Laser surface compound reinforced restoring method and shaft part restored with same

A technology for shaft parts and surface compounding, applied in metal material coating process, coating, etc., can solve the problems that high hardness powder cracking is difficult to solve, and the surface size of worn parts cannot be restored, so as to improve wear resistance and restore size , Improve the effect of hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

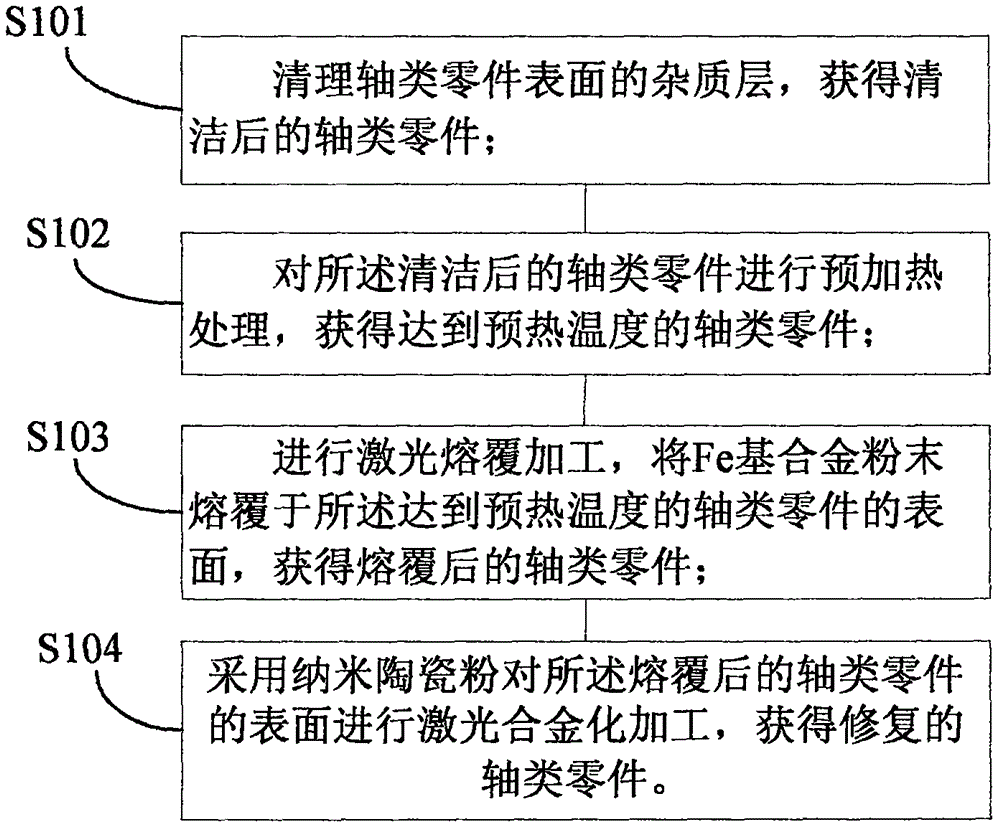

[0025] figure 1 A flow chart of a method for performing laser surface composite strengthening repair on a shaft part of the present invention according to an embodiment of the present invention is shown.

[0026] In some demonstrative embodiments, a method of performing laser surface composite strengthening repair on a shaft part includes:

[0027] S101, cleaning the impurity layer on the surface of the shaft parts to obtain the cleaned shaft parts;

[0028] S102, performing preheating treatment on the cleaned shaft parts to obtain shaft parts reaching the preheating temperature;

[0029] S103, performing laser cladding processing, cladding Fe-based alloy powder on the surface of the shaft part that has reached the preheating temperature, to obtain the clad shaft part;

[0030] S104, using nano-ceramic powder to perform laser alloying on the surface of the cladded shaft part to obtain a repaired shaft part.

[0031] Wherein, the Fe-based alloy powder and nano-ceramic powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com