Bismuth Addition Technology for Free Cutting Steel Containing Bismuth

A free-cutting steel and process method technology, applied in the field of iron and steel metallurgy, can solve the problems of high concentration of alloy elements, serious volatilization of elements, and rising production costs, and achieve high yield, low production cost, and stable feeding process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

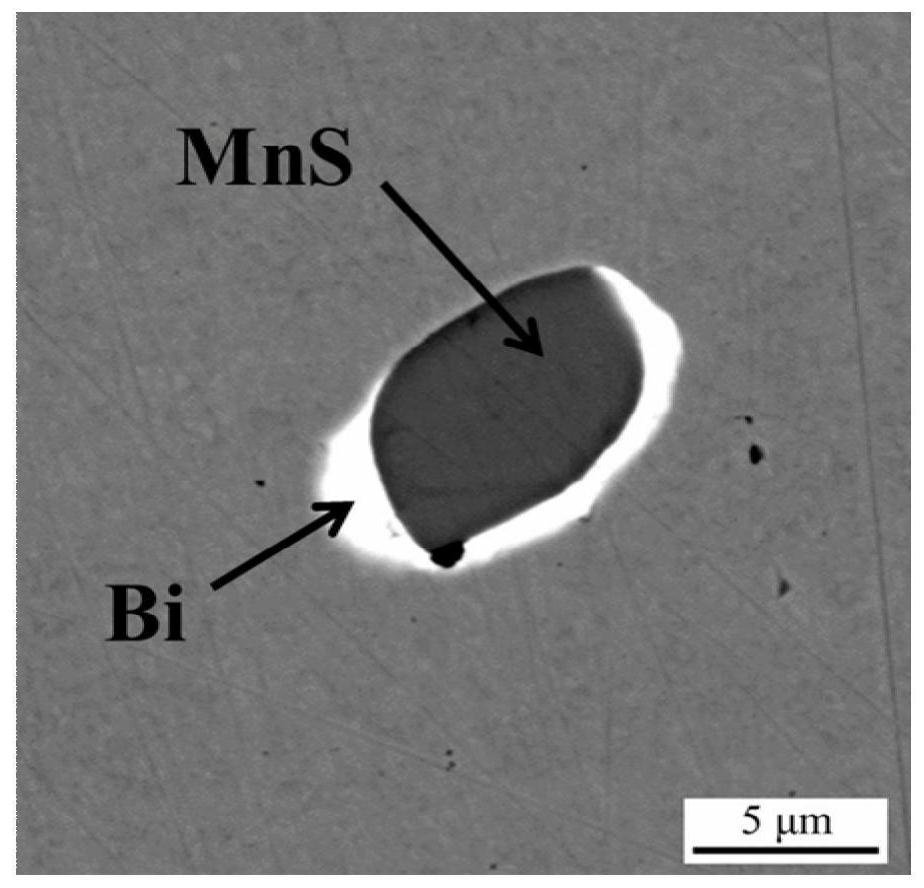

Image

Examples

Embodiment 1

[0057] In this embodiment, a bismuth addition process for bismuth-containing free-cutting steel, the production process of bismuth-containing carbon free-cutting steel is primary smelting→refining→wire feeding→continuous casting→rolling, measured at the end of LF furnace refining The composition of molten steel is C: 0.08%, Si: 0.03%, Mn: 1.15%, P: 0.09%, S: 0.30%, and the balance is iron and unavoidable residual elements. The composition of molten steel meets the requirements of this free-cutting steel According to this requirement, in the final stage of molten steel refining, after the adjustment of other components other than bismuth is completed, the feeding line addition process of bismuth-containing cored wire is carried out to prepare the target bismuth-containing free-cutting molten steel. The feeding line addition process method includes Follow the steps below:

[0058] a. Control the production conditions before feeding the line, mainly to control the molten steel sl...

Embodiment 2

[0076] This embodiment is basically the same as Embodiment 1, especially in that:

[0077] In this embodiment, a bismuth-added process for bismuth-containing free-cutting steel, the production process of bismuth-containing carbon free-cutting steel is primary smelting→refining→line feeding→continuous casting→rolling. The liquid composition is C: 0.14%, Si: 0.05%, Mn: 1.3%, P: 0.10%, S: 0.33%, and the balance is iron and unavoidable residual elements. The liquid steel composition meets the requirements of this free-cutting steel grade , at the end of molten steel refining, after the adjustment of other components except bismuth is completed, the feeding line addition process of bismuth-containing cored wire is carried out to prepare the target bismuth-containing free-cutting molten steel. The feeding line addition process includes the following steps :

[0078]a. Control the production conditions before feeding the line, mainly to control the molten steel slag layer, temperatu...

Embodiment 3

[0096] This embodiment is basically the same as the previous embodiment, and the special features are:

[0097] In this embodiment, a bismuth-added process for bismuth-containing free-cutting steel, the production process of bismuth-containing carbon free-cutting steel is primary smelting→refining→line feeding→continuous casting→rolling. The liquid composition is C: 0.14%, Si: 0.05%, Mn: 0.8%, P: 0.10%, S: 0.25%, and the balance is iron and unavoidable residual elements. The liquid steel composition meets the requirements of this free-cutting steel type , at the end of molten steel refining, after the adjustment of other components except bismuth is completed, the feeding line addition process of bismuth-containing cored wire is carried out to prepare the target bismuth-containing free-cutting molten steel. The feeding line addition process includes the following steps :

[0098] a. Control the production conditions before feeding the line, mainly to control the molten steel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water activity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com