A two-stage coordinated predictive control method for superheated steam temperature of thermal power units

A superheated steam temperature, predictive control technology, applied in the direction of superheated temperature control, steam superheating, steam generation, etc., can solve the problems of large delay characteristics of difficult steam temperature objects, and the coordination problem of two-stage water spray control is not fully considered. The effect of improving control precision and reducing control deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

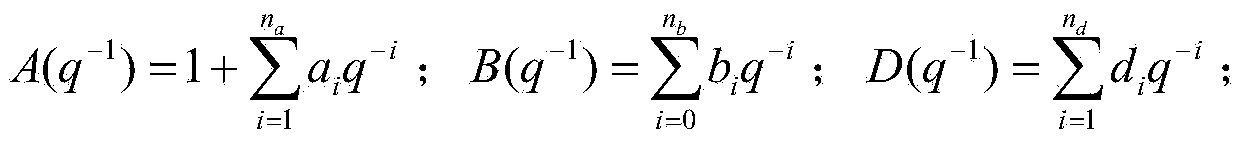

[0083] (1) Before the implementation of the algorithm, the transfer function models of the primary and secondary steam temperature related objects are obtained through the step response test. Since the design process of the first and second level is basically the same, the following will focus on the second level as an example.

[0084] Assume that the step response test is passed, and the transfer function W of the first-stage steam temperature to the opening of the first-stage desuperheating water valve is obtained by using the two-point method 1 (s)=-1.12 / (1+20s) 5 (°C / %); transfer function W of superheated steam temperature to first stage desuperheating water valve opening 3 (s)=-1.43 / (1+20s) 10 (°C / %); The transfer function W of the steam temperature before the second-stage pilot to the opening of the second-stage desuperheating water valve 21 (s)=-0.21 / (1+15s) 2 (°C / %); the transfer function W of the superheated steam temperature to the opening of the secondary desup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com