Single slit diffraction experimental instrument

An experimental instrument and single-slit diffraction technology, applied in the field of physical experiments, can solve the problems of inconvenient adjustment of slit width, narrow width of single slit, and difficult to clean dust, so as to reduce external dust and debris from contaminating the light-blocking plate, reduce the difficulty of operation, The effect of the convenient adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

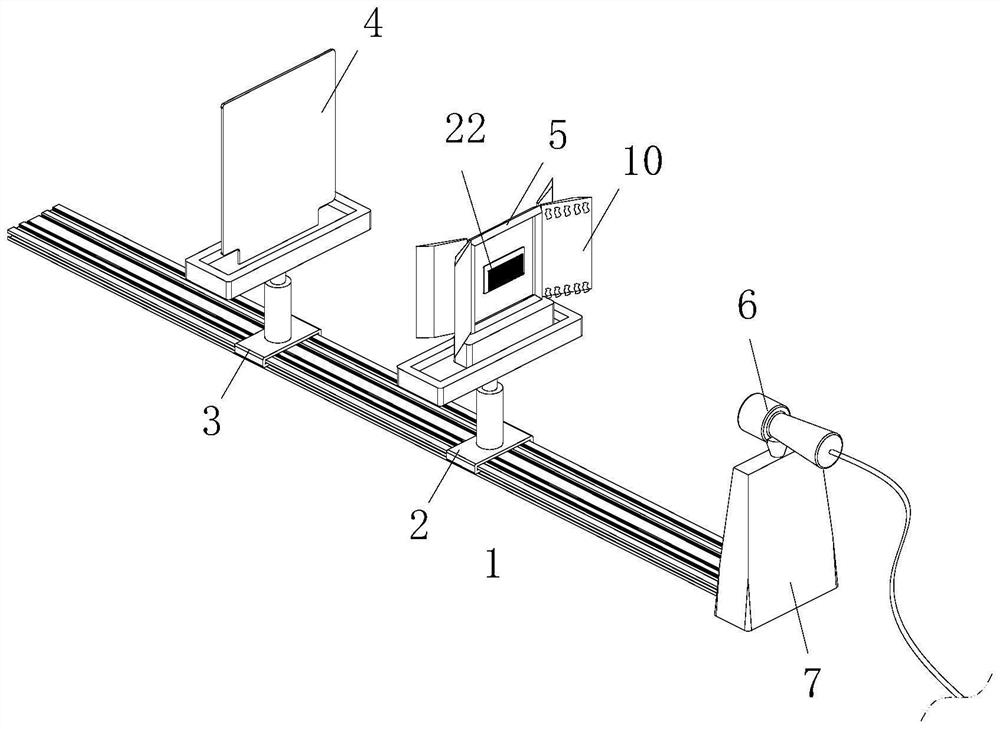

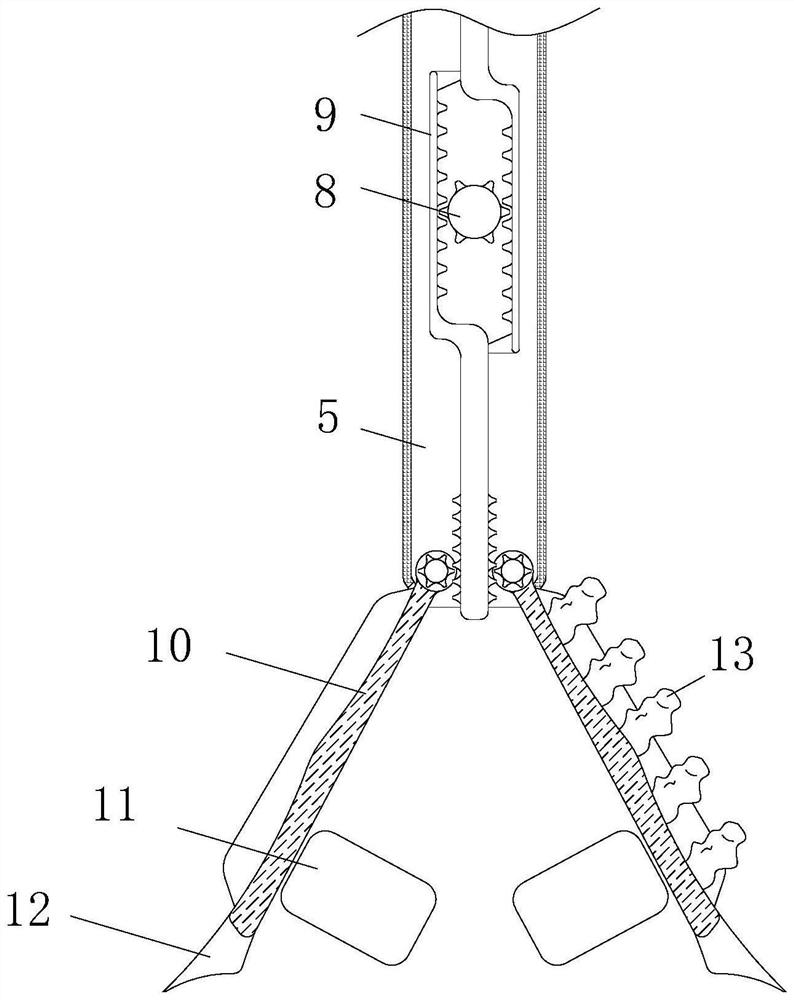

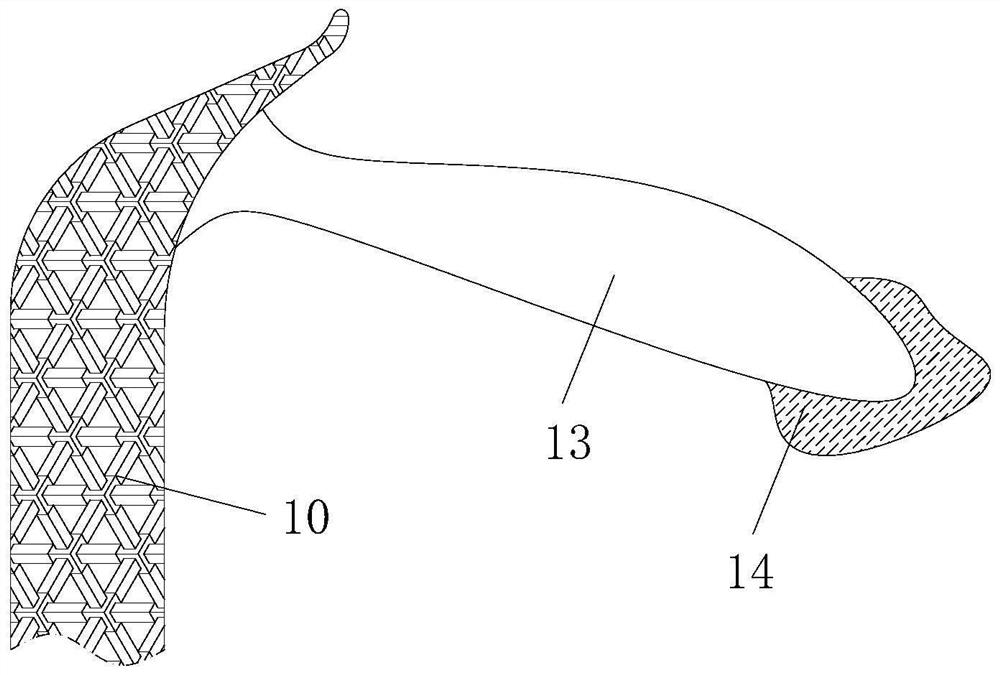

[0030] like Figure 1 to Figure 2As shown in the figure, a single-slit diffraction experimental instrument according to the embodiment of the present invention includes a slideway 1, and the top of the slideway 1 is slidably connected with a first connection seat 2 and a second connection seat 3, and the first connection The top end of the seat 2 is fixedly installed with a drive module, the transmission end of the drive module is fixedly connected with a rectangular frame 5, the drive module is used to drive the rectangular frame 5 to move horizontally, and the top of the second connection seat 3 is fixedly installed with a receiving Plate 4, one end of the slideway 1 is fixedly installed with a support base 7, and the top of the support base 7 is fixedly installed with an illumination module 6, the illumination module 6 is used for emitting test light, and the middle of the rectangular frame 5 is fixed A glass sheet is installed, a light-blocking plate 22 is arranged on the ...

Embodiment 2

[0040] like Image 6 As shown in the comparison example 1, another embodiment of the present invention is: the pressing arm 19 is arranged in a wave shape, and a magnet is fixedly installed at the end of the pressing arm 19 away from the rotating rod 18, and the pressing arm 19 is fixedly installed with a magnet. The inner side wall of the groove 16 is fixedly installed with an iron sheet. When working, it is matched with the structure of the extrusion arm 19, so that the extrusion arm 19 can fully squeeze the corresponding hose 17 during the swinging process, and at the same time, it will not affect the other hose. 17 is squeezed, and the arrangement of the magnet and the iron sheet can ensure that when the inflation bag 13 is inflated, the outgassing hose 17 is fully squeezed to ensure that the inflation bag 13 can be inflated smoothly.

[0041]When working, the light beam is emitted by the irradiation module 6, and the light beam passes through the single slit opened on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com