Method and structure for hoisting prefabricated external wallboards

An external wall panel and panel hanging technology, which is applied in building construction, building material processing, construction, etc., can solve problems such as difficulty in lifting, low construction efficiency, and large weight of prefabricated external wall panels, so as to ensure accuracy, improve The effect of construction efficiency and simple adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

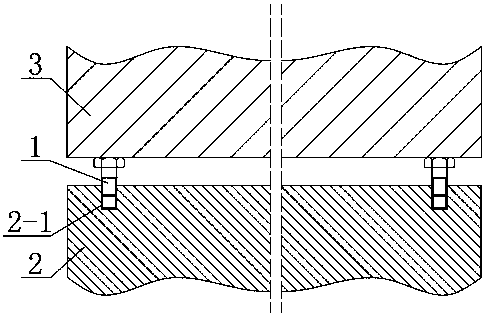

[0015] A method for hoisting prefabricated exterior wall panels in this embodiment, the method utilizes threaded holes at the hoisting end of the lower prefabricated exterior wall panels to cooperate with flat angle bolts to determine the elevation of the upper prefabricated exterior wall panels, specifically comprising the following steps:

[0016] A. Lift the lower prefabricated exterior wall panel to the designated position by the crane, and install it fixedly;

[0017] B. Install flat-angle bolts in the lifting end threaded holes of the lower prefabricated exterior wall panels described in step A, and two flat-angle bolts are installed in this embodiment;

[0018] C. Adjust the horizontal height of the upper end surface of the flat-angle bolt, and measure it with a level gauge, so that the distance from the upper end surface of the flat-angle bolt to the reference plane is consistent with the predetermined elevation of the upper prefabricated exterior wall panel;

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com