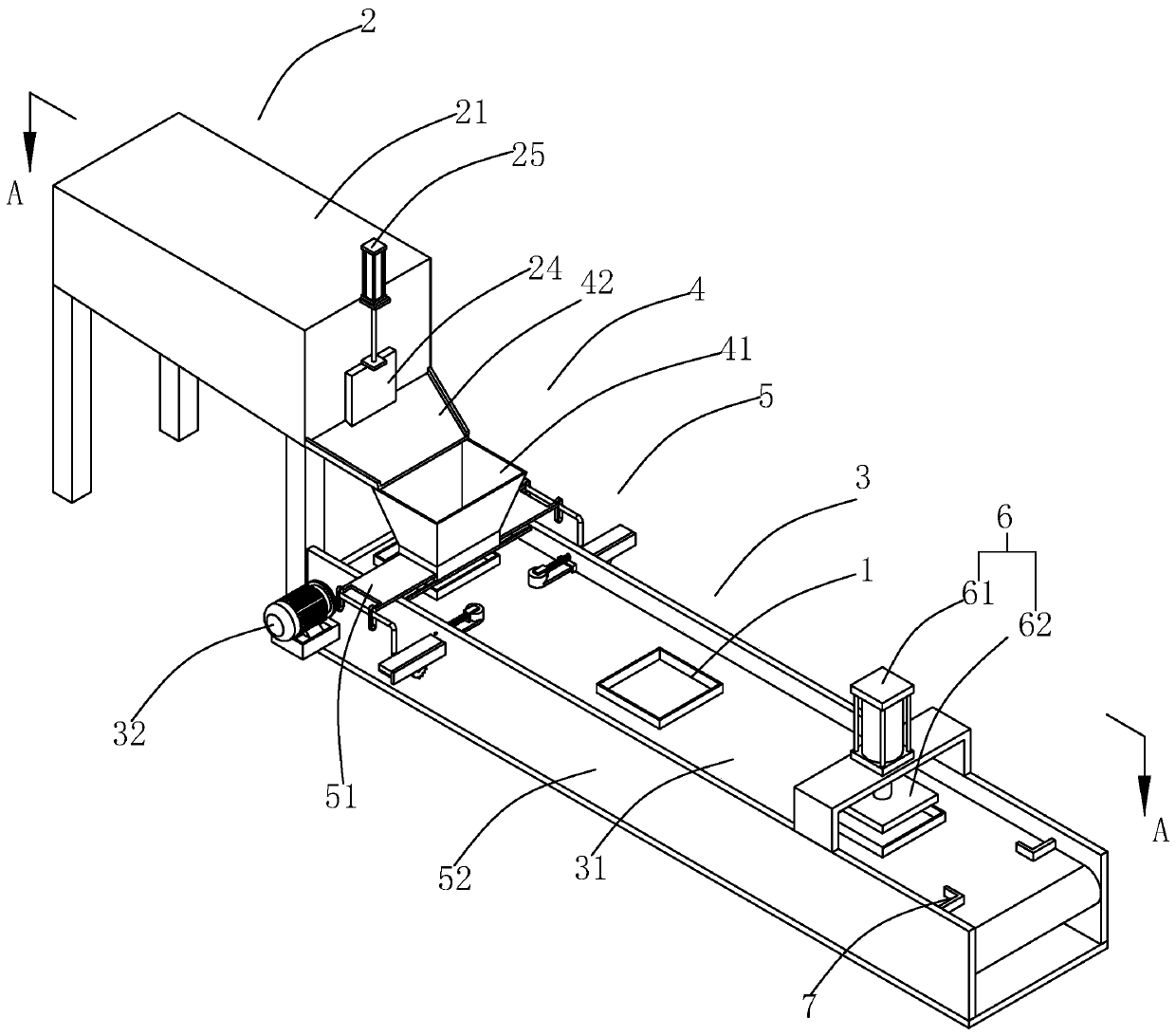

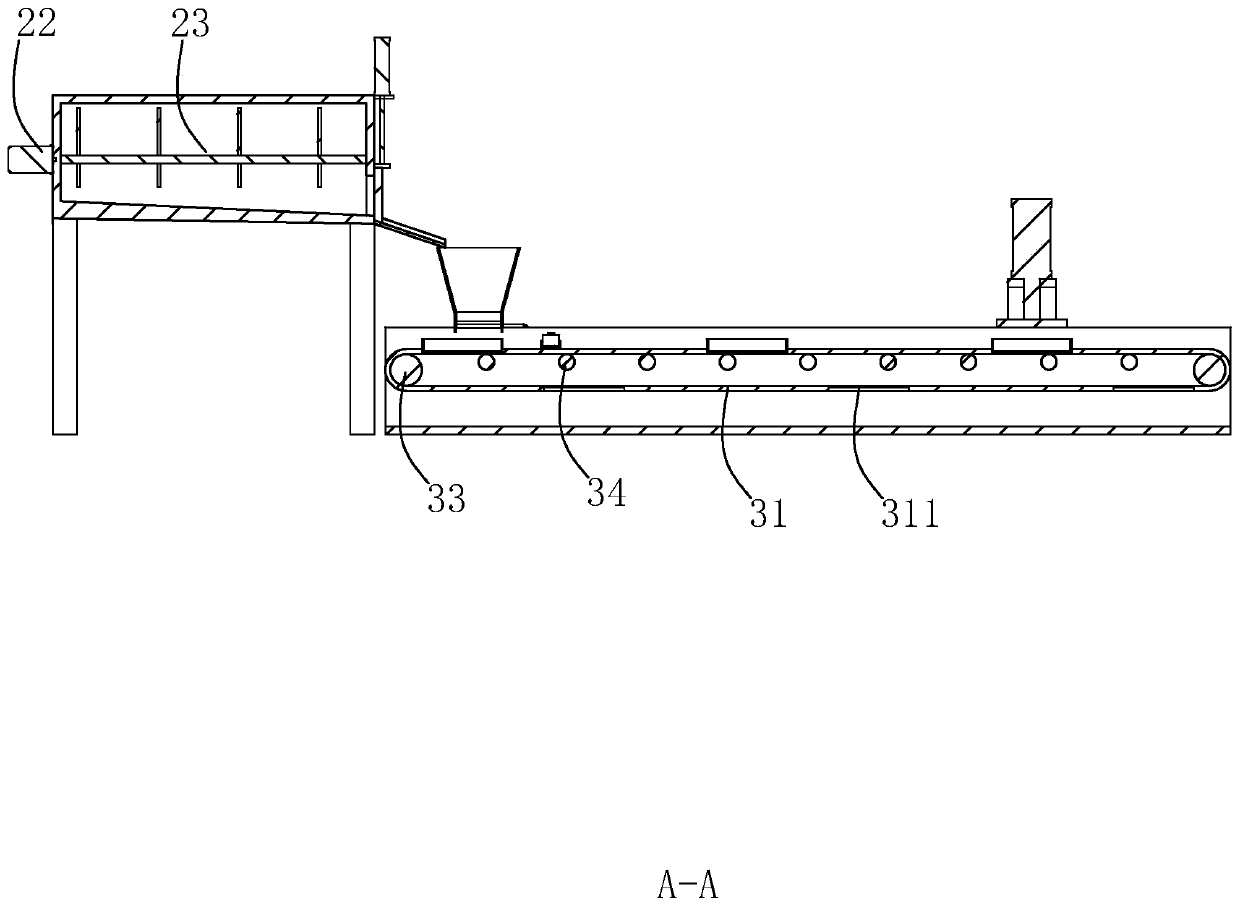

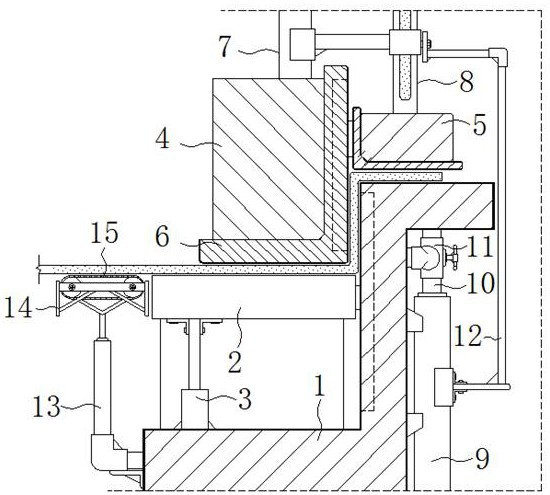

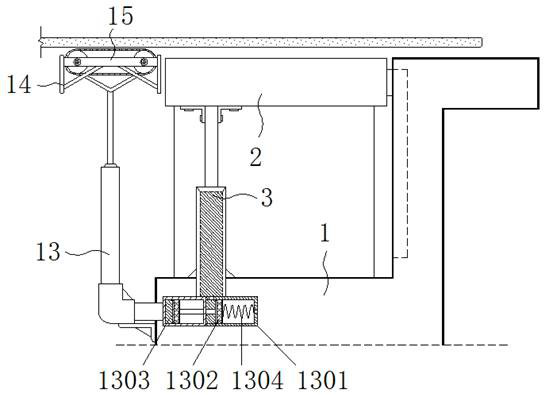

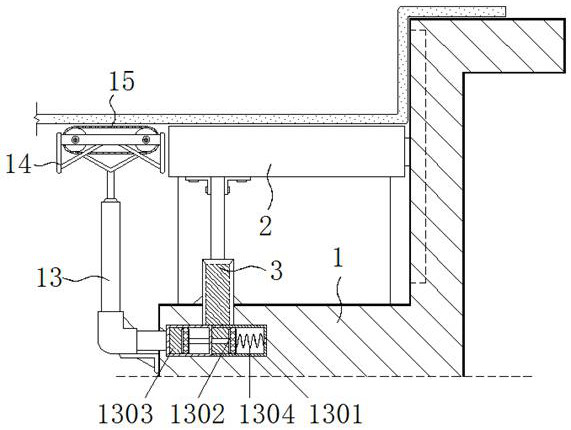

External wall tile manufacturing system and external wall tile manufacturing method

InactiveCN104213684AStable working conditionThe feeding process is stableLamination plant layoutCovering/liningsBrickManufacturing systems

The invention relates to an external wall tile manufacturing system and an external wall tile manufacturing method. The existing external wall tiles are formed by firing, so that the working procedures are complicated, and the cost is higher; furthermore, the external wall tiles obtained by firing are heavier, so that the external wall tiles can easily fall off after being stuck on the wall and can easily hurt people after being damaged and falling off from the high altitude in all probability, the unsafe factor is caused, and the quality and the service life of a building are seriously influenced. The external wall tile manufacturing system comprises an external wall tile manufacturing conveyor device which is connected with a spray-painting device; the spray-painting device is connected with a drying device; the drying device is connected with an external wall tile manufacturing receiving device; the external wall tile manufacturing receiving device is connected with a cut-off machine by an external wall tile bottom plate; the cut-off machine is matched with a forging machine for use; the forging machine is matched with an external wall tile manufacturing gluing device for use. The system and the method are used for manufacturing the external wall tiles.

Owner:张厚

Tellurium Addition Technology of Free Cutting Steel Containing Tellurium

The invention discloses a tellurium adding technology method for tellurium containing free-cutting steel. In the final period of refining, after other components except tellurium are adjusted, tellurium containing core-spun yarn adding is conducted, and the tellurium adding technology method specifically comprises the following steps that firstly, production condition control is conducted before yarn feeding, and a slag layer, the temperature and the oxygen activity of molten steel are controlled; secondly, tellurium containing core-spun yarn feeding is conducted; thirdly, treatment after yarnfeeding is finished is conducted, wherein the intermittent yarn feeding method is adopted in the second step, the tellurium containing core-spun yarn is intermittently fed at least three times, the amount of the core-spun yarn fed each time accounts for 1 / n of the total adding amount, n is the number of the times, and the time interval is 10-20 s during feeding of each part. The technology methodhas the following advantages that firstly, the yarn feeding process is stable, and acute splashing is avoided; secondly, the tellurium element yield is high and reaches 65% or above, and the production cost is low; thirdly, the form of inclusions in steel is good; and fourthly, the cutting performance is excellent. The tellurium adding technology method is suitable for production of carbon free-cutting steel and free-cutting stainless steel, and very high economic value is achieved in the field of tellurium containing free-cutting steel.

Owner:SHANGHAI UNIV

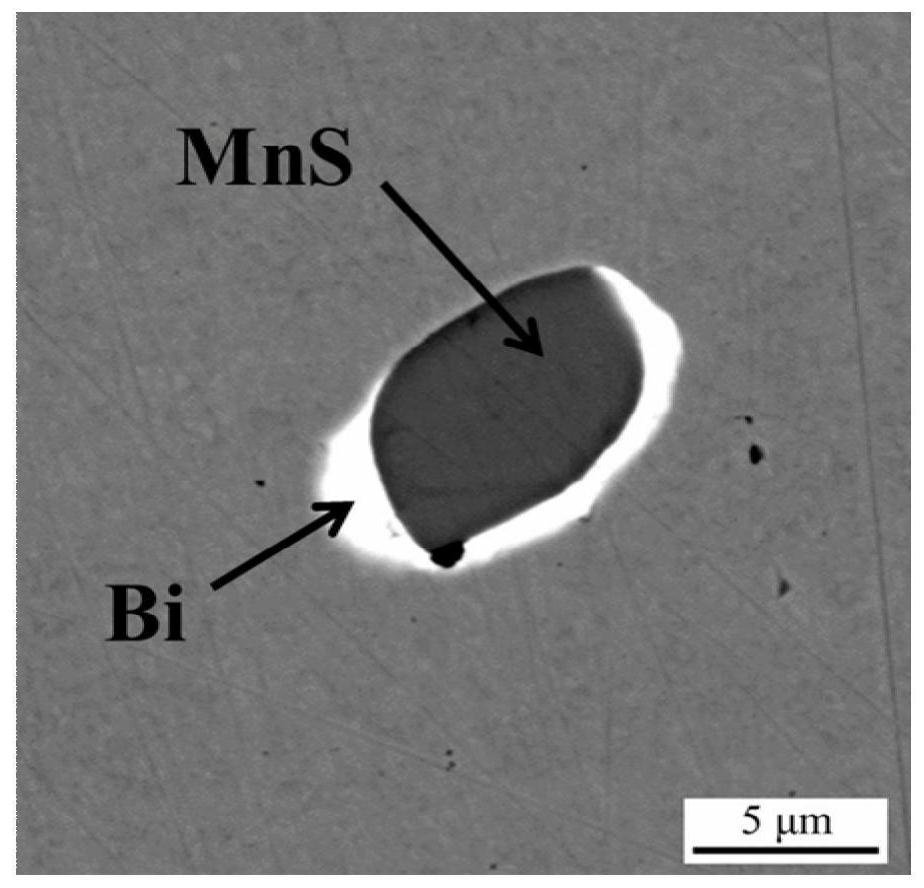

Bismuth Addition Technology for Free Cutting Steel Containing Bismuth

The invention discloses a bismuth adding process method for bismuth-containing free-cutting steel. In the final stage of refining, after the adjustment of other components except bismuth is completed, the bismuth-containing cored wire is added. The specific steps are as follows: 1) Production before wire feeding Condition control, controlling the slag layer, temperature and oxygen activity of molten steel; 2) feeding of bismuth-containing cored wire; 3) processing after wire feeding, wherein, the step 2) adopts intermittent wire feeding method , Feed the bismuth-containing cored wire intermittently at least 3 times, each feeding of the cored wire accounts for 1 / n of the total amount added, n is the number of times, and the interval between each feeding is 15-20s. The technological method of the invention has the following advantages: the wire feeding process is stable without violent splashing; the yield of bismuth element is high, reaching 15-40%, and the production cost is low; the shape of inclusions in steel is good; and the cutting performance is excellent. It is suitable for the production of carbon free-cutting steel and free-cutting stainless steel, and has great economic value in the field of bismuth-containing free-cutting steel.

Owner:SHANGHAI UNIV

Method for modifying carbides in austenitic heat-resistant steel

The invention discloses a method for modifying carbides of austenitic heat-resistant steel. The method comprises sequentially smelting magnesium-containing austenitic heat-resistant steel raw materials through an electric furnace, AOD furnace smelting, LF furnace refining, and feeding Nickel-magnesium cored wire, continuous casting or die casting, blooming or die casting, rolling, total solution and aging solution to obtain the modified austenitic heat-resistant steel; wherein, refining in the LF furnace The nickel-magnesium cored wire is fed at the end, and the nickel-magnesium cored wire includes the following components by mass percentage: Mg 7-25%, Ni 5-45%, Cr 20-40%, N0.1-5.5%, and the balance For Fe and inevitable impurity elements. The method for modifying the austenitic heat-resistant steel of the present invention has stable wire feeding process, gentle reaction, no violent splashing, high yield of magnesium element, reaching 20%-35%, and low production cost.

Owner:上大新材料(泰州)研究院有限公司 +1

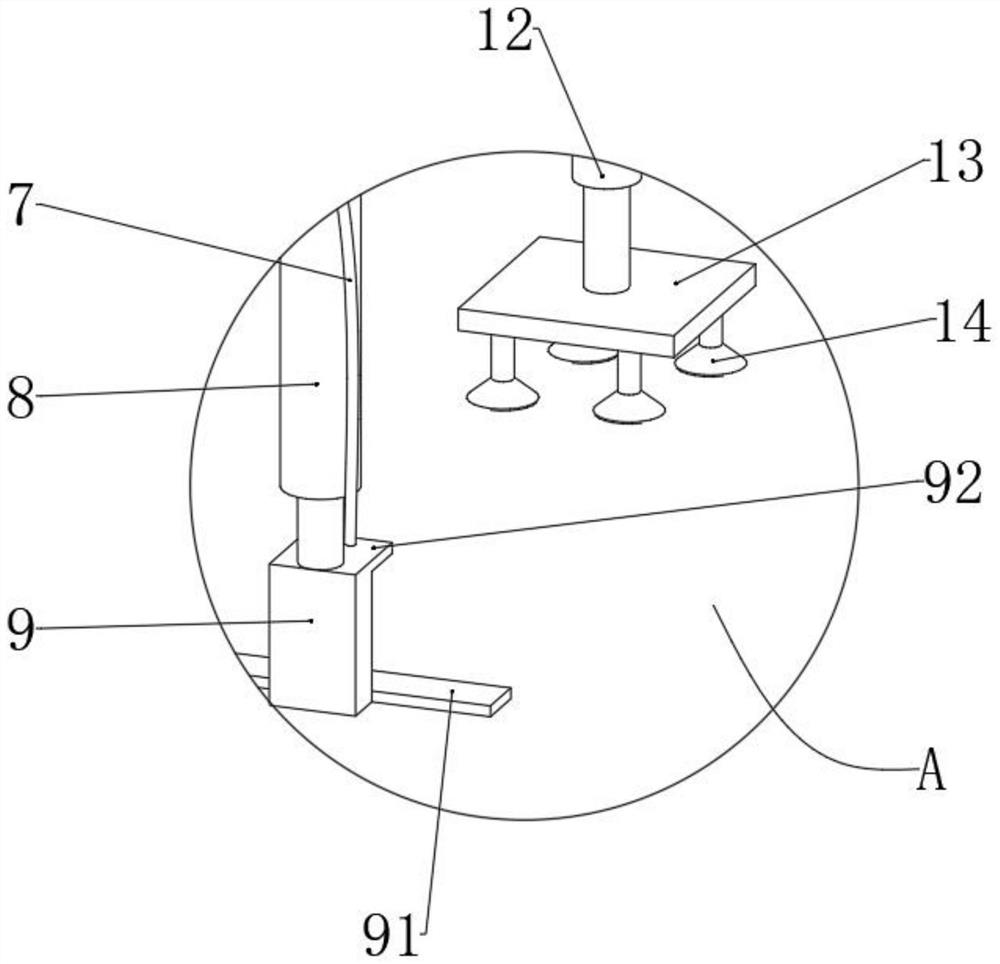

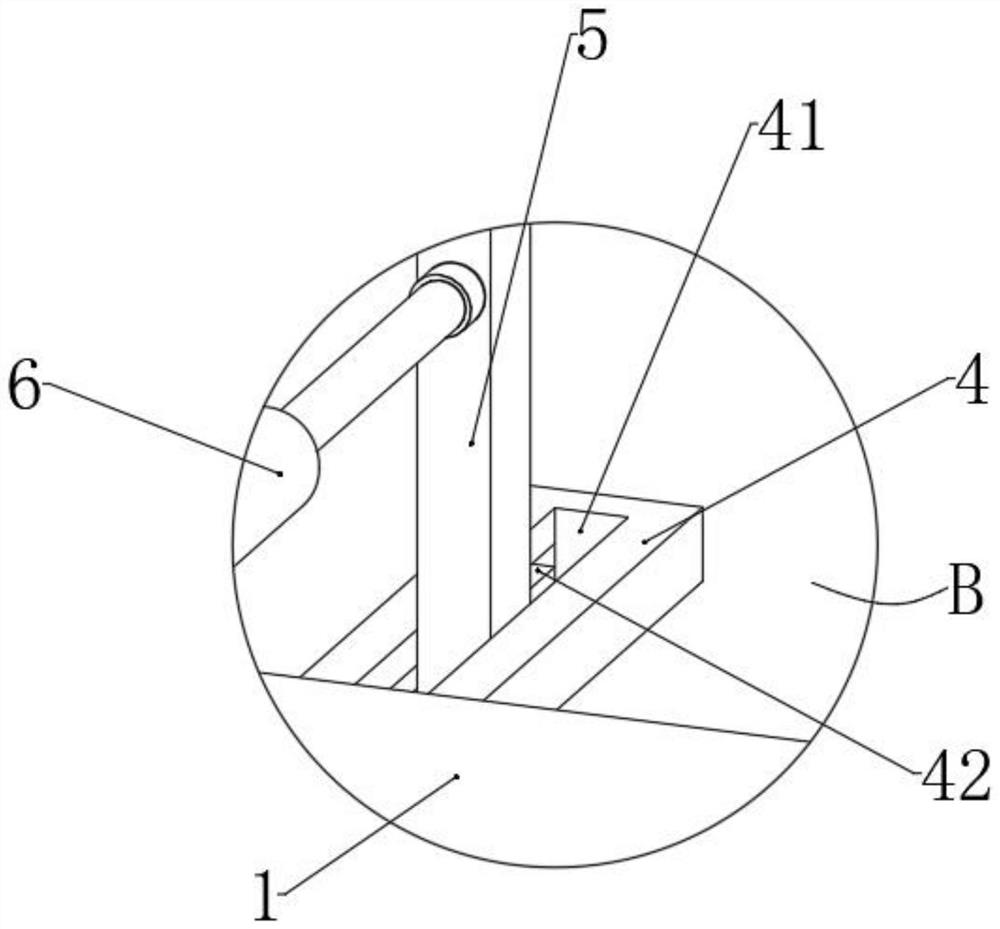

A needle seat directional feeding device

ActiveCN105109975BAvoid the phenomenon of assemblyImprove yieldConveyor partsBase exchangeTransfer mechanism

The invention provides a directional feeding device for needle holders, which belongs to the technical field of medical accessory assembly machines. It solves the technical problem that the assembly of the existing double-leaf injection needles is done manually and the assembly speed is slow. The directional feeding device of the needle seat includes a frame, on which a detection seat and a reversing seat are fixed, and a positioning groove capable of locating the needle seat is provided on the top of the detection seat, and a positioning groove capable of detecting the needle seat is also provided on the detection seat The detection structure of the orientation of the inner needle seat. The reversing seat is provided with a rotating seat that can rotate on the reversing seat and a driving member that can drive the rotating seat to rotate. The rotating seat has a positioning structure that can position the needle seat. On the frame A transfer mechanism capable of transferring the needle seat from the positioning slot to the rotating seat is also provided. The invention can ensure that the direction of the needle seat is consistent during the feeding process of the needle seat, and the feeding process is stable and reliable.

Owner:MAIDER MEDICAL IND EQUIP

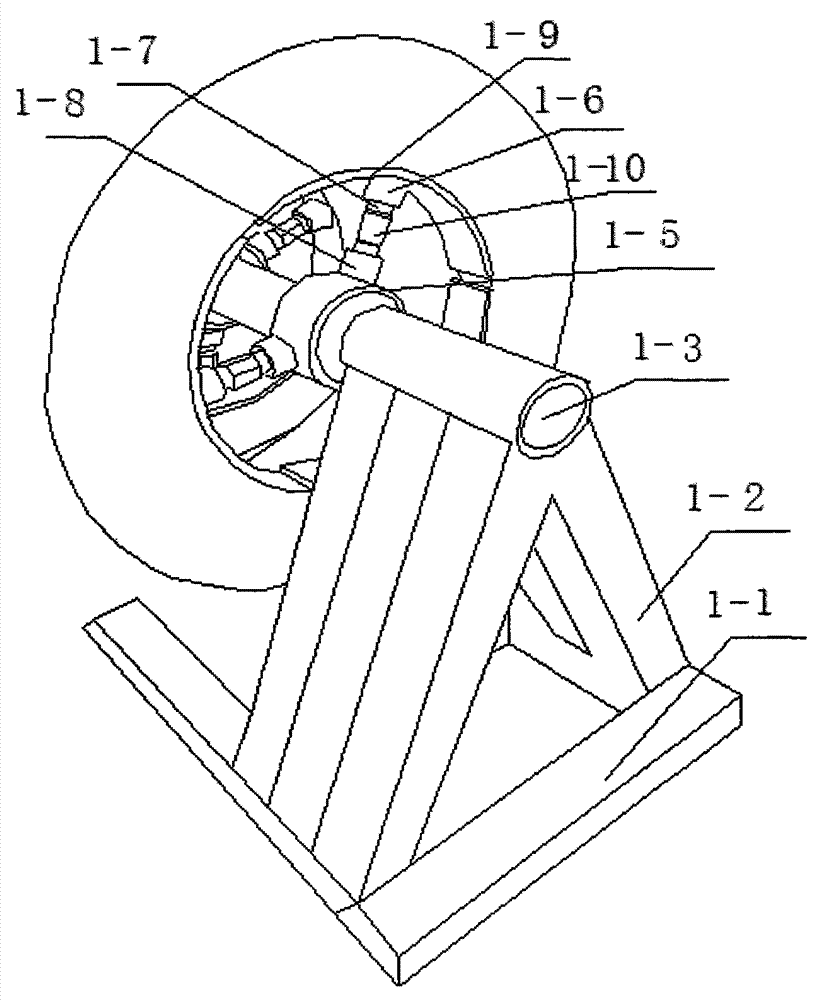

Method and device for additive manufacturing of slurry-feeding metal parts

The invention discloses a slurry feeding type metal part material increase manufacturing method. The method comprises the steps that metal powder, binders and organic solvents are mixed together to form a solid-liquid two-phase slurry material, and slurry is taken as adding materials for material increase manufacturing; the slurry is sent out through a slurry feeding device, a heat source is adopted to conduct heating on the slurry material, fusion between layers of the slurry is achieved, and metal parts are formed by overlaying melt layers of the slurry layer by layer. By means of the slurry feeding type metal part material increase manufacturing method, the problems existing in powder feeding type and wire feeding type metal material increase manufacturing are solved, and advantages of the powder feeding type and the wire feeding type metal material increase manufacturing are synthesized, so that the slurry feeding type metal part material increase manufacturing method has the advantages that the material manufacturing cost is low, the material utilization is over 90%, requirements for the shape and the size of powder are low, powder pollution does not exist, the adding materials are stable and controllable, and the applicability is strong. The invention further discloses the slurry feeding device of the metal part material increase manufacturing method.

Owner:JIANGSU UNIV OF SCI & TECH

Bismuth and tellurium composite addition process for free-cutting steel

The invention discloses a bismuth and tellurium composite adding process method for free-cutting steel. The method is characterized in that at the end of refining, the addition of bismuth-containing core-spun yarn is carried out after the adjustment of components except bismuth is completed. The method comprises the following specific steps of: 1) control of production conditions before yarn feeding: control of the slag layer, the temperature and the oxygen activity of molten steel; 2) feeding of the bismuth-containing core-spun yarn; and 3) treatment after completion of the feeding, wherein in the step 2), the bismuth-containing core-spun yarn is fed at least three separate times at an interval of 10-20s by adopting an intermittent yarn feeding method, the feeding amount of the bismuth-containing core-spun yarn each time accounts for 1 / n of the total feeding amount of the bismuth-containing core-spun yarn and the n is the number of times; and the treatment is carried out after the yarn feeding. The method disclosed by the invention has the advantages that the yarn feeding process is stable without severe splashing; the bismuth element yield is high and greater than 30 percent, thetellurium yield is greater than 50 percent and the production cost is low; the shape of inclusions in the steel is good; the cutting performance of a steel product is excellent; and the method is suitable for the production of carbon free-cutting steel and free-cutting stainless steel and has great economic value in the field of bismuth-containing free-cutting steel.

Owner:SHANGHAI UNIV

Magnesium-calcium addition process for non-quenched and tempered steel containing magnesium-calcium

The invention discloses a process method for adding magnesium and calcium to non-quenched and tempered steel containing magnesium and calcium. In the final stage of refining, after the adjustment of other components except magnesium and calcium is completed, the cored wire containing magnesium and calcium is added. The steps are as follows: production before wire feeding Condition control, controlling the slag layer, temperature and oxygen activity of the molten steel; the feeding of the magnesium-calcium-containing cored wire adopts the intermittent feeding method, and the magnesium-calcium-containing cored wire is fed intermittently for at least 3 times, each Feeding the cored wire each time accounts for 1 / n of the total amount added, n is the number of times, and the interval is 15-20s; the processing after the wire feeding is completed. The wire feeding process of the process of the present invention is stable without violent splashing; the recovery rate of magnesium and calcium elements is high, and the recovery rates of magnesium and calcium respectively reach more than 15% and 10%, and the production cost is low; the inclusions in the steel have good shape; cutting Excellent performance. It is suitable for the production of free-cutting non-quenched and tempered steel containing magnesium and calcium, and has great economic value in the field of free-cutting non-quenched and tempered steel.

Owner:SHANGHAI UNIV

A multifunctional railway transport vehicle

ActiveCN110697588BLow costThe feeding process is stableCranesLoad-engaging elementsControl theoryMechanical engineering

Owner:ZHENGZHOU RAILWAY VOCATIONAL & TECH COLLEGE

An automatic forming production line for thermal insulation felt

ActiveCN111376422BRealize the effect of automatic moldingSmooth transmissionThermal insulationProcess engineering

The invention relates to an automatic molding production line of thermal insulation felt, the technical field of thermal insulation felt molding equipment and molding method, which includes a stirring mechanism for stirring the raw materials of the thermal insulation felt; a transmission mechanism for conveying the mold of the thermal insulation felt; The mechanism is used to pre-store the raw materials after stirring; the discharging mechanism is used to automatically discharge the raw materials in the pre-storage mechanism according to the insulation felt mold transmitted by the transmission mechanism; the compacting mechanism is used to discharge the raw materials after discharging. The raw materials in the insulation felt mold are compacted and formed. The invention has the effect of automatic forming of the thermal insulation felt.

Owner:山东宇能环境工程有限公司

Light sweeping turning device with vibration isolation and glass sweeping machine

ActiveCN109702615BImprove accuracyImprove work efficiencyGrinding machinesGrinding work supportsPolishingEngineering

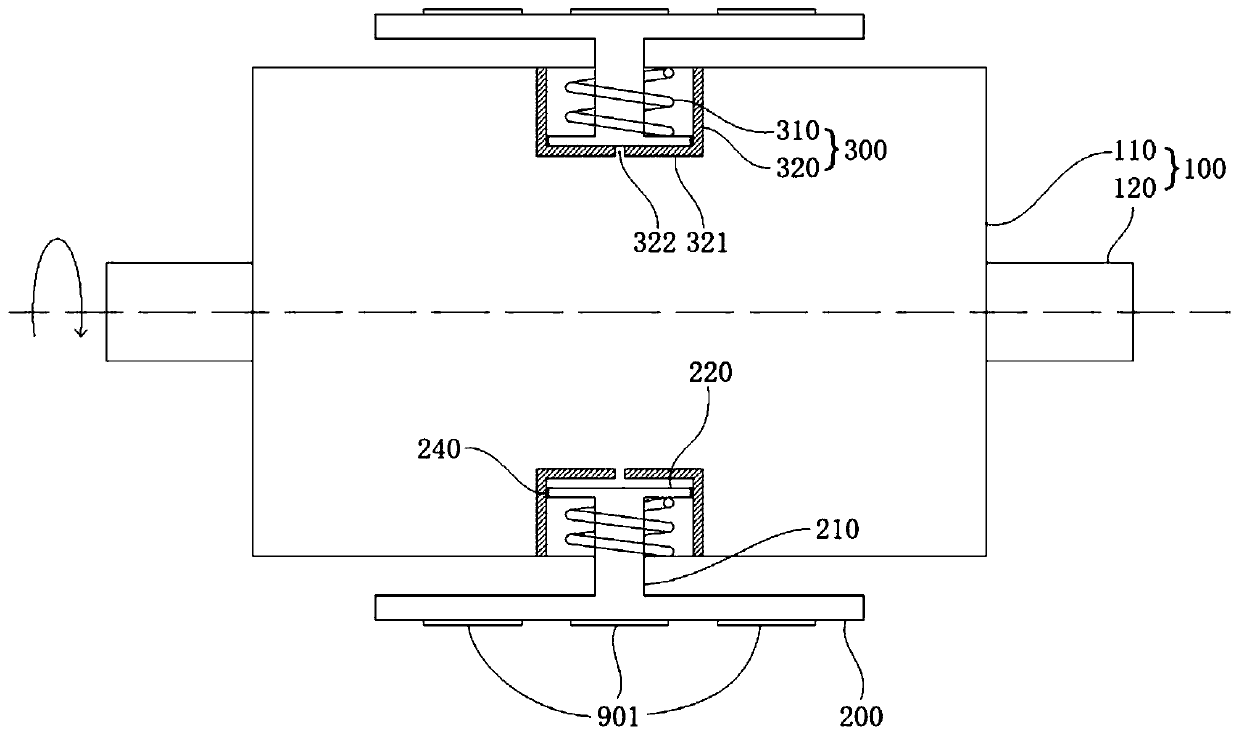

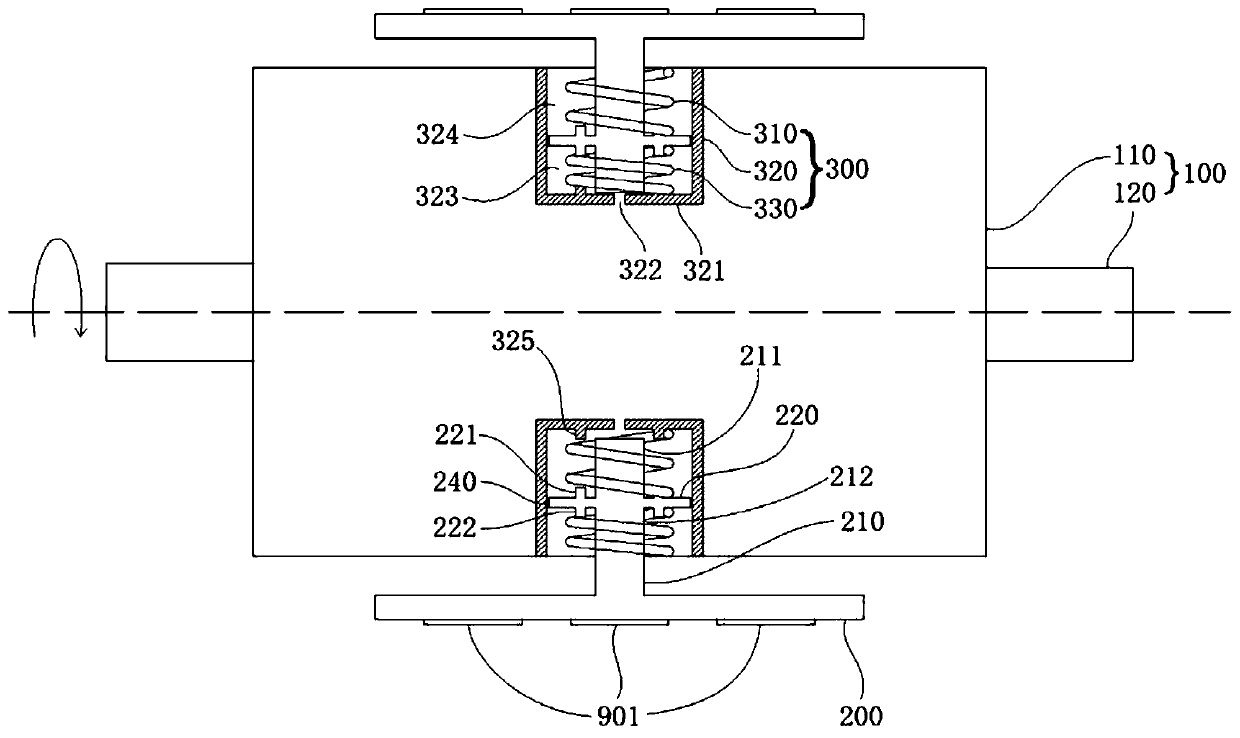

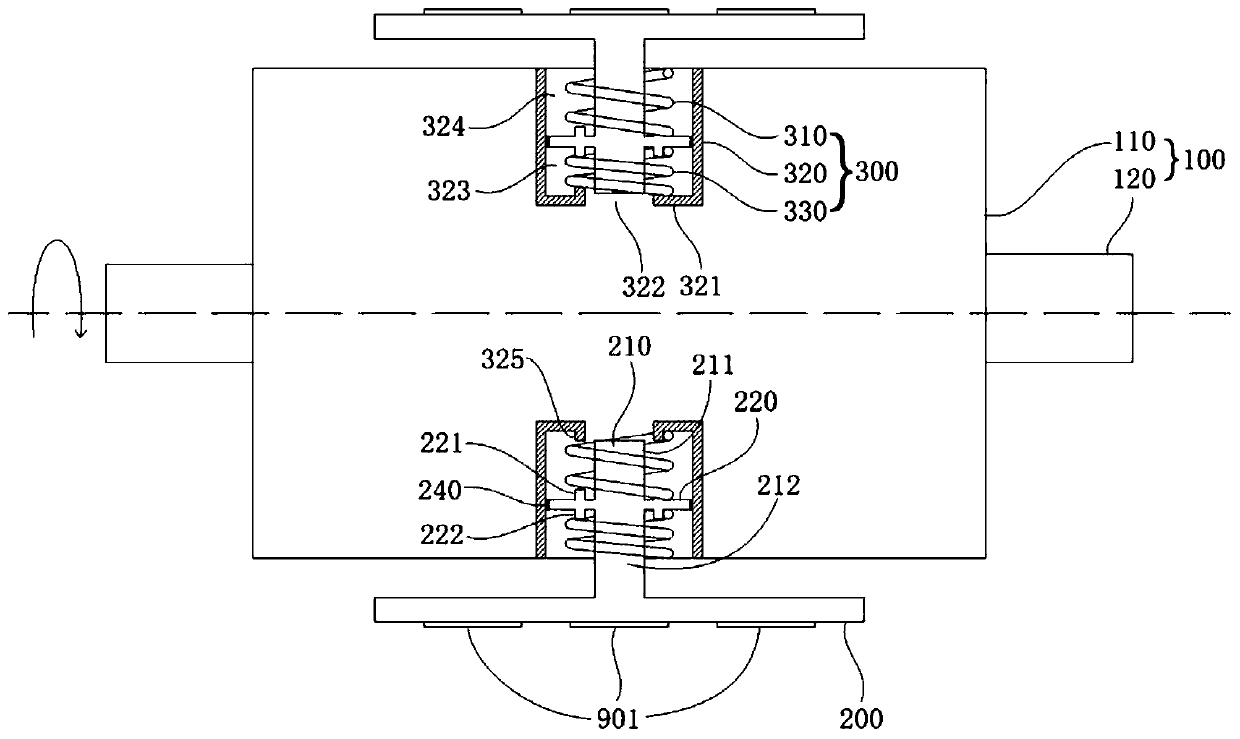

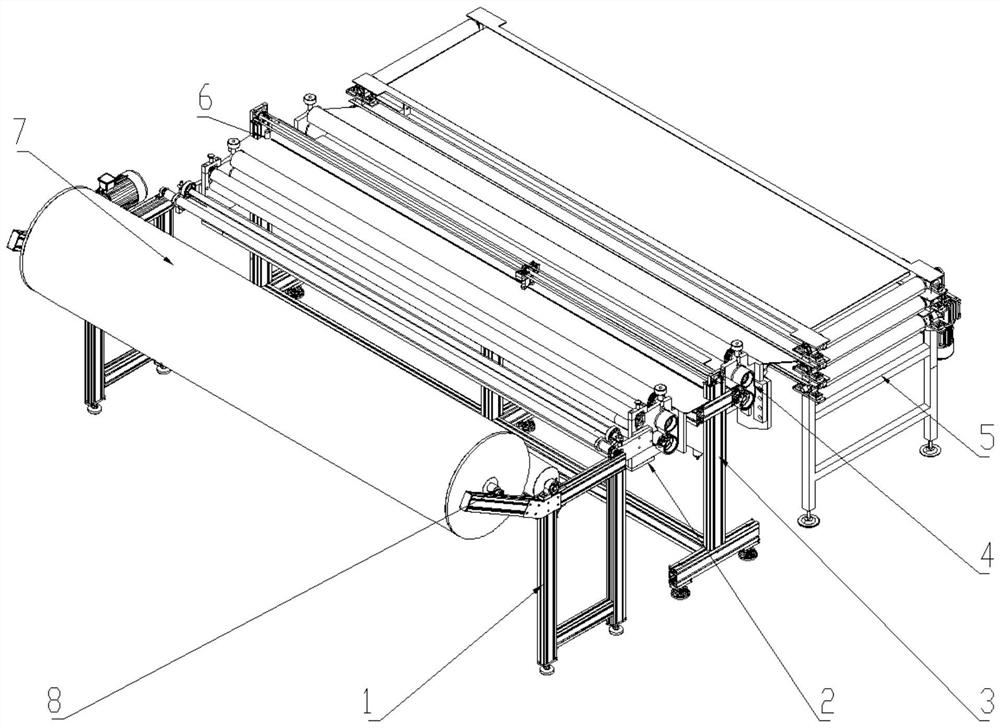

The invention discloses a polishing turnover device with a vibration isolating function. The polishing turnover device comprises a turnover assembly, a plurality of material trays and first vibrationisolating devices, wherein the turnover assembly is rotationally connected with a rotation control device of a glass polishing machine, the plurality of material trays are arranged on different surfaces of the turnover assembly, a main shaft with one end extending into the turnover assembly is arranged on one side of each material tray, a flange is arranged on the outer side of each main shaft, aplurality of first vibration isolating devices are arranged in the turnover assembly, each first vibration isolating device is connected with the corresponding material tray, each first vibration isolating device comprises a first elastic element arranged between the flange and the turnover assembly, and an outer cylinder which sleeves the outer side of each main shaft and is fixedly connected with the turnover assembly, wherein a top cover is arranged at one end of each outer cylinder, and a through hole is formed in each top cover. The device can absorb and isolate vibration in the axial direction generated by the material trays, so that the accuracy of positioning workpieces when the material trays on the other side are used for taking material and feeding is improved, and the working efficiency is improved.

Owner:东莞锐航光电科技有限公司

Intelligent cloth cutting and conveying device

InactiveCN113955535AThe feeding process is stableEffective measurement of cut lengthElectrostatic chargesArticle deliveryAutomatic controlMechanical engineering

The invention provides an intelligent cloth cutting and conveying device, belongs to the technical field of intelligent processing equipment, and aims to solve the problems of low cloth cutting efficiency, poor effect and low intelligent degree. The intelligent cloth cutting and conveying device comprises a pneumatic cutting mechanism and a batch roll, two symmetrical conveying sensors are arranged on the pneumatic cutting mechanism, a feeding mechanism and a material guiding mechanism are arranged on the two sides of the pneumatic cutting mechanism respectively, the material guiding mechanism comprises a material guiding support, a material guiding plate is hinged to the rear side of the material guiding support, a plurality of layers of conveying crawler belts are arranged on the rear side of the material guiding plate, the front side of the feeding mechanism is provided with a discharging mechanism, the discharging mechanism comprises a discharging support, two symmetrical discharging inclined rods are fixed to the front side of the discharging support, a bearing is arranged on the two discharging inclined rods in a sliding mode, and a cloth-roll is arranged on the batch roll. According to the intelligent cloth cutting and conveying device, discharging is stable, and folding is not prone to being formed; intelligent automatic control is achieved, and feeding, cutting and guiding are efficiently and stably conducted; and static electricity can be effectively released, cloth with different cut lengths can be conveyed in a classified mode, and the manual classification cost is reduced.

Owner:刘庆林

Automobile sheet stamping unloading and blanking protection mechanical assembly

PendingCN113732144AAvoid damageImprove stabilityMetal-working feeding devicesPositioning devicesHydraulic cylinderStructural engineering

The invention discloses an automobile sheet stamping unloading and blanking protection mechanical assembly which comprises a lower die set arranged on a machine tool, afirst upper die set, a hydraulic cylinder, an inner hollow pipe and a second telescopic rod,a stamping die set is movably installed on the left side of the lower die set, and a first telescopic rod is fixedly connected between the top of the lower die set and the bottom edge of the stamping die set; the first upper die set is located over the stamping die set, and the right side of the first upper die set is movably connected with a second upper die set; the lower end of an output shaft of the hydraulic cylinder is fixedly connected to the top of the first upper die set; the inner hollow pipe is fixedly mounted on the outer wall of the right side of the lower die set; and the second telescopic rod is fixed on the outer wall of the left side of the lower die set. According to the automobile sheet stamping unloading and blanking protection mechanical assembly, stable discharging and shaping treatment of sheet stamping operation are achieved, pushing type unloading and blanking conveying can be conducted on stamped formed sheets, and workpiece damage during blanking is effectively avoided.

Owner:程秀峰

Quick feeding device for rice straw decoration plate production line

The invention relates to the technical field of plate feeding devices, in particular to a quick feeding device for a rice straw decoration plate production line. The quick feeding device comprises a rack, a first station and a second station, an air pump is mounted in the middle of the left end of the rack, a through groove is formed in the front end of the rack, the rear end of the through groove penetrates to the rear end surface of the rack and a cross beam is slidably installed inside the through groove. The front and rear sides of the cross beam extend to the outside of the through groove. Limiting channels are formed in the middles of the front side and the rear side of the cross beam correspondingly, rectangular rods are slidably mounted in the limiting channels correspondingly, a two-way air cylinder is jointly connected between the tops of the two rectangular rods, and first electric telescopic rods are fixed to the bottoms of the rectangular rods correspondingly. Clamps used for clamping decoration plates are installed at the bottoms of the first electric telescopic rods correspondingly, electric sliding blocks are installed in linear sliding grooves, second electric telescopic rods are fixed to the bottoms of the electric sliding blocks, a fixing base is fixed to the bottoms of the second electric telescopic rods, and suction cups are arranged at the bottoms of the fixing base at equal intervals. Two kinds of structures, namely clamps and suction cups, are provide for adsorb materials, and strong adsorption force is achieved.

Owner:HUNAN UNIV OF HUMANITIES SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com