Fuel injection pressure control device

A technology of fuel injection and controller, which is applied in the direction of fuel injection control, fuel injection device, electrical control, etc., which can solve the problems of engine stalling and inability to fully absorb the reduction of common rail pressure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

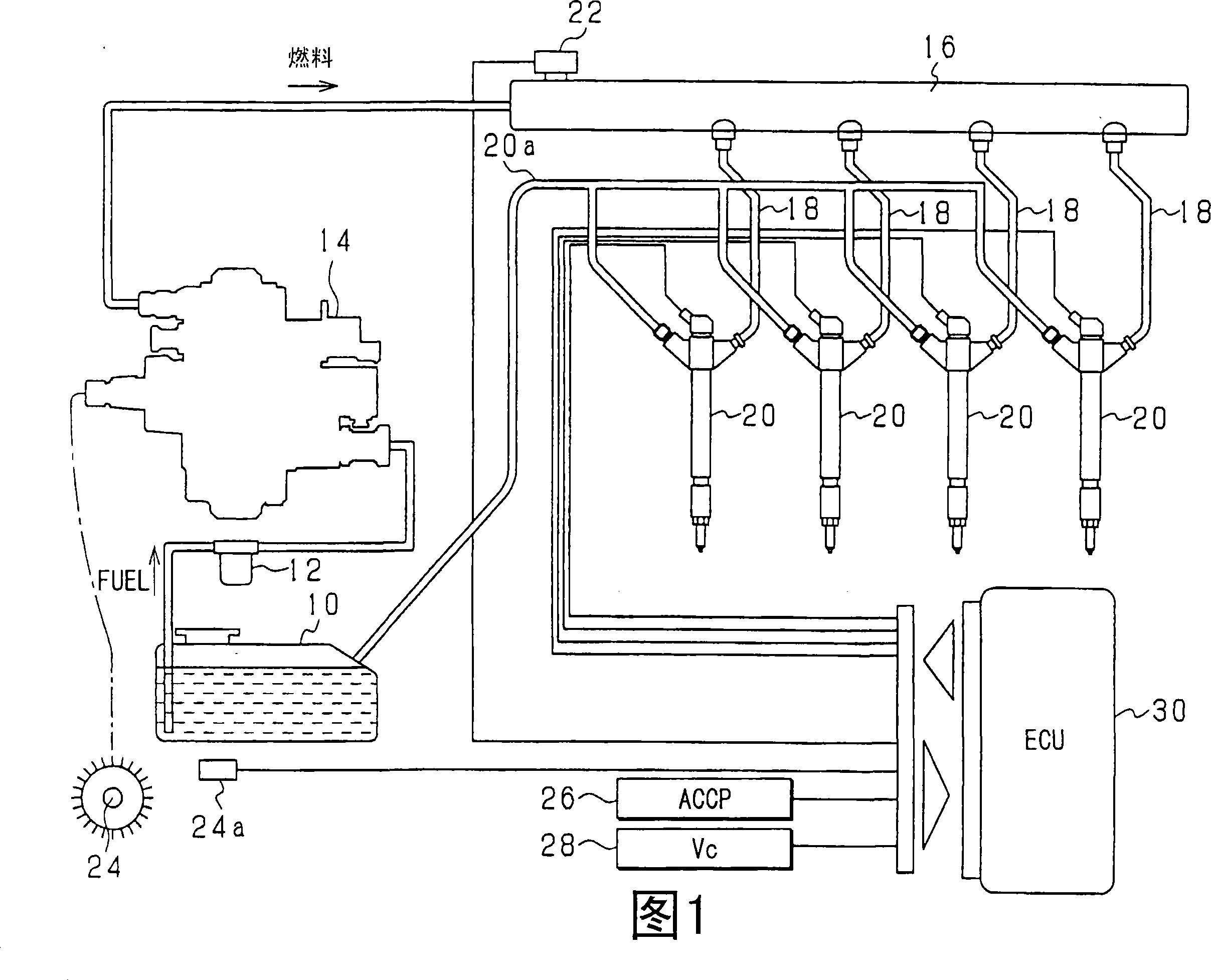

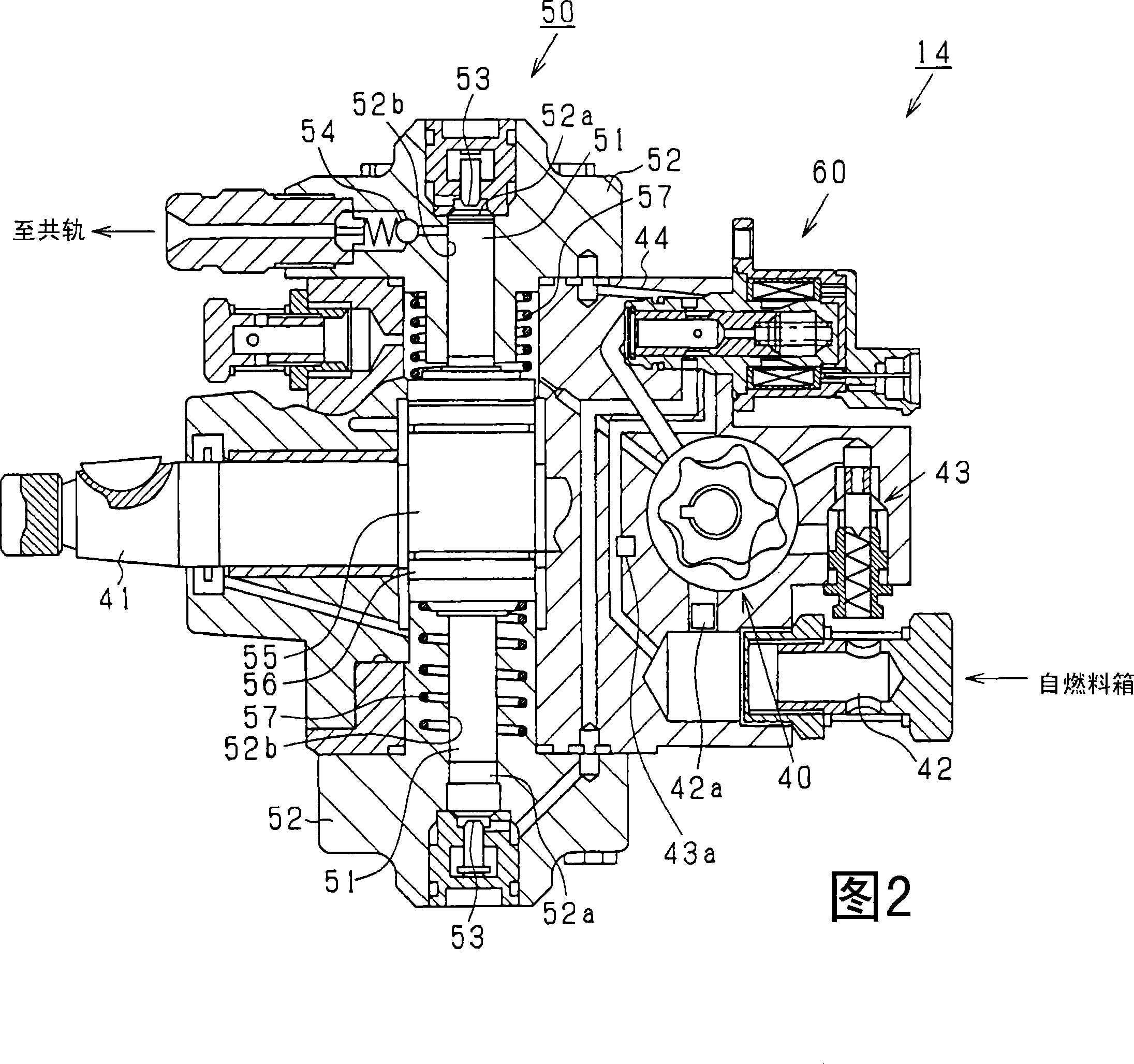

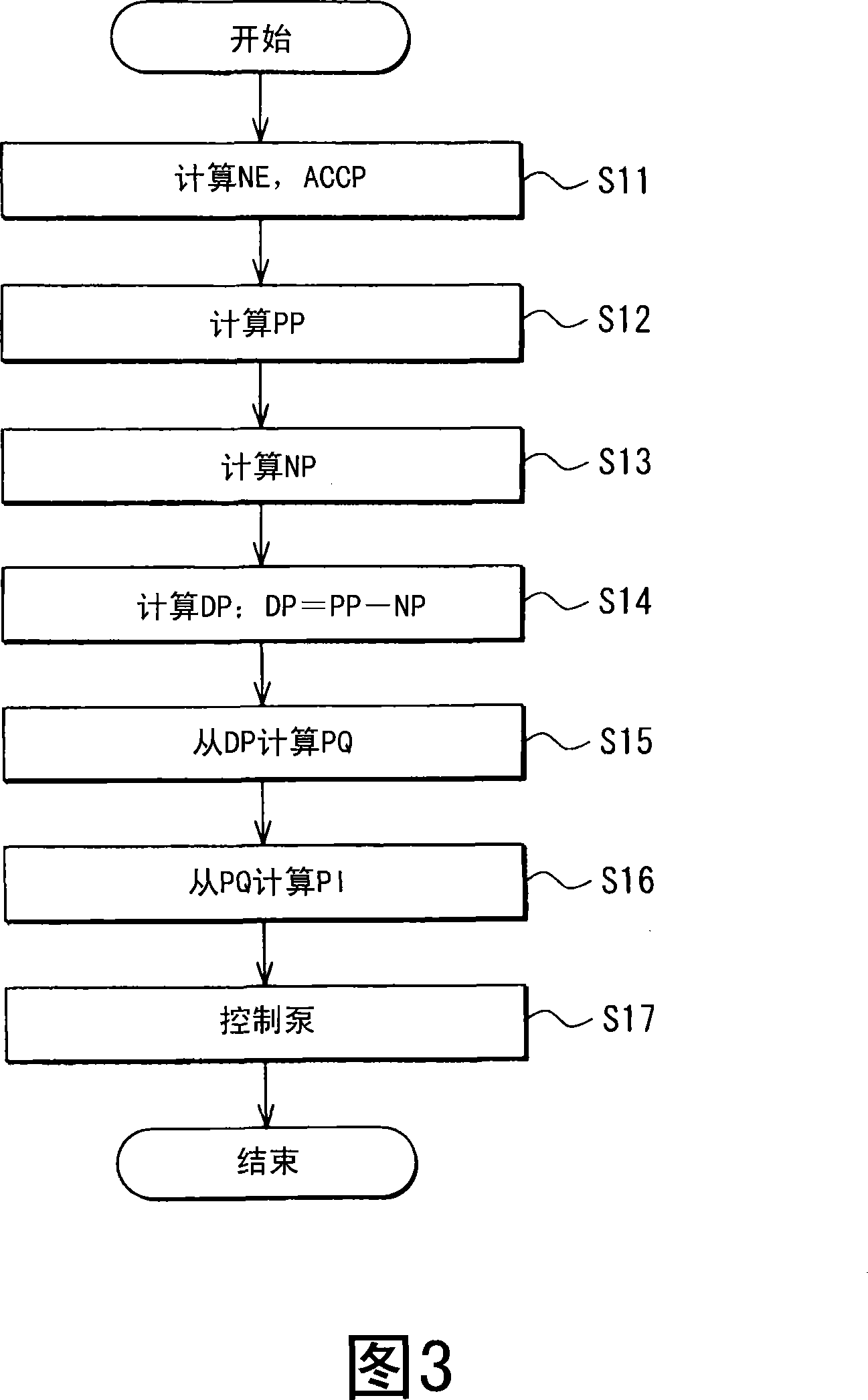

[0033] Now, a fuel injection pressure controller according to an embodiment of the present invention will be described with reference to the accompanying drawings. The controller of the present embodiment is installed in a common rail fuel injection control system (high pressure injection fuel supply system) to control, for example, a reciprocating diesel engine as an automobile engine. Same as the device described in Patent Document 1, the controller of this embodiment is a fuel injection pressure controller of a diesel engine (internal combustion engine), which directly injects high-pressure fuel (such as light oil with an injection pressure of 1000 atm or more) and The controller performs feedback-control (PID control) so that the fuel injection pressure conforms to a target value when supplied into a combustion chamber of a cylinder of a diesel engine.

[0034] First, with reference to FIG. 1 , the gist of the common rail fuel injection control system of the present embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com