Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Small control deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

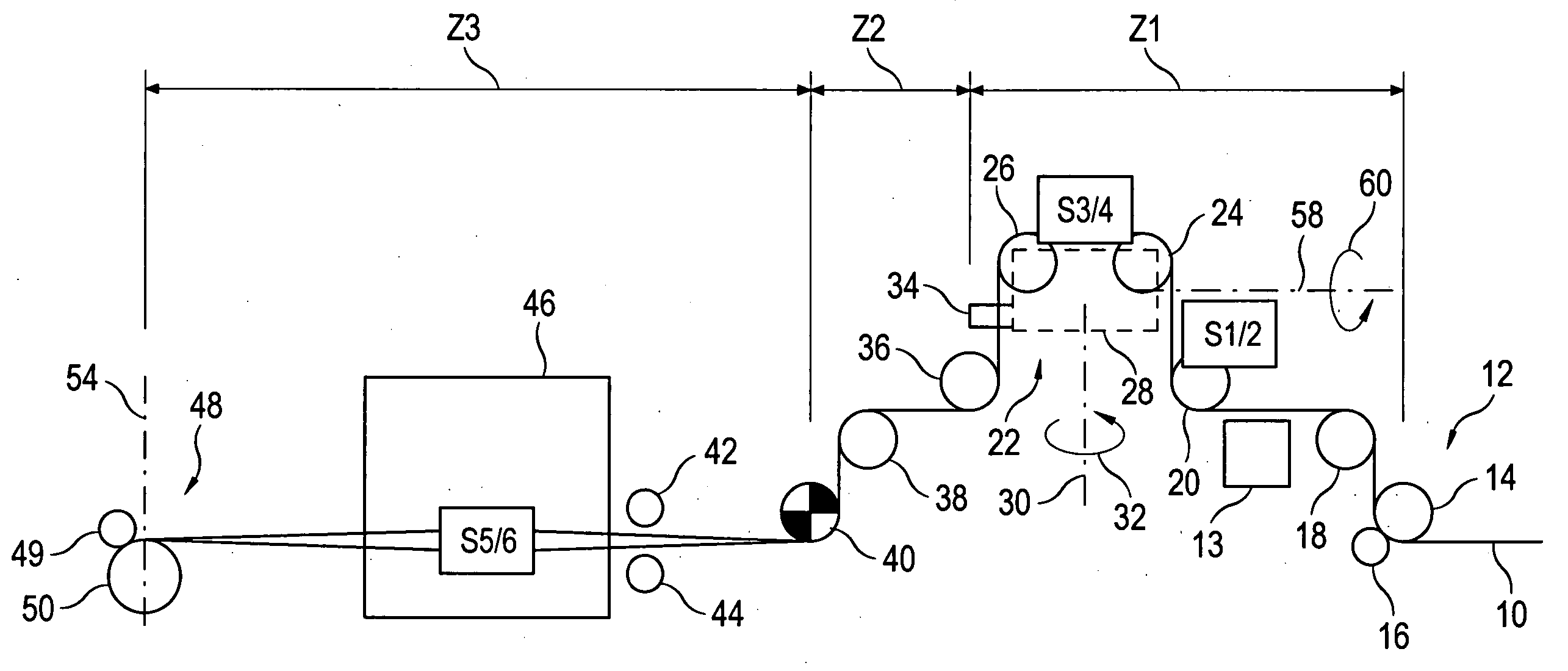

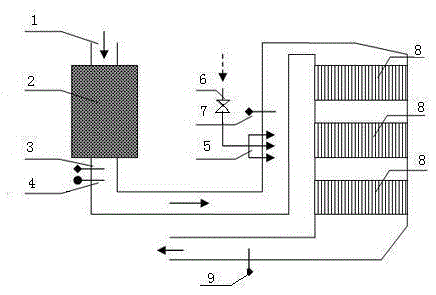

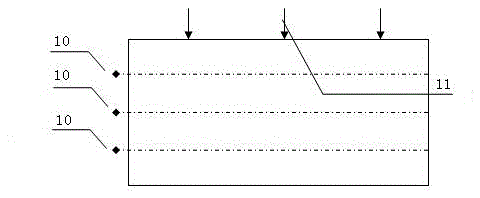

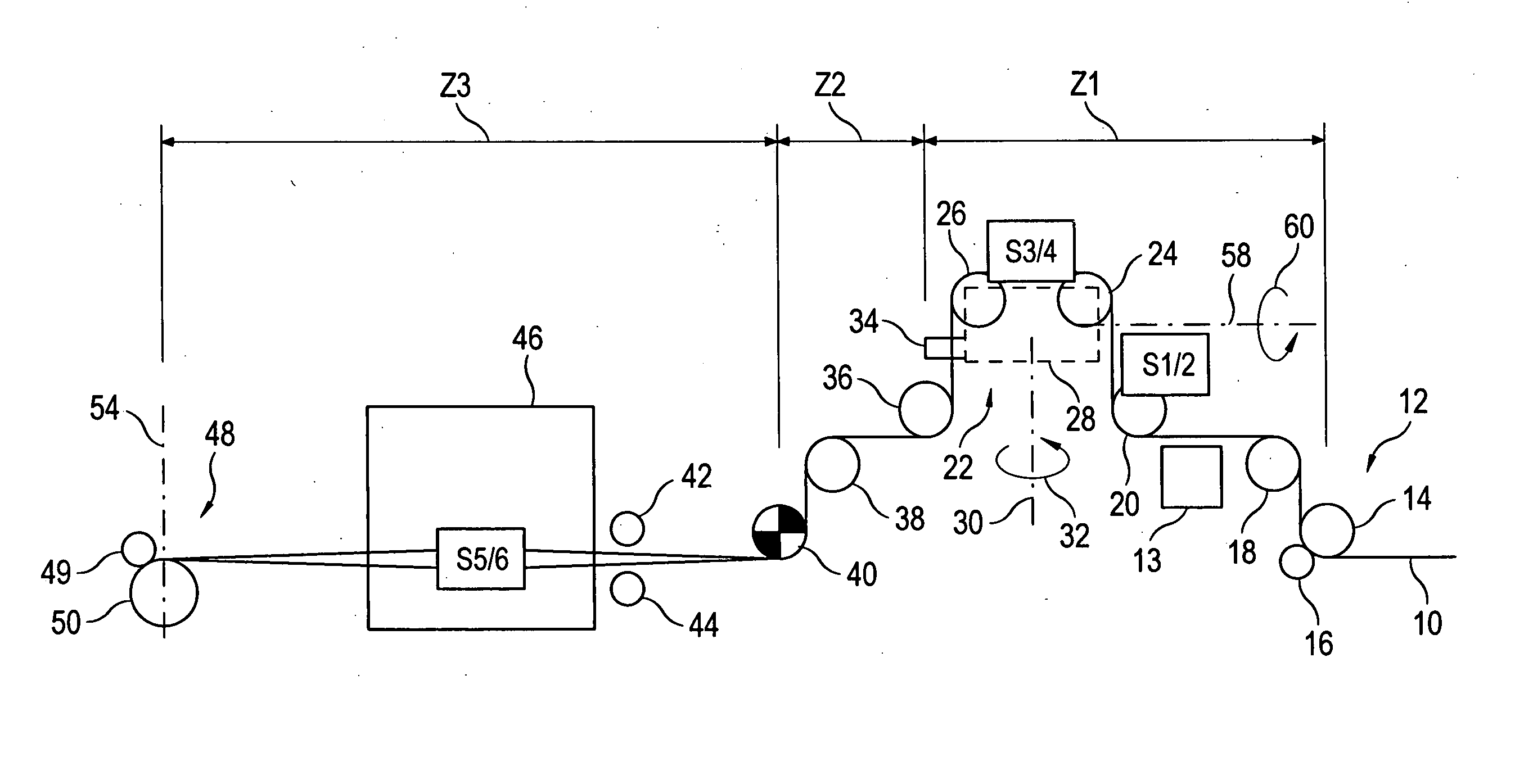

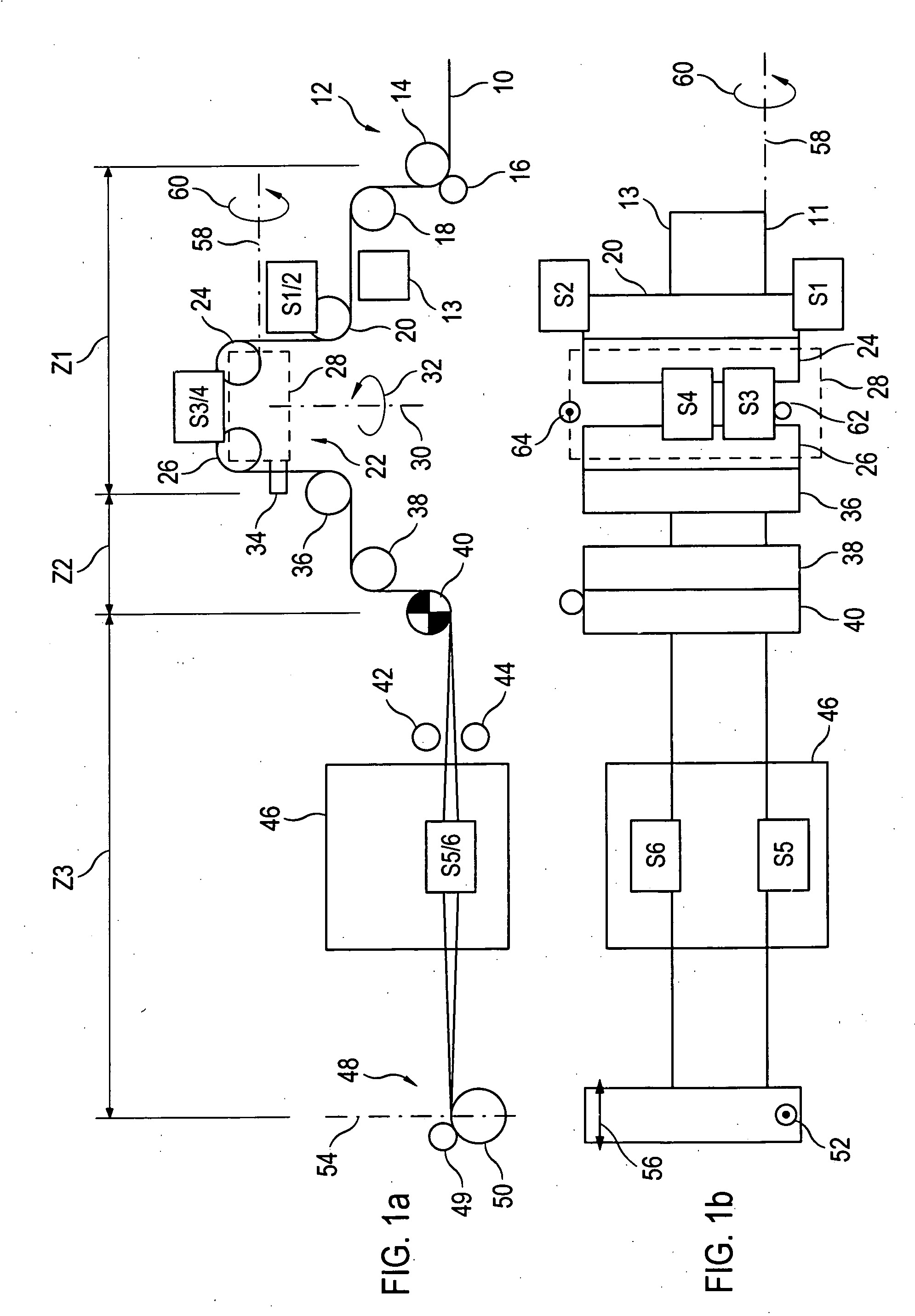

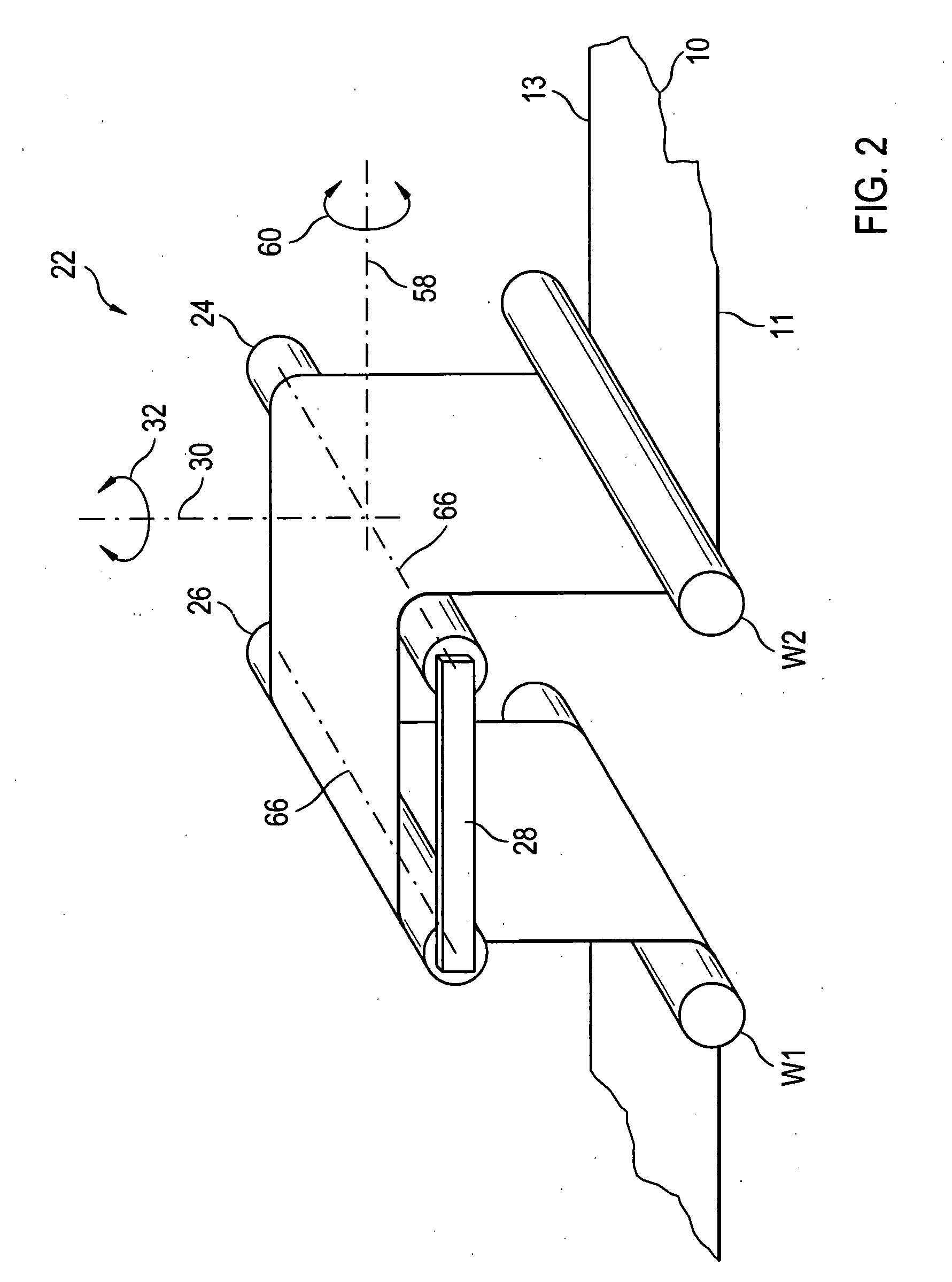

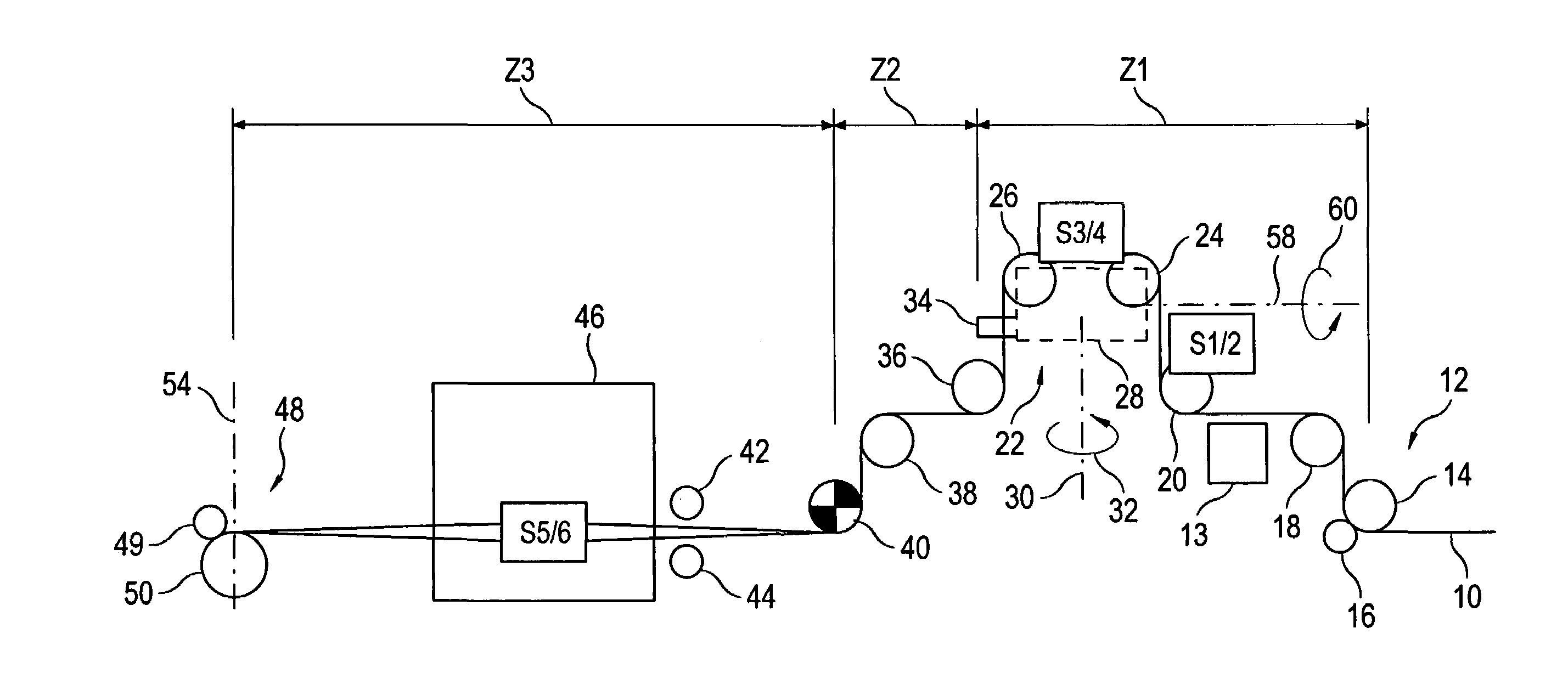

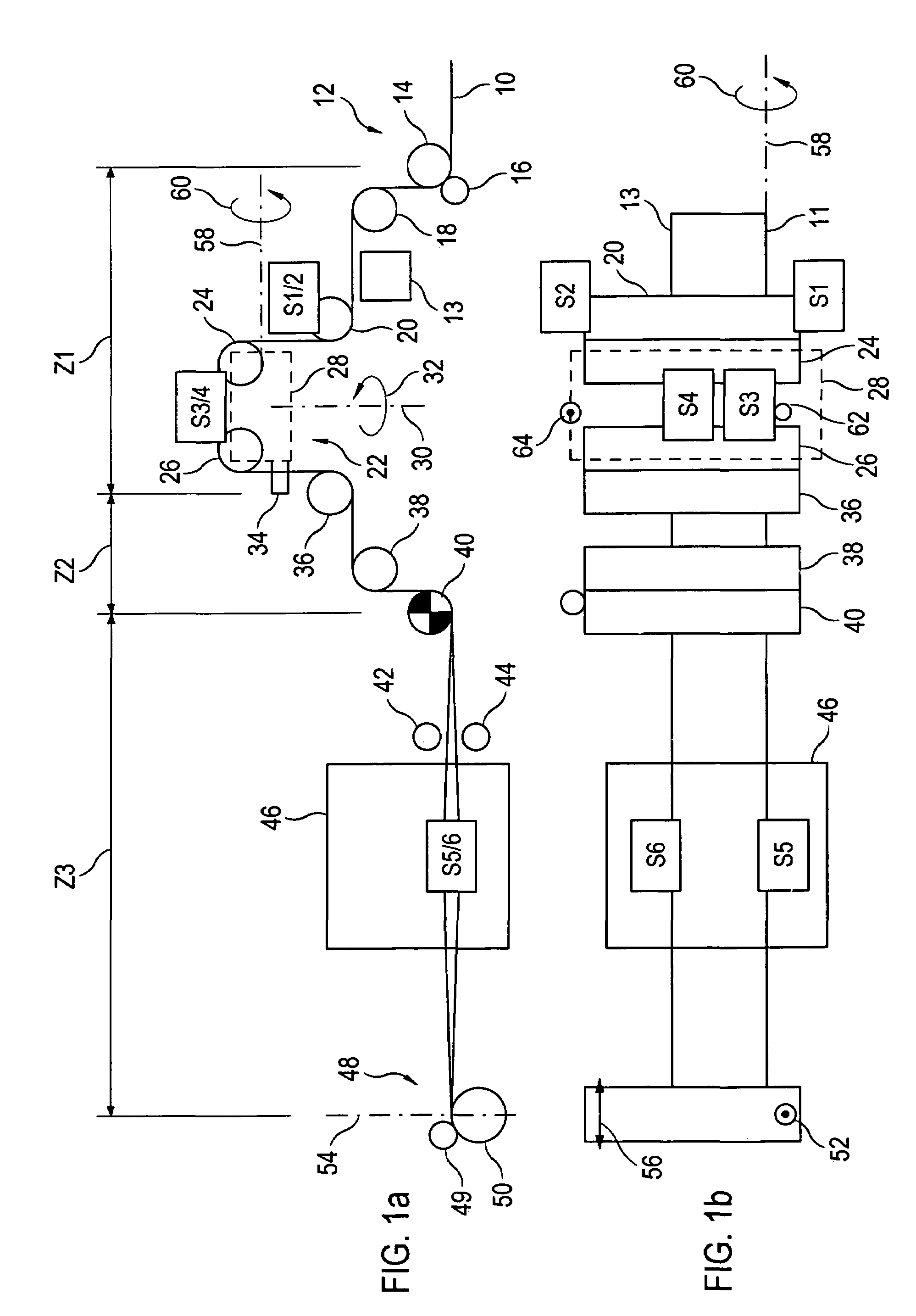

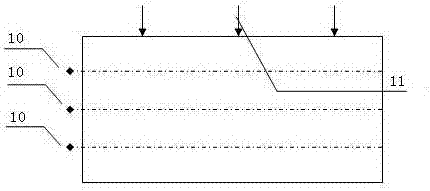

Device and method for controlling the position of the lateral edge of a continuous web

InactiveUS20050002718A1Quality improvementSettling fastAutomatic control devicesPrecision positioning equipmentActuatorControl theory

A device and a method for controlling a position of a lateral edge of a continuous web of a recording medium in a printer or copier provides that sensors are provided. Signals of the sensors are supplied to a control device which includes an actuator. The actuator changes the position of the lateral edge of the web.

Owner:OCE PRINTING SYST

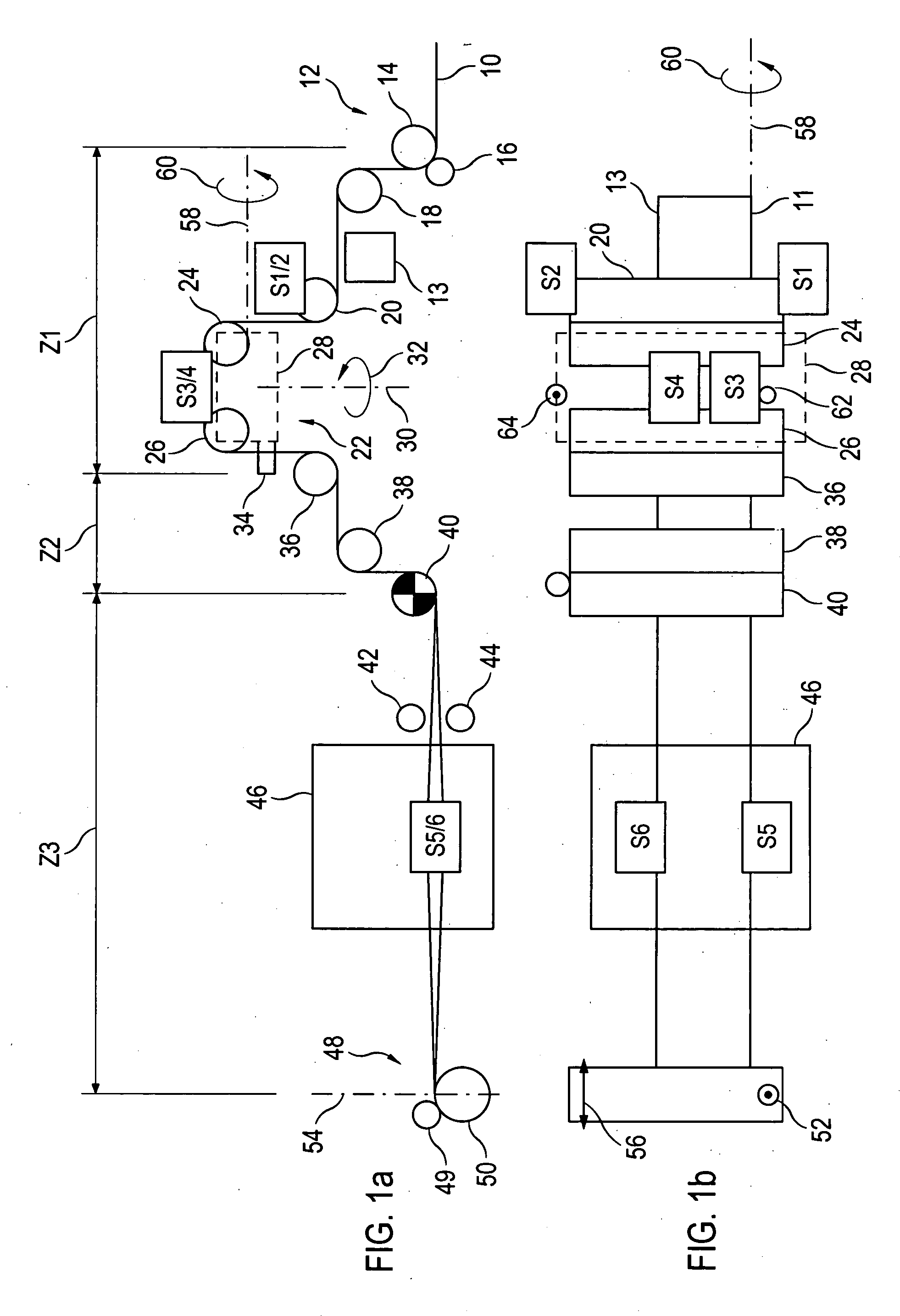

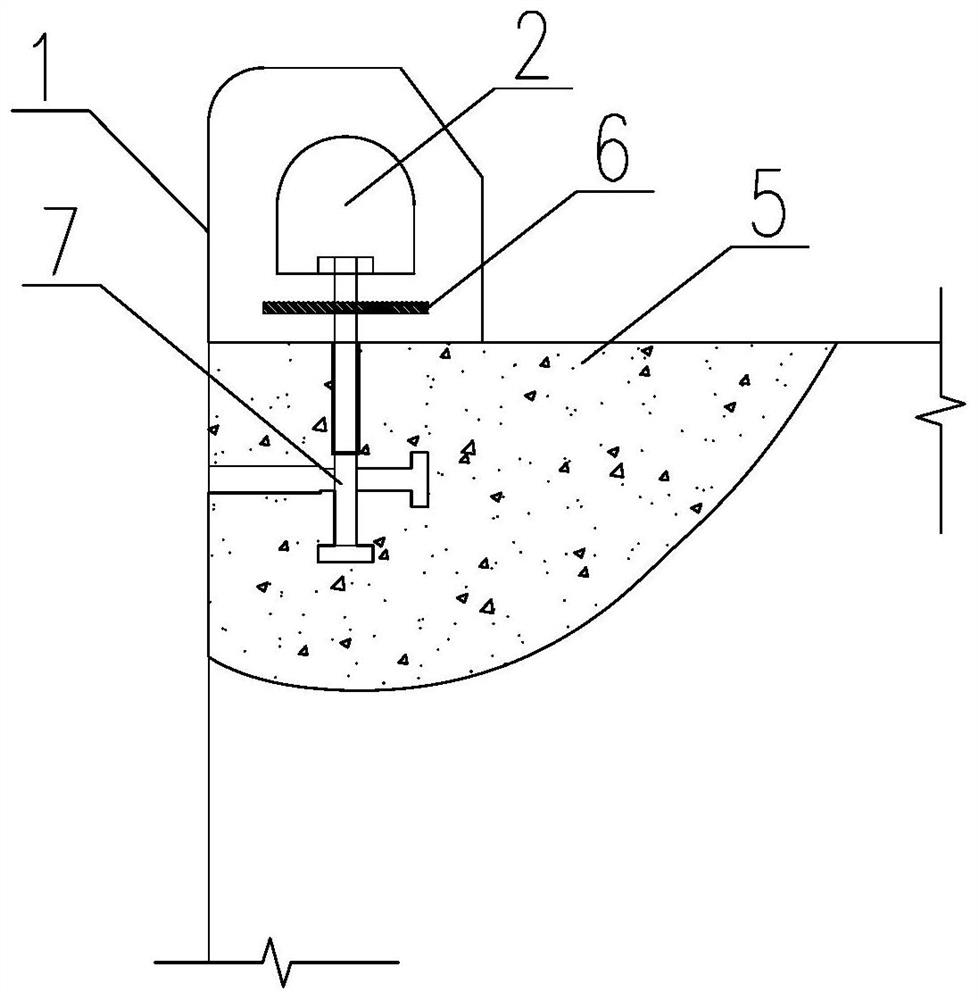

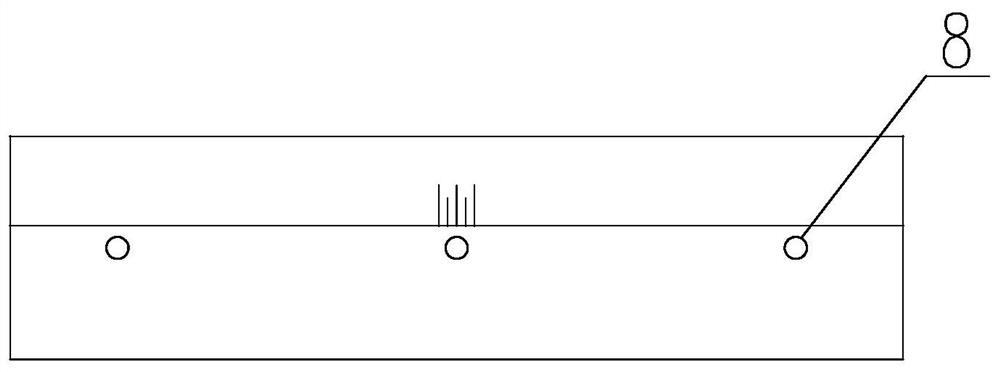

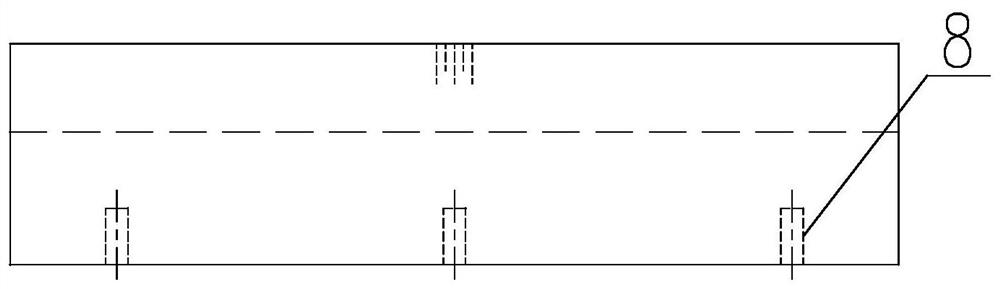

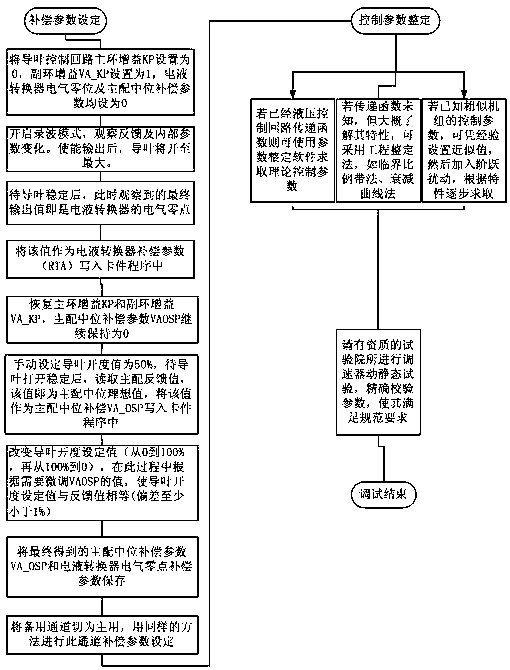

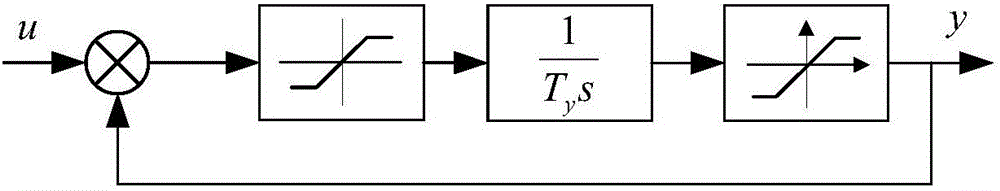

Stroke detection and debugging method of guide vane control loop with pressure distribution valve

ActiveCN106768922AEasy to maintain laterEasy to debugMachine part testingFinal product manufactureHydro energyClosed loop

The invention provides a stroke detection and debugging method of a guide vane control loop with a pressure distribution valve. The method includes the following steps that: a guide vane control block diagram is designed according to the equipment structure of a pumped-hydro energy storage unit, and an electro-hydraulic converter and pressure distribution valve two-stage amplification mode is adopted to make a guide vane servomotor to act through oil pressure; guide vane servomotor and main pressure distribution valve stroke detection modes are determined; a linkage mechanism and a sensor are manufactured and installed, wherein the sensor is used for detecting the strokes of a main pressure distribution valve and a guide vane, and the linkage mechanism is used for converting the strokes of the main pressure distribution valve and the guide vane into the measurement strokes of the sensor; sensor calibration is performed on the guide vane and the main pressure distribution valve; the zero position of an electro-hydraulic converter and the compensation parameter of the neutral position of the main pressure distribution valve are obtained; and guide vane static reaction testing is performed, the acting condition of the guide vane is observed, and the compensation parameter is finely adjusted, so that guide vane control offset can be minimized; and control parameter setting is performed. With the method adopted, it can be ensured that the guide vane control closed-loop is within a reasonable range and has a certain margin, and therefore, later-stage maintenance and debugging can be facilitated.

Owner:广东蓄能发电有限公司

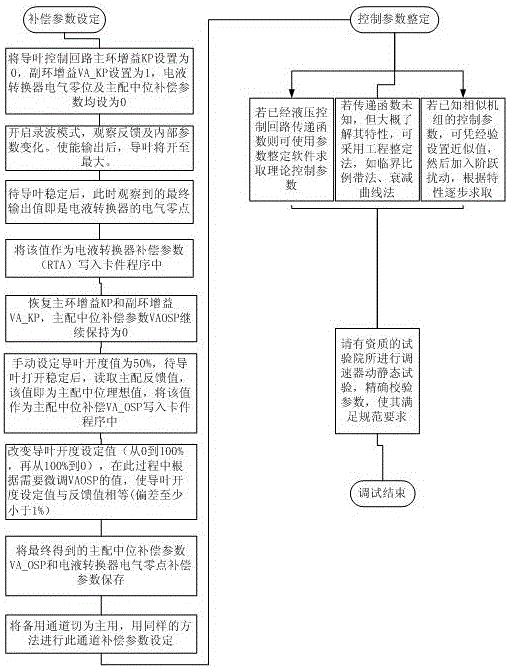

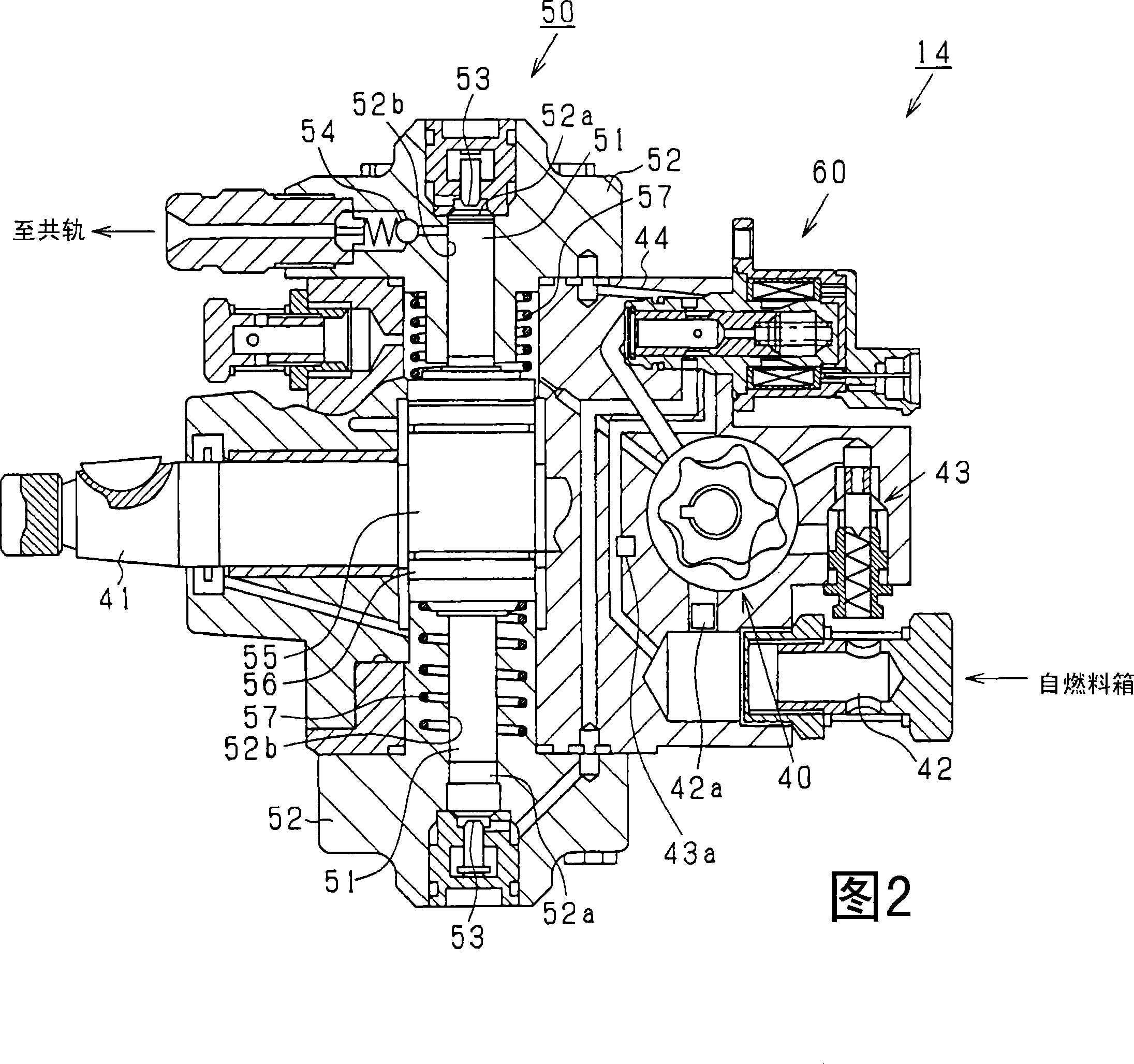

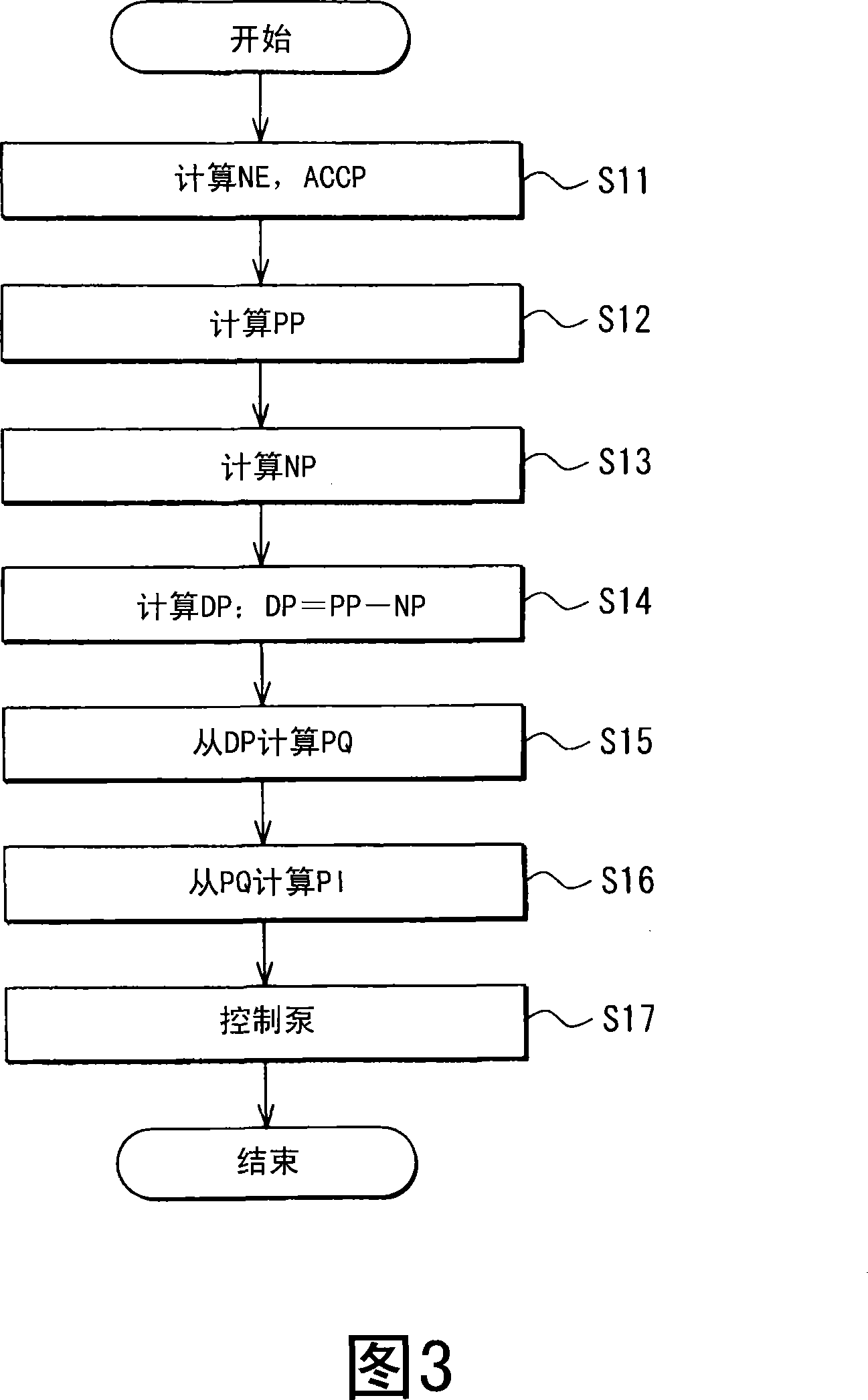

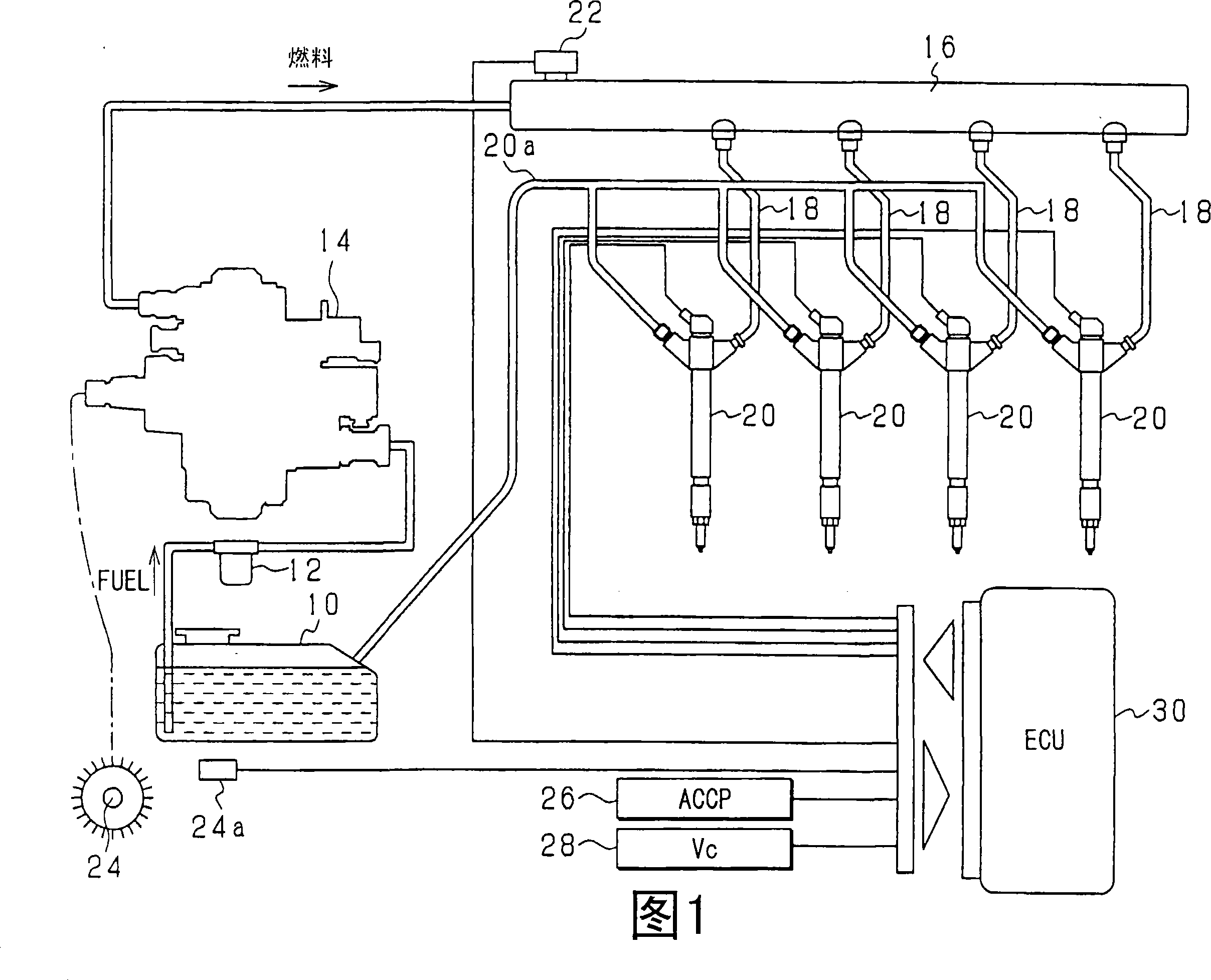

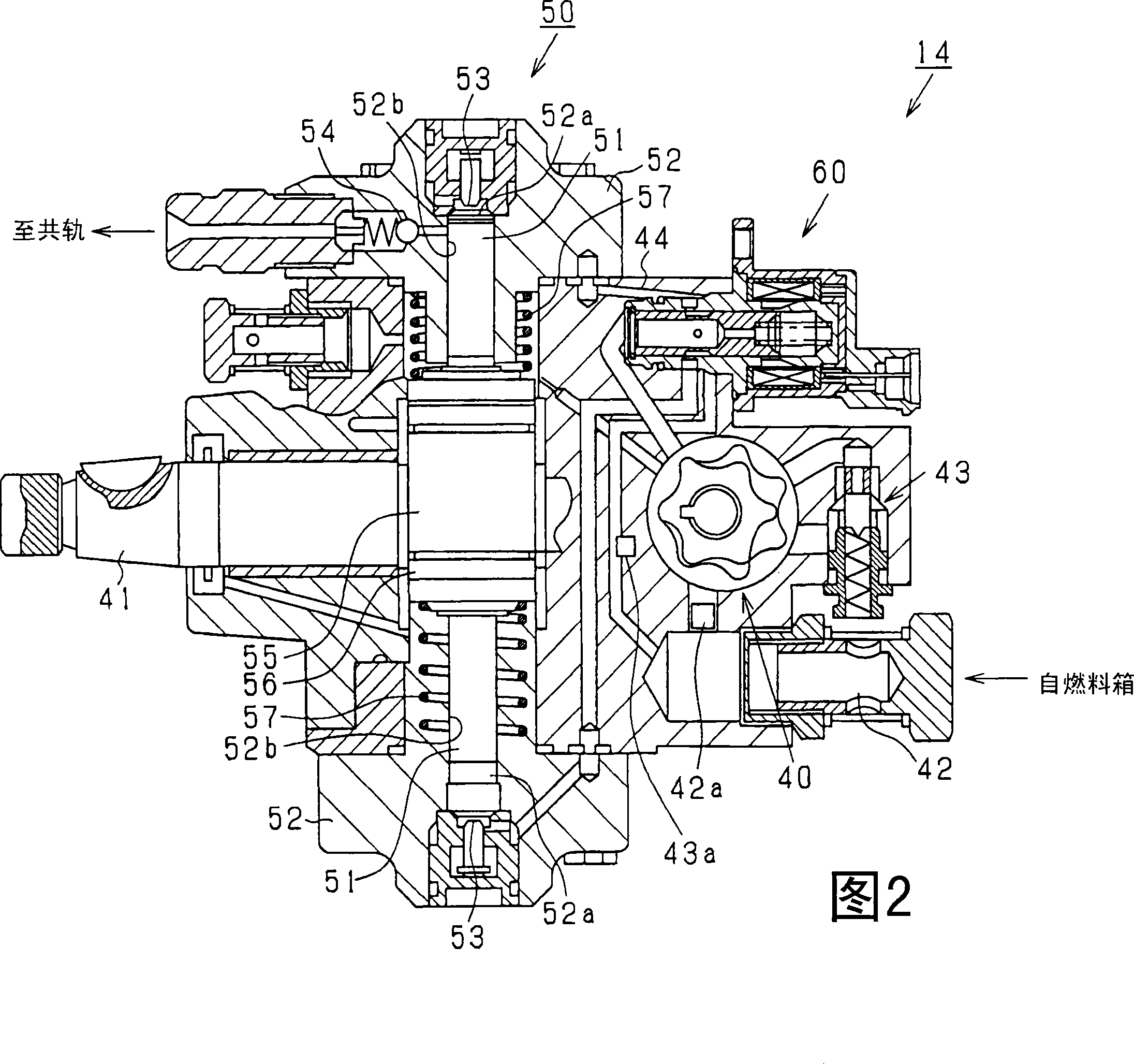

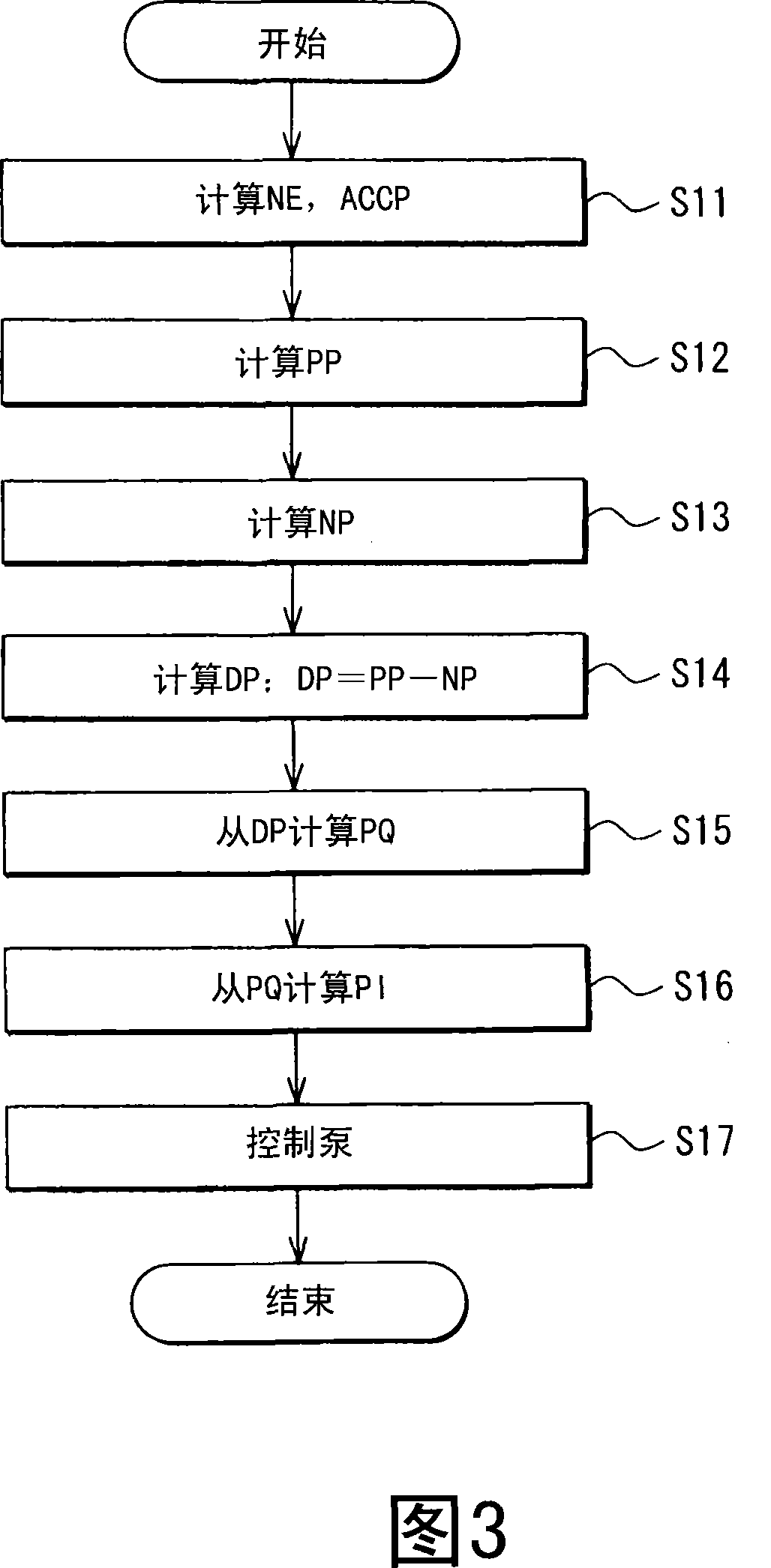

Fuel injection pressure control device

InactiveCN101235756ASmall control deviationDisadvantages of suppressing the occurrence of stallsElectrical controlFuel injection apparatusEngineeringPressure controlled ventilation

The fuel injection pump control device controls a fuel-injector pressure from the injection supply eliminated by the variables of determined measured parameters. The fuel is injected and supplied to a target machine. A learning correction process-implementing device is provided for successive implementation of multiple kinds of learning correction process corresponding to the multiple implemented conditions. The implemented conditions are different in the strictness for a pressure parameter of pressurized parameter as a learning object and are used for the fuel injection pressure controller.

Owner:DENSO CORP

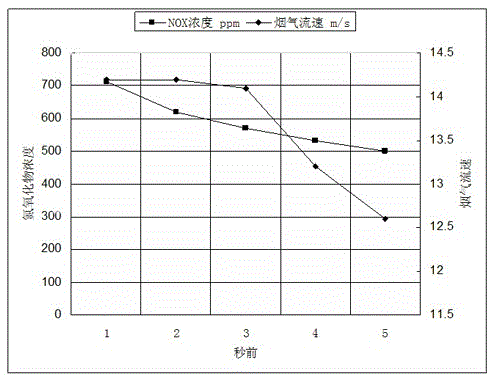

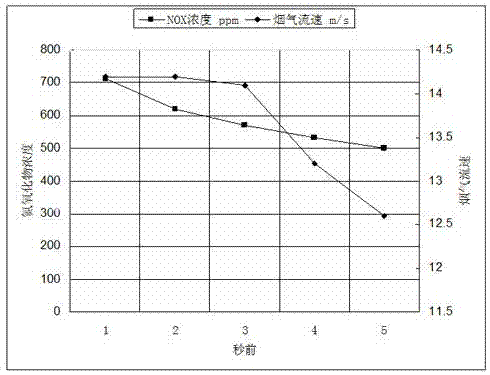

Denitration reductant adding control method based on time difference matching and control device of control method

ActiveCN105597538AEliminate oversprayEliminate the problem of insufficient ammoniaGas treatmentDispersed particle separationGratingNitric oxide

The invention relates to a denitration reductant adding control method based on time difference matching and a control device of the control method. By setting in-situ real-time test points, measuring corresponding parameters and depending on actual characteristics of a catalytic deoxidizing reaction of a denitration device, the time difference of flue gas from a flue gas flow speed and flow rate test point to an ammonia spraying region when the flue gas amount and the concentration of pollutants are changed, and the time difference between ammonia / air for spraying into a grating are mainly calculated, so that synchronous non-time-difference mixing is achieved; meanwhile, the flow speed of front nitric oxide and the flow speed of flue gas are taken as feedforward parameters, the concentration of sprayed and mixed nitric oxide and ammonia is taken as the feedback variable, the weight ratio of the feedforward to the feedback is reasonably set and adjusted, the reductant and the nitric oxide after mixed in flue gas react based on set efficiency before entering the denitration device, the amount of ammonia / nitrogen is rapidly and timely adjusted and matched and flexibly controlled under the working conditions such as various change amplitudes and wild fluctuations, the problem of adverse effects caused by the denitration device, a unit and the like is solved, and a significant effect of promoting pollution reduction is achieved.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Device and method for controlling the position of the latral edge of a continuous web

InactiveUS20050158106A1Quality improvementSettling fastAutomatic control devicesPrecision positioning equipmentActuatorControl theory

A device and a method for controlling a position of a lateral edge of a continuous web of a recording medium in a printer or copier provides that sensors are provided. Signals of the sensors are supplied to a control device which includes an actuator. The actuator changes the position of the lateral edge of the web.

Owner:OCE PRINTING SYST

Device and method for controlling the position of the lateral edge of a continuous web

InactiveUS7284486B2Quality improvementSettling fastAddressographsPlaten pressesActuatorControl theory

Owner:OCE PRINTING SYST

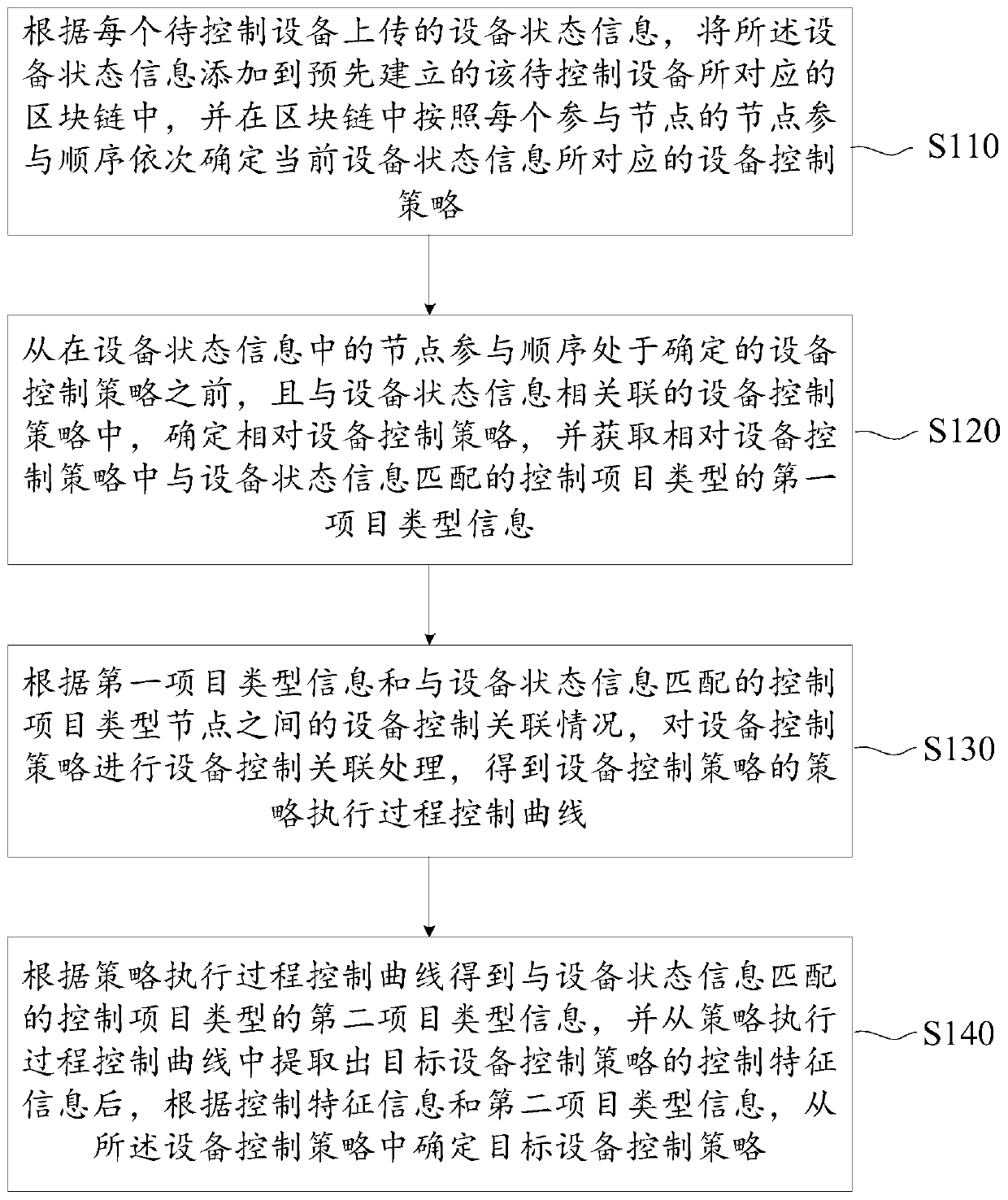

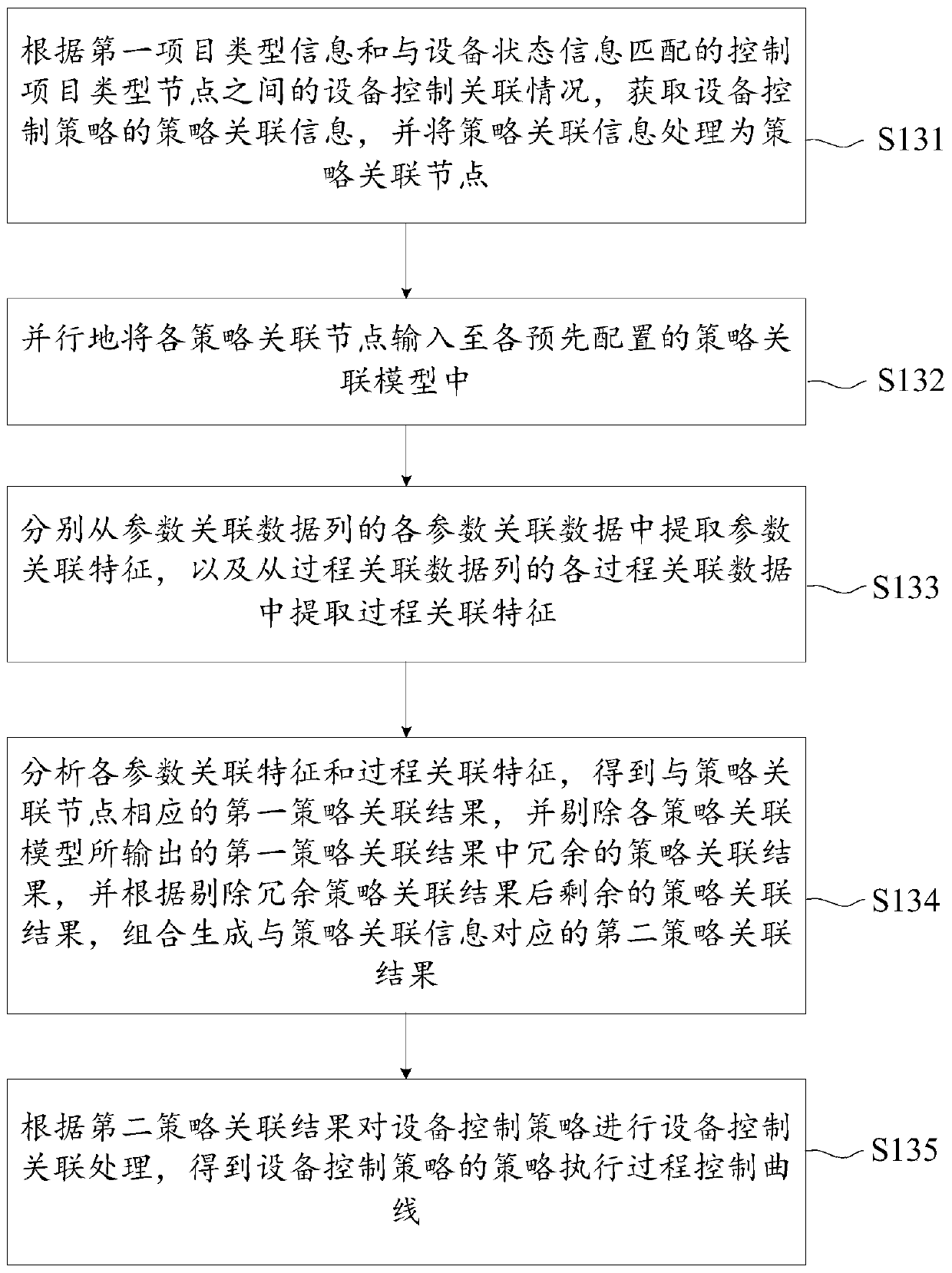

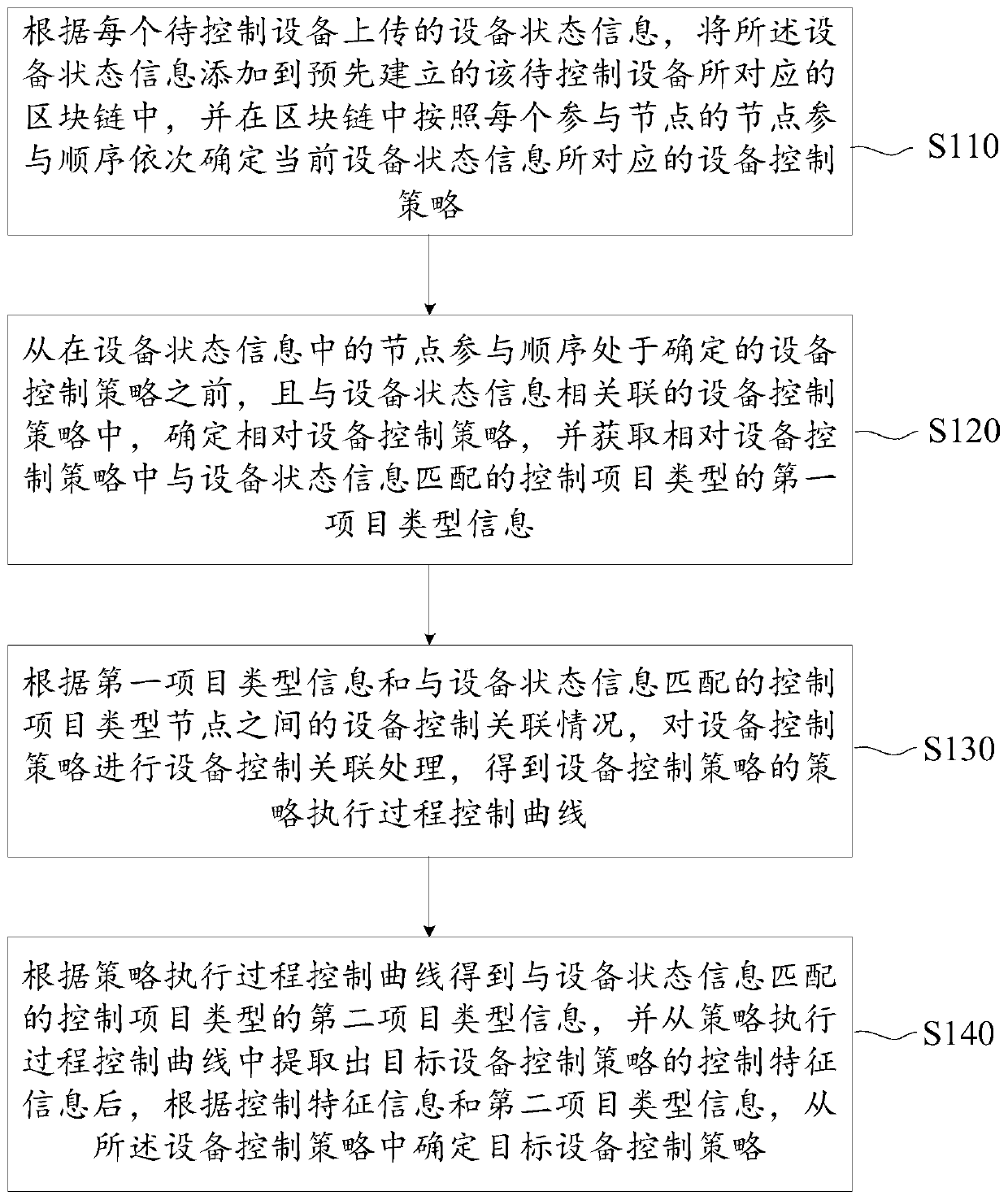

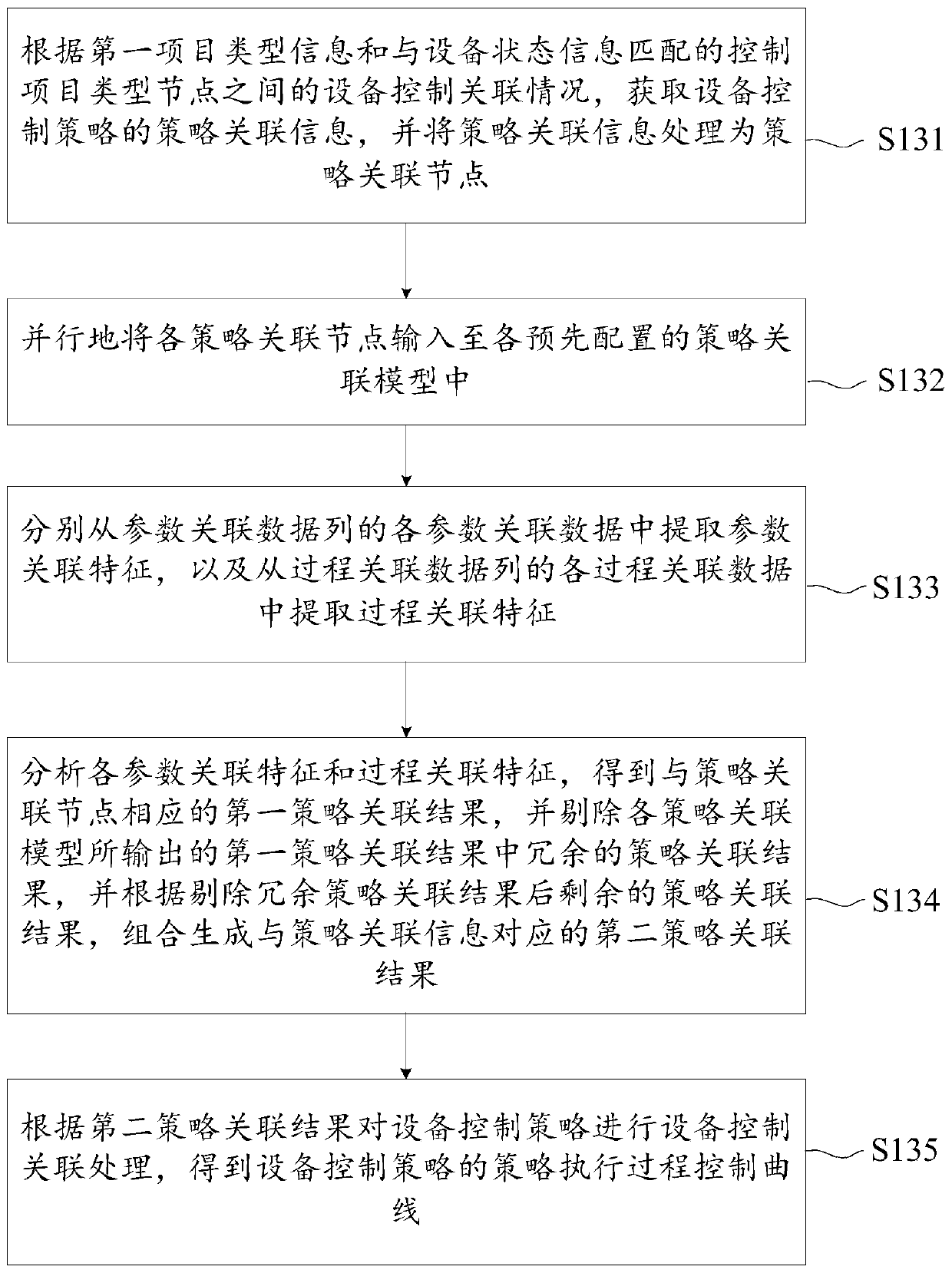

Equipment control method and device based on block chain and server

The embodiment of the invention provides an equipment control method and device based on a block chain and a server. The method comprises the following steps of sequentially determining equipment control strategies corresponding to current equipment state information according to a node participation sequence of each participation node through a pre-established block chain, determining first project type information of a control project type matched with the equipment state information in a relative equipment control strategy; according to the equipment control association condition between the control item type nodes matching the equipment state information, determining a strategy execution process control curve; further determining second project type information; and after the second project type information is combined, determining a target equipment control strategy from the equipment control strategies to carry out equipment control, so that the integral state expression of theequipment control state and the differential expression between different project types are effectively considered, and the control deviation in the actual equipment control process is reduced.

Owner:GUANGDONG AOFEI DATA TECHNOLOGY CO LTD

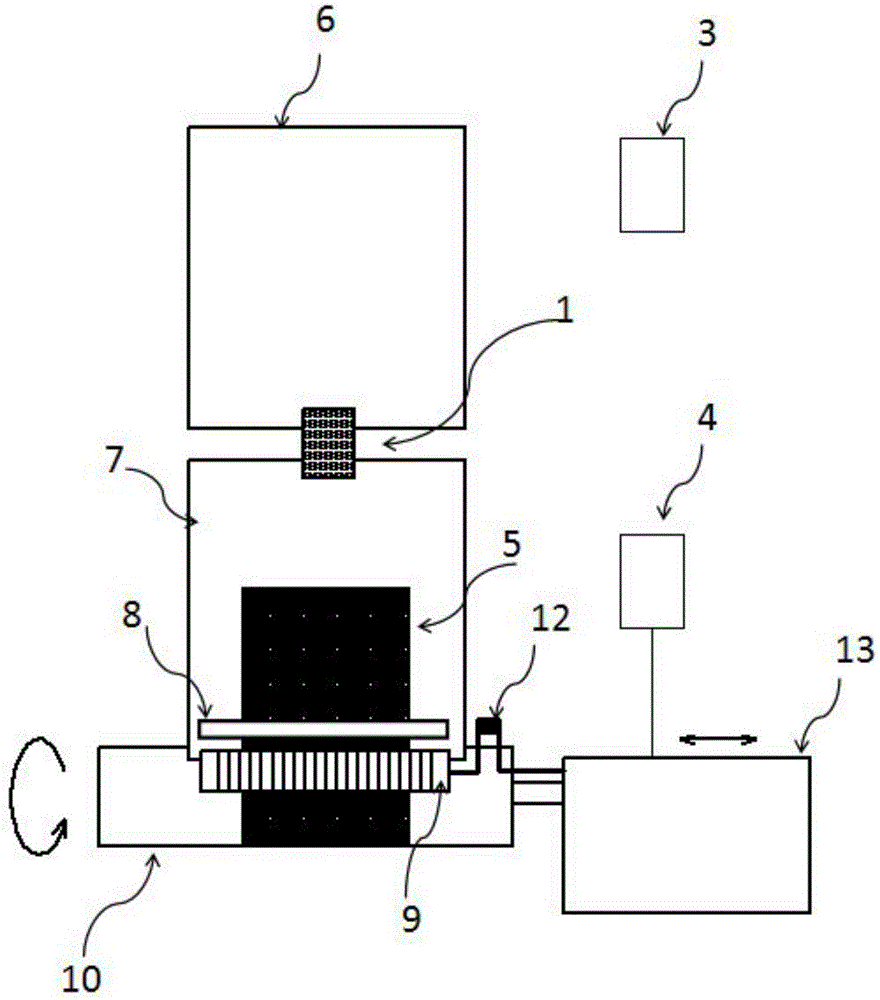

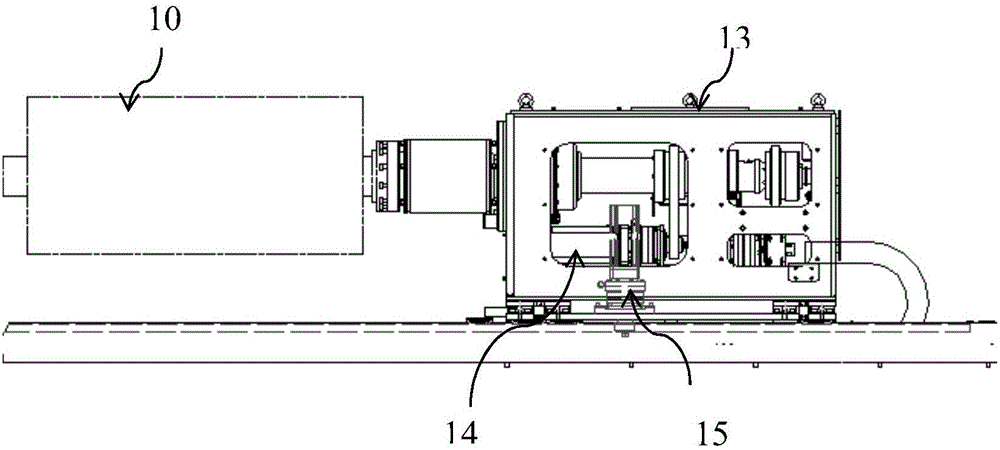

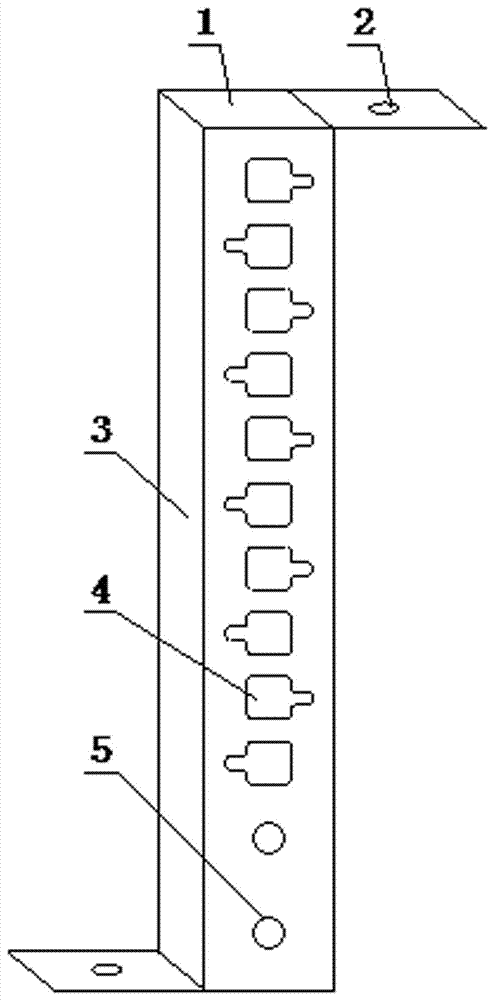

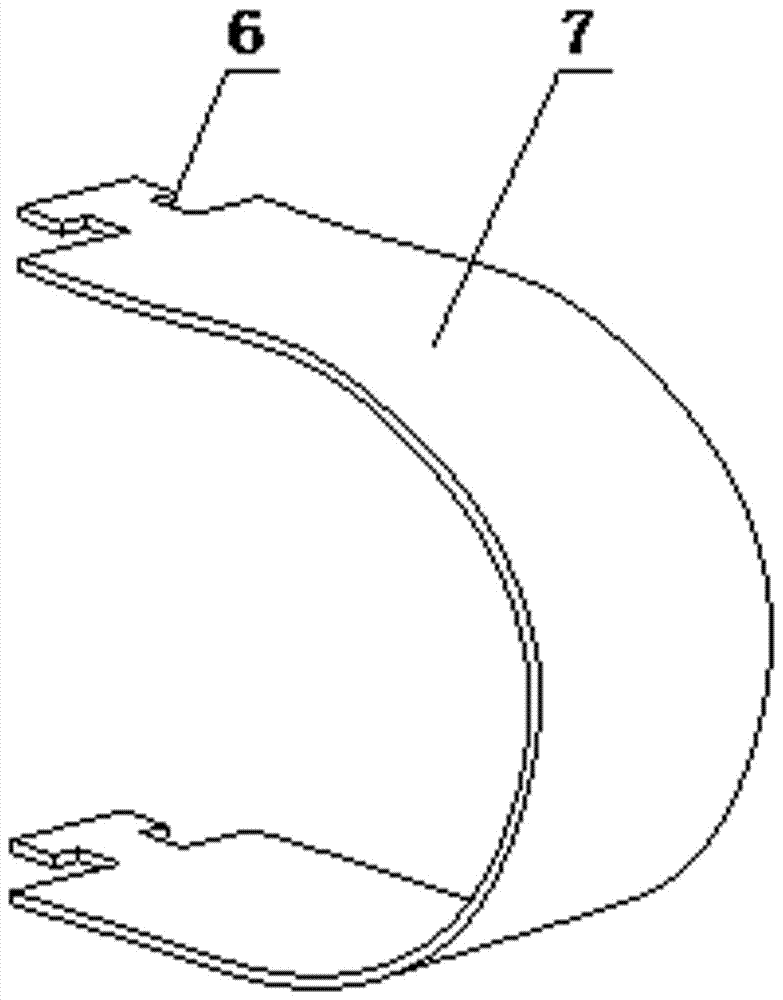

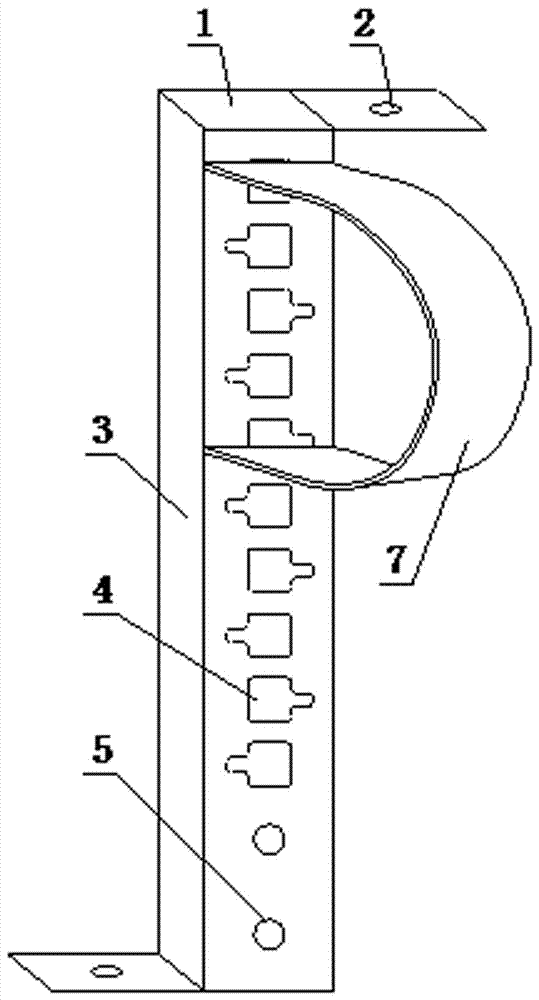

Electric deviation-correcting device

ActiveCN106273591AReduce distractionsReduce the requirement of high dynamic responseTyresData controlReciprocating motion

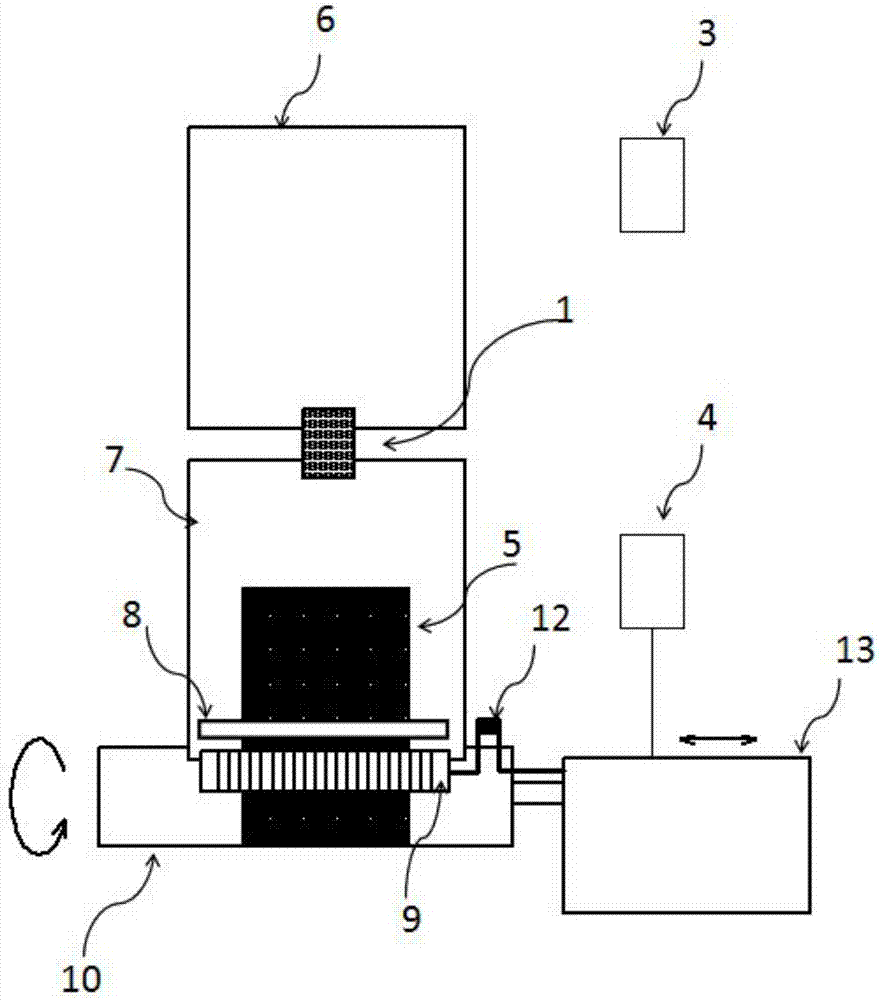

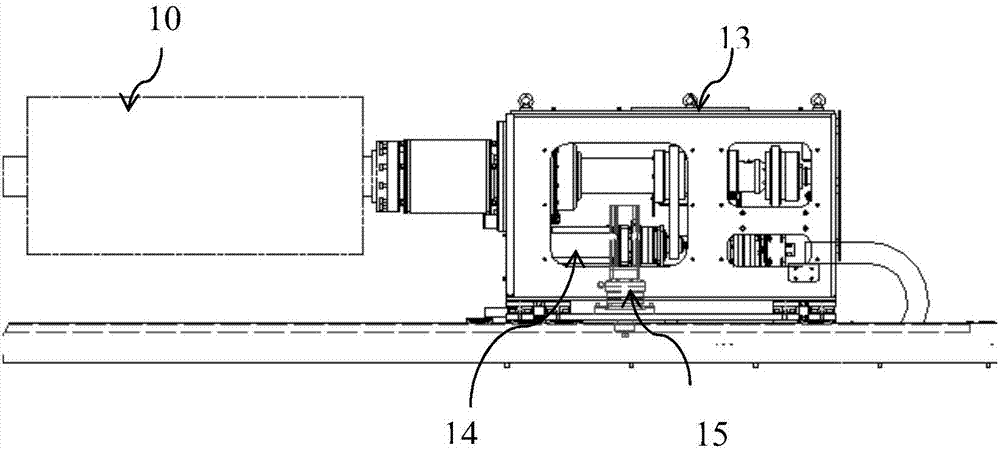

The invention discloses an electric deviation-correcting device. The device comprises a front conveying belt, a rear conveying belt, multiple compression rollers, a drum, a case, a visual sensor, a parallel light source, a high-speed counter, an industrial computer and a PLC; the multiple compression rollers, the drum and the case are relatively and fixedly arranged; the case drives the drum to rotate and can also drive the drum and the multiple compression rollers to reciprocate horizontally; the visual sensor can detect the deviation of the edge of a sizing material from a center line under the assistance of the parallel light source and transmits the deviation to the industrial computer in real time; the high-speed counter feeds the position of the rear conveying belt back to the industrial computer in real time; the industrial computer arranges feedback information into a group of data, stores the data accumulatively and meanwhile transmits the data to the PLC; the PLC controls horizontal motion of the case according to the feedback data, so that the center line of the sizing material and the radial center line of the drum coincide to the largest extent in the winding process. The deviation is corrected in the winding process, the distance between a deviation-correcting control point and a winding point is made close, and the possibility that a deviation-correcting system is disturbed is lowered.

Owner:TIANJIN SAIXIANG TECH

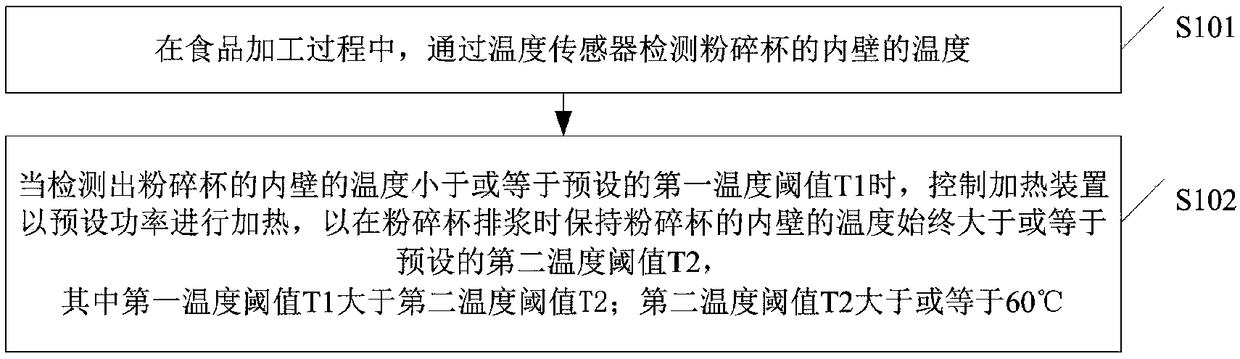

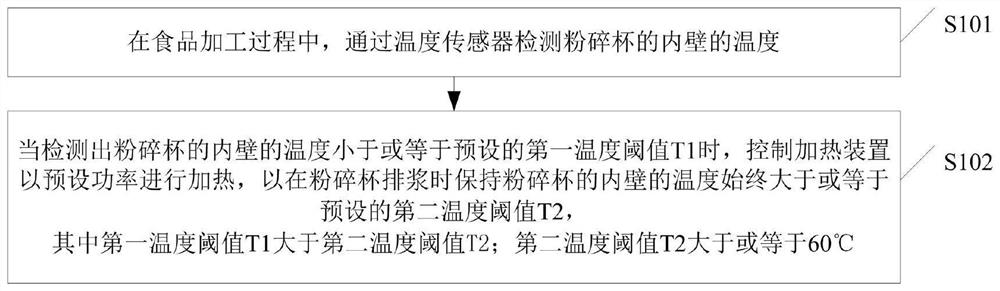

Control method of food processing machine

The embodiment of the invention discloses a control method of a food processing machine. The food processing machine can comprise a pulverizing cup, a heating device, a motor and a temperature sensor.The method can comprise the following steps: detecting the temperature of the inner wall of the pulverizing cup by the temperature sensor in the food processing process; and when detecting that the temperature of the inner wall of the pulverizing cup is less than or equal to a preset first temperature threshold value T1, controlling the heating device to perform heating according to preset powerso as to maintain the temperature of the inner wall of the pulverizing cup to be still more than or equal to a preset second temperature threshold value T2 when the pulverizing cup discharges pulp, wherein the first temperature threshold value T1 is more than the second temperature threshold value T2, and the second temperature threshold value T2 is more than or equal to 60 DEG C. Through the scheme of the embodiment, the temperature of the inner wall of the pulverizing cup still maintains above at least 60 DEG C, the problem that food adhesion on a food processing cup is solved and the cleaning effect is improved.

Owner:JOYOUNG CO LTD

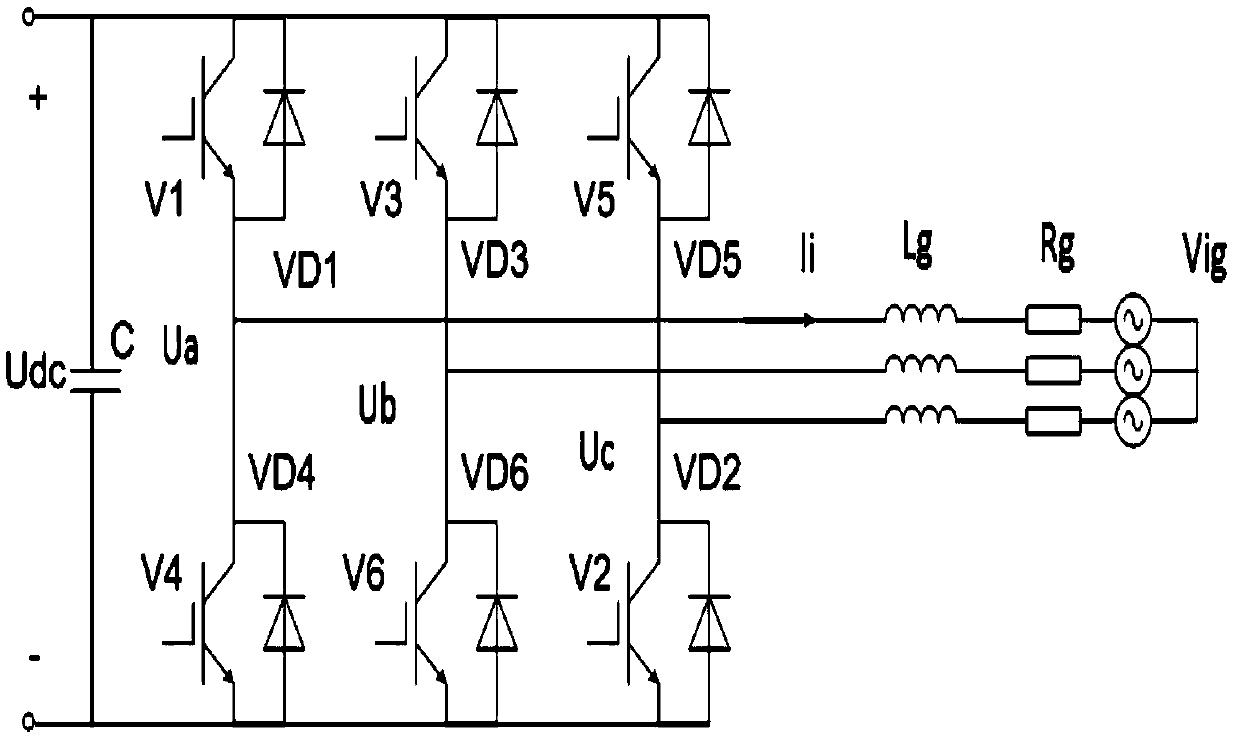

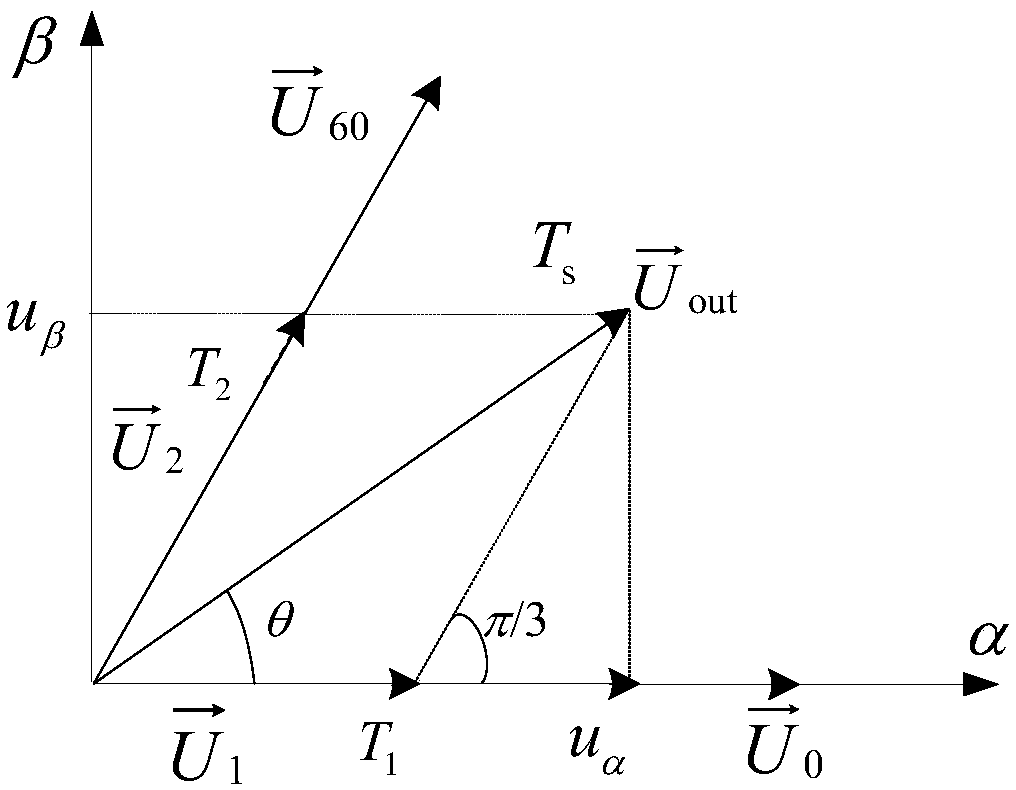

Grid-connected inverter control method combining SVPWM with sliding mode variable structure

InactiveCN109600063AGood dynamic and steady state performancePracticalSingle network parallel feeding arrangementsDc-ac conversion without reversalGrid connected inverterControl objective

The invention discloses a grid-connected inverter control method combining SVPWM with a sliding mode variable structure. The method comprises the following steps: A: establishing a two-level grid-connected inverter mathematical model, and obtaining a differential expression of output current of the inverter; B: deriving a corresponding state space equation based on the differential expression of the current, selecting d-axis and p-axis sliding modes output by an appropriate sliding mode inverter, and using the state space equation as a part of a sliding model current control objective function; and C: achieving current uncoupled control by current feedforward decoupling to reduce the corresponding control deviation. The grid-connected inverter control method disclosed by the invention hasthe advantages of having good dynamic steady state performance, being able to ensure relatively low switching frequency and completely meet the grid connection requirements, having good practicability, realizing the current uncoupled control by the current feedforward decoupling to reduce the corresponding control deviation, and having high tracking precision, low switching loss and easy digitization, etc.

Owner:ZHANGZHOU POWER SUPPLY COMPANY STATE GRID FUJIANELECTRIC POWER +1

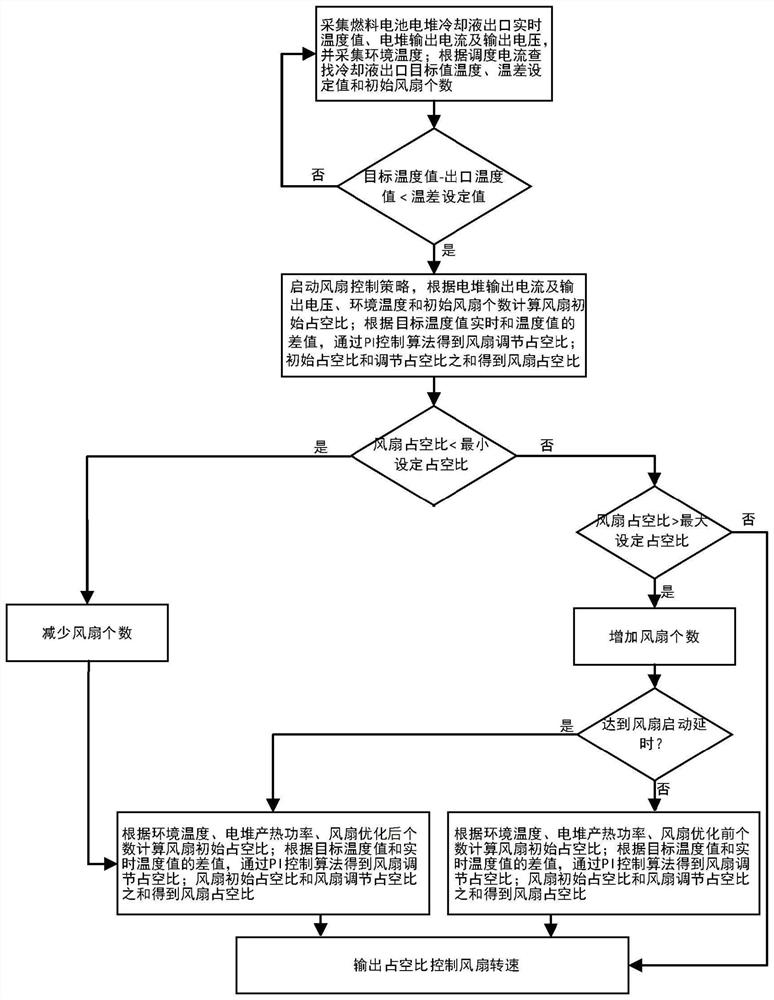

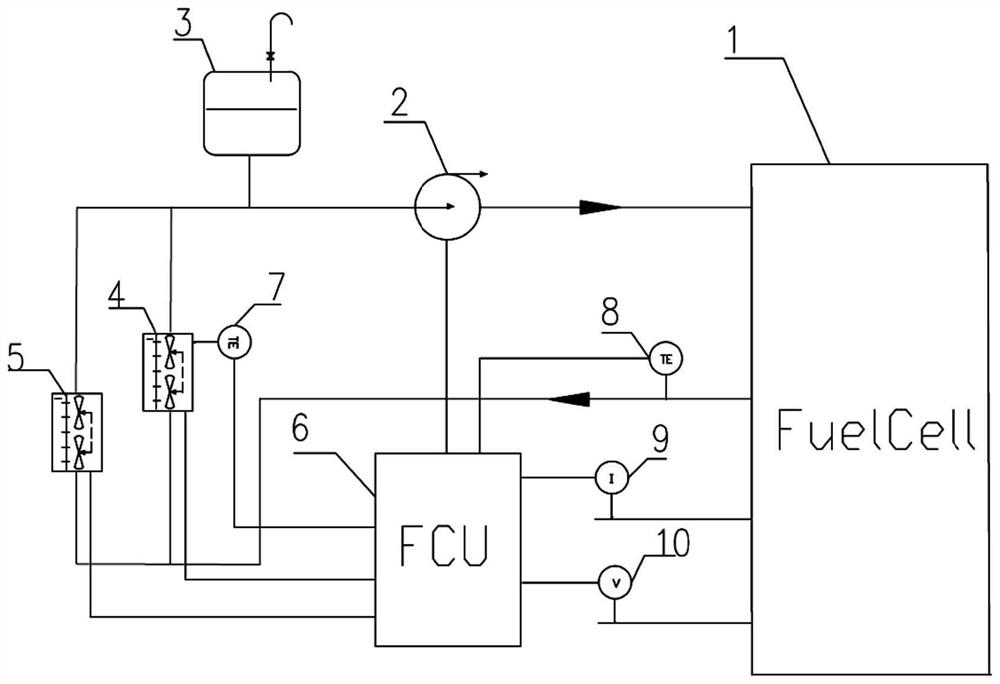

Fuel cell coolant temperature control method, system and controller thereof

PendingCN114447379AShorten closed-loop control timeSmall control deviationFuel cell heat exchangeTemperature controlFuel cells

The invention discloses a fuel cell cooling liquid temperature control method and system and a controller thereof, and the temperature control method comprises the steps: collecting the real-time temperature value and other data of a fuel cell stack cooling liquid outlet, and searching the target value temperature of the cooling liquid outlet, a temperature difference set value and the number of initial fans according to a scheduling current; whether the difference between the cooling liquid outlet target temperature value and the real-time temperature value is smaller than a temperature difference set value or not is judged, if yes, a fan control strategy is started, the fan duty ratio is calculated, then whether the fan duty ratio is larger than or equal to the minimum set duty ratio and smaller than or equal to the maximum set duty ratio or not is judged, and if yes, the fan duty ratio is directly output to control the fan rotating speed; if the duty ratio is smaller than the minimum set duty ratio, the number of fans is reduced, and the fan duty ratio is calculated for controlling the fan rotating speed; and if the duty ratio is larger than the maximum set duty ratio, the number of the fans is increased, and the fan duty ratio is calculated for controlling the fan rotating speed by considering the fan starting delay. The invention can meet the requirements of fuel cell efficiency and service life.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

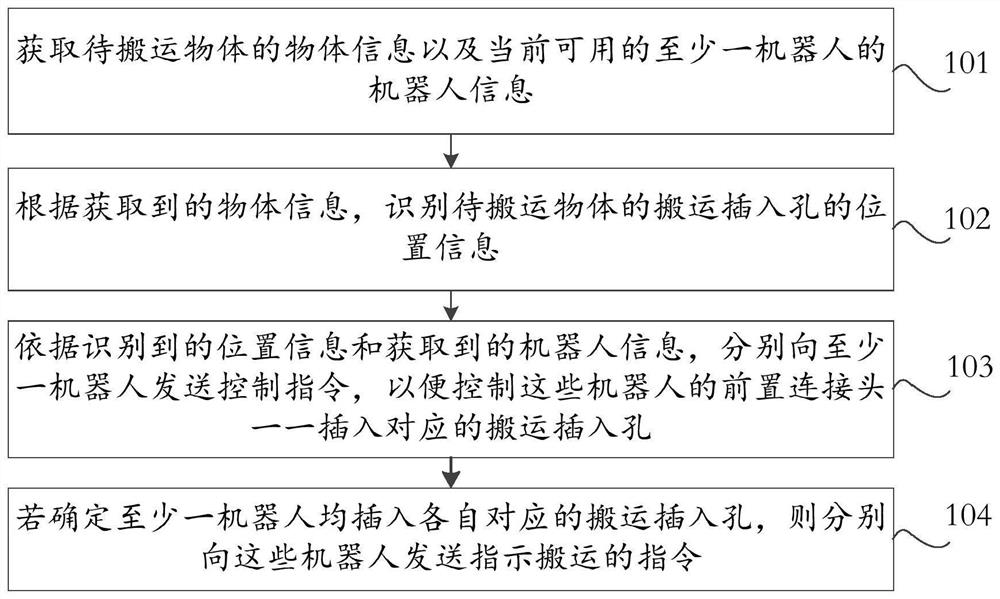

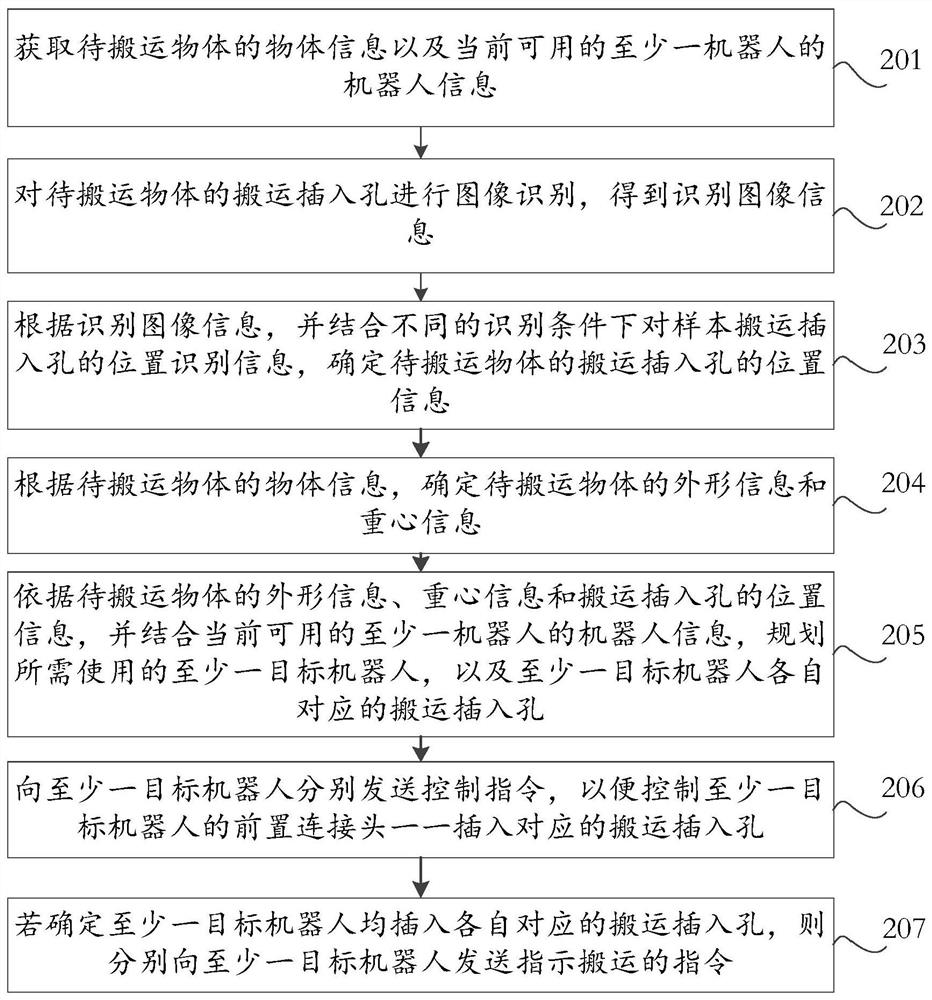

Multi-robot cooperative control method and device and computer equipment

ActiveCN111618848ACollaborative Control PrecisePrevent fallingProgramme-controlled manipulatorTotal factory controlControl mannerSimulation

The invention discloses a multi-robot cooperative control method and device and computer equipment, and relates to the technical field of computers. The method comprises the steps that object information of a to-be-carried object and robot information of current available at least one robot are obtained firstly; according to the object information, position information of carrying insertion holesof the to-be-carried object is recognized; control instructions are sent to at least one robot according to the position information and the robot information, and accordingly front connectors of at least one robot are controlled to be inserted in the corresponding carrying insertion holes in a one-to-one manner; and if it is determined that at least one robot is inserted in the corresponding carrying insertion holes, carrying indication instructions are sent to at least one robot. The multi-robot cooperative control method and device and the computer equipment can replace a manual control manner, accurate cooperative control of multiple robots can be achieved, and control deviation is reduced.

Owner:PING AN TECH (SHENZHEN) CO LTD

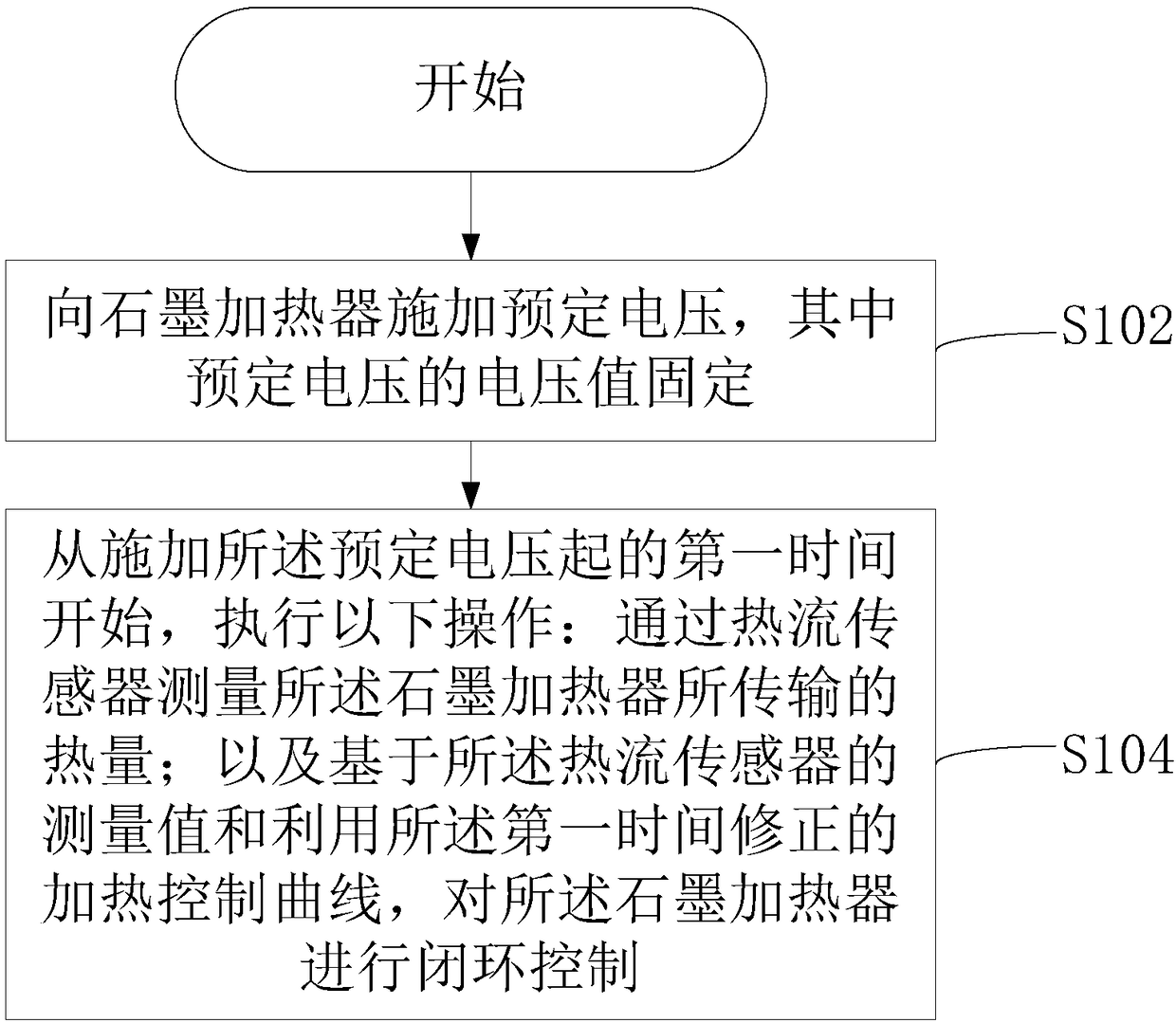

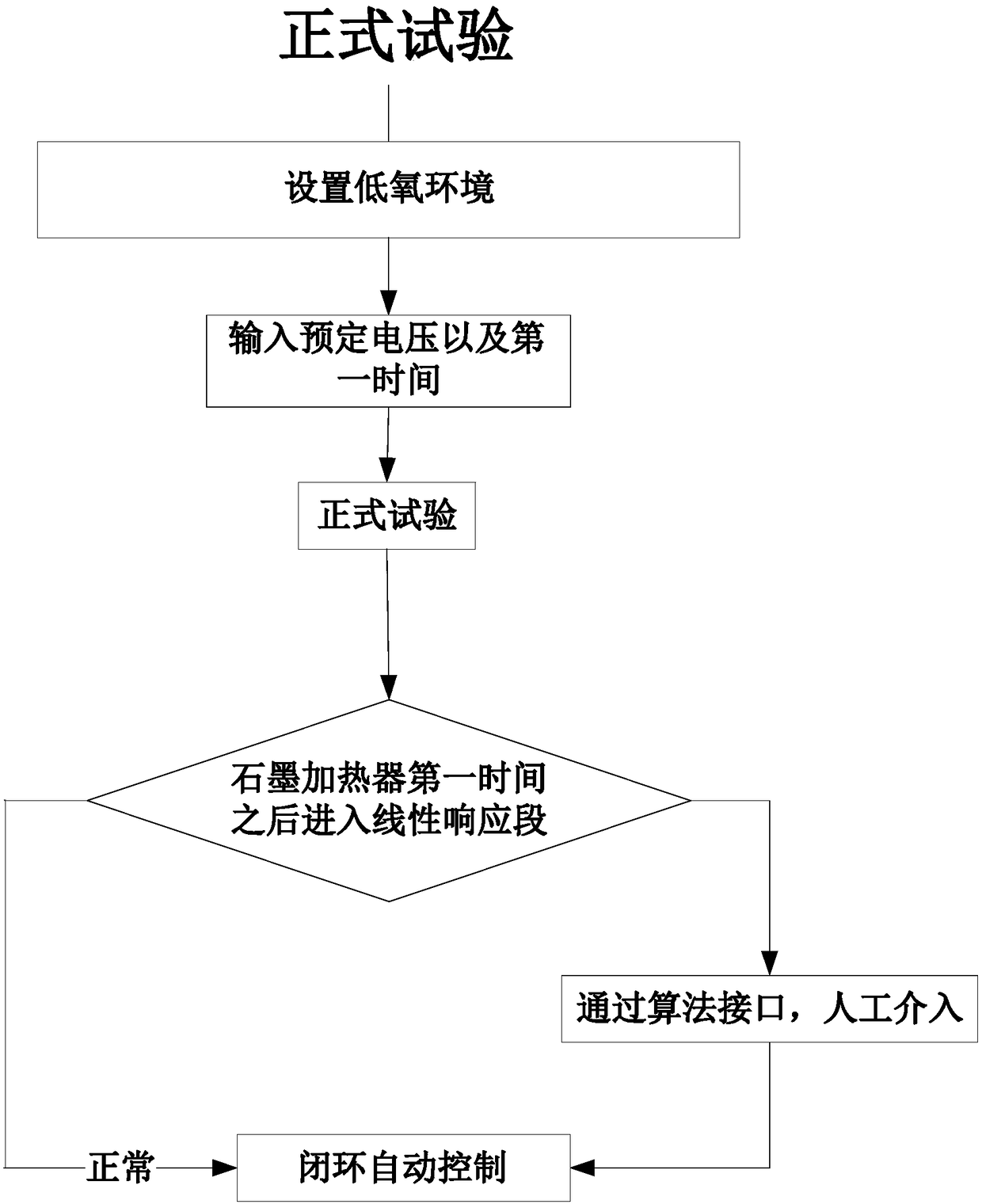

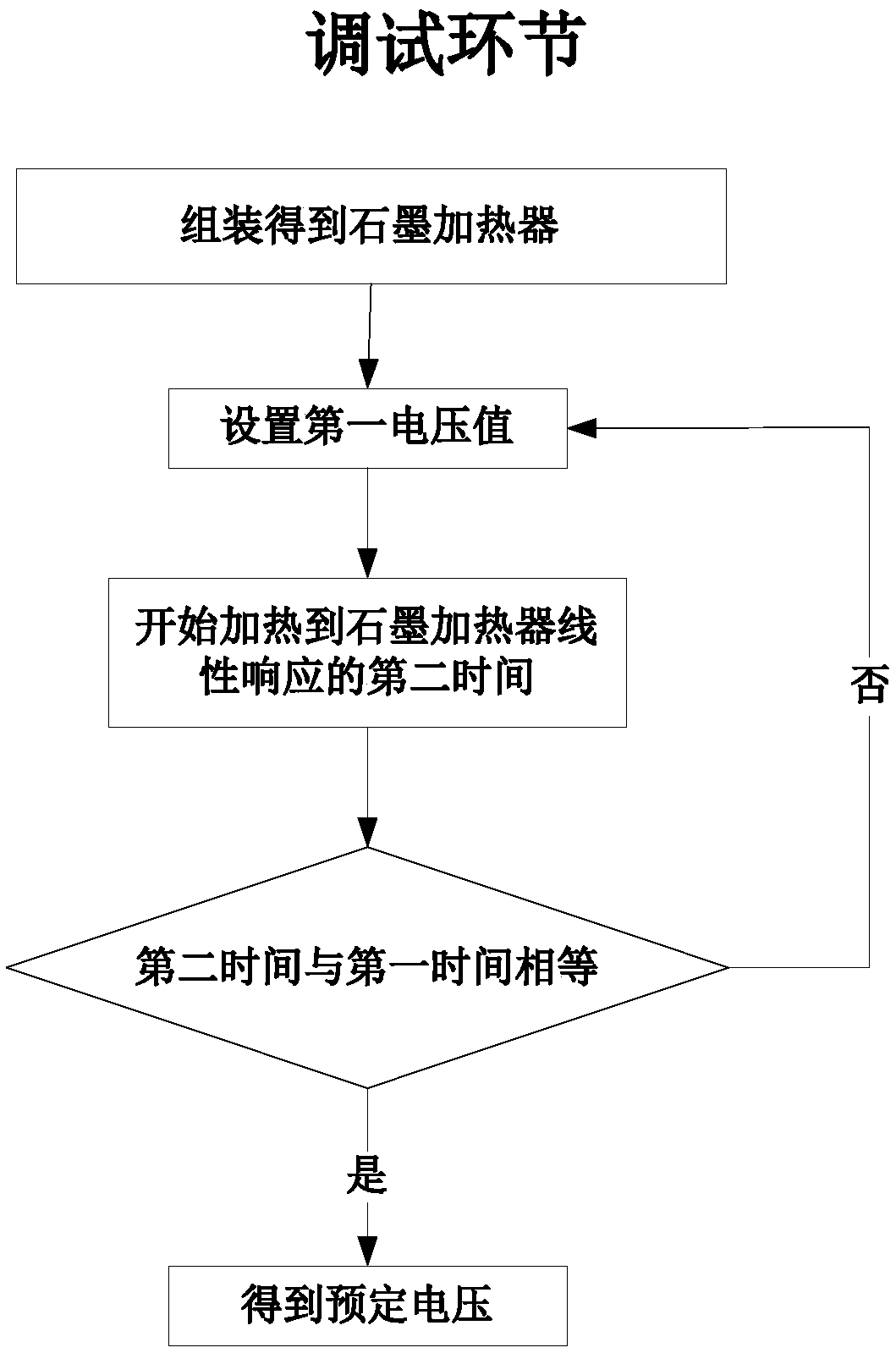

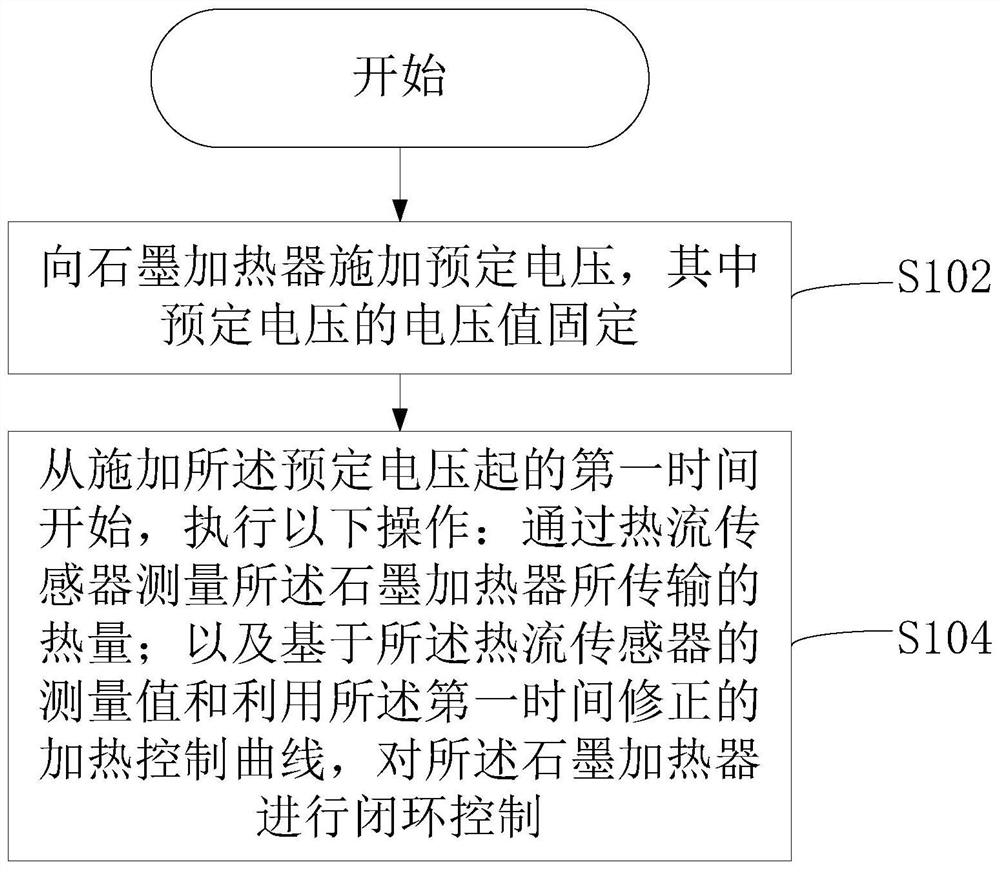

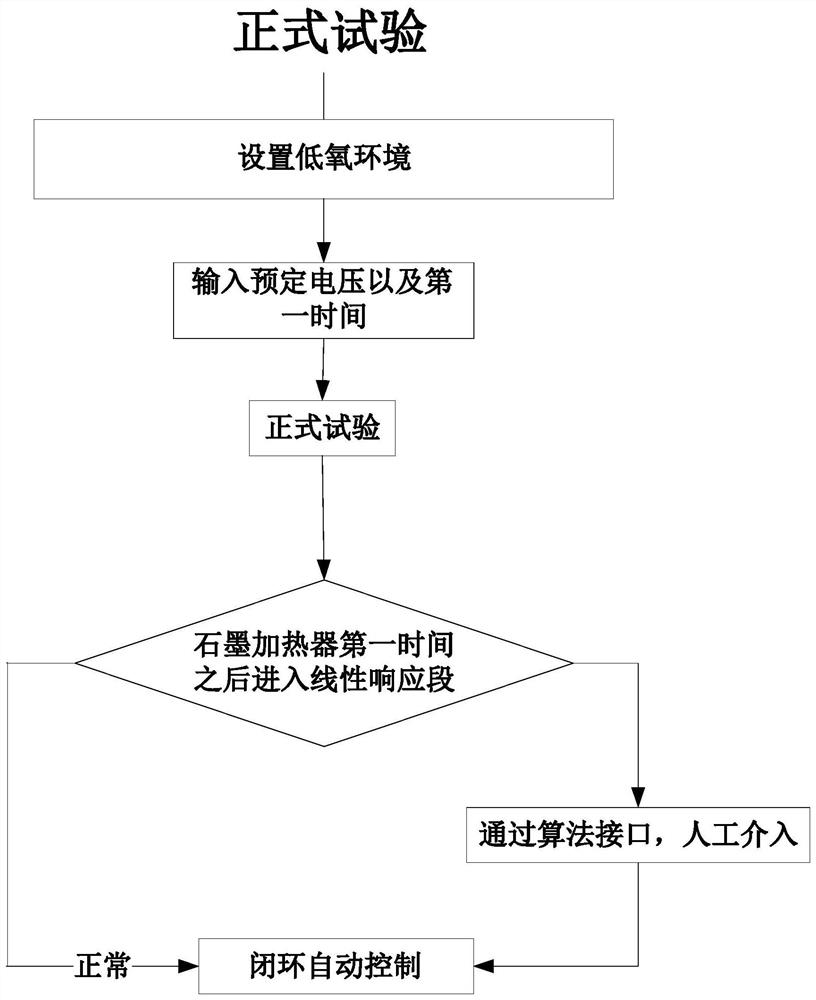

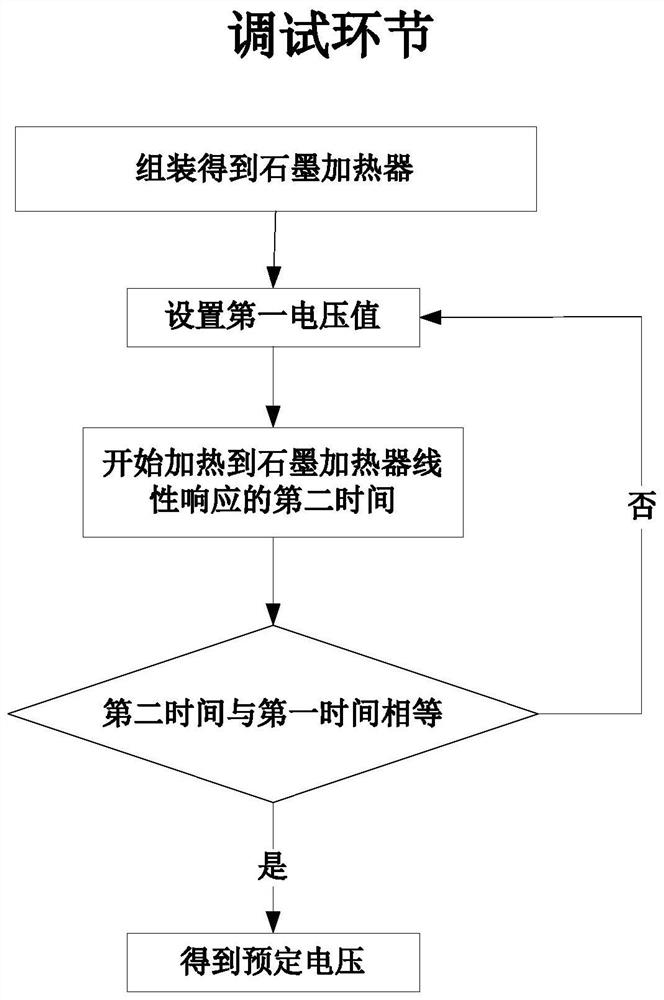

Control method of graphite heater

ActiveCN108419307AImprove accuracySmall control deviationOhmic-resistance heating detailsHeating element materialsHeat flux sensorHeat flow

The invention provides a control method of a graphite heater. The control method includes: applying a predetermined voltage to a graphite heater, wherein a voltage value of the predetermined voltage is fixed; starting from a first time after applying the predetermined voltage, performing the operation of: measuring heat transferred by the graphite heater by a heat flow sensor; and performing closed-loop control on the graphite heater based on the measured value of the heat flow sensor and a heating control curve corrected by the first time, wherein the first time is the time when the graphiteheater starts to make a linear response to the applied voltage.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

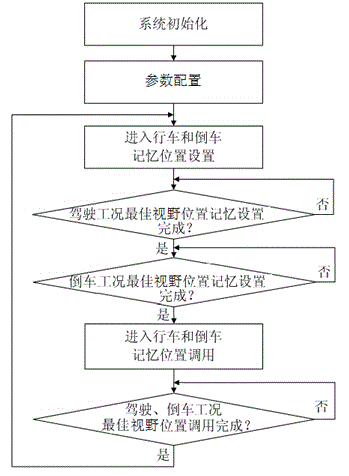

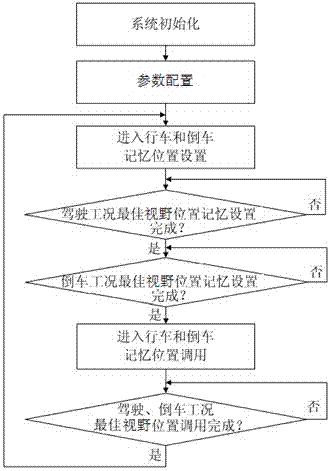

System and method for rearview mirror control based on ripples

ActiveCN104972973AImprove reliabilityImprove control accuracyOptical viewingMicrocontrollerMicrocomputer

The invention discloses a system for rearview mirror control based on ripples. The system comprises a rearview mirror control switch, a single-chip microcomputer, a motor driving module, a rearview mirror and a ripple detection counting module. The rearview mirror control switch is connected with the single-chip microcomputer, and the motor driving module is connected with a motor arranged in the rearview mirror. The motor driving module and the ripple detection counting module are integrated to a ripple detection counting and motor driving integrated circuit. A voltage modulation circuit and a control register are arranged in the ripple detection counting and motor driving integrated circuit, the voltage modulation circuit outputs supply voltage, the ripple detection counting module is in bi-directional connection with the control register, the control register is in output connection with the motor driving module, and the single-chip microcomputer is in communication connection with the control register through an SPI bus. The invention further discloses a method for rearview mirror control based on the ripples. According to the technical scheme, the problems of large control deviation and poor universality of an existing rearview mirror control technology are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A method for controlling a food processing machine

The embodiment of the present invention discloses a method for controlling a food processor. The food processor may include a crushing cup, a heating device, a motor, and a temperature sensor. The temperature of the inner wall; when it is detected that the temperature of the inner wall of the crushing cup is less than or equal to the preset first temperature threshold T1, the heating device is controlled to heat with a preset power, so as to maintain the temperature of the inner wall of the crushing cup when the crushing cup is discharged Always greater than or equal to the preset second temperature threshold T2; wherein, the first temperature threshold T1 is greater than the second temperature threshold T2; the second temperature threshold T2 is greater than or equal to 60°C. Through the solution of this embodiment, the temperature of the inner wall of the crushing cup is kept at least above 60° C., which solves the problem of food sticking on the food processing cup and improves the cleaning effect.

Owner:JOYOUNG CO LTD

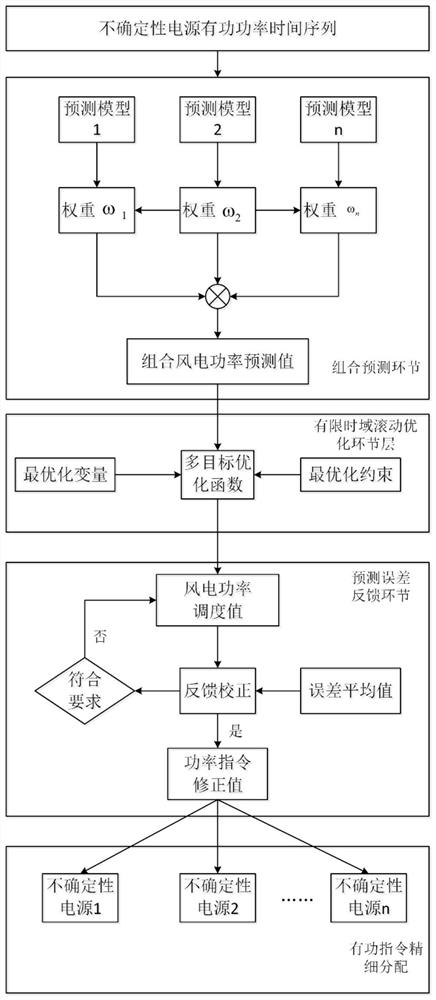

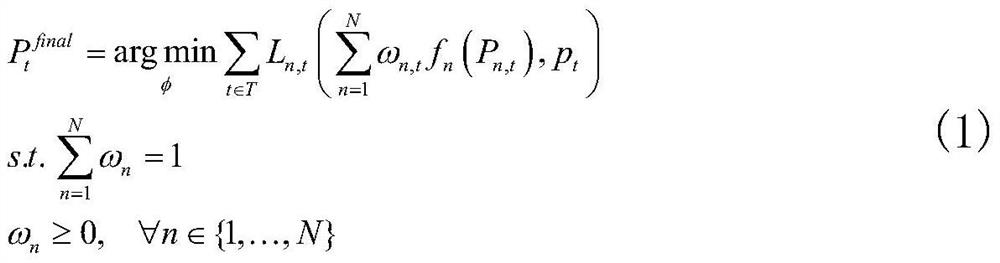

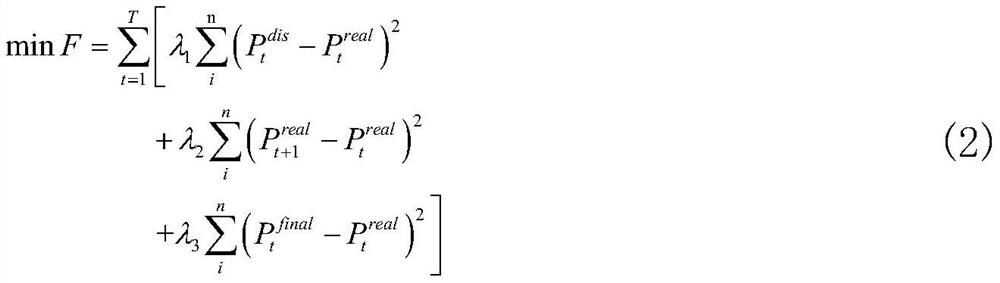

A Method of Active Power Control and Fine Command Distribution for Uncertain Power Sources

ActiveCN112039132BImprove forecast accuracySmall control deviationGeneration forecast in ac networkSingle network parallel feeding arrangementsTime domainSimulation

The present invention relates to an active power control and fine instruction distribution method of an uncertain power supply, comprising the following steps: Step 1, collecting historical active power data and drawing a historical active power curve; Step 2, establishing a combined prediction based on historical active power data Model; step 3, finite time-domain rolling optimization: establish a multi-objective optimization function; step 4, forecast error feedback, use the error correction value to correct the predicted value at the next moment; step 5, finely allocate active commands. In the present invention, by incorporating links such as power prediction, rolling optimization, and feedback correction into uncertain power source active power control and fine command distribution, not only can the prediction accuracy be improved, but also power control deviation can be reduced.

Owner:CHINA AGRI UNIV +1

Novel assembly type multifunctional wheel protection ridge

InactiveCN113512990AImprove energy absorptionImprove impact resistanceClimate change adaptationShipping equipmentFenderEnergy absorption

The invention relates to the technical field of wharf protection equipment, in particular to a novel assembly type multifunctional wheel protection ridge (sill). The wheel protection ridge comprises a wheel protection convex ridge part and a fender part, the wheel protection convex ridge part is made of elastic materials such as rubber, good energy absorption performance and impact resistance are achieved, the wheel protection ridge is installed on the upper portion of a dock breast wall, the reverse thrust performance is good, and the problems that a concrete structure of a traditional concrete prefabricated breast wall and wheel protection ridge integrated structure is poor in impact resistance, prone to being broken, high in maintenance cost, long in period and the like are solved. A ship mooring rope is well protected by adopting the elastic materials, and the problems that the ship mooring rope is easily abraded and damaged by the concrete, and potential safety hazards are brought to mooring of ships operating in a port are solved. The wheel protection ridge is of a strip-shaped structure, is installed in a segmented manner in the using process, has the advantages of being capable of being produced in batches by manufacturers, convenient to assemble and replace, small in control deviation, high in efficiency, low in cost, safe in construction, good in economic benefit and the like, and has obvious advantages in the construction period and the operation period.

Owner:李正武

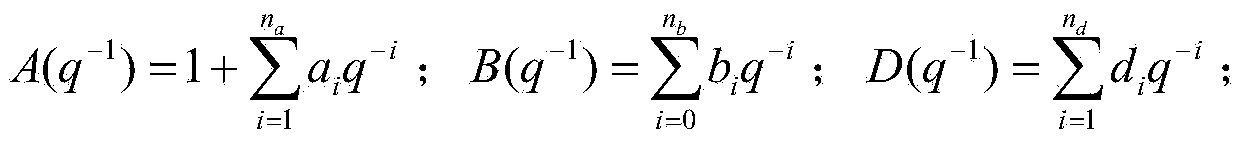

A two-stage coordinated predictive control method for superheated steam temperature of thermal power units

InactiveCN103134046BDoes not cause temperature fluctuationsHigh control precisionSuperheating controlTemperature controlLower limit

The invention discloses a superheated steam temperature two-stage coordination, prediction and control method of a thermal power generating unit. The method designs a two-stage coordination and control algorithm and utilizes a GPC-P (generalized predictive control-proportion) cascade control strategy to respectively achieve the control of first-stage and second-stage desuperheating water spraying and enable the two-stage desuperheating water control to approximately decouple under the situation that a second-stage desuperheating water valve has adjusting allowance, accordingly the adjusting process of the first-stage desuperheating water spraying cannot cause the temperature fluctuation of the outlet of a last-stage superheater; and when the second-stage desuperheating water valve reaches an upper limit or a lower limit, makes full use of the adjusting allowance of the first-stage desuperheating water spraying to assist the second-stage desuperheating water spraying to control superheated steam temperature, and further reduces the deviation between a dynamic state and a steady state of the superheated steam temperature control, thereby improving the control performance of a system.

Owner:SOUTHEAST UNIV

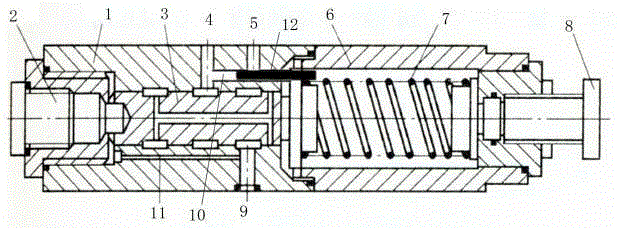

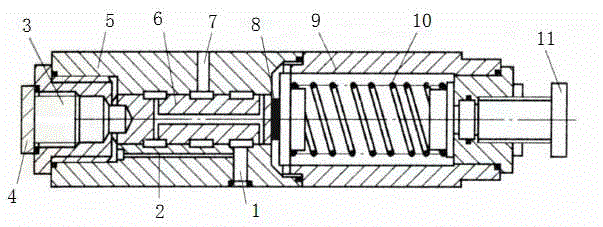

A superposition sequence valve

InactiveCN104265709BReduce volumeEasy to controlOperating means/releasing devices for valvesServomotor componentsMechanical engineeringPressure detection

The invention discloses a stacked sequence valve which comprises a valve body in certain thickness. A valve core is arranged in the valve body. The stacked sequence valve is characterized in that a pressure detection port is arranged on one side of the valve body, a spring is arranged on the other side of the valve body, an adjusting screw is arranged at the tail of the spring, the spring is arranged on one side of the valve body through a valve cover outside, a sealing block is fixedly arranged on the end portion of the spring, an oil inlet is arranged at the bottom of the valve body, an axial hole is formed between the oil inlet and the pressure detection port, at least two oil outlets are arranged at the top of the valve body and connected through a connecting passage, and the sealing block can be hermetically inserted into the connecting passage and can move along the same. Opening or closing states of the oil outlets are controlled through the valve core and the spring respectively, and the stacked sequence valve is simple in structure, low in cost and small in control deviation.

Owner:SUZHOU FURUN MACHINERY

Equipment control system based on blockchain

The embodiment of the invention provides an equipment control system based on blockchain. A method comprises the steps: equentially determining equipment control strategies corresponding to the current equipment state information according to the node participation sequence of each participation node through a pre-established blockchain, determining first project type information of a control project type matched with the equipment state information in a relative equipment control strategy; furthermore, according to the equipment control association condition between the control item type nodes matched with the equipment state information; determining a strategy execution process control curve; further determining second project type information; after the second project type information is combined, determining a target equipment control strategy from the equipment control strategies to carry out equipment control, so the integral state expression of the equipment control state and the differential expression between different project types are effectively considered, and the control deviation in the actual equipment control process is reduced.

Owner:丁奇娜

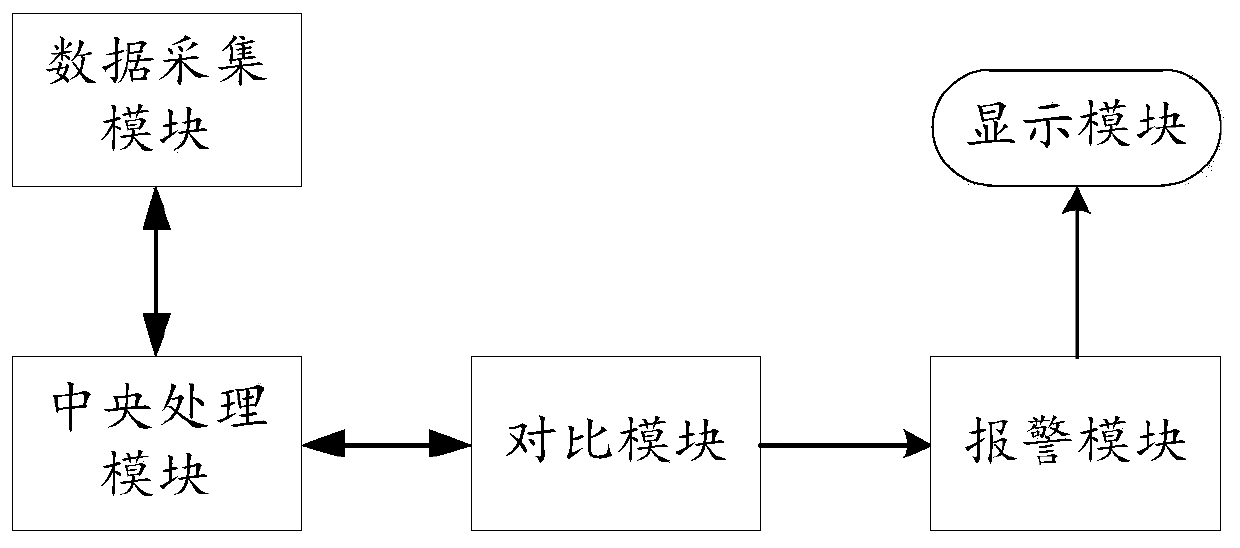

Smart cloud clean room control method and system

PendingCN111464647AImprove real-time monitoring accuracyReduce data shockElectric signal transmission systemsCharacter and pattern recognitionData setData segment

The invention discloses a smart cloud clean room control method and system. The method comprises the following steps that a communication system is initialized, and a data acquisition module acquiresenvironmental data in a clean room; and a central processing module independently divides each type of working environment data segment corresponding to the clean room into n equal parts, records theoffset value corresponding to each equal part point to form a data set and pre-stores the data set, and acquires the offset data set of the acquisition node corresponding to different environmental data acquisition nodes according to the pre-stored offset data set of the acquisition node. According to the invention, the environmental data acquisition node power with extremely small error can be generated by outputting the corresponding bias current, and the control deviation can be quickly and stably reduced.

Owner:KERUITE XIAMEN PURIFICATION TECH

Overlapped sequence valve

The invention discloses an overlapped sequence valve, which comprises a valve body with certain thickness, wherein a valve core is arranged in the valve body. The overlapped sequence valve is characterized in that one side of the valve body is provided with a pressure detection opening, a pressure meter is connected with the pressure detection opening, the other side of the valve body is provided with a spring, one side, near the valve core, of the spring is provided with a force sensor, the other side of the spring is provided with a regulating screw rod, the spring is arranged at one side of the valve body through an external valve cover, the bottom of the valve body is provided with an oil inlet, an axial hole is formed between the oil inlet and the pressure detection opening, and an oil outlet is formed in the top of the valve body. The overlapped sequence valve has the advantages that the structure is simple, the cost is low, the control deviation is small, and the pressure regulating precision is improved.

Owner:SUZHOU FURUN MACHINERY

A control method for a graphite heater

ActiveCN108419307BImprove accuracySmall control deviationOhmic-resistance heating detailsHeating element materialsHeat flowClosed loop

The invention provides a control method of a graphite heater. The control method includes: applying a predetermined voltage to the graphite heater, wherein the voltage value of the predetermined voltage is fixed; starting from the first time when the predetermined voltage is applied, the following operations are performed: measuring the heat transmitted by the graphite heater through a heat flow sensor and based on the measured value of the heat flow sensor and the heating control curve corrected by the first time, the graphite heater is closed-loop controlled, wherein the first time is the graphite heater starts to apply the voltage Time for a linear response.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Electric correction device

ActiveCN106273591BReduce distractionsReduce the requirement of high dynamic responseTyresData controlReciprocating motion

The invention discloses an electric deviation-correcting device. The device comprises a front conveying belt, a rear conveying belt, multiple compression rollers, a drum, a case, a visual sensor, a parallel light source, a high-speed counter, an industrial computer and a PLC; the multiple compression rollers, the drum and the case are relatively and fixedly arranged; the case drives the drum to rotate and can also drive the drum and the multiple compression rollers to reciprocate horizontally; the visual sensor can detect the deviation of the edge of a sizing material from a center line under the assistance of the parallel light source and transmits the deviation to the industrial computer in real time; the high-speed counter feeds the position of the rear conveying belt back to the industrial computer in real time; the industrial computer arranges feedback information into a group of data, stores the data accumulatively and meanwhile transmits the data to the PLC; the PLC controls horizontal motion of the case according to the feedback data, so that the center line of the sizing material and the radial center line of the drum coincide to the largest extent in the winding process. The deviation is corrected in the winding process, the distance between a deviation-correcting control point and a winding point is made close, and the possibility that a deviation-correcting system is disturbed is lowered.

Owner:TIANJIN SAIXIANG TECH CO LTD

A ripple-based rearview mirror control system and method

ActiveCN104972973BImprove reliabilityImprove control accuracyOptical viewingMicrocontrollerMicrocomputer

The invention discloses a system for rearview mirror control based on ripples. The system comprises a rearview mirror control switch, a single-chip microcomputer, a motor driving module, a rearview mirror and a ripple detection counting module. The rearview mirror control switch is connected with the single-chip microcomputer, and the motor driving module is connected with a motor arranged in the rearview mirror. The motor driving module and the ripple detection counting module are integrated to a ripple detection counting and motor driving integrated circuit. A voltage modulation circuit and a control register are arranged in the ripple detection counting and motor driving integrated circuit, the voltage modulation circuit outputs supply voltage, the ripple detection counting module is in bi-directional connection with the control register, the control register is in output connection with the motor driving module, and the single-chip microcomputer is in communication connection with the control register through an SPI bus. The invention further discloses a method for rearview mirror control based on the ripples. According to the technical scheme, the problems of large control deviation and poor universality of an existing rearview mirror control technology are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A denitrification reducing agent addition control method and control device based on time difference matching

ActiveCN105597538BEliminate the problem of poor matchingReduce adverse effectsGas treatmentDispersed particle separationNitric oxidePollution

The invention relates to a denitration reductant adding control method based on time difference matching and a control device of the control method. By setting in-situ real-time test points, measuring corresponding parameters and depending on actual characteristics of a catalytic deoxidizing reaction of a denitration device, the time difference of flue gas from a flue gas flow speed and flow rate test point to an ammonia spraying region when the flue gas amount and the concentration of pollutants are changed, and the time difference between ammonia / air for spraying into a grating are mainly calculated, so that synchronous non-time-difference mixing is achieved; meanwhile, the flow speed of front nitric oxide and the flow speed of flue gas are taken as feedforward parameters, the concentration of sprayed and mixed nitric oxide and ammonia is taken as the feedback variable, the weight ratio of the feedforward to the feedback is reasonably set and adjusted, the reductant and the nitric oxide after mixed in flue gas react based on set efficiency before entering the denitration device, the amount of ammonia / nitrogen is rapidly and timely adjusted and matched and flexibly controlled under the working conditions such as various change amplitudes and wild fluctuations, the problem of adverse effects caused by the denitration device, a unit and the like is solved, and a significant effect of promoting pollution reduction is achieved.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Fuel injection pressure control device

InactiveCN101235756BSmall control deviationDisadvantages of suppressing the occurrence of stallsElectrical controlFuel injection apparatusEngineeringPressure controlled ventilation

The fuel injection pump control device controls a fuel-injector pressure from the injection supply eliminated by the variables of determined measured parameters. The fuel is injected and supplied to a target machine. A learning correction process-implementing device is provided for successive implementation of multiple kinds of learning correction process corresponding to the multiple implementedconditions. The implemented conditions are different in the strictness for a pressure parameter of pressurized parameter as a learning object and are used for the fuel injection pressure controller.

Owner:DENSO CORP

A method for detecting and debugging the stroke of guide vane control circuit with pressure distribution valve

ActiveCN106768922BSmall control deviationEasy to maintain laterMachine part testingFinal product manufactureHydro energyElectro hydraulic

The invention provides a stroke detection and debugging method of a guide vane control loop with a pressure distribution valve. The method includes the following steps that: a guide vane control block diagram is designed according to the equipment structure of a pumped-hydro energy storage unit, and an electro-hydraulic converter and pressure distribution valve two-stage amplification mode is adopted to make a guide vane servomotor to act through oil pressure; guide vane servomotor and main pressure distribution valve stroke detection modes are determined; a linkage mechanism and a sensor are manufactured and installed, wherein the sensor is used for detecting the strokes of a main pressure distribution valve and a guide vane, and the linkage mechanism is used for converting the strokes of the main pressure distribution valve and the guide vane into the measurement strokes of the sensor; sensor calibration is performed on the guide vane and the main pressure distribution valve; the zero position of an electro-hydraulic converter and the compensation parameter of the neutral position of the main pressure distribution valve are obtained; and guide vane static reaction testing is performed, the acting condition of the guide vane is observed, and the compensation parameter is finely adjusted, so that guide vane control offset can be minimized; and control parameter setting is performed. With the method adopted, it can be ensured that the guide vane control closed-loop is within a reasonable range and has a certain margin, and therefore, later-stage maintenance and debugging can be facilitated.

Owner:广东蓄能发电有限公司

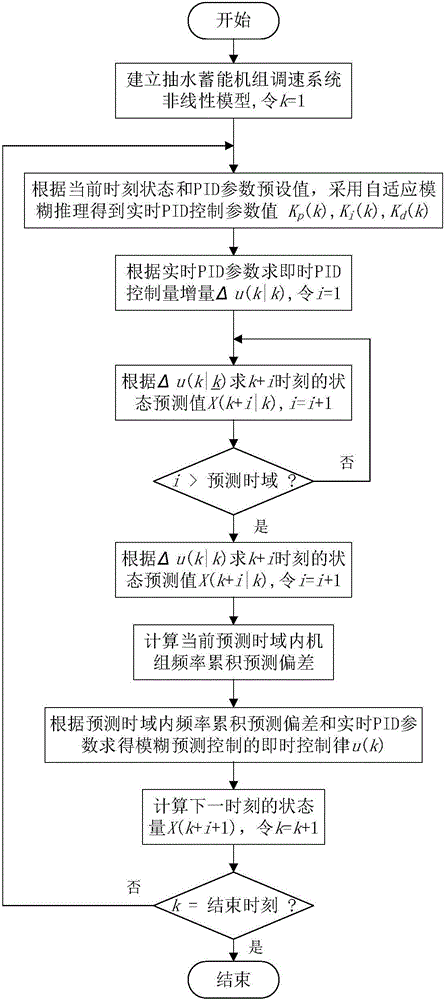

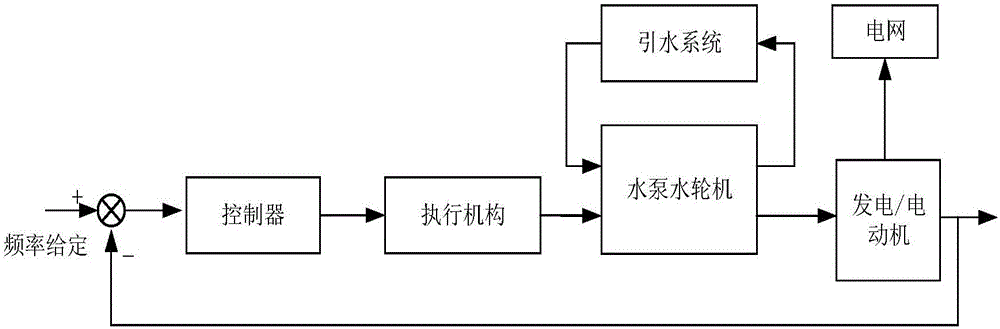

Fast nonlinear fuzzy predictive control method for speed regulation system of pumped storage unit

ActiveCN106014849BFully consider complex nonlinear characteristicsSmall amount of calculationActive/predictive/anticipative controlHydro energy generationTransient stateFuzzy pid control

The invention discloses a quick non-linear fuzzy predictive control method for a speed regulating system of a pumped storage unit. The quick non-linear fuzzy predictive control method includes the three steps of fuzzy PID parameter self-adaption, online rolling prediction and control law computing. By the adoption of the control method, the function that the fuzzy PID control parameters are adjusted automatically along with the working conditions is achieved, the future system state is predicted through a pumped storage unit speed regulating system non-linear model built in a controller by means of the online rolling prediction method, and the future system state quantity deviation information is considered when a real-time control law is set. By the adoption of the quick non-linear fuzzy predictive control method, the requirements of the control process of the pumped storage unit under different working conditions can be met, the control precision of the unit is improved effectively, and the transient state performance of the operating process of the unit is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

S-type stainless steel hanging code

Owner:SICHUAN SHIYANG ELECTRICAL & MECHANICAL EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com