A kind of pressure detection paper and preparation method thereof

A technology for detecting paper and pressure, applied in the field of pressure detection paper and its preparation, can solve the problems of microcapsule rupture, oxidation yellowing, product scrapping, etc., and achieve the effects of reducing usage, slowing down smoothness reduction, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

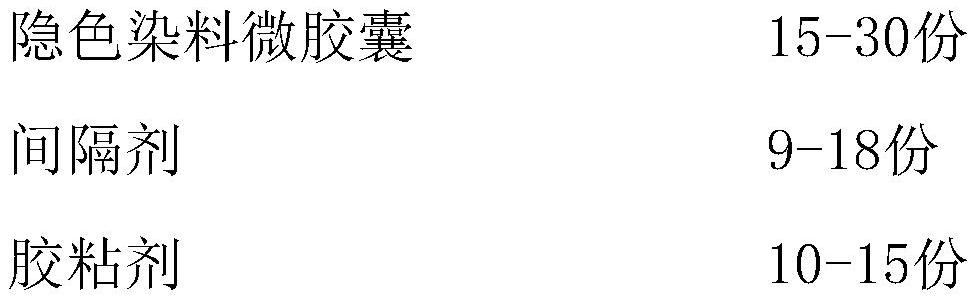

[0048] A pressure detection paper, comprising a paper layer and a pressure-sensitive color-developing layer adhered to the paper layer, the pressure-sensitive color-developing layer is made of the following raw materials by weight:

[0049]

[0050] The particle diameter of the leuco dye microcapsules is 2.2 μm, and the particle diameter ratio of the leuco dye microcapsules, spacer and developer microcapsules is 1:4:2.5.

[0051] The spacer is calcium carbonate, the adhesive is mixed with carboxylated styrene-butadiene latex and modified starch at a weight ratio of 1:2, and the modified starch is oxidized starch.

[0052] The surfactant is sodium carboxymethyl cellulose and methyl cellulose mixed in a weight ratio of 4:1, and the solvent is water.

[0053] The preparation method of every part of said leuco dye microcapsules comprises the steps:

[0054] (A1) Weigh 3 parts of leuco dye, 40 parts of solvent naphtha, 45 parts of esterified modified SMA-water solution with a m...

Embodiment 2

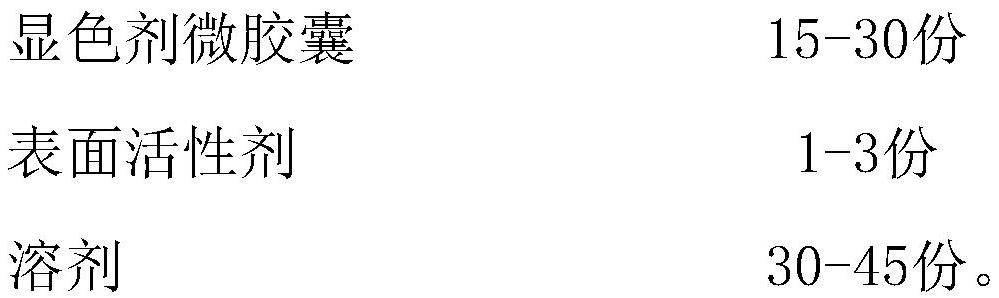

[0075] A pressure detection paper, comprising a paper layer and a pressure-sensitive color-developing layer adhered to the paper layer, the pressure-sensitive color-developing layer is made of the following raw materials by weight:

[0076]

[0077] The particle diameter of the leuco dye microcapsules is 0.2 μm, and the particle diameter ratio of the leuco dye microcapsules, spacer and developer microcapsules is 1:3:2.

[0078] The spacer is calcium carbonate, the adhesive is mixed with carboxylated styrene-butadiene latex and modified starch at a weight ratio of 1:2, and the modified starch is cationic starch.

[0079] The surfactant is sodium carboxymethyl cellulose and methyl cellulose mixed in a weight ratio of 3:1, and the solvent is water.

[0080] The preparation method of every part of said leuco dye microcapsules comprises the steps:

[0081] (A1) Weigh 1 part of leuco dye, 35 parts of solvent naphtha, 40 parts of esterified modified SMA-water solution with a mass...

Embodiment 3

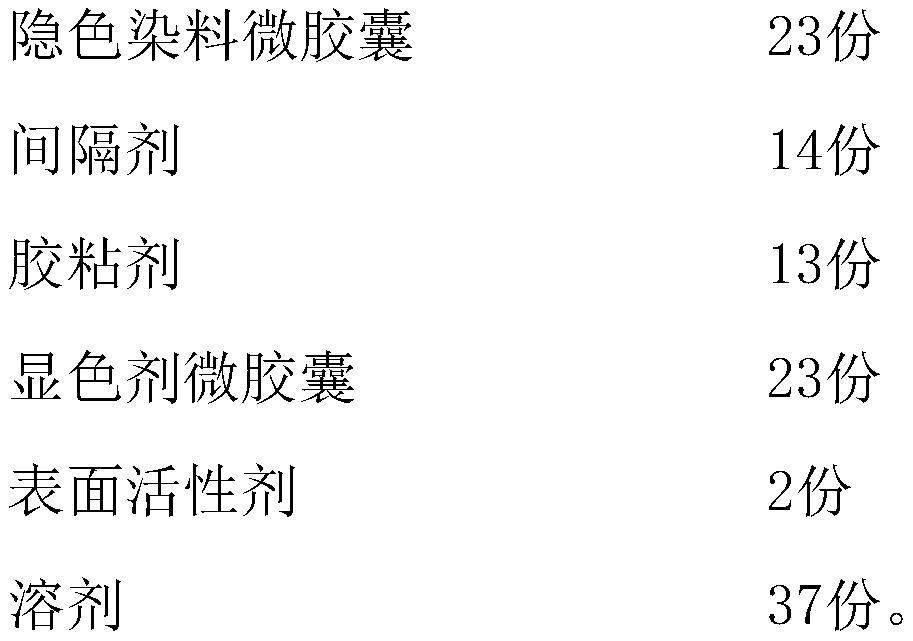

[0102] A pressure detection paper, comprising a paper layer and a pressure-sensitive color-developing layer adhered to the paper layer, the pressure-sensitive color-developing layer is made of the following raw materials by weight:

[0103]

[0104] The particle size of the leuco dye microcapsules is 4 μm, and the particle size ratio of the leuco dye microcapsules, the spacer and the developer microcapsules is 1:5:3.

[0105] The spacer is calcium carbonate, the adhesive is mixed with carboxylated styrene-butadiene latex and modified starch at a weight ratio of 1:2, and the modified starch is oxidized starch.

[0106] The surfactant is sodium carboxymethyl cellulose and methyl cellulose mixed in a weight ratio of 5:1, and the solvent is water.

[0107] The preparation method of every part of said leuco dye microcapsules comprises the steps:

[0108] (A1) Weigh 4 parts of leuco dye, 45 parts of solvent naphtha, 50 parts of esterified modified SMA-water solution with a mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com