Control method of graphite heater

A graphite heater and control method technology, applied in the direction of ohmic resistance heating, heating element materials, ohmic resistance heating parts, etc., can solve problems such as unproposed solutions, achieve the effect of increasing accuracy and reducing control deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

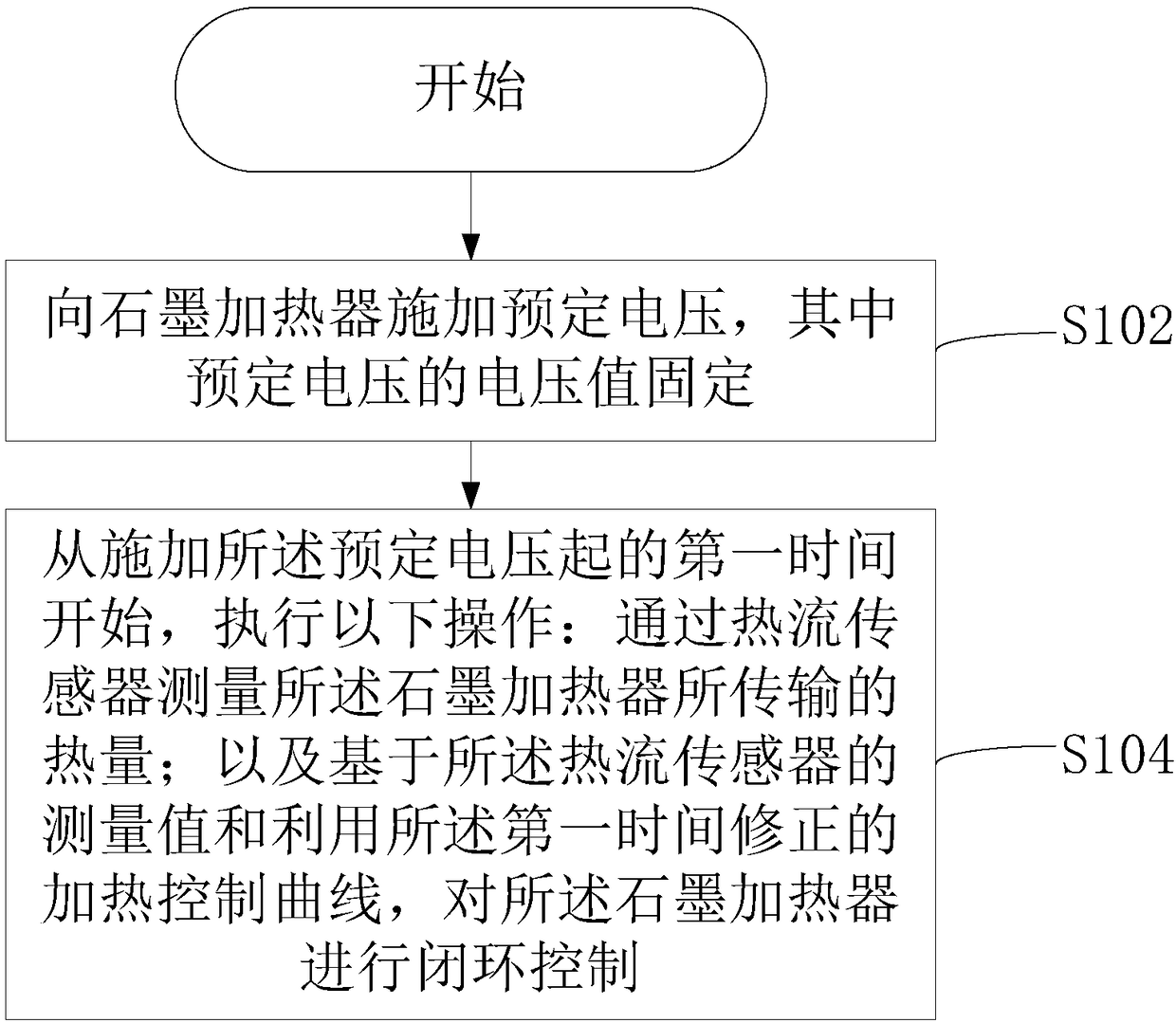

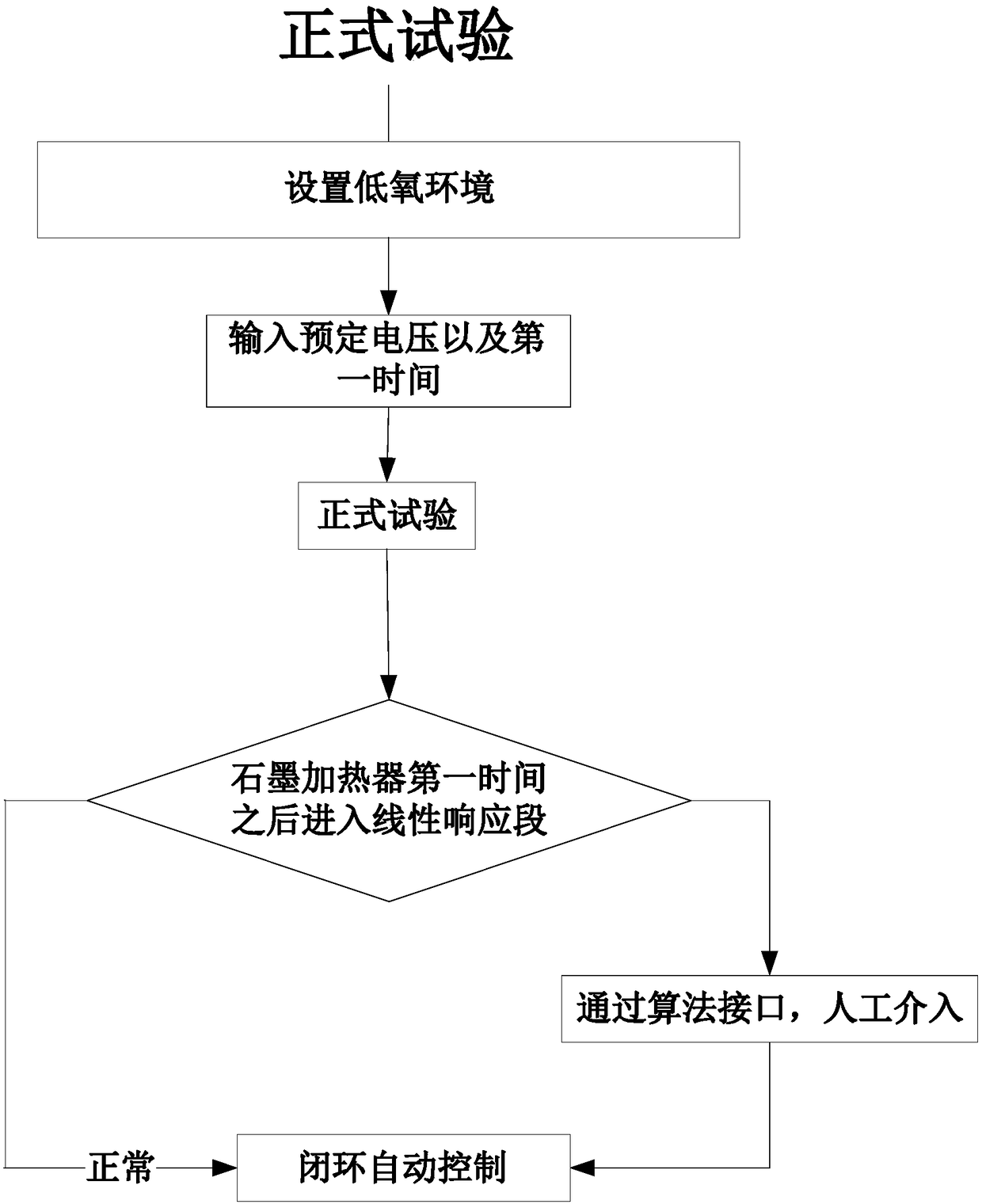

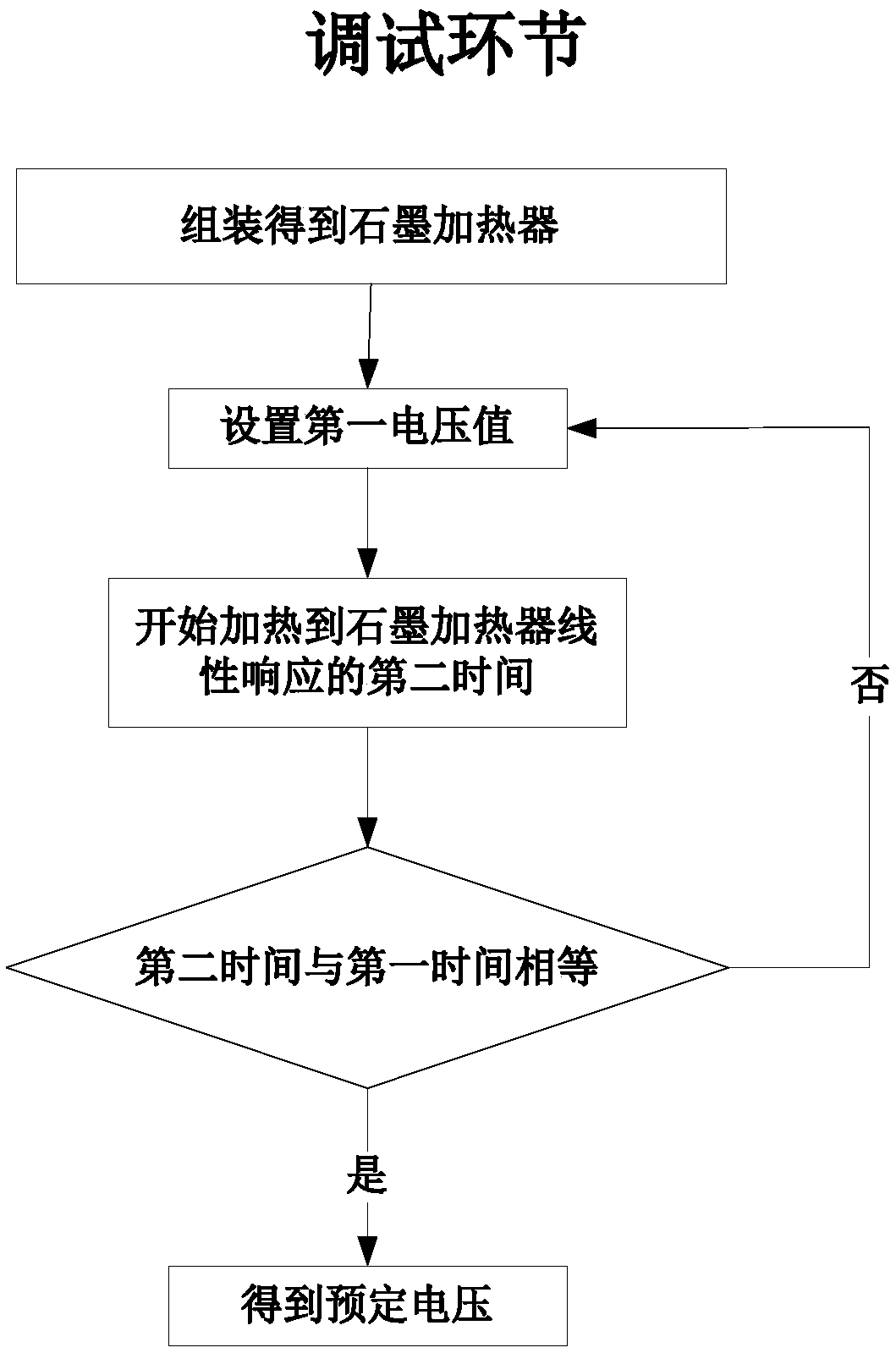

[0028] In combination with the present invention figure 1 and 2 As shown, the present invention provides a control method for a graphite heater. include:

[0029] S102: applying a predetermined voltage to the graphite heater, wherein the voltage value of the predetermined voltage is fixed;

[0030] S104: From the first time when the predetermined voltage is applied, perform the following operations: measure the heat transmitted by the graphite heater through a heat flow sensor; The heating control curve is used to perform closed-loop control on the graphite heater.

[0031] Wherein the first time is the time when the graphite heater starts to respond linearly to the applied voltage.

[0032] Reference attached Figure 4 As shown, in the graphite heating control curve under the traditional method, the thermal inertia of the material itself is large in the hot start stage, the hysteresis phenomenon is serious, the response to the input voltage is slow, and the thermal load ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com