Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Restore size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

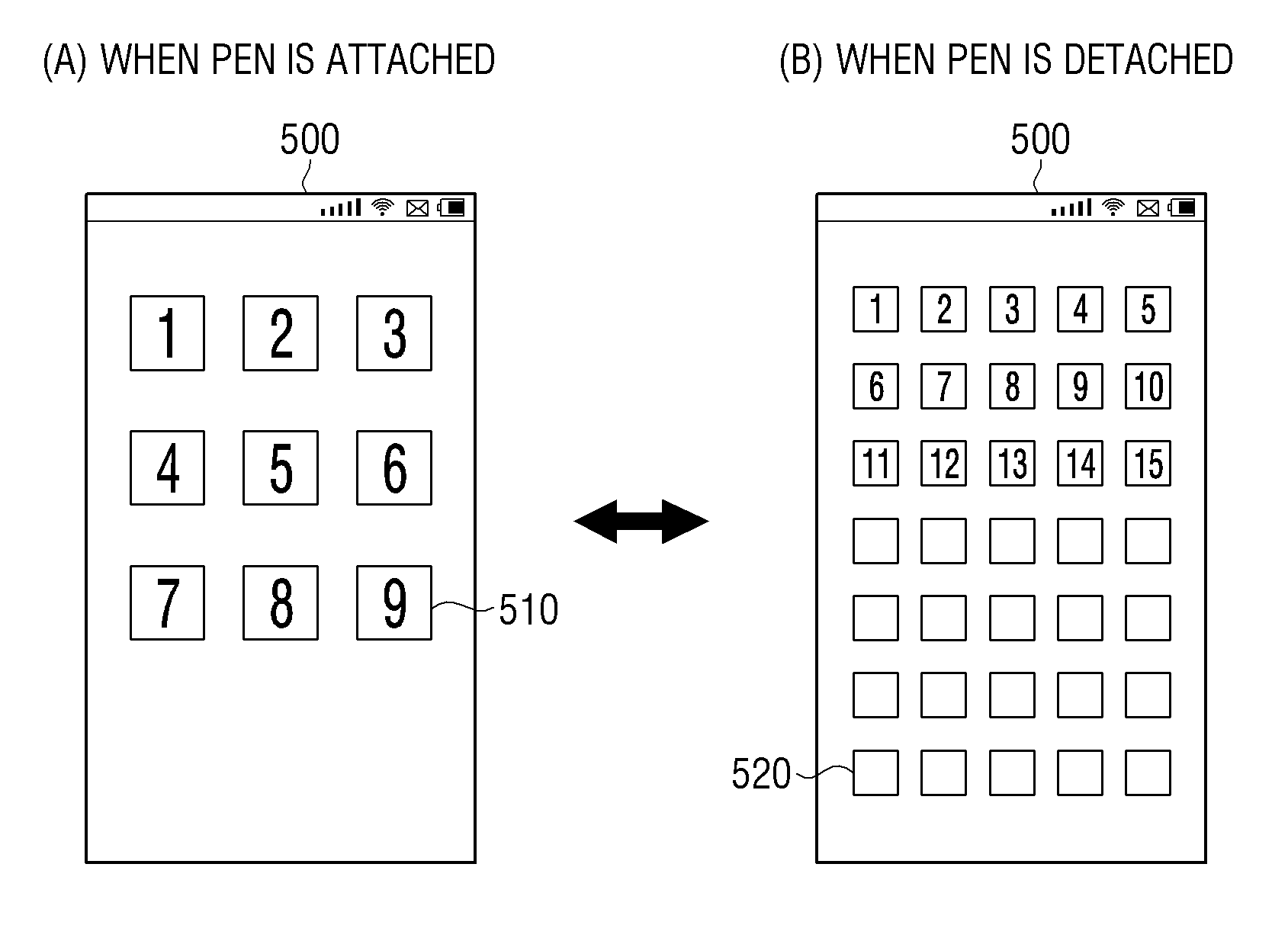

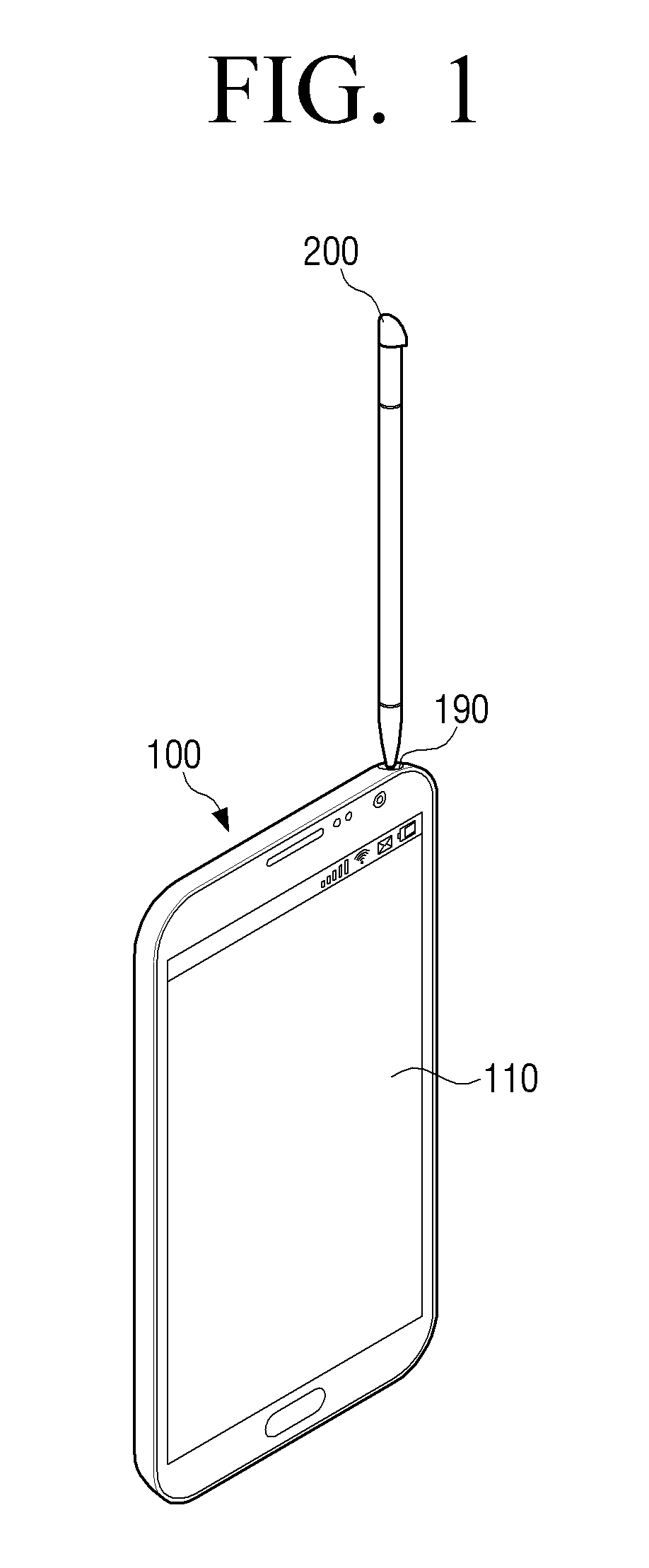

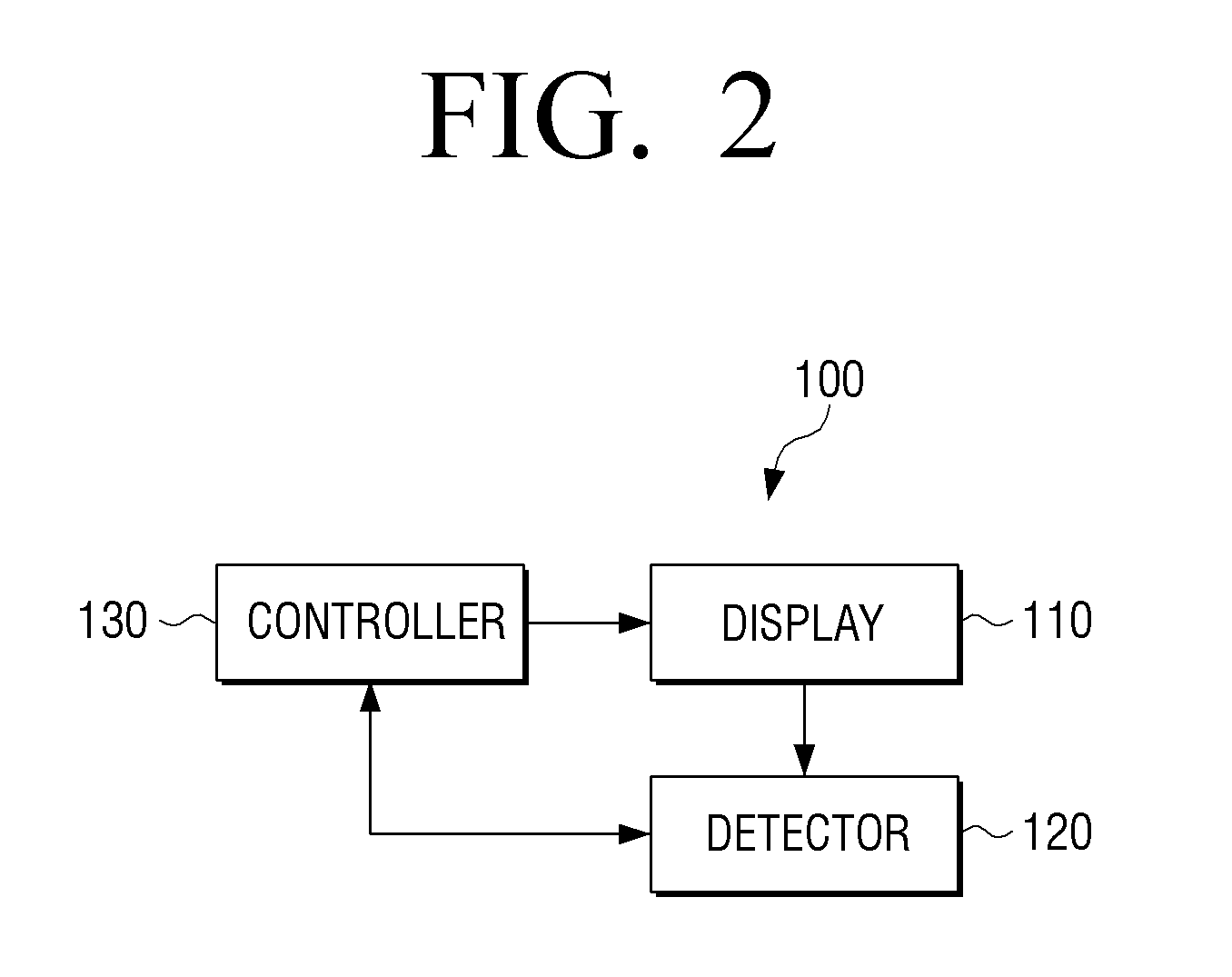

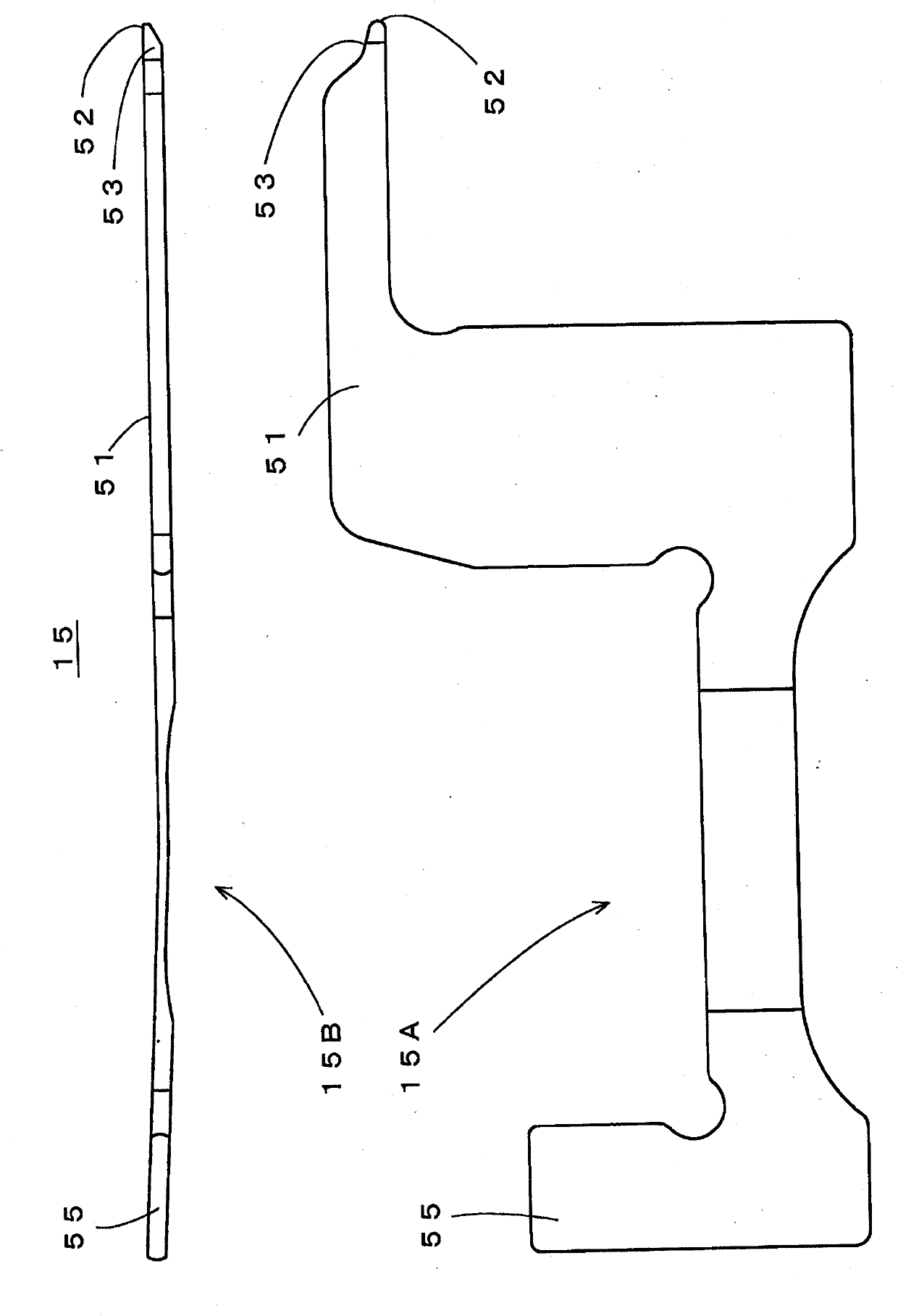

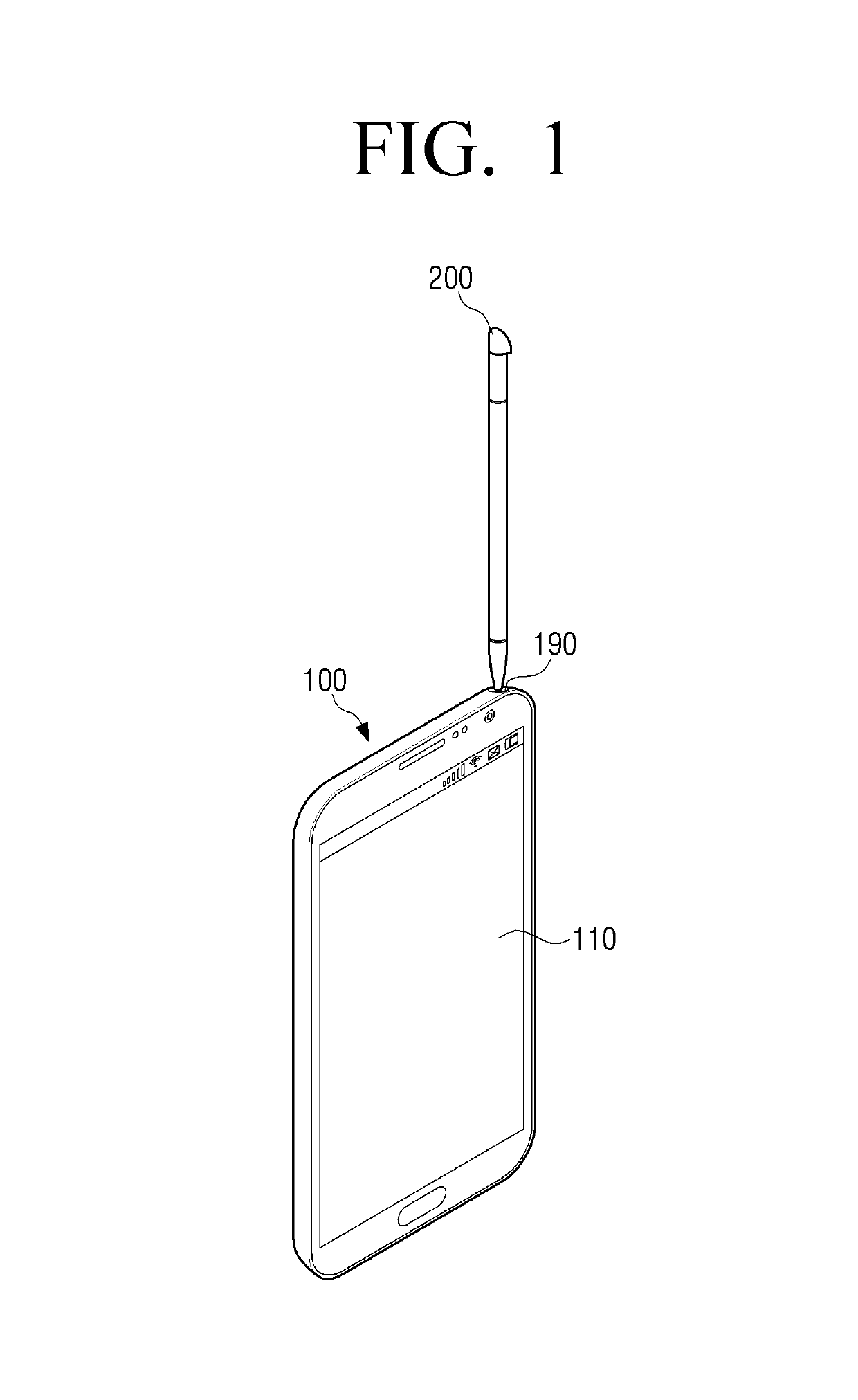

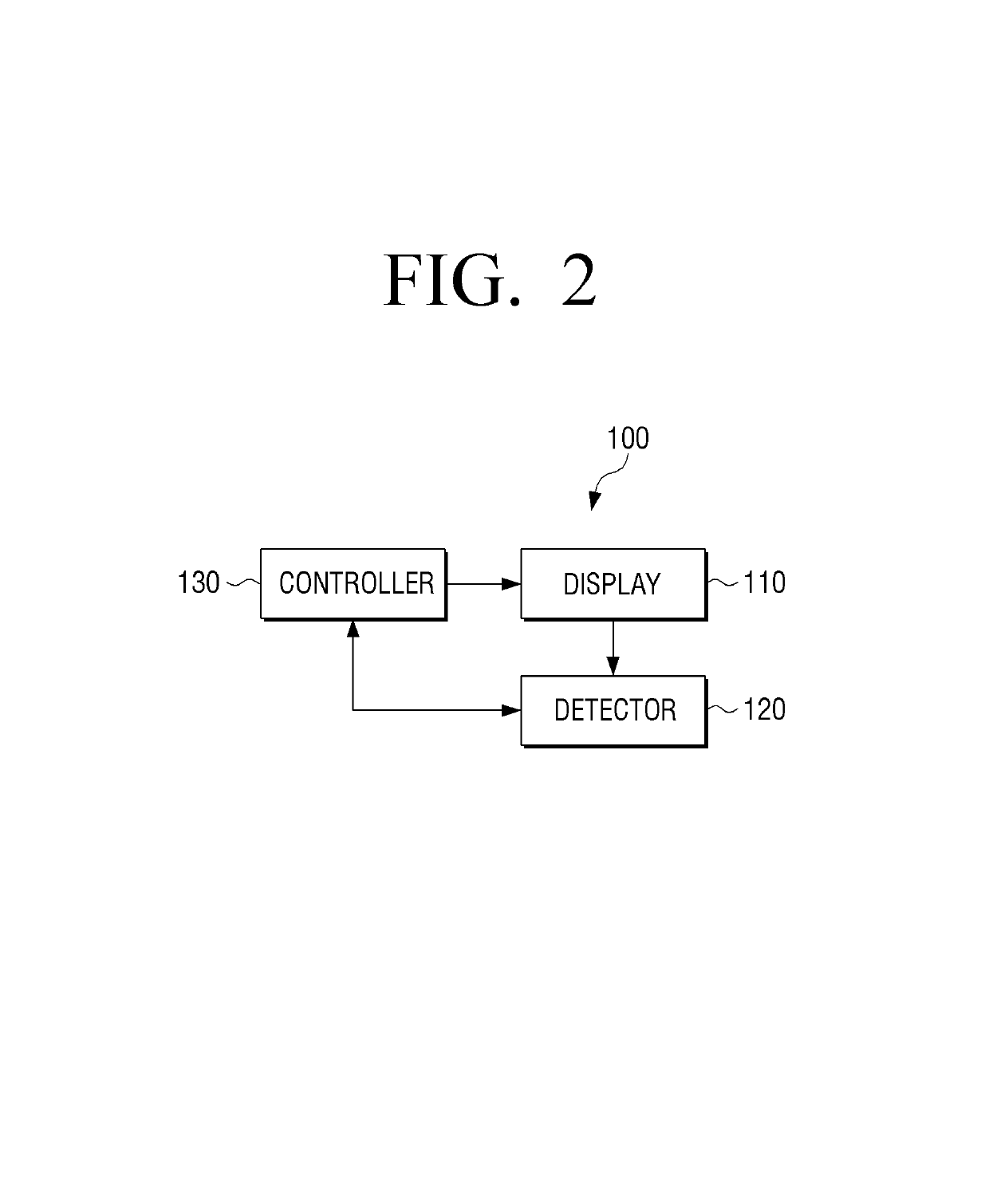

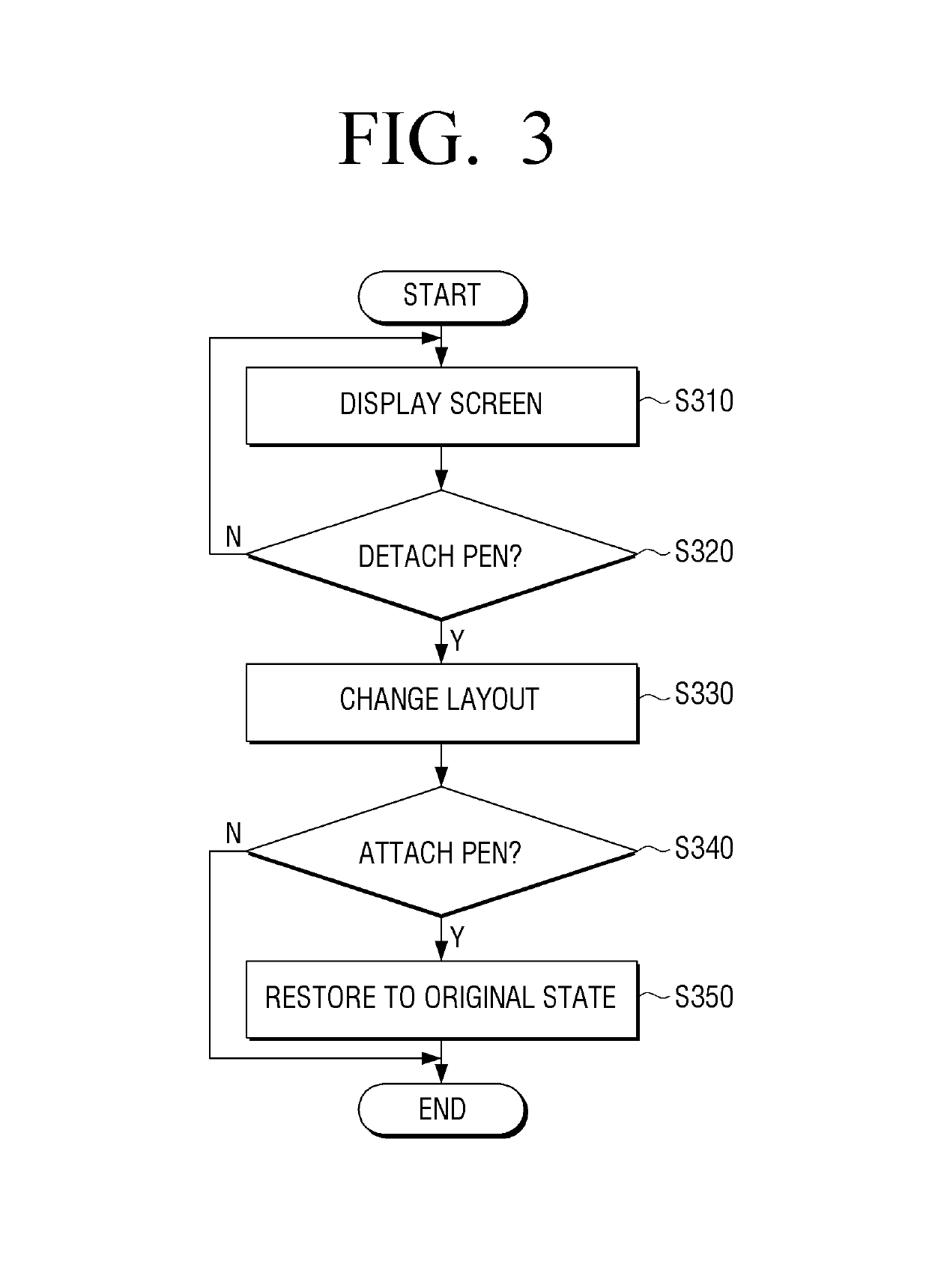

User terminal device with pen and controlling method thereof

ActiveUS20140325402A1Small sizeIncrease in sizeDigital data processing detailsInput/output processes for data processingTerminal equipmentPrimitive state

A user terminal device capable of attaching and detaching a pen is provided. The device includes a detector configured to detect a user manipulation regarding a screen, and a controller configured to change a layout of the screen to correspond to a pen use mode in response to the pen being removed from the user terminal device, perform a control operation corresponding to the detected user manipulation in response to the user manipulation using the pen being detected, and restore the layout of the screen to its original state in response to the pen being remounted on the user terminal apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

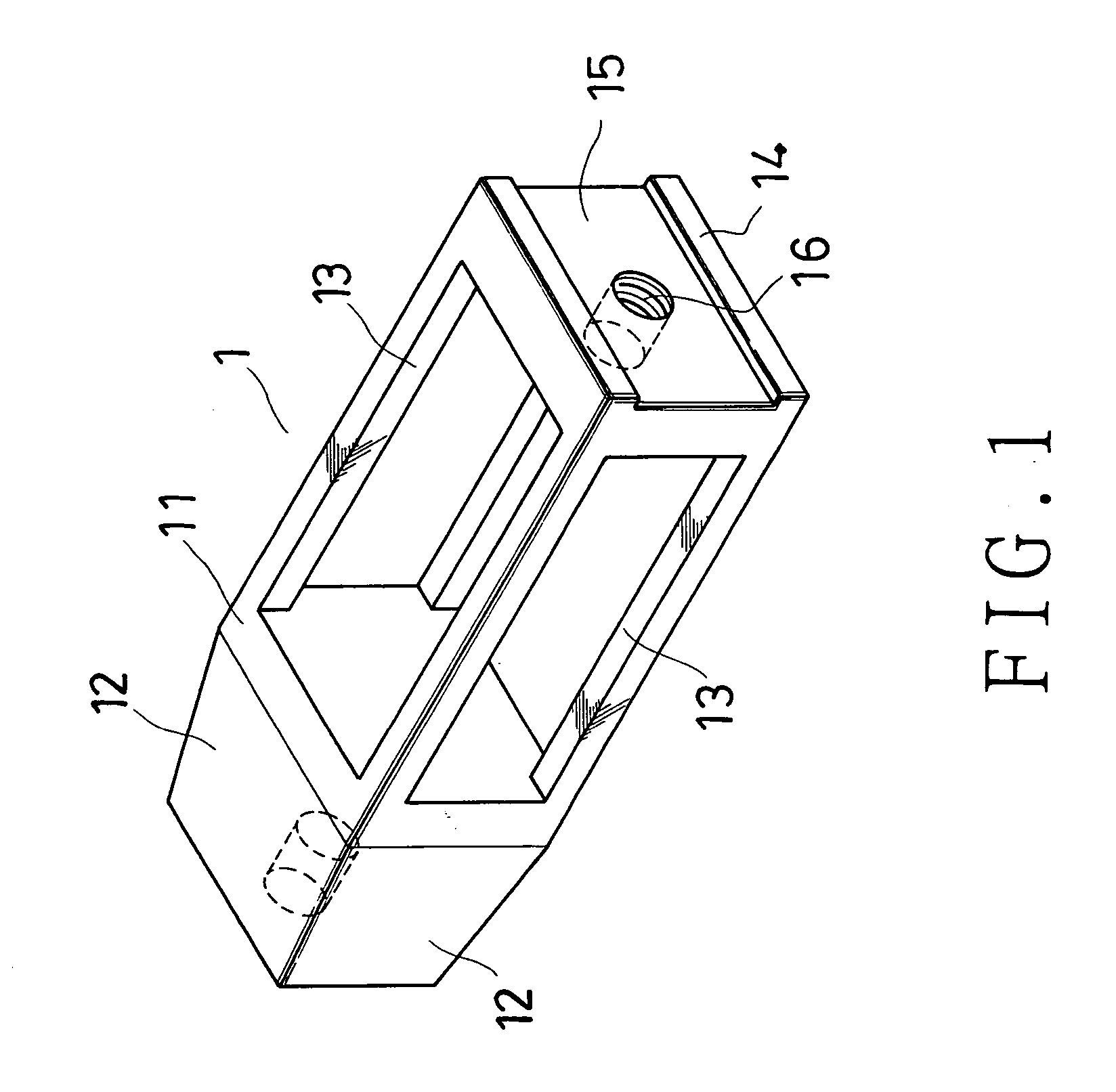

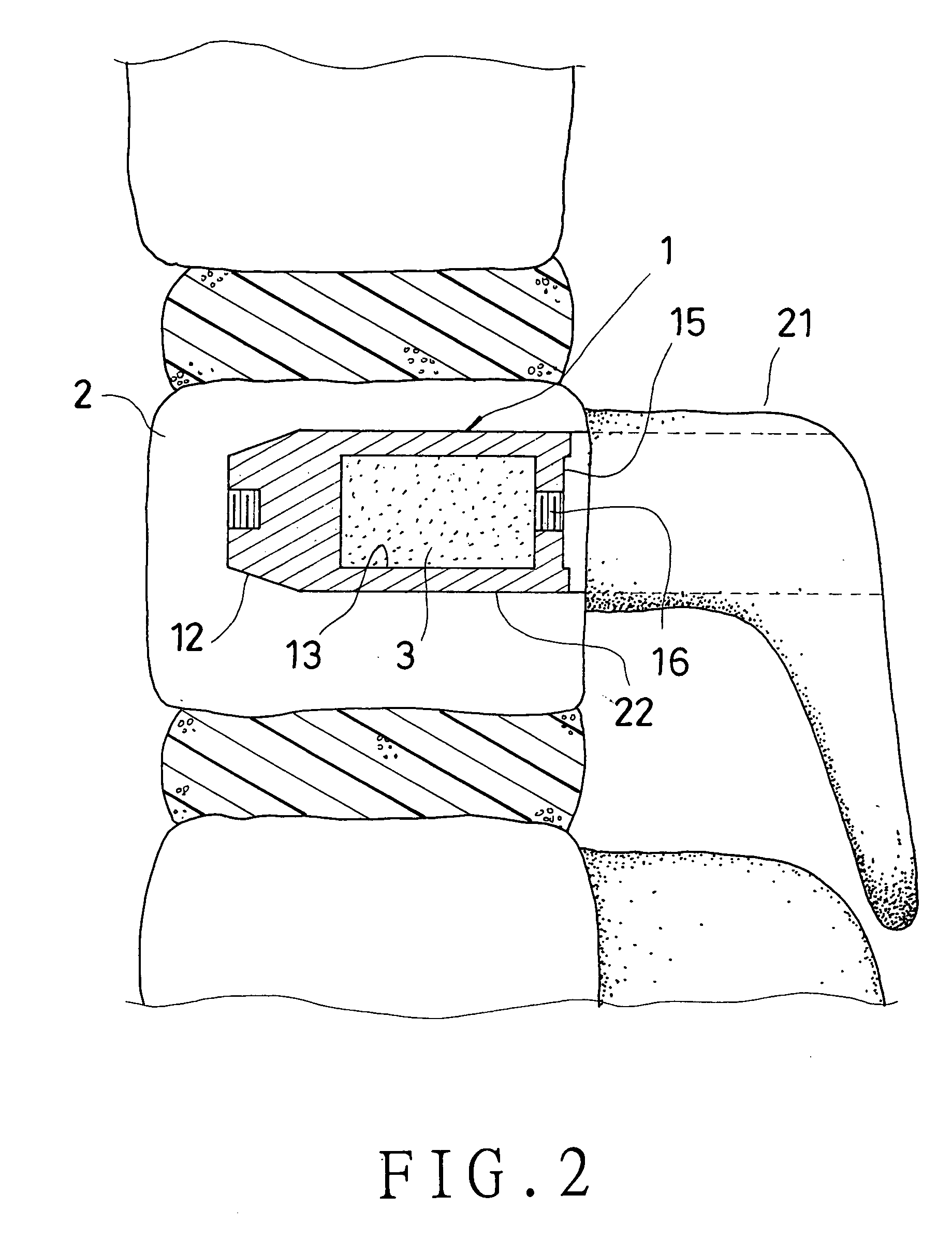

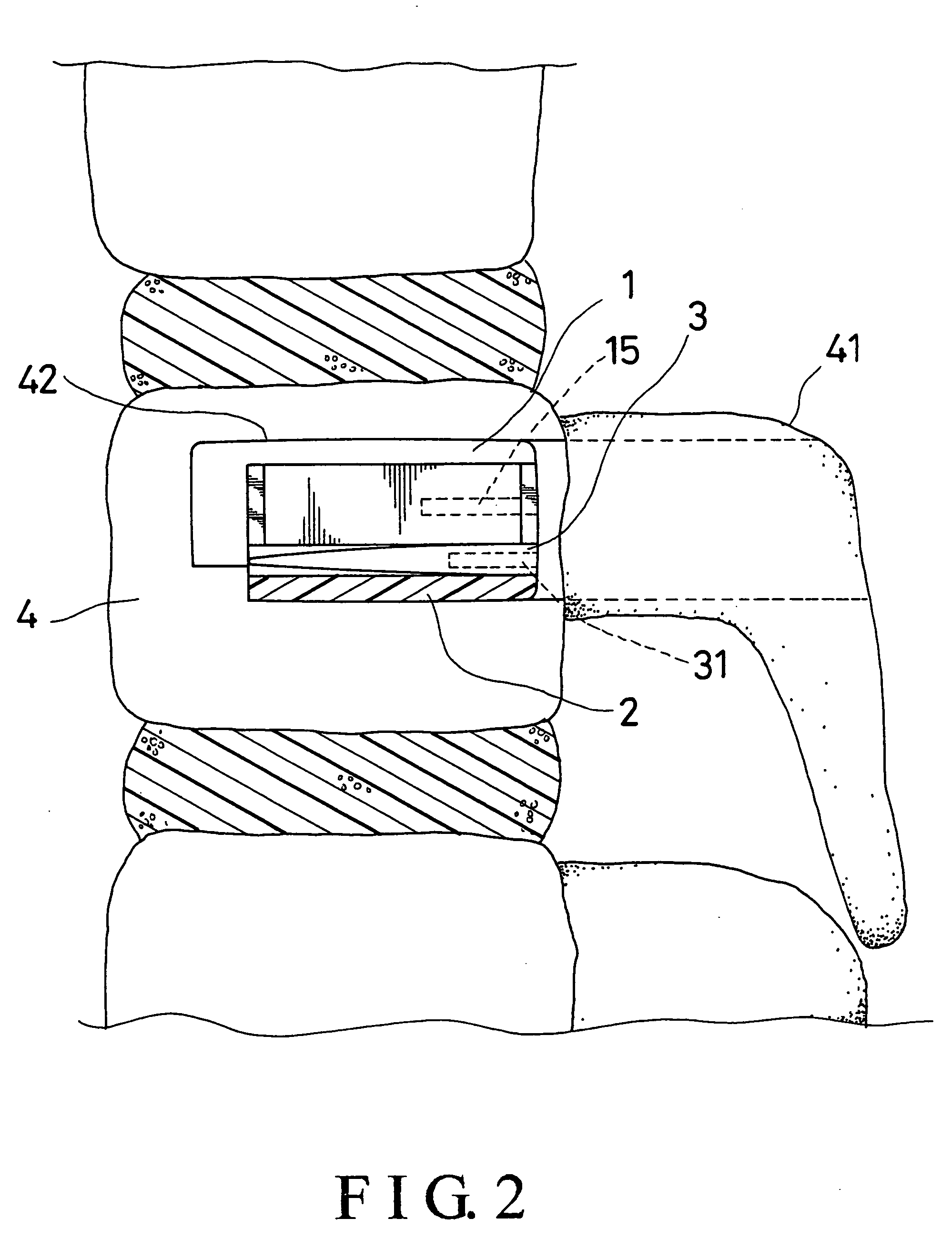

Body augmenter capable of being planted through a pedicle for vertebral body reconstruction

InactiveUS20060025860A1Maintain restoreRestore positionInternal osteosythesisSpinal implantsBone growthNormal position

A pedicle augmenter is provided for reconstruction of a vertebra subjected to loss of bone mass or fracture, and is to be planted into the vertebra from a pedicle of the vertebra for helping maintain or restore normal position and size of the vertebra. Through the pedicle, a device, fit the pedicle anatomy, was created to reconstruct the fractured or collapsed vertebral body. The device has a rectangular bar-shape, and has a first end, a second end, four sides, a recess on the second end, and a screw hole lengthwise formed on the second end; each of the four sides has a sloping portion near to the first end; the four sides of the body augmenter have cavities on other portions thereof, which cavities communicate with each other to form a hollow area together. The fractured body was reduced and maintained by such device until the bone growth and fracture union.

Owner:LI KUNG CHIA

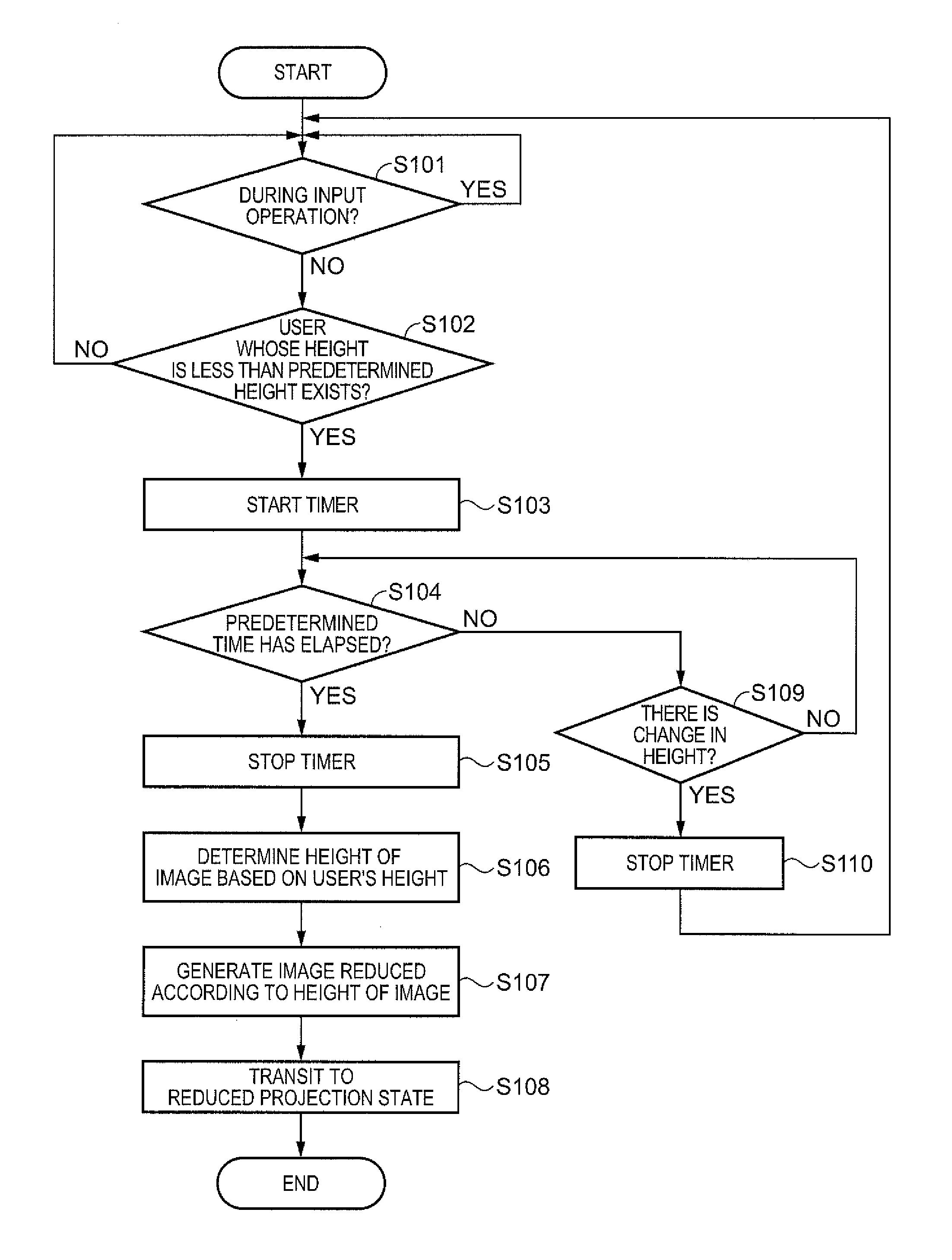

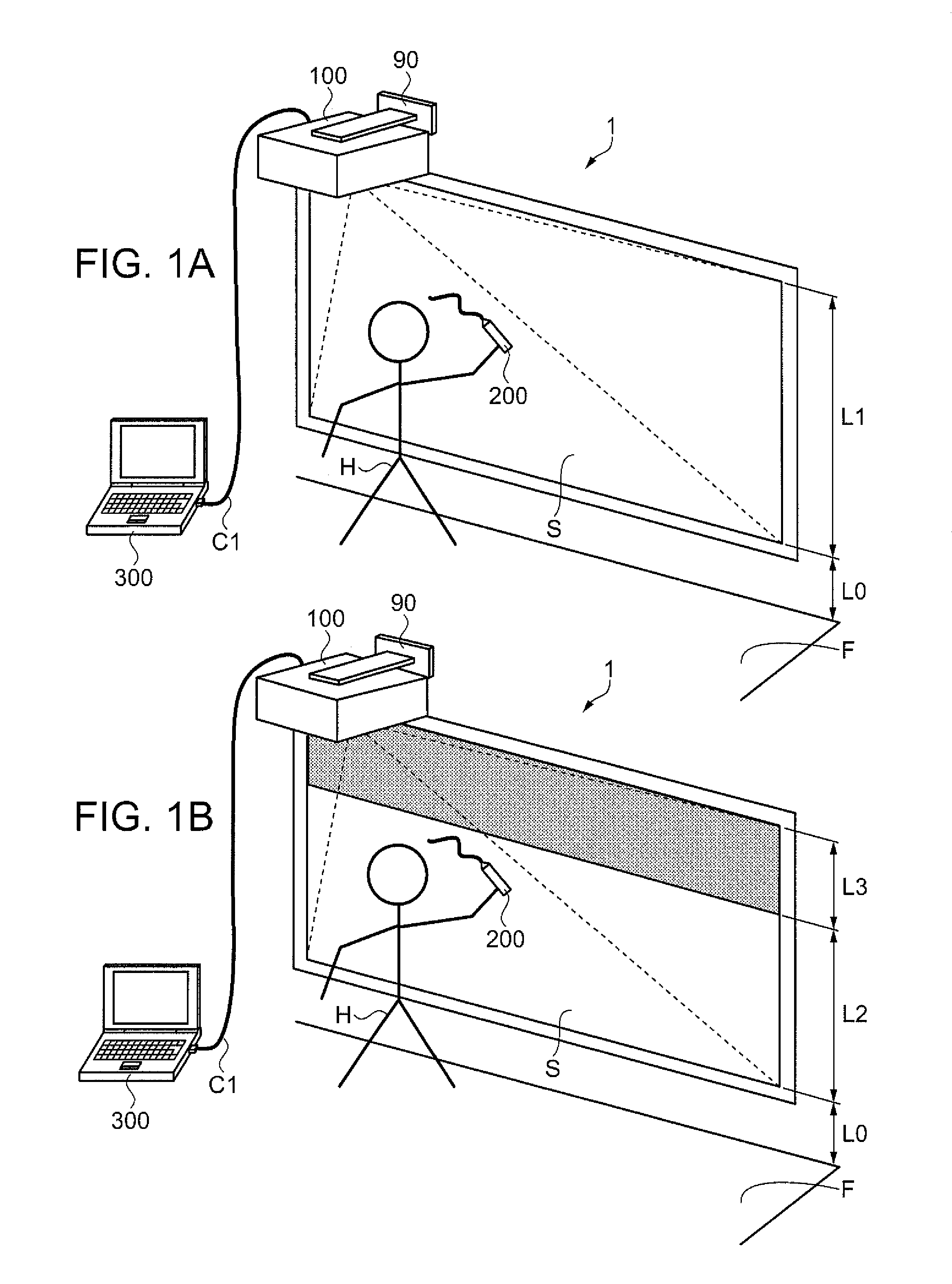

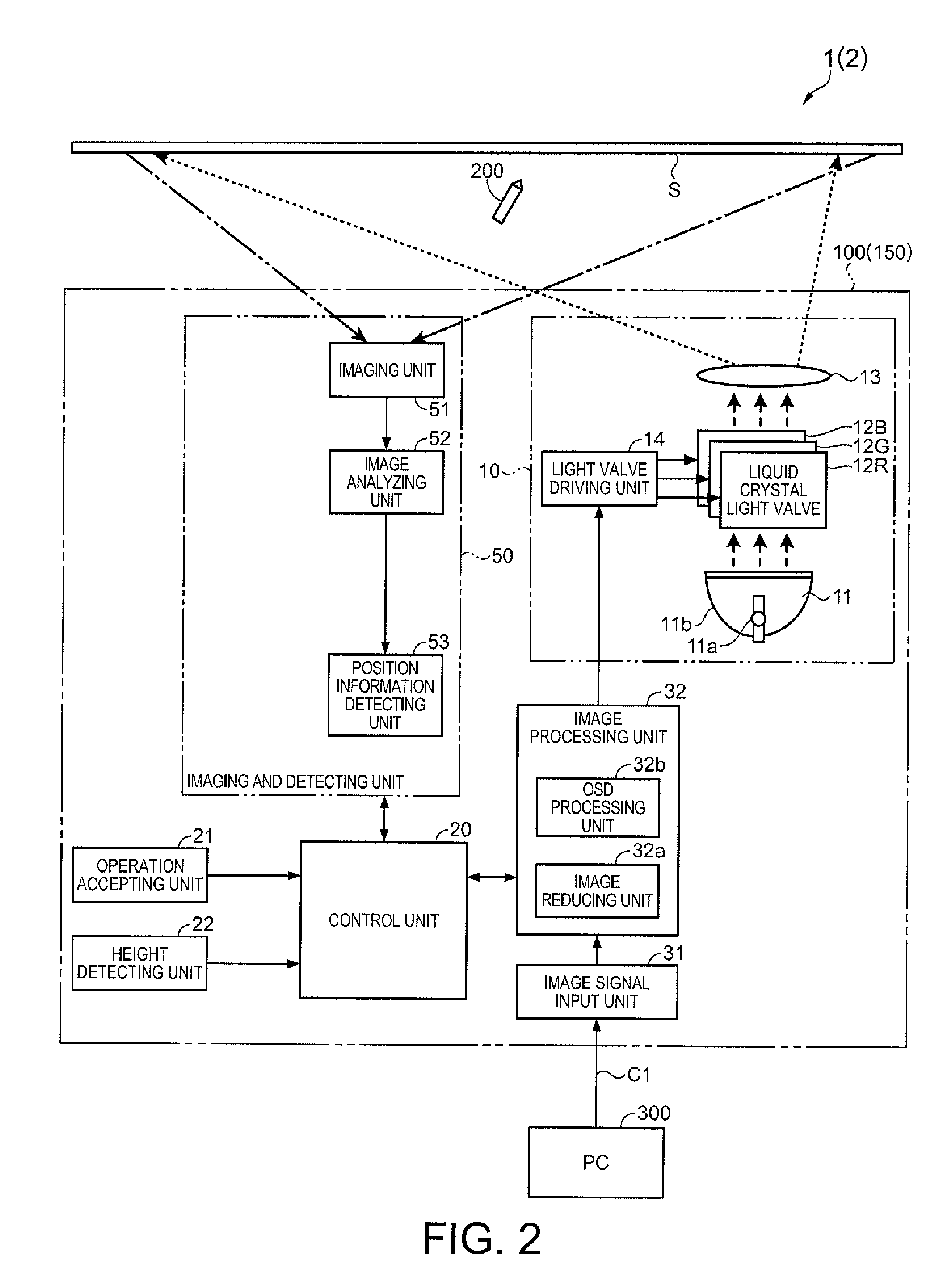

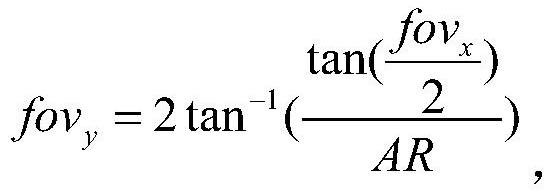

Projector system and control method thereof

ActiveUS20140192089A1Improve convenienceRestore sizeGeometric image transformationProjectorsLocation detectionComputer graphics (images)

A projector system includes: a position detecting unit that detects a pointed position of a pointer on a projection surface; a drawing unit that performs drawing on the projection surface according to the pointed position detected by the position detecting unit; a height detecting unit that detects a height of a user of a projector; and a display changing unit that changes, according to the user's height detected by the height detecting unit, at least one of a shape of the image projected onto the projection surface and a display position of the image on the projection surface.

Owner:SEIKO EPSON CORP

Process for repairing pits in titanium alloy aircraft sliding rail in argon arc welding way

ActiveCN103949757ARestore sizeReduce use costArc welding apparatusVehicle componentsStressed stateTitanium alloy

The invention belongs to the technical field of welding, relates to a process for repairing pits in a titanium alloy aircraft sliding rail in an argon arc welding way, and is particularly applied to the repair of the pits in the titanium alloy aircraft sliding rail after long-term serving in the field of maintenance of aircraft engines. According to the method, reasonable argon arc welding process parameters are used for repairing the pits in a pitted titanium alloy aircraft sliding rail workpiece, and the surface compressive stress state is recovered by shot peening strengthening after repair; the deformation of the repaired sliding rail is slight, and is controlled within a tolerance range; a repaired part is free of crack defects; the operational performance of the repaired workpiece is recovered; the titanium alloy aircraft sliding rail repaired by the method passes verification before installation, and is successfully installed for use.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

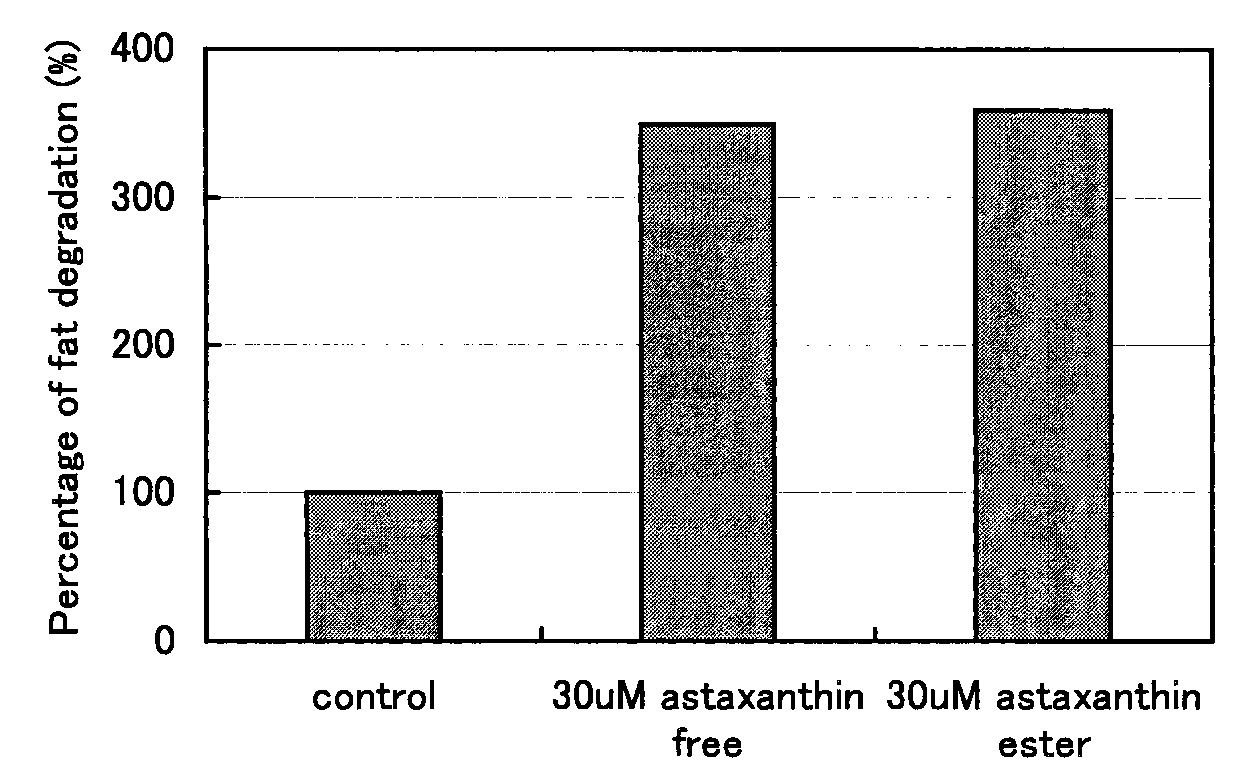

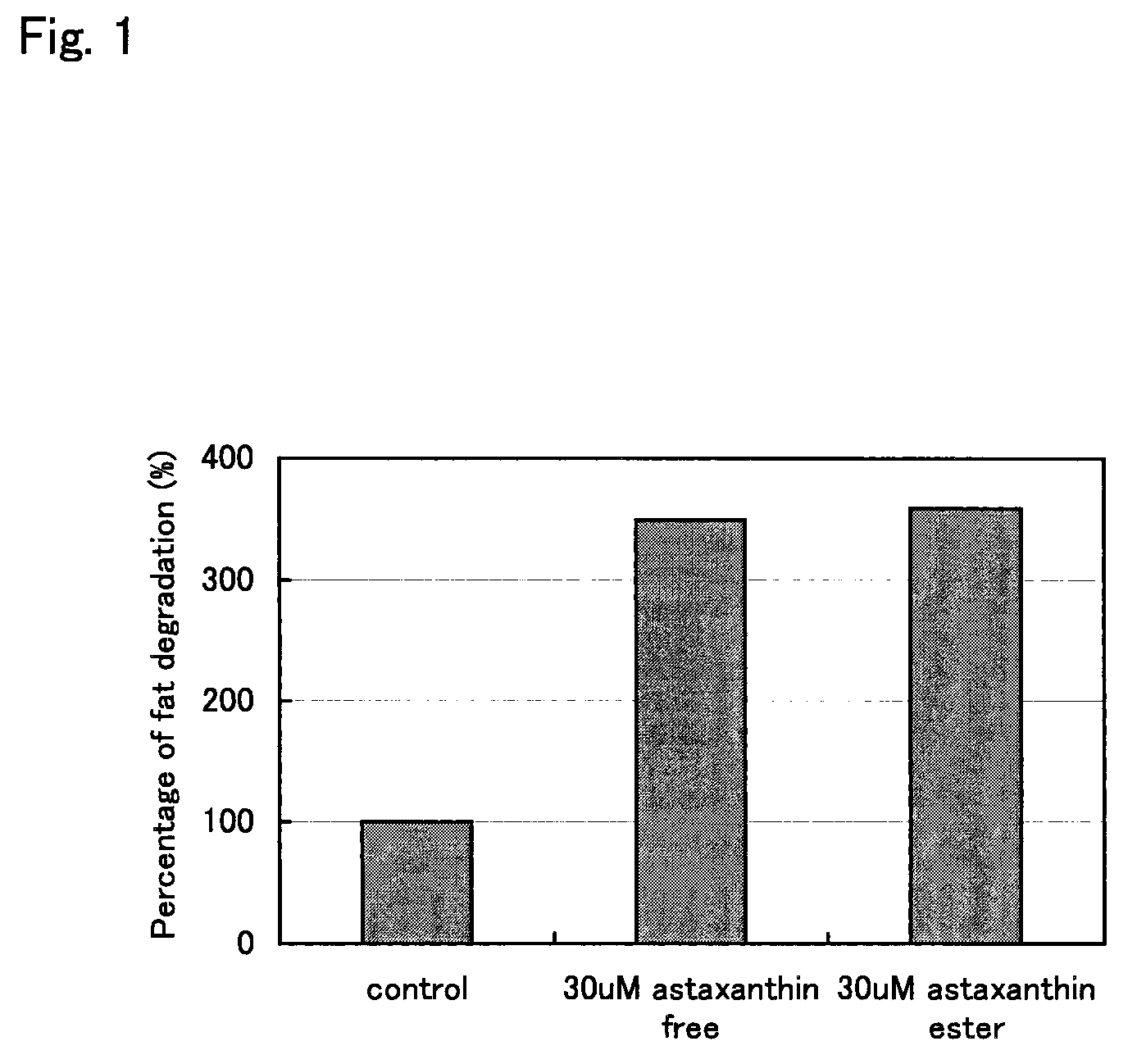

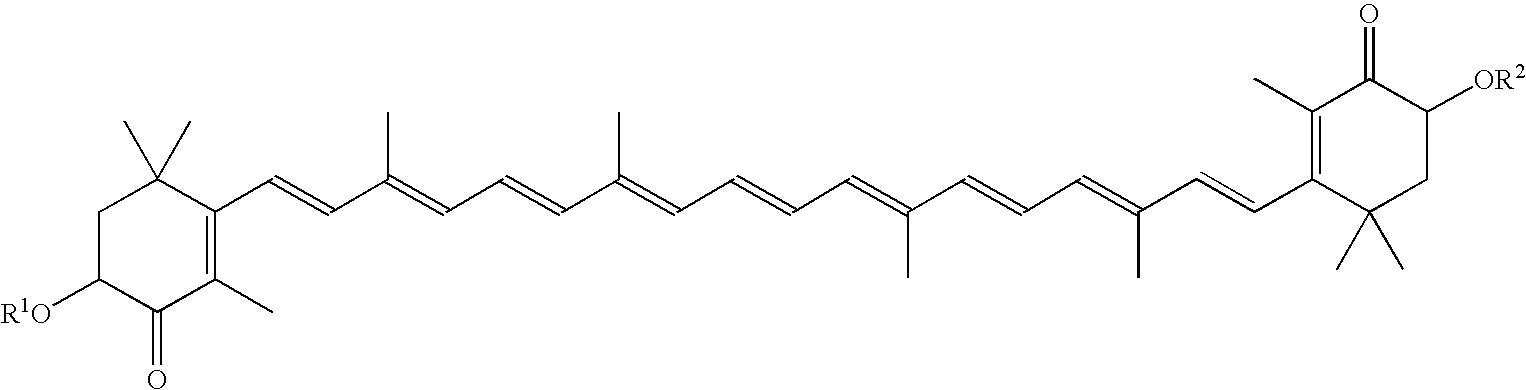

A Method for Promoting Fat Degradation

InactiveUS20090018210A1Promote lipolysisHighly effectiveBiocideOrganic active ingredientsIncreased LipolysisPhysiology

A novel, new, and highly effective agent for promoting fat degradation that contains astaxanthin and / or an ester thereof as active ingredient is provided. The agent for promoting fat degradation of the present invention has an effect of reducing fat by lipolysis of fat in either a subject who is in a condition in which fat has already accumulated or a subject who is in a condition in which fat has not yet been accumulated. Accordingly, the agent for promoting fat degradation of the present invention can restore hypertrophied adipocytes to a normal size.

Owner:YAMAHA MOTOR CO LTD

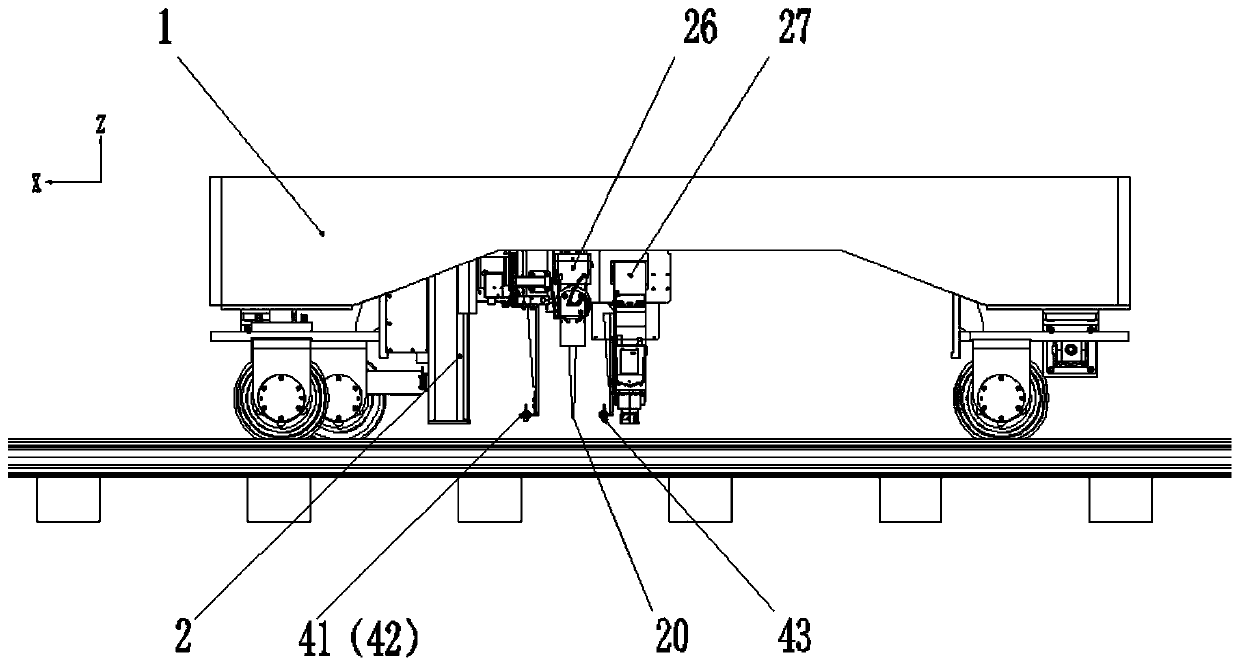

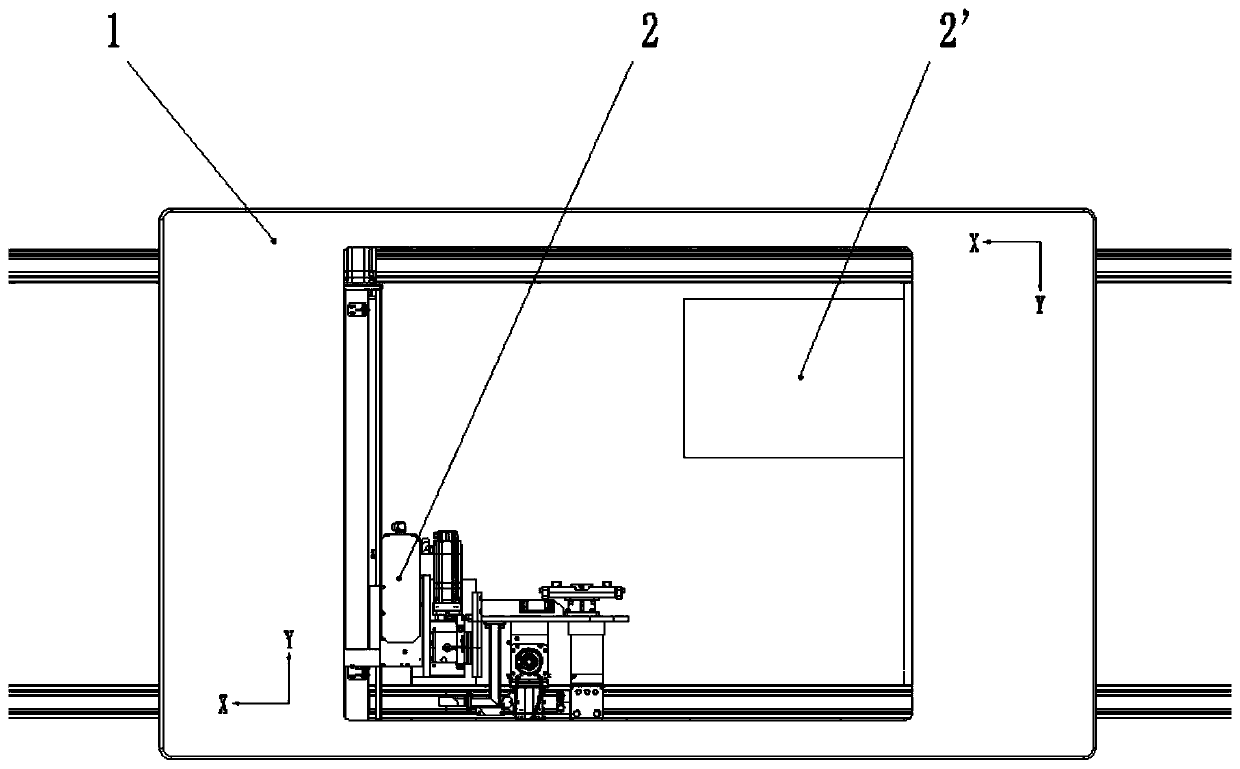

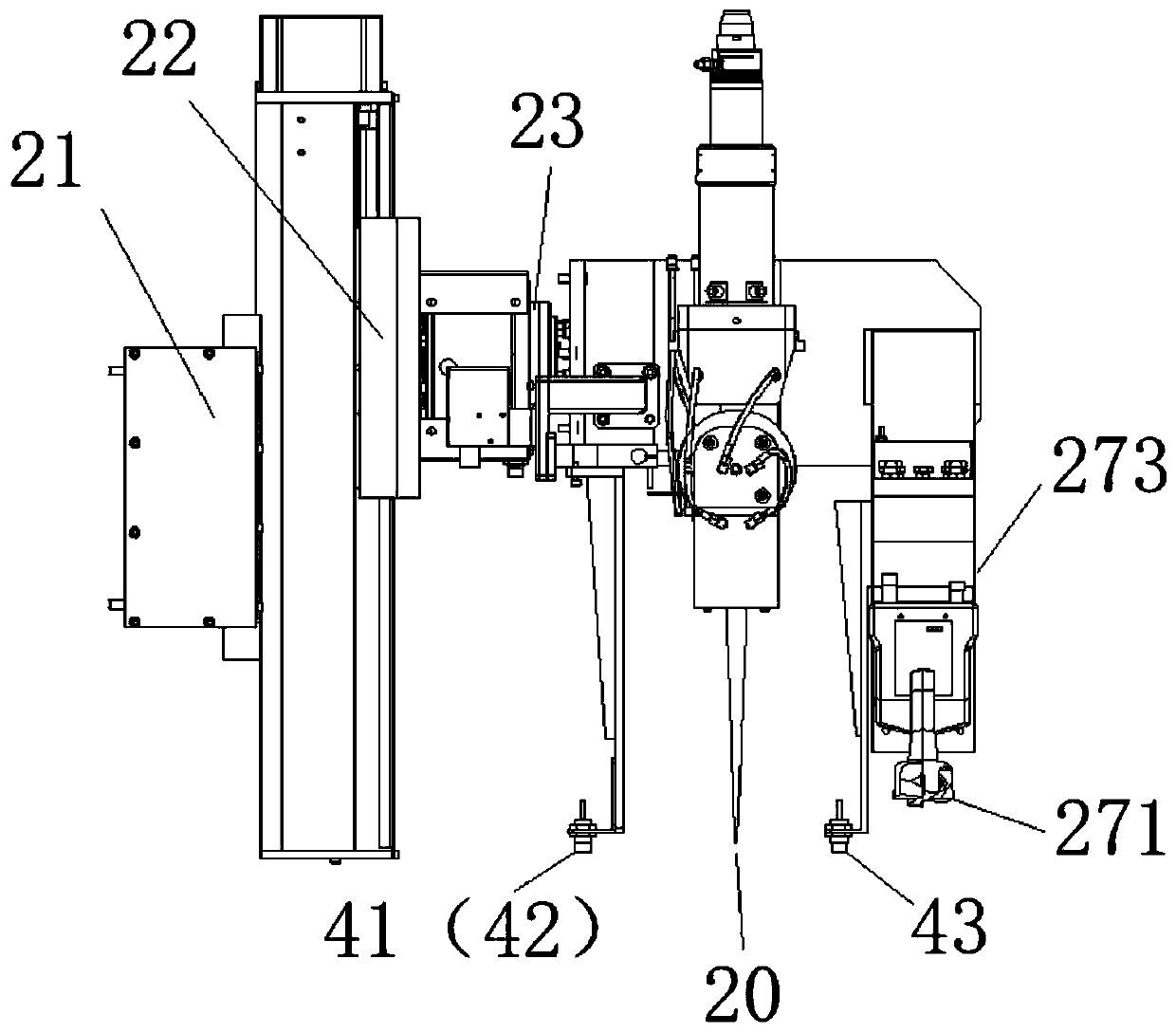

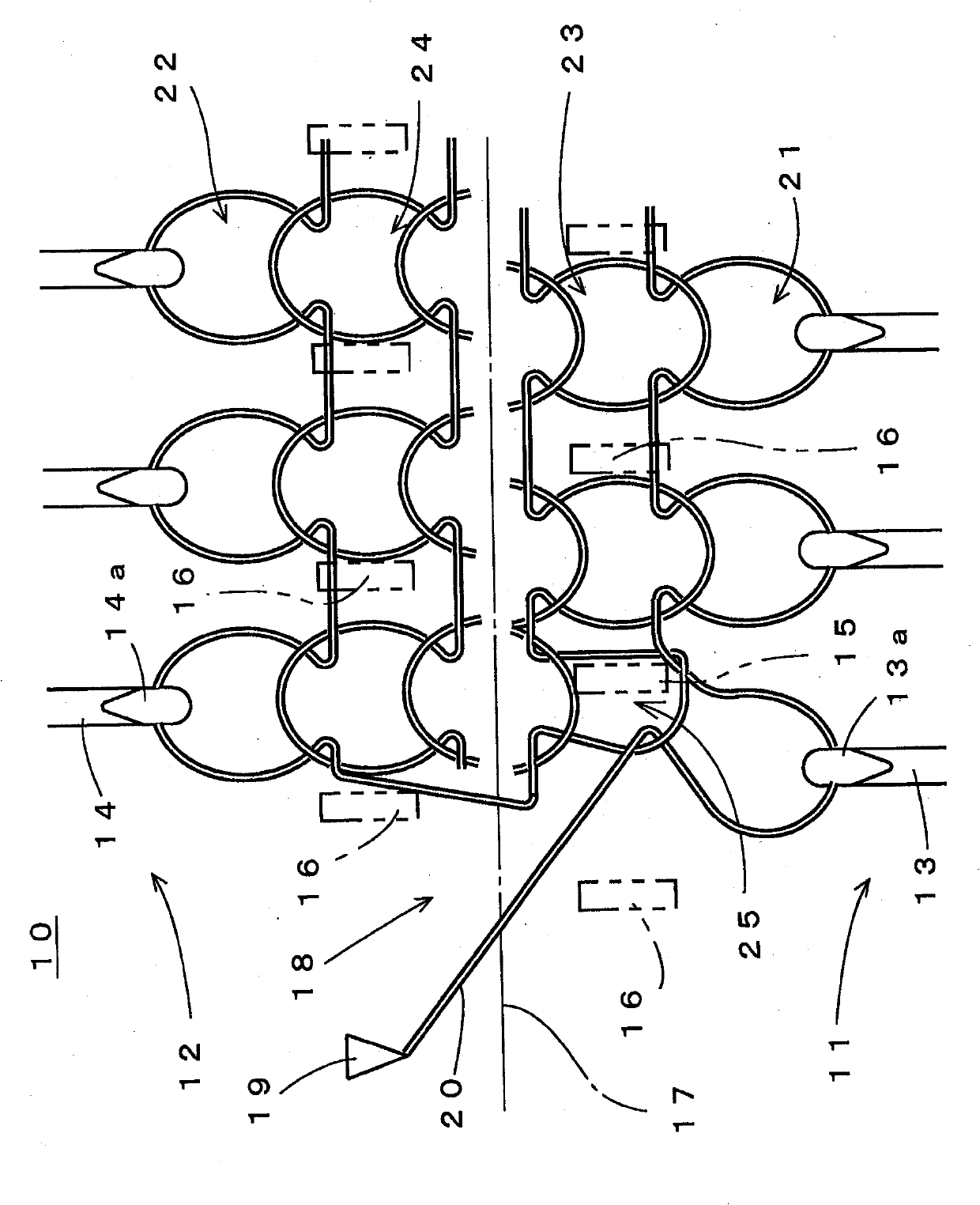

Device and method for additive manufacturing and subtractive manufacturing repairing of steel rail by combining laser cladding with machining

ActiveCN110080049AImproving the Efficiency of Online Laser Cladding RepairGuaranteed repair qualityRailway track constructionMulti axisMachining

The invention discloses a device for additive manufacturing and subtractive manufacturing repairing of a steel rail by combining laser cladding with machining. The device is characterized in that thedevice comprises a laser cladding and machining material increasing and decreasing moving carrier (1) and motion executing components (2 and 2') arranged on the laser cladding and machining material increasing and decreasing moving carrier (1), the motion executing components (2 and 2') are each of a multi-axis mechanism, laser cladding machining heads (26) and machining heads (27) of the motion executing components (2 and 2') are mounted on the same axis in the multi-axis mechanism, by moving and rotationally adjusting the position and the posture, the laser cladding machining heads (26) conduct laser cladding machining on different parts of the steel rail (40), and then the machining heads (27) conduct machining on different normal angles of all cladding channels. According to the device, integrated additive manufacturing and subtractive manufacturing steel rail repairing combining laser cladding with machining is achieved, universality is high, and the device can adapt to laser cladding material increasing repairing and machining such as milling, polishing or grinding of steel rails abraded in different situations.

Owner:HUAZHONG UNIV OF SCI & TECH +1

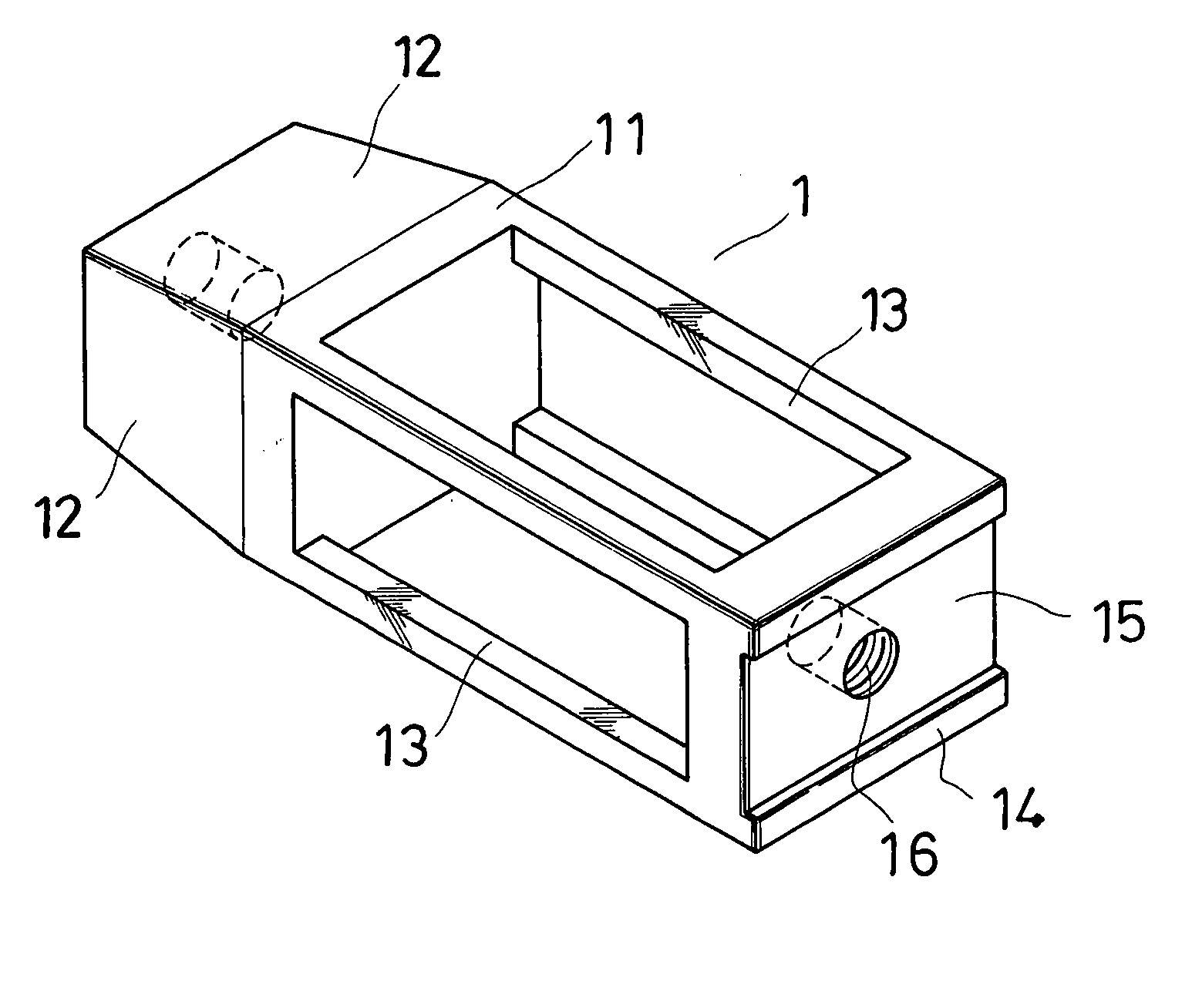

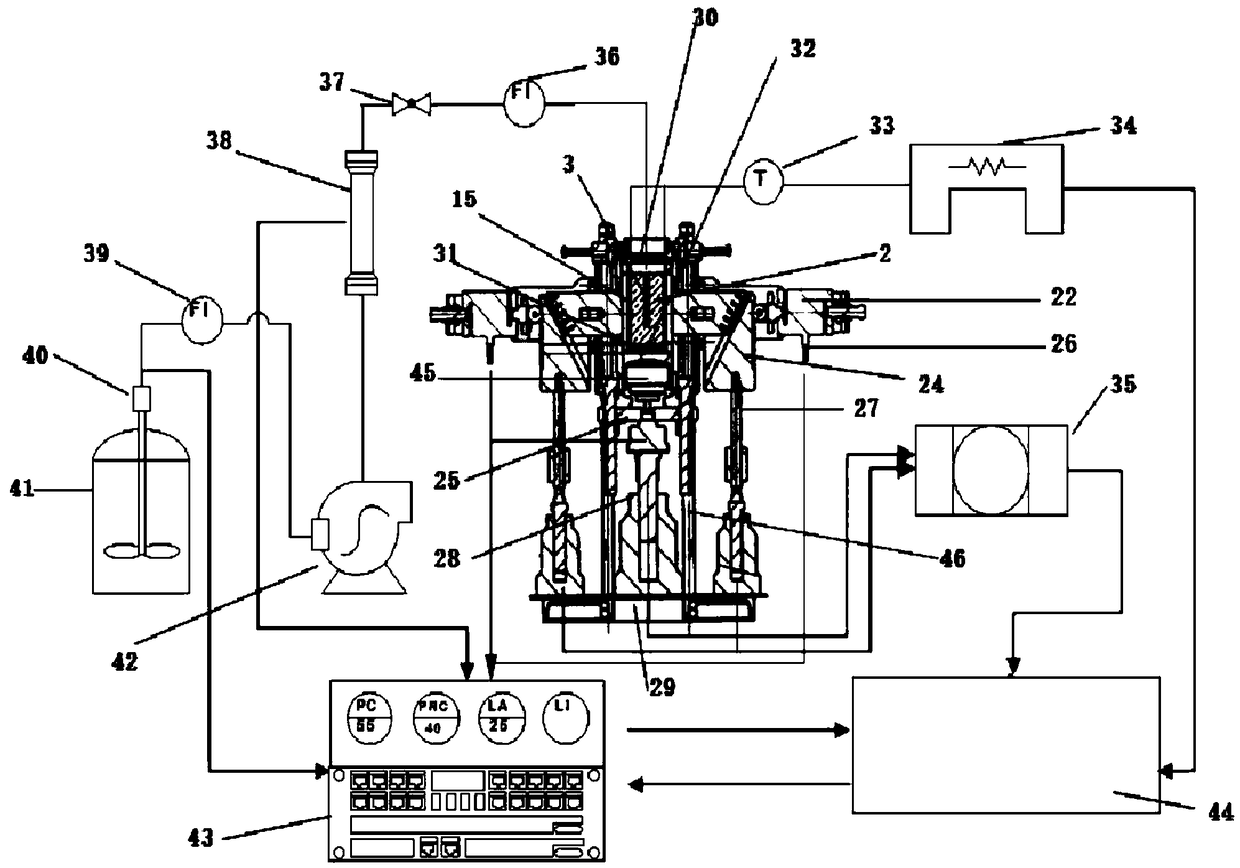

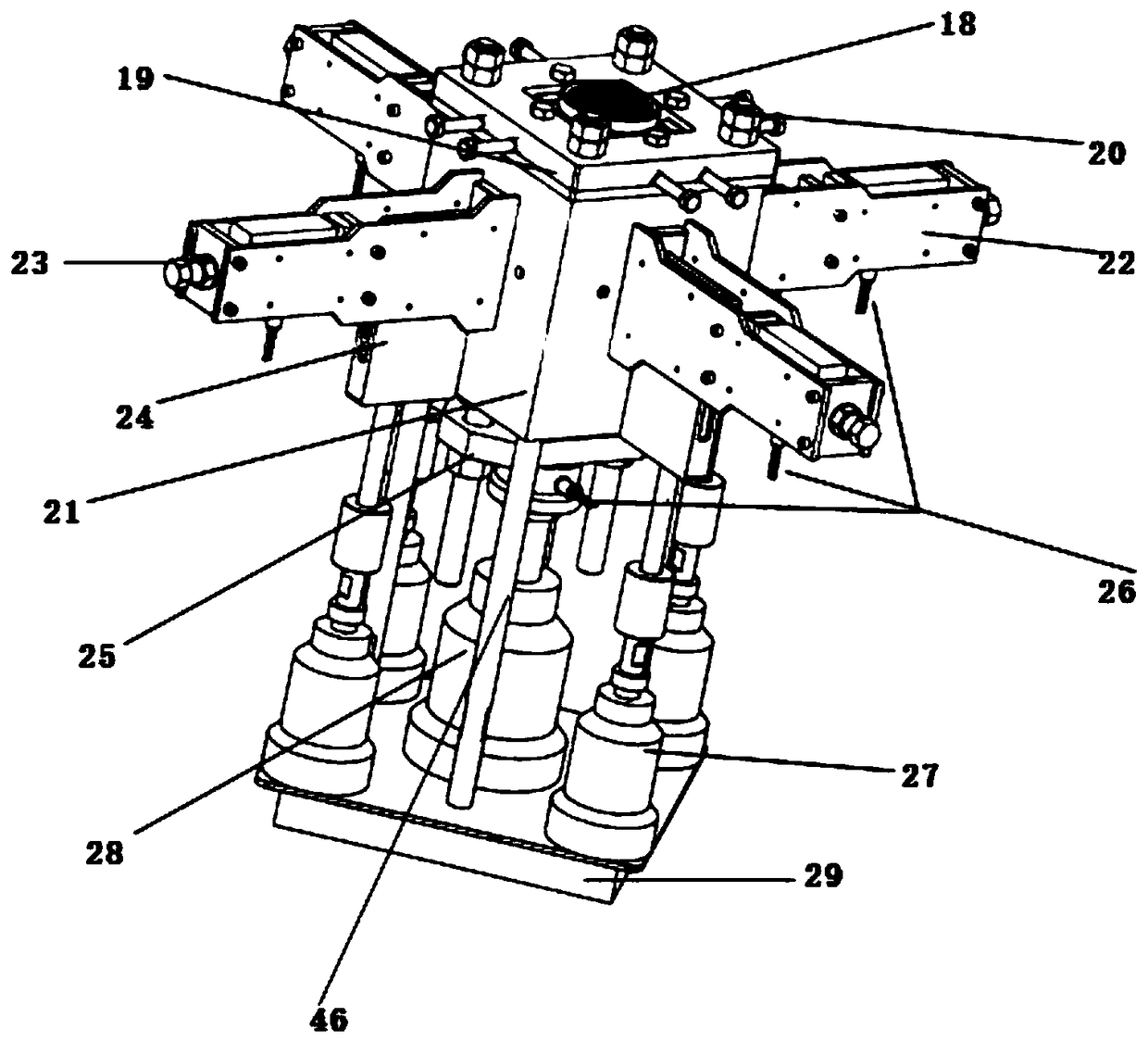

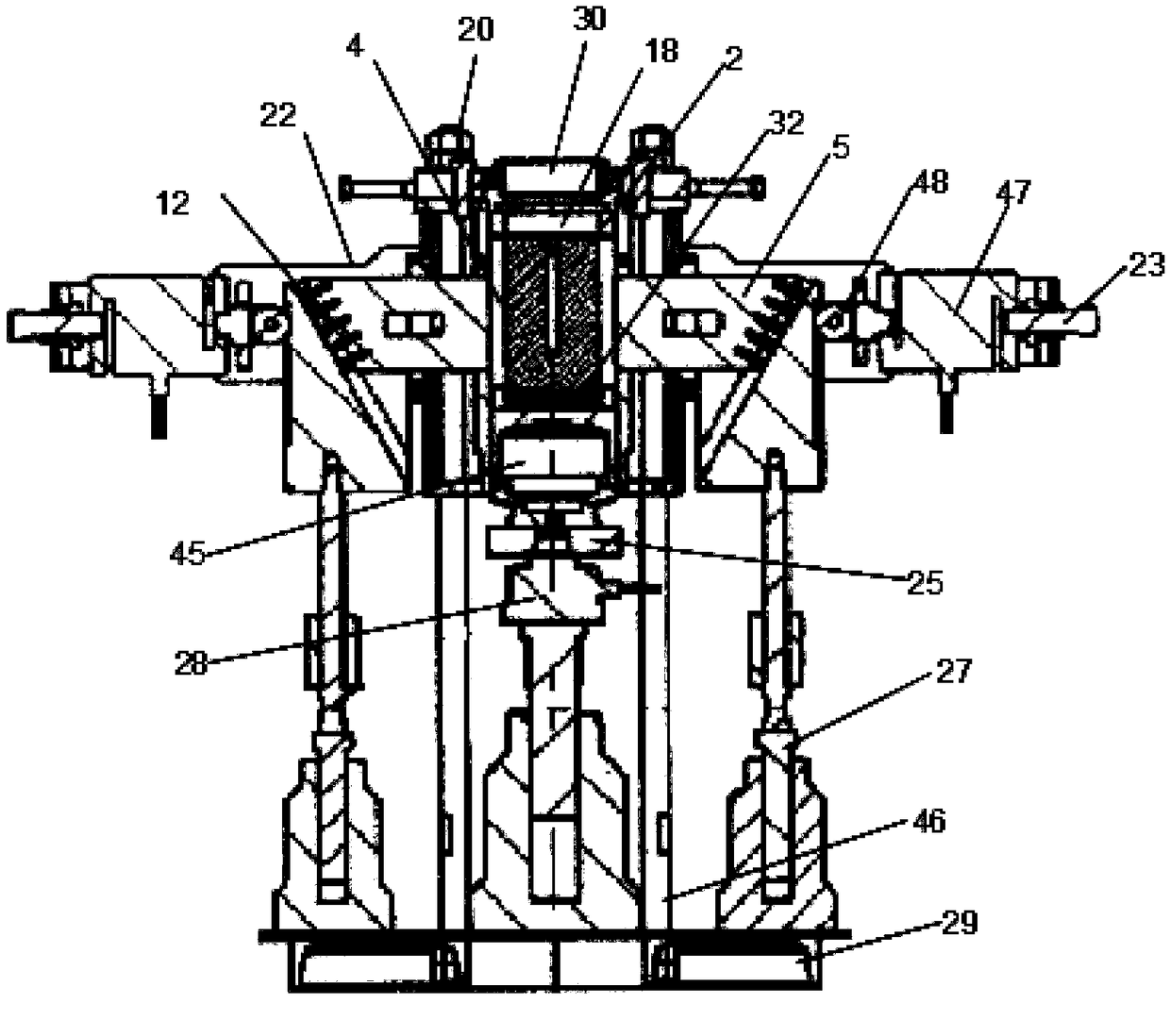

Rock fracturing physical simulation system and test method

ActiveCN108801799ARestore distributionRestore sizeMaterial strength using tensile/compressive forcesAxial pressureFracturing fluid

The invention provides a rock fracturing physical simulation system and a test method and belongs to the technical field of rock physical simulation tests. The rock fracturing physical simulation system comprises a main body frame, a rock sample room for accommodating to-be-measured rock samples, an axial pressure device, a radial pressure device, an annular confining pressure device connected with the radial pressure device and applying a circumferential pressure to the to-be-measured rock samples, and a fluid conveying device for injecting fracturing fluid into the rock sample room. The invention also provides the test method of the rock fracturing physical simulation system. The test method comprises the following steps: loading a to-be-measured rock sample, applying an axial pressure and an annular confining pressure, injecting the fracturing fluid to break the rock sample, re-solidifying the broken rock sample, and scanning the solidified rock sample. Compared with the prior art,the rock fracturing physical simulation system and the test method provided by the invention truly restore the distribution and magnitude of ground stress, comprehensively simulate the stress state during rock fracturing, and provide reliable data for analyzing the mechanical properties and fracturing effect of rock.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

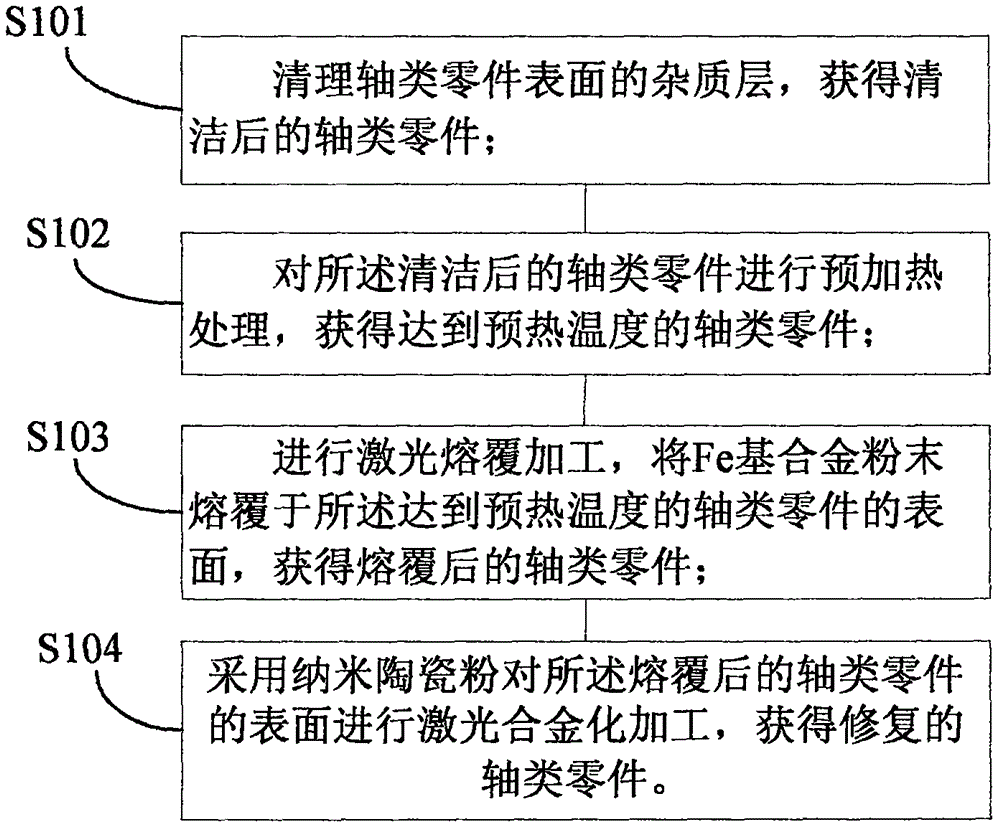

Laser surface compound reinforced restoring method and shaft part restored with same

InactiveCN105734563AImprove wear resistanceHigh hardnessMetallic material coating processesHardnessImpurity

The invention provides a laser surface compound reinforced restoring method and a shaft part restored with the same. A shaft part material is made to have high corrosion resistance, surface hardness and corrosion resistance of the material are improved obviously, the surface size of the abraded shaft part can be restored, and high hardness of the part surface is ensured without cracking. The method includes the steps that an impurity layer on the surface of the shaft part is cleared to obtain the cleaned shaft part; the cleaned shaft part is heated in advance to obtain the shaft part at the preheating temperature; laser cladding machining is conducted, the surface of the shaft part at the preheating temperature is clad with Fe-based alloy powder to obtain the clad shaft part; nano ceramic powder is adopted to conduct laser alloy machining on the clad surface of the shaft part to obtain the restored shaft part.

Owner:山西玉华再制造科技有限公司

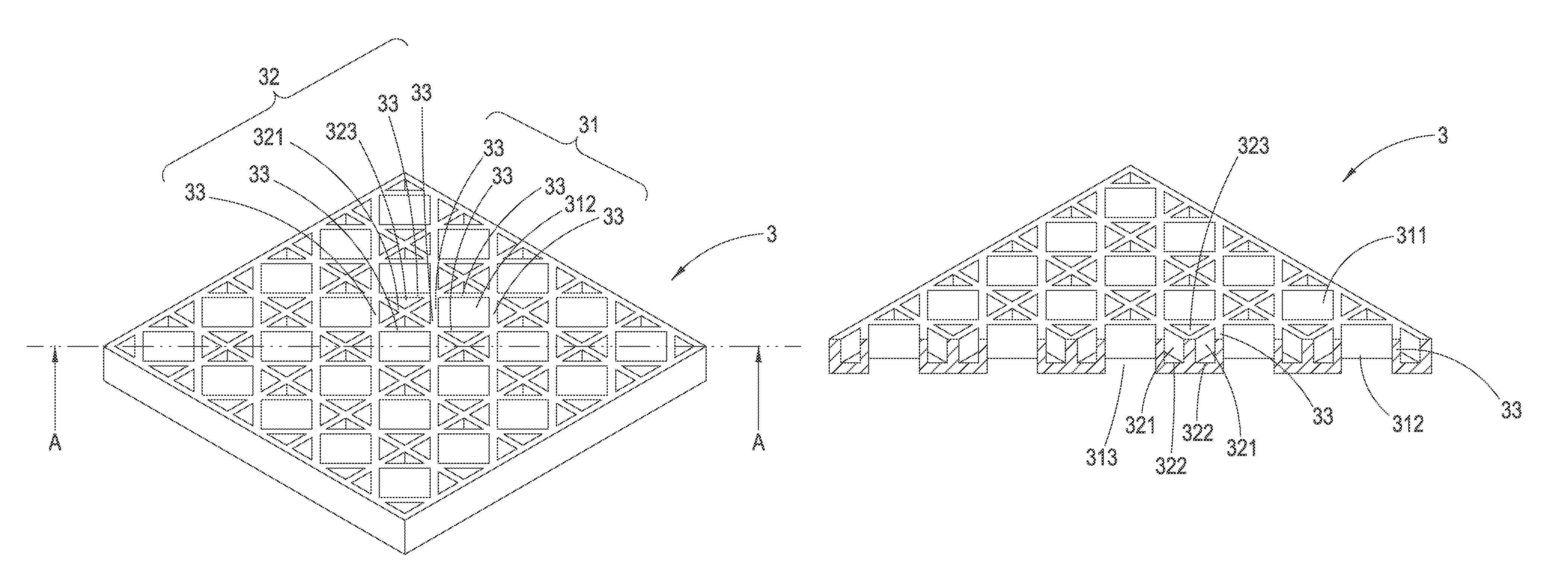

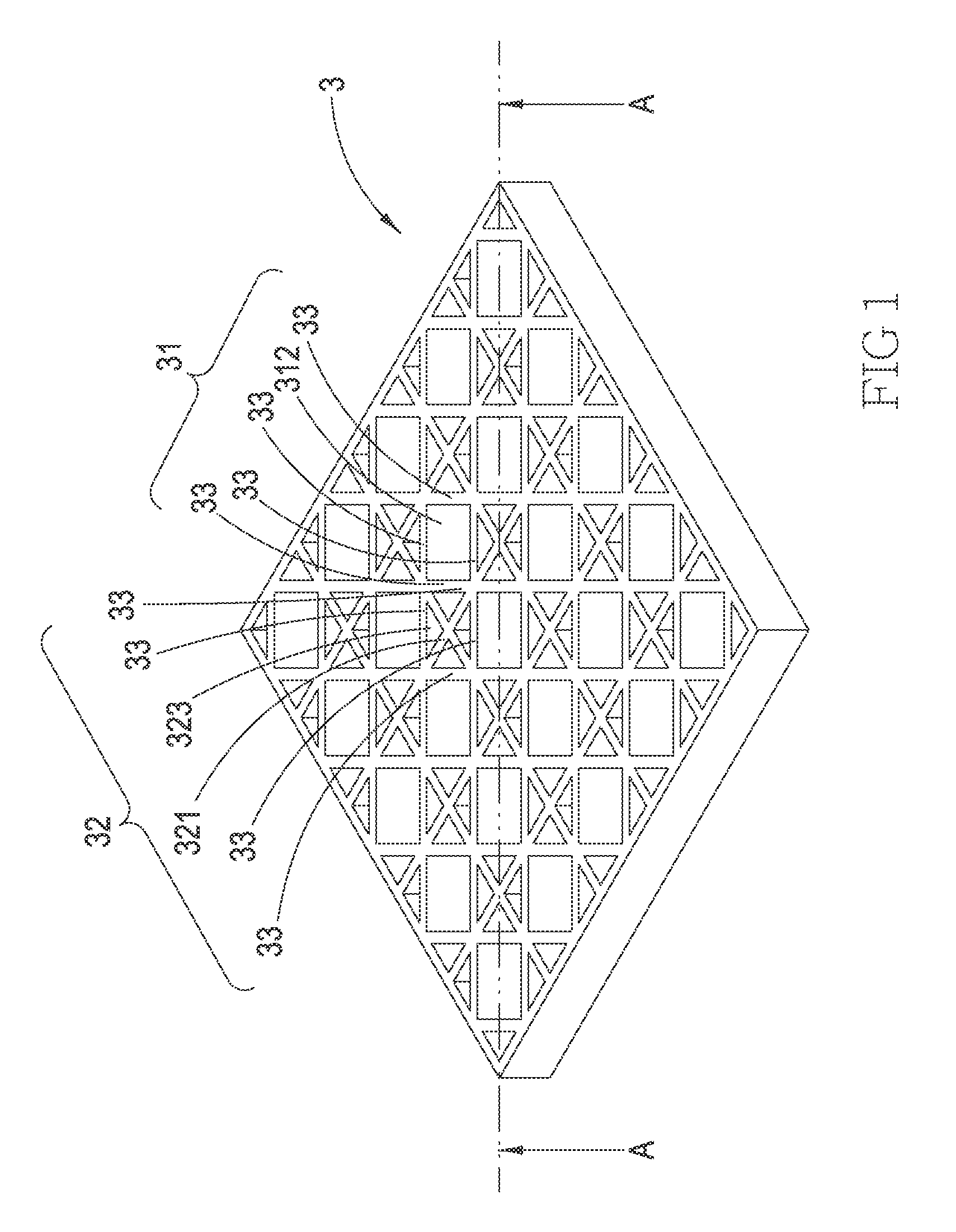

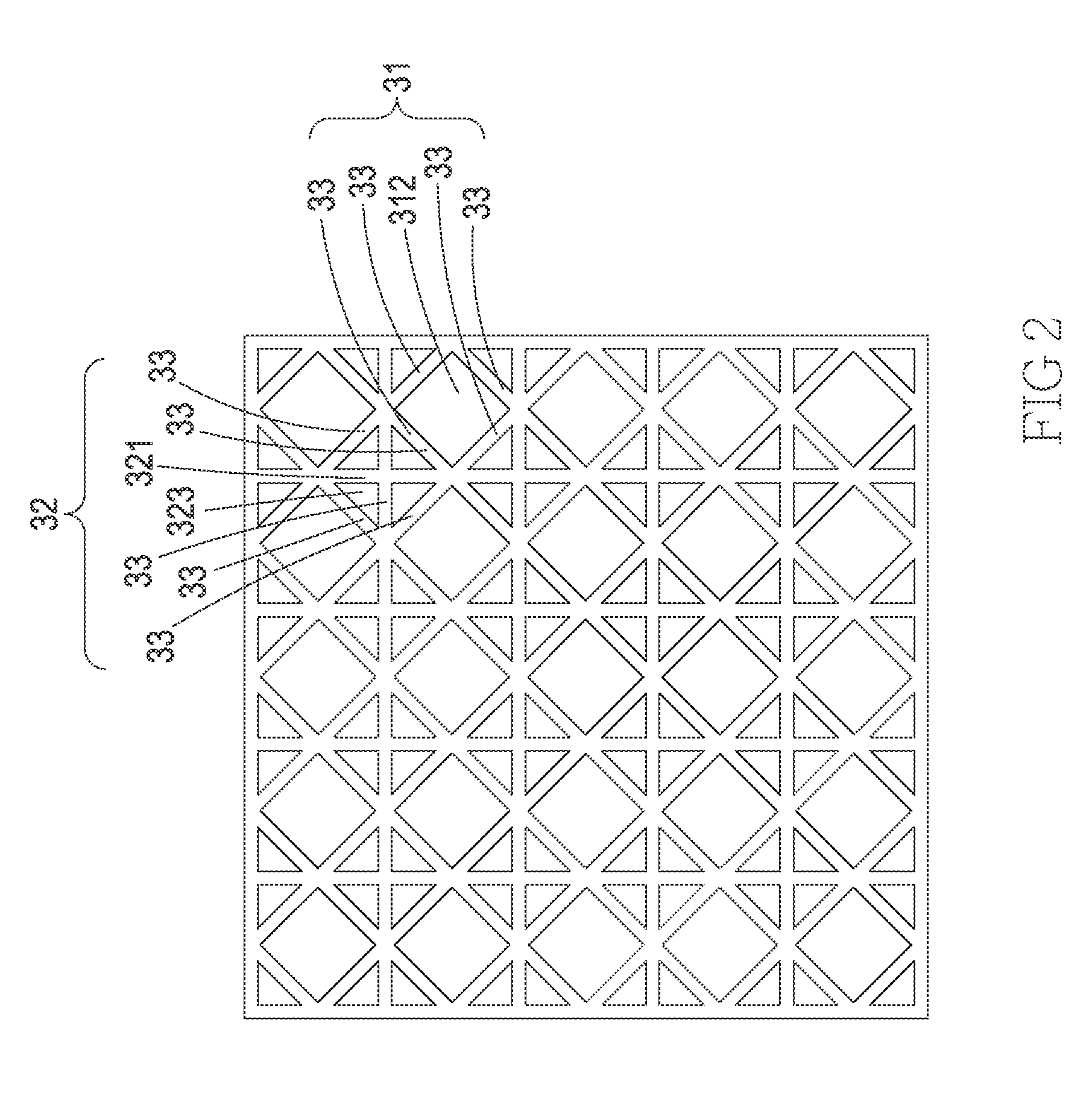

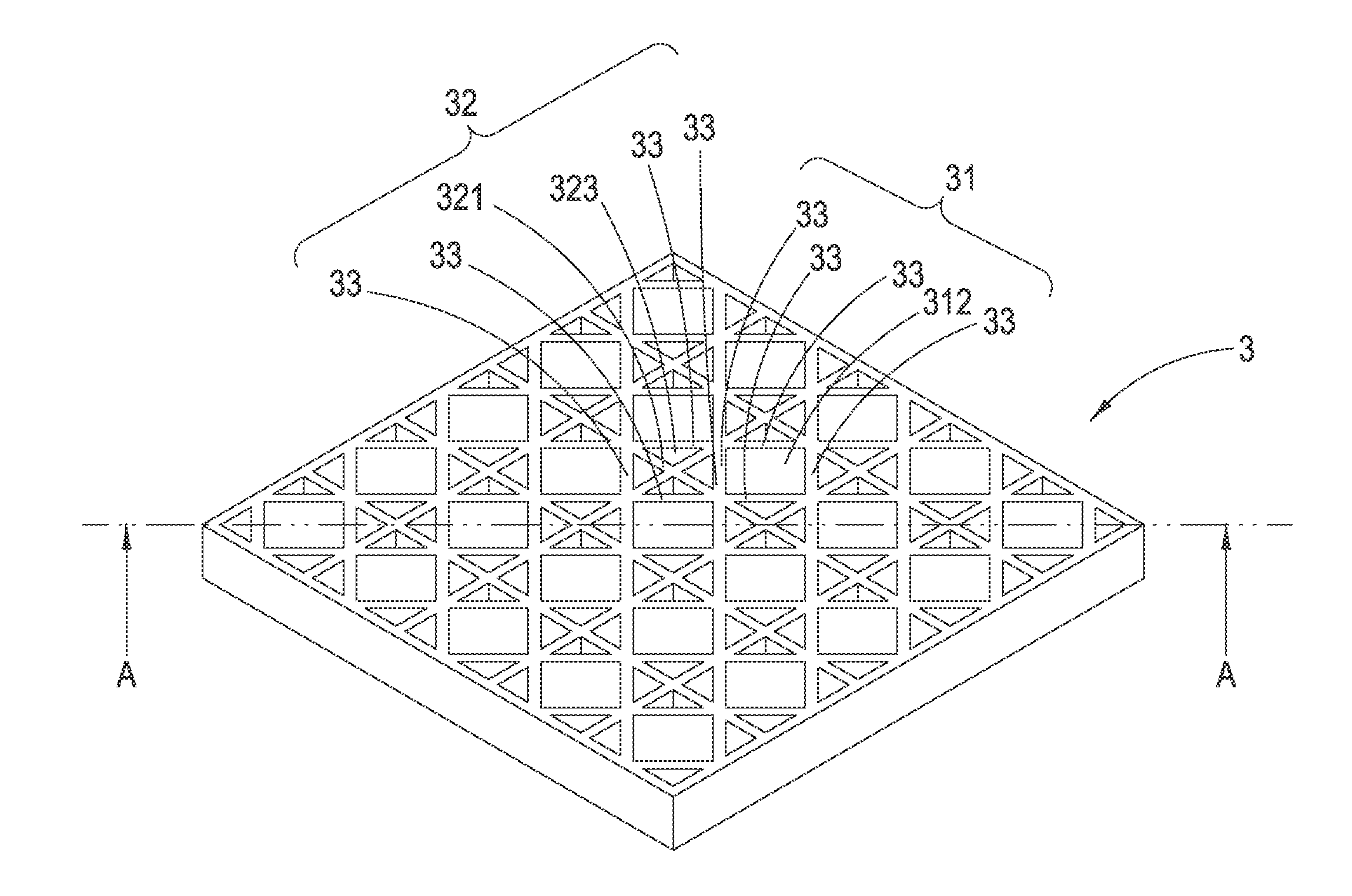

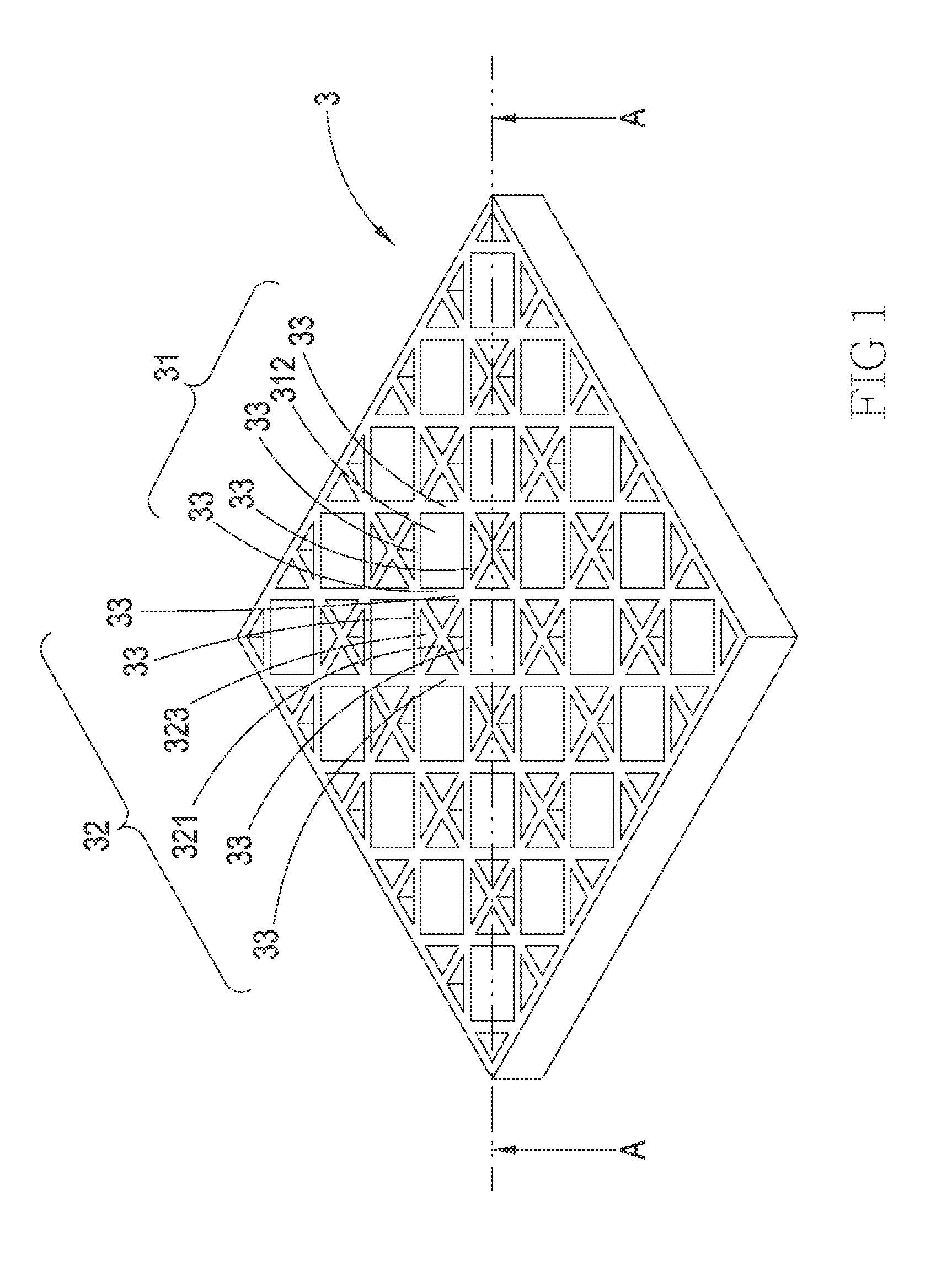

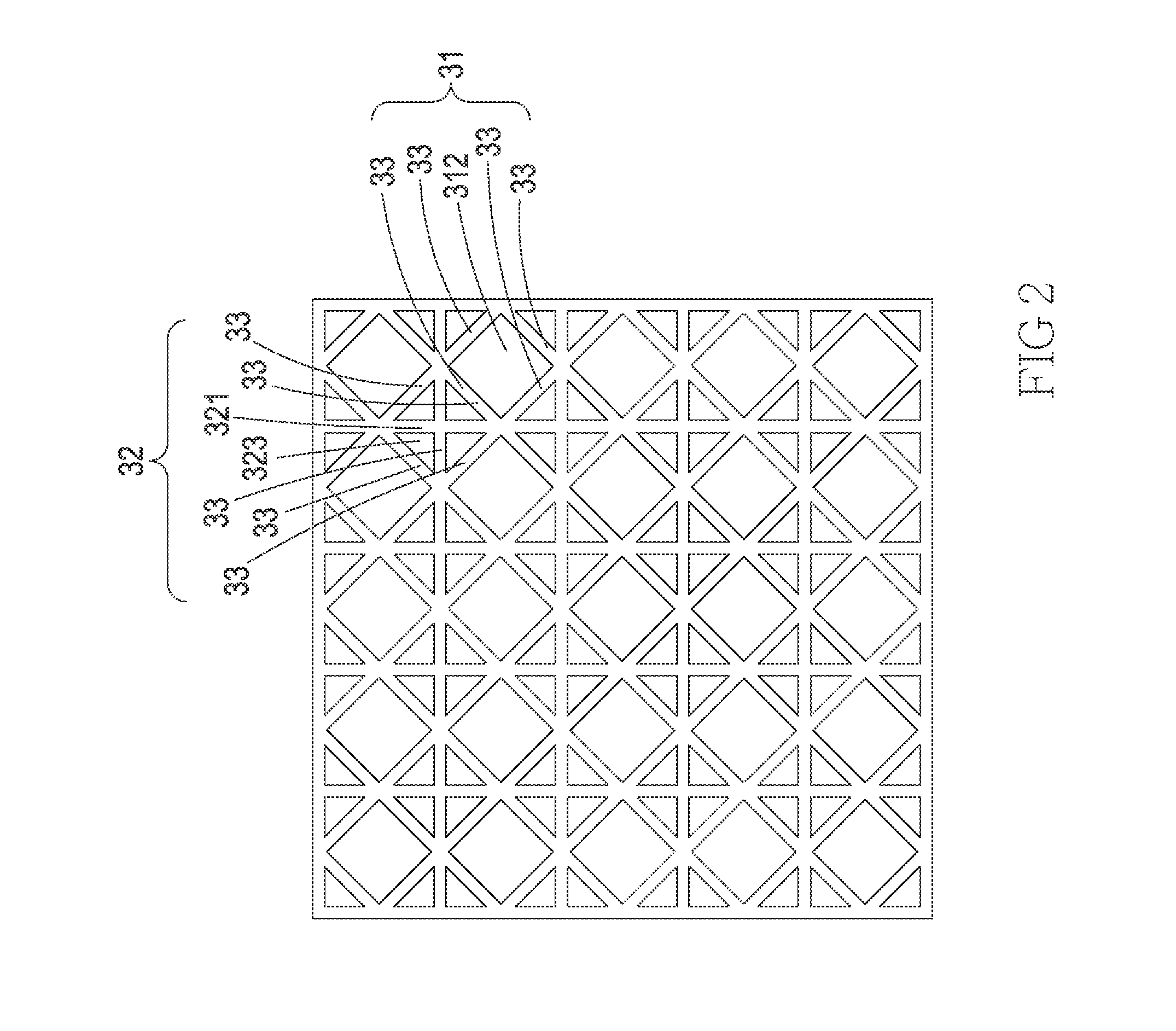

Solid gel cushion system

ActiveUS9049944B2Inferior heat dissipationIncrease pressureFluid mattressesStoolsEngineeringAtmosphere

A solid gel cushion system is provided. The solid gel cushion system includes a first elastic quadrilateral body having a first elastic surrounding sidewall to define a first space allowing for a heat exchange. The first elastic quadrilateral body defines a first top surface and a first bottom surface with respect to the first elastic surrounding sidewall, both of which are communicative of surrounding atmosphere in order to form an air passage. The cushion system further includes a second elastic quadrilateral body having a second elastic surrounding sidewall defining a second space in which two interleaving elastic supporting ribs are formed. The first elastic quadrilateral body is surrounded by the four second elastic quadrilateral bodies.

Owner:FORMOSA SOUNDING

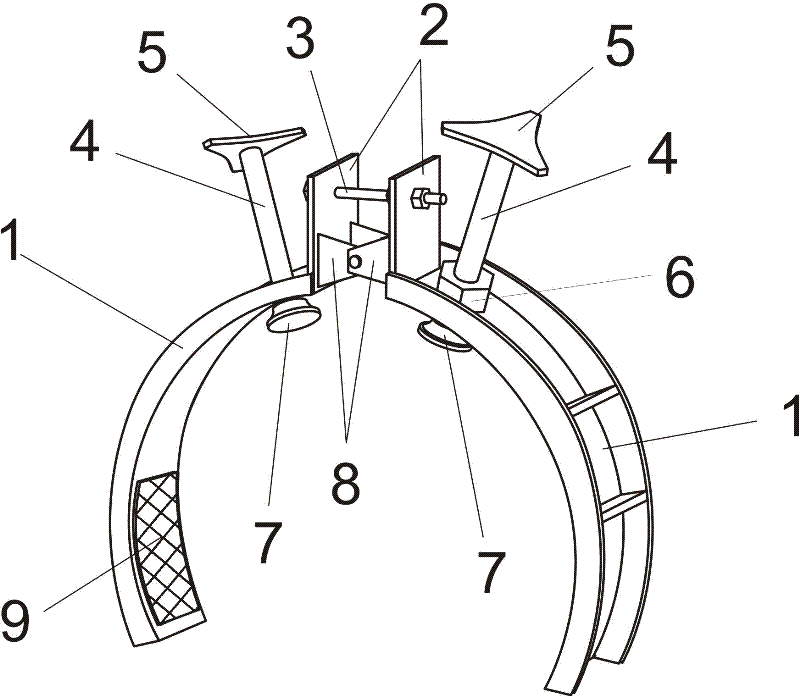

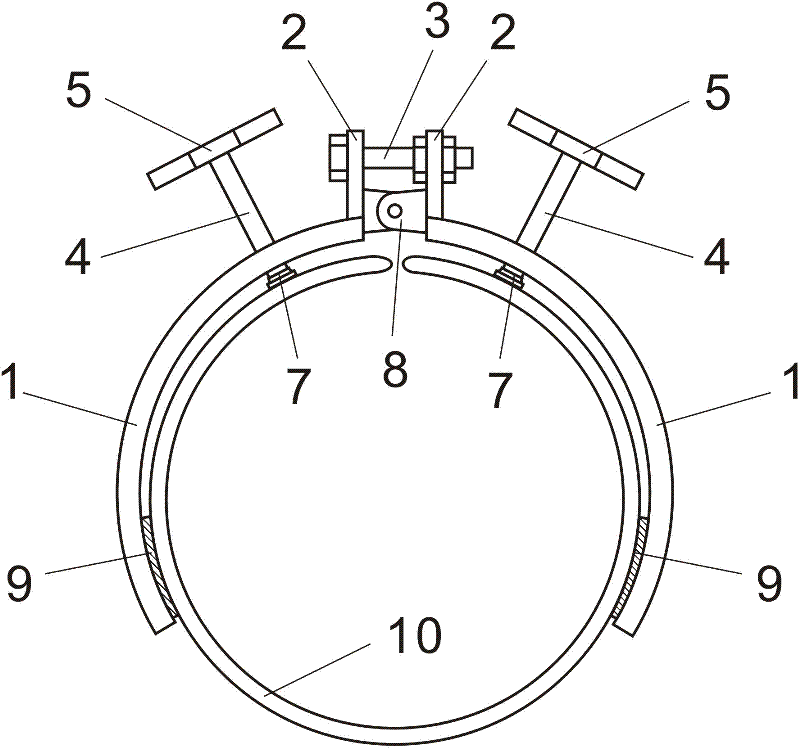

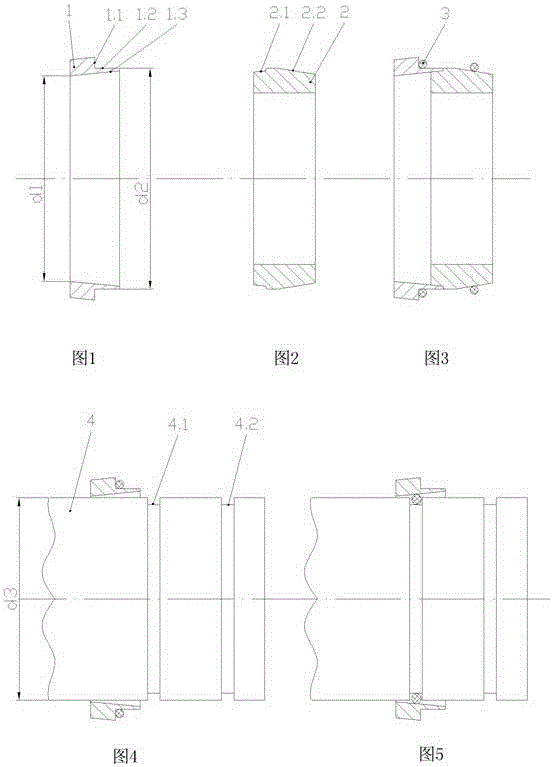

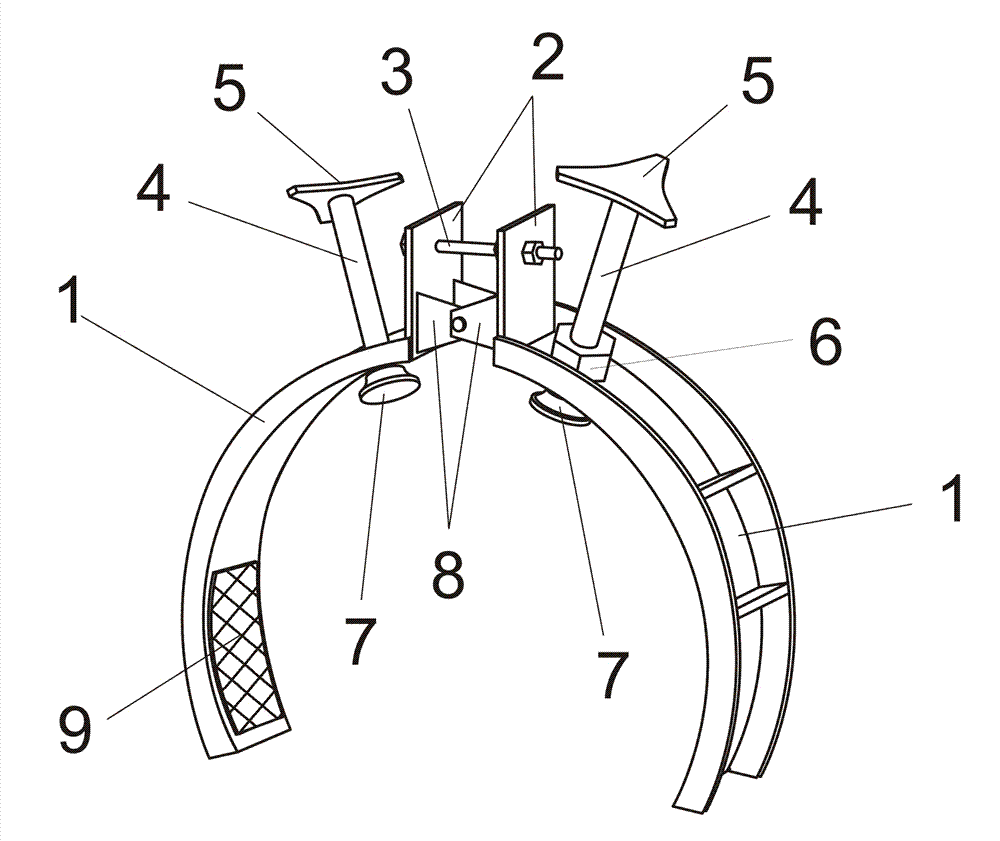

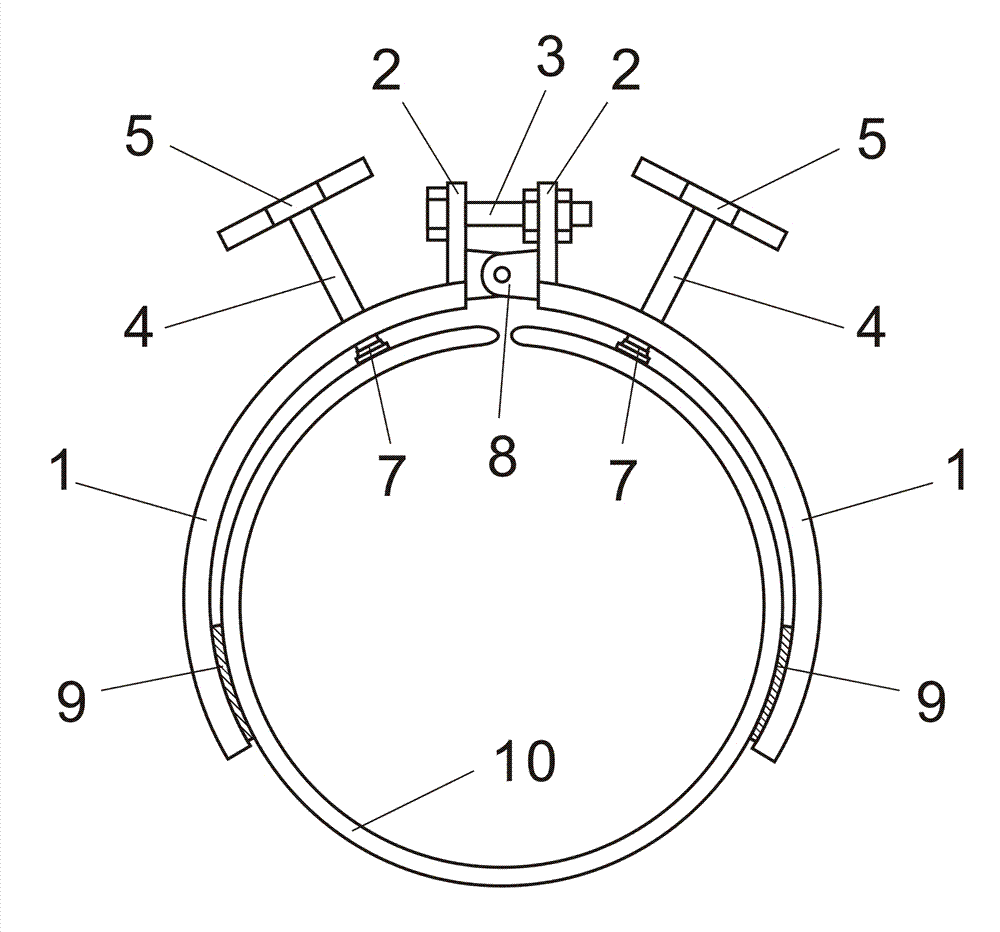

Method and device for correcting drum waist deformation during rolling of cylindrical body

The invention belongs to the field of manufacturing of machinery, in particular to a method and device for correcting drum waist deformation during rolling of a cylindrical body. The device comprises two symmetrical arc-shaped components, an adjusting bolt and a working bolt, wherein the symmetrical arc-shaped components are hinged with each other through a connecting sheet to form a clamp-shapedstructure. The correcting method comprises the following steps of: sleeving the device into the cylindrical body, wherein the opening of the cylindrical body faces the hinged position of the two arc-shaped components; making the two arc-shaped components cling to the cylindrical body by adjusting a nut on the adjusting bolt; and applying pressure to the drum waist deformation position of the cylindrical body opening by adjusting the screwing depth of the working bolt to restore the drum waist position to a designed size. By adopting of the method and the device, the drum waist deformation during rolling of the cylindrical body is corrected in a semi-mechanical way instead of a purely manual knocking way, so that the workpiece size can be recovered accurately, the workpiece welding qualityis improved, the labor intensity of workers is lowered, the production efficiency is increased, noise pollution is avoided, and a good effect is achieved.

Owner:CRRC ZIYANG CO LTD

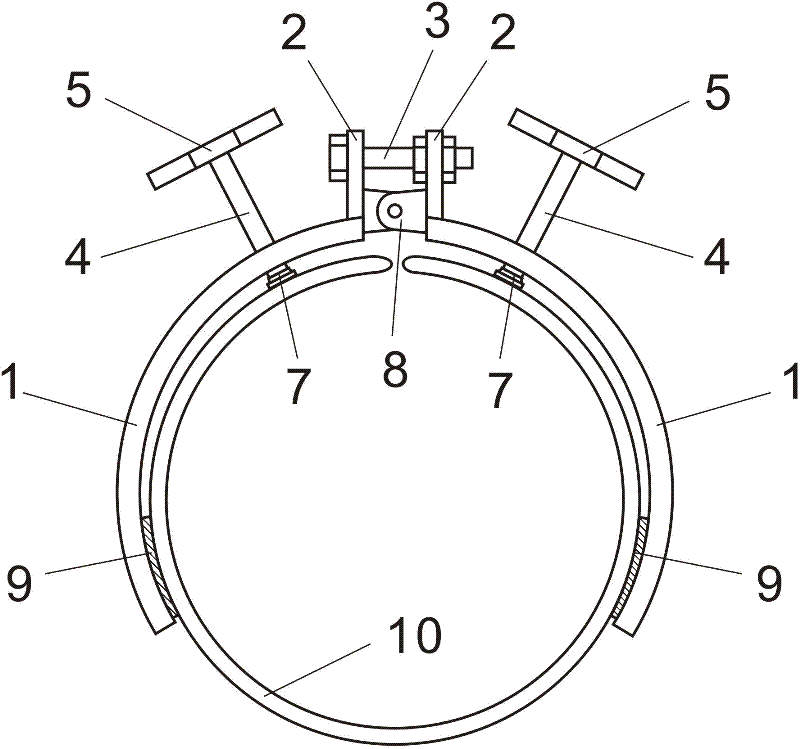

Flat knitting machine for knitting cylindrical knitted fabric and method of knitting cylindrical knitted fabric

ActiveCN101768825ARestore sizeReduce expansionCircular knitting machinesFlat-bed knitting machinesYarnBiomedical engineering

The present invention provides a flat knitting machine for knitting cylindrical knitted fabric having un-conspicuous boundaries and a method of knitting cylindrical knitted fabric. The knitting width is reduced when knitting needles (13, 14) cast off and are transferred to a mouth (18), therefore an old coil (25) from a knitting needle (13) of the end of the knitting width is shrank in a mode of being bias from a new coil (21) toward the inner side of the knitting width, if the position of an expansion component (15) is arranged to be identical with that of the old coil (25), the frontend of the expansion component (15) is capable of entering into the mouth (18) and is inserted into the old coil (25), if the shape of the frontend of the expansion component (15) is designed to be a taper shape which is thin and has a small variation of diameter, the frontend can be easily inserted into the old coil (25) for expanding the old coil (25) gradually, and even through being reduced, the sizeof a new coil (21) finally formed by reversing the direction of supplying knitting yarn (20) can be recovered through the expending of the expansion component (15) by transferring the front end of the expansion component to the mouth (18) to form the old coil (25) after round knitting.

Owner:SHIMA SEIKI MFG LTD

Pumping Fluid To Seal A Subterranean Fracture

InactiveUS20150233205A1Lower the volumeReduce fluid pressureSurveyFlushingHigh concentrationEngineering

The disclosure teaches a method of sealing fractures in a wellbore wherein the steps comprise pumping a first sealing fluid into a wellbore under pressure, monitoring the hydraulic pressure of the sealing fluid in the wellbore for an indicator of seal initialization, stopping the pumping of fluid into the wellbore, monitoring the hydraulic pressure of the sealing fluid in the wellbore, and pumping a second sealing fluid into the wellbore. The disclosure also includes the method wherein the concentration of sealing materials in the first fluid is greater than the concentration of sealing materials in the second fluid and the method wherein the first sealing fluid contains a higher concentration of larger diameter sealing materials than the second sealing fluid. The disclosure also includes a method wherein the pumping rate change between the first pumping of sealing fluid and the pumping of the second sealing fluid. The first and second sealing fluids can be the same. The sealing materials of a sealing fluid are selected such that some of the sealing materials are larger than an estimated original fracture size.

Owner:SHARP ROCK TECH

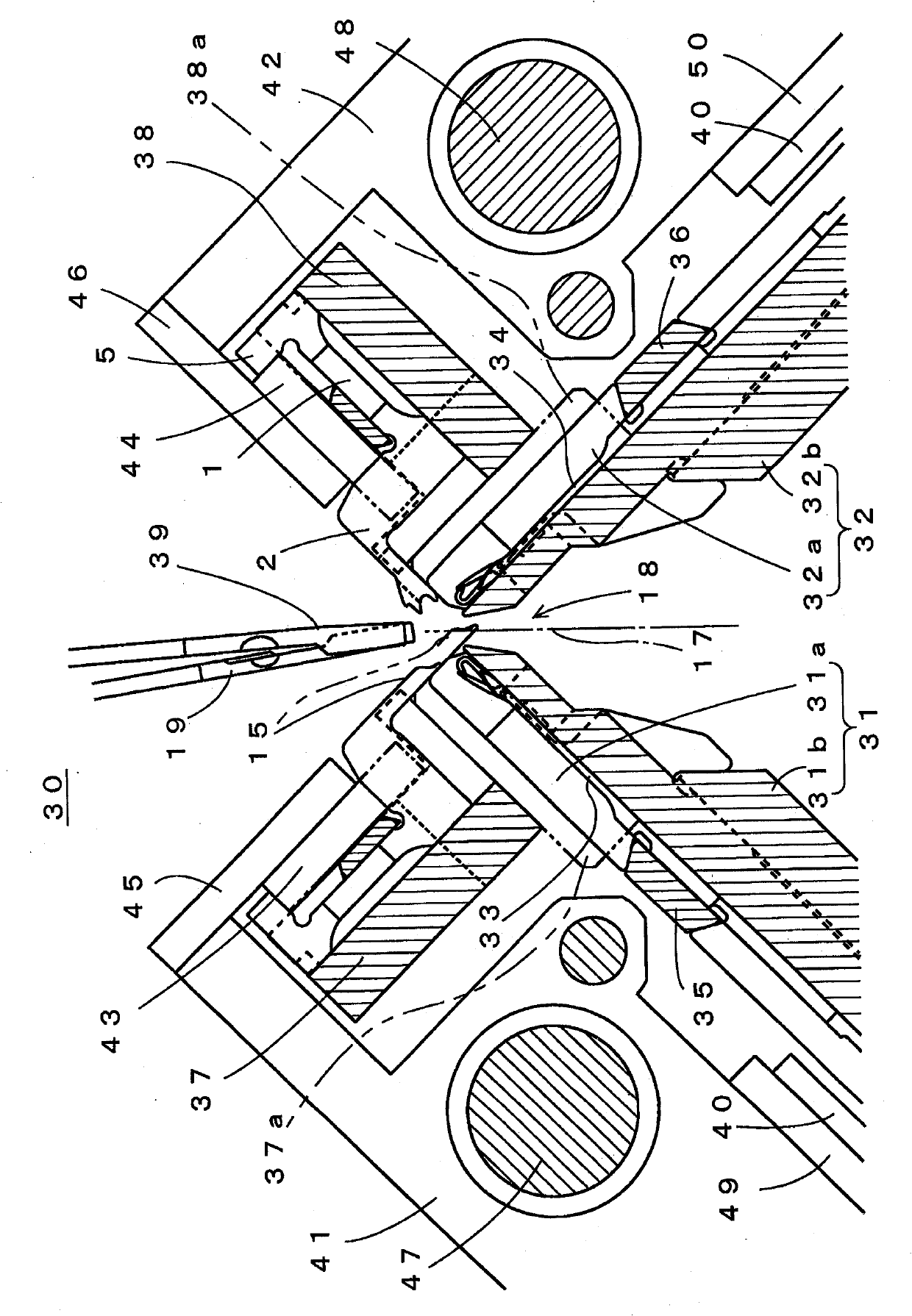

Shaft seal installation tool and installation method

InactiveCN105757251ARestore sizeAvoid cutsEngine sealsMetal-working hand toolsConical surfaceSupport surface

The invention discloses a shaft seal installation tool and a shaft seal installation method. The shaft seal installation tool is characterized in that an installation ring comprises a radial supporting surface, an axial supporting surface and an inner hole conical surface; the outer diameter of the axial supporting surface is greater than the minimum inner diameter of the inner hole conical surface, and the width of the axial supporting surface is greater than the cross section diameter of a seal ring; and the minimum inner diameter of the inner hole conical surface is matched with a predetermined seal size of the seal ring and slightly greater than the outer diameter of a shaft required to be installed with the seal ring. The installation ring further can form a combined installation tool together with a guide ring. During installation, the seal ring is used for sleeving the axial supporting surface of the installation ring directly or through the guide ring, the installation ring is moved to the left side of a seal groove in the shaft, the seal ring is pushed in the seal groove, the installation ring is taken out reversely, and the inner hole conical surface is extruded for enabling the expanded and deformed seal ring to be recovered in size; and by repeating the steps, a plurality of seal rings can be installed. By applying the shaft seal installation tool and installation method, the seal rings can be conveniently installed and the cutting damage of the seal rings during subsequent parts assembly can be prevented.

Owner:张辉

Pitting Corrosion and Peeling Repair Technology of Rotary Kiln Tire and Support Roller

The invention discloses a process for repairing pitting and spalling of a tyre and a carrier roller of a rotary kiln. The process comprises the following steps of: cutting the pitting and spalling positions of the tyre and the carrier roller matrixes of the rotary kiln, performing expansion and polishing and orderly cladding a joint layer and a transition layer, and then performing grinding and polishing. The process for repairing pitting and spalling of the tyre and the carrier roller of the rotary kiln provided in the invention is low in investment, simple and convenient in technique, convenient to operate, easy to learn, easy to master, novel in technology, low in cost, and cogent and reliable; the process makes an enormous contribution to not only increase income and reduce expenditure for the state, but also reduce consumption, save energy and improve efficiency for enterprises.

Owner:WUHAN KAIMING HIGH TECH

Regeneration repair method for tubular parts of die-casting machine

The invention discloses a regeneration repair method for tubular parts of a die-casting machine. The regeneration repair method comprises the steps that bearizing is conducted, i.e., wear portions of the old tubular parts are eliminated through a turning lathe or a grinding tool; welding is conducted, i.e., the portions eliminated after the tubular parts are abraded are repaired with a bead welding method by adoption of an inner diameter automatic welding device; machining is conducted, i.e., the turning lathe and a grinder are reused for deep machining, so that the tubular parts are restored to be in an original size or a size required according to an original drawing; and surface treatment is conducted, i.e., nitrogen treatment is conducted on the surfaces of the tubular parts after regeneration repair, and the whole repair process is completed. According to the regeneration repair method for the tubular parts of the die-casting machine, by means of the independently developed special inner diameter welding technology, the bead weld regeneration repair becomes possible, the bead welding method is used for welding repair, and the tubular parts can be restored to be in the original size. The tube regeneration cost is 60-80% that of new products, regeneration can be conducted for three to five times, the cost can be effectively reduced, the repaired tubular parts are same as or longer than the new products in service life, and the regeneration repair is economical and protects the environment.

Owner:上海环方佐鸣工贸有限公司

Projector system and control method thereof

ActiveUS9396520B2Improve convenienceRestore sizeGeometric image transformationProjectorsComputer graphics (images)Computer vision

A projector system includes: a position detecting unit that detects a pointed position of a pointer on a projection surface; a drawing unit that performs drawing on the projection surface according to the pointed position detected by the position detecting unit; a height detecting unit that detects a height of a user of a projector; and a display changing unit that changes, according to the user's height detected by the height detecting unit, at least one of a shape of the image projected onto the projection surface and a display position of the image on the projection surface.

Owner:SEIKO EPSON CORP

Electro chemical machining nano Ni-Fe alloy coat and its electroplate liquid, preparation method and use

Owner:FUZHOU UNIV

Solid Gel Cushion System

ActiveUS20150074913A1Deficient supportivenessInferior heat dissipationSofasFluid mattressesEngineeringAtmosphere

A solid gel cushion system is provided. The solid gel cushion system includes a first elastic quadrilateral body having a first elastic surrounding sidewall to define a first space allowing for a heat exchange. The first elastic quadrilateral body defines a first top surface and a first bottom surface with respect to the first elastic surrounding sidewall, both of which are communicative of surrounding atmosphere in order to form an air passage. The cushion system further includes a second elastic quadrilateral body having a second elastic surrounding sidewall defining a second space in which two interleaving elastic supporting ribs are formed. The first elastic quadrilateral body is surrounded by the four second elastic quadrilateral bodies.

Owner:FORMOSA SOUNDING

User terminal device with pen and controlling method thereof

ActiveUS10289268B2Small sizeIncrease in sizeDigital data processing detailsInput/output processes for data processingTerminal equipmentHuman–computer interaction

A user terminal device capable of attaching and detaching a pen is provided. The device includes a detector configured to detect a user manipulation regarding a screen, and a controller configured to change a layout of the screen to correspond to a pen use mode in response to the pen being removed from the user terminal device, perform a control operation corresponding to the detected user manipulation in response to the user manipulation using the pen being detected, and restore the layout of the screen to its original state in response to the pen being remounted on the user terminal apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD

A laser cladding repair method for the surface of aircraft vertical pins and bolts

ActiveCN105349992BReduce use costReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention discloses a laser cladding repairing method for airplane normal pin and bolt part surfaces. The method comprises the steps that spherical superhigh-strength steel metal powder is selected for faults such as mechanical and corrosive wear to the part surfaces, reasonable laser cladding technology parameters are adopted, appropriate heat treatment is adopted for removing residual stress and hydrogen atoms in the cladded parts, and therefore the performance of the airplane normal pin and bolt parts is recovered, and life extension repair is achieved. The deformation probability of the repaired normal pin and bolt parts is almost zero, and the depth of a heat affected zone is controlled within 0.5 mm; the repaired portion has no crack or melting or slag inclusion or other defects; and the using performance of normal pins and bolts is recovered. The airplane normal pin and bolt parts repaired through the method pass authentication before installation, and are installed and used successfully.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

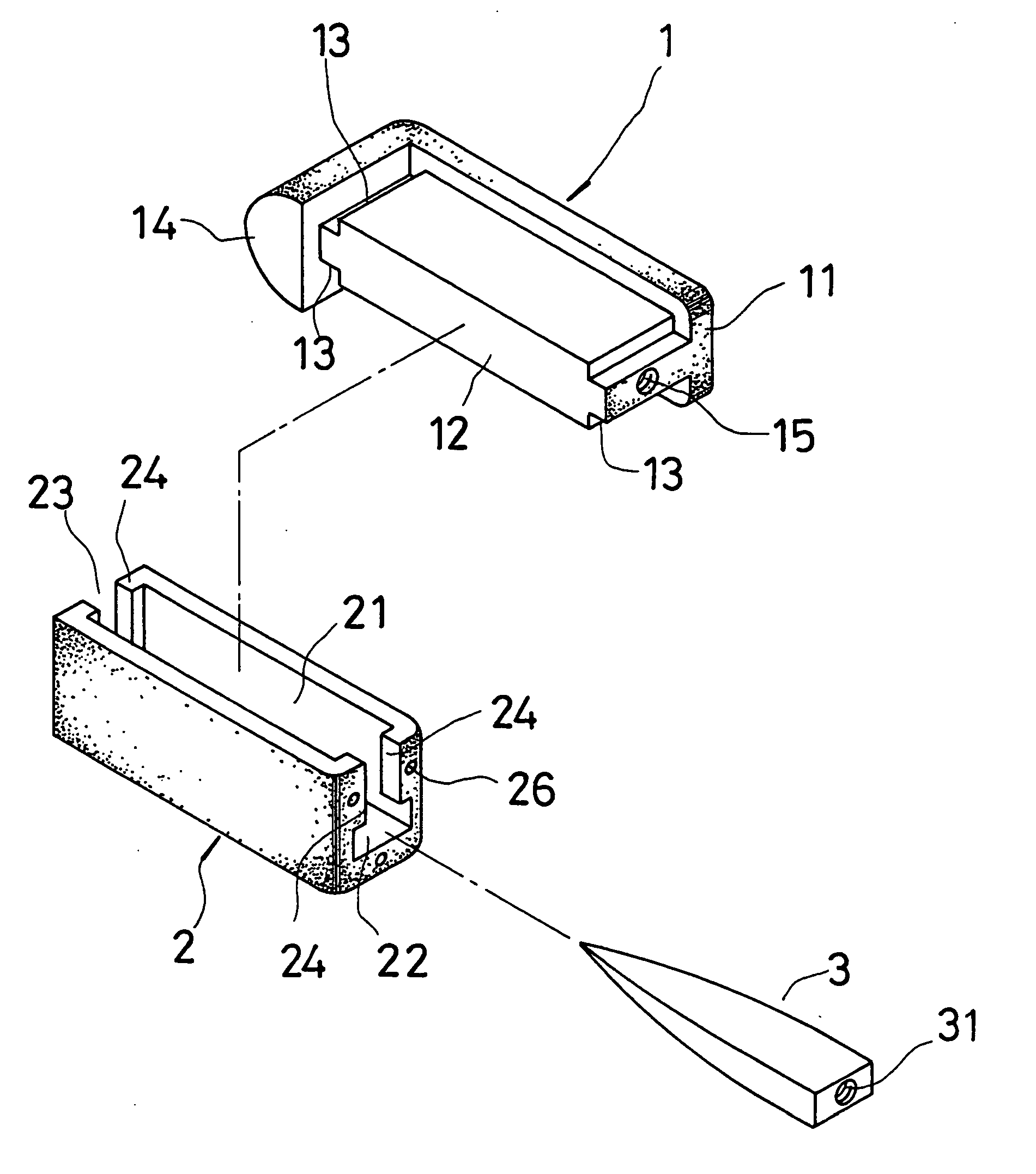

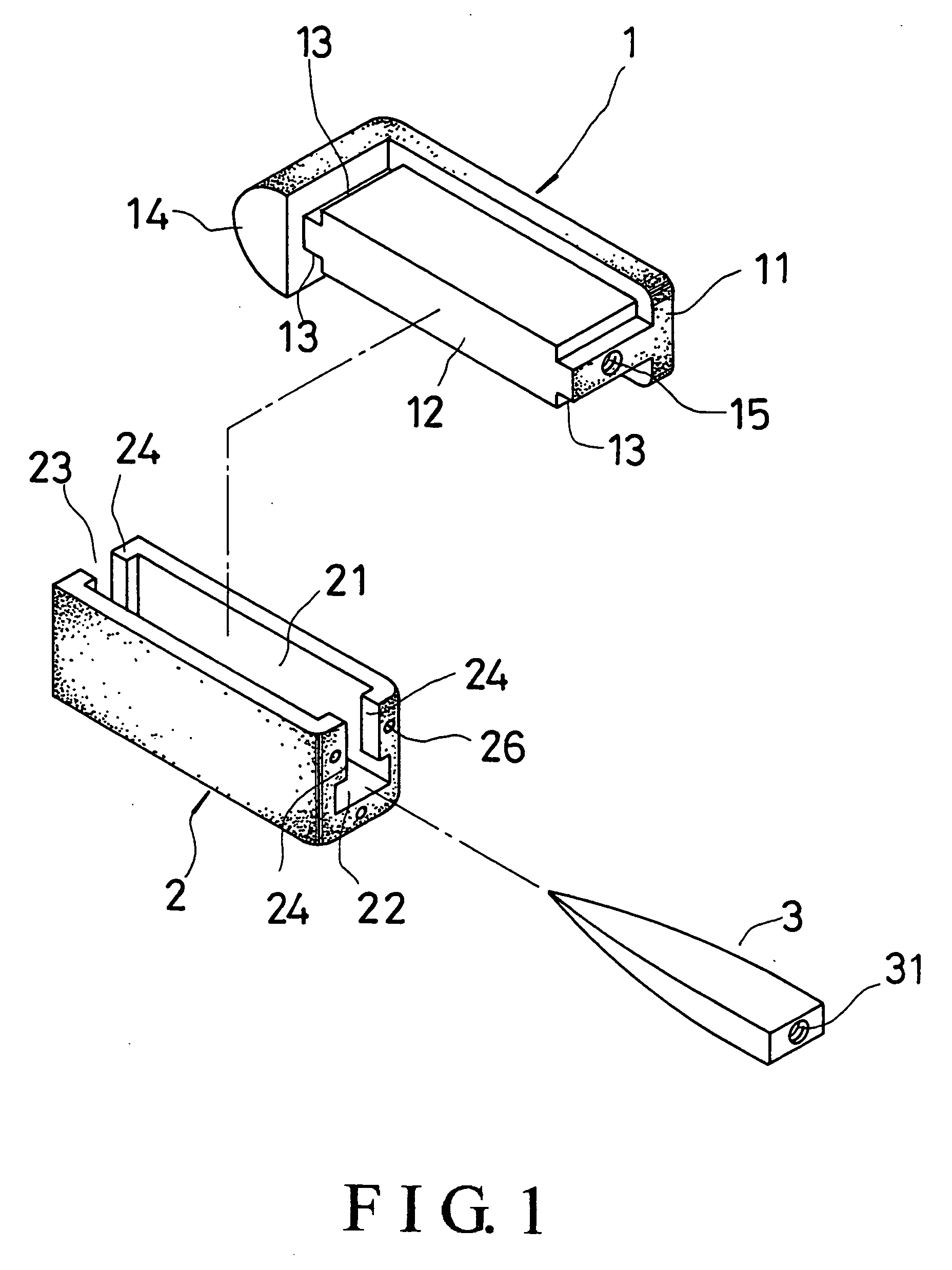

Distractable body augmenter capable of being planted through a pedicle for vertebral body reconstruction

InactiveUS20060085007A1Maintain restoreRestore positionInternal osteosythesisSpinal implantsMedicineLowering plants

A distractable body augmenter is provided for reconstruction of a vertebra subjected to loss of bone mass or fracture, and is planted in the vertebra from a pedicle of the vertebra for helping maintain or restore normal position and size of the vertebra; through the pedicle, the augmenter, fitting the pedicle anatomy, was created to reconstruct the fractured or collapsed vertebral body; the augmenter includes a lower planted block, an upper planted block fitted to the lower block in a longitudinally displaceable manner, and a wedge-shaped bar, which is inserted between the upper and the lower blocks for changing the height of the augmenter after the upper and the lower blocks have been planted in a vertebra via a planting tunnel on a pedicle of the vertebra; the fractured body was reduced and maintained by the augmenter until the bone growth and fracture union.

Owner:LI KUNG CHIA

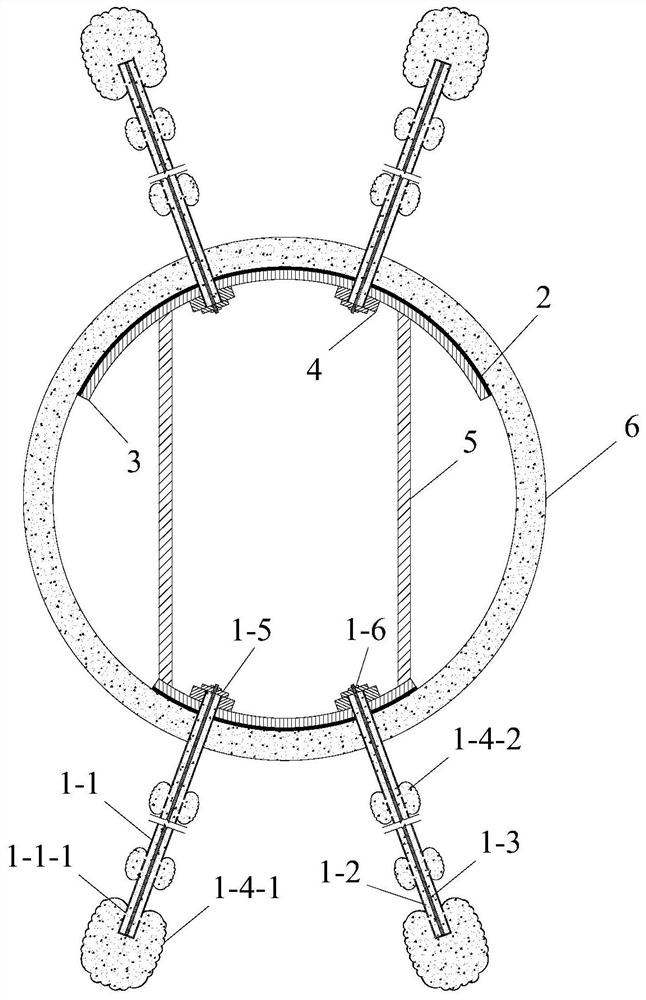

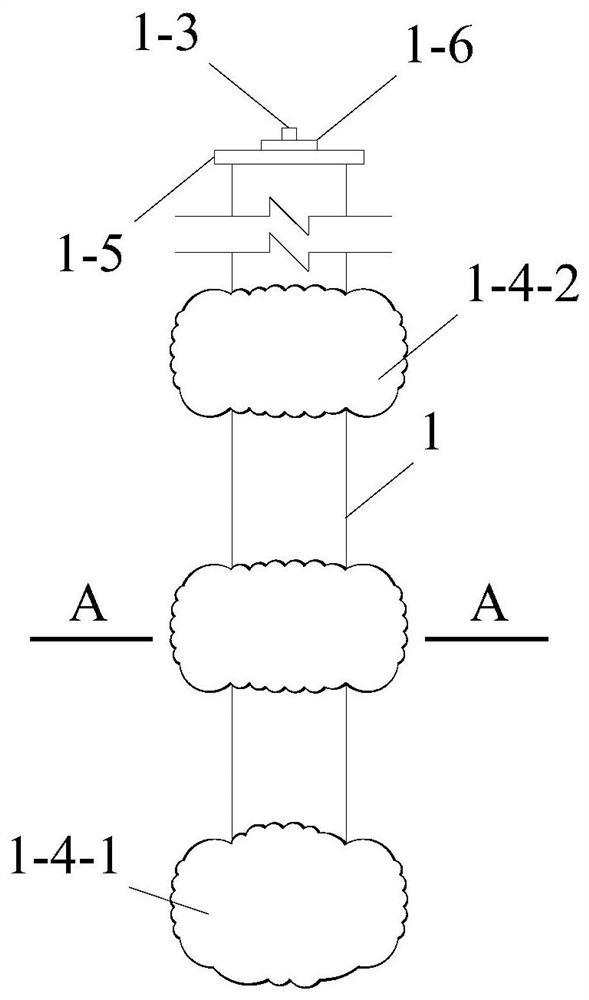

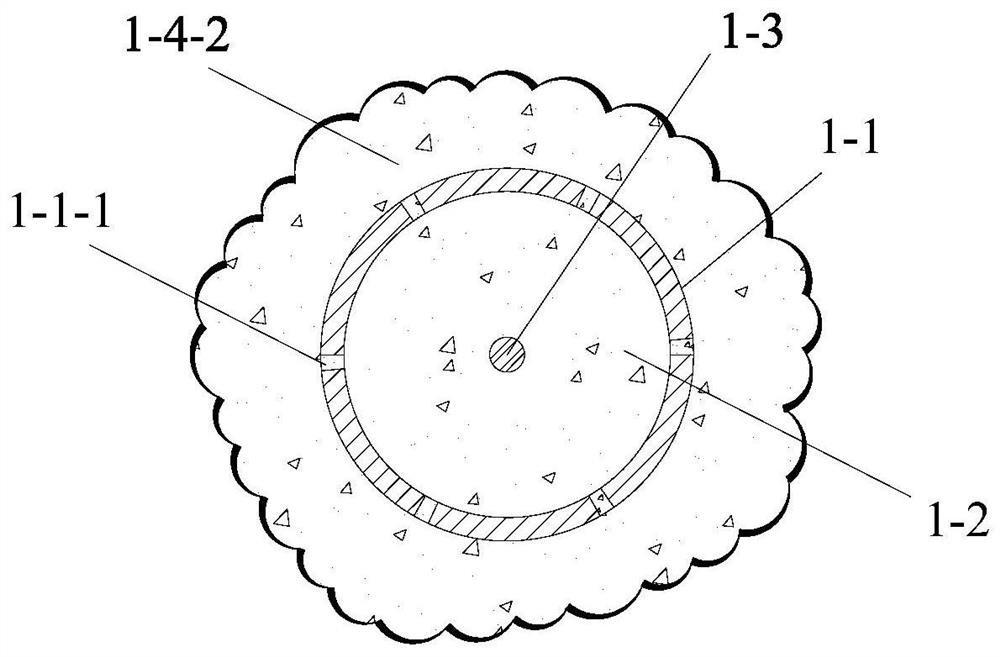

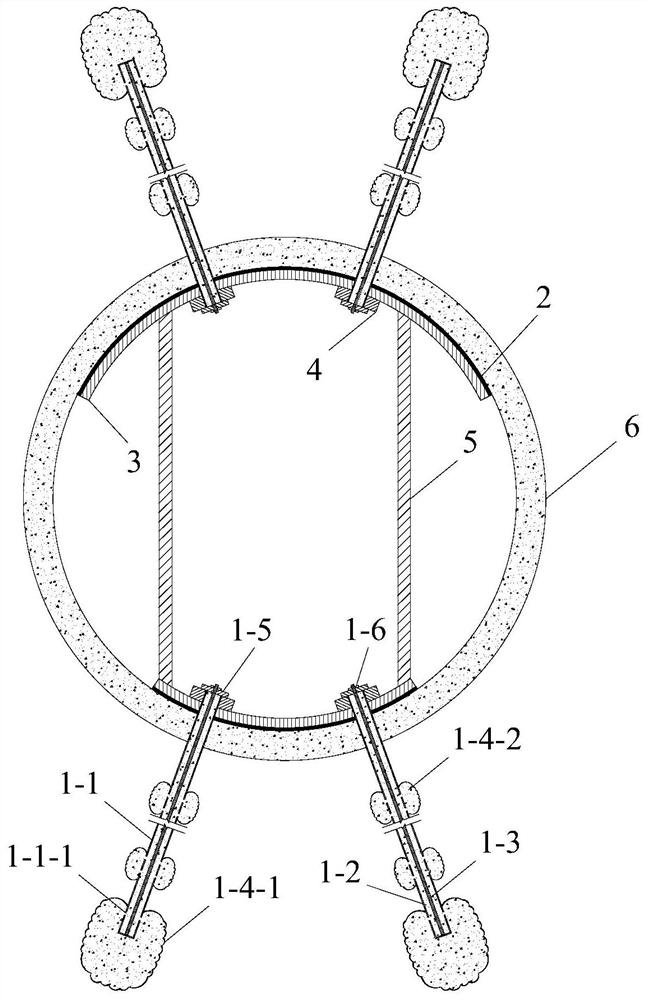

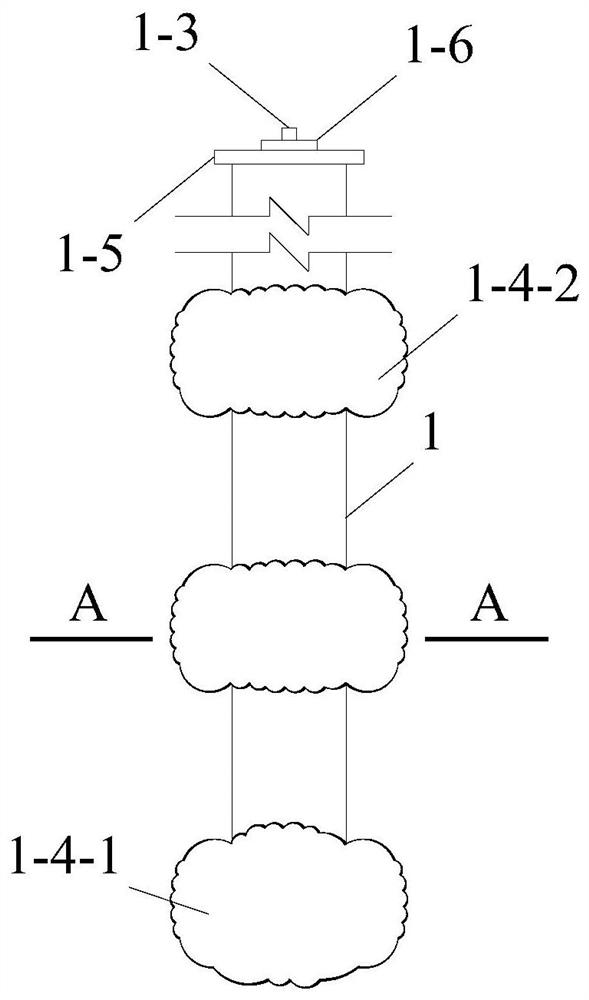

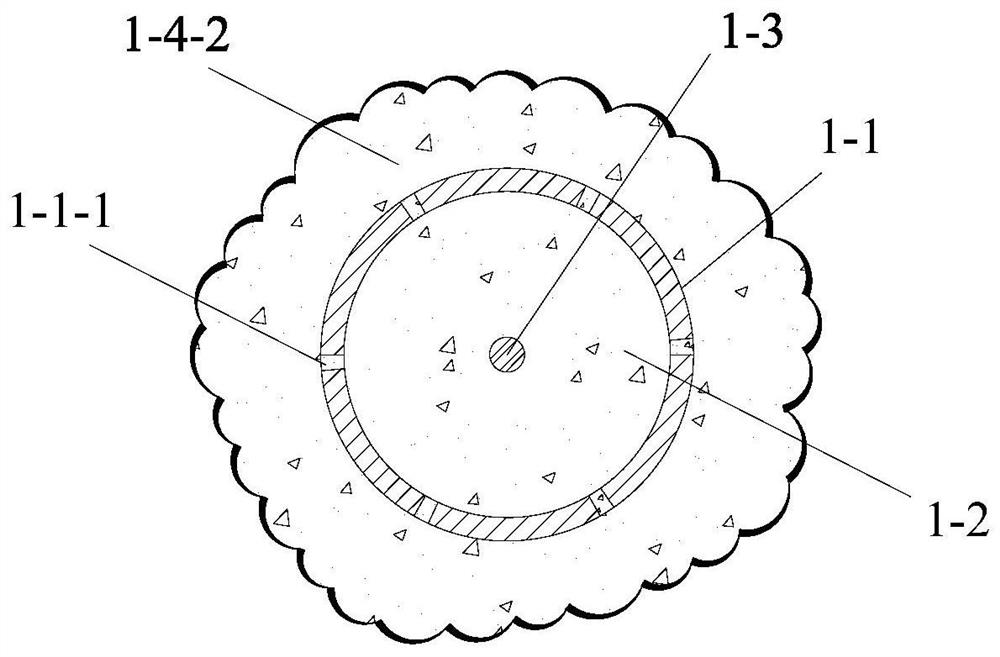

Treatment structure of shield tunnel operation period over-limit convergence deformation and construction method thereof

ActiveCN113137257APrevention of convergence deformationImprove pullout resistanceUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a treatment structure of shield tunnel operation period over-limit convergence deformation and a construction method thereof. The structure comprises bag expansion type prestressed anchor rods, a waterproof layer, annular steel beams, longitudinal steel beams and diagonal bracing trusses. The contact area of the bag expansion type prestressed anchor rods and surrounding soil of a shield tunnel is increased through expansion type bags, so that the pulling resistance is increased; the prestress of the bag expansion type prestressed anchor rods which are symmetrically arranged on the section of the shield tunnel and the counterforce of jacks of the diagonal bracing trusses are applied cooperatively, so that the over-limit convergence deformation of the section of the shield tunnel can be efficiently treated, and the operation of the shield tunnel can be recovered as soon as possible; and after the section of the shield tunnel returns to normal, the bag expansion type prestressed anchor rods continues to be used normally so as to effectively serve the convergence deformation prevention and control in the whole life cycle of the operation period of the shield tunnel.

Owner:江苏中车城市发展有限公司 +2

Method for preparing hypoallergenic flavored yogurt product

PendingCN112314704AAllergenicity reductionImproves antioxidant activityMilk preparationOther dairy technologyBiotechnologyHydrolysate

The invention relates to a hypoallergenic flavored yogurt product and a preparation method thereof. The hypoallergenic flavored yogurt product is prepared from the following raw materials in parts bymass: 1-18 parts of actinidia arguta juice, 0.05-0.9 part of alpha-cyclodextrine, 1-18 parts of erythritol, 0.5-9 parts of lactobacillus yogurt zymophyte and 54.1-97.45 parts of enzymatic hydrolysateof skim milk, wherein the lactobacillus yogurt zymophyte has a viable count of 1010-1011CFU / g, and comprises one or more of lactobacillus bulgaricus, streptococcus thermophilus, lactobacillus acidophilus, lactobacillus plantarum and lactobacillus casei; on the basis of reducing the sensitization of the cow milk through an enzymolysis technology, the cow milk enzymatic hydrolysate serving as a basematerial is combined with the actinidia arguta juice by a multi-strain fermentation technology, so that the cow milk has low sensitization, rich taste and high nutritional value, is favorable to digestion and absorption of human bodies and has a wide market development prospect.

Owner:SHENYANG AGRI UNIV

Process for repairing pitting and spalling of tyre and carrier roller of rotary kiln

Owner:WUHAN KAIMING HIGH TECH

A control structure and construction method for overrun convergence deformation of shield tunnel during operation period

ActiveCN113137257BPrevention of convergence deformationImprove pullout resistanceUnderground chambersTunnel liningPre stressArchitectural engineering

The invention discloses a control structure and a construction method for over-limit convergence deformation of a shield tunnel during the operation period. The structure includes a bag-expanded prestressed anchor rod, a waterproof layer, a circumferential steel beam, a longitudinal steel beam, and a paired truss ;The contact area between the expanded bladder prestressed anchor rod and the surrounding soil layer of the shield tunnel is increased by the enlarged bladder, and the pull-out resistance is increased. The expanded bladder prestressed anchor rod symmetrically arranged on the section of the shield tunnel The application of the prestressing force and the application of the jack reaction force to the support truss, the two work together, can effectively control the over-limit convergence deformation of the section of the shield tunnel, and resume the operation of the shield tunnel as soon as possible; after the section of the shield tunnel returns to normal, the capsule The expanded prestressed anchor will continue to be used normally, effectively serving the prevention and control of convergence deformation during the entire life cycle of the shield tunnel in operation.

Owner:江苏中车城市发展有限公司 +2

The technology of repairing the pit of aircraft titanium alloy slide rail by argon arc welding

ActiveCN103949757BRestore sizeReduce use costArc welding apparatusVehicle componentsAviationStressed state

The invention belongs to the technical field of welding, relates to a process for repairing pits in a titanium alloy aircraft sliding rail in an argon arc welding way, and is particularly applied to the repair of the pits in the titanium alloy aircraft sliding rail after long-term serving in the field of maintenance of aircraft engines. According to the method, reasonable argon arc welding process parameters are used for repairing the pits in a pitted titanium alloy aircraft sliding rail workpiece, and the surface compressive stress state is recovered by shot peening strengthening after repair; the deformation of the repaired sliding rail is slight, and is controlled within a tolerance range; a repaired part is free of crack defects; the operational performance of the repaired workpiece is recovered; the titanium alloy aircraft sliding rail repaired by the method passes verification before installation, and is successfully installed for use.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

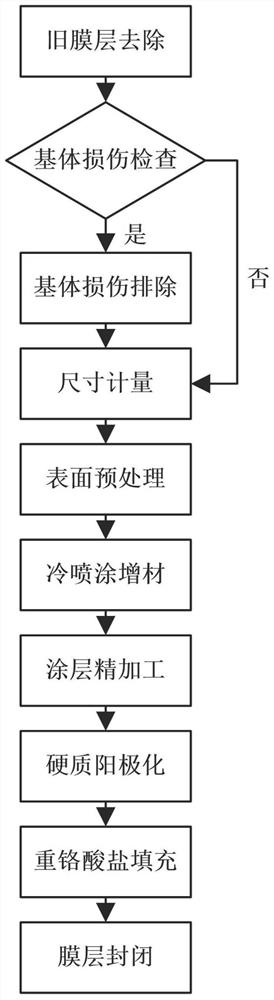

Repair method of airplane hydraulic system aluminum alloy piston rod wear-resisting layer damage

PendingCN111996524ARestore sizeOvercome size reductionAnodisationPressure inorganic powder coatingAnodizingSpray coating

The invention relates to a repair method of airplane hydraulic system aluminum alloy piston rod wear-resisting layer damage. The repair method comprises the following specific steps: removing an old film layer on an aluminum alloy piston rod through an alkali corrosion method; checking whether corrosion, gouges, scratches, abrasion and other damage exist on the surface of an aluminum alloy pistonrod base body or not in a visual mode, and eliminating the existing damage; and measuring the size of the excircle surface of the piston rod, calculating the thickness size, and increasing the thickness of a spraying coating by 1-2mm on the thickness size. The repair method has the advantages that on the basis of an existing repair method, the repair technology and process are optimized, a cold spraying additive manufacturing working procedure is added, the size recovery of the piston rod is achieved through cold additive forming operation, hard anodizing of the coating is carried out on the basis, then a film layer is sealed through a hole sealing technology, and the sealing performance of the film layer is further improved. The problem that the size of the piston rod is reduced after theold film layer is removed through alkali corrosion and hard anodizing is conducted again in the traditional repair process is solved.

Owner:国营芜湖机械厂

Method and device for correcting drum waist deformation during rolling of cylindrical body

The invention belongs to the field of manufacturing of machinery, in particular to a method and device for correcting drum waist deformation during rolling of a cylindrical body. The device comprises two symmetrical arc-shaped components, an adjusting bolt and a working bolt, wherein the symmetrical arc-shaped components are hinged with each other through a connecting sheet to form a clamp-shapedstructure. The correcting method comprises the following steps of: sleeving the device into the cylindrical body, wherein the opening of the cylindrical body faces the hinged position of the two arc-shaped components; making the two arc-shaped components cling to the cylindrical body by adjusting a nut on the adjusting bolt; and applying pressure to the drum waist deformation position of the cylindrical body opening by adjusting the screwing depth of the working bolt to restore the drum waist position to a designed size. By adopting of the method and the device, the drum waist deformation during rolling of the cylindrical body is corrected in a semi-mechanical way instead of a purely manual knocking way, so that the workpiece size can be recovered accurately, the workpiece welding qualityis improved, the labor intensity of workers is lowered, the production efficiency is increased, noise pollution is avoided, and a good effect is achieved.

Owner:CRRC ZIYANG CO LTD

Field remanufacturing method for upper seam allowance of cylinder body of marine diesel engine

The invention discloses a field remanufacturing method for an upper seam allowance of a cylinder body of a marine diesel engine. The field remanufacturing method includes the following steps that end face milling and rough machining are conducted; oil removing and rust removing are conducted; coating of a strengthening layer is conducted; end face milling and finish machining are conducted; end face grinding is conducted; and quality inspecting is conducted. An adopted coating method includes one-step method flame spray welding or induction melt coating. According to the field remanufacturing method for the upper seam allowance of the cylinder body of the marine diesel engine, the problem that difficulty and cost are high when the marine diesel engine is moved out of a cabin is solved, corrosion of the upper seam allowance of the cylinder body of the marine diesel engine is successfully repaired, the size of the upper seam allowance is recovered, the problem of water leakage between the cylinder body and a cylinder sleeve is solved, the remanufacturing cost is obviously reduced, the remanufacturing and maintaining period is greatly shortened, and obvious economic benefits are achieved.

Owner:河南汉工机械再制造技术有限公司

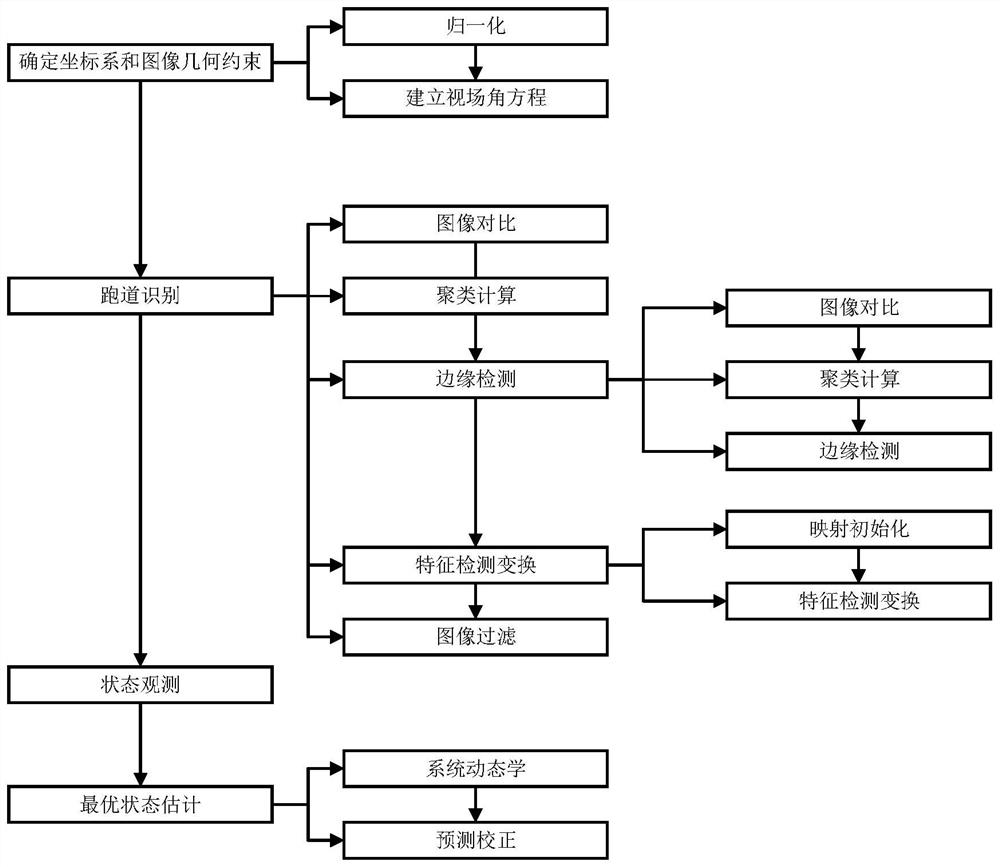

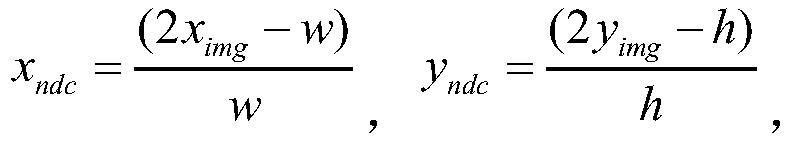

Vision-based unmanned aerial vehicle landing attitude estimation method

PendingCN114485577ARestore monochrome markersImprove lighting conditionsAngle measurementPicture taking arrangementsAutomatic landingCamera control

A vision-based unmanned aerial vehicle landing attitude estimation method uses a clustering technology to identify runway marks, uses an edge detector and feature detection transformation to verify whether the marks are located at a recovery target, uses an optimizer to match the detected marks with coordinates in a three-dimensional space, and uses a three-dimensional space to estimate the landing attitude of the unmanned aerial vehicle. Using nonlinear transformation and a projection solver to observe the position and direction of the camera, and using an extended Kalman filter to obtain optimal attitude estimation; target images, corner marker colors, edge colors, and runway target geometry are input, an onboard camera will provide images, and attitude estimates will be passed to a camera controller and an automatic landing controller, the former being used to adjust the angle of view.

Owner:丁莹莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com