Pulp mixing system in papermaking process

A pulp mixing and process technology, applied in the field of papermaking, can solve the problems that long fibers and pulp masses cannot pass, cannot achieve the effect of refining pulp, and affect the effect of refining pulp, so as to avoid invalid start-up time, improve appearance quality, and improve pulp quality. The effect of boosting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with embodiment.

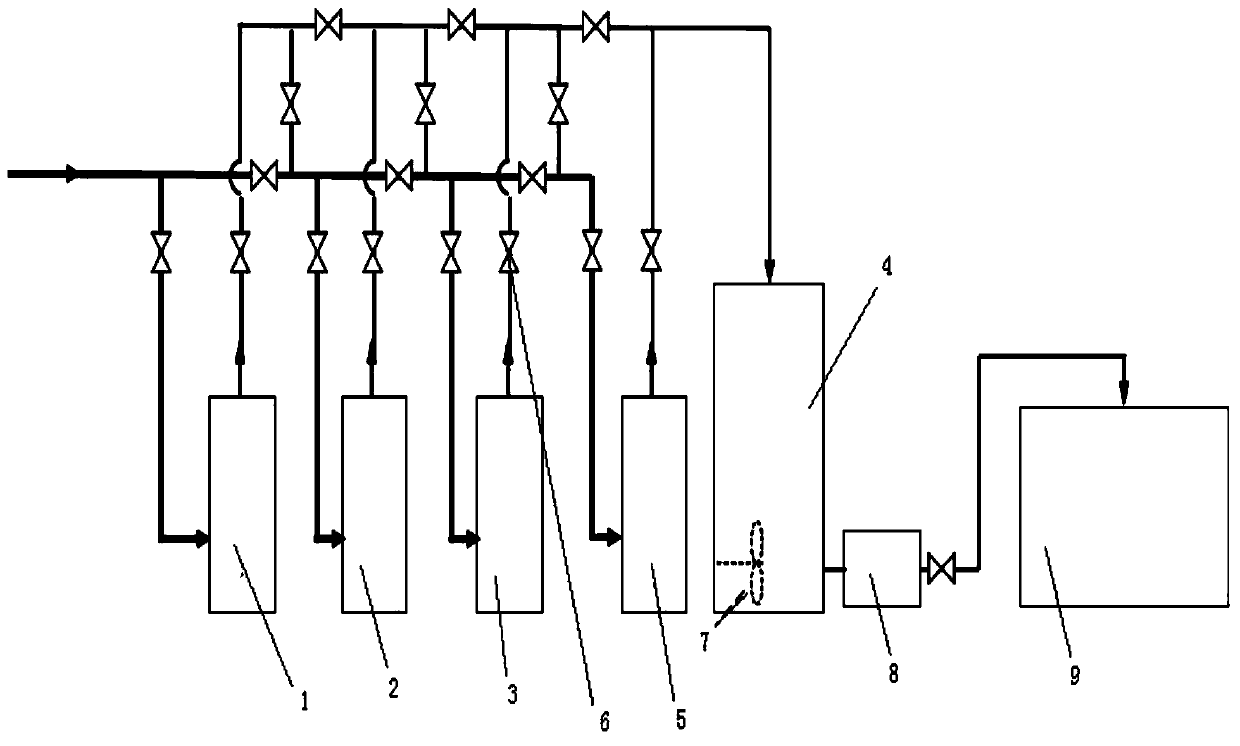

[0015] Such as figure 1 Shown is a pulp mixing system in the papermaking process. The difference between this system and the traditional system is that the serial production of 2 refiners is changed to 3 serial production. Adding the first one is a half pulp knife refiner to loosen and cut off the long-fiber pulp clusters in the initial treatment pulp of the beater, which can not only shorten the beating time, but also improve the pulp passing capacity of the subsequent refiner, (35 ×35×7)

[0016] After 1# refiner 1 decomposes the pulp evenly, 2# refiner 2 and 3# refiner 3 step by step to reduce the gap between the knife distances, and the cutting current required by the process can be reached after starting up, ensuring the effect of refinement (2 #: 35×19×7; 3#: 35×12×10). Add a mixing tank 4 to stir and mix the pulp after the three refiners are refined to ensure that the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com