Processing die of car window guide rail

A technology for processing molds and guide rails, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long time-consuming, complicated adjustment process of the integral surface, and large limitations, so as to facilitate the increase or decrease and adjustment process Simple, fast, and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

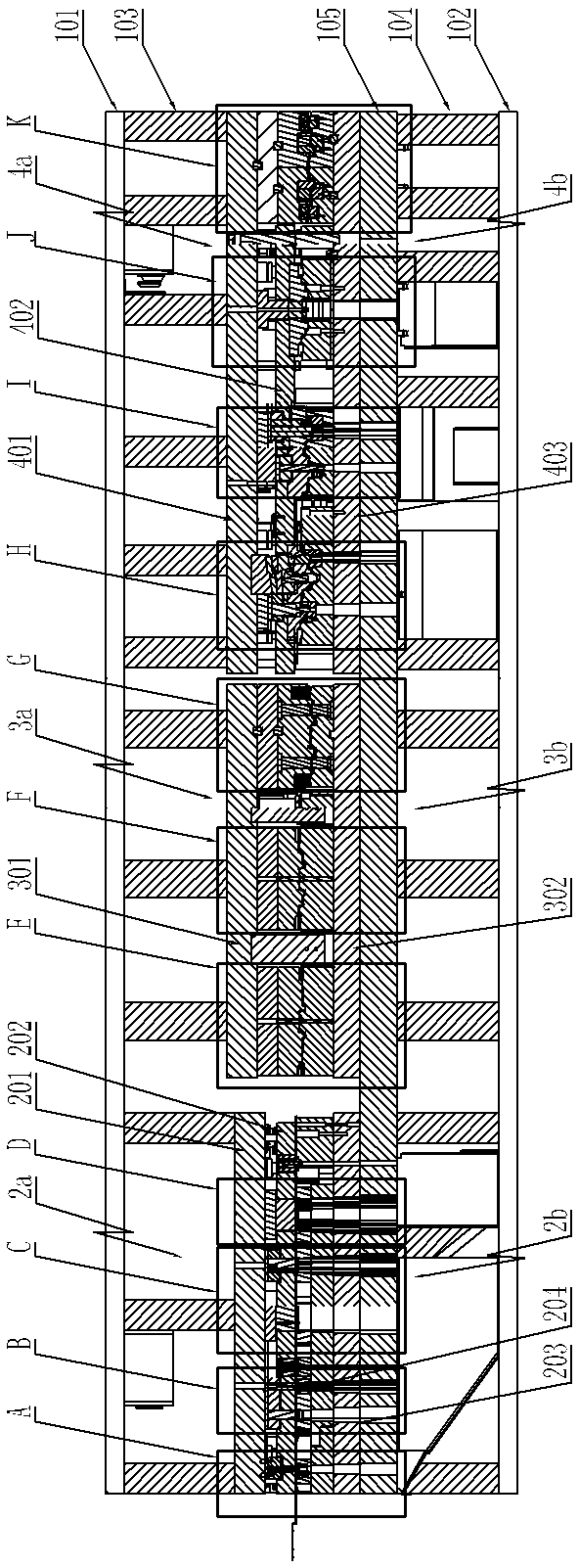

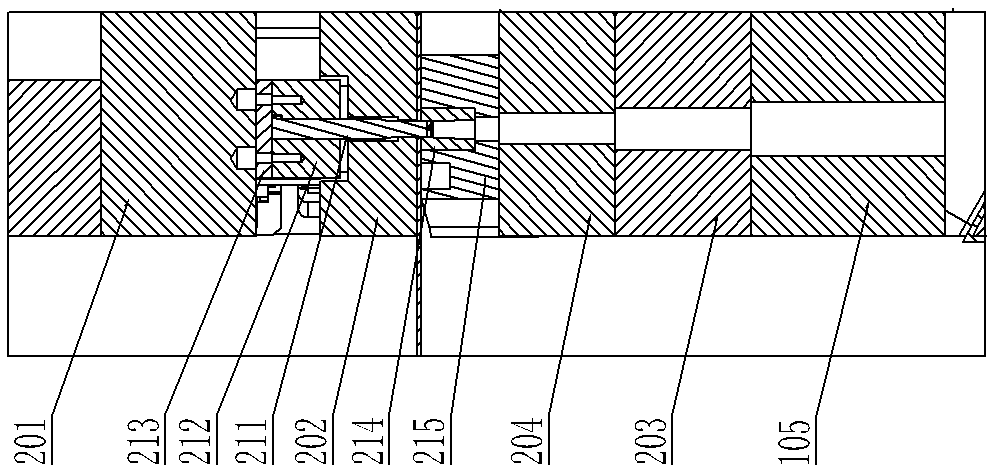

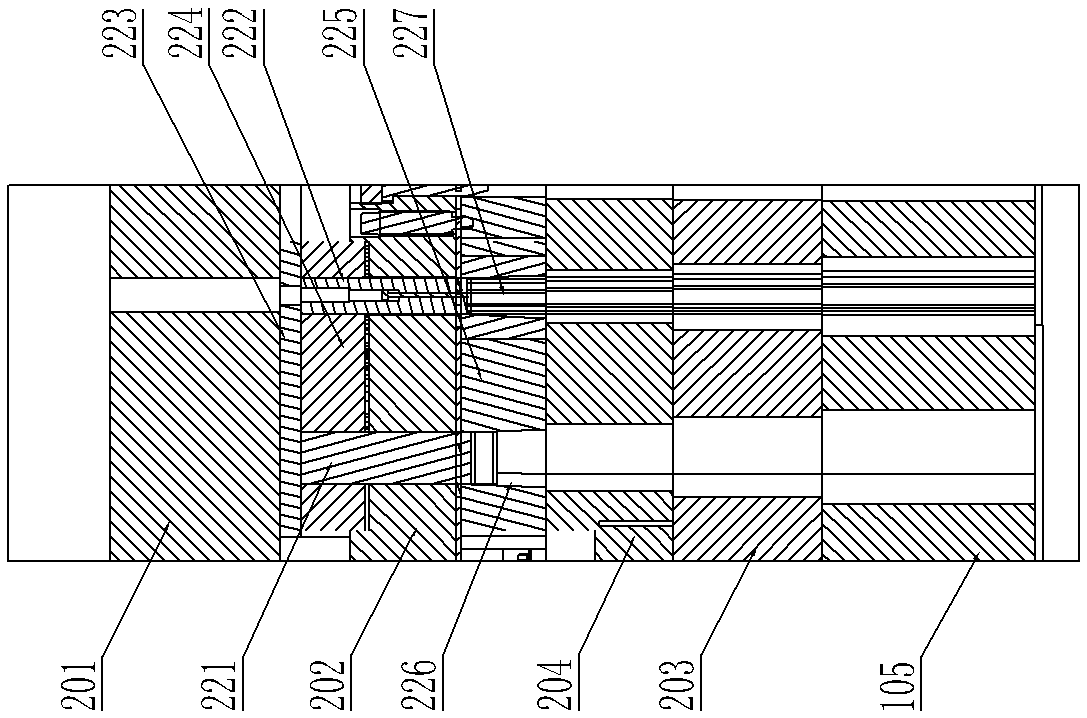

[0039] A processing mold for a window guide rail, such as figure 1 , Figure 12 with Figure 13 As shown, it includes an integral structure. The integral structure is provided with a pair of integral upper die inserts and integral lower die inserts for the profile to be adjusted. The upper end surface of the integral upper die insert and the integral The lower end surface of the lower mold insert is detachably connected with a gasket assembly through a connecting piece, and the gasket assembly is provided with more than 2 pieces of gaskets; the detachable connecting piece includes a first bolt and a second bolt, and the first bolt runs through the Each gasket of the gasket assembly is fixedly connected with the corresponding integral upper mold insert / integral lower mold insert, and the second bolt passes through the corresponding integral upper mold insert / integral lower mold insert and the gasket in turn Each gasket of the component is fixedly connected with the upper mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com