Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44results about How to "Refill time shortened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

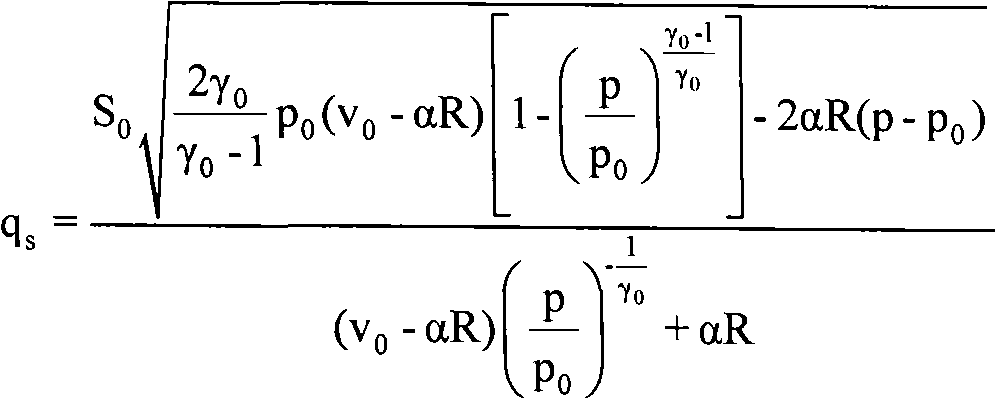

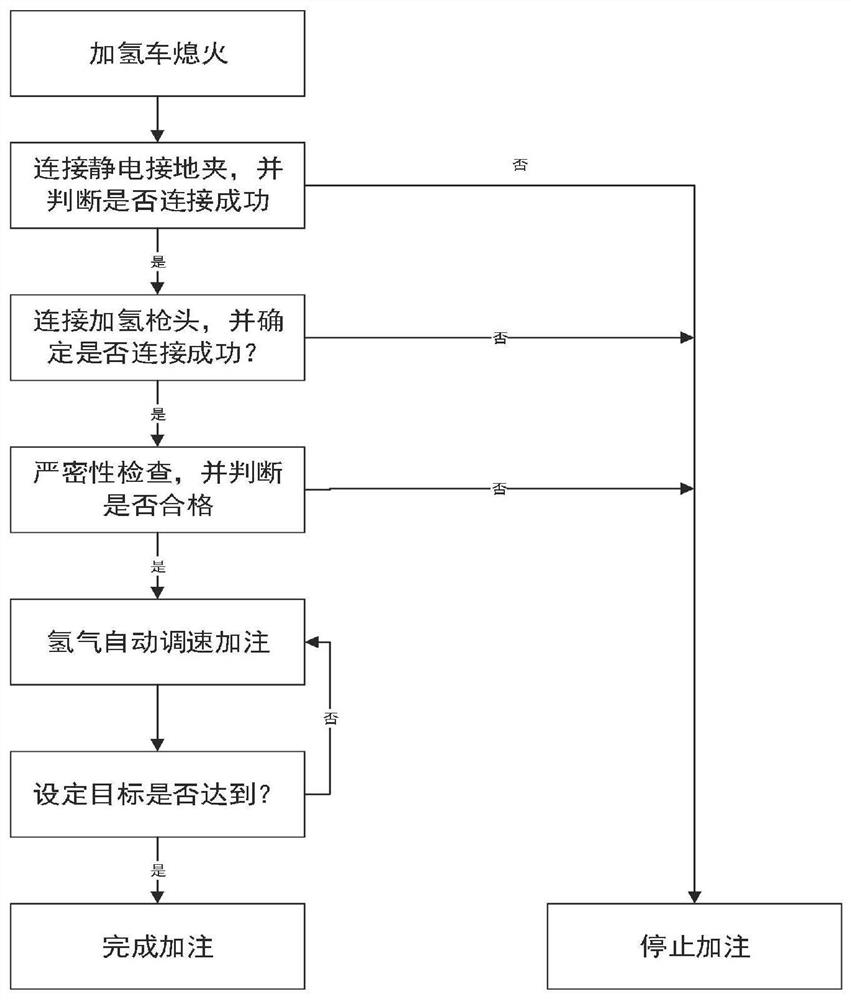

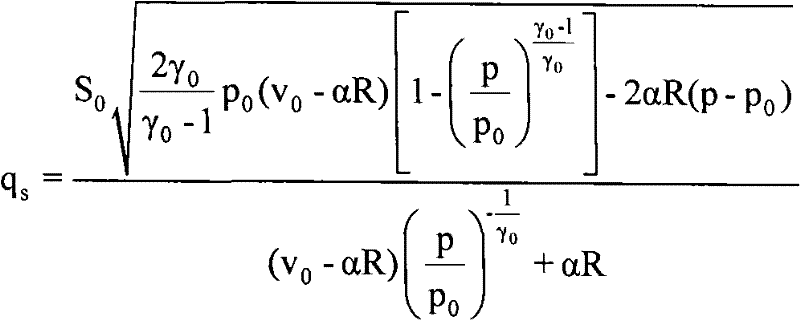

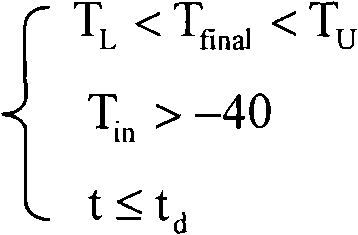

Hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and system thereof

ActiveCN101832467AReduce energy consumptionLow energy operationContainer discharging methodsContainer filling under pressureNew energyProgrammable logic controller

The invention relates to the field of renewable, clean and environment-friendly new energy, aiming at providing a hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and a system thereof. The method comprises the steps of: establishing a database arranged inside a programmable logic controller (PLC), and using the database to record the corresponding relationship between the corresponding filling initial condition and the opening value of a needle valve; according to the filling initial condition, using the PLC to inquire the opening value of the needle valve when hydrogen storage tanks with different pressure levels are used for taking gas; and according to the data inquired by the PLC, arranging the needle valve at the corresponding demarcated position, and carrying out the filling operation. The invention can run at the lower power consumption of a cooling device, ensures the temperature of a vehicle hydrogen storage container to be strictly controlled within the required range, and remarkably shortens the filling time, thus leading the whole system to effectively, safely and reliably fill high pressure hydrogen, and having the advantages of high gas taking efficiency, low power consumption and the like.

Owner:ZHEJIANG UNIV

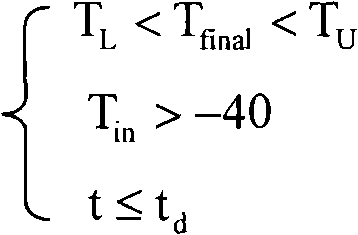

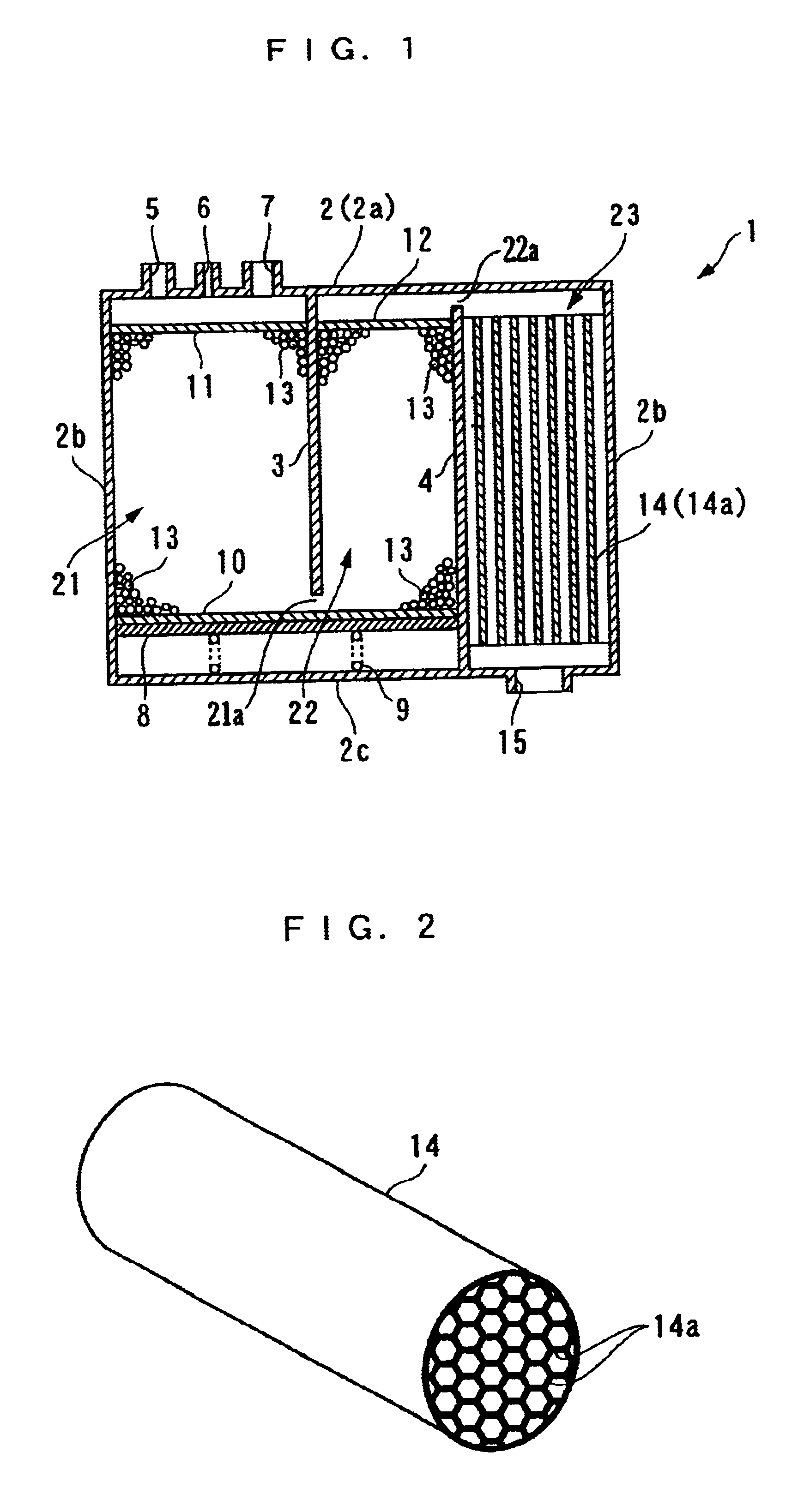

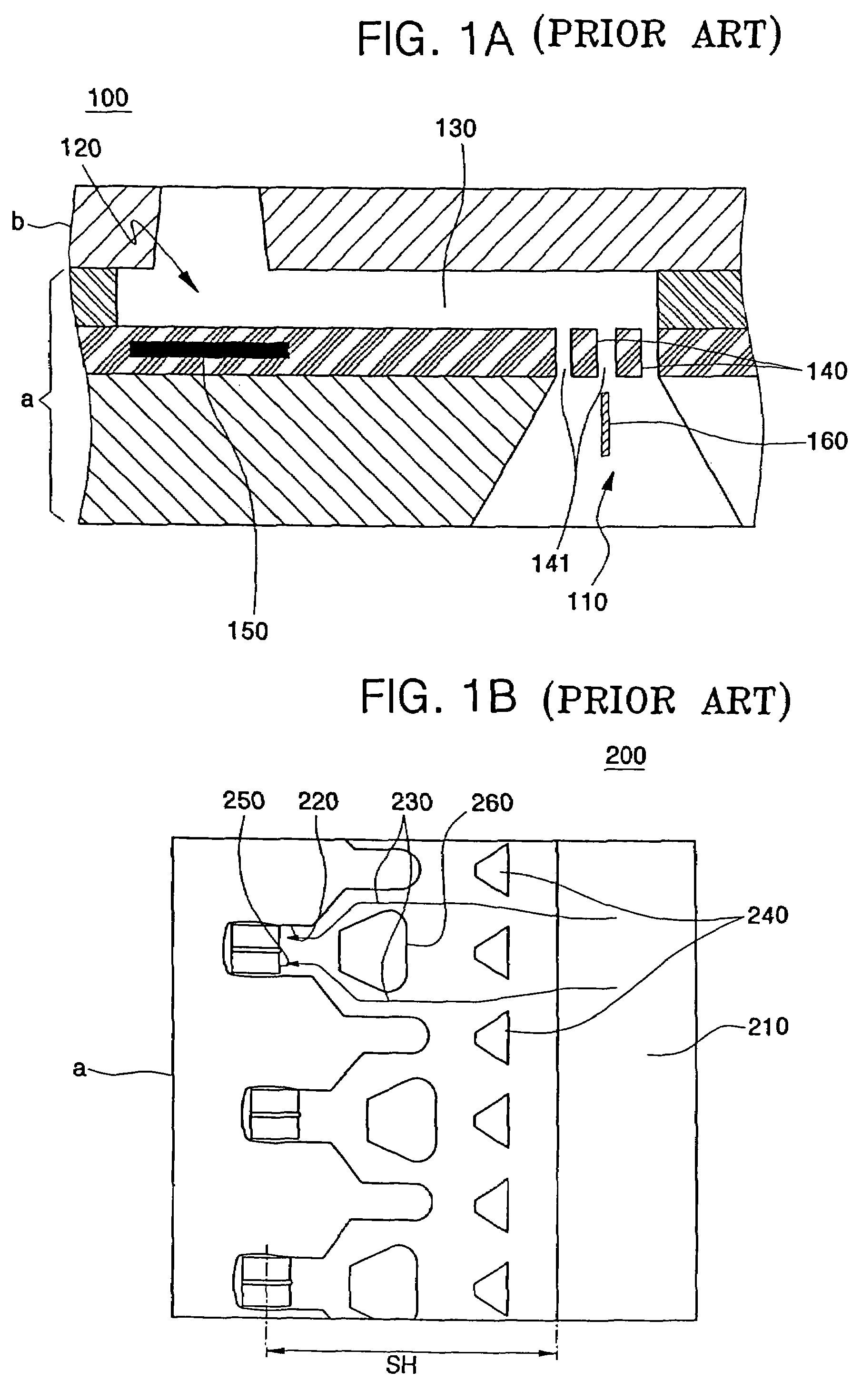

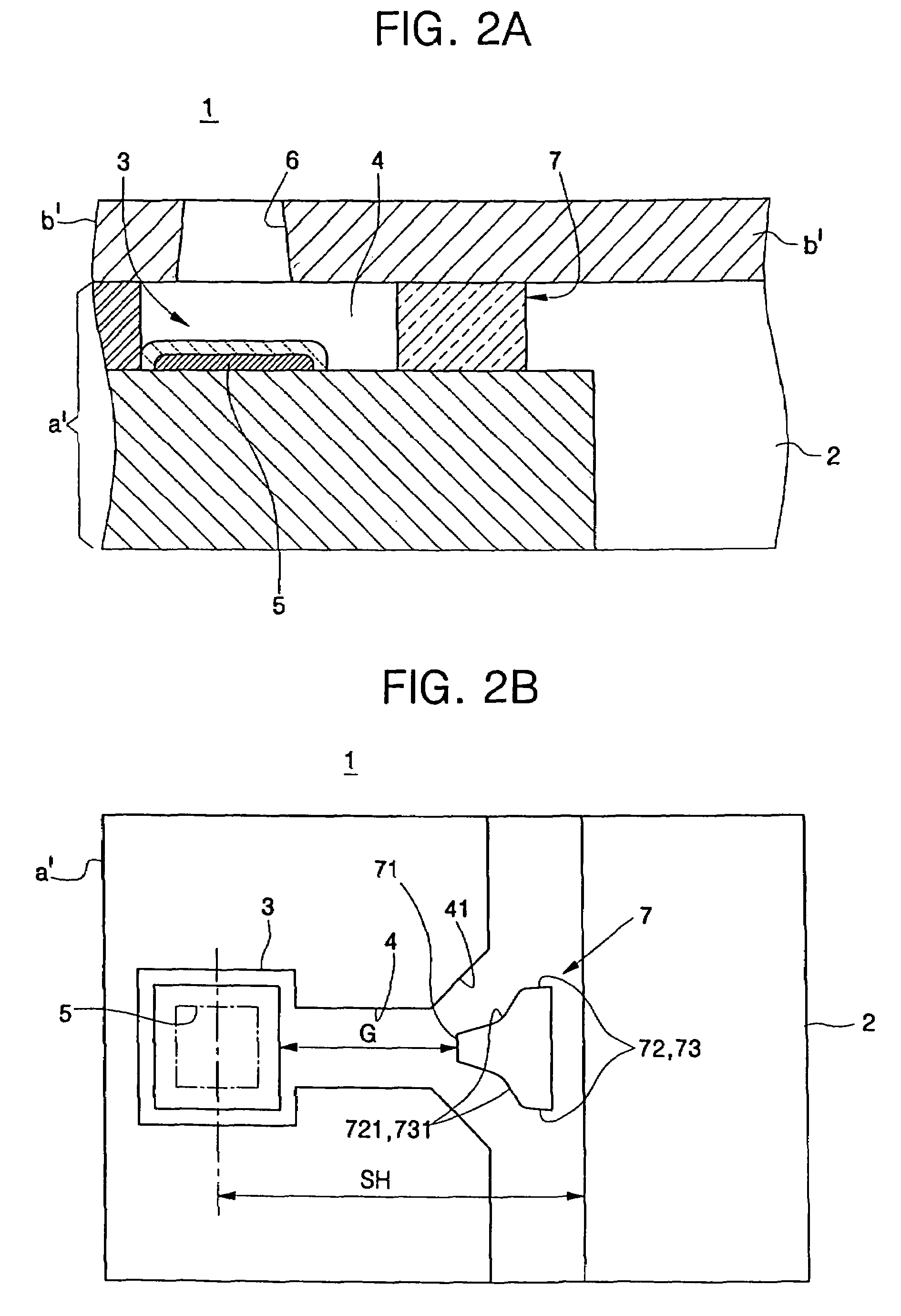

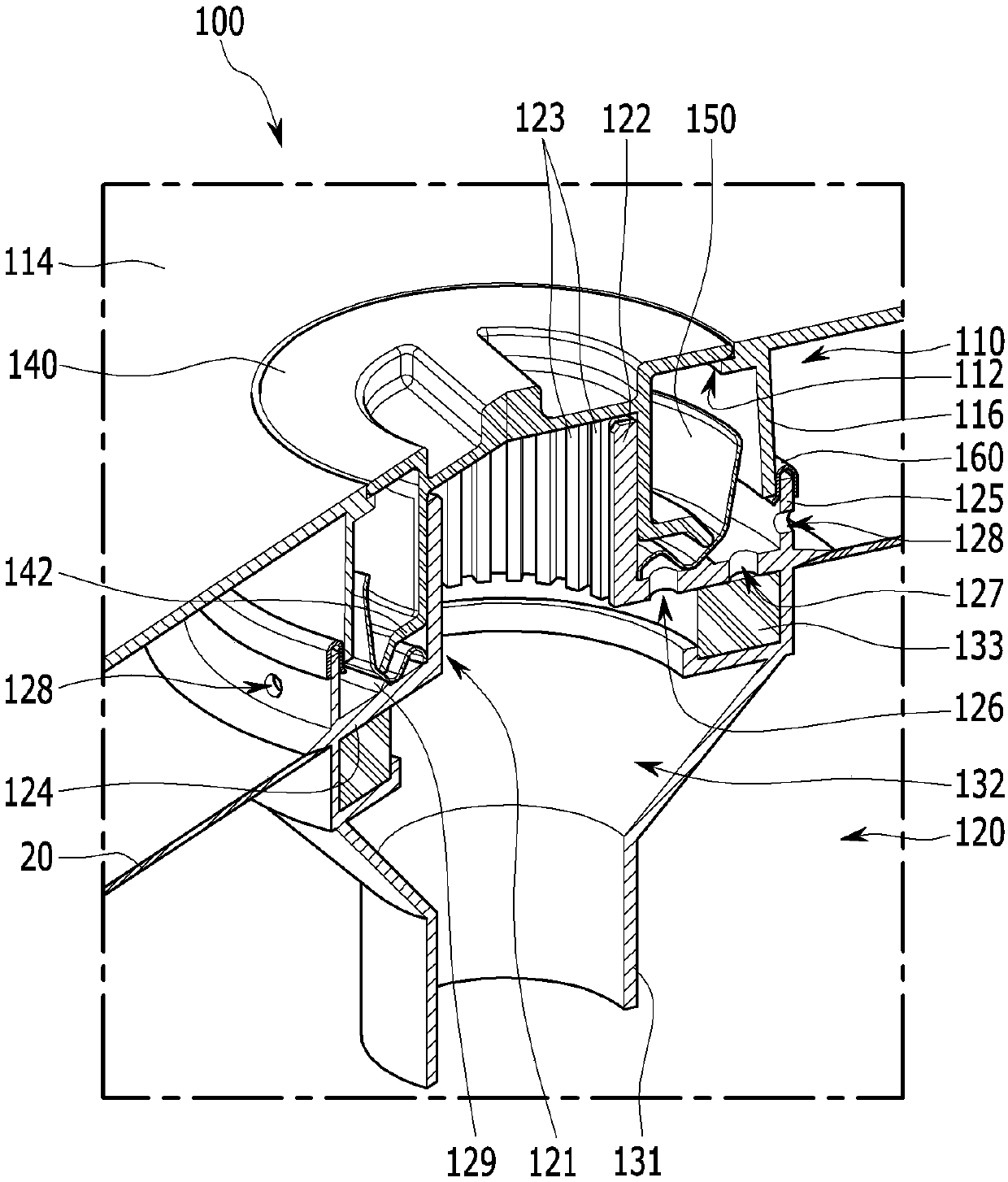

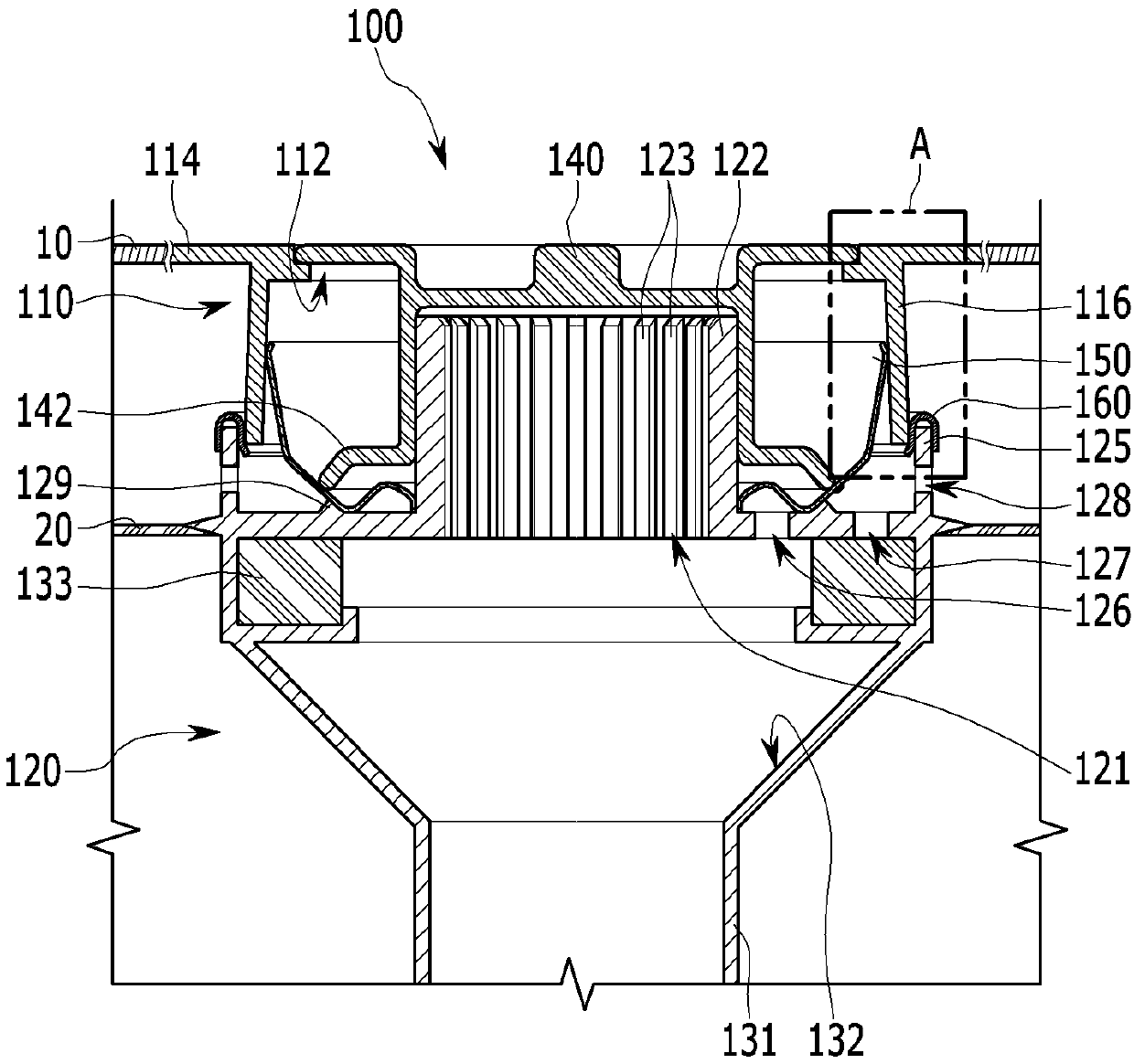

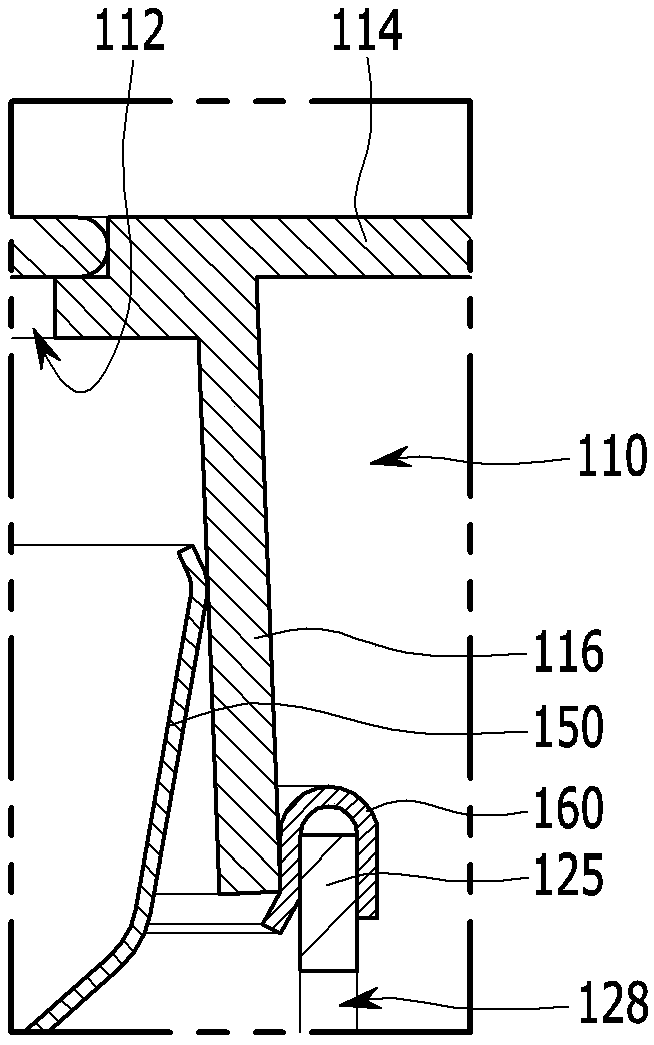

Evaporated fuel treatment apparatus

InactiveUS6695896B2Refill time shortenedSatisfactory performanceGas treatmentNon-fuel substance addition to fuelActivated carbonDesorption

An evaporated fuel treatment apparatus is provided for reducing a refilling time, ensuring satisfactory adsorption / desorption performance for an evaporated fuel, and reducing the manufacturing cost through a simplified structure. The evaporated fuel treatment apparatus comprises a casing having formed therein a first chamber in communication with the fuel tank, a second chamber in communication with the first chamber, and a third chamber in communication with the second chamber and the atmosphere. Active carbons are contained in the first chamber and second chamber for adsorbing fuel components in an evaporated fuel introduced from the fuel tank. An adsorbent is contained in the third sub-chamber for adsorbing fuel components in the evaporated fuel introduced from the second chamber. The adsorbent has an air-flow resistance which is set smaller than that of the active carbons.

Owner:HONDA MOTOR CO LTD

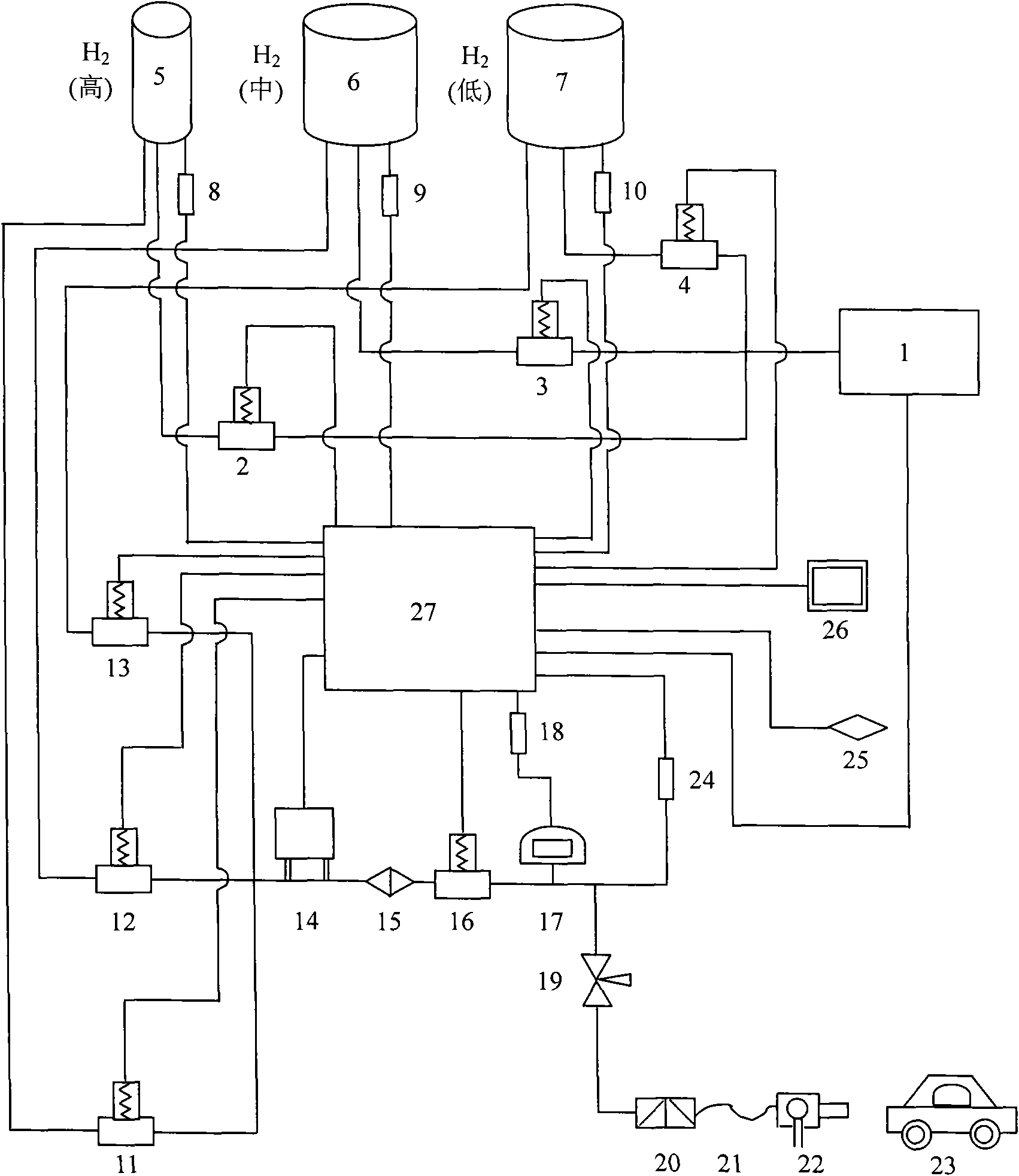

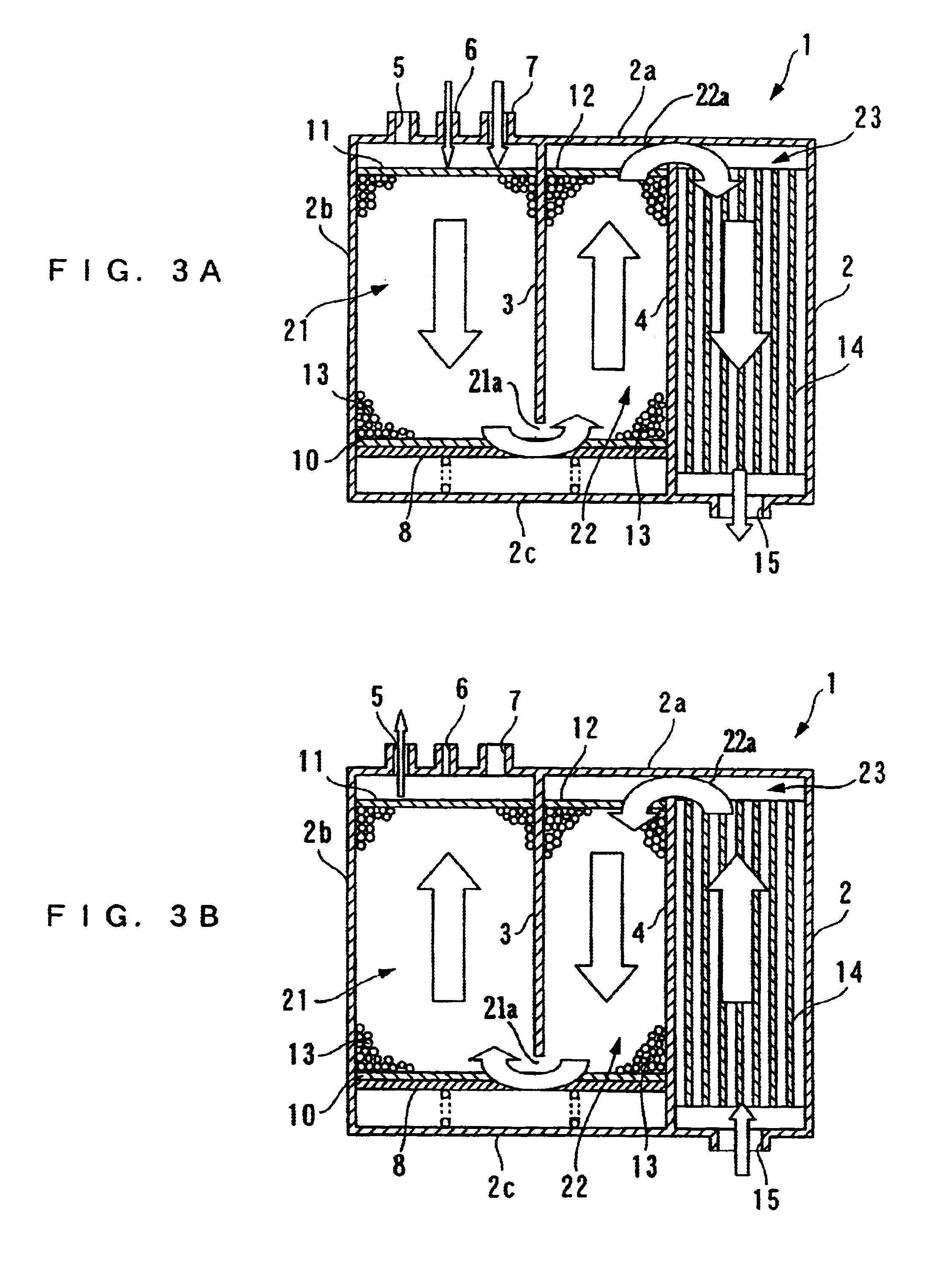

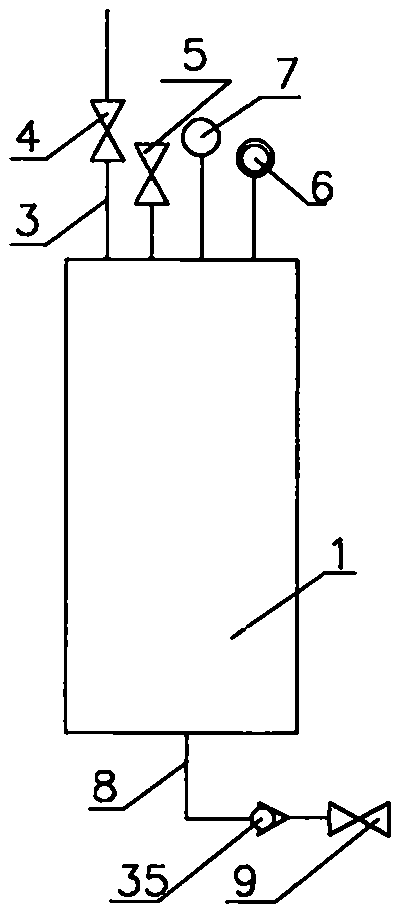

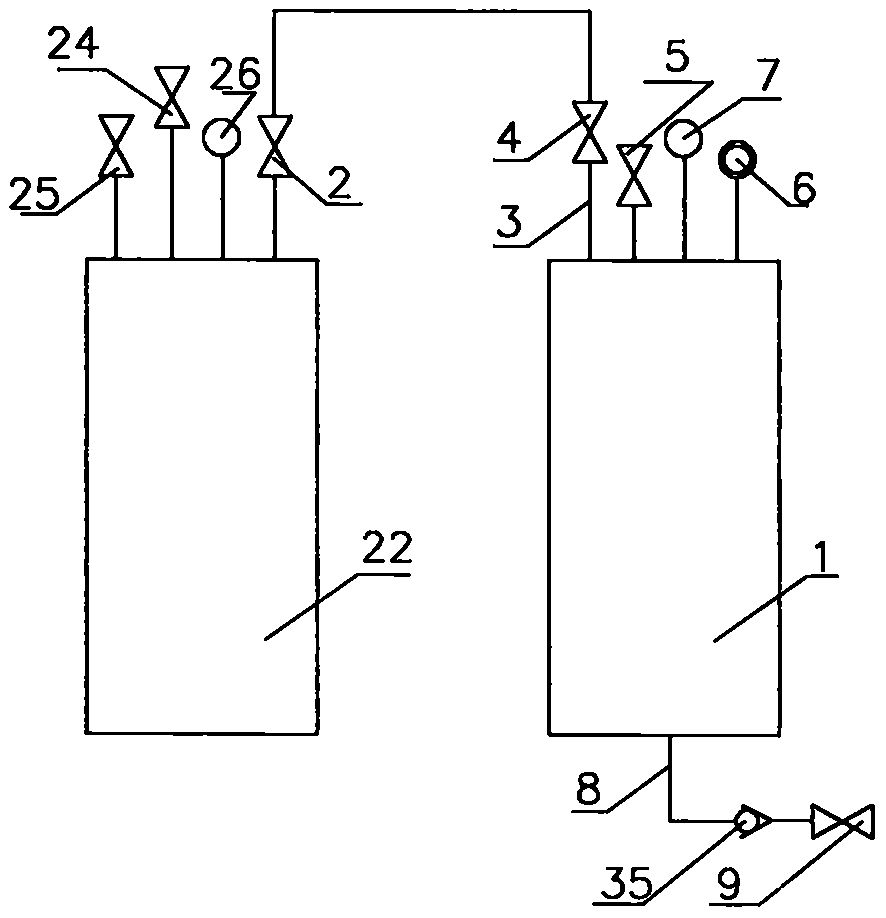

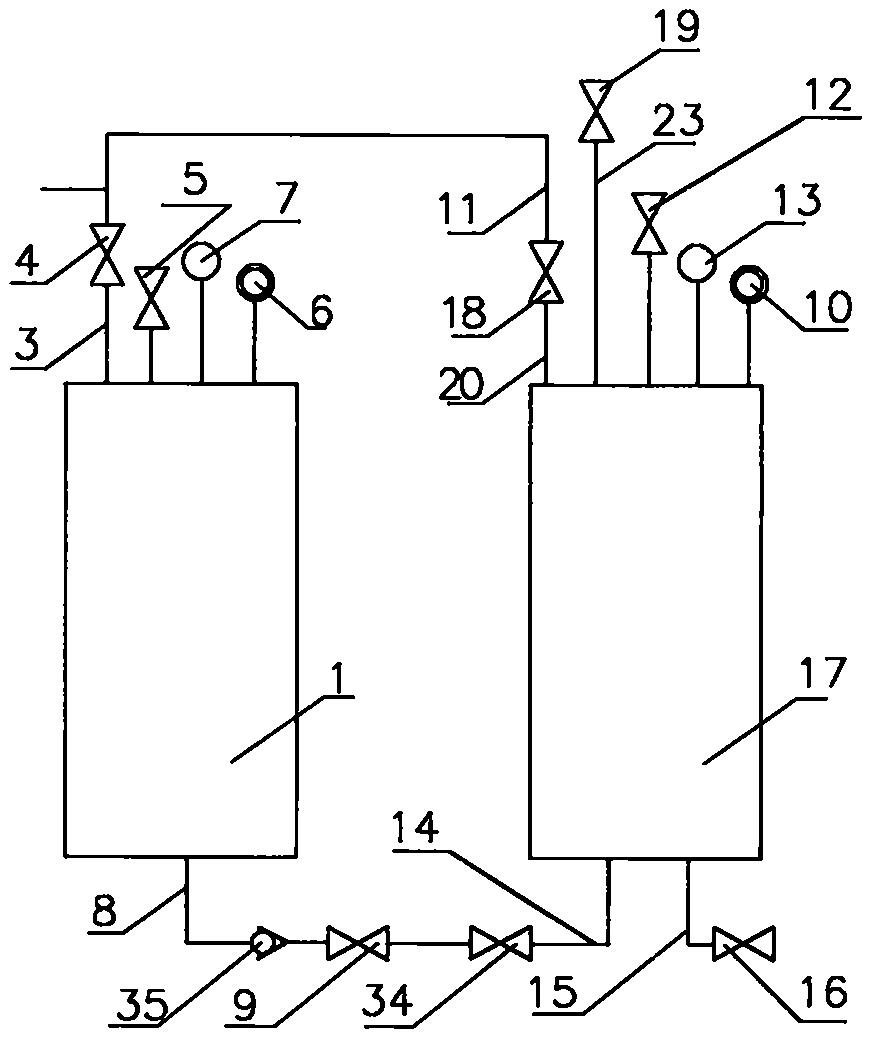

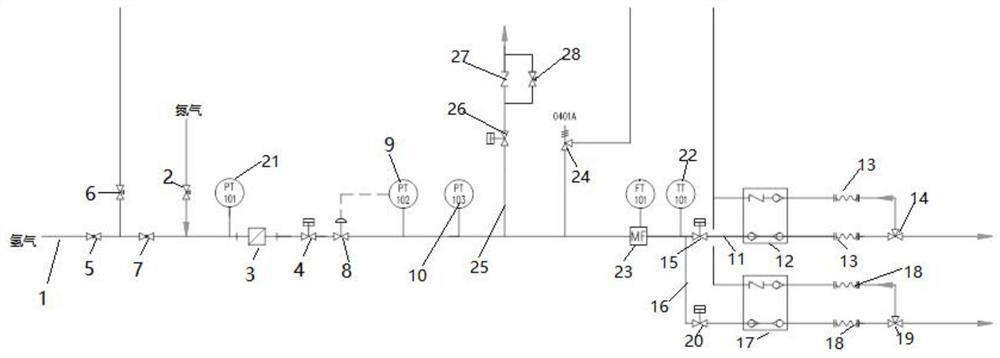

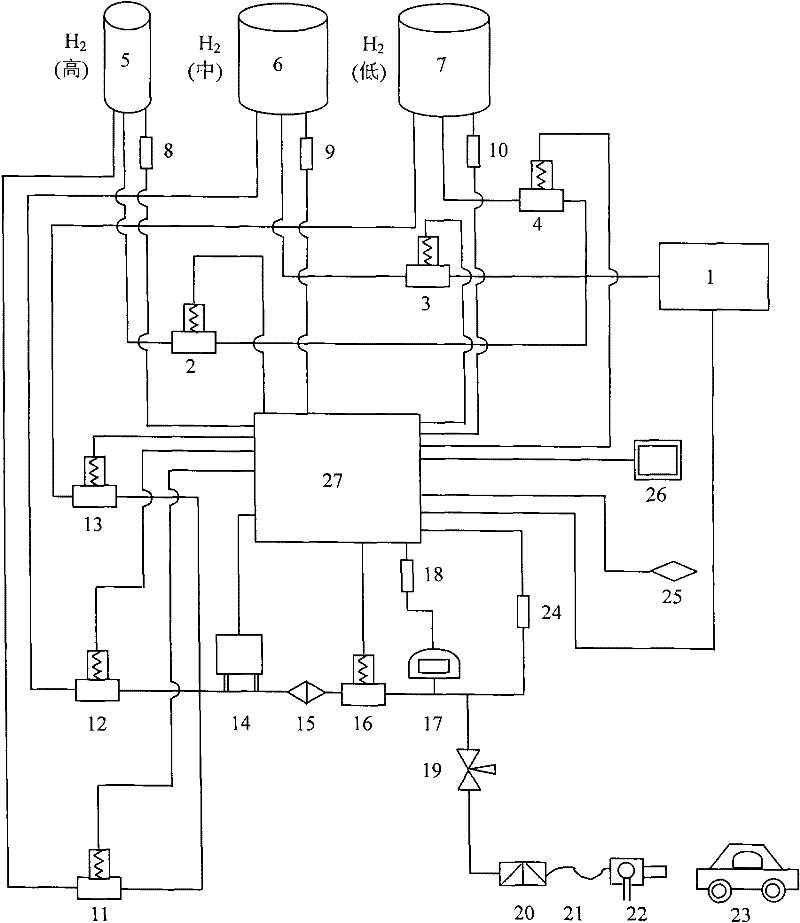

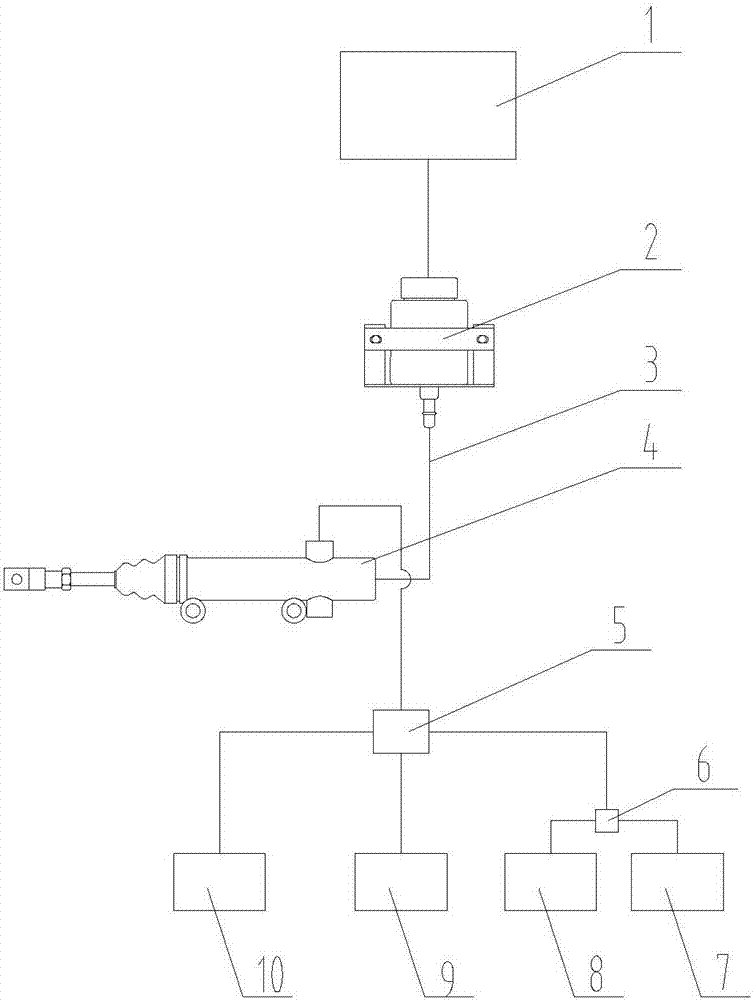

Three-level charging-up optimizing control method and system for hydrogenation station high-efficiency hydrogenation

ActiveCN101315545ARefill time shortenedEasy to reinforceAdaptive controlContainer filling under pressureThree levelSystems design

The invention relates to a hydrogen-refueling optimized control method and a corresponding system, aiming at providing a three-level refueling optimized method for a hydrogen-refueling station with high-effective hydrogen-refueling, namely, a hydrogen-storing tank in the hydrogen-refueling station is divided into three groups which are high, middle and low.. A multi-object optimization algorithm is put forward and a constraint method is adopted to convert a multi-object problem into a plurality of single-object optimization problems so as to realize high effective hydrogen-taking and quick refueling. Each single-object schedule problem belongs to the dynamic schedule scope and a forward sequential searching method is adopted. A detailed program control flow is figured out according to the optimized result so as to design the optimal refueling mode for the refueling system of the hydrogen-refueling station. The invention also provides a hydrogen refueling system which is used for the high-effective hydrogen-refueling three-level optimized control method of the hydrogen-refueling station and comprises a hydrogen-storing container, a hydrogen-charging valve, a pressure sensor, a hydrogen distributor, a flow meter and a check valve; the hydrogen-storing container comprises a low-pressure hydrogen-storing container, a middle-pressure hydrogen-storing container and a high-pressure hydrogen-storing container; and also a program controller.

Owner:ZHEJIANG UNIV

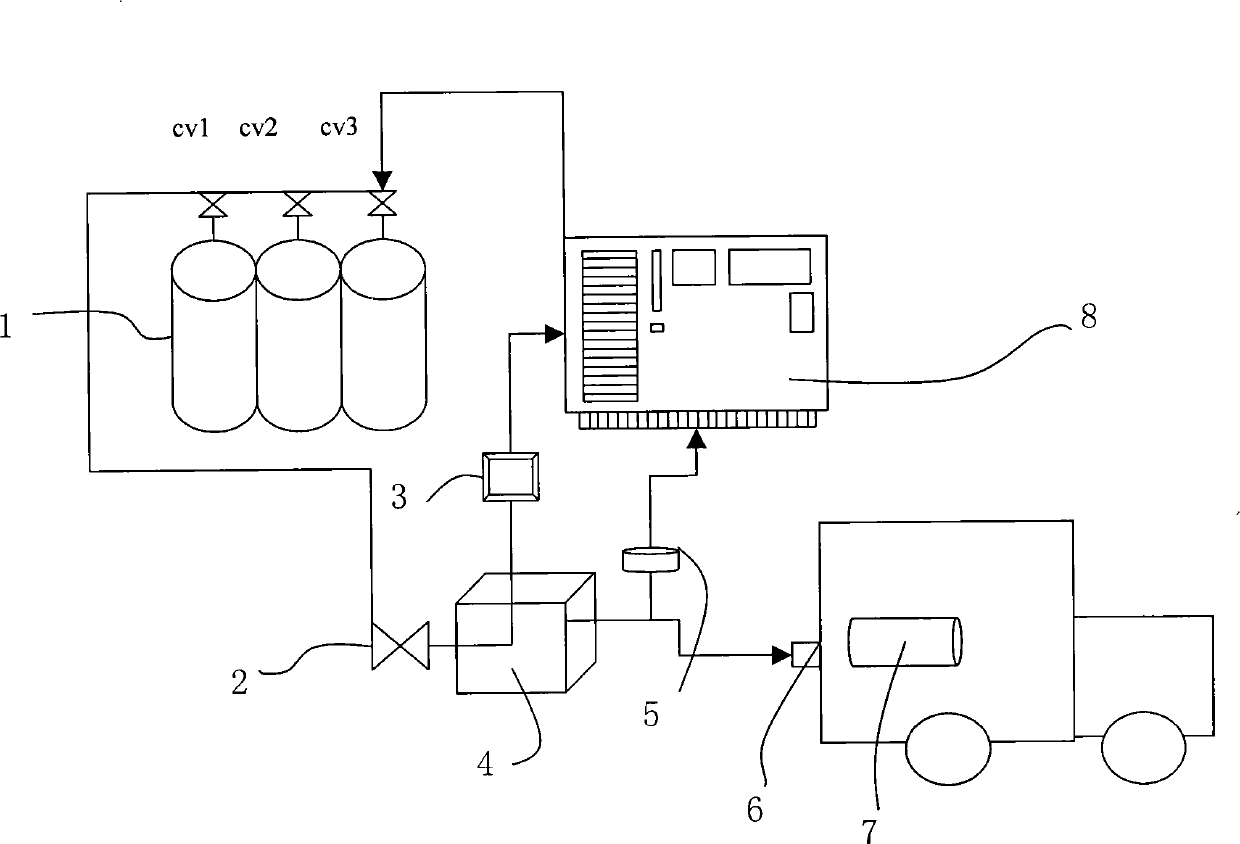

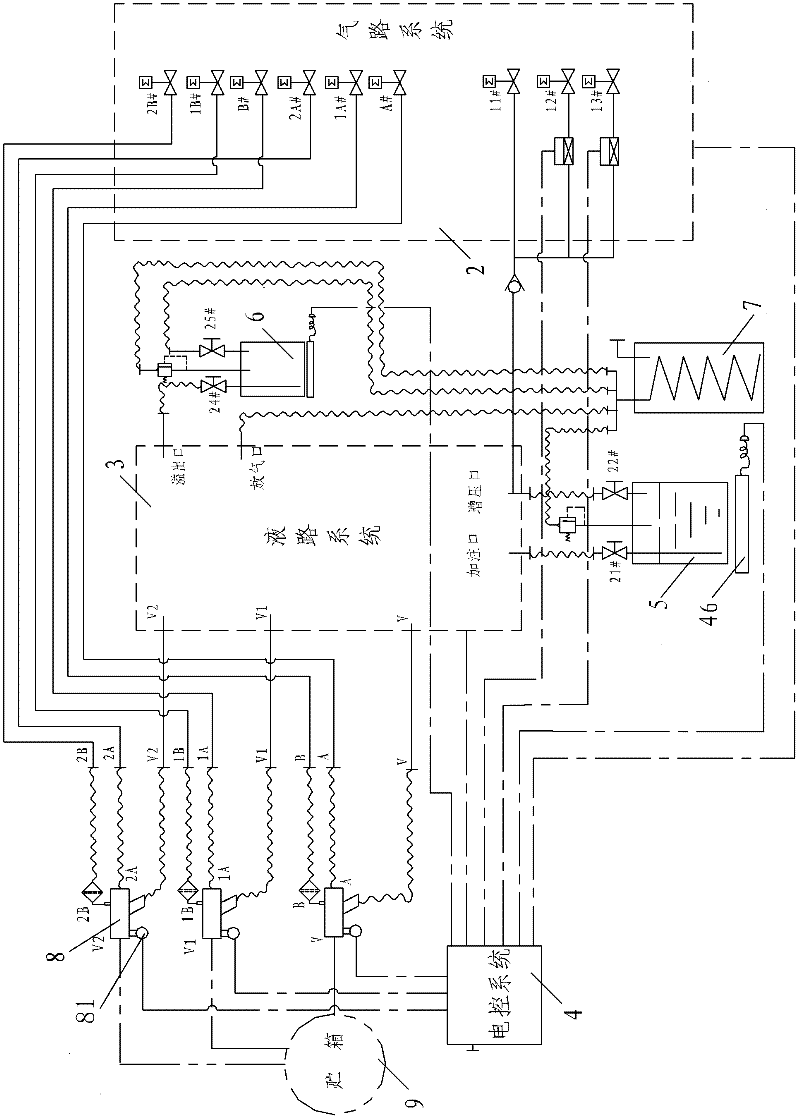

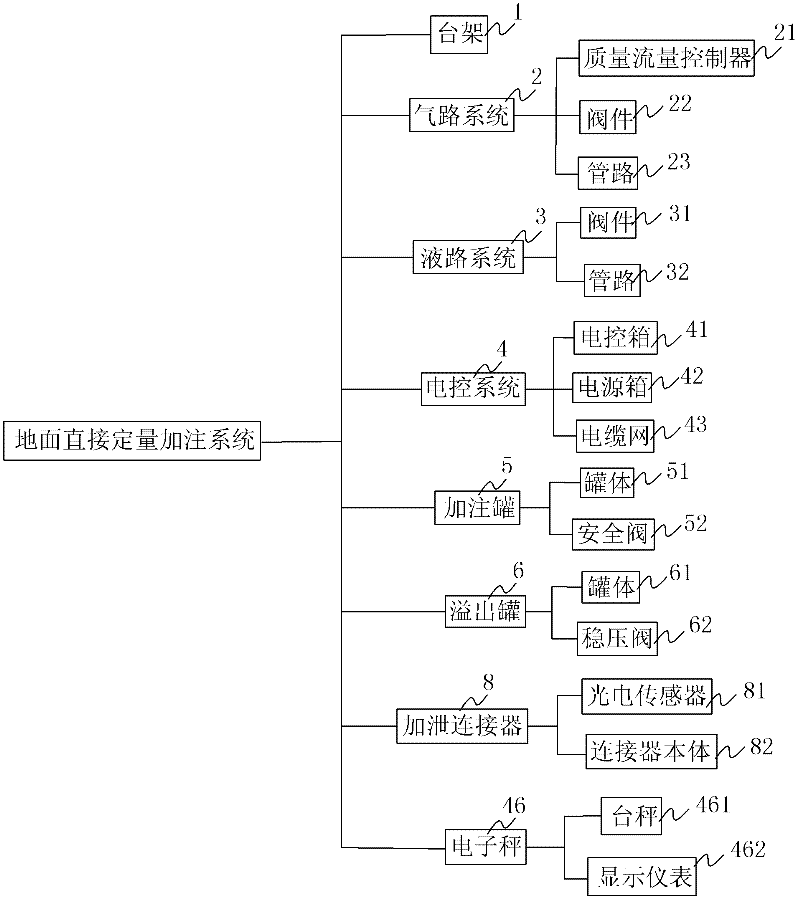

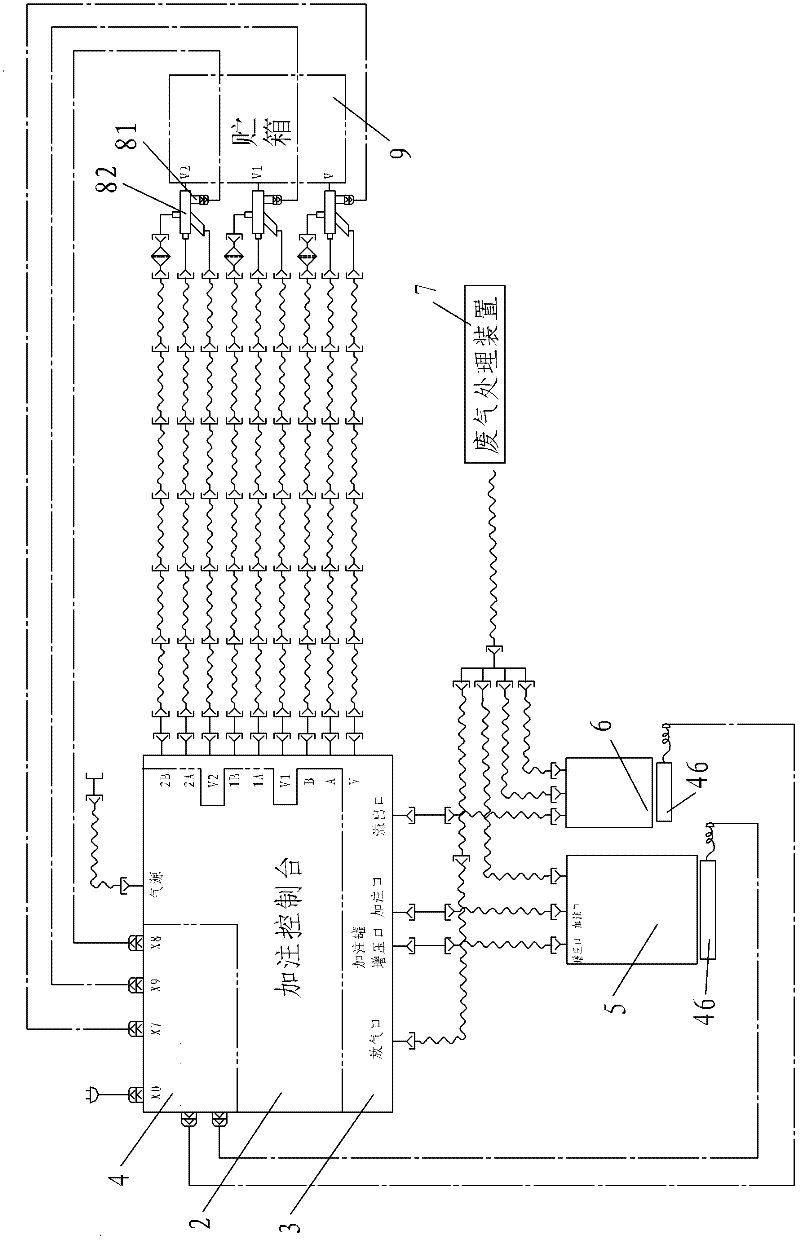

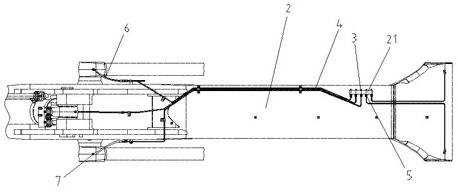

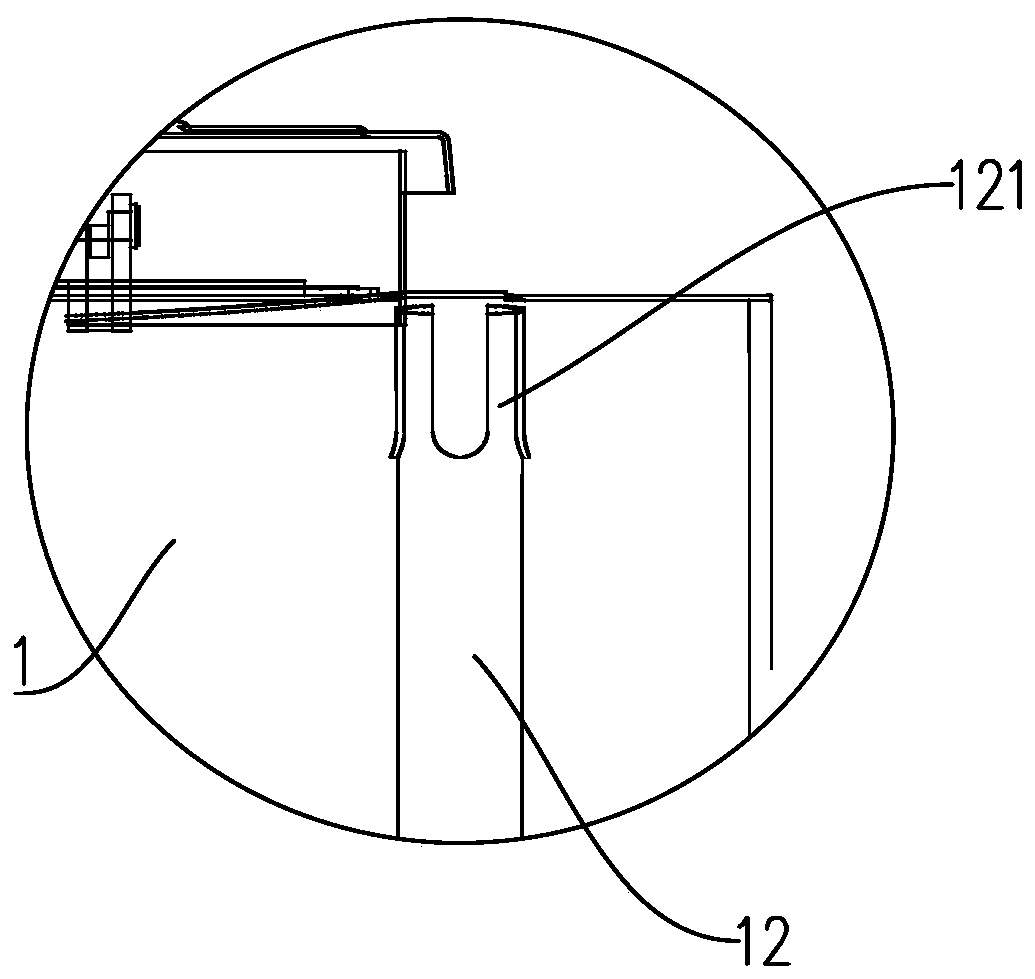

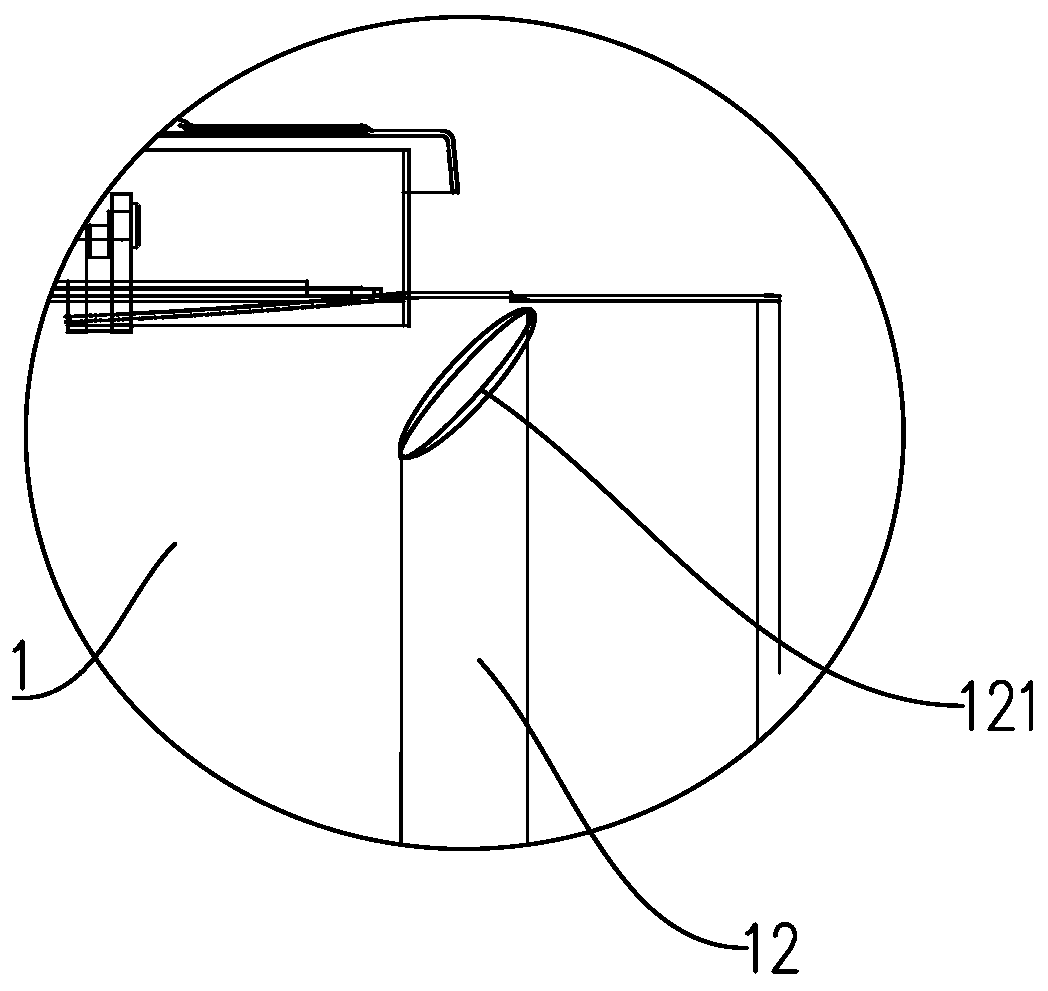

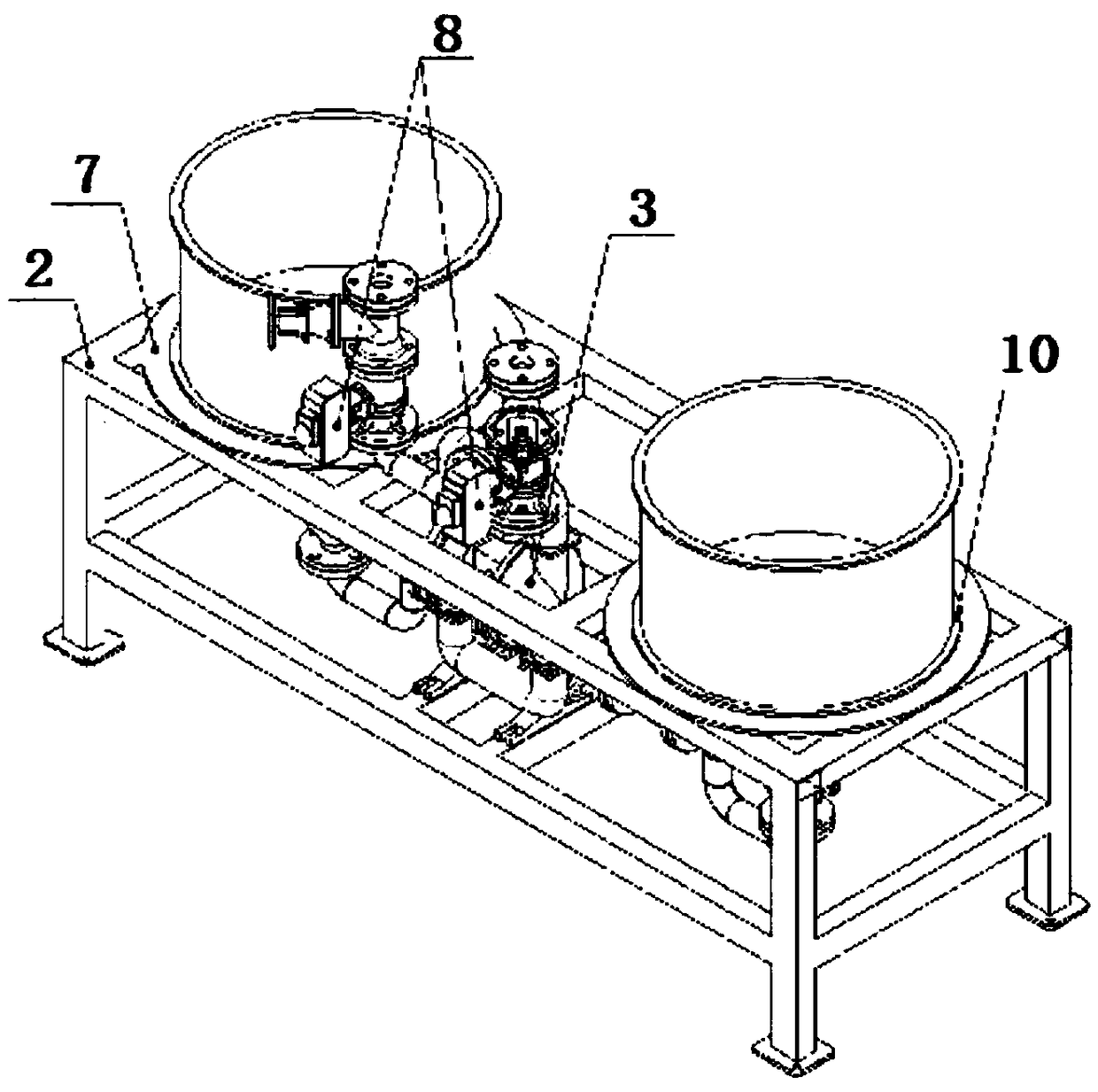

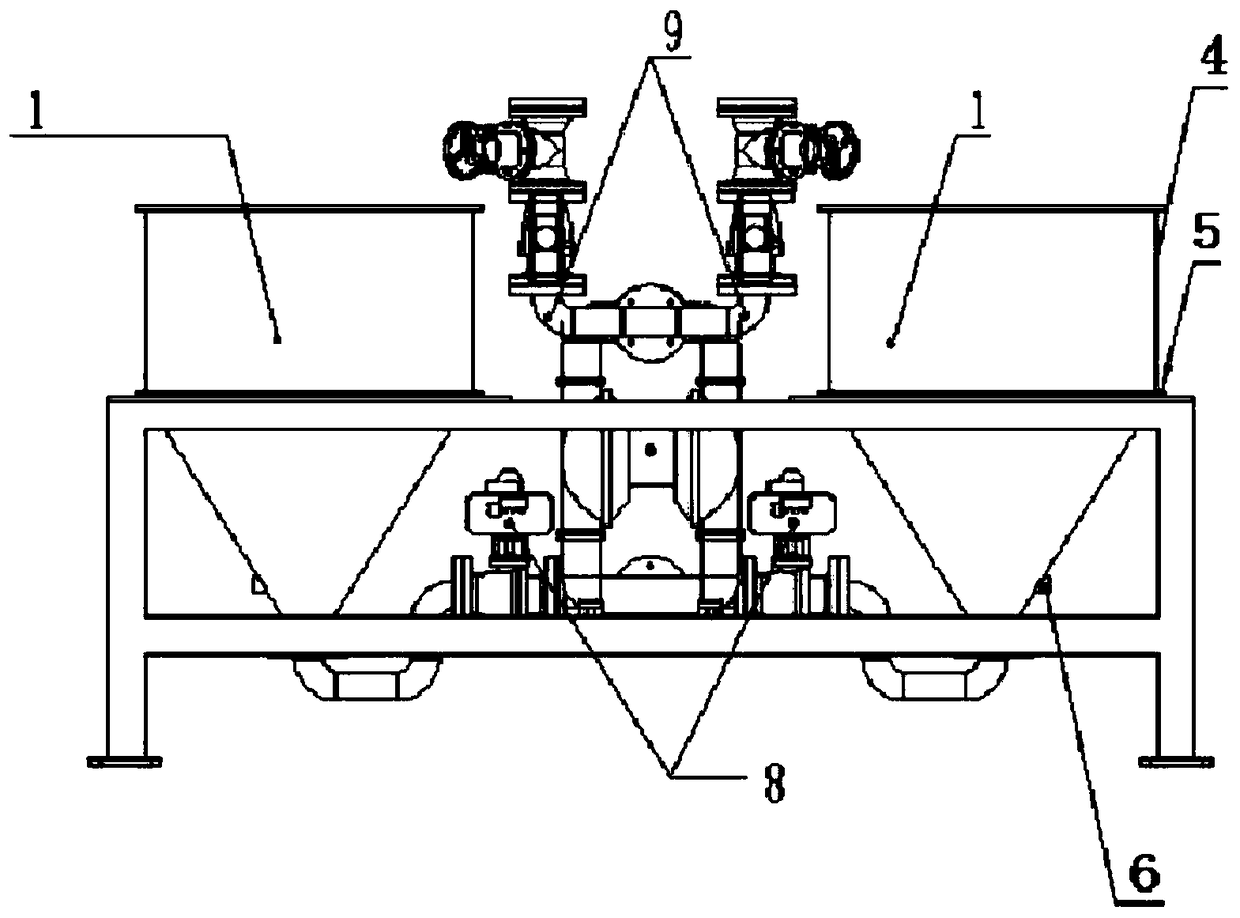

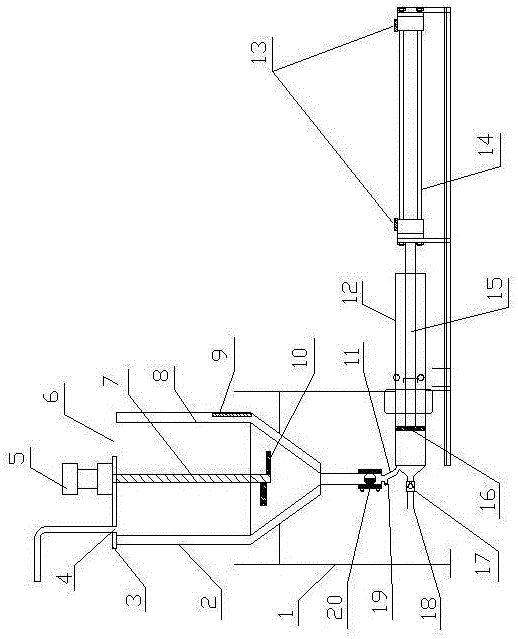

Ground direct and quantitative filling system and method

ActiveCN102464291ARefill time shortenedReduce technical preparation timeLiquid transferring devicesPipeline systemsRocketStreamflow

The invention relates to a ground direct and quantitative filling system and a ground direct and quantitative filling method, which are used for filling an end correction storage container. The ground direct and quantitative filling system comprises a rack, an air channel system, a liquid path system, an electronic control system, a filling tank, an overflow tank, a waste gas treatment device, a filling and draining connector and an electronic scale, wherein the liquid path system, the air channel system and the electronic control system are positioned in the rack and are used for starting working procedures, controlling a valve, monitoring display, controlling a filling amount and filling accuracy and regulating filling speed. The filling method comprises the following steps of: controlling the filling accuracy, controlling filling flow, controlling the filling process, controlling filling time and controlling filling counter pressure. In the ground direct and quantitative filling system and the ground direct and quantitative filling method, the filling accuracy is close to the filling accuracy reached in a quantitative mode of the storage container on a rocket by utilizing technologies of controlling the filling accuracy, the filling flow, the filling process, the filling time and the like, 'one-button' type filling is realized, and the requirement of filling accuracy of the end correction storage container is met.

Owner:BEIJING INST OF SPACE LAUNCH TECH

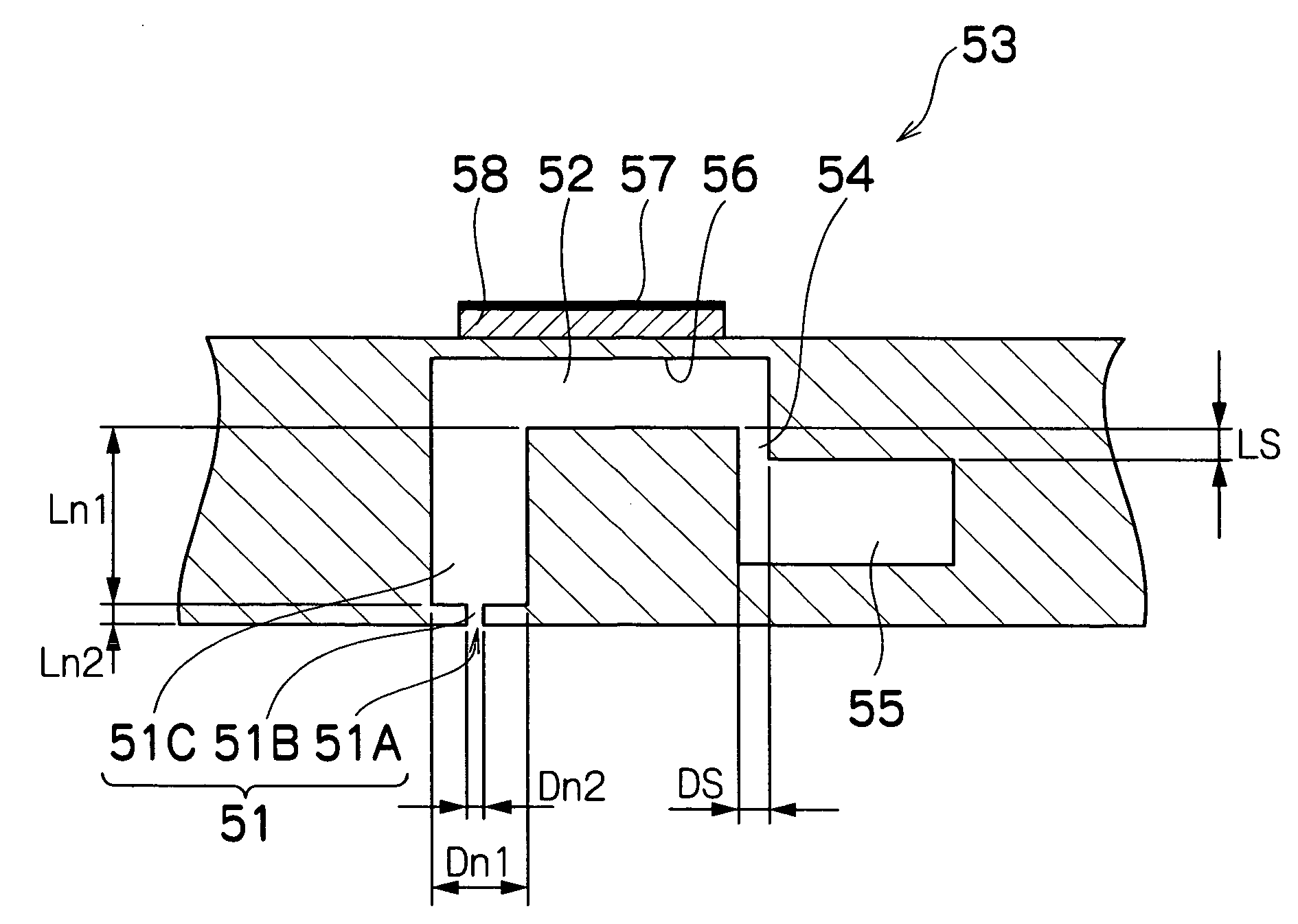

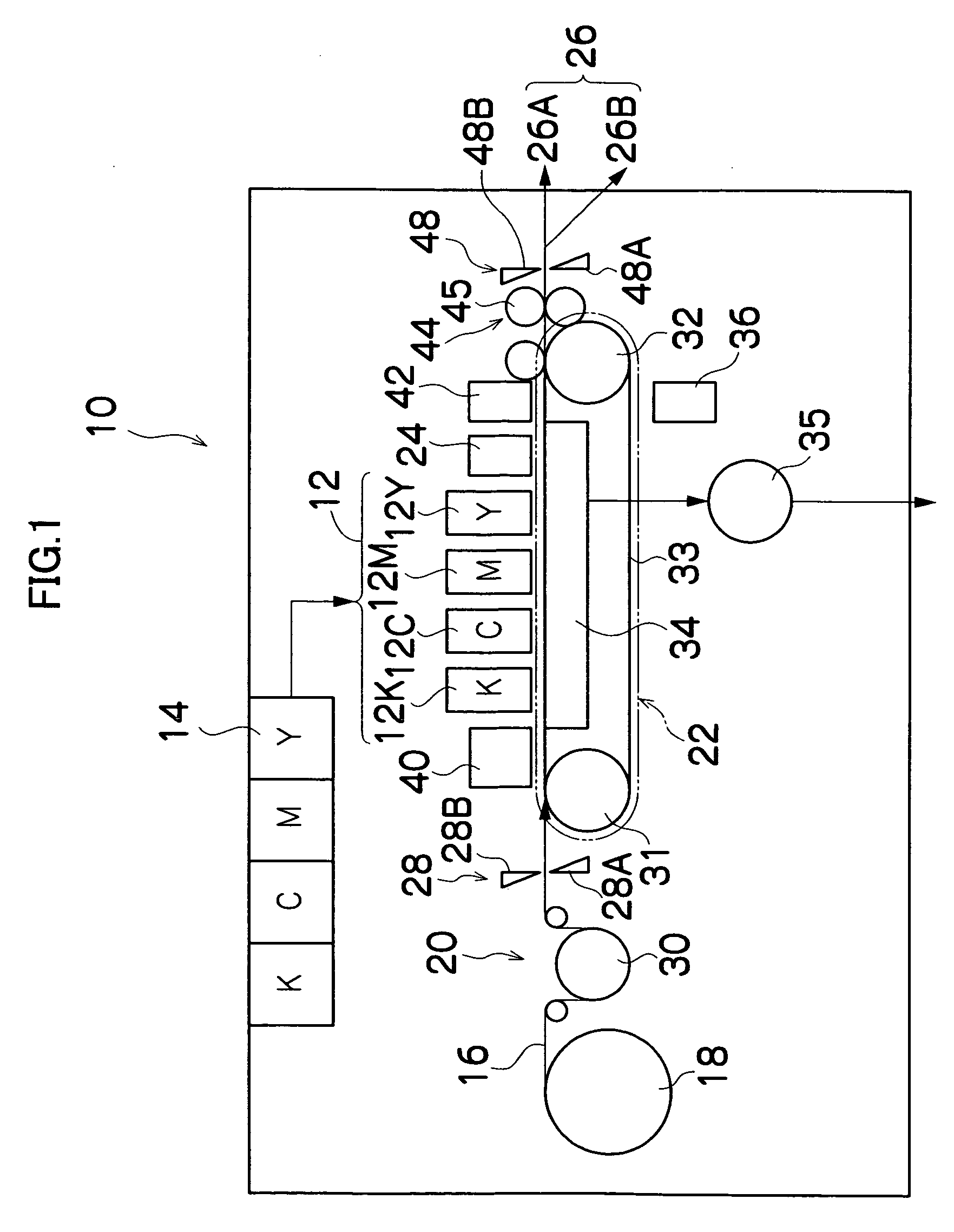

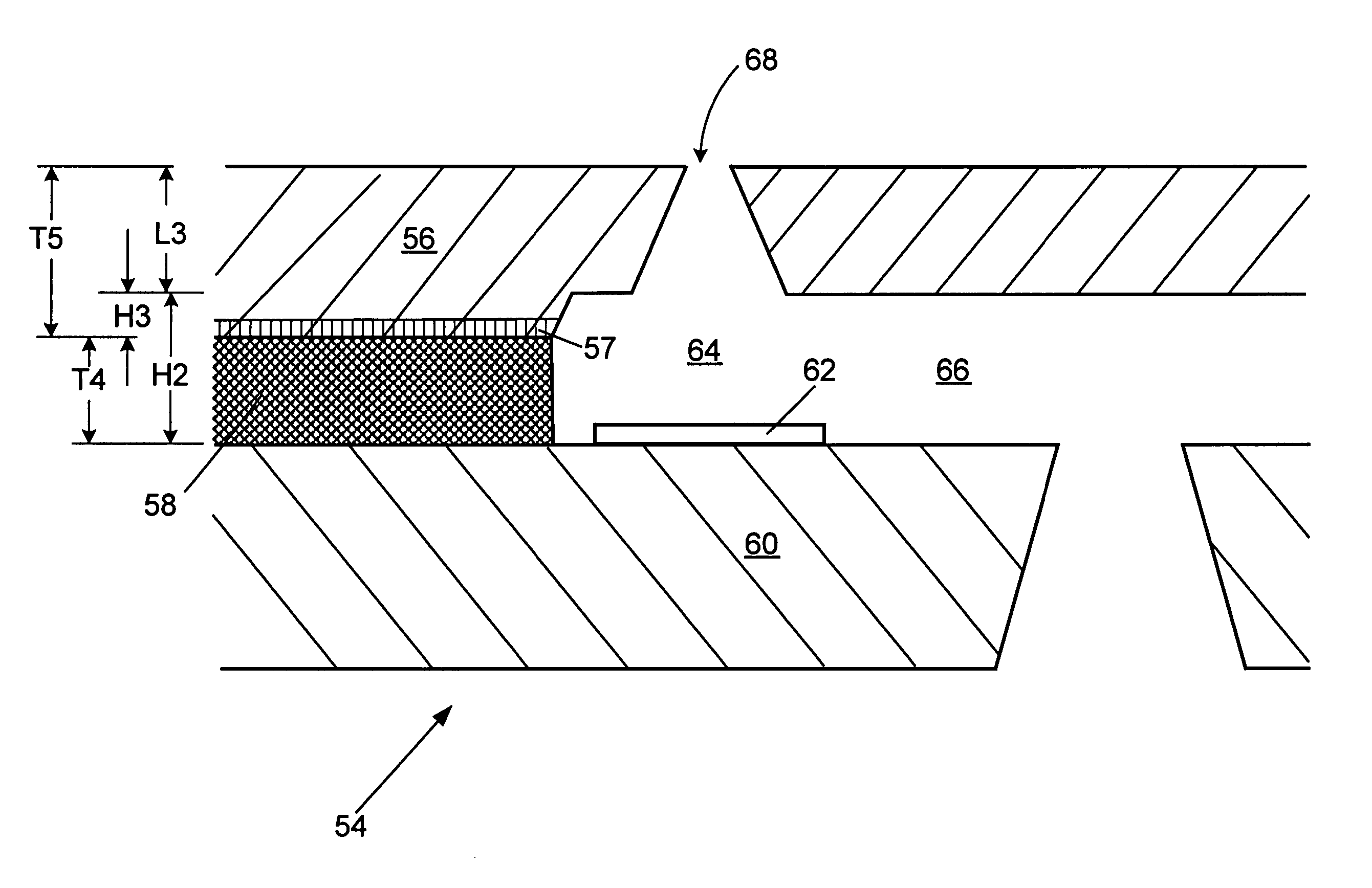

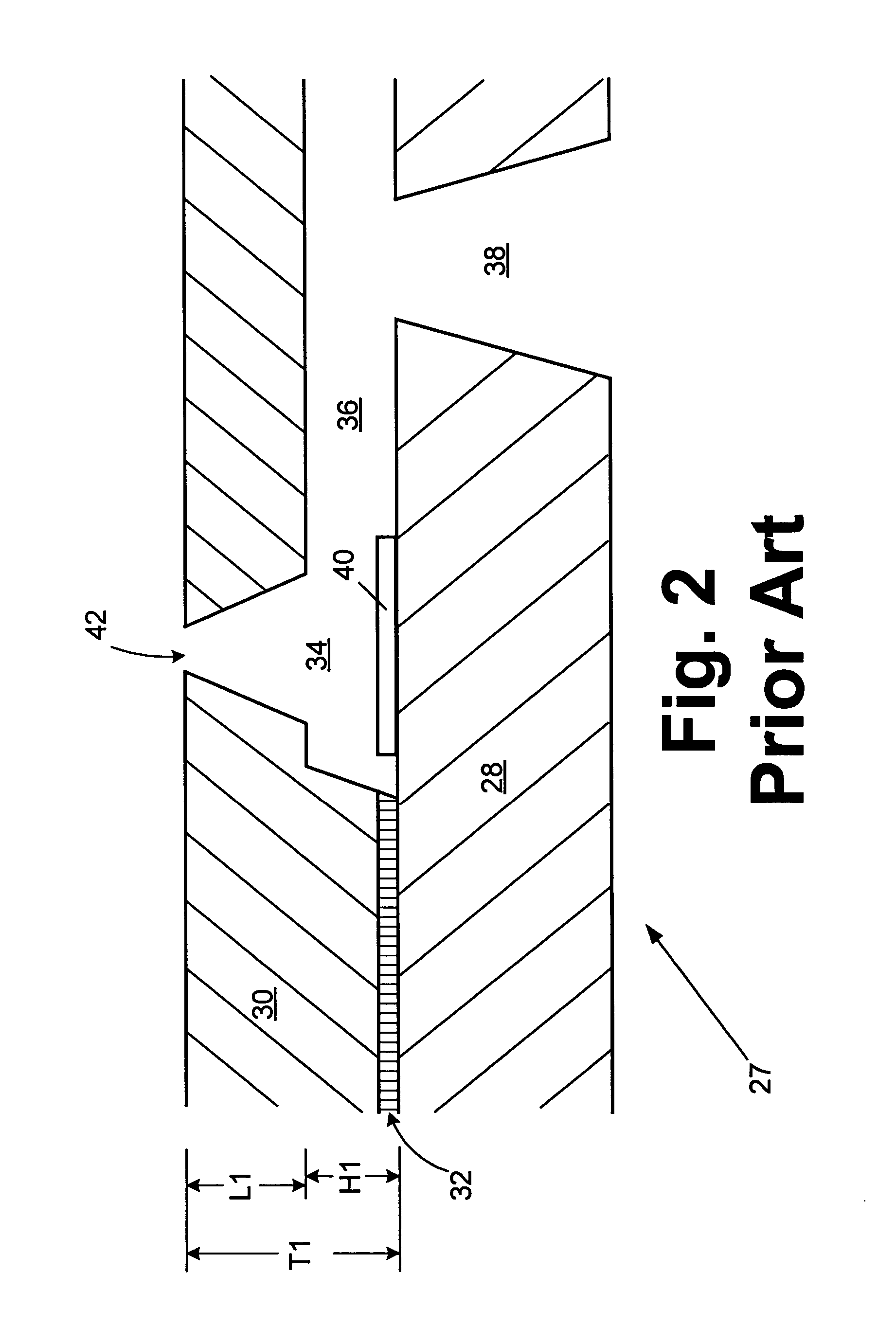

Liquid ejection head, liquid ejection apparatus, and drive control method

InactiveUS20060023029A1Increase volumeRefill time shortenedInking apparatusOther printing apparatusLiquid jetEngineering

The liquid ejection head comprises: a nozzle through which liquid is ejected; a pressure chamber which stores the liquid ejected through the nozzle; a pressurizing device which changes a volume of the pressure chamber to apply pressure to the liquid stored in the pressure chamber; and a supply port through which the liquid is supplied to the pressure chamber, wherein the liquid ejection head has a structure such that inertance Mn of the nozzle, liquid resistance Rn of the nozzle, compliance Cn caused by a surface tension of the liquid in the nozzle, inertance Ms of the supply port, and liquid resistance Rn of the supply port satisfy the following inequality: 4·(Mn+Ms)Cn≤(Rn+Rs)2,so that oscillation of a meniscus surface located in vicinity of the nozzle is controlled at a time of refill when the liquid is filled in the pressure chamber through the supply port after the liquid is ejected from the nozzle.

Owner:FUJIFILM CORP

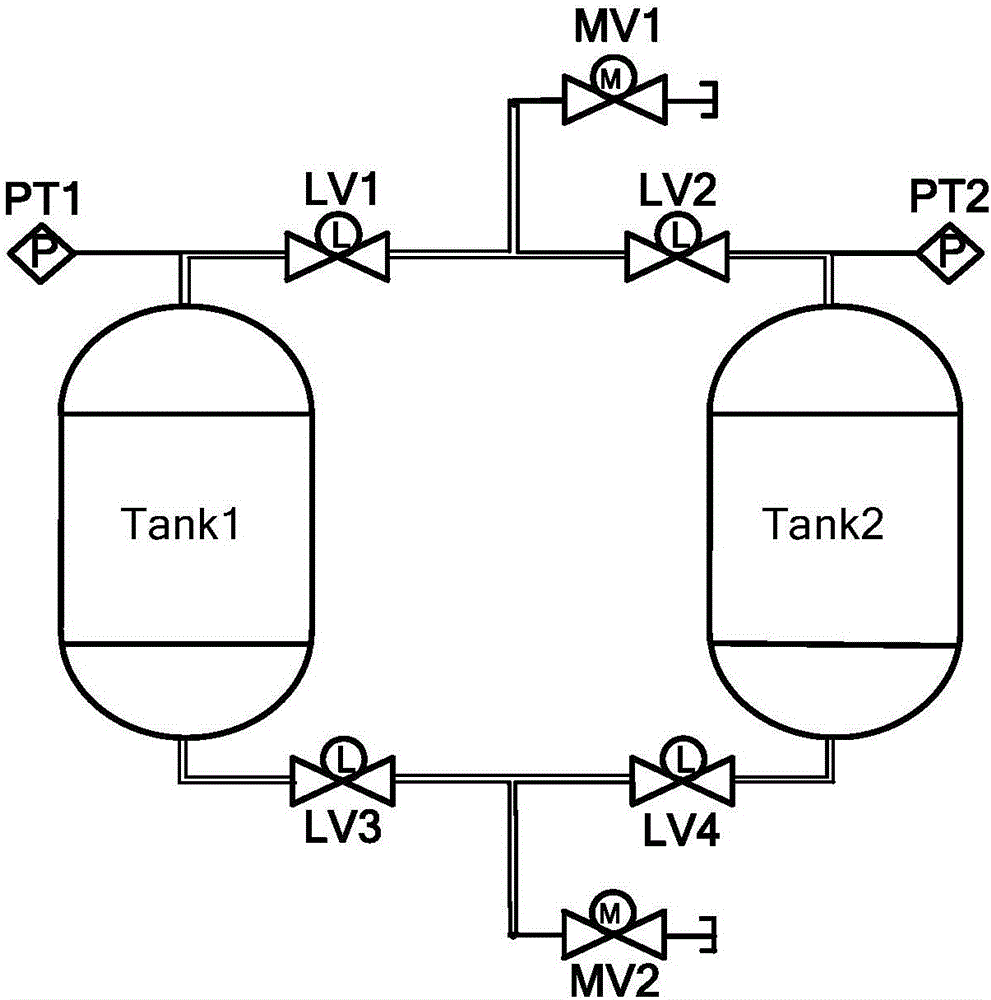

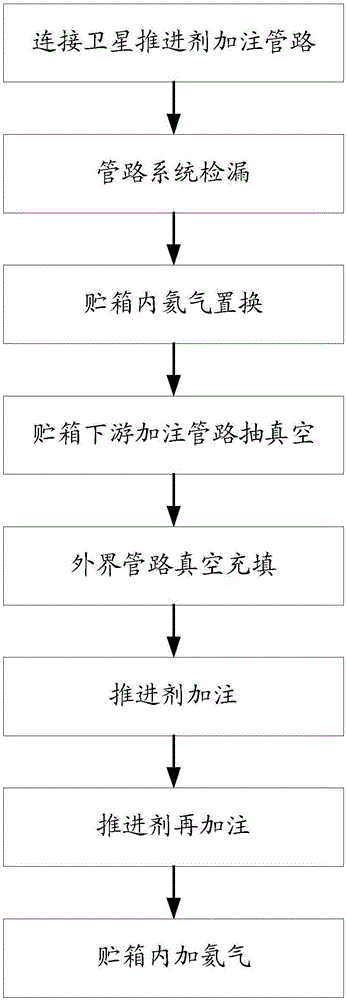

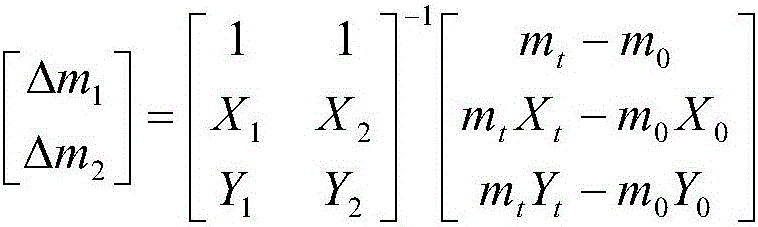

Parallel balanced filling method for high-capacity semi-management surface tension storage tank

ActiveCN106762224AReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

Inkjet print head

InactiveUS20050264627A1Increase printing speedReduce distanceInking apparatusEngineeringMulti-function structure

An inkjet print head including a chamber layer provided with an ink via, at least one ink chamber having a heater, and at least one ink channel connecting the ink via and the ink chamber; and a nozzle layer provided with at least one nozzle at a position corresponding to the ink chamber. The ink channel is provided with a multi-functional structure. The multi-functional structure performs functions of a filter and a restrictor.

Owner:S PRINTING SOLUTION CO LTD

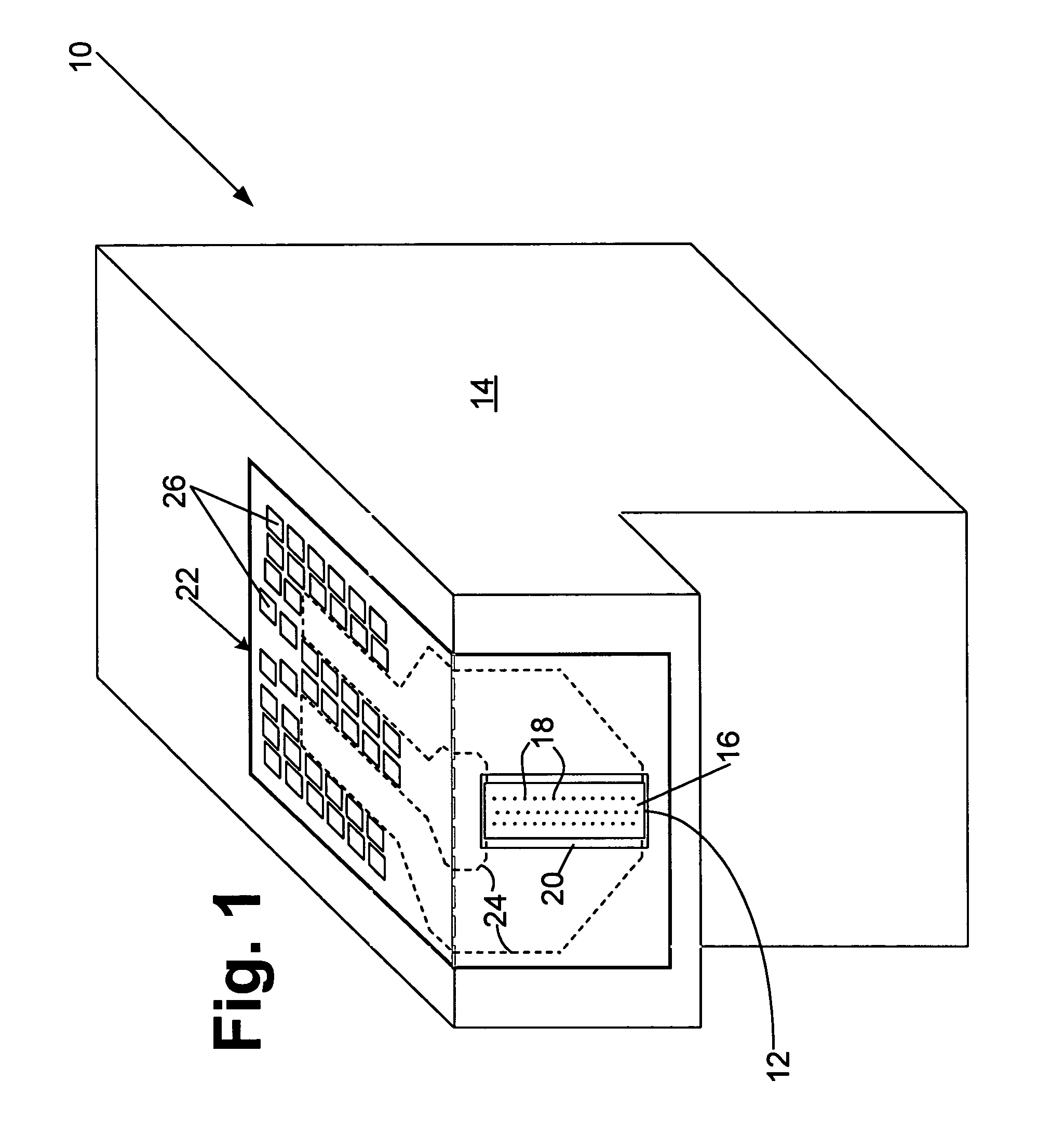

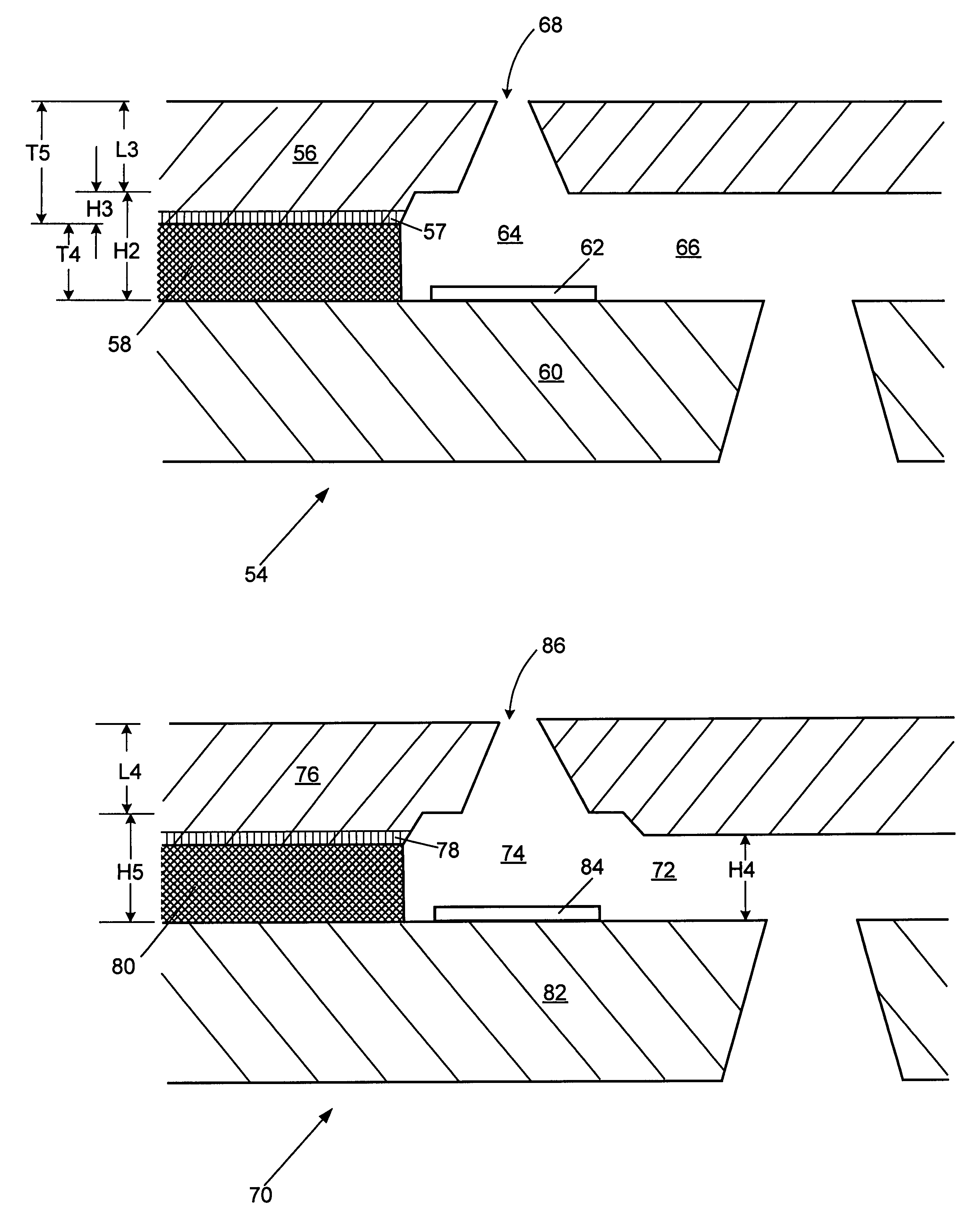

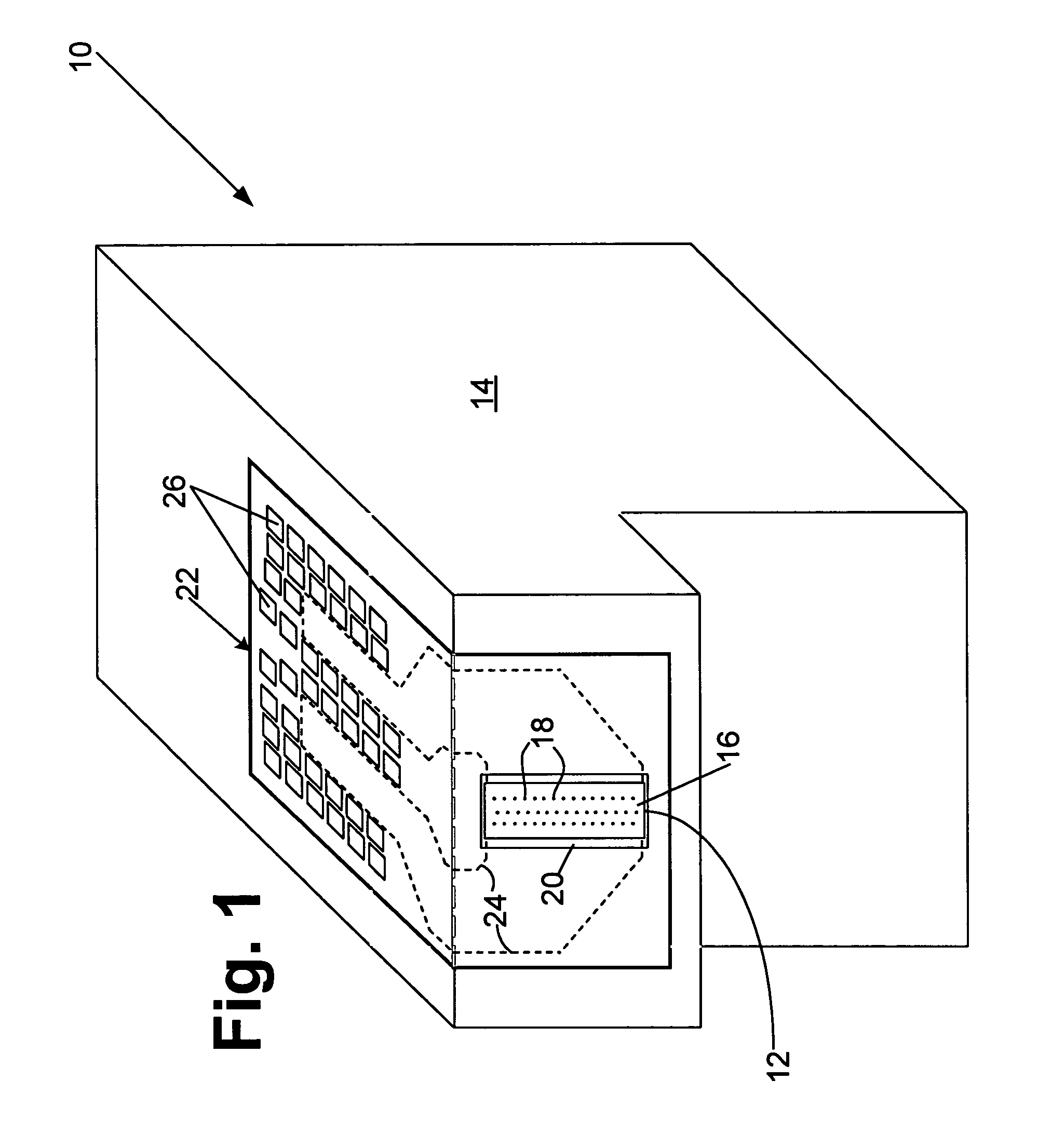

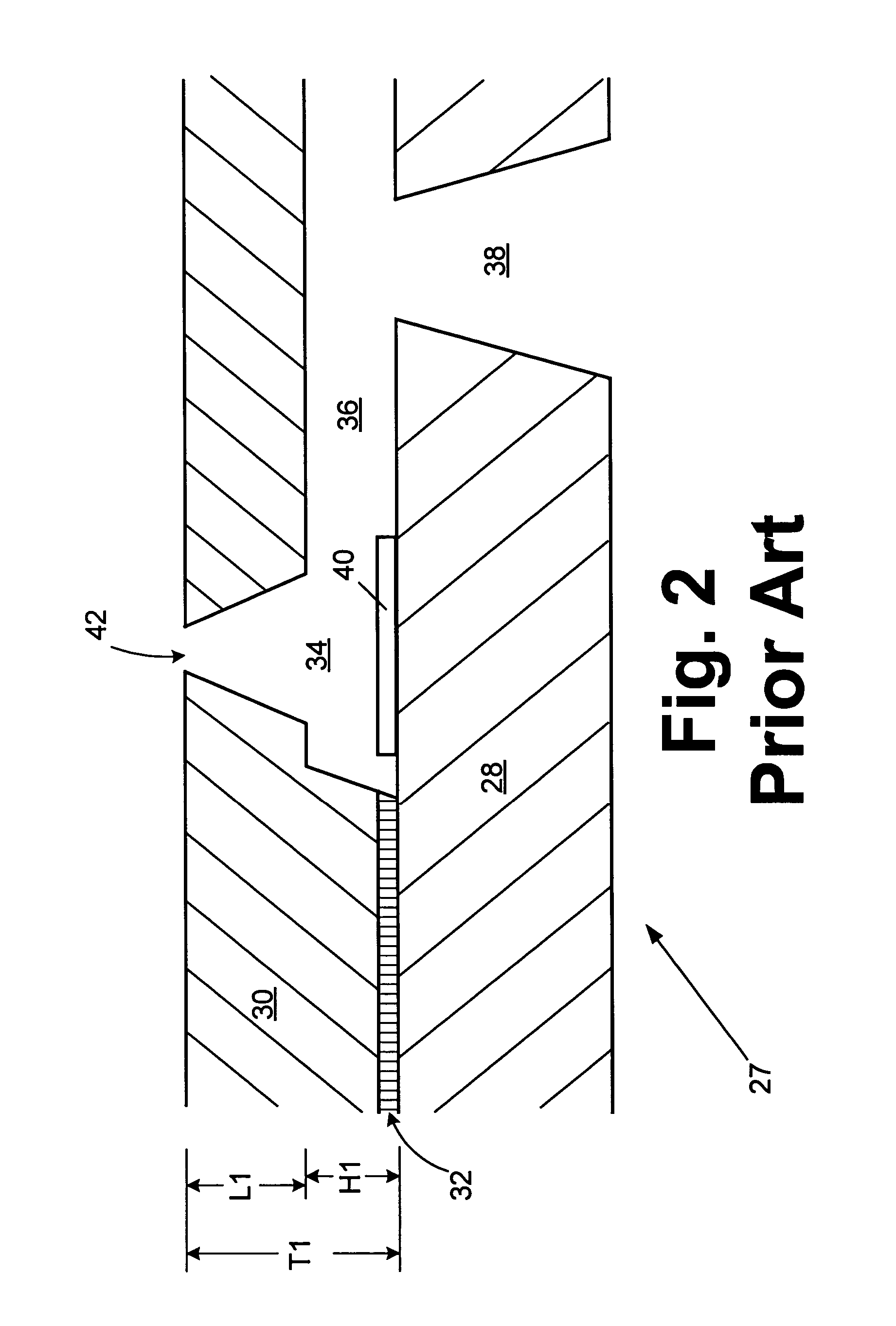

Micro-fluid ejection devices and method therefor

An improved ink jet printhead for an ink jet printer and method therefor. The printhead includes a semiconductor substrate containing ink ejection devices. A thick film layer is attached to the substrate. A nozzle plate is attached to the thick film layer. The nozzle plate contains a plurality of ink ejection nozzles corresponding to the ink ejection devices. The printhead contains flow features having a height dimension and a width dimension formed therein for flow of ink to the plurality of ink ejection devices for ejection through the nozzles. At least a portion of the flow feature dimensions for at least one of the nozzles is formed in both the thick film layer and laser ablated in the nozzle plate, wherein the thick film layer contains at least 12% of the flow feature dimensions.

Owner:FUNAI ELECTRIC CO LTD

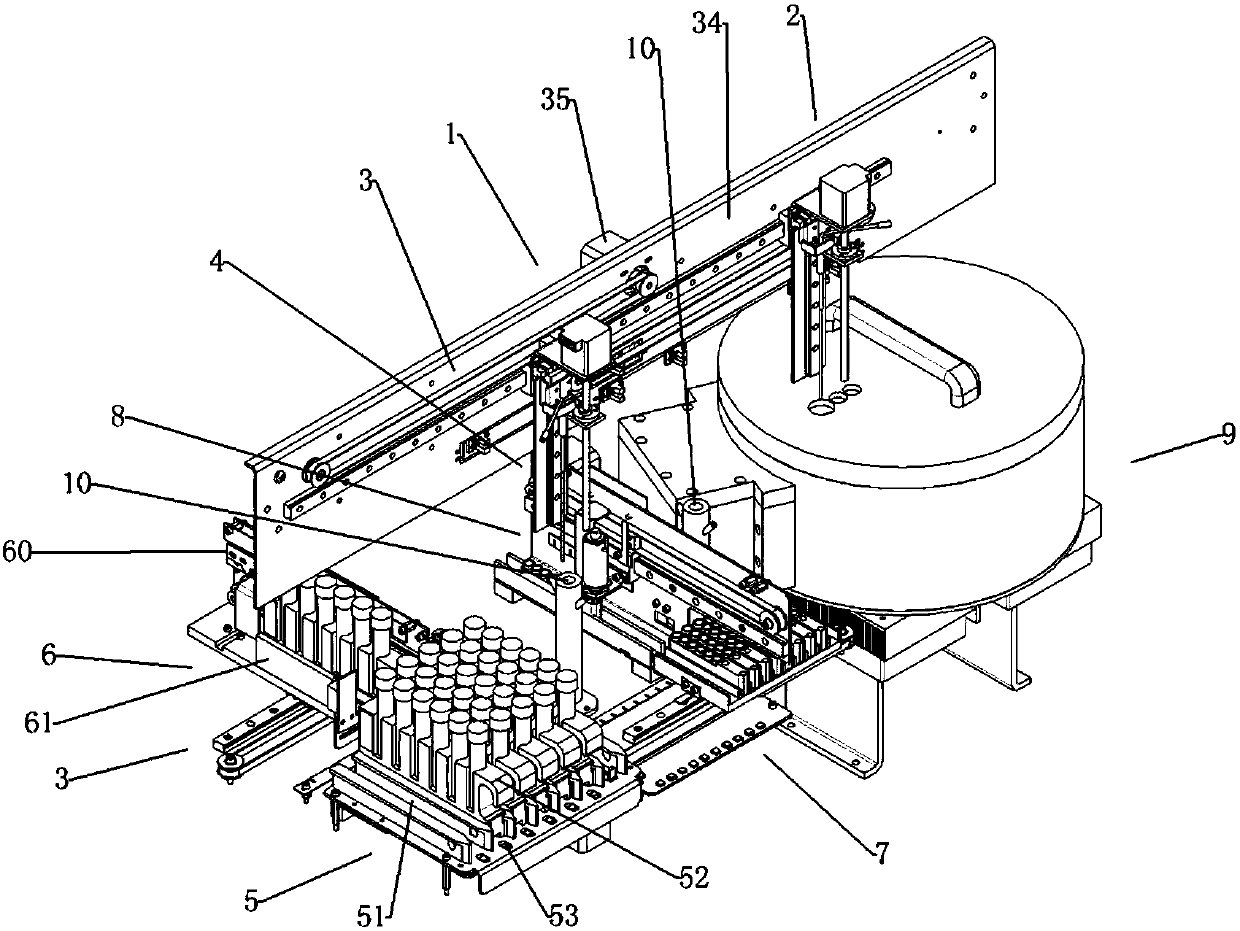

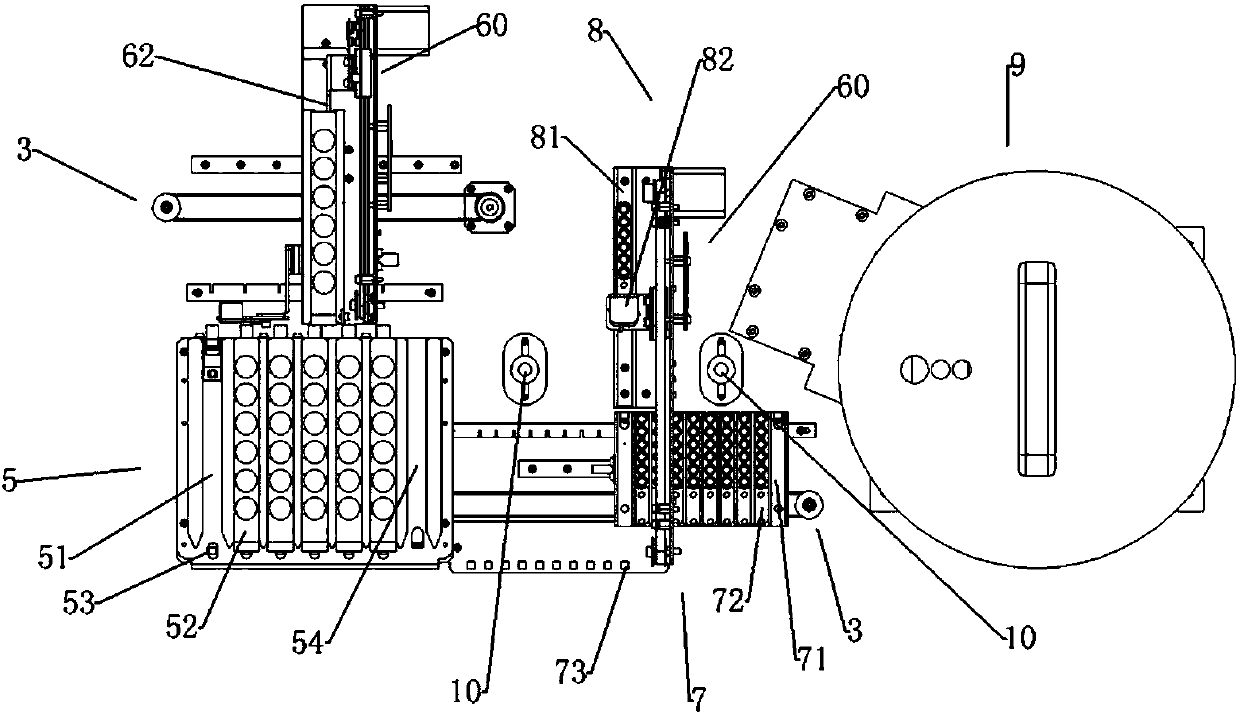

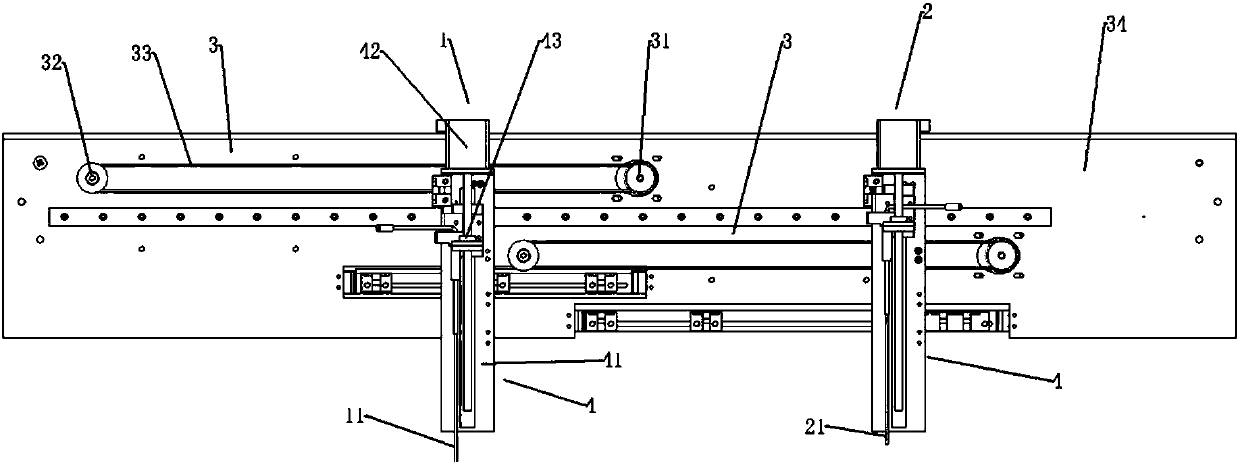

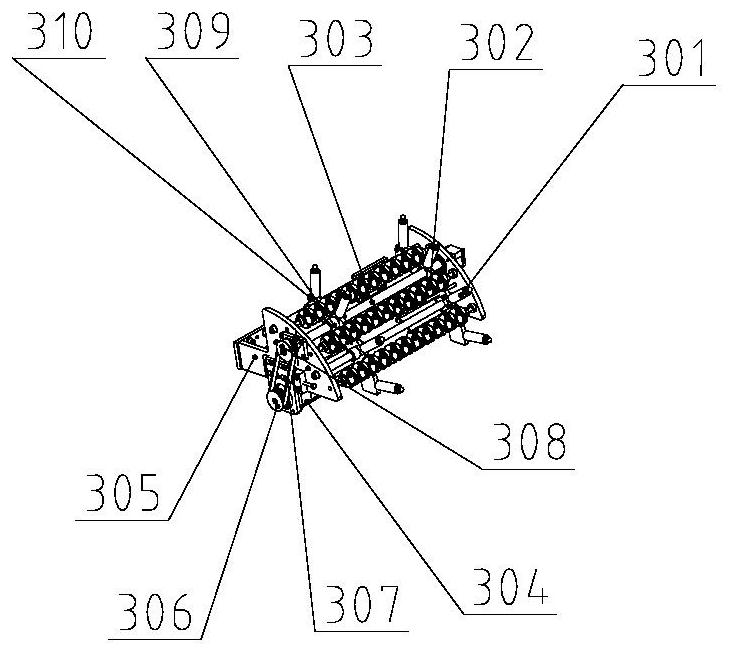

Sampling device of full-automatic chemiluminescent analyzer and sampling method of sampling device

The invention provides a sampling device of a full-automatic chemiluminescent analyzer and a sampling method of the sampling device. The chemiluminescent analyzer comprises a sampling needle system, areagent needle system, a sample area, an injection area and a reagent area, wherein the sample area, the injection area and the reagent area are sequentially arranged from left to right; the samplingneedle system and the reagent needle system are fixed on a same transverse guide track; a reaction cup area perpendicular to the injection area is arranged between the reagent area and the sample area; needle cleaning devices are respectively arranged between the sample area and the injection area and the reagent area and the injection area; sampling positions of the sample area, the injection area, the reagent area and the two needle cleaning devices are on a same straight line; a sampling needle passes through sampling positions of the sample area and the injection area; a reagent needle passes sampling positions of the reagent area and the injection area. According to the sampling device of the full-automatic chemiluminescent analyzer and the sampling method of the sampling device, thesampling positions, the injection positions, grooves and a cleaning area are positioned on a same straight line, so that the injection speed is increased; the sampling positions and the injection positions are fixed, so that the error probability is reduced.

Owner:天津博硕科技有限公司

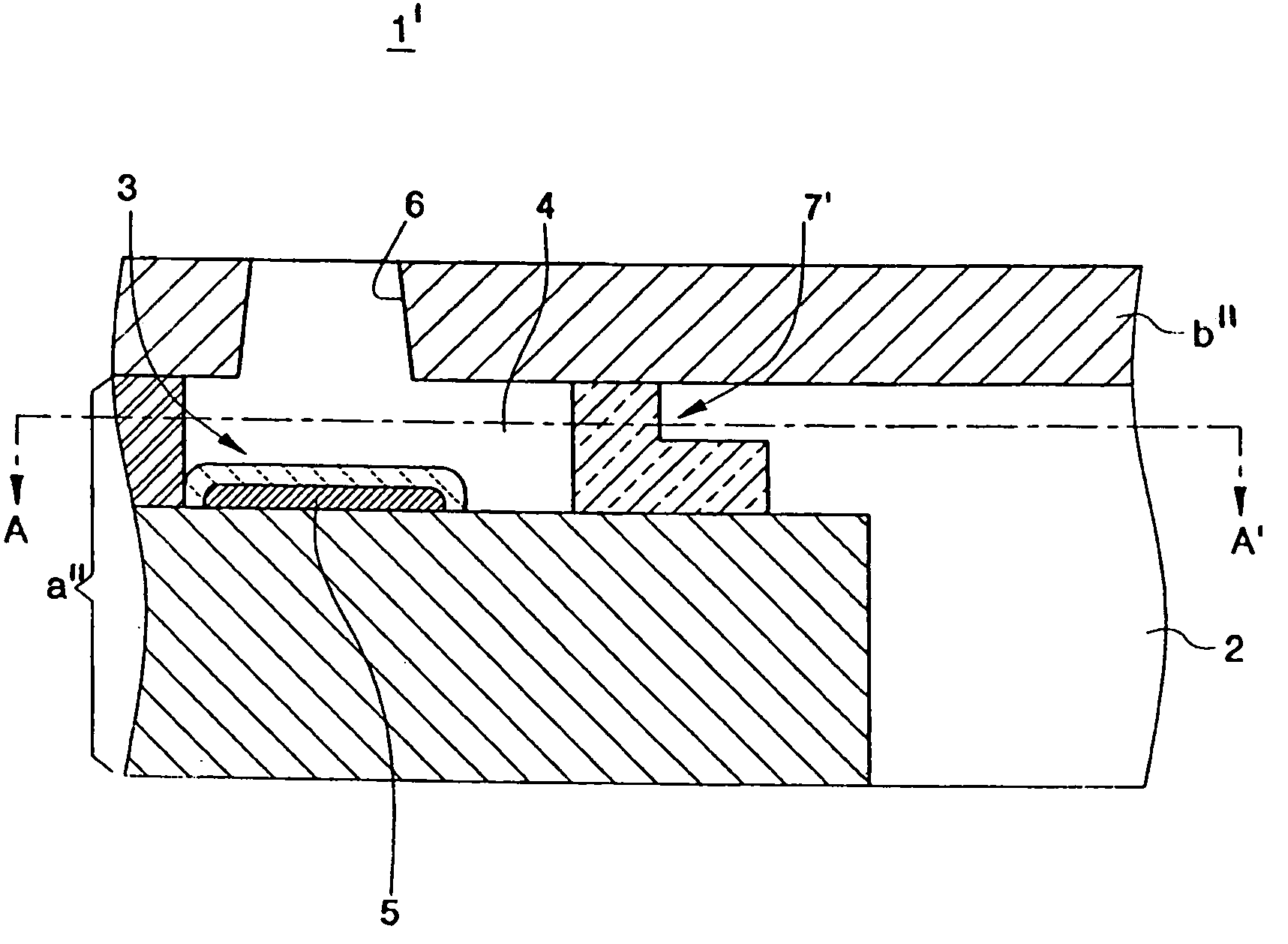

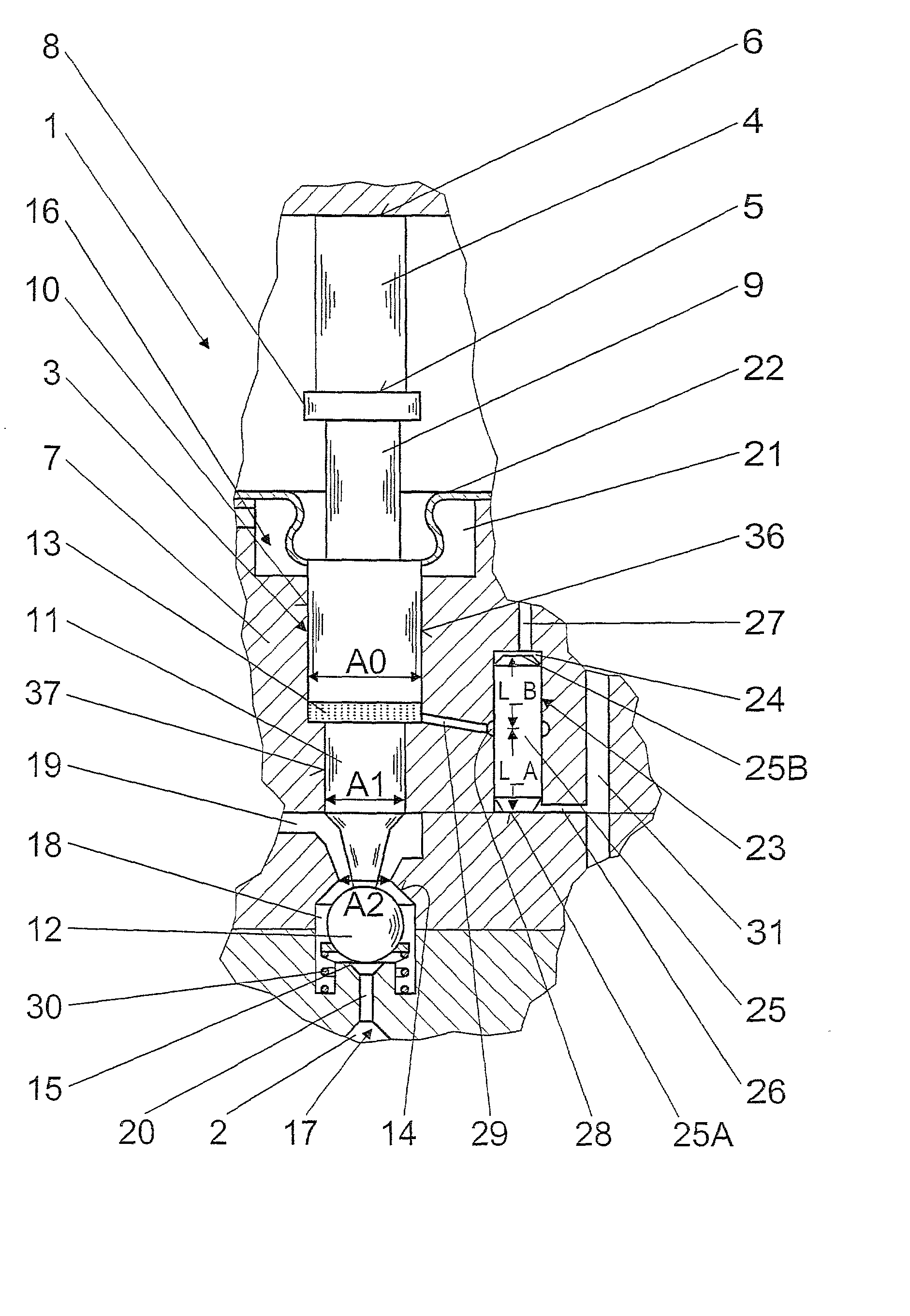

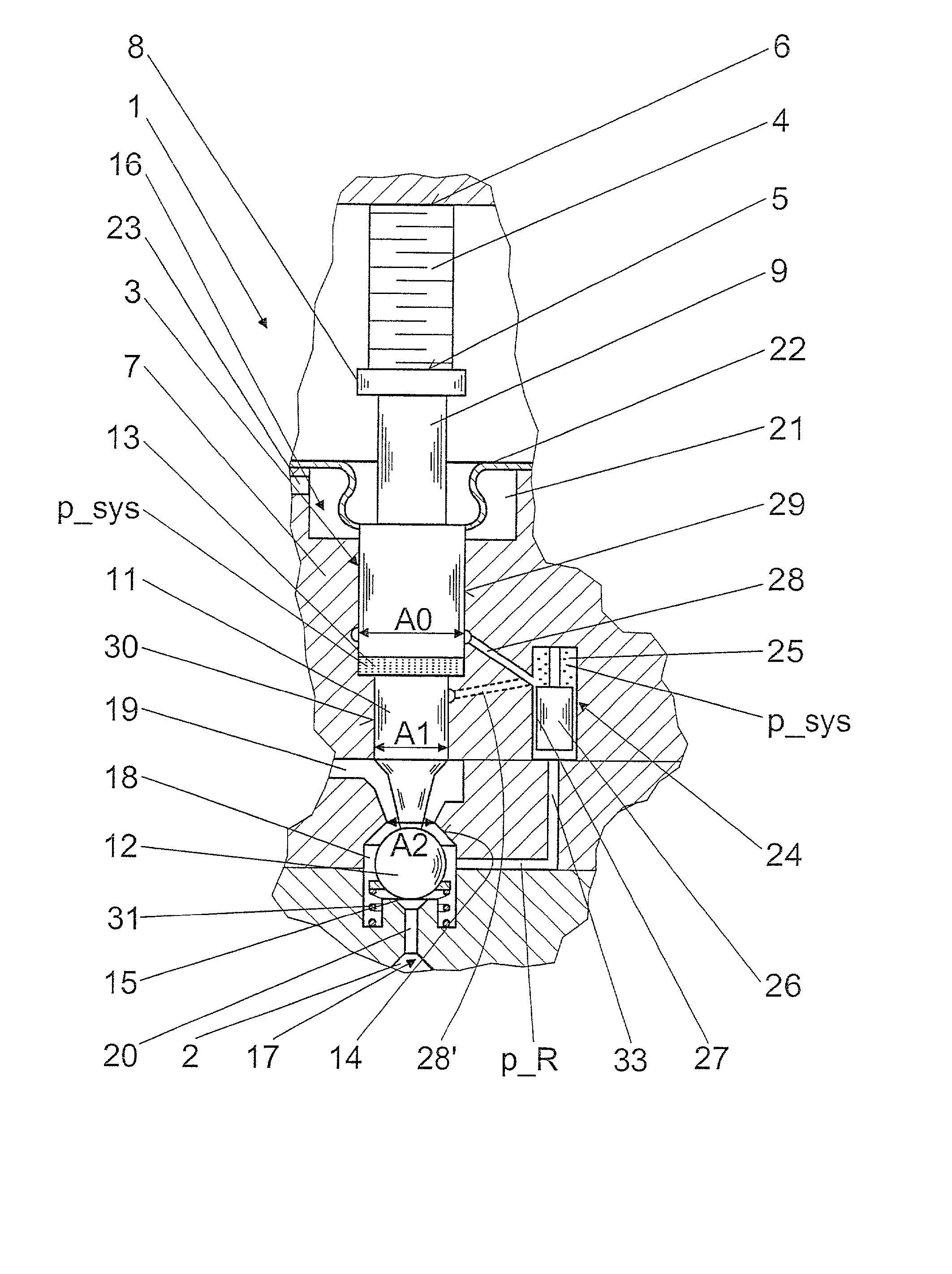

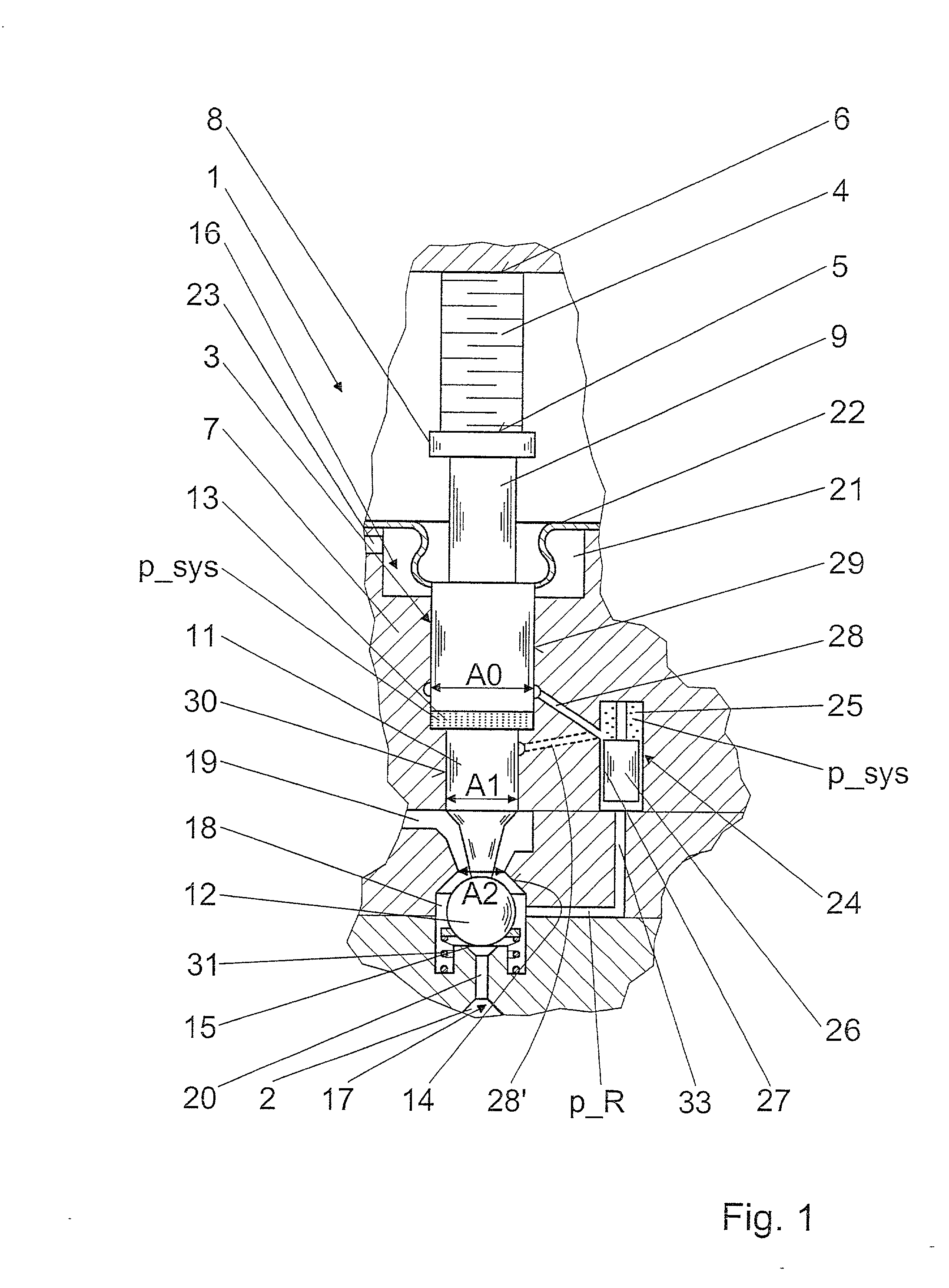

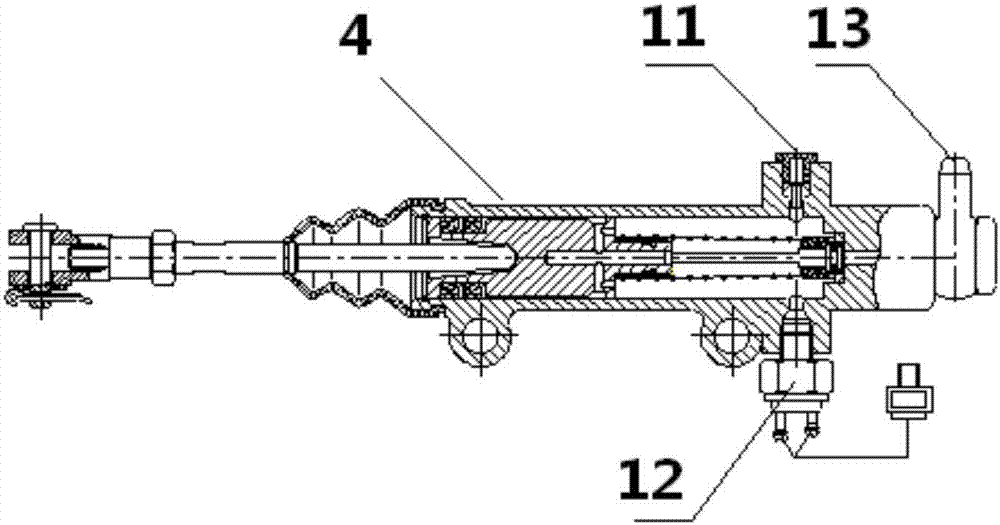

Valve for regulating fluids

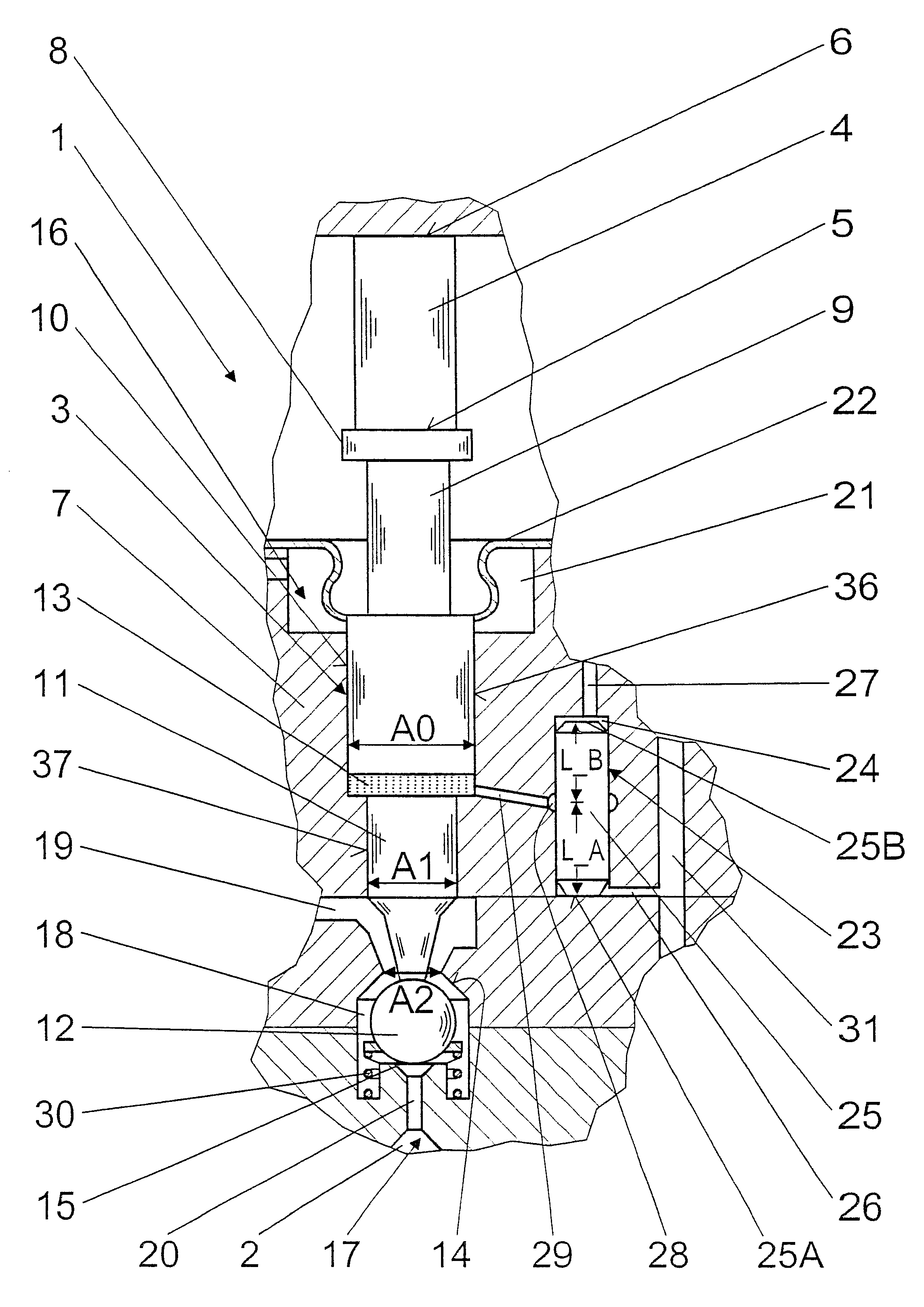

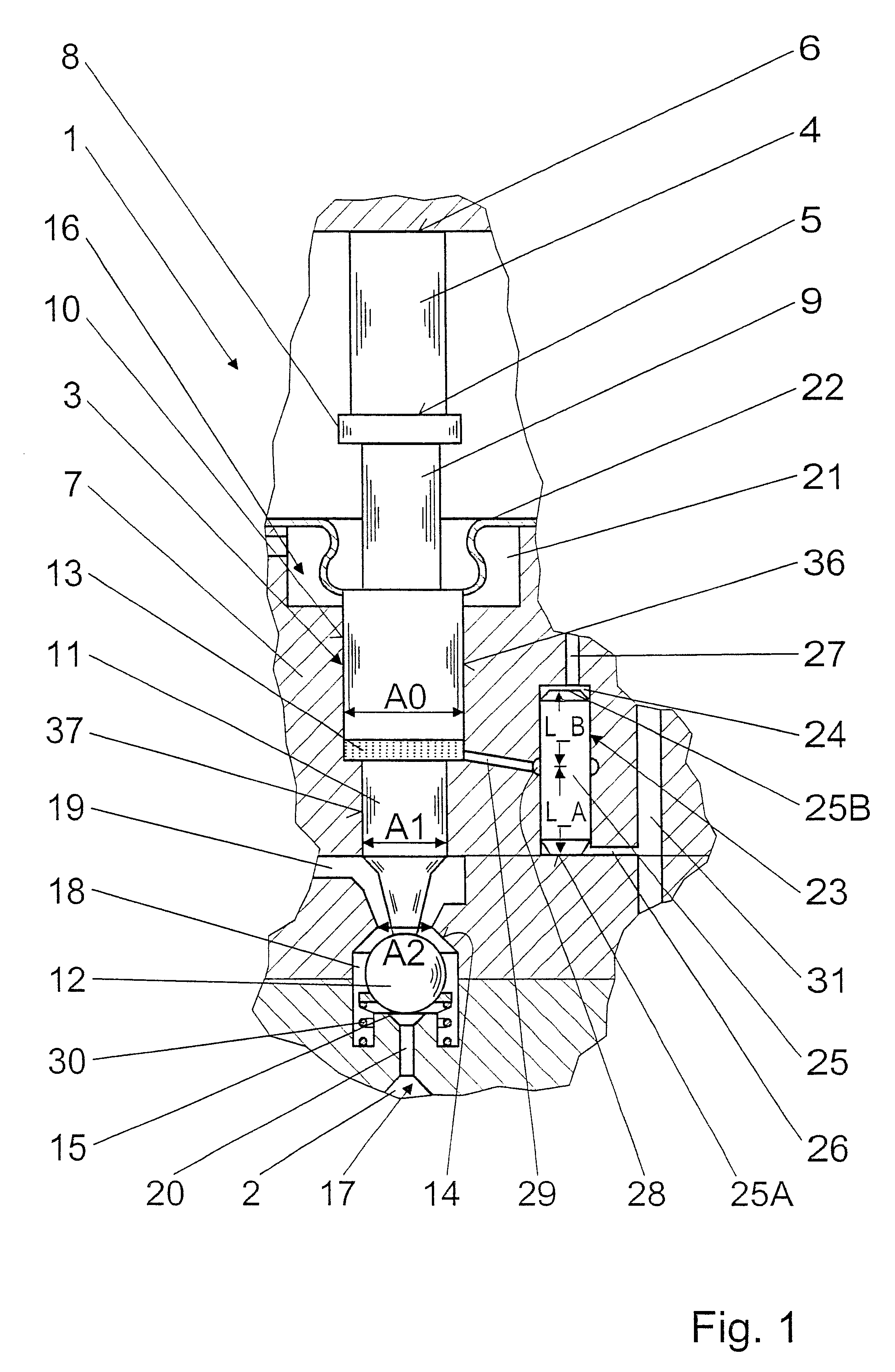

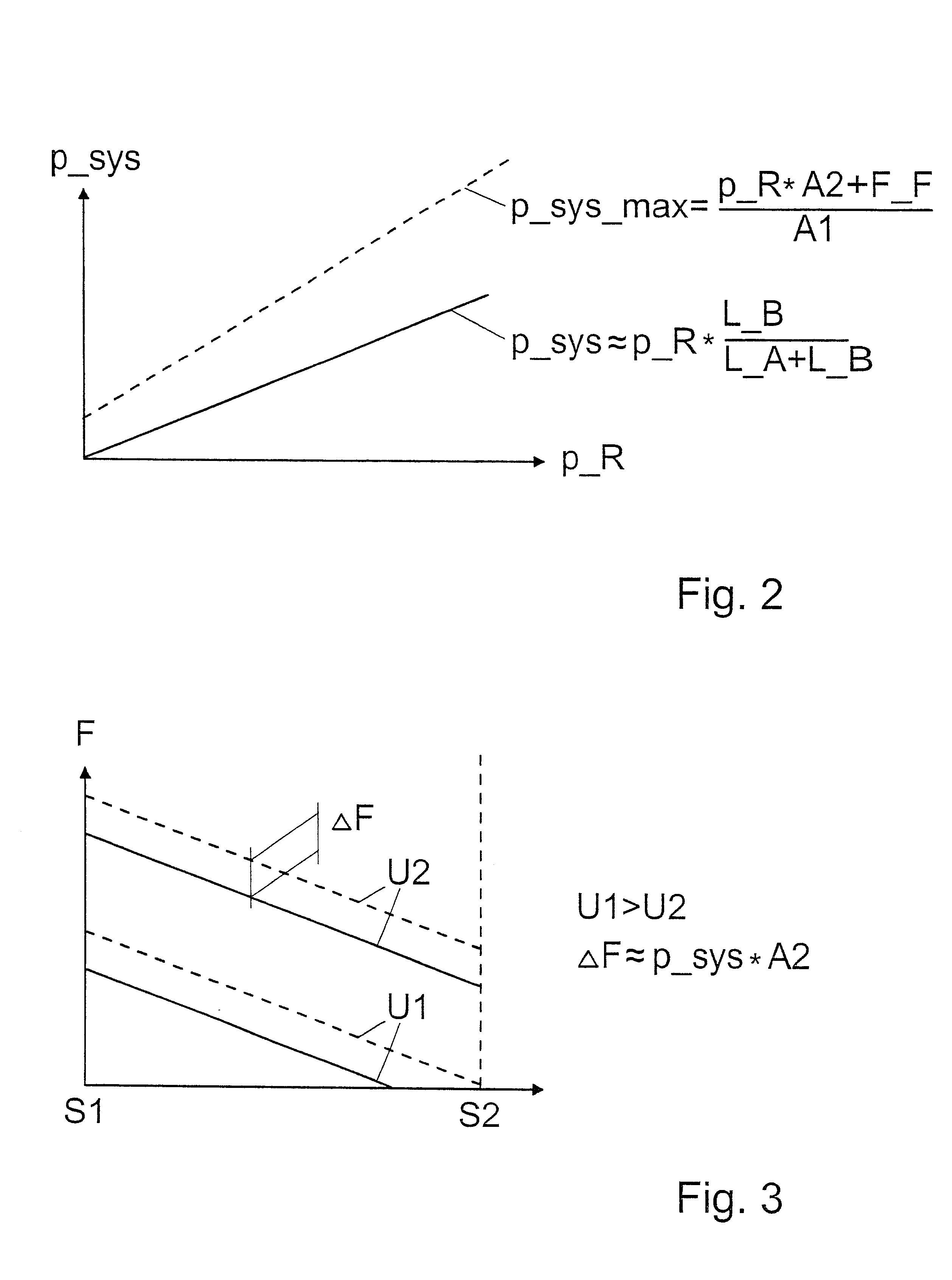

InactiveUS20020139946A1Reduce voltageSmaller, less-expensive piezoelectric unitOperating means/releasing devices for valvesMovable spraying apparatusSystem pressureHigh pressure

The invention relates to a valve for controlling fluids, having a piezoelectric unit (4) for actuating a valve member (3), with which a valve closing member (12) is associated that divides a low-pressure region (16) at system pressure from a high-pressure region (17). The valve member (3) has at least one first piston (9) and one second piston (11), between which a hydraulic chamber (13) is embodied. To compensate for leakage losses, a filling device (23) is used, which can communicate with the high-pressure region (17) and which has at least one channel-like hollow chamber (24), in which a solid body (25) is disposed, with a gap surrounding it, in such a way that on one end (25A) of the solid body (25), a line (26) branching off from the high-pressure region (17), and on its opposite end (25B) a leakage line (27) discharges into the hollow chamber (24), and that a line (29) leading to the hydraulic chamber (13) branches off along the length of the solid body (25), and the system pressure (p_sys) in the hydraulic chamber (13) is adjustable by geometric definition of the branching point (28).

Owner:ROBERT BOSCH GMBH

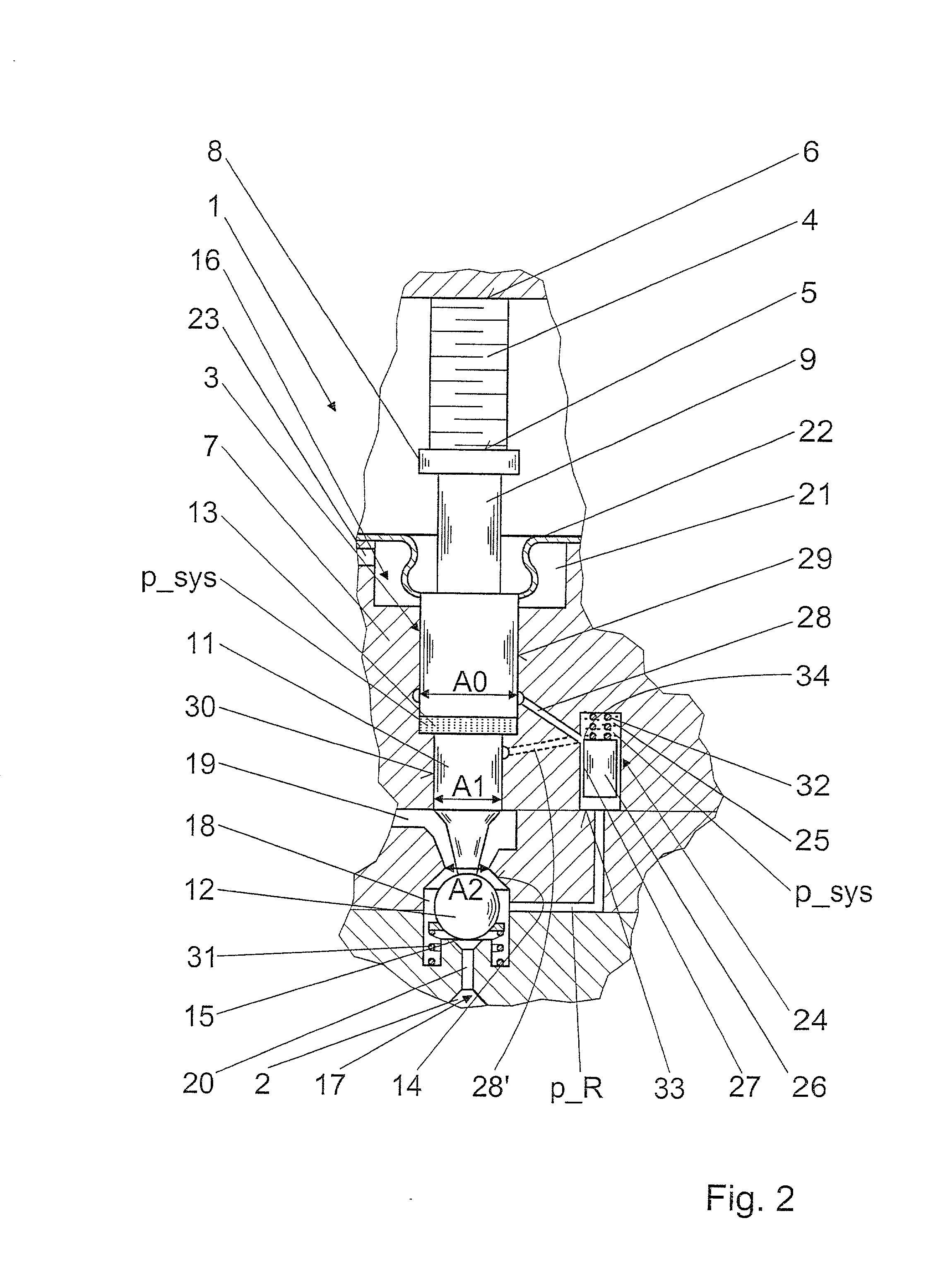

Valve for controlling liquids

InactiveUS20020104976A1Reduce voltageIncrease system pressureOperating means/releasing devices for valvesMovable spraying apparatusLine tubingSystem pressure

The invention relates to a valve for controlling fluids, having an actuator unit (4) for actuating a valve member (3) which has a first piston (9) and a second piston (11), separated from it by a hydraulic chamber (13), and which actuates a valve closing member (12) that divides a low-pressure region (16) at system pressure from a high-pressure region (17). For leakage compensation, a filling device (27) connectable to the high-pressure region (17) is provided with a hollow chamber (25), in which a throttle body (26) is disposed such that a line (33) leading to the high-pressure region (17) discharges into the hollow chamber (25) on one end of the throttle body (26), and on the other end a system pressure line (28) leading to the hydraulic booster branches off. The system pressure (p_sys) is built up as a function of the prevailing pressure (p_R) in the high-pressure region (17), by means of geometrically defining the throttle body (26), a gap (27) surrounding it, and the dimensions of the piston (9) along which the system pressure is reduced (<cross-reference target="DRAWINGS">FIG. 1< / cross-reference>).

Owner:ROBERT BOSCH GMBH

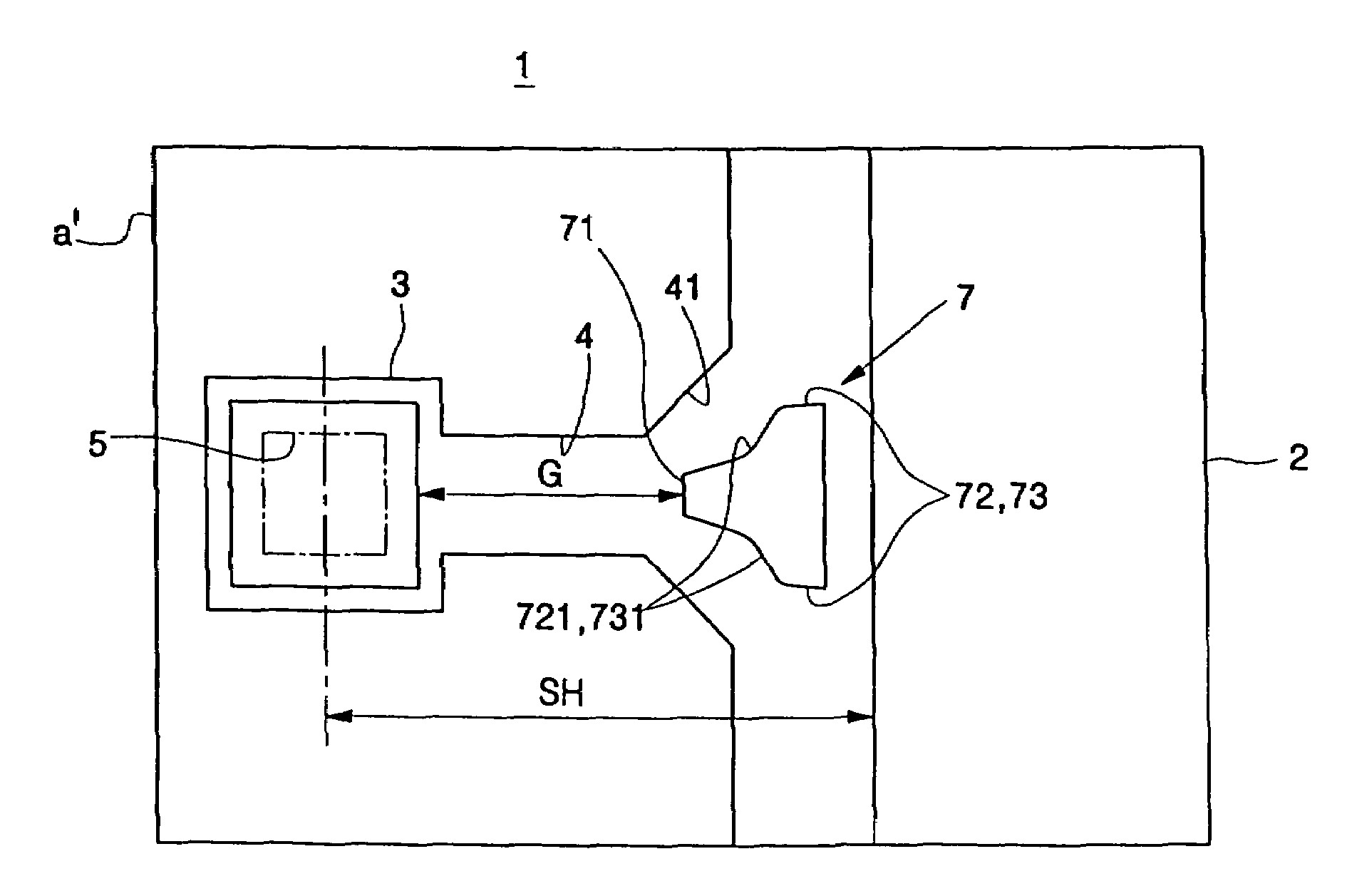

Inkjet print head with multi-functional structure

InactiveUS7357499B2Reduce distanceIncrease printing speedInking apparatusEngineeringMulti-function structure

An inkjet print head including a chamber layer provided with an ink via, at least one ink chamber having a heater, and at least one ink channel connecting the ink via and the ink chamber; and a nozzle layer provided with at least one nozzle at a position corresponding to the ink chamber. The ink channel is provided with a multi-functional structure. The multi-functional structure performs functions of a filter and a restrictor.

Owner:S PRINTING SOLUTION CO LTD

Liquid hydrogen vaporization and self-pressurizing device

ActiveCN108953988ASimple processReduce energy consumptionPressure vesselsFluid handledHigh pressure hydrogenVaporization

The invention relates to a liquid hydrogen vaporization device, and specifically relates to a liquid hydrogen vaporization and self-pressurizing device. The liquid hydrogen vaporization and self-pressurizing device is used in the process of vaporizing liquid hydrogen into gasified hydrogen through an evapourizer and increasing the pressure of the hydrogen to form high-pressure hydrogen. When applied to the hydrogen energy field, the liquid hydrogen vaporization and self-pressurizing device can be specifically applied in hydrogen refueling stations adopting vaporization and pressure increasingof transported liquid hydrogen. When the high-pressure liquid hydrogen vaporization device is used for vaporizing the liquid hydrogen and achieving self-pressurizing, the pressure ranges from 10MPa to200MPa, a hydrogen compressor is not needed, and energy consumption is reduced. The invention further relates to three ways of filling the liquid hydrogen into the high-pressure liquid hydrogen vaporization device. In the two ways, pressure difference squeezing is adopted, and the liquid hydrogen in a high-pressure liquid hydrogen storage tank is conveyed into the high-pressure liquid hydrogen vaporization device; in the other way, the liquid hydrogen is conveyed to the high-pressure liquid hydrogen vaporization device through a liquid hydrogen high pressure pump. Cold energy of the liquid hydrogen is fully utilized by the liquid hydrogen vaporization and self-pressurizing device. Compared with prior equipment, the liquid hydrogen vaporization and self-pressurizing device can work withoutthe hydrogen compressor in the liquid hydrogen vaporizing and self-pressurizing process, and energy consumption is reduced obviously.

Owner:靳殷实

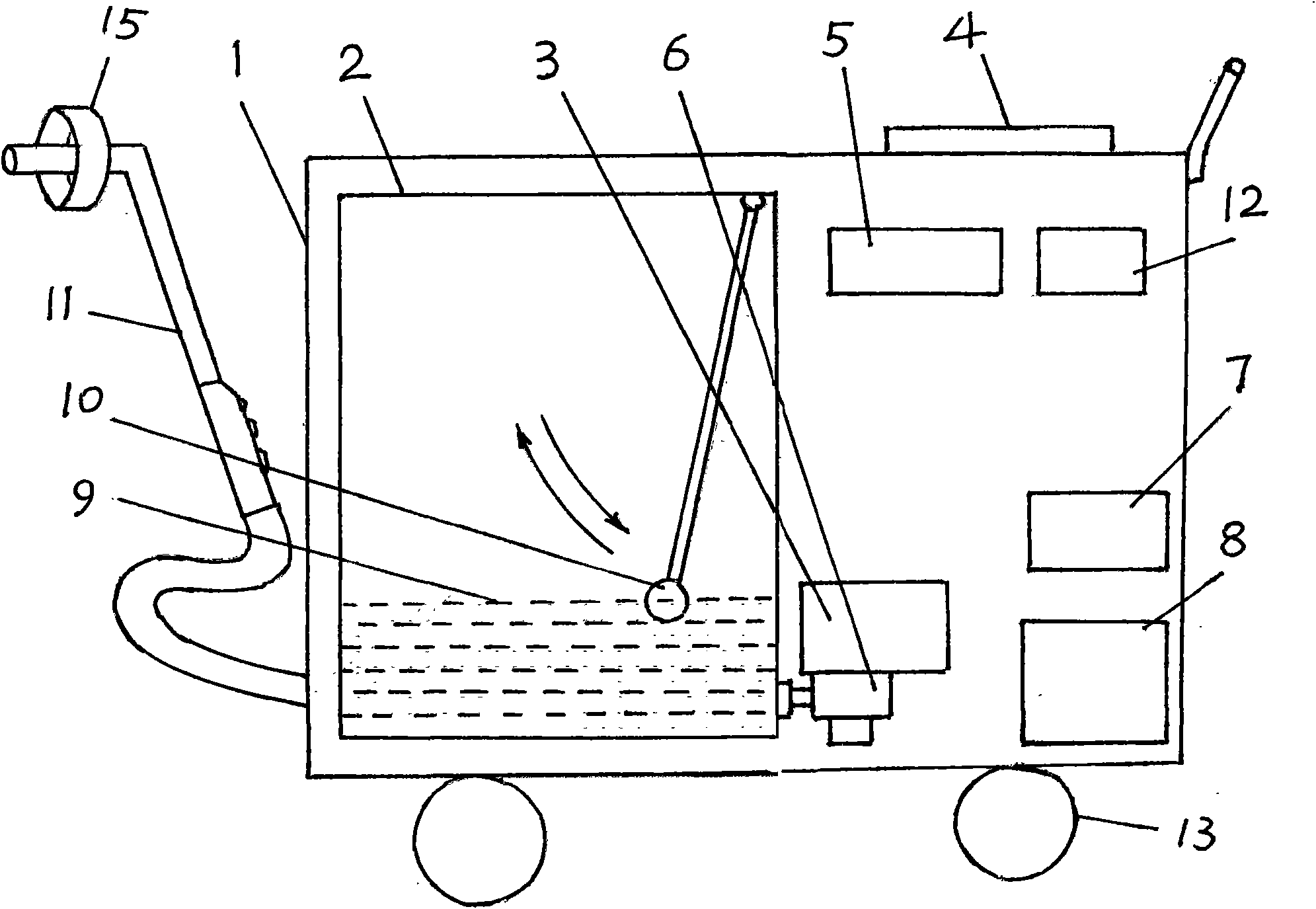

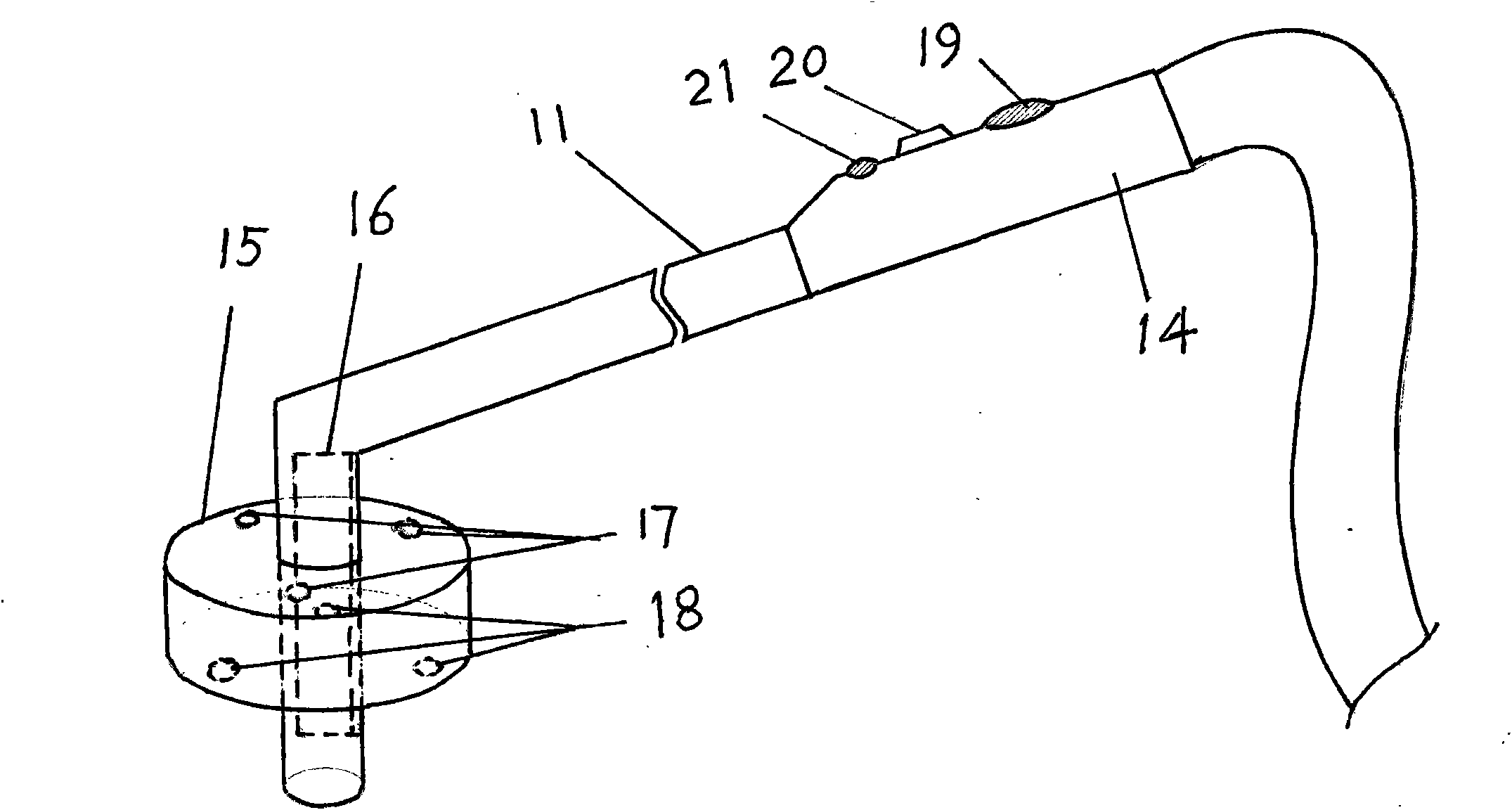

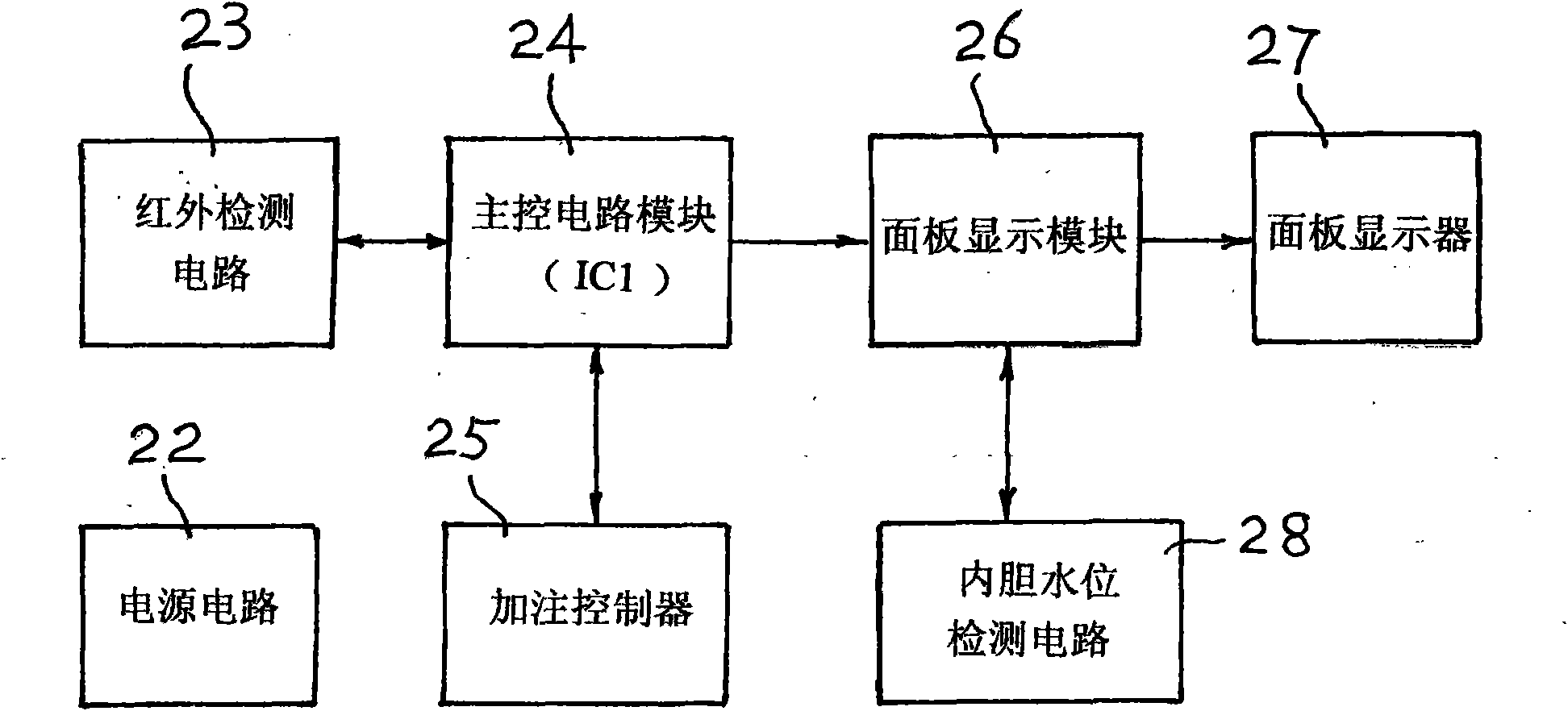

Automatic acid storage battery supplementing liquid injecting machine of vehicle

InactiveCN101891139AEasy to realize single-person mobile operationPrecise positioningLiquid transferring devicesVehicle servicing/repairingDetector circuitsControl signal

The invention relates to an automatic acid storage battery supplementing liquid injecting machine of a vehicle, which comprises a machine shell, an inner container, an electric injecting pump device and a circuit control board, wherein an injecting gun which is connected with an outlet of an electric injecting pump is arranged outside the machine shell; the circuit control board comprises a power supply circuit module, a main control circuit module with a single chip machine processor, a gun head infrared detecting circuit module, an injecting controller circuit module and a panel display module, and the gun head infrared detecting circuit module, the injecting controller circuit module and the panel display module are respectively connected with the main control circuit module, namely the single chip machine processor; the gun head infrared detecting circuit module is internally provided with an infrared emitting and receiving induction circuit for detecting whether supplementing liquid is filled or not and is used for transmitting an inducing signal to the single chip machine processor; and a control signal of the single chip machine processor is transmitted to an injecting controller for starting or shutting down the electric injecting pump. The invention can prevent storage battery liquid from easily sputtering or over flowing, prevent a waste and rusting phenomenon which is easily caused by the traditional manual injecting operation, greatly shortens the injecting time and ensures the safety and health of operators and improves the working efficiency.

Owner:FUZHOU PUBLIC TRANSPORT GROUP

Hydrogen conveying system for hydrogenation vehicle

PendingCN113390017ARefill time shortenedBoost slowlyContainer filling methodsSecondary cellsThermodynamicsPressure curve

The invention provides a hydrogen conveying system for a hydrogenation vehicle. The hydrogen conveying system comprises a hydrogen conveying pipeline, a hydrogen conveying pressure adjusting assembly and a control unit, wherein the hydrogen conveying pressure adjusting assembly is arranged on the hydrogen conveying pipeline; the hydrogen conveying pressure adjusting assembly is connected with the control unit; and the hydrogen conveying pressure adjusting assembly adjusts the hydrogen conveying pressure in the hydrogen conveying pipeline behind the hydrogen conveying pressure adjusting assembly according to a pressure curve set in the control unit. The problem that in the existing hydrogenation process, due to the fact that the pressure difference value between a hydrogen storage tank in a hydrogenation machine and a vehicle-mounted hydrogen storage bottle is large, the hydrogen flow in the hydrogen conveying pipeline is large and then small, the possibility that the temperature exceeds the standard after hydrogen is injected into the vehicle-mounted hydrogen storage bottle in the hydrogenation vehicle is likely to occur, and the hydrogen flow in the hydrogen conveying pipeline is reduced along with the reduction of the pressure difference between the hydrogen storage tank in the hydrogenation machine and the vehicle-mounted hydrogen storage bottle, so that the hydrogenation time in the hydrogen storage bottle in the hydrogenation vehicle is long is solved.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

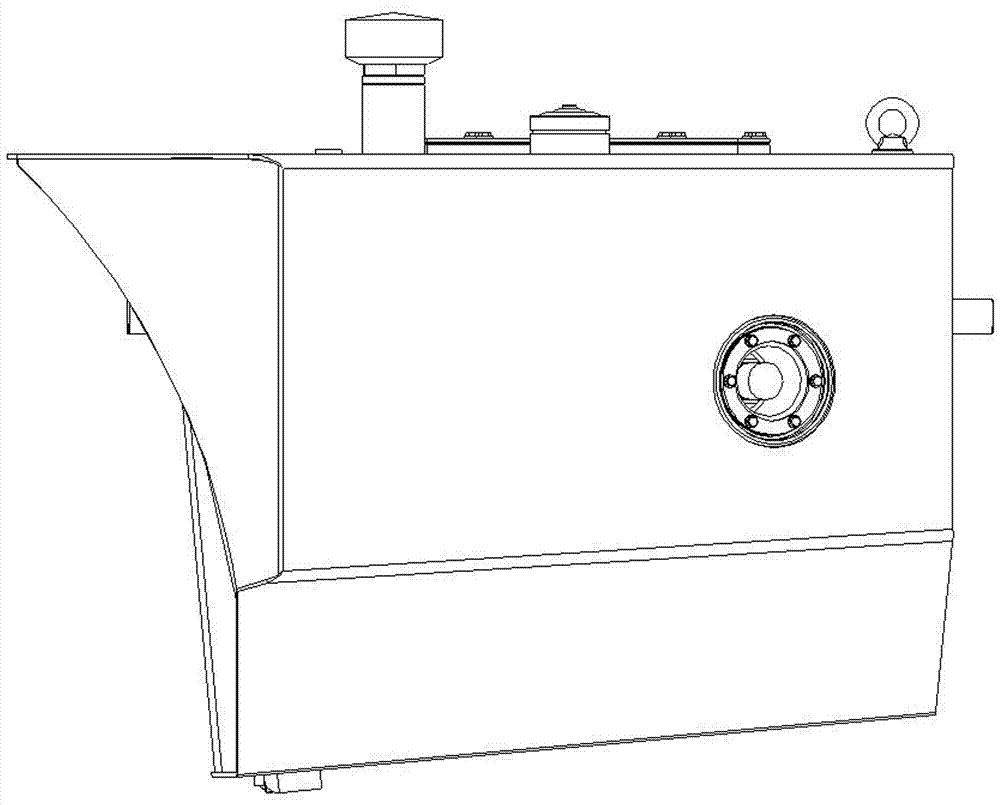

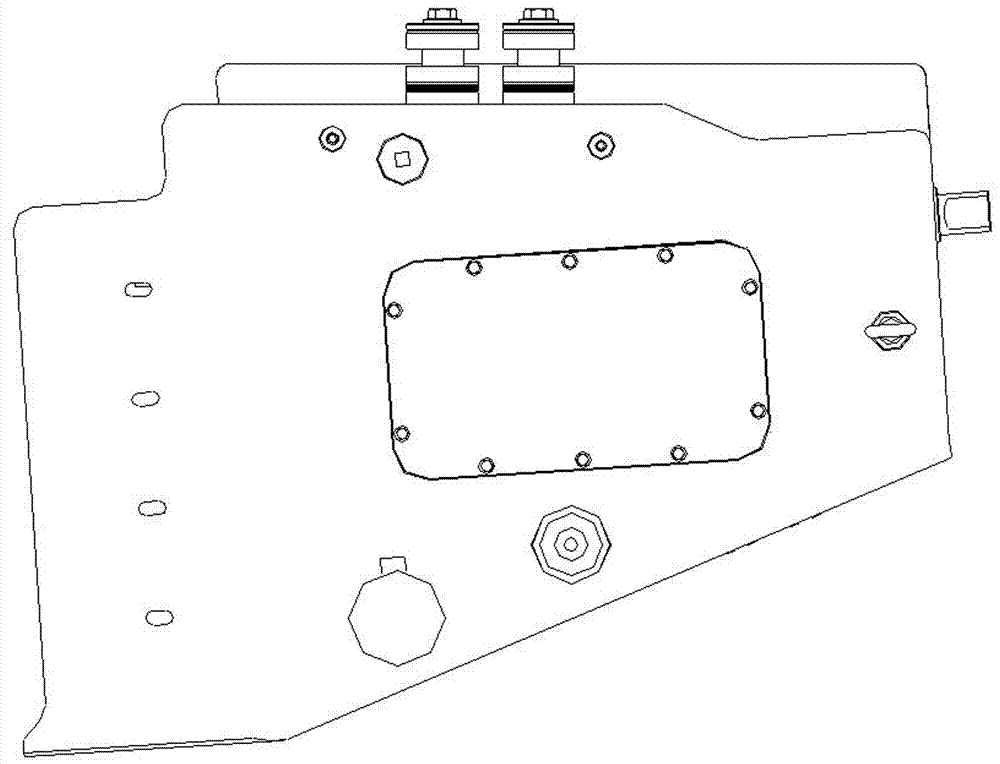

Articulated type dump truck fuel tank

PendingCN107351677AReduce cross motionReduce vibration in the front and rear directionsUnderstructuresFuel supplyMarine engineeringFuel tank

The invention discloses an articulated type dump truck fuel tank. The articulated type dump truck fuel tank comprises a fuel tank body. The fuel tank body is composed of a front plate, a left side plate, a right side plate and a rear plate, a rapid refueling assembly is arranged on the front side surface of the front plate, a breather, a lock cover, a cleaning opening cover and a liquid level sensor are installed on the top surface of the front plate, and a magnetic fuel dumping screw plug is installed on the bottom surface of the front plate; and a plurality of dampers are installed on the rear plate, the whole tank body of the inner portion of the fuel tank body is divided into four cavities through a transverse baffle and a longitudinal baffle, and through-flow holes are formed in the transverse baffle and the longitudinal baffle correspondingly. According to the articulated type dump truck fuel tank, the problems that the occupied installation space of a traditional fuel tank is large, and the extroversion tendency in the steering process is caused are solved, and the articulated type dump truck fuel tank can effectively reduce the displacement of the fuel tank in the left-right direction and the vibration of the fuel tank in the front-back direction.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

Liquid filling equipment

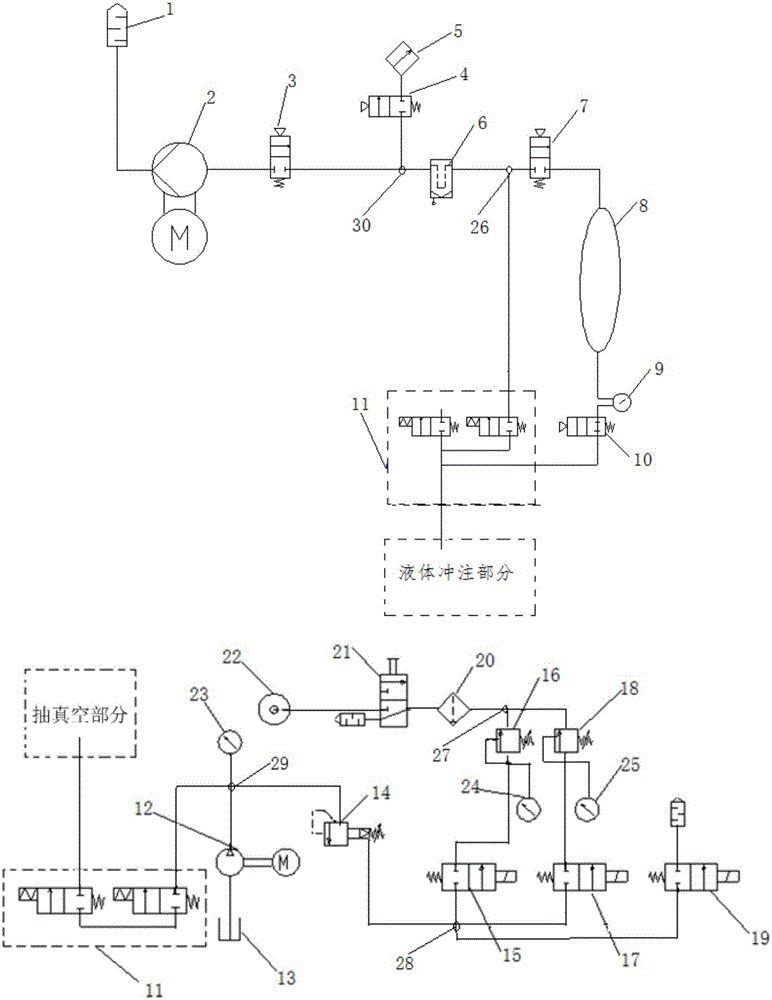

InactiveCN106564847AImprove dosing efficiencyFast vacuumingLiquid transferring devicesSolenoid valveEngineering

The invention provides liquid filling equipment. The liquid filling equipment comprises a vacuumizing part, a filling part and a filling gun head. The vacuumizing part comprises a vacuum pump, a vacuum tank, a vacuum pump on / off control valve, a first vacuum tank connection / disconnection control valve and a second vacuum tank connection / disconnection control valve. The filing part comprises a filling pump, a pilot type overflow valve, an air source, a first solenoid valve, a second solenoid valve, a first remote pressure regulating valve and a second remote pressure regulating valve. By the adoption of the liquid filling equipment, the liquid filling time of vehicles can be shortened, and the filling efficiency of the vehicles is improved.

Owner:CHERY AUTOMOBILE CO LTD

Valve for regulating fluids

InactiveUS6655605B2Reduce voltageSmaller, less-expensive piezoelectric unitOperating means/releasing devices for valvesMovable spraying apparatusSystem pressureEngineering

The invention relates to a valve for controlling fluids, having a piezoelectric unit (4) for actuating a valve member (3), with which a valve closing member (12) is associated that divides a low-pressure region (16) at system pressure from a high-pressure region (17). The valve member (3) has at least one first piston (9) and one second piston (11), between which a hydraulic chamber (13) is embodied. To compensate for leakage losses, a filling device (23) is used, which can communicate with the high-pressure region (17) and which has at least one channel-like hollow chamber (24), in which a solid body (25) is disposed, with a gap surrounding it, in such a way that on one end (25A) of the solid body (25), a line (26) branching off from the high-pressure region (17), and on its opposite end (25B) a leakage line (27) discharges into the hollow chamber (24), and that a line (29) leading to the hydraulic chamber (13) branches off along the length of the solid body (25), and the system pressure (p_sys) in the hydraulic chamber (13) is adjustable by geometric definition of the branching point (28) (FIG. 1).

Owner:ROBERT BOSCH GMBH

Micro-fluid ejection devices and method therefor

An improved ink jet printhead for an ink jet printer and method therefor. The printhead includes a semiconductor substrate containing ink ejection devices. A thick film layer is attached to the substrate. A nozzle plate is attached to the thick film layer. The nozzle plate contains a plurality of ink ejection nozzles corresponding to the ink ejection devices. The printhead contains flow features having a height dimension and a width dimension formed therein for flow of ink to the plurality of ink ejection devices for ejection through the nozzles. At least a portion of the flow feature dimensions for at least one of the nozzles is formed in both the thick film layer and laser ablated in the nozzle plate, wherein the thick film layer contains at least 12% of the flow feature dimensions.

Owner:FUNAI ELECTRIC CO LTD

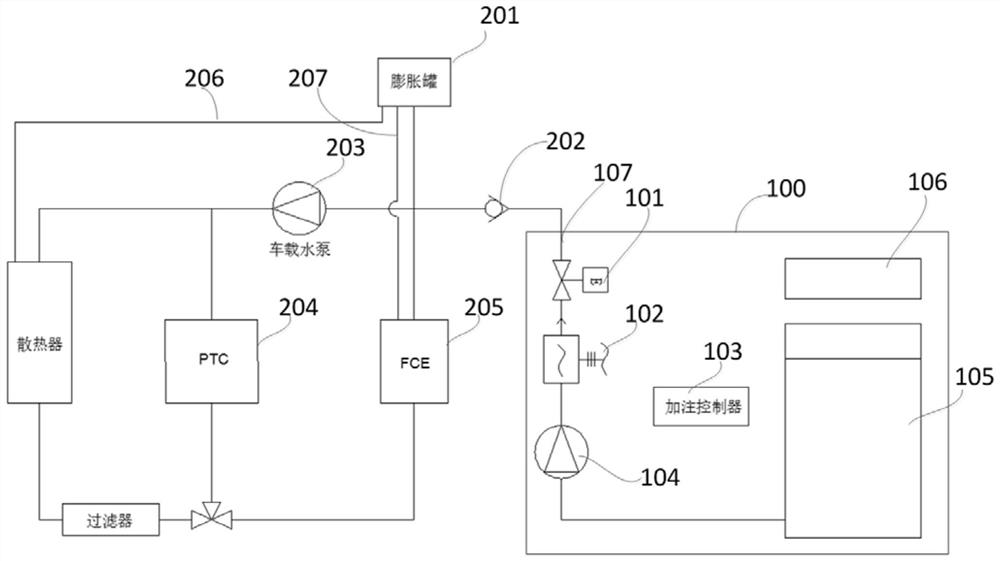

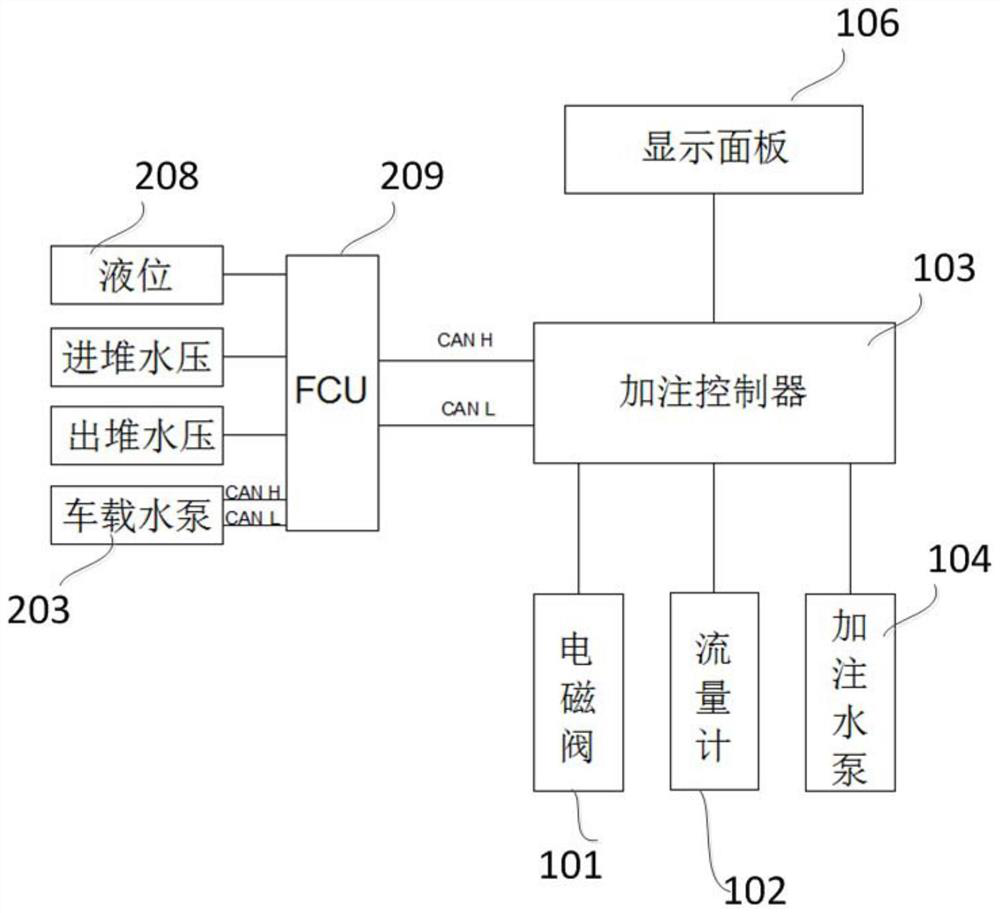

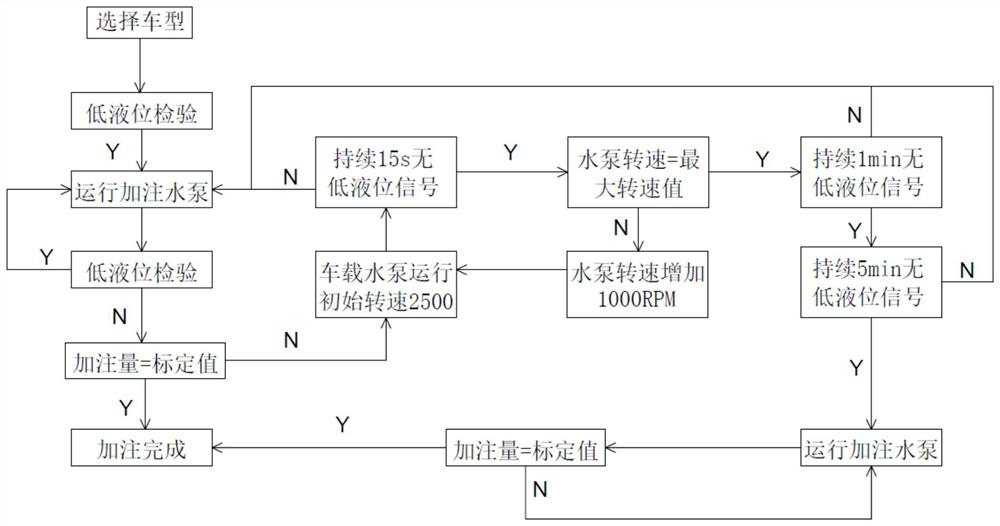

Filling method and filling device for cooling liquid in fuel cell vehicle

ActiveCN112758882ARefill time shortenedReduce the difficulty of operationLiquid transferring devicesExpansion tankThermodynamics

The invention provides a filling method and a filling device for a cooling liquid in a fuel cell vehicle. The filling device comprises a main pipeline, a filling water pump, a flow meter, a liquid level sensor and a filling controller, wherein the main pipeline is connected with a cooling liquid tank and used for conveying the cooling liquid; the filling water pump is arranged on the main pipeline; the flow meter is arranged on the main pipeline and used for detecting the conveying amount of the cooling liquid; the liquid level sensor is arranged in an expansion tank and used for detecting the liquid level of the cooling liquid in the expansion tank; the filling water pump and the flow meter are both connected with the filling controller; the filling controller is in signal connection with a vehicle-mounted controller; and the liquid level sensor and a vehicle-mounted water pump are both connected with the vehicle-mounted controller. Through the combination with the vehicle-mounted water pump exhaust control, the automated filling with the cooling liquid is achieved, so that time to fill a FCV with the cooling liquid can be shortened, the operating difficulty of onsite operating personnel in an assembly plant can be reduced, the vehicle launching and debugging rhythm can be improved, and the production efficiency can be improved.

Owner:SHANGHAI CHONGSU ENERGY TECH CO LTD

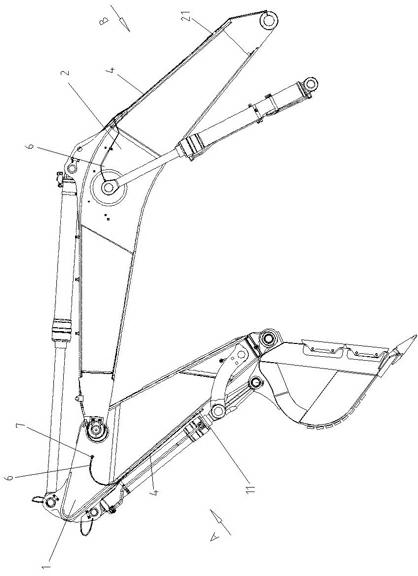

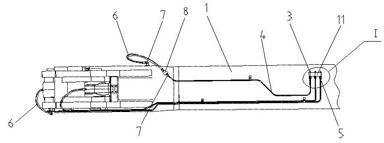

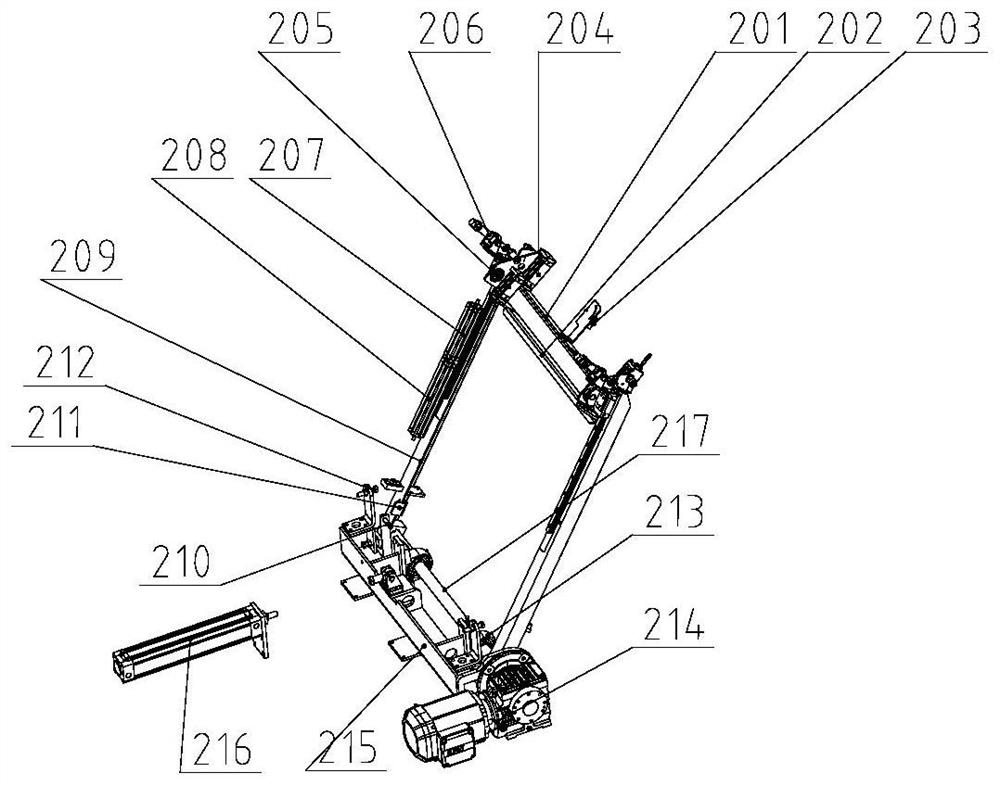

Centralized lubrication mechanism for excavator working device

InactiveCN102493525AImprove work efficiencyImprove filling efficiencySoil-shifting machines/dredgersOil canExcavator

The invention discloses a centralized lubrication mechanism for an excavator working device, which comprises a plurality of lubricating oil nozzle manifold blocks, a plurality of lubricating oil nozzles and a plurality of oil ducts, wherein the lubricating oil nozzle manifold blocks are respectively arranged in the lower end of a bucket rod or the lower end of a swing arm; the lubricating oil nozzles are respectively fixed on one sides of the lubricating oil nozzle manifold blocks; one ends of the oil ducts are respectively fixed on the other side surfaces of the lubricating oil nozzle manifold blocks by oil duct joints and are communicated with the corresponding lubricating oil nozzle via the respective oil line in each lubricating oil nozzle manifold block; and the other ends of the oil ducts are respectively introduced to the hinged surface of each movable joint of the working device via hoses and hose joints. The centralized lubrication mechanism for the excavator working device has the advantages of simple structure and high integration degree, lubricating oil can be conveniently injected into the lubricating oil nozzle manifold blocks on the lower end of the bucket rod and the lower end of the swing arm only by lowering the swing arm and the bucket rod once, so that the lubricating oil filling efficiency is greatly improved, the lubricating oil filling time is shortened, and therefore, the working efficiency of an excavator is improved.

Owner:中外合资沃得重工(中国)有限公司

Hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and system thereof

ActiveCN101832467BReduce energy consumptionLow energy operationContainer discharging methodsContainer filling under pressureNew energyProgrammable logic controller

The invention relates to the field of renewable, clean and environment-friendly new energy, aiming at providing a hydrogen refueling station hydrogen optimizing filling method based on temperature rise and energy consumption control and a system thereof. The method comprises the steps of: establishing a database arranged inside a programmable logic controller (PLC), and using the database to record the corresponding relationship between the corresponding filling initial condition and the opening value of a needle valve; according to the filling initial condition, using the PLC to inquire the opening value of the needle valve when hydrogen storage tanks with different pressure levels are used for taking gas; and according to the data inquired by the PLC, arranging the needle valve at the corresponding demarcated position, and carrying out the filling operation. The invention can run at the lower power consumption of a cooling device, ensures the temperature of a vehicle hydrogen storage container to be strictly controlled within the required range, and remarkably shortens the filling time, thus leading the whole system to effectively, safely and reliably fill high pressure hydrogen, and having the advantages of high gas taking efficiency, low power consumption and the like.

Owner:ZHEJIANG UNIV

Imbibition bottle fluid adding device and method for imbibition experiment

PendingCN110987766AGuaranteed filling effectEasy to operate manuallyPermeability/surface area analysisPressure generationRock core

The invention discloses an imbibition bottle fluid adding device and method for an imbibition experiment. The imbibition bottle fluid adding device comprises a negative pressure generation system, animbibition bottle and a fluid supply system. The top of a capillary metering tube of the imbibition bottle is connected with the negative pressure generation system, and an inlet of a glass wide-mouthbottle of the imbibition bottle is connected with the fluid supply system. A rock core sample is arranged in the glass wide-mouth bottle, and the capillary metering tube is connected with the glass wide-mouth bottle; and the glass wide-mouth bottle inlet of the imbibition bottle is connected with the fluid supply system. Imbibition liquid in the fluid supply system is pumped into the imbibition bottle by utilizing the negative pressure generation system; the negative pressure generation system stops working when the imbibition bottle is full of the imbibition liquid. The glass wide-mouth bottle inlet and the fluid supply system are separated from a connection portion, a rubber plug is inserted into the glass wide-mouth bottle inlet, and the top of the capillary metering tube and the negative pressure generation system are separated from the connection portion. The experimental result accuracy is improved, the operation difficulty of an imbibition liquid adding link is reduced, the time consumed by the imbibition liquid adding link is shortened, and the experimental efficiency is greatly improved.

Owner:XI'AN PETROLEUM UNIVERSITY

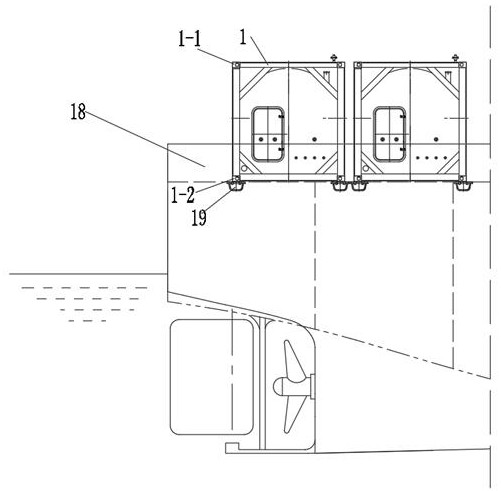

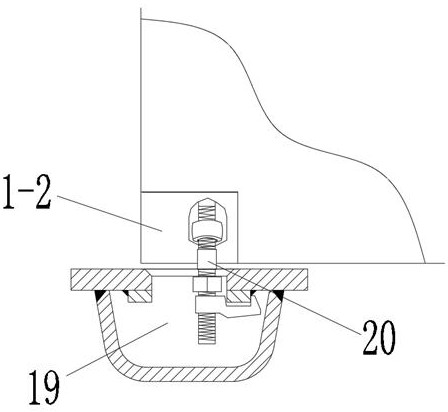

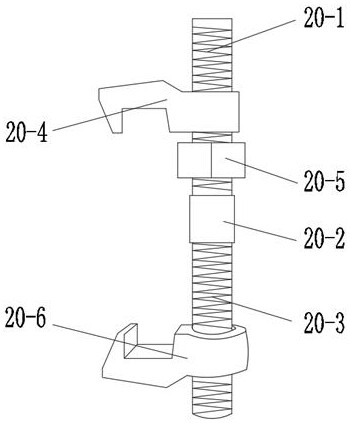

Liquefied natural gas (LNG) power ship fuel tank capable of being quickly replaced and mounted

PendingCN112923238ARefill time shortenedQuick connectionVessel mounting detailsPropulsion power plantsFuel tankPowered watercraft

The invention discloses a liquefied natural gas (LNG) power ship fuel tank capable of being quickly replaced and mounted. The LNG power ship fuel tank comprises a fuel tank frame and an LNG low-temperature gas storage tank arranged in the fuel tank frame, and first fixed connecting holes are respectively formed in the six corners of the upper end of the fuel tank frame. Second fixed connecting holes are formed in the six corners of the bottom of the fuel tank frame correspondingly. Pre-embedded lock fasteners are arranged on the deck of a power ship, and after the fuel tank frame is placed on a ship body, the second fixed connecting holes in the six corners of the bottom of the fuel tank frame are in butt joint with the pre-embedded lock fasteners and then are relatively locked through stud locks. The LNG power ship fuel tank capable of being replaced and mounted can be separated from the ship and can be rapidly connected with the ship, the filling mode requirement of ship LNG fuel supply is met, and the problems that existing ship filling is difficult, the filling station approval procedure is tedious, and the safety risk is large are solved.

Owner:宏远航运有限公司

Harvester brake fluid vacuum filling system and method

InactiveCN107235464AEasy to operateRefill time shortenedLiquid transferring devicesVacuum pumpingClamp connection

The invention relates to a harvester brake fluid vacuum filling system and method. The system comprises a brake oil can and a brake main pump; an oil outlet of the brake oil can is connected with an oil inlet of the brake main pump through a brake pipeline, and the system is characterized by further comprising a vacuum filling machine; a filling gun head of the vacuum filling machine is in clamped connection with an oil filling opening of the brake oil can in a seal manner; the filling gun head of the vacuum filling machine is clamped on the oil adding opening of the brake oil can, gas in the brake oil can, the brake pipeline, the brake main pump and an output pipeline of the brake main pump is subject to vacuum pumping through the filling gun head, brake liquid is injected in to the brake oil can in a pressured manner through the filling gun head, and oil in the brake oil can is sucked through the filling gun head until the height of the liquid level in the brake oil can reaches the set value. A hydraulic execution element does not need to loosened and fastened, the vacuum gun head is directly clamped on the filling opening of the brake oil can, vacuum pumping and filling can be finished, operation is more convenient, filling time is shortened, and the filling efficiency is effectively improved.

Owner:HENAN RICHUANG GENERAL MACHINERY MFR

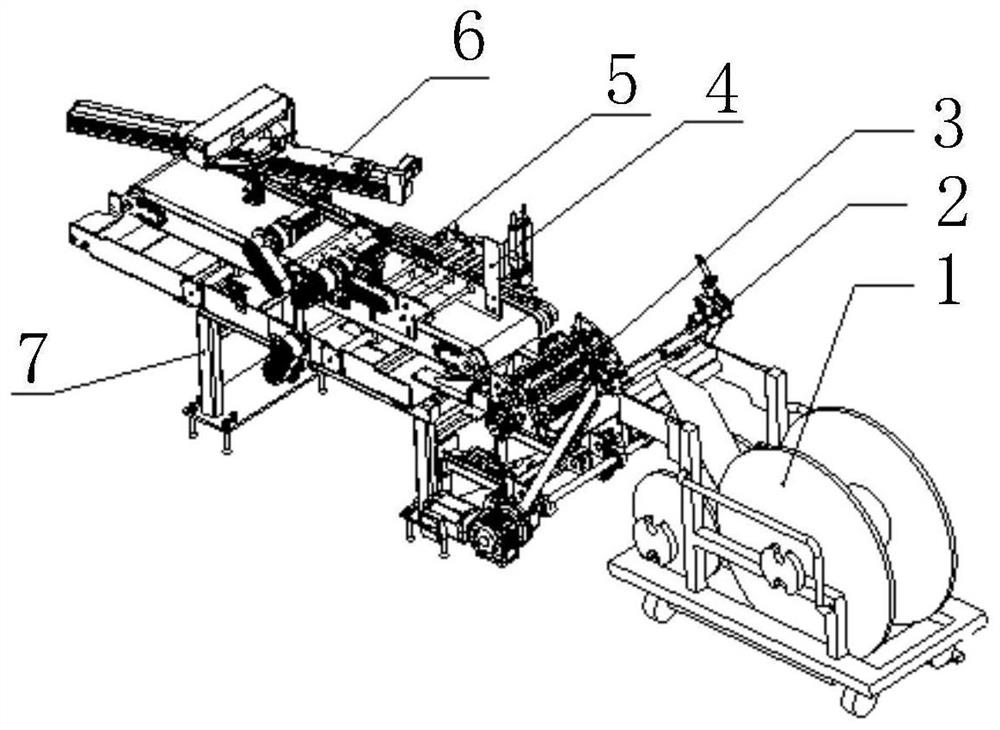

Automatic feeding device for rubber material with steel wire

The invention discloses an automatic feeding device for rubber materials with steel wires. The automatic feeding device comprises a rack, and a clamping assembly, a template assembly and a sewing assembly are arranged on the rack; the material clamping assembly is used for clamping a material head of a rubber material with a steel wire and can convey the material head to the template assembly; the template assembly comprises a material head conveying unit and a material tail conveying unit, the starting end of the material head conveying unit is used for receiving the material head conveyed by the material clamping assembly, and the terminal end of the material head conveying unit is connected with the starting end of the material tail conveying unit; the sewing assembly is used for conducting rolling sewing on the material heads and the material tails at the designated positions. According to the automatic feeding device, the whole process of automatically feeding the rubber material with the steel wire is mainly completed by the automatic feeding device, so that the feeding time is greatly shortened, the downtime of the whole machine is shortened, and the automation degree and the production efficiency are greatly improved.

Owner:MESNAC +1

Urea solution filler neck device

ActiveCN109681301AImprove maintainabilityOptimize layoutInternal combustion piston enginesExhaust apparatusMechanical engineeringUrea

The invention discloses a urea solution filler neck device which comprises: a cover body mounted on a floor of a vehicle body to correspond to a urea solution tank, the cover body has a through hole,afiller pipe body disposed at the bottom of the cover body and installed On the urea solution tank,an opening and closing cover, which is installed at the top of the through hole at the top of the filling pipe body and selectively opens and closes the through hole and the filling pipe body,and a sealing member, which is mounted on the filler pipe body within a space formed by the cover body and the filling pipe body, and a urea solution leaking from the urea solution tank is prevented from flowing into the interior of the vehicle.

Owner:HYUNDAI MOTOR CO LTD +1

Sweeper and water tank system thereof

The invention relates to a sweeper and a water tank system thereof. The water tank system comprises a plurality of water storage tanks and a plurality of first communicating pipes. The water storage tanks comprise a first water storage tank and a second water storage tank. The bottom plates of the first water storage tank and the second water storage tank are installed on a frame and located on the same horizontal plane. One end of each first communicating pipe is connected with the bottom plate of the first water storage tank and the other end of each first communicating pipe is connected with the bottom plate of the second water storage tank such that the first water storage tank and the second water storage tank are communicated. The first water storage tank comprises a first water injection connector, the first water injection connector is arranged on a top plate of the first water storage tank, a second water injection connector is arranged on the second water storage tank, and the second water injection connector is arranged at the top of the second water storage tank. According to the embodiment of the invention, the water storage tanks are communicated through the pluralityof first communicating pipes, and the water injection connectors are arranged, so that the water injection efficiency can be improved, and the water injection modes are more diversified.

Owner:长沙普罗科环境装备有限责任公司

An intelligent feeding device for a variety of coating raw slurry for casting

ActiveCN106001463BRefill time shortenedImprove filling efficiencyMoulding toolsTuning forkDiaphragm pump

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

A viscous liquid automatic heating injection device

A viscous liquid automatic heating and injecting apparatus comprises a supporting frame, and an automatic heating device and an injecting device arranged on the supporting frame, and the injecting device is arranged below the automatic heating device. The automatic heating device and the injecting device are arranged to substitute manual direct operation use of a viscous liquid, so the problem of insufficient fusion of the viscous liquid and a material liquid in a reaction kettle during manual injection is solved, the injection time is saved, and unsafe contact of humans is avoided; a certain weight of the prepared viscous liquid is fully added into the reaction liquid in the reaction kettle, so the waste of the residual of the viscous liquid in a beaker container during manual operation is avoided, and the intermediate formula is accurate and effective; a feeding pipeline and a discharging pipeline are arranged, so the viscous liquid thinned by heating is sent into the stirring reaction kettle; a pneumatic ball valve and a non-return valve are arranged to guarantee unidirectional conveying of the viscous liquid, so the normal running of the viscous liquid is not affected; and a cylinder is arranged to reduce the labor intensity, so feeding is stable, accurate and effective.

Owner:JIANGSU HHCK NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com