Non-woven fabric writing paper and preparation method thereof

A technology of non-woven fabrics and writing paper, which is applied in the field of papermaking and can solve problems such as high prices, limited wood fiber resources, and lack of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

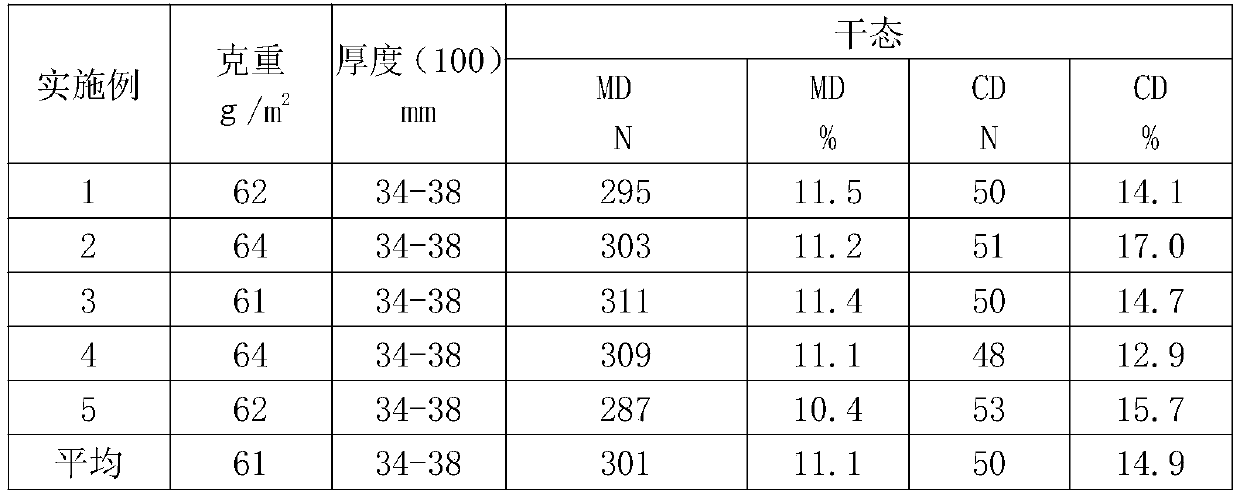

Examples

Embodiment 1

[0023] Embodiment 1 A kind of preparation of non-woven writing paper

[0024] Raw materials: mixing 65 parts by mass of low-denier polyester fibers of 33-38DTEX;

[0025] Carding into a web: Carding the prepared fibers; interlacing the carded fibers into a polyester fiber web,

[0026] Sizing: sizing the polyester fiber web with sizing, which is prepared by 30 parts by mass of soft adhesive, 4 parts by mass of hard adhesive, 1 part by mass of water repellent and 35 parts by mass of water;

[0027] Drying: Dry the sized polyester fiber web at 200° C. for 30 minutes to obtain non-woven writing paper.

[0028] In this embodiment, the SHD soft adhesive of Transfar Chemical is used as the soft adhesive, the 351HA hard adhesive of Transfar Chemical is used as the hard adhesive, and the FS01 waterproofing agent of Transfar Chemical is used as the waterproofing agent.

[0029] The slurry mixed with soft and hard binders will bind the fibers and reinforce the writing paper at the sam...

Embodiment 2

[0030] Embodiment 2 A kind of preparation of non-woven writing paper

[0031] Raw materials: mixing 60 parts by mass of low-denier polyester fibers of 33-38DTEX;

[0032] Carding into a web: Carding the prepared fibers; interlacing the carded fibers into a polyester fiber web,

[0033] Sizing: sizing the polyester fiber web with sizing, the sizing is prepared by 25 parts by mass of soft adhesive, 3 parts by mass of hard adhesive, 1 part by mass of water repellent plus 24 parts by mass of water;

[0034] Drying: Dry the sized polyester fiber web at 220° C. for 30 minutes to obtain non-woven writing paper.

Embodiment 3

[0035] Embodiment 3 A kind of preparation of non-woven writing paper

[0036] Material preparation: mixing 80 parts by mass of low-denier polyester fiber of 33-38DTEX;

[0037] Carding into a web: Carding the prepared fibers; interlacing the carded fibers into a polyester fiber web,

[0038] Sizing: sizing the polyester fiber web with sizing, the slurry is prepared from 35 parts by mass of soft adhesive, 5 parts by mass of hard adhesive, 2 parts by mass of water repellent and 50 parts by mass of water;

[0039] Drying: drying the sized polyester fiber web at 180° C. for 60 minutes to obtain non-woven writing paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com