Sole Structure for a Shoe

a technology for soles and shoes, applied in the field of sole structures, can solve the problems of easy deterioration of the cushioning properties of the midsole, and achieve the effect of improving the flexibility of the sole structure and easy deformation elastically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Alternative Embodiment 1

[0079]In the above-mentioned embodiment, an example was explained in which the heel part of the plate 4 is formed in a heel-cup shape by providing the upraised portion 41 at the region extending from the heel rear end of the body portion 40 of the plate 4 to the heel medial and lateral sides, but the application of the present invention is not limited to such an embodiment. Of the entire upraised portion 41 of the body portion 40, the upraised portion 41 provided at the heel rear end may be omitted.

[0080]In the event that the upraised portion 41 is provided at the heel rear end of the plate 4, when impact load in the forward direction is applied to the plate 4 at the time of impacting the ground the upraised portion 41 at the heel rear end may interfere with the heel rear end surface of the upper sole 2A and the forward movement of the plate 4 may be restricted. However, by removing the upraised portion at the heel rear end of the plate 4, the forward movemen...

embodiment 2

Alternative Embodiment 2

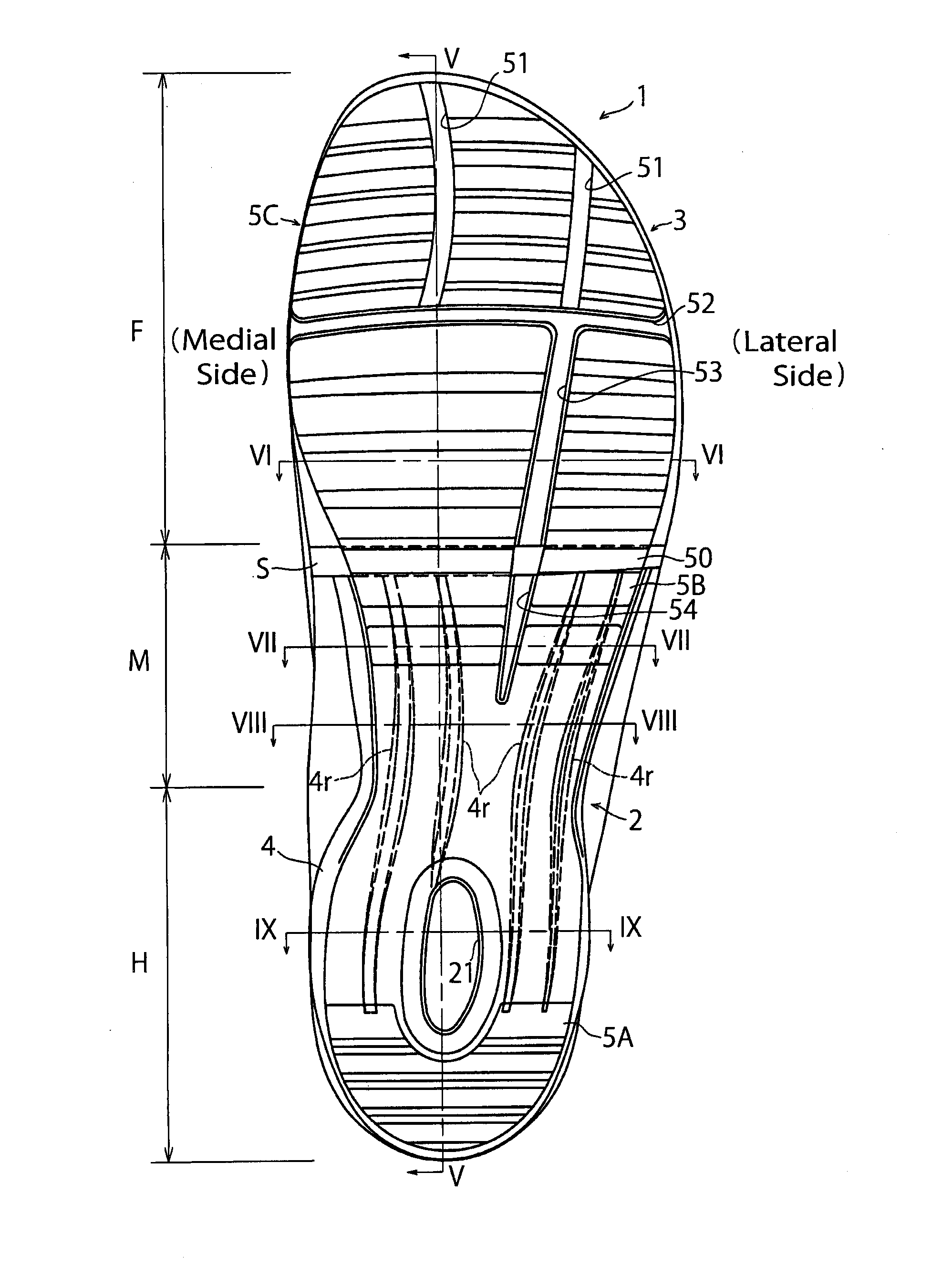

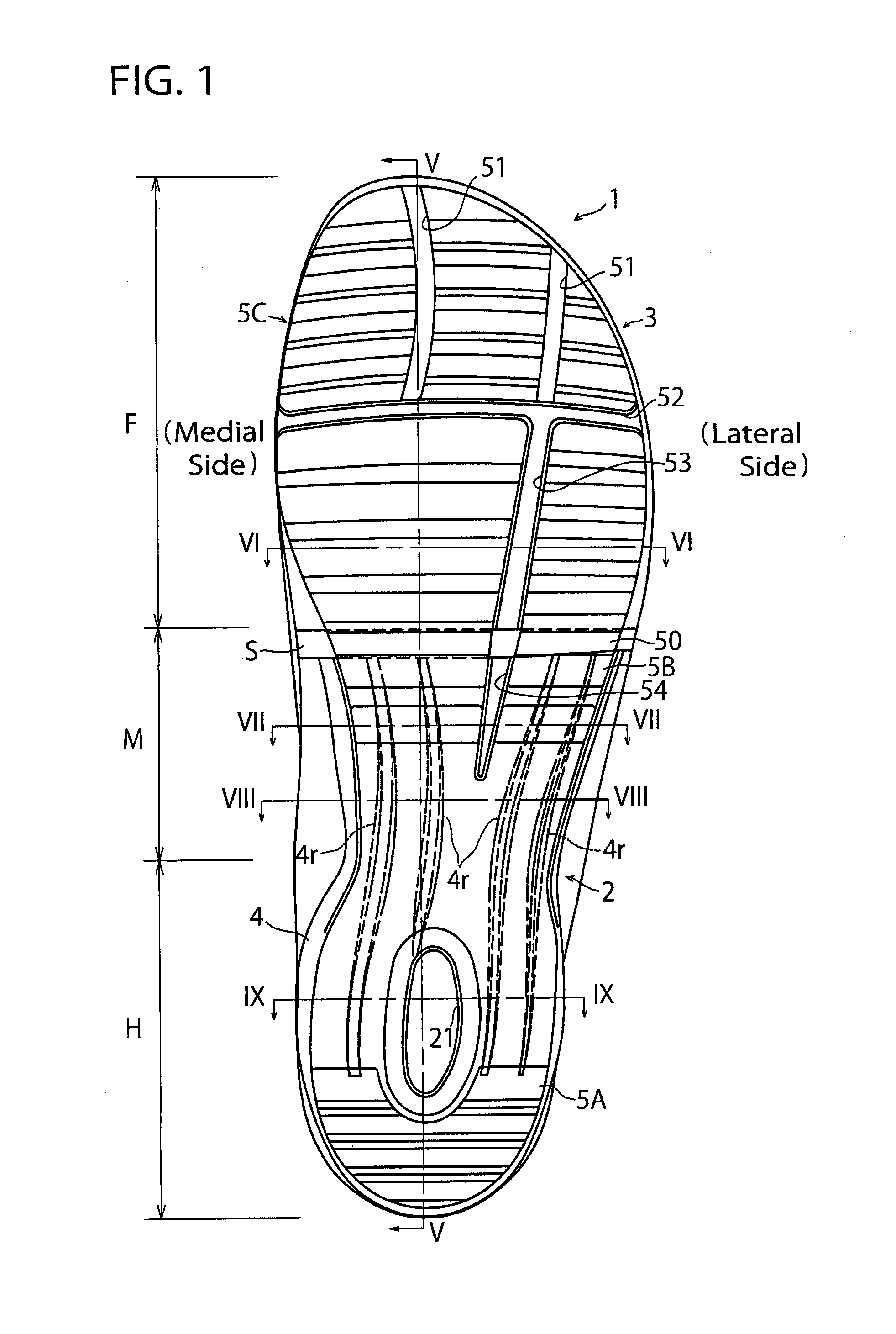

[0081]In the above-mentioned embodiment, as a preferred embodiment, an example was shown where the plate 4 extends along the rear foot region from the heel part H to the midfoot part M of the sole structure 1. However, at the heel part H, the plate 4 has only to be placed to cover the position directly under at least the calcaneus CA, and at the midfoot part M, the plate 4 has only to be placed at the position to cover at least the proximal portions of the first to fifth metatarsus MB1 to MB5. This is for receiving the shock load securely at the time of heel contact and midfoot contact during running. The present invention also has application to the structure where the plate 4 is provided either at the heel part H only or at the midfoot part M only.

[0082]In the event that the plate 4 is provided only at the heel part H, for example, the plate 4 is provided along the heel portion of the rear foot sole 2B (to cover the position directly under at least the calc...

embodiment 3

Alternative Embodiment 3

[0083]In the above-mentioned embodiment, an example was shown where the connection 50 has a single bent portion of an inverted V-shape or U-shape (see FIGS. 2, 3, 5), but the present invention also has application to the case in which the connection 50 has a plurality of bent portions of inverted V-shapes or U-shapes. In this case, the connection 50 is bent in a bellows-shape as viewed from the side thereof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com