Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Smooth deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

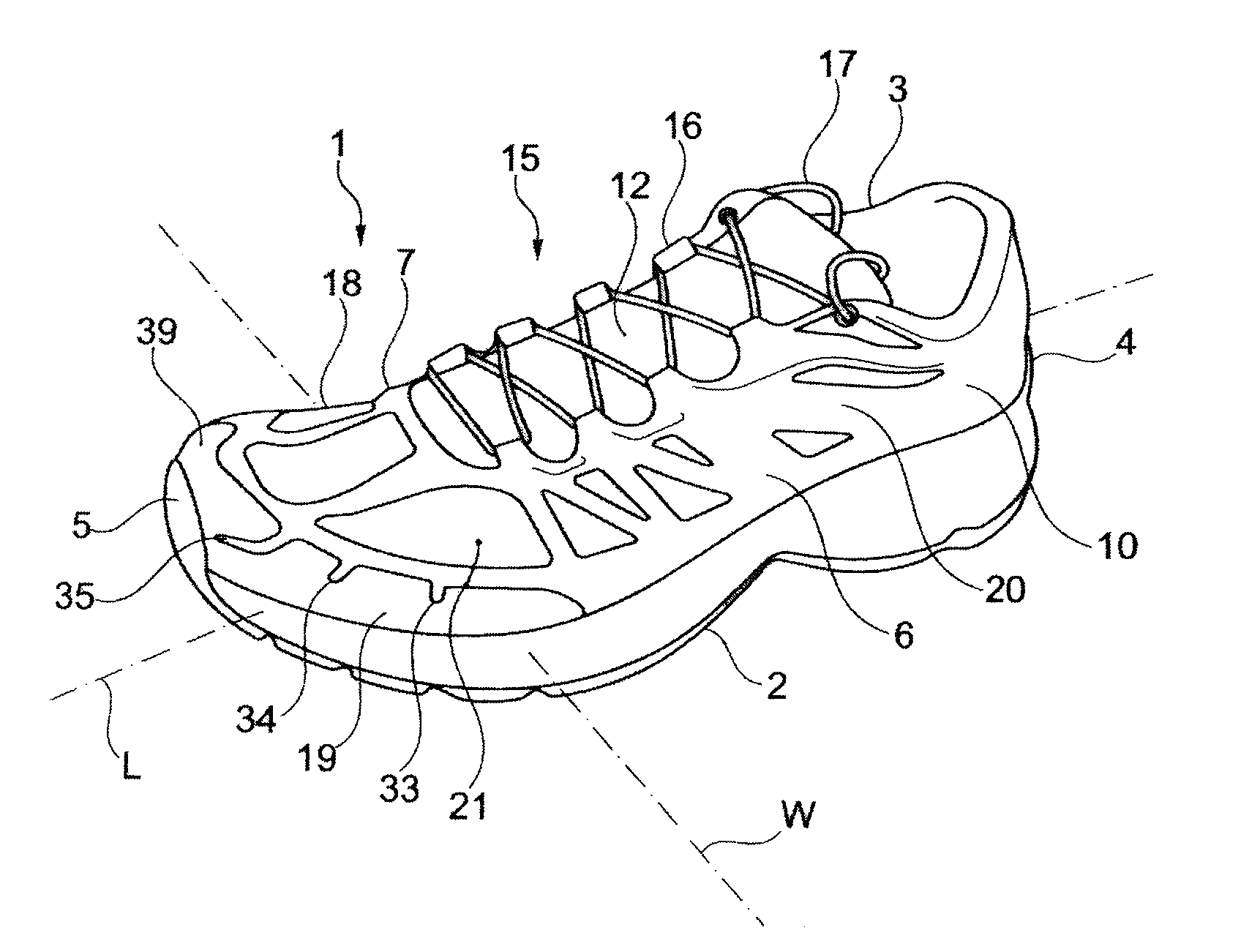

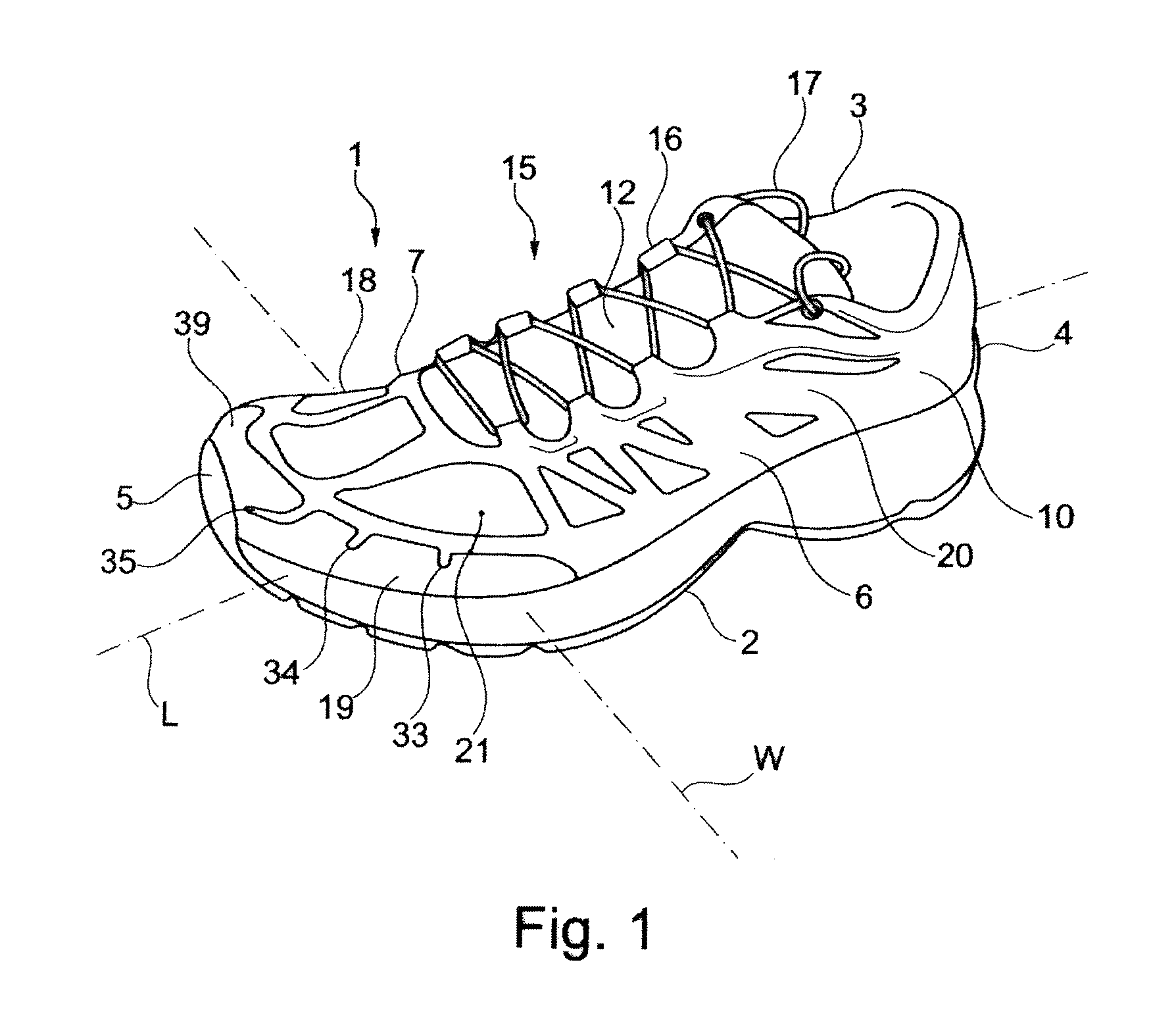

Full length cartridge cushioning system

The invention relates to a shoe sole for an article of footwear, in particular a sports shoe. The sole includes a first area having a first deformation element and a second area having a second deformation element. The first deformation element includes a foamed material and the second deformation element includes an open-walled or honeycomb-like structure that is free from foamed materials.

Owner:ADIDAS

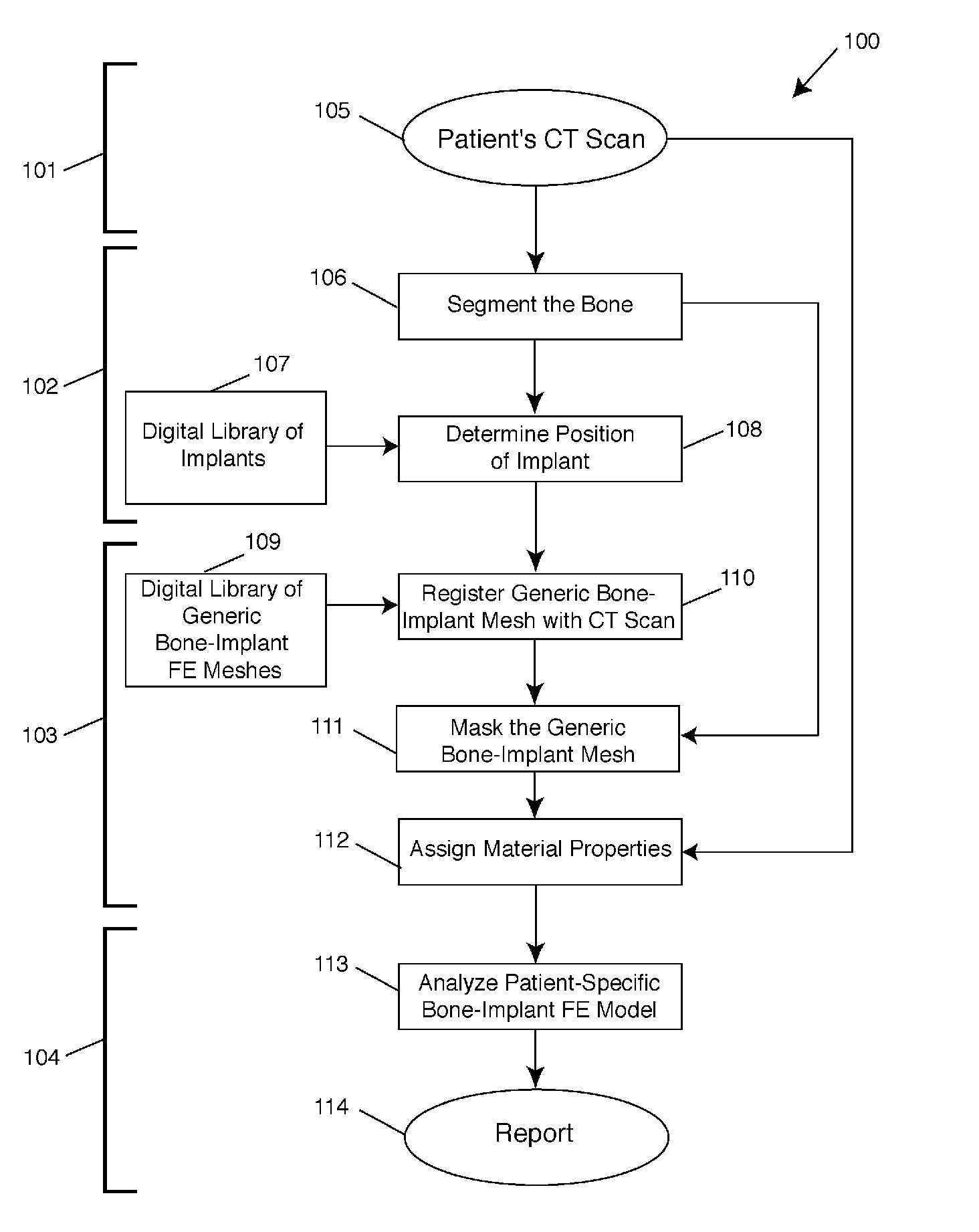

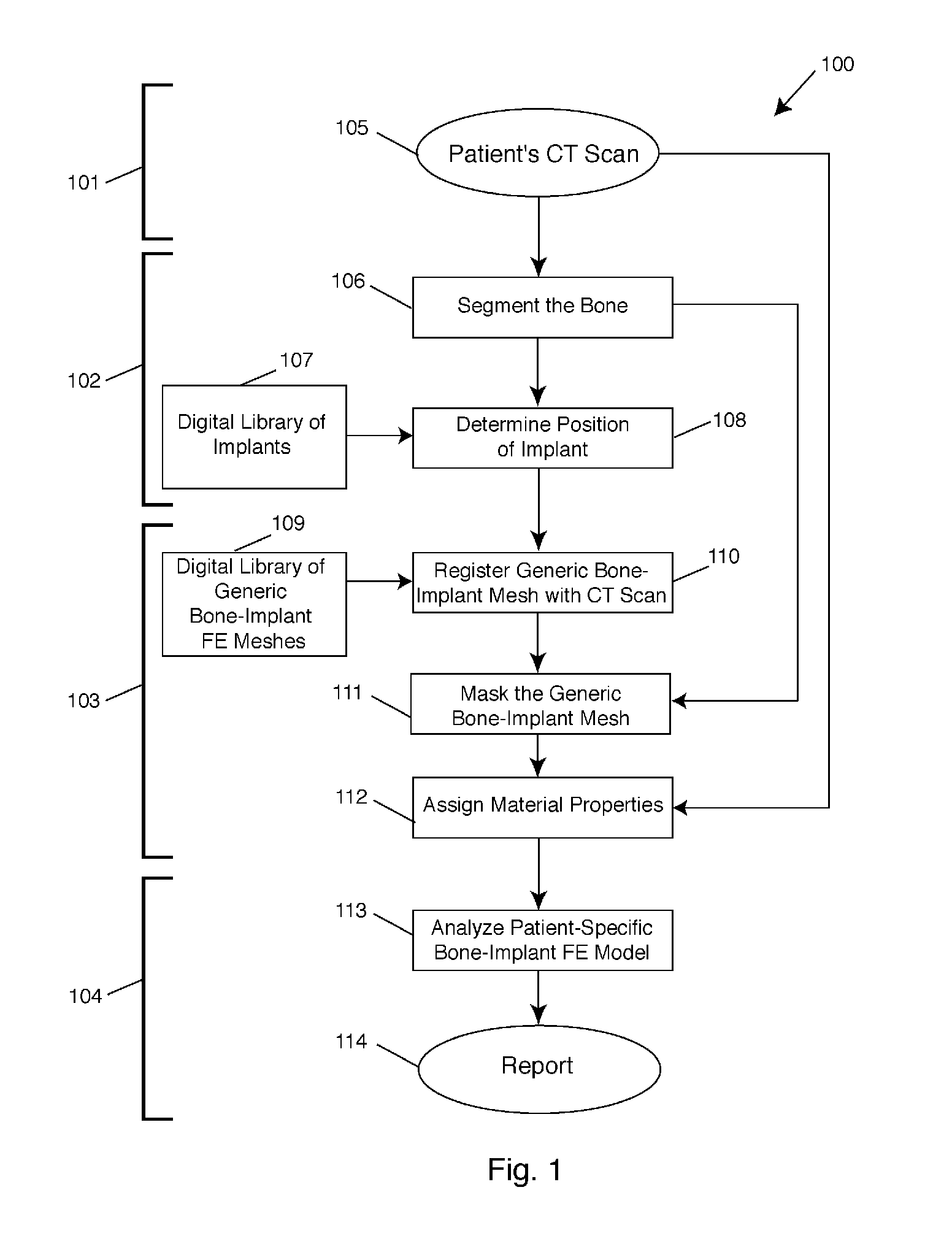

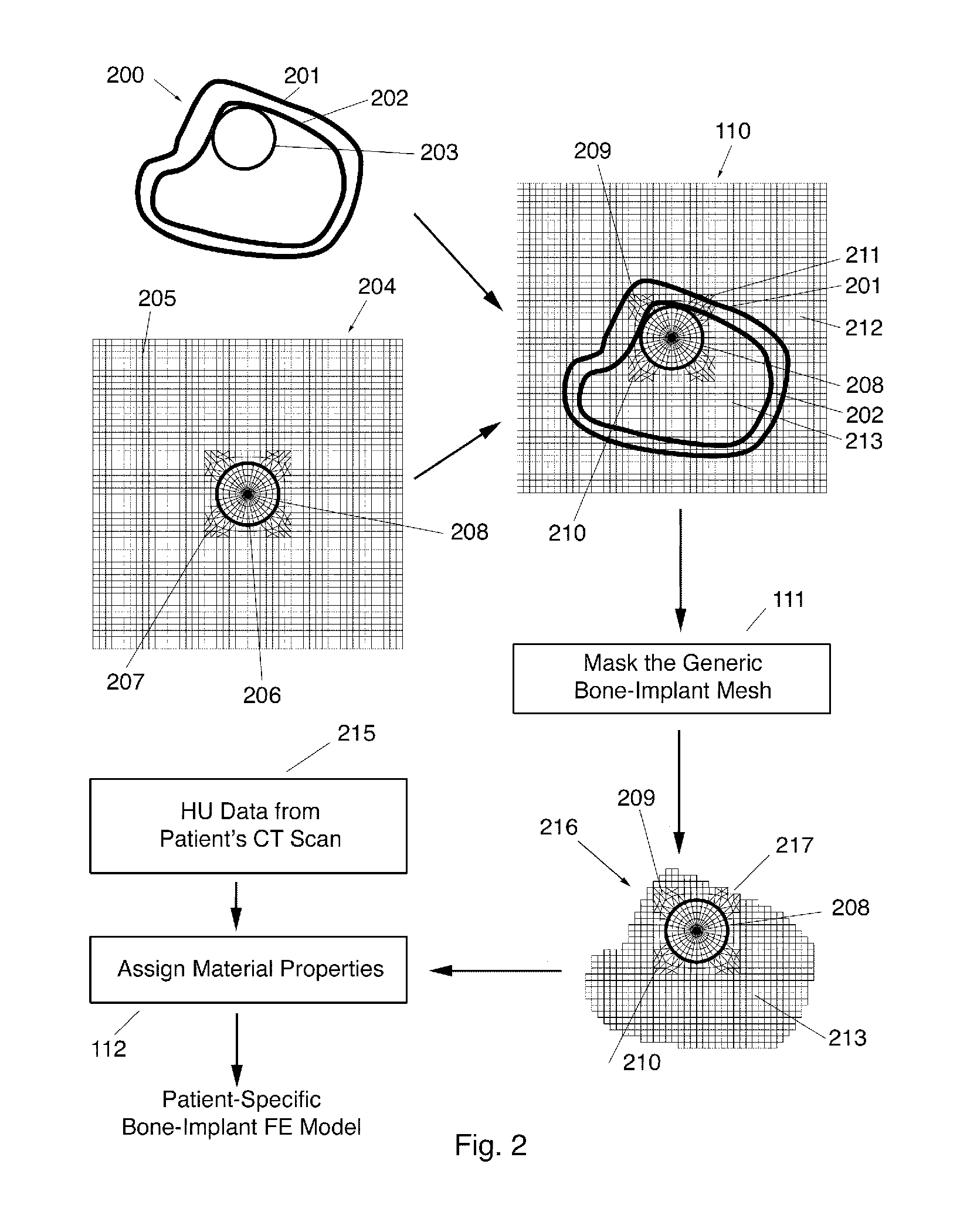

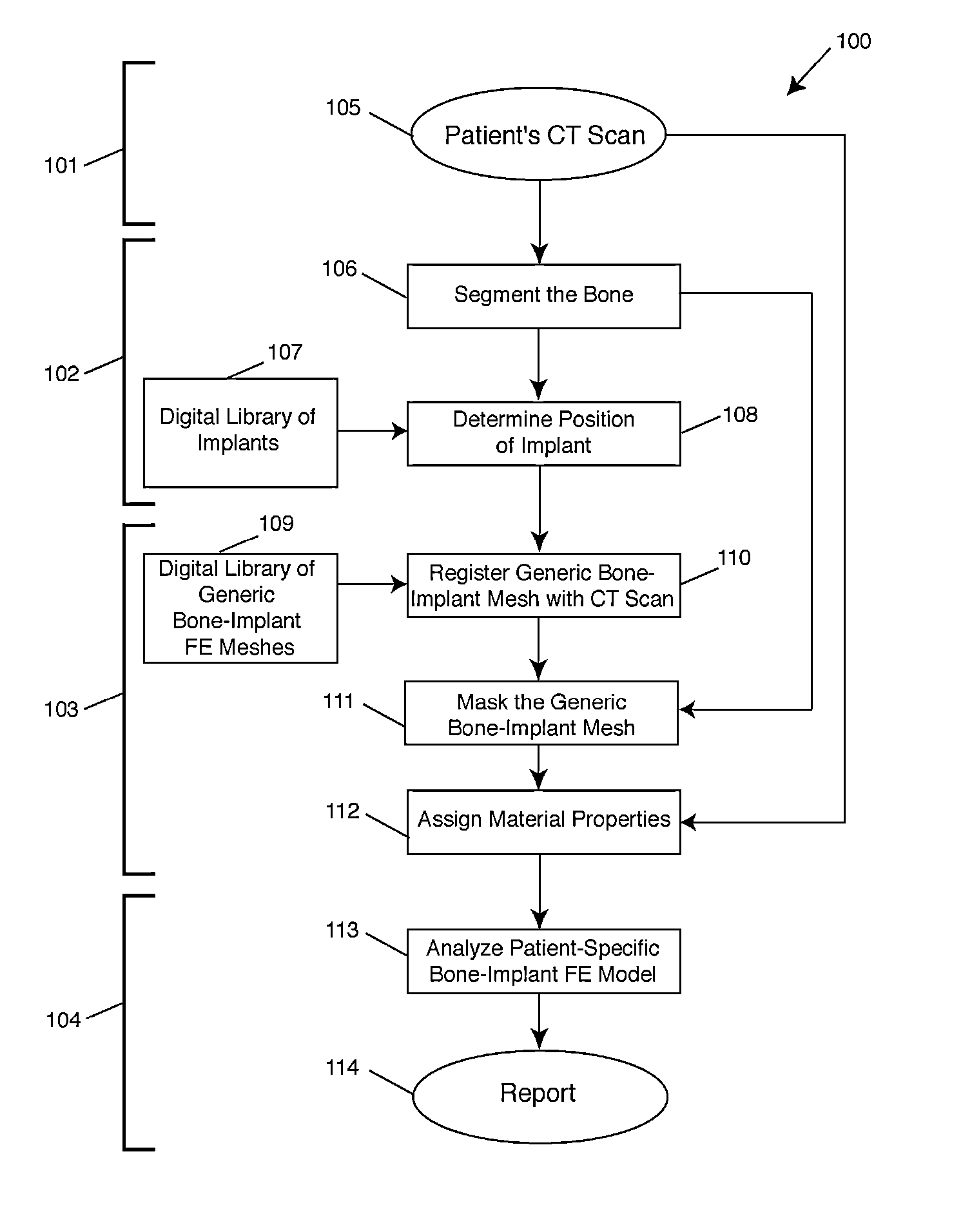

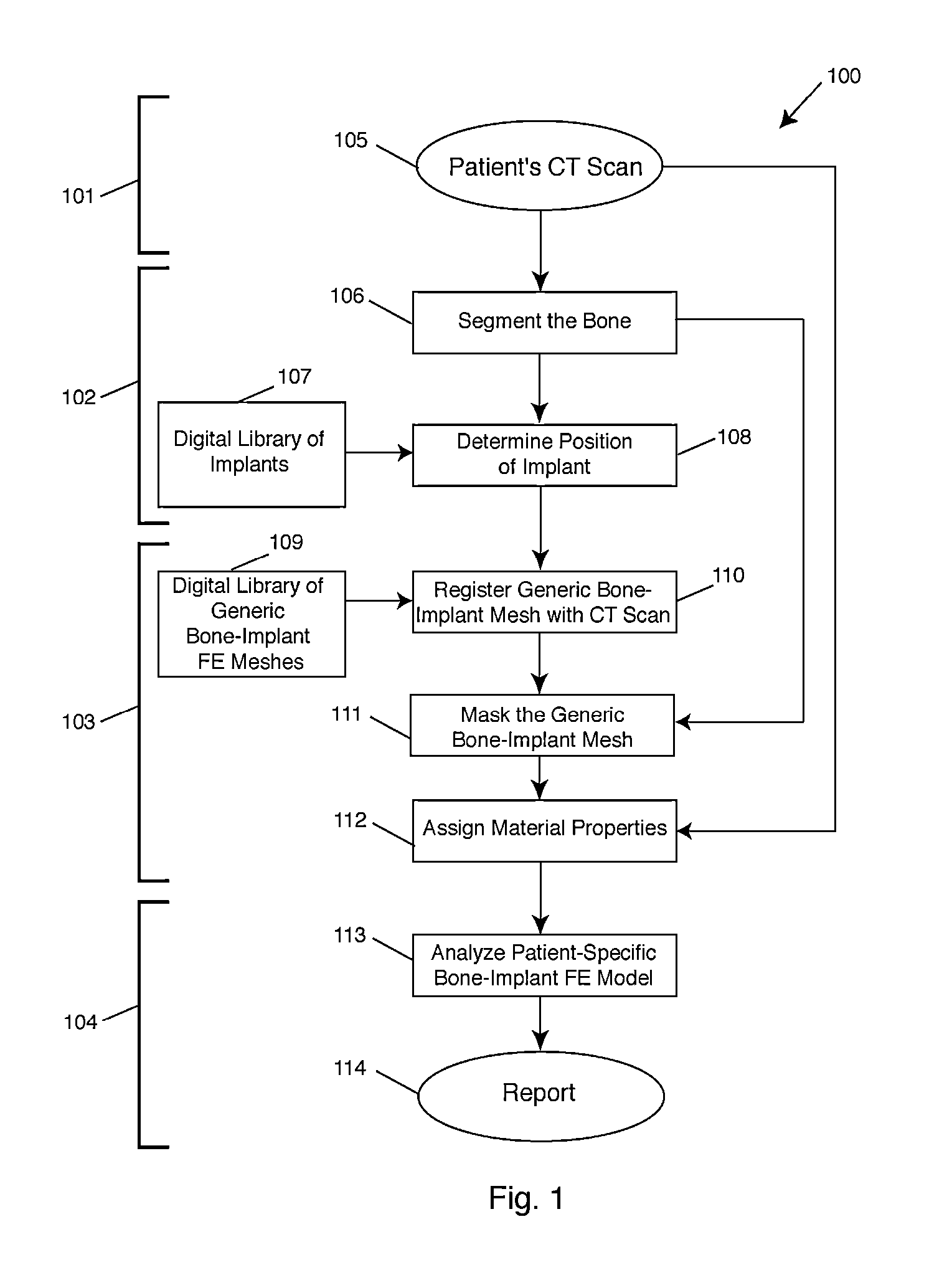

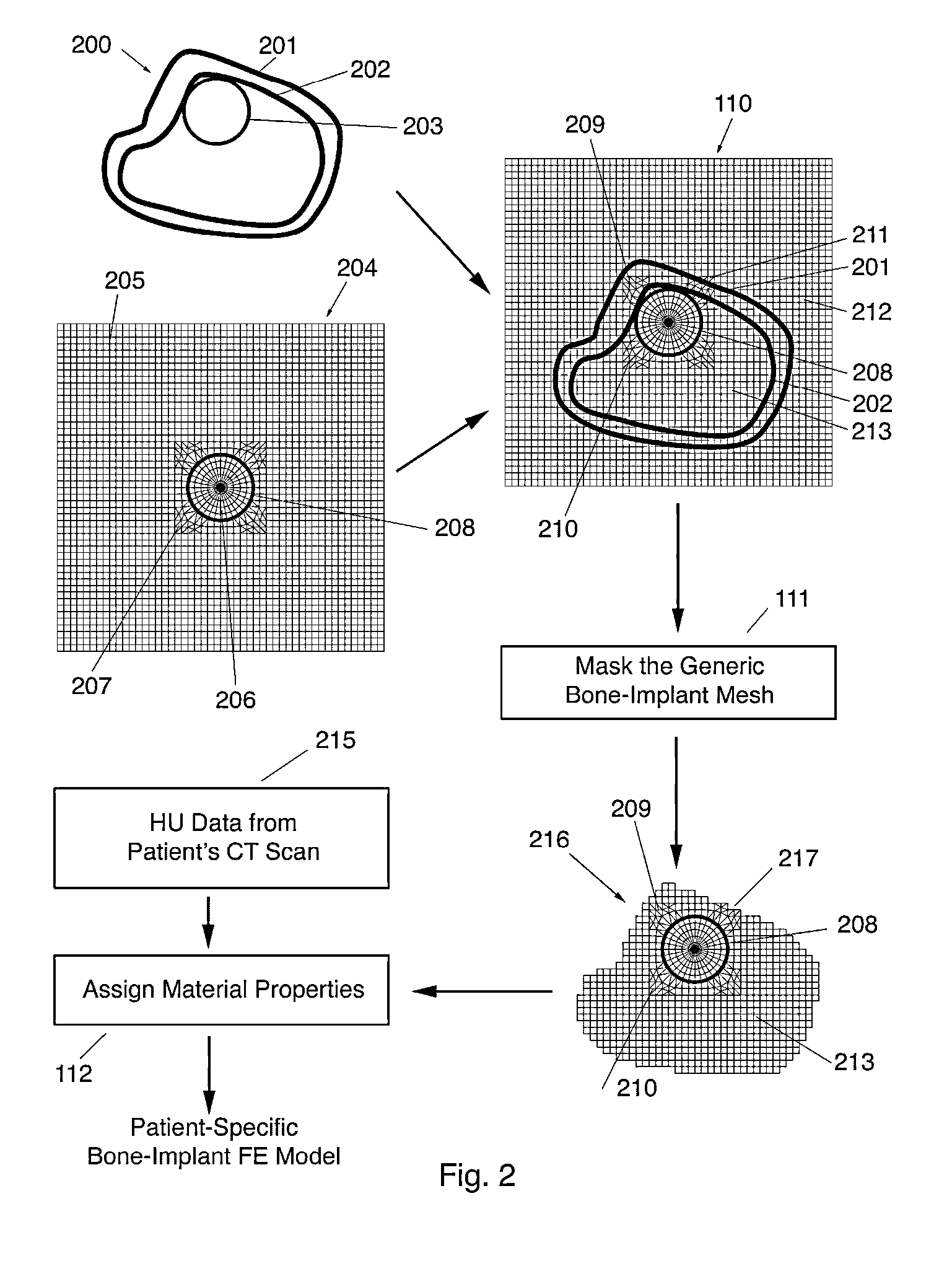

Automated patient-specific bone-implant biomechanical analysis

ActiveUS8855389B1Eliminate needRule out the possibilityMedical simulationMechanical/radiation/invasive therapiesBiomechanicsElement analysis

Owner:O N DIAGNOSTICS

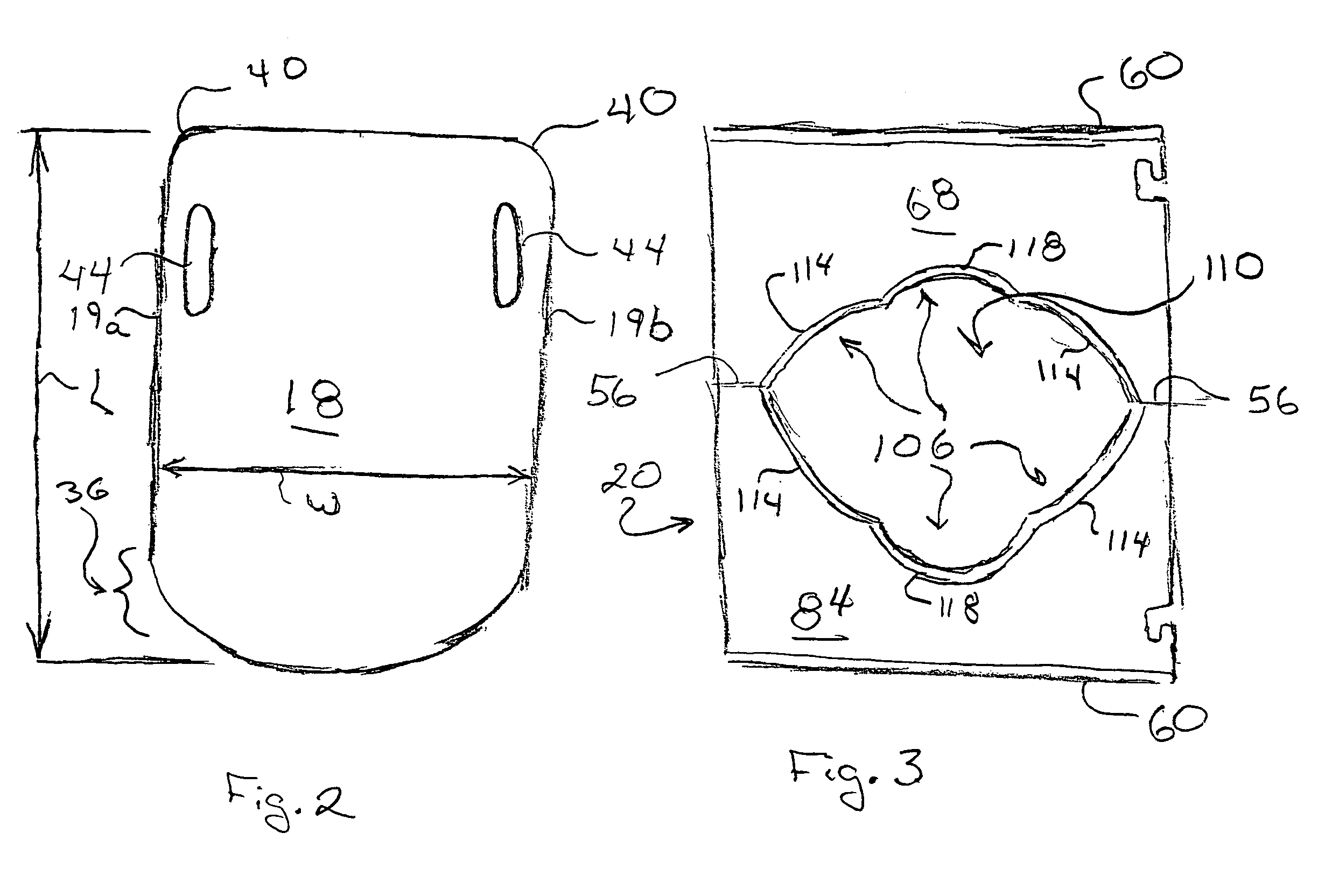

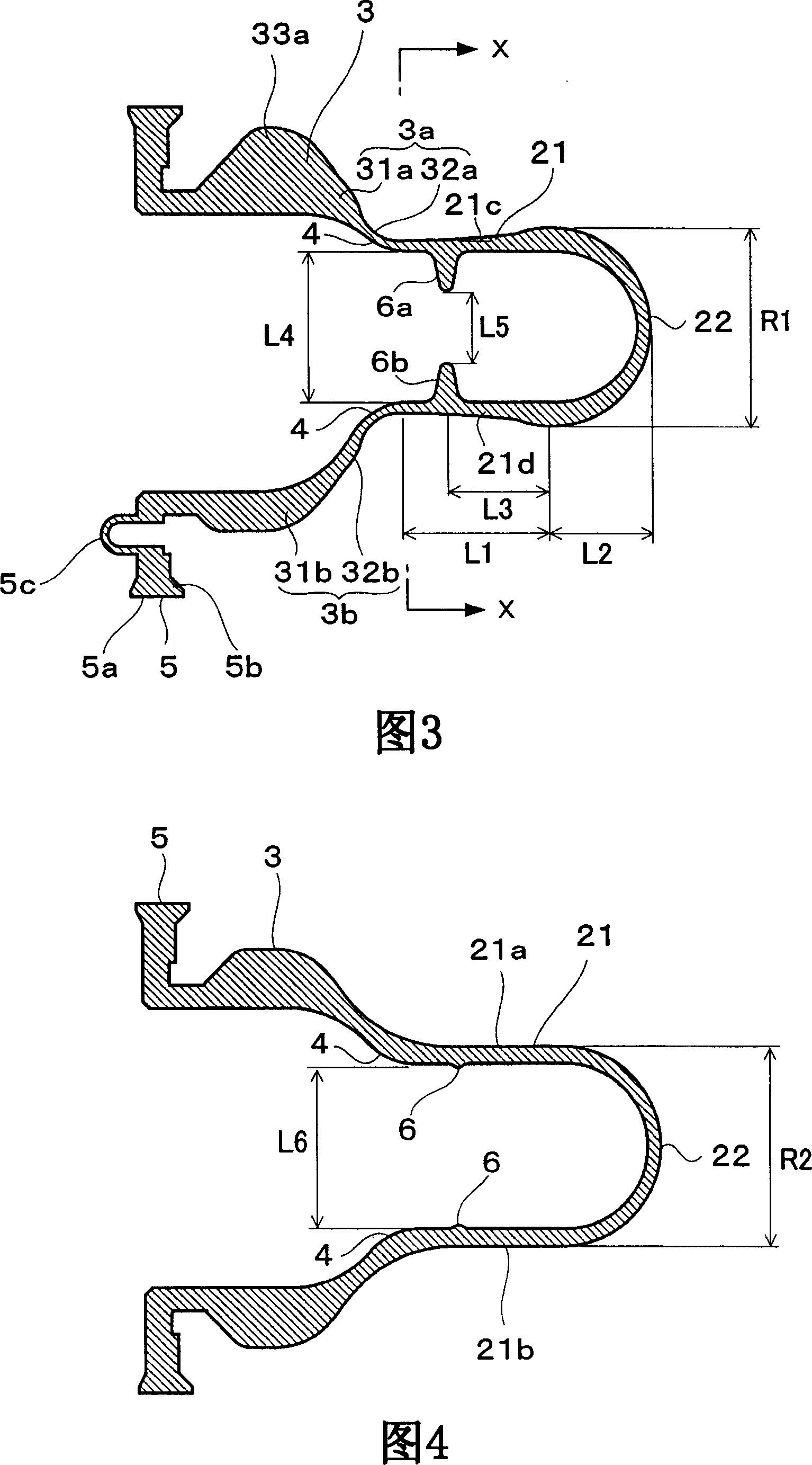

Artificial nipple for a nursing bottle

The invention aims to provide an artificial nipple for a nursing bottle which permits close fitting of the nipple to the sucking fossa of an infant while avoiding deformation of the nipple while providing a form that is similar to a human nipple, and which can prevent the upper and lower sides of the nipple from contacting each other during peristalsis-like movements. In view of this, the present invention provides an artificial nipple for a nursing bottle having: a nipple top part having at its tip a dispensing hole for dispensing a liquid drink; and an artificial nipple body which is continuous to the nipple top part, and whose diameter and wall thickness are greater than those of the nipple top part. The artificial nipple is made of a flexible material. The nipple top part has a rib, which prevents contact between an upper side and a lower side of the nipple top part when the nipple top part is compressed flat, at a portion where gums of an infant touch when an upper lip of the infant is in contact with the artificial nipple body or at an internal surface in the vicinity of the portion.

Owner:OTSUKA PHARM CO LTD

Automated patient-specific bone-implant biomechanical analysis

ActiveUS8644568B1Eliminate needRule out the possibilityMedical simulationImage analysisBiomechanicsElement analysis

An apparatus, method, and computer program product for providing information for surgical planning based on automated biomechanical analysis of a bone-implant system using finite element analysis of a patient's 3D medical image, including automated biomechanical analysis of bone-implant systems for use in surgical planning both pre-operatively and intra-operatively and for use in research and development studies.

Owner:O N DIAGNOSTICS

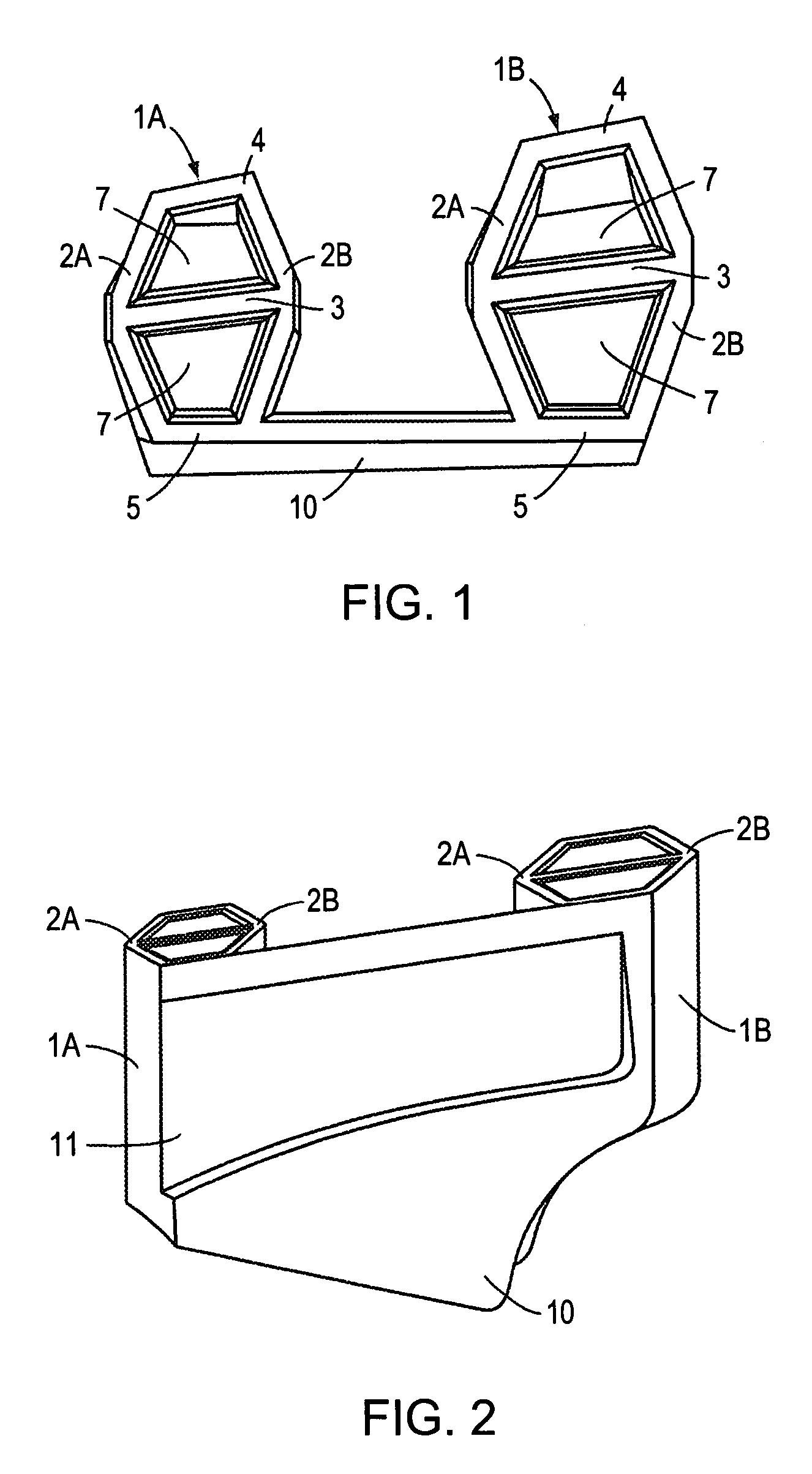

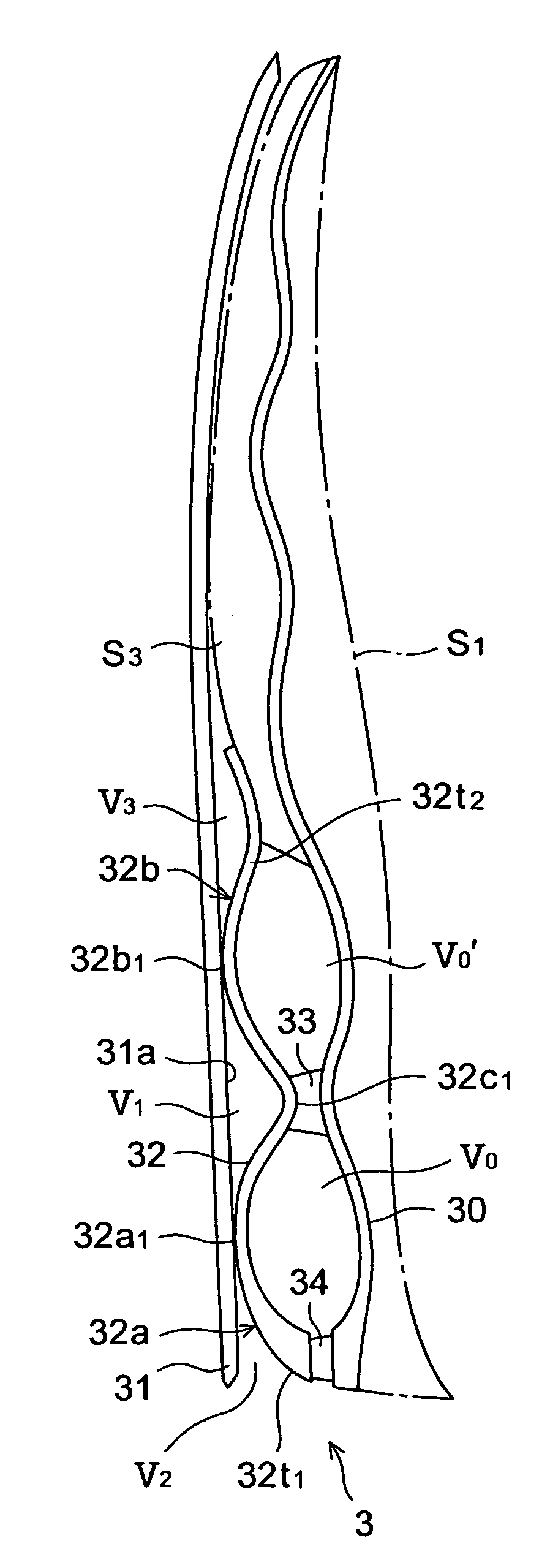

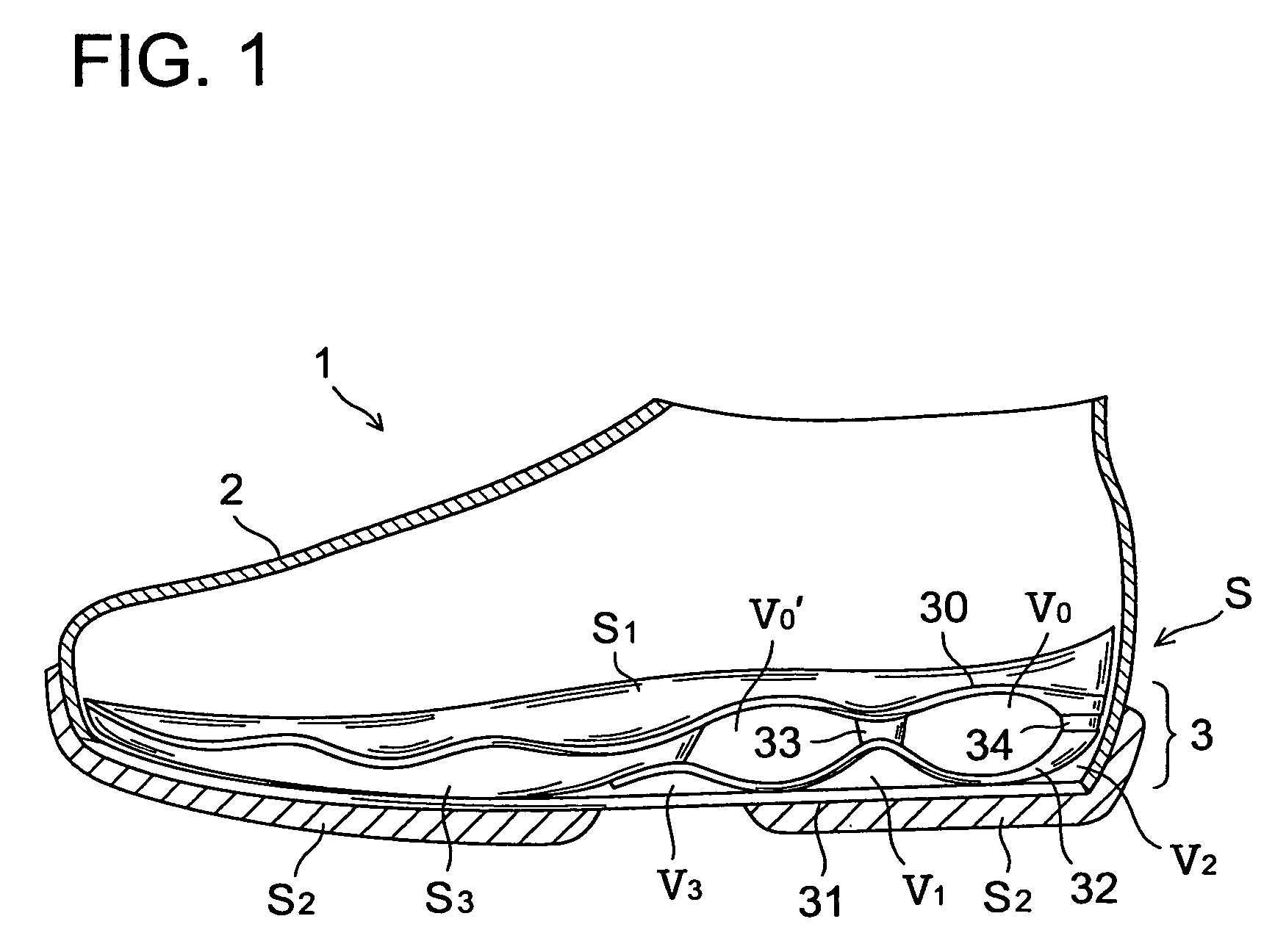

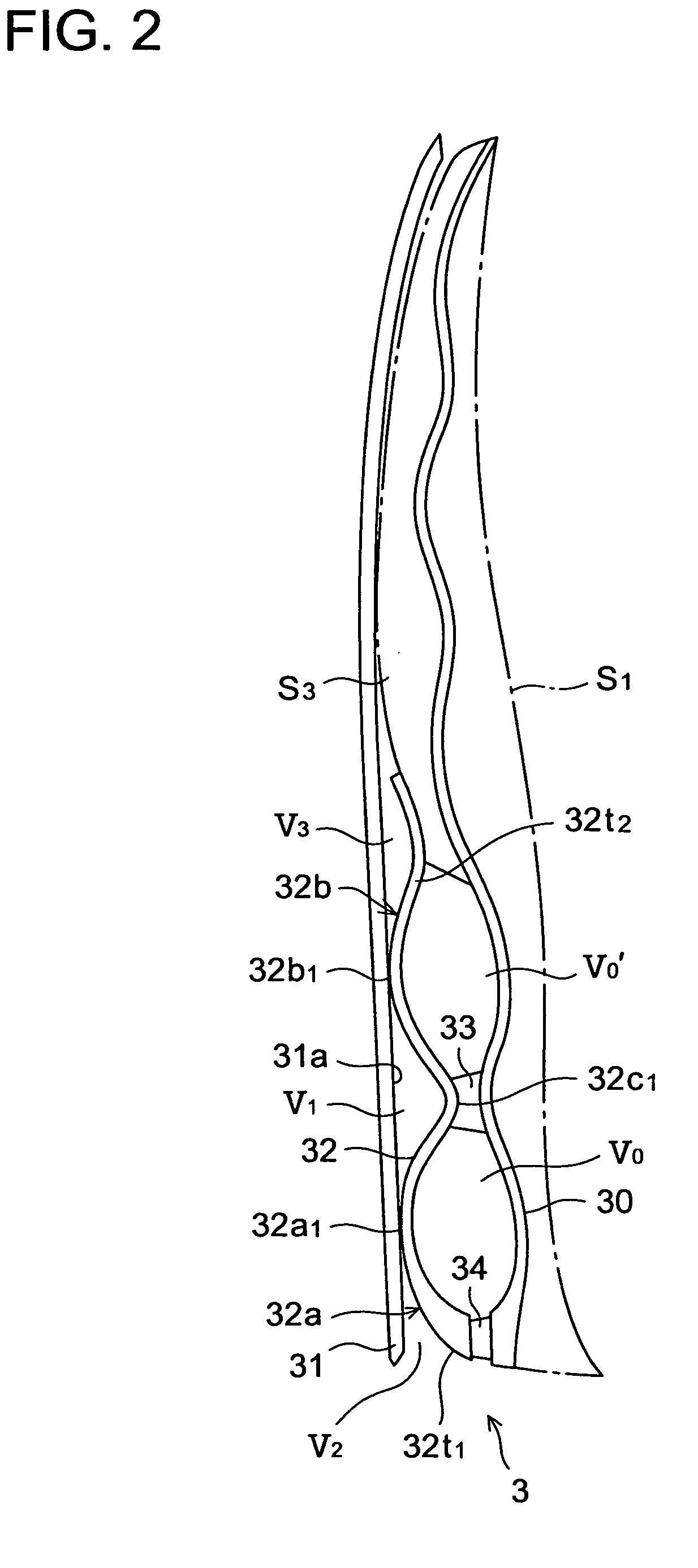

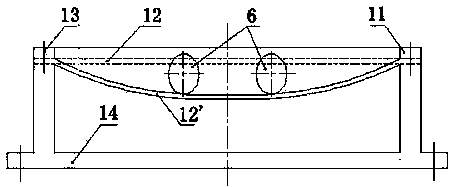

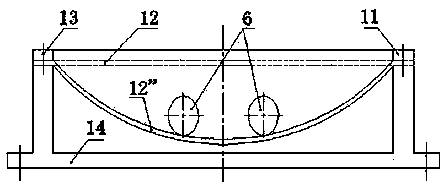

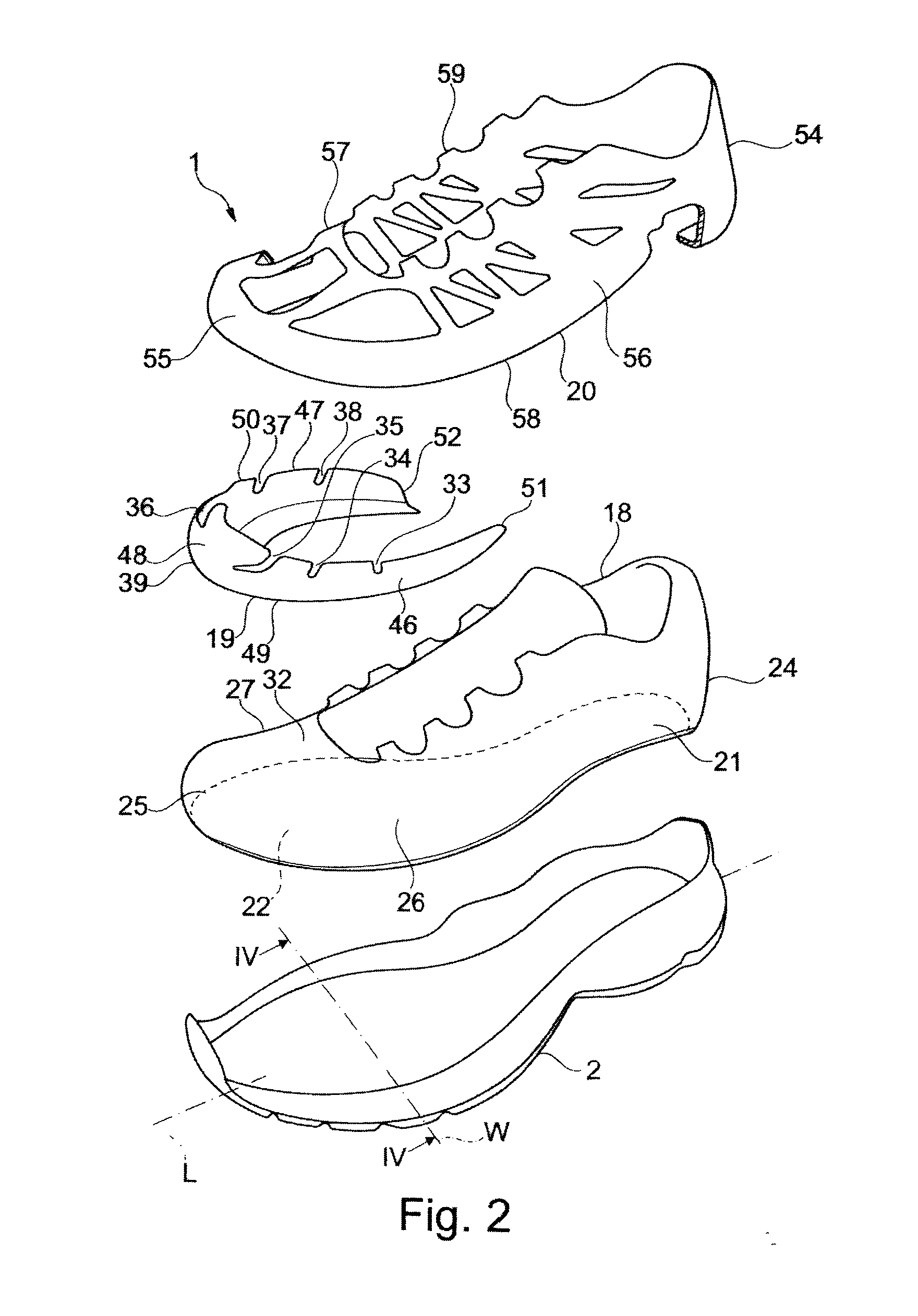

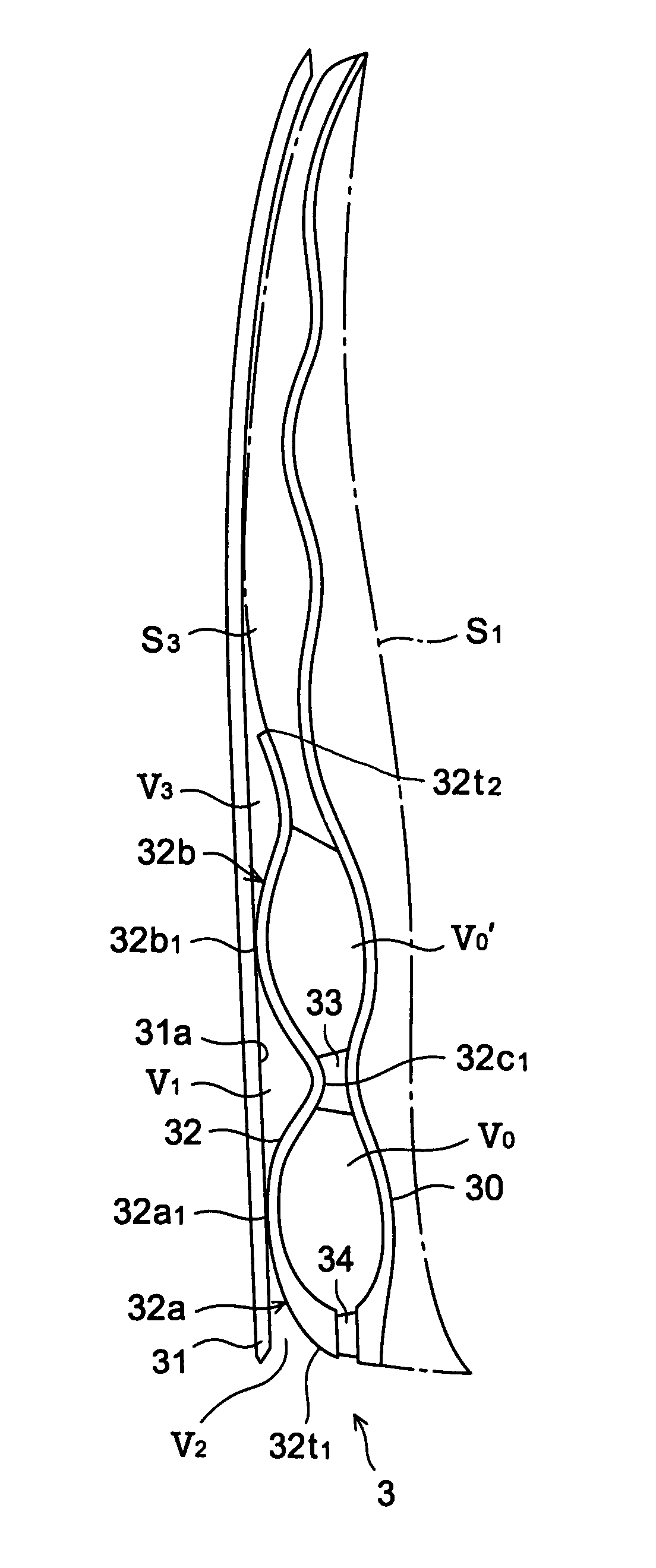

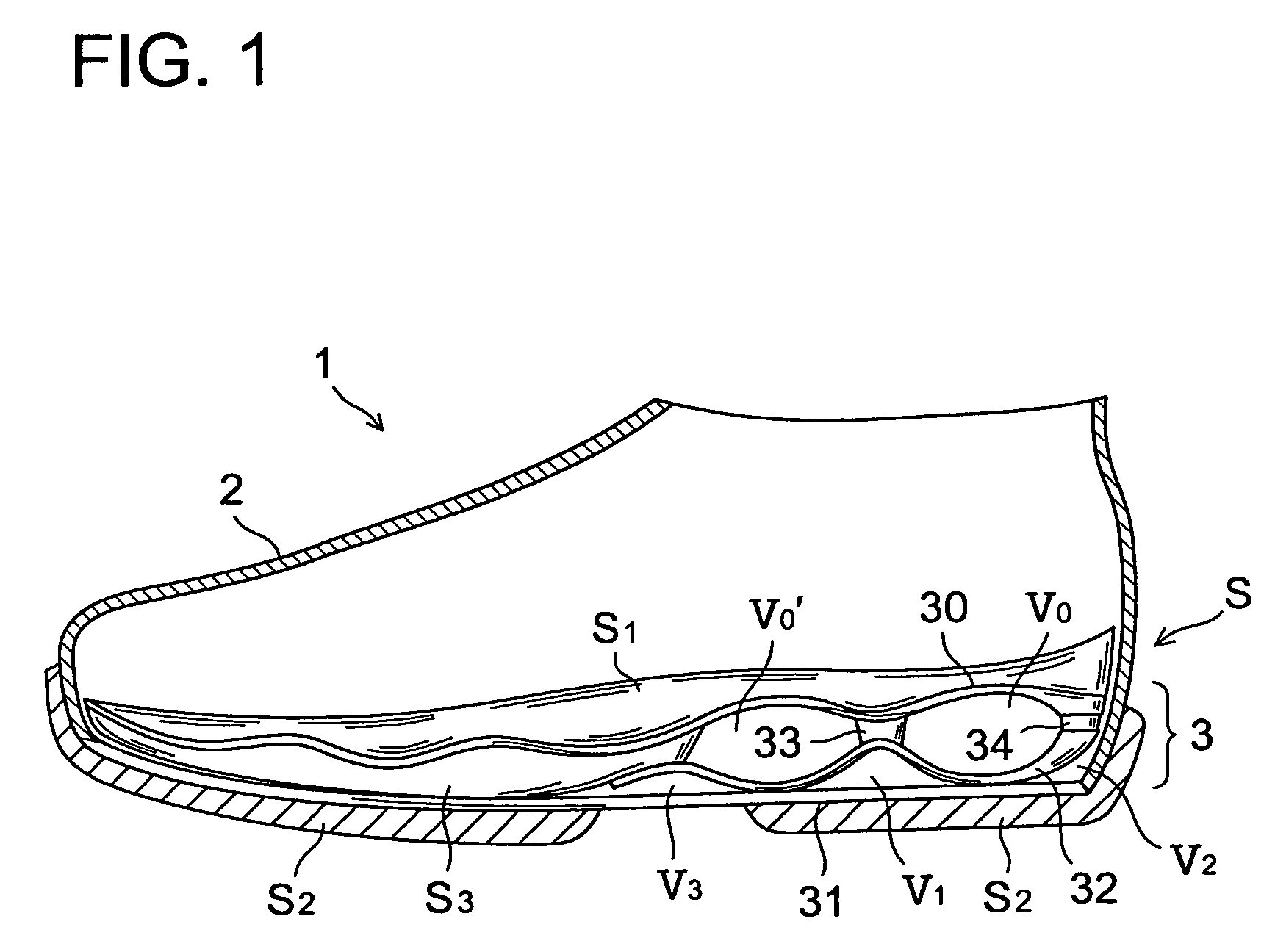

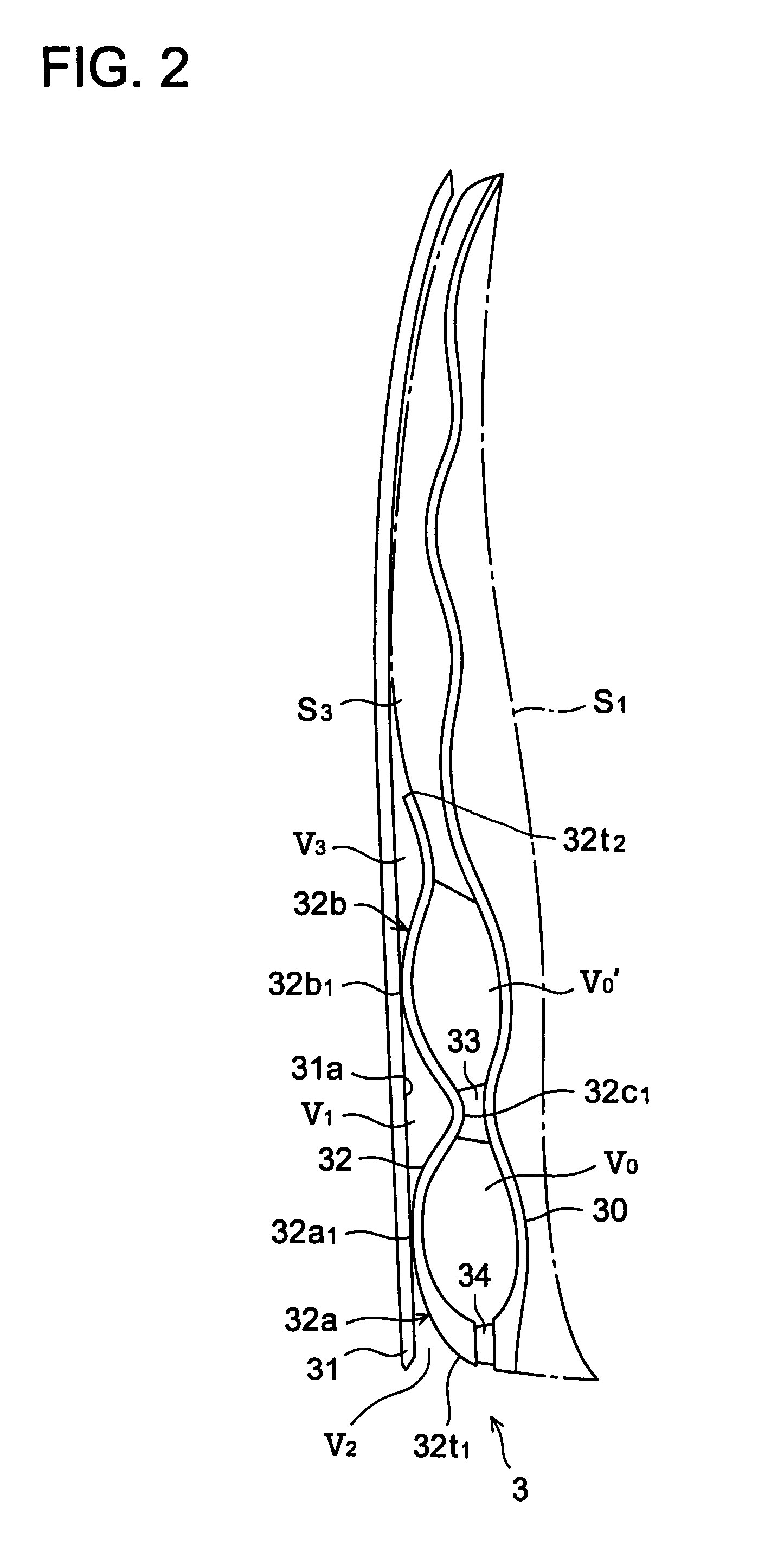

Inner sole structure for a sports shoe

InactiveUS20090241373A1Cushioning ability can be adjustedPrevents an excessive sinking of the upperSolesInsolesMechanical engineeringCompressive deformation

An inner sole structure 3 for a sports shoe 1 includes an upper sheet member 30 disposed on an upper side of a heel region of the shoe 1, a lower sheet member 31 disposed below the upper sheet member 30, and a wavy corrugated sheet member 32 that is interposed between the upper sheet member 30 and the lower sheet member 31, that has at least two downwardly protruding protrusions 32a, 32b adapted to form voids V0, V1′, V1 with the upper and lower sheet members 30, 31, and that is in contact with an upper surface 31a of the lower sheet member 31. Each of downwardly convex portions 32a1, 32b1 of the protrusions 32a, 32b of the wavy corrugated sheet member32 slides longitudinally on the lower sheet member 31 at the time of compressive deformation of the protrusions 32a, 32b.

Owner:MIZUNO CORPORATION

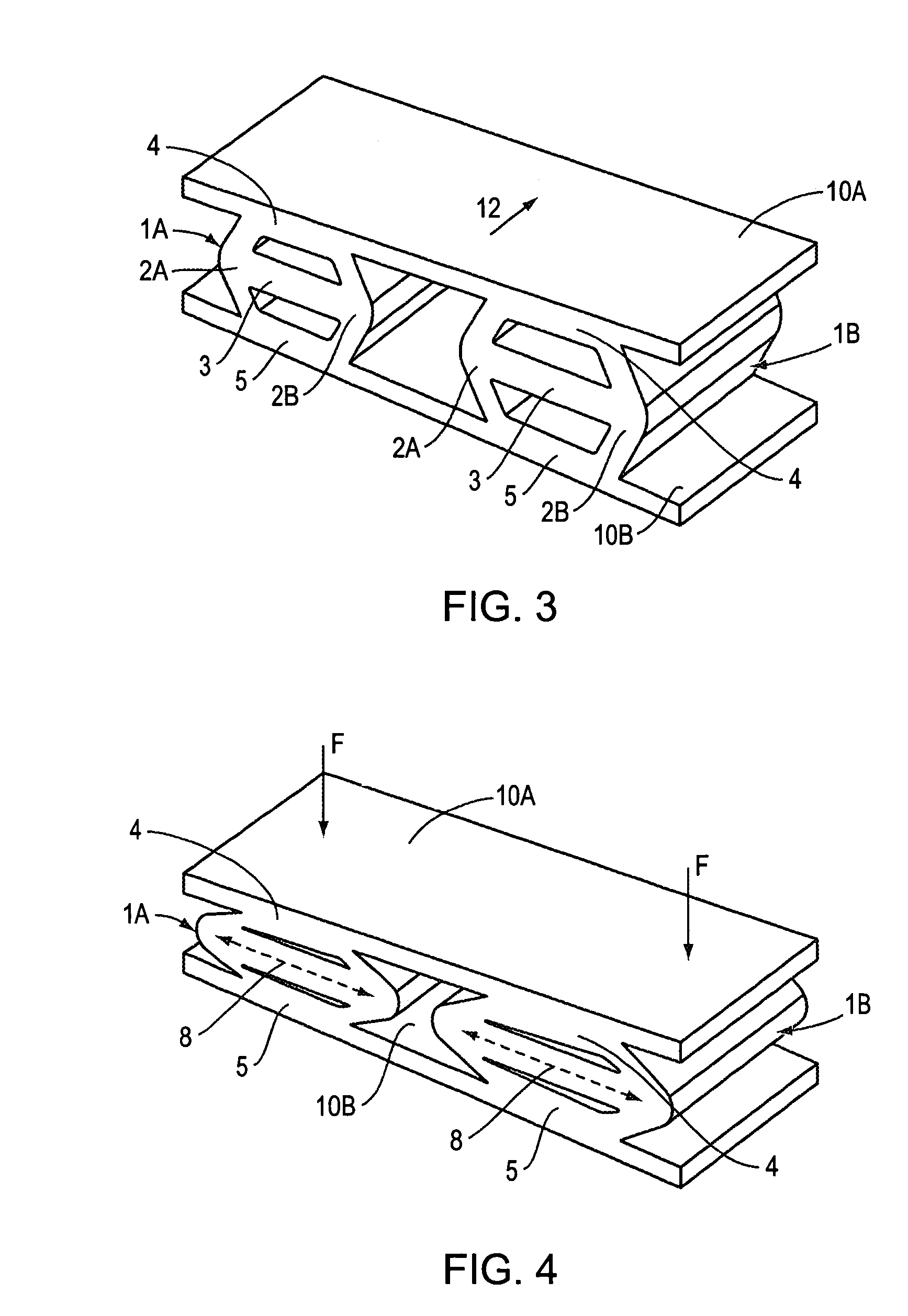

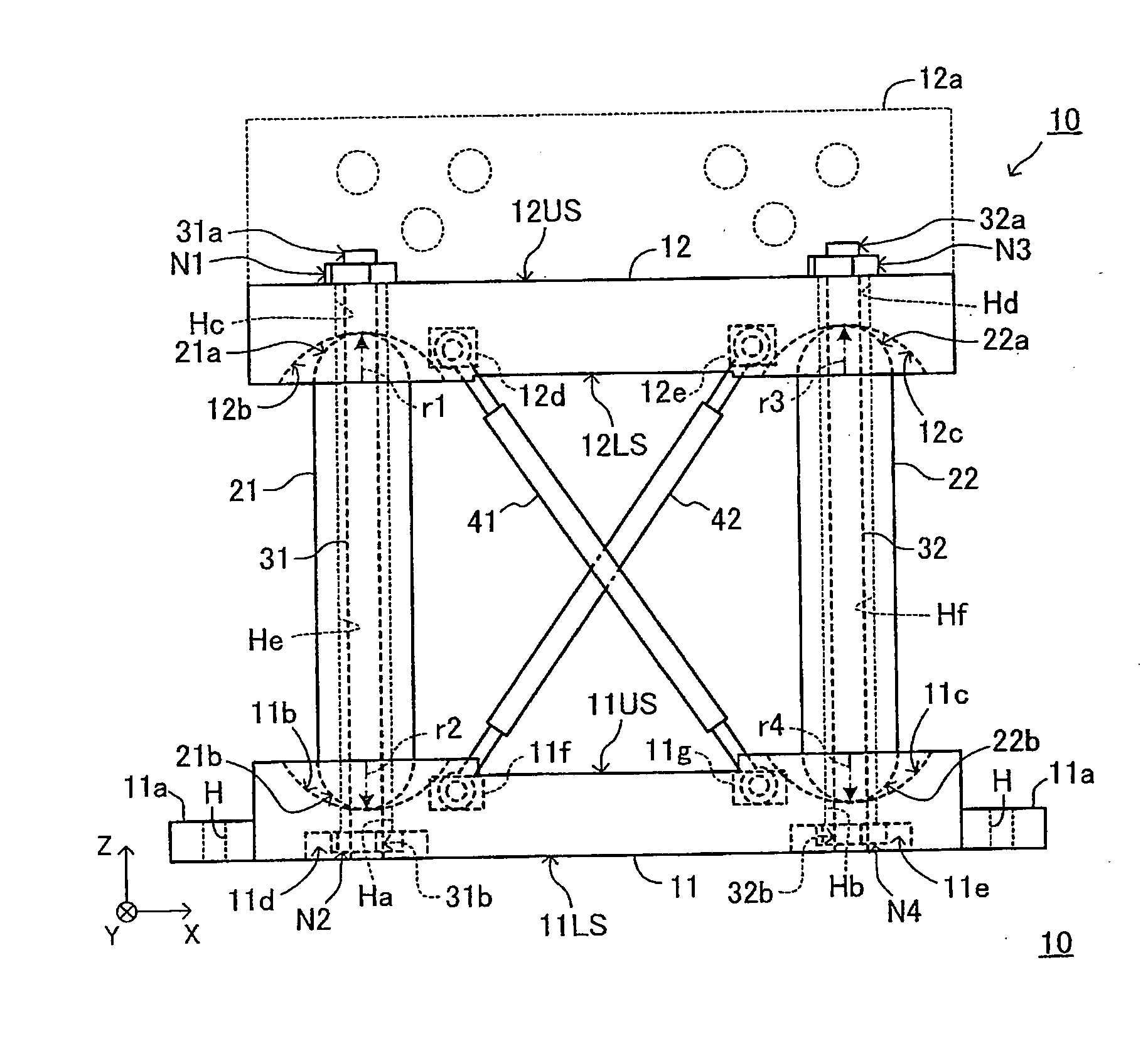

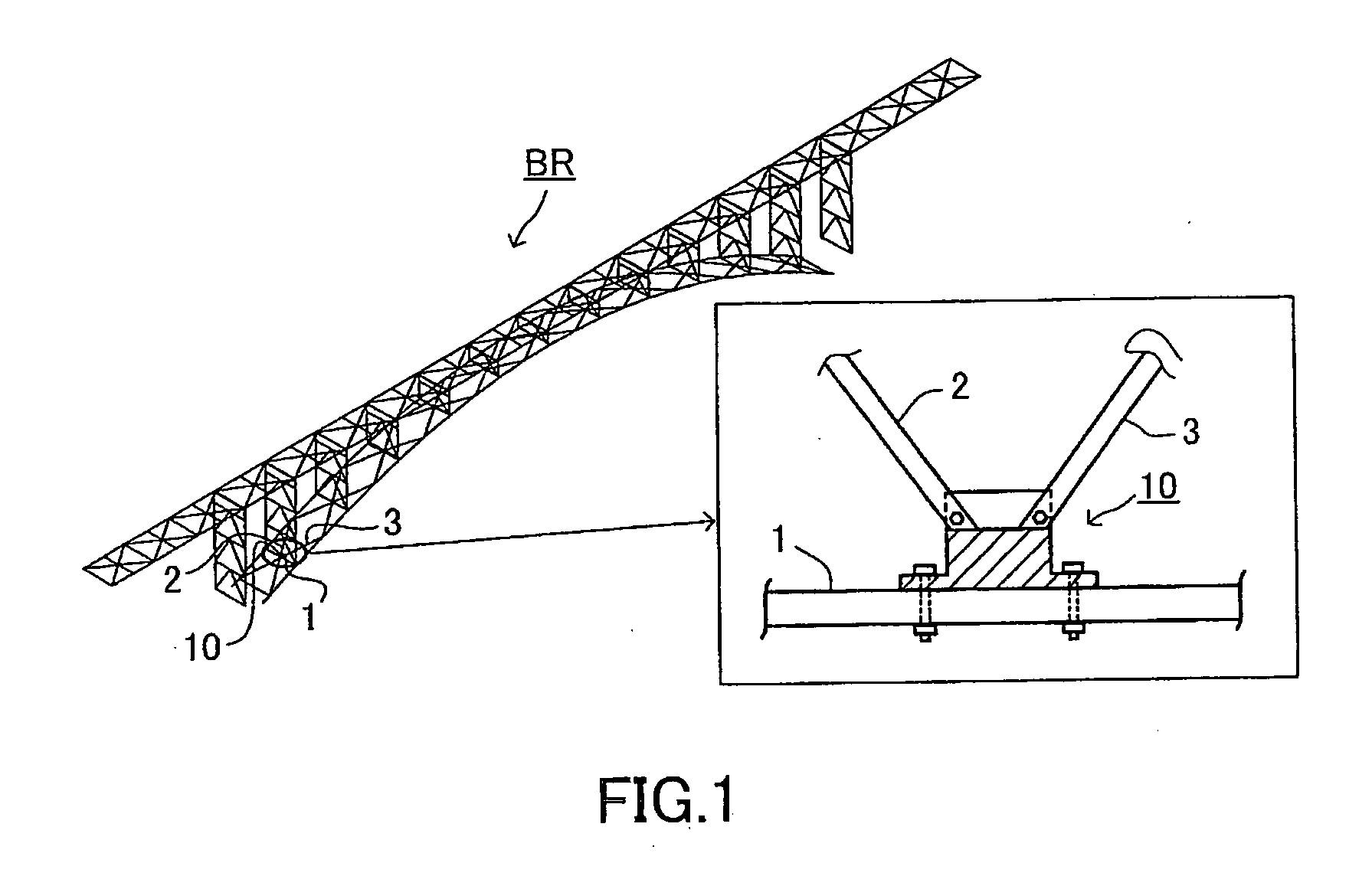

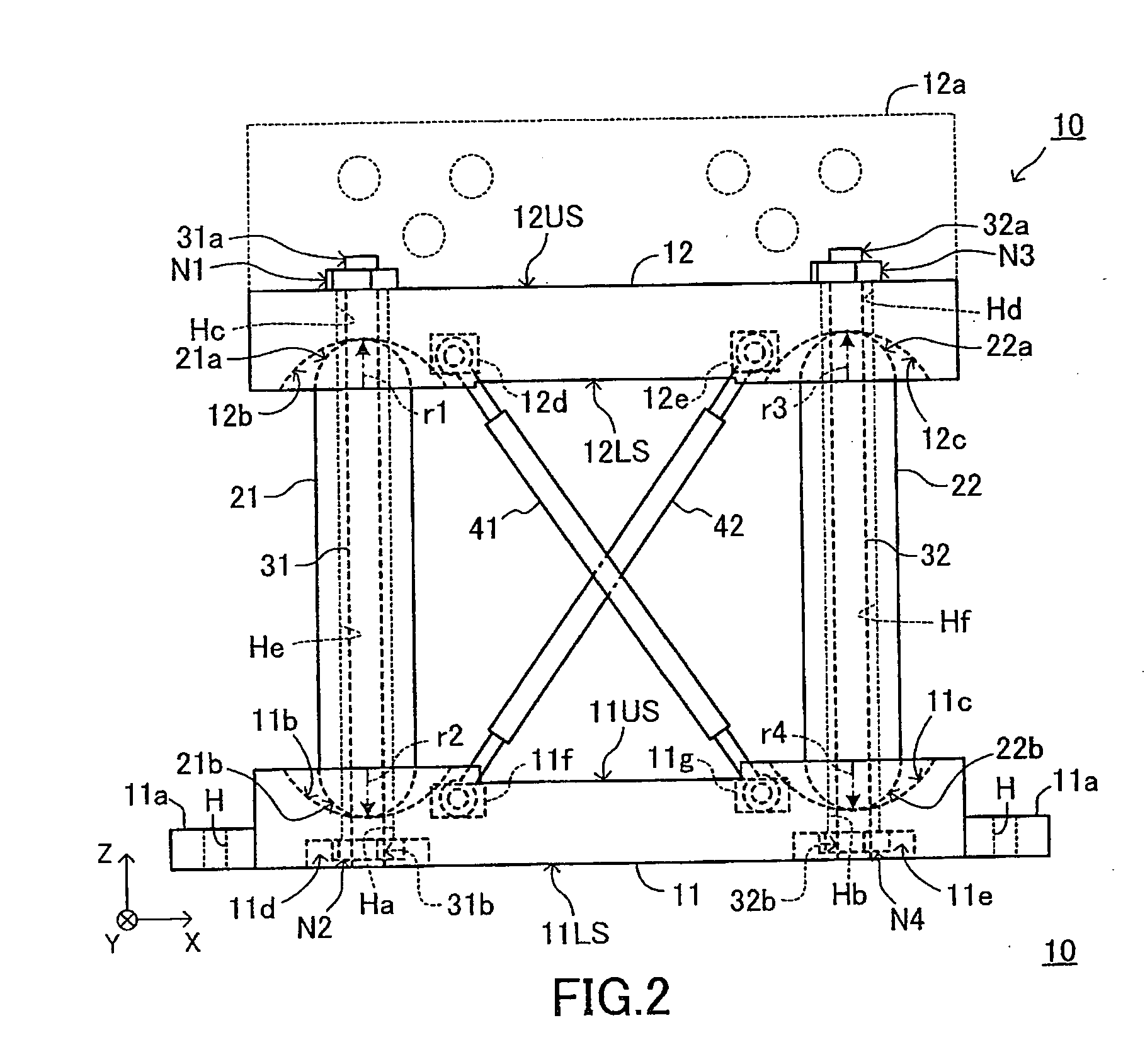

Self-centering compact damper unit applicable to structures for seismic energy dissipation

InactiveUS20110239551A1Smooth deformationNon-rotating vibration suppressionBridge structural detailsSteel barSeismic energy

The damper unit 10 is applicable to structures for seismic energy dissipation. The damper unit 10 comprises, a lower beam 11, an upper beam 12, a left column 21, a right column 22, axially yielding dampers 41, 42 functioning as an energy dissipating means, a left post-tensioned steel bar 31, and a right post-tensioned steel bar 32. The left and right post-tensioned steel bars 31 and 32 are inserted in the left and right columns 21 and 22, respectively. Upper ends of the steel bars 31 and 32 are connected with the upper beam 12. Lower ends of the steel bars 31 and 32 are connected with the lower beam 11. The columns 31 and 32 are semi-rigid connected with the upper beam 12 and the lower beam 11 by compressive forces generated from the steel bars 31 and 32. Therefore, the damper unit 10 possesses both self-centering and seismic energy dissipation characteristics.

Owner:NAGOYA INSTITUTE OF TECHNOLOGY

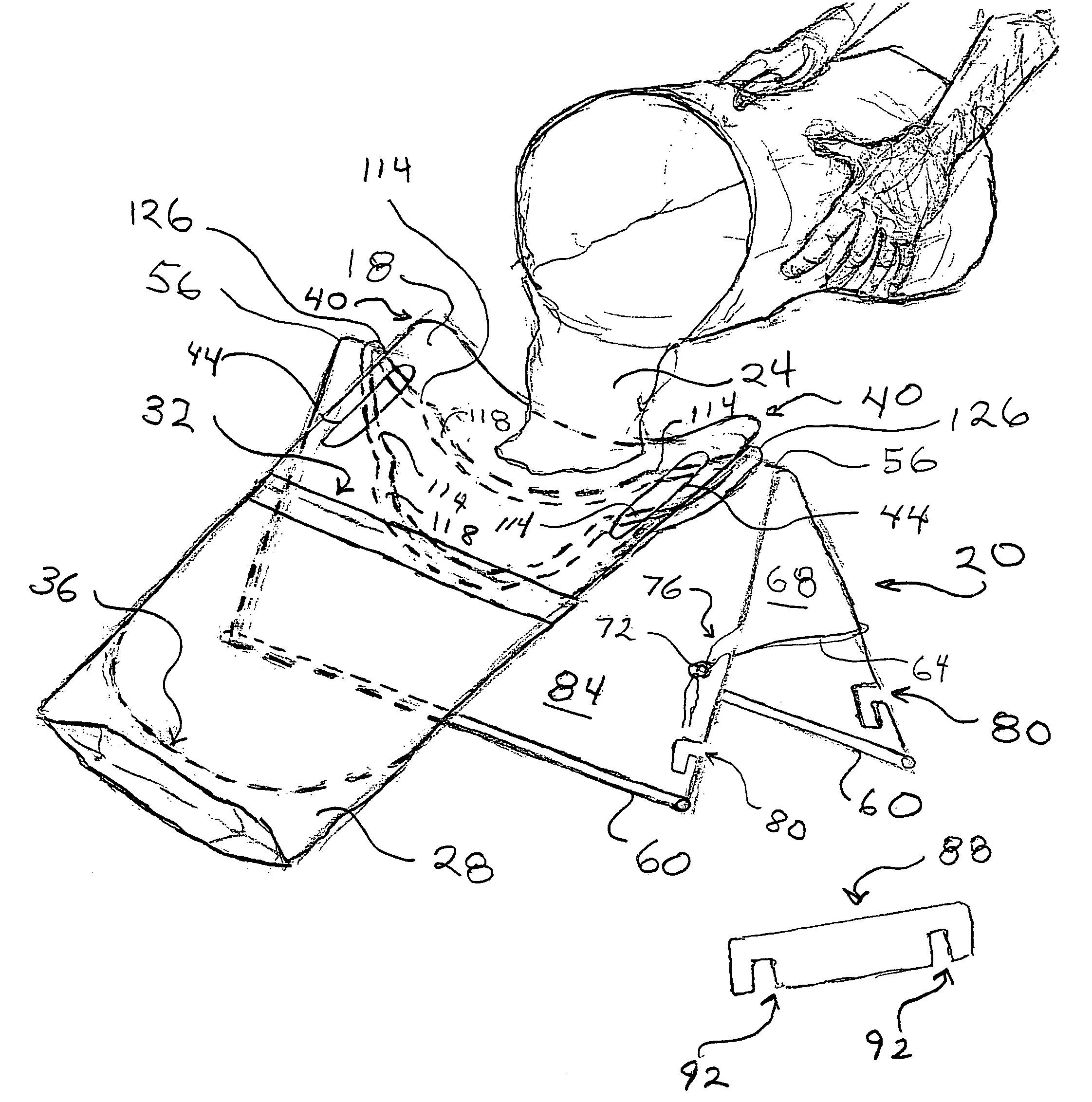

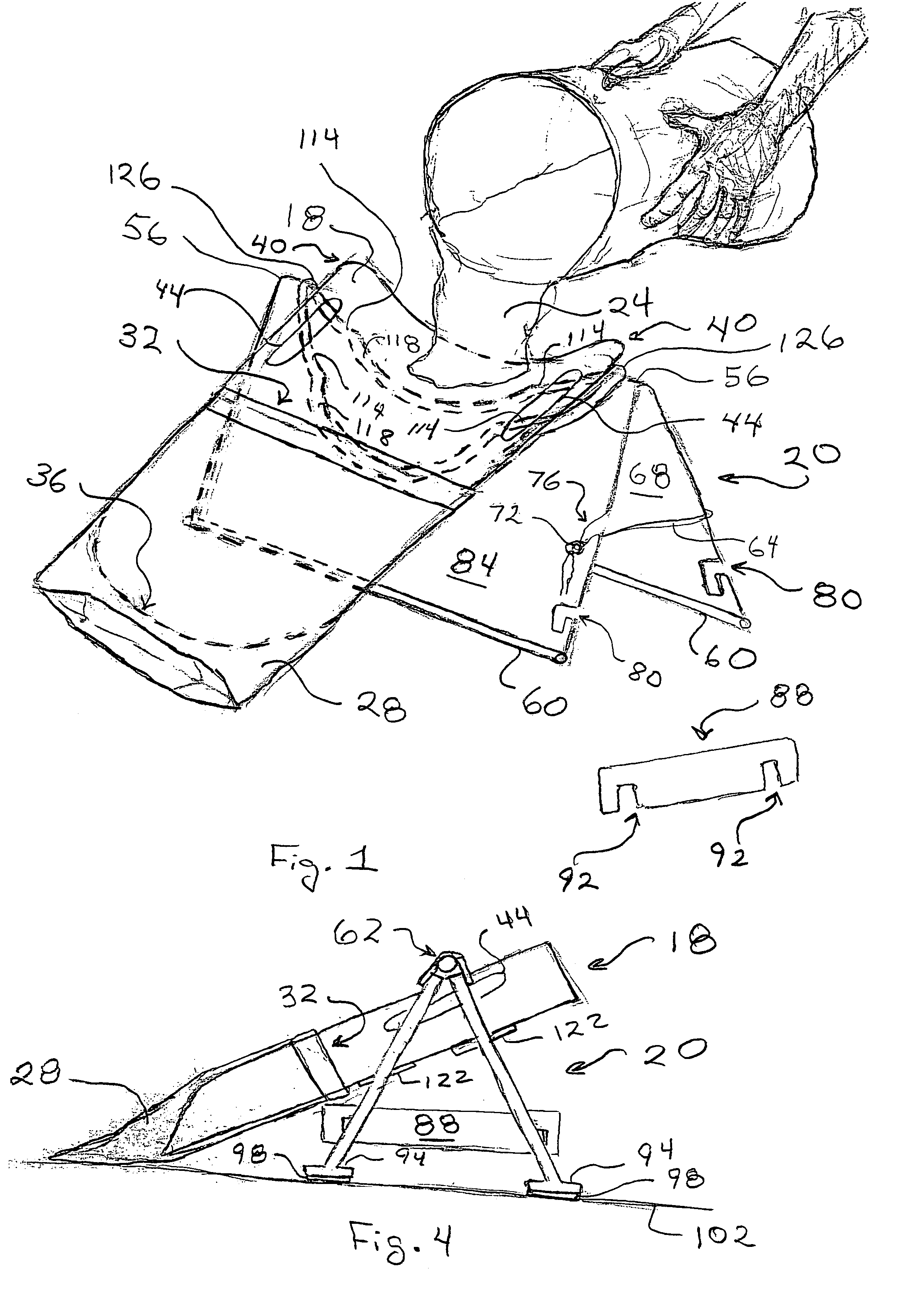

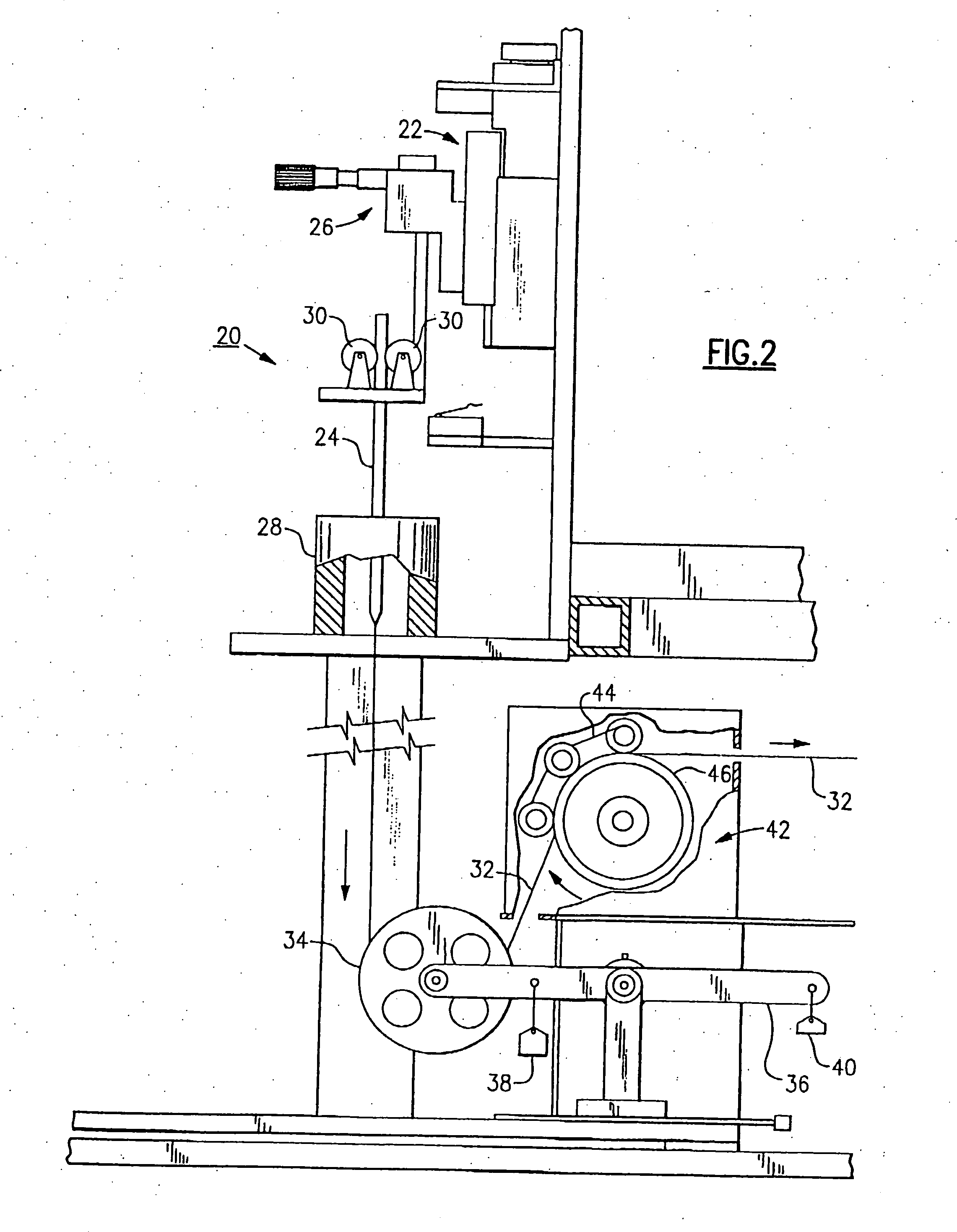

Method and device for inserting a food stuff into a pliable bag

InactiveUS7246641B2Easy and efficient in depositingReduce exposureLiquid fillingBlanketProcess engineeringBending force

A resilient foodstuff bag opener is disclosed, wherein the resilient bag opener is forcibly bent or bowed for easily entering a pliable food stuff bag, and upon relaxation of the bending forces, the bag opener resiliently deforms from its bent configuration to thereby open the food stuff bag in a manner that allows a food stuff residing on a food support surface of the bag opener to flow into the food stuff bag. The food support surface of the bag opener may be also used for processing foods such as cutting, dicing, washing, straining, etc. depending on the embodiment used. An inclined support may be optionally provided for maintaining the bag opener in a “hands-free” inclined position so that a food stuff provided on the food support surface can flow into the food stuff bag without a user having to hold the bag opener.

Owner:BLESSMAN BRAD

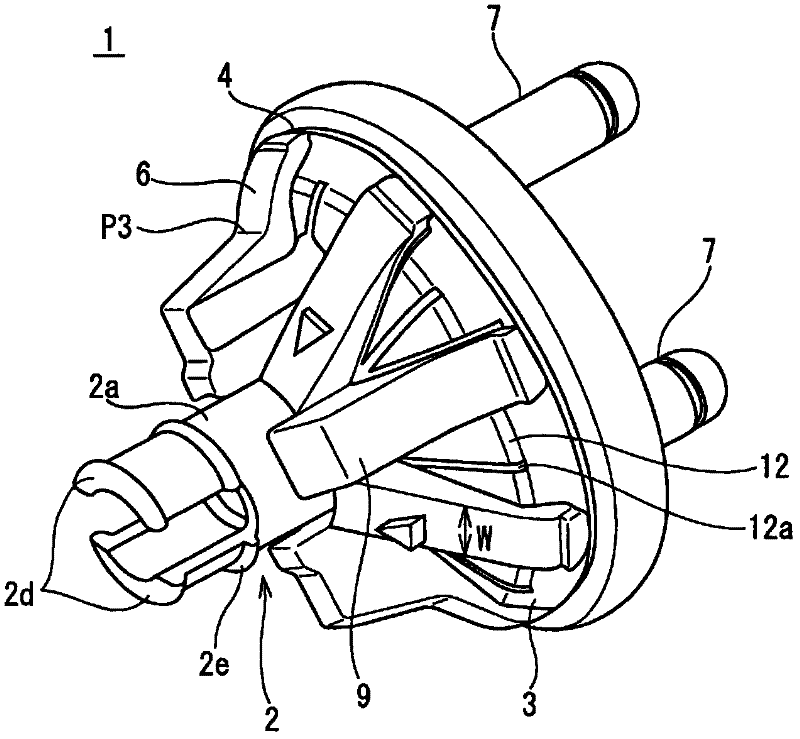

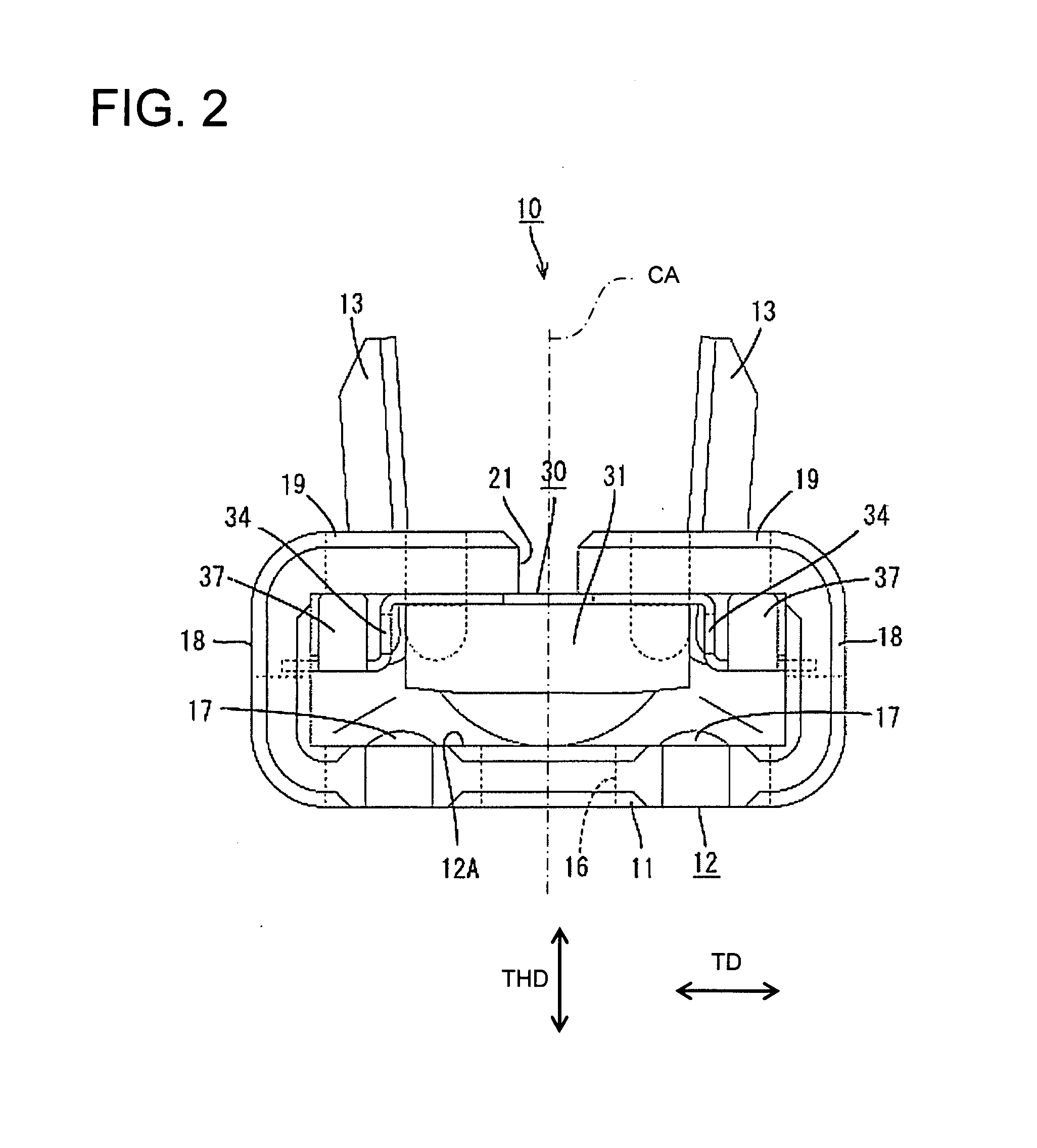

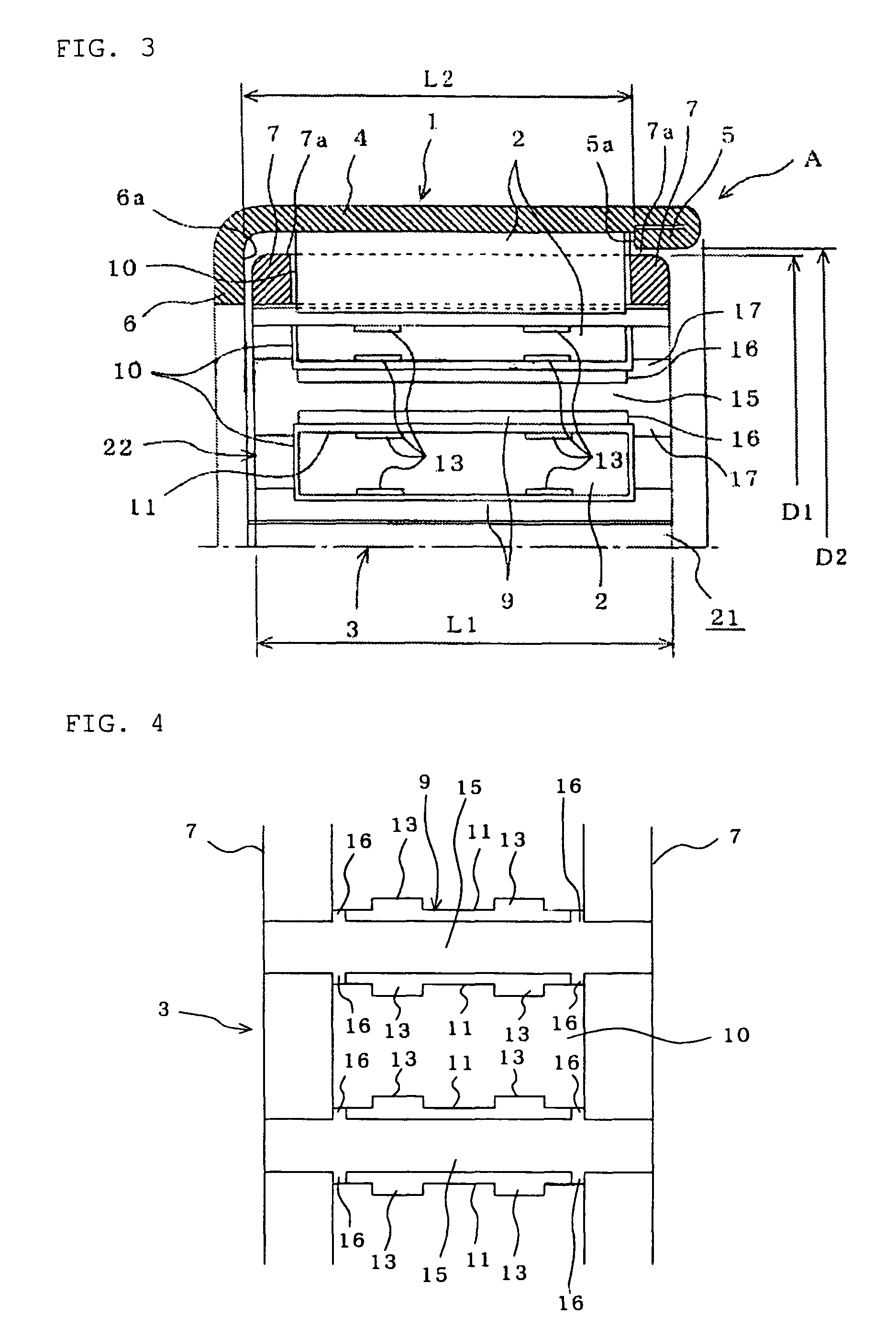

Grommet

InactiveCN102239617AReduce the number of winding operationsGood shape retentionElectric/fluid circuitInsulating bodiesEngineeringGrommet

A grommet mounted in a through-hole in a vehicle body panel and through which a wire harness is passed. Even if taping only one side, the grommet shape is retained and the grommet is prevented from deforming in the direction in which an engaging recess of the grommet separates from the peripheral edge of the through-hole. The grommet comprises: an enlarged-diameter tube which connects to the outer periphery of the longitudinal intermediate section of a small-diameter tube through which wires are tightly passed, and which is enlarged in diameter to surround the other side of the small-diameter tube; an engaging recess which is annularly formed in the outer peripheral surface of the enlarged-diameter tube on the large diameter side thereof; inner ribs provided at intervals in the circumferential direction and connecting between the inner periphery of the enlarged-diameter tube and the outer peripheral surface of the other side of the small-diameter tube; and wire insertion tubes which connect to through-holes for wires formed in the enlarged-diameter tube and which extend through the inside of the enlarged-diameter tube and project from the opening end on the large-diameter side. The inner ribs stick out with a clearance from the inner peripheral surface of the enlarged-diameter tube from the position where the enlarged-diameter tube contacts the inner peripheral surface of the through-hole of the vehicle body panel to a position facing the engaging recess.

Owner:SUMITOMO WIRING SYST LTD

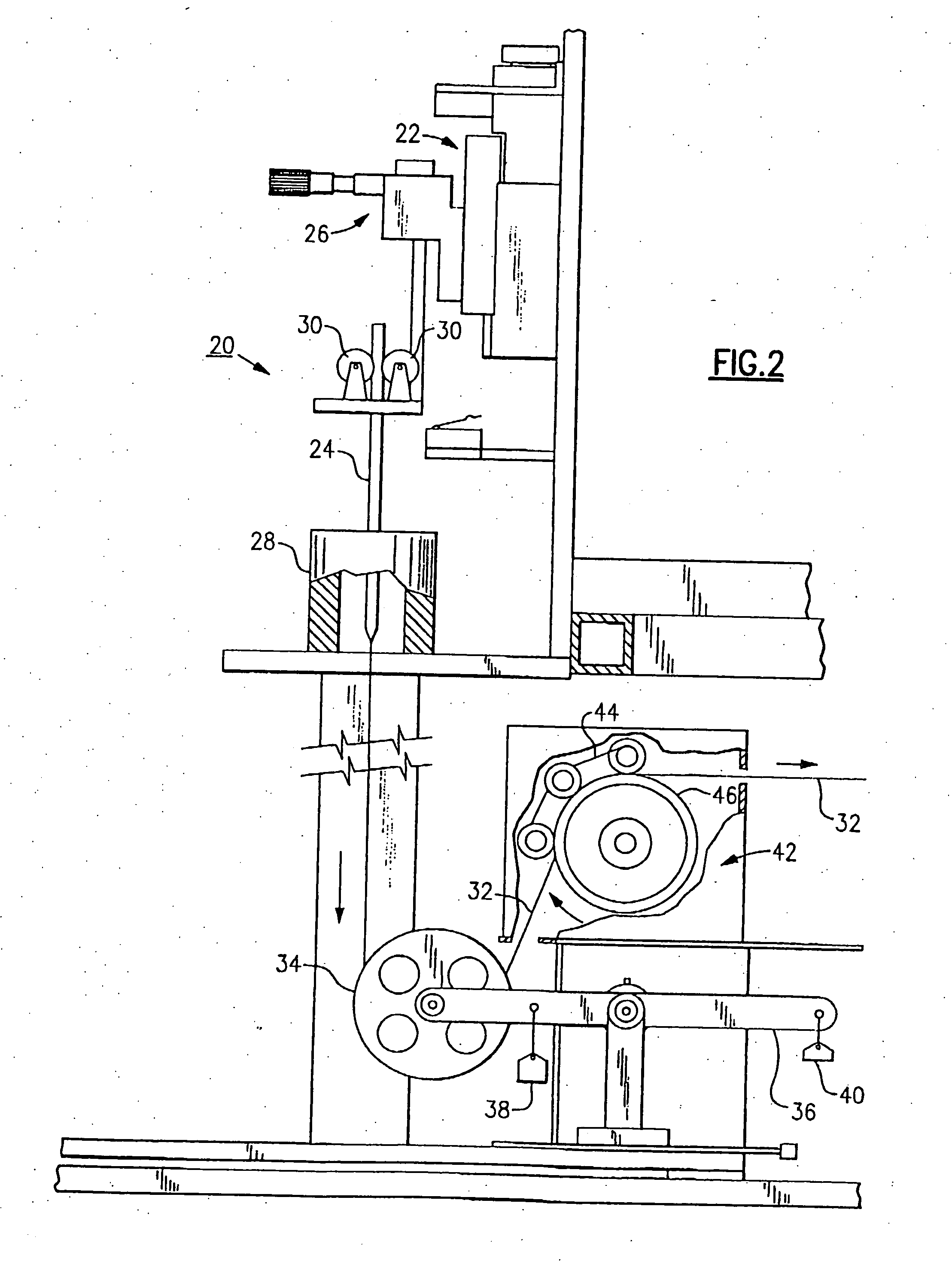

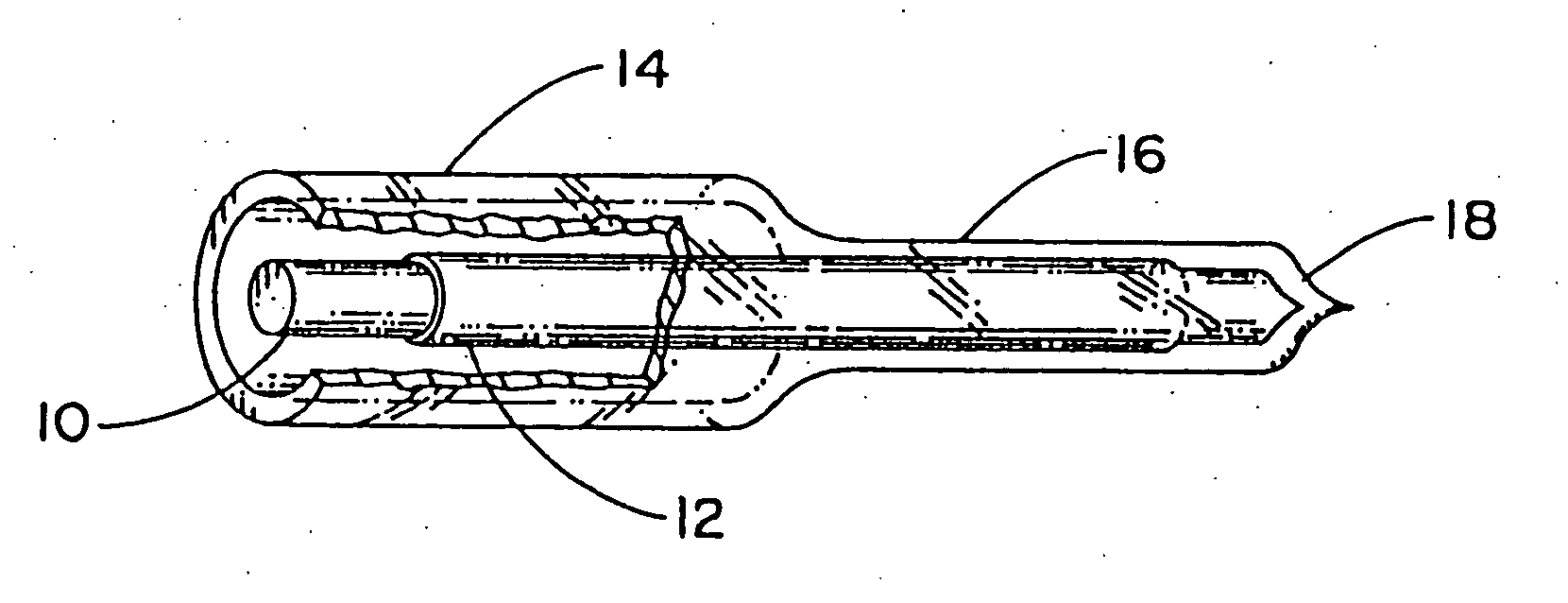

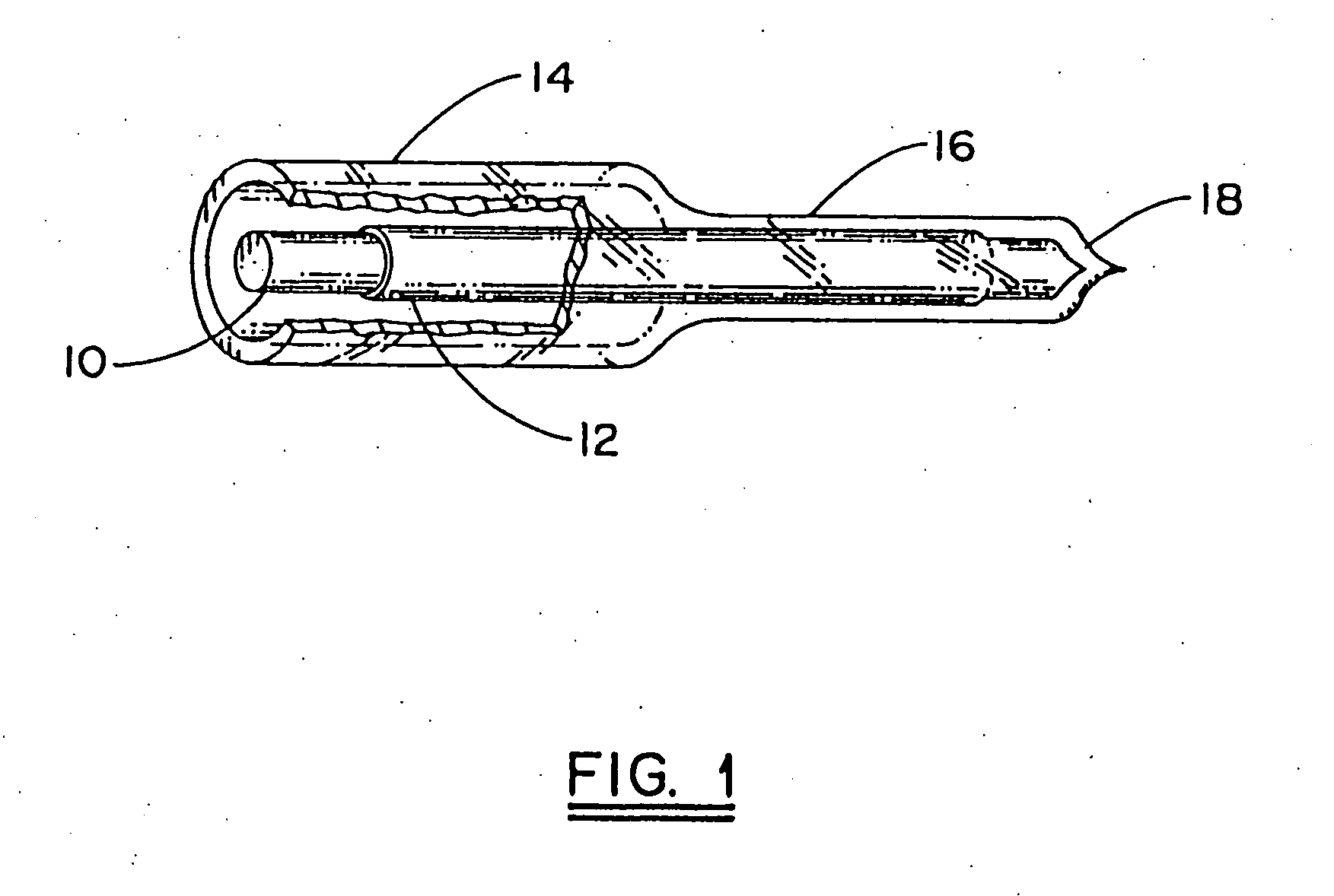

Method of fabricating a cylindrical optical fiber containing a light interactive film

InactiveUS20050252248A1Ensure continuityThe material is lowGlass making apparatusOptical fibre with multilayer core/claddingMetal alloyThermal coefficient

A method of forming a preform which has a glass core surrounded by an outer glass cladding with a coating of a light interactive material disposed between the core and cladding. The method includes providing a glass core having a viscosity which lies within a given preselected temperature range, followed by forming a substantially homogeneous coating of a light interactive material over the surface of the core, with the coating material having a viscosity which is equal to or less than the viscosity of the glass core. A glass cladding is formed over the coated layer, with the cladding glass having a viscosity which overlaps the viscosity of the core glass and a thermal coefficient of expansion compatible with that of the core. The light interactive material is an inorganic material which includes a metal, metal alloy, ferrite, magnetic material and a semiconductor.

Owner:SYRACUSE UNIVERSITY

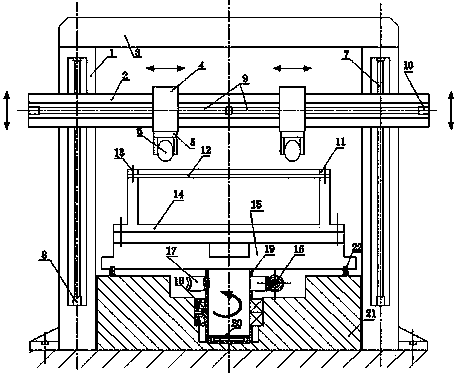

Large diameter-thick ratio and vertical distance ratio seal head rotary percussion forming device and rotary percussion method thereof

ActiveCN104275378AImprove the shortcomings of easy wrinkling and instabilityInhibition of deformation and instabilityRotary stageStamping

The invention relates to a large diameter-thick ratio and vertical distance ratio seal head rotary percussion forming device and a rotary percussion method thereof. The forming device comprises a machine tool gantry formed by stand columns and a top beam, a base, a cross beam, double rotary wheel carriers, a rotating platform, a cylinder-shaped mould, a ring-shaped pressure plate fixture, and the like, wherein the rotating platform is arranged on the base of a machine tool; the cylinder-shaped mould is arranged on the rotating platform; a workpiece to be processed is closely clamped on the cylinder-shaped mould, so that the workpiece and the mould can synchronously rotate along with the rotating platform; the two rotary wheel carriers are respectively arranged at the left side and right side of the cross beam, and each rotary wheel carrier is provided with a rotating wheel as a spinning tool; the vertical-direction feed and the horizontal-direction feed of the rotating wheel are realized by a stepping motor and a screw rod. The double-rotating wheel structure is adopted, so that the stress stability of the workpiece can be improved in the spinning forming process, and the influence of vibration to the machining process can be reduced. According to the spinning method, double rotating wheels are respectively used for feeding and extruding the workpiece so as to form the workpiece along the symmetrical arc shapes from the left side and right side of the periphery of the workpiece to the center. The device is simple, the stamping of a drum roller is avoided, is stable in forming process, and is capable of avoiding the phenomenon of instability in the forming process of a large diameter-thick ratio and vertical distance ratio seal head, thus realizing the whole precision shaping of the large diameter-thick ratio and vertical distance ratio seal head.

Owner:长沙超旋机械科技有限责任公司

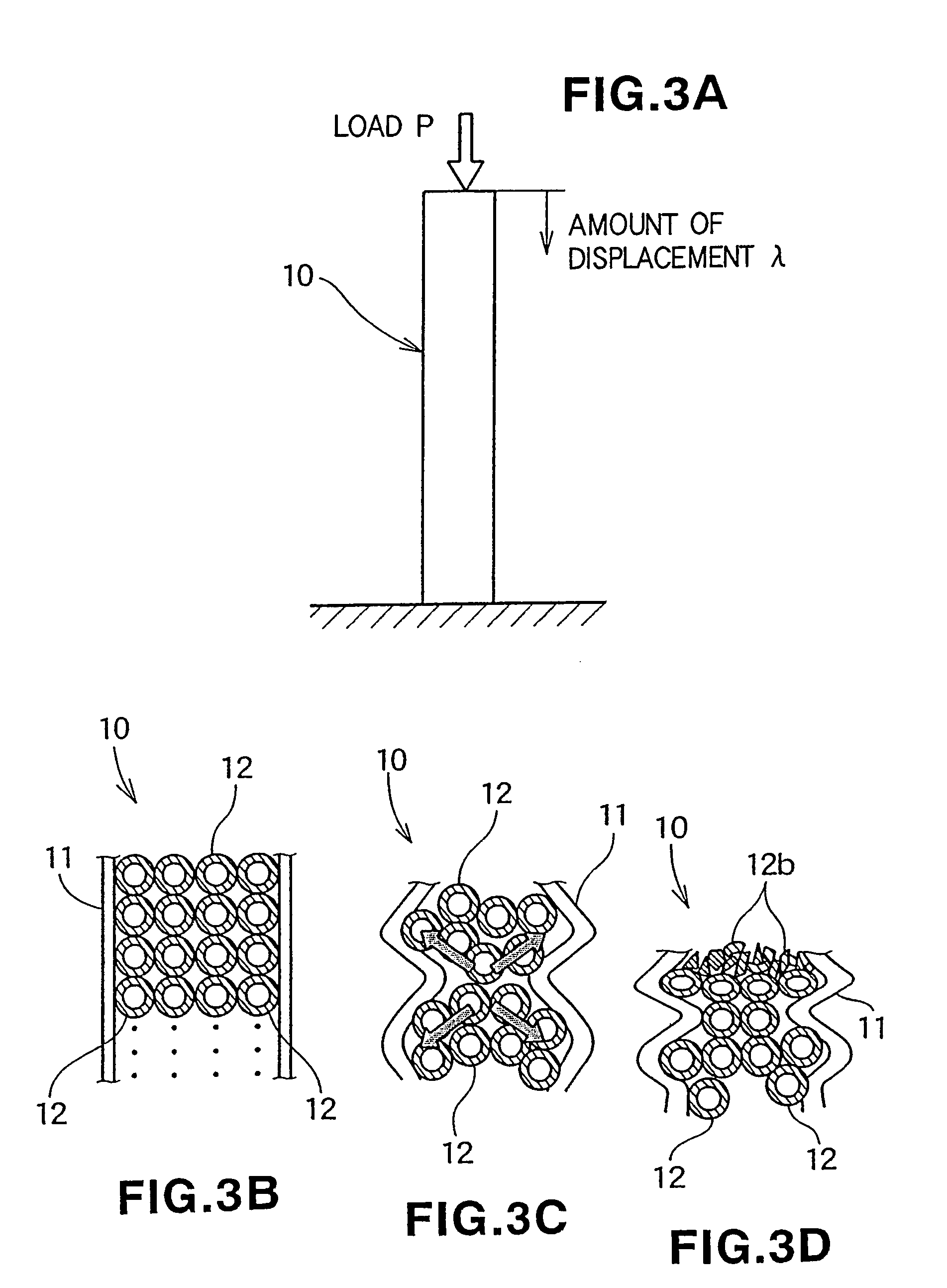

Skeleton member structure

InactiveUS20050124730A1Weight increaseHigh impact energyVehicle seatsElastic dampersMaterials scienceGranular material

A skeleton member structure having a tubular structural member (11, 211) filled with granular materials for absorbing impact energy. The granular materials includes a granular material having a hollow portion (12a, 212a) or a porous granular material. When the skeleton member receives an impact, the granular materials are deformed or collapsed, and impact energy is stably absorbed. Since the granular materials are hollow or porous, the weight of the skeleton member filled with the granular materials is reduced.

Owner:HONDA MOTOR CO LTD

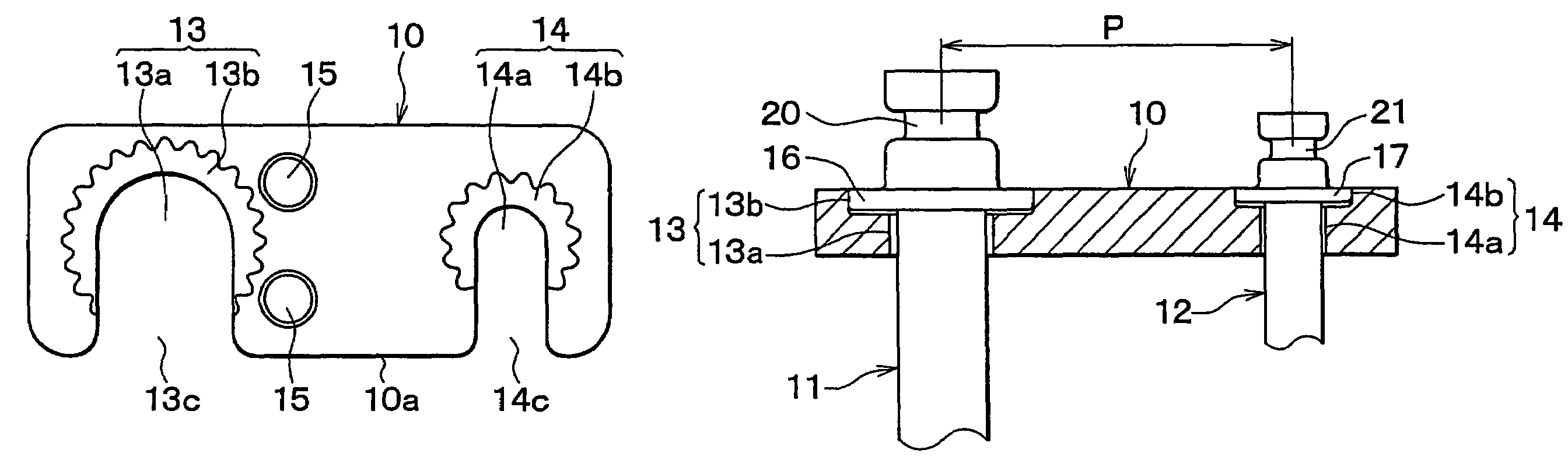

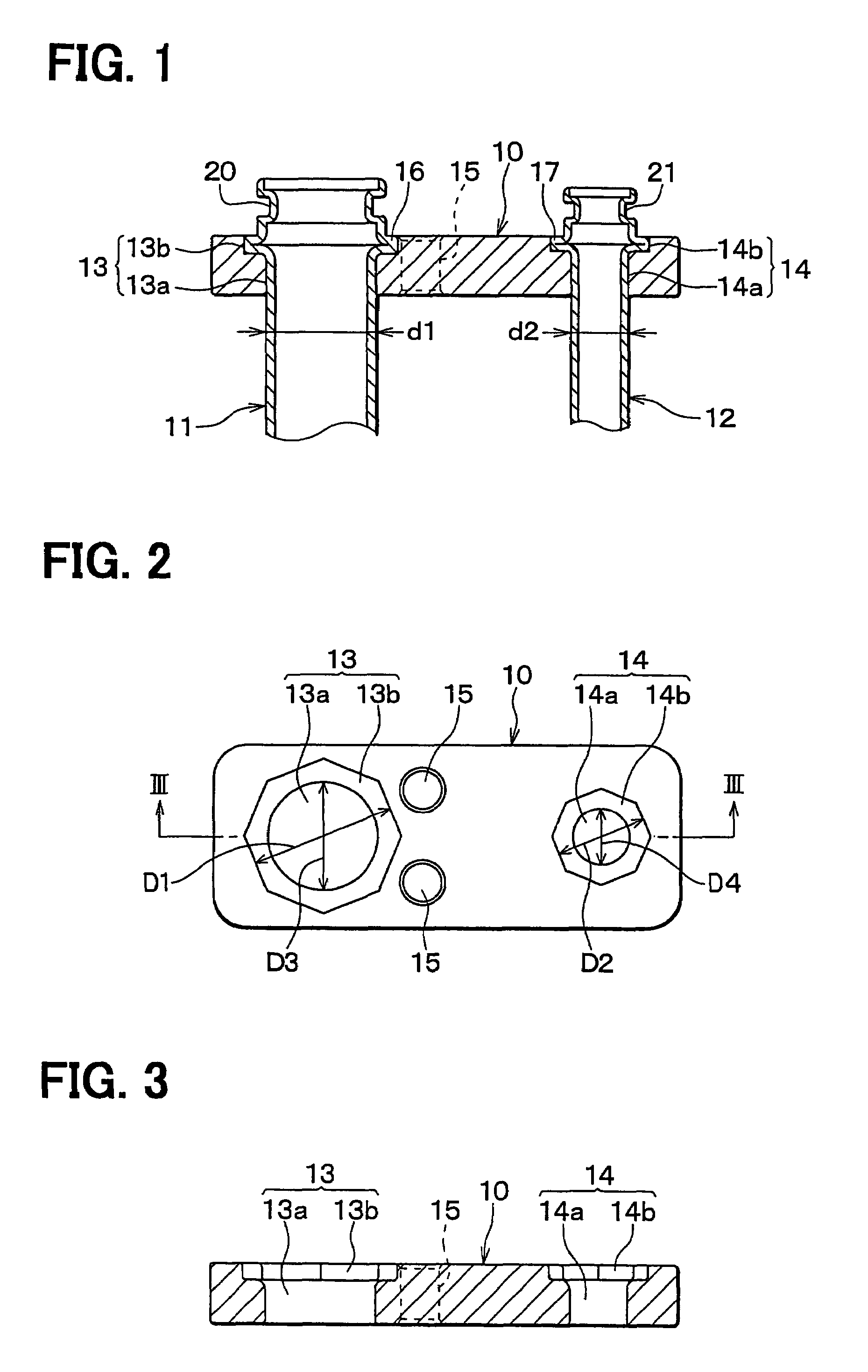

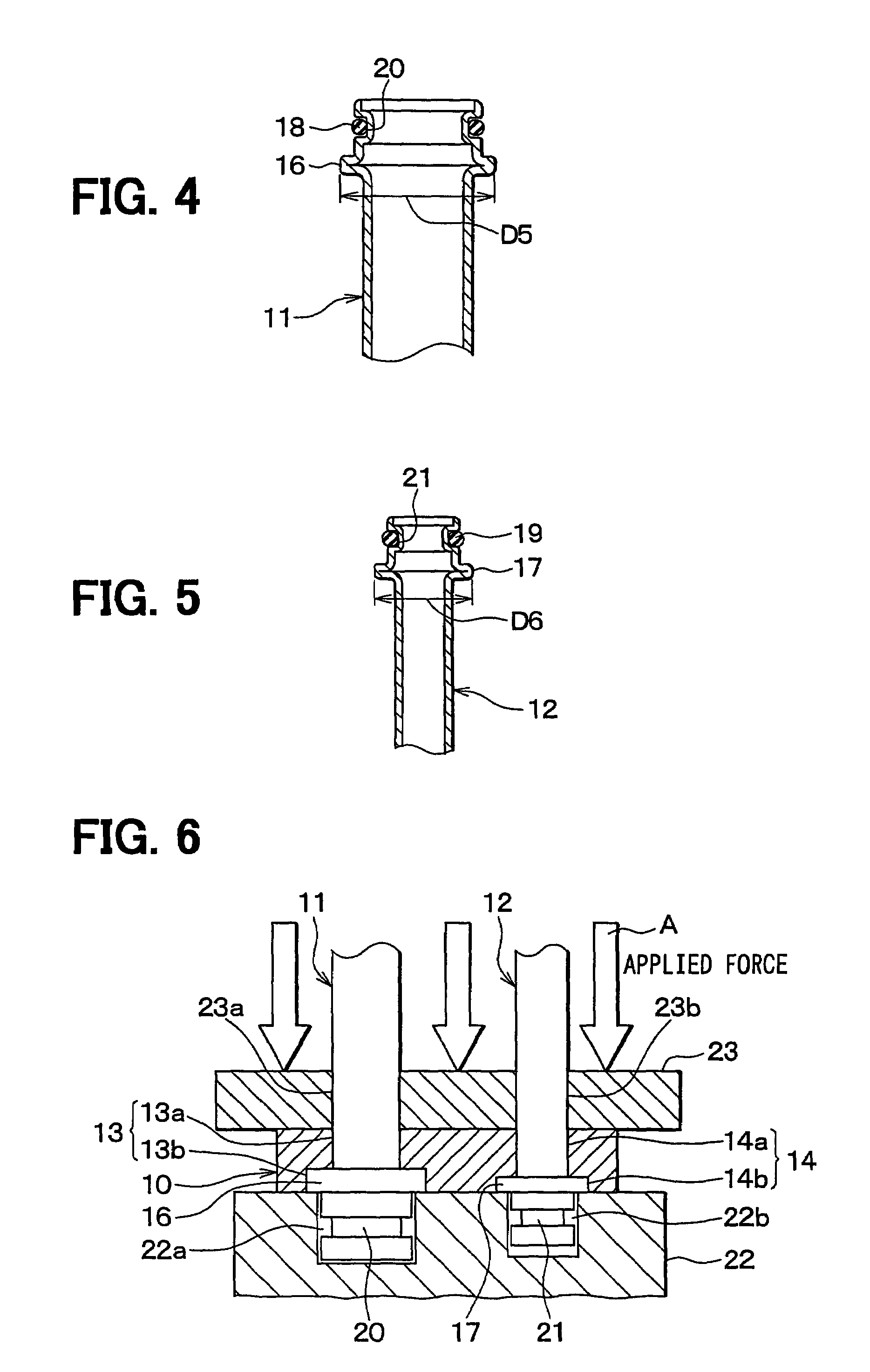

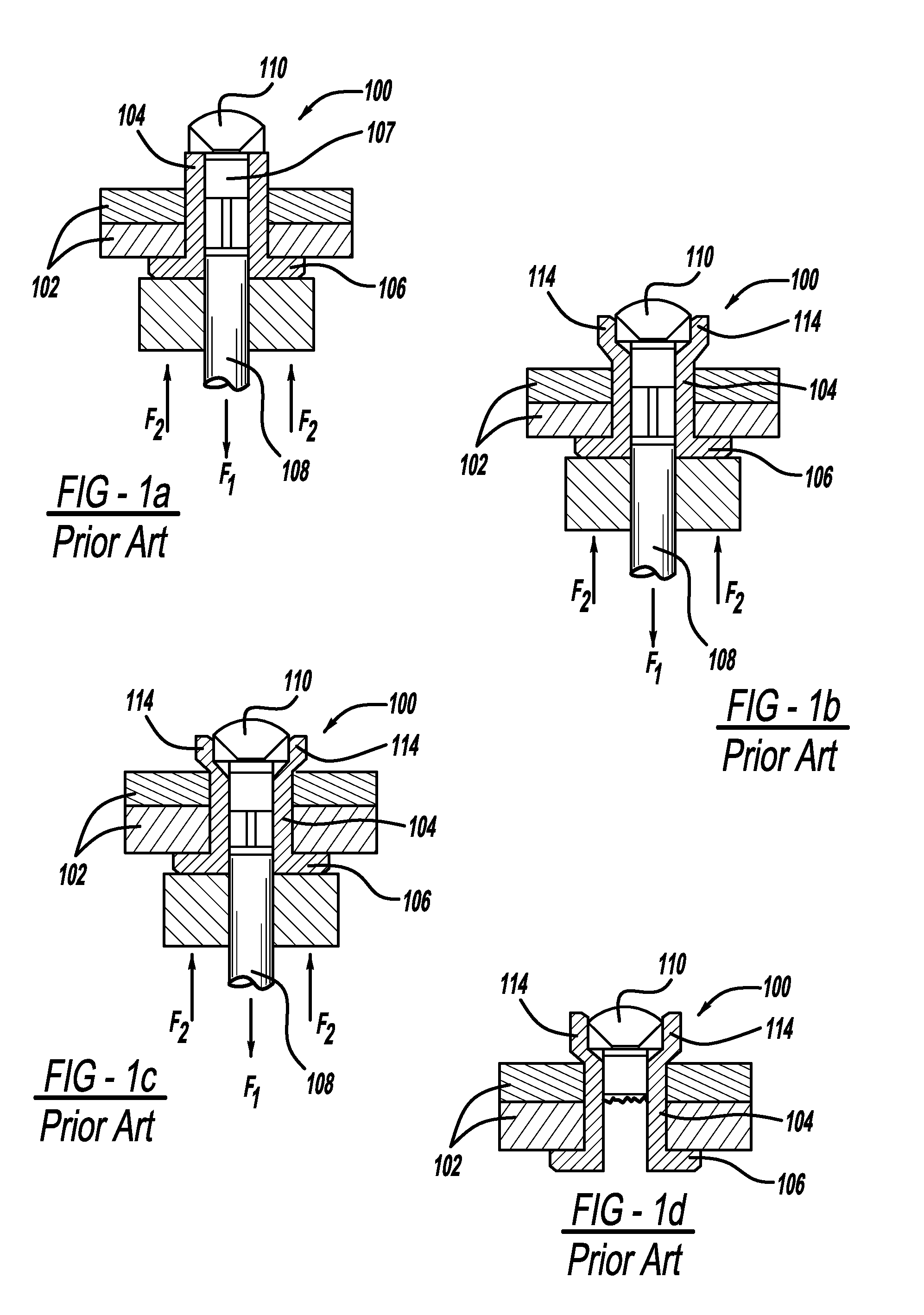

Pipe joint structure and method for fabricating the same

InactiveUS7469934B2Reduce the overall heightSuppress manufacturing costPipe supportsAir-treating devicesEngineeringFlange

A pipe joint structure capable of reducing the joint height (H) and fabrication costs has a connection flange member provided with a through hole piercing the thickness of the flange member. A polygonal enlarged recess greater than the inner diameter of the through hole is formed at one end of the through hole. Meanwhile, an annular protrusion protruding radially outward is formed near an end of a pipe having an outer diameter capable of insertion into the through hole. This annular protrusion has an outer diameter greater than the incircle diameter of the polygonal enlarged recess. The annular protrusion is press-fitted and fixed to the polygonal enlarged recess.

Owner:DENSO CORP

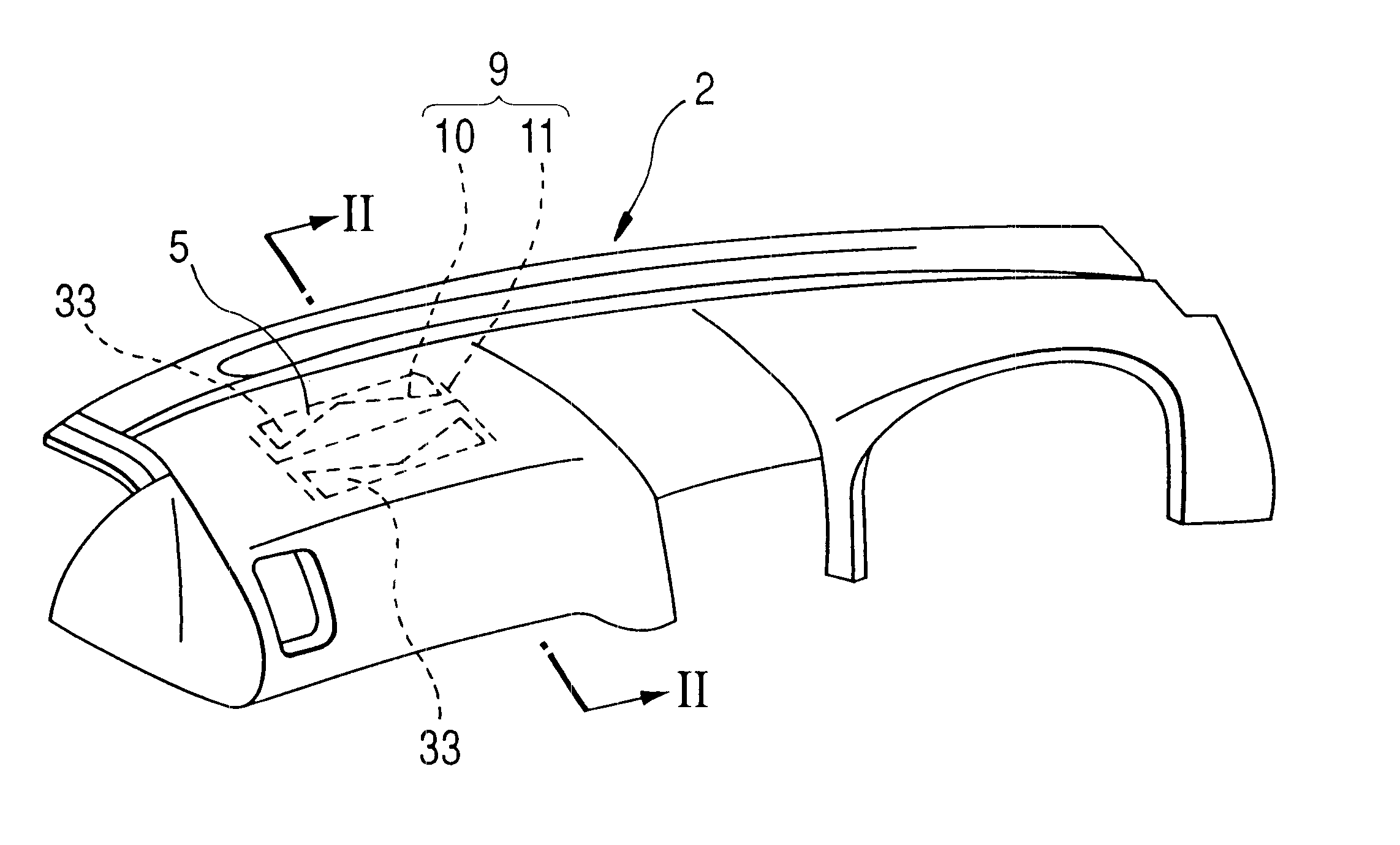

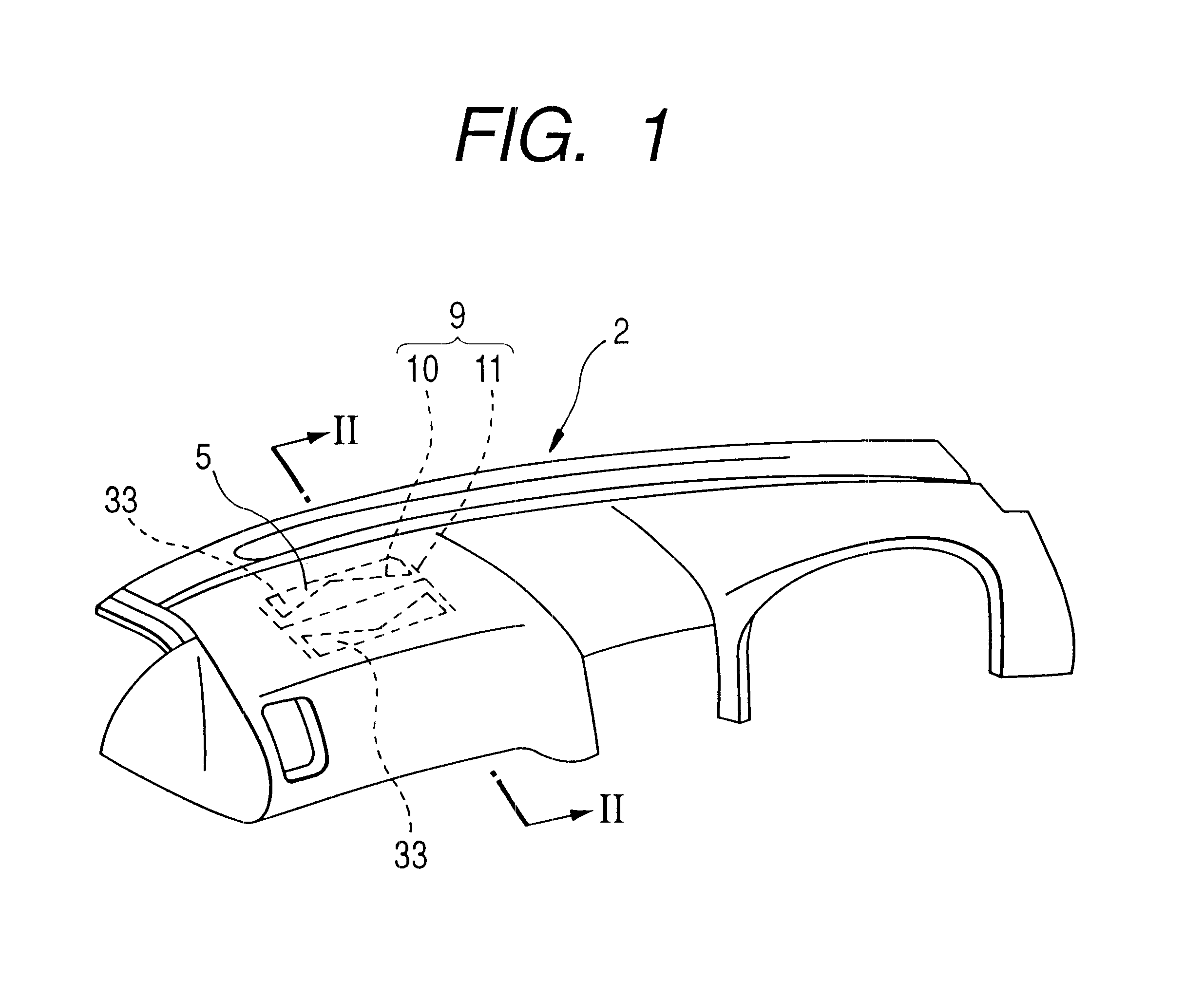

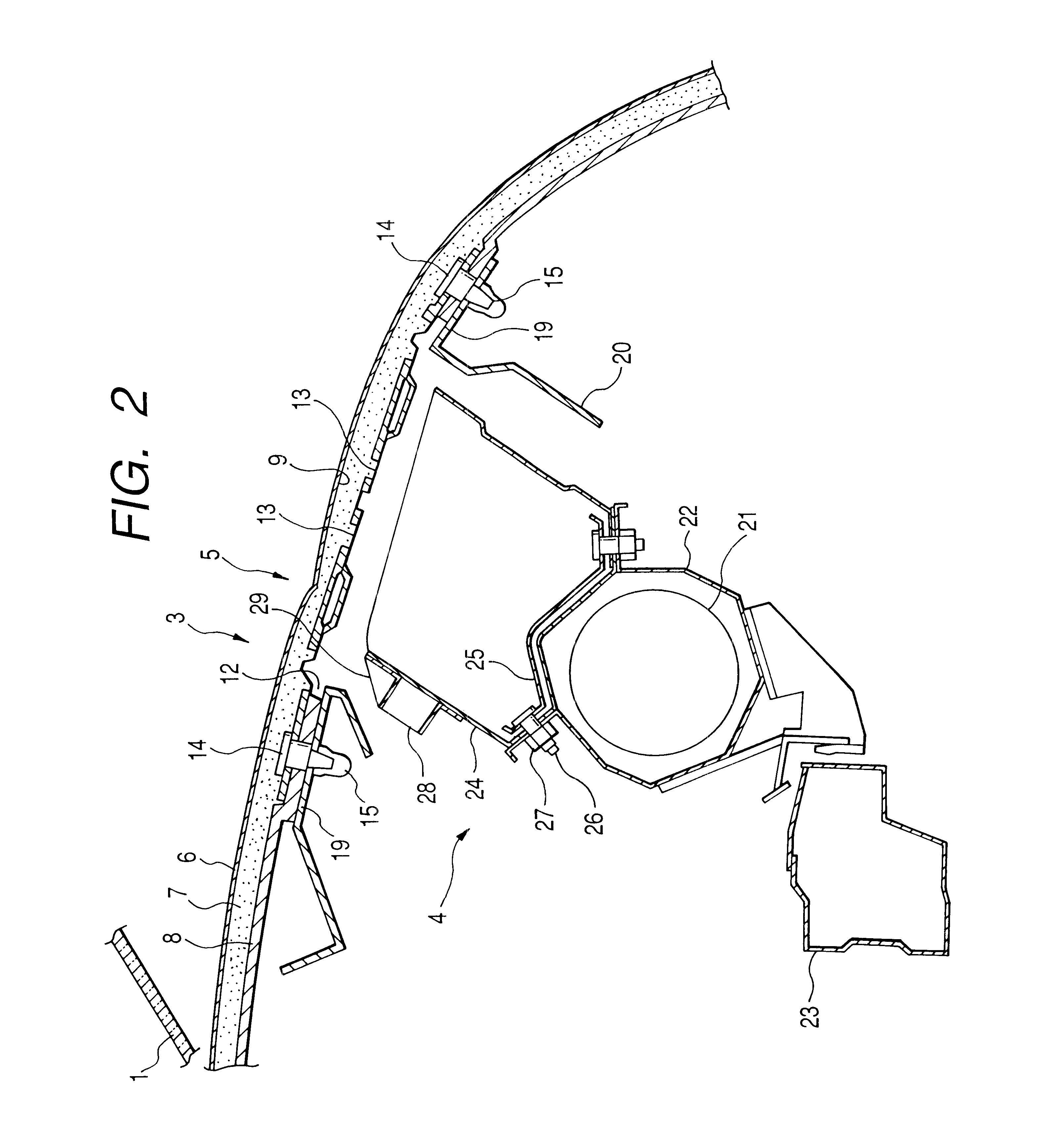

Vehicular air-bag lid structure

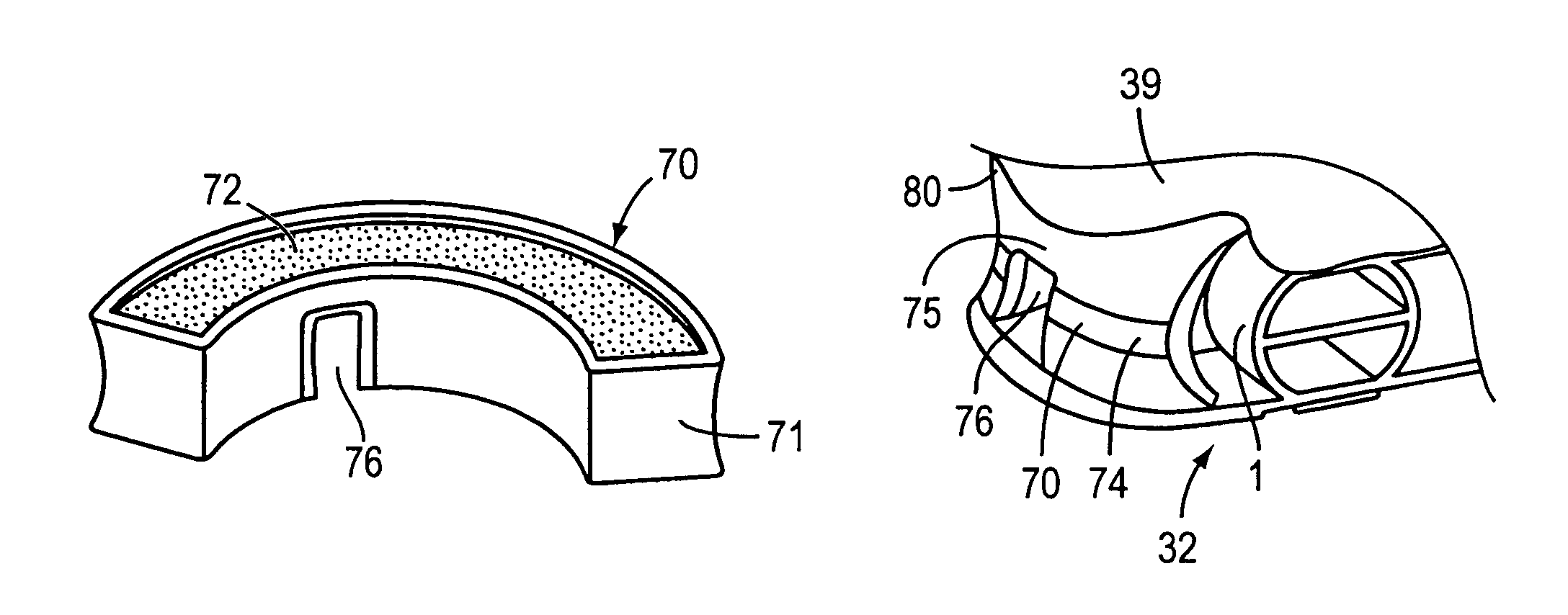

InactiveUS6460876B1Smooth deformationSmooth changePedestrian/occupant safety arrangementAirbag deploymentEngineering

A vehicular air-bag lid having a three-layer structure including an outer skin (6), a foaming layer (7), and a core material (8). Substantially square door members (13) are fitted within an opening (12) and are opened about a hinge portion at the time of air bag inflation. A pair of substantially triangular-shaped, in plan view, recessed bead portions (30) project toward the undersides of the respective door members (13). A reinforcing plate (31) accompanies the whole recessed bead portion on the surface side of each door member (13). Each recessed bead portion (30) has two of its three sides respectively disposed along the side of a door member (13) and along a hinge portion.

Owner:CALSONIC KANSEI CORP

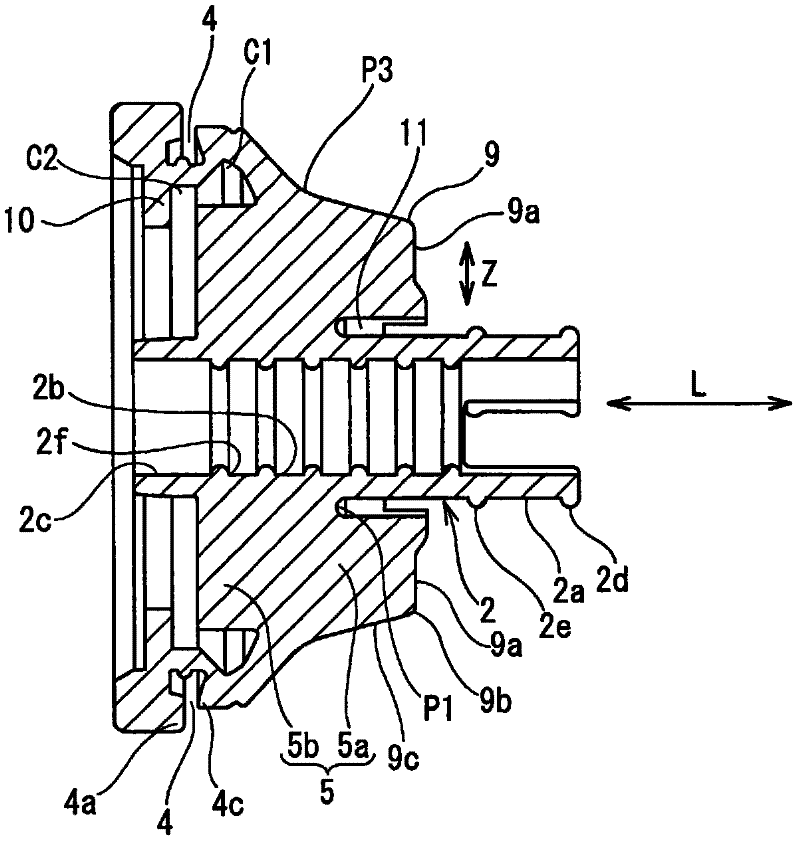

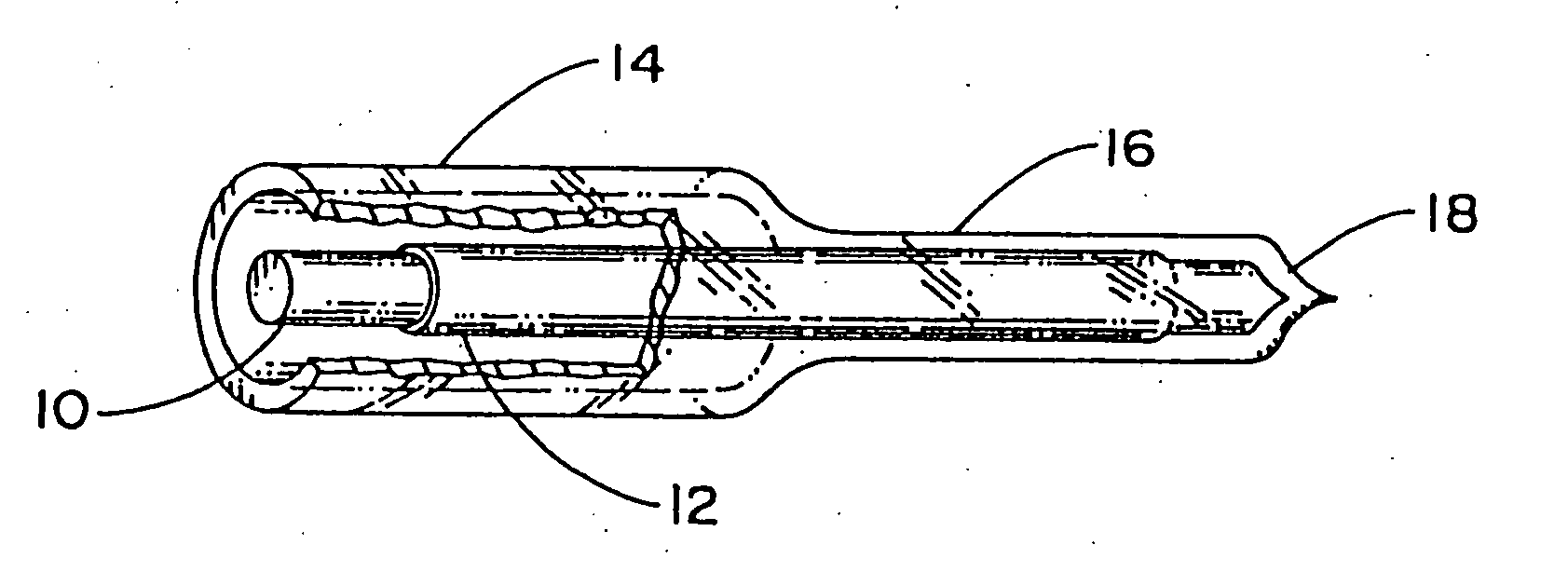

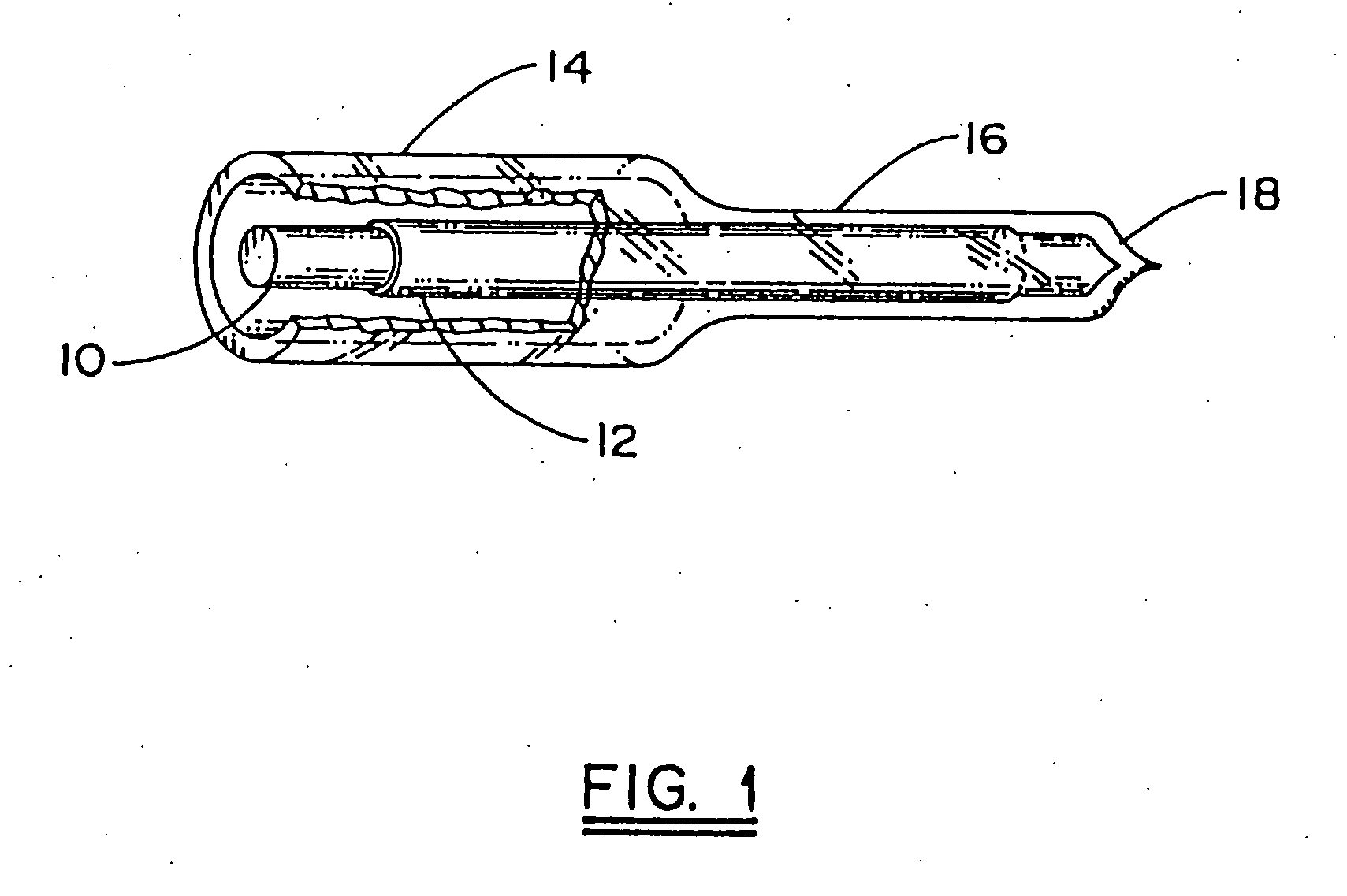

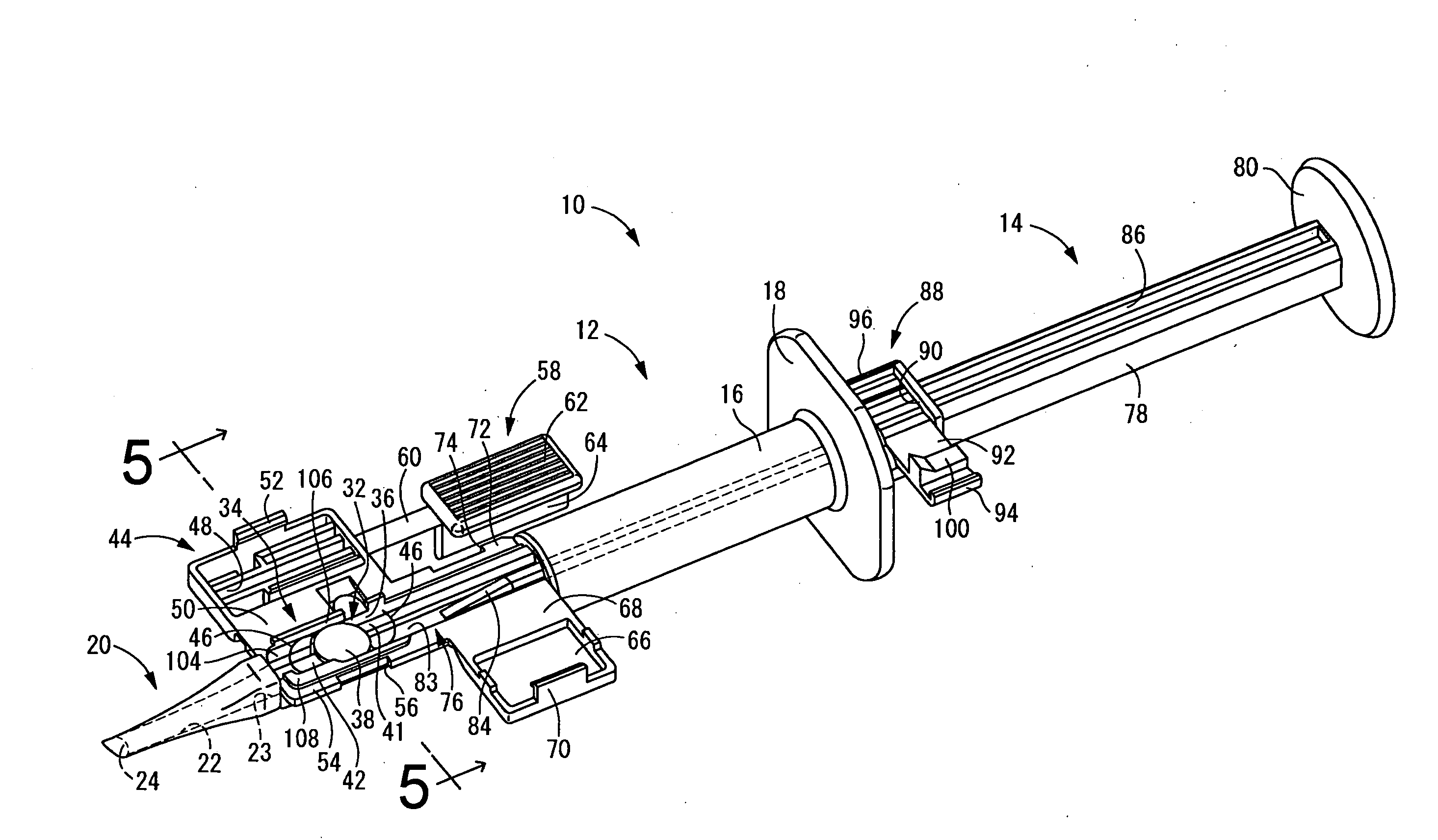

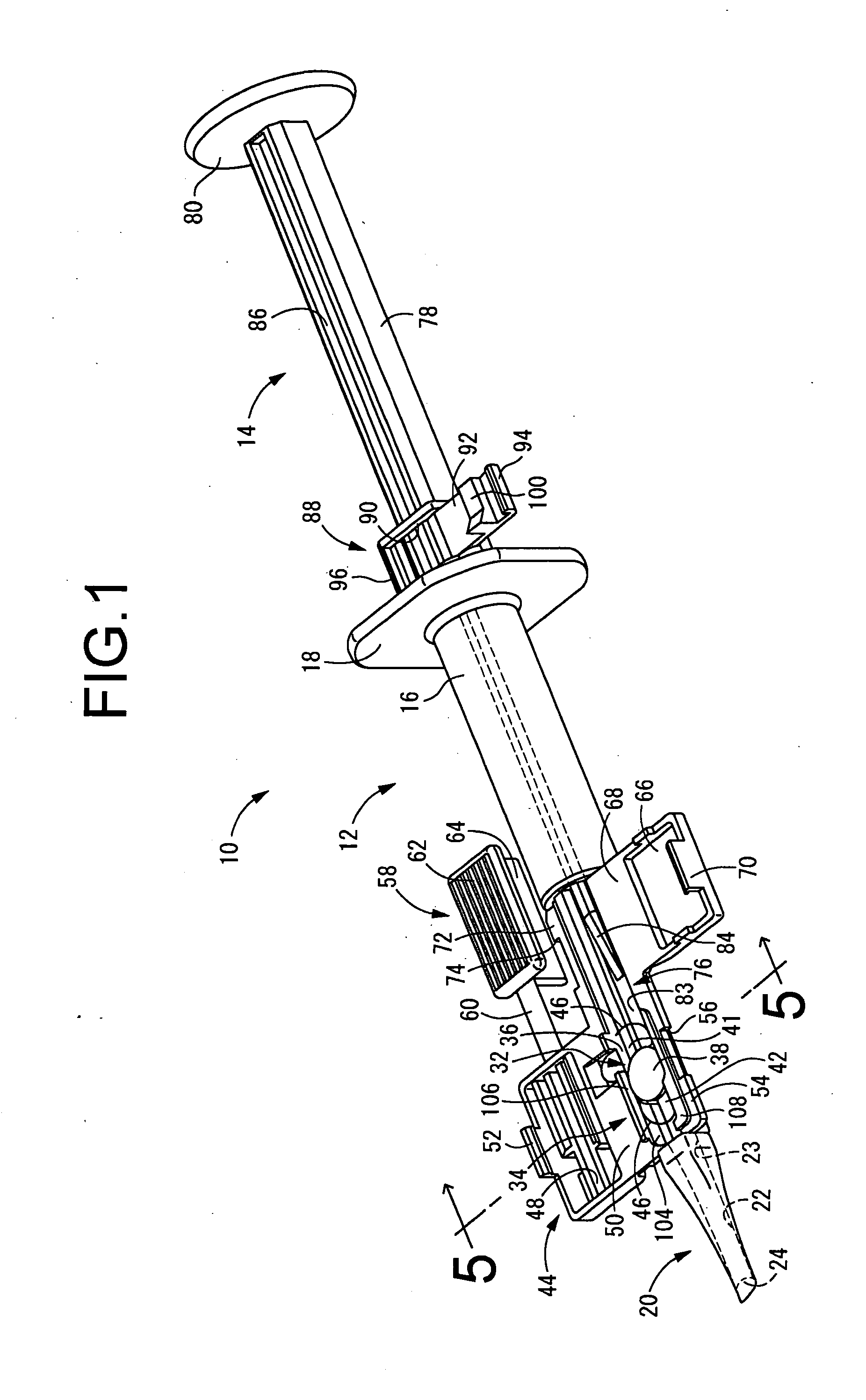

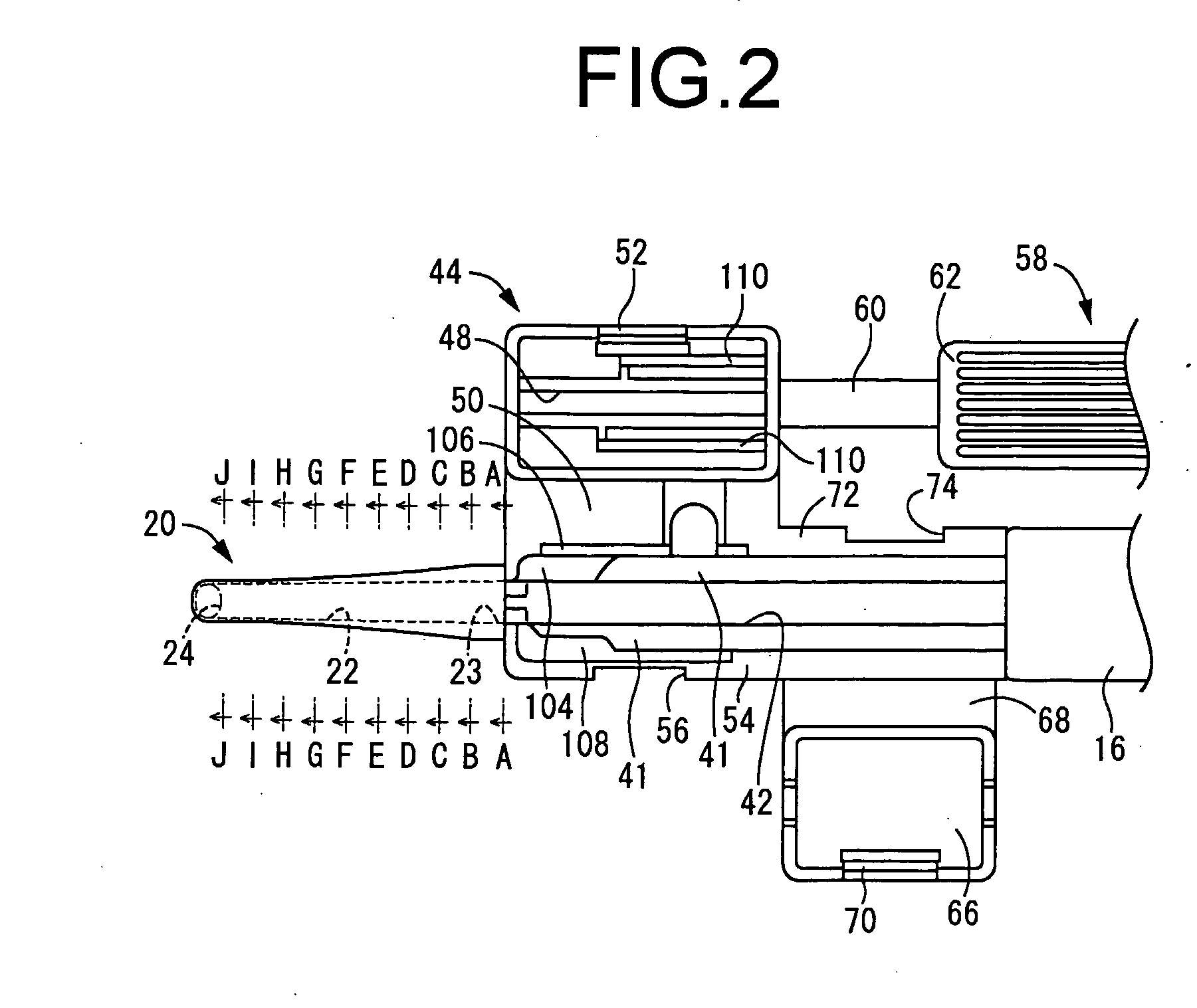

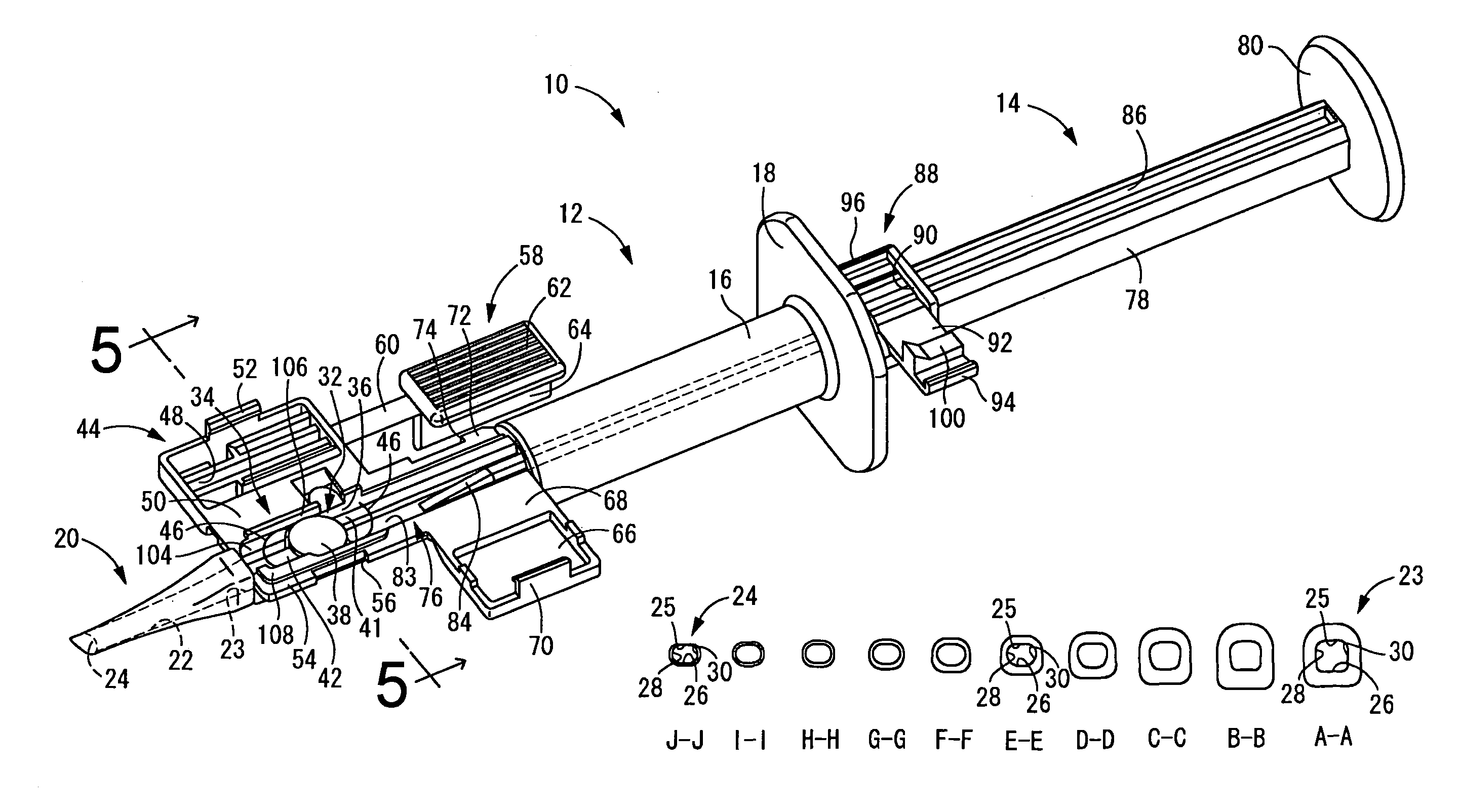

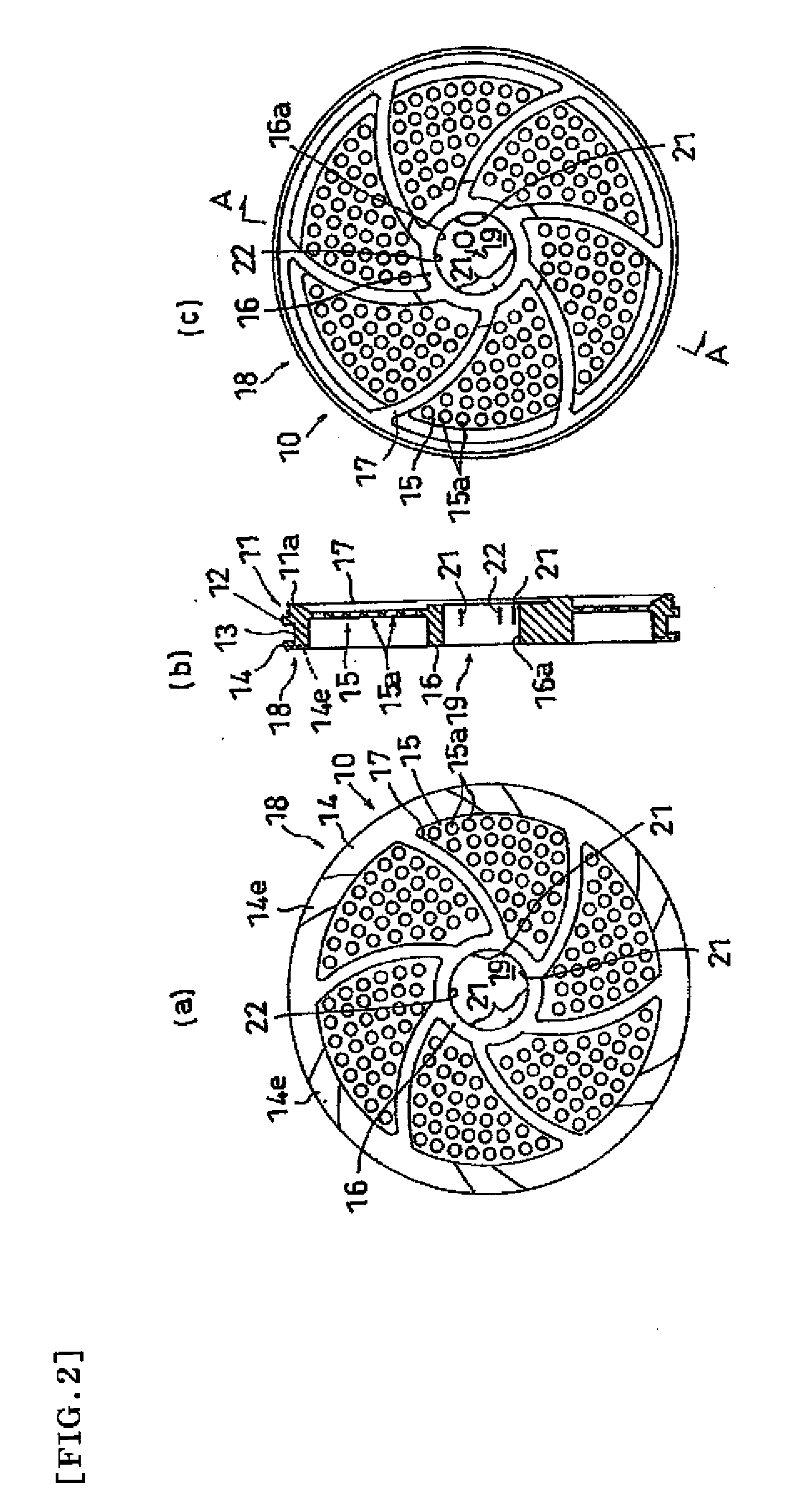

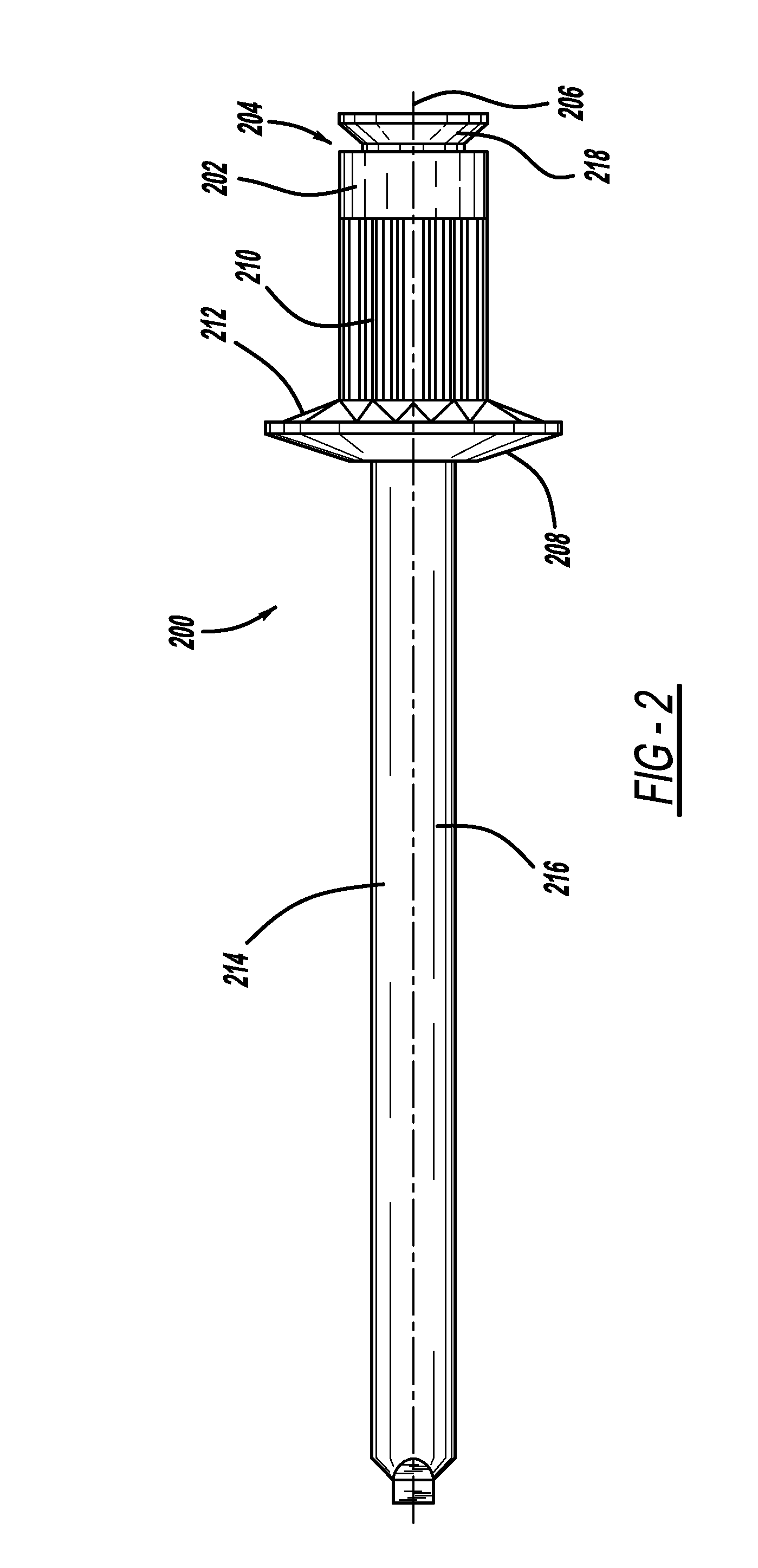

Intraocular lens insertion tool

ActiveUS20090292294A1Convenient restSteady initial deformationEye surgeryIntraocular lensIntraocular lens insertionLeft wall

An insertion tool of an intraocular lens of novel structure in which the intraocular lens can be deformed into smaller one while rotation of the intraocular lens in an insertion tube is effectively prevented. Upper and lower flat planes (25, 26) are formed to spread flatly over an entire length of a through hole (22) in the insertion tube (20) and the upper and lower flat planes (25, 26) are connected smoothly with right and left wall faces (30, 28) over the entire length of the through hole (22). At least a part of the through hole (22) in an extending direction thereof, the right and left wall faces (30, 28) have longitudinal linear portions extending substantially in parallel in a vertical direction on a proximal end opening (23) side. On the other hand, with its radius of curvature decreasing gradually in a covered shape which becomes inwardly concave as it approaches a distal end opening (24), the upper flat plane (25) is allowed to gradually approach the lower flat plane (26), and a tapered portion having a reduced cross-sectional area is formed, thus obtaining the distal end opening of substantially oval shape.

Owner:KOWA CO LTD

Shoe with improved structure

InactiveUS20160213096A1Reduce the amount requiredMore deformableUpperBootlegsMedial sideMechanical engineering

A shoe including an outer sole assembly and an upper. The shoe extends lengthwise from a rear end to a front end, widthwise between a lateral side and a medial side, and height-wise from the outer sole assembly to an upper end. The shoe further includes a first shell and a reinforcing structure arranged opposite the first shell. The reinforcing structure includes holes on at least a portion of its surface.

Owner:SALOMON SA

Intraocular lens insertion tool

InactiveUS8021423B2Deformation MinimizationEffectively preventing the intraocular lens from rotatingEye surgeryIntraocular lensIntraocular lens insertionEngineering

An insertion tool of an intraocular lens permits the lens to be deformed while rotation of the lens in an insertion tube is effectively prevented. Upper and lower flat planes are formed to spread flatly over a length of a through hole in the insertion tube and the upper and lower flat planes are connected smoothly with right and left wall faces over the length of the through hole. The right and left wall faces have longitudinal linear portions extending substantially in parallel in a vertical direction on a proximal end opening side. With its radius of curvature decreasing gradually in a covered shape which becomes inwardly concave as it approaches a distal end opening the upper flat plane gradually approaches the lower flat plane, and a tapered portion having a reduced cross-sectional area is formed, thus obtaining the distal end opening of substantially oval shape.

Owner:KOWA CO LTD

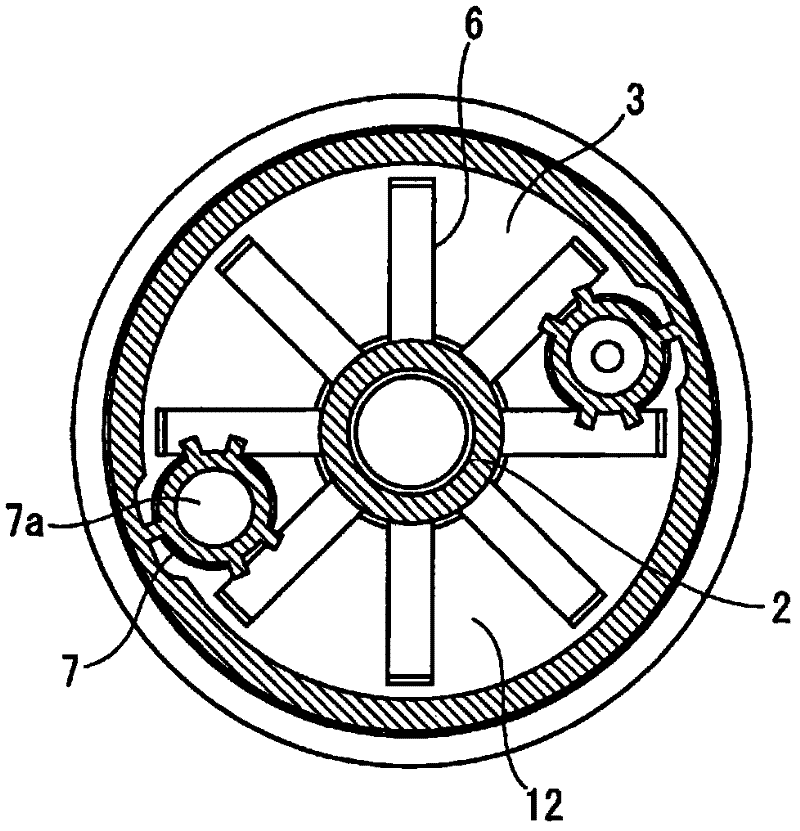

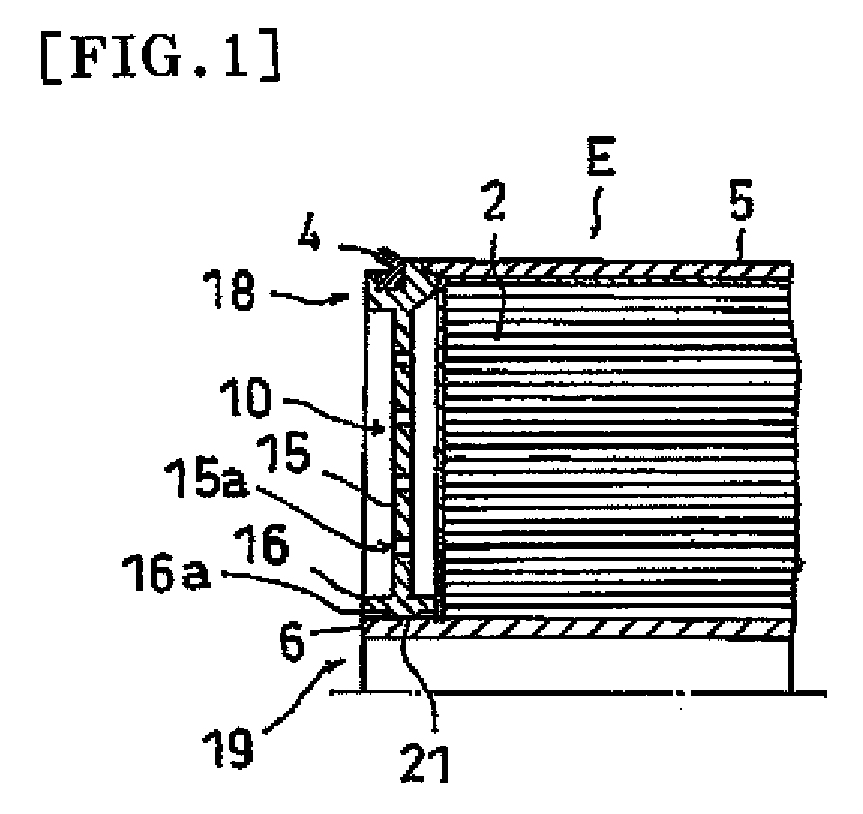

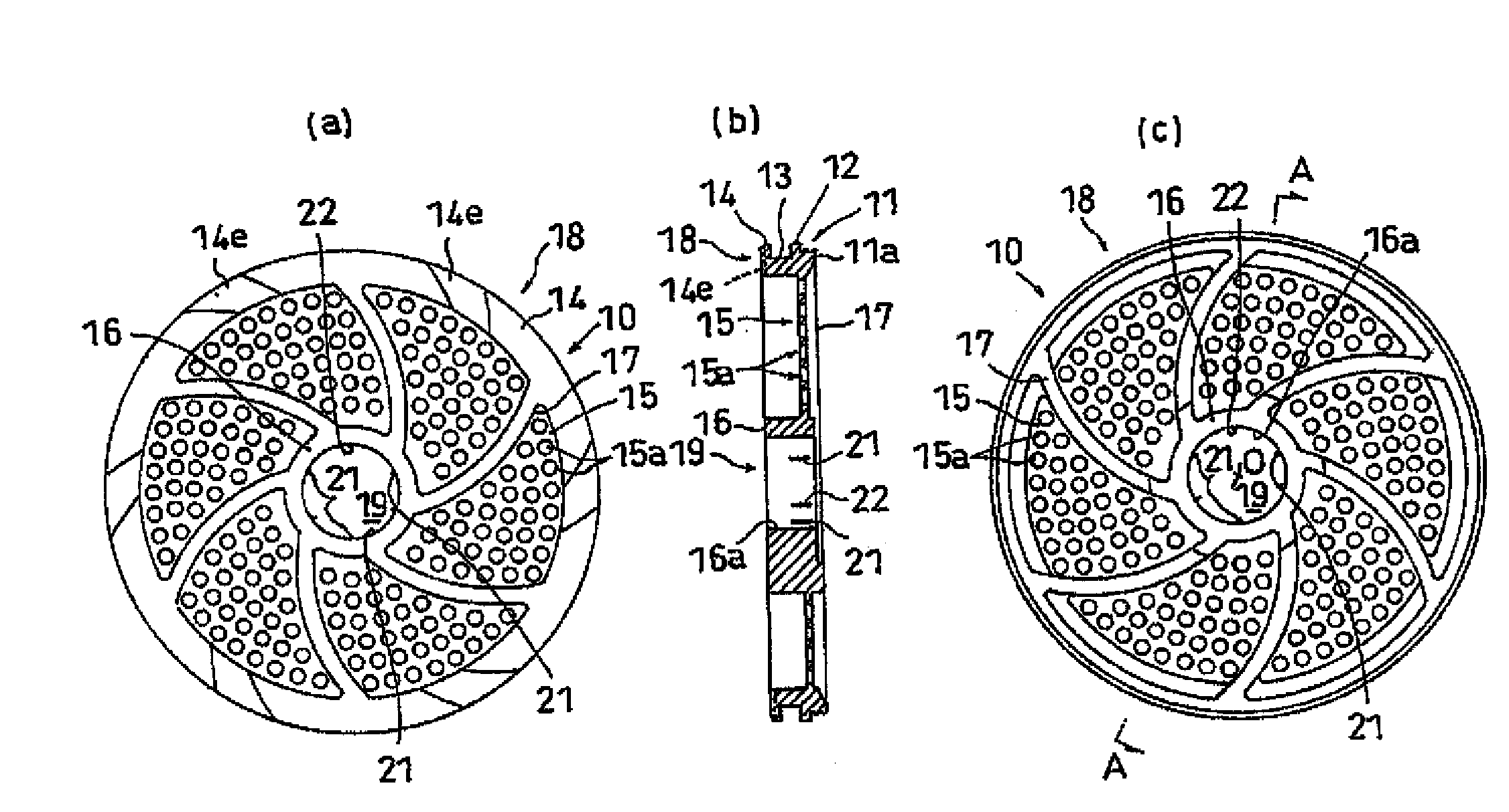

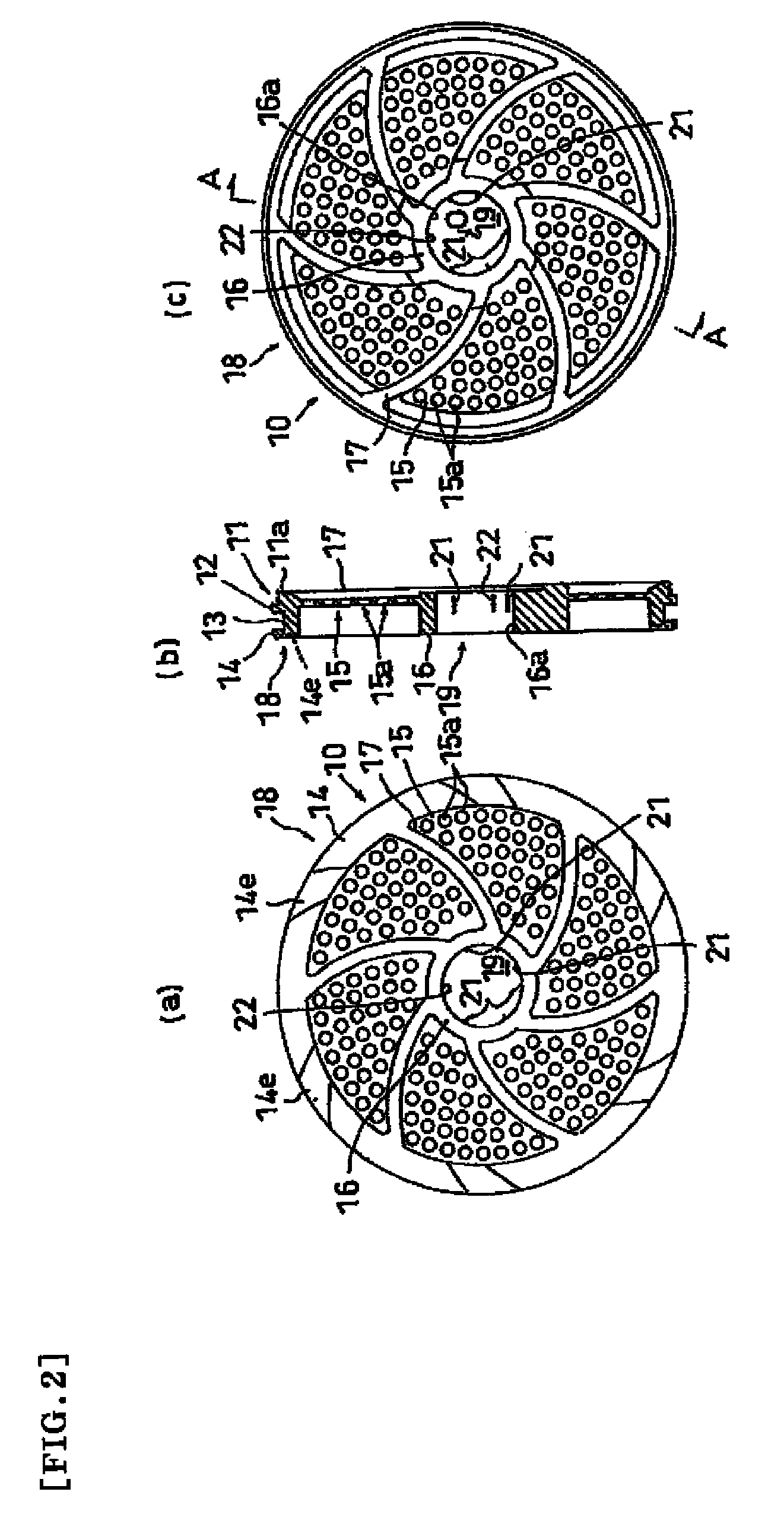

Membrane element sealing material holding member and membrane element

ActiveUS20090095670A1Smooth deformationEasy to insertMembranesSemi-permeable membranesBiomedical engineeringSpiral membrane

A membrane element sealing material holding member that even when the dimension of outer diameter of center tube varies, enables holding of the center tube in the center and further enables easy insertion of the center tube; and a membrane element utilizing the same. The membrane element sealing material holding member comprises central opening (19) for insertion of a center tube of spiral membrane element, peripheral orifice (15a) for flowing of a raw liquid into a membrane end portion of membrane element and outer circumferential part (18) for holding of circular sealing material, wherein the central opening (19) has inner circumferential surface (16a) of cylindrical form with a diameter larger than the outer diameter of the inserted center tube, and wherein at three or more positions on the inner circumferential surface (16a), there is provided projection (21) that has sloping face (21a) on its side of center tube (6) insertion and is deformable at the time of insertion of center tube (6) with an outer diameter larger than that of incircle.

Owner:NITTO DENKO CORP

Skeleton member structure

InactiveUS7226120B2Weight increaseHigh impact energyVehicle seatsElastic dampersMaterials scienceGranular material

A skeleton member structure having a tubular structural member (11, 211) filled with granular materials for absorbing impact energy. The granular materials includes a granular material having a hollow portion (12a, 212a) or a porous granular material. When the skeleton member receives an impact, the granular materials are deformed or collapsed, and impact energy is stably absorbed. Since the granular materials are hollow or porous, the weight of the skeleton member filled with the granular materials is reduced.

Owner:HONDA MOTOR CO LTD

Manufacturing method for nickel composite board end sockets

The invention relates to a metal material machining technology and manufacturing method, in particular to a manufacturing method for nickel composite board end sockets. The manufacturing method comprises the steps of designing a die; calculating the diameter of an upper die pressure head, the diameter of an outlet of a lower die pull ring, the gap between an upper die and a lower die and the circular bead of the lower die pull ring; splicing composite boards; carrying out penetrant flaw detection; carrying out ultrasonic detection; polishing and cleaning the die; carrying out earlier stage processing of blanks; carrying out heating through a natural gas furnace; carrying out stamping forming, wherein three-time forming is adopted for the forming technology; carrying out spinning forming; cutting grooves; carrying out acid dipping; carrying out polishing; carrying out penetrant flaw detection and ultrasonic detection; stacking the end sockets. By means of the method, the stamping process is stable, transformation is even and smooth, a determined hot working system is feasible, the technology parameters are reasonable, control over the dimension of workpieces is good, metal streamline distribution is reasonable, and performance is stable.

Owner:无锡市前洲西塘锻压有限公司

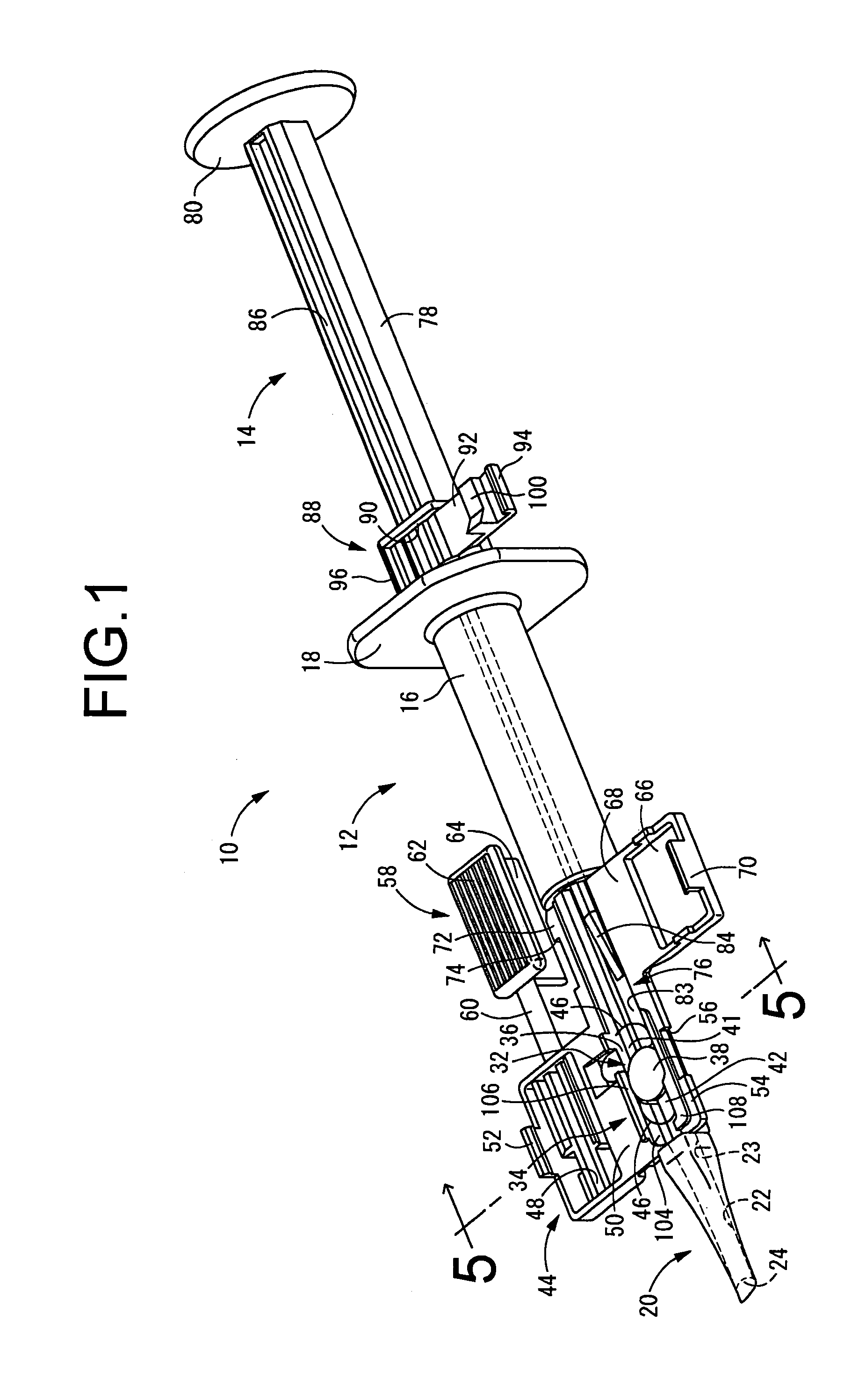

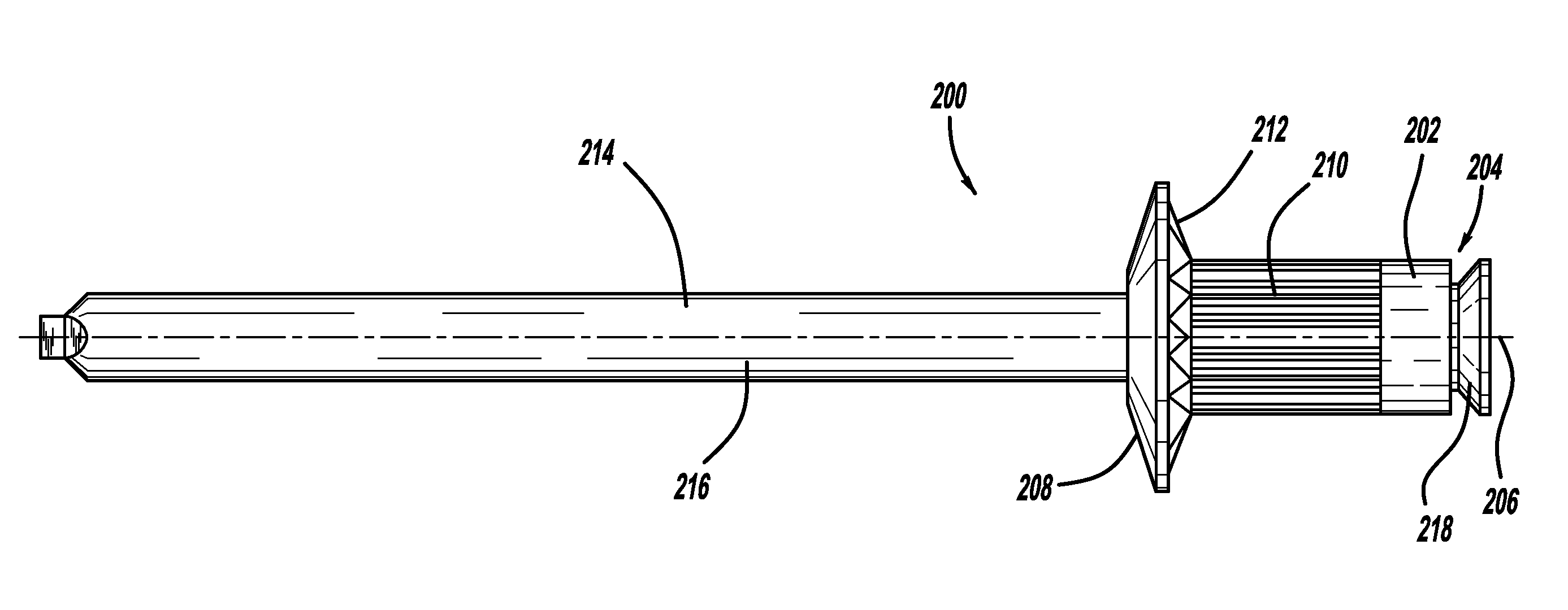

Blind rivet

InactiveUS20120210557A1Smooth deformationImprove gripRivetsScrewsElectrical and Electronics engineeringRivet

A blind rivet 200 comprises a mandrel 214 having a deformable mandrel head 218 such that when the blind rivet is received in a pair of aligned apertures of dissimilar sizes in a pair of components 220, 222 to be joined, the mandrel head is adapted to be deformed and cause deformation of a rivet body 202 such that the blind rivet engages the inner surfaces defined by both of the apertures before the mandrel and its head are pulled free of the rivet body.

Owner:NEWFREY

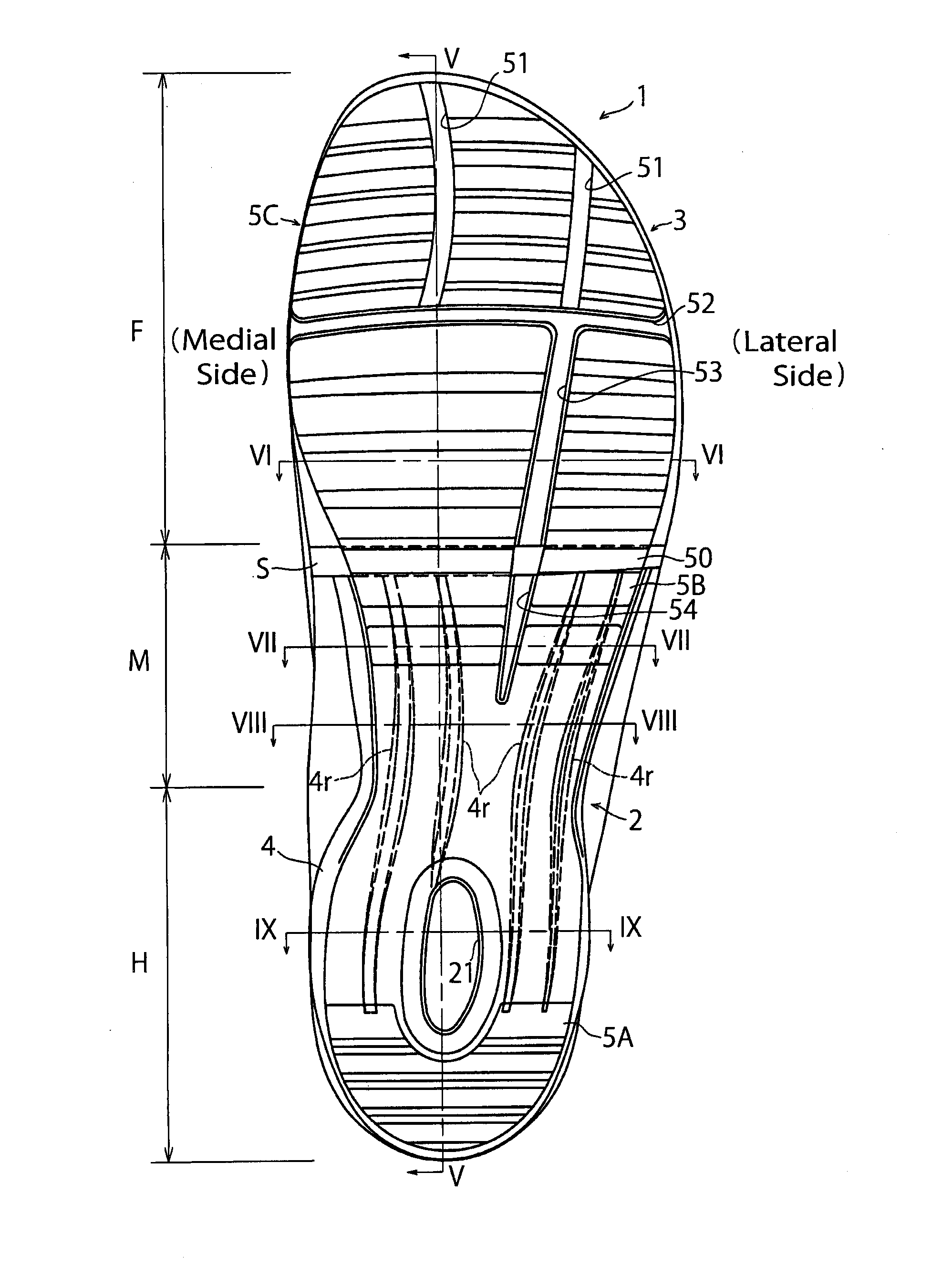

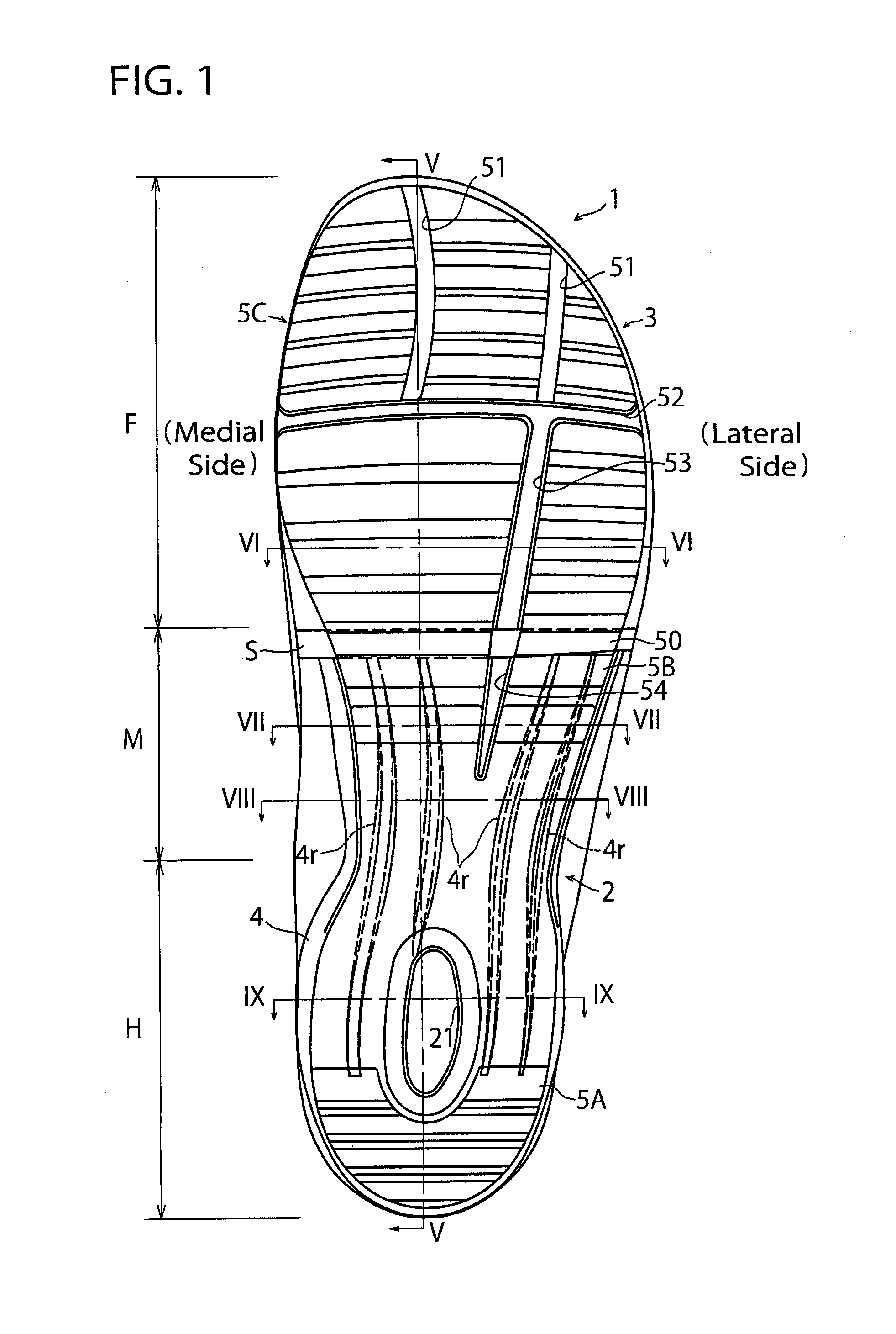

Sole Structure for a Shoe

InactiveUS20160081427A1Improve bending deformationDeterioration of cushioning performance of the rear foot region of the sole structure can be preventedSolesFoot regionCurve shape

The invention provides a sole structure that can not only prevent deterioration of cushioning performance and improve cushioning properties but also enhance flexibility. The sole structure 1 includes a rear foot sole 2 disposed at a rear foot region of the sole structure 1, a forefoot sole 3 disposed at a forefoot part F of the sole structure 1, and a plate 4 disposed at the rear foot region of the sole structure 1 and having an upwardly convexly curved shape along a heel part H to a midfoot part M of the sole structure 1. A front end portion 4f of the plate 4 is disposed at a front end portion 2Af, 2Bf of the rear foot sole 2 (i.e. upper and lower soles 2A, 2B). There is formed a gap S in front of the front end portion 4f of the plate 4 between the front end portion 2Af, 2Bf of the rear foot sole 2 and a rear end portion 3r of the forefoot sole 3.

Owner:MIZUNO CORPORATION

Method of fabricating a cylindrical optical fiber containing a light interactive film

InactiveUS20060042323A1Ensure continuityThe material is lowGlass making apparatusCladded optical fibreMetal alloyThermal coefficient

A method of forming a preform which has a glass core surrounded by an outer glass cladding with a coating of a light interactive material disposed between the core and cladding. The method includes providing a glass core having a viscosity which lies within a given preselected temperature range, followed by forming a substantially homogeneous coating of a light interactive material over the surface of the core, with the coating material having a viscosity which is equal to or less than the viscosity of the glass core. A glass cladding is formed over the coated layer, with the cladding glass having a viscosity which overlaps the viscosity of the core glass and a thermal coefficient of expansion compatible with that of the core. The light interactive material is an inorganic material which includes a metal, metal alloy, ferrite, magnetic material and a semiconductor.

Owner:SYRACUSE UNIVERSITY

Artificial nipple for a nursing bottle

The invention aims to provide an artificial nipple for a nursing bottle which permits close fitting of the nipple to the sucking fossa of an infant while avoiding deformation of the nipple while providing a form that is similar to a human nipple, and which can prevent the upper and lower sides of the nipple from contacting each other during peristalsis-like movements. In view of this, the present invention provides an artificial nipple for a nursing bottle having: a nipple top part having at its tip a dispensing hole for dispensing a liquid drink; and an artificial nipple body which is continuous to the nipple top part, and whose diameter and wall thickness are greater than those of the nipple top part. The artificial nipple is made of a flexible material. The nipple top part has a rib, which prevents contact between an upper side and a lower side of the nipple top part when the nipple top part is compressed flat, at a portion where gums of an infant touch when an upper lip of the infant is in contact with the artificial nipple body or at an internal surface in the vicinity of the portion.

Owner:OTSUKA PHARM CO LTD

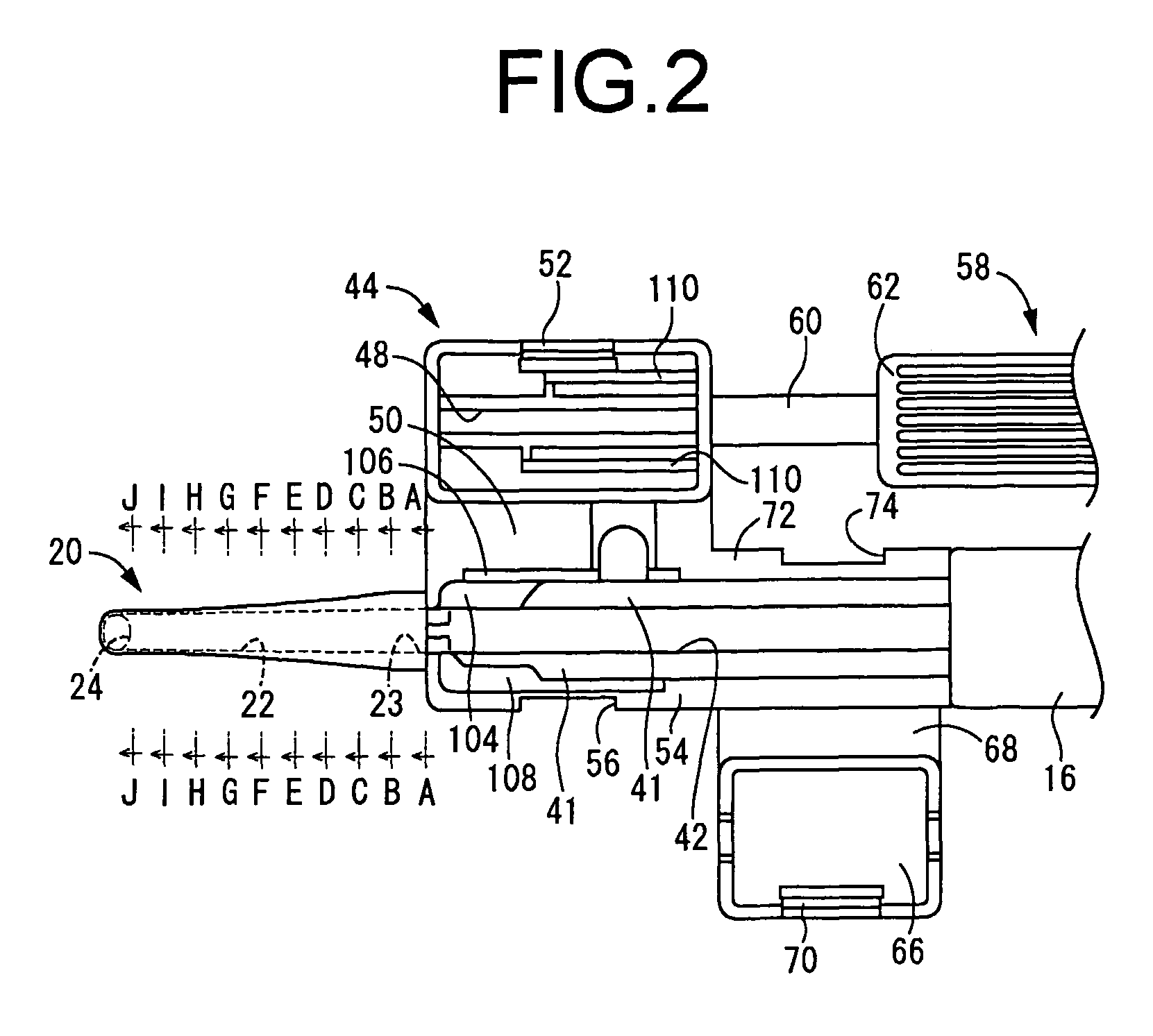

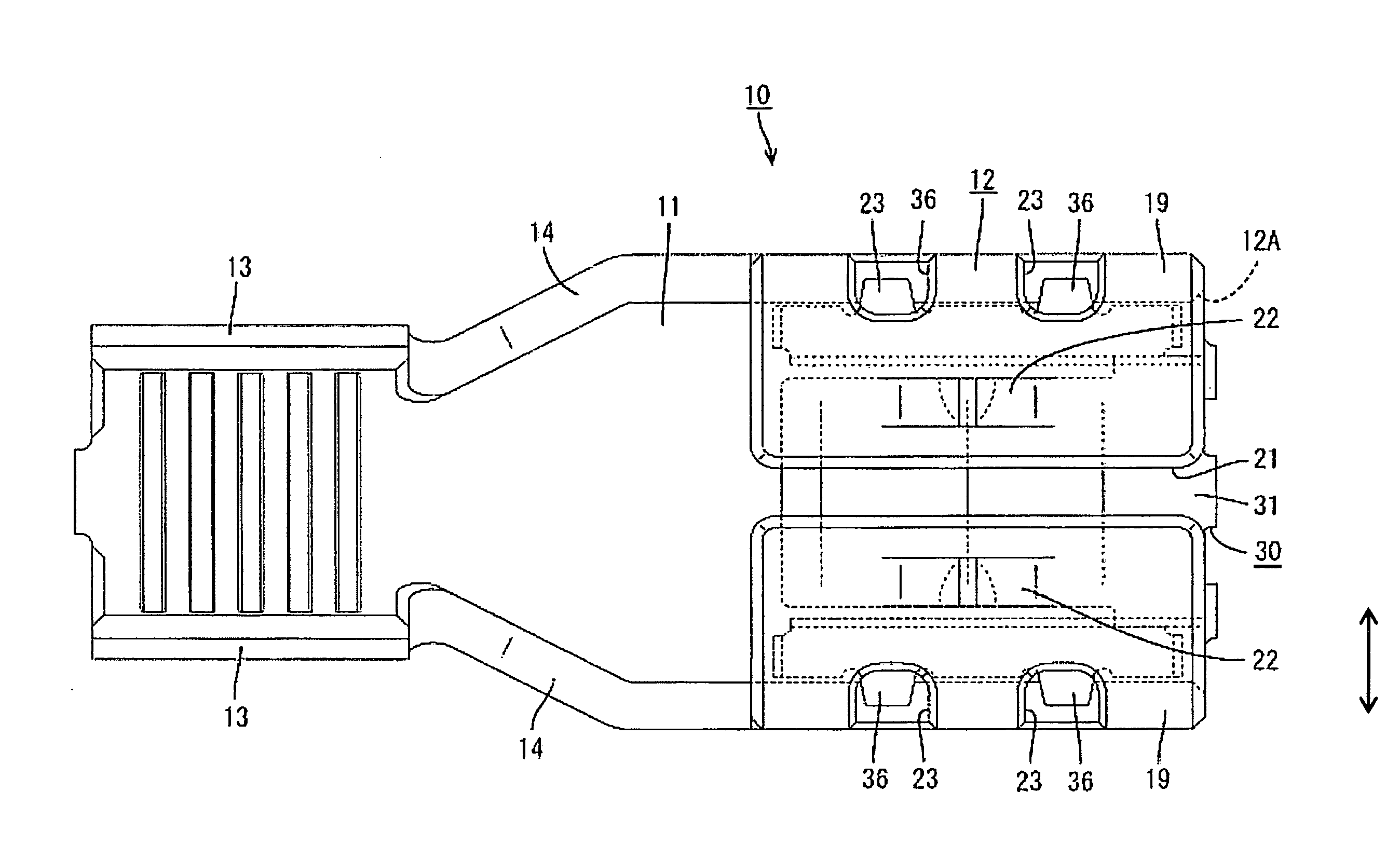

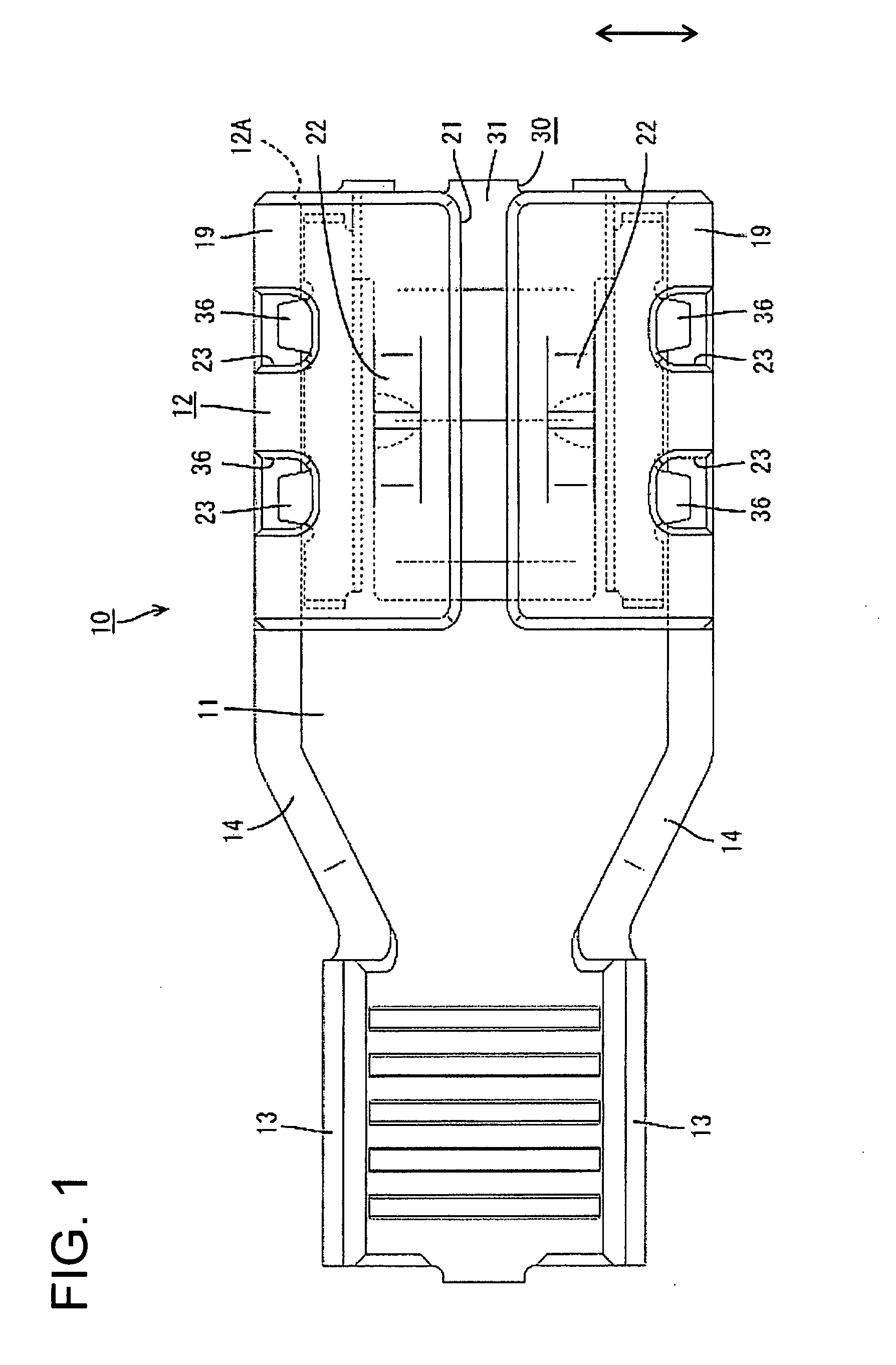

Female terminal fitting

InactiveUS20080096442A1Avoid shakingImprove contact reliabilitySecuring/insulating coupling contact membersCoupling contact membersAnatomyContact position

A female terminal fitting (10) has a tube (12) with a tab insertion opening (12A) for receiving a male tab (80). A contact piece (30) and receiving pads (17) are provided in the tube (12) for sandwiching the male tab (80). The contact piece (30) includes a resiliently deformable contact main body (31) that is curved to come closer to the receiving pads (17) and can resiliently contact a widthwise middle part of a plate surface of the male tab (80) at a convex contact position along the curve. Shake preventing portions (32) are formed at opposite sides of the contact main body (31) and contact opposite sides of the male tab (80) for preventing the male tab (80) from shaking about the center of axis thereof.

Owner:SUMITOMO WIRING SYST LTD

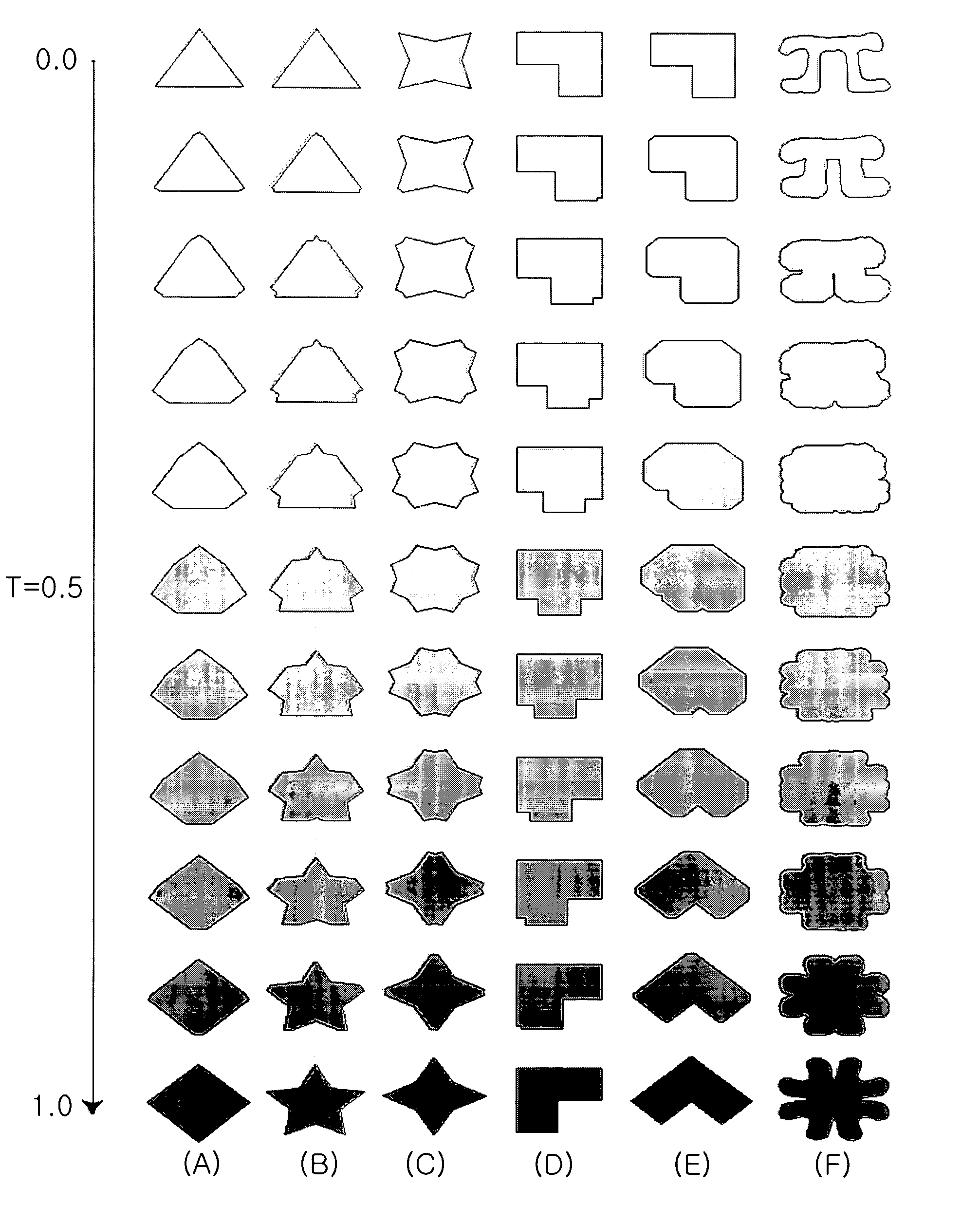

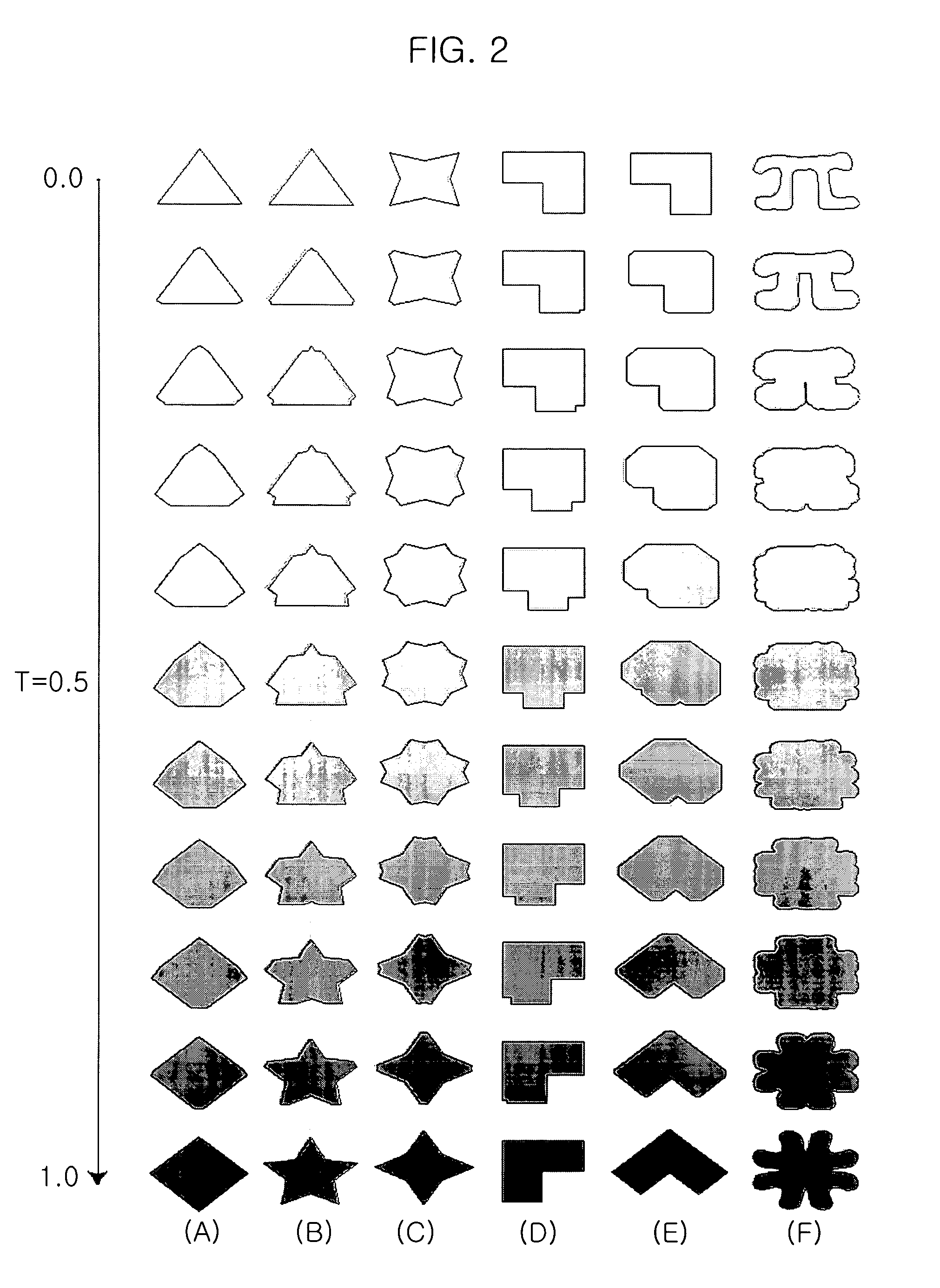

Method for morphing geometric shapes based upon direction map

InactiveUS7091995B2Smooth deformationFlat shapeImage enhancementGeometric image transformationMorphingAlgebra of physical space

The present invention provides a method for morphing different geometric shapes while not using algebraic characteristics and overcoming inefficiency of Minkowski sum computation. The method for geometric shape morphing by using direction map so as to smoothly morph more than two different geometric shapes includes the steps of: a) extracting each direction map of the geometric shape; b) merging the direction maps; c) scaling the merged direction map by group; and d) generating a polygon by using an inverse function of a direction map.

Owner:ELECTRONICS & TELECOMM RES INST

Inner sole structure for a sports shoe

InactiveUS8291615B2Prevents an excessive sinking of the upperRestrains deformation of upperSolesInsolesSliding contactCompressive deformation

An inner sole structure for a sports shoe includes an upper sheet, a lower sheet below the upper sheet, and a wavy corrugated sheet interposed between the upper and lower sheets. The wavy corrugated sheet has at least two downwardly convex protrusions that form voids between the wavy corrugated sheet and the lower sheet, and that are in sliding contact with an upper surface of the lower sheet. The downwardly convex protrusions of the wavy corrugated sheet slide longitudinally along the lower sheet member when they are subjected to compressive deformation.

Owner:MIZUNO CORPORATION

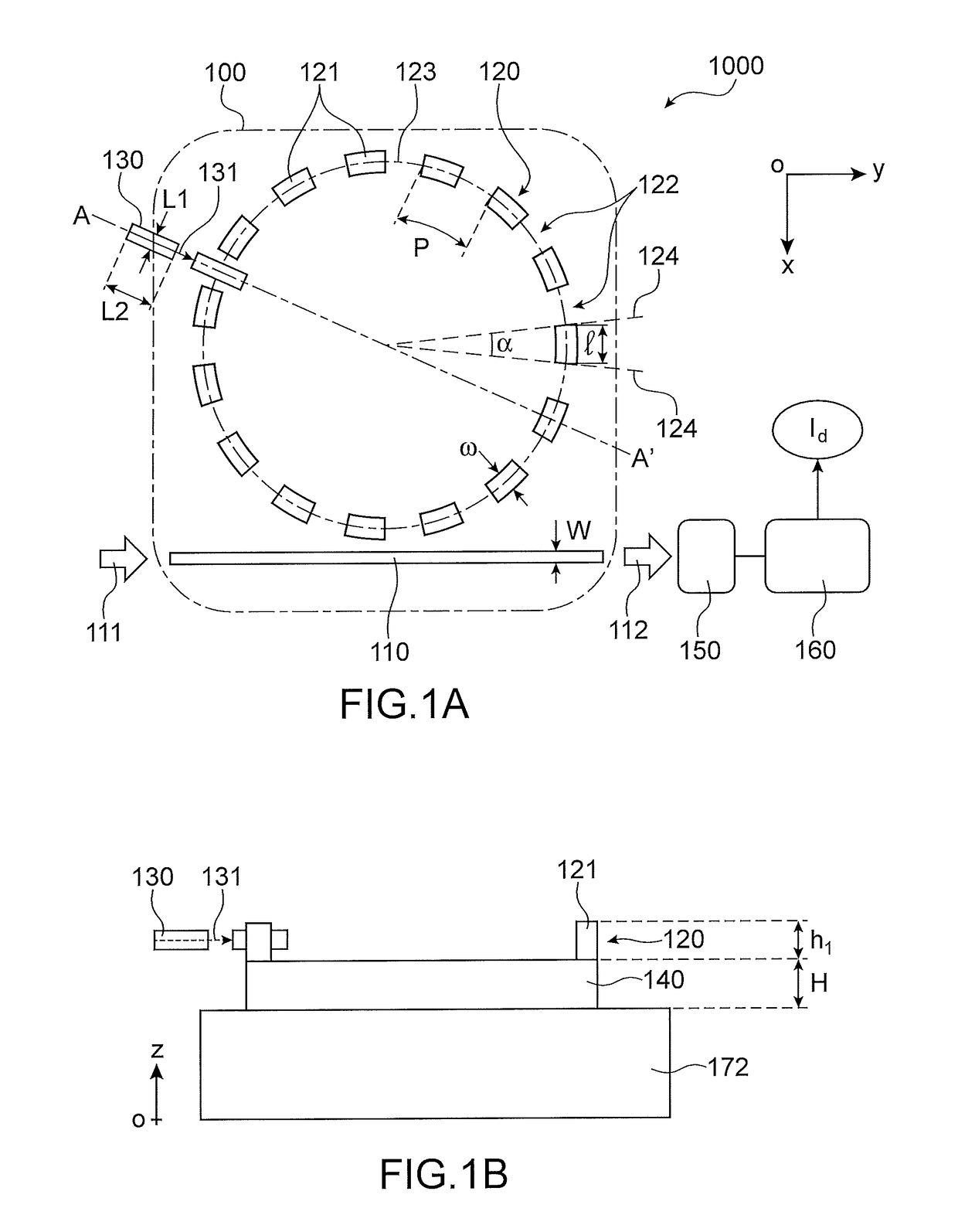

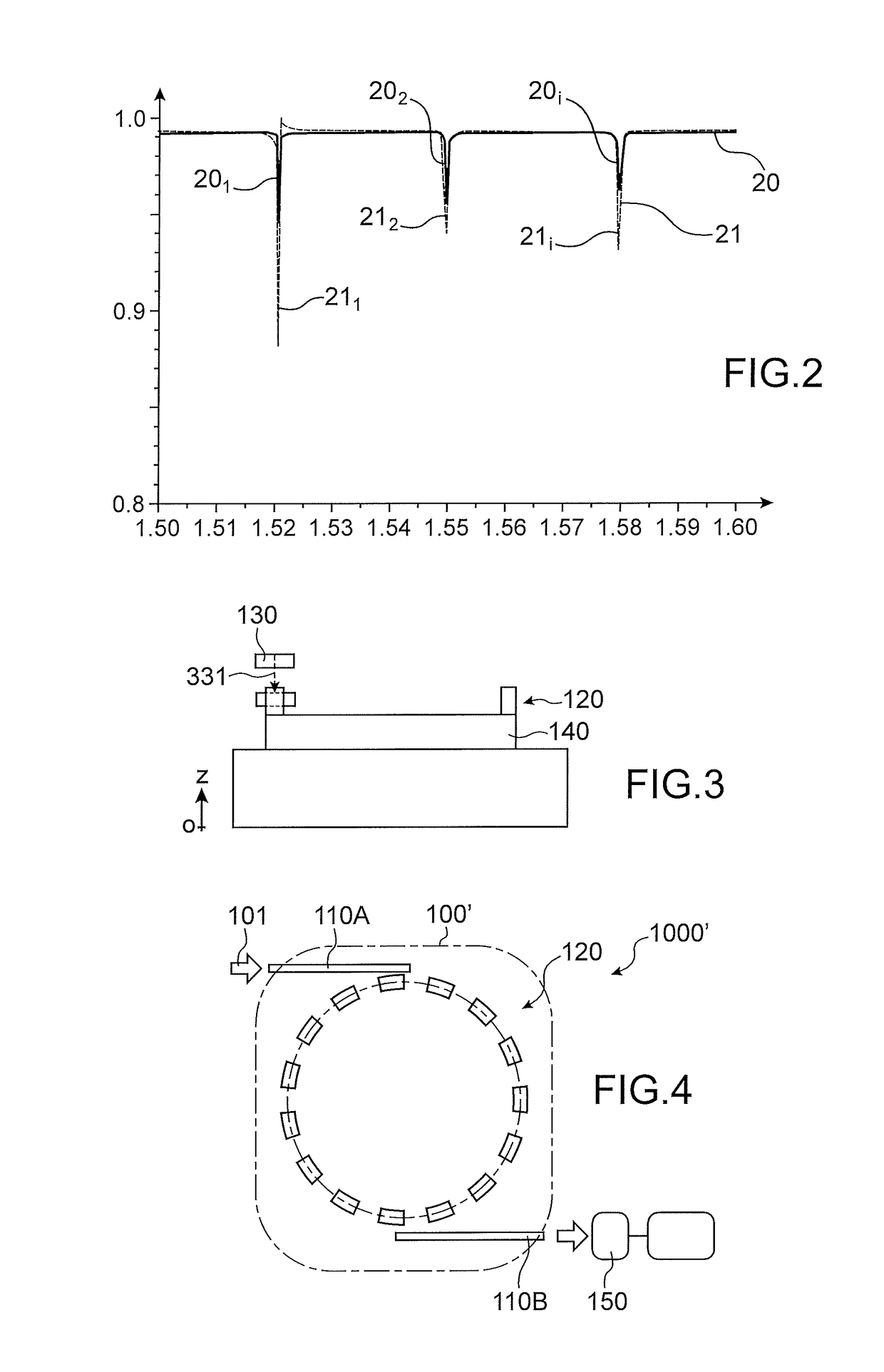

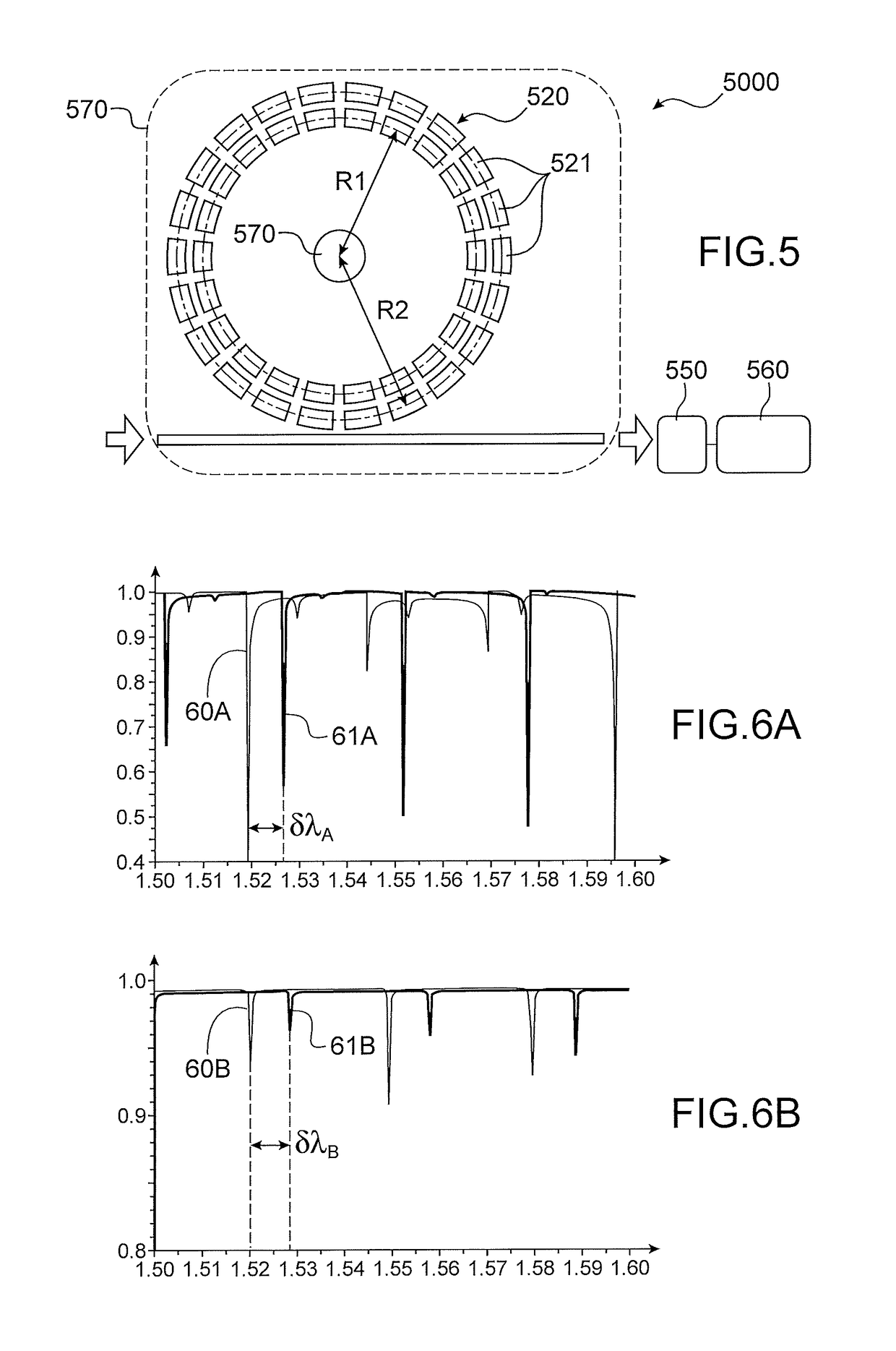

Displacement sensor with segmented ring microresonator

ActiveUS20190011261A1Increase lossSmooth deformationSagnac effect gyrometersConverting sensor outputPhotovoltaic detectorsPhotodetector

An optical sensor includes an optical device including a microresonator, laid out to guide a light beam along a closed loop optical path, and an injection and / or extraction waveguide, optically coupled to the microresonator; a photodetector, arranged at the output of the injection and / or extraction waveguide; and an analysis device, receiving a signal supplied by the photodetector, and deducing therefrom information relative to a displacement. The microresonator is constituted of a plurality of elementary waveguides spaced apart from each other, and arranged one after the other according to a loop shaped layout. The optical sensor offers increased sensitivity to the measurement of nanometric displacements.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

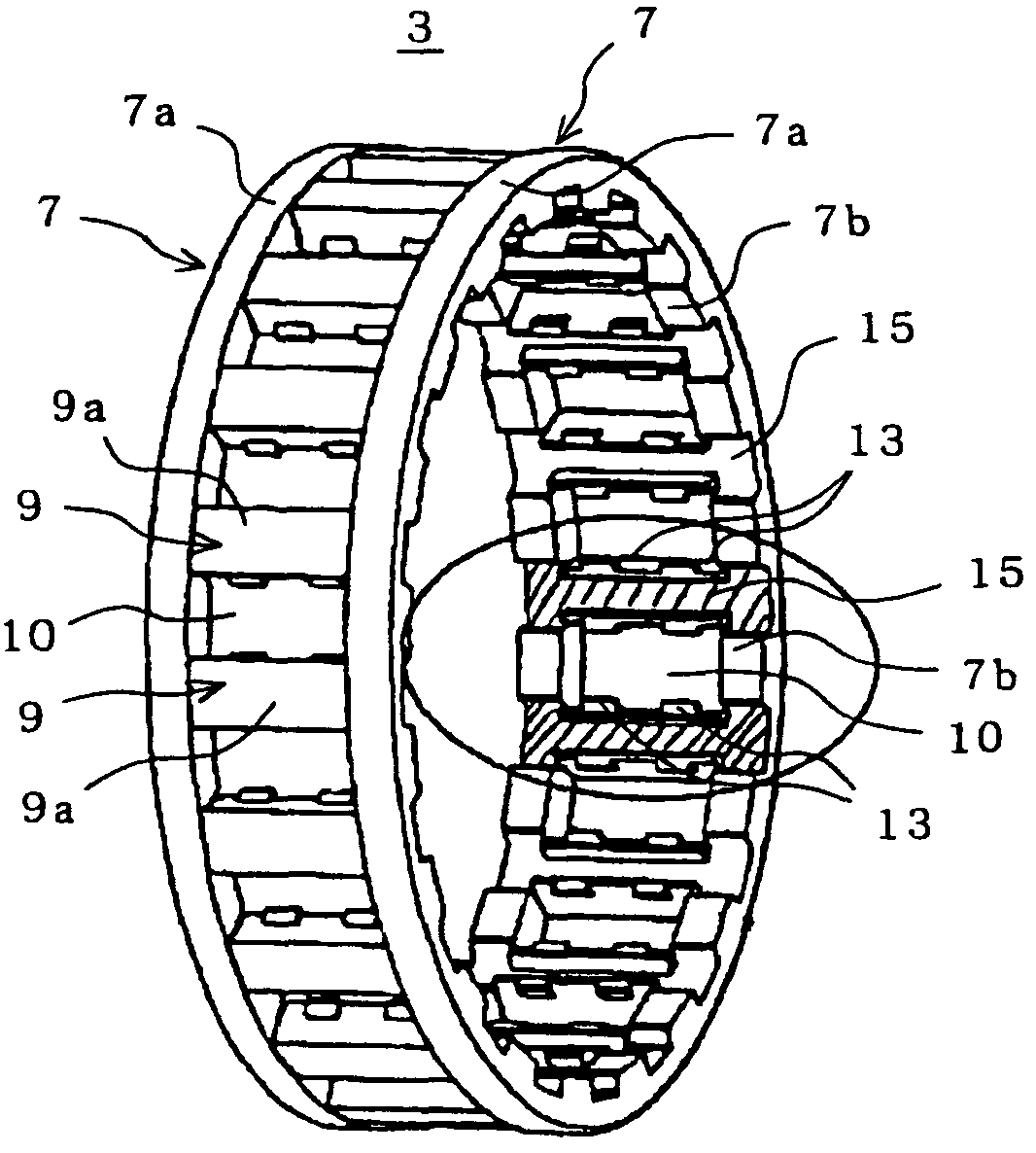

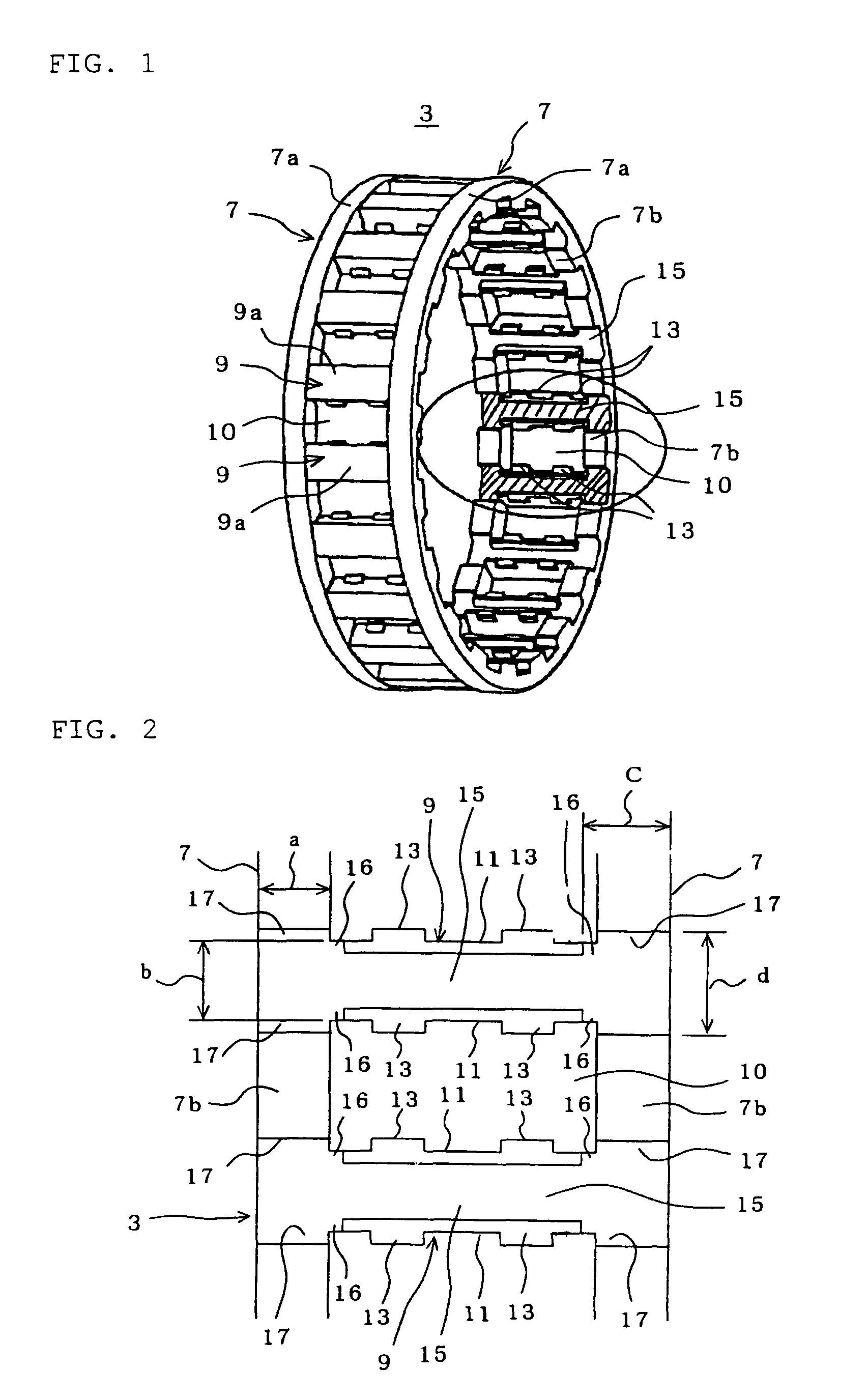

Cage for roller bearing

InactiveUS7832943B2Easy to transformAvoid deformationRoller bearingsShaftsMechanical engineeringRoller bearing

A roller bearing cage includes annular portions provided respectively at opposite ends thereof, a plurality of pillar portions interconnecting the annular portions, a plurality of pockets for respectively holding needle rollers, and roller retaining portions formed respectively on circumferentially-opposed wall surfaces and of each pocket portion. A concave groove smaller in width than the pillar portion is formed axially in a back surface of each pillar portion and those portion of back surfaces of the annular portions disposed respectively at opposite ends of each pillar portion. Separation groove portions are formed respectively at opposite sides of those portions of the concave groove disposed respectively at the opposite ends of the pillar portion, and extend respectively to corresponding circumferentially-opposite side surfaces of the pillar portion, and each separation groove portion separates the corresponding roller retaining portion and annular portion from each other.

Owner:JTEKT CORP

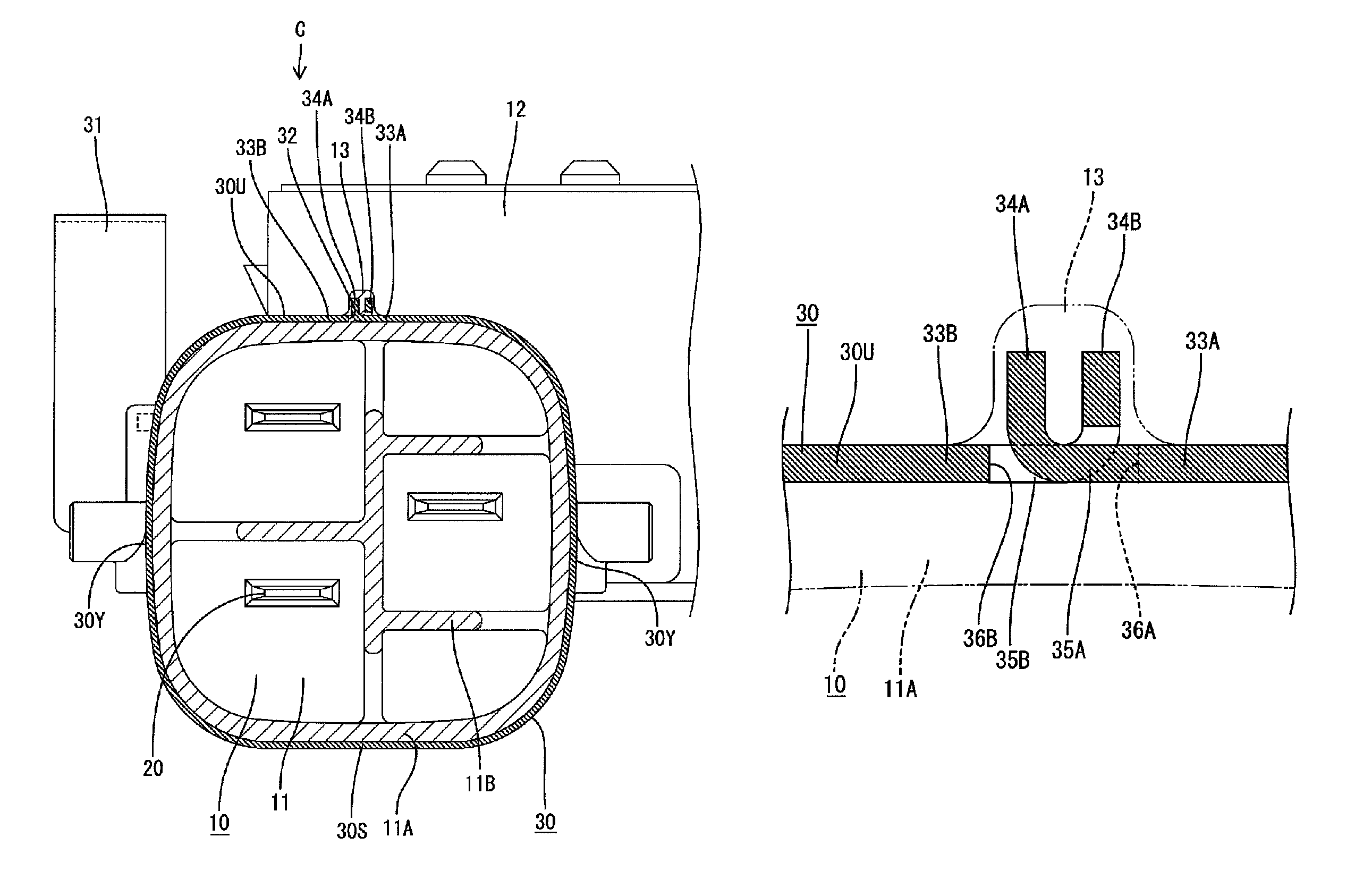

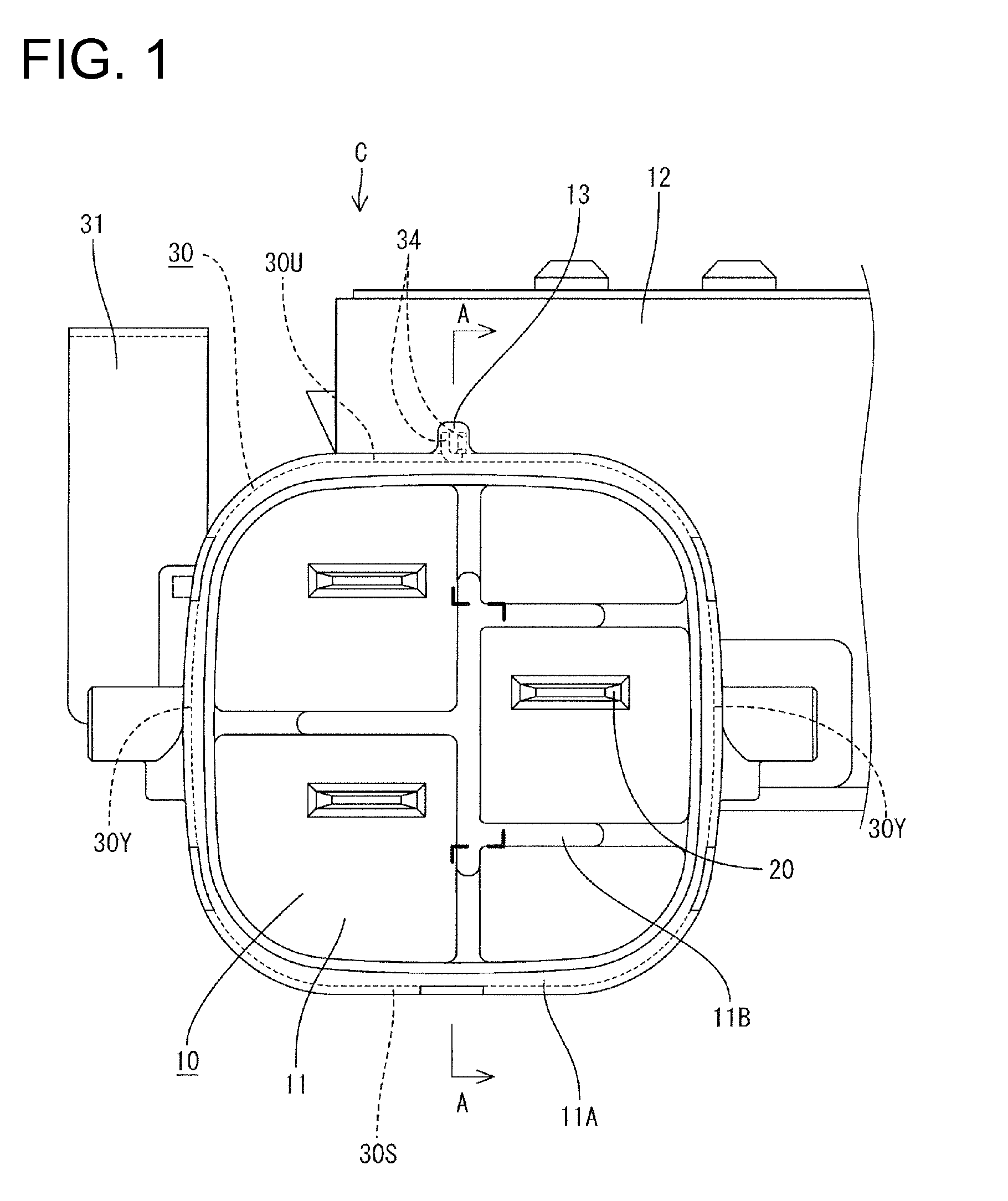

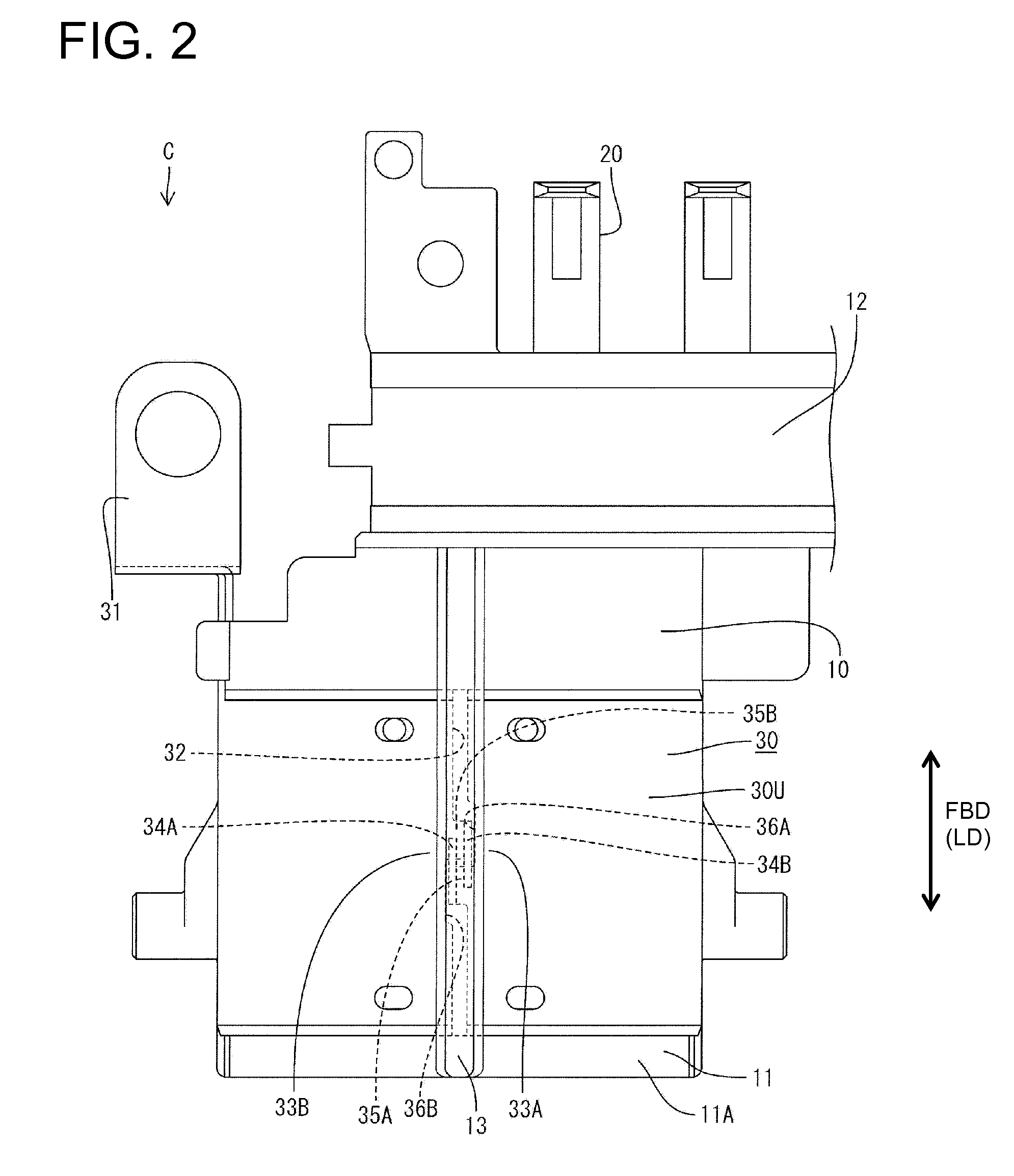

Shield connector

InactiveUS8133077B2Easy to transformReduce the overall diameterElectrically conductive connectionsContact member assembly/disassemblyStructural engineeringMechanical engineering

A shield connector (C) includes a tubular metallic shield shell (30) integrally attached to the outer circumferential surface of a housing (10) made of resin by insert molding. The shield shell (30) is formed with a cut (32) extending between opposite ends in a longitudinal direction, and a pair of opening preventing pieces (34A, 34B) which extend radially inward or outward, circumferentially face each other and can come into contact with each other when edges (33A, 33B) at the opposite sides of the cut (32) are displaced in directions away from each other are provided on the opposite edges (33A, 33B) of the shield shell 30 facing each other with the cut (32) therebetween.

Owner:SUMITOMO WIRING SYST LTD

Membrane element sealing material holding member and membrane element

ActiveUS7867394B2Smooth deformationEasy to insertSemi-permeable membranesMembranesBiomedical engineeringSpiral membrane

A membrane element sealing material holding member comprising a central opening for insertion of a center tube of spiral membrane element, peripheral orifice for flowing of a raw liquid into a membrane end portion of membrane element and outer circumferential part for holding of circular sealing material, wherein the central opening has inner circumferential surface of cylindrical form with a diameter larger than the outer diameter of the inserted center tube, and wherein at three or more positions on the inner circumferential surface, there is provided projection that has sloping face on its side of center tube insertion and is deformable at the time of insertion of center tube with an outer diameter larger than that of incircle.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com