Overlapped sequence valve

A sequential valve, superimposed technology, used in fluid pressure actuation devices, servo motor components, mechanical equipment, etc., can solve the problems of reduced pressure regulation accuracy, large control deviation, spring deformation, etc., to improve pressure regulation accuracy, control The effect of small deviation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

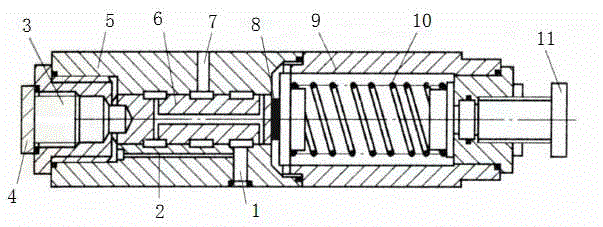

[0014] like figure 1 As shown, a superimposed sequence valve includes a valve body 5 with a certain thickness, a valve core 6 is arranged in the valve body 5, a pressure detection port 3 is arranged on one side of the valve body 5, a pressure gauge 4 and a pressure detection port Port 3 is connected, the other side of the valve body 5 is provided with a spring 10, the spring 10 is provided with a force sensor 8 on the side close to the valve core 6 and the other side is provided with an adjusting screw 11, the spring of the spring 10 can be adjusted by adjusting the screw 11 Force, the spring 10 is set on one side of the valve body 5 through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com