Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Smooth paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of transparent nano-cellulose paper with fluorescence properties

InactiveCN104130429AEvenly dispersedImprove stabilityLuminescent compositionsPolymer scienceCellulose fiber

The invention discloses a preparation method of a transparent nano-cellulose paper with fluorescence properties. According to the method, TEMPO (2, 2, 6, 6-tetramethylpiperidine-1-oxyl) is employed to perform oxidation modification on natural nano-cellulose fiber, and the coordination mechanism of rare earth complexes is utilized for the first time to graft a rare earth complex with fluorescence properties to the modified nano-cellulose fiber in situ so as to obtain a nano-cellulose sol with fluorescence properties, and finally through a high pressure filtration method, the self-assembled fluorescent transparent natural nano-cellulose paper can be synthesized by one step. The transparent nano-cellulose paper with fluorescence properties provided by the invention has the characteristics of naturalness, environmental protection, no toxicity or harm, high light transmission, good flexibility, easy excitation, and advanced synthetic process, etc.

Owner:SHANGHAI UNIV

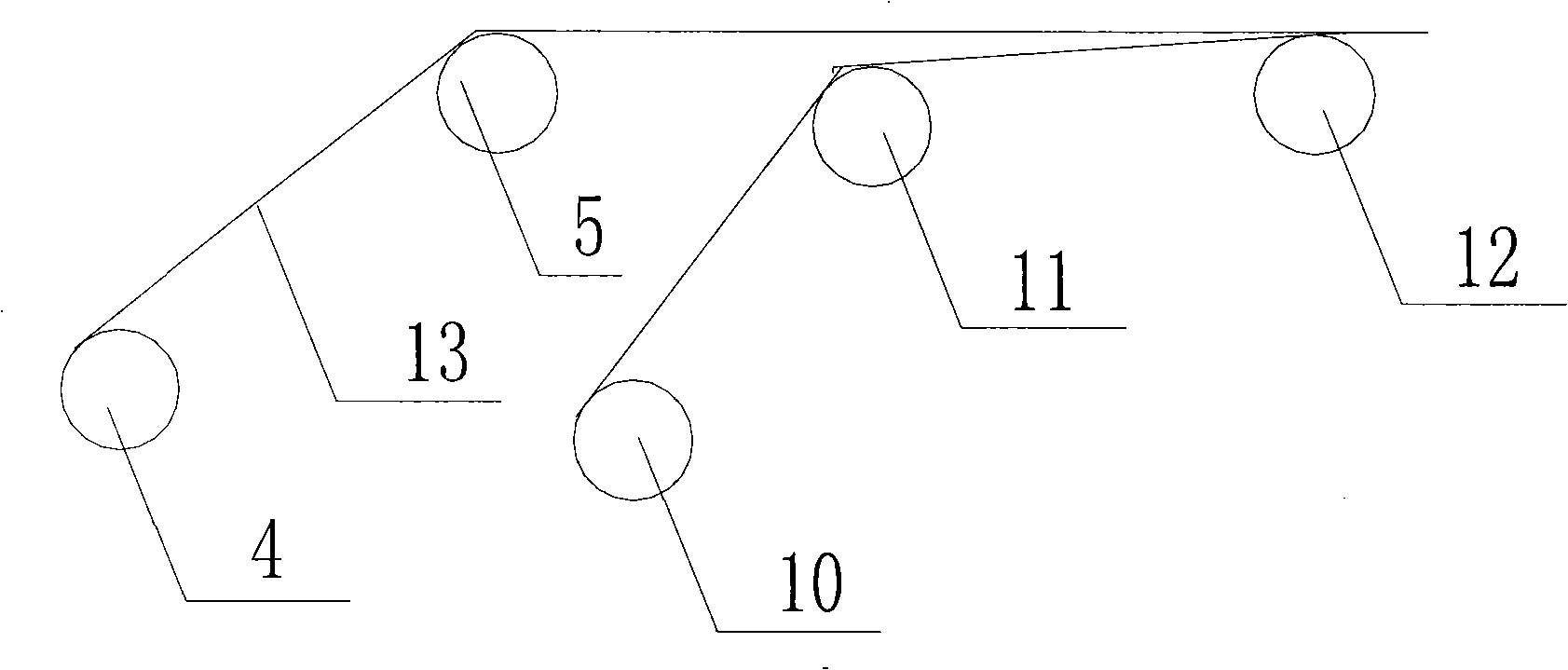

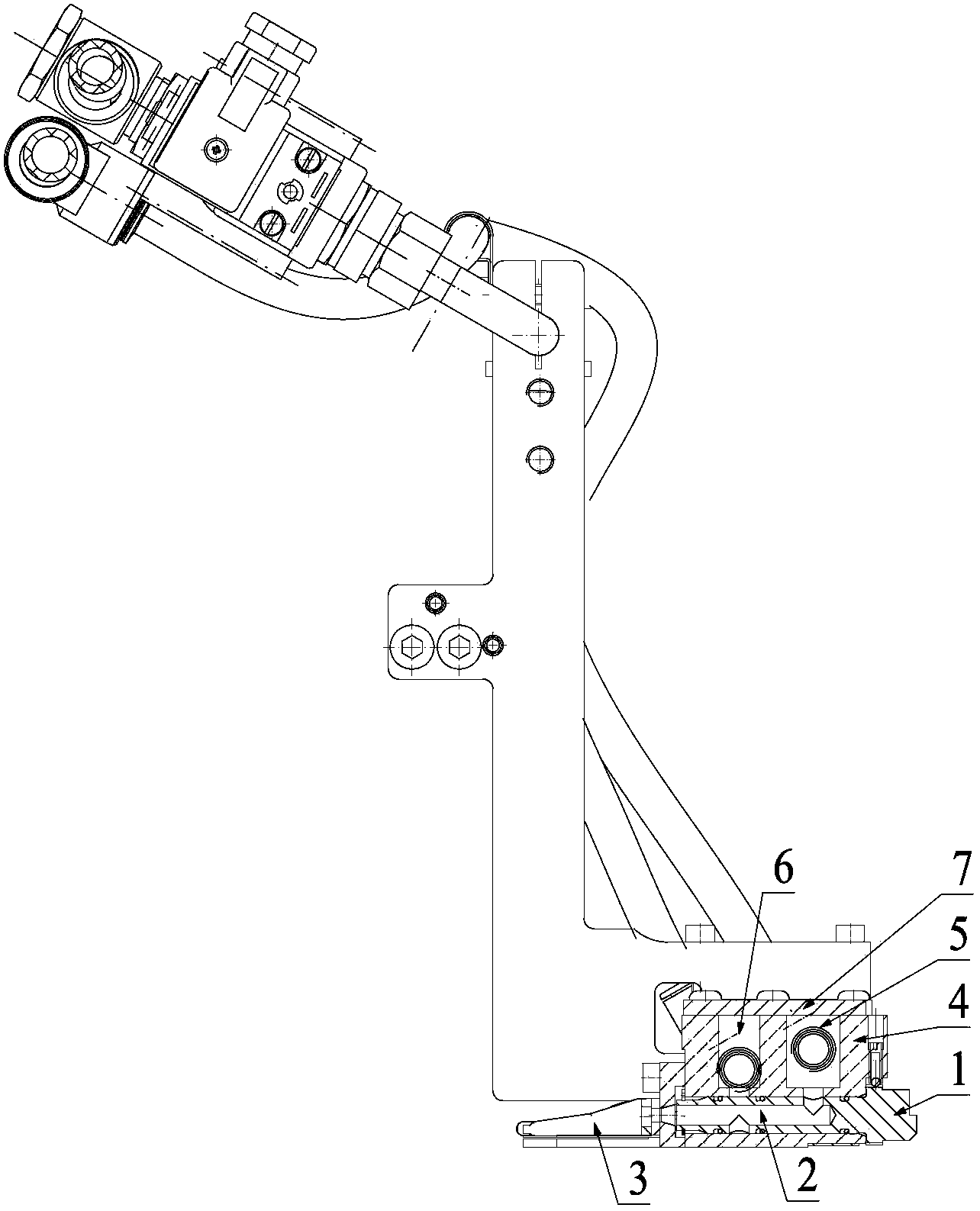

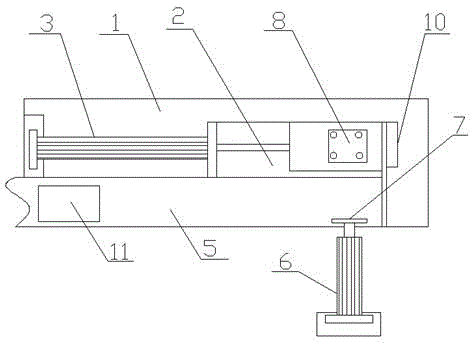

Corrugated paper forming and manufacturing system

ActiveCN110712394ASmooth paperUniform thicknessLiquid surface applicatorsMechanical working/deformationAdhesive glueMechanical engineering

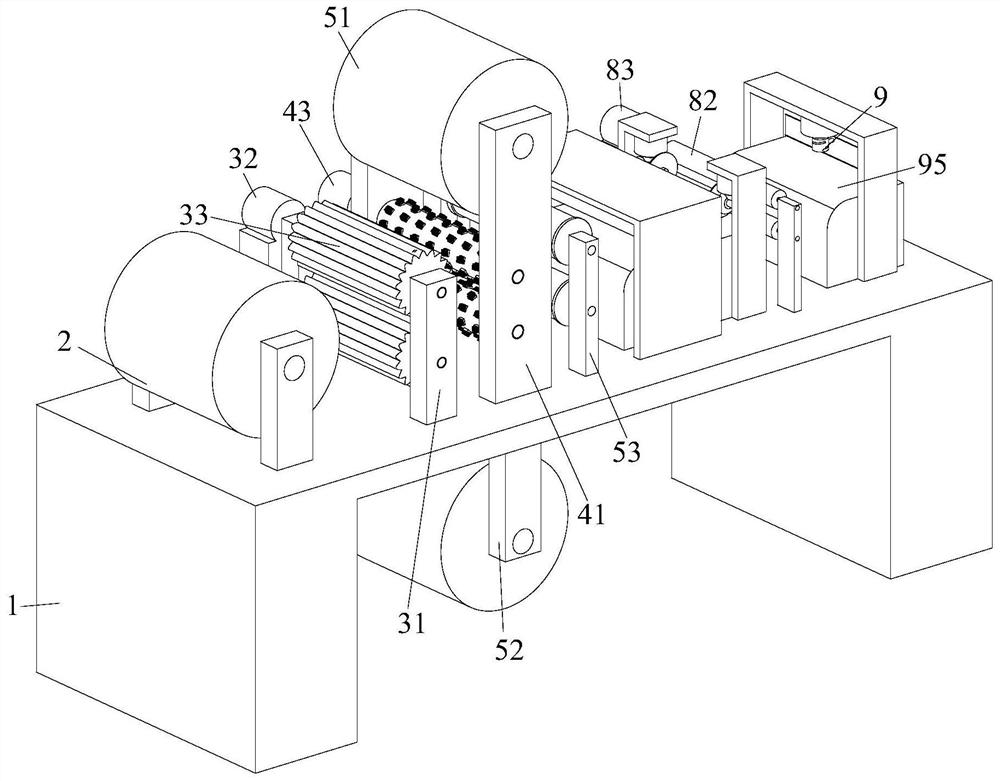

The invention relates to a corrugated paper forming and manufacturing system which comprises a mounting table, a core paper bracket, an indentation device, a gluing device, a surface paper feeding device, a pressing device, two edge cutting devices, a traction device and a cutting device; and the mounting table is sequentially provided with the core paper bracket, the indentation device, the gluing device, the surface paper feeding device, the pressing device, the two edge cutting devices, the traction device and the cutting device from left to right. By adopting the corrugated paper forming and manufacturing system provided by the invention, the problems that the paper surface of corrugated paper processed by existing corrugated paper processing equipment is uneven, is inconsistent in thickness and has phenomena of wrinkles, cracks and holes as well as the problems that the processed corrugated paper is not closely attached to surface paper, a large quantity of glue is wasted, and themanufacturing cost is increased and the like are solved.

Owner:东莞市世昌智能制造科技有限公司

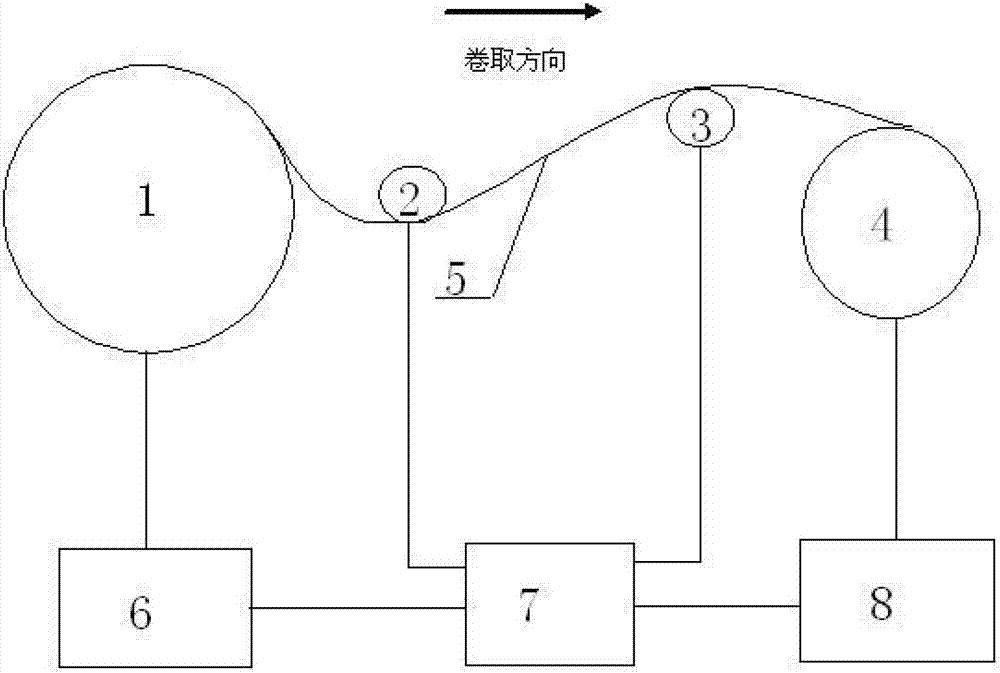

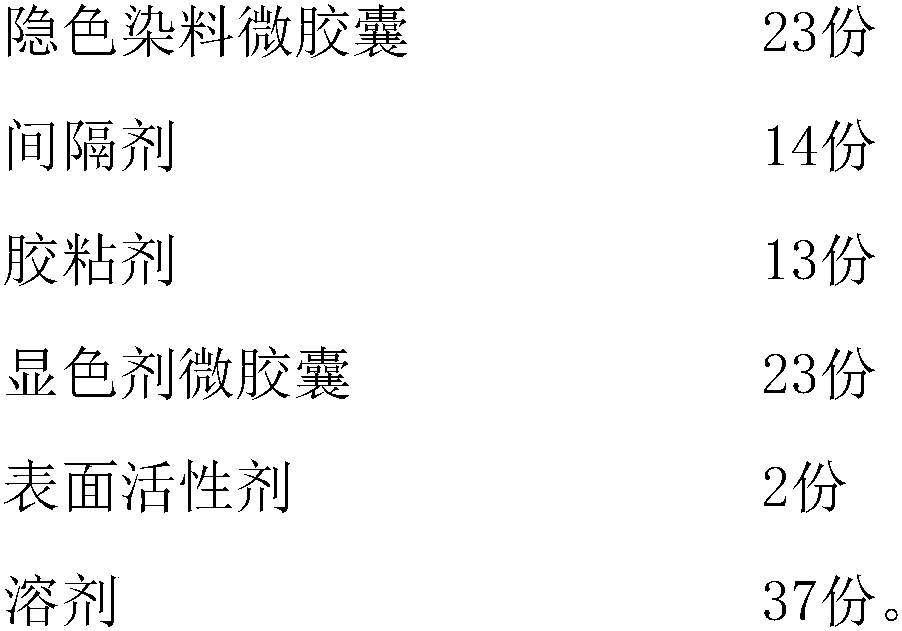

Tipping paper rewinding machine on basis of servo system

InactiveCN103043471ASmooth paperAchieve cycle regulationWebs handlingPulp and paper industryMiddle line

The invention discloses a tipping paper rewinding machine on the basis of a servo system. The tipping paper rewinding machine is characterized in that a linear speed is measured by a speed measuring roll in a tipping paper take-up procedure, real-time disc diameters of an unwinding disc and a winding disc are computed according to the real-time linear speed, a rotational speed of an unwinding motor and a rotational speed of a winding motor, and then the rotational speed of the unwinding motor and the rotational speed of the winding motor are computed according to the obtained disc diameters and a linear speed, which is given by a machine, in the tipping paper take-up procedure, and are adjusted via a central processing unit. The tipping paper rewinding machine has the advantages that circular adjustment is realized, so that the linear speed in a procedure for rolling tipping paper on the rewinding machine is consistent with the given speed, tension on the surface of the tipping paper in the take-up procedure keeps constant, disc surfaces are flat, and the winding quality is improved.

Owner:苏州市博海激光科技有限公司

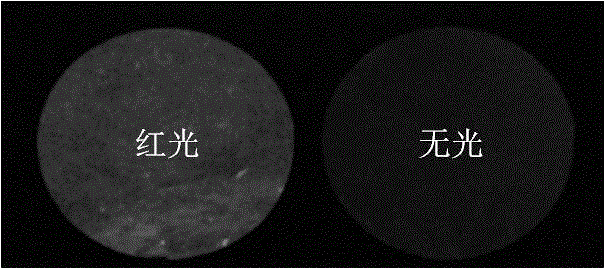

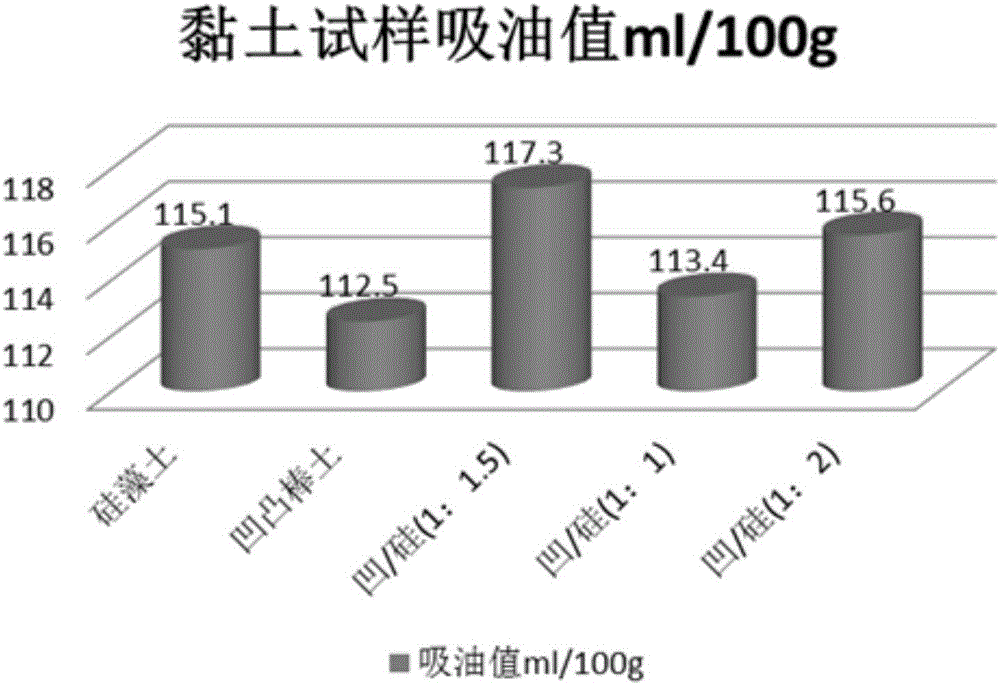

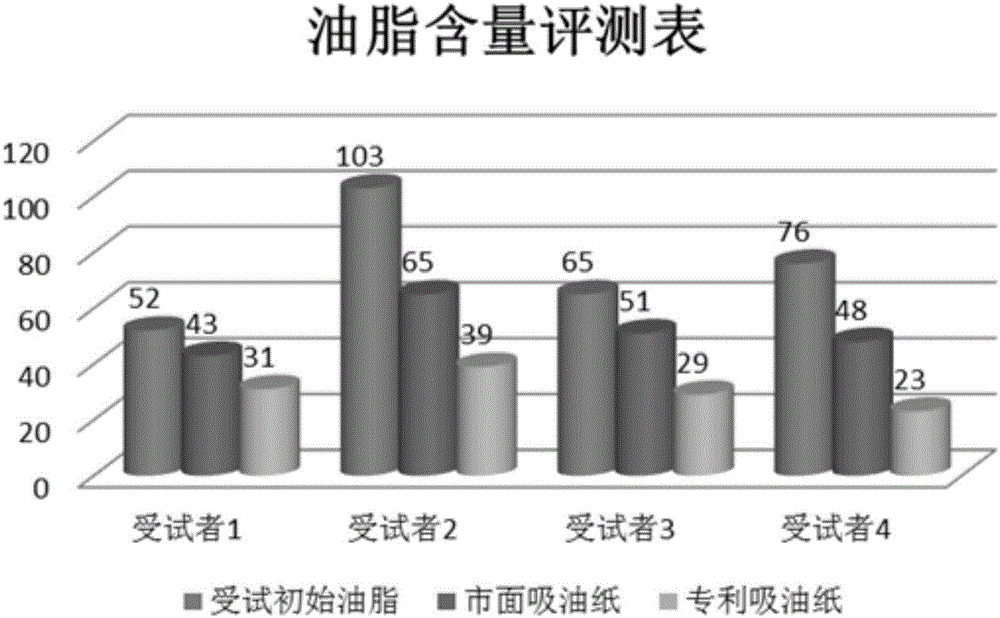

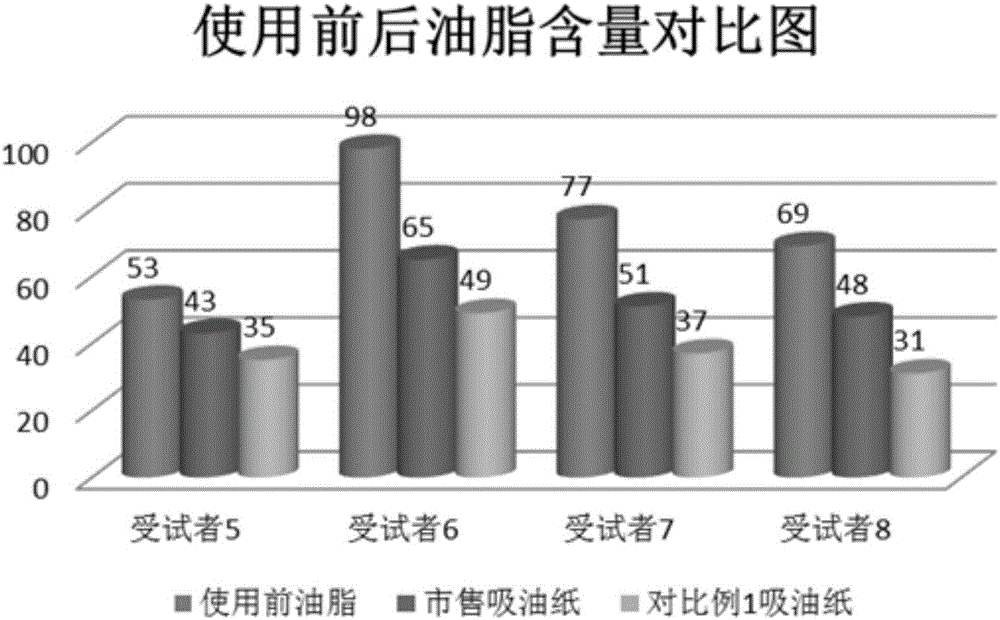

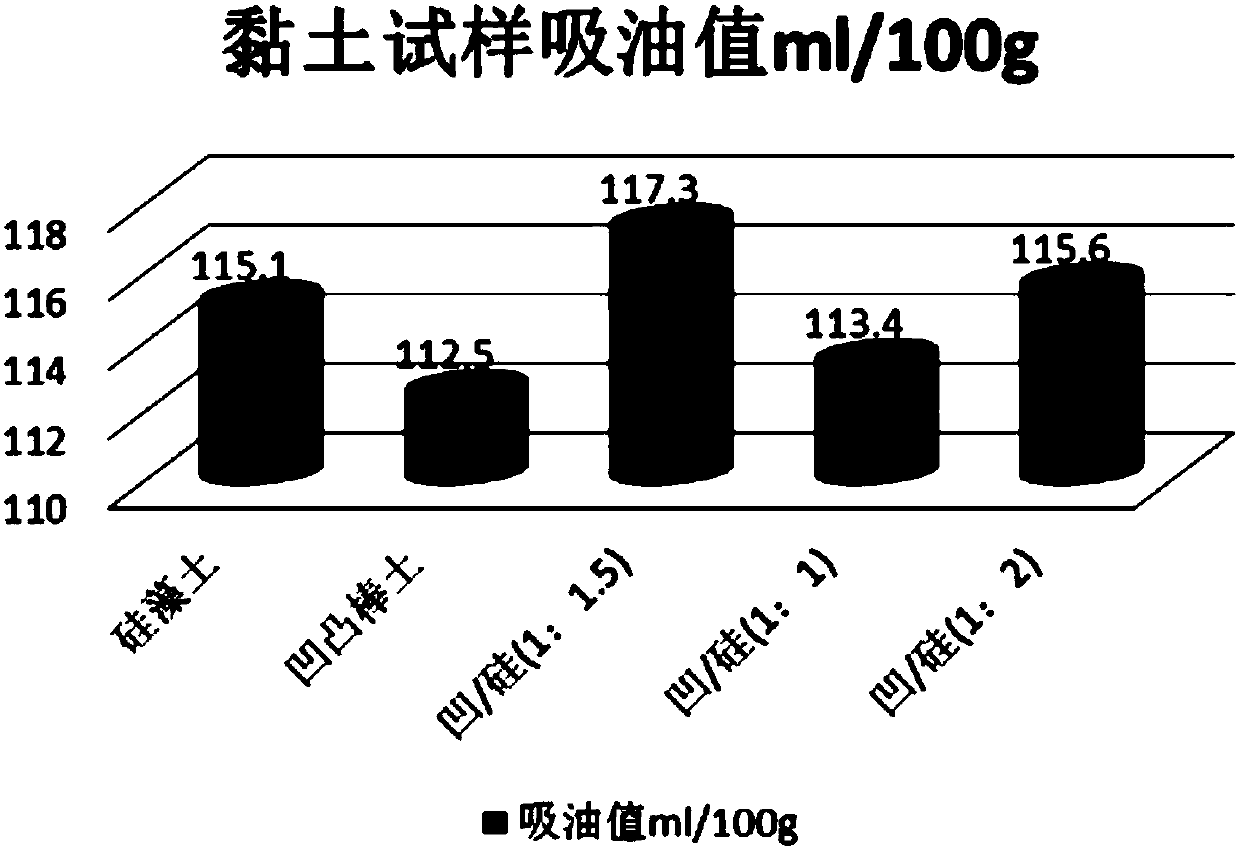

Mineral skincare oil absorbing sheet and preparation method thereof

ActiveCN106676929AGood dispersionImprove adsorption capacityAntibacterial agentsCosmetic preparationsTrace elementBacillus acnes

The invention relates to a mineral skincare oil absorbing sheet and a preparation method thereof. The mineral skincare oil absorbing sheet comprises a paper carrier, and filler which is dispersed in the paper carrier, wherein the paper carrier is made of bamboo pulp, the filler comprises attapulgite and diatomite in a weight ratio of (1 to 1) to (1 to 5), and the amount of the filler is 2 to 6 percent of the weight of the bamboo pulp. By adopting the mineral skincare oil absorbing sheet, people with oily skin can avoid the embarrassment of glossy face in the business negotiation and traveling process and can keep a clean and dry face, the potential injury of PM2.5, contaminants, heavy metals and the like attached to the face can be eliminated at any time in any place, the bacteria and microorganisms can be effectively absorbed, the potential risk of whelk and acne caused by propionibacterium acnes can be eliminated, fresh face and oil control can be realized, and people can enjoy the skin care of the mineral trace elements.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

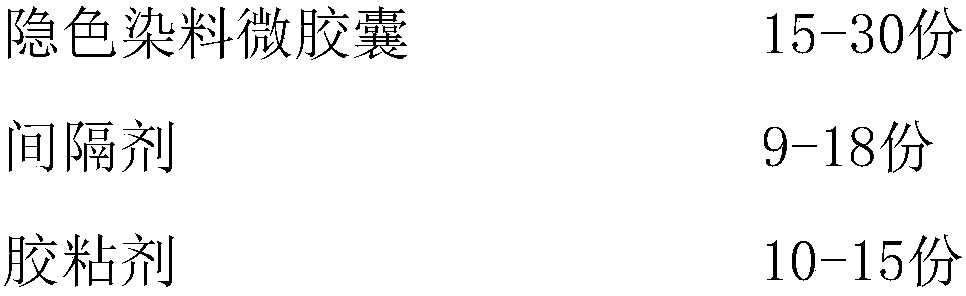

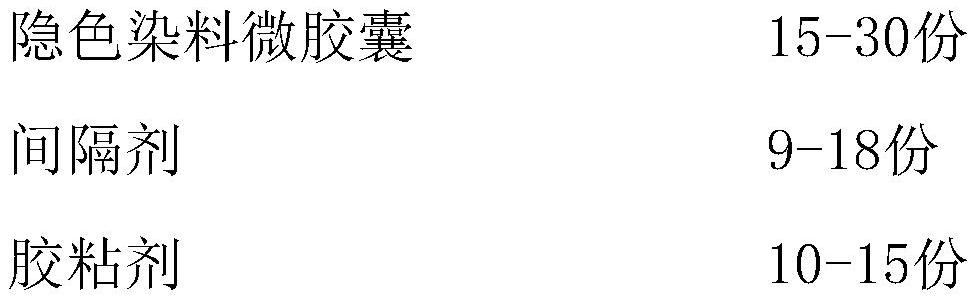

Pressure detecting paper and preparation method thereof

ActiveCN109374165ASmooth paperImprove stress resistanceForce measurement by measuring optical property variationTO-18Pulp and paper industry

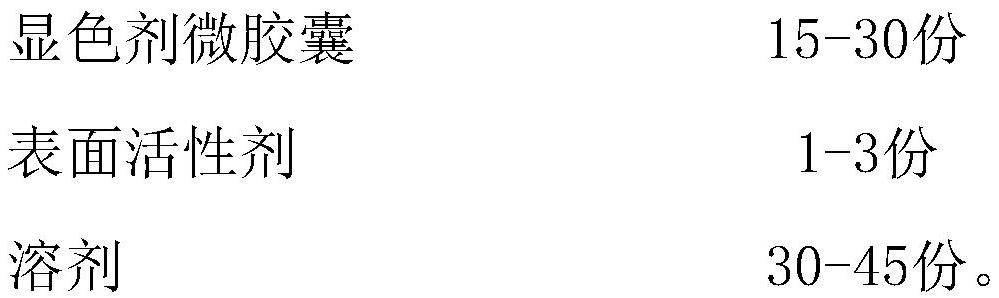

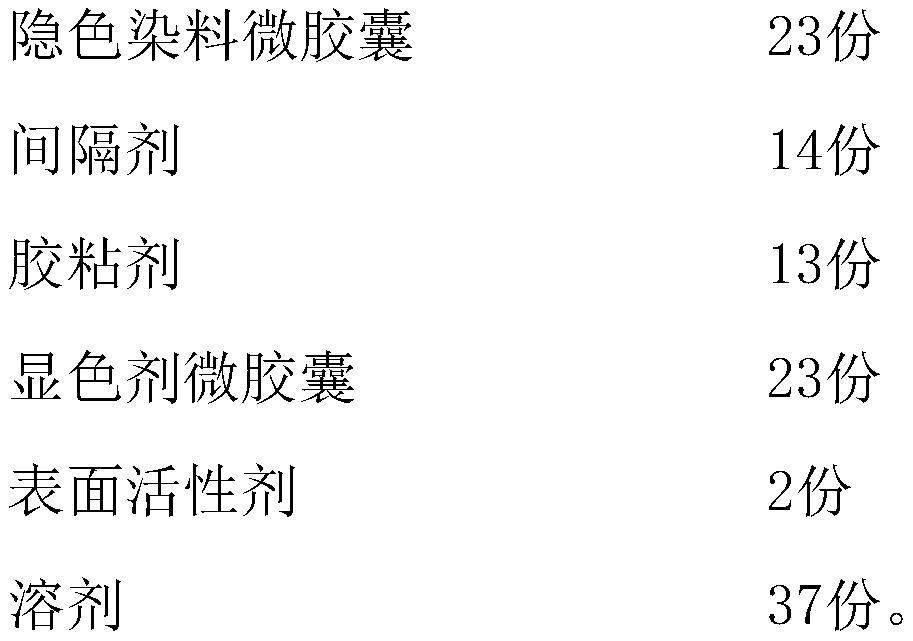

The present invention relates to the technical field of display, in particular to a piece of pressure detecting paper and a preparation method thereof. The pressure detecting paper comprises a paper layer and a pressure sensitive color developing layer adhered to the paper layer. The pressure sensitive color developing layer is prepared by the following raw materials, by weight: 15 to 30 parts ofleuco dye microcapsules, 9 to 18 parts of spacing agents, 10 to 15 parts of adhesives, 15 to 30 parts of developer microcapsules, 1 to 3 parts of surfactants, and 30 to 45 parts of solvents. The pressure detecting paper has the flat paper surface and the smooth surface; the pressure sensitive color developing layer coated on the paper layer is not easy to fall and has good staining-resistant and yellowing-resistant performances; and the color displaying density and color development speed are good.

Owner:东莞市亚马电子有限公司

Corrugated paper front edge paper feeding and digital inkjet integrated machine

ActiveCN109760420AEven by forceSmooth paperTypewritersOther printing apparatusCardboardPulp and paper industry

The invention provides a corrugated paper front edge paper feeding and digital inkjet integrated machine. The corrugated paper front edge paper feeding and digital inkjet integrated machine comprisesa rack, a front edge air bellow paper feeding device mounted on the rack, an attraction air bellow paper discharge device installed at the rear end of the front edge air bellow paper feeding device and an ink-jet printing device installed above the attraction air bellow paper discharge device; the front edge air bellow paper feeding device comprises a front edge suction fan, a front edge paper feeding air bellow, a paper pressing positioning mechanism, an active flower roller and a passive flower roller; and the attraction air bellow paper discharge device comprises a main platform air bellow,a main platform fan, a belt active polished roller, an attraction belt, a belt polished roller, a paper pressing rubber roller and a drive mechanism. According to the corrugated paper front edge paper feeding and digital inkjet integrated machine, the structure of paper discharge through the attraction air bellow after paper feeding and printing through the front edge paper feeding air bellow isadopted, the paper surface is flat and even in stress in the paper feeding, printing and paper discharging processes of paperboards, and the ink-jet printing quality is improved.

Owner:广东品龙精工科技有限公司

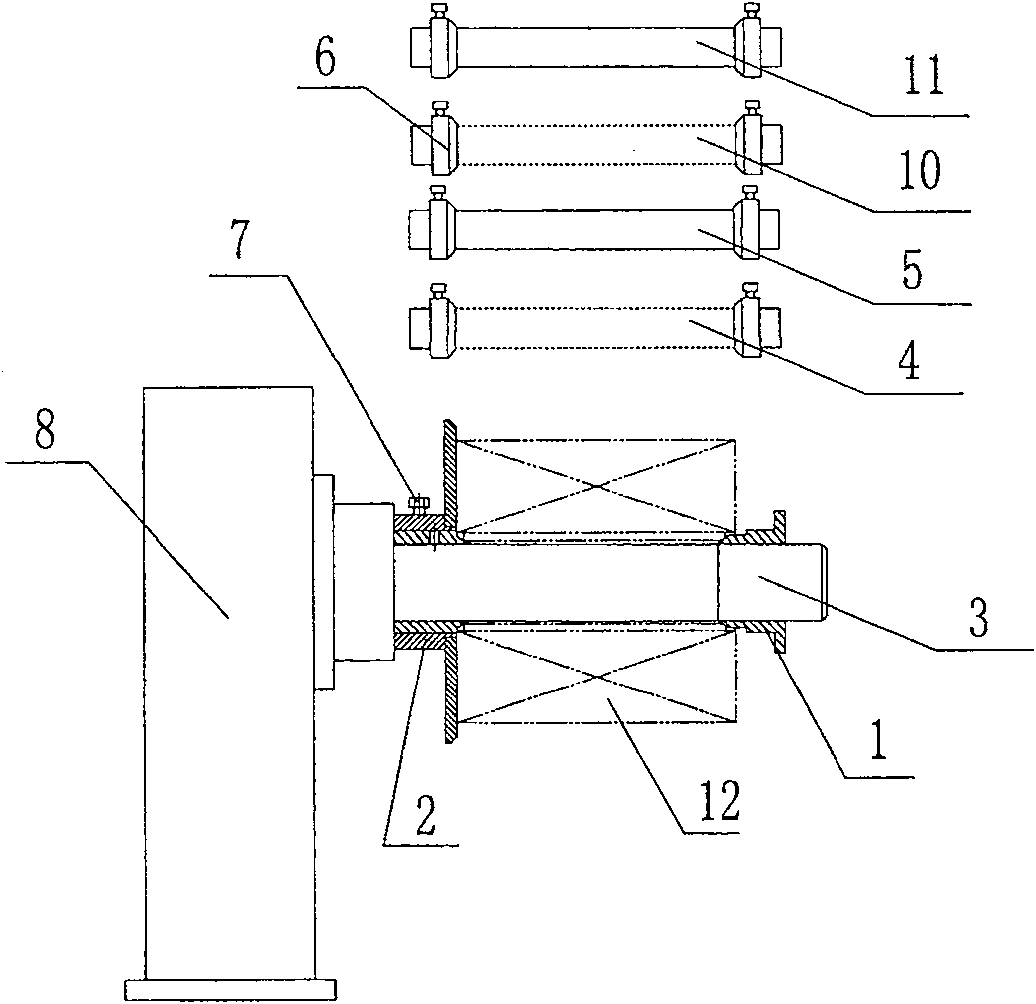

Insulating paper combination wind apparatus for transformer

InactiveCN101301968AEasy windingSmooth paperInductances/transformers/magnets manufactureWebs handlingTransformerEngineering

The invention relates to the transformer field, in particular to an insulating-paper compound-roll winding device used by a transformer, comprising a winding cart, two discharging shafts, two positioning shafts and a rotary shaft which is arranged on a base at one side of the winding cart parallelly with the positioning shafts and the discharging shafts in a suspension-arm way and is connected with the winding cart in a transmission way. A first sleeve provided with a taper-shaped upper end and a column-shaped lower end is fixed at the free end of the rotary shaft by screws. A second sleeve which is provided with a disk and of which the diameter is more than or equal to that of the insulating-paper compound-roll is fixed at one end of the rotary shaft neighboring the base of the winding cart by screws. Due to the adoption of the technical proposal, the invention can conveniently complete the winding of the insulating-paper compound-roll used for the transformer, conserving manpower and time, and the winded insulating-paper compound-roll has an even surface, therefore, manufacturing quality and efficiency are largely enhanced.

Owner:上海置信能源综合服务有限公司 +2

Electrolytic aluminum foil blowing switching module at outlet of stamping unit

InactiveCN104344022ASmooth paperImprove performanceMultiple way valvesBronze printingStamping processNoise level

The invention relates to an electrolytic aluminum foil blowing switching module at the outlet of a stamping unit. The electrolytic aluminum foil blowing switching module is mounted at the outlet of a stamping machine for control the air output of a blowing device. The electrolytic aluminum foil blowing switching module comprises a switching rod and a blowing main body which are connected; the end portion of the switching rod is provided with an air outlet, and the inside of the switching rod is provided with an air outlet pipe; the blowing main body is connected to the switching rod, and the inside of the blowing main body is provided with two air cavities which are communicated with the air outlet pipe inside the switching rod for controlling different air output. Compared with the prior art, by means of the switching rod, the electrolytic aluminum foil blowing switching module can convert a single blowing device into an aluminum foil blowing device or a paper blowing device and meanwhile conveniently achieve the conversion, thereby well achieving the effects of evening paper and well releasing the paper after a stamping process, and meanwhile, by optimizing the nozzle of the blowing device and enhance the integral performance, can reduce air consumption as well as lower the noise level during operation.

Owner:BOBST SHANGHAI

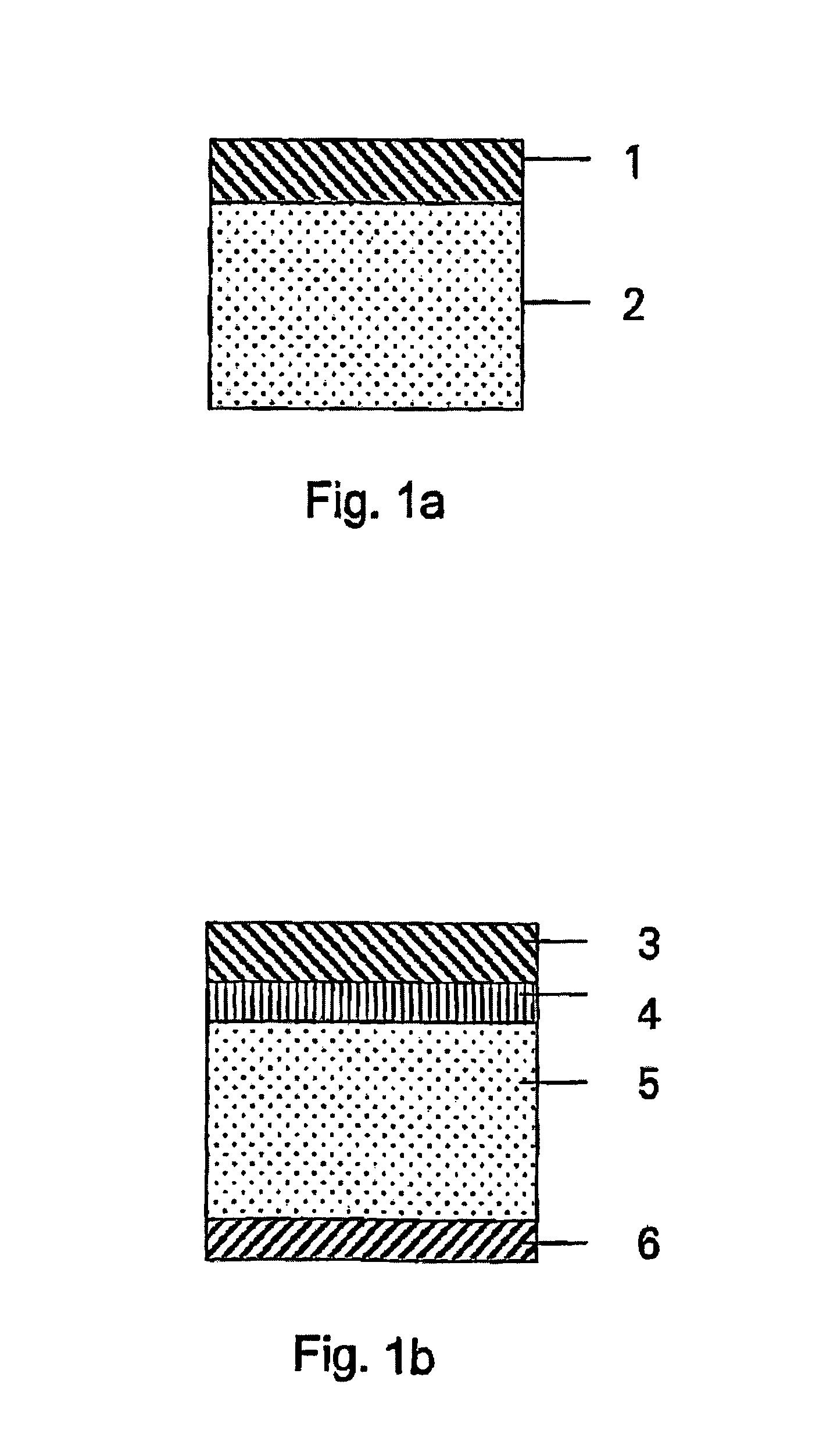

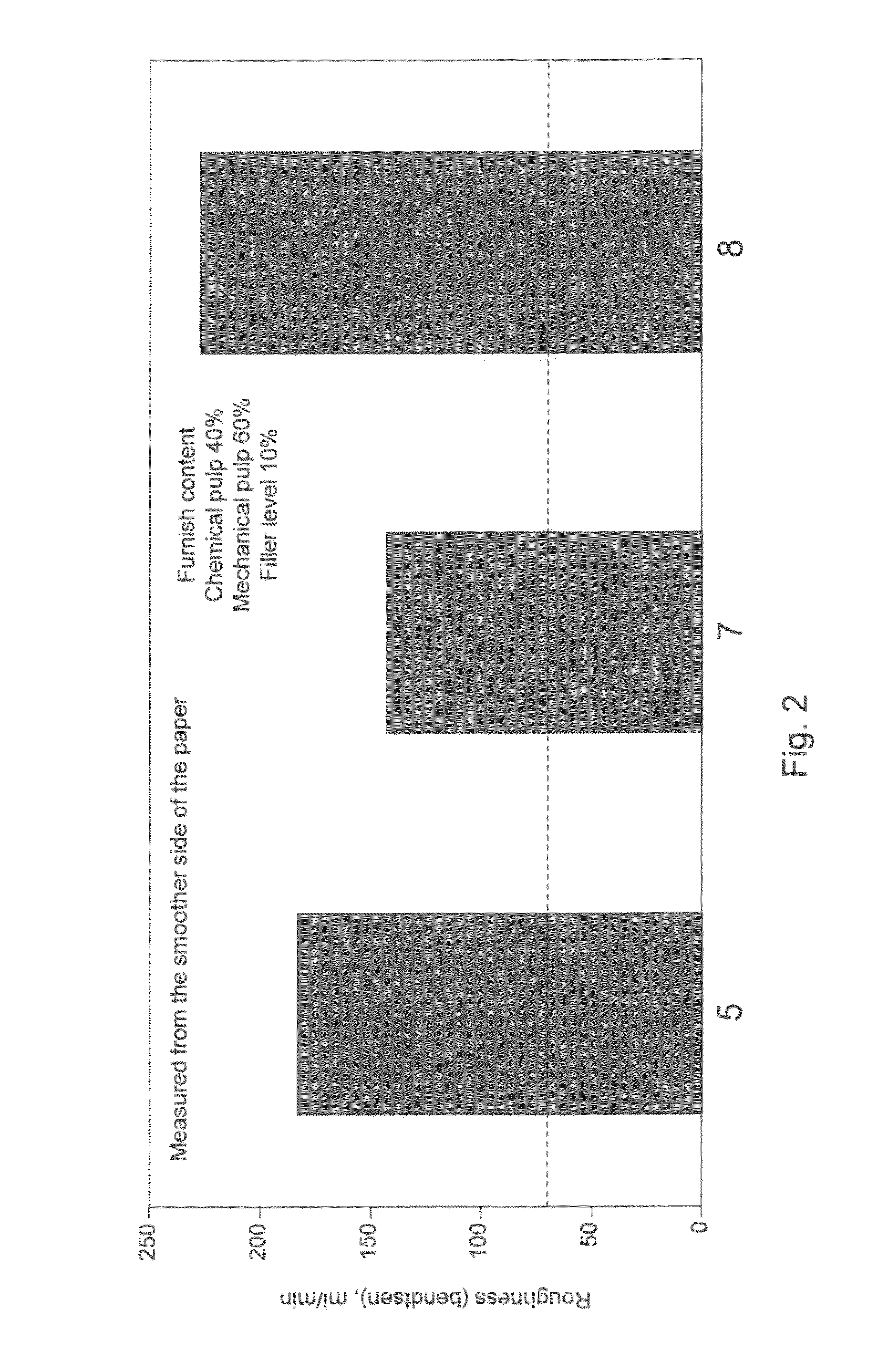

Method for producing fiber product

InactiveUS8608905B2Avoid uneven qualityConsiderable benefitPigmenting treatmentNatural cellulose pulp/paperCelluloseSurface layer

Owner:MINTEQ UK

Semi-transparent paper preparation method

InactiveCN108978298ASave resourcesImprove product qualitySpecial paperPaper recyclingPapermakingSemi transparent

The invention relates to the technical field of papermaking, and provides a semi-transparent paper preparation method, solving the technical problem of how to use waste paper to replace a part of pulpto prepare semi-transparent paper. The semi-transparent paper preparation method includes the steps of (1), preparing pulp from waste paper; (2), removing sand and dregs; (3), preparing pulp from wood-pulp boards and deinked pulp; (4), blending the pulp and conditioning; (5), manufacturing paper with the pulp and calendering and shaping.

Owner:福建省晋江优兰发纸业有限公司

Manufacturing method of fireproof board core paper

InactiveCN111962332AImprove uniformityQuantitatively stableDefoamers additionSpecial paperFiberPapermaking

The invention discloses a manufacturing method of a fireproof board core paper. The invention belongs to the technical field of papermaking, needle-leaved wood, broad-leaved wood and camphorwood are used as fiber raw materials, the preparation method comprises the following steps: cooking, extracting, performing oxygen delignification, performing hydrogen peroxide micro-bleaching, washing, pulping, preparing pulp, slushing, screening and purifying, sizing, dehydrating and forming a net part, squeezing, performing pre-drying, performing surface sizing, performing post-drying, coiling, rewindingand packaging, wherein the ratio of the needle-leaved wood to the broad-leaved wood to the camphorwood is (4.5-5): (3-4): 1. The fireproof board core paper manufactured through the method is good inuniformity, stable in quantification, consistent in tightness, smooth in paper surface, good in laminating performance, free of impurities on the appearance of the paper surface and free of lint on the end face, and the flame retardant property and the sound insulation property of the core paper are improved simultaneously.

Owner:YUEYANG FOREST & PAPER CO LTD

Tipping Paper Rewinder Based on Servo System

The invention discloses a tipping paper rewinding machine on the basis of a servo system. The tipping paper rewinding machine is characterized in that a linear speed is measured by a speed measuring roll in a tipping paper take-up procedure, real-time disc diameters of an unwinding disc and a winding disc are computed according to the real-time linear speed, a rotational speed of an unwinding motor and a rotational speed of a winding motor, and then the rotational speed of the unwinding motor and the rotational speed of the winding motor are computed according to the obtained disc diameters and a linear speed, which is given by a machine, in the tipping paper take-up procedure, and are adjusted via a central processing unit. The tipping paper rewinding machine has the advantages that circular adjustment is realized, so that the linear speed in a procedure for rolling tipping paper on the rewinding machine is consistent with the given speed, tension on the surface of the tipping paper in the take-up procedure keeps constant, disc surfaces are flat, and the winding quality is improved.

Owner:苏州市博海激光科技有限公司

A kind of pressure detection paper and preparation method thereof

ActiveCN109374165BSmooth paperFlat surfaceSpecial paperSurfactants additionPolymer scienceActive agent

The present invention relates to the field of display technology, in particular to a pressure detection paper and a preparation method thereof, comprising a paper layer and a pressure-sensitive color-developing layer adhered to the paper layer, wherein the pressure-sensitive color-developing layer is prepared from the following raw materials by weight : 15-30 parts of leuco dye microcapsules, 9-18 parts of spacer, 10-15 parts of adhesive, 15-30 parts of developer microcapsules, 1-3 parts of surfactant and 30-45 parts of solvent. The pressure detection paper has a flat surface and a smooth surface, and the pressure-sensitive color developing layer coated on the paper layer is not easy to drop powder, has stain resistance and yellowing resistance, and has good color development density and color development speed.

Owner:东莞市亚马电子有限公司

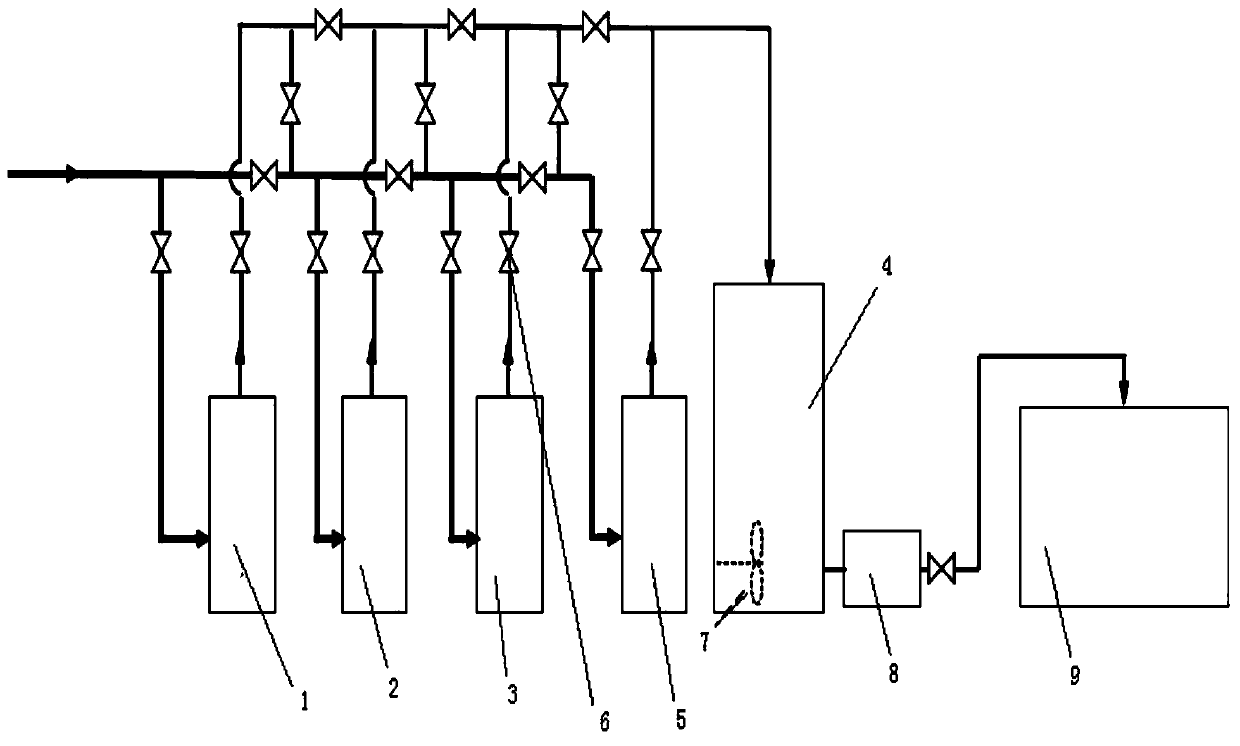

Pulp mixing system in papermaking process

The invention provides a pulp mixing system in a papermaking process. The system comprises three refiners connected in series, wherein inlet ends of the refiners are connected with a pulp inlet pipe,outlet ends are connected with a pulp mixing tank through a pipeline, and the pulp mixing tank is connected with a post-pulp pumping pool through a pulp pump and a pipeline. According to the pulp mixing production process of multiple refiners connected in series, the pulp is mixed uniformly, the fiber uniformity is good, the paper surface of a cotton pulp board is flat, and the appearance qualityis improved. Production is carried out by multiple refiners connected in series, the pulp refining effect is improved, and then stirring and pulp mixing are performed through the pulp mixing tank, different pulps produced by ingredients are mixed uniformly, folding resistance of a finished product is maintained to be uniform and consistent, a ratio of cotton velvet is reduced somewhat, and the annual cost saving is estimated to be about 100000 Yuan. The total energy saving and consumption reduction is 400000 Yuan.

Owner:合肥银山棉麻股份有限公司

A corrugated paper molding production system

ActiveCN110712394BSmooth paperUniform thicknessLiquid surface applicatorsMechanical working/deformationAdhesive glueMechanical engineering

The invention relates to a corrugated paper forming and manufacturing system which comprises a mounting table, a core paper bracket, an indentation device, a gluing device, a surface paper feeding device, a pressing device, two edge cutting devices, a traction device and a cutting device; and the mounting table is sequentially provided with the core paper bracket, the indentation device, the gluing device, the surface paper feeding device, the pressing device, the two edge cutting devices, the traction device and the cutting device from left to right. By adopting the corrugated paper forming and manufacturing system provided by the invention, the problems that the paper surface of corrugated paper processed by existing corrugated paper processing equipment is uneven, is inconsistent in thickness and has phenomena of wrinkles, cracks and holes as well as the problems that the processed corrugated paper is not closely attached to surface paper, a large quantity of glue is wasted, and themanufacturing cost is increased and the like are solved.

Owner:东莞市世昌智能制造科技有限公司

Device for cutting insulation support for transformer body

The invention discloses a device for cutting an insulation support for a transformer body, comprising a workbench body. The workbench body comprises a workbench surface, four rectangular tubes which are arranged under the workbench surface to support the workbench surface, three cantilevers which are fixed on the workbench body and bulge out of the workbench surface, two guide rails which are arranged on the cantilevers in parallel and four moving guide plates which can move and be fixed by passing through the two guide rails. The device improves the working efficiency and can conveniently finishing cutting the insulation support for the transformer body and save time and labor, and the cut insulation support has flat paperboard, thus greatly improving the production quality and the production efficiency. The jig saw is held by both hands so that the jig saw is stable with force, and both hands are not contacted with the paperboard of the insulation support, thus avoiding the possibility that the jig saw is liable to hurting own hands in the original cutting mode.

Owner:SHANGHAI ZHIXIN INTELLIGENT ELECTRIC CO LTD +2

Preparation method of boot sleeve applicable to boot-shaped squeezing roller

The invention discloses a preparation method of a boot sleeve applicable to a boot-shaped squeezing roller. The preparation method comprises the steps of coating a die with a mould release agent, pouring bottom-layer polyurethane, weaving a reinforced Kevlar fiber yarn layer, pouring core-layer polyurethane, sheathing a core net, pouring a surface-layer polyurethane layer and cutting grooves. The boot sleeve produced by adopting the method is reasonable in structure, high in stability, strong in crack resistance, high in surface hardness, not prone to damage, long in service life and applicable to high-speed paper machines; when being used, the boot sleeve produced by adopting the method is strong in squeezing and dewatering performance and good in wet paper water squeezing property; produced paper is smooth and stable.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

Manufacturing method of shoe cover for shoe press roll

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

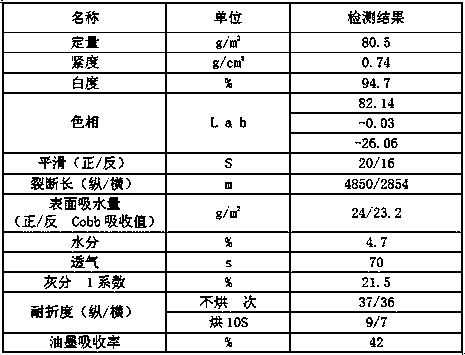

A papermaking process of single-sided blue engineering paper

ActiveCN106676942BImprove absorption rateImprove uniformityCoatings with pigmentsReinforcing agents additionIsothiazolinoneSolid content

The invention provides a coating process of single-sided blue engineering paper. The coating process comprises a paint preparation step, and according to the paint preparation, solid content of paintis 2%-3%, viscosity of the paint is 3-5 mpa.s, and pH value of the paint is 8.2-8.4. The paint is prepared from components in percentage by mass as follows: 0.2% of a color toner, 1.5% of latex, 0.1%of CMC and 0.08% of isothiazolinone. According to single-sided blue engineering paper prepared with the process, deviation of basis weight in cross direction is smaller than or equal to 3 g / m<2>, dustcontent is lower than or equal to 40 / m<2>, and water content is 4.2%-4.7%.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

Paper making process of single-side blue engineering raw paper

ActiveCN108755237AImprove absorption rateImprove uniformityCoatings with pigmentsReinforcing agents additionFiberSulfate

The invention provides a paper making process of single-side blue engineering raw paper. The process comprises a pulp preparation step; the pulp preparation includes the preparation of long fiber pulpand the preparation of poplar pulp. For the preparation of long fiber pulp, bleached sulfate needle leaf long fiber wood pulp with the fiber length being 2.5 to 2.7mm is used; the pulping concentration is 4.0 to 4.3 percent; the pulping degree is 38 to 40 degrees SR. For the preparation of poplar pulp, the pulping concentration is 4.0 to 4.3 percent; the pulping degree is 36 to 38 degrees SR. Theink absorption rate of the prepared single-side blue engineering raw paper is 42 to 45 percent.

Owner:WEIFANG HENGLIAN SPECIALTY PAPER

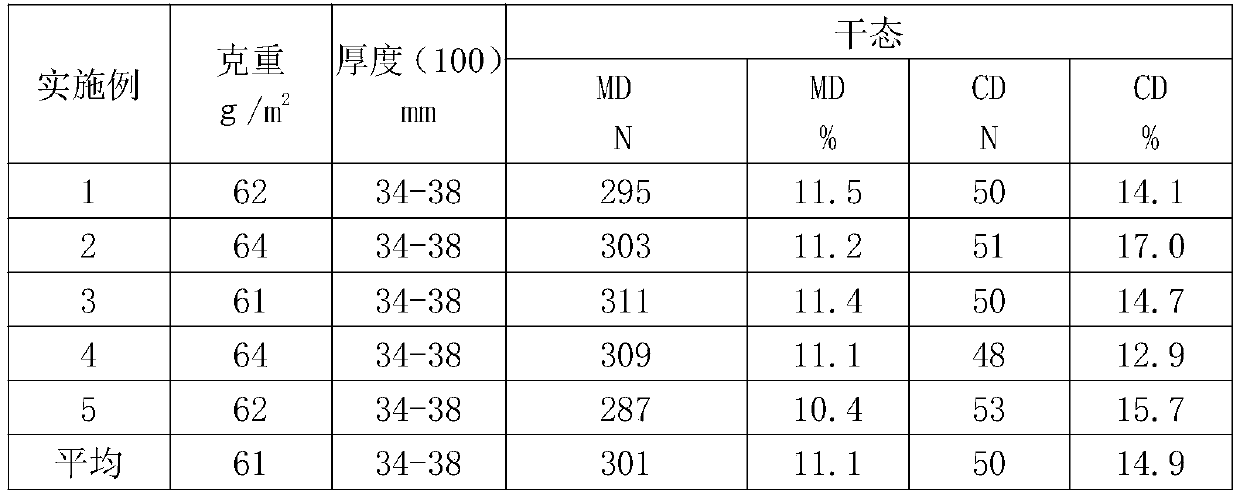

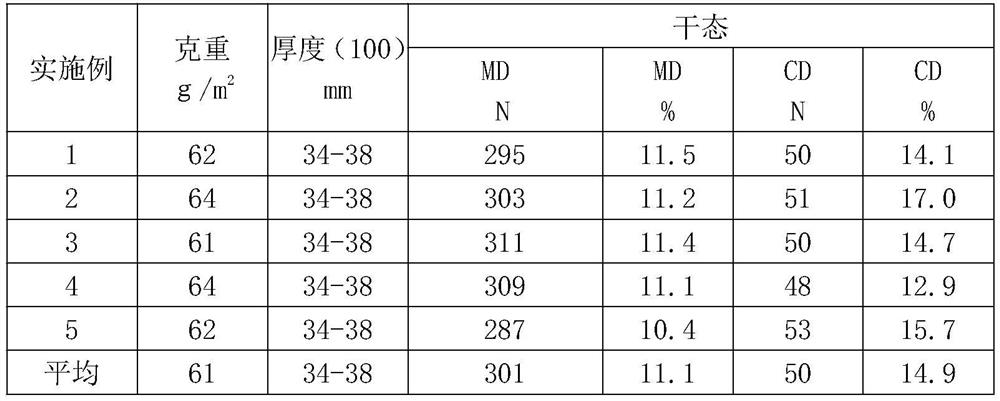

Non-woven fabric writing paper and preparation method thereof

The invention discloses a preparation method of non-woven fabric writing paper. The preparation method comprises the following steps: preparing materials, namely uniformly mixing polyester fibers or mixed fibers containing more than 80wt% of polyester fibers; carding and web forming: carding for forming net: carding the fibers and laying the carded fibers in a staggered mode to form a polyester fiber net; sizing, specifically, sizing the polyester fiber net, wherein a sizing agent is prepared from an adhesive, a waterproof agent and water; and drying: drying the sized polyester fiber net to obtain the non-woven fabric writing paper. According to the technical scheme, the non-woven fabric writing paper is prepared by taking polyester fibers as raw materials. When the weight of the non-wovenfabric writing paper is 60 g, the thickness of the non-woven fabric writing paper is 34-38 mm (100 pieces), the paper surface is smooth, the paper has toughness, and permeation is not likely to happen in the writing process.

Owner:温州新宇无纺布有限公司

A thermal sublimation digital transfer paper and its production method

ActiveCN107435275BSimple production methodImprove efficiencyCoatings with pigmentsSpecial paperAdhesiveSolid content

The invention discloses heat sublimation digital transfer paper and a production method. The heat sublimation digital transfer paper comprises base paper, at least a receiving layer and at least a back coating layer; and the heat sublimation digital transfer paper is characterized in that the base paper is manufactured by 100% of wood pulp; the receiving layer is composed of 30%-70% by weight of a white pigment and 30%-70% by weight of an adhesive, the solid content of the receiving layer is 10%-50%, the viscosity is 400cps-1800cps, and the coating weight of the receiving layer is 1g / m<2>-20g / m<2>; and the back coating layer is composed of natural glue or synthetic glue, the solid content of the back coating layer is 2-10%, the viscosity is 5-200cp,and the coating weight is 0.5-2g / m<2>; and the production method comprises the following steps: a, producing the base paper: producing the base paper by the wood pulp on a fourdrinier, wherein surface sizing of the base paper is membrane transfer sizing; and b, performing coating on the receiving layer and the back coating layer, wherein coating of the receiving layer and the back coating layer is finished on a coating machine.

Owner:MINFENG SPECIAL PAPER

Ultrathin heat sublimation transfer paper and preparation method thereof

The invention discloses an ultrathin heat sublimation transfer paper. The ultrathin heat sublimation transfer paper comprises a base material, a binding agent and a coating coated on the surface of the base material, wherein the coating comprises carboxymethyl cellulose, sucrose, glycerol, starch, polyvinyl chloride resin, polyethylene glycol fatty acid ester, fumed silica, aluminum oxide, calciumcarbonate, a bactericide, a polysaccharide derivative, kaolin, titanium dioxide, sodium polyacrylate, bentonite powder and a dispersing agent. The invention further discloses a preparation method ofthe ultrathin heat sublimation transfer paper, the preparation method is that the materials of all the components is carried out dissolving, mixing, heating, uniformly stirring, and discharging by steps. According to the method, the polysaccharide derivative and glycerol are added, so that the paper surface is smooth, the phenomenon of bending deformation is not easy to occur, and the heat sublimation printing quality is improved, so that the application of the ultrathin heat sublimation transfer paper is realized, and the transfer rate of the produced paper is improved, and the application ofthe ultrathin paper in the field of thermal sublimation is improved.

Owner:SUZHOU JIGU NEW MATERIAL CO LTD

Insulating paper combination wind apparatus for transformer and the usage method

InactiveCN100564208CEasy windingSmooth paperInductances/transformers/magnets manufactureWebs handlingPulp and paper industryConductor Coil

Owner:上海置信能源综合服务有限公司 +2

Corrugated paper leading edge feeding digital inkjet all-in-one machine

ActiveCN109760420BEven by forceSmooth paperTypewritersOther printing apparatusCardboardStructural engineering

The invention provides a corrugated paper leading edge paper feeding digital inkjet integrated machine, comprising: a frame; a leading edge bellows paper feeding device installed on the frame, the leading edge bellows paper feeding device includes a leading edge adsorption fan, a front Edge paper feeding bellows, paper pressing positioning mechanism, active pattern roller and passive pattern roller; adsorption bellows paper output device installed at the rear end of the front edge bellows paper feeding device, the adsorption bellows paper output device includes main platform bellows, main platform fan, Belt driving smooth roller, suction belt, belt smooth roller, platen rubber roller and driving mechanism; and an inkjet printing device installed above the paper output device of the suction bellows. This corrugated paper leading edge feeding digital inkjet all-in-one machine adopts the structure of leading edge bellows feeding paper and absorbing bellows paper output after printing, so that the paper surface of the cardboard is smooth and the force is even during the process of paper feeding, printing and paper output, and the inkjet is improved. ink print quality.

Owner:广东品龙精工科技有限公司

A kind of non-woven writing paper and preparation method thereof

A method for preparing non-woven writing paper, the preparation method comprising the following steps: preparing materials: mixing polyester fibers or mixed fibers containing more than 80 wt% polyester fibers; carding into a web: carding fiber pairs; The fibers are interlaced to form a polyester fiber web, sizing: sizing the polyester fiber web, and the slurry is prepared from adhesives, waterproofing agents and water; drying: drying the sized polyester fiber web to obtain non-woven writing paper . The above technical proposal adopts polyester fiber as a raw material to prepare non-woven writing paper. When the non-woven writing paper is 60g, the thickness is 34-38mm (100 sheets), the paper surface is flat, the paper has toughness, and it is not easy to seep through during the writing process.

Owner:温州新宇无纺布有限公司

Manufacturing method of warp self-feeding and seaming polyester three-layer forming fabric for papermaking

The invention relates to a manufacturing method of a warp self-feeding and seaming polyester three-layer forming fabric for papermaking. Polyester or nylon monofilaments are interweaved into three different weaving structures of a finished paper layer, a middle connecting layer and a machine layer by 16 heald frames, and the three different weaving structures are connected into an integral composite intertexture, wherein the minimum organization unit comprises 16 polyester monofilaments as warps and 40 polyester or nylon monofilaments as wefts; the ratio of the number of warps of the finishedpaper layer to that of the machine layer is 1:1; the ratio of the number of wefts of the finished paper layer to that of the machine layer is 3:2; the finished paper layer adopts a 1 / 1 plain weaving method; the machine layer adopts an 8-heald satin weaving method; and the middle connecting layer is formed by self-feeding and seaming of warps of the finished paper layer and warps of the machine layer. The invention has the advantages of flat paper surface, firm interlayer binding force, no internal wear, tight and even fabric structure, wear resistance of the machine layer, small thickness, long service life and strong dehydration performance.

Owner:JIANGSU JINNI ENGINEERED FABRIC CO LTD

A kind of anti-counterfeiting paper and its manufacturing method

ActiveCN103103890BIncrease contrastEasy to identifyNon-fibrous pulp additionSpecial paperFiberWater soluble

A security paper comprises at least two layers of independently molded paper pages. A fiber textile belt is arranged between the two paper pages and provided with a security element; the fiber textile belt comprises a silk screen layer woven from a hot melting material with melting point at 50-100 DEG C; the fiber textile belt forms a white watermark on the paper page; and the security element forms a black watermark on the paper page. The invention solves technical problems in the prior art that a positioning security component addition method is not suitable for a molded security element and that security element addition using a water-soluble material as a carrier requires a long processing time and results in poor paper effect. The security paper provided by the invention is particularly suitable for the production of valuable documents and security document.

Owner:CHINA BANKNOTE SECURITY PRINTING TECH RES INST CO LTD +1

High-efficiency packaging machine for tissue production

InactiveCN106608386AImprove packaging efficiencySmooth paperPaper article packagingPaper sheetSizing

The invention discloses a high-efficiency packaging machine for tissue production. The machine comprises a packaging table; a tissue sizing zone is arranged on the packaging table; a first electric push rod is arranged on one side of the tissue sizing zone; a first push plate is arranged at the top end of the first electric push rod and is located in the tissue sizing zone; a conveying belt parallel with the first electric push rod is arranged on one side of the tissue sizing zone; a second electric push rod perpendicular to the conveying belt is arranged on one side of the conveying belt; a second push plate is arranged at the top end of the second electric push rod and directly faces the tissue sizing zone; a third electric push rod is arranged above the tissue sizing zone; a third push plate is arranged at the lower end of the third electric push rod; and a packaging port is formed in the other side, directly facing the first push plate, of the tissue sizing zone. The machine has the beneficial effects that the packaging efficiency is high and products are flat.

Owner:FUQUAN YUNXI PAPER IND

Mineral skin care oil-absorbing paper and preparation method thereof

ActiveCN106676929BEliminate potential harmEnjoy pamperingAntibacterial agentsCosmetic preparationsMicroorganismTrace element

The invention relates to a mineral skincare oil absorbing sheet and a preparation method thereof. The mineral skincare oil absorbing sheet comprises a paper carrier, and filler which is dispersed in the paper carrier, wherein the paper carrier is made of bamboo pulp, the filler comprises attapulgite and diatomite in a weight ratio of (1 to 1) to (1 to 5), and the amount of the filler is 2 to 6 percent of the weight of the bamboo pulp. By adopting the mineral skincare oil absorbing sheet, people with oily skin can avoid the embarrassment of glossy face in the business negotiation and traveling process and can keep a clean and dry face, the potential injury of PM2.5, contaminants, heavy metals and the like attached to the face can be eliminated at any time in any place, the bacteria and microorganisms can be effectively absorbed, the potential risk of whelk and acne caused by propionibacterium acnes can be eliminated, fresh face and oil control can be realized, and people can enjoy the skin care of the mineral trace elements.

Owner:HUNAN YUJIA COSMETICS MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com