Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Simple adjustment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

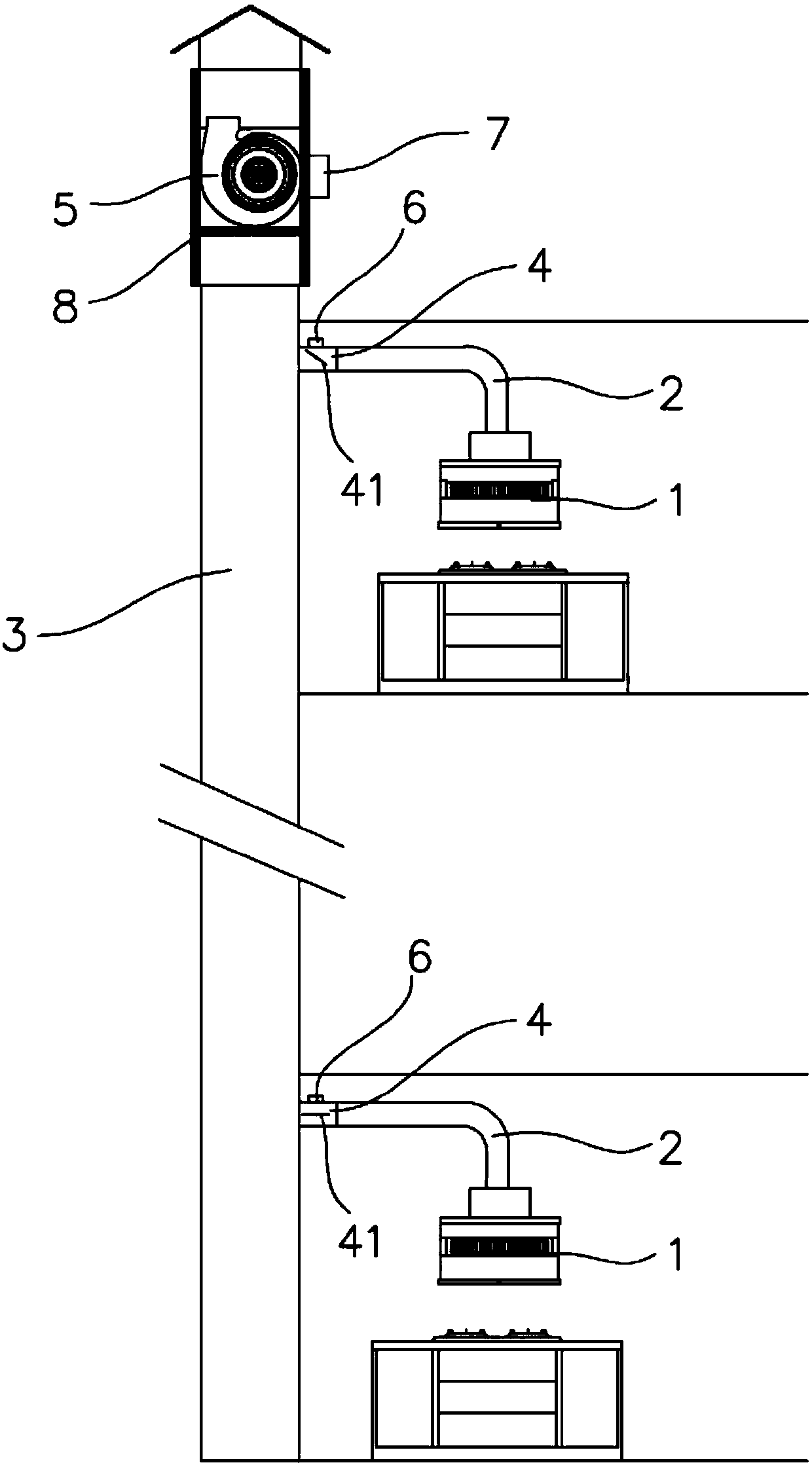

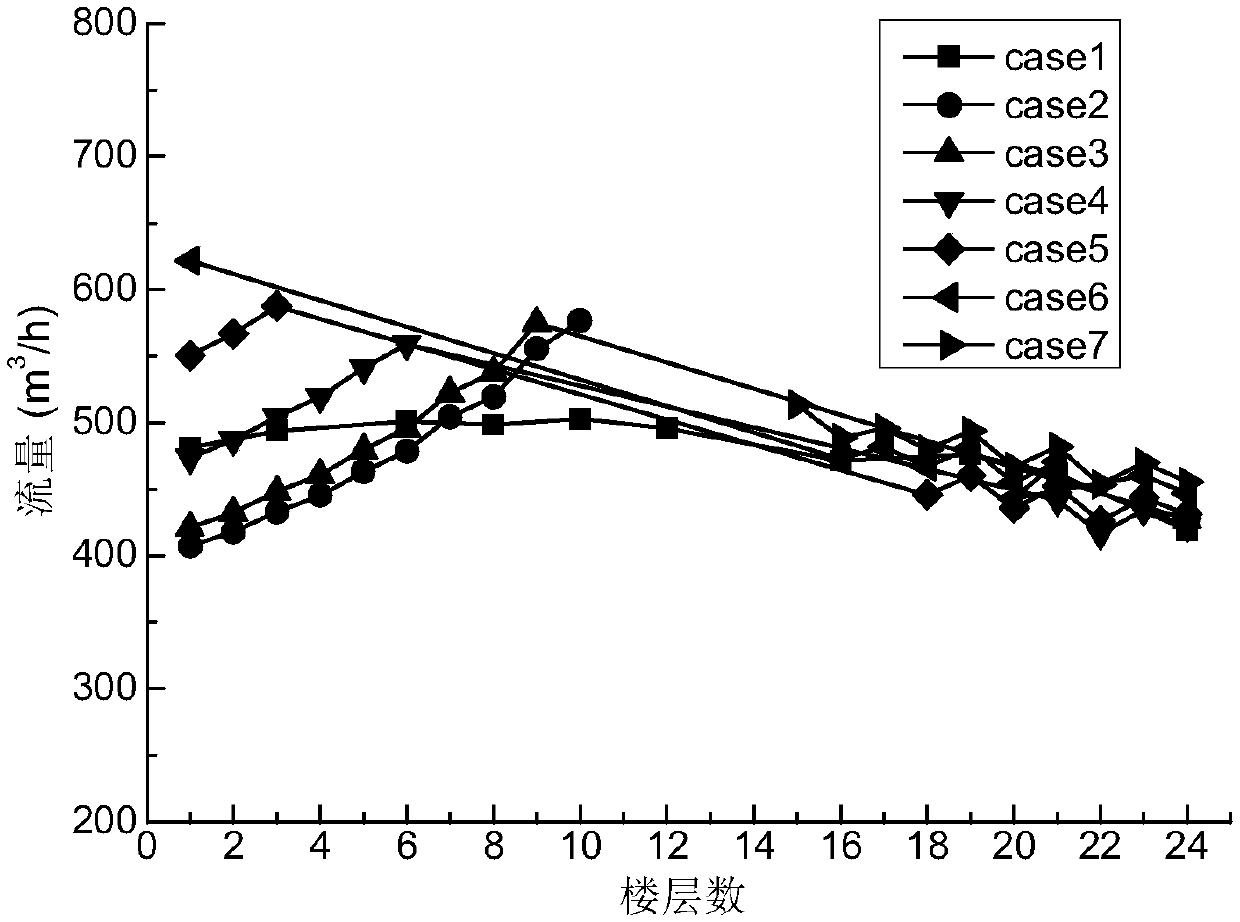

Central flue system and uniform flow distribution method thereof

InactiveCN111076249AEven flow distributionSimple adjustment processDomestic stoves or rangesLighting and heating apparatusFlueProcess engineering

The invention discloses a central flue system. The central flue system comprises range hoods, an outdoor control system and a check valve control system, wherein an air outlet of each range hood is incommunication with a public flue through a respective smoke pipe, an adjustable check valve is mounted in each smoke pipe, a flue fan is mounted in the public flue, the range hoods are unpowered range hoods, the outdoor control system is used for controlling the rotating speed or frequency of the flue fan, the check valve control system is used for adjusting the opening angle of a valve plate ofthe adjustable check valve, and the check valve control system and the outdoor control system can communicate with each other. The invention further discloses a flow uniform distribution method of thecentral flue system, an extractor hood of the central flue system is an unpowered extractor hood, the rotating speed or frequency of the flue fan is adjusted through the outdoor control system, the opening angle of the valve plate is controlled through the check valve control system, the flow uniform distribution method only needs to preset the preset angles of the valve plate under two differentstarting rates, uniform flow distribution can be ensured through judgment of the startup rate, and the adjustment process is simple and efficient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

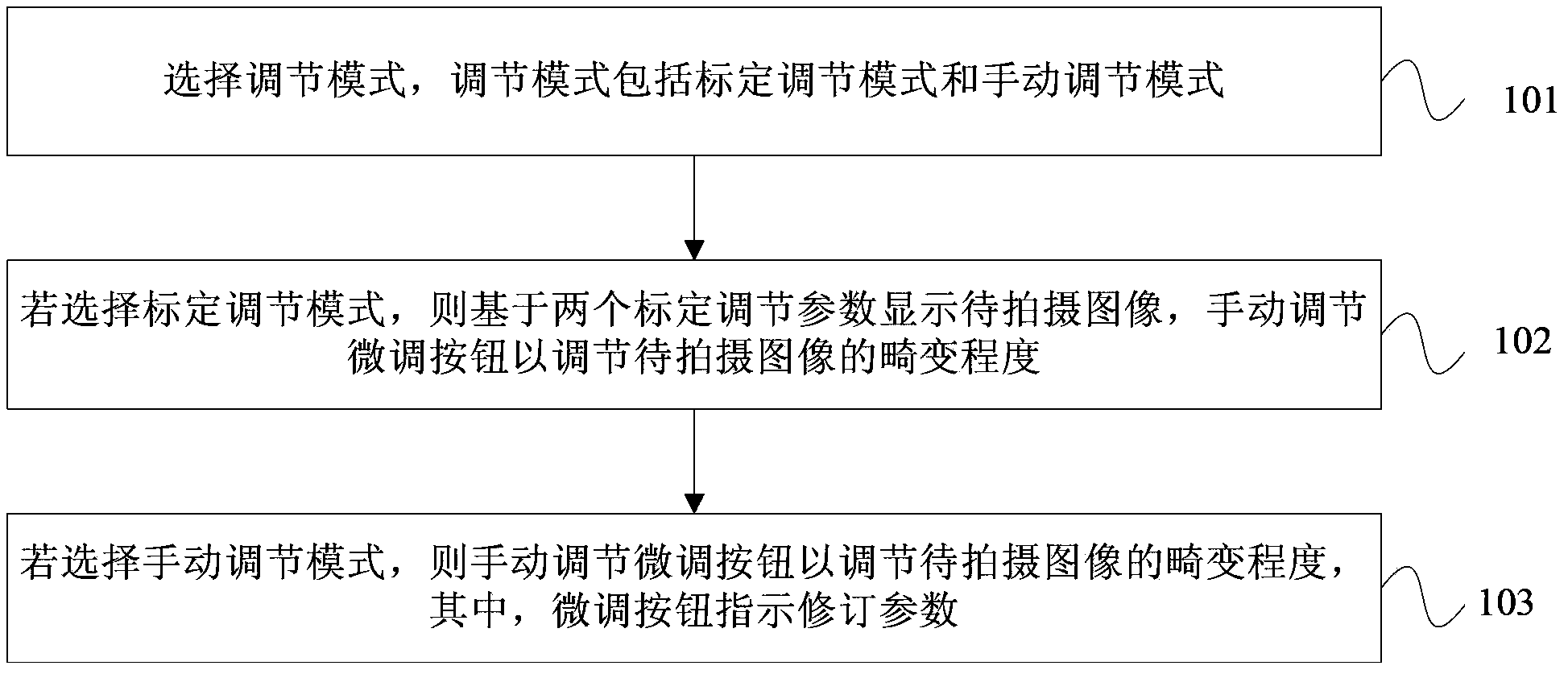

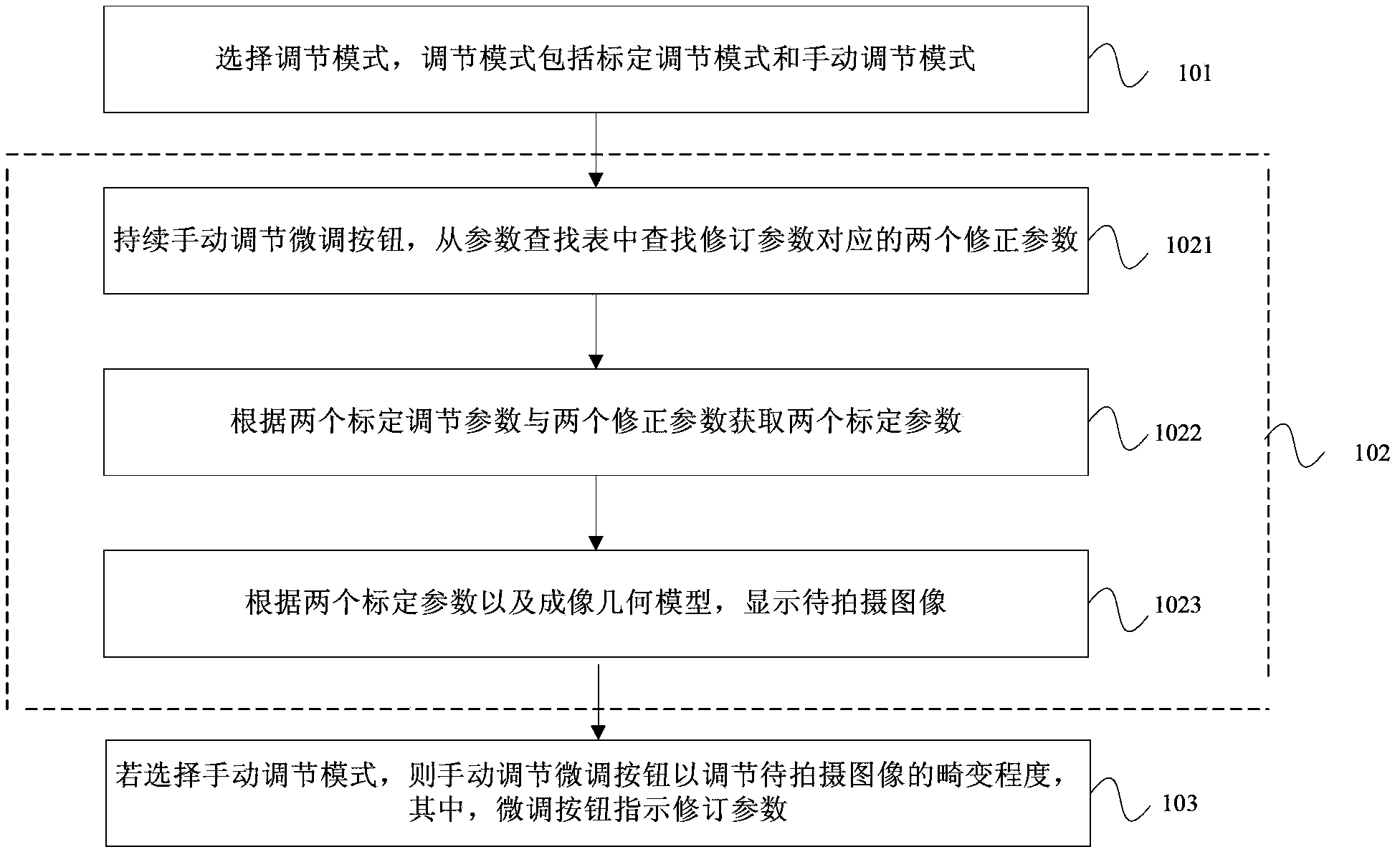

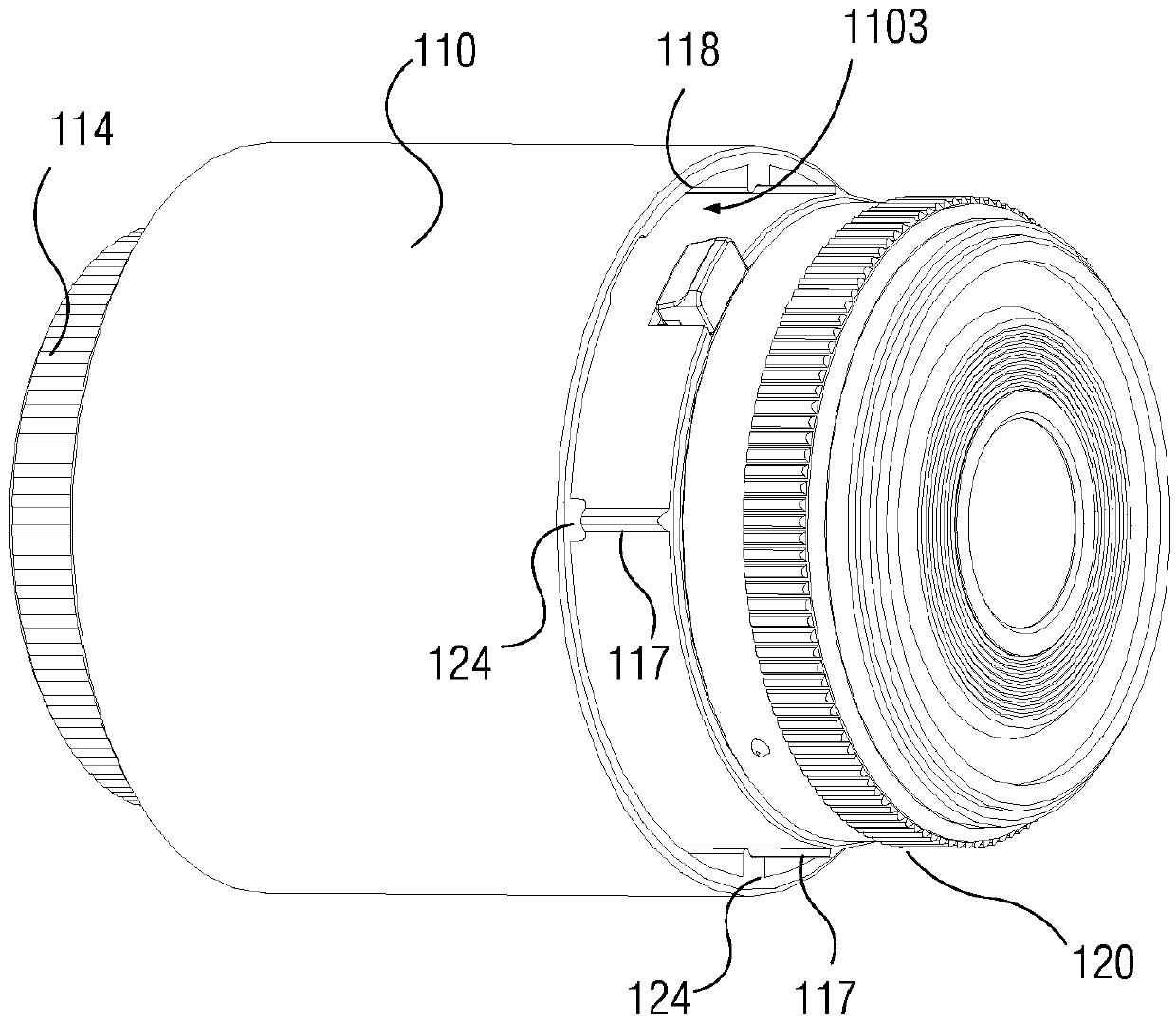

Lens distortion parameter adjustment method and device and camera shooting device

ActiveCN103458181ASimple adjustment processReduce lens distortionTelevision system detailsColor television detailsDistortionCamera lens

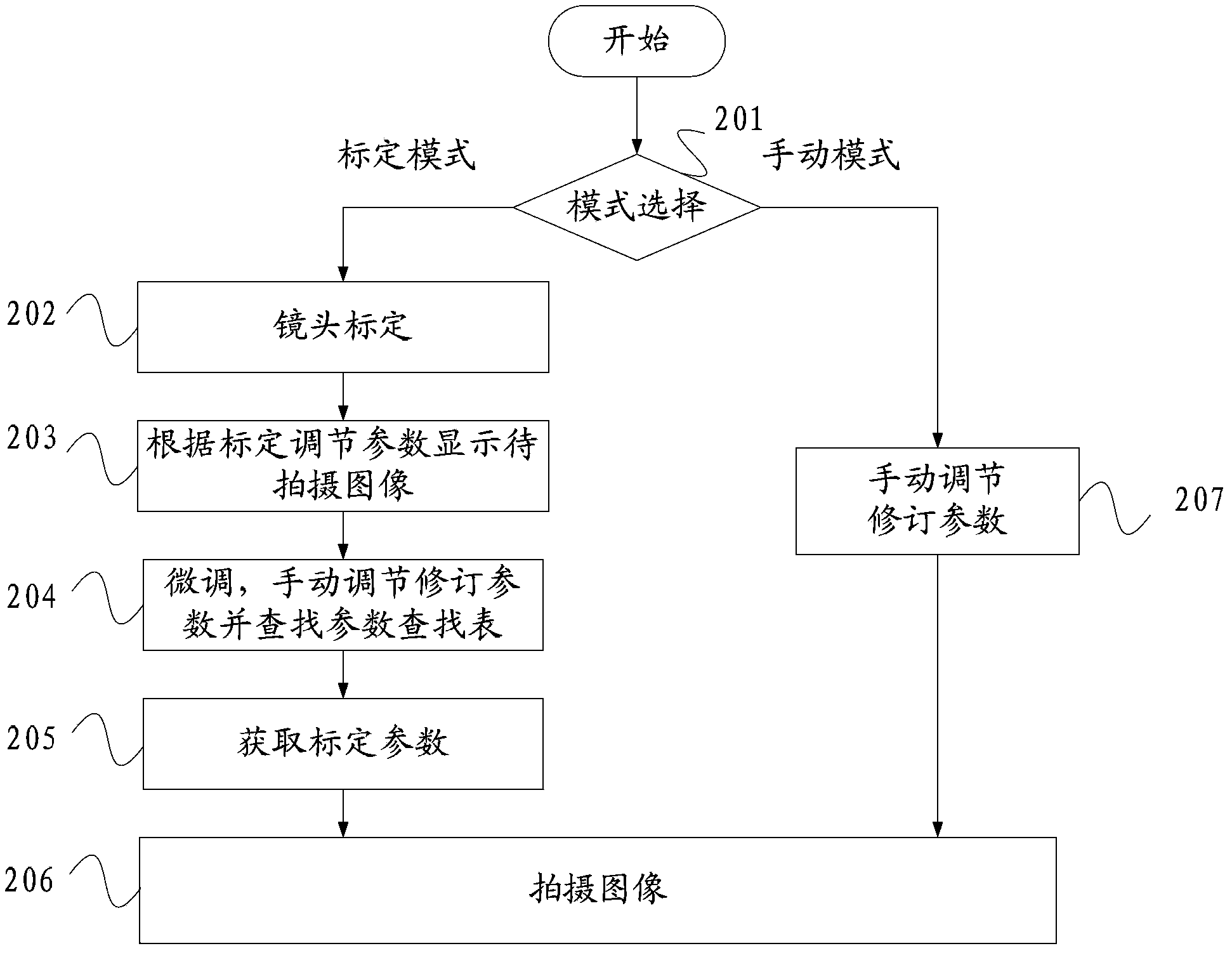

The embodiment of the invention provides a lens distortion parameter adjustment method and device and a camera shooting device. The method includes the steps of selecting adjustment modes which include a calibration adjustment mode and a hand adjustment mode, adjusting a spin button by hand to adjust the distortion degree of an image to be shot after calibrating the image to be shot if selecting the calibration adjustment mode, and otherwise, adjusting the spin button by hand to adjust the distortion degree of an image to be shot if selecting the hand adjustment mode. According to the lens distortion parameter adjustment method and device and the camera shooting device, in the calibration adjustment mode and the hand adjustment mode, a user adjusts only one parameter by hand, namely, the user adjusts the revision parameter through one spin button, therefore, the adjusting process is simple, and lens distortion can be effectively reduced.

Owner:HUAWEI TECH CO LTD

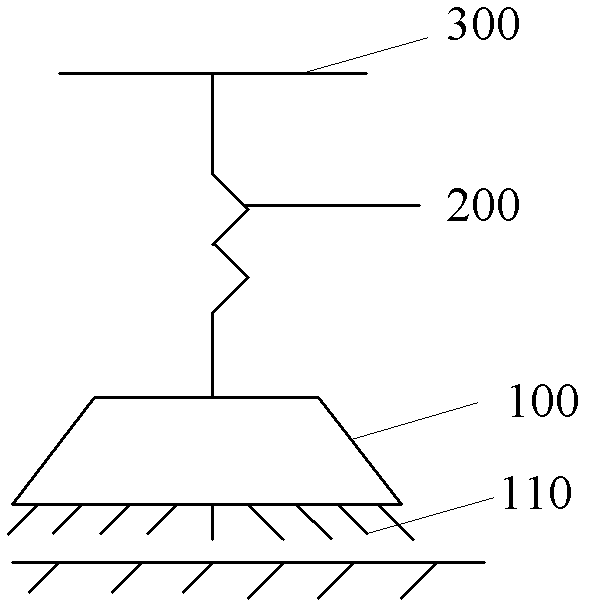

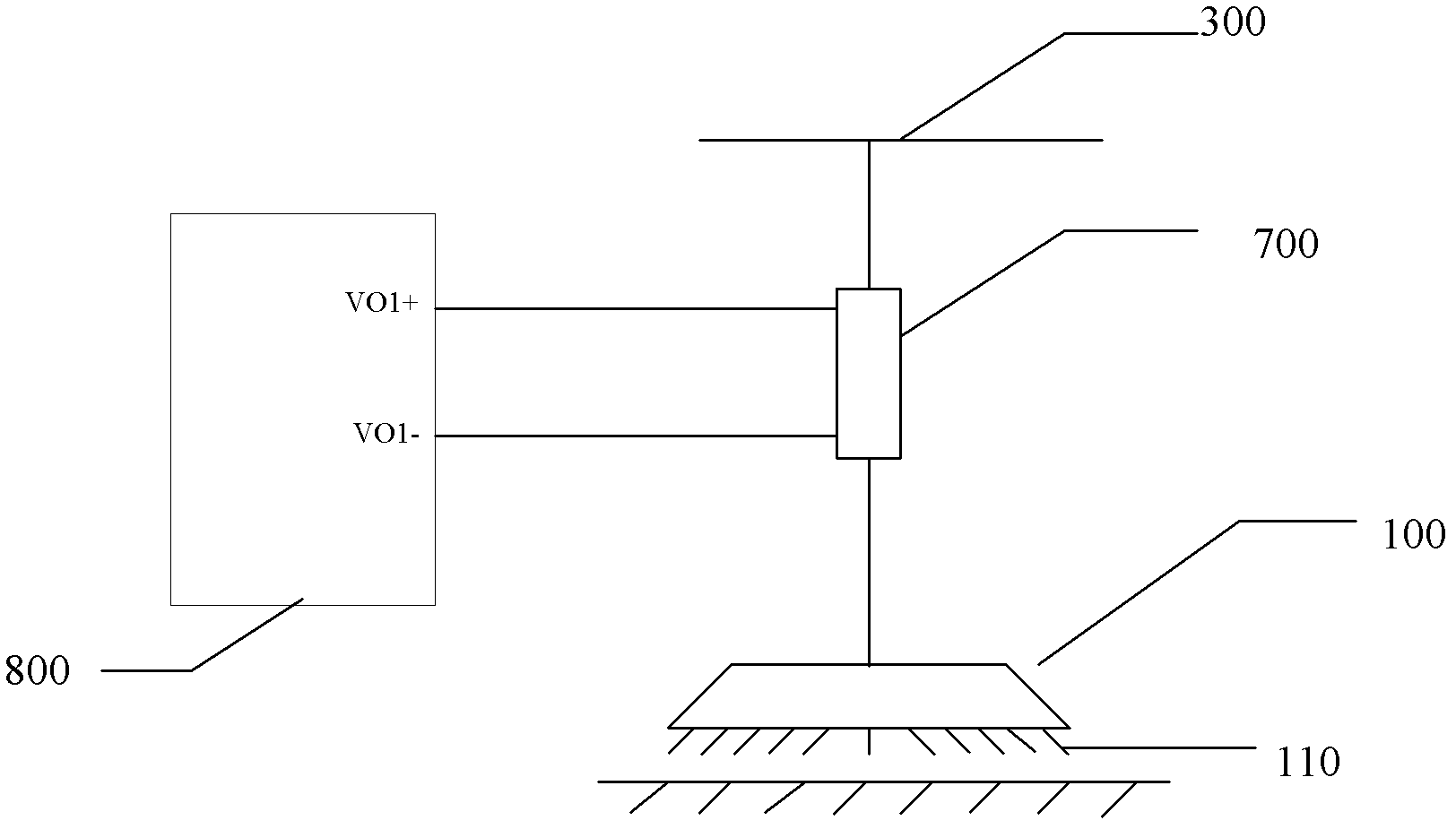

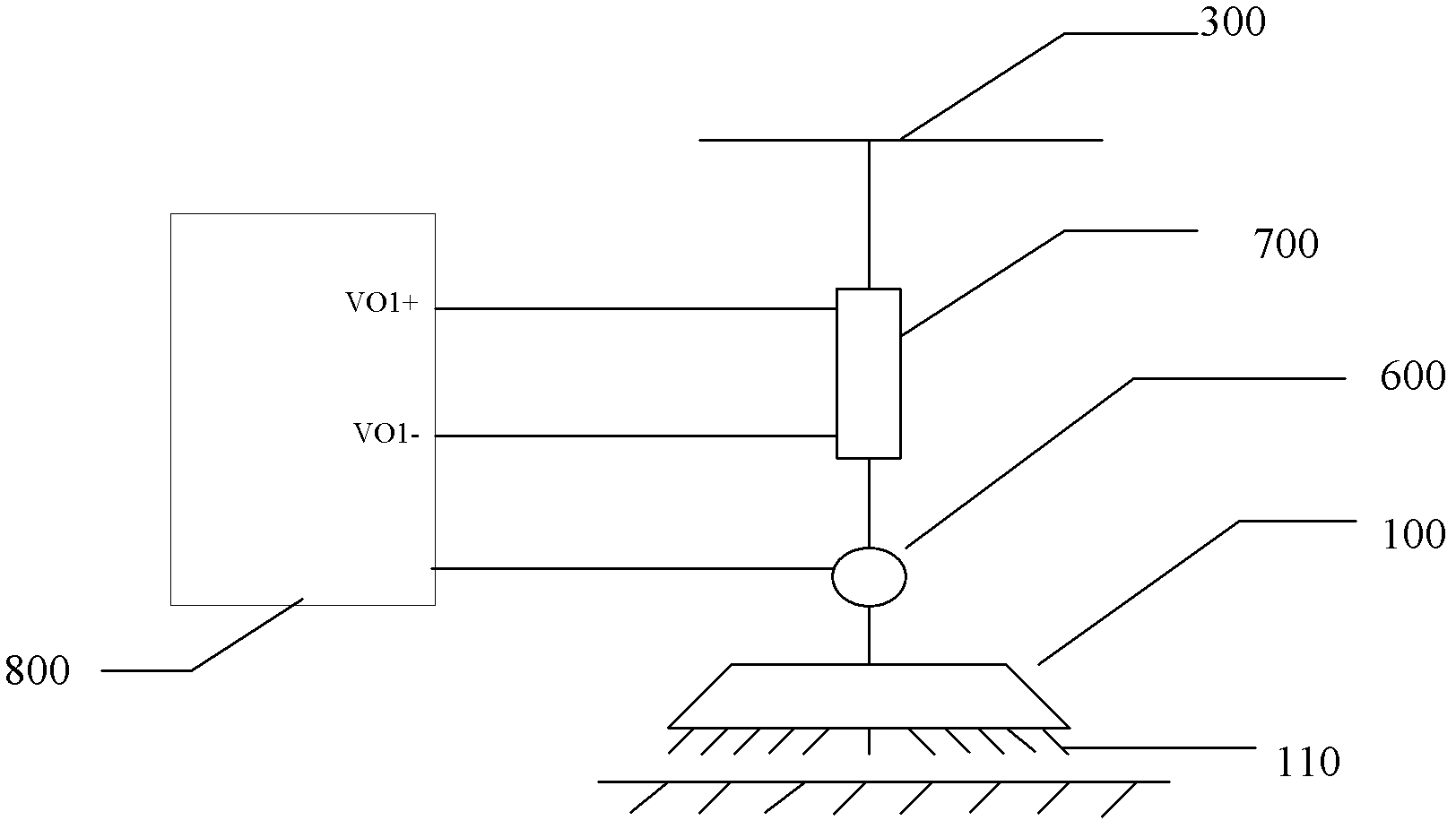

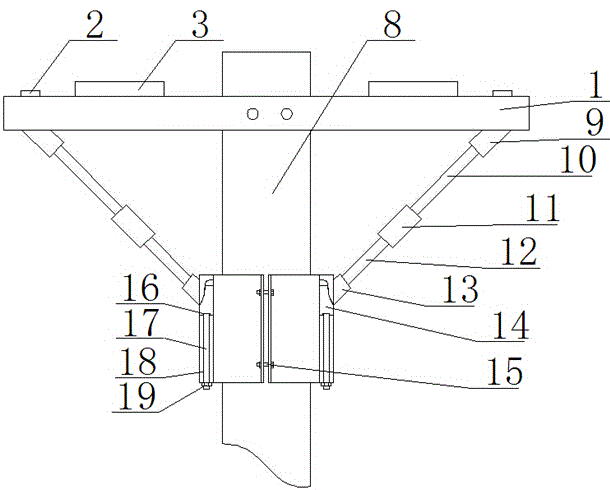

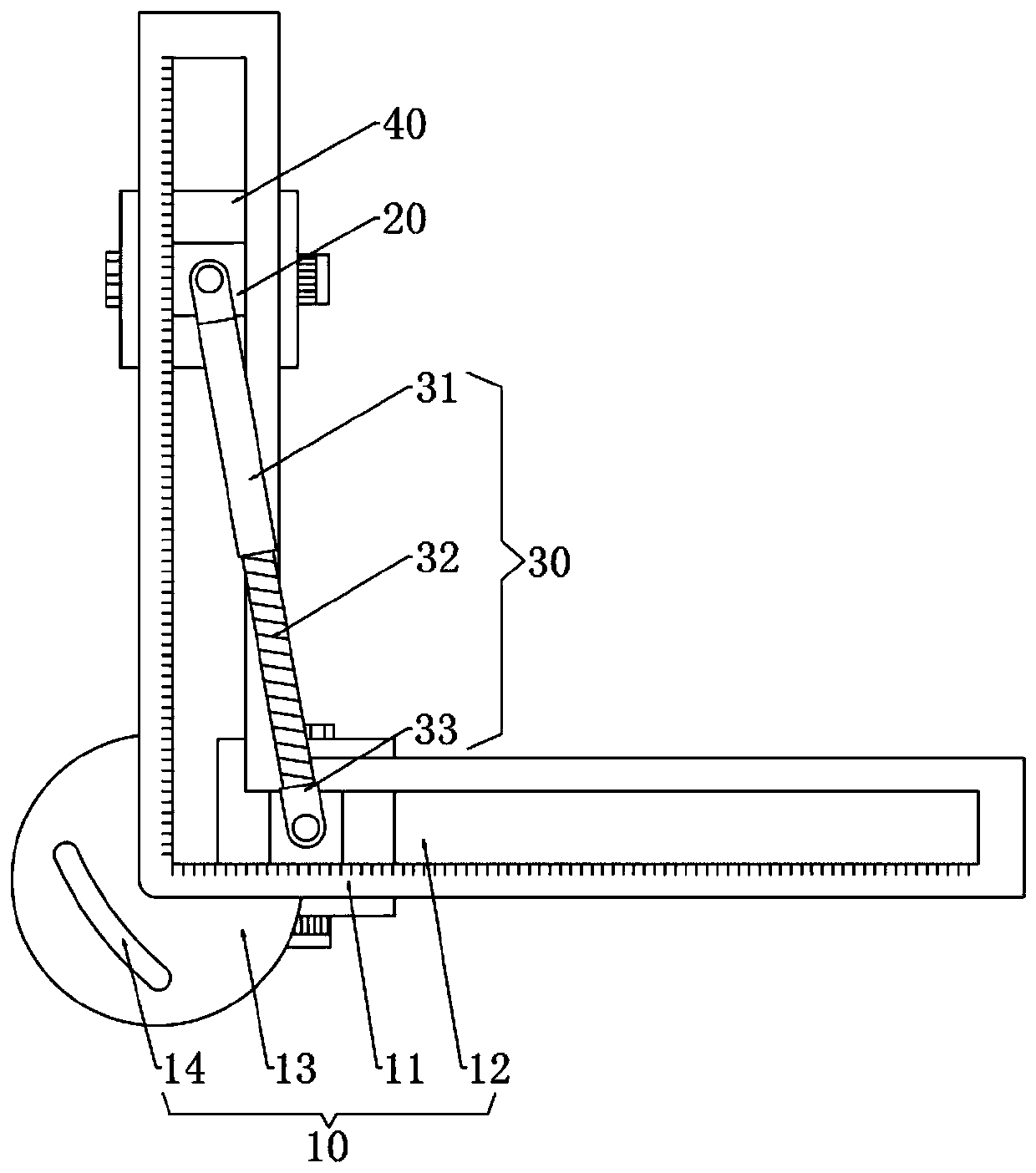

Sweeping equipment, motor sweeper and method for adjusting sweeping plate

ActiveCN102444098ASimple adjustment processRealize automatic adjustmentRoad cleaningEngineeringControl unit

The invention discloses sweeping equipment, a motor sweeper and a method for adjusting a sweeping plate. The method is used for simplifying process of adjusting the sweeping plate and improving performances of the sweeping equipment. The sweeping equipment comprises the sweeping plate, an equipment support, an electric telescopic connecting rod and a control unit, wherein the sweeping plate is connected with the equipment support through the electric telescopic connecting rod, and the control unit is connected with the electric telescopic connecting rod and controls stretching and retracting of the electric telescopic connecting rod.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

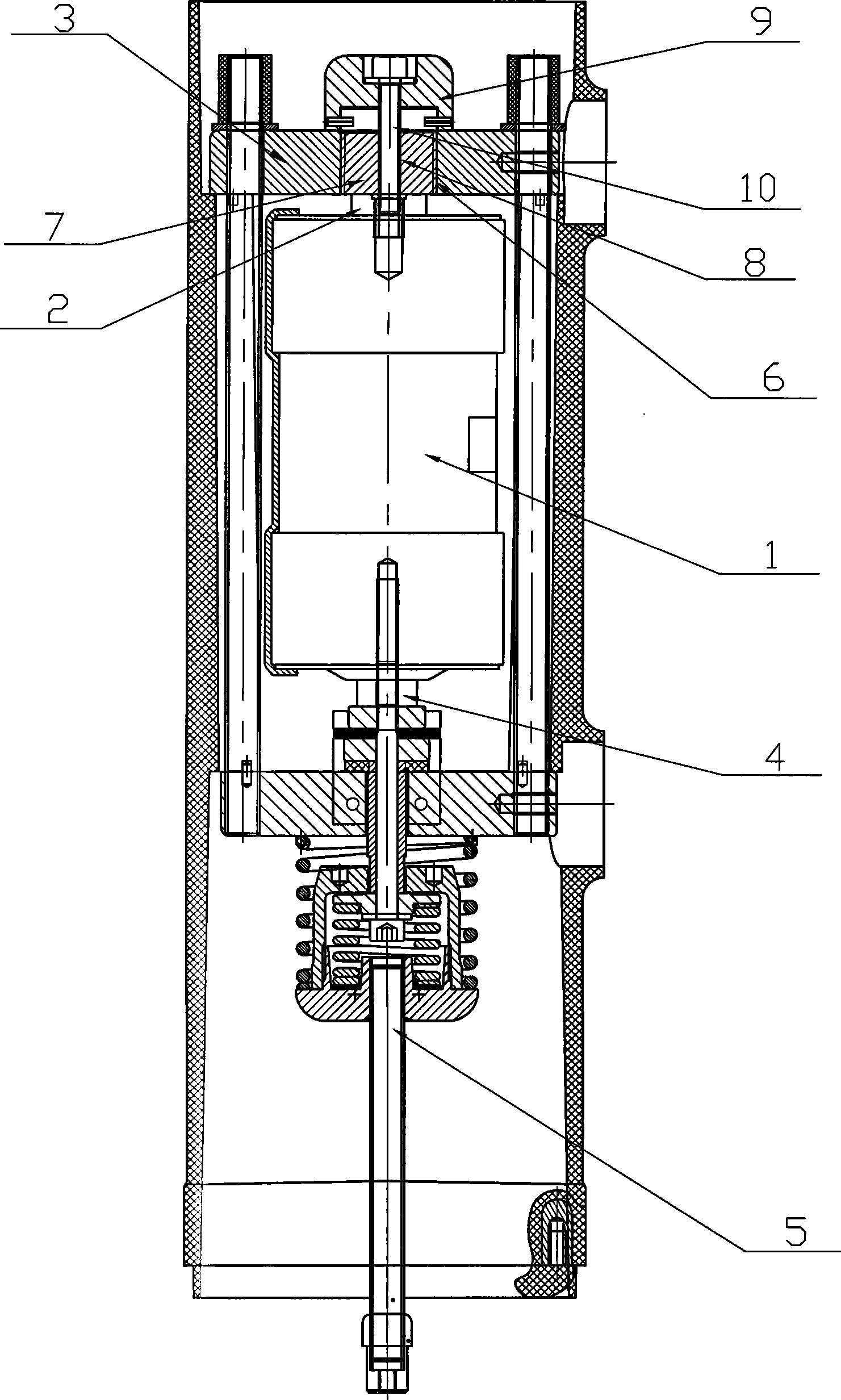

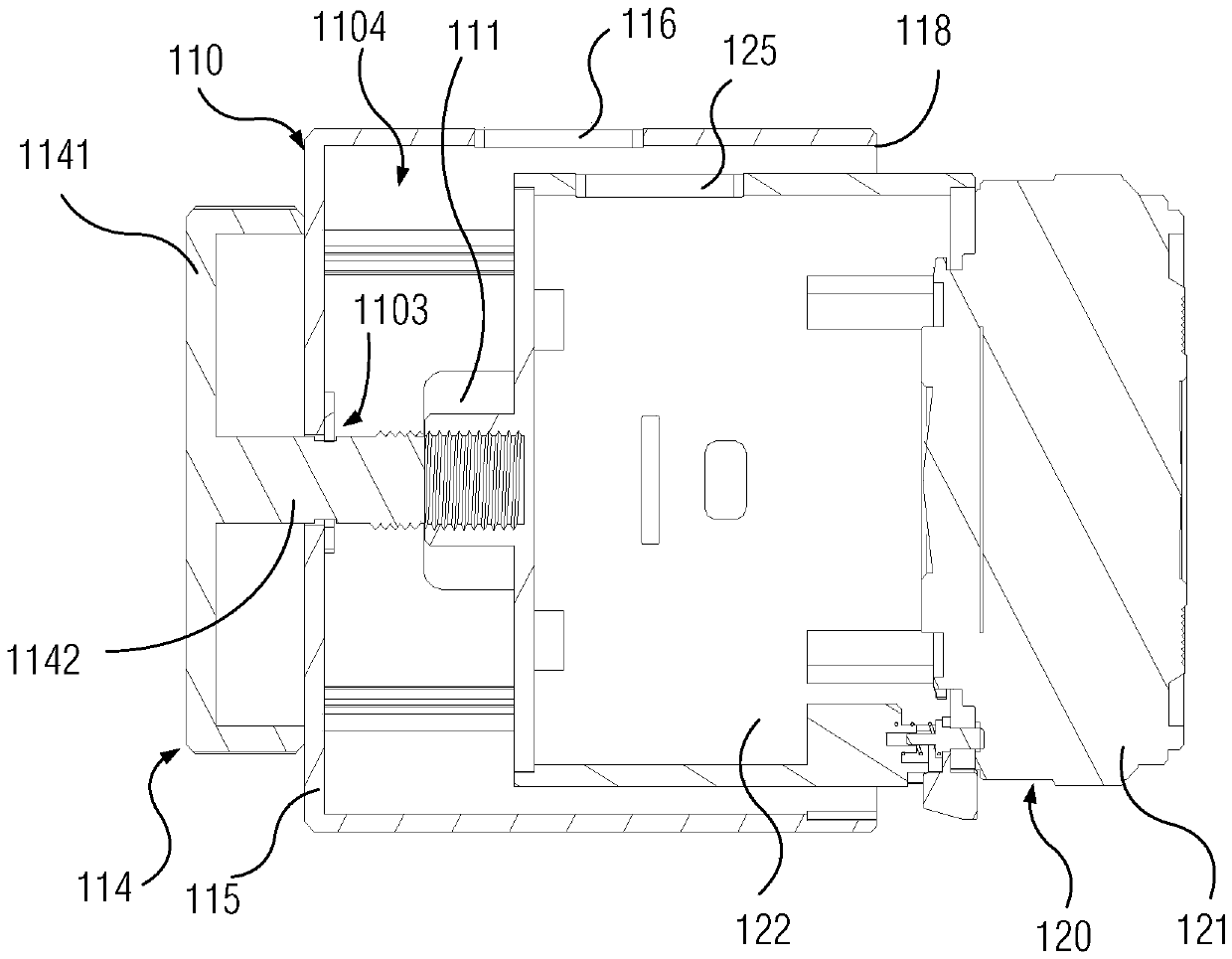

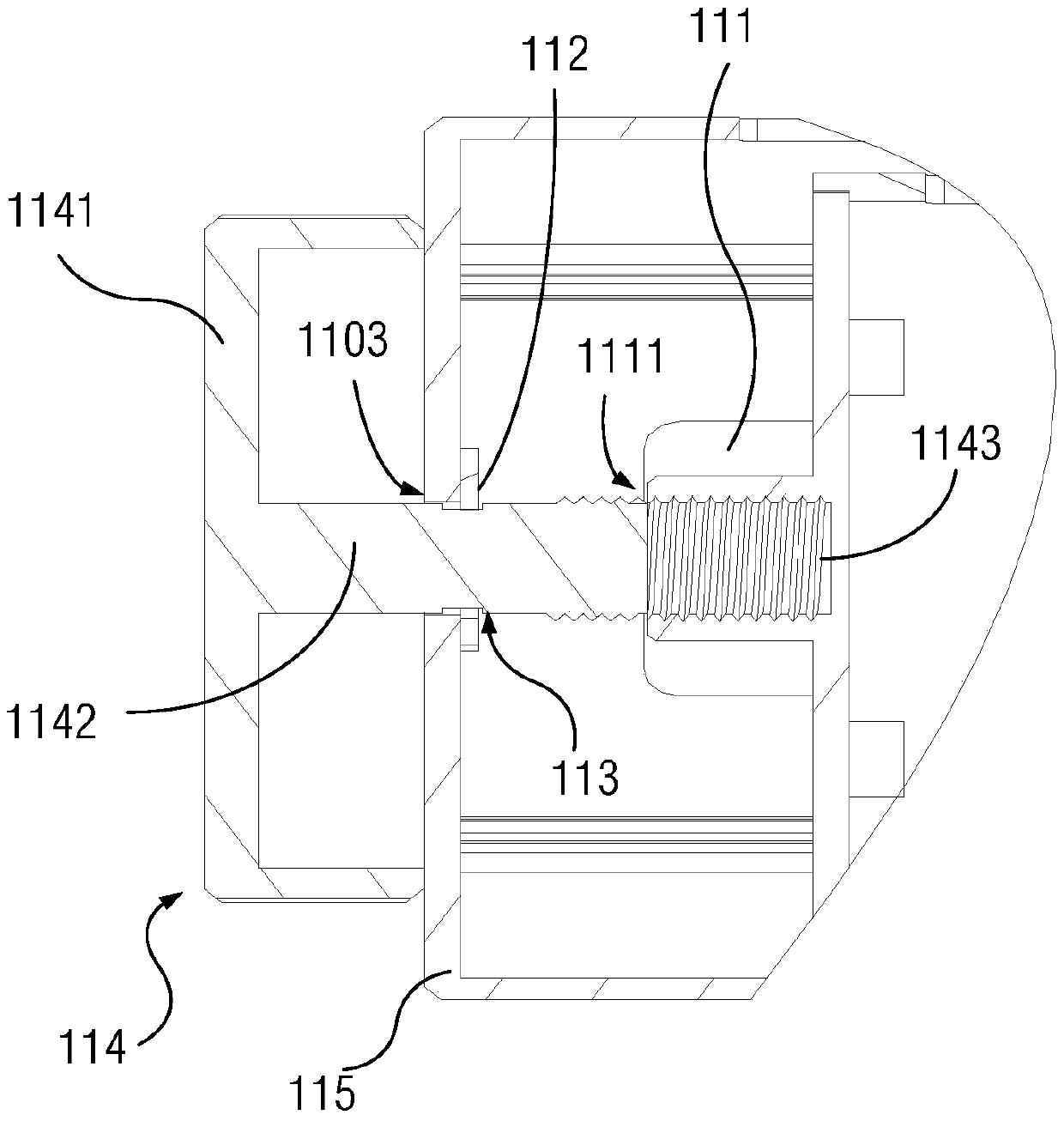

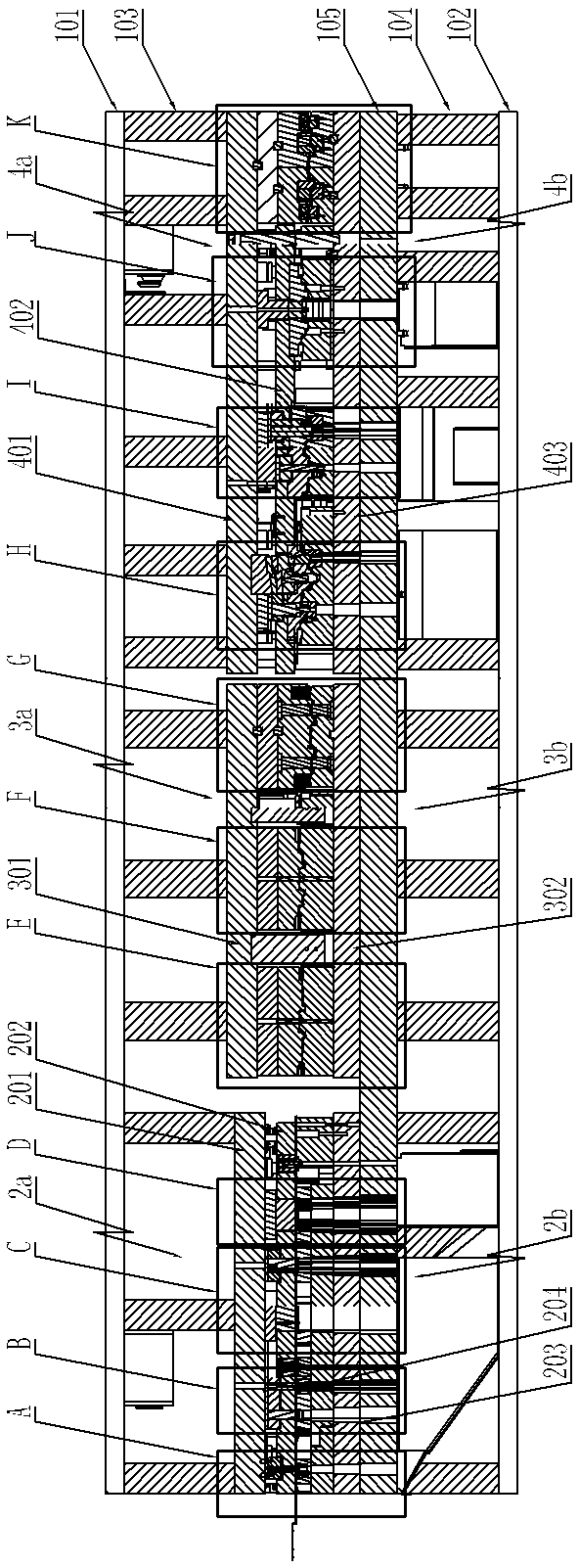

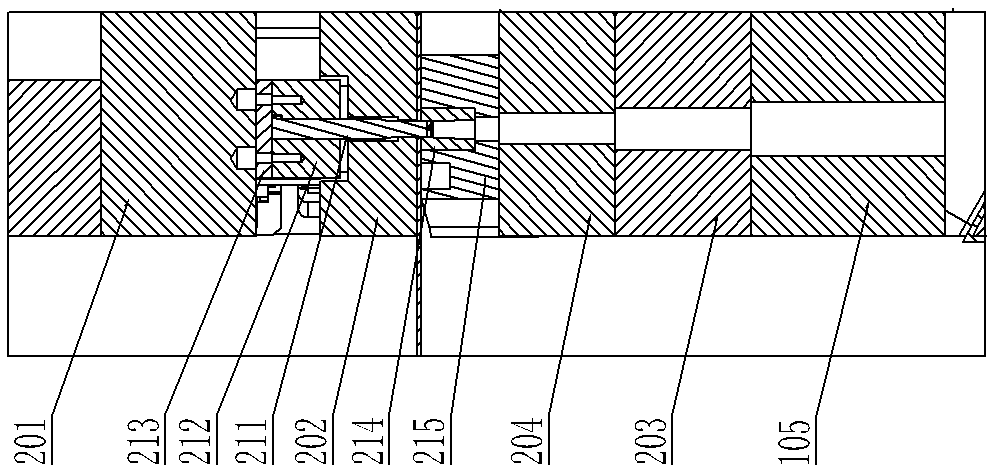

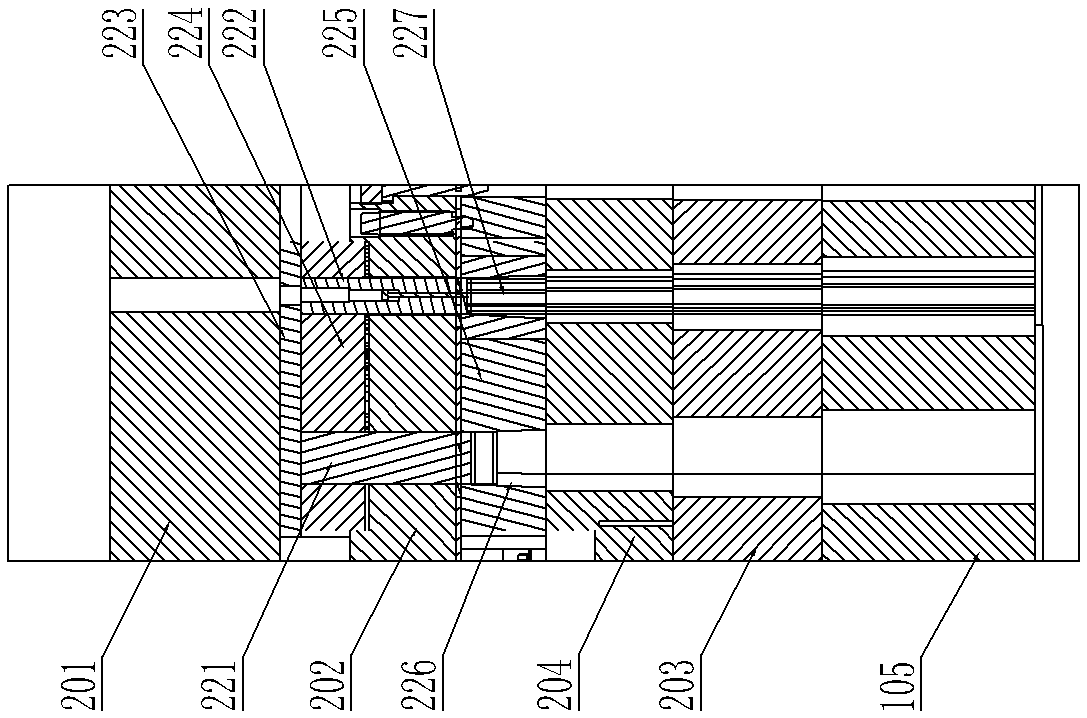

Vacuum circuit-breaker

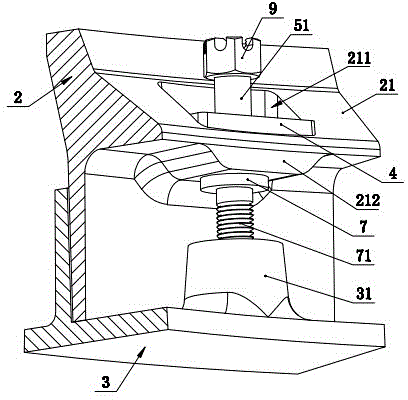

InactiveCN101383244ASimple adjustment processChange final installation heightHigh-tension/heavy-dress switchesAir-break switchesFastenerHigh pressure

The invention belongs to a high-voltage transmission and distribution device which relates to a vacuum breaker. The vacuum breaker comprises a vacuum explosion chamber, the upper end of the vacuum explosion chamber is provided with a fixing electric conducting plate which is used for connecting a fixed contact in an electric conducting mode, the electric conducting plate is connected with an electric conducting bracket of the breaker, a moving contact which is arranged on the lower end of the vacuum explosion chamber is connected with a driving member through an insulation screw rod, the center of the electric conducting plate is provided with a threaded hole which is matched with a regulating block with external threads, and the regulating block and the upper end of the fixed contact of the vacuum explosion chamber are connected and fixed by a fastener. Because the regulating mode of the vacuum breaker is carried out on one end of the fixed contact, parts are relatively fewer in the position, and the operation space is larger, parts which need to be disassembled are fewer too, therefore, the regulating process is simple and convenient.

Owner:镇江大全智能电气有限公司

Cross arm for electric power circuit

InactiveCN104963543ASimple adjustment processReduce electric leakage accidentsTowersEngineeringTower

The invention provides a cross arm for an electric power circuit. According to the technical scheme, the cross arm comprises two cross arm bodies fixed to a tower. The two ends of the two cross arm bodies are fixedly provided with two longitudinal arm bodies. The cross arm is characterized in that the inner sides of the two cross arm bodies are each provided with a first clamping ring matched with the tower, the cross arm further comprises second clamping rings matched with the tower and located below the cross arm bodies and the longitudinal arm bodies, the bottoms of the two longitudinal arm bodies are each hinged to a pull rod, and the other ends of the pull rods are in sliding connection with the second clamping rings. By adjusting the cross arm, the cross arm is in the balanced state and can be firmly fixed to the tower, maintenance is performed by workers conveniently, and the electric leakage accident caused by the cross arm is reduced.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

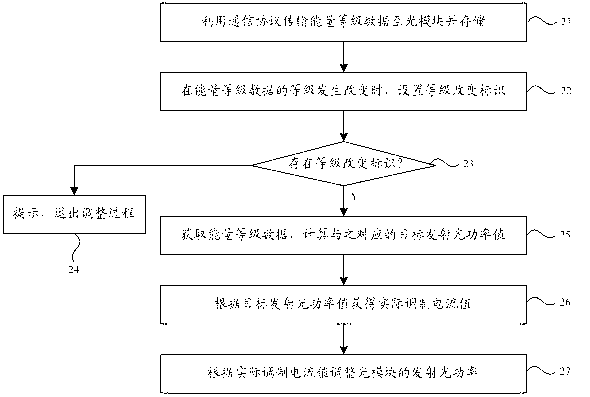

Method and device for adjusting emitted light power of optical module

ActiveCN102843191ASimple adjustment processHigh adjustment efficiency and accuracyElectromagnetic transmissionEnergy levelClosed loop

The invention discloses a method and a device for adjusting the emitted light power of an optical module. The method comprises the following steps of: (1) transmitting and storing energy level data related to the transmission distance of the optical module to the optical module by using a communication protocol; (2) acquiring the energy level data by the optical module, and calculating a target emitted light power value corresponding to the energy level data; (3) adjusting the modulation current in a closed loop way according to the target emitted light power value to acquire a corresponding actual modulation current value when the actual emitted light power value equals to the target emitted light power value; and (4) adjusting the emitted light power of the optical module according to the actual modulation current value. With the method and the device provided by the invention, the dynamic adjustment of the emitted light power of the optical module can be realized, the power consumption of the optical module is reduced, and the generality of the optical module is increased.

Owner:HISENSE BROADBAND MULTIMEDIA TECH

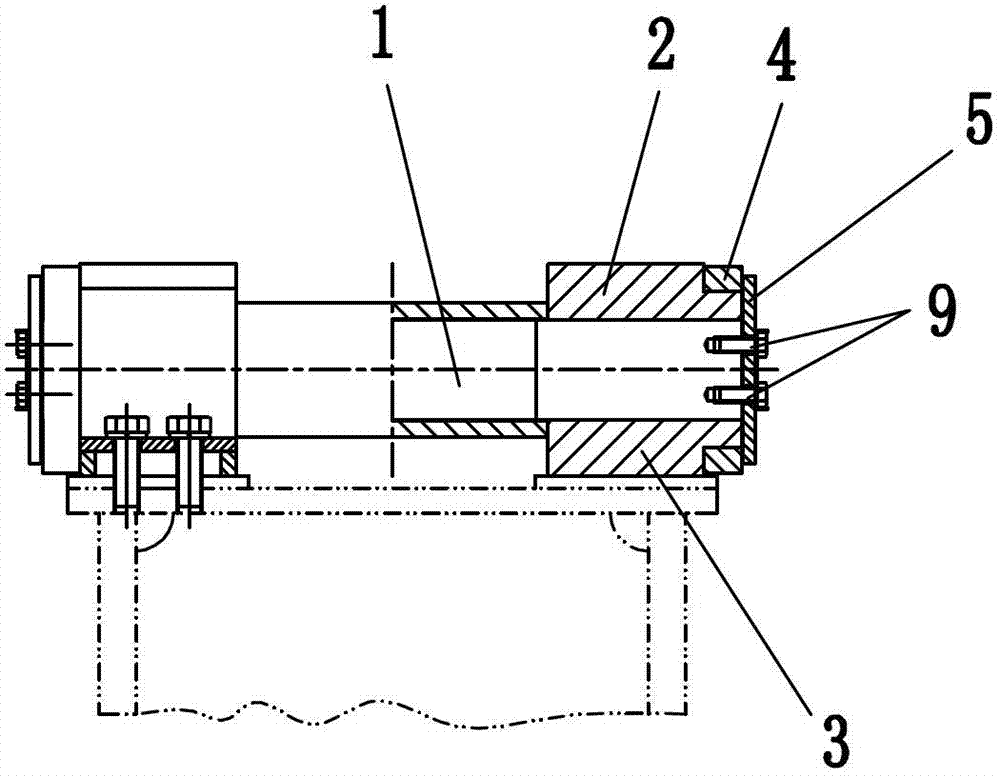

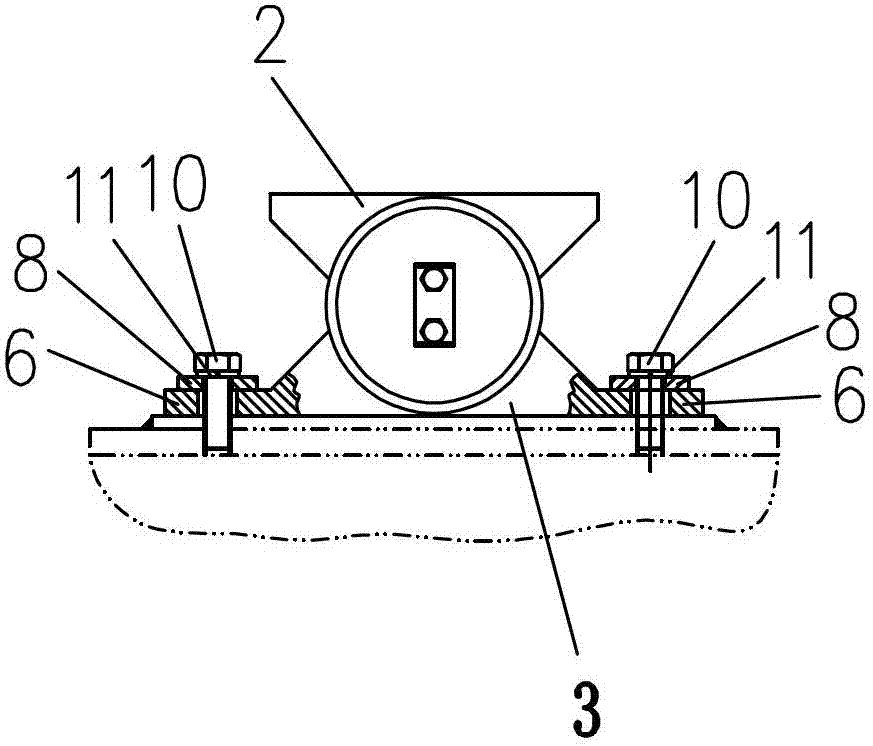

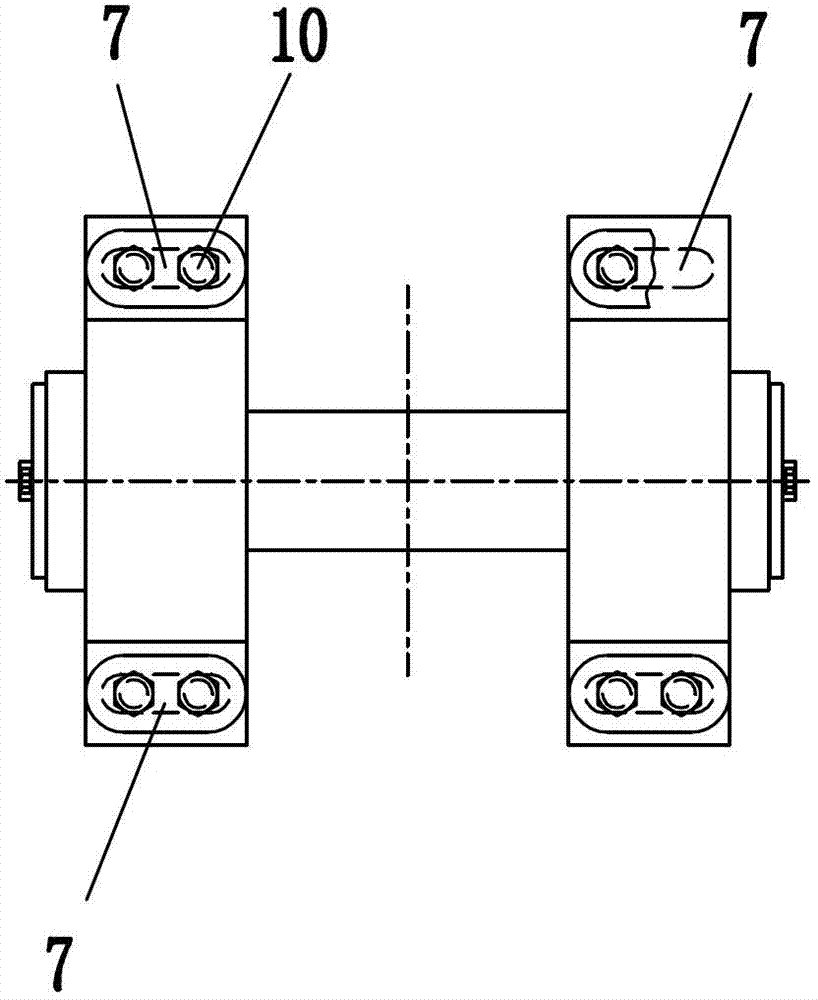

Hough hinge capable of adjusting level angle and lateral displacement of trolley

InactiveCN102829067APreventing rail gnawing problemsSimple adjustment processPivotal connectionsTravelling gearHinge angleThermal deformation

The invention discloses a hough hinge capable of adjusting a level angle and a lateral displacement of a trolley. The hough hinge comprises a hinge shaft. Outer parts of two ends of the hinge shaft are respectively provided with an upper hinged support and a lower hinged support. The hinge shaft is arranged in the upper hinged support and the lower hinged support. A lantern ring is sleeved on outer ends of the upper hinged support and the lower hinged support so that the upper hinged support and the lower hinged support are fixed with each other. Covers are fixed to two end surfaces of the hinge shaft respectively by bolts. The hough hinge is characterized in that two sides of the top of the upper hinged support and / or two sides of the bottom of the lower hinged support respectively and radially extend outward to form side plates; each one of the side plates is provided with a through-hole; bolts pass through the through-holes; the through-hole surrounds a bolt track; and positions of the bolts can be adjusted freely. The lower hinged support is fixed to the trolley by a bolt fixing method and thus new homotopic difference and corner difference are not produced by welding thermal deformation. A level angle and a lateral displacement of the trolley can be adjusted by adjusting positions of the bolts in the long through-holes of the lower hinged support so that rail gnawing is prevented.

Owner:ELEPHANT KING HEAVY IND

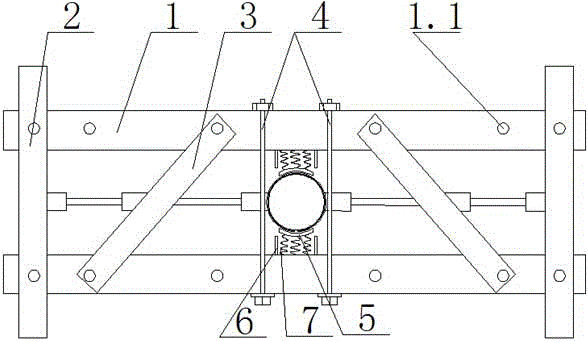

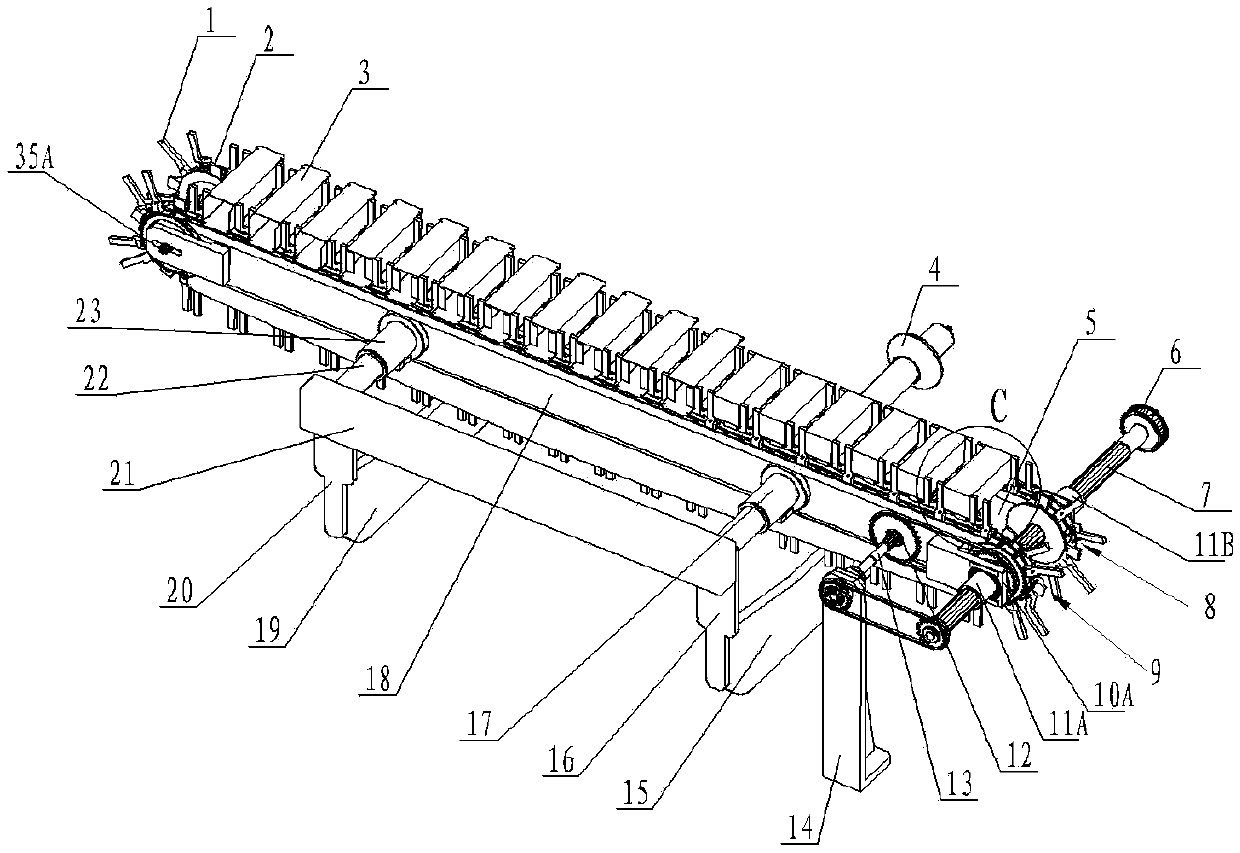

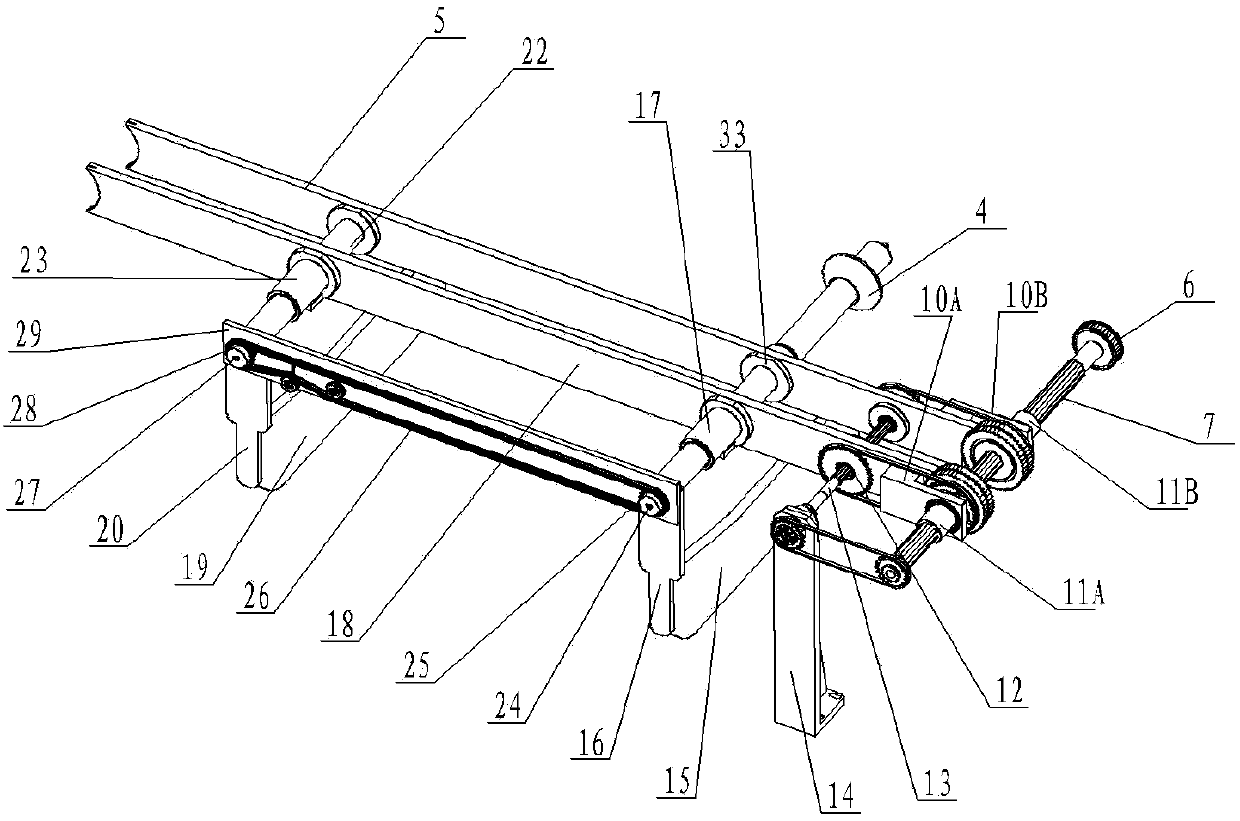

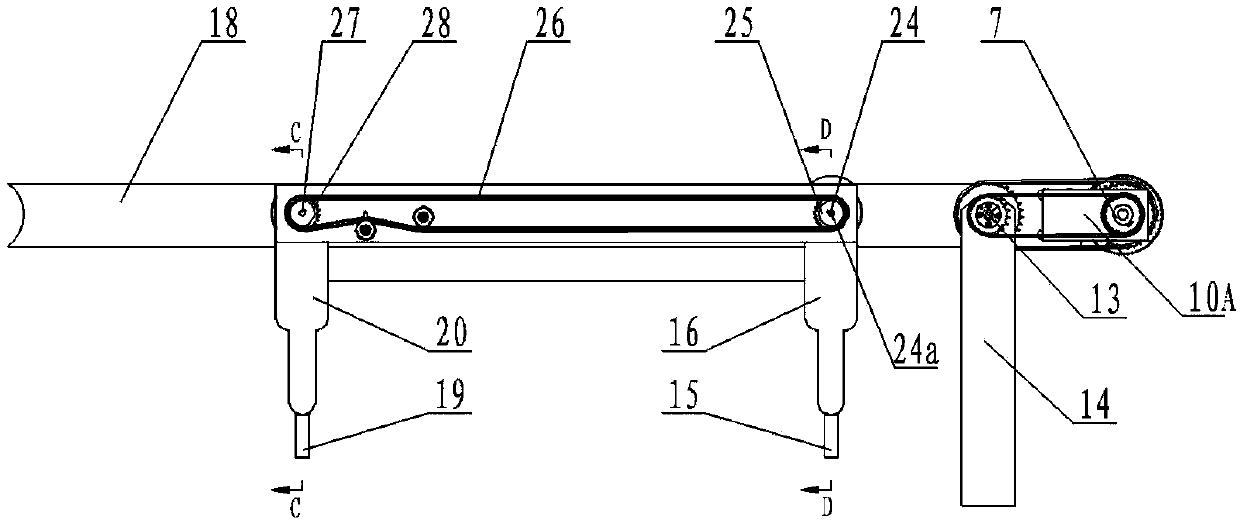

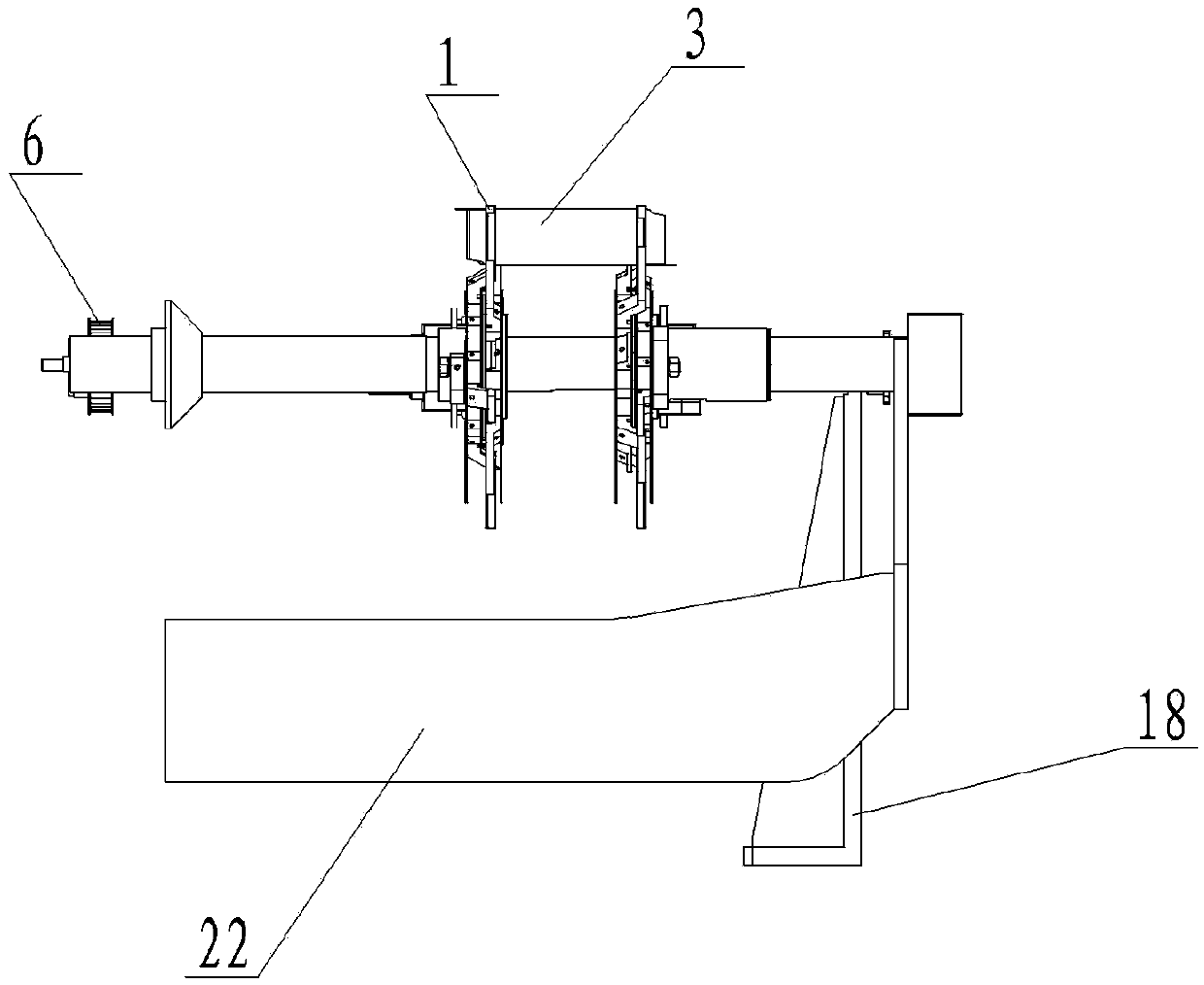

Carton continuous conveying adjustment device for multiple length specifications

PendingCN107892040AReduce labor intensity and timeSimple adjustment processPackagingWrenchEngineering

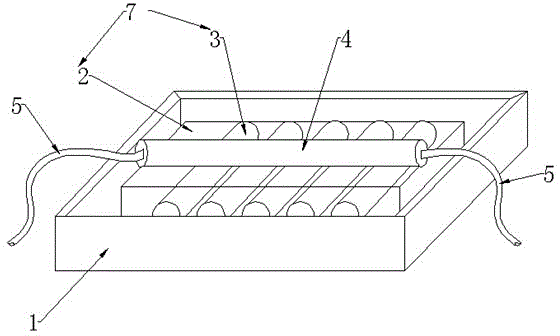

The invention discloses a carton continuous conveying adjustment device for multiple length specifications. The device comprises an inner side conveying module and an outer side conveying module; theinner side conveying module and the outer side conveying module are fixedly arranged on an inner side mounting plate and an outer side mounting plate; common spline main shafts are arranged at the right ends of the inner side conveying module and the outer side conveying module; the spline main shafts are driven through driving wheels, and provide power to the inner side conveying module and the outer side conveying module; front and back slide base sleeves are arranged on the outer side mounting plate; the spline main shafts are connected with the outer side mounting plate through an outer side connecting base and an outer side main shaft spline sleeve; spline secondary shafts are connected with the outer side mounting plate through secondary shaft spline sleeves; the main shaft spline sleeves and the secondary shaft spline sleeves can slide on the spline main shafts and secondary shafts; front and back fixed arms penetrate through the front and back slide base sleeves to fixedly connect to the inner side mounting plate and a fixed plate; internal hexagonal spanner adjusting holes are formed in outer ends of screw rod main shafts; and the purpose of continuously conveying carbonswith multiple length specifications is achieved through adjusting a distance between the outer side conveying module and the inner side conveying module.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

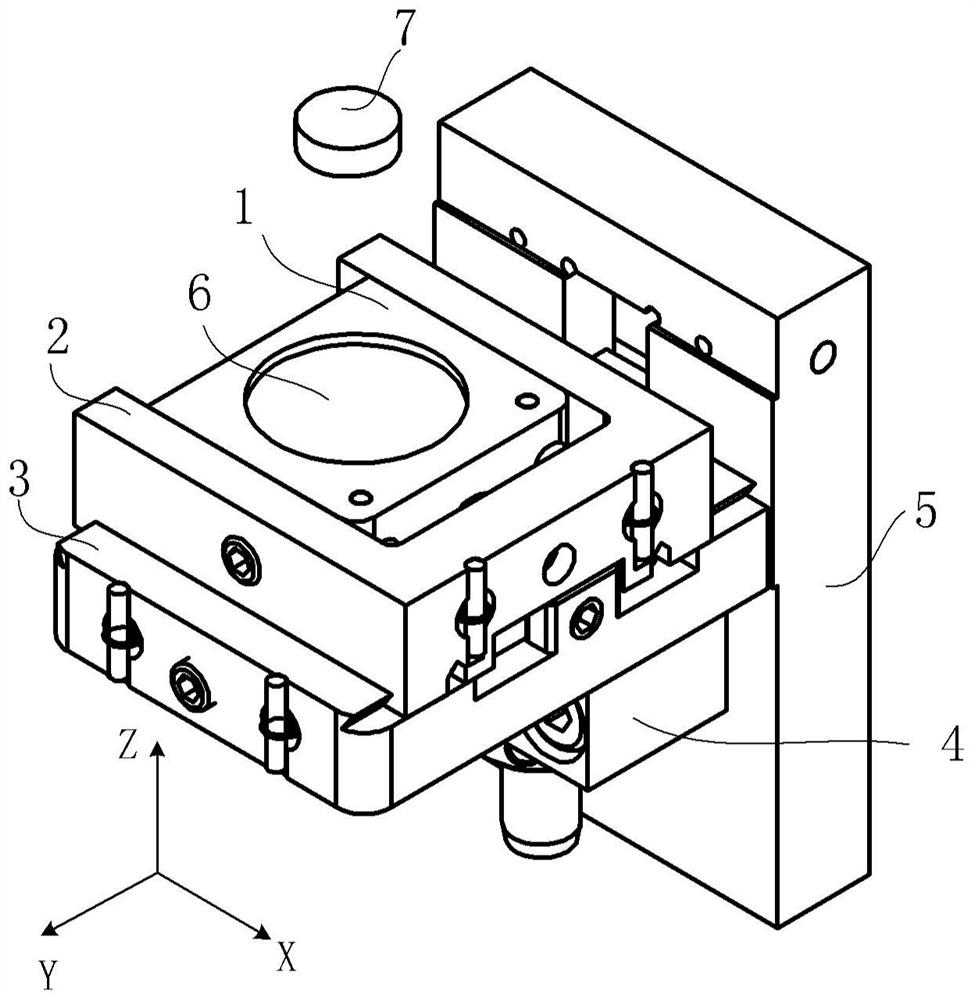

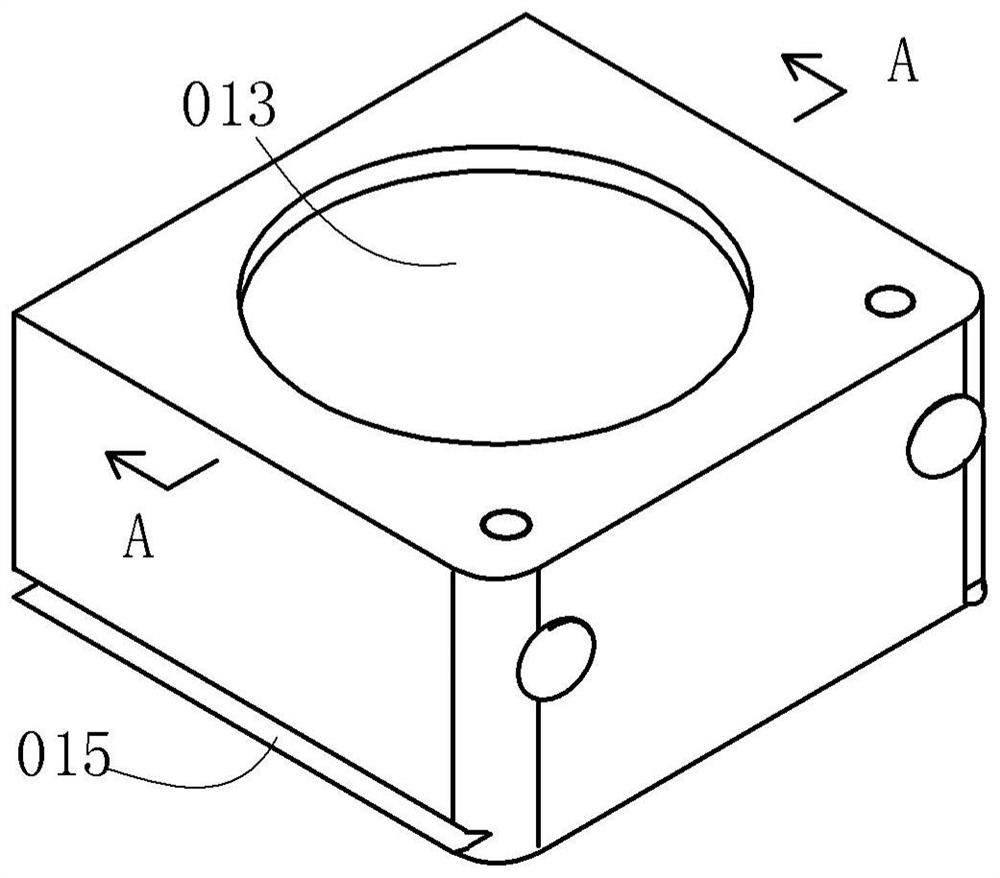

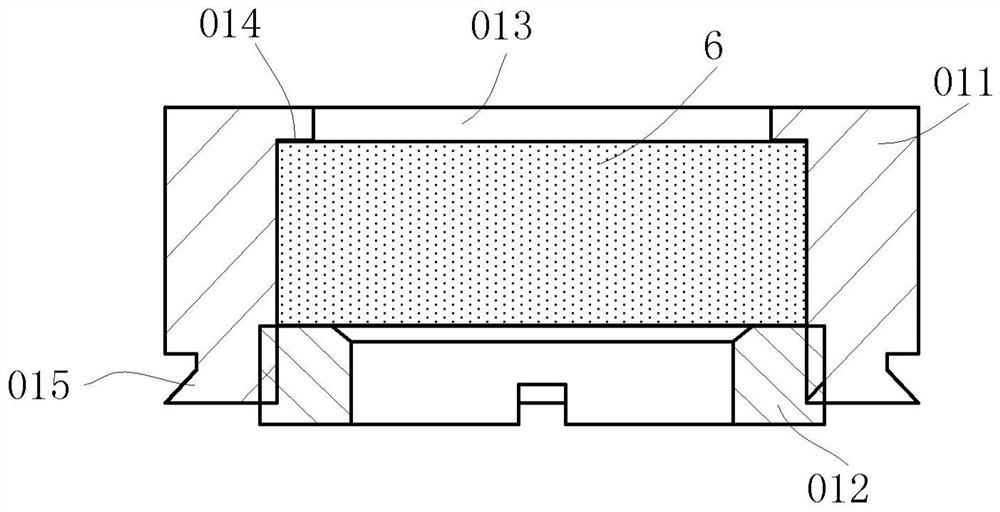

Platform camera for aircraft and aircraft using same

ActiveCN105573022AEasy to operateSimple adjustment processAircraft componentsCamera body detailsFlight vehicleGravitation

Owner:POWERVISION ROBOT INC

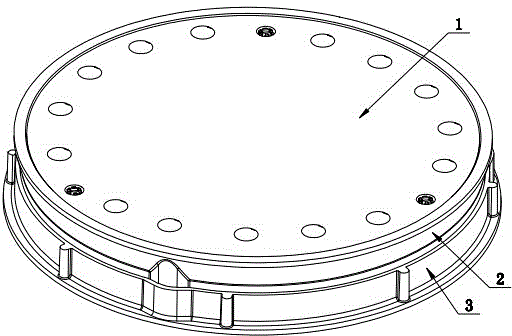

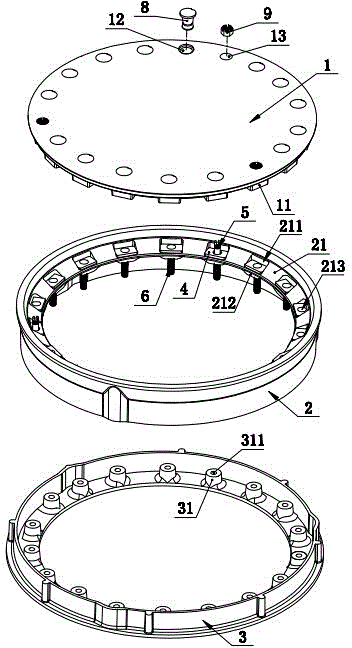

Anti-settlement adjustable well lid

ActiveCN104452820AReduce difficultySimple adjustment processArtificial islandsUnderwater structuresRoad surfaceMechanical engineering

The invention discloses an anti-settlement adjustable well lid which comprises a well lid body, a well seat and a base. The well seat is located between the well lid body and the base. The inner ring face of the well seat is provided with a protruding ring, the circumference of the upper end face of the protruding ring is evenly provided with a plurality of insertion-connecting grooves, and the lower end face of the well lid body are correspondingly provided with insertion-connecting protruding blocks which can form inserting-connection and matching with the insertion-connecting grooves in a one-to-one correspondence mode; the positions, below all the insertion-connecting grooves, of the base are each provided with a boss in a corresponding mode; an adjusting screw is arranged between each boss and each insertion-connecting groove, part of the screws are long screws, and the remaining screws are short screws. By the adoption of the structure, when the partial portion of the well lid is higher or lower than the surrounding road surface, people can adjust the adjusting bolts corresponding to the partial position of the well lid, and therefore the corresponding partial portion of the well lid can be flush with the surrounding road surface.

Owner:ZHEJIANG RESIN MUNICIPAL FACILITY

Method and structure for hoisting prefabricated external wallboards

PendingCN107842202ASimple adjustment processGuaranteed accuracyBuilding material handlingUpper floorBuilding construction

Owner:深圳市鹏城建筑集团有限公司 +1

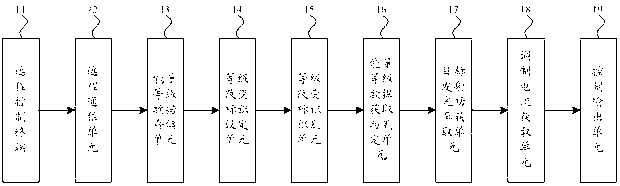

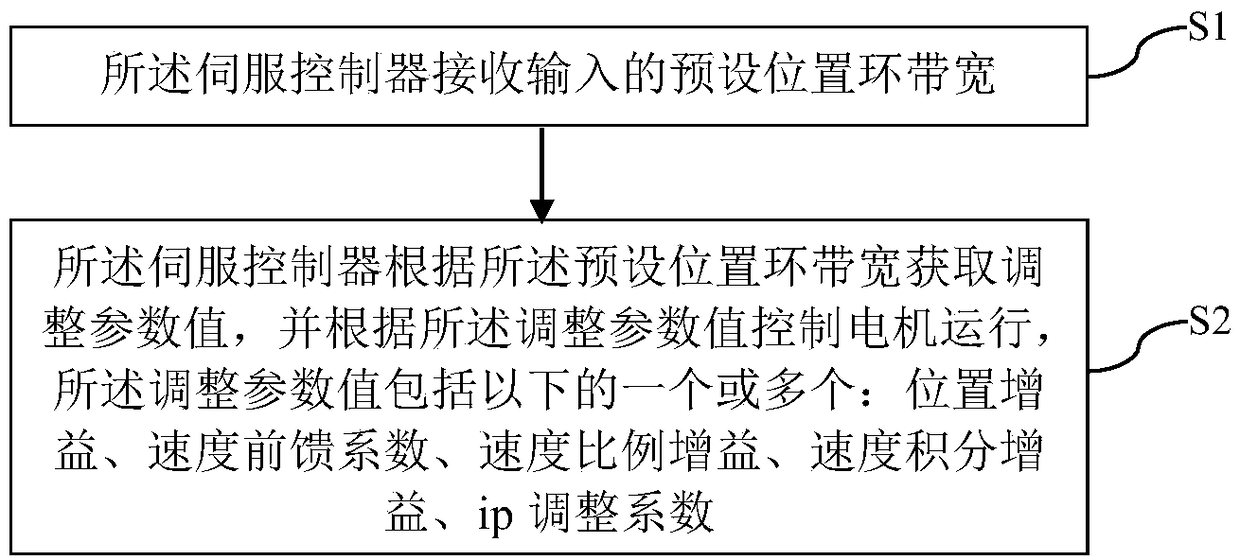

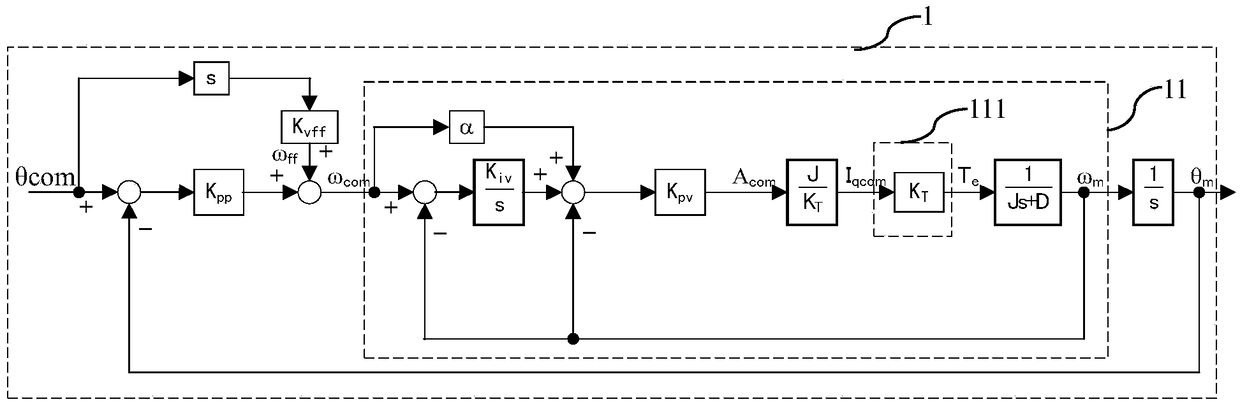

Parameter self-adjusting method and device and computer readable storage medium

ActiveCN109412495ASimple adjustment processShorten adjustment timeMotor parameters estimation/adaptationServo controlPosition loop

Embodiments of the invention provide a parameter self-adjusting method and device and a computer readable storage medium. The parameter self-adjusting method is used for realizing parameter adjustmentof servo controllers, and comprises the following steps of: receiving an input preset position loop bandwidth by the servo controller; and obtaining adjustment parameter values by the servo controller according to the preset position loop bandwidth and controlling a motor to be operated according to the adjustment parameter value, wherein the adjustment parameter values comprise one or more of aposition gain, a velocity feed-forward coefficient, a velocity proportional gain, a velocity integral gain and an ip adjustment coefficient. According to the method, related adjustment values such asthe position gain, the velocity feed-forward coefficient, the velocity proportional gain, the velocity integral gain and the ip adjustment coefficient are calculated according to theoretical derivation according to the preset position loop bandwidth, thereby simplifying the adjustment process and saving the adjustment time.

Owner:SUZHOU INOVANCE TECH CO LTD

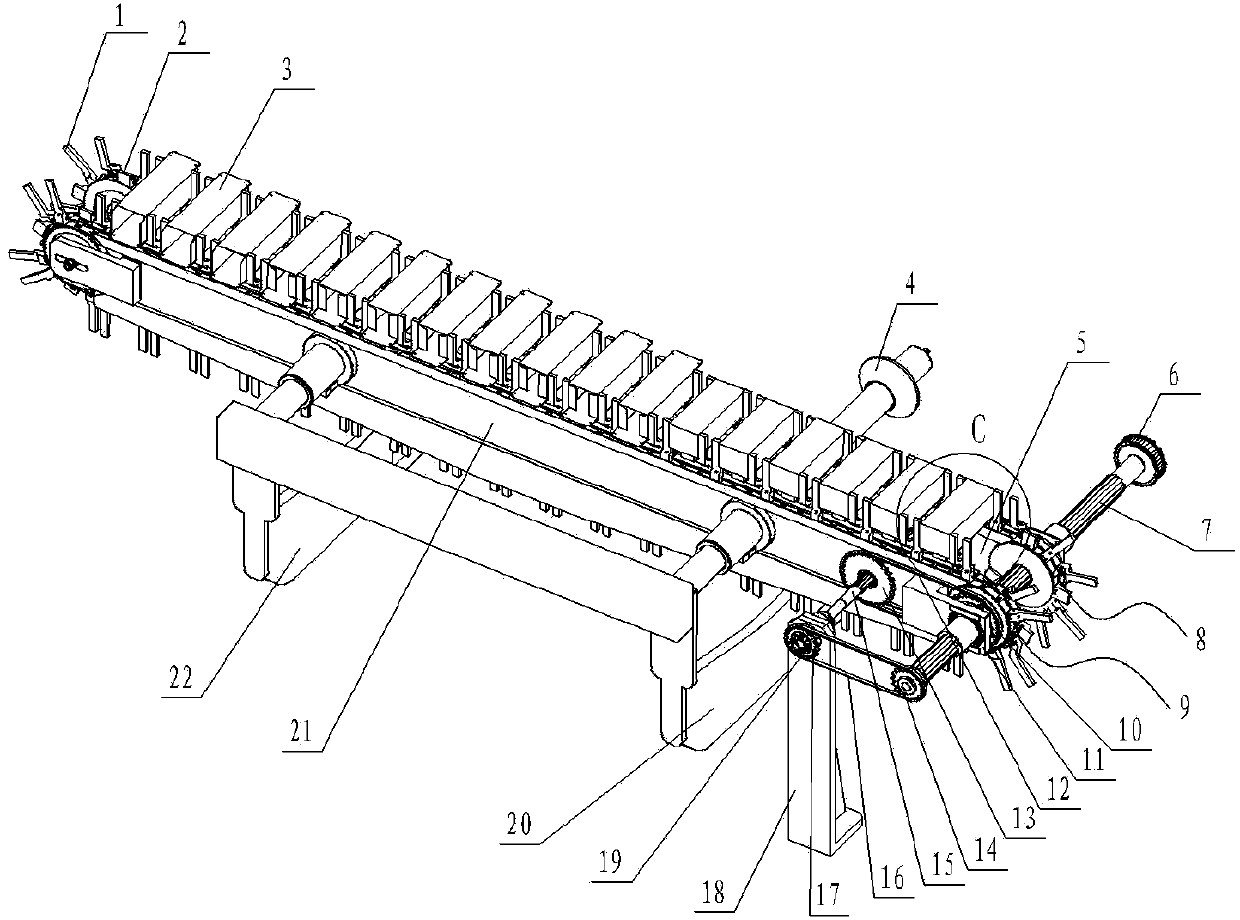

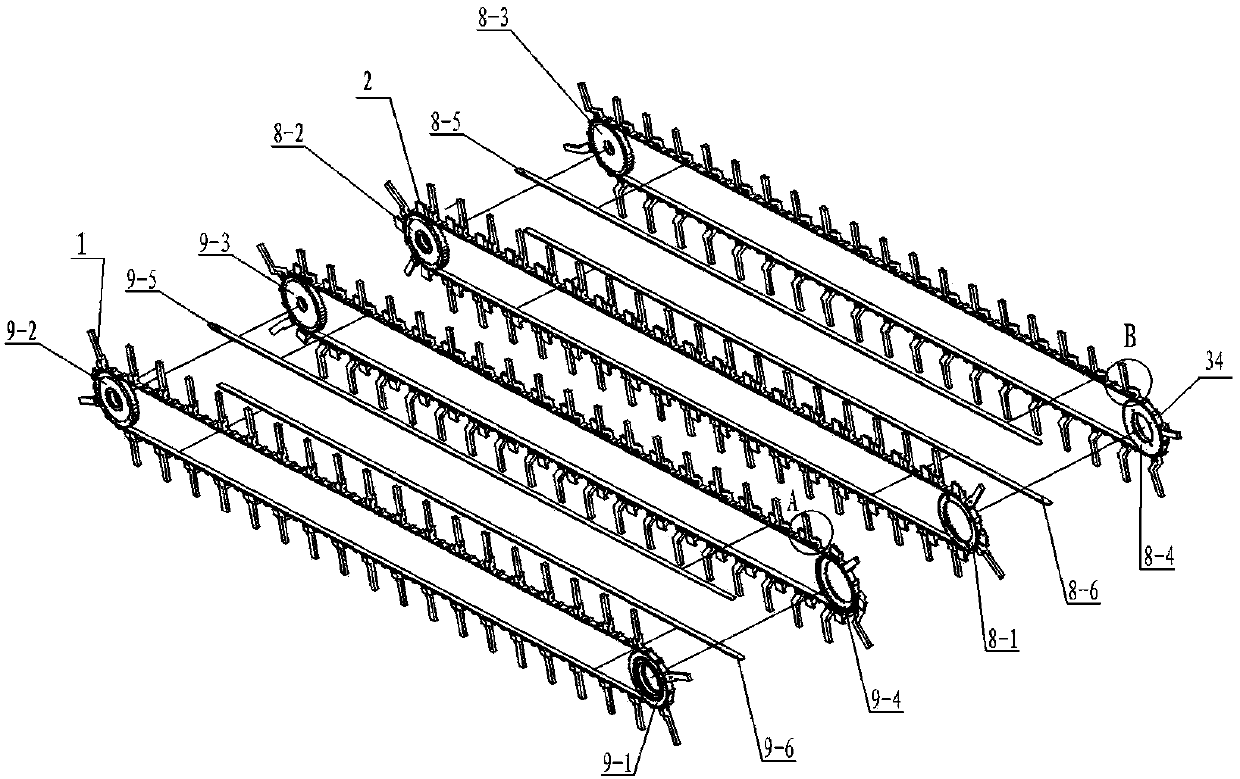

Carton continuous conveying and adjusting device adapted to various width specifications

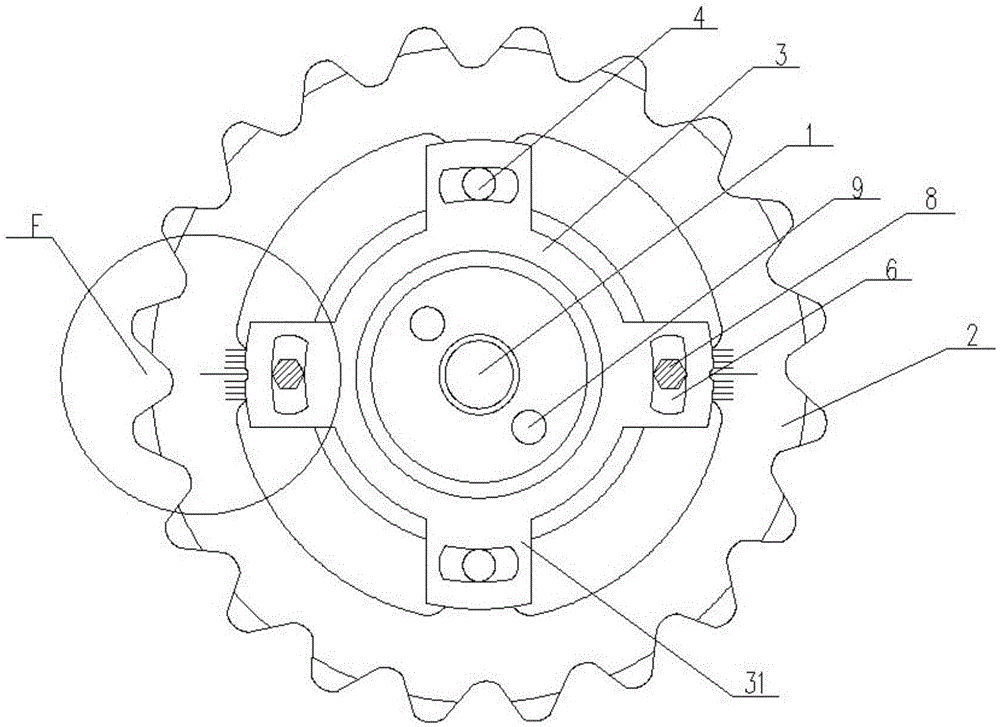

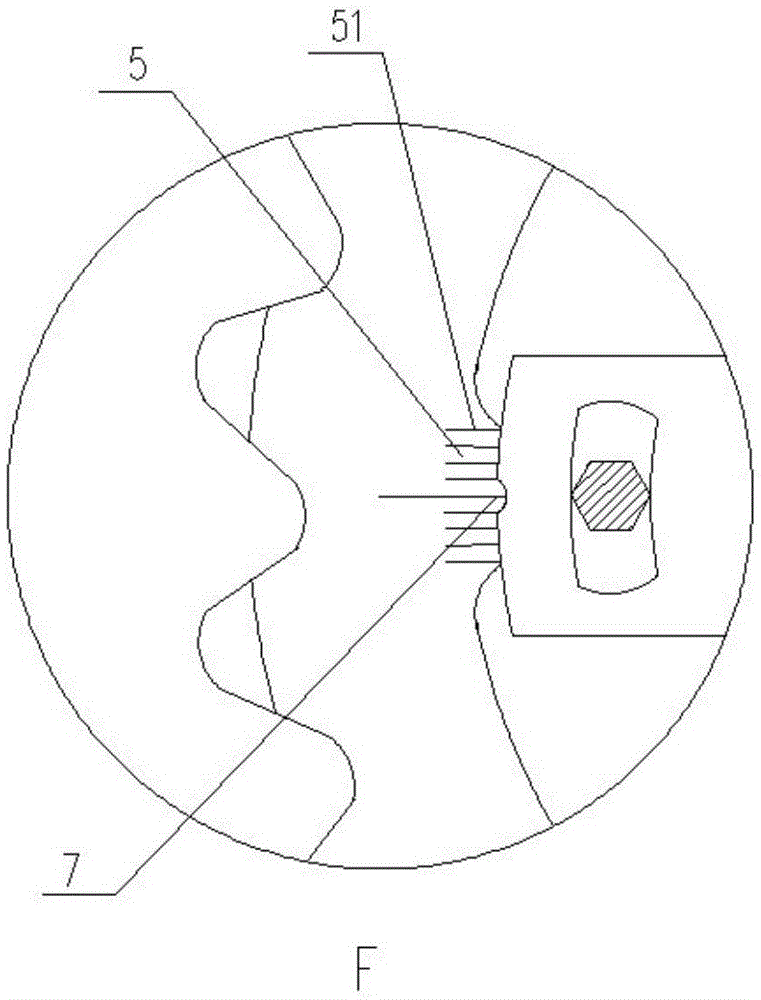

PendingCN107902169AReduce the time and labor intensity of changing specificationsSimple adjustment processPackagingPaper recyclingSide chainSprocket

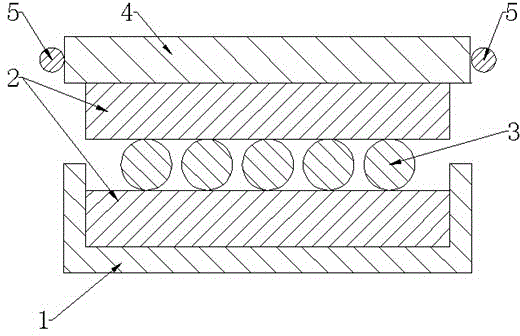

Disclosed is a carton continuous conveying and adjusting device adapted to various width specifications. The carton continuous conveying and adjusting device includes three sets of sprocket transmission mechanisms of the outer side sprocket transmission mechanism, the middle sprocket transmission mechanism and the inner side sprocket transmission mechanism. The three sets of sprocket transmissionmechanisms are connected with one another in sequence through a spline spindle and a spline auxiliary shaft which are arranged in parallel and at intervals. The outer side sprocket transmission mechanism provides power transmission for the spline spindle and the spline auxiliary shaft. The spline shaft transmits power to the spline auxiliary shaft through an outer side chain, a middle chain and aninner side chain. The outer side chain is arranged on a main sprocket and an outer side transition sprocket. The middle chain is arranged on an outer side connecting sprocket and a middle transitionsprocket. The inner side chain is arranged on an inner side connecting sprocket and an inner side transition sprocket. The middle sprocket transmission mechanism adjusts the spacing between two sets of first limiting parts connected to two synchronous belts with attachments correspondingly on an outer side conveying assembly, the inner side sprocket transmission mechanism adjusts the spacing between the two sets of first limiting parts fixed to the two synchronous belts with the attachments of an inner side conveying assembly, and finally the purposes of adjusting and adapting to the width ofdifferent specifications of cartons are achieved.

Owner:SHANGHAI TOFFLON SCI & TECH CO LTD

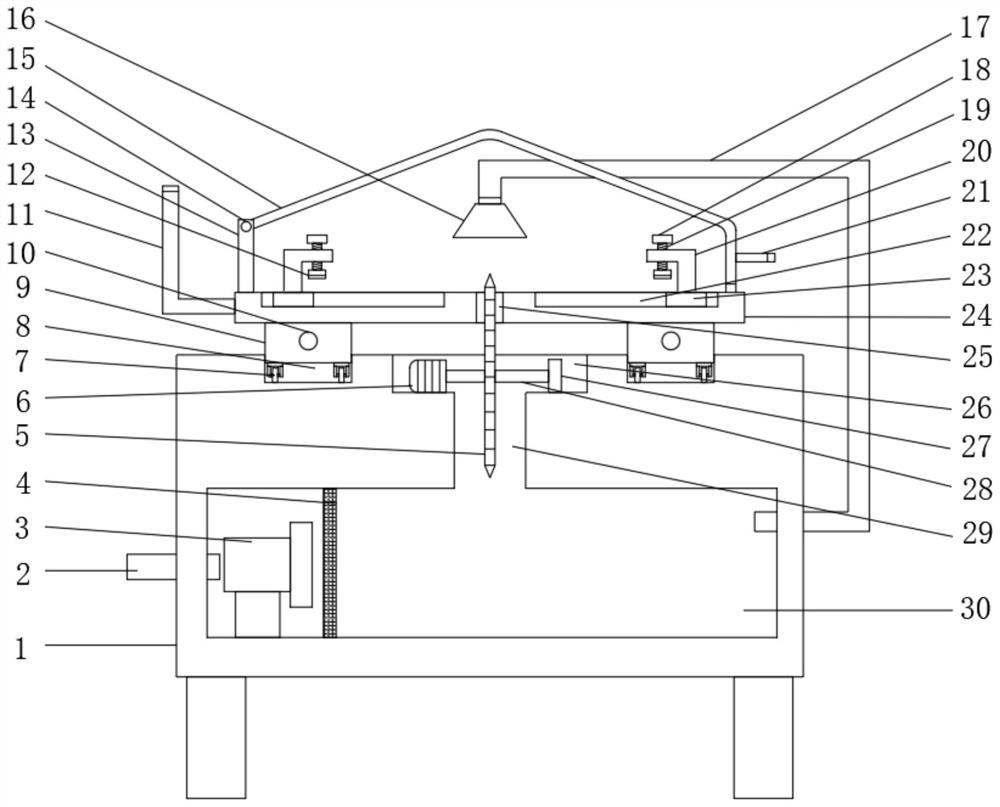

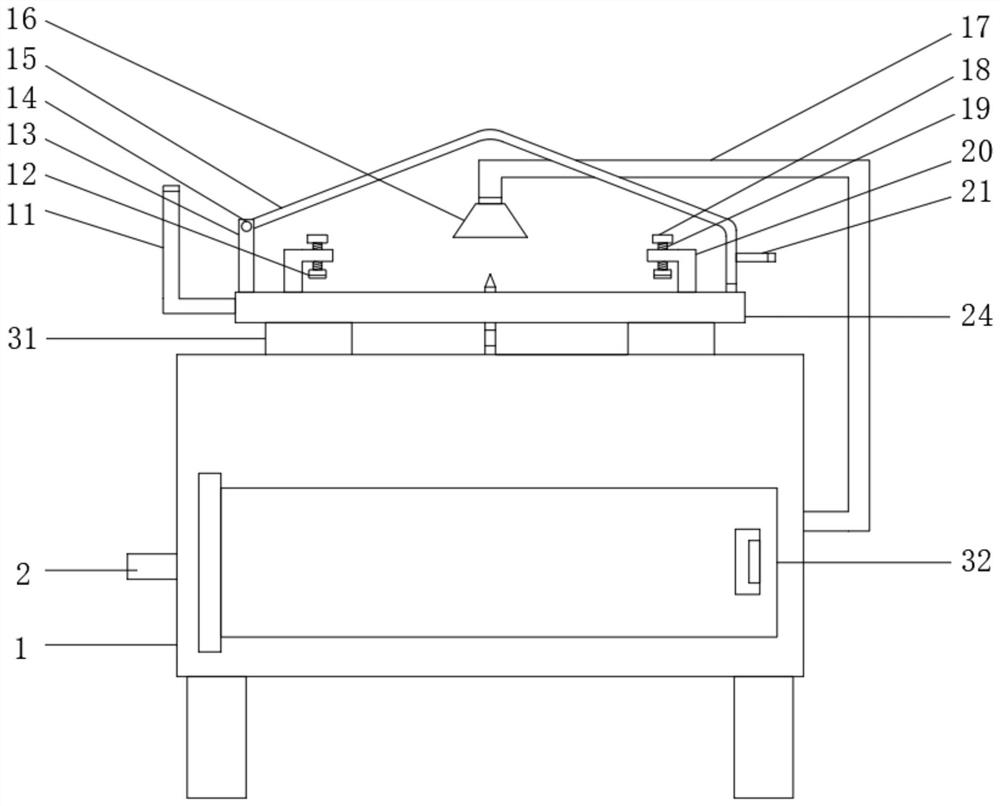

Cutting machine for panel furniture production

InactiveCN112192672ASimple adjustment processSave time and effortProfiling/shaping machinesBark-zones/chip/dust/waste removalElectric machineryScrap

The invention relates to the technical field of cutting machines, and discloses a cutting machine for panel furniture production. The cutting machine comprises a base, a groove and two first sliding grooves are formed in the top of the base, a connecting cavity and a scrap collecting cavity are formed inside the base, the connecting cavity is located above the scrap collecting cavity, the scrap collecting cavity, the connecting cavity and the groove communicate with one another, and an exhaust fan is fixedly installed at the bottom of the scrap collecting cavity. Through arrangement of a second sliding groove and a rectangular cavity, when plates of different sizes need to be cut, only fixing bases need to be moved to clamp the plates between the two pairs of fixing bases, then the platesare fixed and cut by screwing rotating caps, time and physical strength can be greatly saved while it is guaranteed that the plates of different sizes can be cut, and through threaded connection of alead screw and a first sliding block, when two second motors are started, the first sliding block automatically slides along the lead screw to cut the plates, the plates do not need to be pushed by hands, and the safety of operators is improved.

Owner:田佳豪

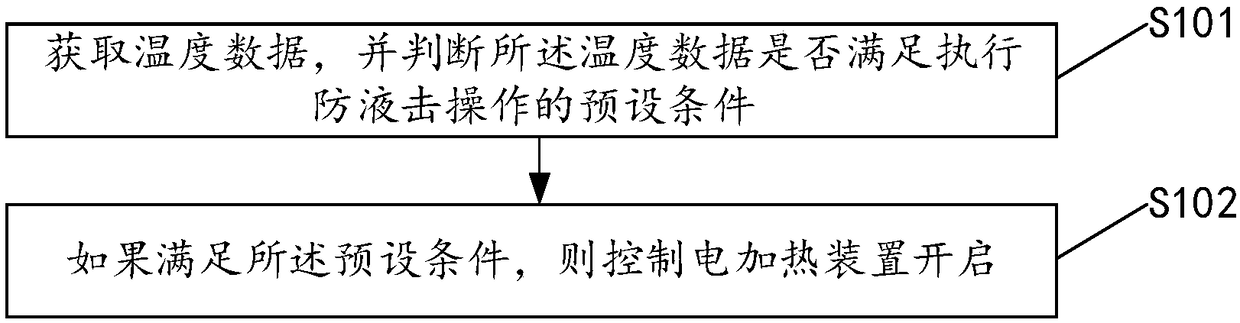

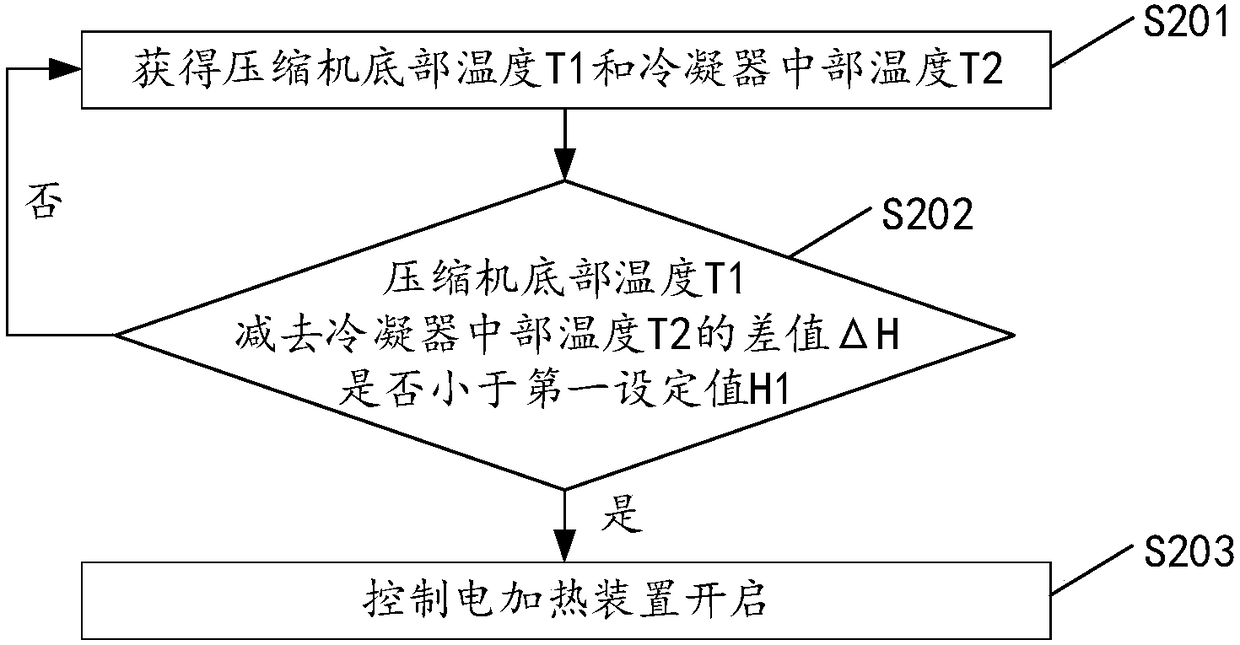

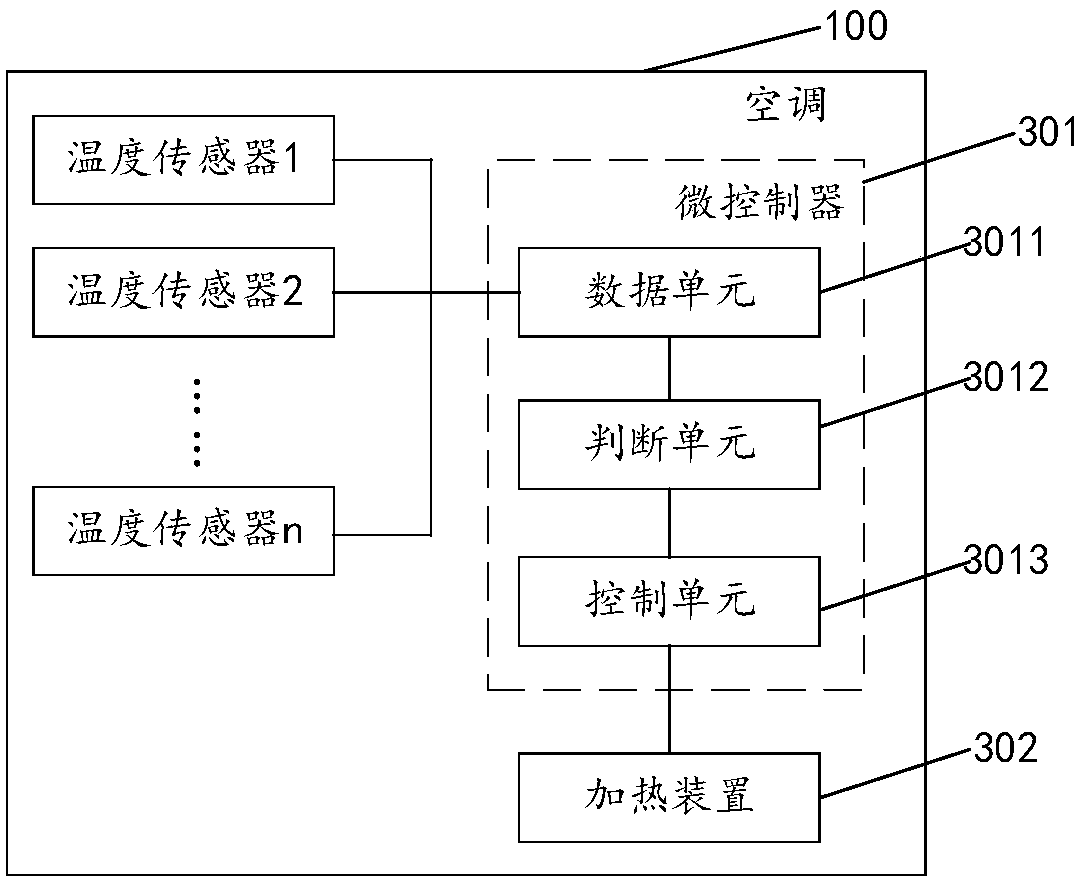

Control method for anti-liquid-impact of air conditioning system and air conditioner

InactiveCN108397868ASimple adjustment processPrevent liquid shockMechanical apparatusSpace heating and ventilation safety systemsElectric heatingFixed frequency

The invention discloses a control method for anti-liquid-impact of an air conditioning system, and belongs to the field of air conditioner control. The method comprises the steps that temperature dataare acquired, whether the temperature data meet preset conditions for executing the anti-liquid-impact operation is judged; if the preset condition is met, an electric heating device is controlled tobe started. According to the embodiment of the control method for anti-liquid-impact of the air conditioning system and an air conditioner, whether the anti-liquid-impact operation needs to be carried out or not is determined according to the temperature data obtained in real time, when the anti-liquid-impact operation needs to be carried out, the electric heating device is started, the adjustingprocess is simple, and the liquid-impact of a compressor with fixed frequency can be effectively avoided in time. The invention further discloses the air conditioner.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

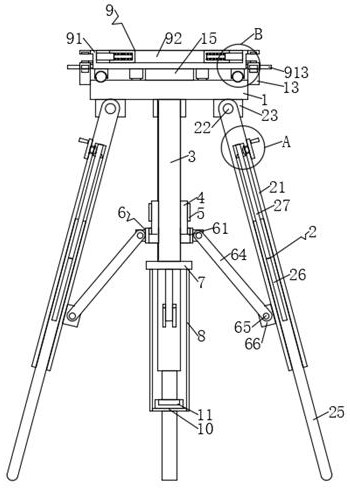

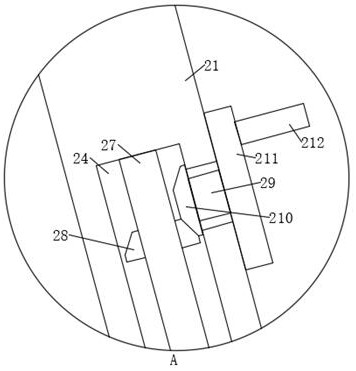

Mounting bracket for hydrological-engineering-environmental geological environment monitoring equipment

PendingCN113803591AAvoid leaningSimple adjustment processMeasurement apparatus componentsEarth material testingEnvironmental monitoringStructural engineering

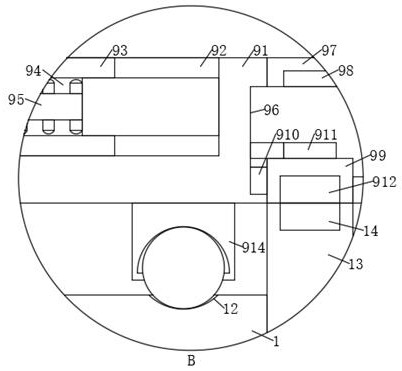

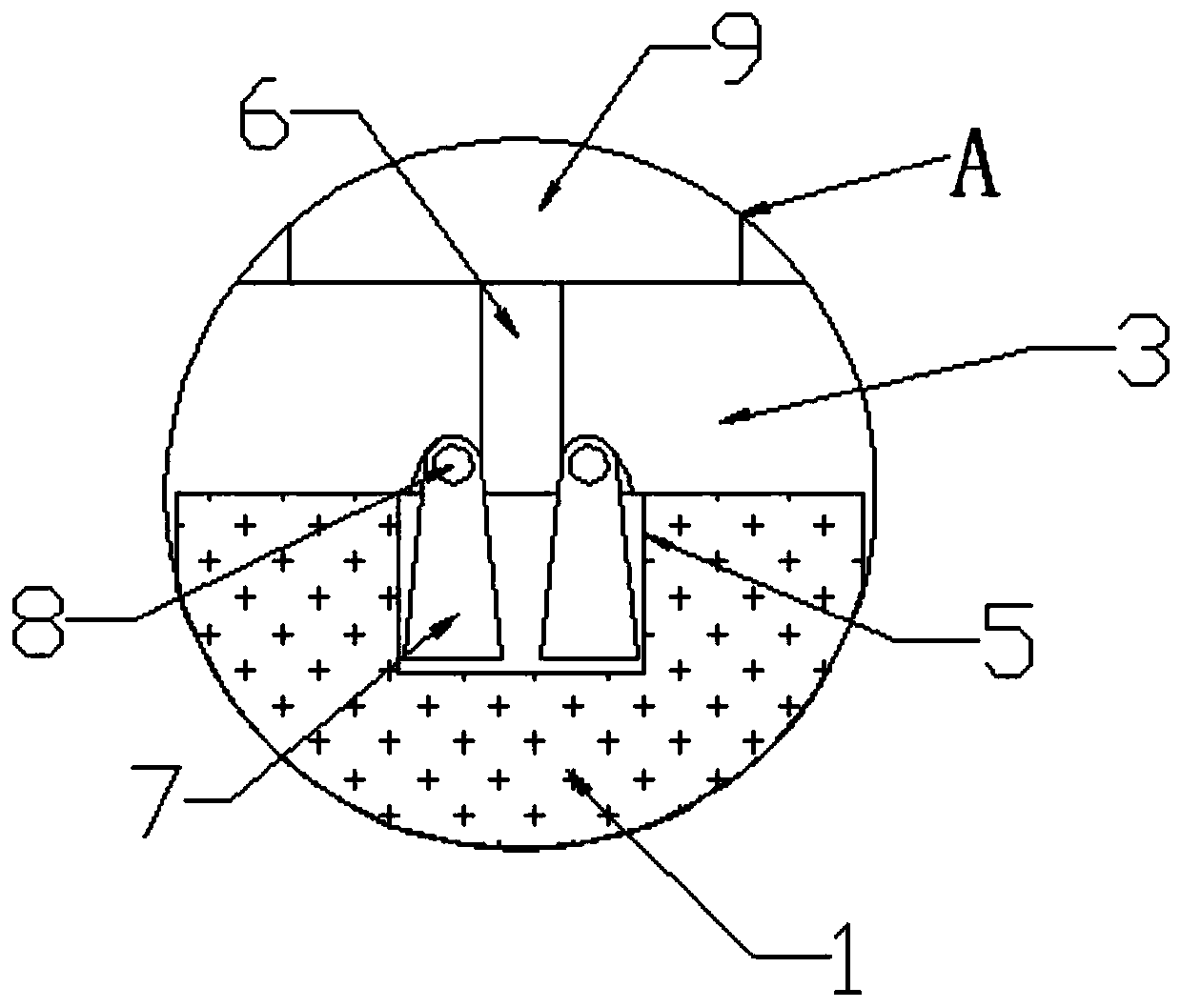

The invention relates to the field of hydrological-engineering-environmental geological environment monitoring, in particular to a mounting bracket for hydrological-engineering-environmental geological environment monitoring equipment, which comprises a carrier plate, wherein the carrier plate is of a circular structure, three supporting mechanisms are mounted at the edge of the lower end of the carrier plate at equal intervals, and a second screw is fixedly connected to the middle of the lower end of the carrier plate; and the circumferential outer wall of the middle part of the second screw is sleeved and in threaded connection with a screw sleeve. The upper end of the carrier plate is connected to a placing mechanism through a movable shaft, a sliding ring provided with a first magnet ring is mounted on a carrying disc of the placing mechanism, the first magnet ring corresponds to a second magnet ring mounted on the carrying plate; during use, monitoring equipment can be fixed in the placing groove in the carrying disc, then the carrying disc is rotated, so that the angle of the monitoring equipment is adjusted; Then the first magnet ring is attracted to the second magnet ring, the position of the carrying disc is fixed, then the alignment direction of the monitoring equipment is fixed, the monitoring equipment does not need to be moved in the process, and therefore, the situation that the monitoring equipment inclines is avoided.

Owner:山东省地质矿产勘查开发局第四地质大队

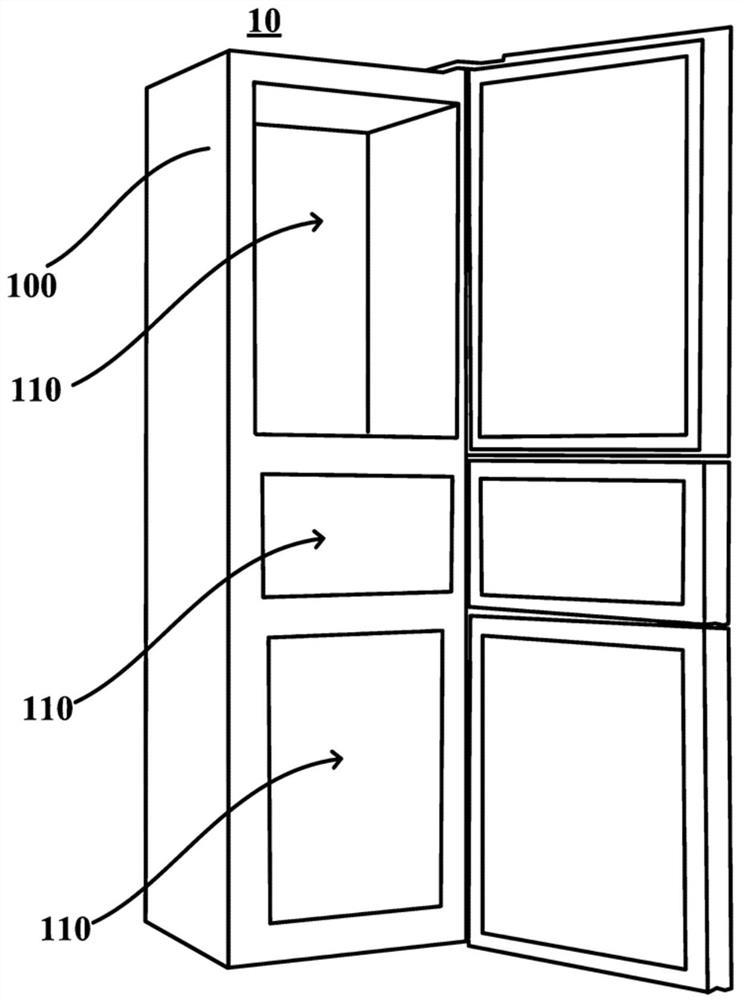

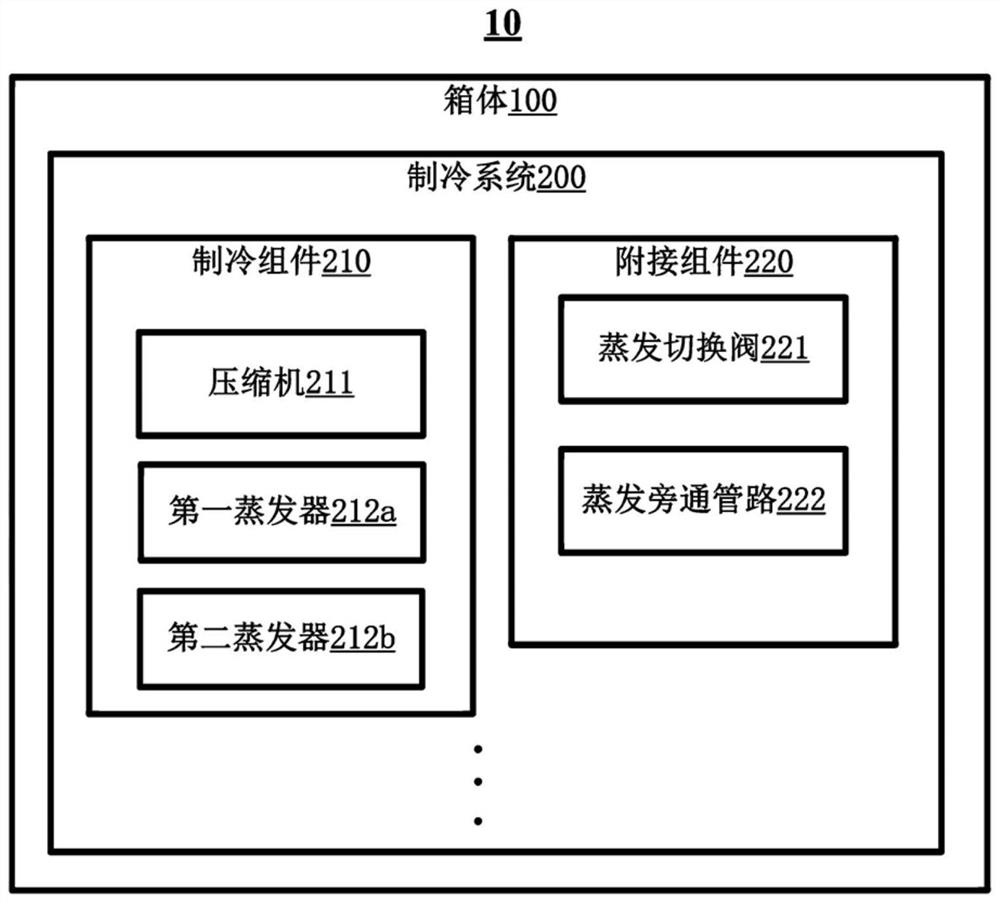

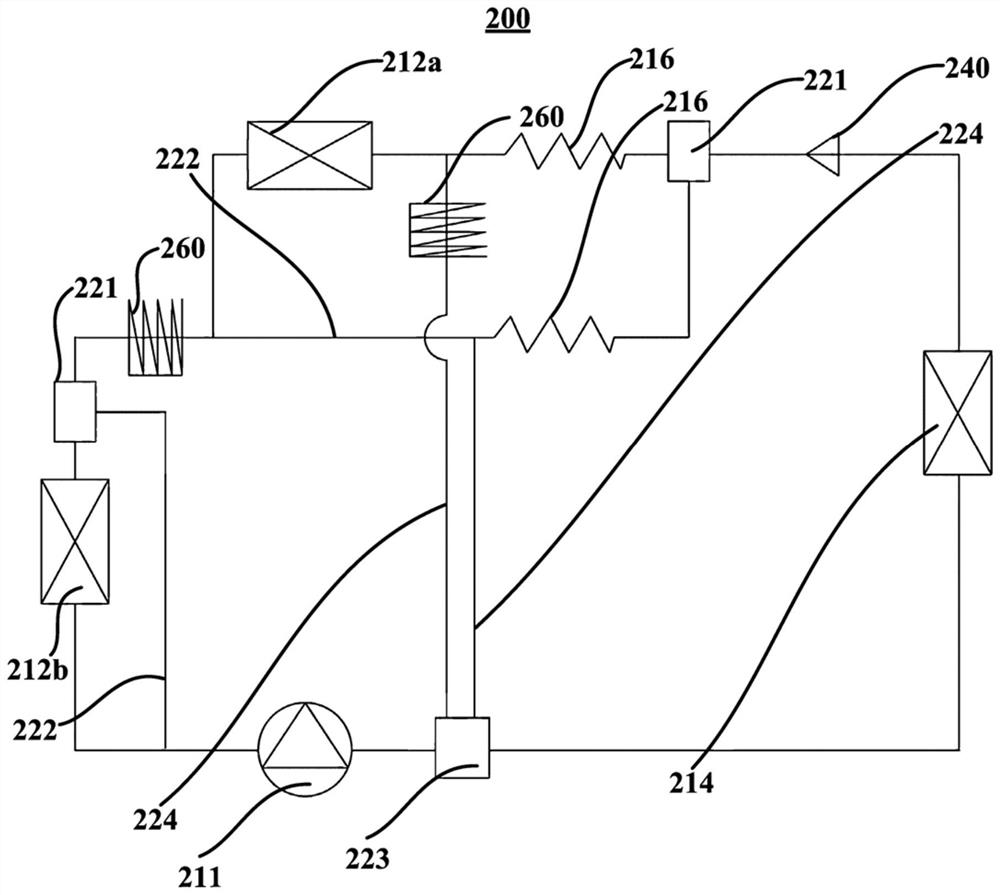

Refrigerating system for refrigerating and freezing device and refrigerating and freezing device with refrigerating system

PendingCN113834257AIncrease flexibilitySimple adjustment processLighting and heating apparatusDomestic refrigeratorsRefrigerantCool storage

The invention provides a refrigerating system for a refrigerating and freezing device and the refrigerating and freezing device with the refrigerating system. The refrigerating system comprises a refrigerating assembly and an attachment assembly, wherein the refrigerating assembly is provided with a compressor and a plurality of evaporators which form a refrigerating loop; the attachment assembly is connected to the refrigerating loop and provided with a plurality of evaporation switching valves arranged in one-to-one correspondence with the evaporators and a plurality of evaporation bypass pipelines arranged in one-to-one correspondence with the evaporators; each evaporation switching valve is provided with a valve port used for communicating with the corresponding evaporator and a valve port used for communicating with the corresponding evaporation bypass pipeline; and each evaporation switching valve is configured to adjust a refrigerant flowing path flowing through the evaporation switching valve by adjusting the opening and closing state of each valve port of the evaporation switching valve, so that the working state of the corresponding evaporator is adjusted. The structure of the refrigerating system is improved, the flowing paths of refrigerants are diversified through the attachment assembly, and therefore the working state of each evaporator can be independently adjusted conveniently.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

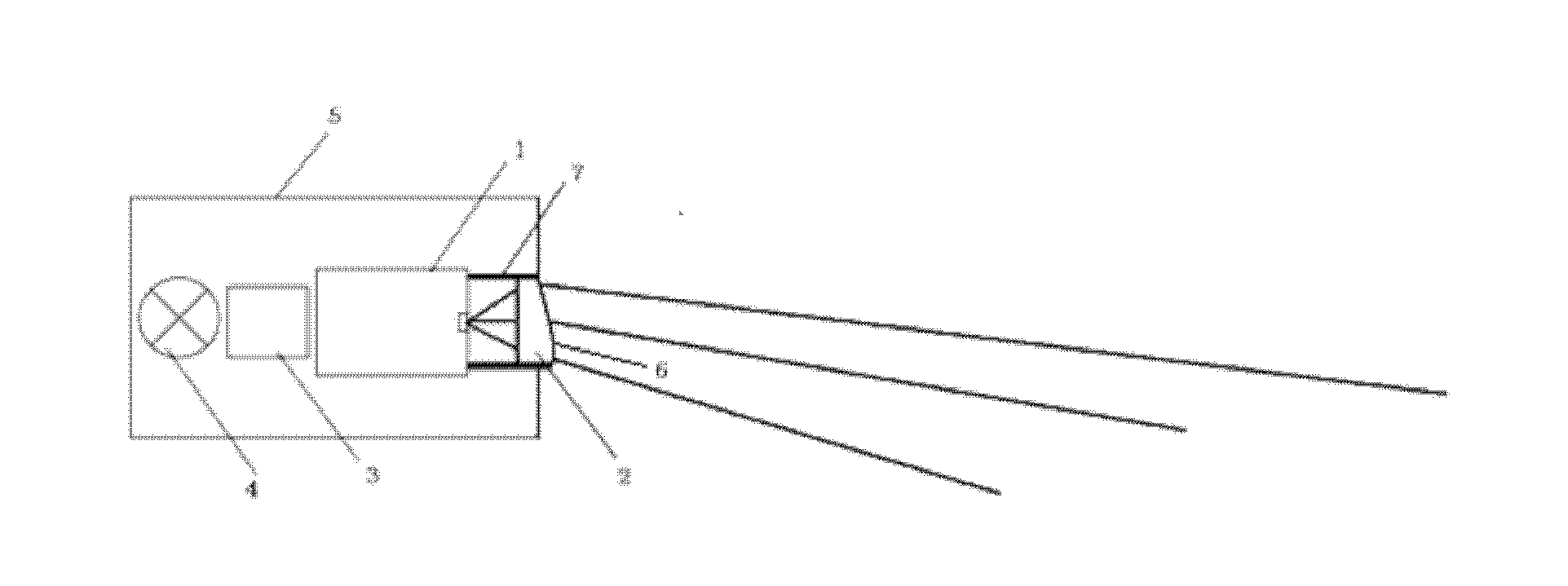

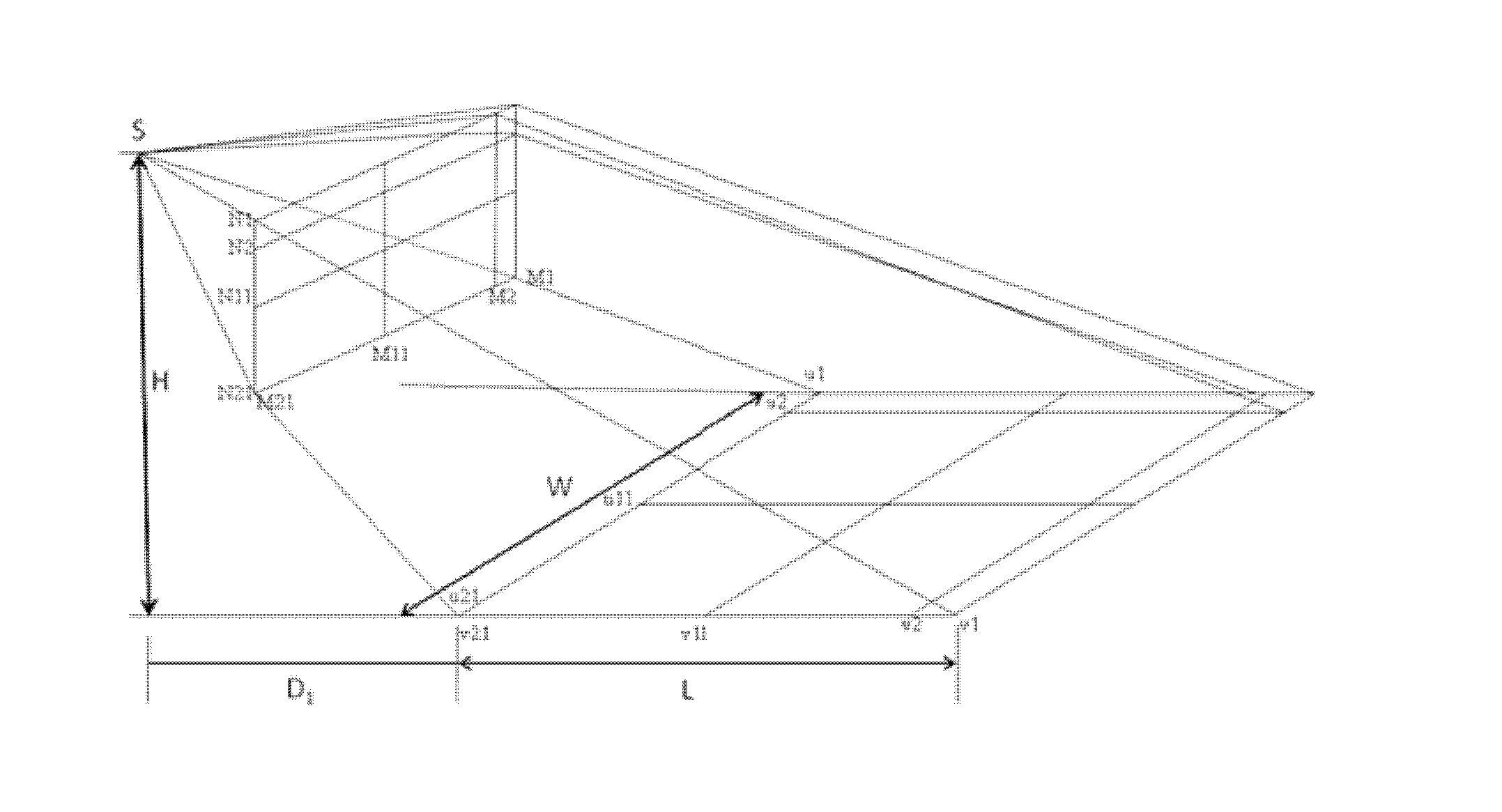

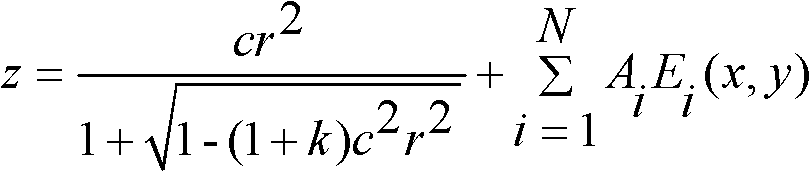

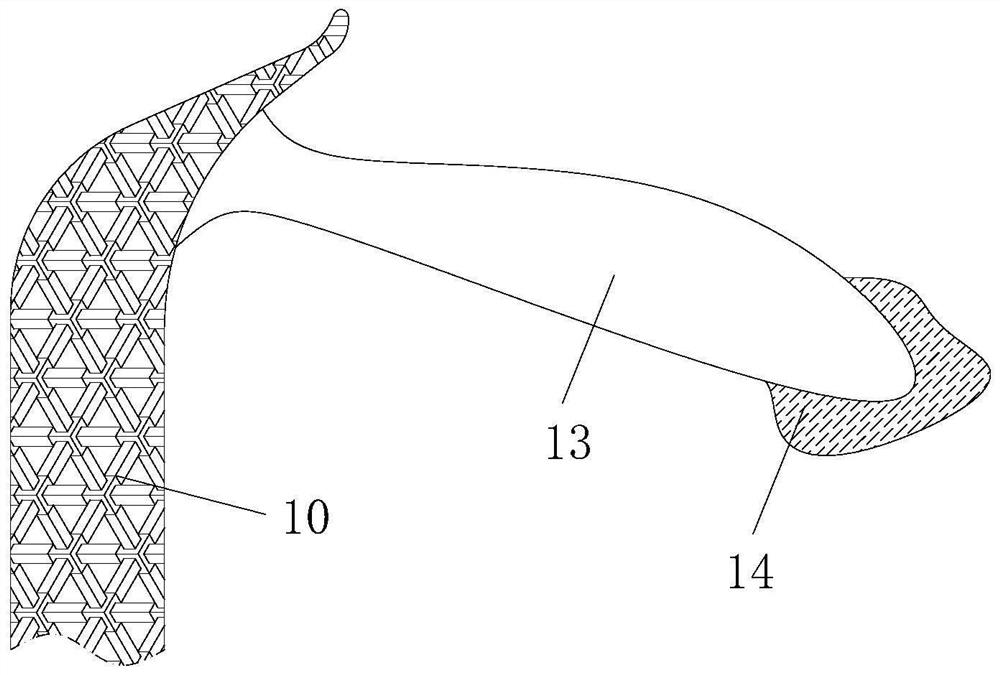

Infrared laser lamp device for uniformly illuminating road surface

An infrared laser lamp device for uniformly illuminating a road surface belongs to the field of semiconductor illumination and comprises a driving circuit board, a fan, a mechanically packaged shell, a semiconductor laser tube and a lens. Optical fibers are adhered on the surface of the semiconductor laser tube, after the angle of light emitted from the semiconductor laser tube is shaped by the optical fibers, fast axis light is compressed to form a rectangular light spot, wherein a fast axis diffusion angle of the rectangular light spot is 10 degrees while a slow axis diffusion angle of the rectangular light spot is 8 degrees, and after receiving the rectangular light spot, the lens uniformly projects the light to the ground in the distance. The lens with a free curved surface distributes energy of laser light beams, is designed according to an energy corresponding mode, and can guarantee that the energy is uniform in a road surface illumination range under the condition that an illuminator is placed horizontally. The laser illuminator with a free curved surface is simple in adjustment process, and only needs to be placed horizontally, a downward pitching angle does not need to be adjusted, the light beams can naturally deflect downwards to illuminate the road surface, adjustment time is shortened, and installation cost is lowered.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Constructional engineering basement pipeline laying casing pipe groove arrangement digging device

ActiveCN111531730AImprove slotting efficiencySimple adjustment processWorking accessoriesStone-like material working toolsEnvironmental geologyStructural engineering

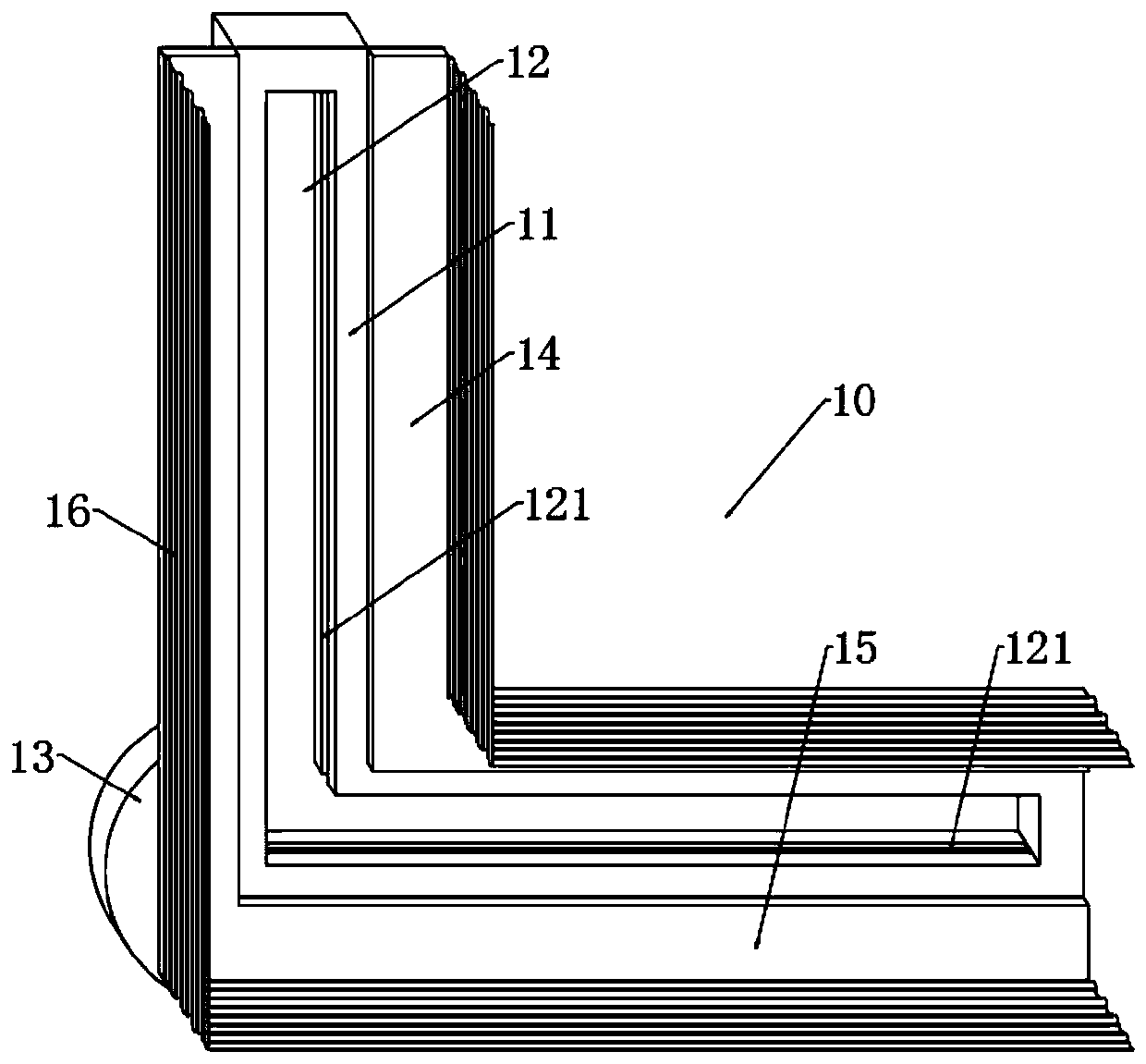

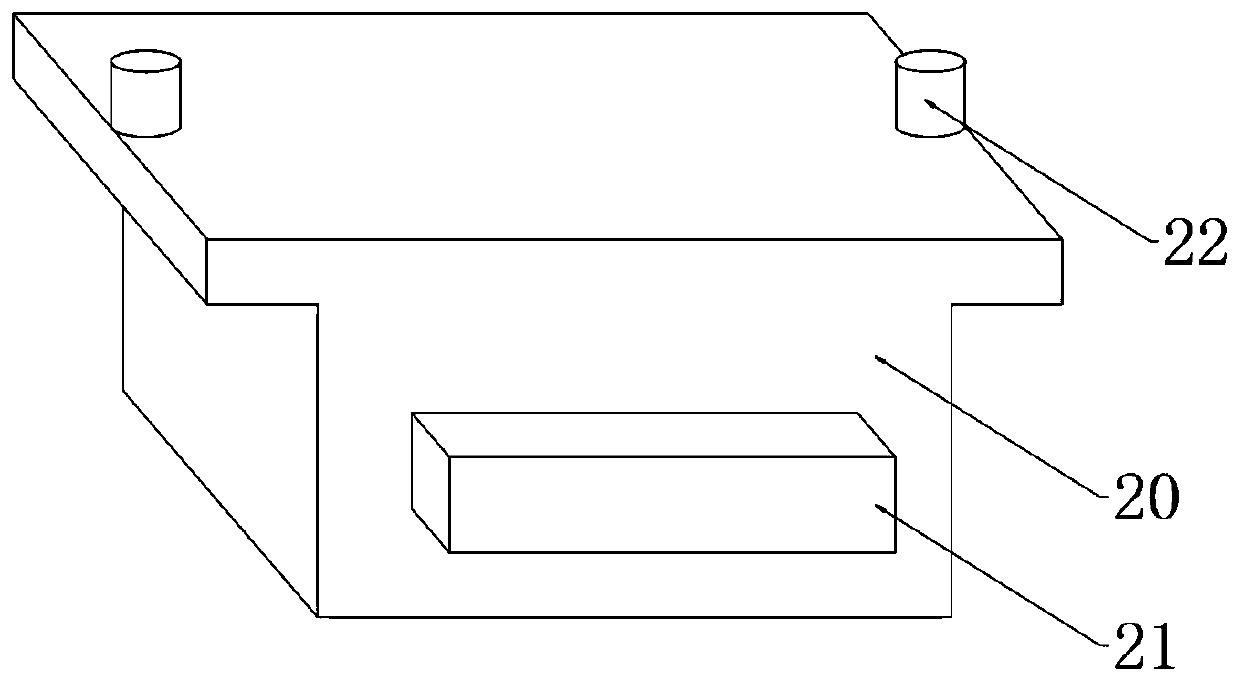

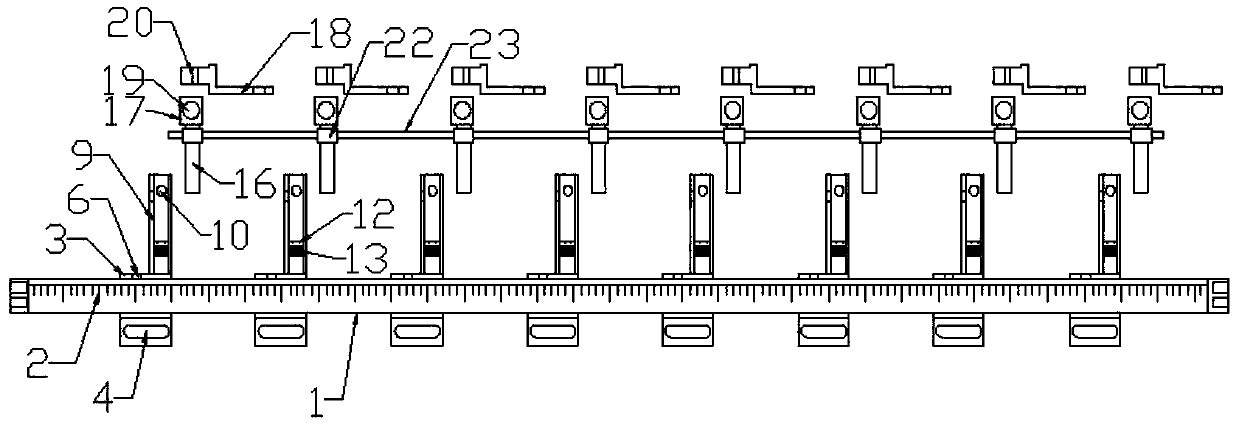

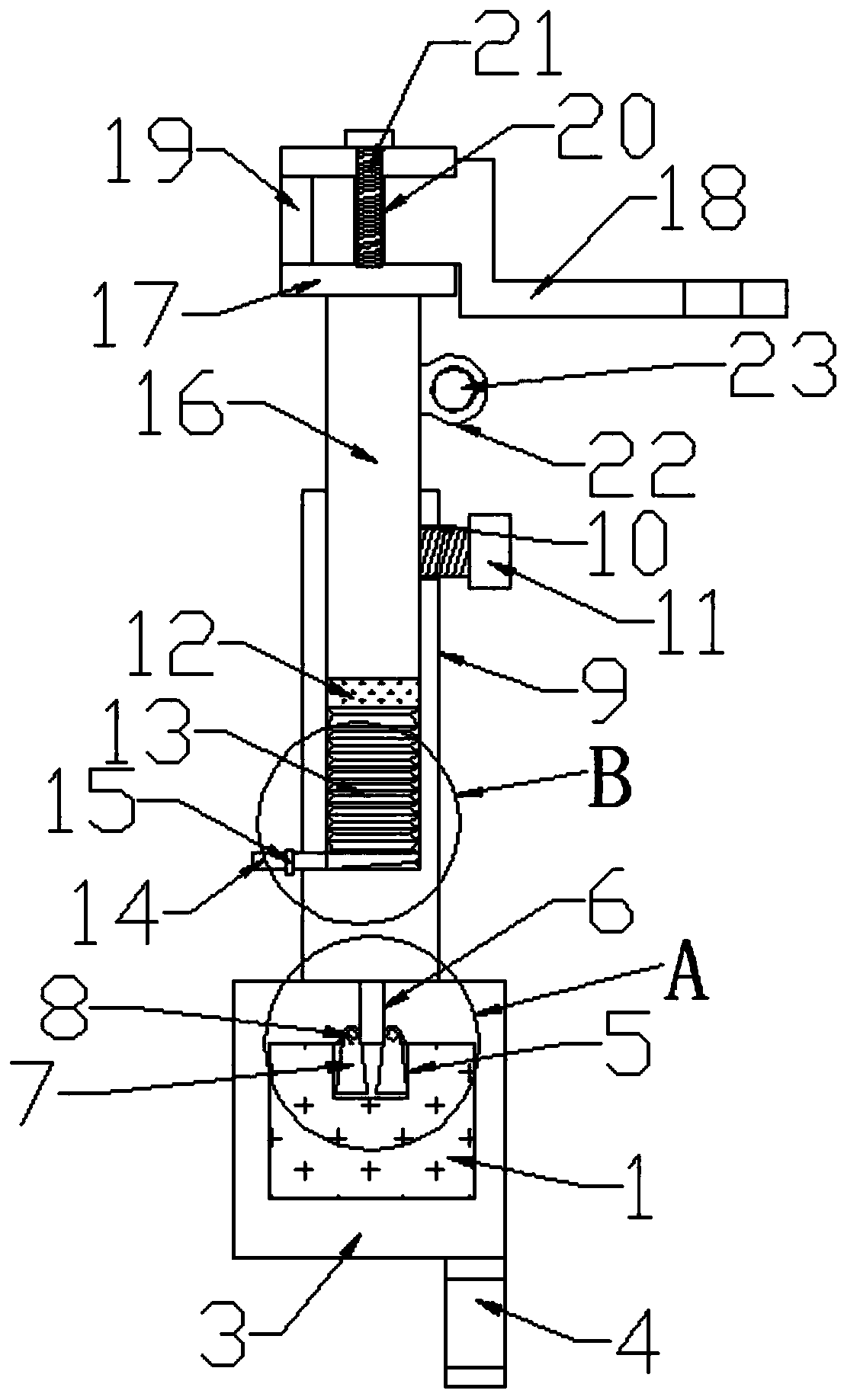

The invention relates to a constructional engineering basement pipeline laying casing pipe groove arrangement digging device, and the device comprises an L type guiding mechanism and two sets of moving blocks arranged in the L type guiding mechanism in sliding form, a link mechanism is arranged between the moving blocks, two ends of the link mechanism are respectively in hinge joint with the moving blocks, and back surfaces of the moving blocks are provided with detachable slotting mechanisms. In the constructional engineering basement pipeline laying casing pipe groove arrangement digging device, the two sets of moving blocks are connected together through the link mechanism, when one set of moving block drives the slotting mechanism to move, the other set of moving block moves with the previous set of moving block under action of the link mechanism, thus, simultaneous slotting of a horizontal groove and a vertical groove is realized, and slotting efficiency is improved. According tothe constructional engineering basement pipeline laying casing pipe groove arrangement digging device, by a guiding function of an L type through hole to the moving blocks, and the grooves formed by the slotting mechanism can be more straighter; and in the constructional engineering basement pipeline laying casing pipe groove arrangement digging device, by rotation of a rotating rod, a cutting disk of corresponding width can be rotated to a position of a transmission shaft, thus, grooves of different width can be formed, and an adjusting process of width of the cutting disk is simplified.

Owner:ANHUI HUALI CONSTR GRP

Bundling component of electronic yarn drawing equipment

PendingCN109629020AEasy to operateSimple adjustment processNew-spun product collectionYarnEngineering

The invention discloses a bundling component of electronic yarn drawing equipment. The bundling component comprises a stainless steel strip, sliding blocks, fixed rods, adjustable upright rods and bundling wheel brackets, the sliding blocks sleeve the stainless steel strip, and the fixed rods are welded to all the sliding blocks; the adjustable upright rods are inserted in the fixed rods and fixedly locked by first bolts, installing blocks are further welded to the top ends of the adjusting upright rods, and the connecting ends of the bundling wheel brackets are inserted in installing groovesformed in the installing blocks and fixedly locked by second bolts; sleeving rings are further welded to the upper sides of the adjustable upright rods and sleeve the same long rod; according to the bundling component, the stainless steel strip is connected with multiple single bundling wheel brackets, under driving of foldable airbags, the adjustable upright rods can move up and down, and the long rod can make adjusting heights of multiple single adjustable upright rods consistent, and the adjusting process is convenient; the bundling wheel brackets are improved, space is expanded relatively,and the bearing force of a crossbeam is increased.

Owner:LINZHOU GUANGYUAN NEW MATERIAL TECH

Magnetic field sensor probe sensitivity improving method

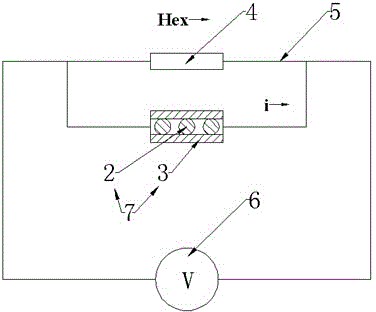

ActiveCN104931899AEnergy savingSimple adjustment processMagnetic measurementsTest objectMaterials science

A magnetic field sensor probe sensitivity improving method belongs to the sensor sensitive probe application field; a sensor probe is arranged in a bias magnetic field; a sensor probe easy magnetizing direction is vertical to a bias magnetic field easy magnetizing direction; two ends of the sensor probe are connected with a power supply. A soft-magnetic material can excite the bias magnetic field, so no extra power consumption is generated, thus saving energy; the bias magnetic field and a to be tested object are connected in a non fixed manner; a debug process is simple, dismounting is easy, and operation is simple; the magnetic field sensor probe sensitivity improving method uses the bias magnetic field to improve magnetic material GMI sensitivity, and no damage is caused to raw material, thus saving material.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

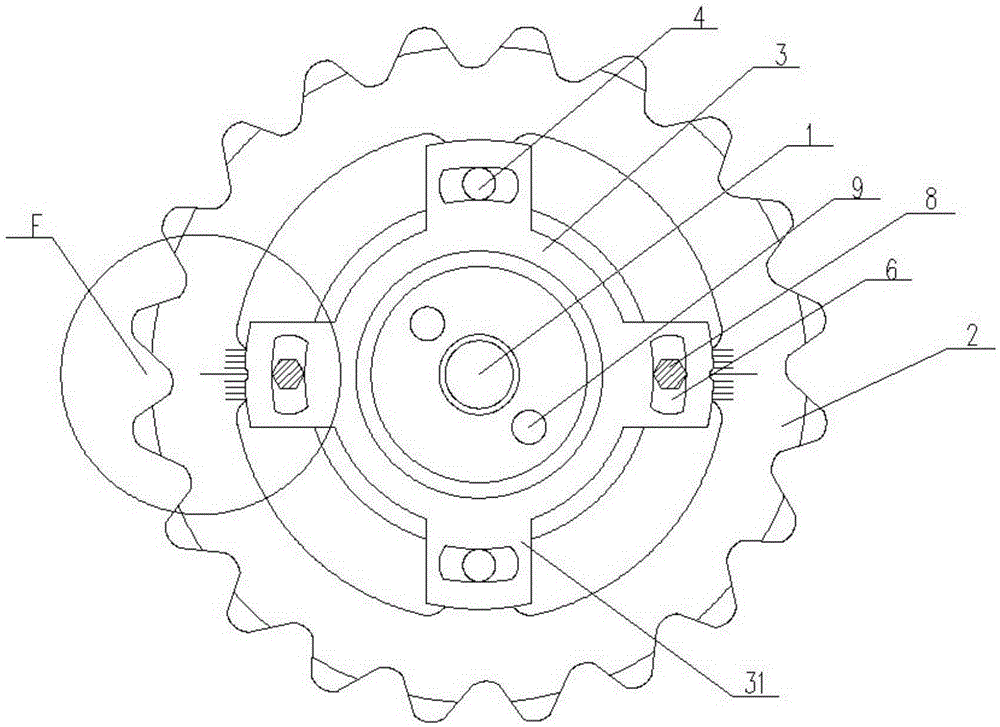

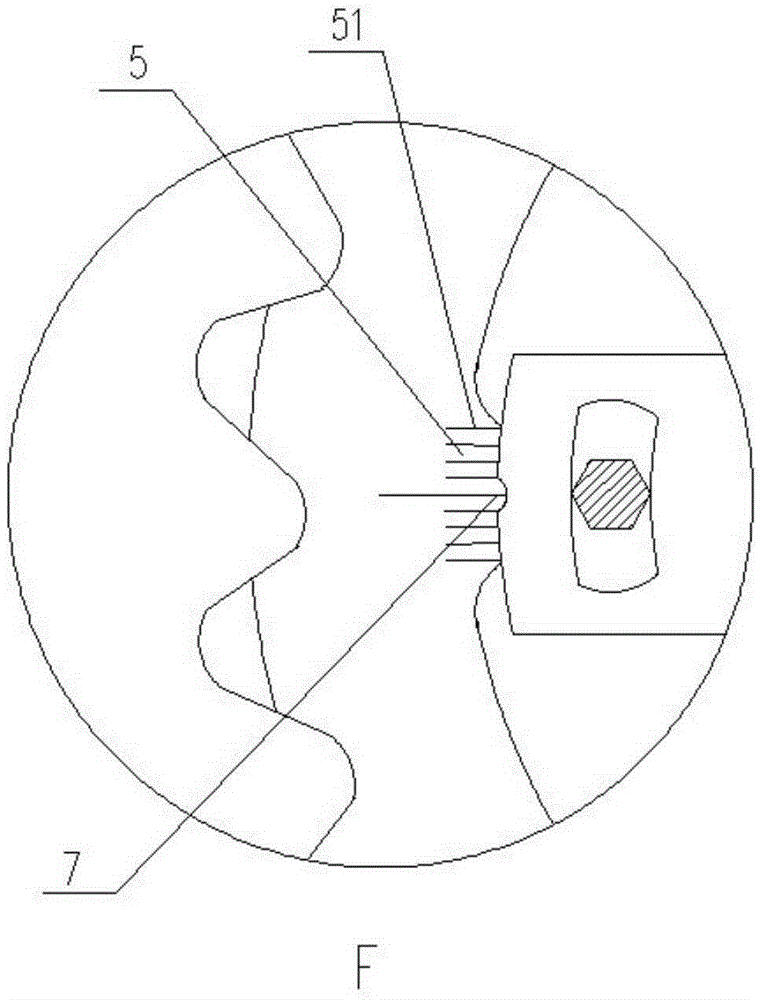

Novel cam shaft

InactiveCN105545397ALarge adjustment rangeSimple adjustment processValve arrangementsMachines/enginesPistonSprocket

The invention discloses a novel cam shaft. The novel cam shaft comprises a cam shaft, a chain wheel and a holder, wherein the chain wheel is fixed with one end of the cam shaft through the holder, a first screw hole and scales are arranged on the chain wheel, an arc-shaped through hole is formed in the part, corresponding to the first screw hole, of the holder, an indication part is arranged at the part, corresponding to the scales, of the holder, and the screw penetrates through the arc-shaped through hole and is connected with the first screw hole. The arrangement of the scales is increased on the cam shaft, the relative position of the cam shaft to the chain wheel is regulated through matching the scales with the indication part, the regulating range of the time sequence difference between a piston and a valve is increased to realize a fine adjustment effect, and at the same time, the regulating process is simplified.

Owner:重庆华楷农业科技有限公司

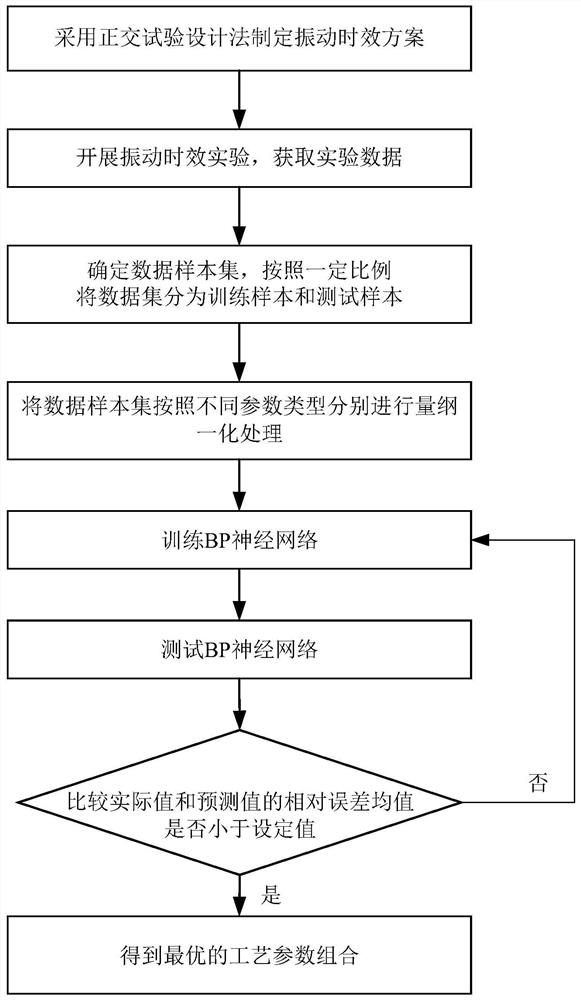

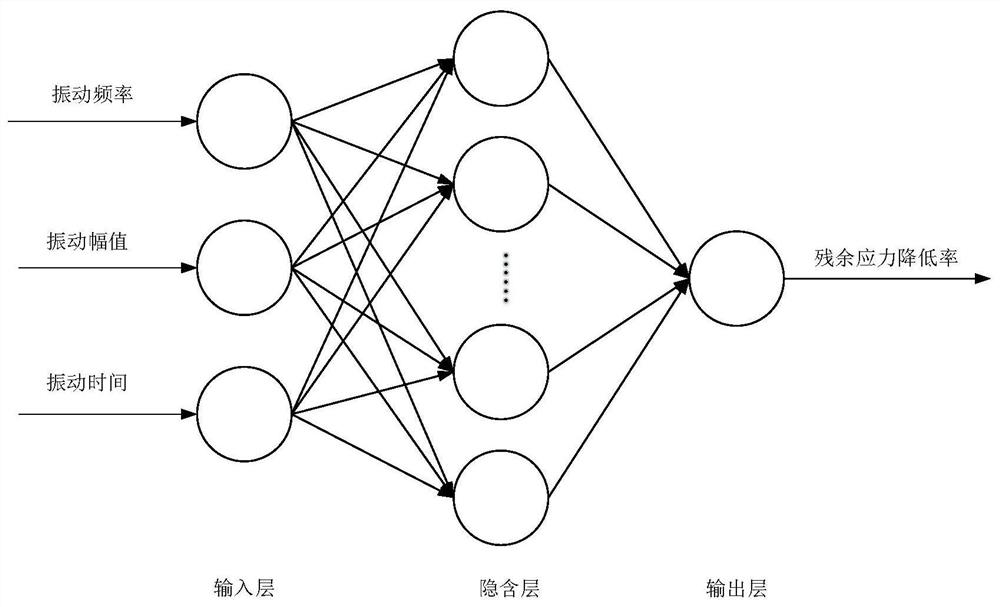

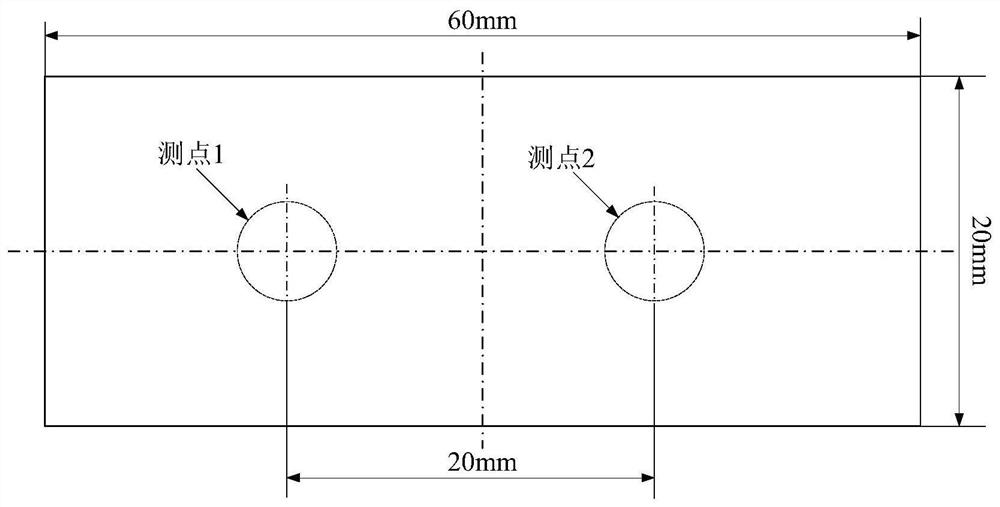

Vibration aging process parameter optimization method based on BP neural network

The invention discloses a vibration aging process parameter optimization method based on a BP neural network. The method is characterized by comprising the following steps that an orthogonal experiment design method is adopted to formulate a vibration aging experiment scheme, a vibration aging experiment is carried out, and experiment data are obtained; dimension normalization processing is carried out on obtained data sample sets respectively according to different parameter categories, and the data sets are divided into two parts, namely a training sample and a test sample according to a certain proportion; the BP neural network is trained and tested by using the data subjecte to dimension normalization; and according to errors of residual stress values obtained through tests and experiments, weights and threshold values of all layers of the network are corrected till a relative error mean value of a predicted value and an actual value is smaller than a set value, an optimal technological parameter combination is obtained, and finally the vibration aging technological parameter optimization method based on the BP neural network is formed. The method has the advantages that a vibration aging process parameter adjusting process is simplified, and the optimal process parameters are obtained.

Owner:SHANGHAI MARITIME UNIVERSITY

Camshaft structure

InactiveCN105401994ALarge adjustment rangeSimple adjustment processValve arrangementsMachines/enginesPistonSprocket

The invention discloses a camshaft structure, which comprises a camshaft, a chain wheel and a fixing seat, wherein the chain wheel is fixed to one end of the camshaft through the fixing seat, a first screw hole is formed in the chain wheel and scales are arranged on the chain wheel; an arc-shaped through hole is formed in the part, corresponding to the first screw hole, of the fixing seat, and an indicating part is arranged at the part, corresponding to the scales, of the fixing seat; a screw penetrates through the arc-shaped through hole and is connected with the first screw hole. The scales are added on the camshaft and are matched with the indicating part to adjust the relative positions of the camshaft and the chain wheel, the adjustment range of time sequence errors of a piston and a valve is increased, a fine adjustment effect is achieved, and meanwhile the adjustment process is simplified.

Owner:重庆玛斯特机械制造股份有限公司

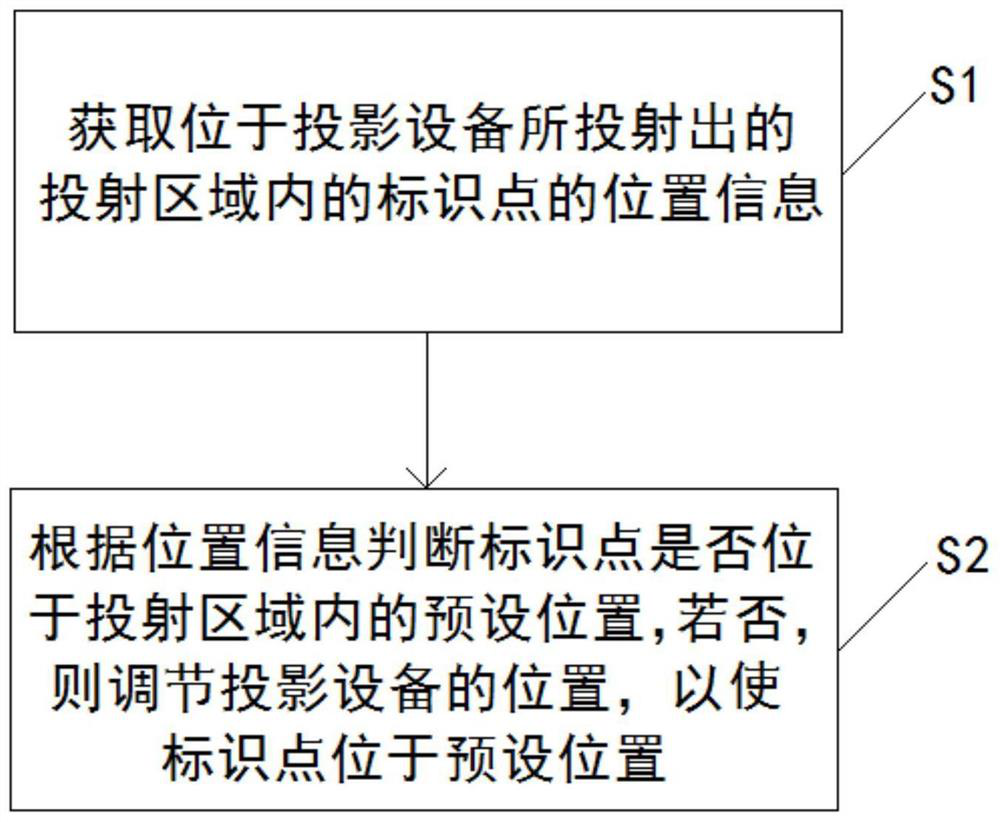

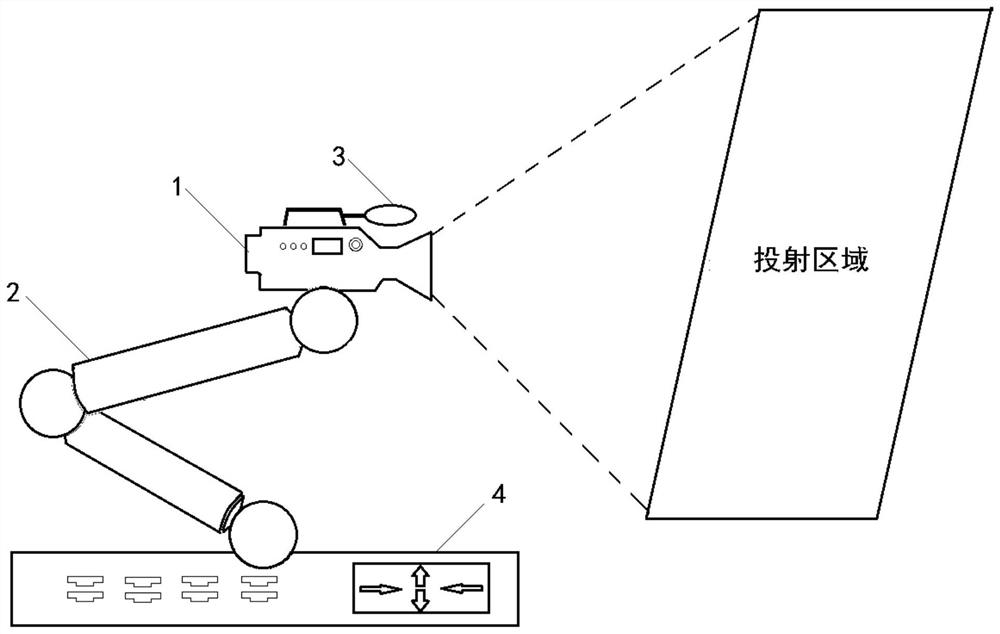

Projection device, projection system and projection method

InactiveCN112415841ASimple adjustment processImprove operating experienceProjectorsProjection systemComputer graphics (images)

The invention discloses a projection device, a projection system and a projection method. The projection method comprises the following steps: acquiring position information of an identification pointin a projection area projected by projection equipment; and judging whether the identification point is located at a preset position in the projection area according to the position information, andif not, adjusting the position of the projection equipment to enable the identification point to be located at the preset position. According to the projection method, the position of the projection equipment can be quickly fixed again, and the operation experience is improved.

Owner:GEER INTELLIGENT TECH CO LTD

Water spray pipe for cooling roller

ActiveCN104801545ASimple adjustment processReduce the difficulty of adjustmentRollsMetal rolling arrangementsCooling fluidWater spray

The invention discloses a water spray pipe for cooling a roller. The water spray pipe comprises an arc-shaped pipe body and a plurality of nozzles, two ends of the arc-shaped pipe body are of closed structures, the nozzles are arrayed on a circle center side of the arc-shaped pipe body and communicated with the arc-shaped pipe body, each nozzle comprises a flexible short pipe and a nozzle head, one end of each flexible short pipe is communicated with the arc-shaped pipe body, and the other end of each flexible short pipe is connected with the corresponding nozzle head. The water spray pipe for cooling the roller can narrow cooling liquid flow by adjusting the spray angles of the nozzles, a cooling device can meet the requirements of different rollers and wires for cooling liquid spray angles, the adjusting process of the spray angles of the cooling device is simplified, and difficulty in adjusting the spray angles is reduced.

Owner:长沙山水节能研究院有限公司

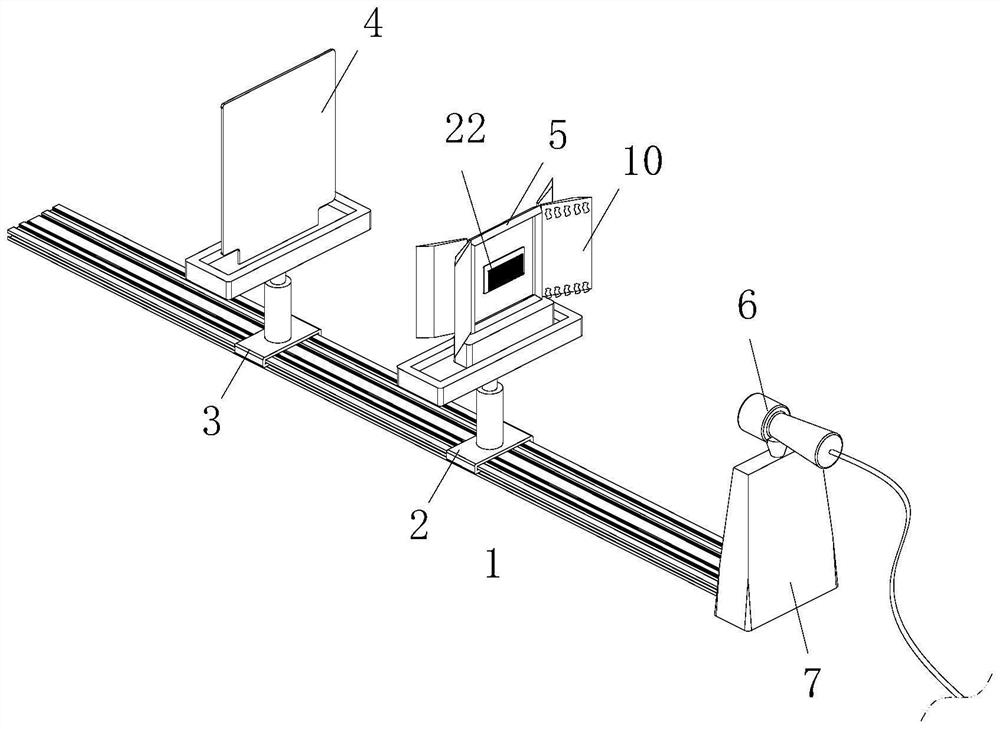

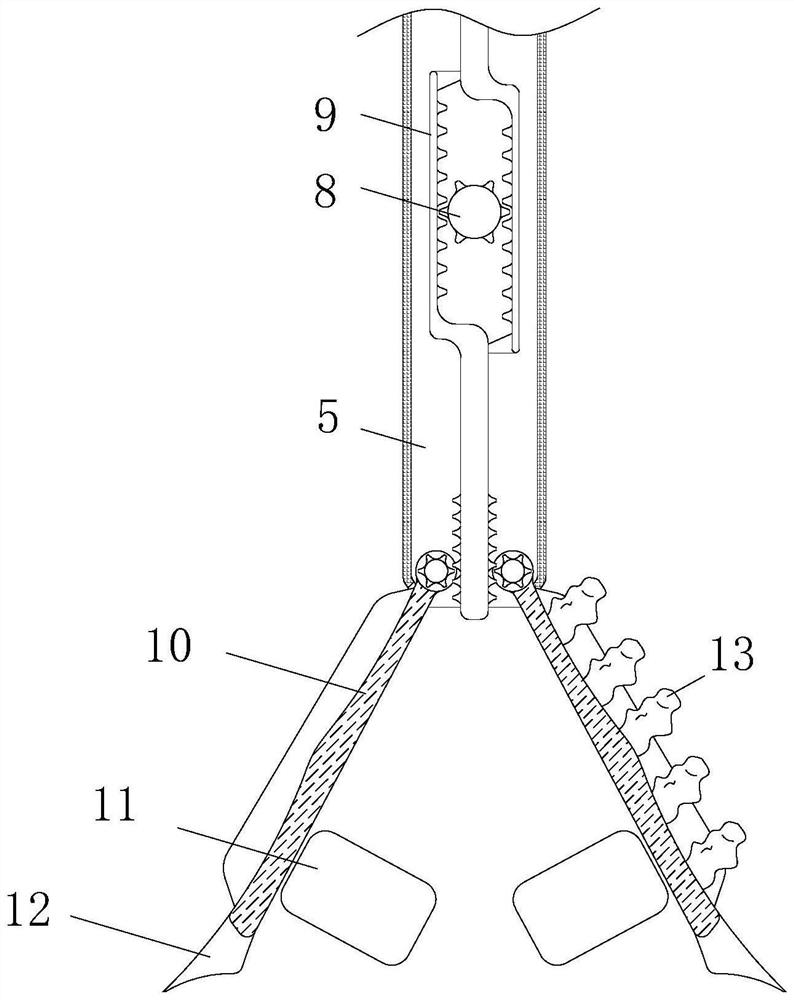

Single slit diffraction experimental instrument

ActiveCN114694463ASimple adjustment processReduce the difficulty of operationEducational modelsEngineeringInstrumentation

The invention belongs to the field of physical experiments, and particularly relates to a single-slit diffraction experimental instrument which comprises a slide way, the top end of the slide way is slidably connected with a first connecting seat and a second connecting seat, a driving module is fixedly mounted at the top end of the first connecting seat, and the transmission end of the driving module is fixedly connected with a rectangular frame. The driving module is used for driving the rectangular frame to move horizontally, a receiving plate is fixedly installed at the top end of a second connecting base, a supporting base is fixedly installed at one end of a sliding way, and an irradiation module is fixedly installed at the top end of the supporting base. The driving module can be an electric telescopic rod and is matched with the single slit with the gradually-increased width formed in the light blocking plate, so that in the experiment process, the width of the single slit irradiated by light can be changed only by driving the rectangular frame to move through the driving assembly, the adjustment process is greatly facilitated, and the operation difficulty is reduced.

Owner:CHAOHU UNIV

Optical device adjusting device

PendingCN113176645ASimple adjustment processAchieving decoupled adjustmentsMountingsEngineeringMechanical engineering

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Processing die of car window guide rail

PendingCN107552643ASimple adjustment processEasy to increase or decreaseShaping toolsGasketTime-Consuming

The invention provides a processing die of a car window guide rail. The processing die aims to solve the technical problems of a complex adjustment process, high time consumption and large limitationfor profile shaping in the prior art. The processing die comprises a shaping structure, wherein shaping upper die inserts and shaping lower die inserts which are arranged in pairs are arranged on theshaping structure relative to to-be-adjusted profiles. The processing die is characterized in that gasket assemblies are detachably connected to the upper end surfaces of the shaping upper die insertsand the lower end surfaces of the shaping lower die inserts respectively by virtue of connecting pieces, and each gasket assembly comprises more than two gaskets.

Owner:WUXI WEITANG IND TECH CO LTD

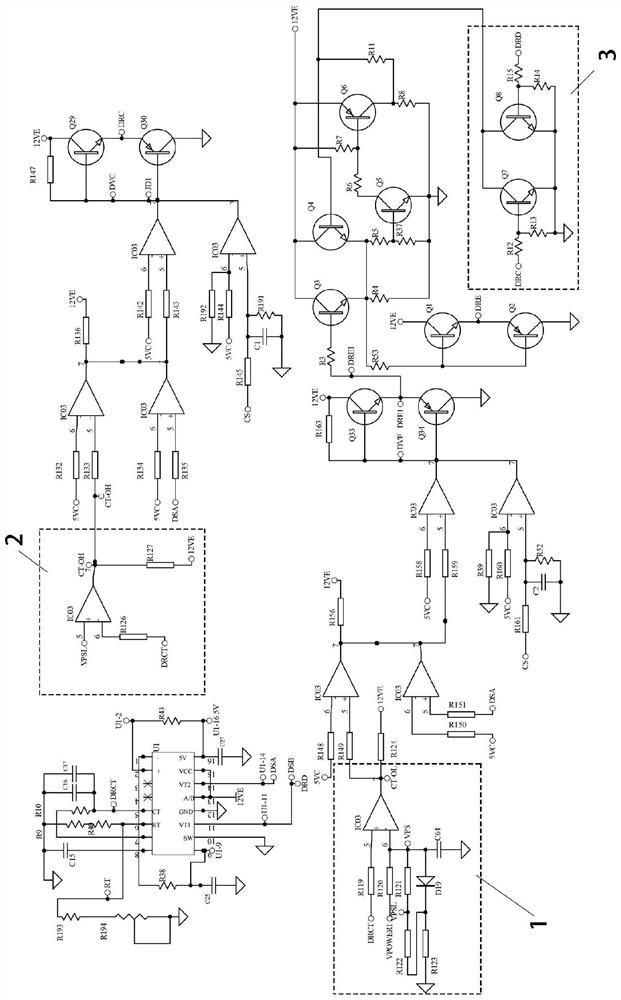

Asymmetric half-bridge stepless power regulation device and method

ActiveCN112953212AReasonable and ingenious structural designSimple adjustment processDc-dc conversionElectric variable regulationPower regulationHemt circuits

The invention provides an asymmetric half-bridge stepless power regulation device and method. The asymmetric half-bridge stepless power regulation device comprises: a power regulation signal generation circuit used for providing a power regulation signal; a square wave signal generation circuit used for generating and outputting a first square wave signal and a second square wave signal which are complementary; a time sequence modulation signal generation circuit used for receiving the power regulation signal and generating a first time sequence modulation signal and a second time sequence modulation signal; a first modulation circuit used for receiving the first square wave signal and the second time sequence modulation signal and modulating to generate a first power switch tube driving signal; a second modulation circuit used for receiving the first square wave signal and the first time sequence modulation signal and modulating the first square wave signal and the first time sequence modulation signal to generate a third square wave signal; and a signal combination processing circuit used for modulating and generating a second power switch tube driving signal. Continuous stepless adjustment of the asymmetric half-bridge output power is realized.

Owner:东莞声索电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com