Constructional engineering basement pipeline laying casing pipe groove arrangement digging device

A technology for pipeline laying and construction engineering, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of cumbersome adjustment process, low efficiency, incomplete horizontal or vertical grooves, etc., to simplify the adjustment process and improve the opening. Slot efficiency, reduce dust flying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

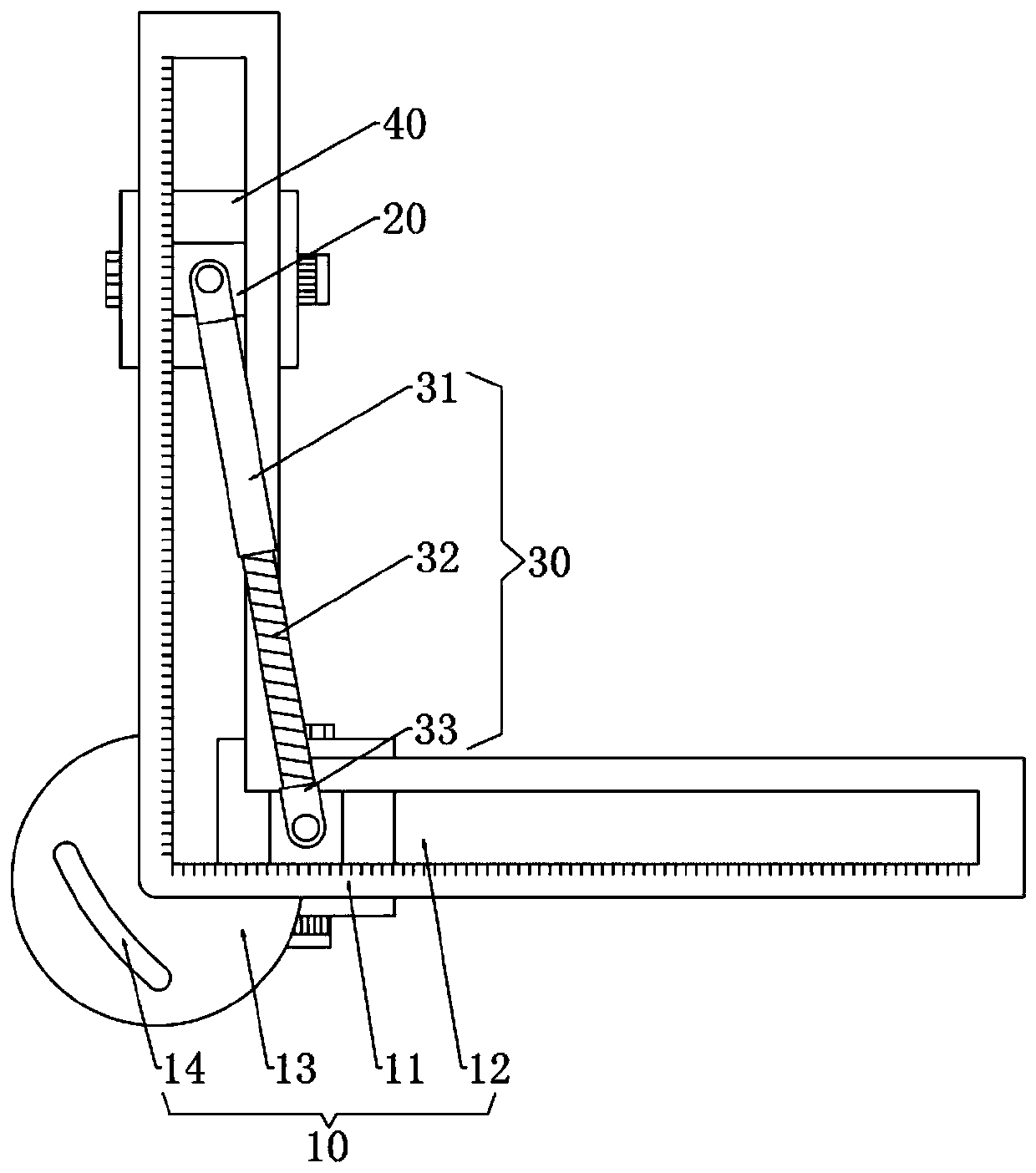

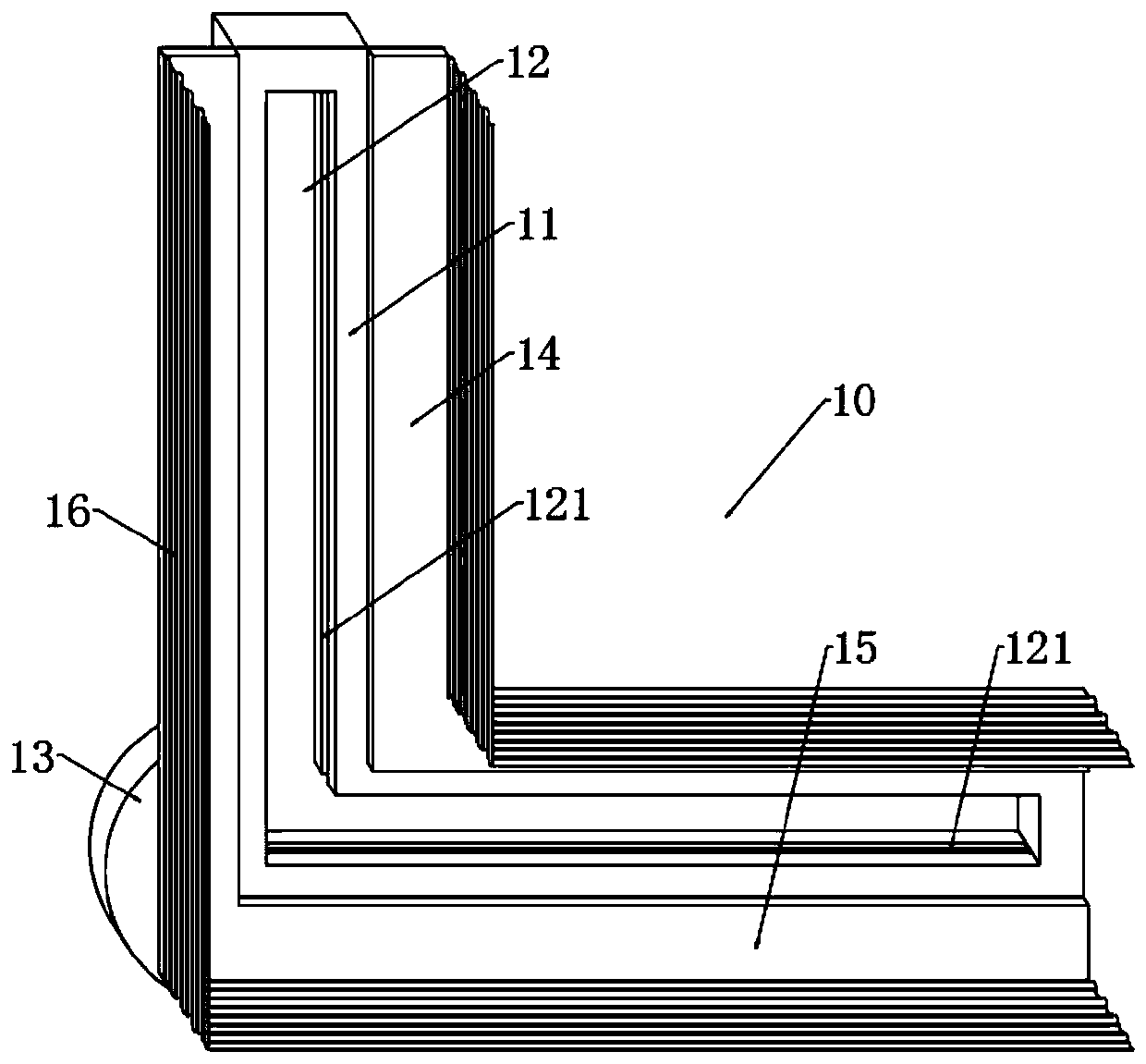

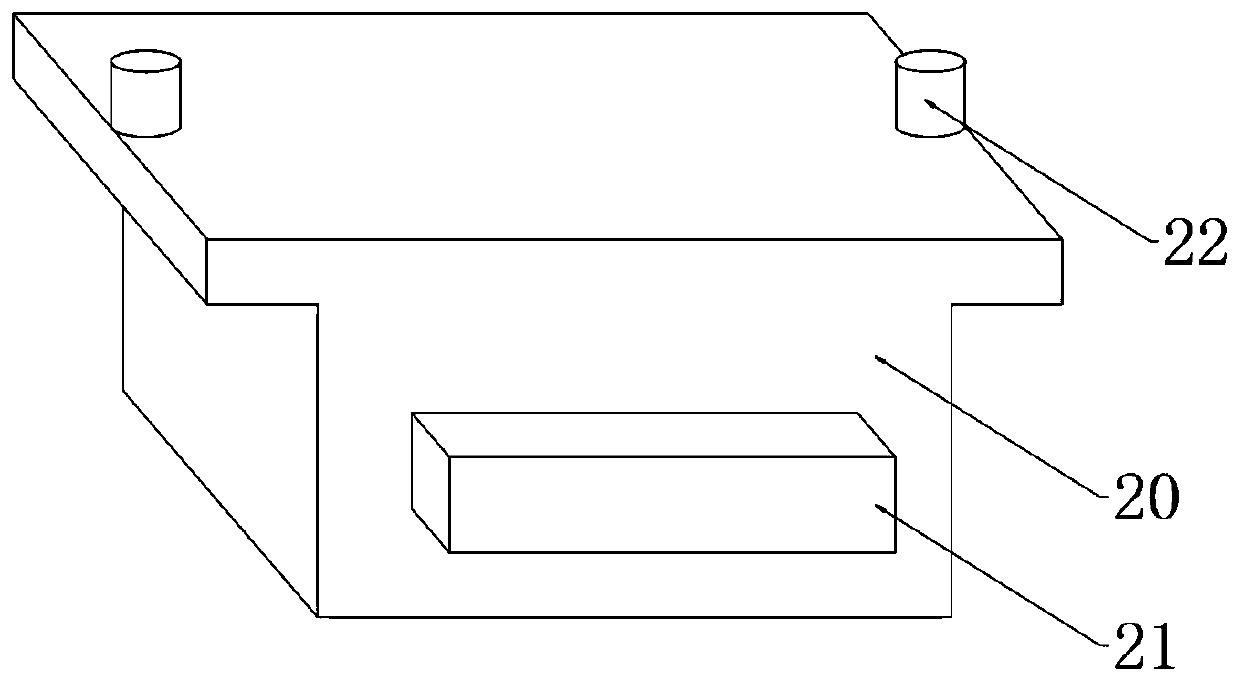

[0031] Such as figure 1 As shown, a construction engineering basement pipeline laying casing groove arrangement excavation device includes an L-shaped guide mechanism 10 and two sets of moving blocks 20 slidably arranged in the L-shaped guide mechanism 10, and the two sets of moving blocks 20 are connected by connecting The rod mechanism 30 is connected, and the connecting rod mechanism 30 comprises a threaded pipe 31 and a threaded rod 32 screwed in the threaded pipe 31. The ends of the threaded pipe 31 and the threaded rod 32 are connected with a connecting plate 33 by bearing rotation, and the connecting plate 33 and The front of the moving block 20 is hingedly connected, and the back of the moving block 20 is provided with a detachable slotting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com