Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Stress relief concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

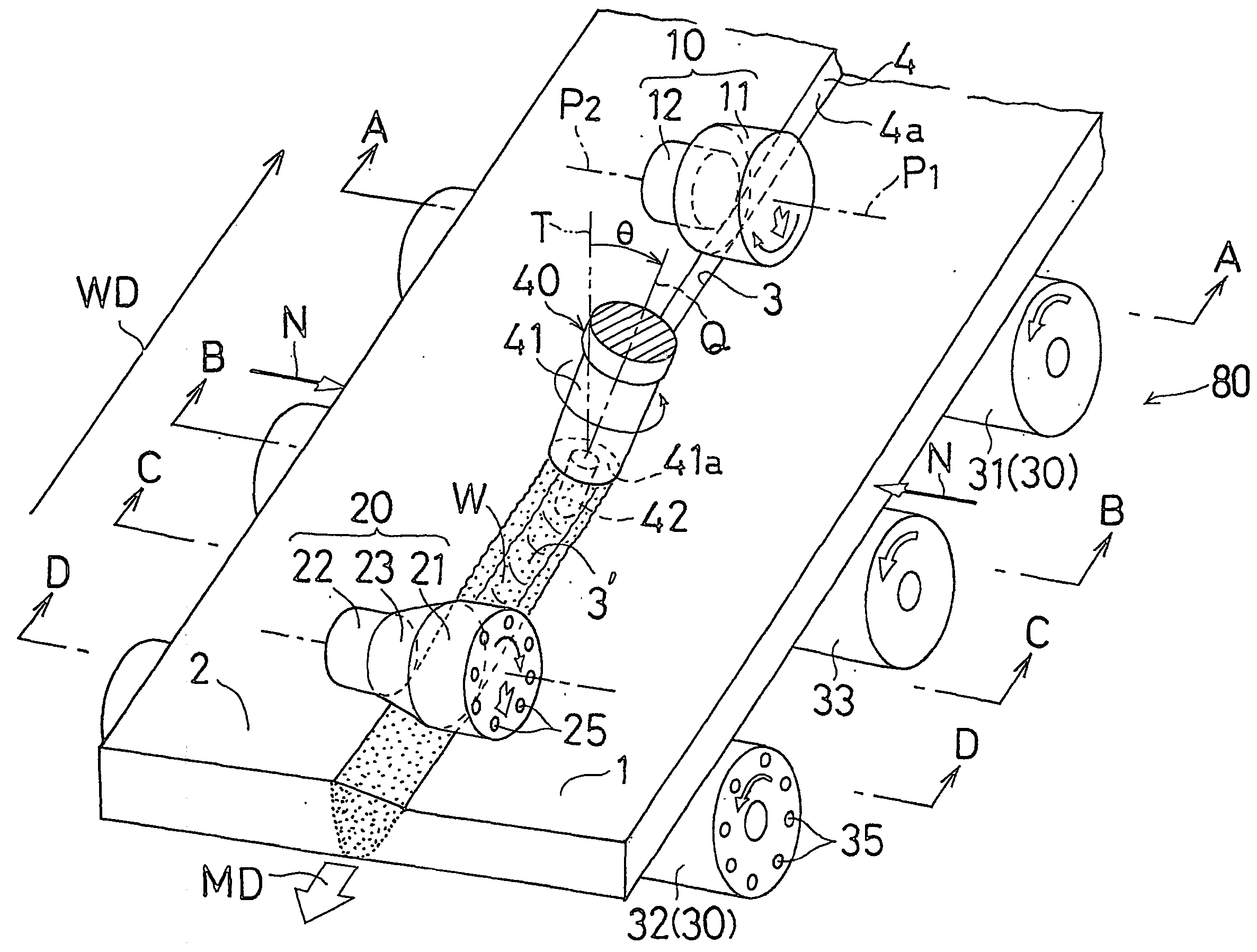

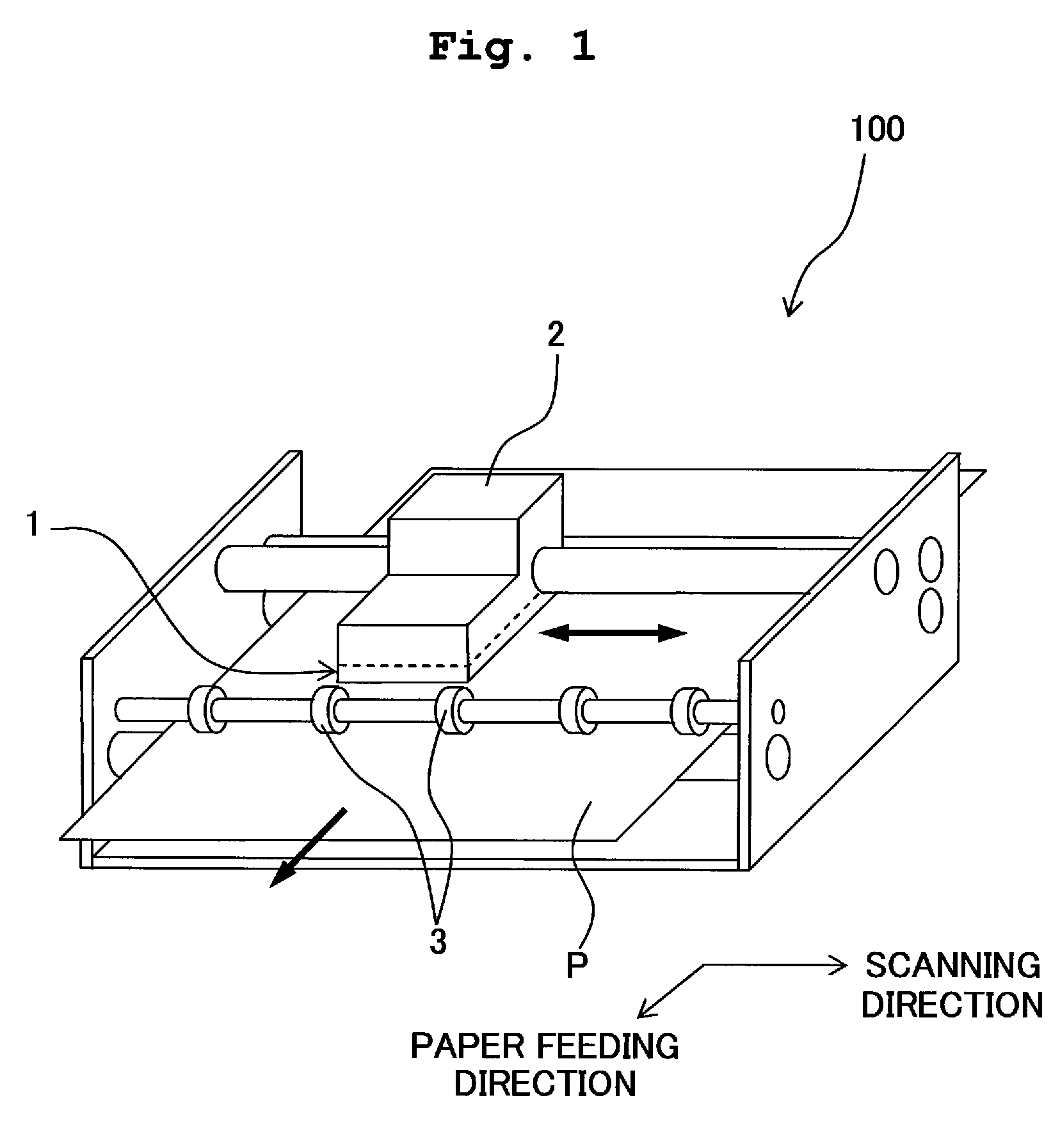

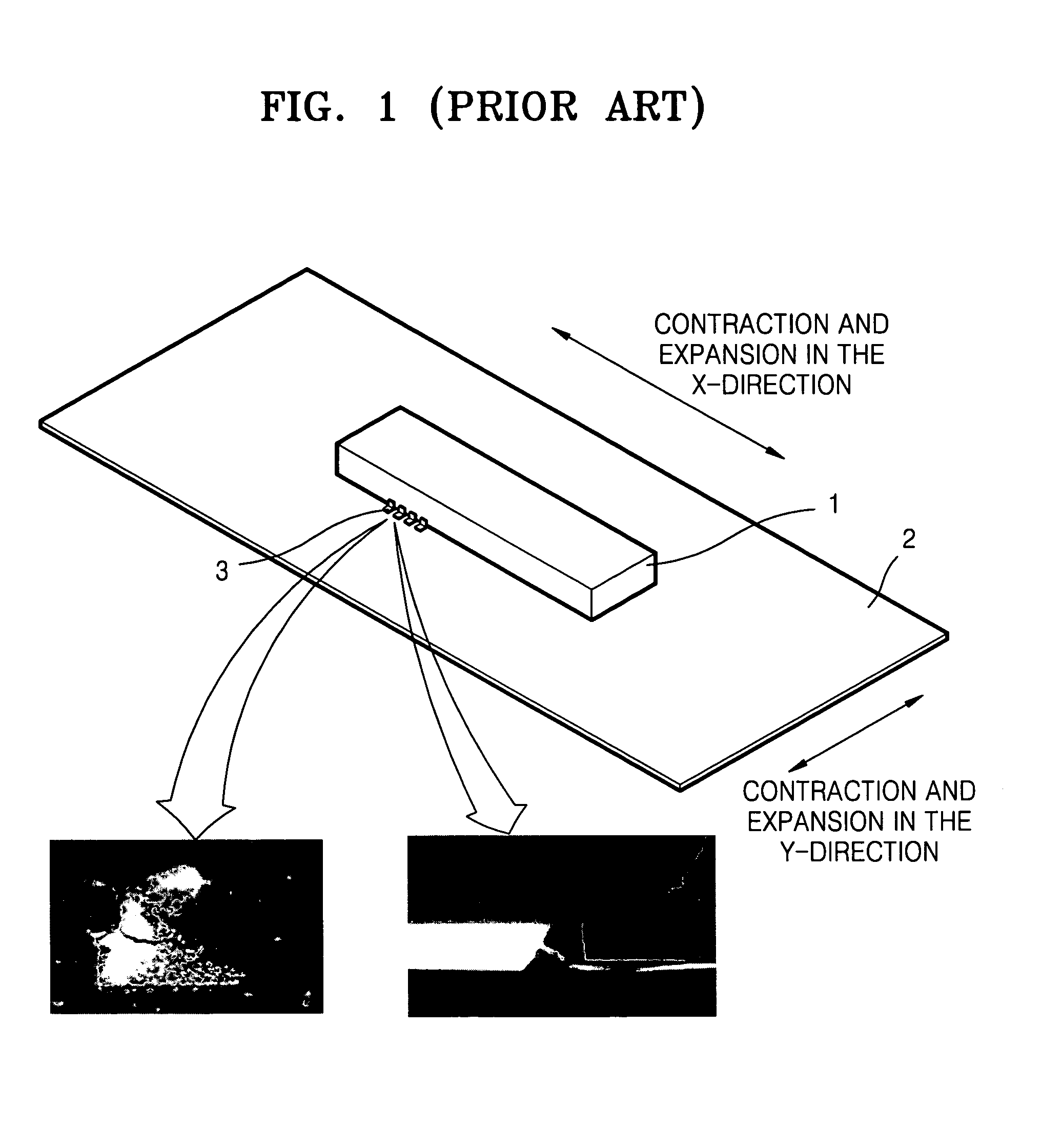

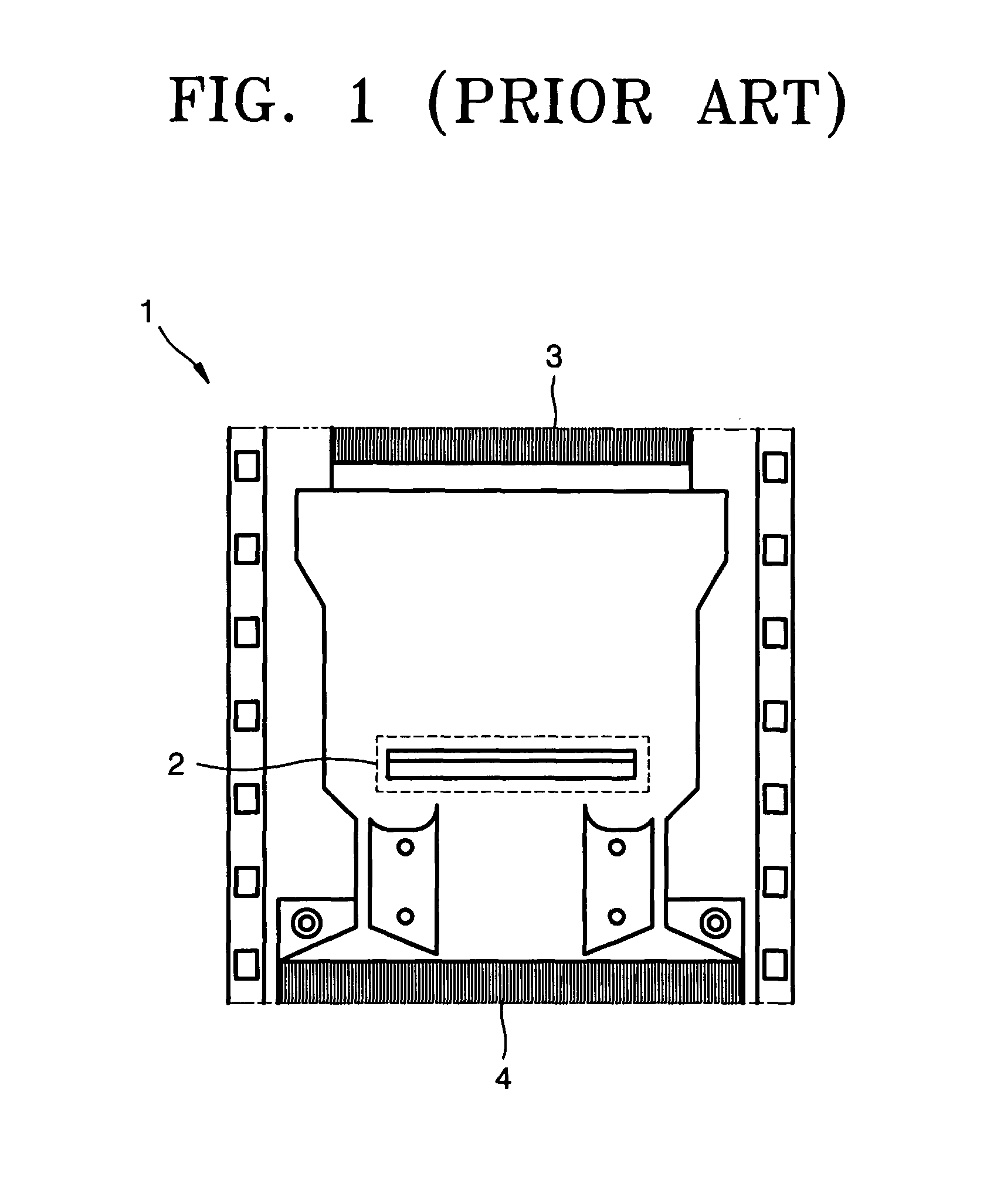

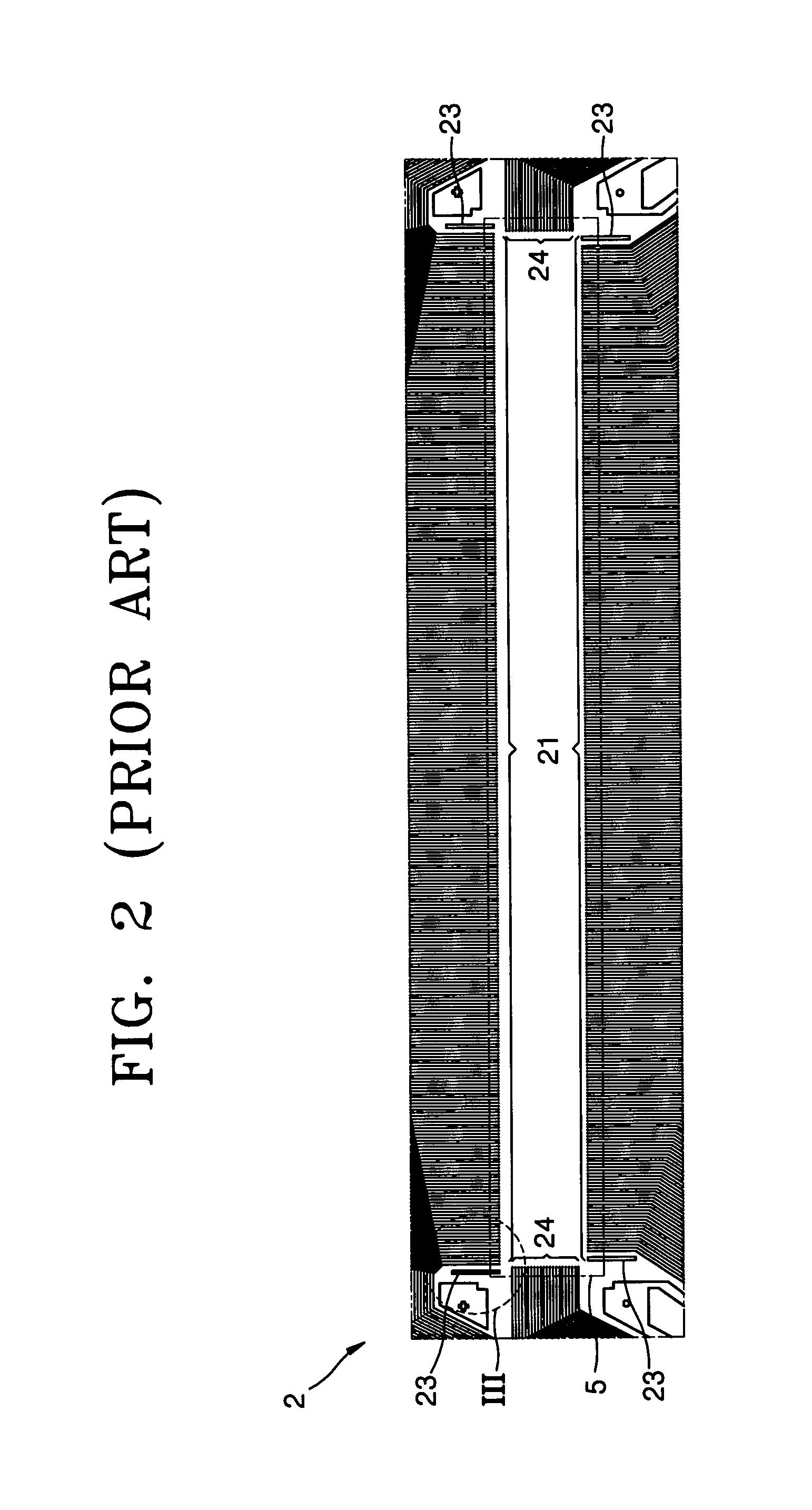

Friction agitation joining method method for manufacturing joined butted members and friction agitation joining apparatus

InactiveUS20040134971A1Quality improvementAvoid mistakesNon-electric welding apparatusMechanical engineeringPhysics

Owner:HONDA MOTOR CO LTD

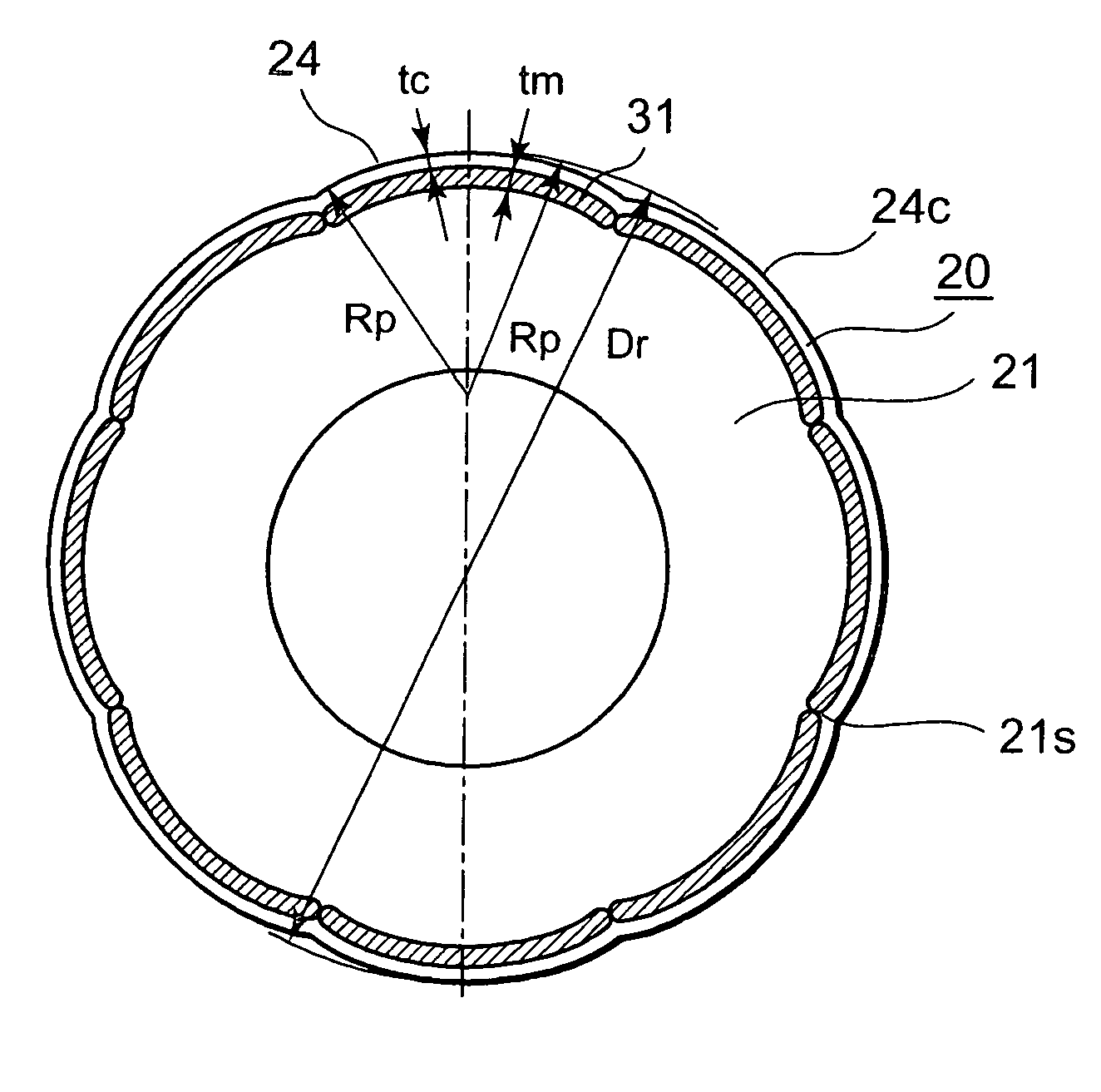

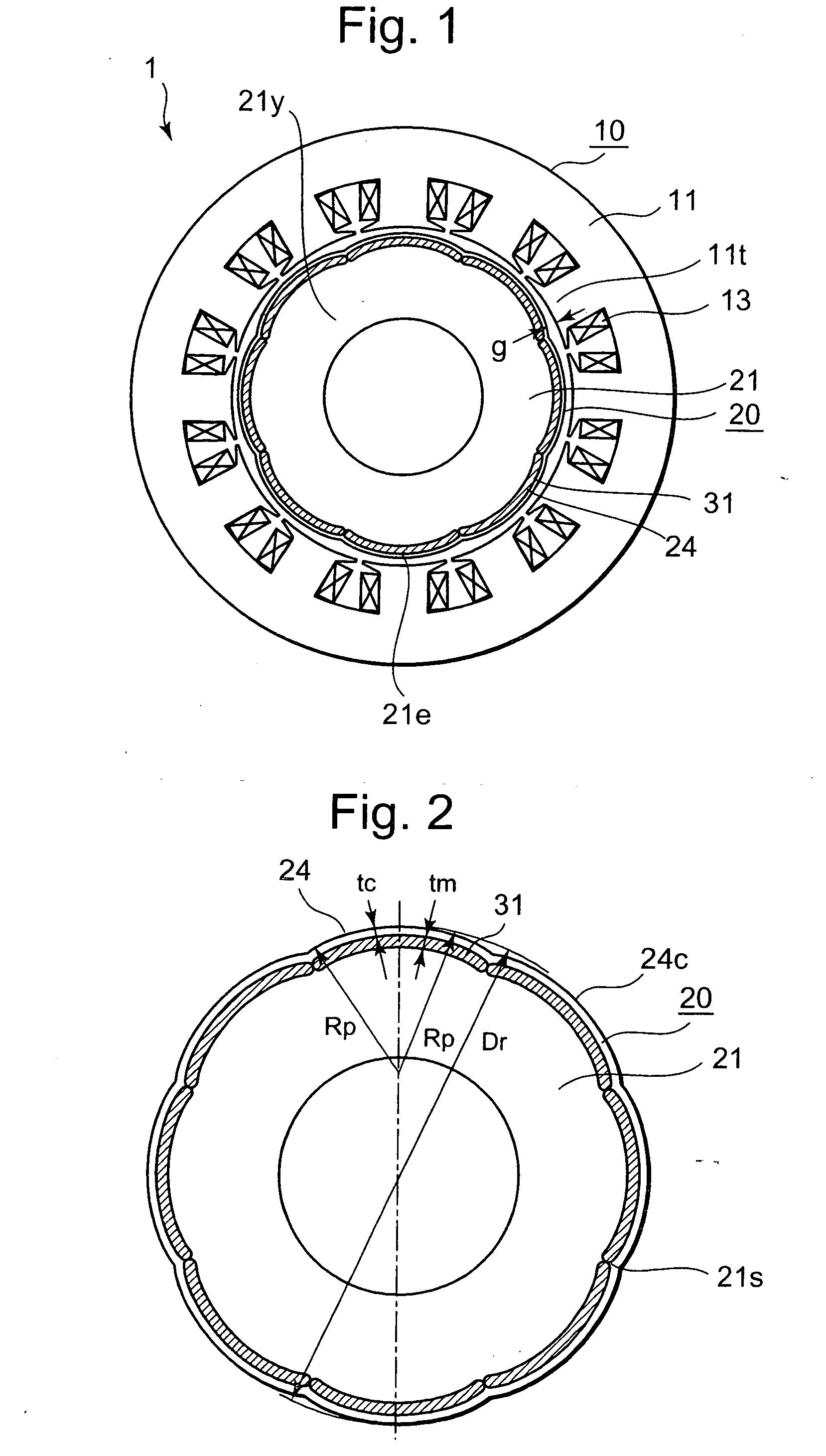

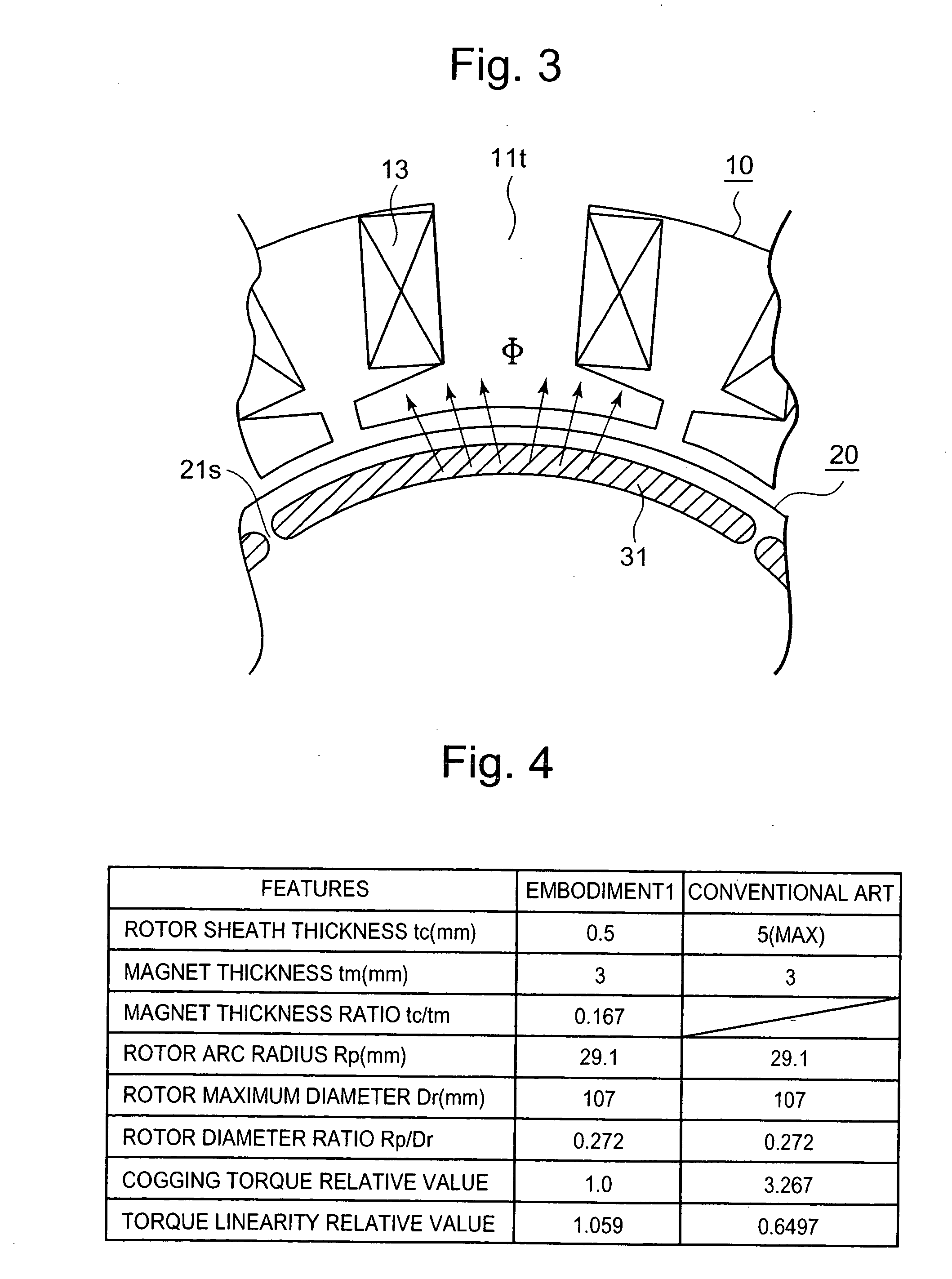

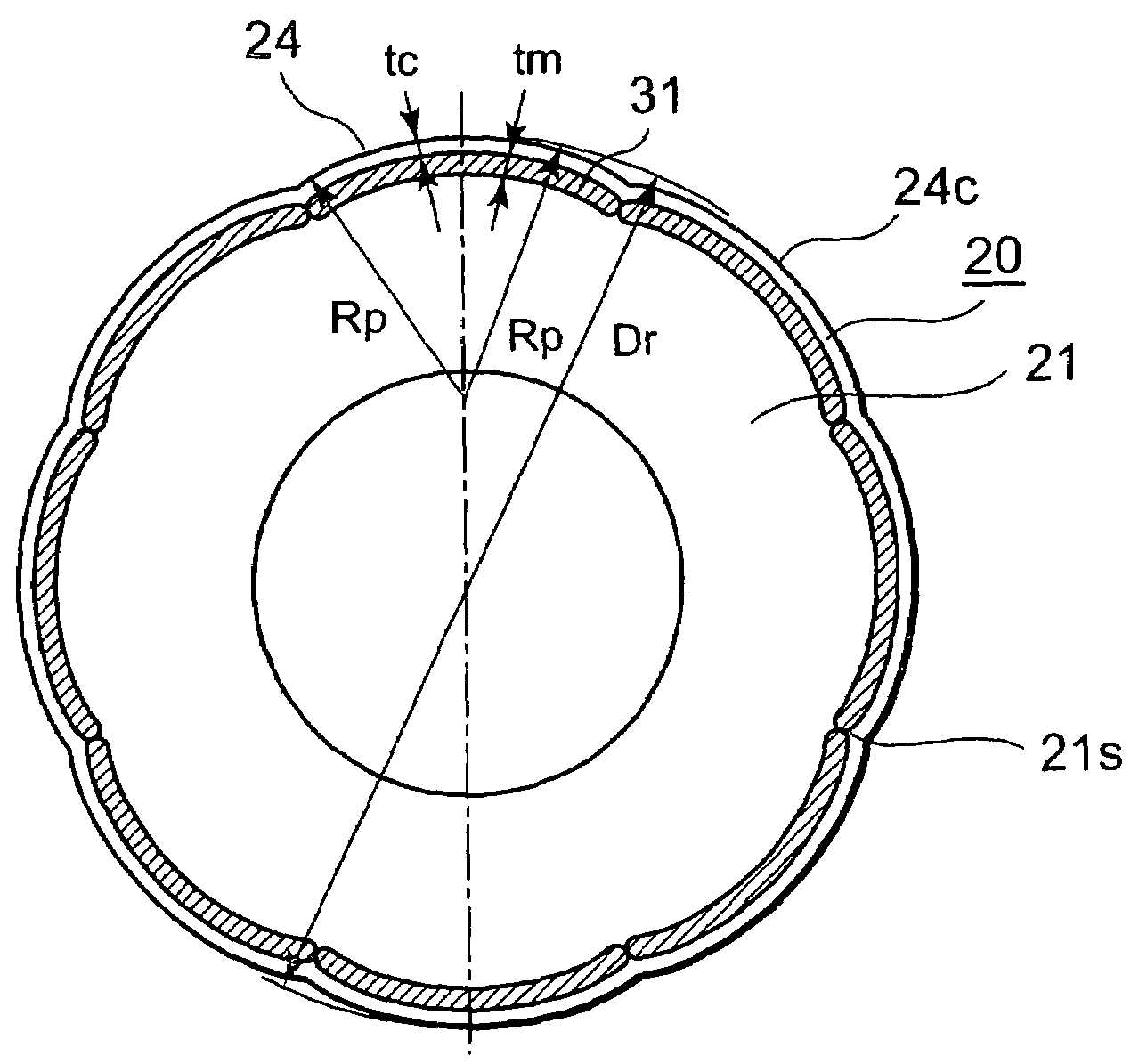

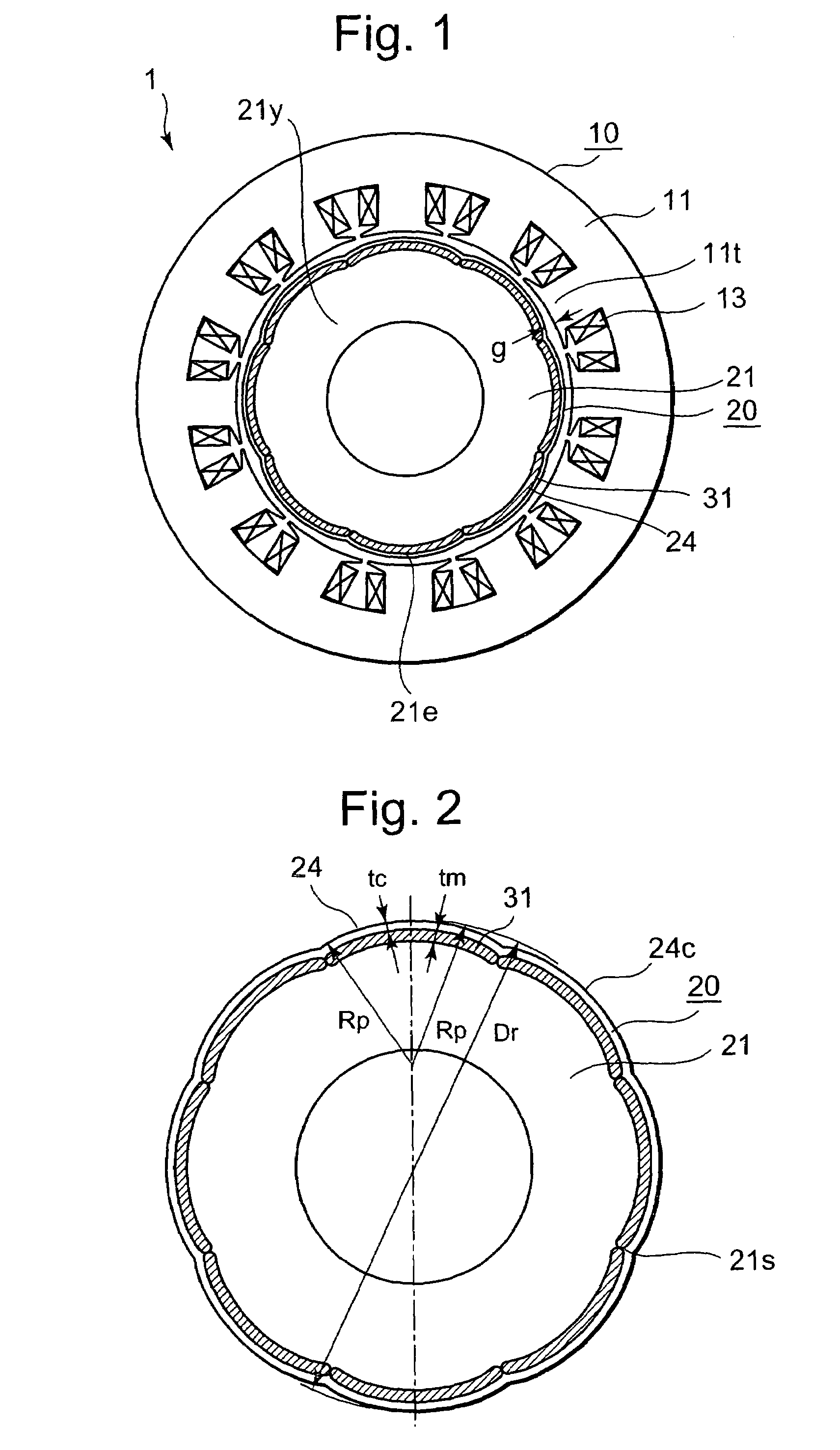

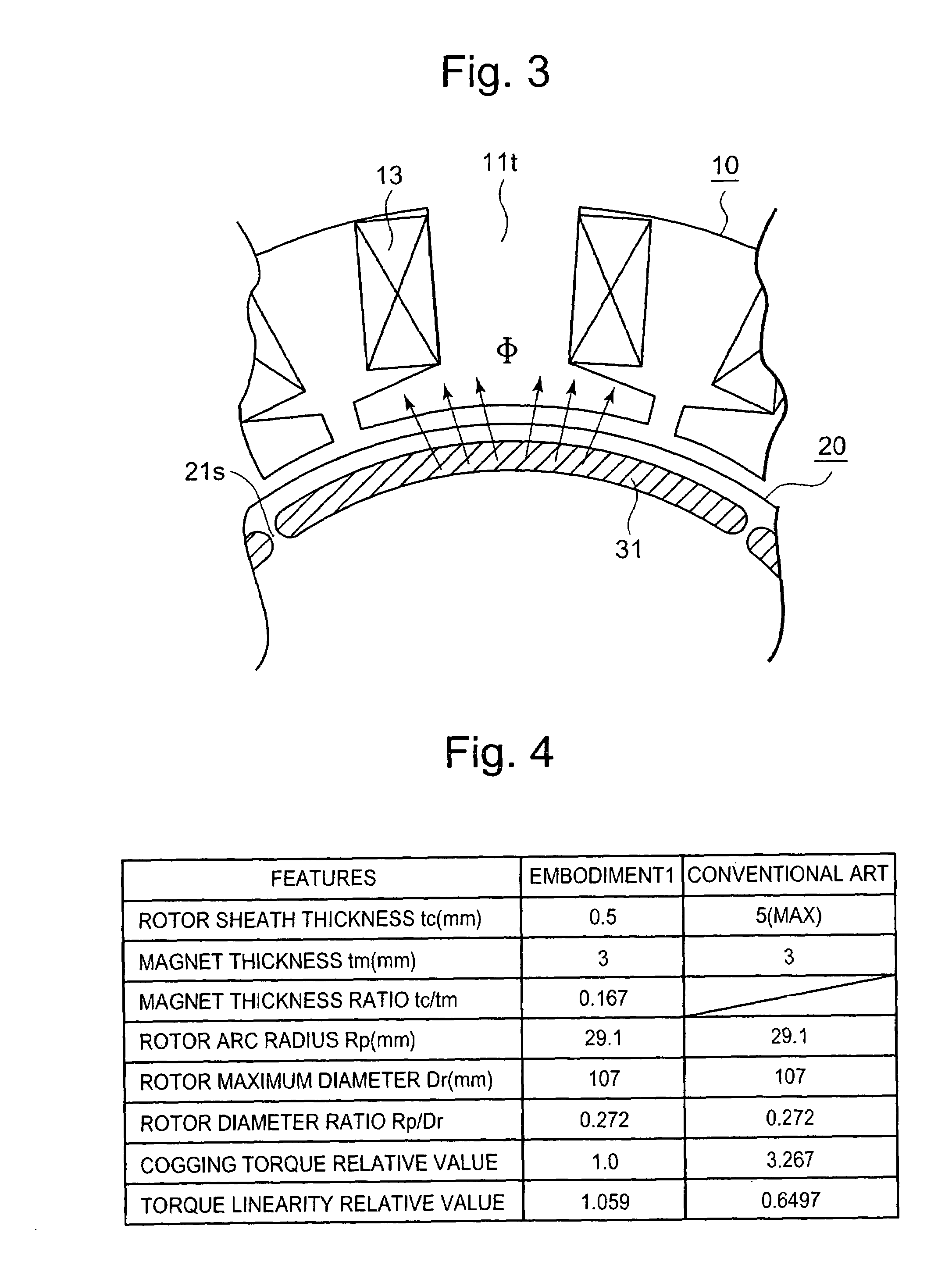

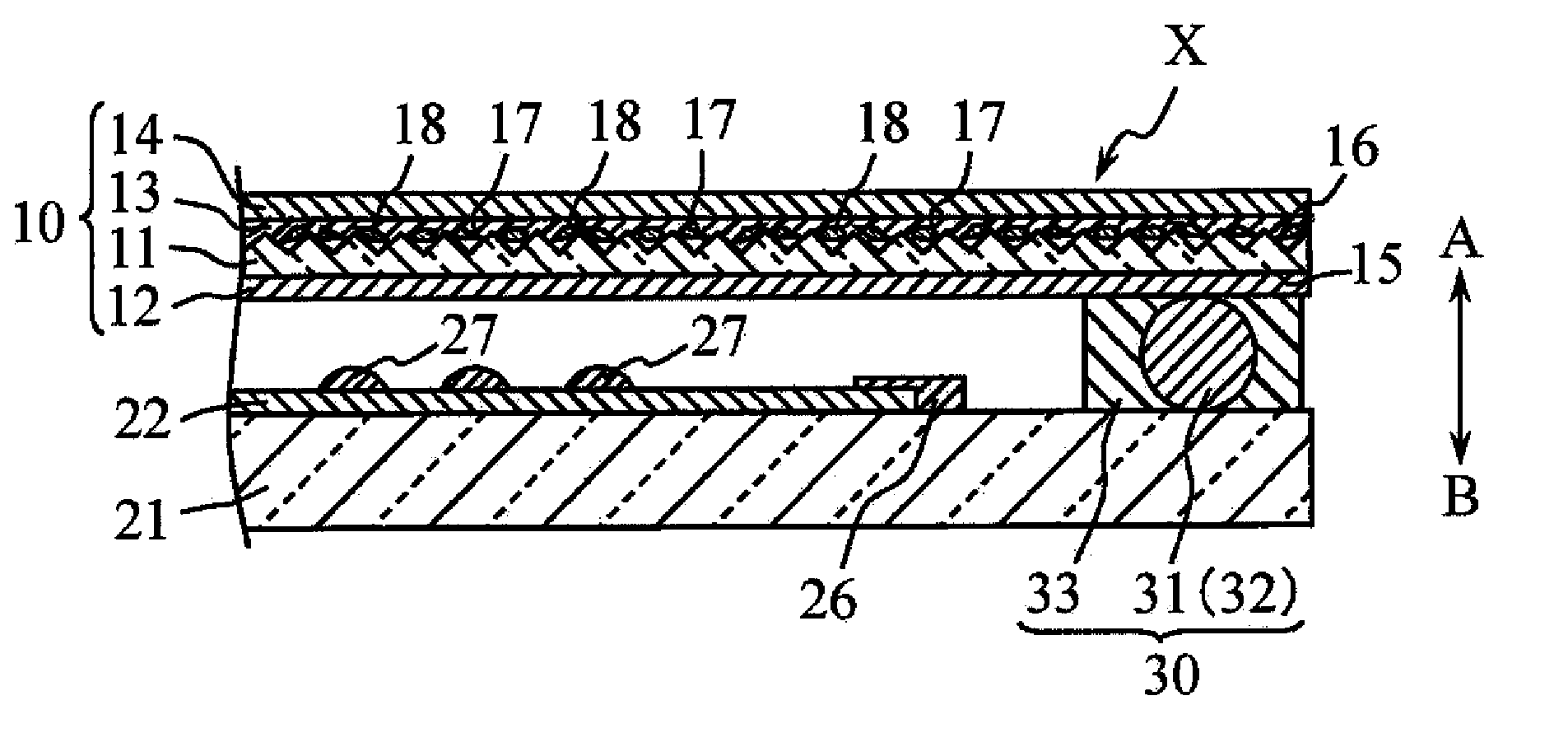

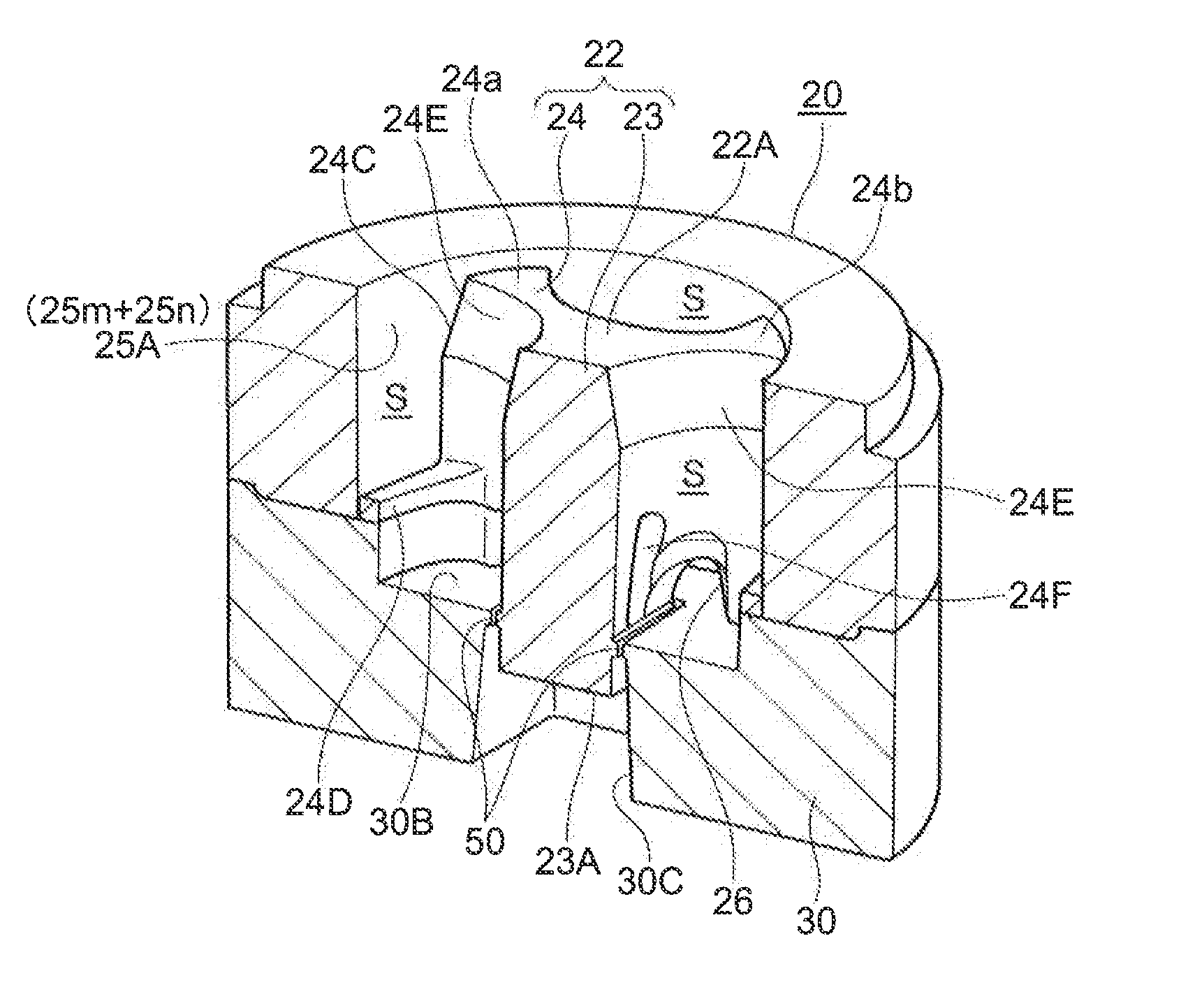

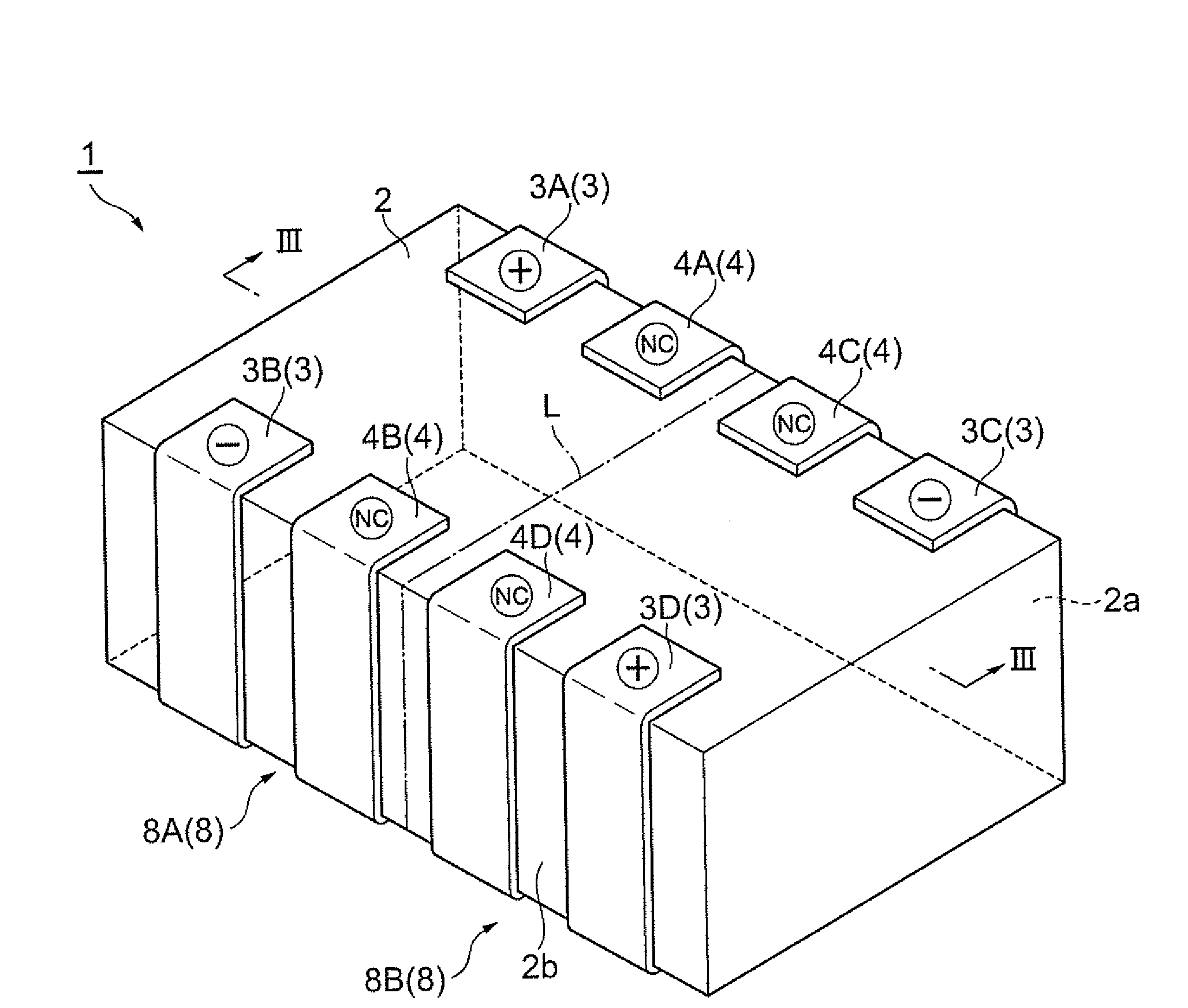

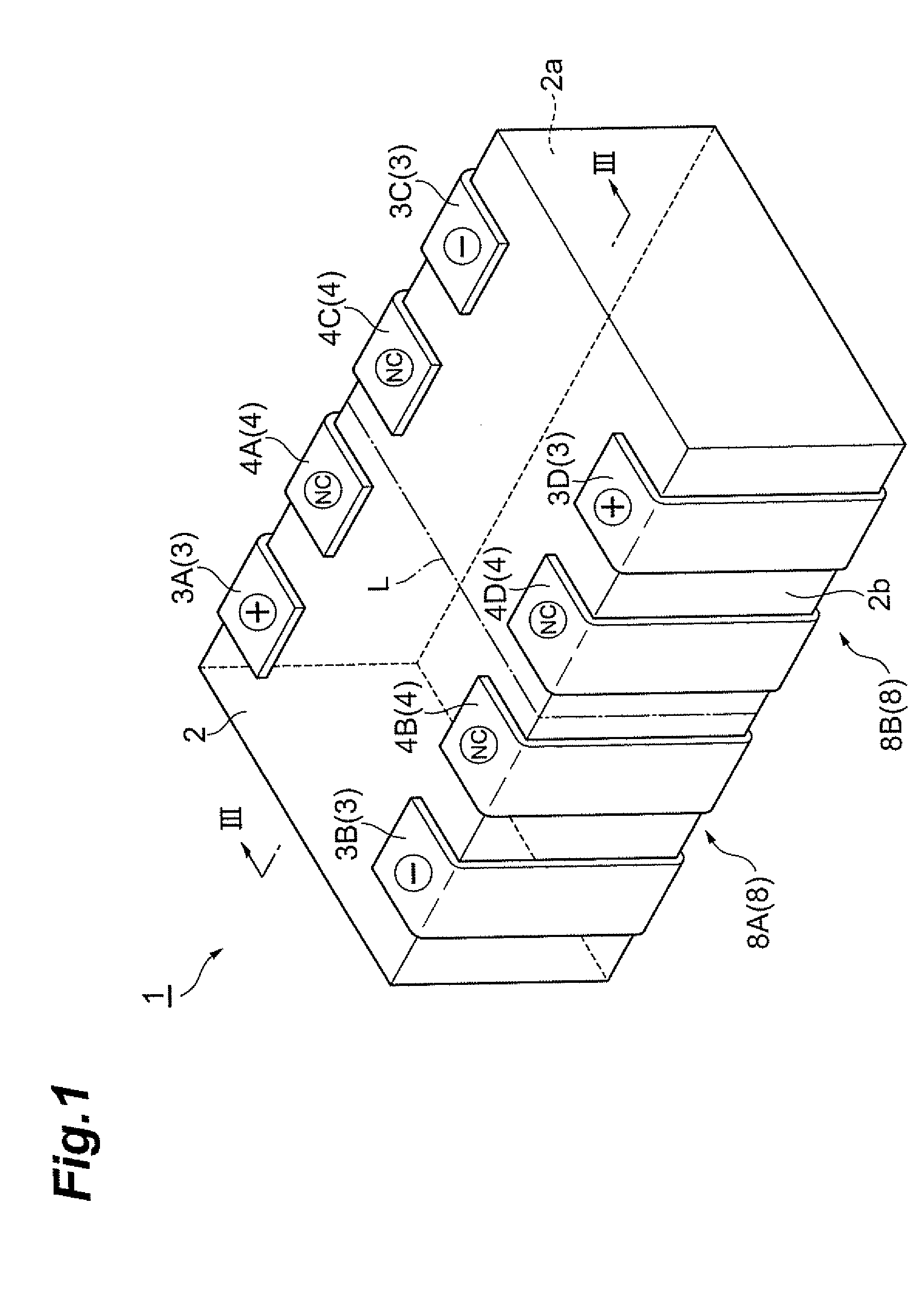

Permanent magnet type motor

InactiveUS20060131976A1Reducing cogging torqueCogging torque is smallMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPermanent magnet motor

A permanent magnet motor 1 includes a rotor in which permanent magnets 31 are fixed. In the rotor 20, the outer peripheral shape of rotor magnetic-pole portions 24 is formed so that, in the circumferentially central portion, the distance from the center of the rotor iron core 21 is longest, and, at the inter-polar space, the distance from the center of the rotor iron core is shortest, and so that the outermost surface of the rotor magnetic-pole portions 24 forms an arc, and given that sheath thickness tc formed by the outer-side surface of each permanent magnet 31 and the outermost surface of each rotor magnetic-pole portion 24 is practically constant, and letting the thickness of the permanent magnets be the magnet thickness tm, then the relation tc / tm≦0.25 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

Permanent magnet motor

InactiveUS7474027B2Cogging torque is smallImprove linearityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesPermanent magnet motor

A permanent magnet motor 1 includes a rotor in which permanent magnets 31 are fixed. In the rotor 20, the outer peripheral shape of rotor magnetic-pole portions 24 is formed so that, in the circumferentially central portion, the distance from the center of the rotor iron core 21 is longest, and, at the inter-polar space, the distance from the center of the rotor iron core is shortest, and so that the outermost surface of the rotor magnetic-pole portions 24 forms an arc, and given that sheath thickness tc formed by the outer-side surface of each permanent magnet 31 and the outermost surface of each rotor magnetic-pole portion 24 is practically constant, and letting the thickness of the permanent magnets be the magnet thickness tm, then the relation tc / tm≦0.25 is satisfied.

Owner:MITSUBISHI ELECTRIC CORP

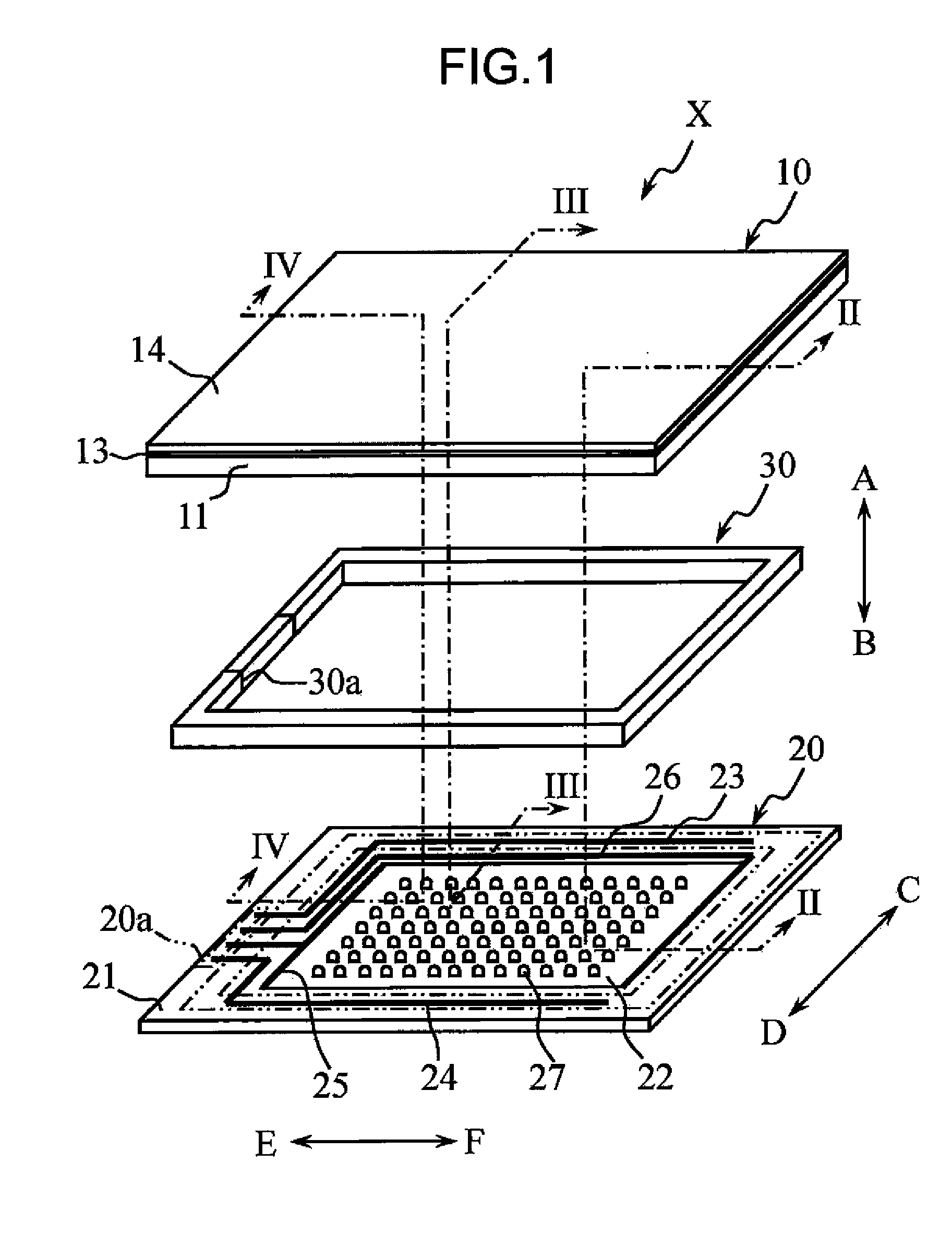

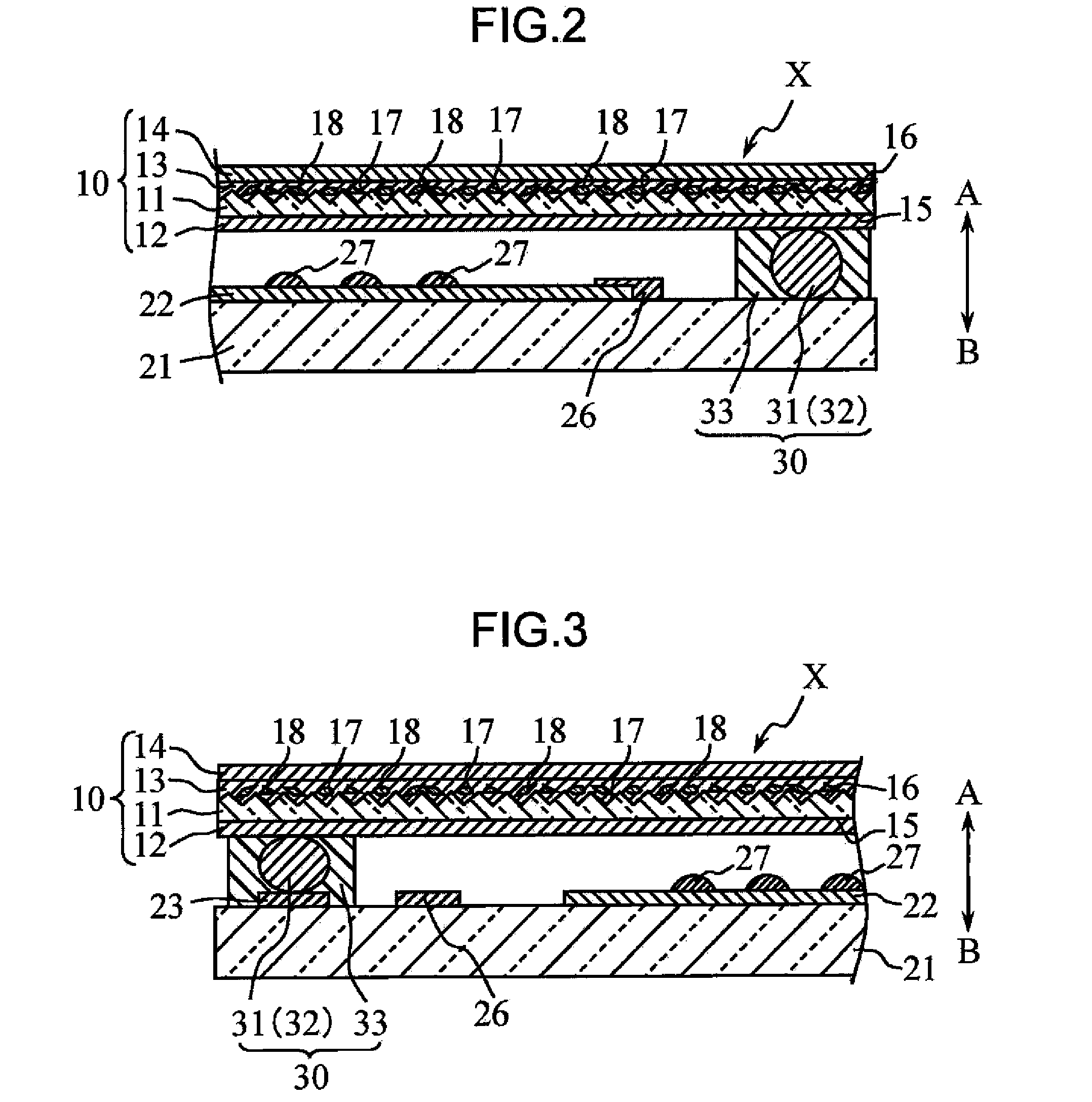

Touch Panel and Display Apparatus

InactiveUS20110069030A1Reduces reflected glareImprove reliabilityNon-linear opticsInput/output processes for data processingOptoelectronicsTouchscreen

According to one embodiment, a touch panel includes: a first substrate, a second substrate, and at least one light diffusing particle. The first substrate includes a first principal surface, a second principal surface positioned at a side opposite to the first principal surface, and at least one recess on the second principal surface. The second substrate is arranged to face the first principal surface. At least a portion of the light diffusing particle is positioned corresponding to the recess.

Owner:KYOCERA CORP

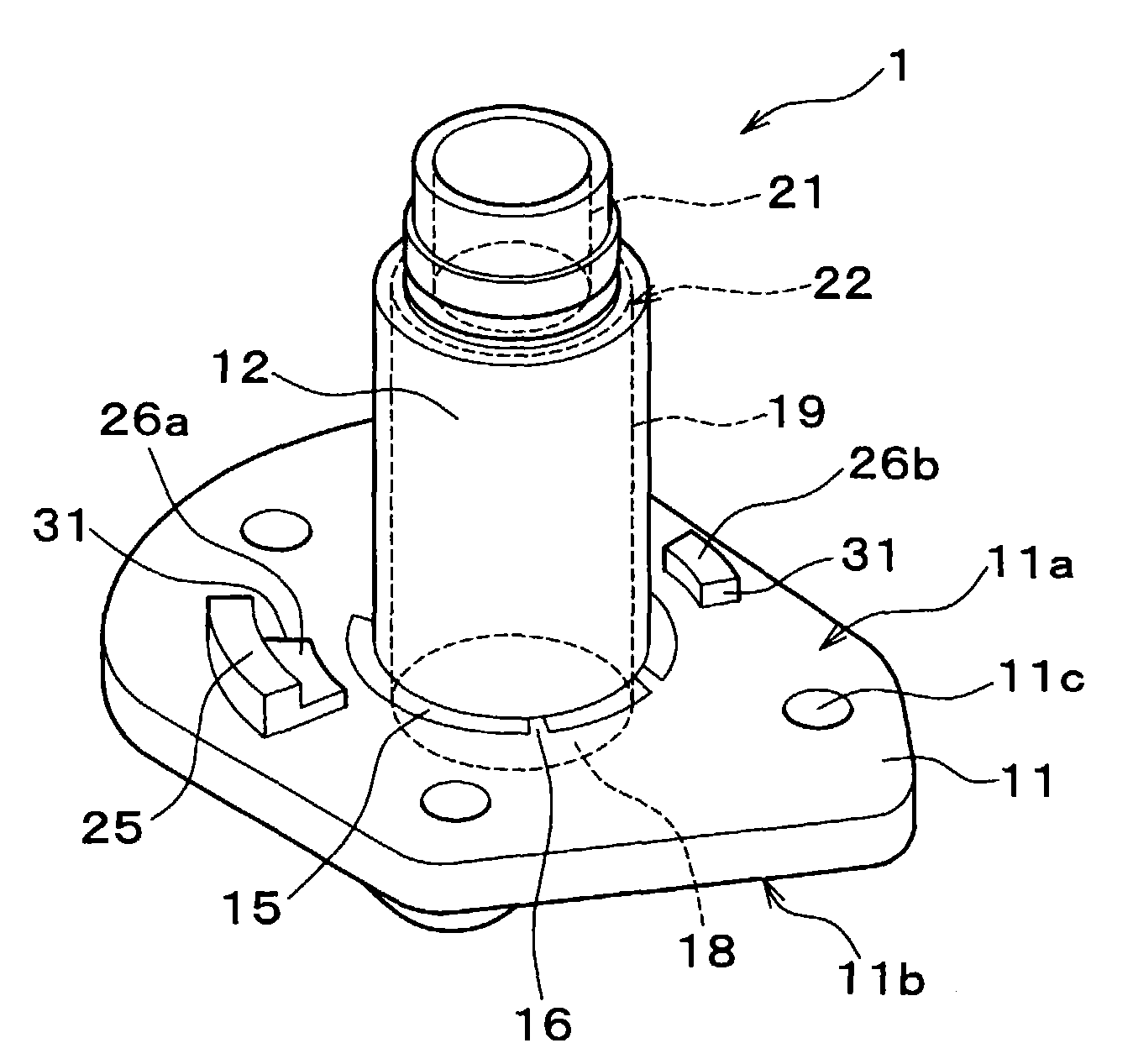

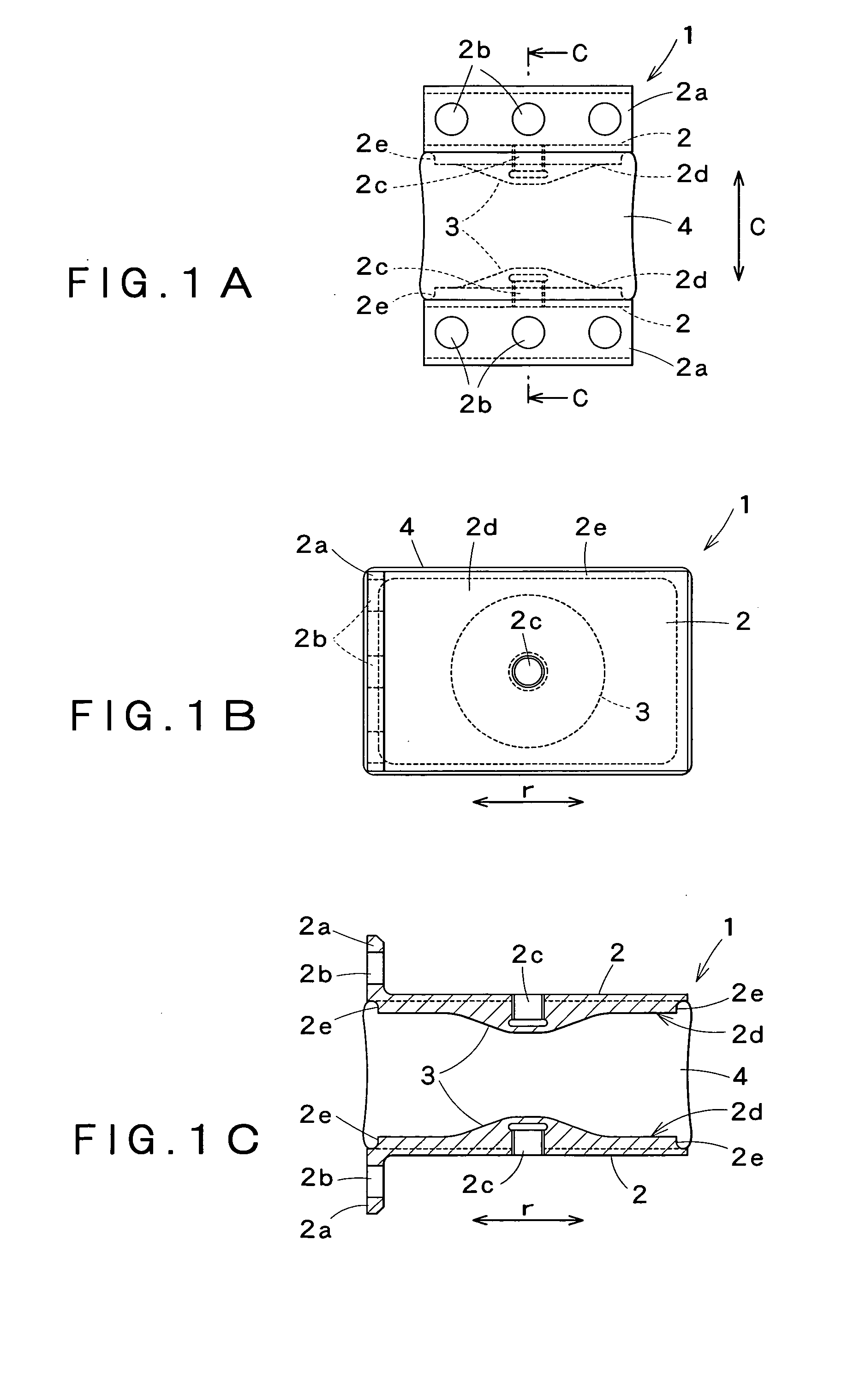

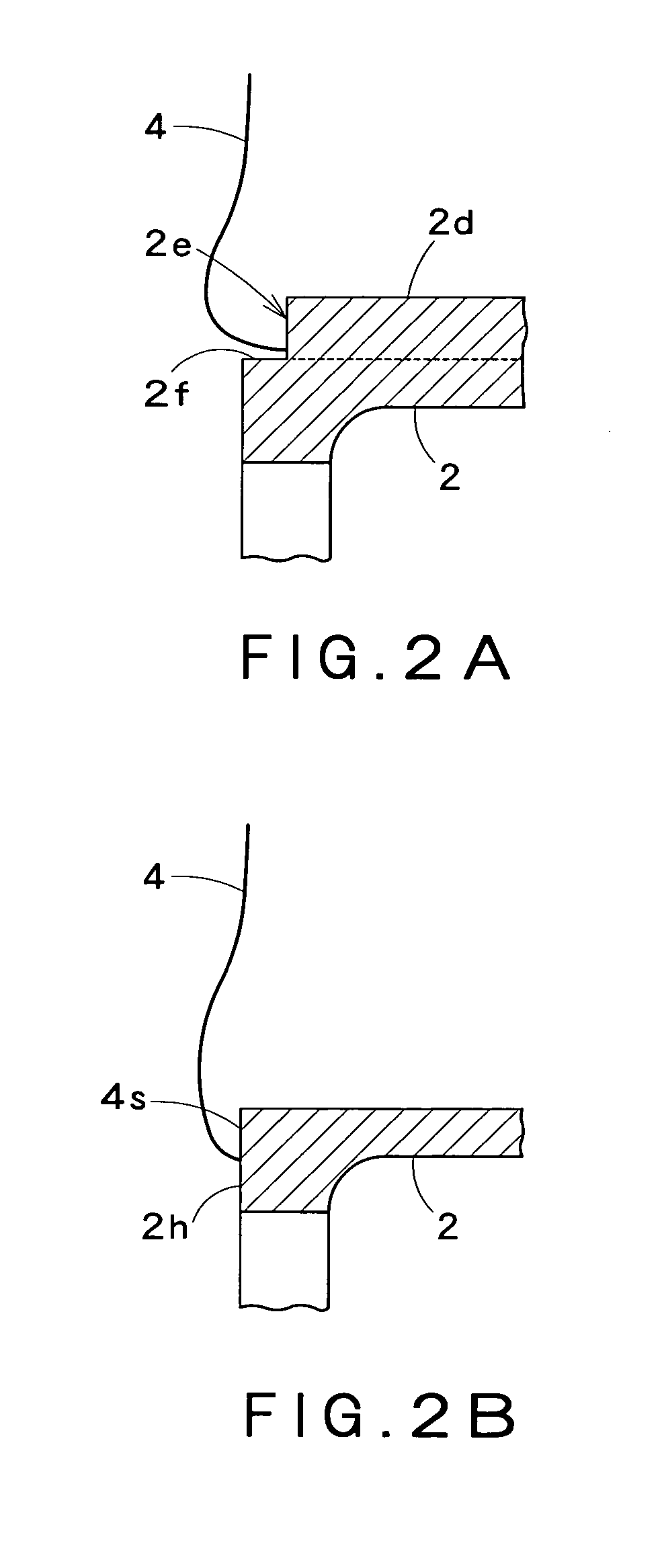

Door mirror set plate

InactiveUS6979091B2Excels in strength and functionalityStress relief concentrationMirrorsPicture framesPeepholeWing mirror

A door mirror set plate is formed of synthetic resin. On a base plate, a support shaft is vertically provided to rotatively support a door mirror body. A curved surface section is embedded at an outside periphery of a base of the support shaft. A flat section is formed to support a thrust washer so as to cross the curved surface section. Inside the support shaft, there is formed a wiring hole provided with a large diameter section, a small diameter section, and a step section. When a conducting wire is inserted into the wiring hole, the tip of a covering touches the step section for positioning. A stopper and a positioning protrusion are integrally formed on a base plate top surface. The stopper restricts rotational angles of the door mirror body. The positioning protrusion holds the door mirror body at a neutral position.

Owner:MURAKAMI CORP

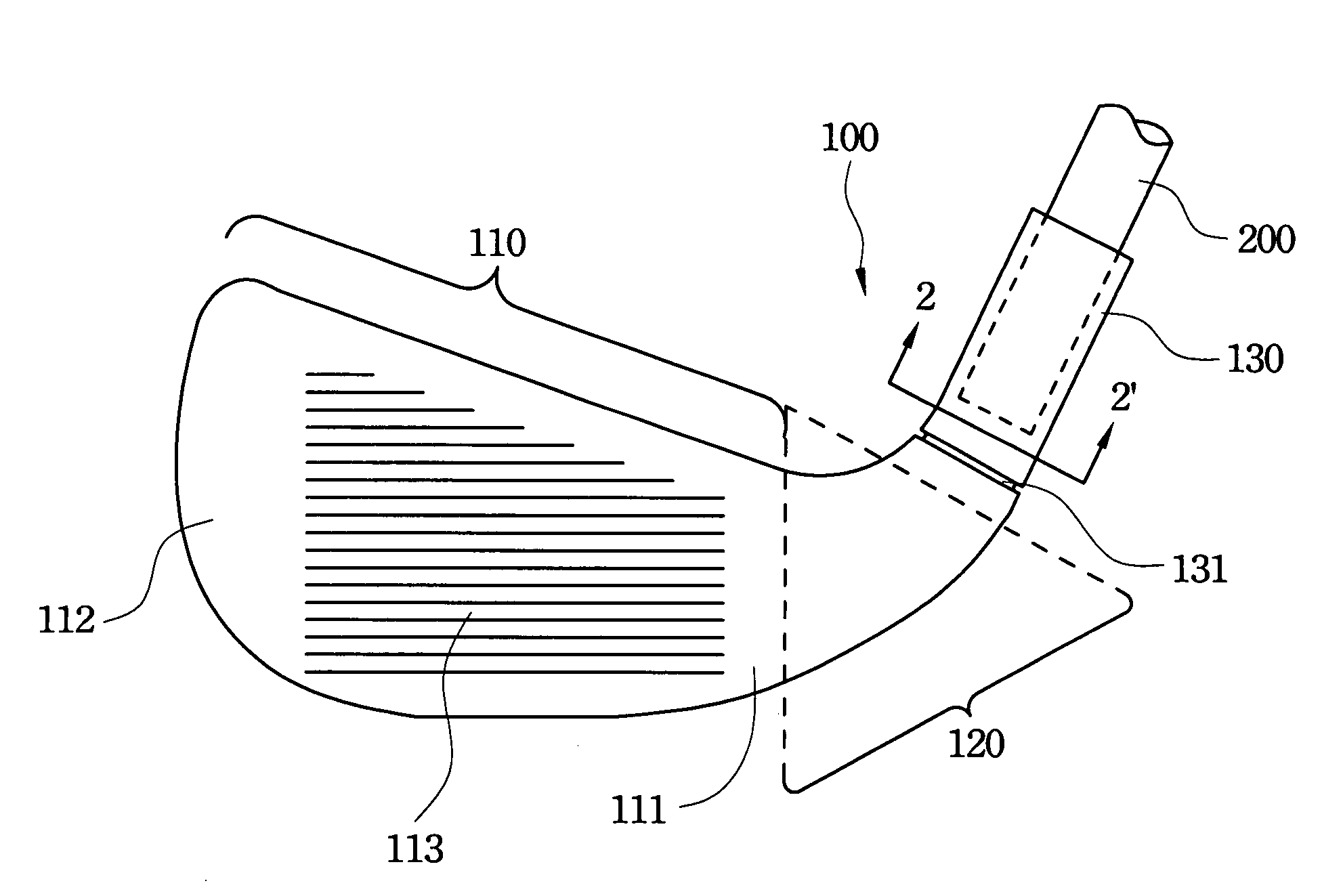

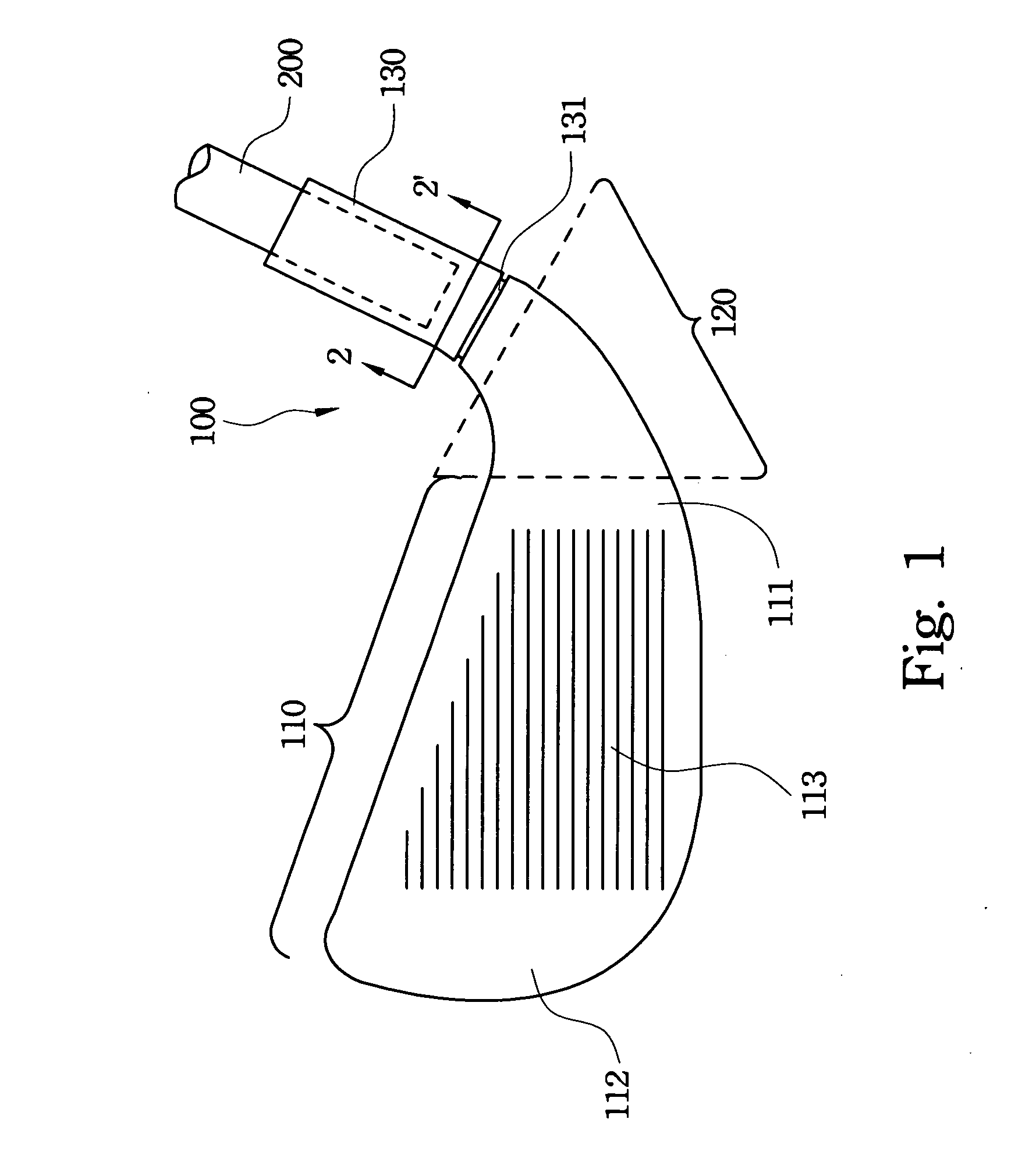

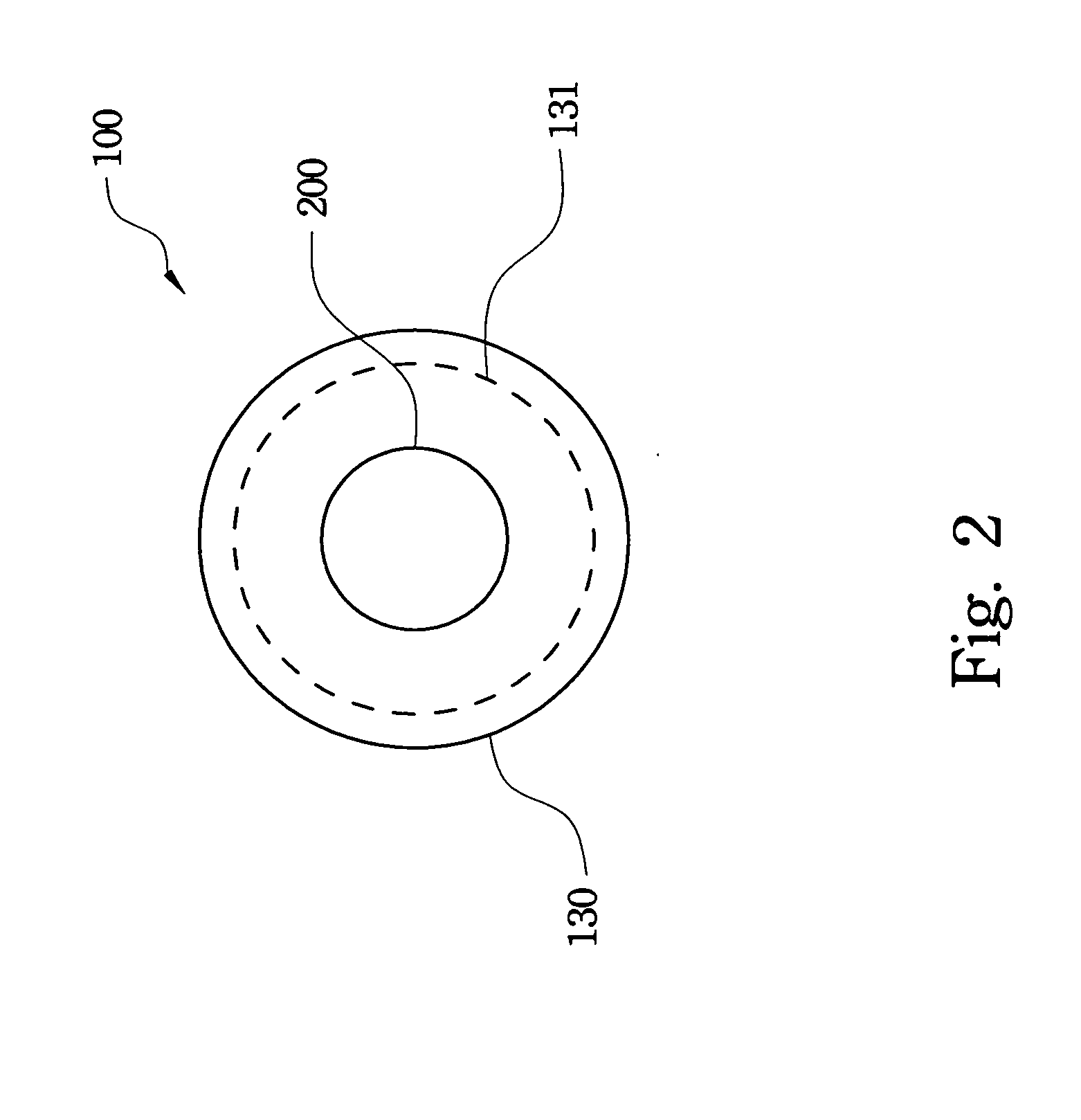

Golf club head

A golf club head is disposed. The golf club head comprises a main body, a neck portion, a hosel, and at least one adjusting groove. The main body has a heel portion and a toe portion. The neck portion is connected to the heel portion of the main body. The hosel is connected to the main body via the neck portion, and the adjusting groove is disposed around the peripheral surface of the neck portion or the hosel.

Owner:NELSON PRECISION CASTING +1

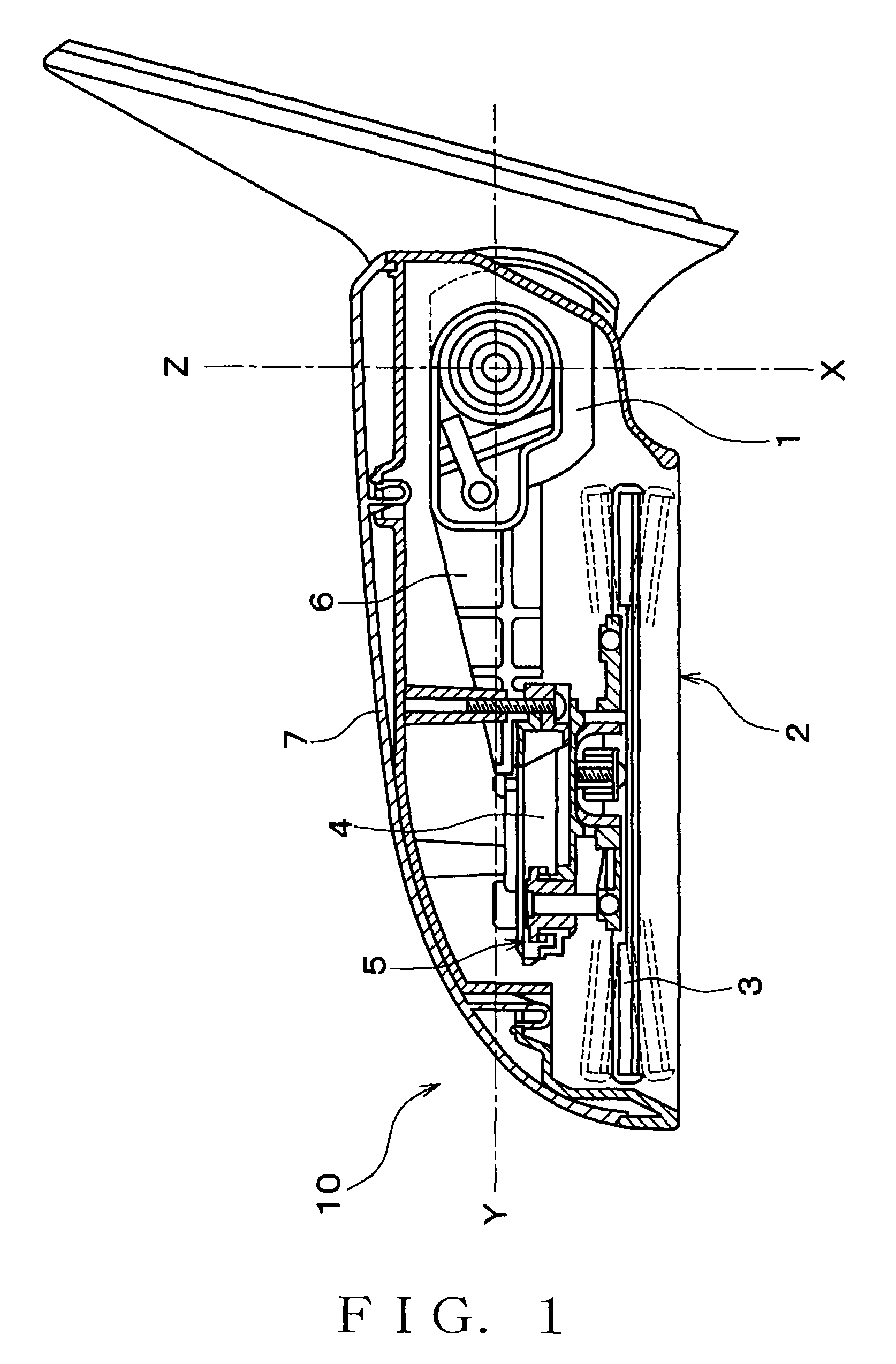

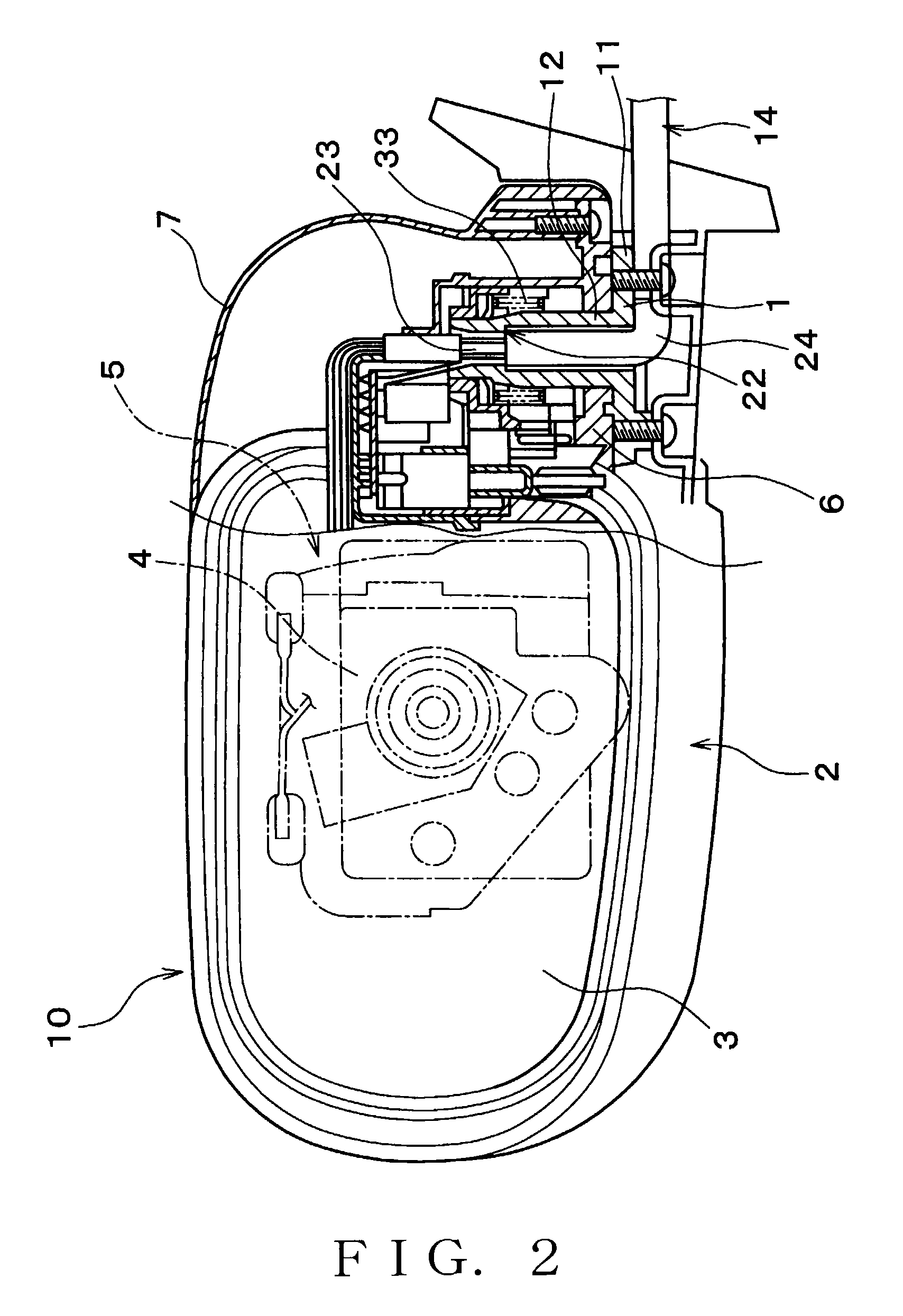

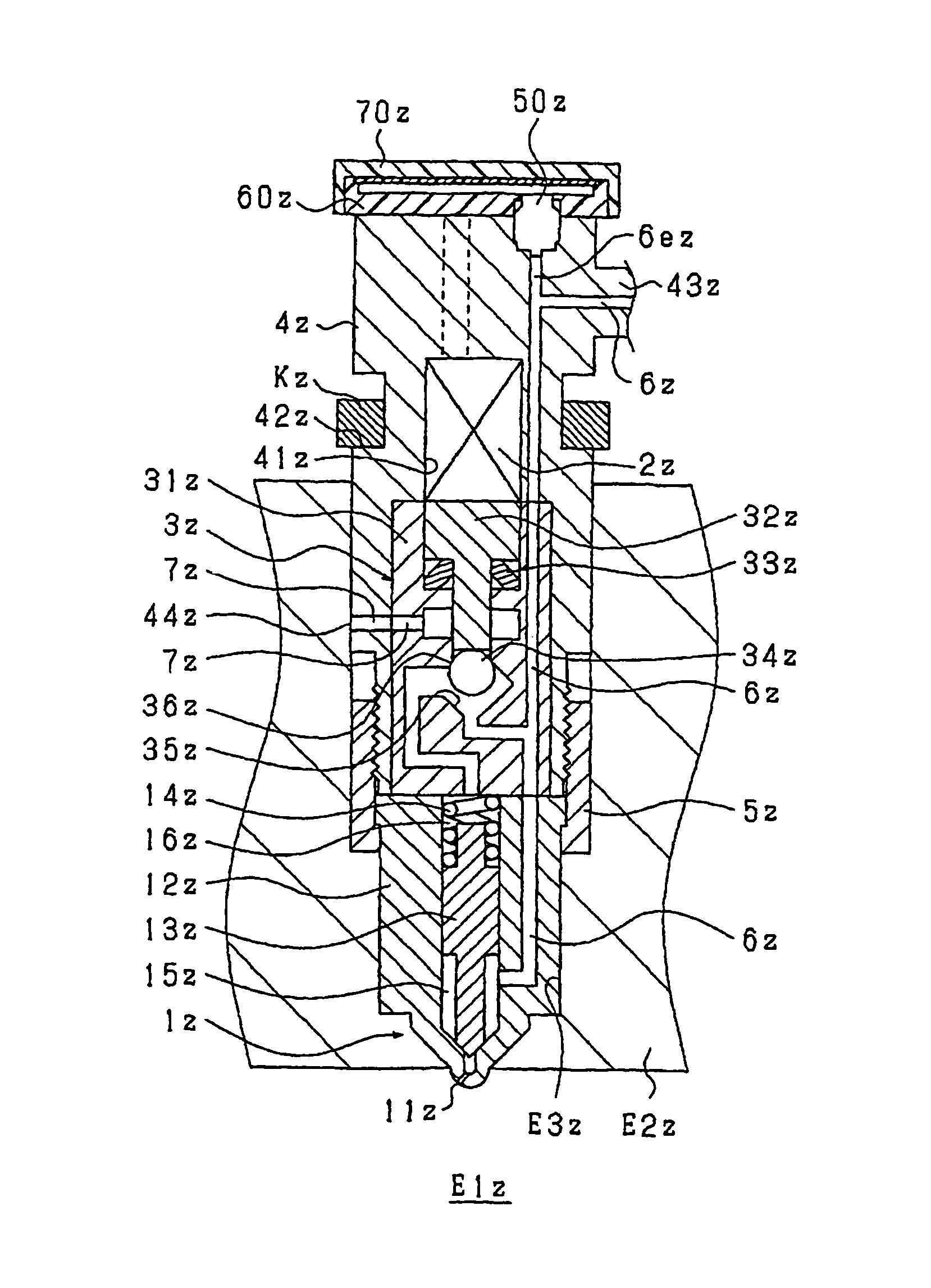

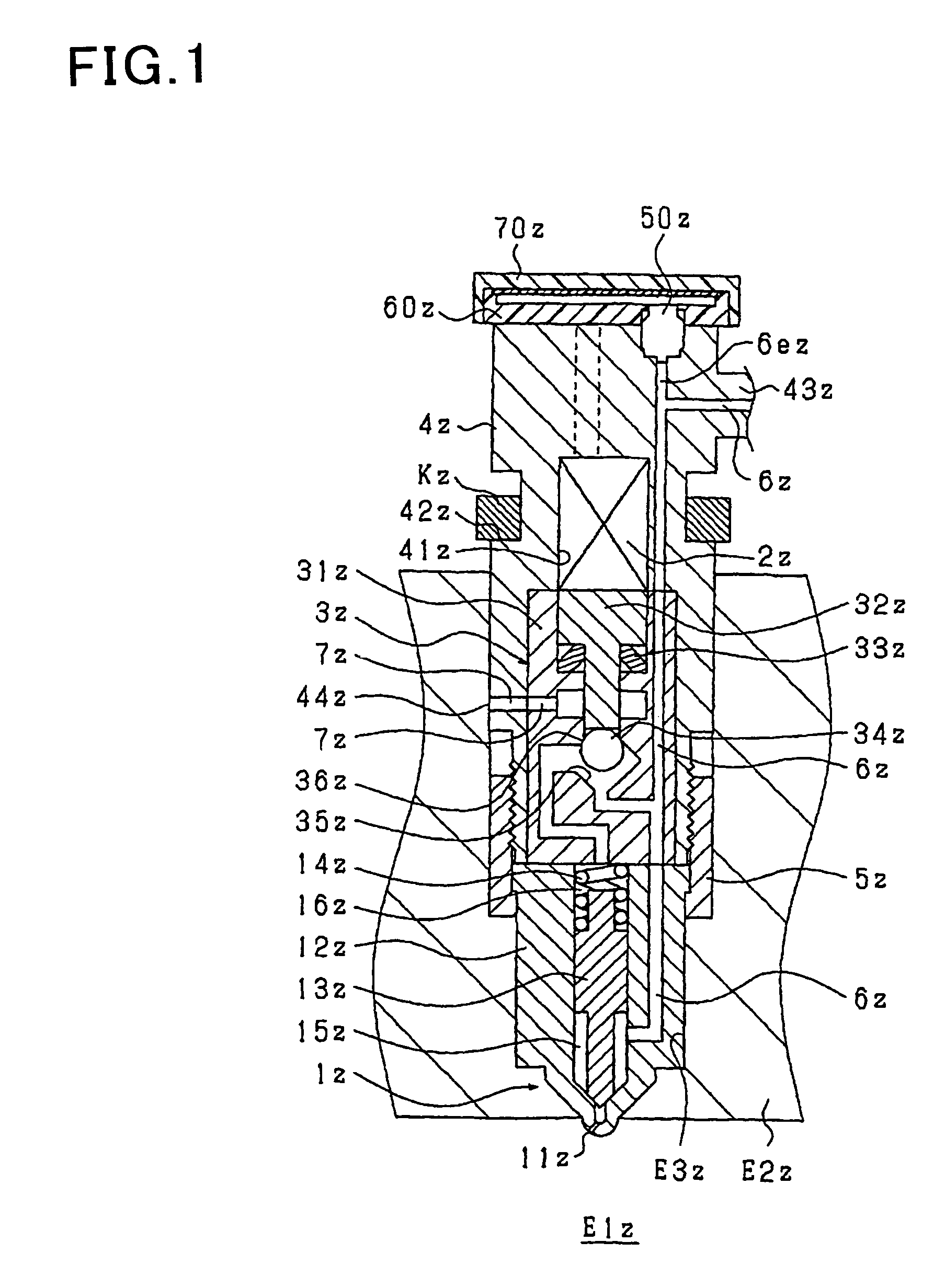

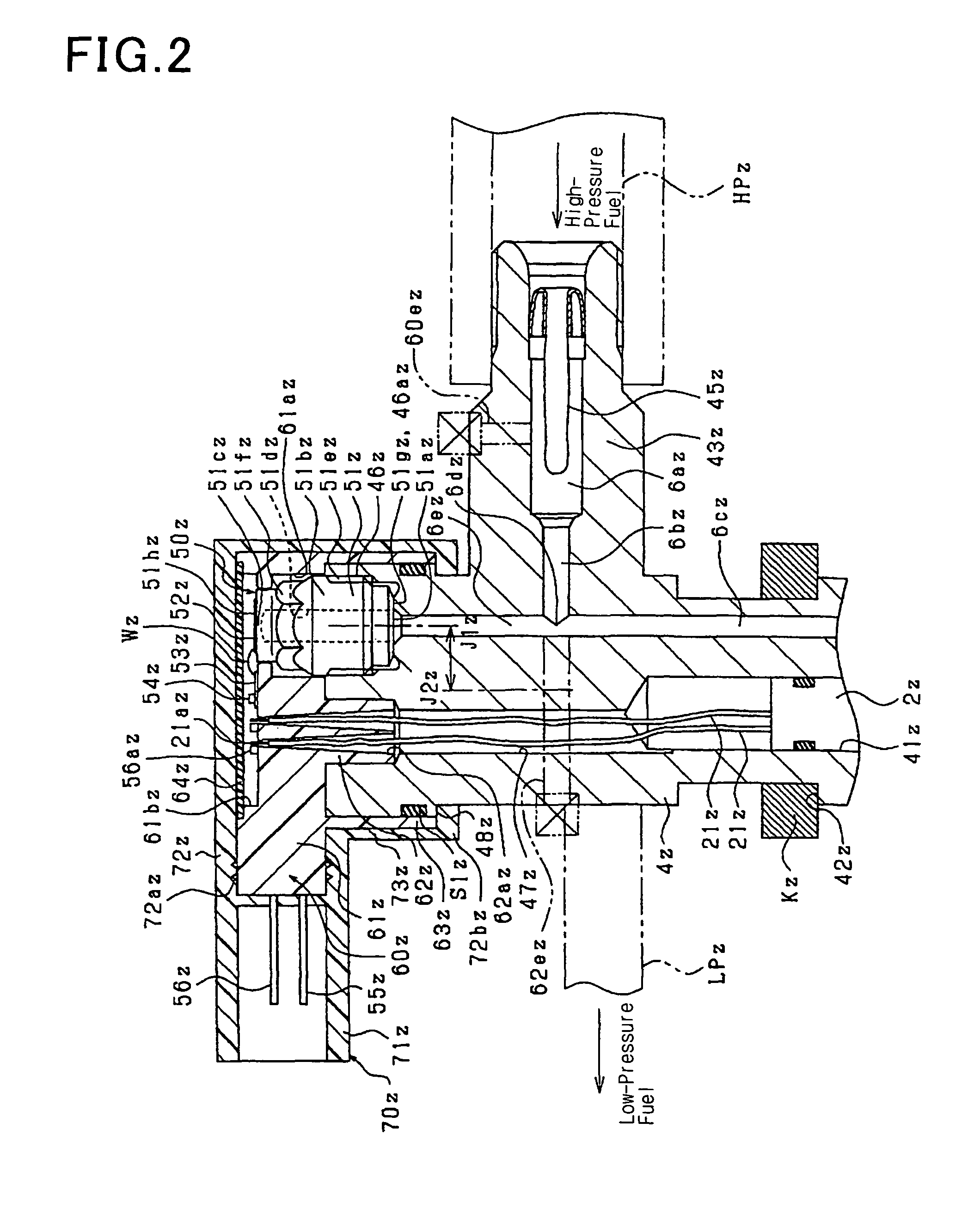

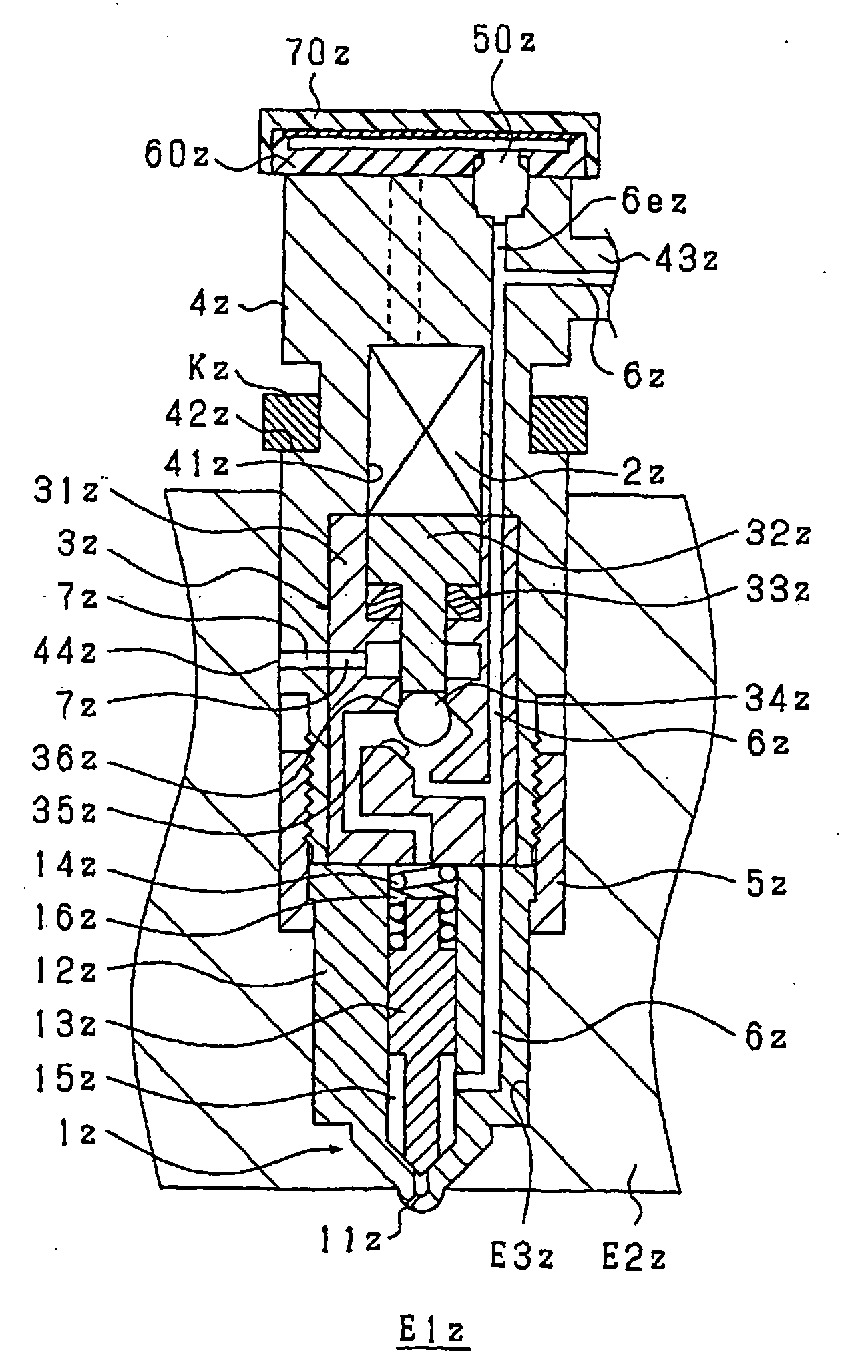

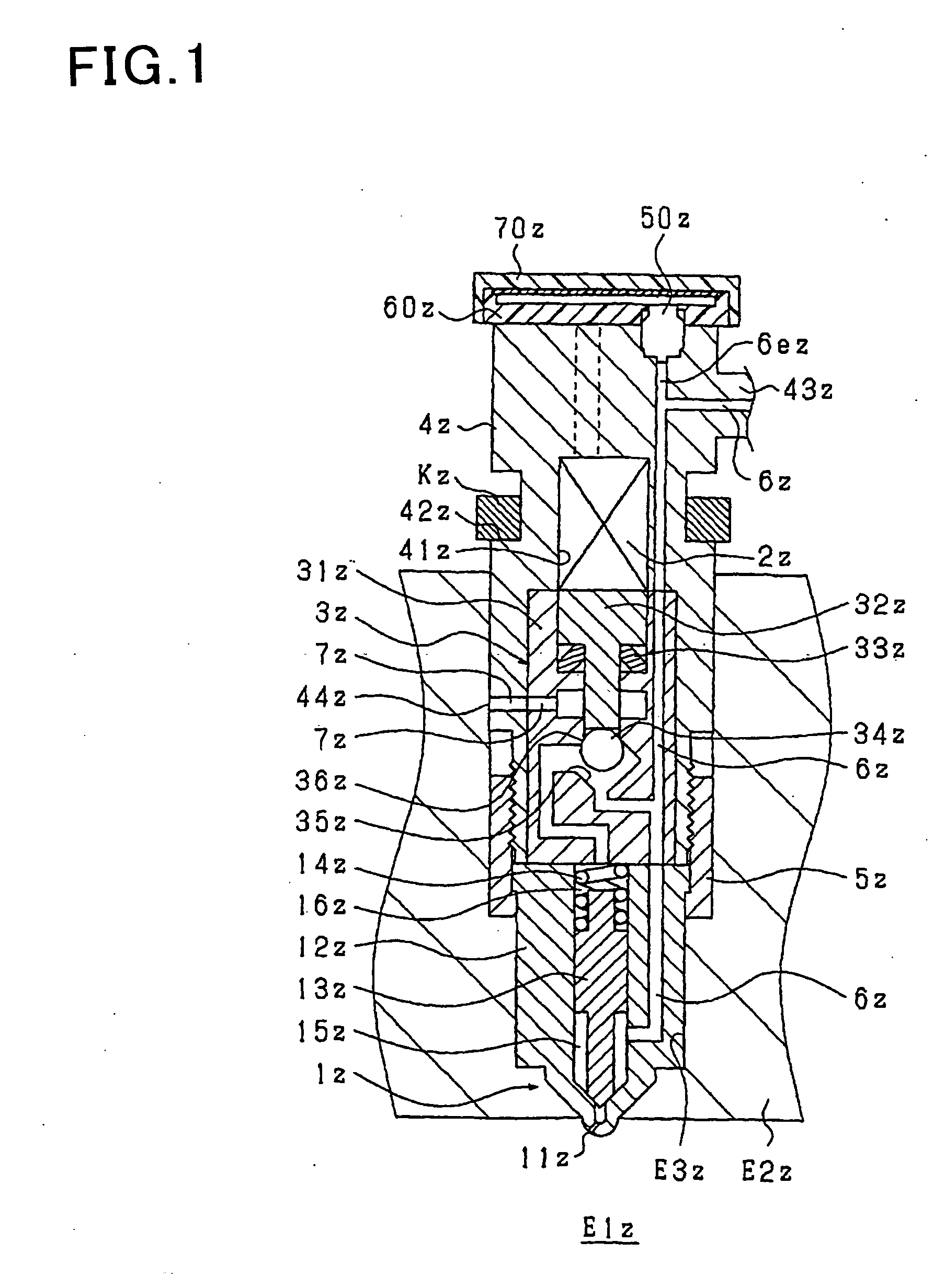

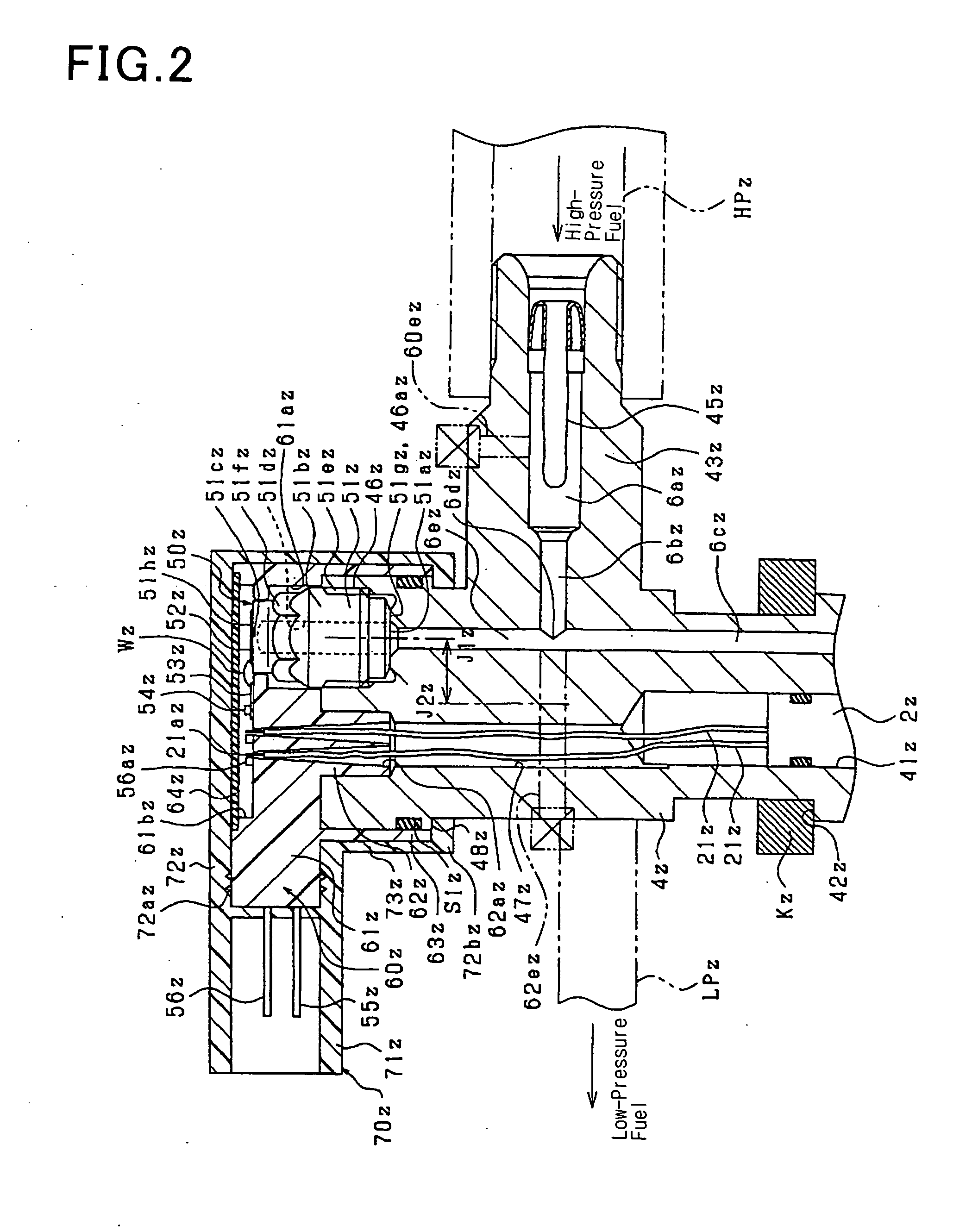

Fuel injection valve and fuel injection device

ActiveUS8297259B2Avoid low measurement accuracyImprove accuracyLow-pressure fuel injectionMachines/enginesActuatorHigh pressure

It is equipped with an injector body 4z which has formed therein high-pressure paths 6az, 6bz, and 6cz through which high-pressure fuel flows to a spray hole and stores therein a piezo-actuator 2z (i.e., an opening / closing mechanism) and a back-pressure control mechanism 3z (i.e., an opening / closing mechanism) which open or close the spray hole, and a fuel pressure sensor 50z installed in the body 4z to measure the pressure of the high-pressure fuel. The body 4z has formed therein a branch path 6ez diverging from the high-pressure paths 6bz and 6cz to deliver the high-pressure fuel to the fuel pressure sensor 50z.

Owner:DENSO CORP +1

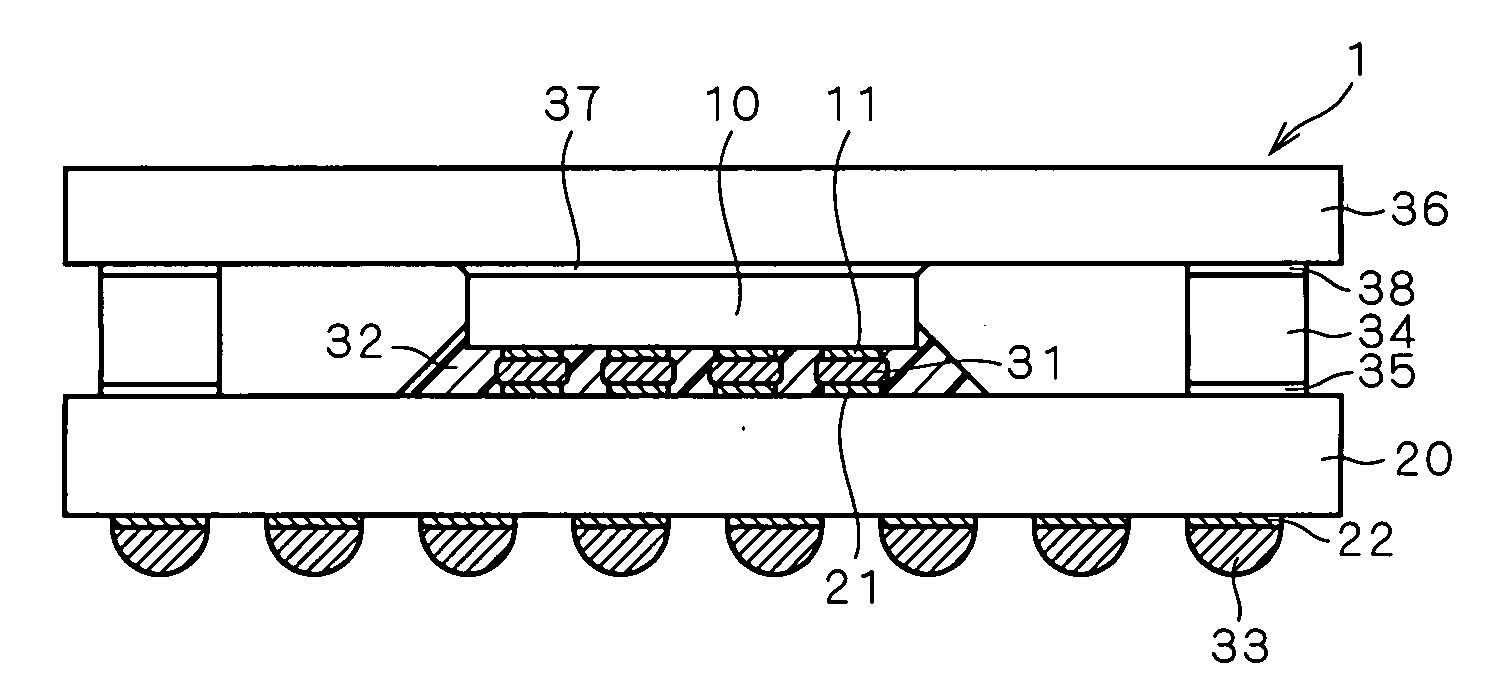

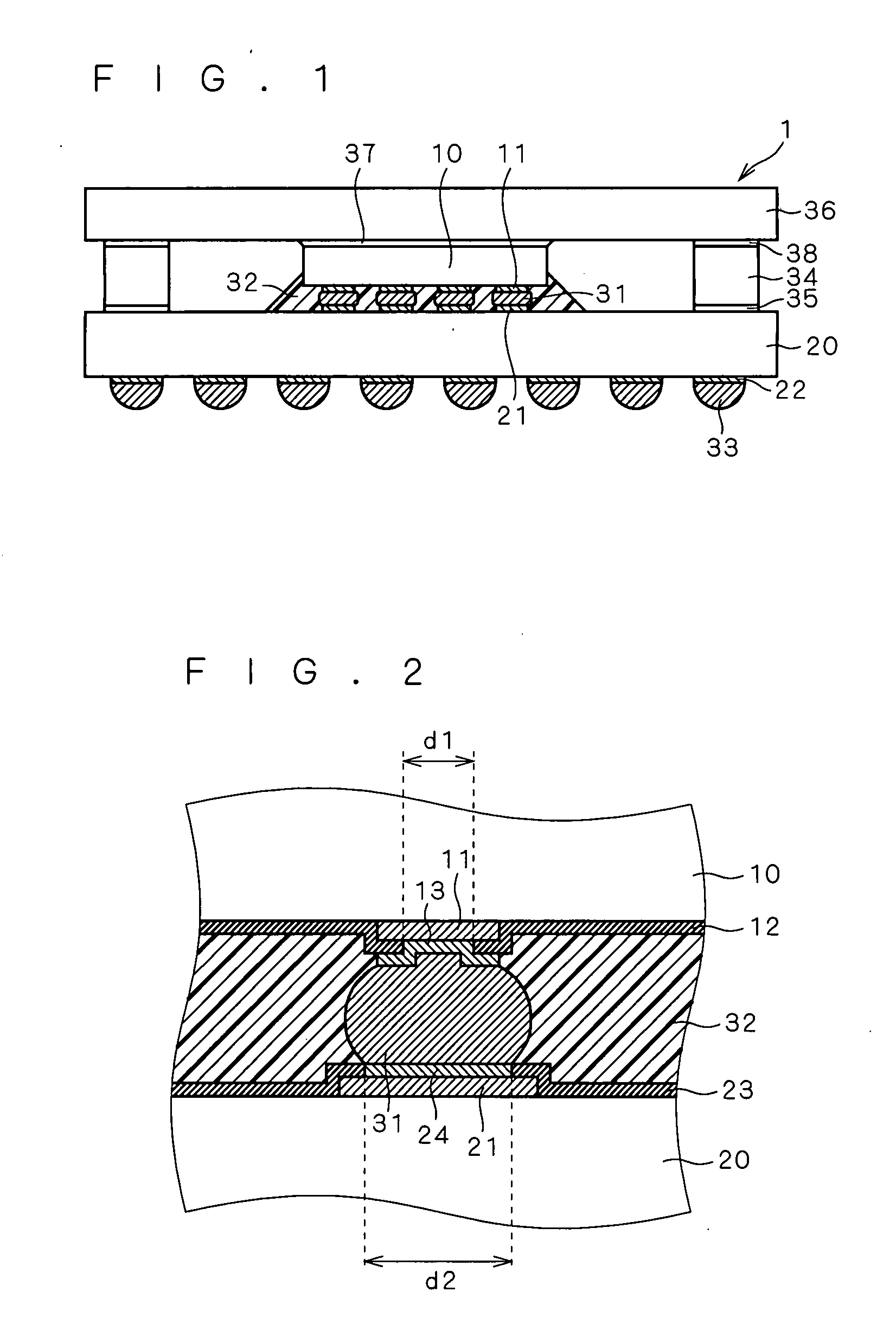

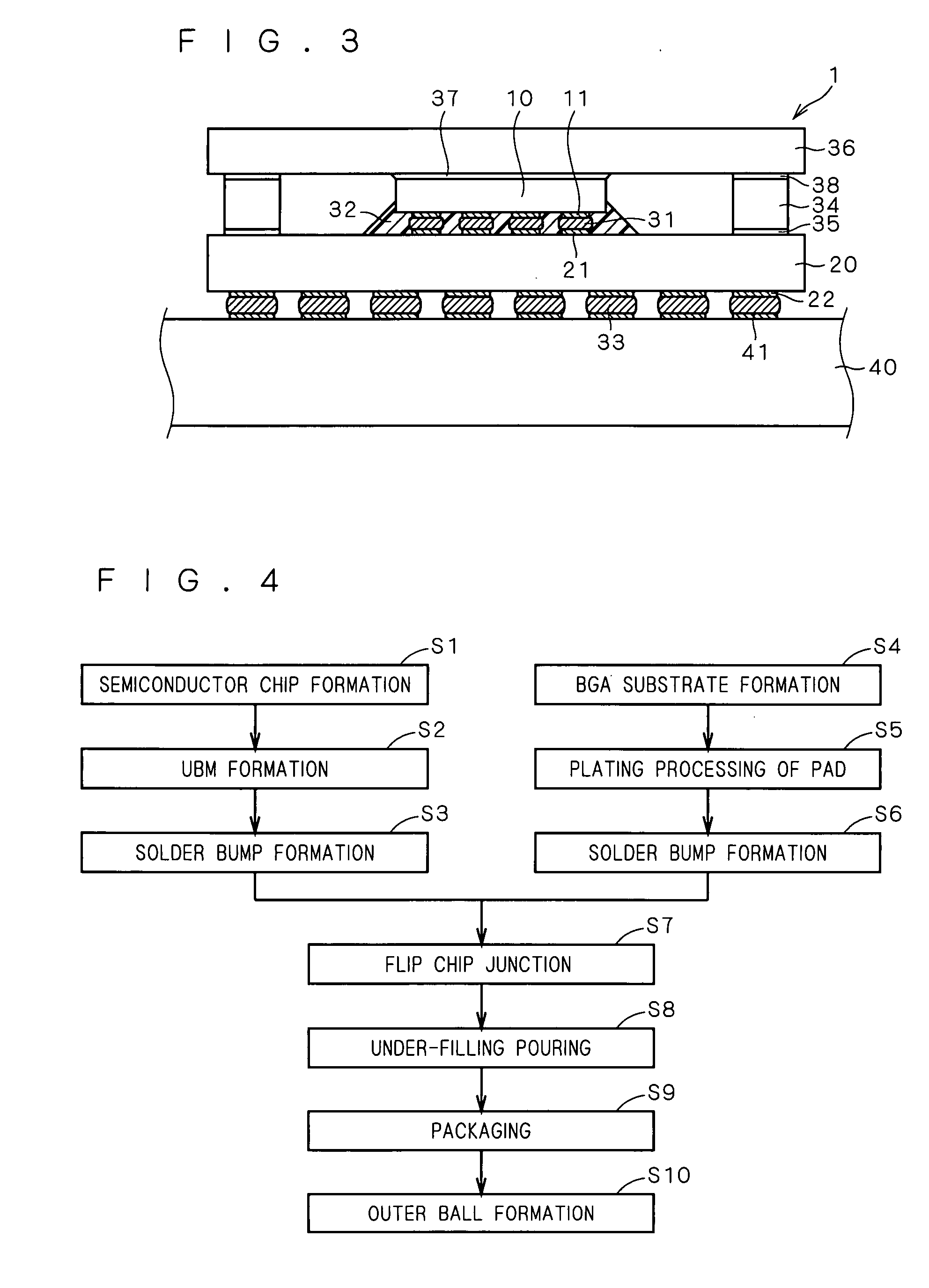

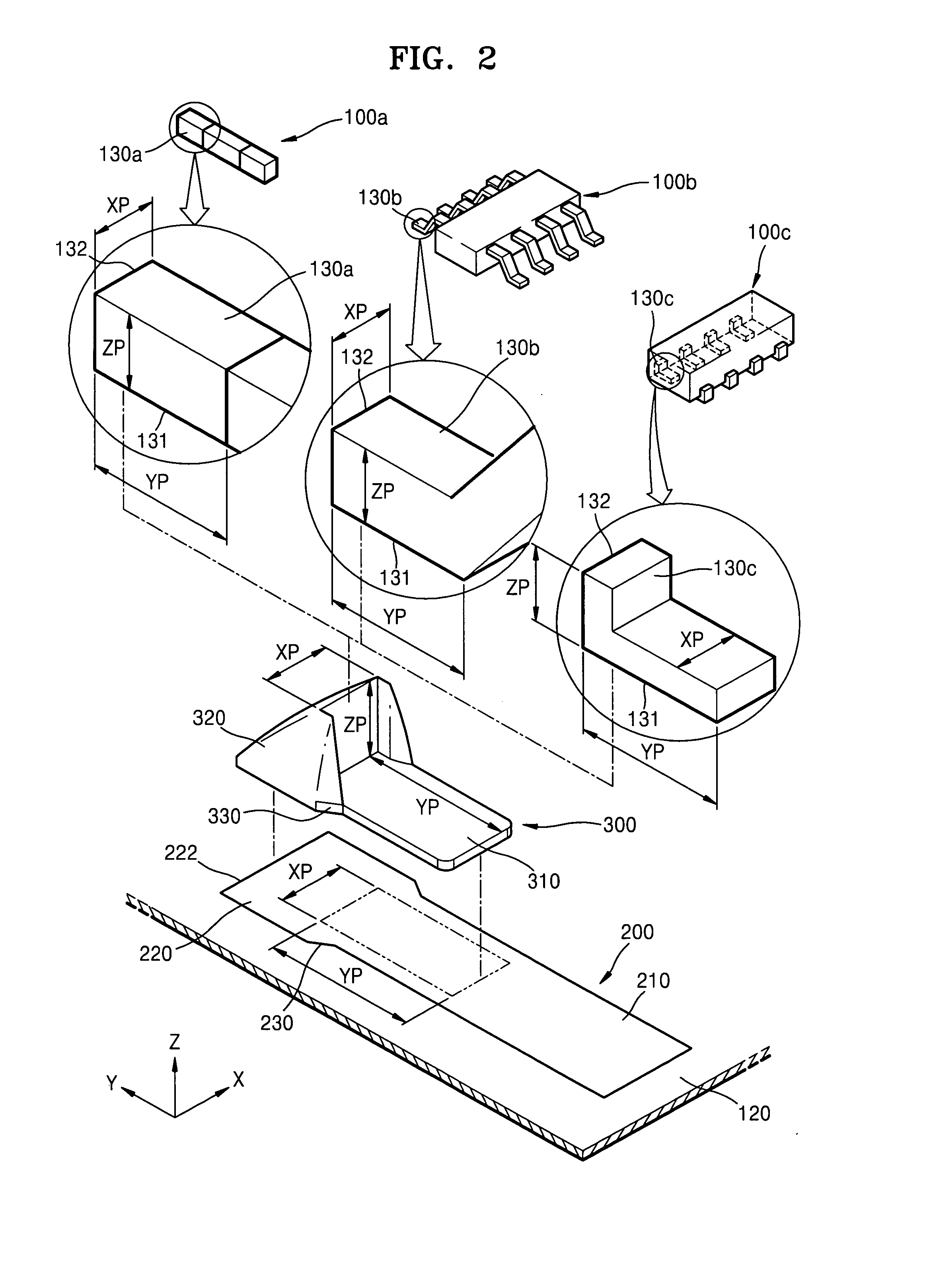

Semiconductor Device

InactiveUS20080128887A1Stress relief concentrationDisconnectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipSolder ball

Regarding a semiconductor device, especially the present invention suppresses disconnection of the connection structure concerned in the semiconductor device which has the electric and mechanical connection structure using solder, and aims at improving connection reliability. And to achieve the above objects, the semiconductor device has the solder bump which electrically connects a semiconductor chip and a package substrate, the under-filling resin with which it filled up between the semiconductor chip and the package substrate, and a solder ball which electrically connects a package substrate with the outside, and the solder bump's elastic modulus is made lower than the elastic modulus of a solder ball.

Owner:RENESAS ELECTRONICS CORP

Fuel injection valve and fuel injection device

ActiveUS20100313850A1Avoid low measurement accuracyHigh measurement accuracyLow-pressure fuel injectionMachines/enginesEngineeringActuator

It is equipped with an injector body 4z which has formed therein high-pressure paths 6az, 6bz, and 6cz through which high-pressure fuel flows to a spray hole and stores therein a piezo-actuator 2z (i.e., an opening / closing mechanism) and a back-pressure control mechanism 3z (i.e., an opening / closing mechanism) which open or close the spray hole, and a fuel pressure sensor 50z installed in the body 4z to measure the pressure of the high-pressure fuel. The body 4z has formed therein a branch path 6ez diverging from the high-pressure paths 6bz and 6cz to deliver the high-pressure fuel to the fuel pressure sensor 50z.

Owner:DENSO CORP +1

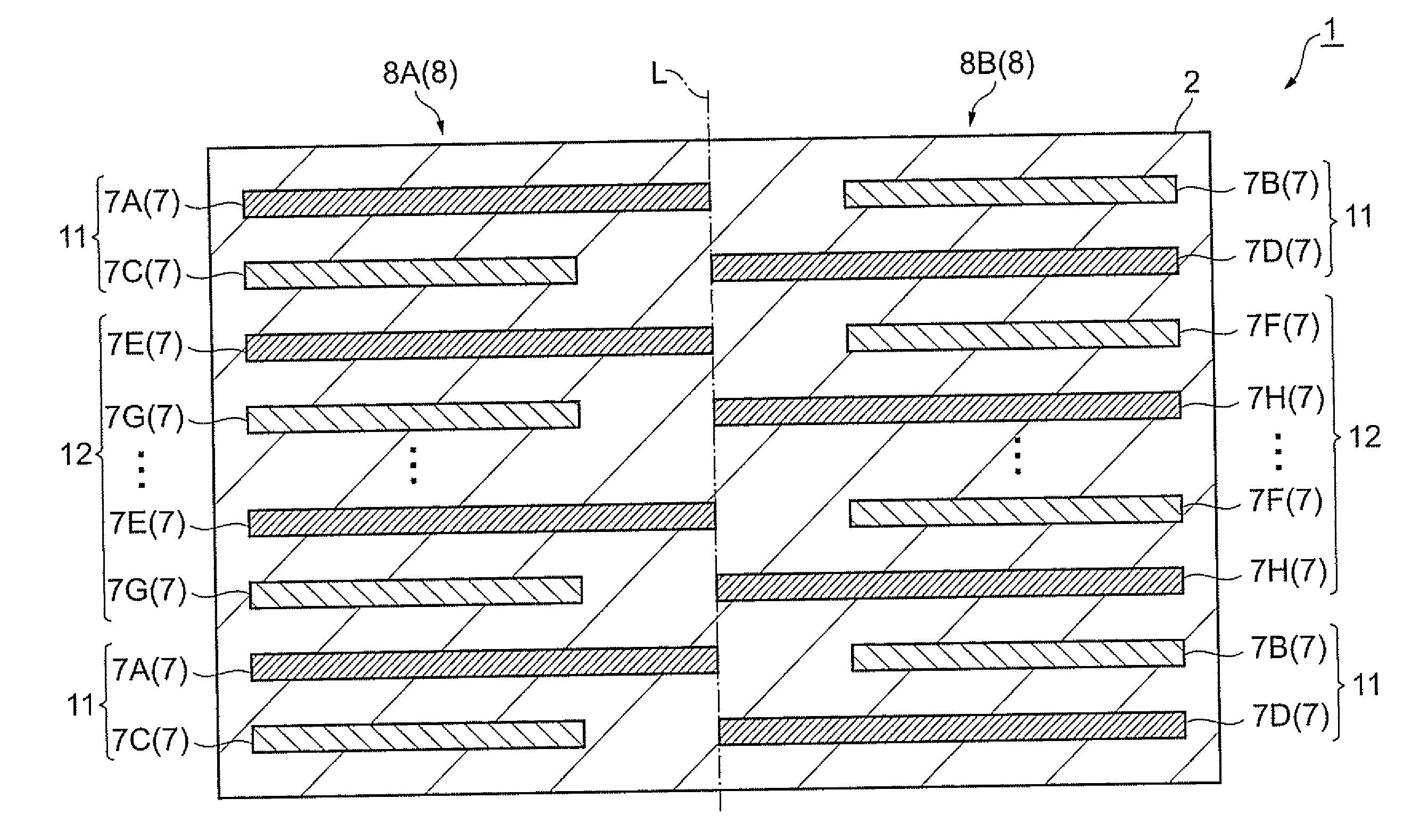

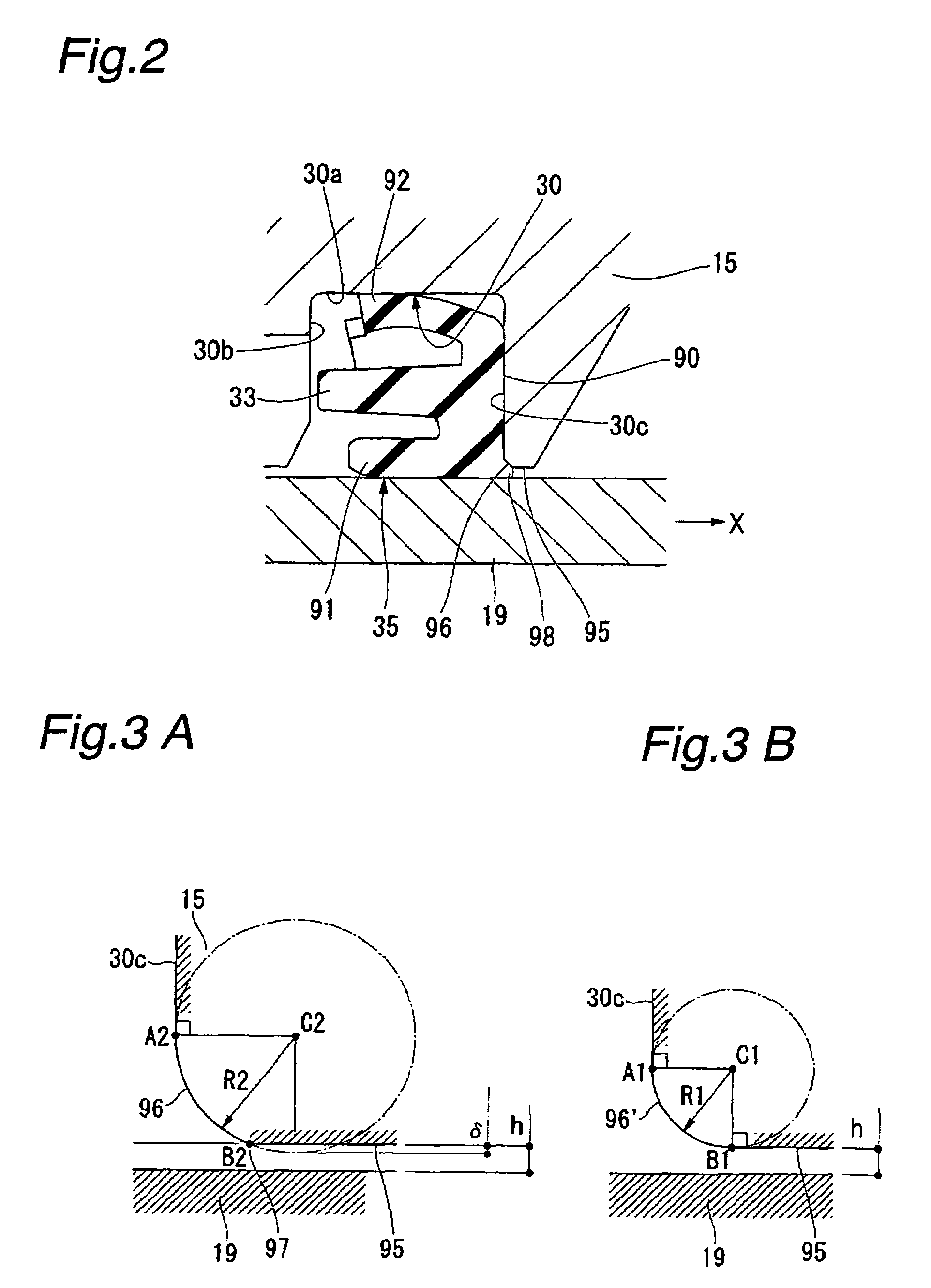

Multilayer capacitor array having terminal conductor, to which internal electrodes are connected in parallel, connected in series to external electrodes

ActiveUS8107214B2High ESRStress relief concentrationFixed capacitor electrodesFixed capacitor dielectricStress concentrationCapacitance

A multilayer capacitor array achieves a high ESR because terminal conductors to which internal electrodes in capacitance sections are connected in parallel are connected in series through internal electrodes in ESR control sections to external electrodes. Since in the multilayer capacitor array the internal electrodes extend as far as a boundary between capacitor element portions, electrostriction occurs in an entire laminate including a region near the boundary between the capacitor element portions, with application of a voltage from the outside. Therefore, concentration of stress due to electrostriction is avoided, so as to suppress occurrence of cracking or the like.

Owner:TDK CORPARATION

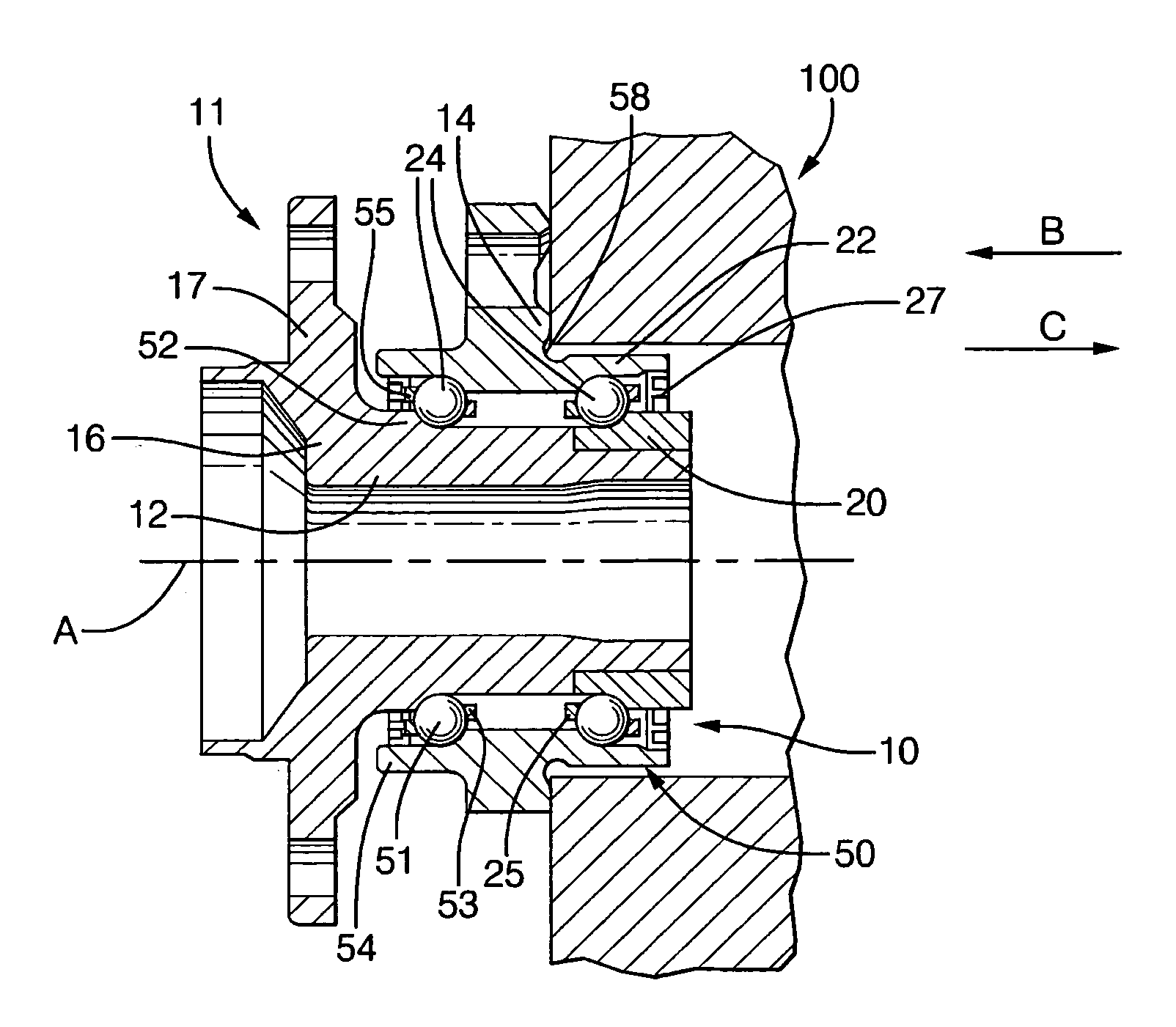

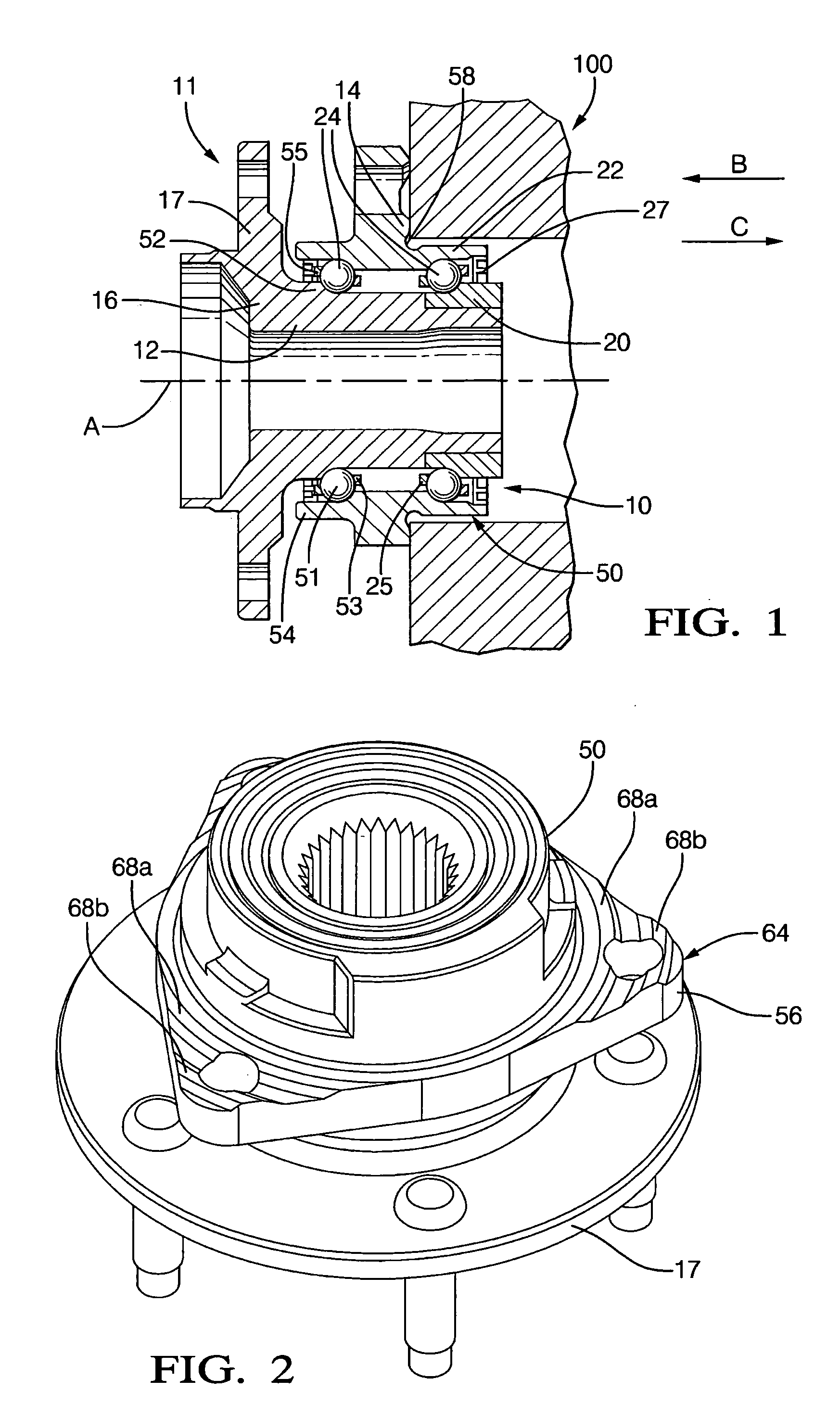

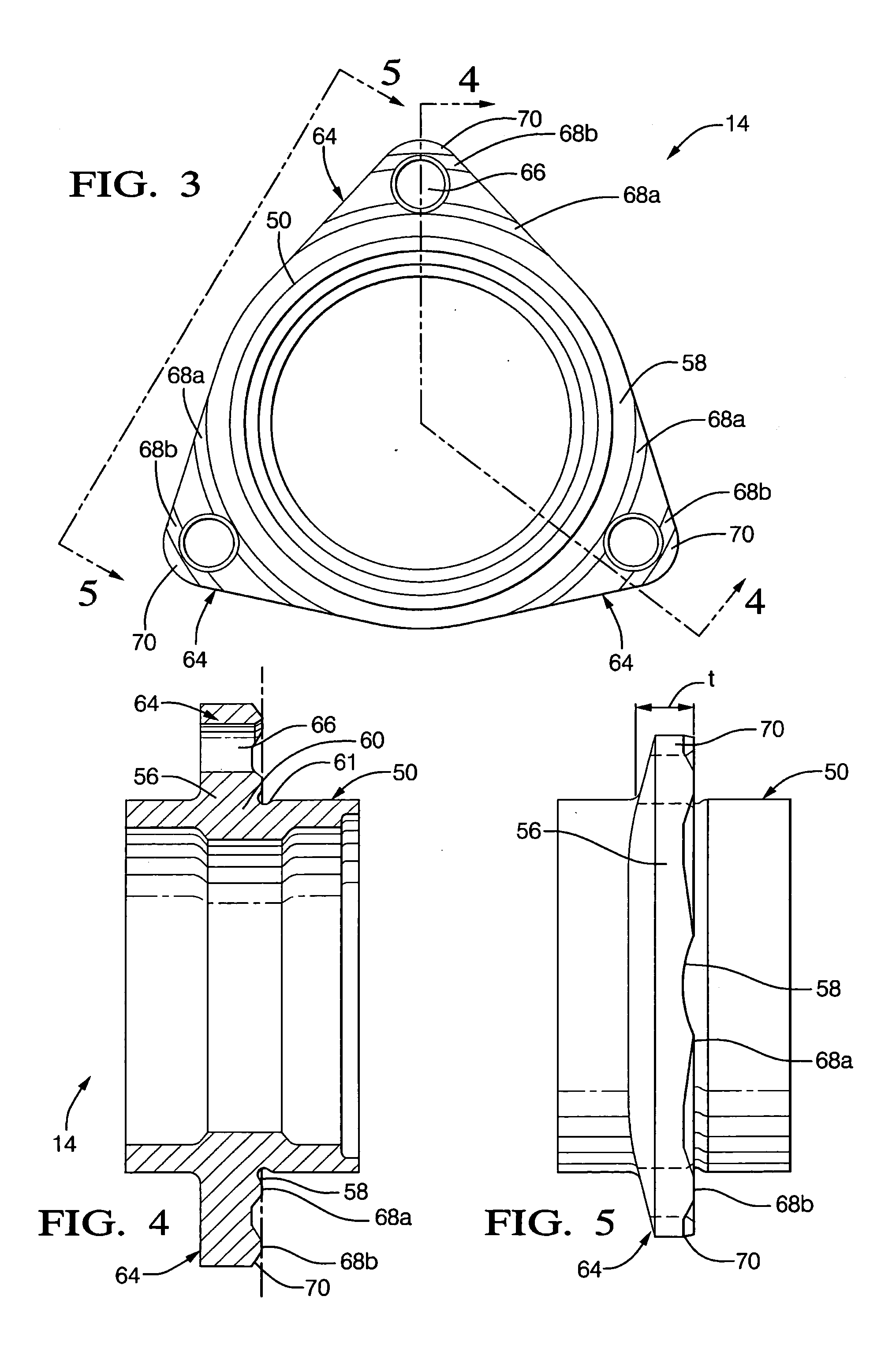

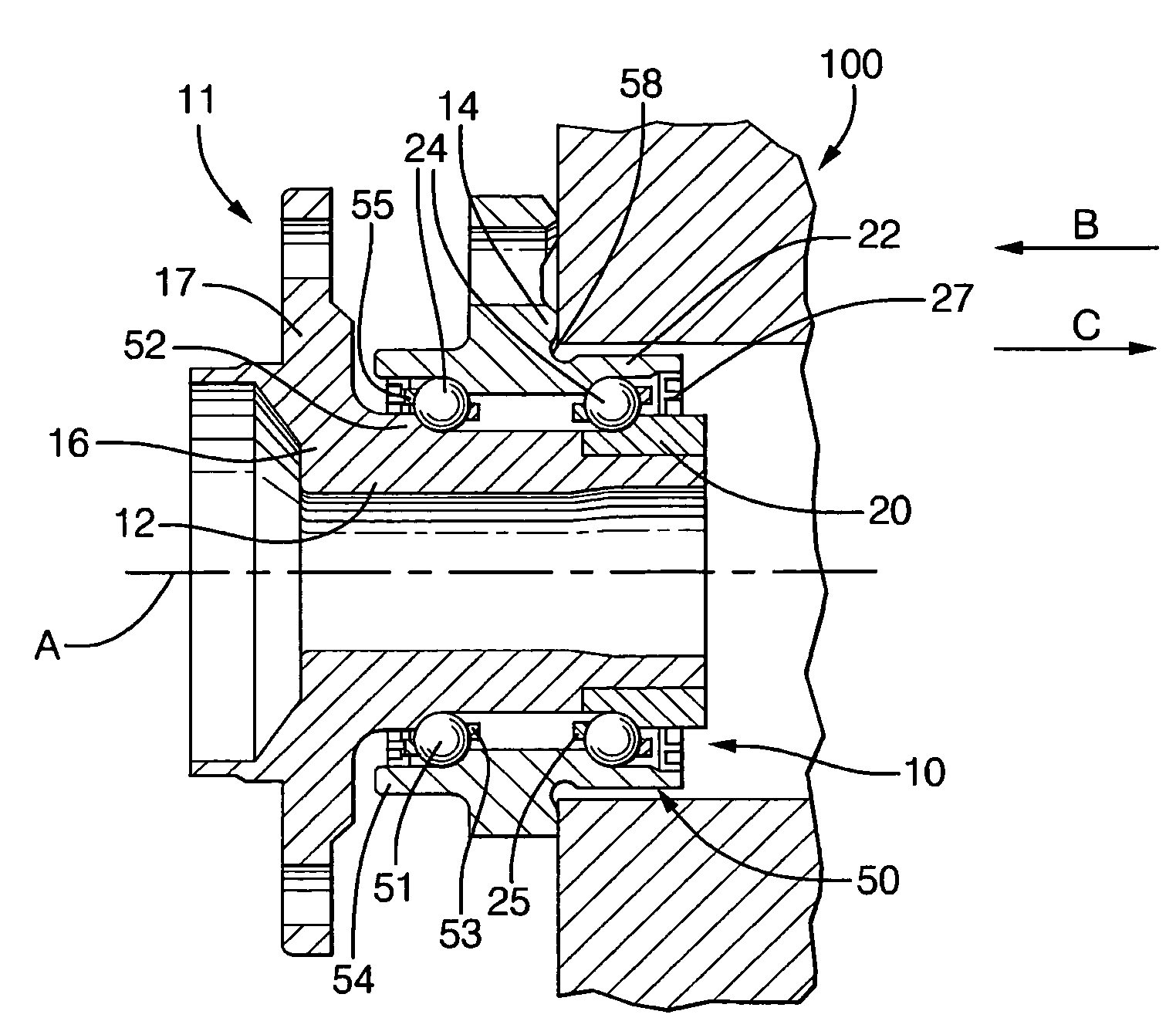

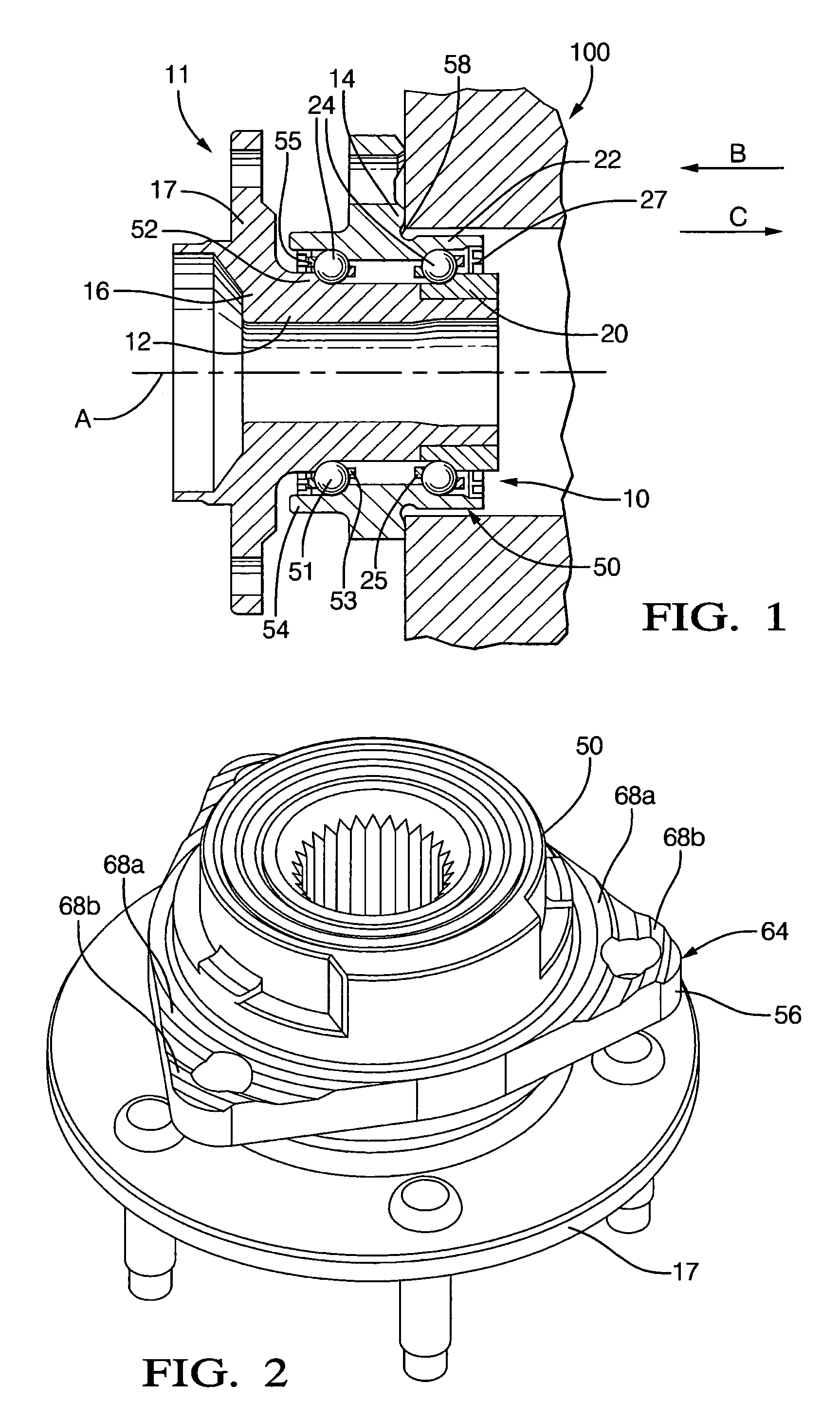

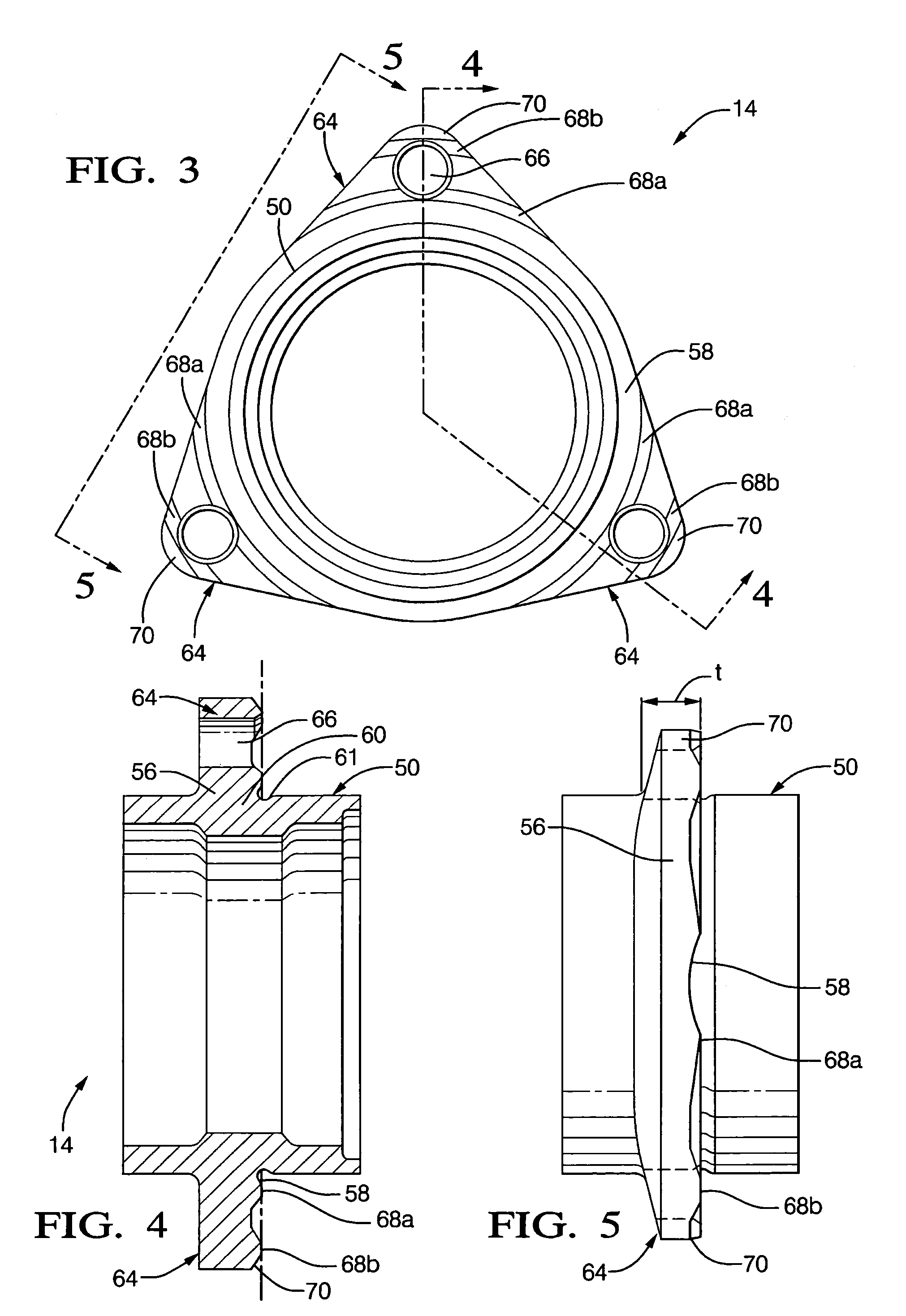

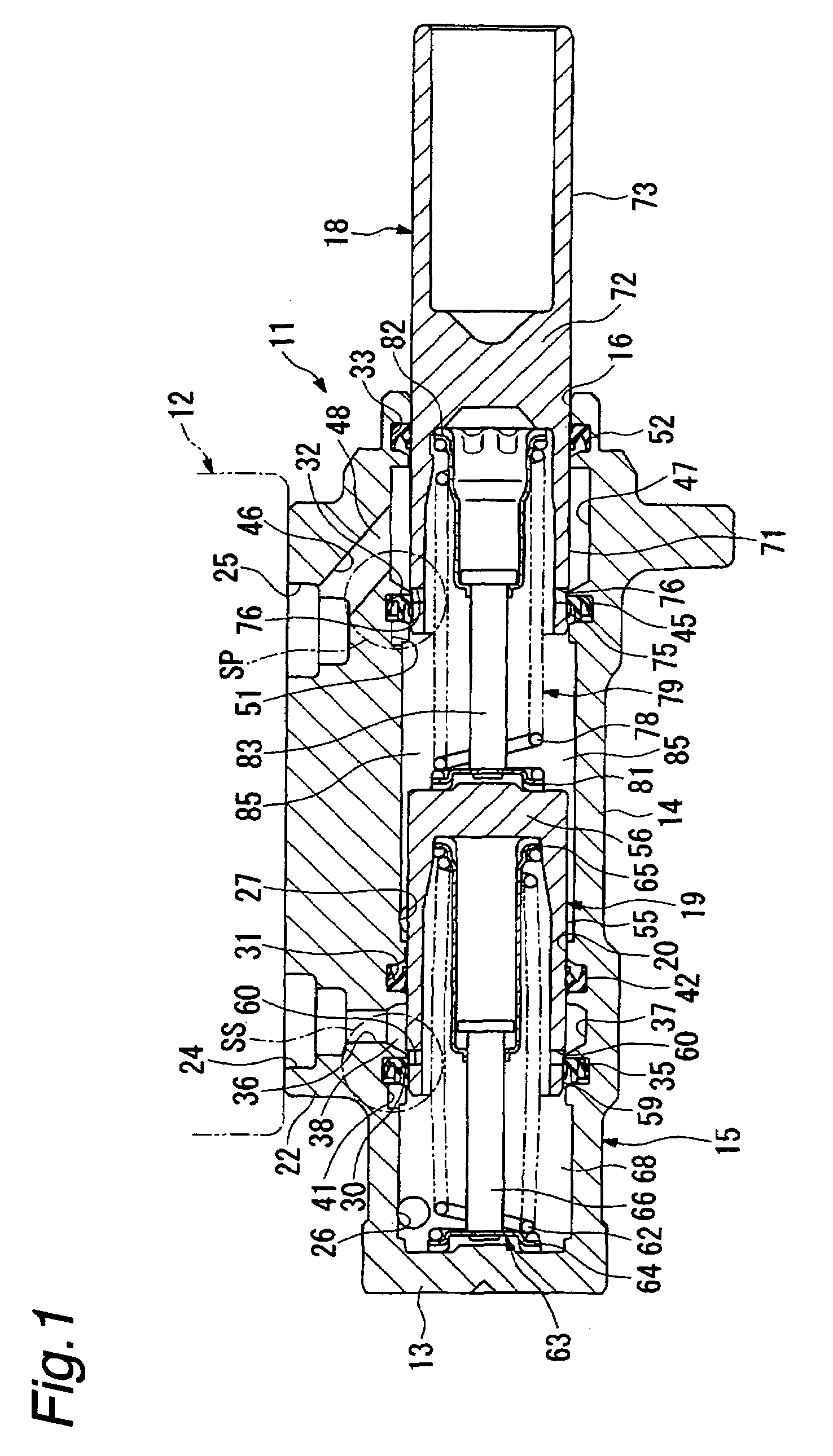

Wheel bearing assembly mount with force attenuation

ActiveUS20060133708A1Stress relief concentrationReduce contact areaRolling contact bearingsHubsUltrasound attenuationEngineering

A support member (14) for rotatably coupling a first element to a second element. The support member includes a sleeve (50) for rotatably supporting the first element, and a flange (56) having a concave central portion. The flange (56) is coupled to the sleeve (50). The flange (56) has bearing surfaces (68a, 68b) formed thereon along which the flange (56) is mounted to the second element. In one embodiment, the first element is a spindle (12) of a vehicle wheel assembly (11) and is rotatably supported in the sleeve (50) by rollable bearing elements positioned therein. Multiple tapered lobes (64) extend outwardly from the sleeve (50), and the support member (14) is mounted to a vehicle via bearing surfaces (68a, 68b) along the lobes (64). Due to the concave portion of the flange (56), the bearing surfaces (68a, 68b) are the only portions of the flange (56) in contact with the vehicle when the support member (14) is secured to the vehicle, reducing the contact area between the flange (56) and the vehicle, and reducing impact forces transferred to the bearings. A portion of the flange (56) may act as a spring member, enabling the flange (56) to flex in response to an impact load experienced by the wheel bearing assembly (11). This enables the flange (56) to absorb a portion of the side impact load, thereby attenuating the portion of the load transmitted to the bearings. A wheel bearing assembly (10) incorporating the support member (14) is also disclosed.

Owner:SKF USA INC

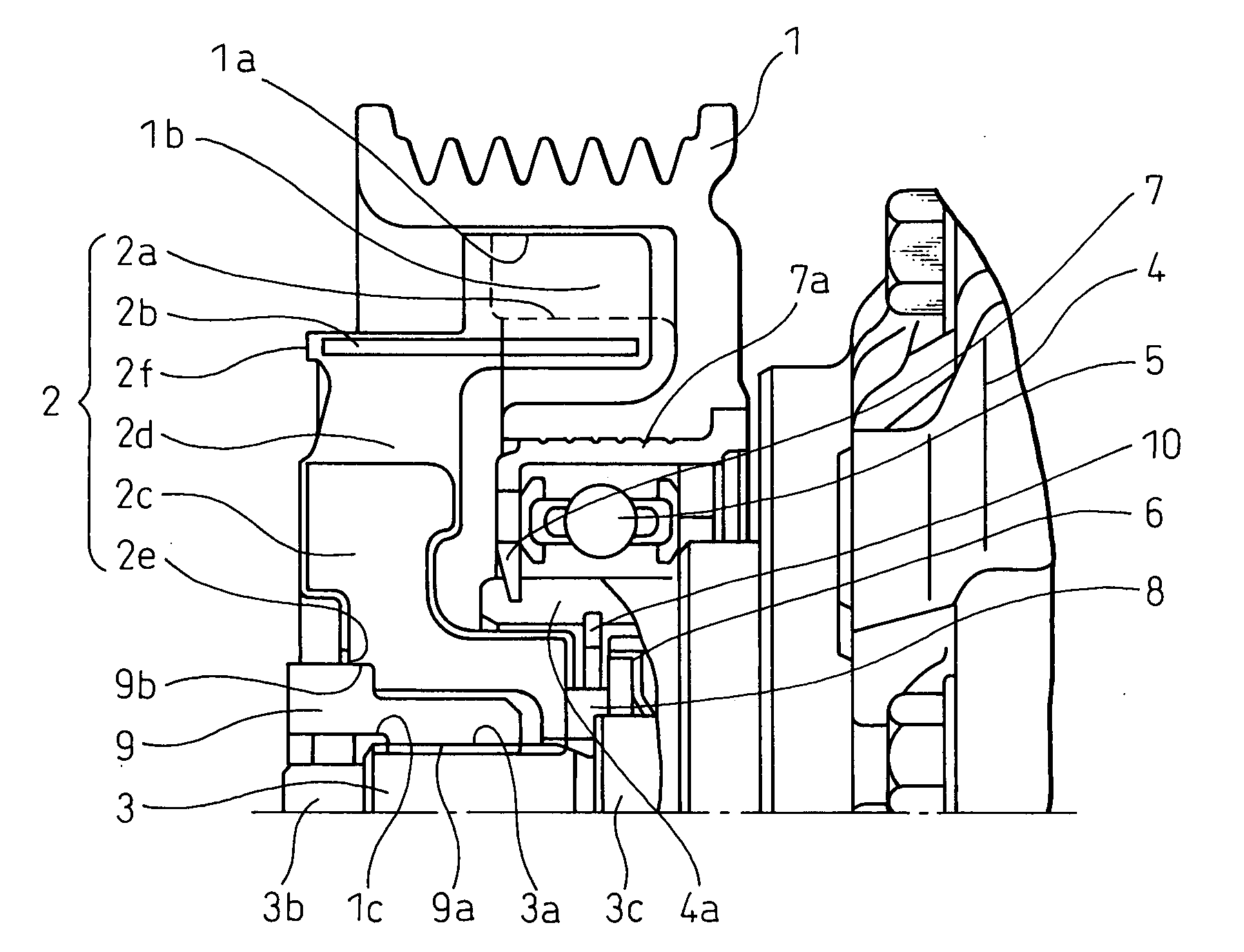

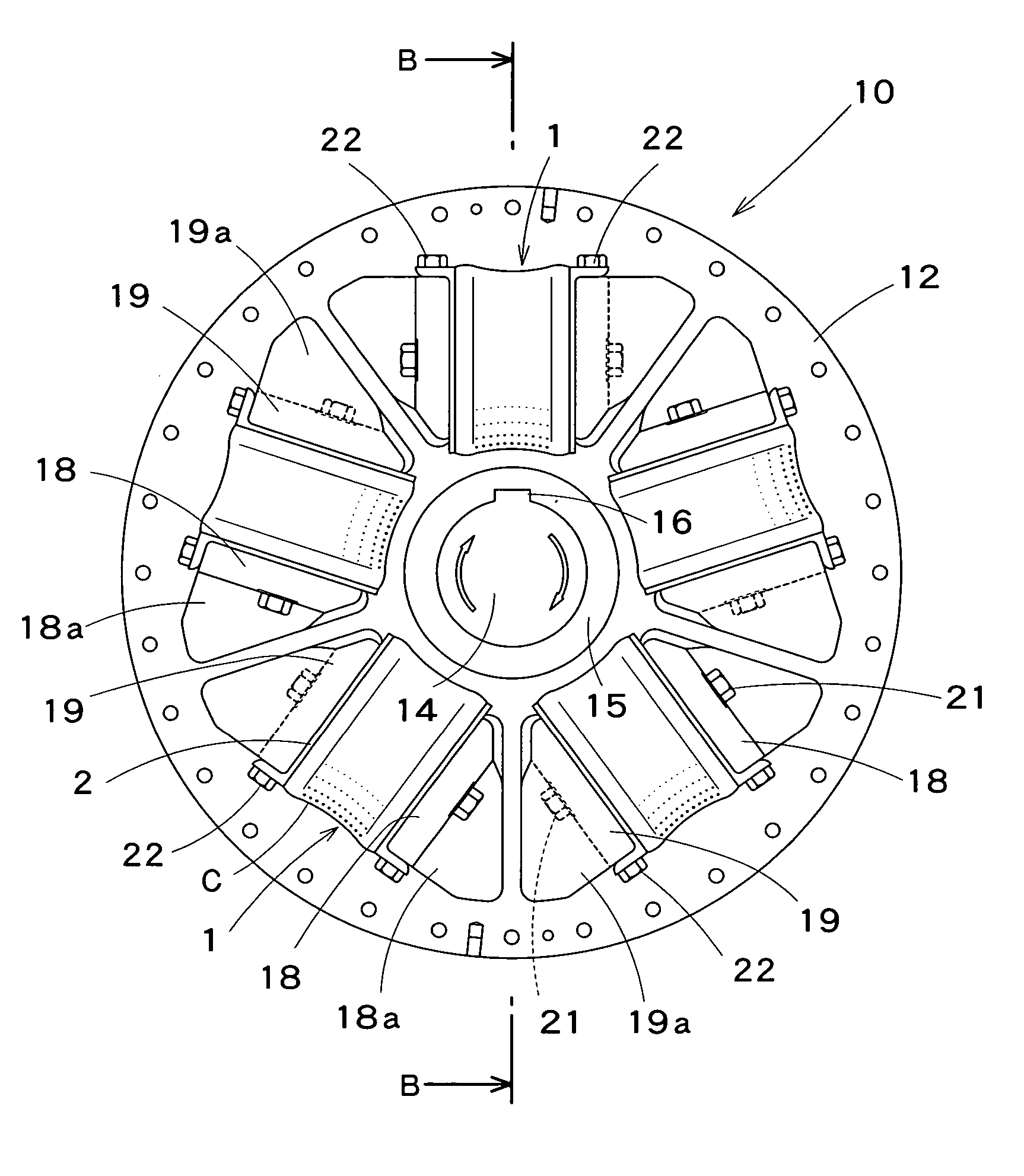

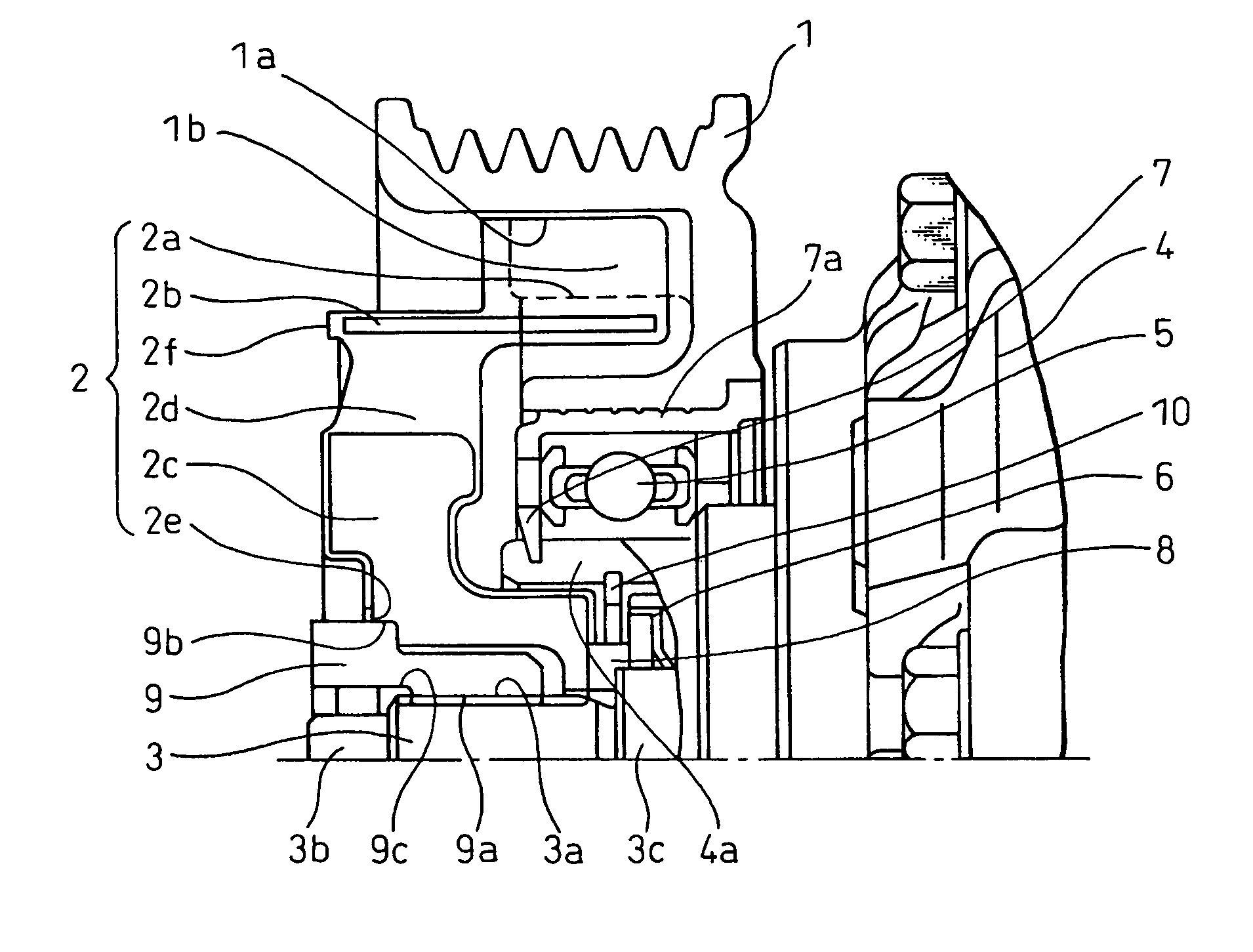

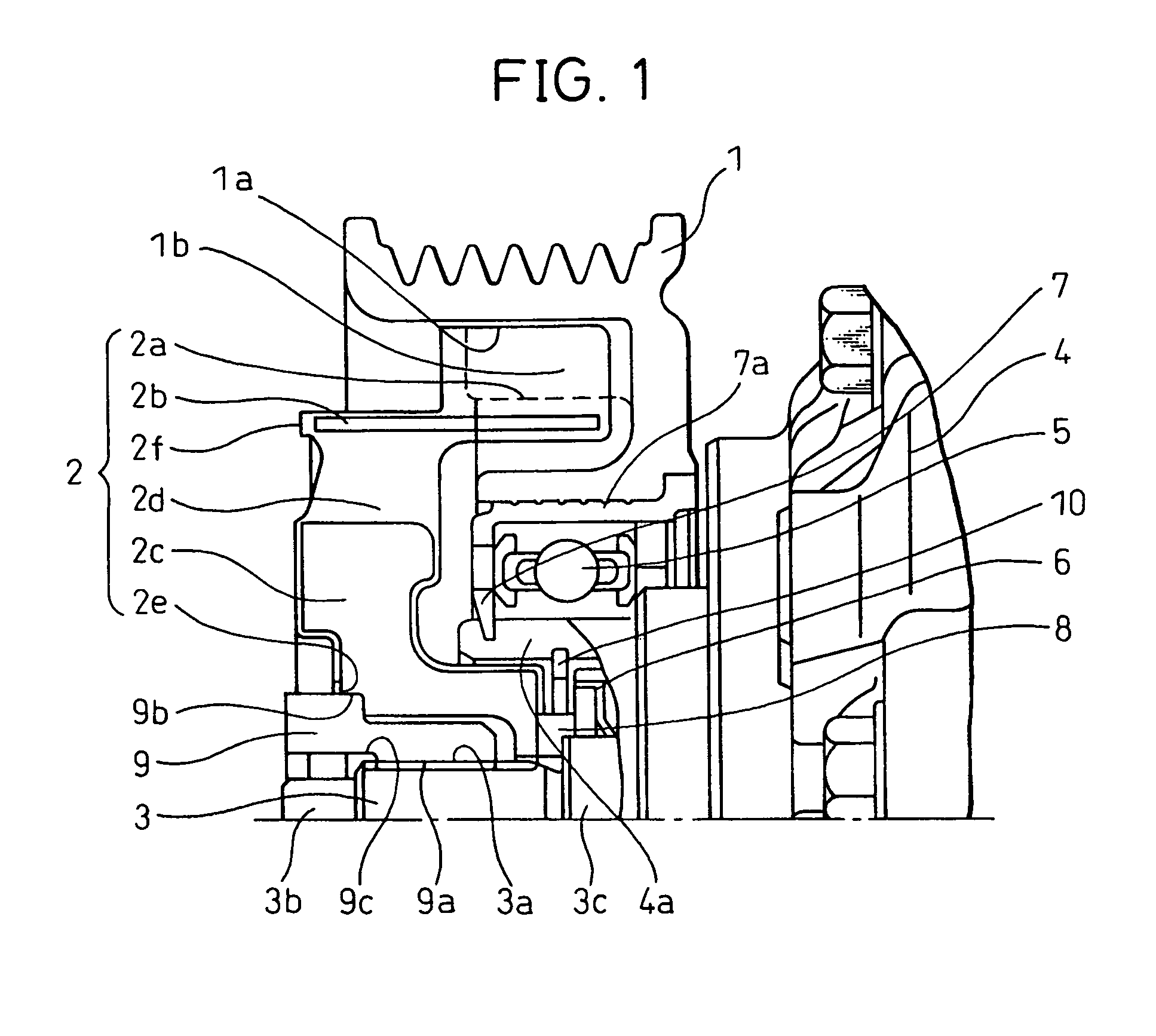

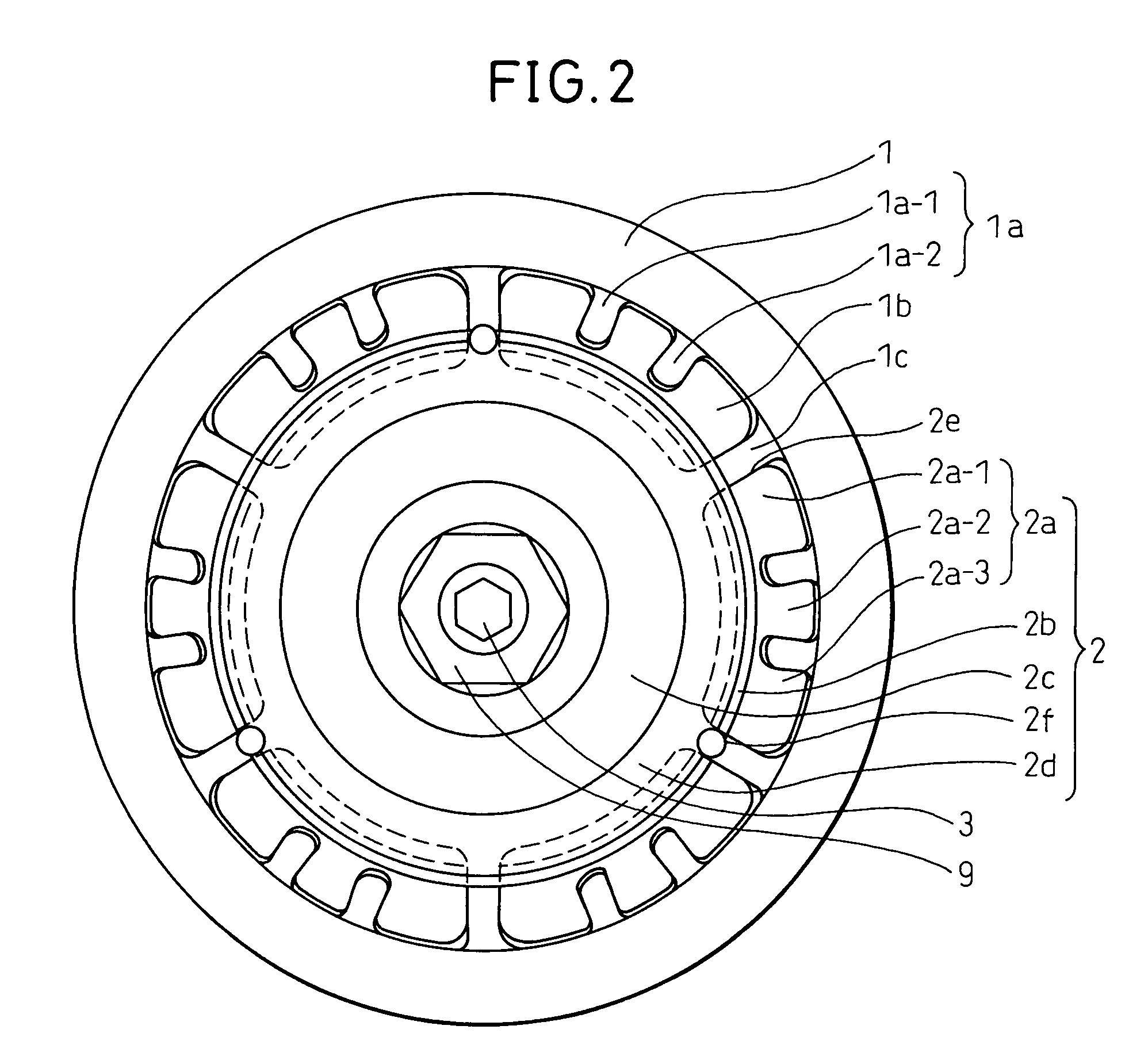

Power transmission system

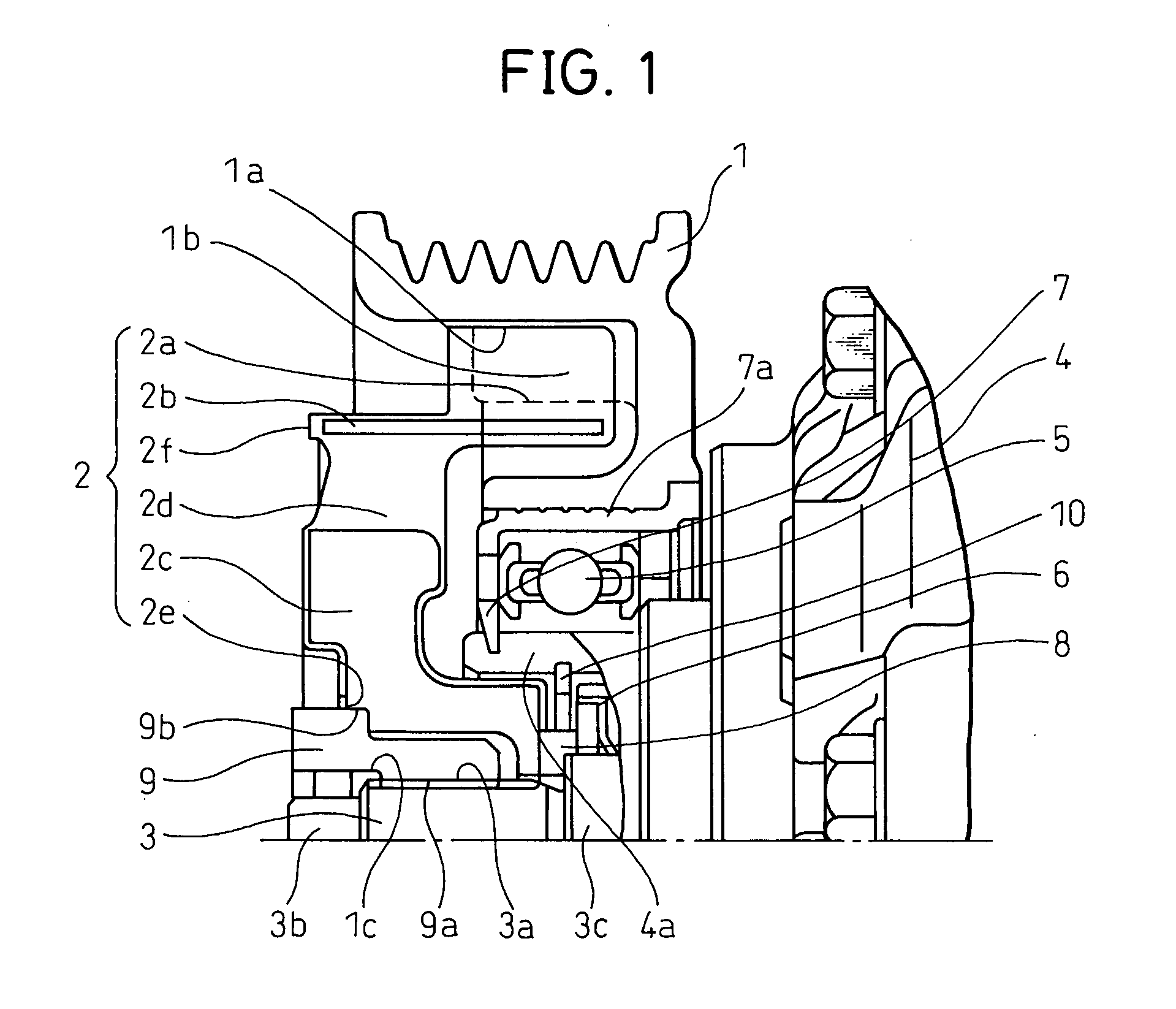

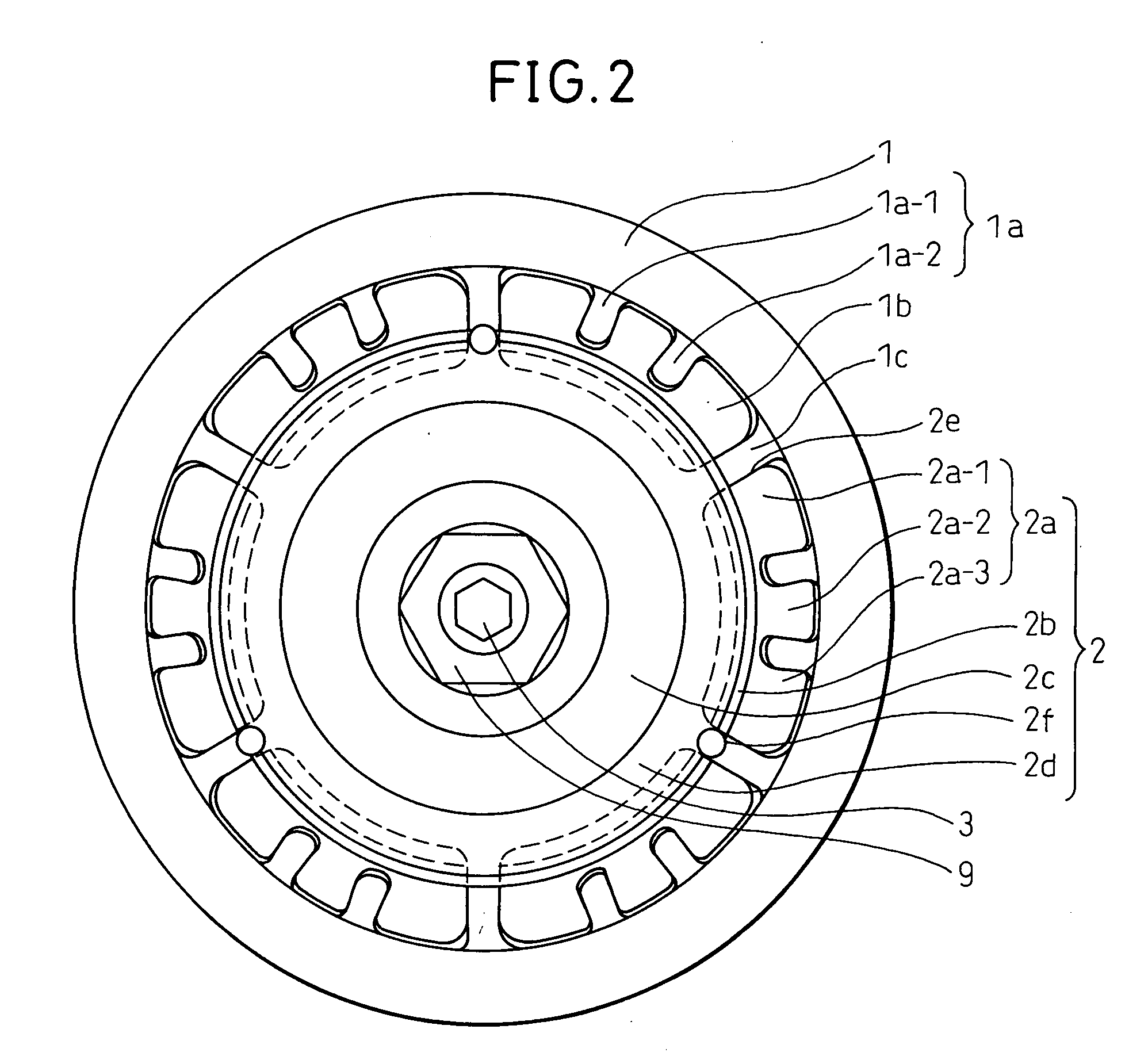

InactiveUS20070270257A1Avoid stress concentrationIncreased durabilityYielding couplingGearingElectric power transmissionDrivetrain

A power transmission system including an integrally molded hub and elastic member, where stress is inhibited from concentrating at the gate marks remaining after integral molding. In a pulley driven by a belt, a plastic pulley side relief section 1a provided at a pocket section of the pulley and a plastic hub side relief section provided on an iron outer ring of the hub engaged at the pocket section whereby power is transmitted from the pulley to the shaft. The hub side relief section and outer ring forming parts of the hub, the iron inner hub to be fastened to the shaft, and the plastic cylindrical part are integrally molded so that the gate mark for plastic injection is formed near to or further to the outer circumference of the outer ring.

Owner:DENSO CORP

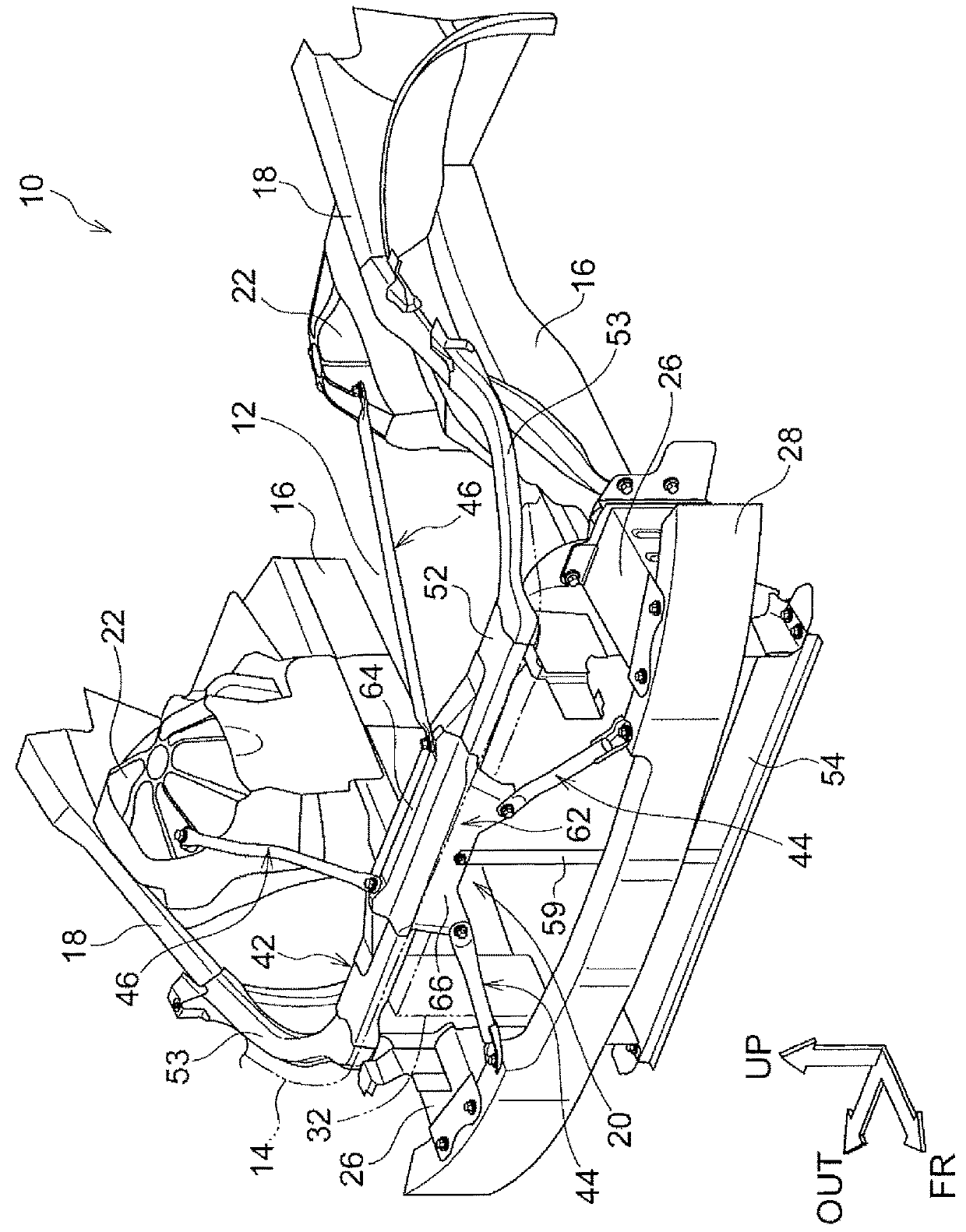

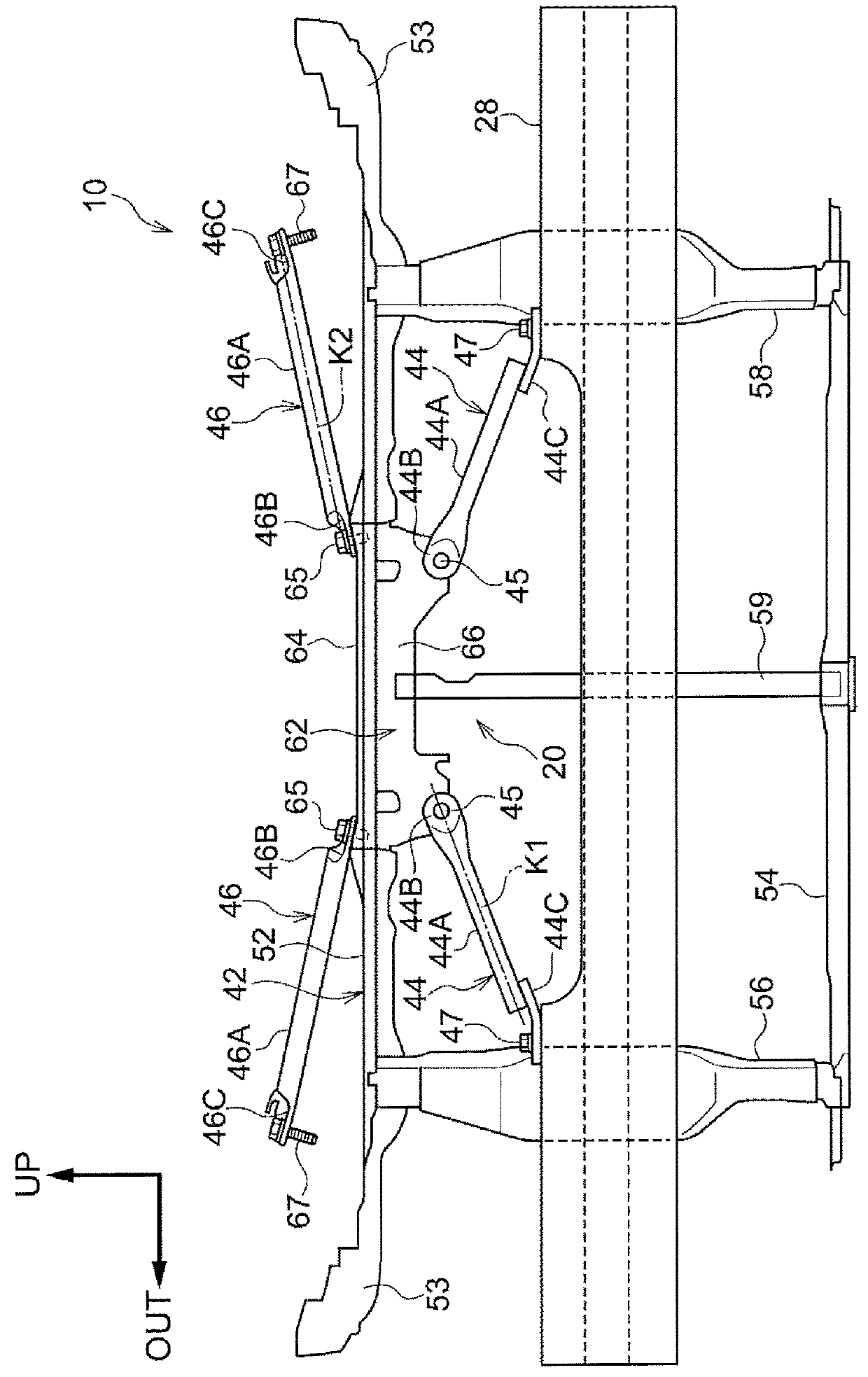

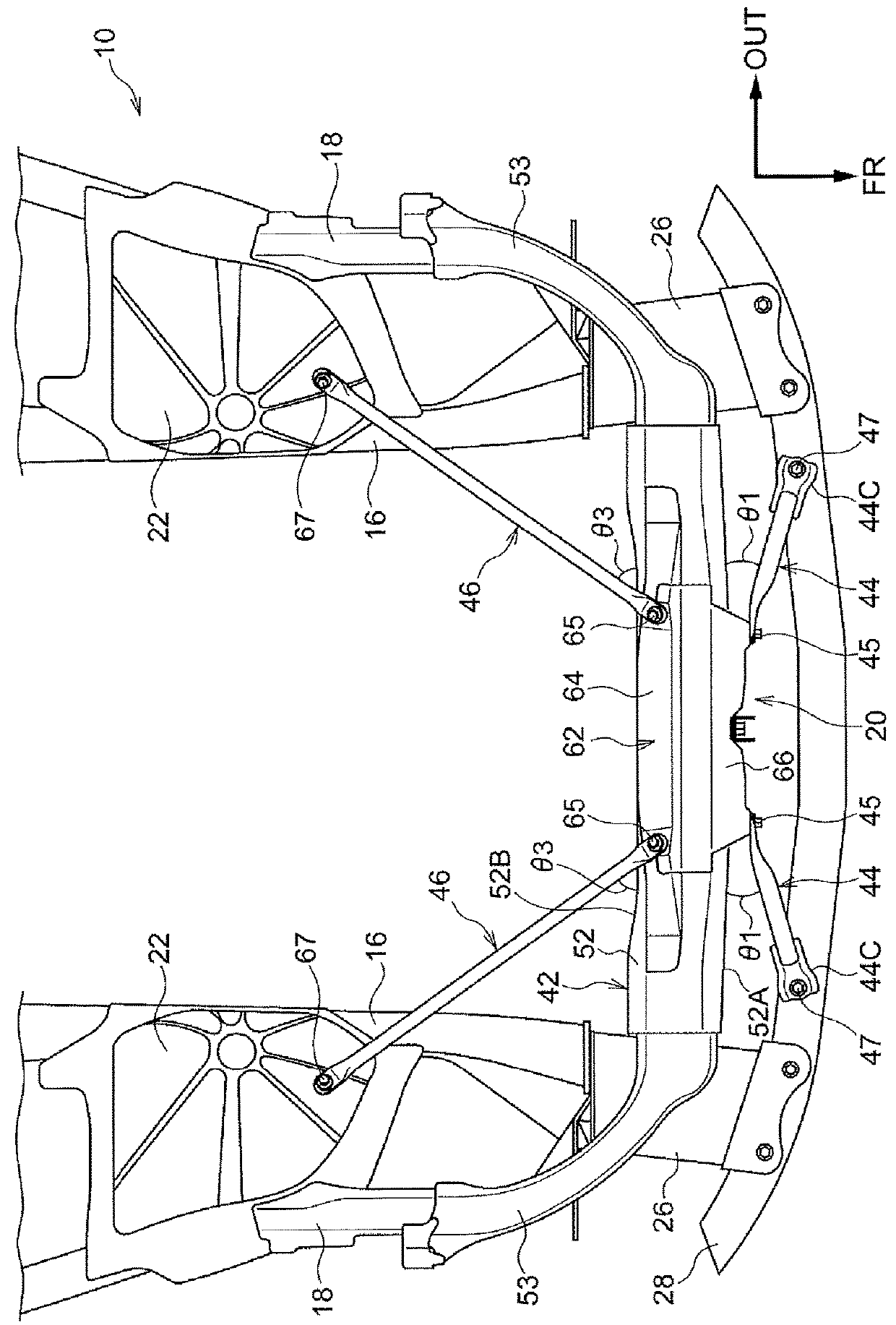

Vehicle front structure

ActiveUS20180178845A1Stress concentration is thereby relievedEasy inputUnderstructuresVehicle sub-unit featuresEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

Wheel bearing assembly mount with force attenuation

ActiveUS7470067B2Reduce contact areaStress relief concentrationRolling contact bearingsHubsUltrasound attenuationSurface mounting

A support member (14) for rotatably coupling a first element to a second element. The support member includes a sleeve (50) for rotatably supporting the first element, and a flange (56) having a concave central portion. The flange (56) is coupled to the sleeve (50). The flange (56) has bearing surfaces (68a, 68b) formed thereon along which the flange (56) is mounted to the second element. In one embodiment, the first element is a spindle (12) of a vehicle wheel assembly (11) and is rotatably supported in the sleeve (50) by rollable bearing elements positioned therein. Multiple tapered lobes (64) extend outwardly from the sleeve (50), and the support member (14) is mounted to a vehicle via bearing surfaces (68a, 68b) along the lobes (64). Due to the concave portion of the flange (56), the bearing surfaces (68a, 68b) are the only portions of the flange (56) in contact with the vehicle when the support member (14) is secured to the vehicle, reducing the contact area between the flange (56) and the vehicle, and reducing impact forces transferred to the bearings. A portion of the flange (56) may act as a spring member, enabling the flange (56) to flex in response to an impact load experienced by the wheel bearing assembly (11). This enables the flange (56) to absorb a portion of the side impact load, thereby attenuating the portion of the load transmitted to the bearings. A wheel bearing assembly (10) incorporating the support member (14) is also disclosed.

Owner:SKF USA INC

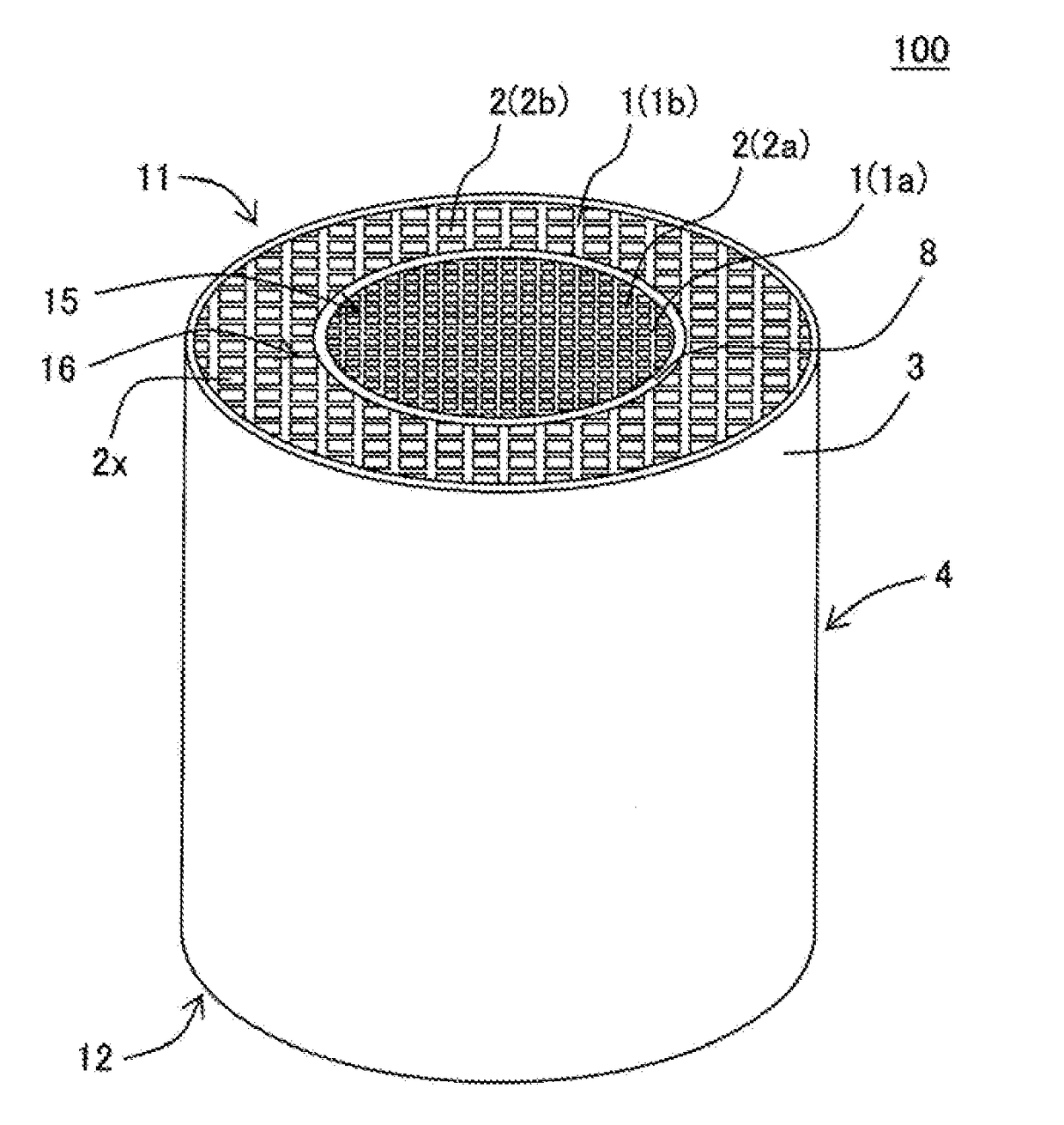

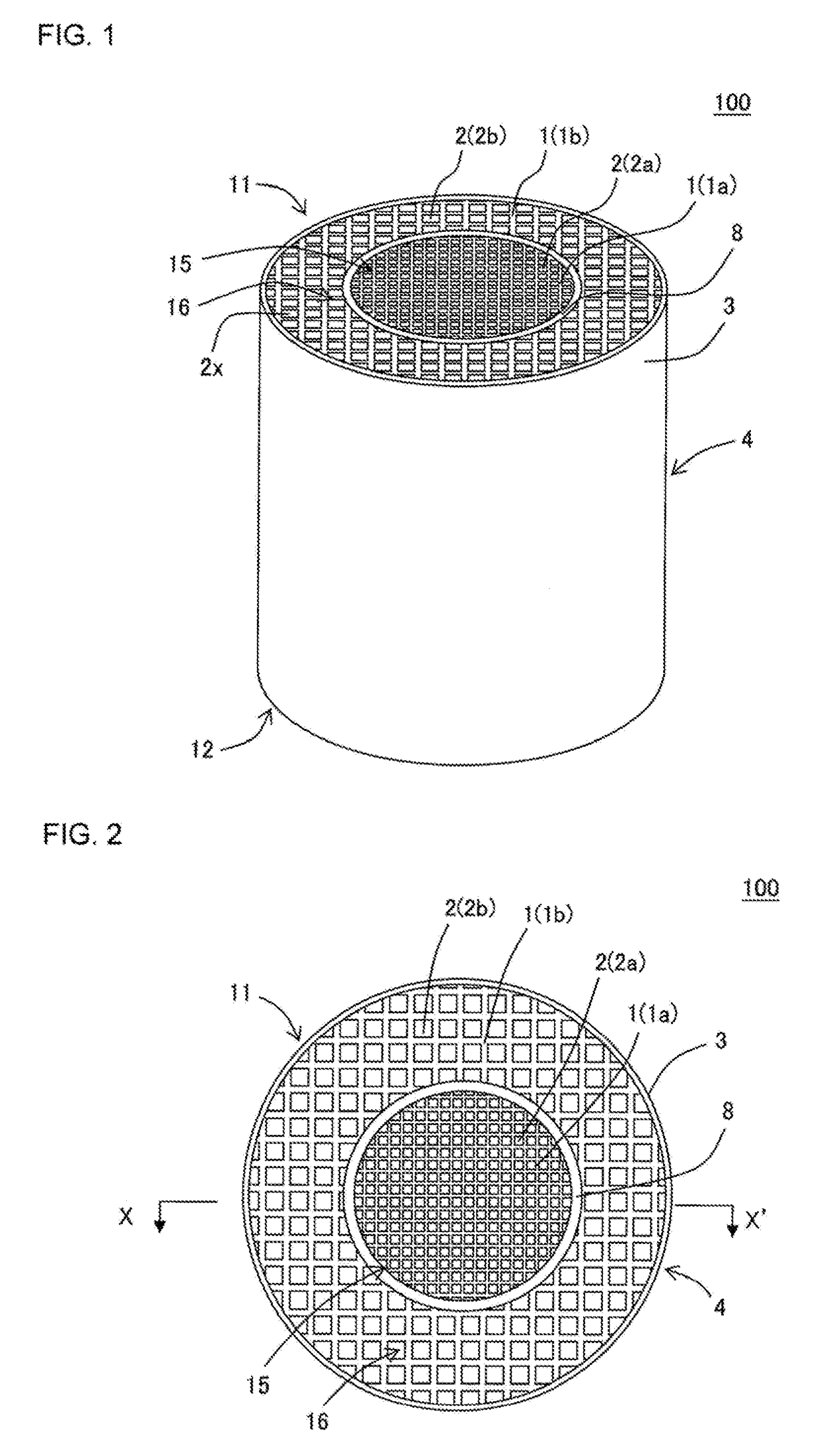

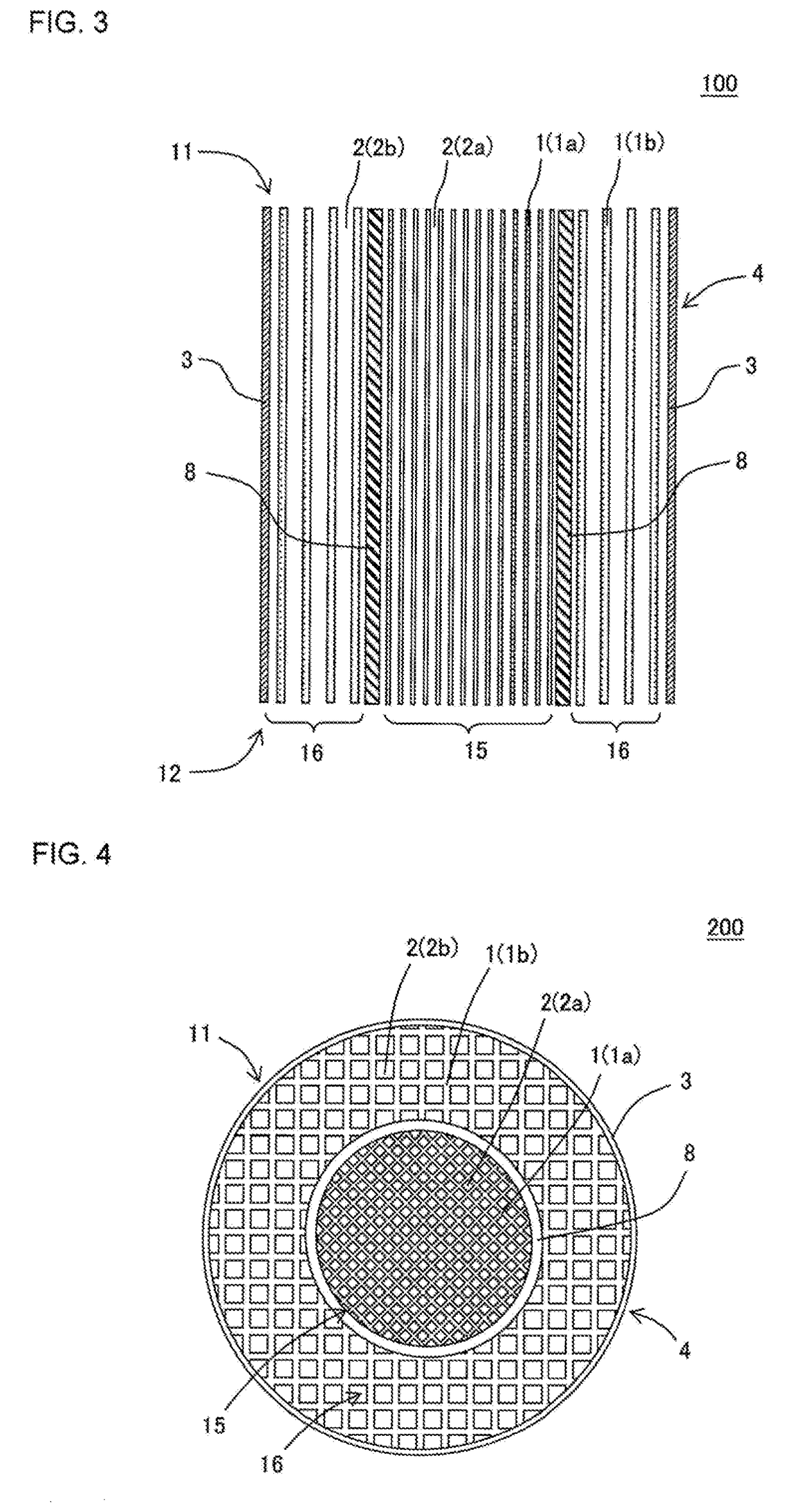

Honeycomb structure

ActiveUS20170274554A1Stress concentration is thereby relievedInhibit deteriorationPhysical/chemical process catalystsInternal combustion piston enginesEngineeringUnit structure

A honeycomb structure has a pillar-shaped honeycomb structure body having porous partition walls which defines cells which forms a passage of liquid extended from an inflow end face toward an outflow end face, a circumferential wall arranged to surround a circumference of the partition walls. The honeycomb structure body has an outermost circumference cell structure including a complete cell arranged at the outermost circumference of the honeycomb structure body, a center cell structure formed by the cells arranged at a center part at an inner side to the outermost circumference cell structure, and a boundary wall arranged at a boundary part between the outermost circumference cell structure and the center cell structure. The outermost circumference cell structure and the center cell structure are formed as different structures to each other, and a thickness of the boundary wall is set to be thicker than a thickness of the circumferential wall.

Owner:NGK INSULATORS LTD

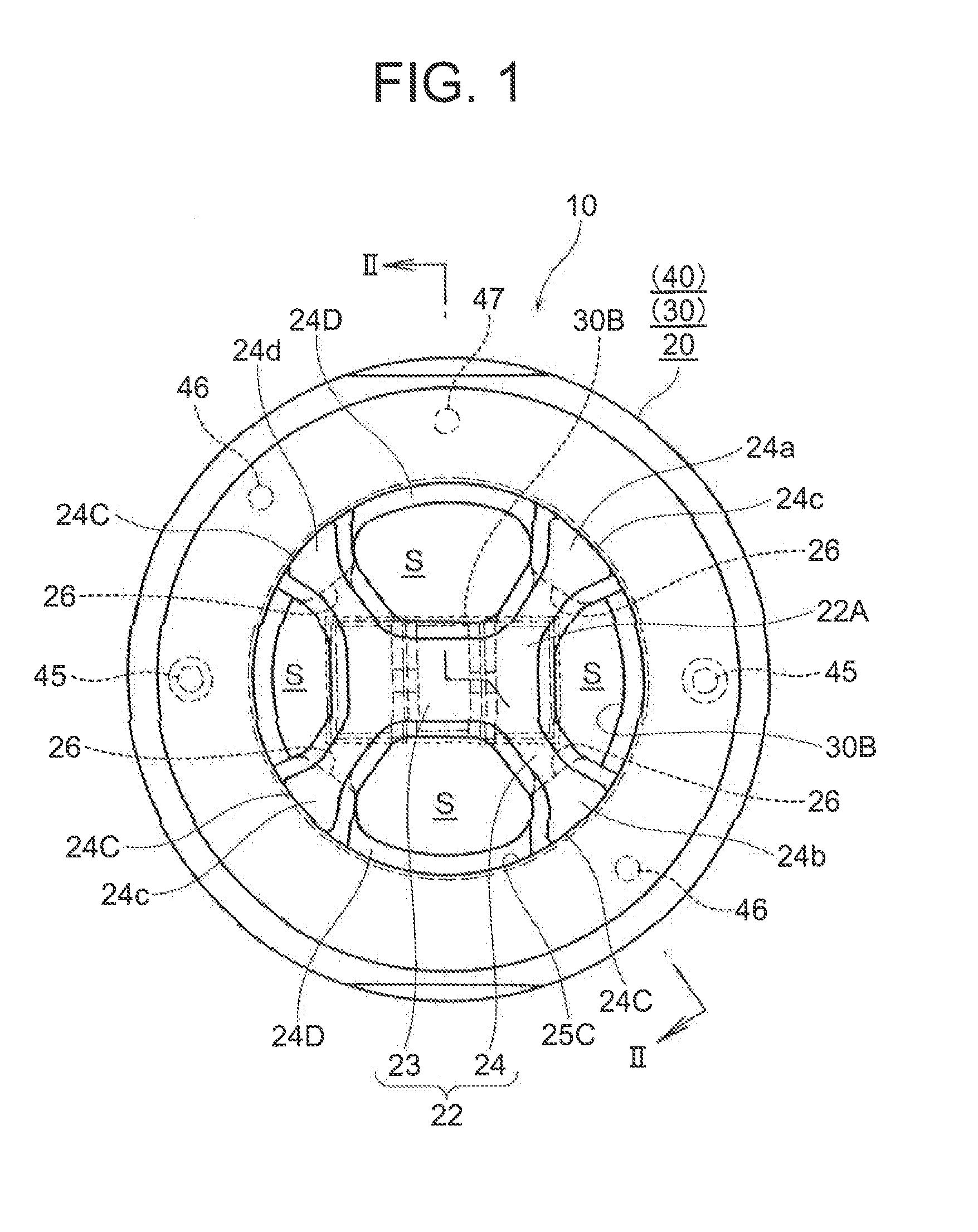

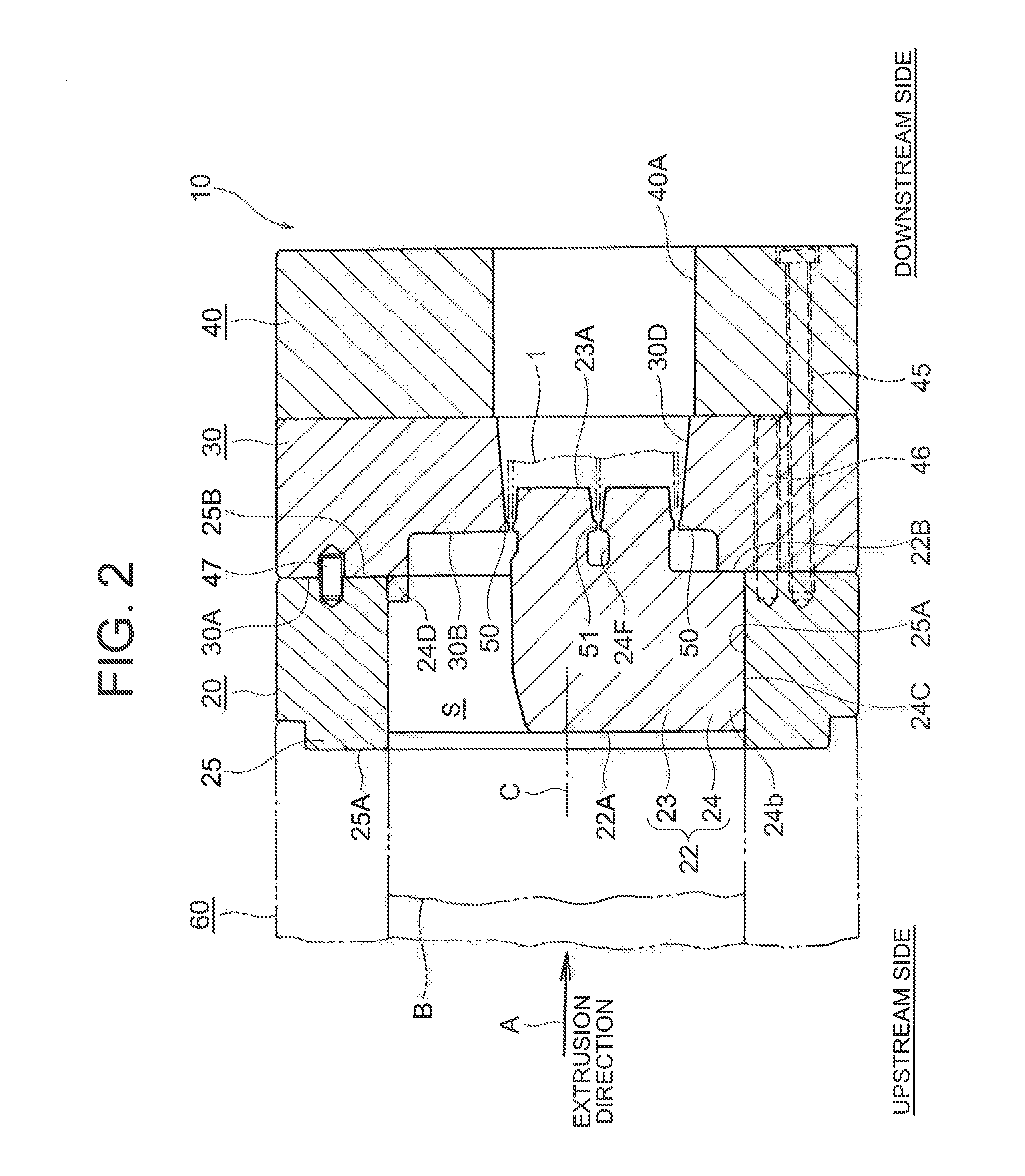

Extrusion die for forming hollow material

ActiveUS20140283577A1Avoid breakingStress relief concentrationExtrusion diesDrawing profiling toolsShrink-fittingEngineering

An extrusion die is provided with a male die through which a billet is extruded from an upstream side to a downstream side and, the male die adapted for forming an inside shape of a hollow material; and a female die for holding the male die and forming an outside shape of the hollow material. The male die is formed of a spider and a holder for holding the spider. The spider is formed of a mandrel and a plurality of bridge parts for supporting the mandrel, and enabling a distal-end outer peripheral surface to engage with a bridge-holding surface. The distal-end outer peripheral surface of each of the bridge parts and the bridge-holding surface of the holder are joined by shrink-fitting.

Owner:NIPPON LIGHT METAL CO LTD +1

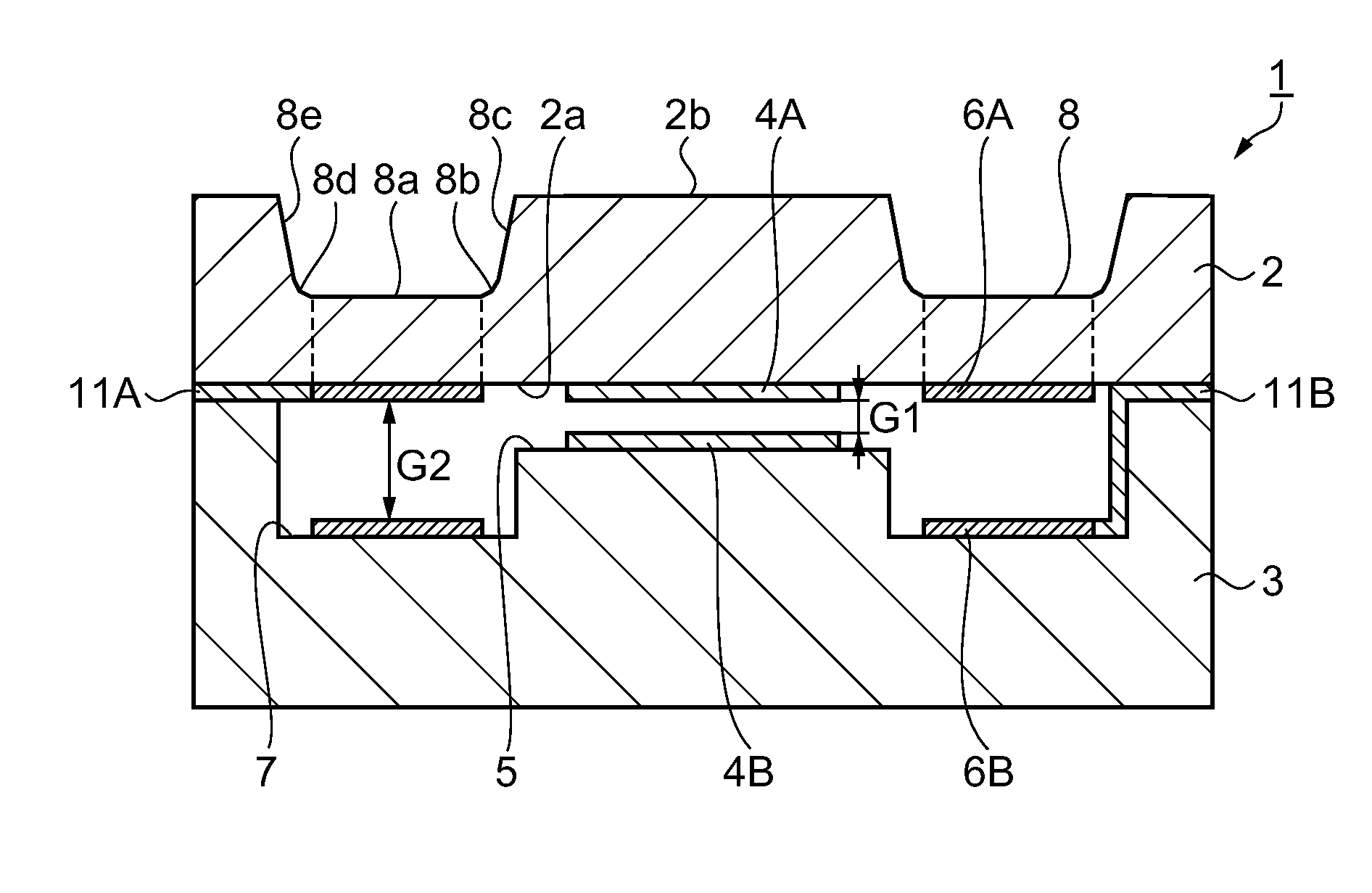

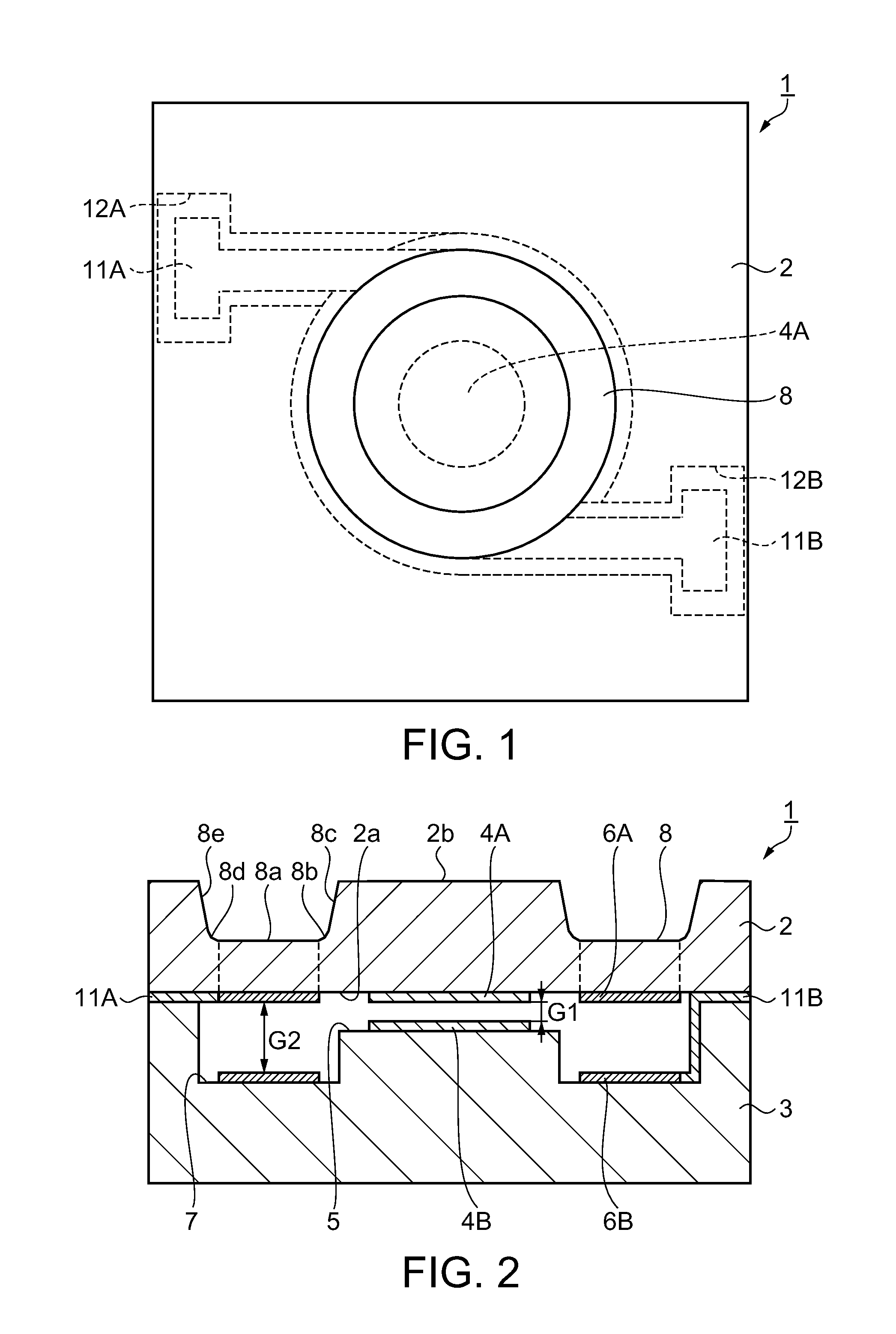

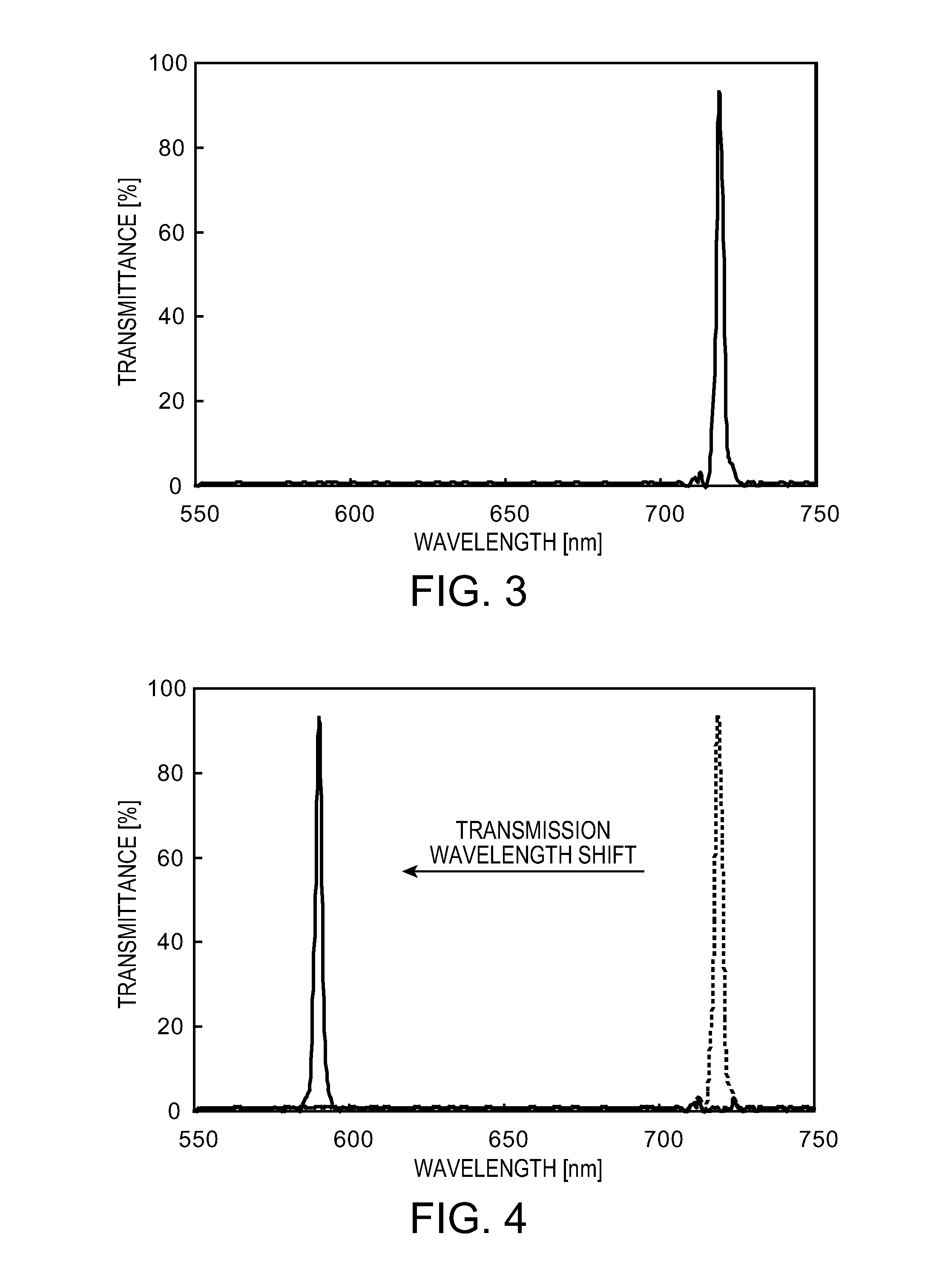

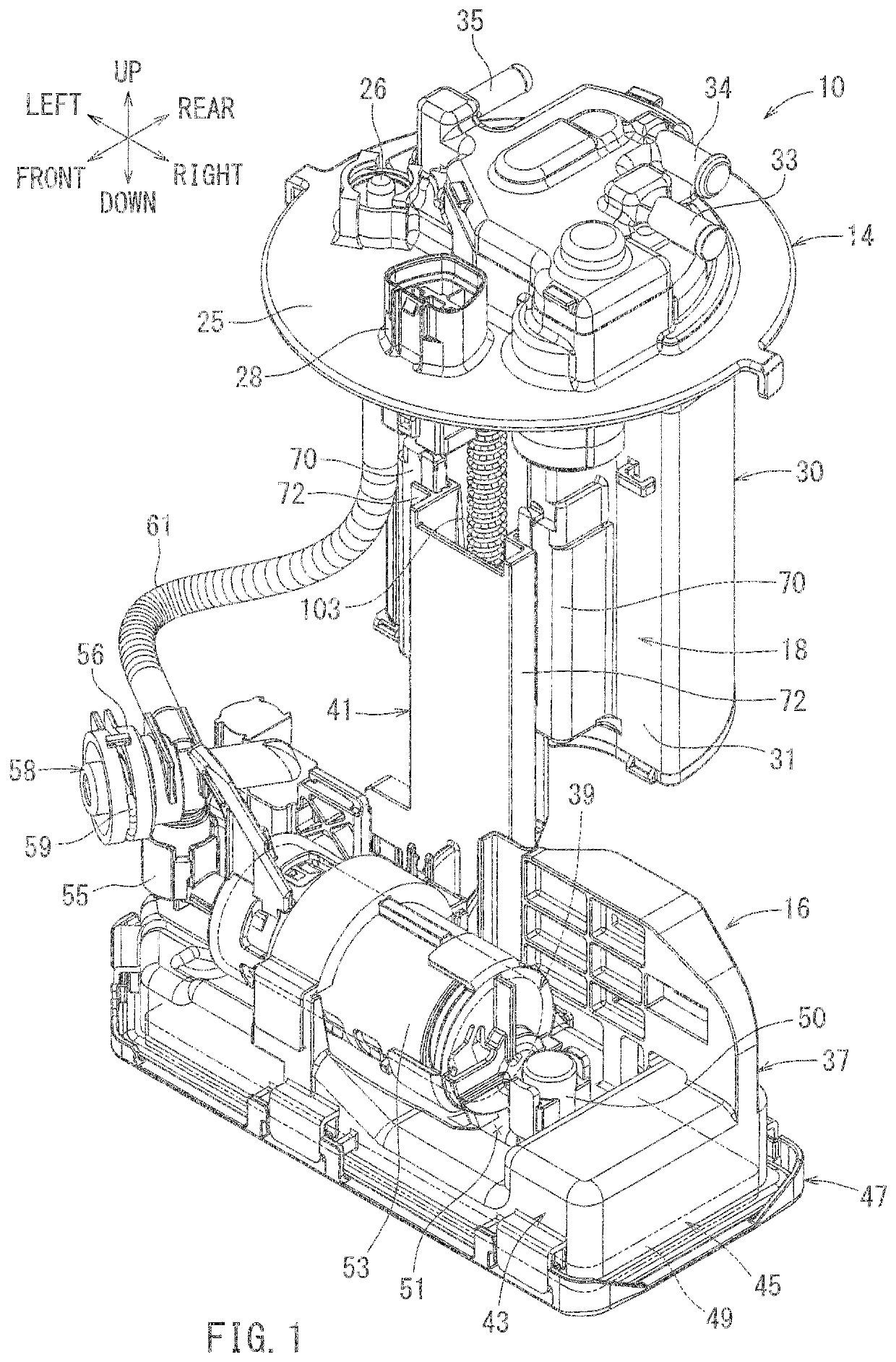

Optical filter and analytical instrument

InactiveUS20110228396A1Increased intensityHigh strengthPhotomechanical apparatusSemiconductor/solid-state device manufacturingEngineeringExtremity Part

An optical filter includes: a lower substrate; a lower mirror provided to the lower substrate; a lower electrode provided to the lower substrate; an upper substrate disposed so as to be opposed to the lower electrode; an upper mirror provided to the upper substrate, and opposed to the lower mirror; and an upper electrode provided to the upper substrate, and opposed to the lower electrode, wherein the upper substrate has a groove surrounding the upper mirror in a plan view, the groove includes a first side surface section, a second side surface section, a bottom surface section, a first end section located between the first side surface section and the bottom surface section, and a second end section located between the second side surface section and the bottom surface section, in a cross-sectional view, and the first end section and the second end section each have a curved surface.

Owner:SEIKO EPSON CORP

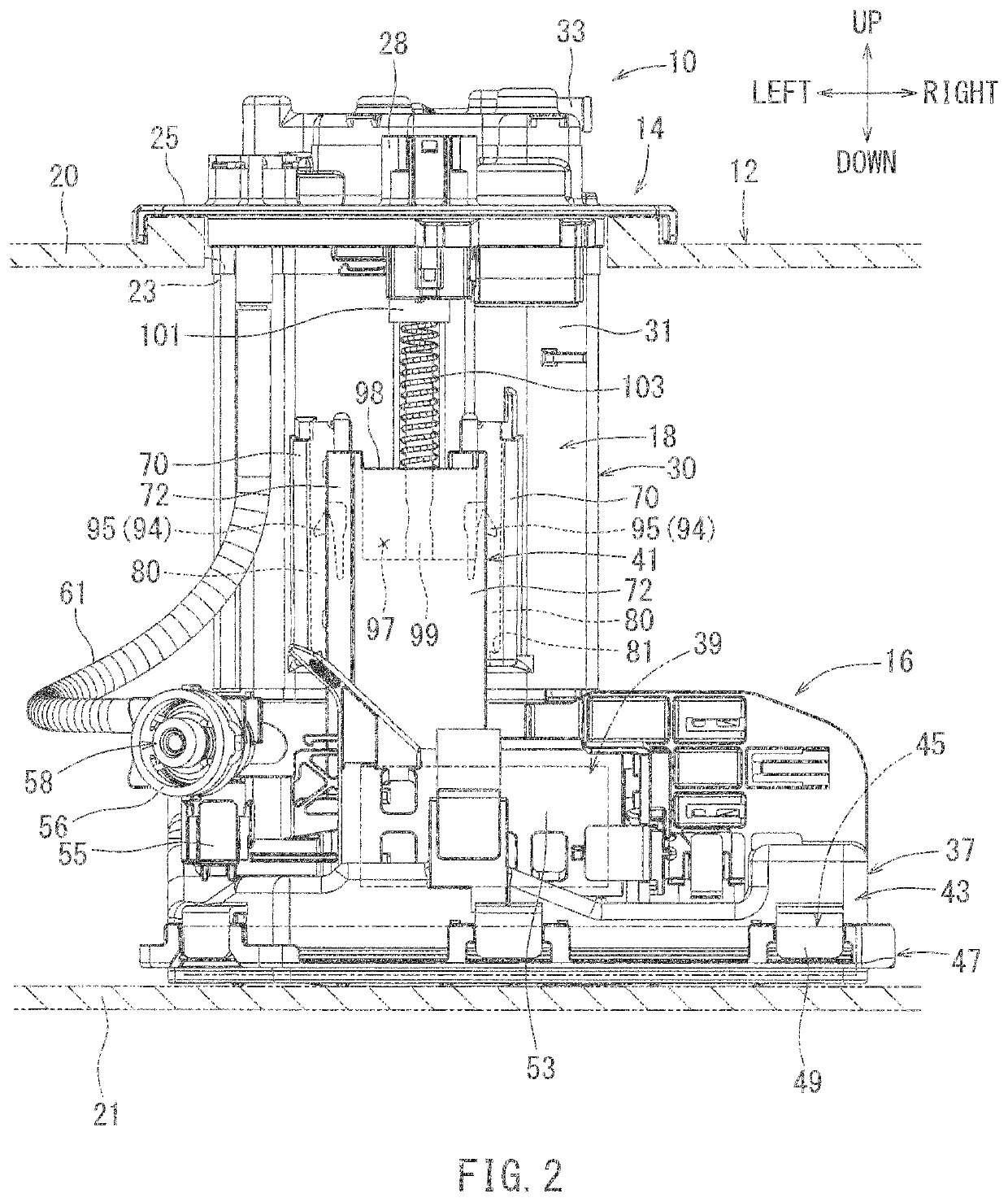

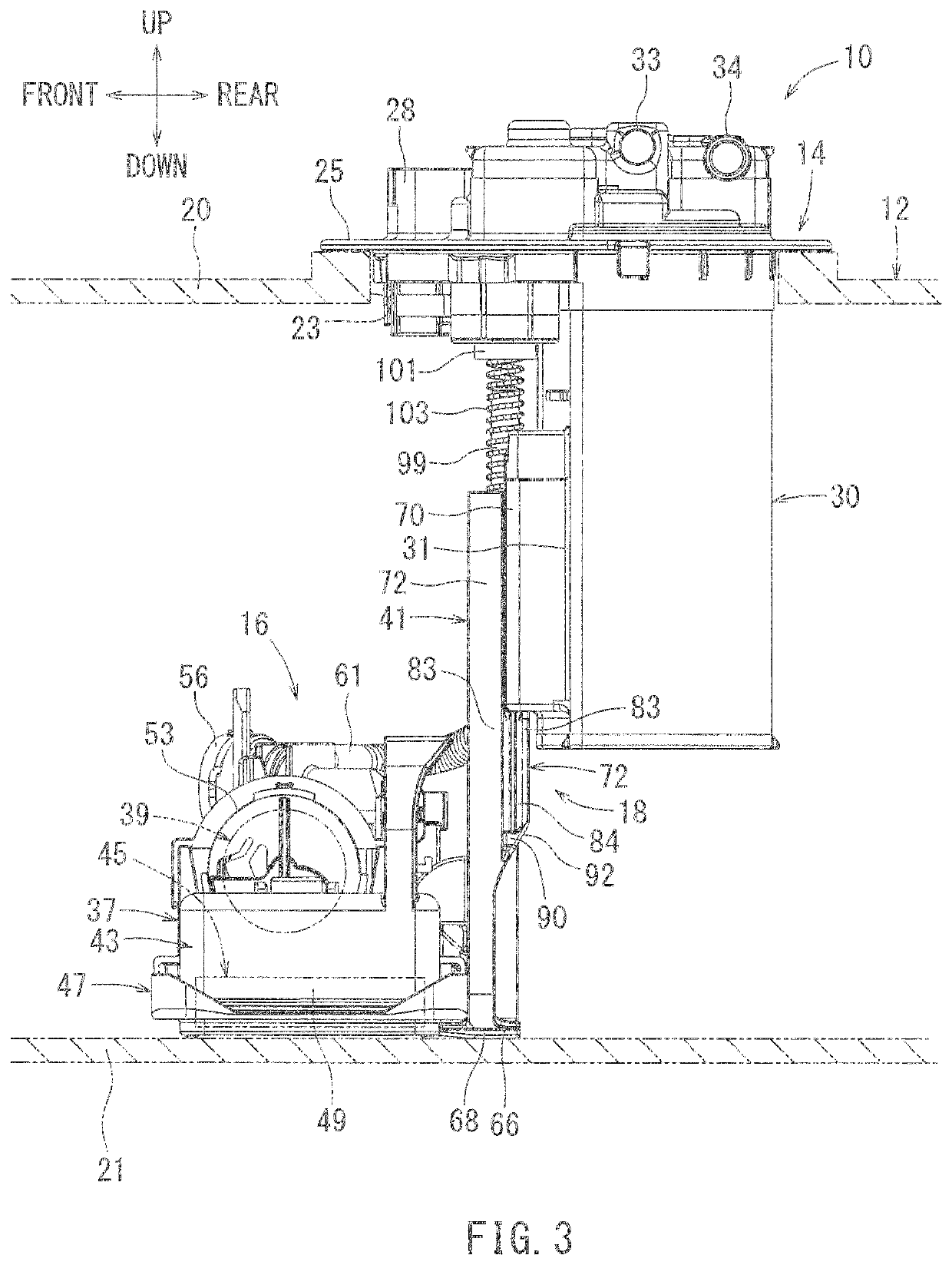

Fuel supply device

ActiveUS10544762B2Stress relief concentrationRelieve stressUnderstructuresMachines/enginesFuel tankFuel supply

A fuel supply device includes a flange unit configured to be attached to an upper wall of a fuel tank to close an opening of the fuel tank, a pump unit configured to be disposed within the fuel tank, and a coupling mechanism moveably coupling the pump unit to the flange unit in a vertically slidable manner. The coupling mechanism includes a fixed-side rail member having a rail portion extending vertically from the flange unit, and a movable-side rail member having a channel-groove shaped rail groove extending from the pump unit. The channel-groove shaped rail groove is slidably engaged with the rail portion of the fixed-side rail member. A recess having a semi-circular cross section is formed at a corner of the rail groove of the movable-side rail member.

Owner:AISAN IND CO LTD

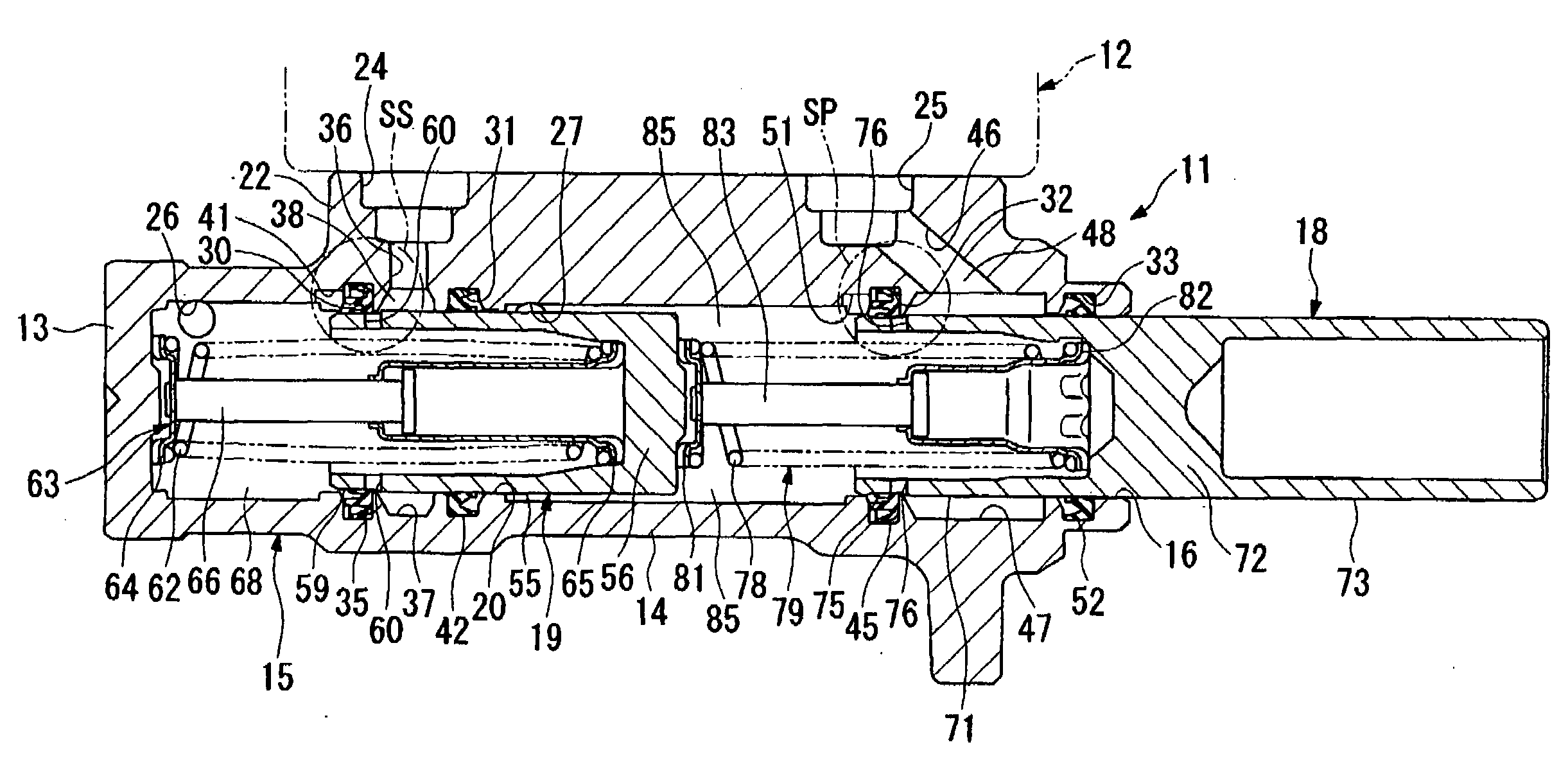

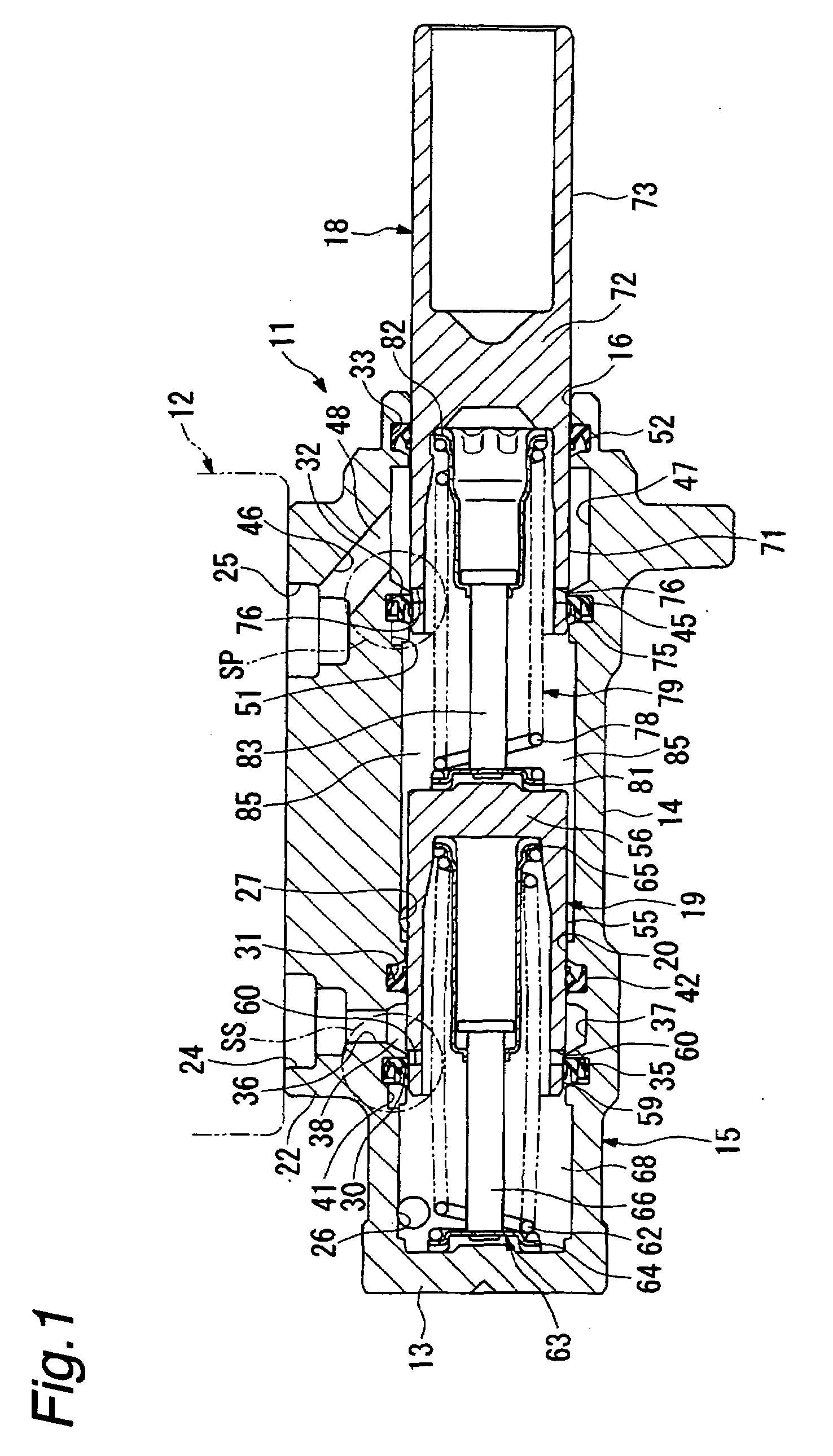

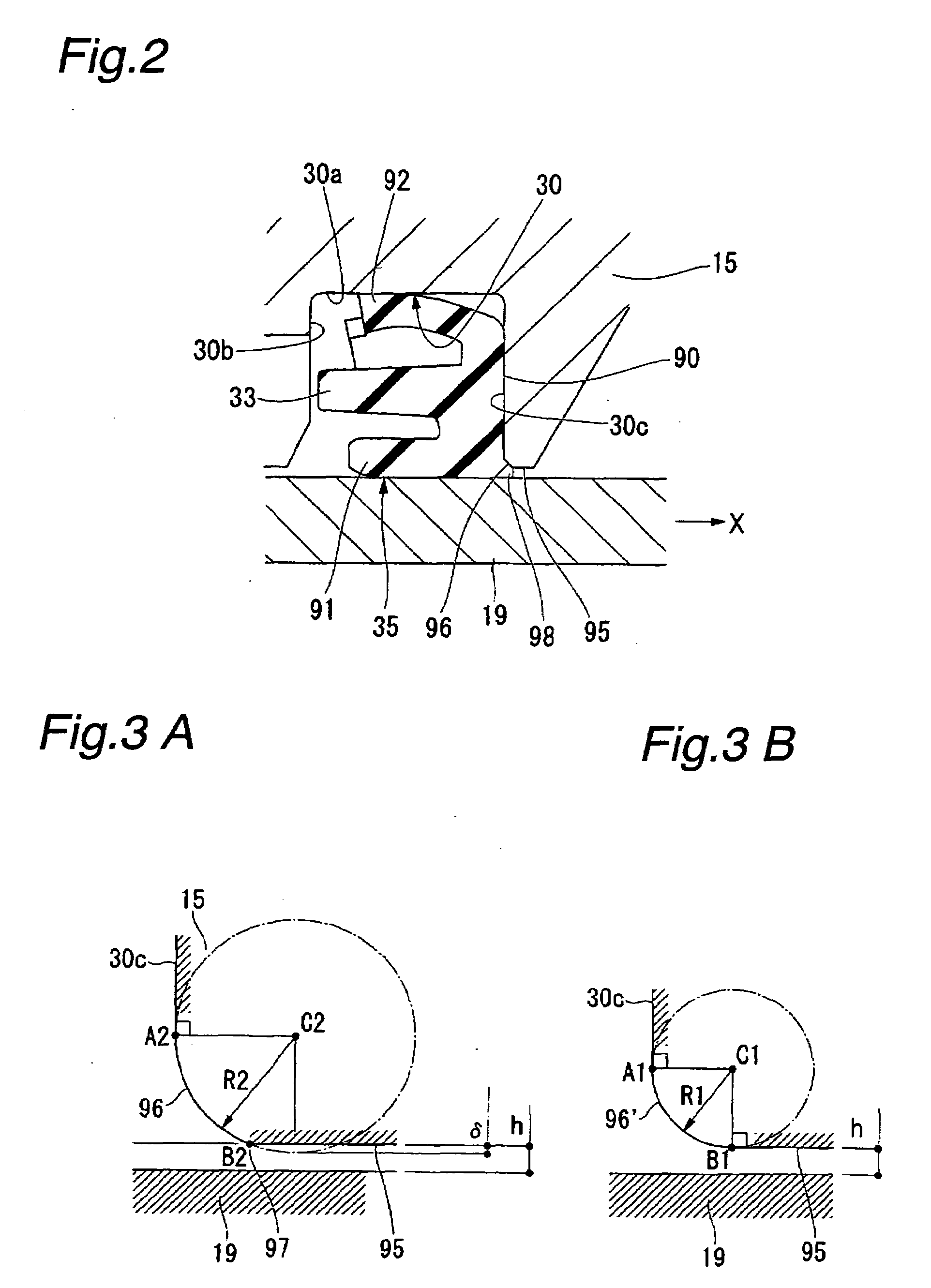

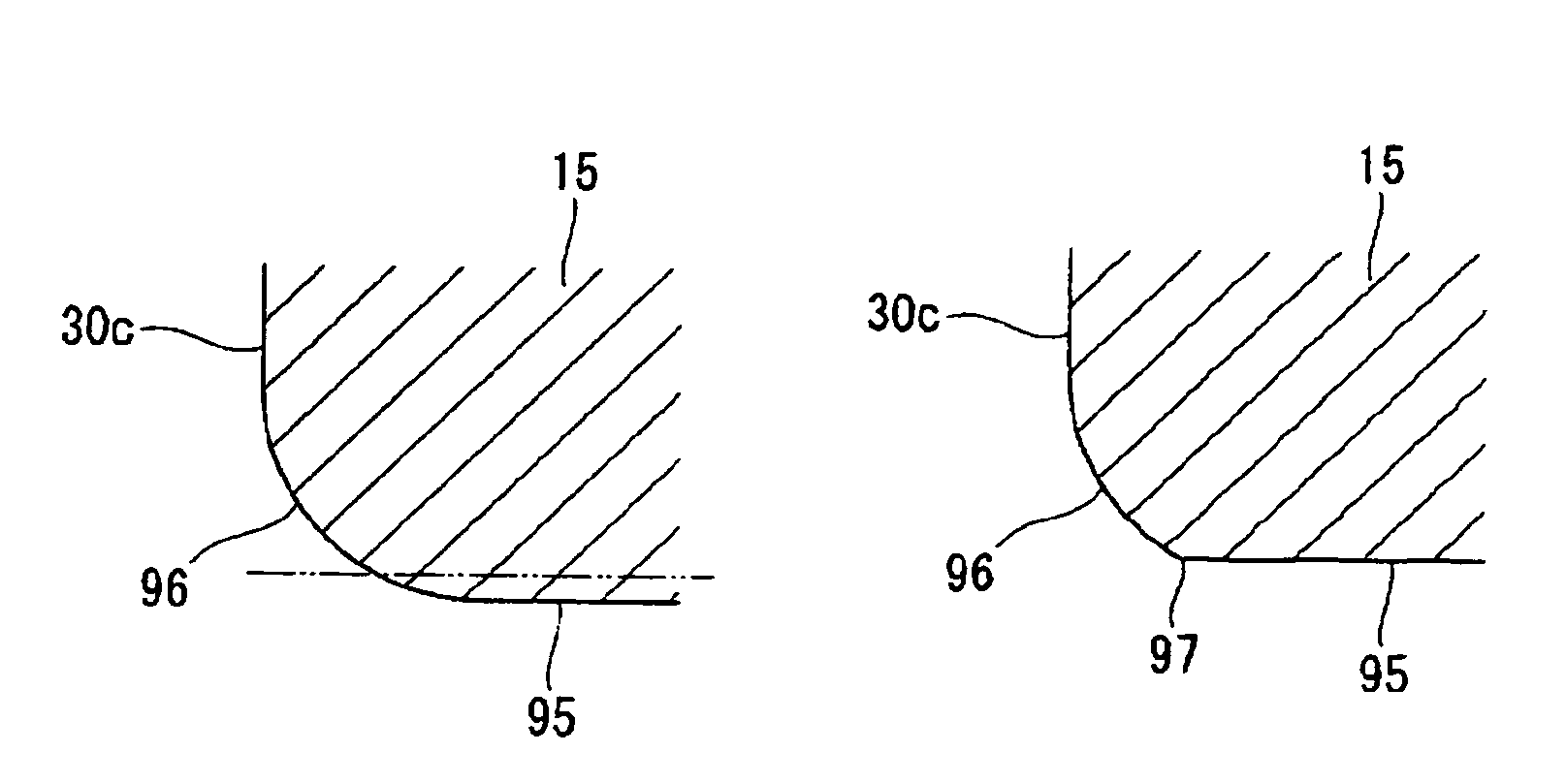

Master cylinder and method of manufacturing the same

InactiveUS20080264248A1Relieve stress concentrationPrevent be damagePiston ringsRotary clutchesCurve shapeMaster cylinder

An object of the present invention is to provide a master cylinder capable of controlling an increase in an intruding amount of a cup seal while relieving a stress concentration therein to thereby prevent the cup seal from being damaged. Provided is a master cylinder in which a piston is moved in slidable contact with an inner circumference of a cup seal held in a cylinder main body so as to pressurize a brake fluid in a pressure chamber formed of the piston and the cylinder main body, wherein an annular wall configured integrally with the cylinder main body is provided behind the cup seal. Further, a chamfered portion having a curved shape in a cross-section taken along a diameter direction of the cylinder main body is provided between the annular wall and a cylinder wall to which the piston is facing. One end of the chamfered portion is formed continuously so that a tangent thereto is in line with the annular wall, and the other end of the chamfered portion is formed to constitute a flexed portion in combination with the cylinder wall.

Owner:HITACHI LTD

Rubber element for compression elastic coupling

ActiveUS20070093300A1Good effectImprove fatigue strengthYielding couplingRubber-like material springsCouplingEngineering

Owner:KAWASAKI HEAVY IND LTD

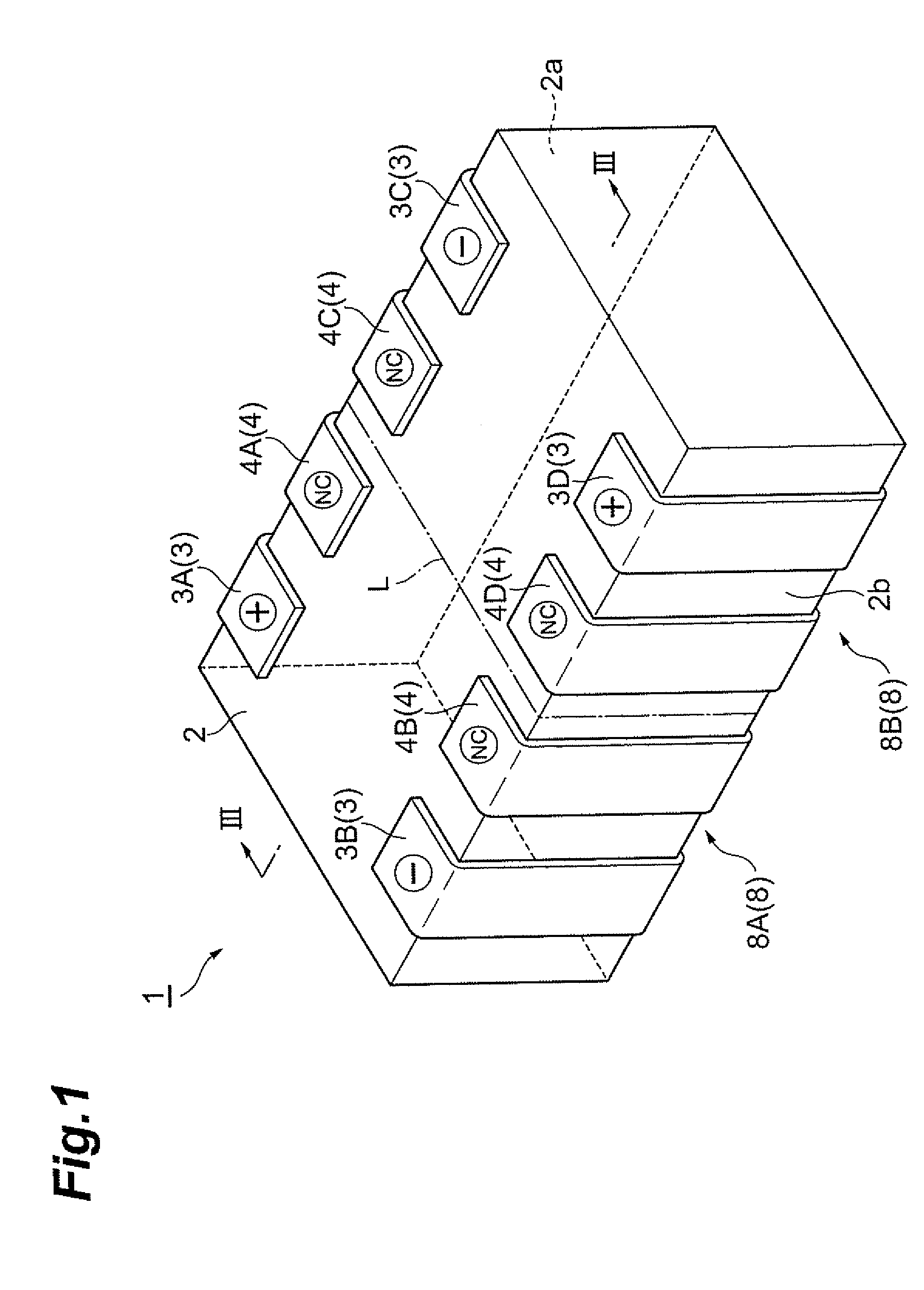

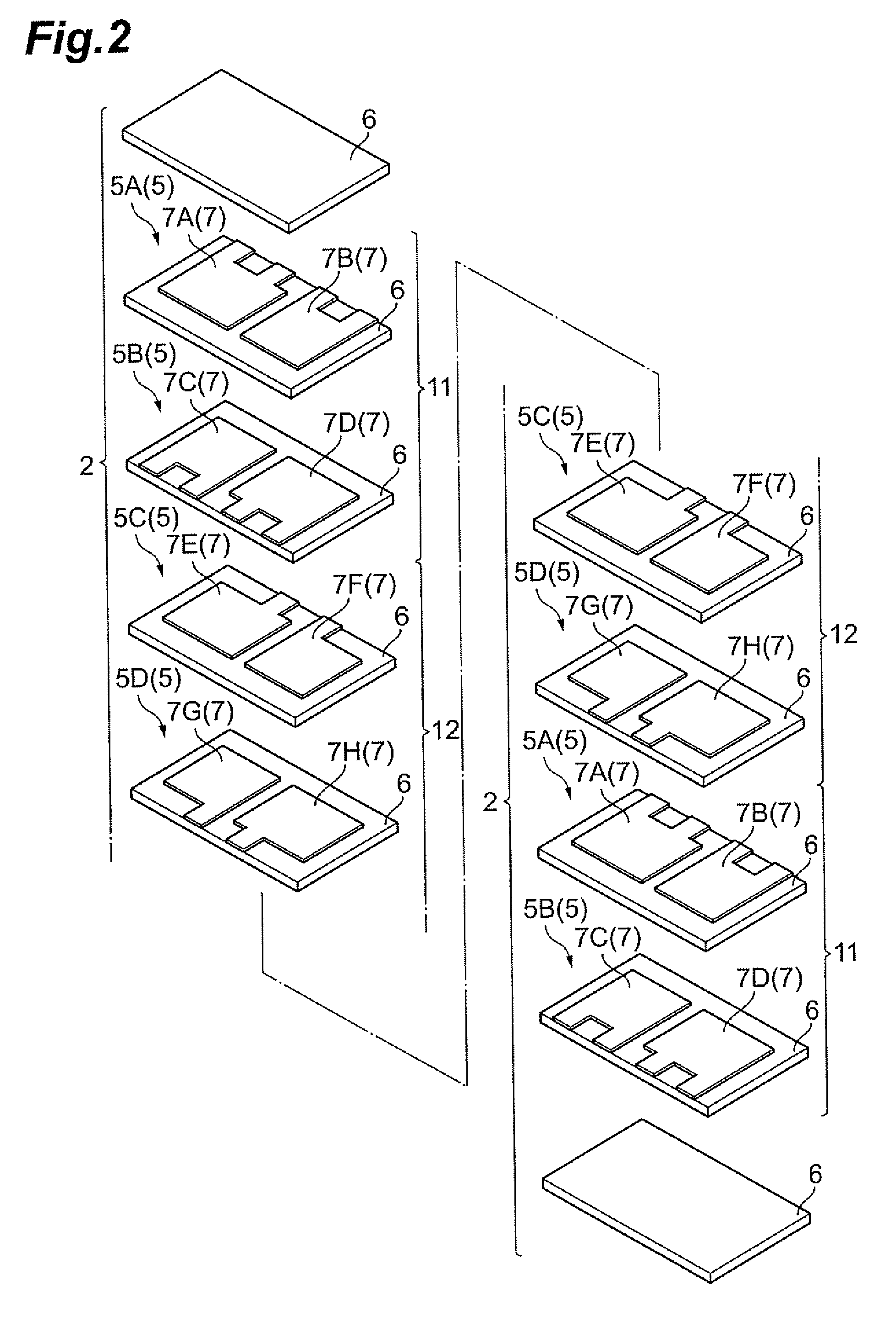

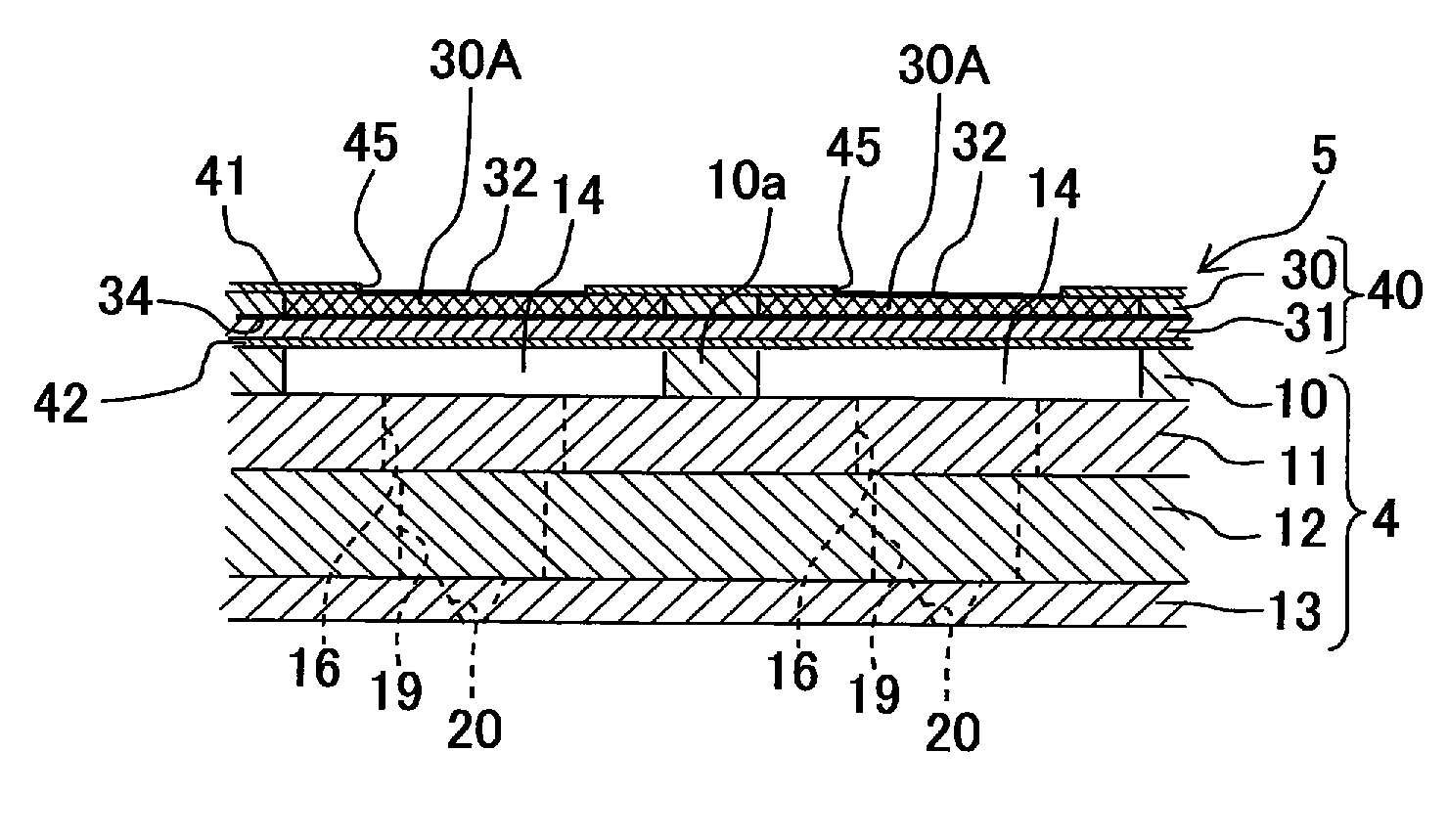

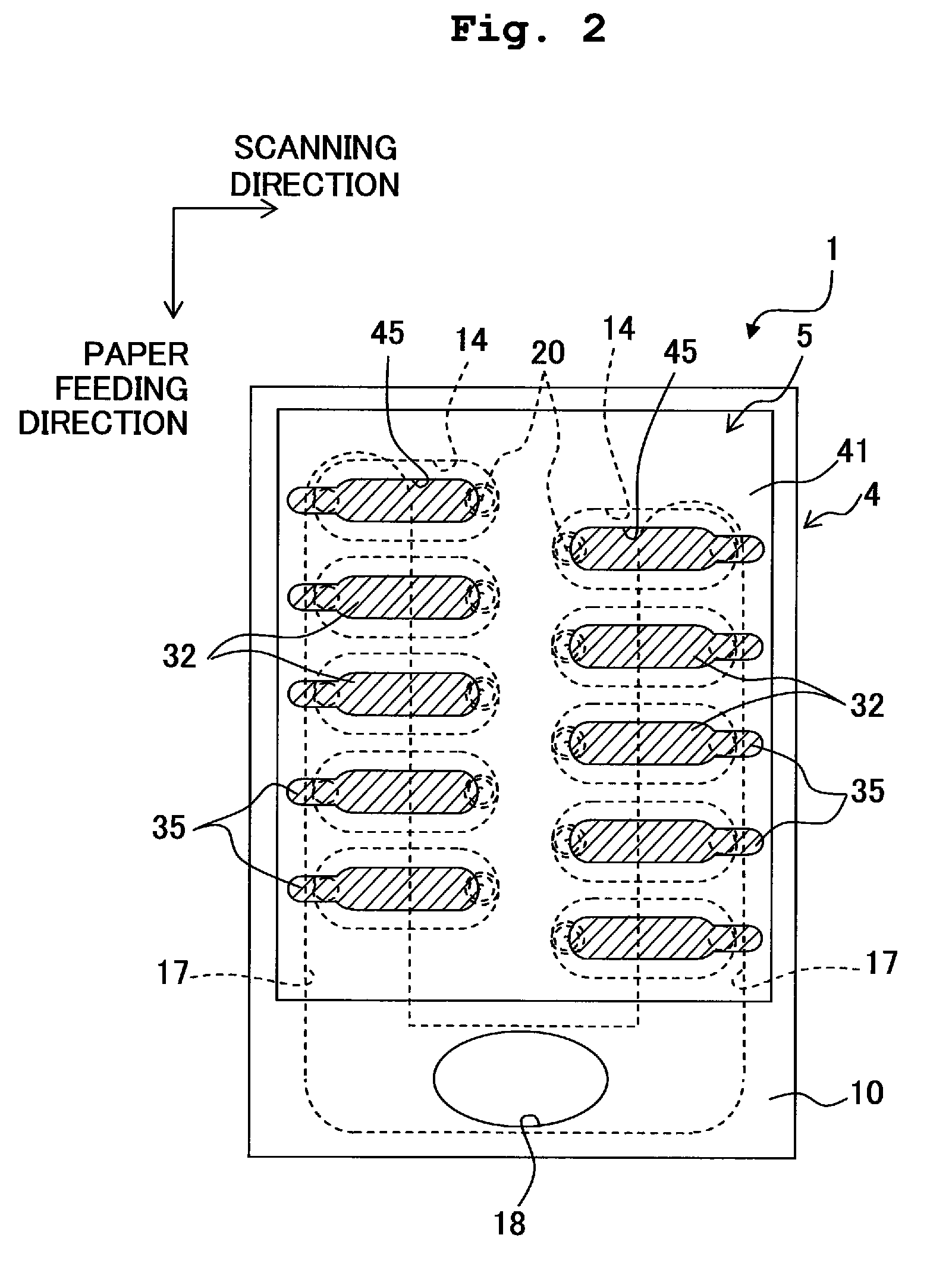

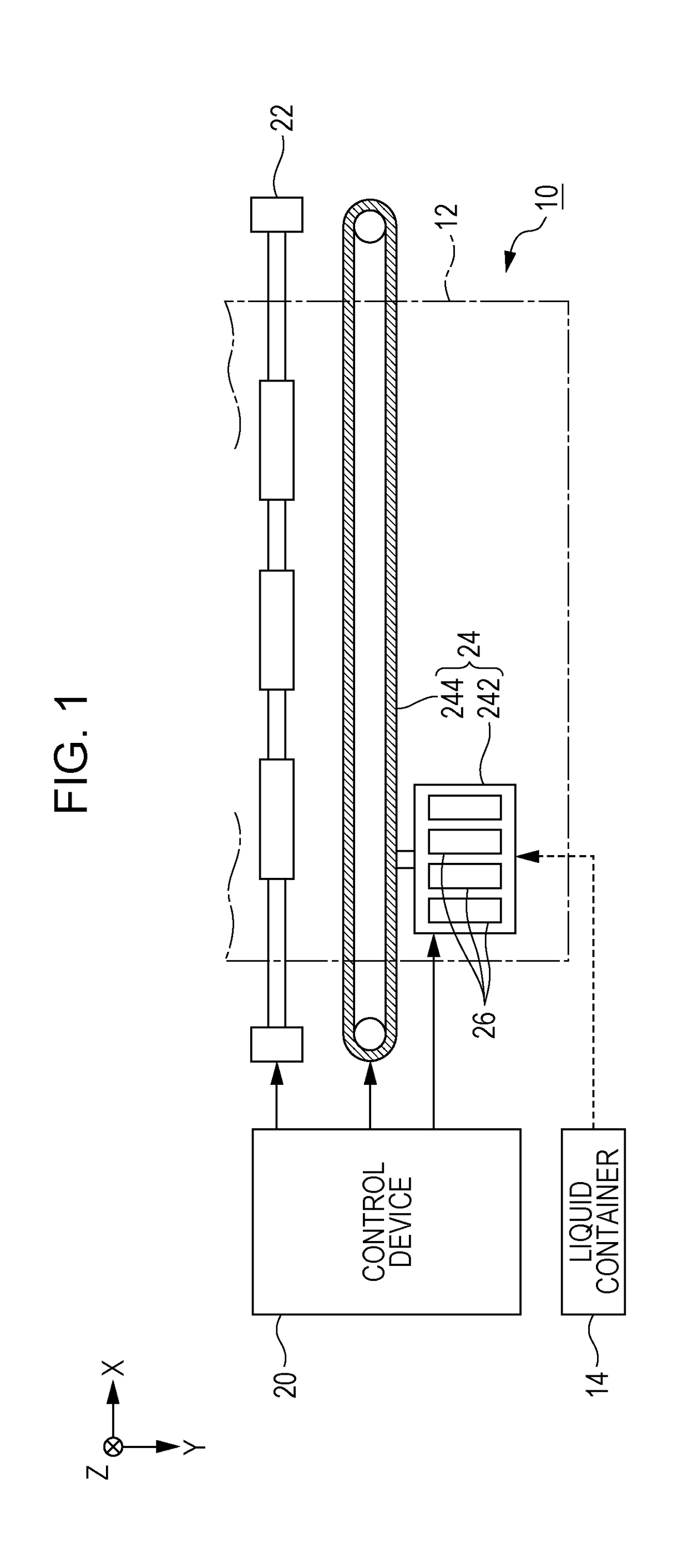

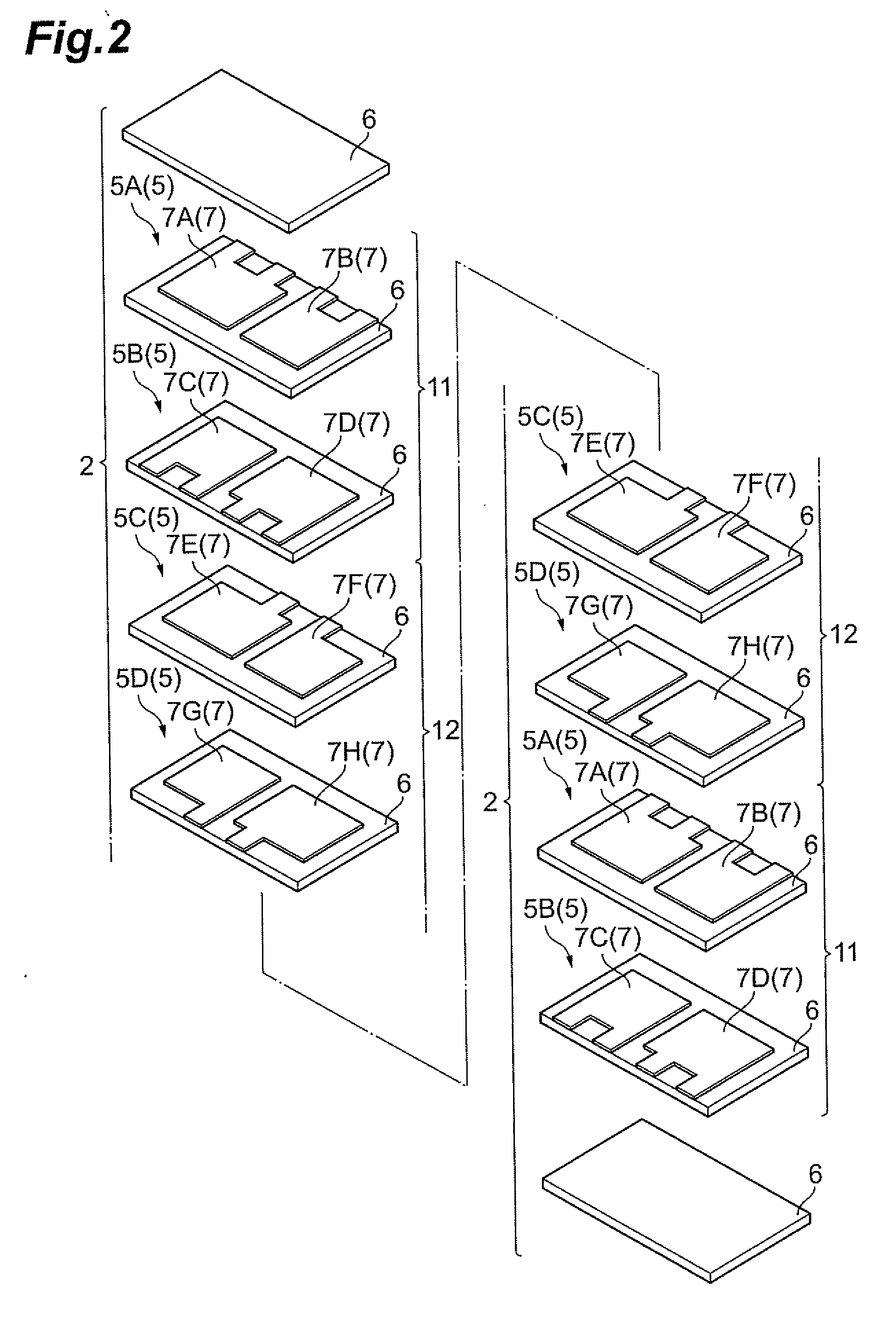

Method for manufacturing piezoelectric actuator, method for manufacturing liquid transporting apparatus, piezoelectric actuator, and liquid transporting apparatus

ActiveUS7980680B2Avoid damageStress relief concentrationPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsEngineering

Owner:BROTHER KOGYO KK

Surface mounting structure for electronic component

InactiveUS20080006918A1Avoid generatingInhibit growthPrinted circuit assemblingFinal product manufactureSurface mountingEngineering

A surface mounting structure for an electronic component is provided. A lead of the electronic component is soldered to a land including a first land portion to which a bottom surface of the lead is soldered, and a second land portion having a greater width than the first land portion and to which an end portion of the lead is soldered. The structure ensures stability and reliability while utilizing a small area of a circuit board.

Owner:SAMSUNG ELECTRONICS CO LTD

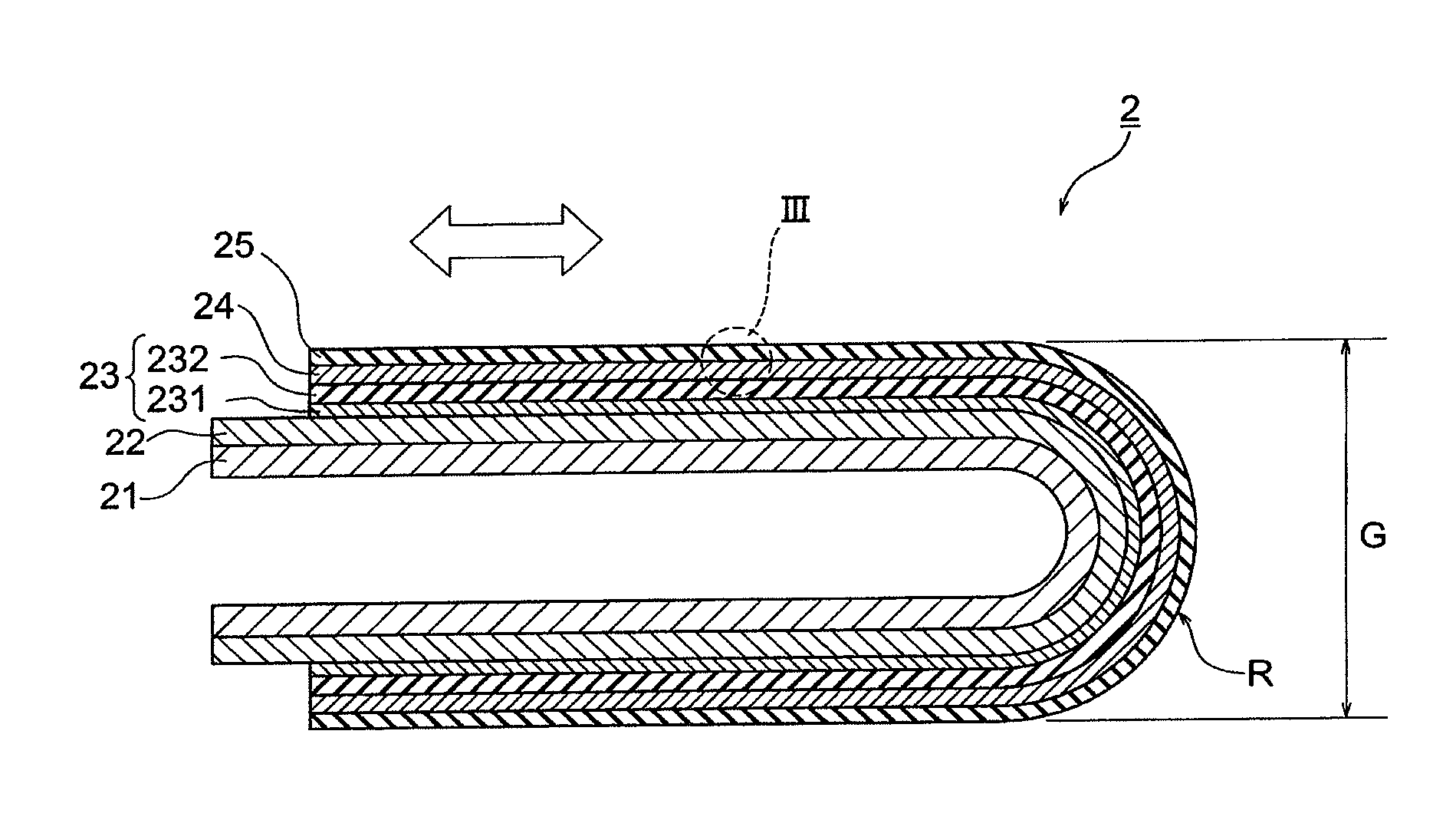

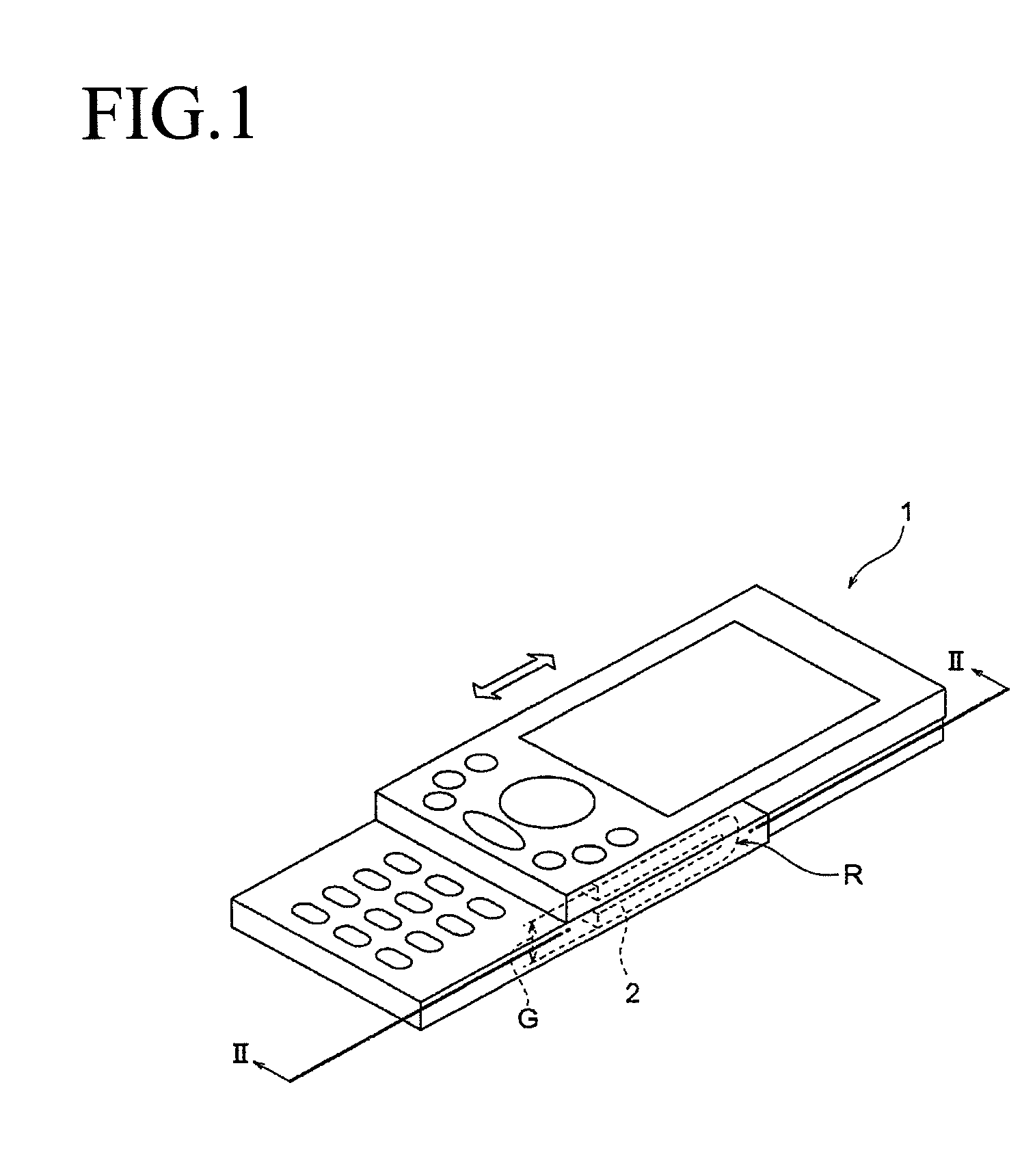

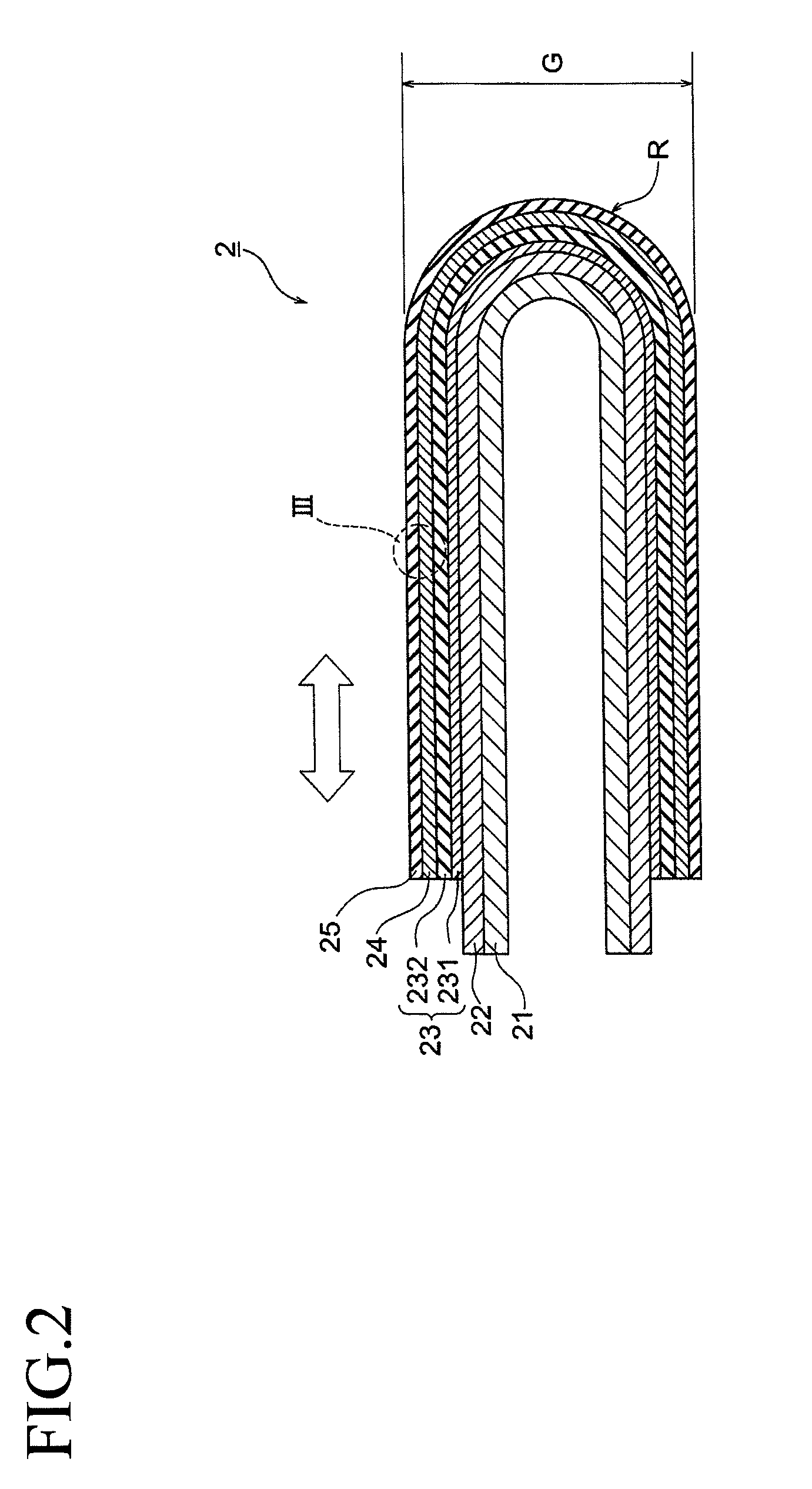

Flexible printed board and method of manufacturing same

ActiveUS8809687B2Stress concentrationImprove bending performanceMagnetic/electric field screeningCross-talk/noise/interference reductionEngineeringElastic modulus

[Object]To provide a flexible printed board improved in bendability.[Means for solving]The flexible printed board 2 comprises: an insulating substrate 21; a circuit wiring 22 laid on the insulating substrate 21; a circuit protection layer 23 laid on the circuit wiring 22; a shield conductive layer 24 laid on the circuit protection layer 23; and a shield insulating layer 25 laid on the shield conductive layer 24, and is characterized by meeting the following Expression (1).0.75≦E2 / E1≦1.29 Expression (1)Note that E1 denotes the tensile elastic modulus of the shield conductive layer 24 and E2 denotes the tensile elastic modulus of the shield insulating layer 25.

Owner:THE FUJIKURA CABLE WORKS LTD

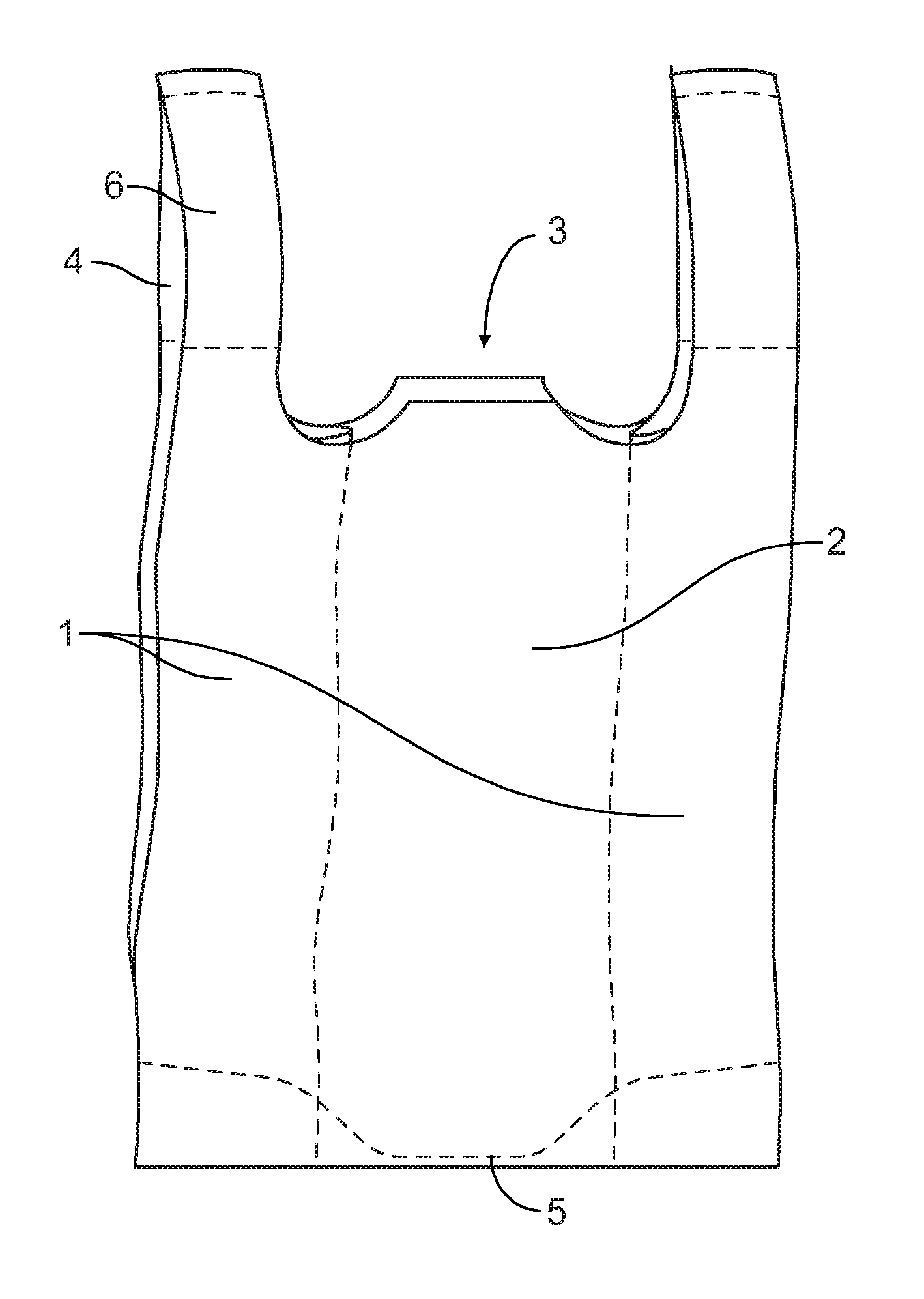

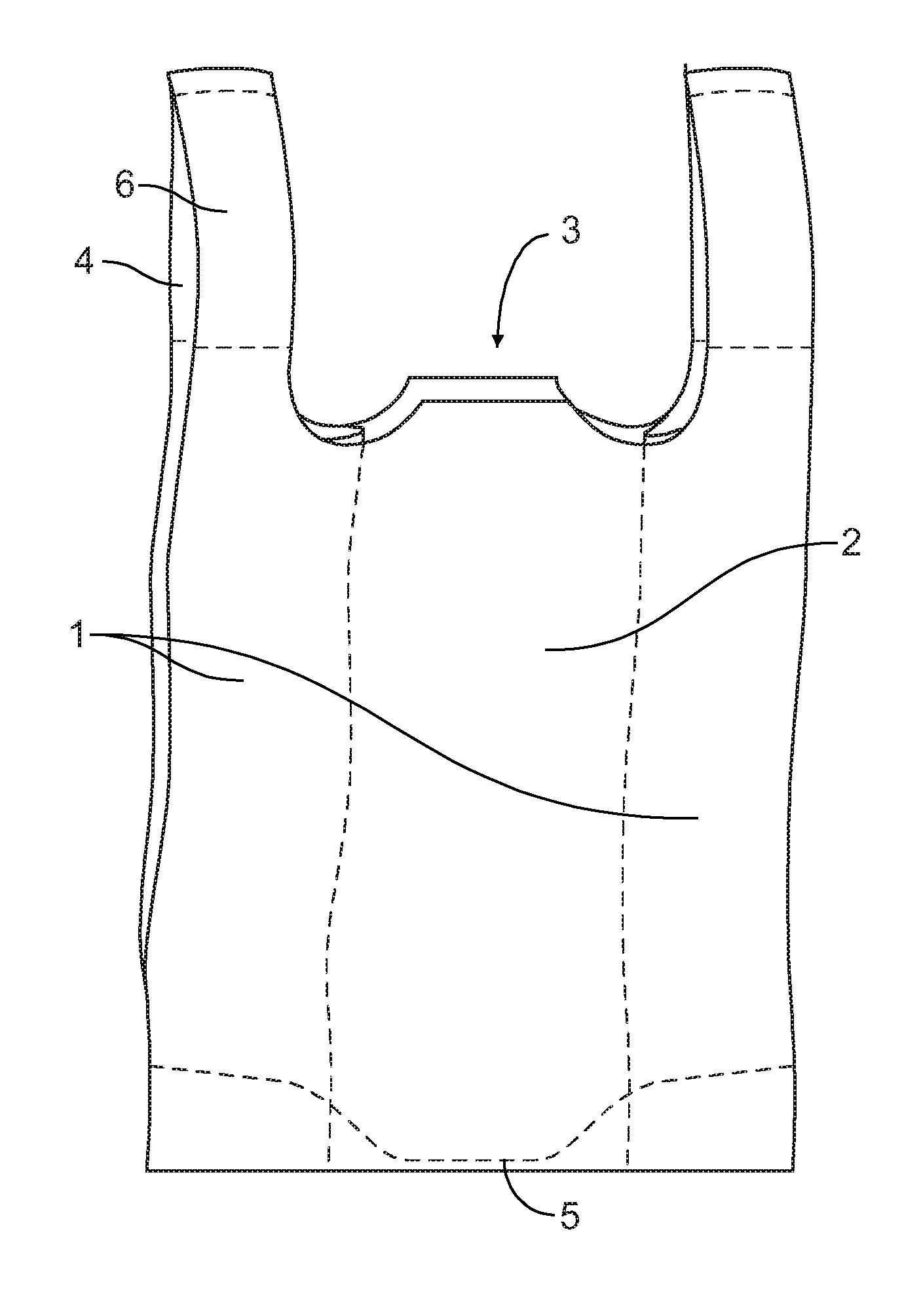

Plastic film bag to increase load bearing capacity

A plastic bag includes a plastic bag body with 4-layer gussets on two sides and 2-layer film in the middle. The plastic bag body is provided with a curved hot-seal line near a bottom edge of the bag body. The curved hot seal line turns upward on two sides and is recessed in the middle. Since plastic bags with the structure referred to herein eliminate a stress concentration at a bottom hot-seal location, such plastic bags have increased load-bearing capacity.

Owner:IPS INDS

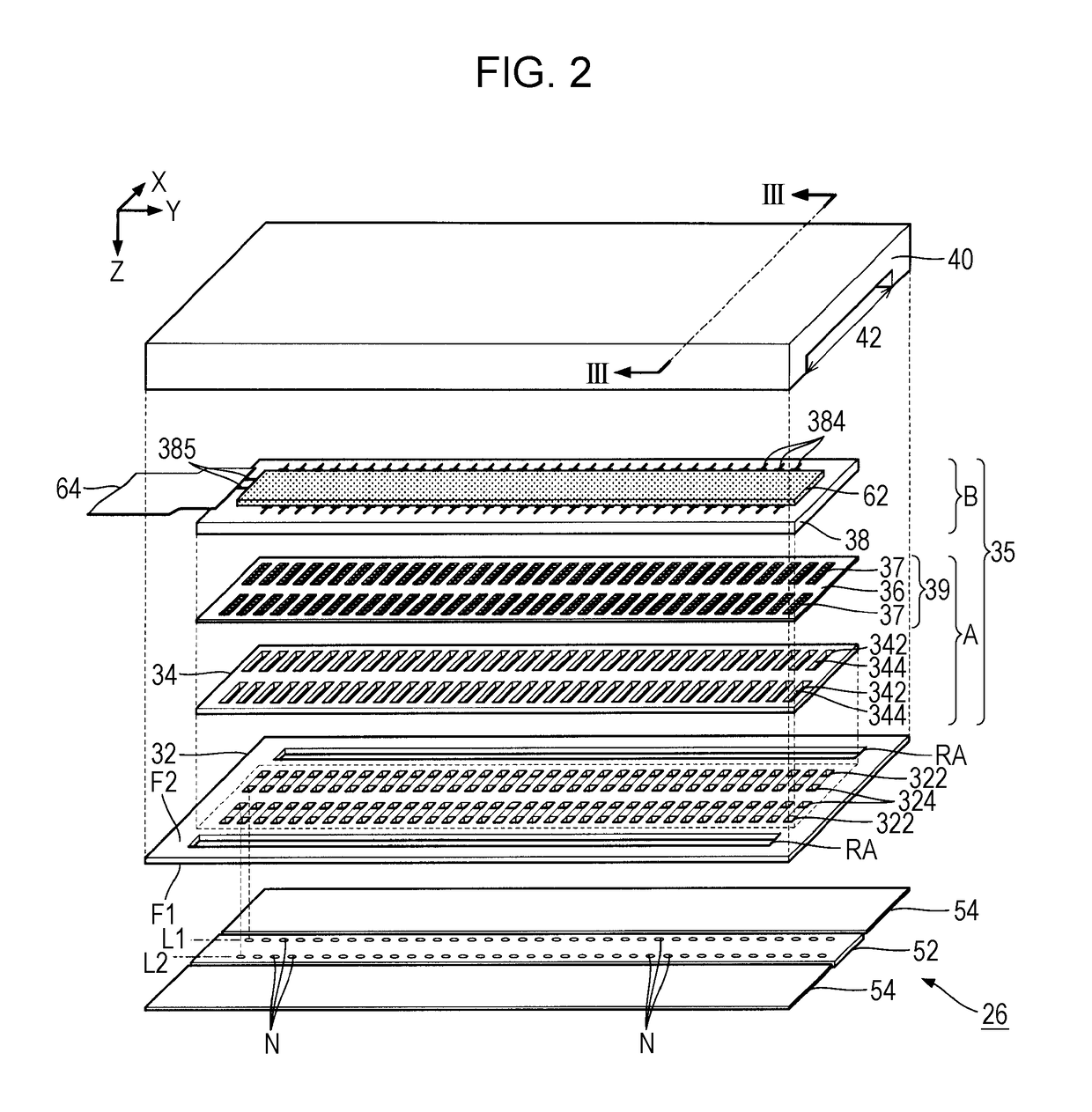

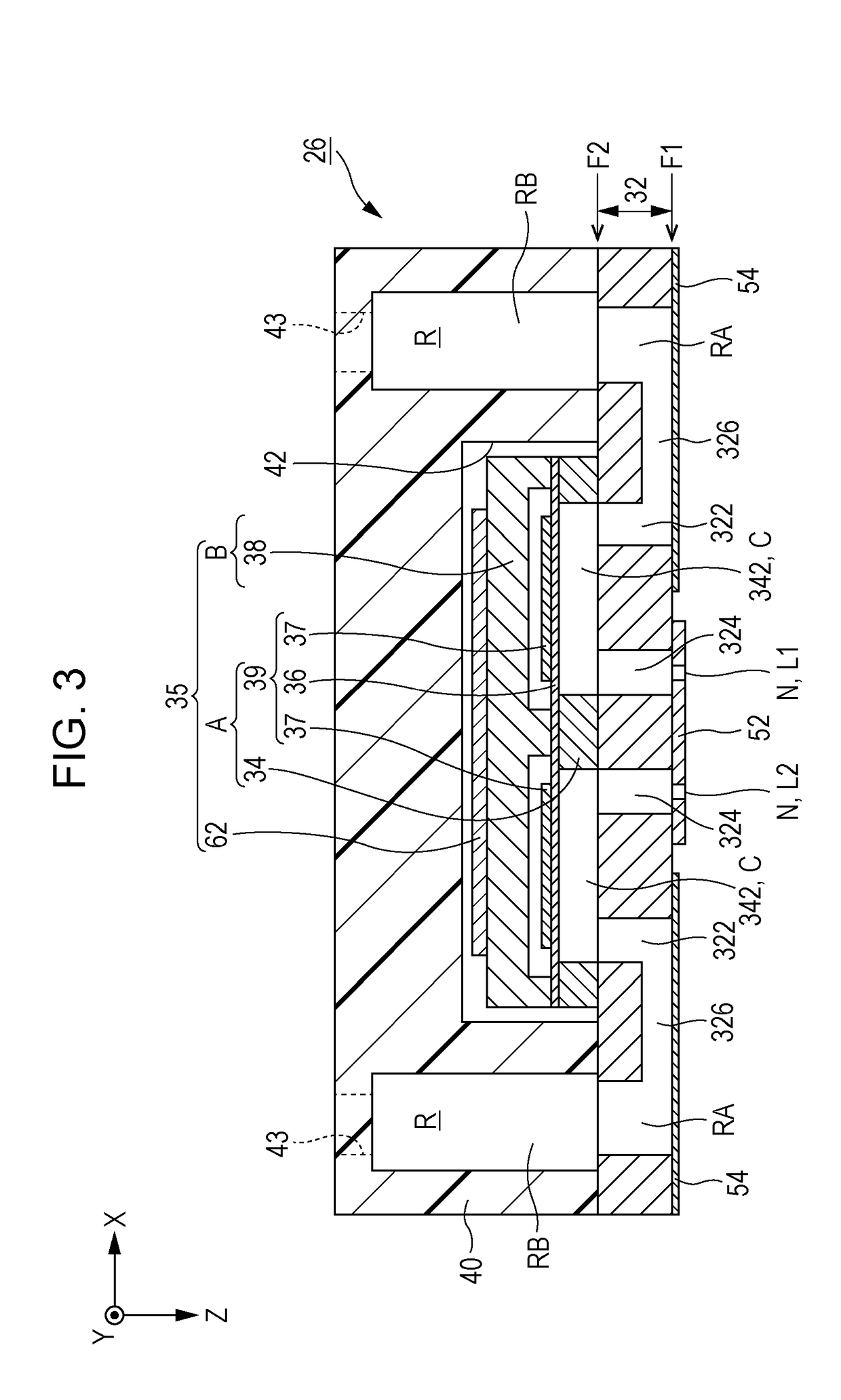

Piezoelectric device, liquid discharging head, and liquid discharging apparatus

InactiveUS20180342665A1Suppress generationLittle strengthInking apparatusMechanical vibrations separationEngineeringCrystal plane

There is provided a piezoelectric device including a pressure chamber, a piezoelectric element, and a diaphragm disposed between the pressure chamber and the piezoelectric element. The diaphragm has a crystal plane of an anisotropic single crystal silicon base of which a Poisson's ratio varies according to a direction in the crystal plane. In a vibration region of the diaphragm, which overlaps the pressure chamber in plan view, the Poisson's ratio of the diaphragm in a short axis direction of the smallest rectangle, which includes the vibration region, is included in a range of a minimum value of the Poisson's ratio in the crystal plane inclusive to an average value of the Poisson's ratios in the crystal plane exclusive.

Owner:SEIKO EPSON CORP

Power transmission system

InactiveUS7922611B2Avoid stress concentrationIncreased durabilityYielding couplingGearingElectric power transmissionDrivetrain

A power transmission system including an integrally molded hub and elastic member, where stress is inhibited from concentrating at the gate marks remaining after integral molding. In a pulley driven by a belt, a plastic pulley side relief section 1a provided at a pocket section of the pulley and a plastic hub side relief section provided on an iron outer ring of the hub engaged at the pocket section whereby power is transmitted from the pulley to the shaft. The hub side relief section and outer ring forming parts of the hub, the iron inner hub to be fastened to the shaft, and the plastic cylindrical part are integrally molded so that the gate mark for plastic injection is formed near to or further to the outer circumference of the outer ring.

Owner:DENSO CORP

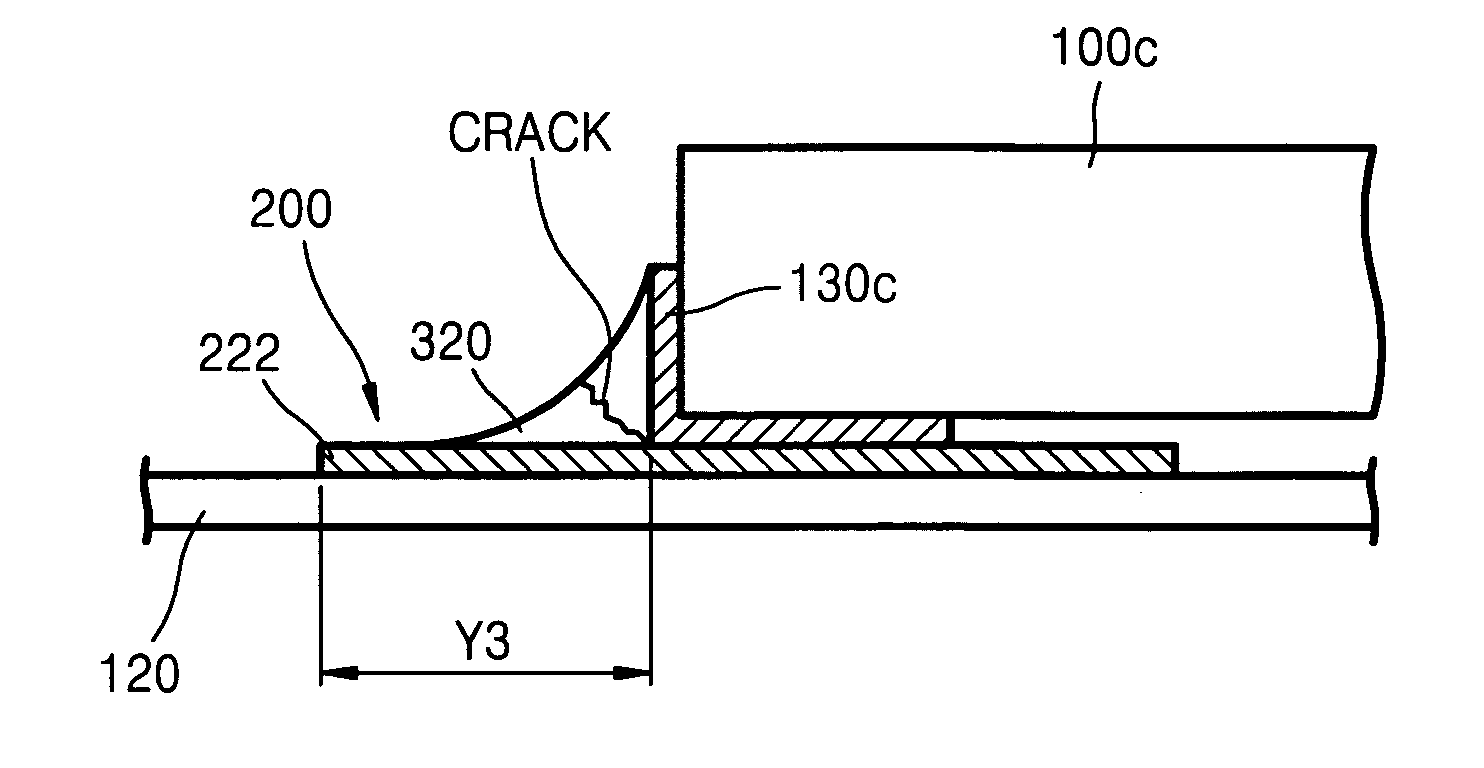

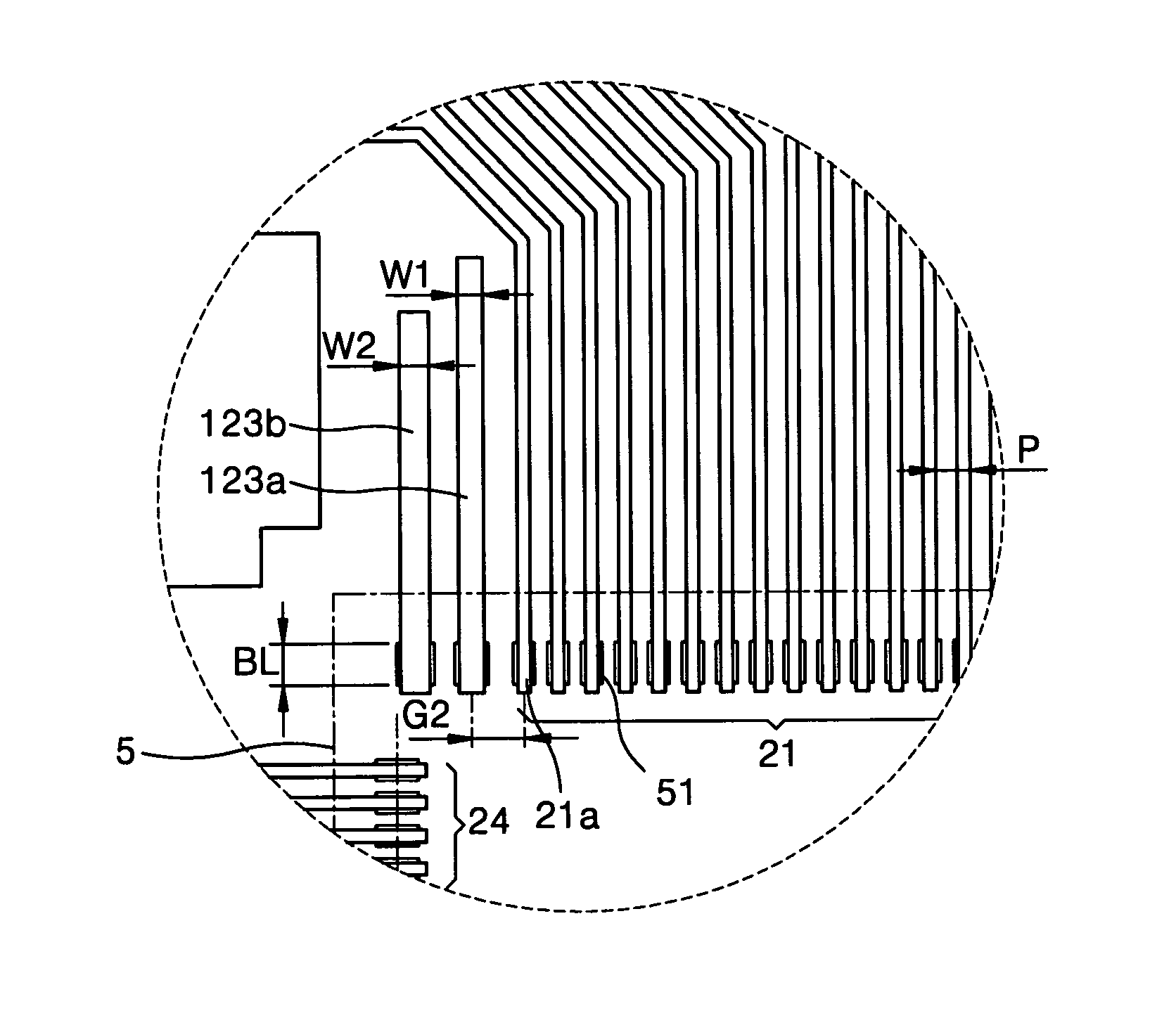

Printed circuit board having structure for relieving stress concentration, and semiconductor chip package equipped with the same

InactiveUS7804693B2Stress relief concentrationElectrically conductive connectionsFinal product manufactureStress concentrationSemiconductor package

There are provided a printed circuit board having a structure for relieving a stress concentration on an outer most lead of leads, due to a difference in thermal expansion coefficients between the semiconductor device and the printed circuit board when the semiconductor device is mounted on the printed circuit board. The printed circuit board includes an inner lead portion to be connected to the semiconductor device. The inner lead portion includes a plurality of leads, arranged in parallel with a same pitch in a predetermined area, and additional leads located near both ends of the predetermined area in which the plurality of leads are arranged in parallel, respectively, wherein each of the plurality of leads has a pitch smaller than 30 μm and a width of the additional lead is wider than 20 μm. There are also provided a semiconductor chip package equipped with the printed circuit board according to the present invention.

Owner:HAESUNG CO LTD

Multilayer capacitor array

ActiveUS20090201627A1Stress concentration is thereby relievedHigh ESRFixed capacitor electrodesFixed capacitor dielectricStress concentrationCapacitance

A multilayer capacitor array achieves a high ESR because terminal conductors to which internal electrodes in capacitance sections are connected in parallel are connected in series through internal electrodes in ESR control sections to external electrodes. Since in the multilayer capacitor array the internal electrodes extend as far as a boundary between capacitor element portions, electrostriction occurs in an entire laminate including a region near the boundary between the capacitor element portions, with application of a voltage from the outside. Therefore, concentration of stress due to electrostriction is avoided, so as to suppress occurrence of cracking or the like.

Owner:TDK CORPARATION

Master cylinder and method of manufacturing the same

InactiveUS7866155B2Stress relief concentrationAvoid damageRotary clutchesMetal-working apparatusStress concentrationCurve shape

An object of the present invention is to provide a master cylinder capable of controlling an increase in an intruding amount of a cup seal while relieving a stress concentration therein to thereby prevent the cup seal from being damaged. Provided is a master cylinder in which a piston is moved in slidable contact with an inner circumference of a cup seal held in a cylinder main body so as to pressurize a brake fluid in a pressure chamber formed of the piston and the cylinder main body, wherein an annular wall configured integrally with the cylinder main body is provided behind the cup seal. Further, a chamfered portion having a curved shape in a cross-section taken along a diameter direction of the cylinder main body is provided between the annular wall and a cylinder wall to which the piston is facing. One end of the chamfered portion is formed continuously so that a tangent thereto is in line with the annular wall, and the other end of the chamfered portion is formed to constitute a flexed portion in combination with the cylinder wall.

Owner:HITACHI LTD

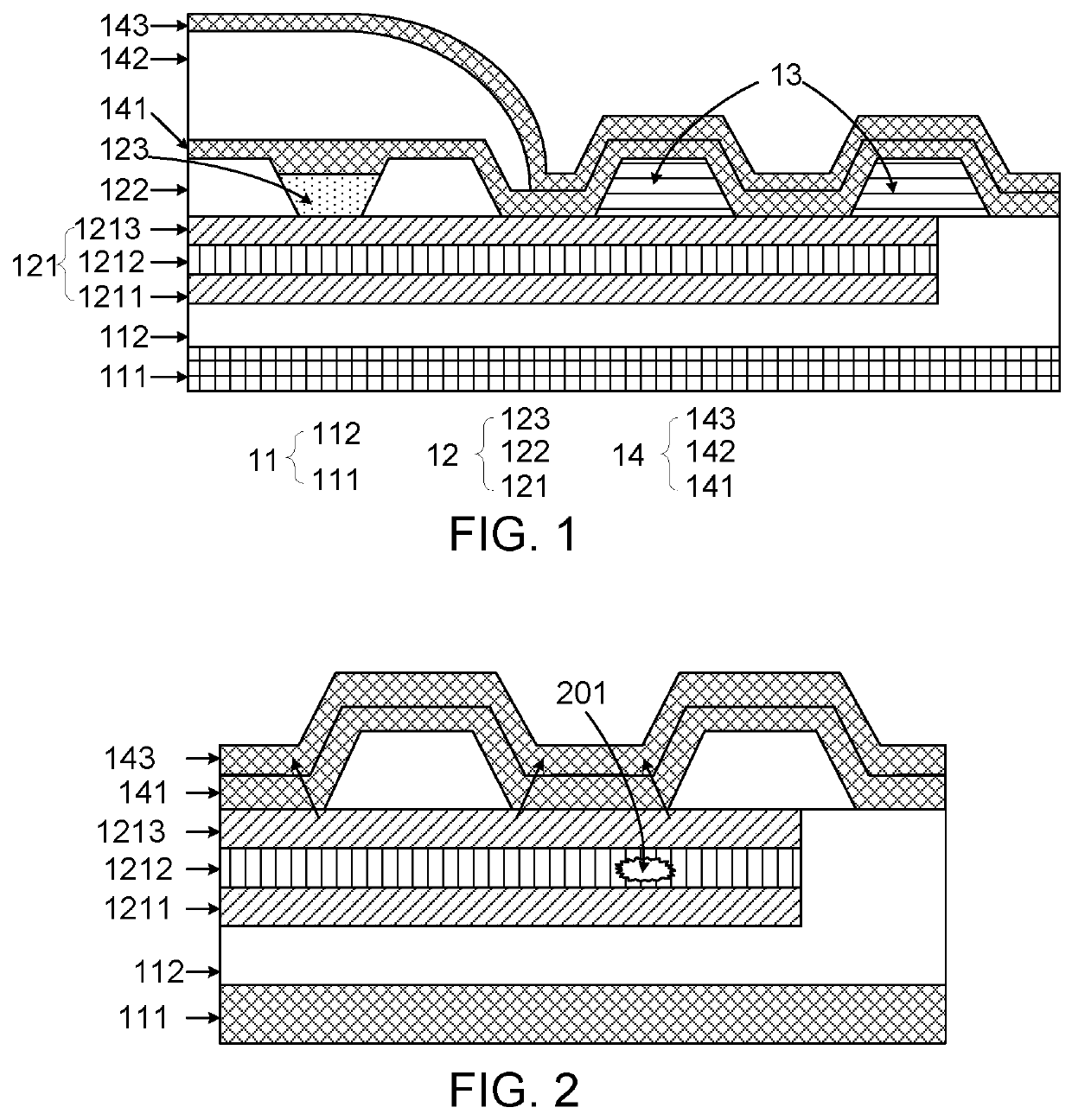

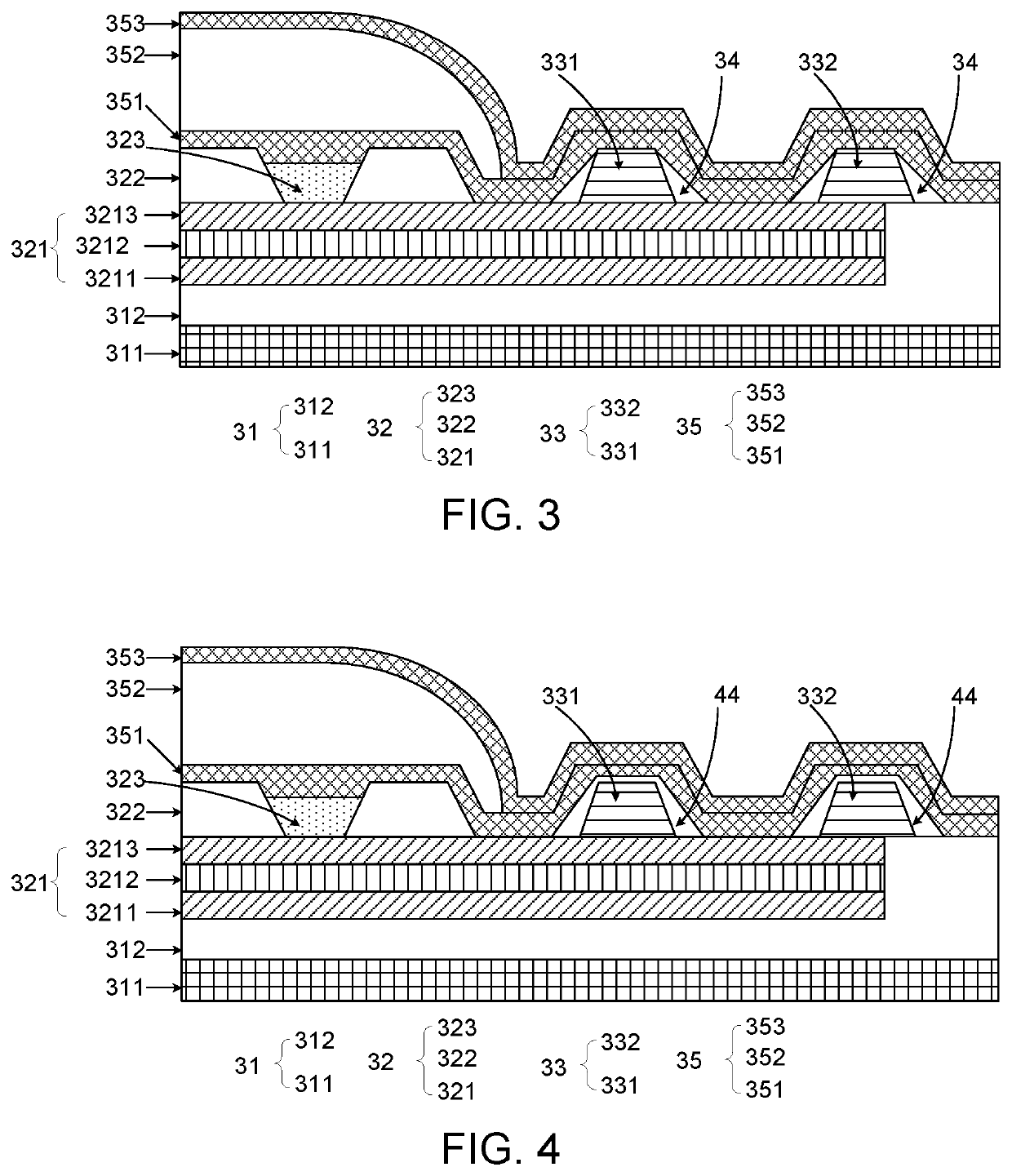

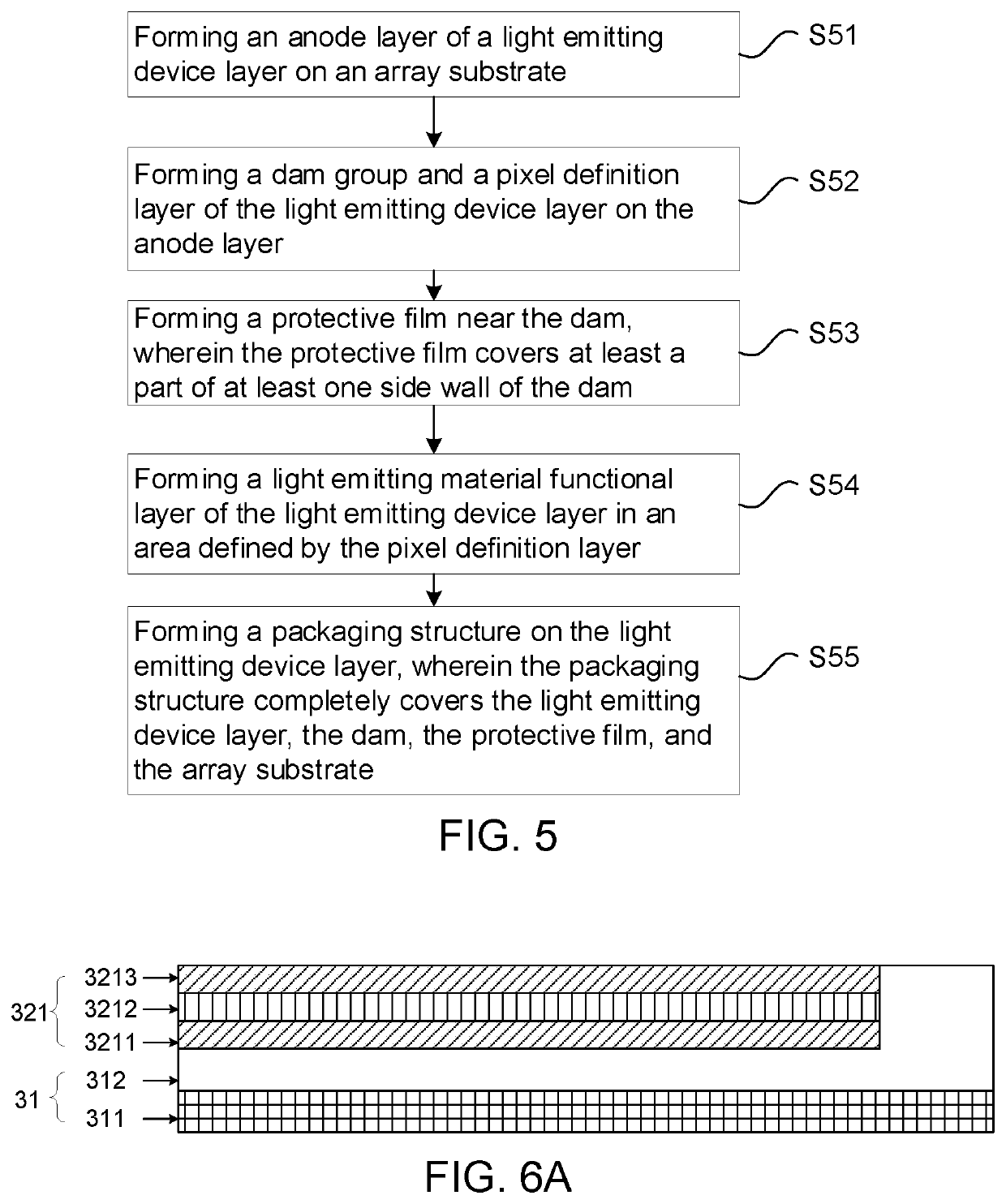

Flexible display panel and manufacturing method thereof

ActiveUS20210408460A1Slow down slopeReduce stress concentration effectsSolid-state devicesSemiconductor/solid-state device manufacturingFlexible displayMechanical engineering

A flexible display panel and a manufacturing method thereof are provided. By filling a protective film in a stress concentration area of an inorganic film layer at a corner of a dam, a slope of a side wall of the dam can be effectively reduced, and stress concentration effect of the inorganic film layer in an upper packaging structure is reduced to a certain extent. When the protective film is subjected to stress, it can effectively relieve the stress and weaken or even eliminate stress effect of the packaging structure on an anode layer at a corner of the dam.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com