Method for modifying martensite gas valve steel carbide

A martensitic and valve steel technology, applied in the field of modified martensitic valve steel carbides, can solve the problems of reducing structure and hardness uniformity, increasing deformation and cracking tendency, deteriorating mechanical properties, etc., and achieving segregation improvement , improve quality and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

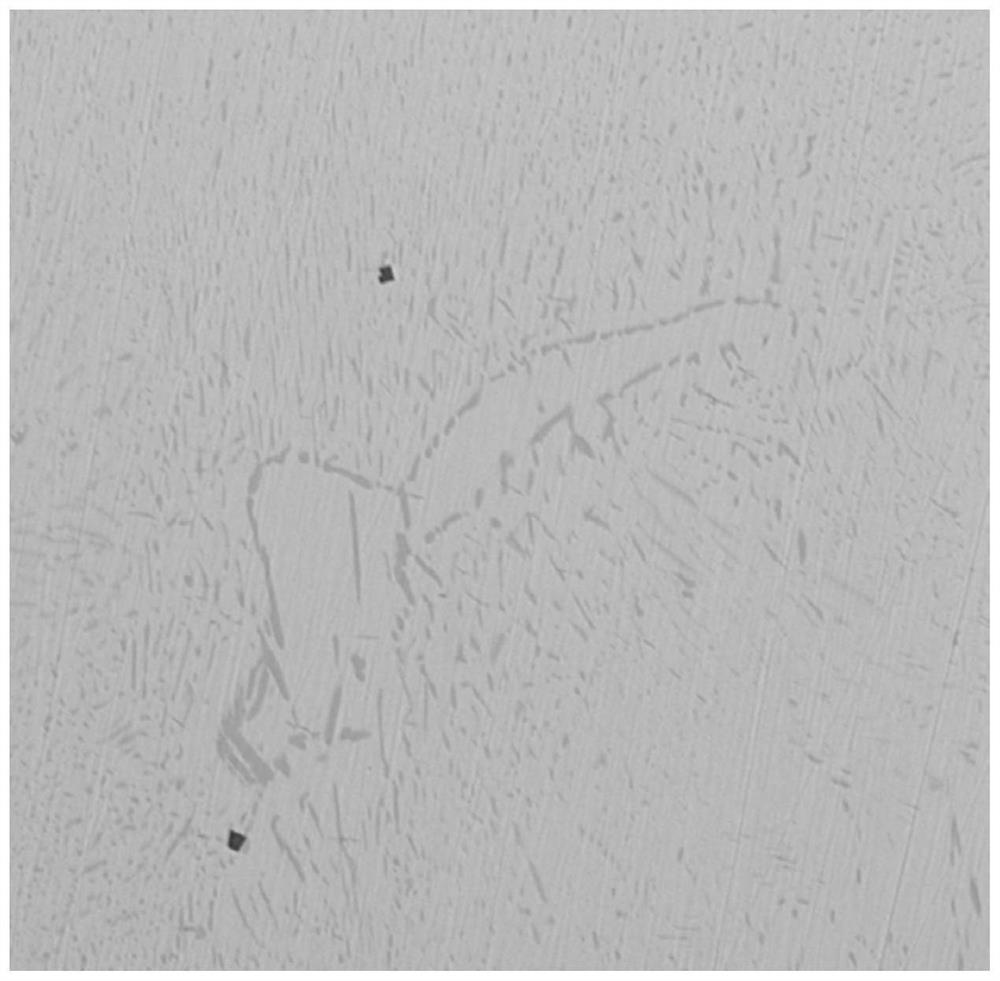

Embodiment 1

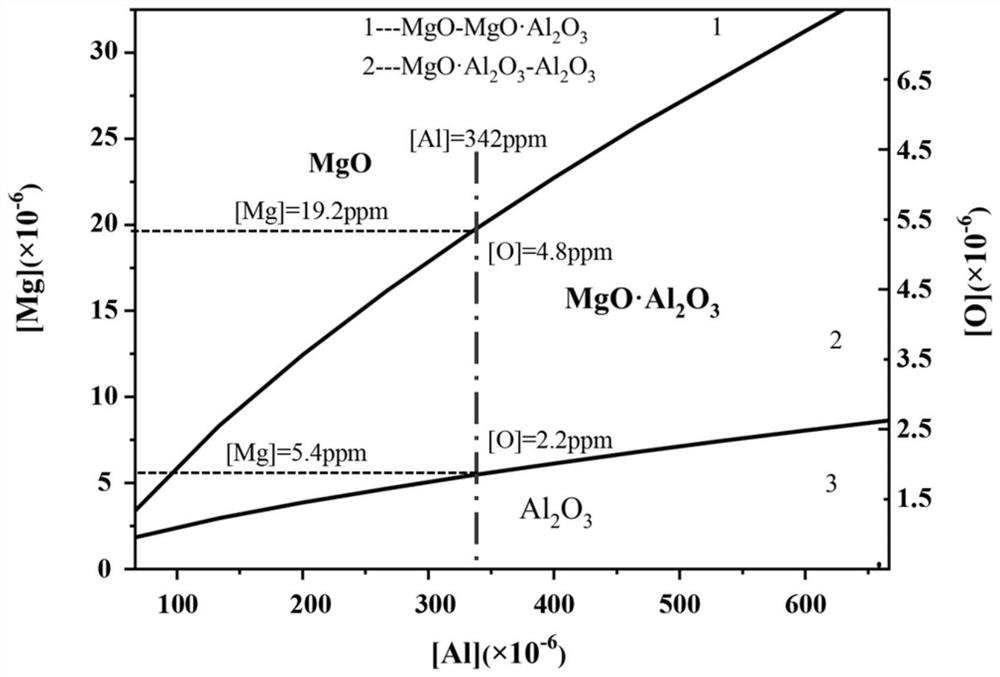

[0060] This embodiment provides a method for modifying carbides of martensitic gas valve steel, which includes the following steps: sequentially smelting the raw material of martensitic gas valve steel in electric furnace, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling and pickling to obtain modified martensitic gas valve steel; among them, at the end of LF furnace molten steel refining, when the molten steel temperature and composition are adjusted in place, the addition process of magnesium-containing cored wire is carried out. During electric furnace smelting, The oxygen content of the molten steel is reduced to below 300ppm; when the AOD furnace is smelting, the basicity of the steel slag is greater than 5, and the active oxygen is less than 100ppm at the end of the AOD furnace smelting.

[0061] At the end of LF furnace refining, before feeding the magnesium-containing cored wire, the alkalinity of the slag layer is 4.5. At the same time, the ...

Embodiment 2

[0066] The method for modifying carbides of martensitic gas valve steel in this embodiment comprises the following steps: sequentially smelting the raw material of martensitic gas valve steel in electric furnace, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling and Pickling to obtain modified martensitic valve steel. The difference between this implementation and embodiment 1 is:

[0067] At the end of LF furnace smelting, the basicity of the slag layer is 4.5. At the same time, the white slag production time is 30 minutes. At the same time, at the end of LF furnace smelting, the oxygen activity of the molten steel when tapping is 4.5ppm.

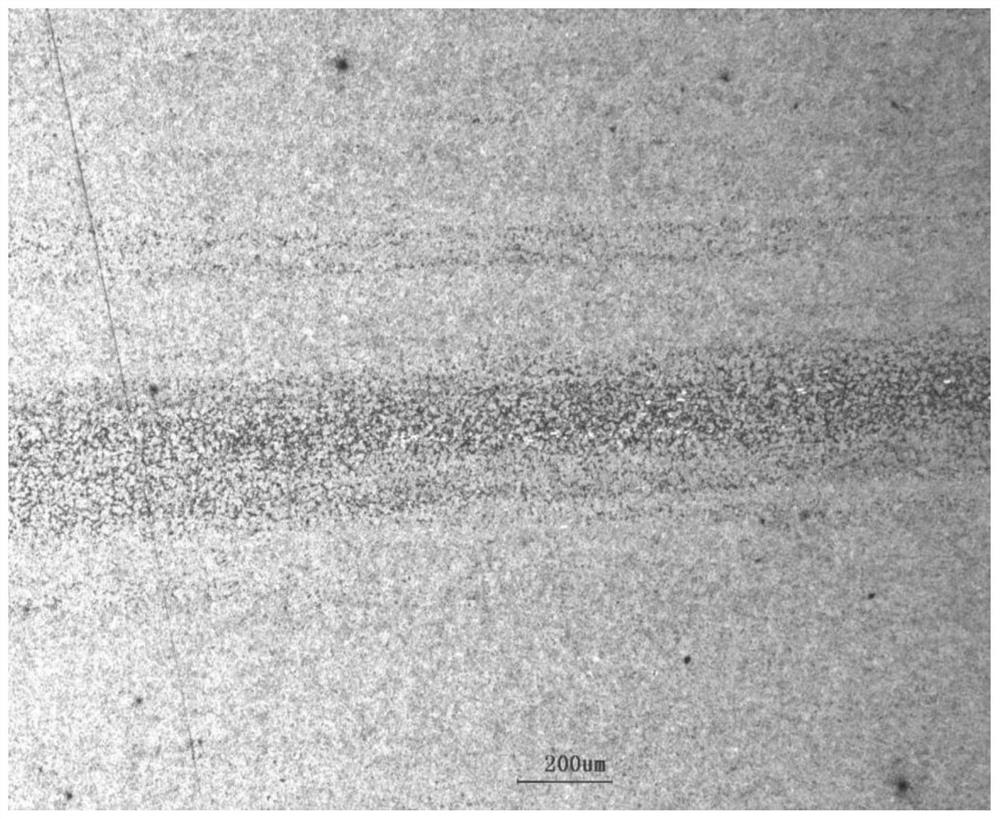

[0068] In this example, the oxygen activity of molten steel at the end of LF refining is higher than that of Example 1, and most of the carbides in the produced heat-resistant steel are distributed in the range of 12-30 μm.

Embodiment 3

[0070] The method for modifying carbides of martensitic gas valve steel in this embodiment comprises the following steps: sequentially smelting the raw material of martensitic gas valve steel in electric furnace, smelting in AOD furnace, refining in LF furnace, continuous casting, rolling and Pickling, obtains the improved martensitic valve steel; The difference between this implementation and embodiment 1 is:

[0071] At the end of LF furnace refining, the basicity of the slag layer is 3, and when the steel is tapped at the end of LF refining, the oxygen activity of molten steel is 5.5ppm.

[0072] In this example, the basicity of the slag layer during the refining period of the LF furnace is lower than that of Example 1, resulting in higher oxygen activity during tapping, and the average size of carbides in the produced heat-resistant steel is 15-35 μm.

[0073] From Examples 2 and 3, it can be seen that the higher the basicity of slag in the final stage of LF furnace refini...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com