Automatic forming production line of insulation quilt

A technology of automatic forming and thermal insulation felt, which is applied in the field of automatic forming production line of thermal insulation blanket, which can solve the problems of reduced automation, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

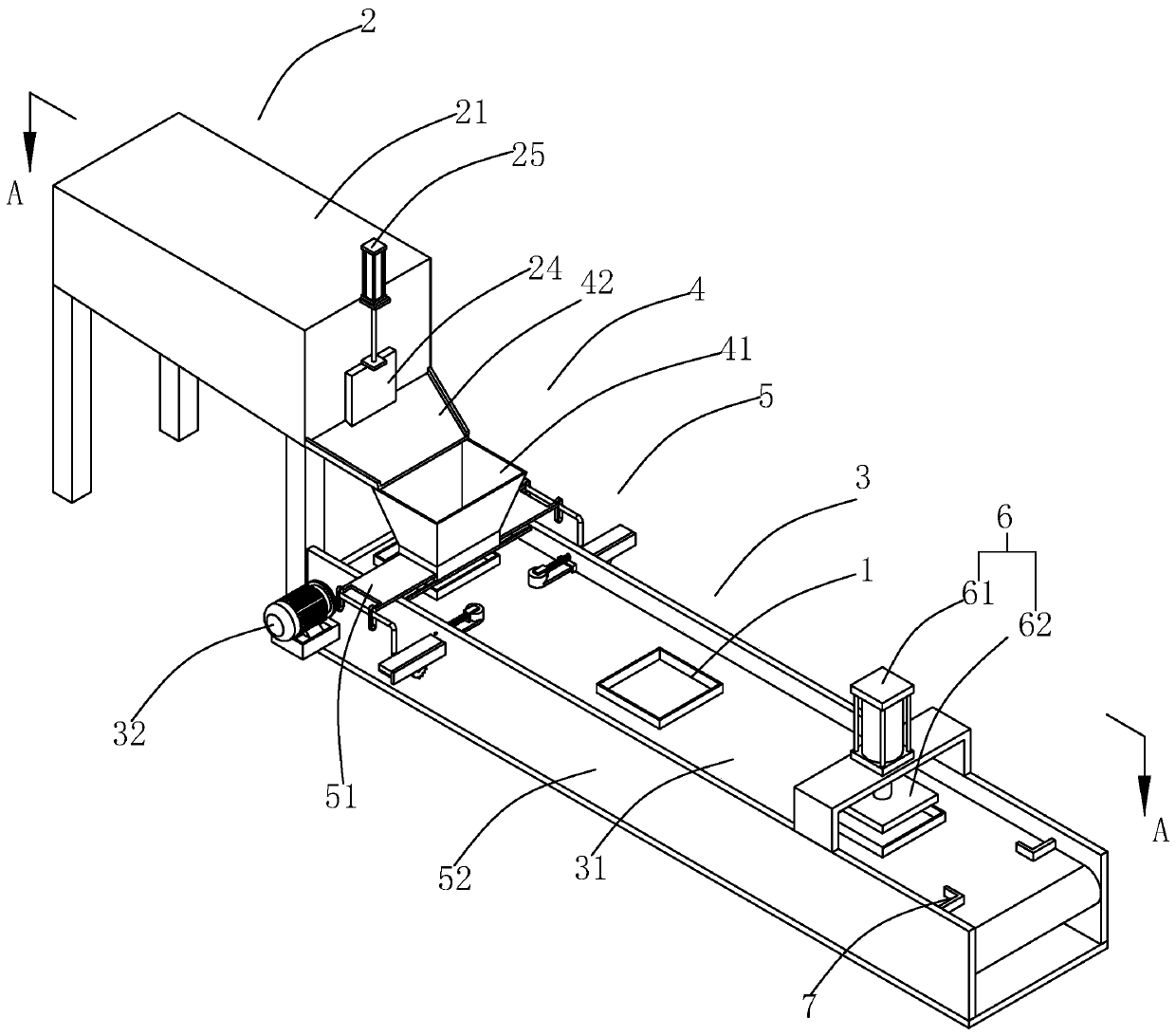

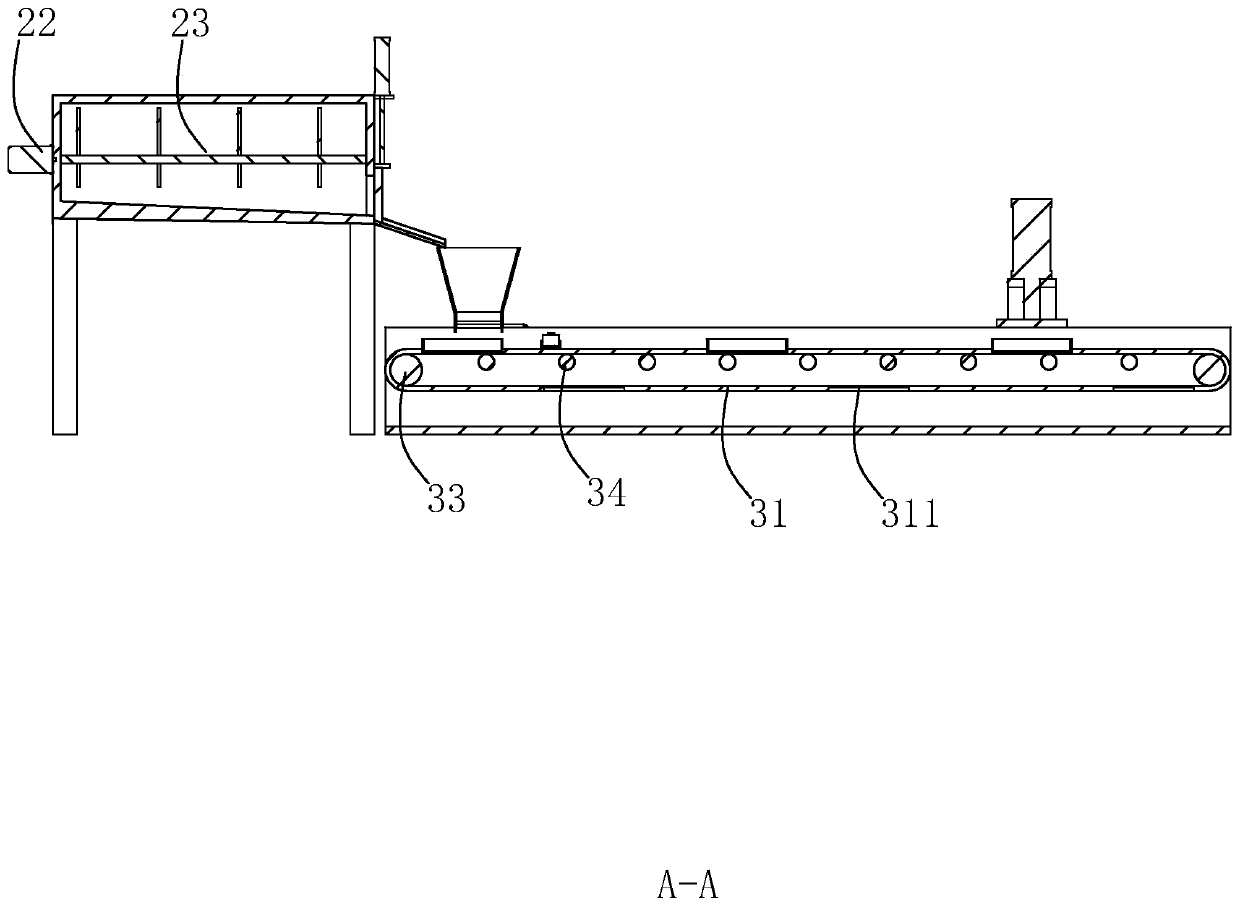

[0037] refer to figure 2 , image 3 , which is an automatic forming production line for thermal insulation felt disclosed by the present invention, comprising:

[0038]Stirring mechanism 2, stirring mechanism 2 comprises stirring box 21, stirring paddle 23 and drive motor 22, four corners of stirring box 21 bottom surface are respectively connected with supporting legs extending vertically downwards, four supporting legs are equal in length Realize the support to the mixing box 21. The stirring paddle 23 is horizontally placed in the stirring box 21 , and the two ends of the stirring paddle 23 are respectively rotatably connected with the two ends of the stirring box 21 . The base of the driving motor 22 is installed on the outer wall of one end of the stirring box 21, and the output shaft of the driving motor 22 is parallel to the stirring paddle 23 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com