A viscous liquid automatic heating injection device

An automatic heating and injection device technology, which is applied in the field of injection devices, can solve problems such as poor mixing uniformity, inability to ensure mixing, and human injury, and achieve the effects of avoiding unsafe contact, saving filling time, and avoiding injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

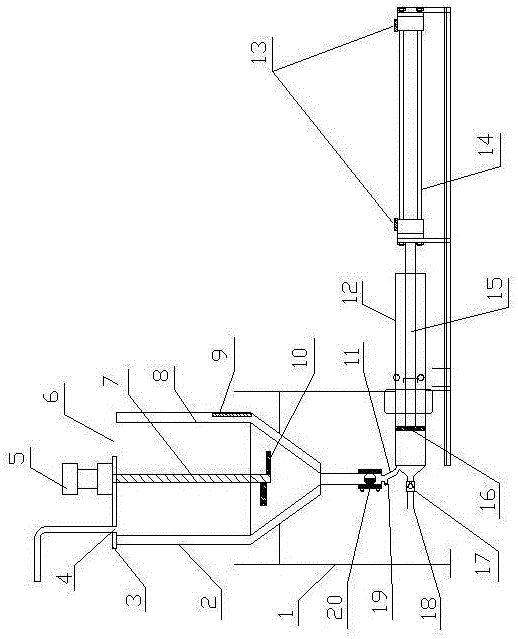

[0015] Embodiment 1, with reference to figure 1 , an automatic heating injection device for viscous liquid, comprising a support frame 1 and an automatic heating device and an injection device arranged on the support frame 1, the injection device is arranged below the automatic heating device;

[0016] The automatic heating device comprises a tank body 2 containing viscous matter and a sealing cover 3 arranged on the top of the tank body 2, the sealing cover 3 is provided with a material inlet 6 and a ventilation hole 4, and the bottom of the tank body 2 is provided with a material outlet , the tank body 2 is provided with a stirring device, and the inner wall of the tank body 2 is provided with a heating device 8;

[0017] The injection device is a syringe type injection device, and the syringe type injection device includes a syringe 12, a piston 16 disposed in the syringe 12 and a piston drive mechanism, and the head of the syringe 12 is provided with two through holes, whe...

Embodiment 2

[0018] Embodiment 2, in the viscous liquid automatic heating injection device described in Embodiment 1: the tank body 2 is provided with a temperature control switch for controlling the stirring device, the heating device and the operation of the pneumatic ball valve 20, and on the pneumatic ball valve 20 A first pneumatic solenoid valve is provided, and the first pneumatic solenoid valve is connected to the temperature sensor 9 arranged on the inner wall of the tank body 2 through a temperature control switch; the piston driving mechanism is a cylinder 14, and the piston rod 15 at the inner end A magnetic block is provided, and a magnetic sensor 13 is provided at both ends of the cylinder body of the cylinder 14 , and a second pneumatic solenoid valve and a time relay connected with the magnetic sensor 13 are provided on the cylinder 14 .

Embodiment 3

[0019] Example 3, in the viscous liquid automatic heating injection device described in Example 1: a compressed air inlet and an intermittent air inlet 19 are provided on the feed pipeline 11 at the pneumatic ball valve 20, and the compressed air inlet is convenient. After conveying the material, the viscous liquid in the feed pipe 11 and the syringe 12 is cleaned to improve the cleaning speed and cleaning efficiency, and the intermittent air inlet 19 is convenient for cleaning the feed pipe 11 and the syringe 12 during the conveying process. The viscous liquid is cleaned up.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com