A method for detecting and debugging the stroke of guide vane control circuit with pressure distribution valve

A stroke detection and control circuit technology, which is applied in the field of stroke detection and debugging of the guide vane control circuit with a pressure distribution valve, can solve the complex guide vane control circuit, high commissioning or consulting costs, adverse effects of pumped storage unit assessment indicators, etc. problem, to achieve the effect of convenient later maintenance and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

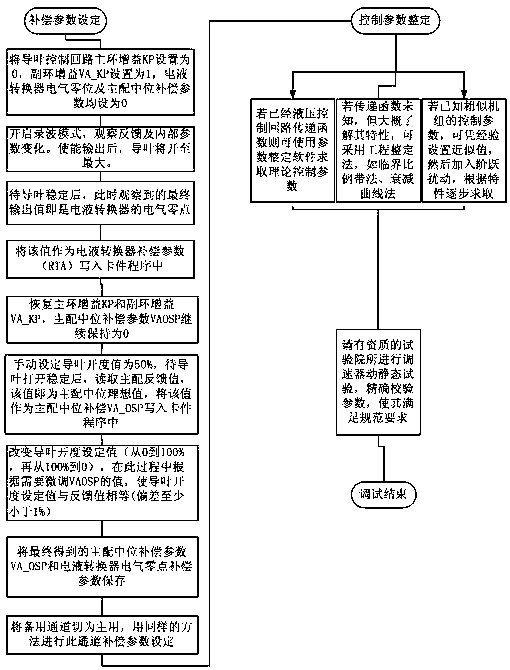

[0045] Such as Figure 1-2 As shown, a guide vane control circuit stroke detection and debugging method with a pressure distribution valve includes the following steps:

[0046] S1: Design the guide vane control block diagram according to the mechanical equipment structure of the pumped storage unit, and use the two-stage amplification method of the electro-hydraulic converter and the pressure distribution valve to drive the guide vane servomotor to move through the oil pressure; therefore, the general design in the guide vane control circuit Cascaded way;

[0047] S2: Determine the stroke detection method of the guide vane servomotor and the main pressure distribution valve;

[0048] S3: making and installing a linkage mechanism and a sensor, the sensor is used to detect the stroke of the main pressure distribution valve and the guide vane, and the linkage mechanism is used to convert the stroke of the main pressure distribution valve and the guide vane into the measuring st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com