Preparation method of transparent nano-cellulose paper with fluorescence properties

A technology of nanocellulose and fluorescence characteristics, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of limited development space, serious environmental pollution, complex preparation process, etc., and achieve difficult imitation, uniform dispersion and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

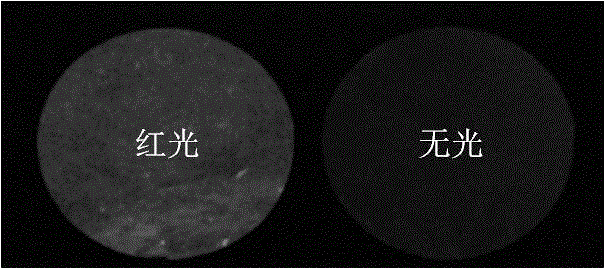

Embodiment 1

[0025] NCF was dispersed in 50 mL deionized water, and ultrasonically dispersed to form a stable suspension with a mass fraction of 1w / v%; TEMPO and NaBr were dissolved in 50 mL deionized water at 0.002 mol / L and 0.03 mol / L, respectively, to obtain a light yellow transparent solution; the solution was added dropwise to the NCF suspension, and then NaClO solution was added to adjust the pH value to 10, and reacted at room temperature for 3 h; after the reaction was completed, the pH value was adjusted to 7, and washed with water several times to obtain ONCF; the obtained ONCF was obtained by 0.2 w / v% dispersed in 50 mL absolute ethanol, add 5 mg Eu(dbm) 3 (H 2 O) 2 , Ultrasonic dispersion to obtain fluorescent ONCF ethanol suspension; pour the suspension into a high-pressure filter press, adjust the pressure to 0.6MPa, and press the high-pressure filter until there is no more filtrate flowing out, and the filter press is over; carefully take out the filter membrane in the filt...

Embodiment 2

[0027] NCF was dispersed in 50 mL deionized water, and ultrasonically dispersed to form a stable suspension with a mass fraction of 1w / v%; TEMPO and NaBr were dissolved in 50 mL deionized water at 0.002 mol / L and 0.03 mol / L, respectively, to obtain a light yellow transparent solution The solution was added dropwise to the NCF suspension, NaClO solution was added, the pH value was adjusted to 10, and the reaction was carried out at room temperature for 3 h; the reaction was completed, the pH value was adjusted to 7, and ONCF was obtained by washing with water several times; v% was dispersed in 50 mL absolute ethanol, and 7.5 mg Tb(Tfacac) was added 3 (H 2 O) 2 , Ultrasonic dispersion to obtain fluorescent ONCF ethanol suspension; pour the suspension into a high-pressure filter press, adjust the pressure to 0.6MPa, and press the high-pressure filter until there is no more filtrate flowing out, and the filter press is over; carefully take out the filter membrane in the filter pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com